Opening-nozzle saddle-shaped seam welding equipment

A welding equipment, saddle-shaped technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor processing quality, low efficiency, high cost, etc., and achieve the effect of compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

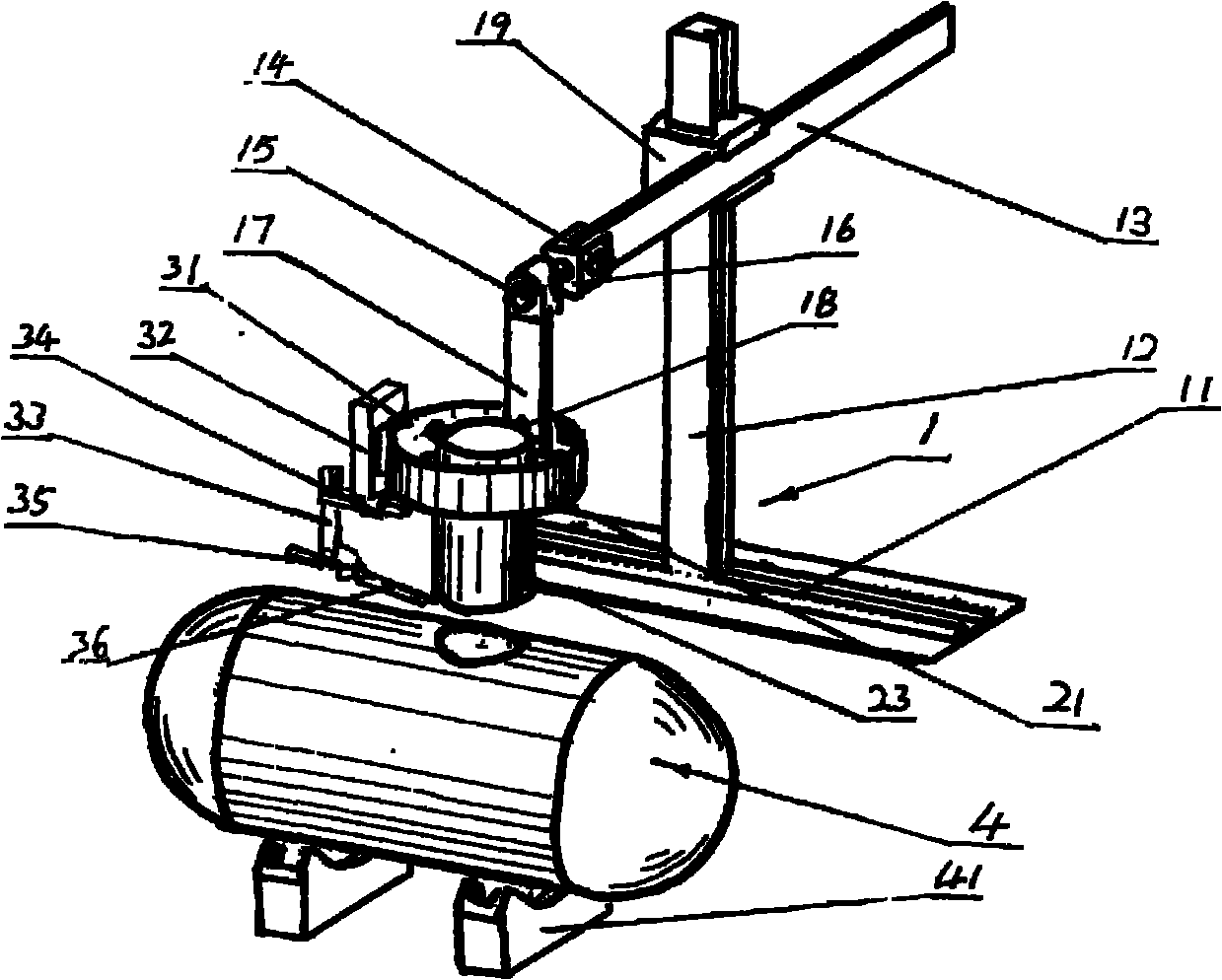

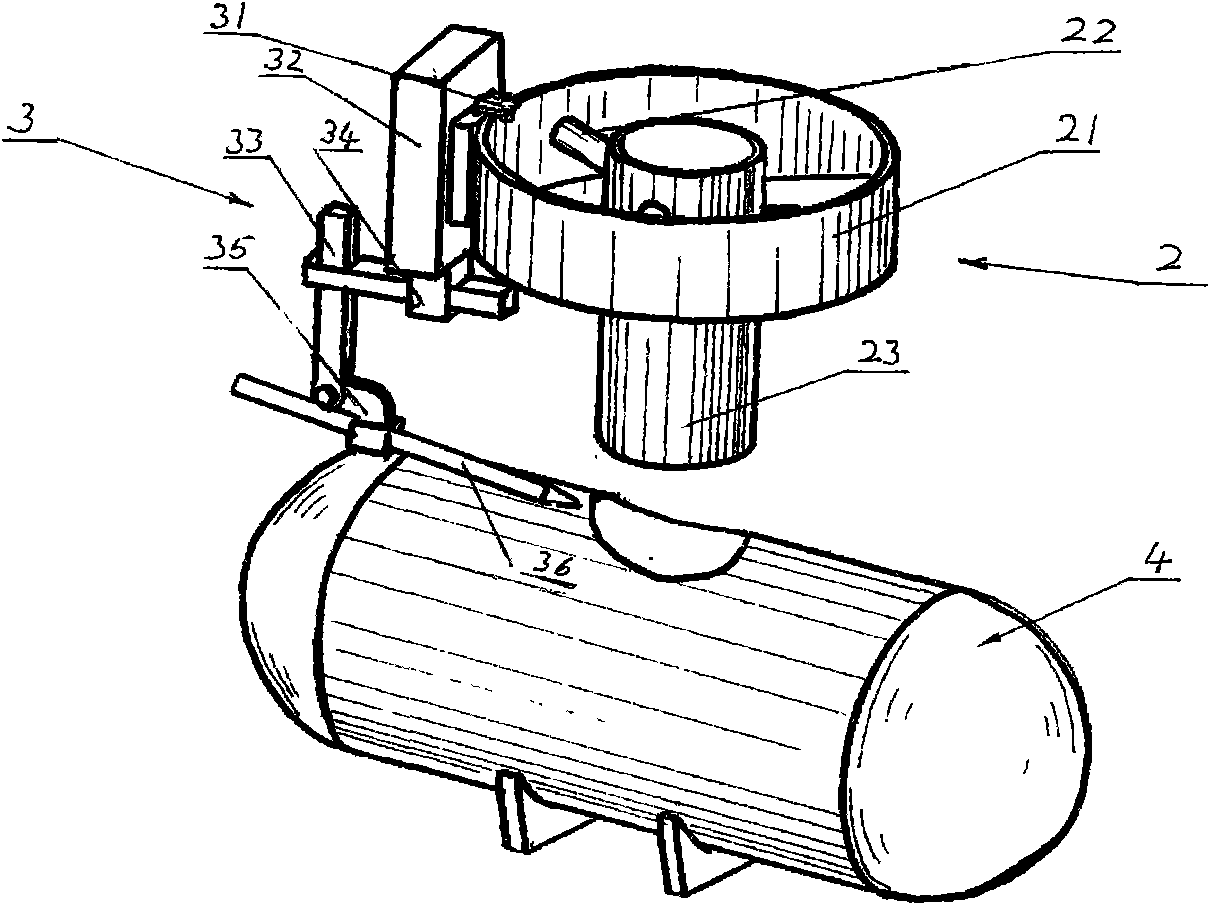

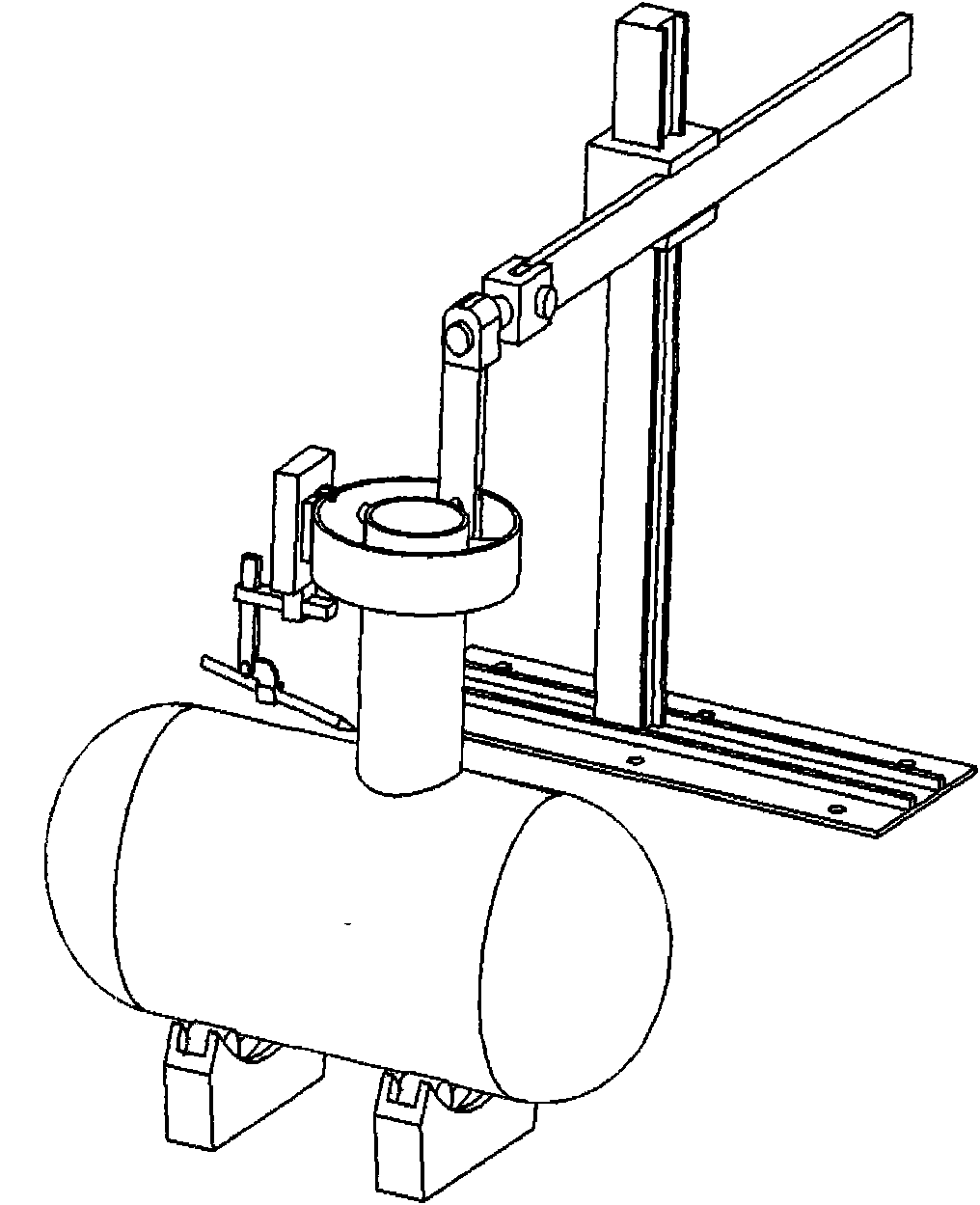

[0012] by Figure 1 to Figure 3 Shown, a hole-opening nozzle and saddle-shaped welding seam welding equipment is mainly composed of a cross-type automatic operating machine 1, a welding head track 2, a welding head 3 and a cylindrical workpiece 4. Among them: the cross-type automatic operating machine 1 The axial moving device 11 is connected to the corresponding base part by bolts, the vertical lifting arm 12 is fixed to the axial moving device 11, and the horizontal moving arm 13 is sleeved with the vertical lifting arm 12 through the kit 19, and can slide laterally along the kit 19, A fork 16 with an axis B is connected to one end of the transverse moving arm 13 through an axis A, and is connected to a suspension arm 17 through an axis B of the fork 16; the welding head track 2 is formed by a circular track 21 and connected to it. It is composed of a built-in three-jaw clamping device 22, and the workpiece 23 is clamped by the three-jaw clamping device 22. The ring-shaped we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com