Patents

Literature

257results about How to "Prevent displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

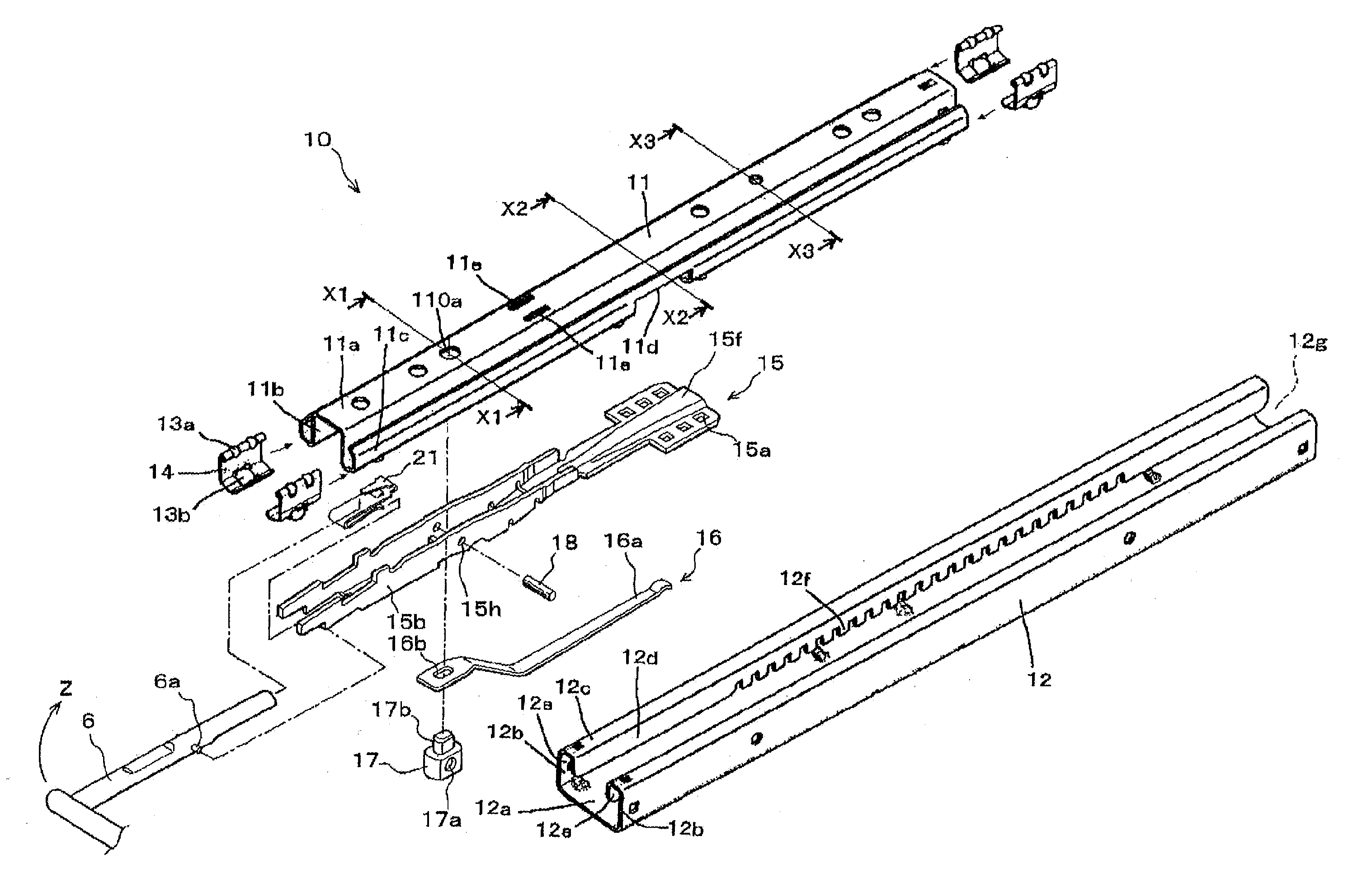

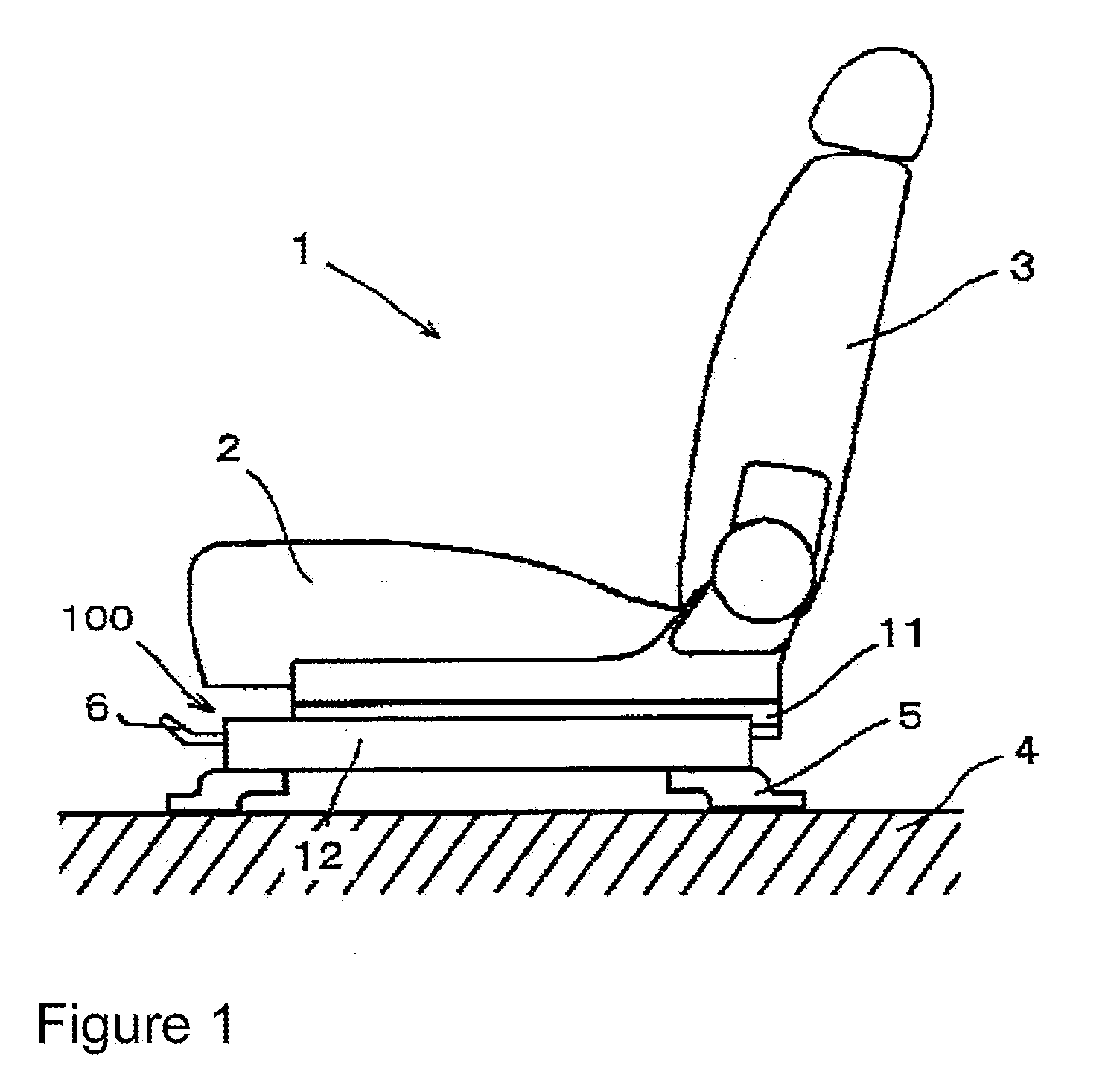

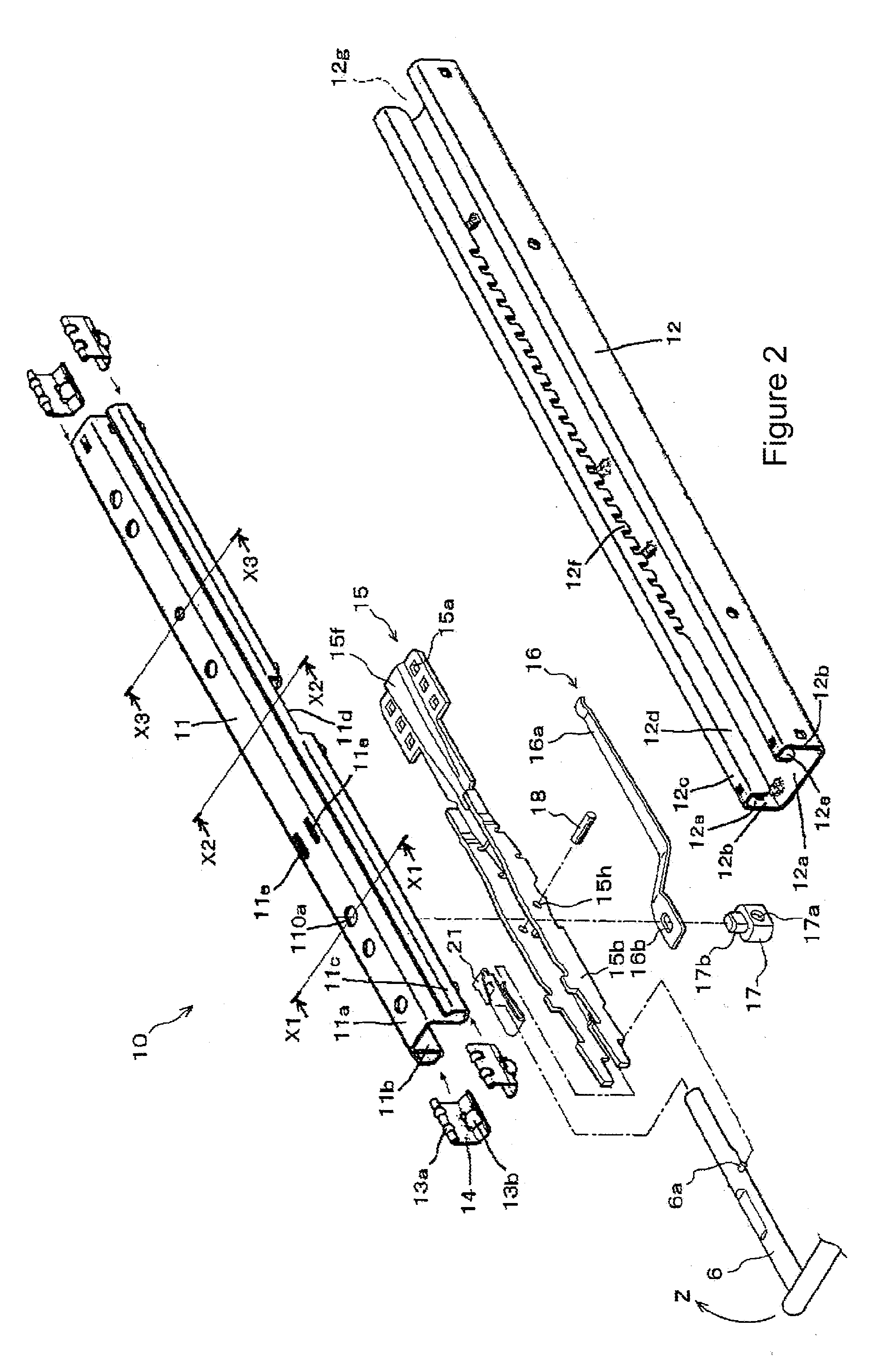

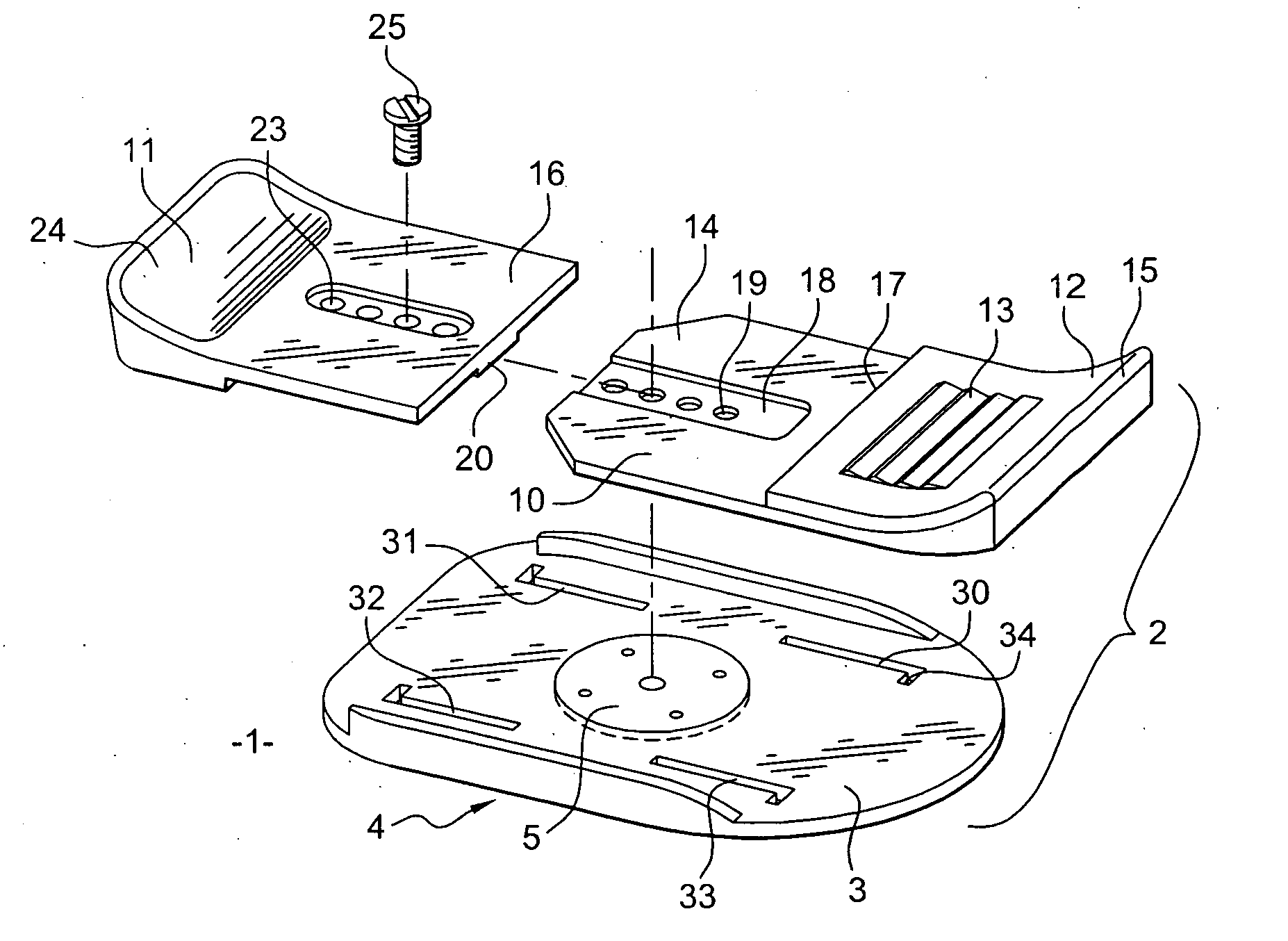

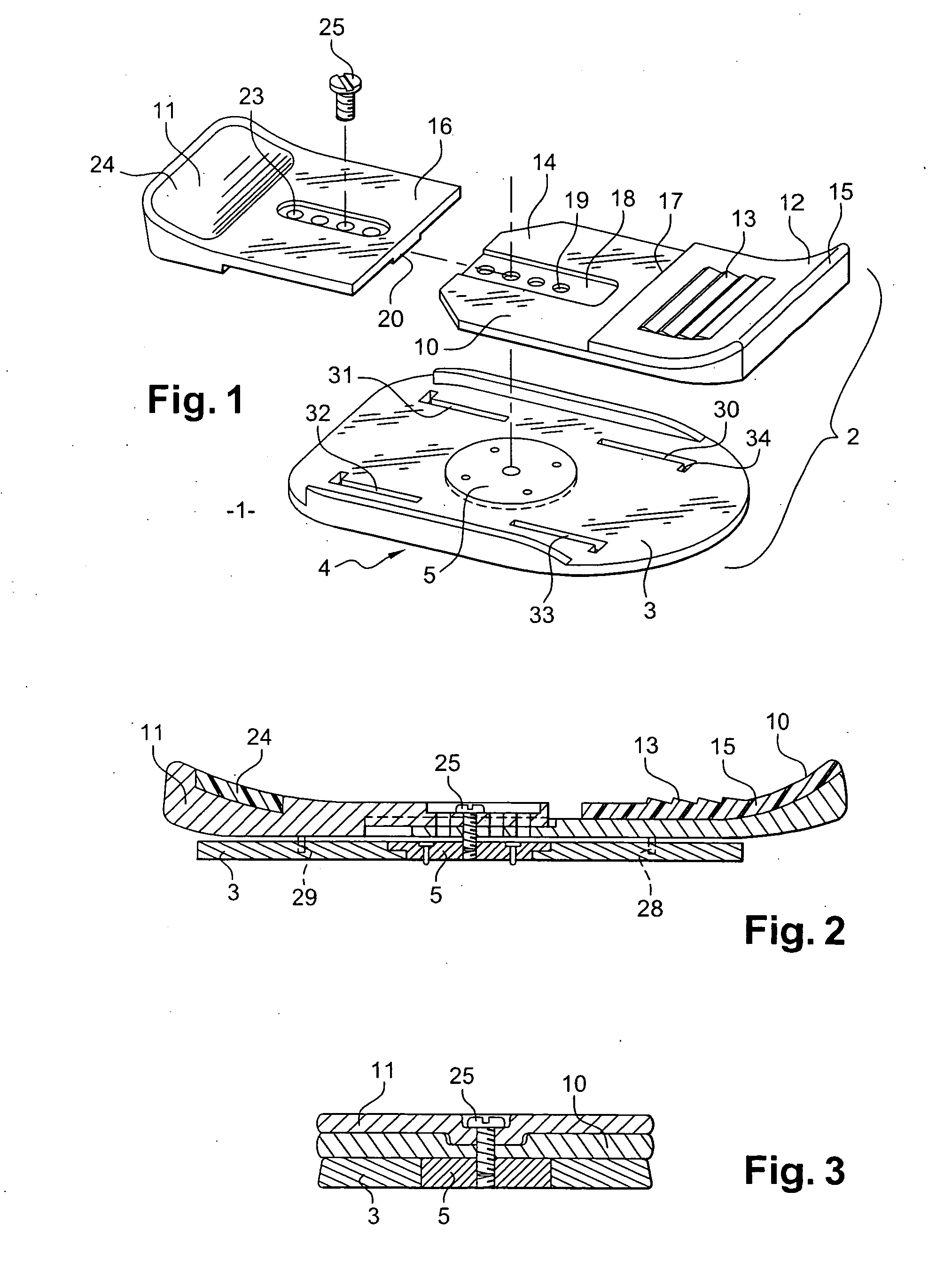

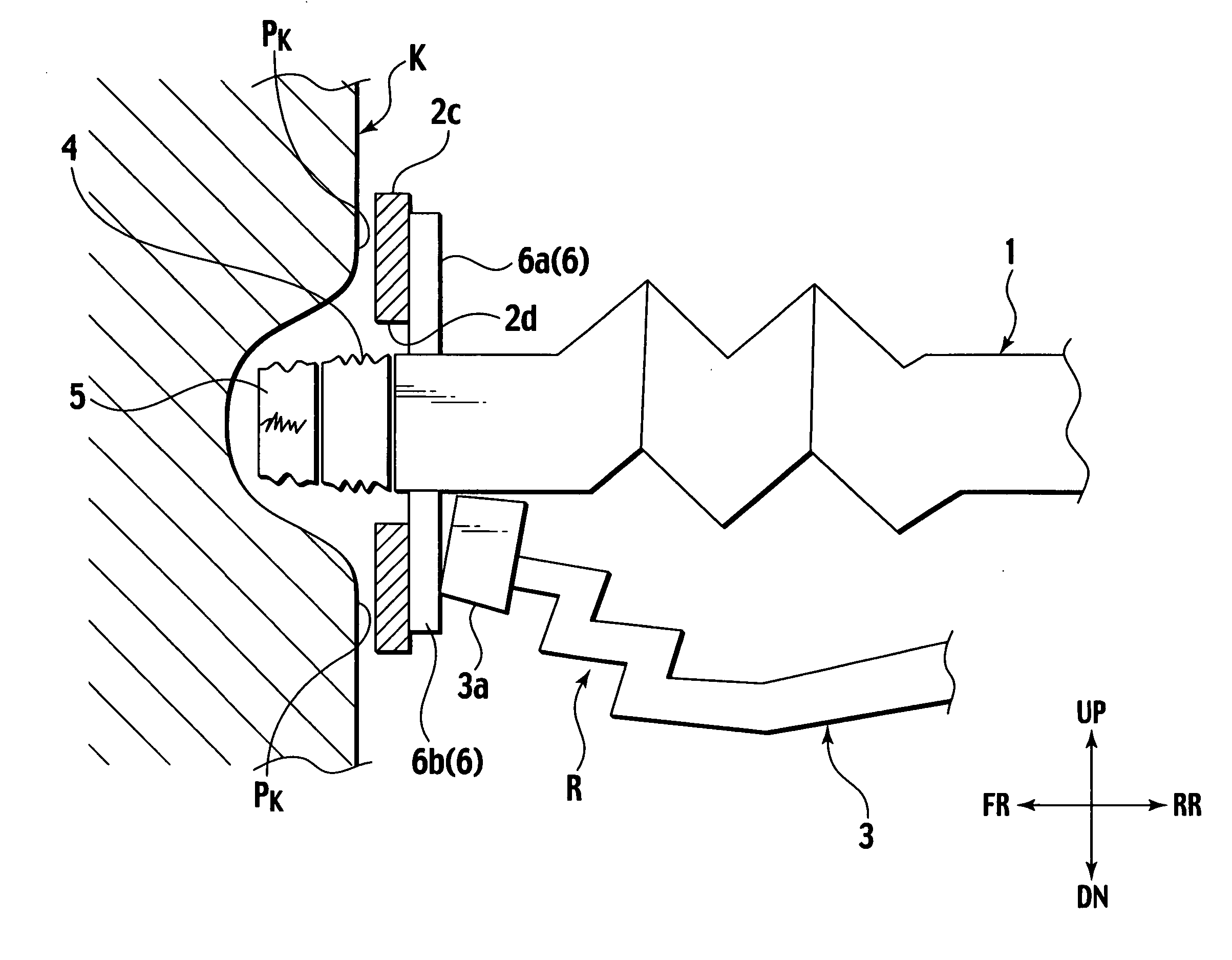

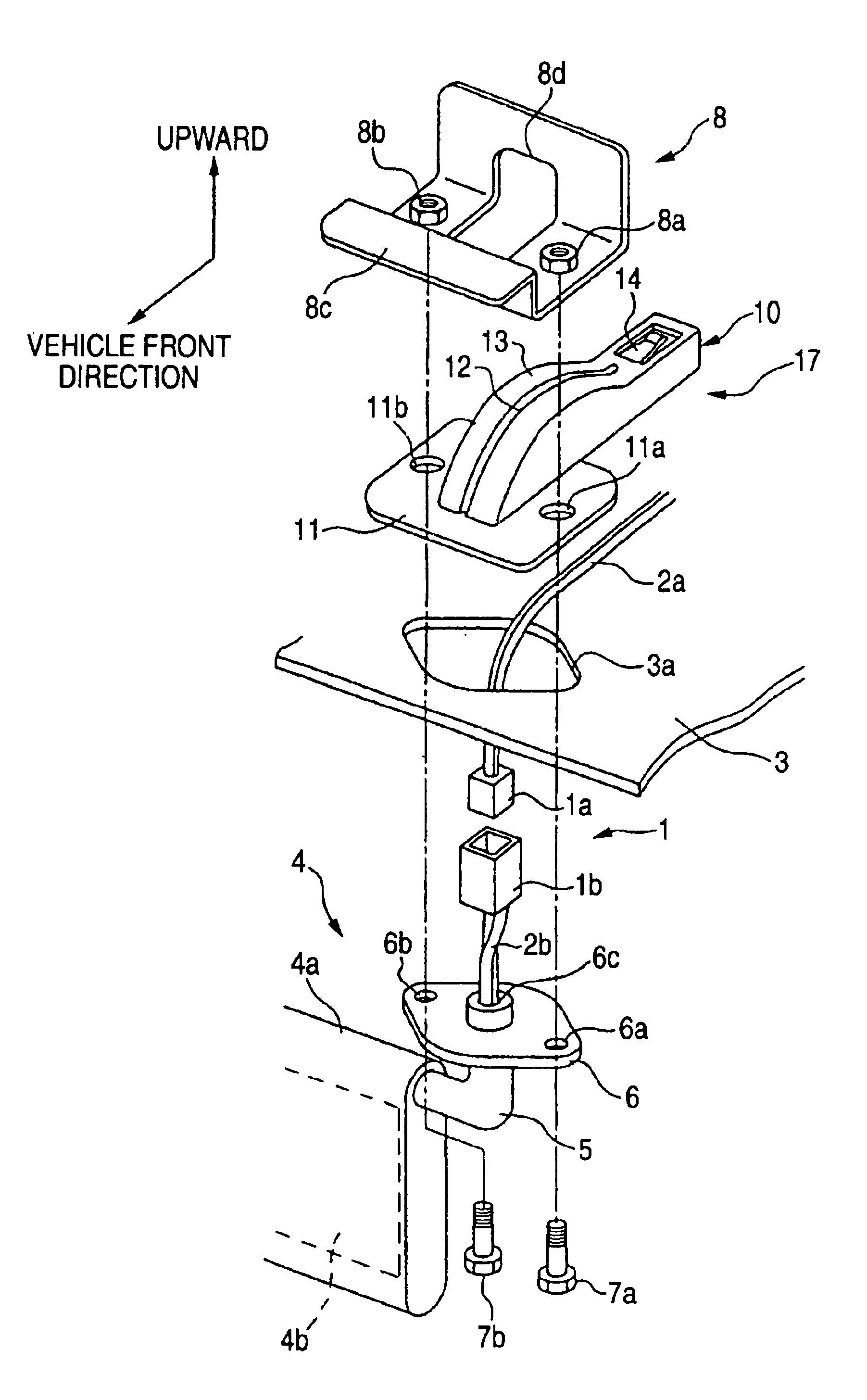

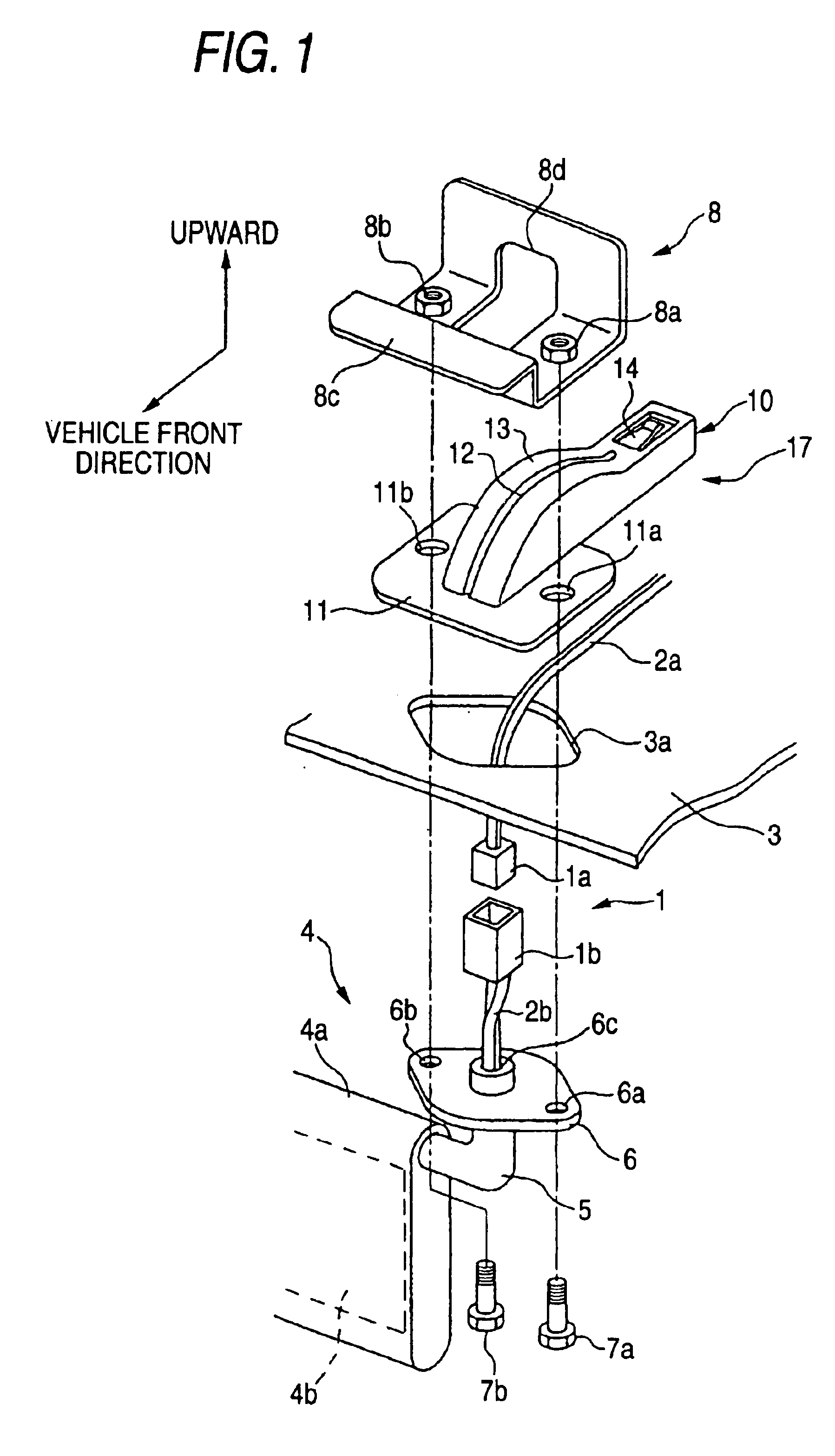

Slide rail unit

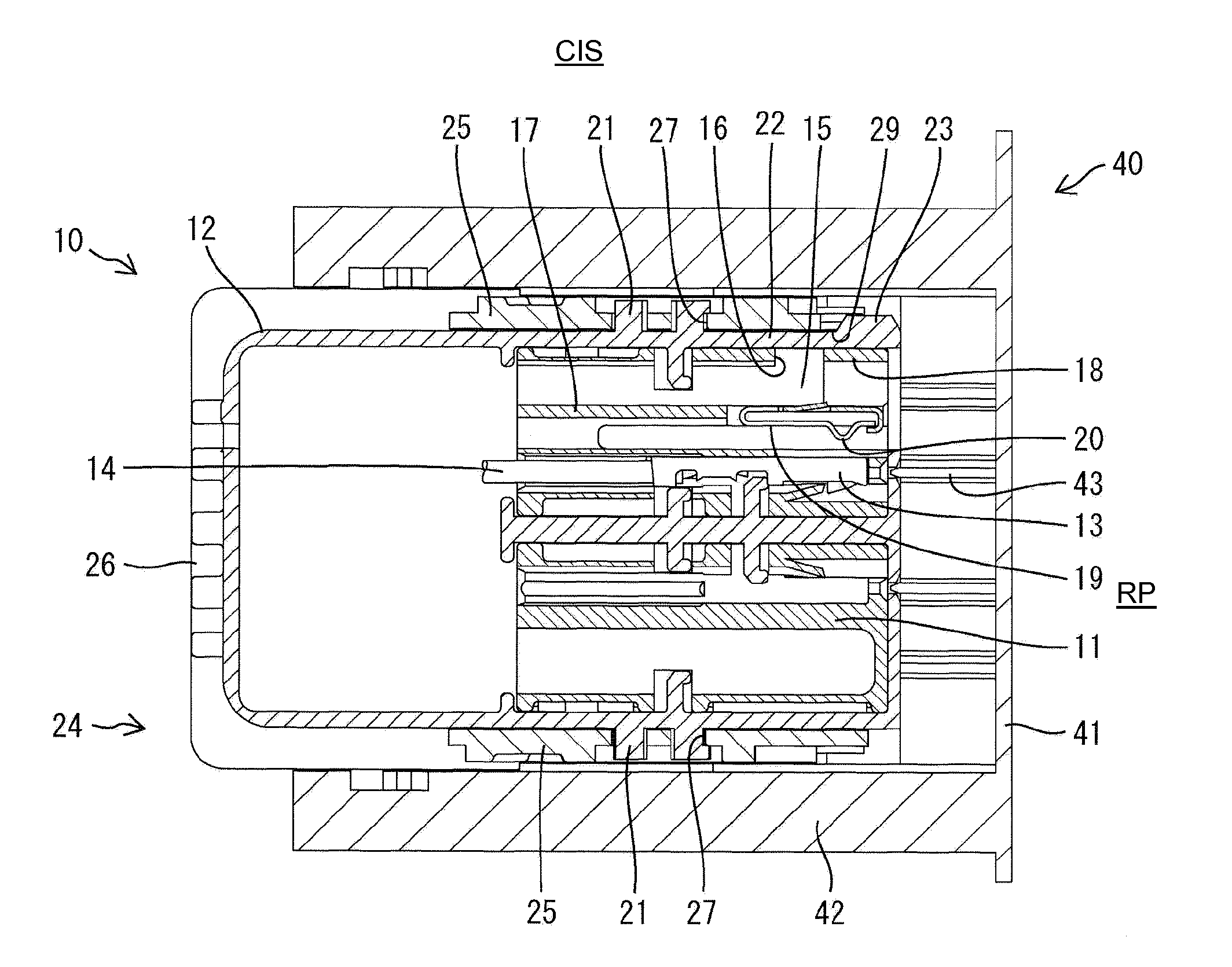

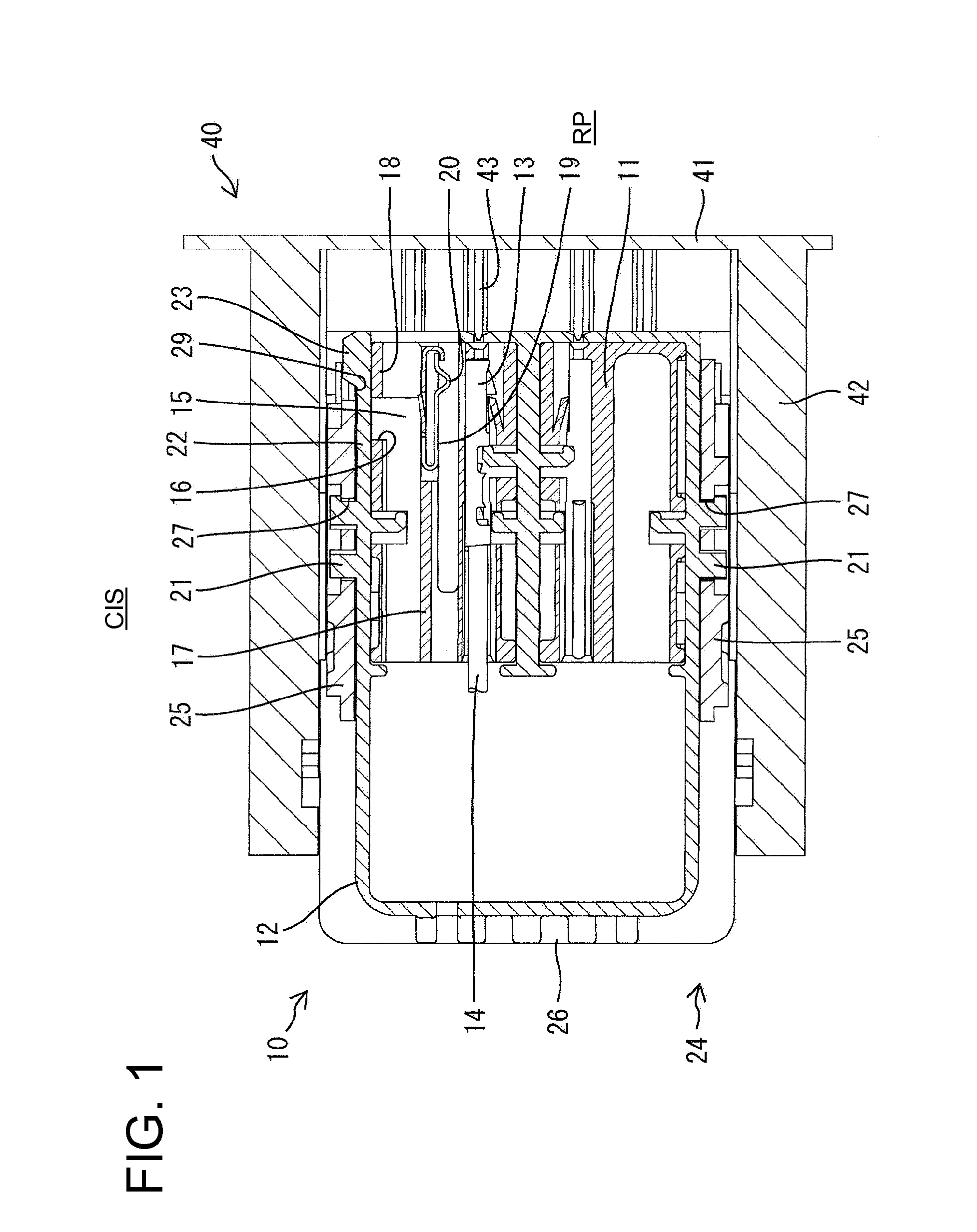

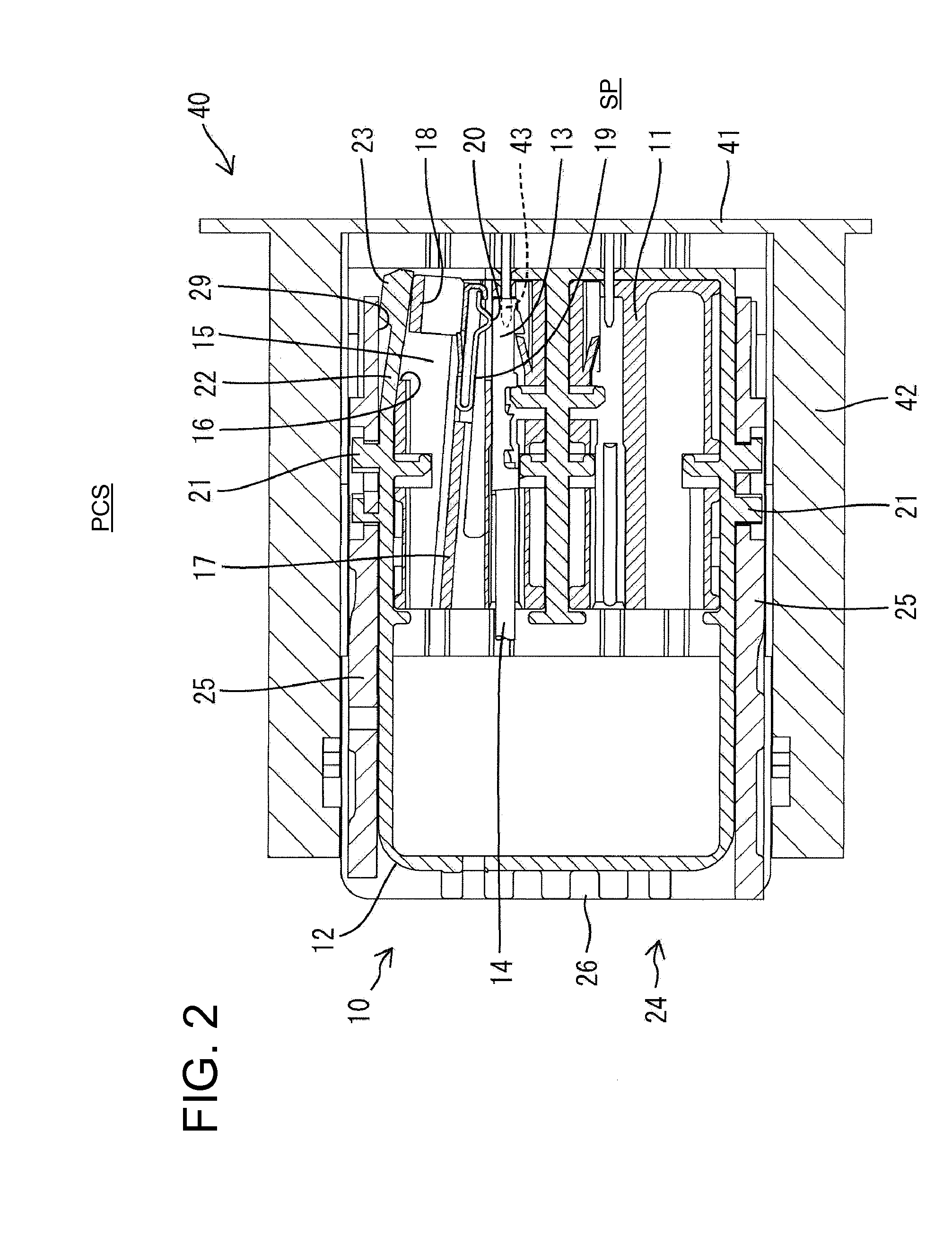

ActiveUS20080231101A1Prevent displacementReliably completeSafety beltsPedestrian/occupant safety arrangementLeaf springEngineering

A simple, compact and easy-to-assemble slide rail unit is provided. The slide rail unit reliably restrains right and left rails from sliding even when the right and left rails are installed onto the vehicle floor at an inclination angle different from each other in a longitudinal direction thereof. The slide rail unit includes a slide rail member having an upper rail member and an upper rail member slidably engaged with each other and a lock lever rotatably pivoted to the upper rail member so as to engage with / disengage from an engagement portion formed on the lower rail member. The slide rail unit also includes an operation lever connected to the lock lever within the slide rail member. Between the lock lever and the operation lever, a leaf spring member is disposed for connecting the lock lever and the operation lever therebetween.

Owner:IMASEN ELECTRIC IND

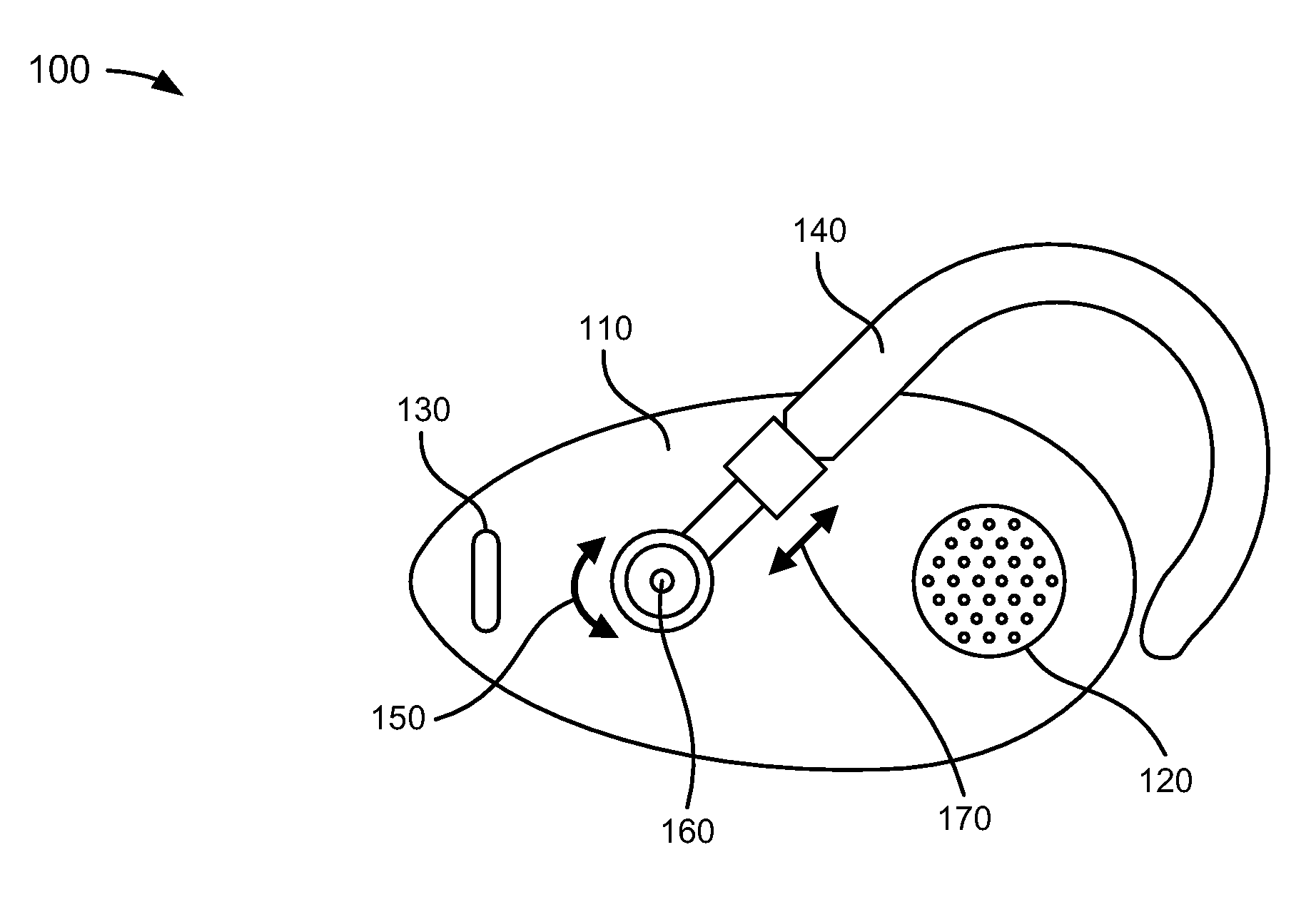

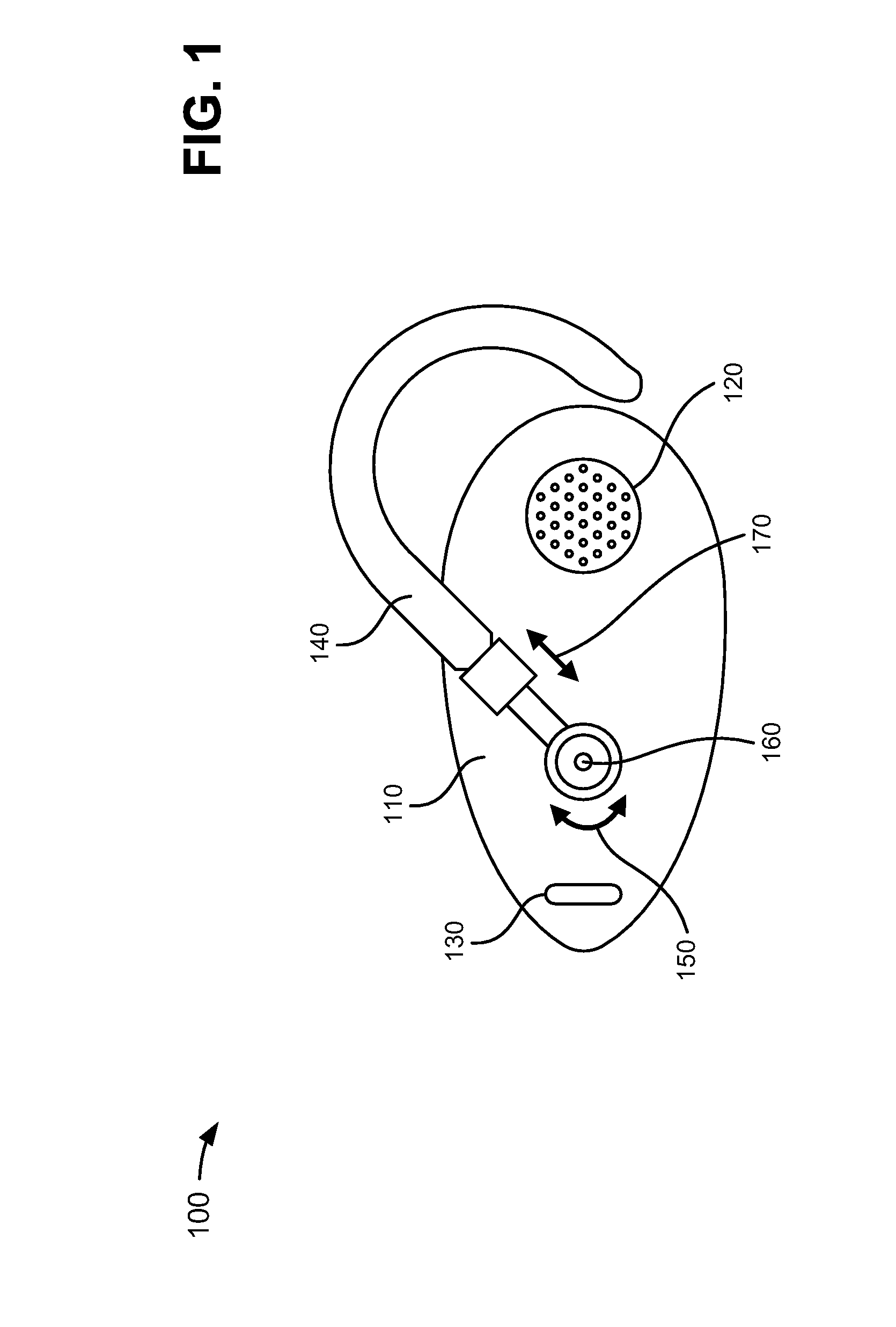

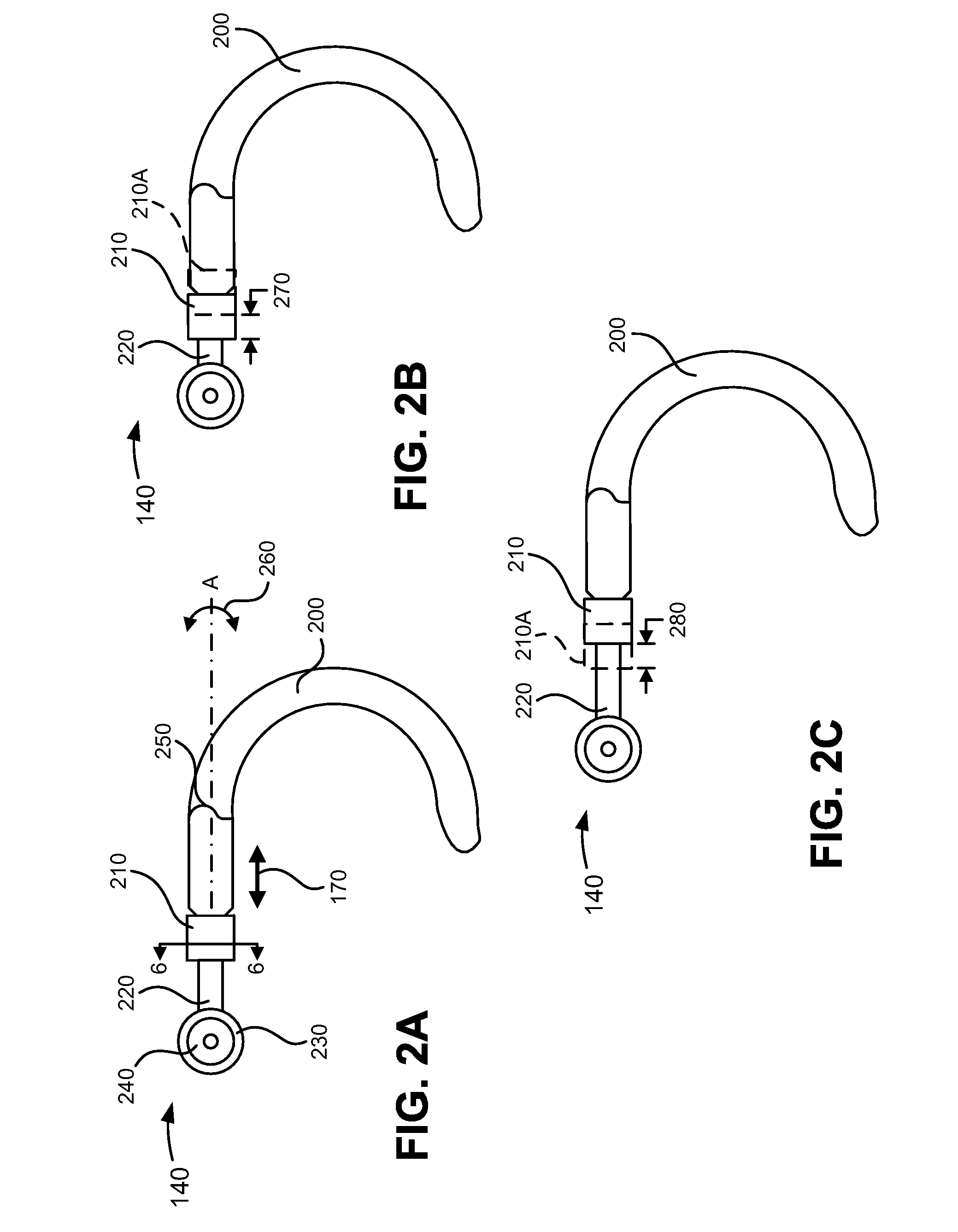

Adjustable earpiece

InactiveUS20080080704A1Prevent displacementPrevent movementInterconnection arrangementsSupra/circum aural earpiecesRelative displacementHinge angle

An adjustable earpiece for a communications headset includes a hook, an arm to displaceably connect to the hook, a hinge to connect to the arm and to the communications headset, and a connection mechanism to adjustably prevent relative displacement of the arm and the hook.

Owner:SONY ERICSSON MOBILE COMM AB

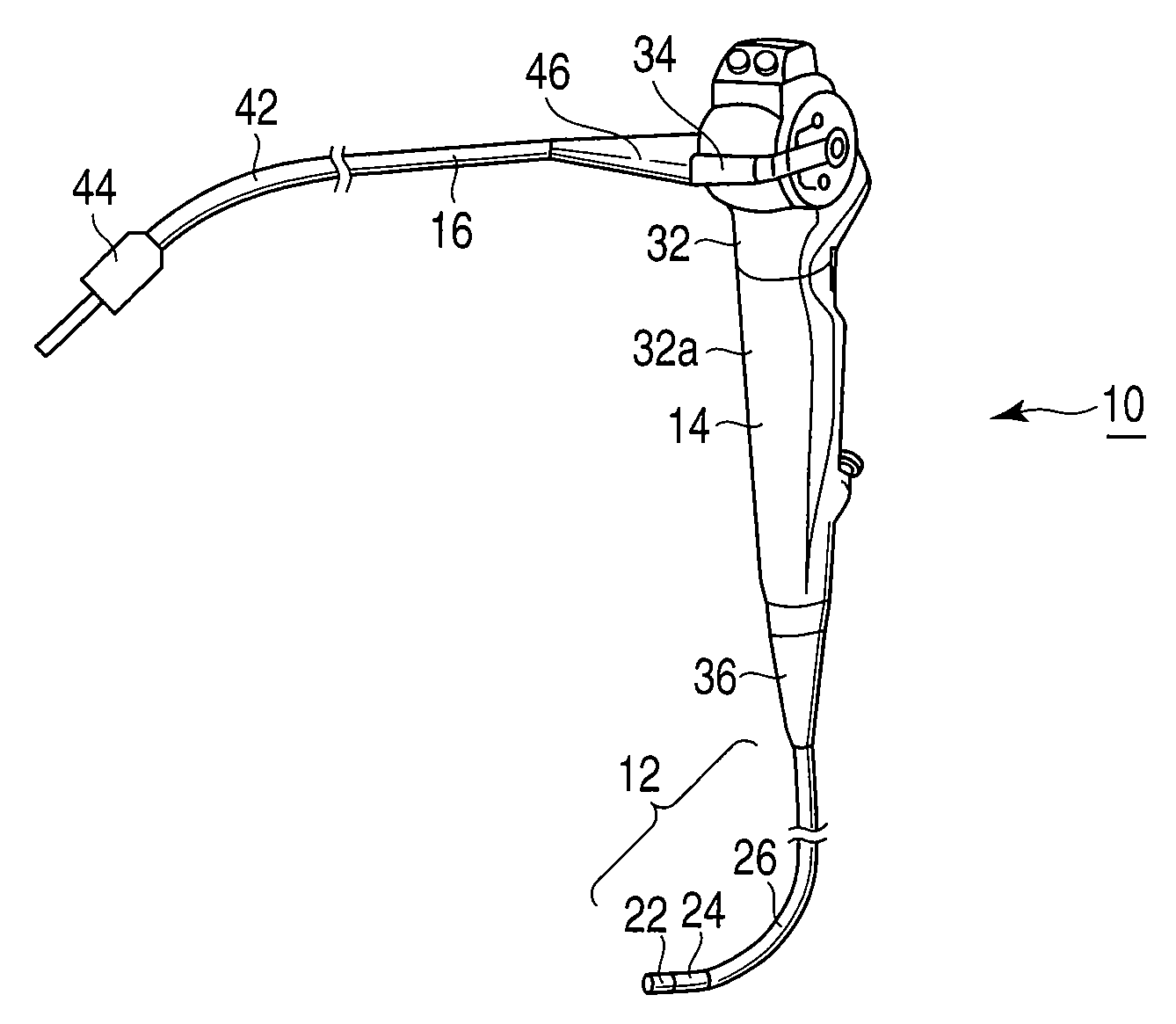

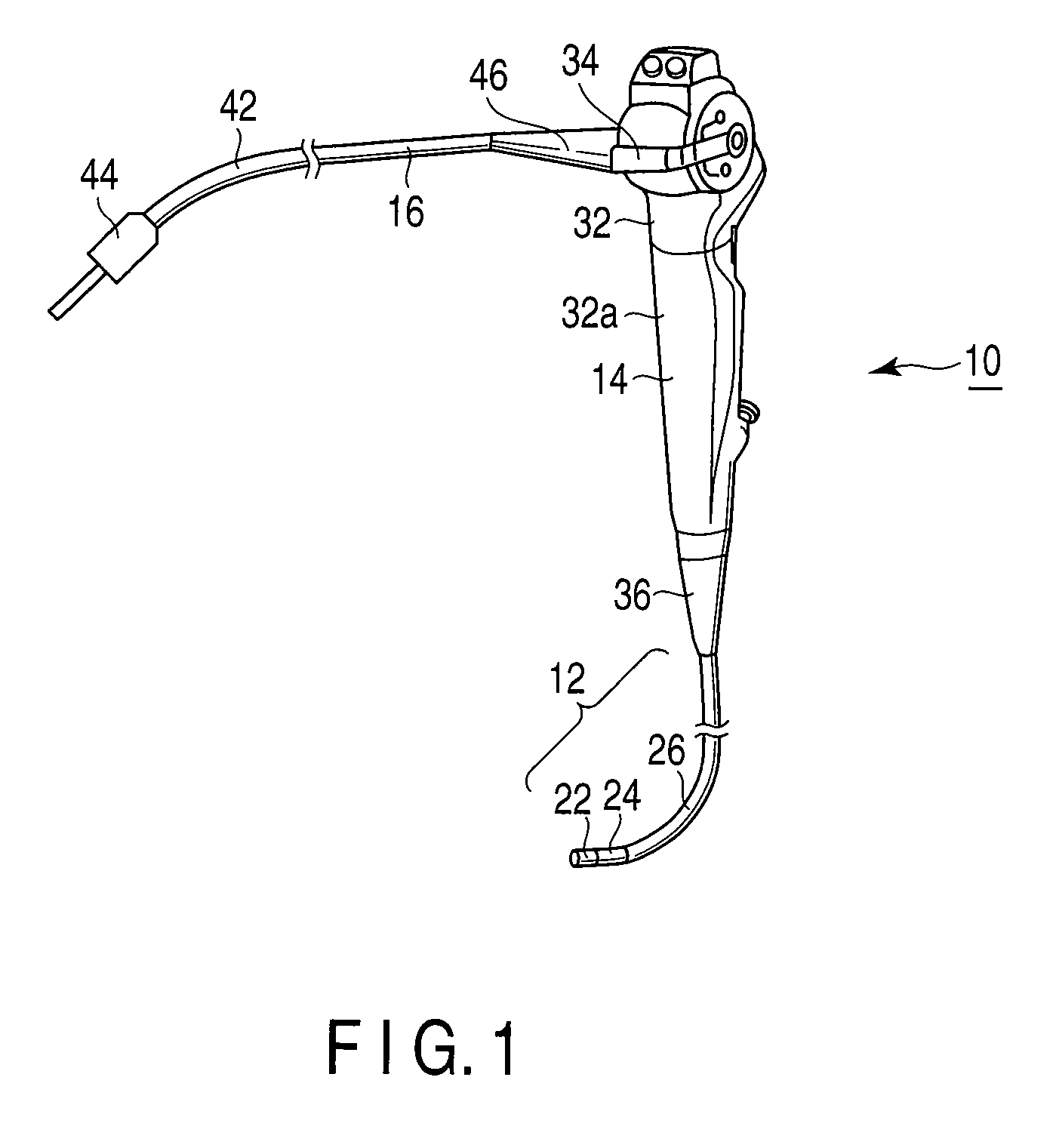

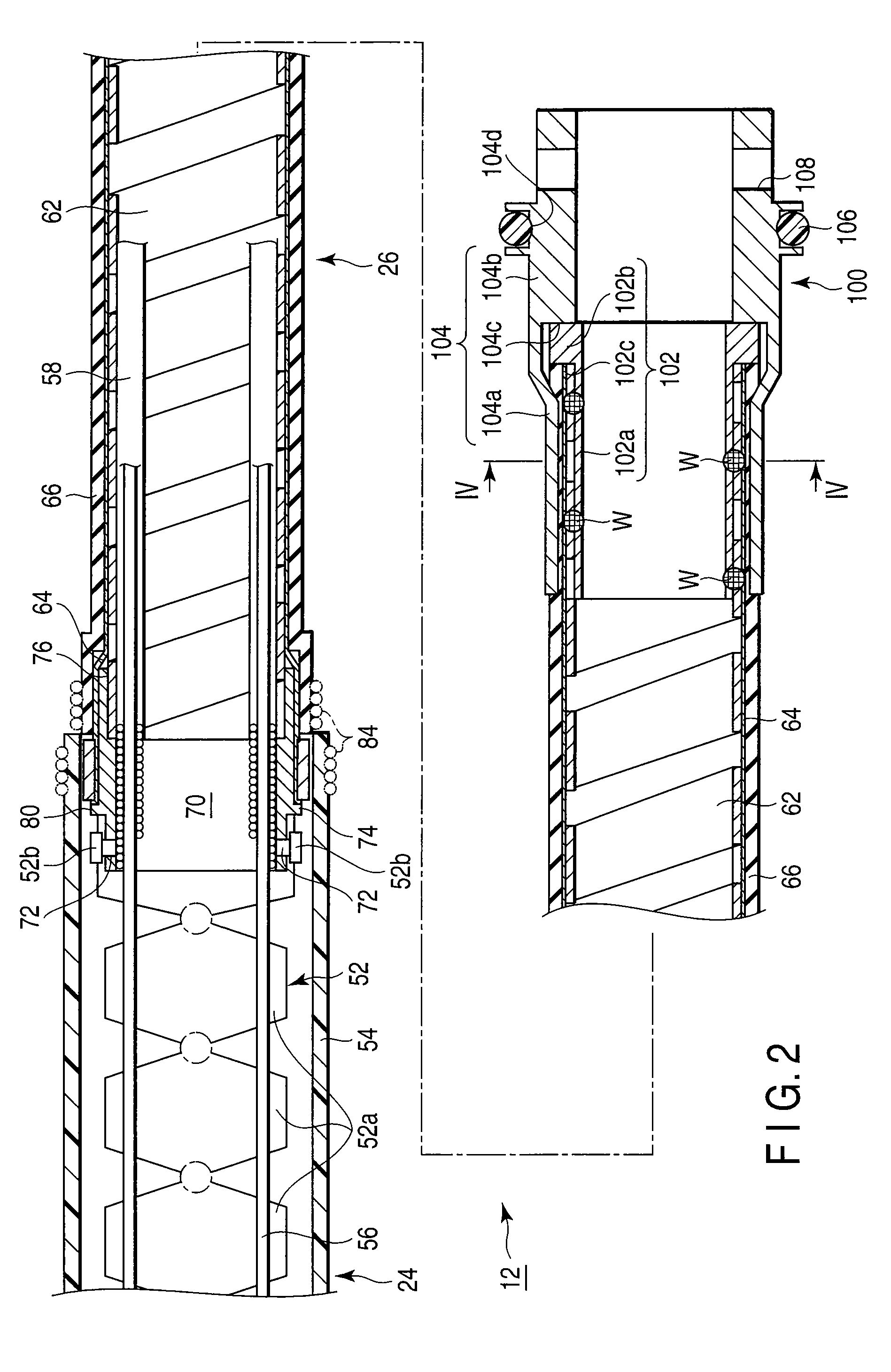

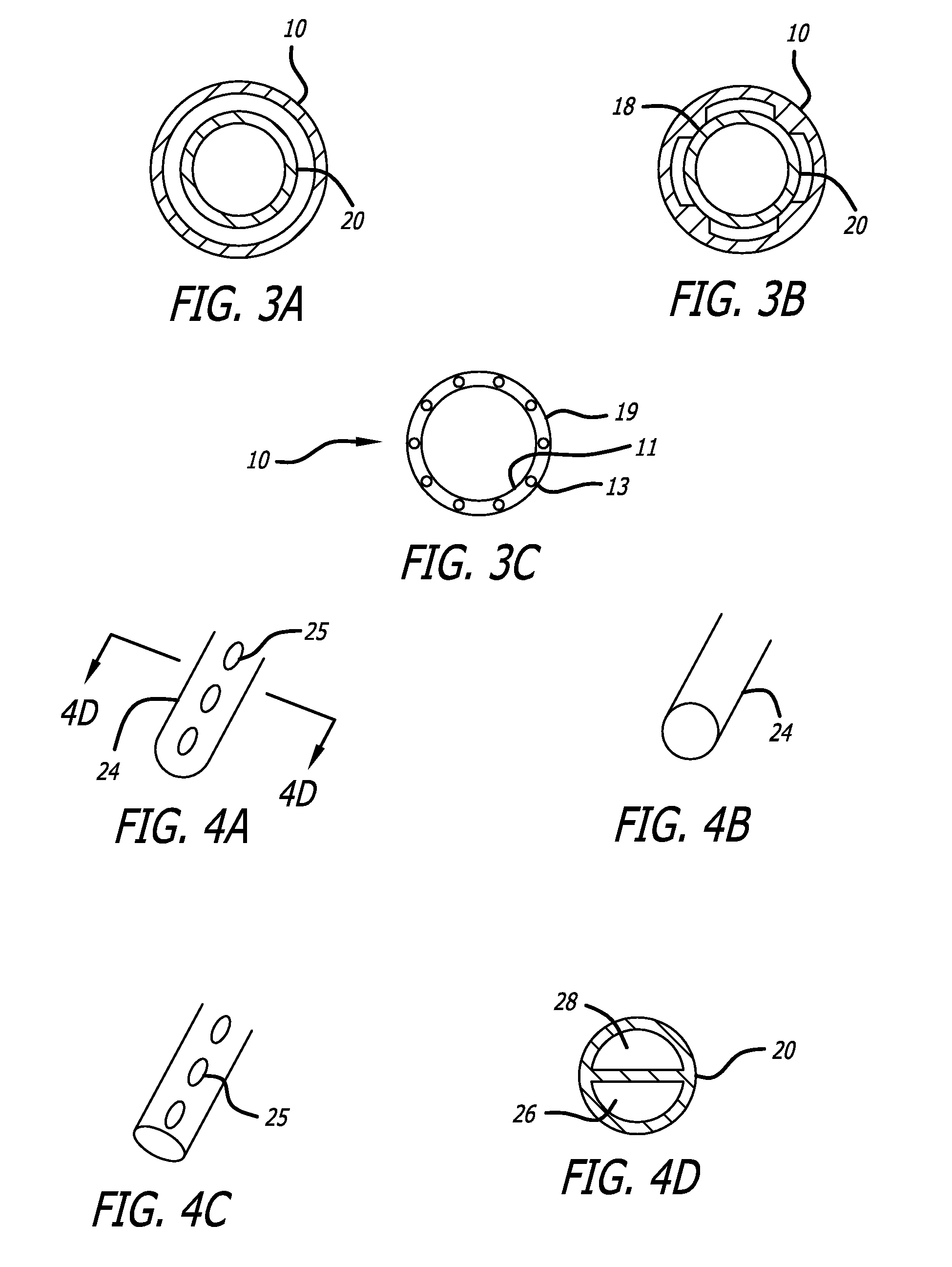

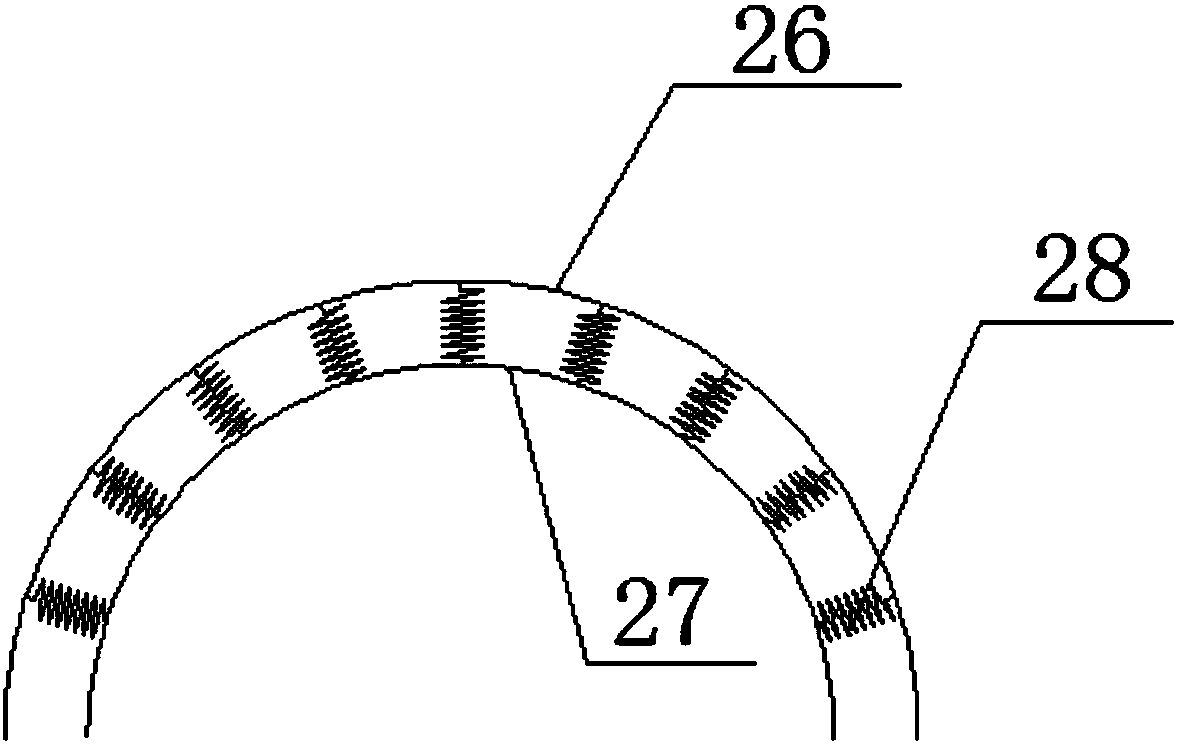

Endoscope and attaching method of connection mouth ring to end of endoscopic flexible tube

An endoscope includes a flexible tube having a helical tube in which a thin strip plate is helically wound, a braid tube covering the outside of the helical tube, and a flexible outer tube covering the outside of the braid tube, a connection mouth ring plastically deformed and fixed to an end of the flexible tube, and a helical tube displacement preventing portion which prevents displacement of the strip plate of the helical tube at the end of the flexible tube to which the connection mouth ring is fixed, when the connection mouth ring is fixed to the end of the flexible tube.

Owner:OLYMPUS CORP

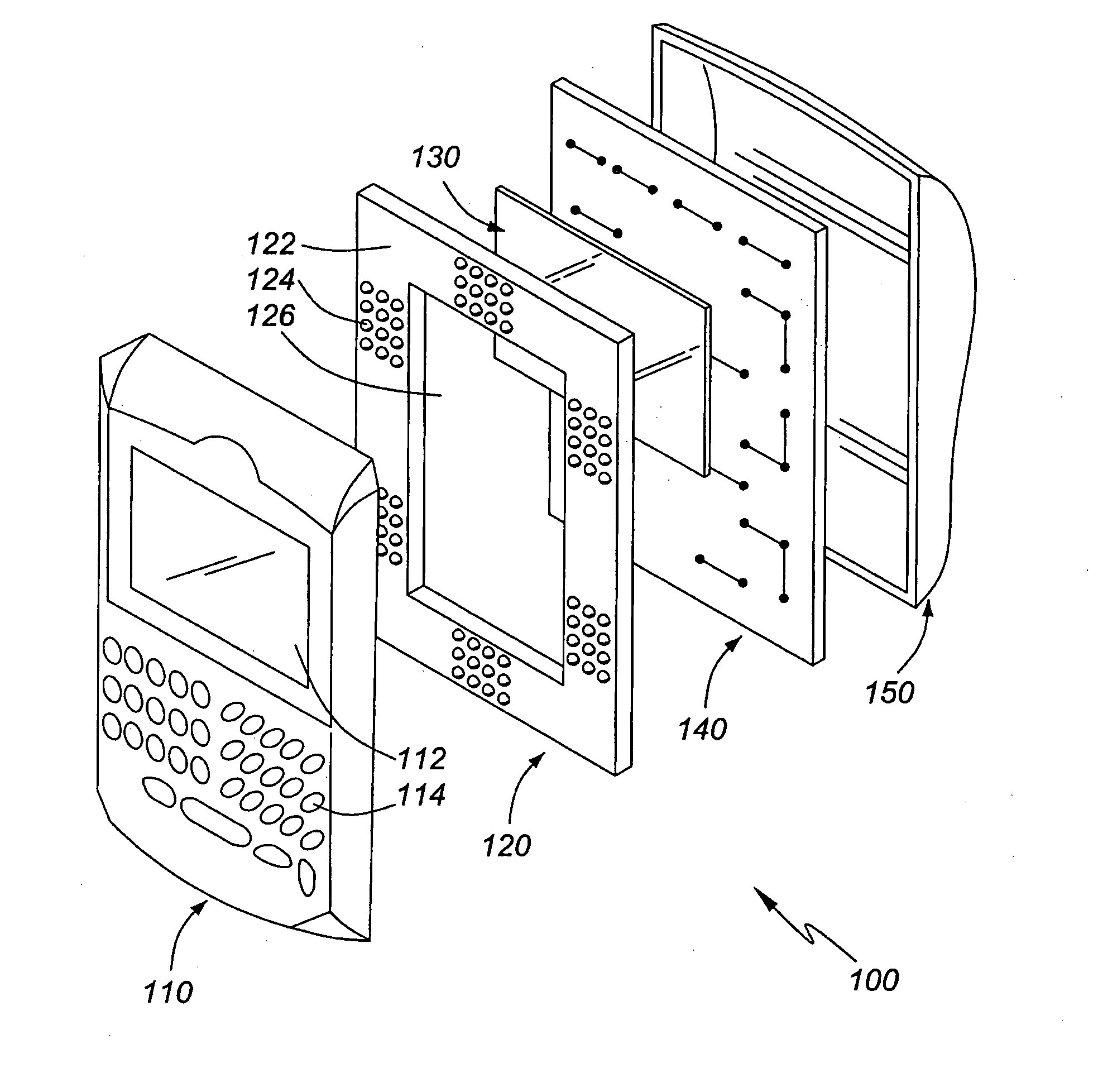

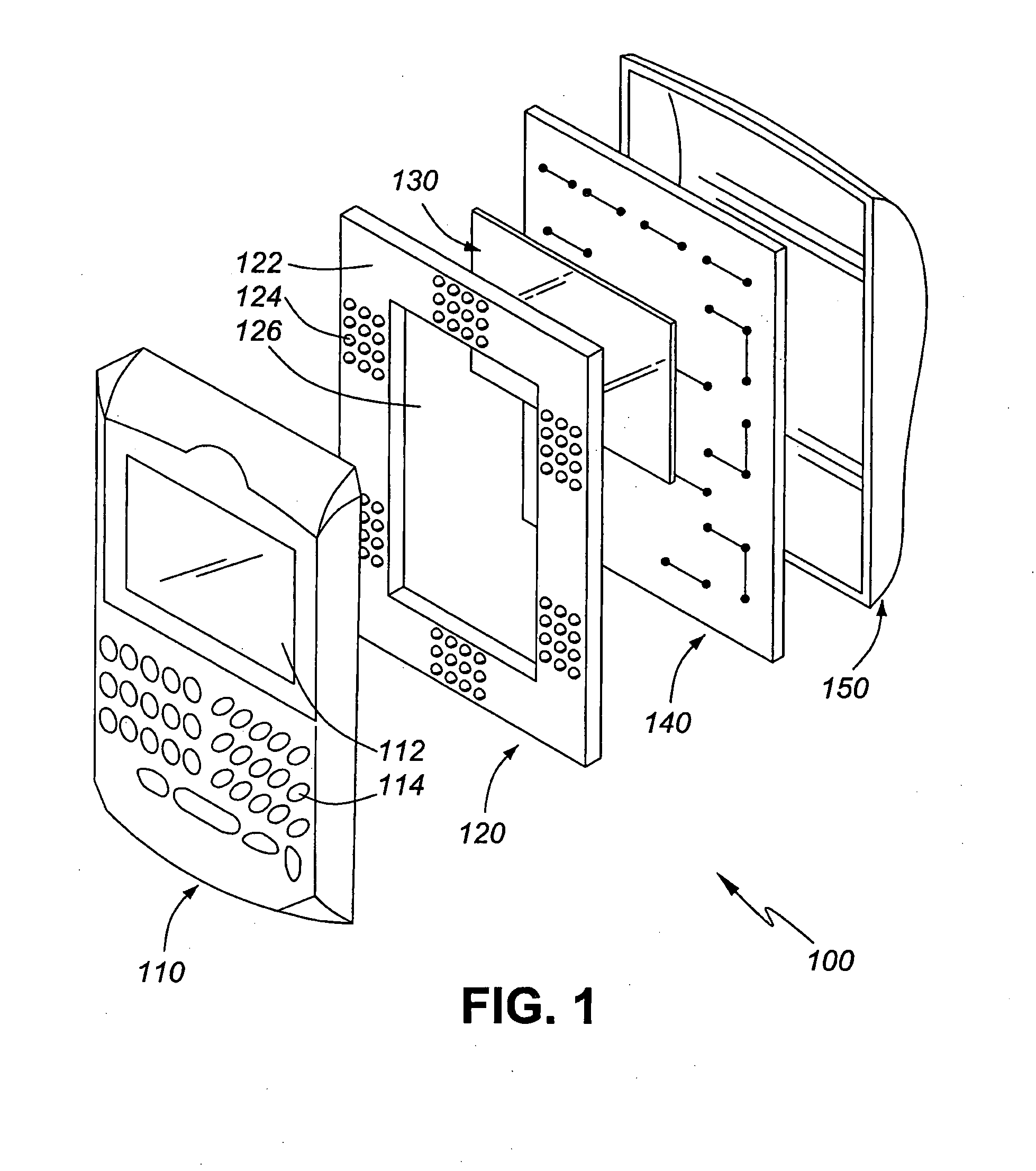

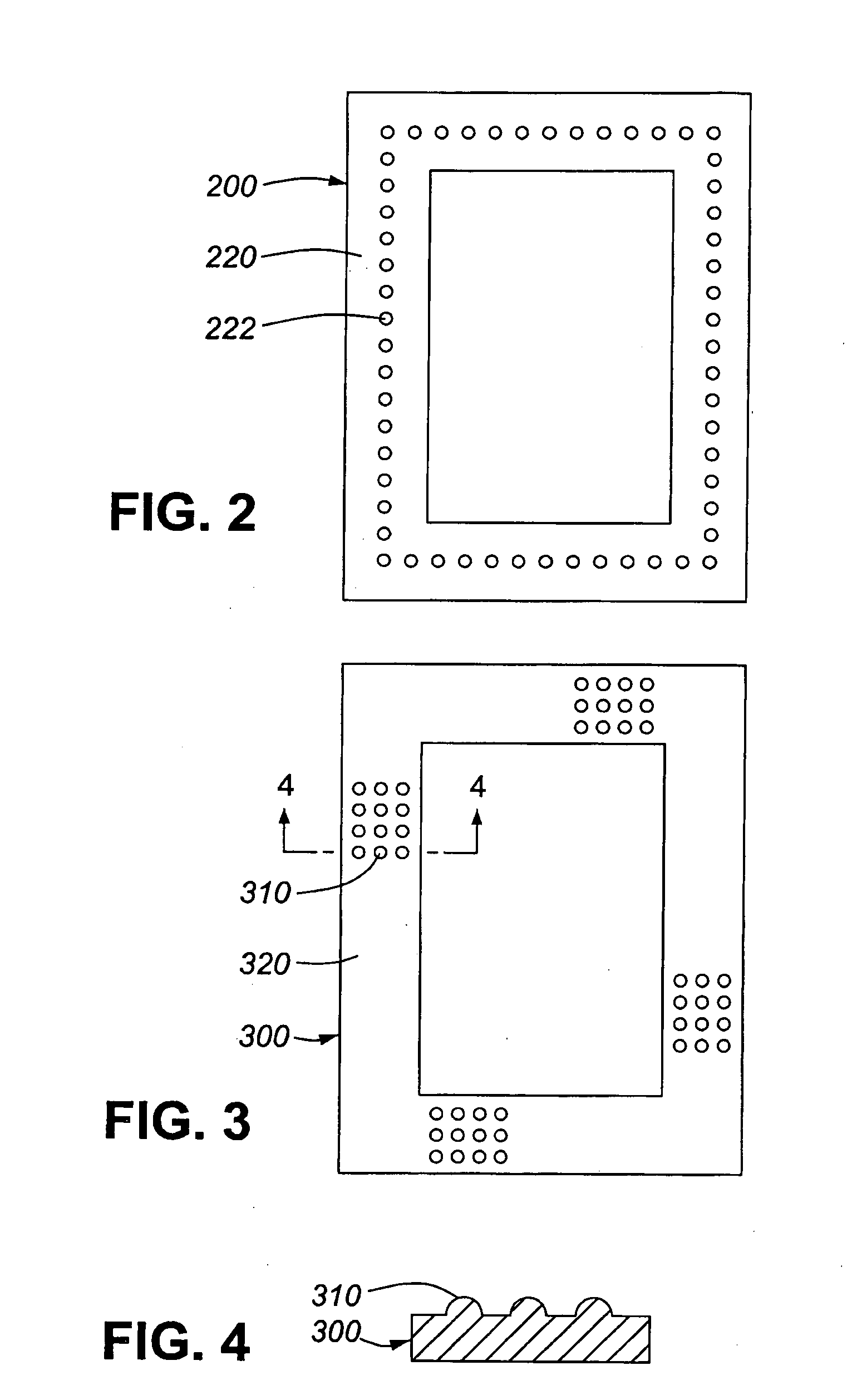

Component assembly cushioning device for mobile devices

InactiveUS20050011659A1Prevent displacementRimsSemiconductor/solid-state device detailsBiomedical engineeringCompressible material

A spacer for use in a mobile device fills the space between a component assembly and a housing. The spacer includes a layer of compressible material for insertion between the component assembly and the housing. A plurality of compressible features are provided on a face of the layer. Upon insertion of the component assembly and assembly of the housing, the compressible features are compressed to fill a gap between the component assembly and the housing without over-compressing the main body of the spacer, allowing the body of the spacer to cushion any subsequent impact to the mobile device.

Owner:BLACKBERRY LTD

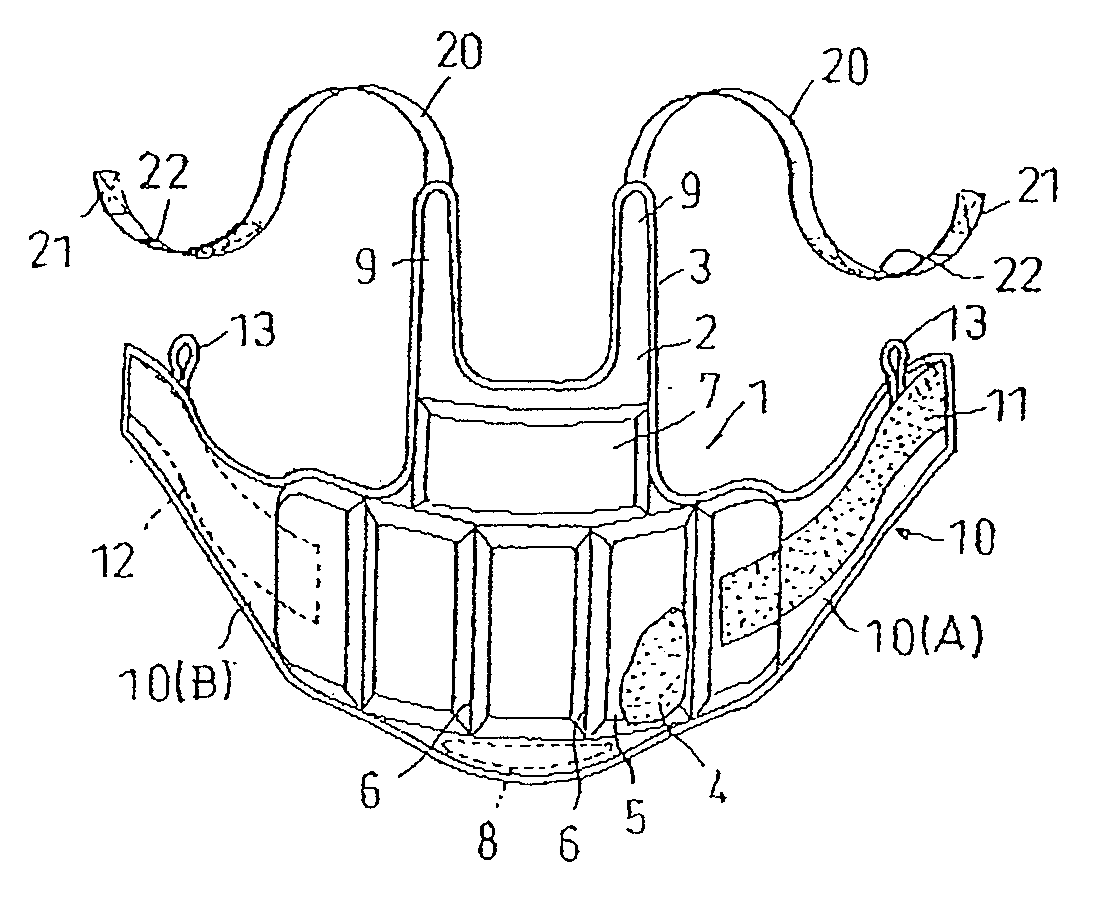

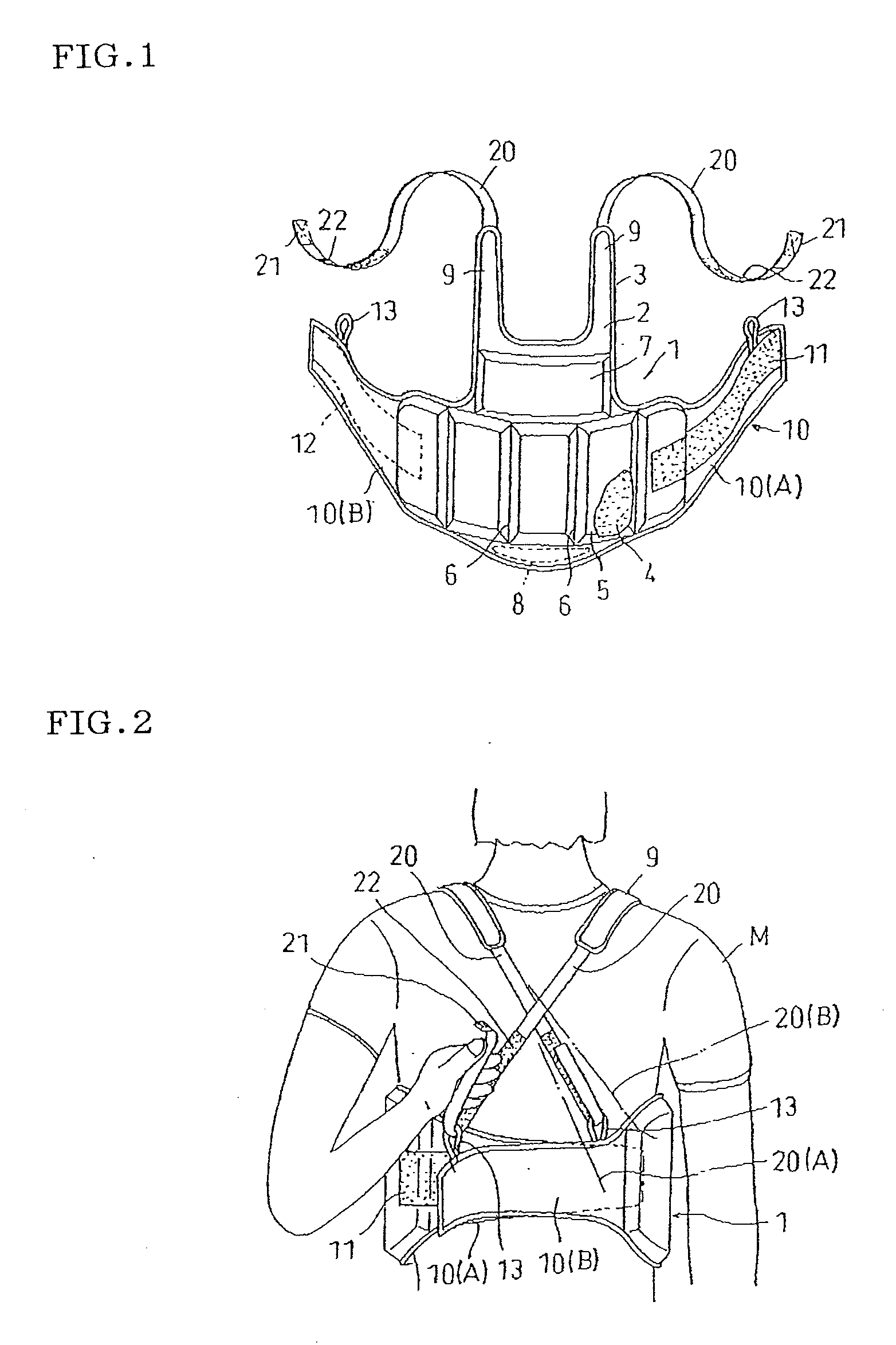

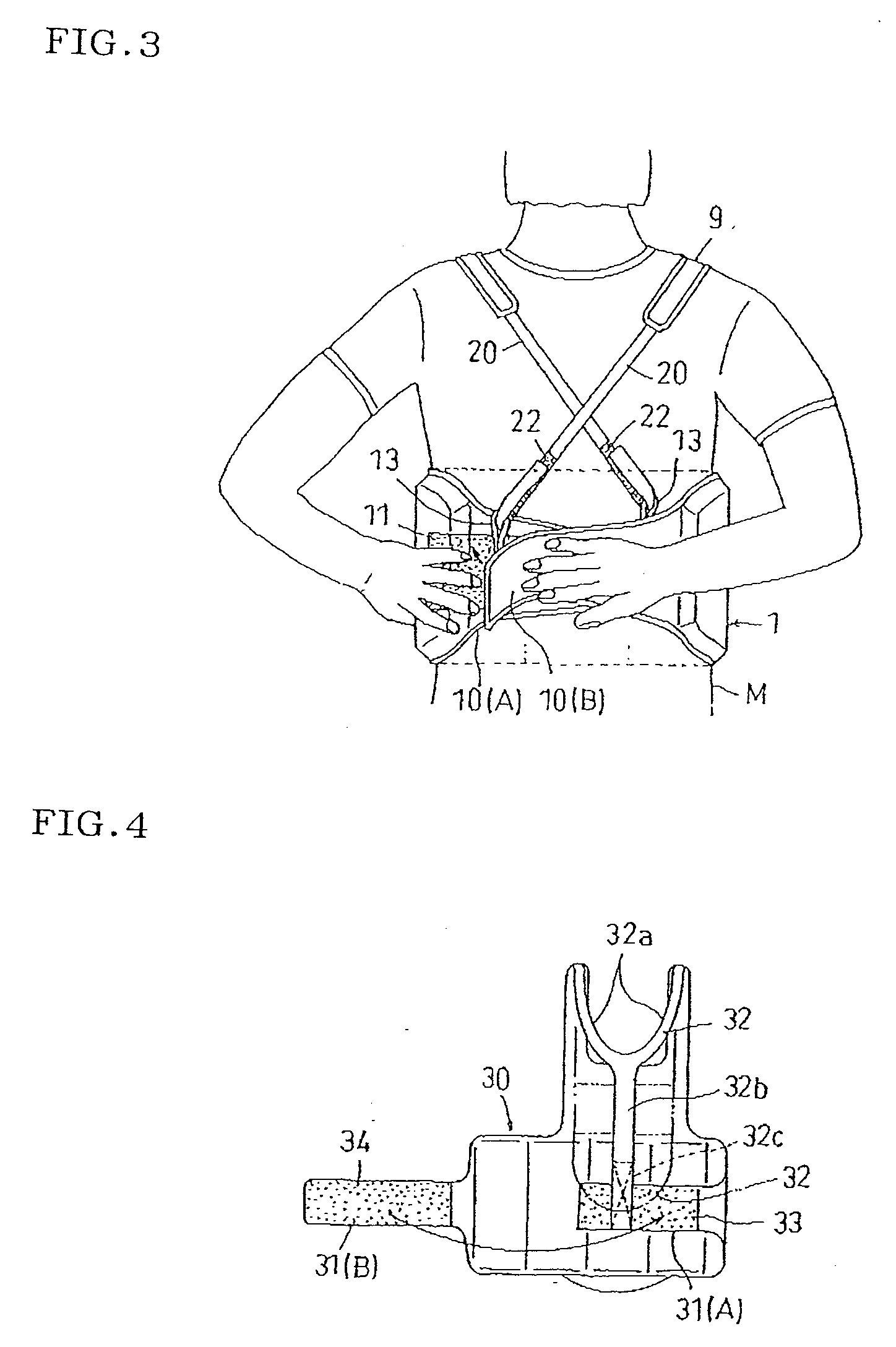

Body protector

InactiveUS20080120768A1Good balancePrevent displacementShoulder strapCombat sportsFastenerEngineering

The invention provides a body protector which can be simply and easily installed and detached by hands of an athlete himself or herself, and can be finely adjusted properly by the hands of the athlete himself or herself after installation. Fastening bands are made detachable via a surface fastener provided during an overlapping under a relation that the fastening bands are structured as a pair of right and left parts respectively extending from both right and left side portions of a protector main body so as to be overlapped with each other, suspending bands are structured such as to extend from two right and left symmetrical positions in an upper portion of the protector main body, and a leading end side of the suspending band is freely attached to and detached from the fastening bands via the surface fastener.

Owner:TSUJIMOTO TAKESHI

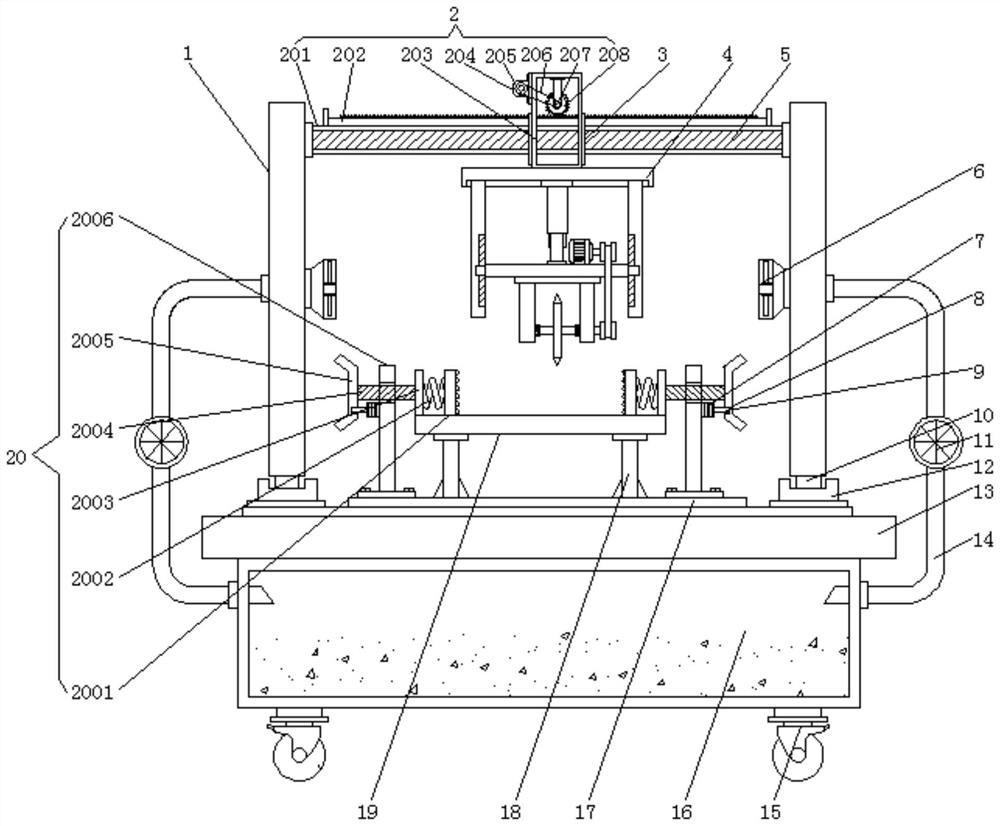

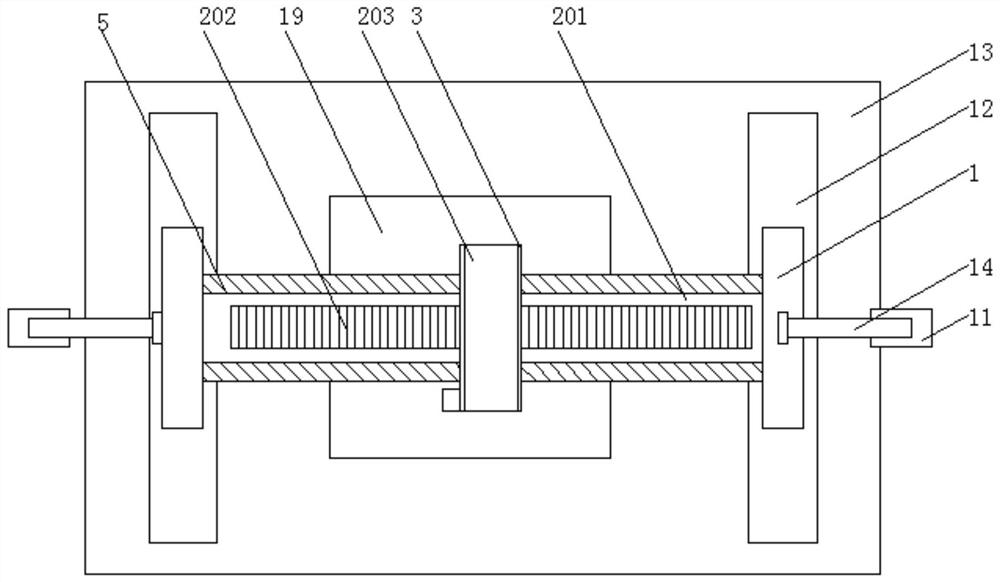

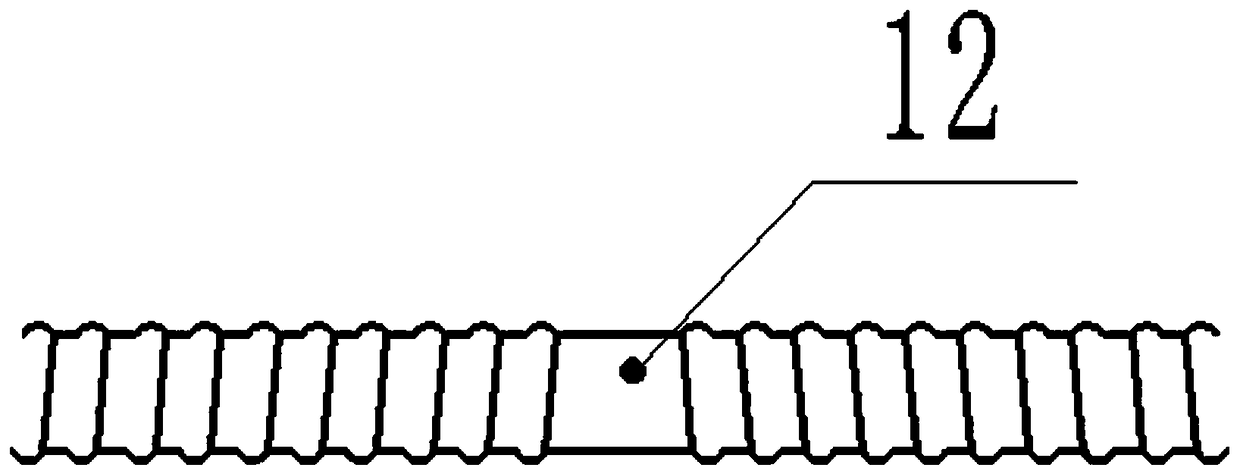

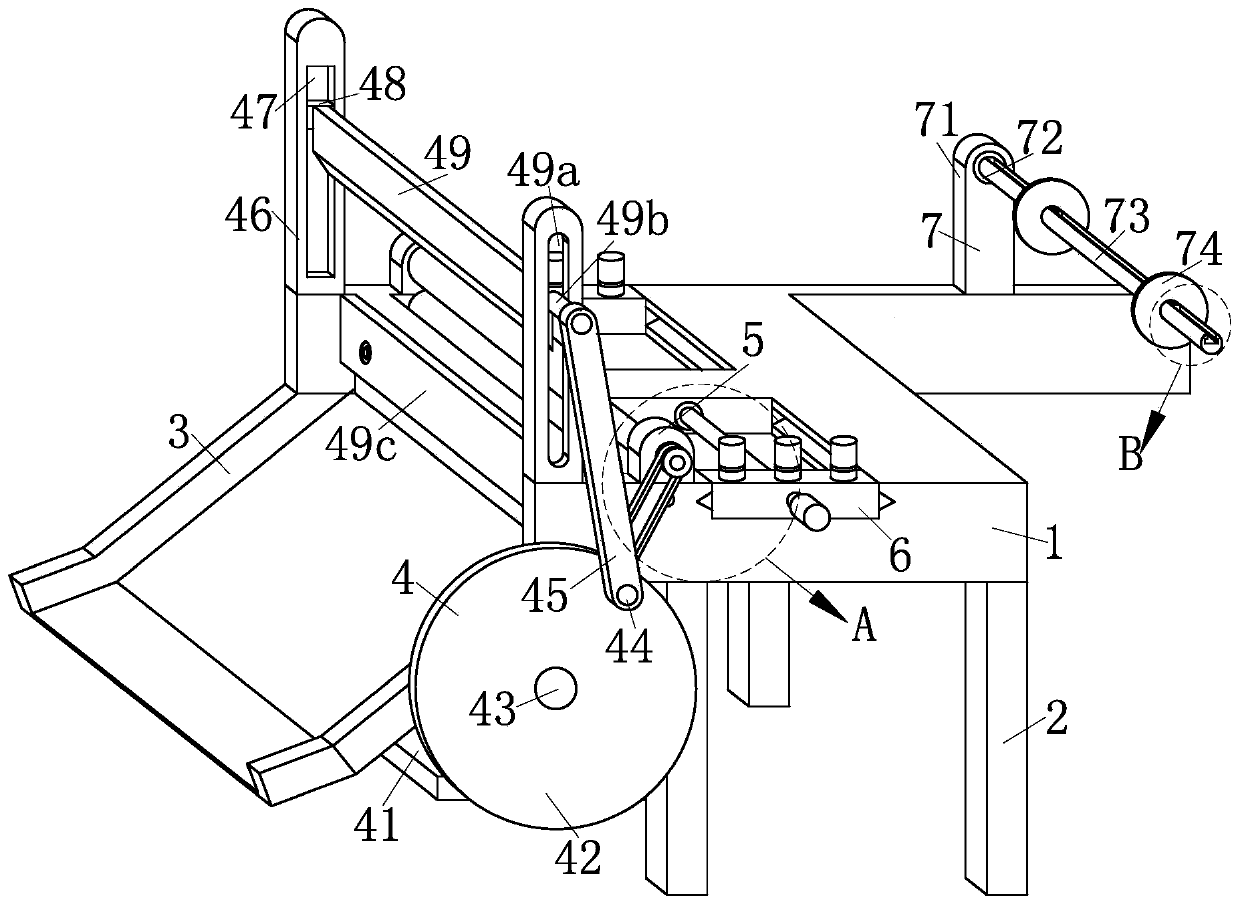

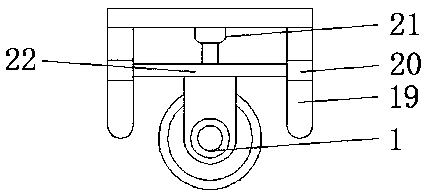

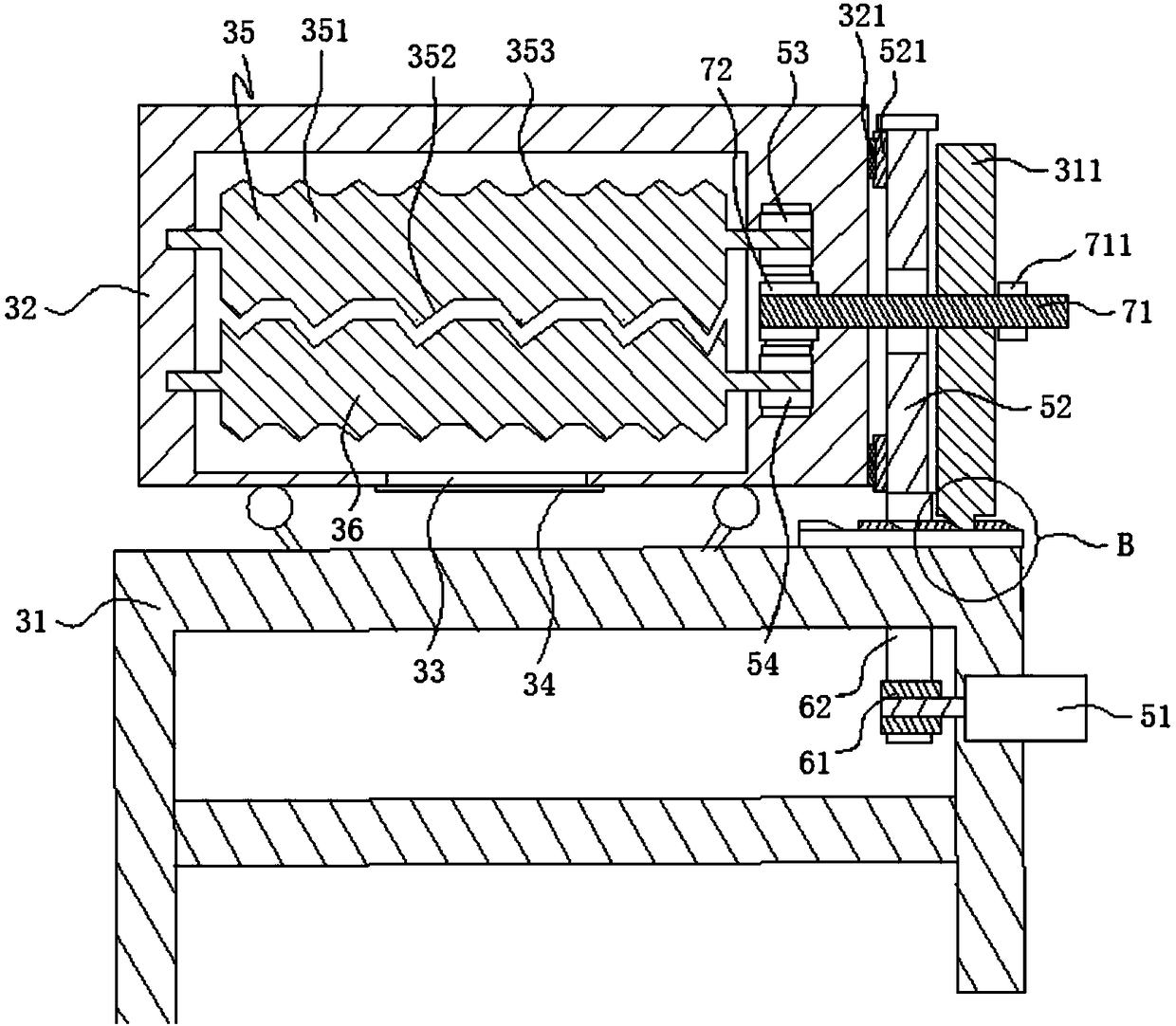

Sheet hardware cutting device for hardware electromechanical

PendingCN111673503AEasy to fixWith bufferFeeding apparatusLarge fixed membersStructural engineeringMechanical engineering

The invention discloses a sheet hardware cutting device for hardware electromechanical. The sheet hardware cutting device for the hardware electromechanical comprises a box body, wherein four cornersat the bottom of the box body are provided with rollers, the front face of the box body is hinged with a door body through a hinge shaft, a control panel is installed at the center of the front face of the door body, the left and right side walls at the top of the box body are symmetrically provided with conduits, sliding cavities are formed in the outer walls of the conduits, a fixed seat is installed at the top of the box body, the two ends of the top of the fixed seat are provided with electric sliding rails, and sliding bars are slidingly installed in the electric sliding rails. Accordingto the invention, the sheet hardware to be cut is placed above a worktable, a turntable is rotated so that the turntable drives a baffle to move, the baffle drives a splint to approach the hardware until the hardware is fixed and clamped by the splint, the hardware is convenient to fix, displacement during cutting is avoided, under the action of a positioning spring, the splint has a certain buffer force on the hardware, and the hardware is avoided to be pinched.

Owner:江苏锡沂钢模有限公司

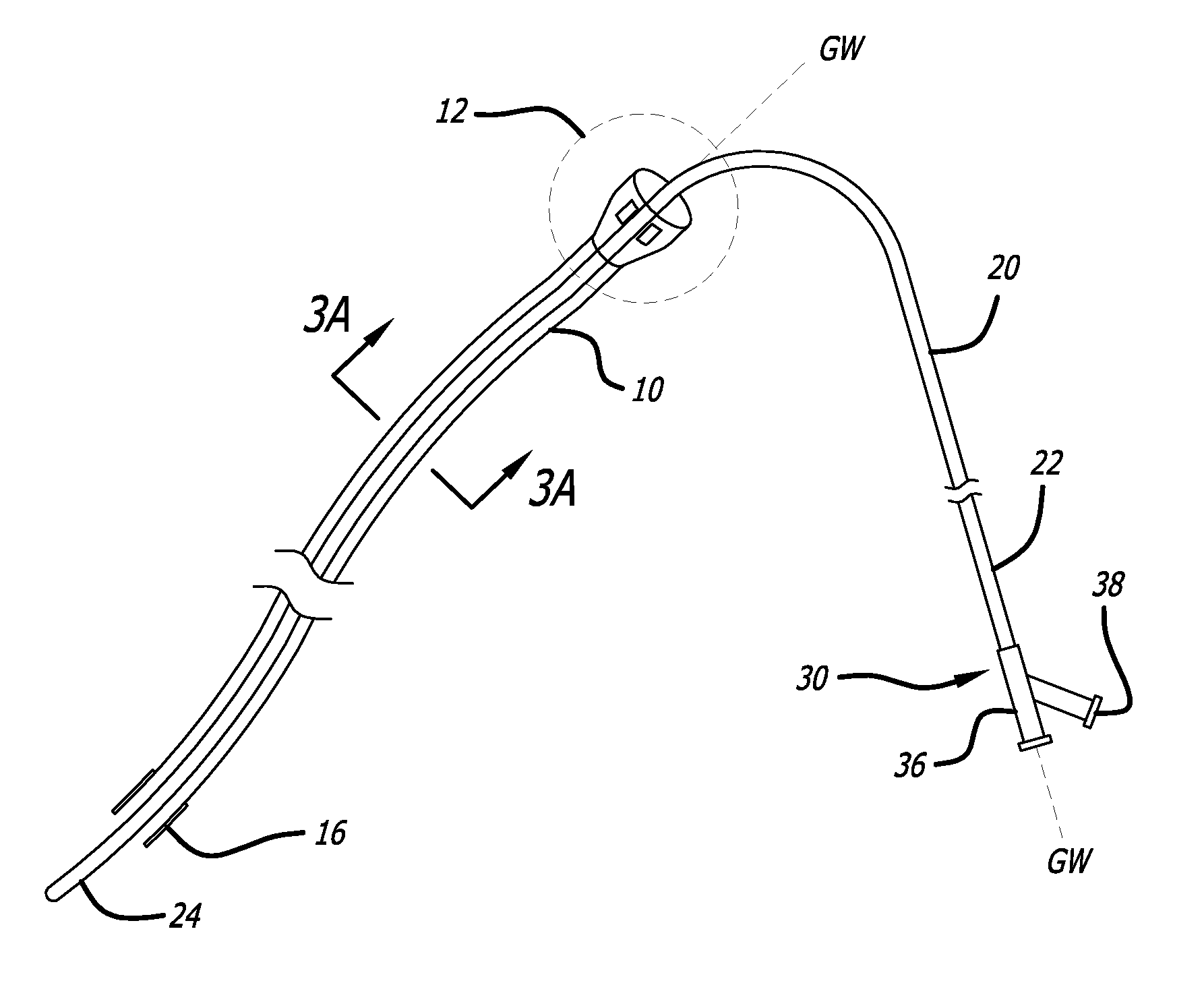

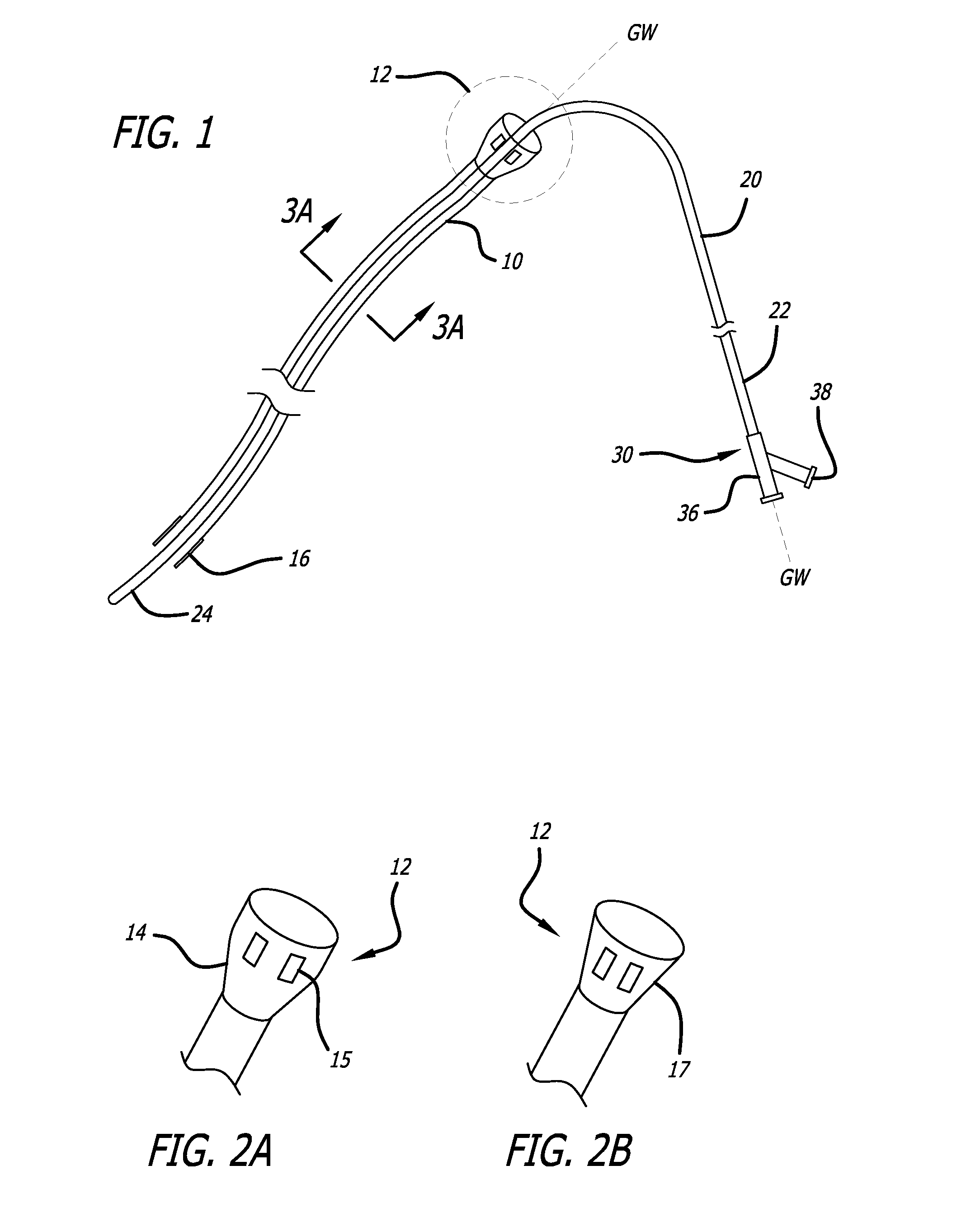

Dual Cannula System for Enteric Feeding

InactiveUS20130158471A1Reduce needPrevent displacementGuide needlesMedical devicesPharmacological therapyInner Cannula

A dual cannula apparatus is provided for insertion into the gastrointestinal tract. One end of a first outer cannula is placed within the small intestine providing a guide for advancement of a second inner cannula. The second inner cannula extends beyond the first outer cannula and provides a source of nutritional support and pharmacological therapy. The first outer cannula has a radiopaque tip to facilitate placement thereof under x-ray or fluoroscopic guidance. The first outer cannula can also be provided with a flared end for maintenance with the naris. The second inner cannula includes one or more openings for flow of the nutritional support or pharmacological therapy into the small intestine.

Owner:NEEL JAMES V +2

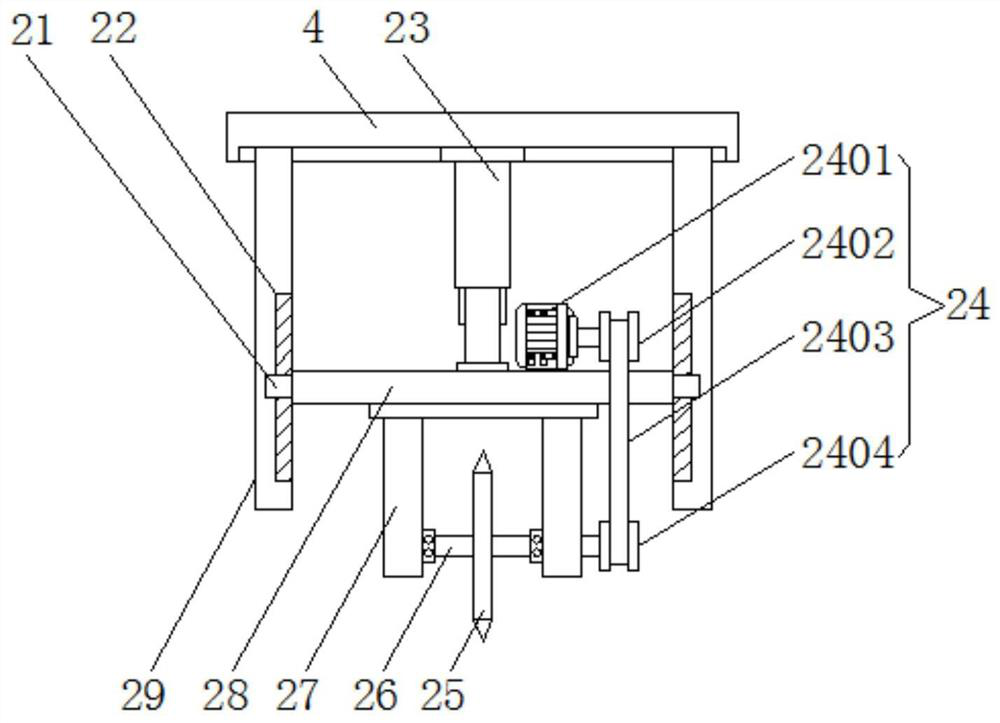

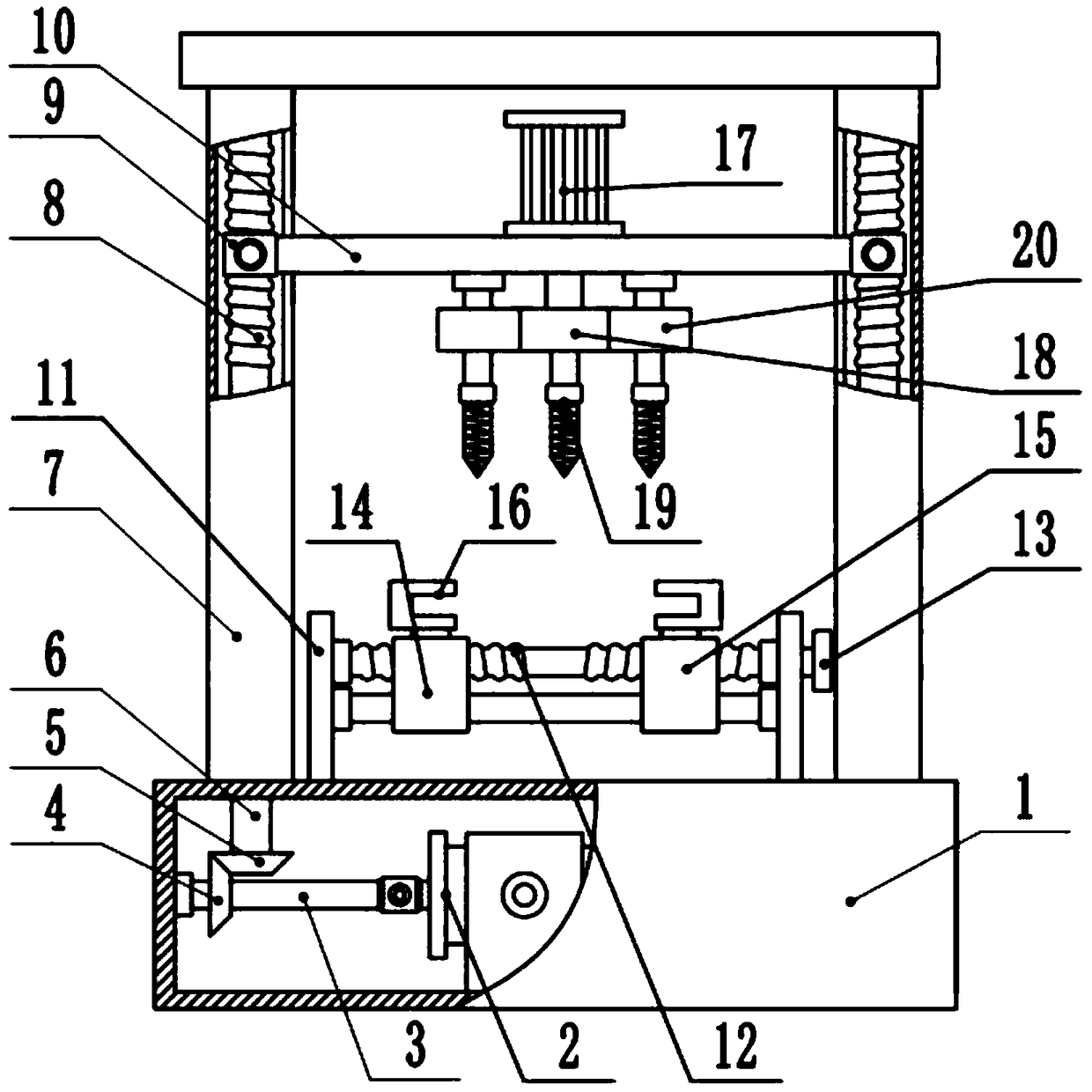

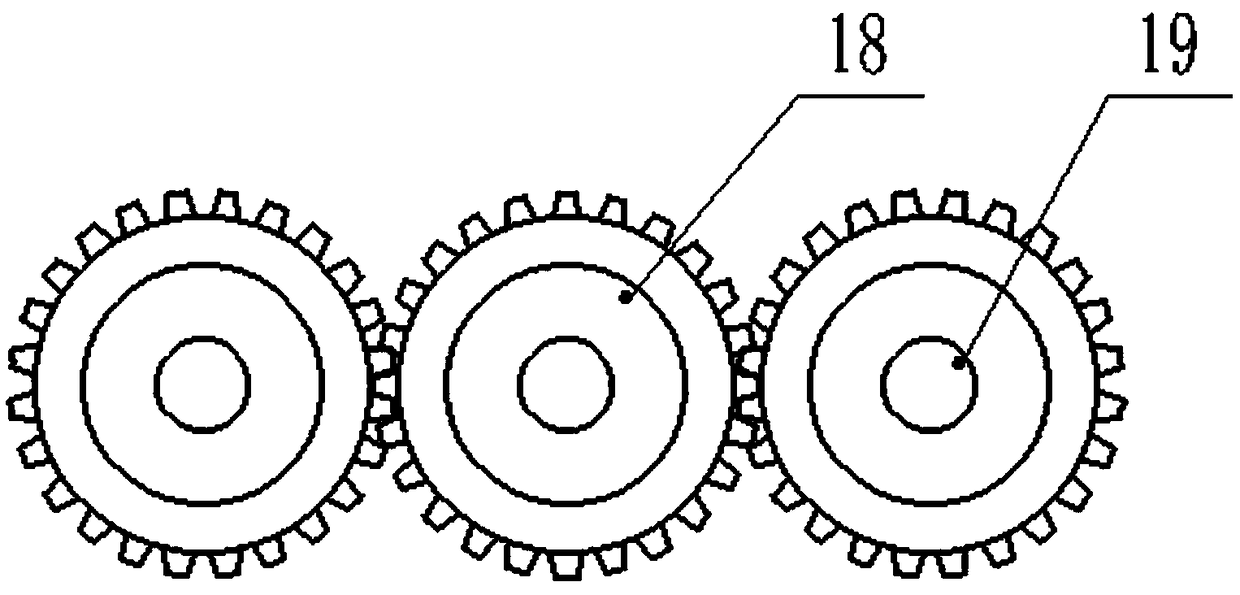

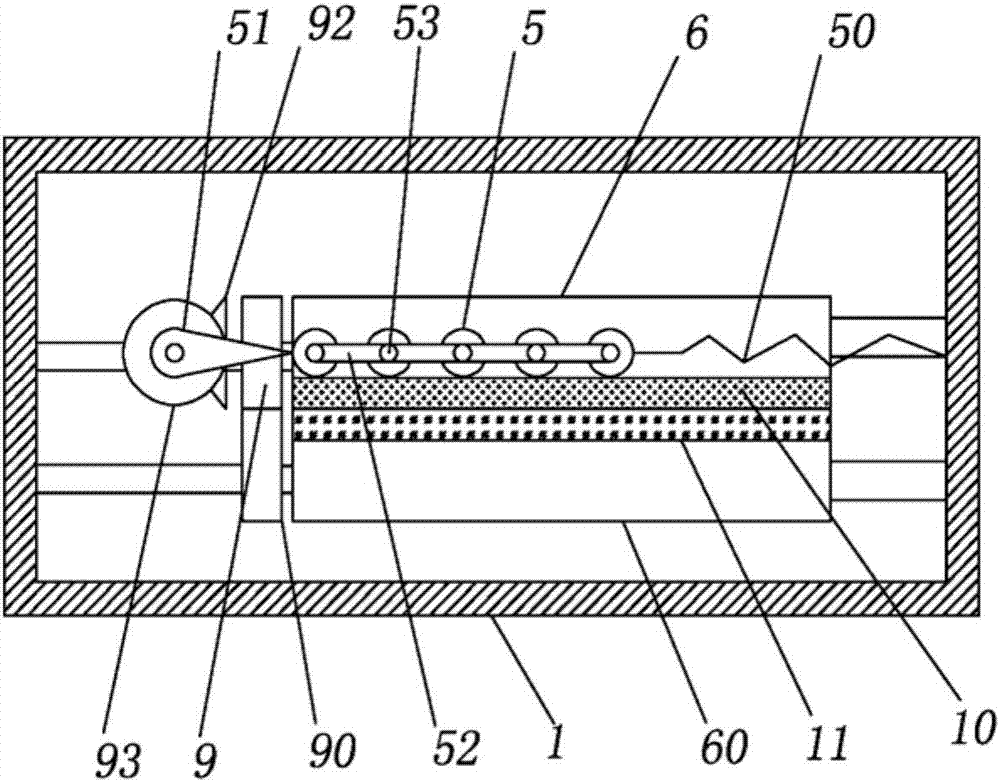

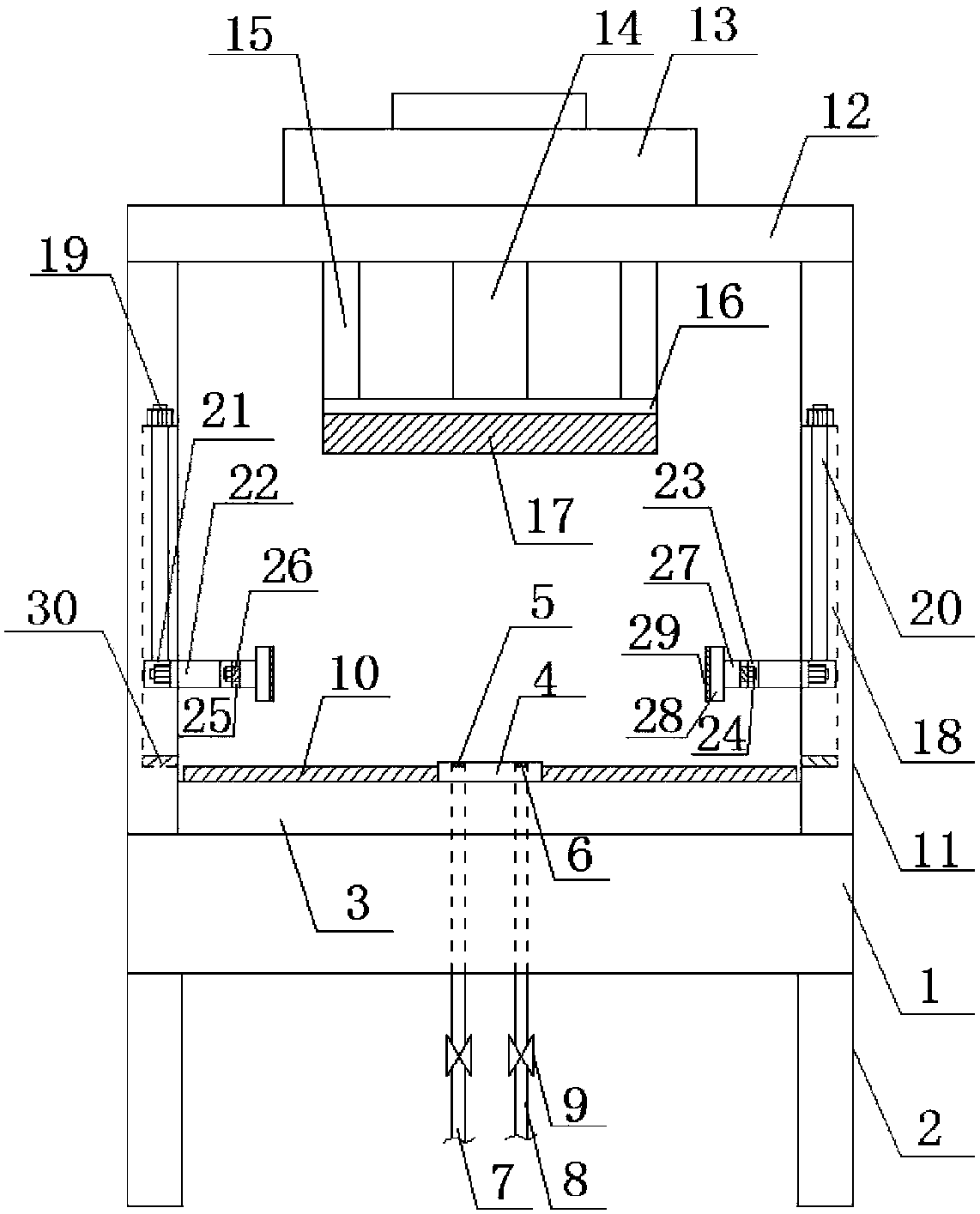

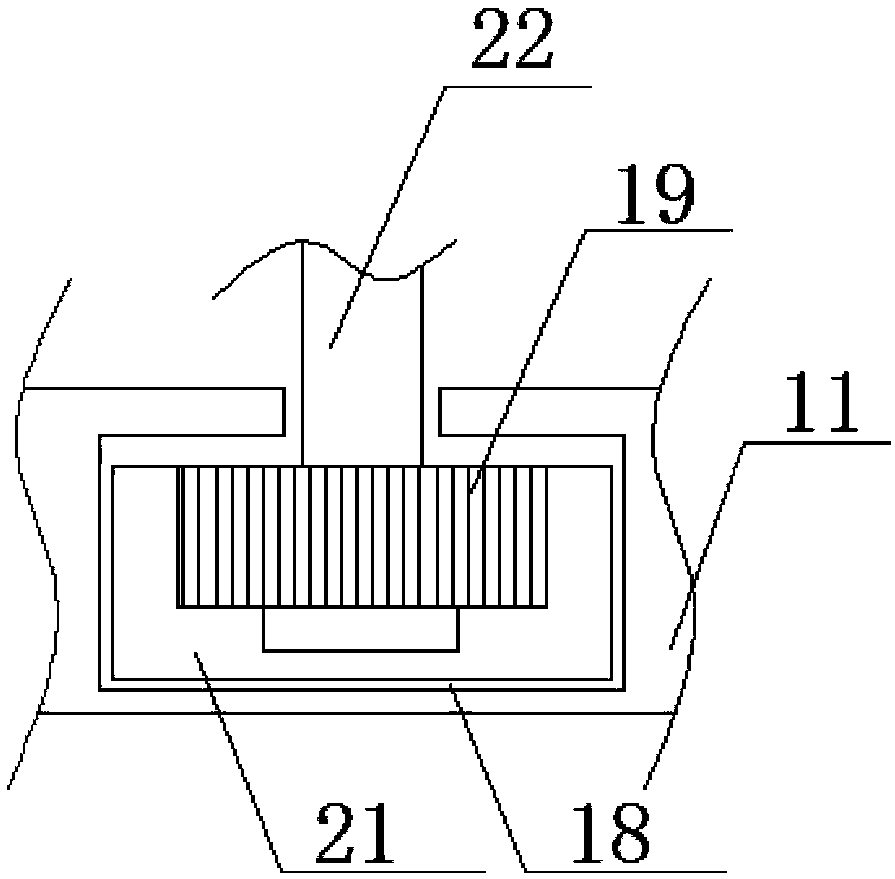

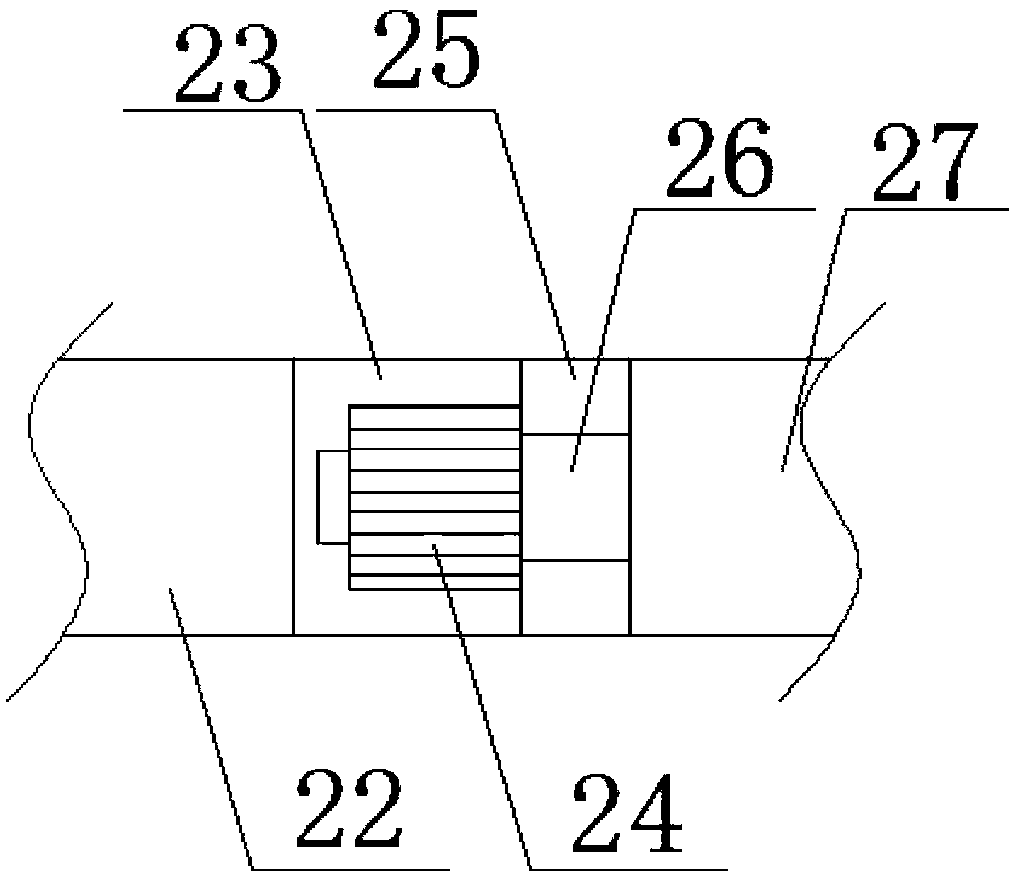

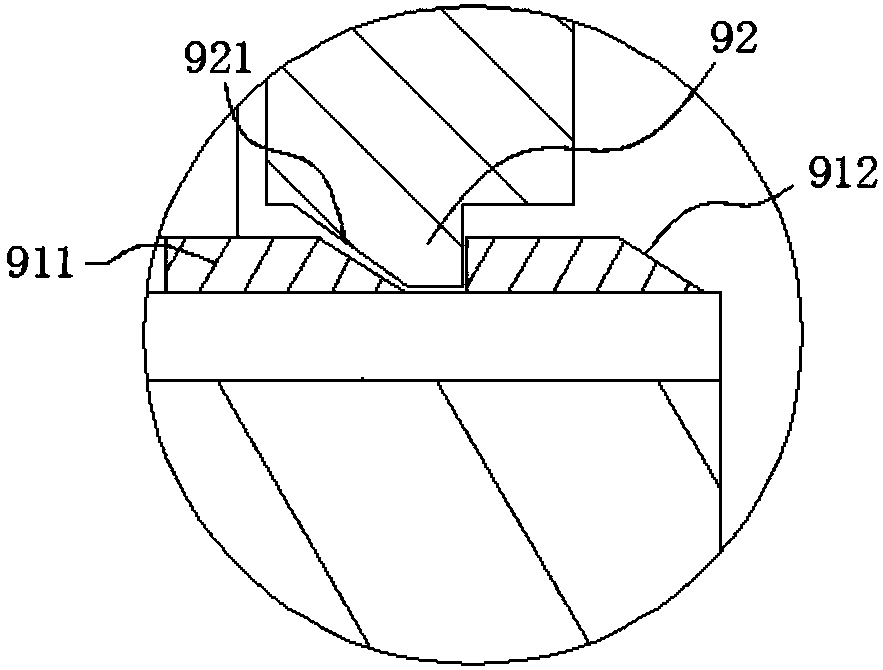

Intelligent mold production and processing device

InactiveCN108608027AImprove stabilityPrevent displacementPositioning apparatusBoring/drilling componentsEngineeringDrive motor

The invention discloses an intelligent mold production and processing device which comprises a base, sliding blocks, a cross beam, a drive motor and drill bits. Mounting plates are symmetrically arranged on the left side and the right side of the upper surface of the base and are fixedly connected with the base through self-tapping screws. A threaded lead screw is rotationally mounted between themounting plates on the left side and the right side through bearings. The right end of the threaded lead screw penetrates out of the corresponding mounting plate and is fixedly connected with an adjusting wheel. A left sliding block and a right sliding block are mounted on threads on the left part and the right part of the threaded lead screw in a threaded manner and are mounted on a limiting column in a sliding manner. Clamping claws are welded to the upper sides of the left sliding block and the right sliding block. Through mutual displacement of the clamping claws, drilling of molds of different widths is met; the structure is simple, operation is easy, and stop can be immediately achieved when operation is stopped; and stability during mold drilling is greatly improved, and the situation of mold displacement during drilling is effectively avoided.

Owner:荆门它山之石电子科技有限公司

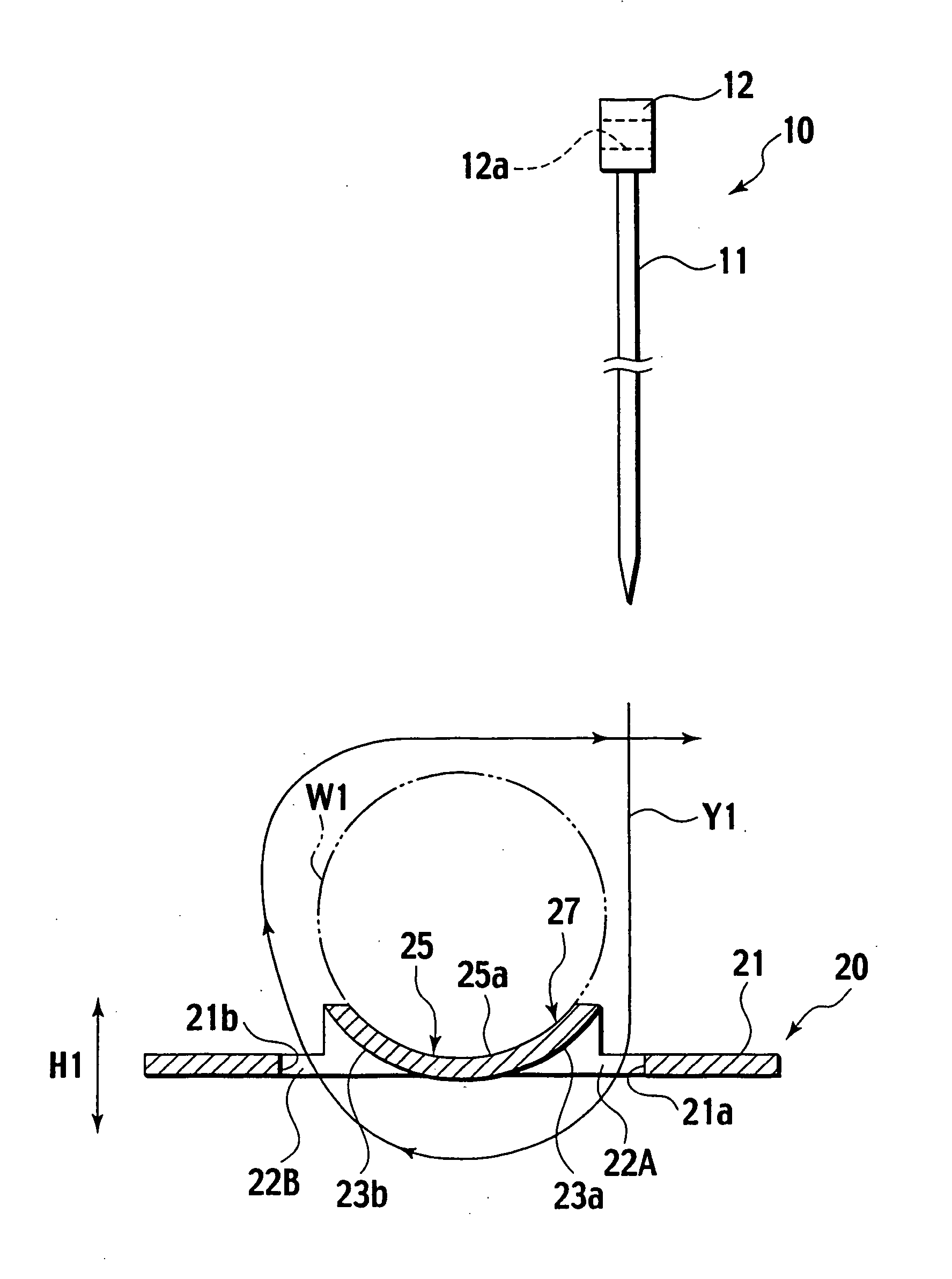

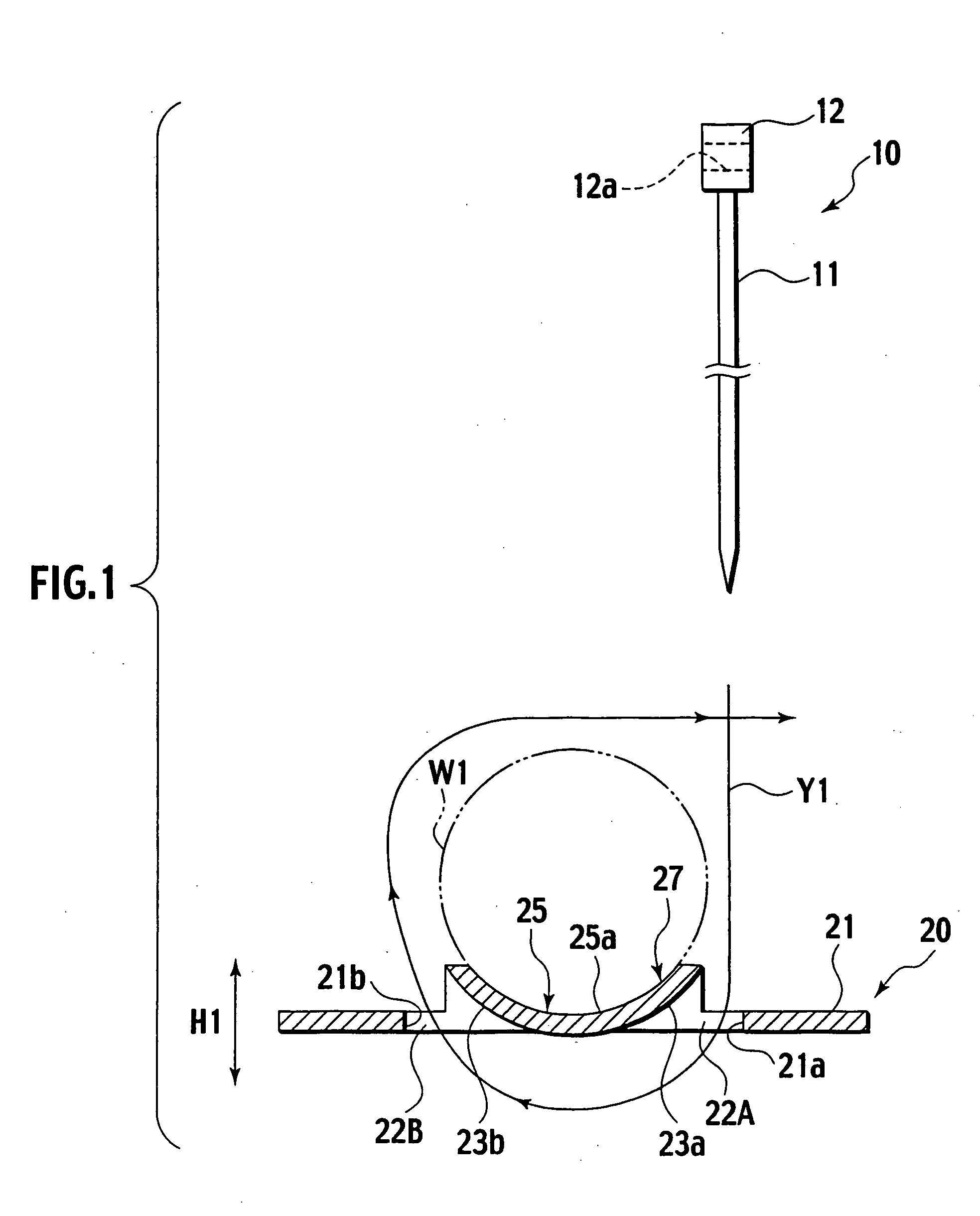

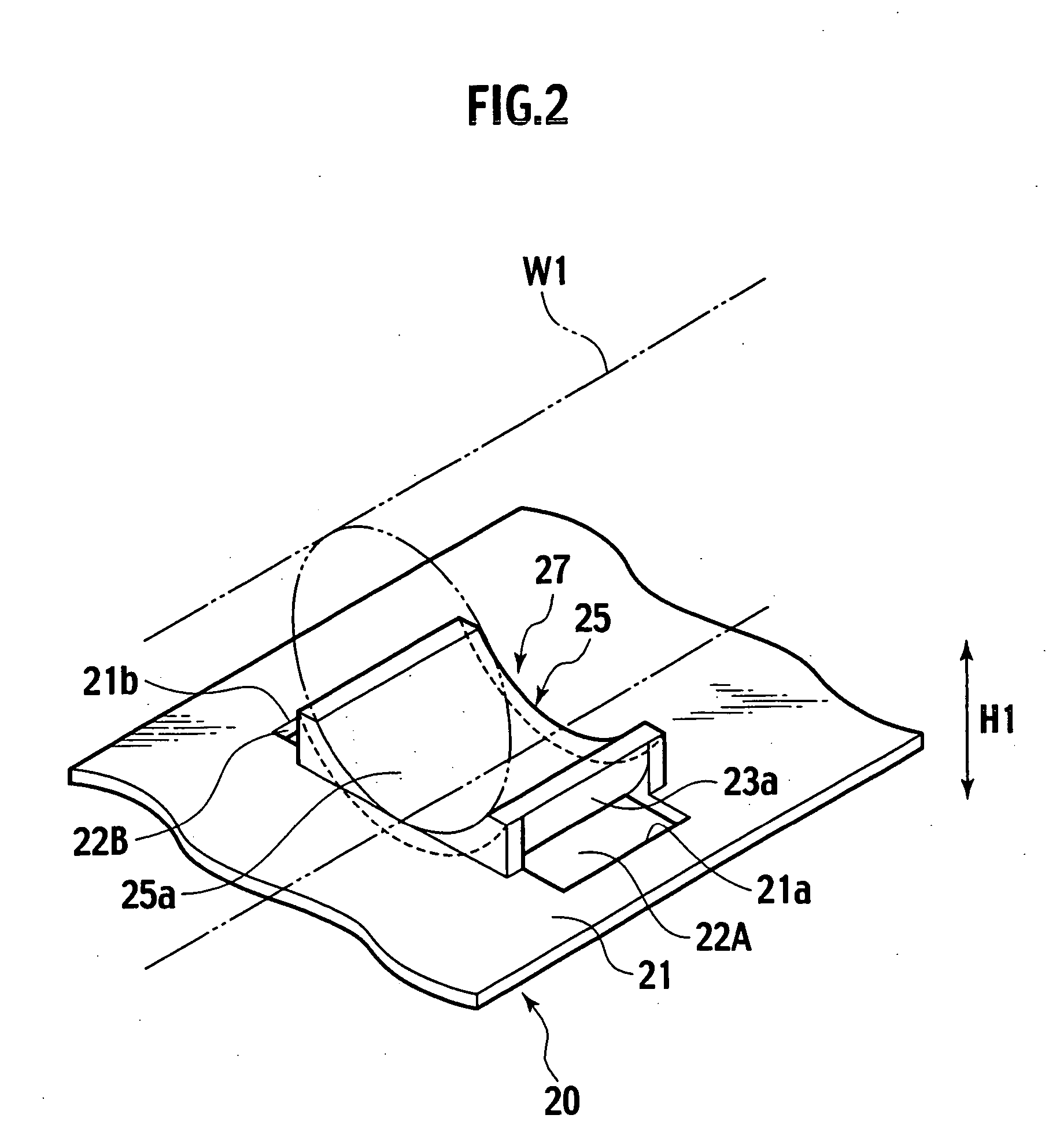

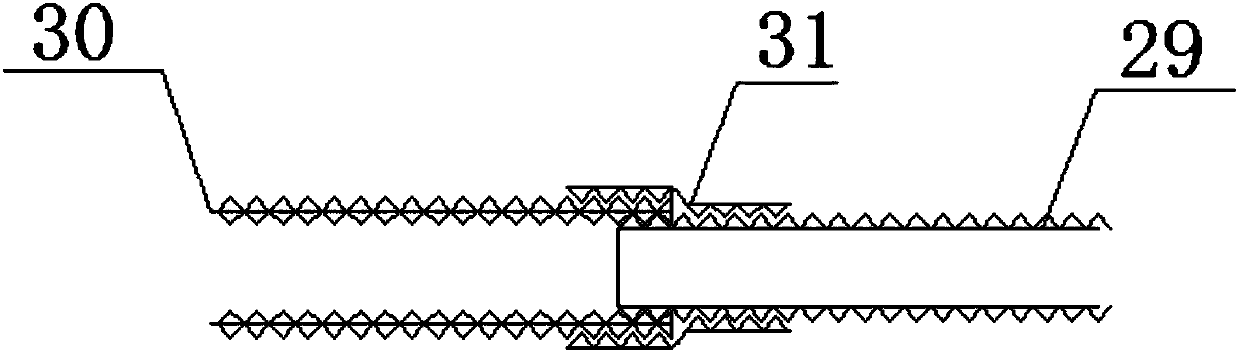

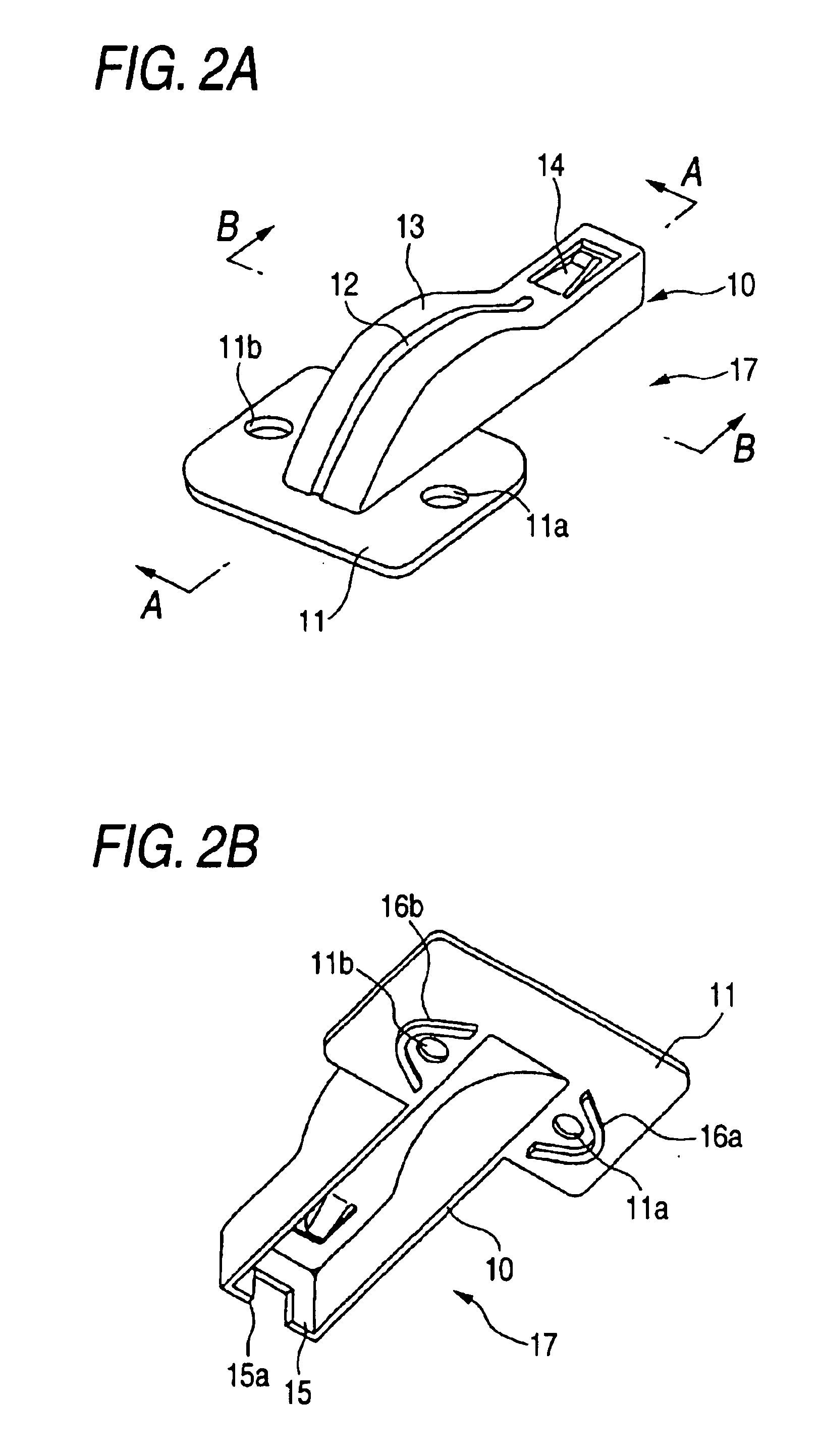

Striate-body fixation fixture, wire-harness protector and fixation clip

InactiveUS20050257347A1Prevent displacementEasy to insertPipe supportsElectrical apparatusEngineeringCable harness

A striate-body fixation fixture includes a base plate a first side and a second side opposite to each other. The fixture includes a positioning plate included in the base plate for mounting the striate body in position on the first side of the base plate. The fixture includes first and second insertion holes extending through the base plate and opposed to each other with respect to the positioning plate. The fixture includes a guide wall defining at least one of the first and second insertion holes and approaching the other insertion hole for guiding a band to secure the striate body on the fixture as the guide wall extends toward the second side of the base plate.

Owner:YAZAKI CORP

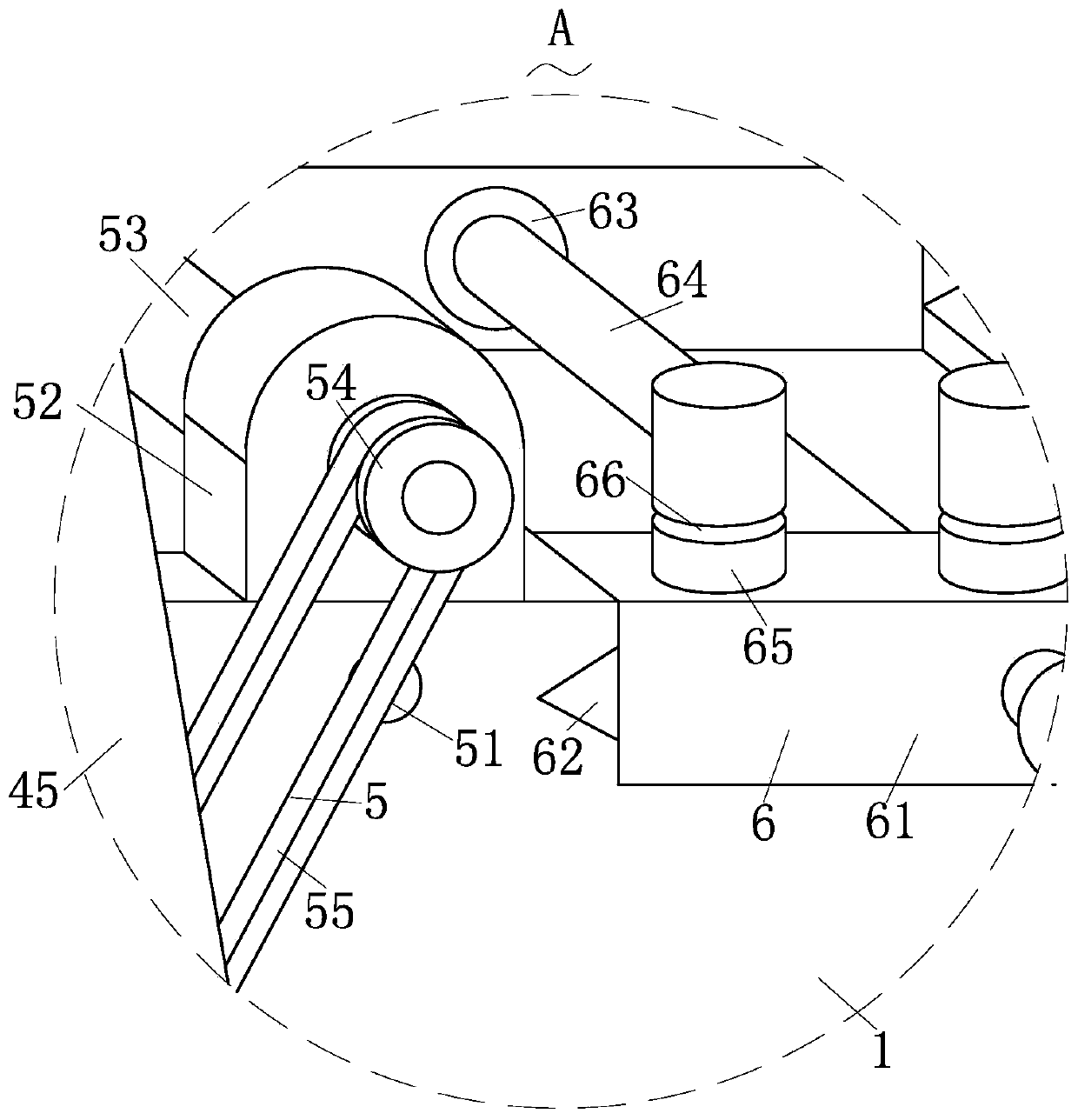

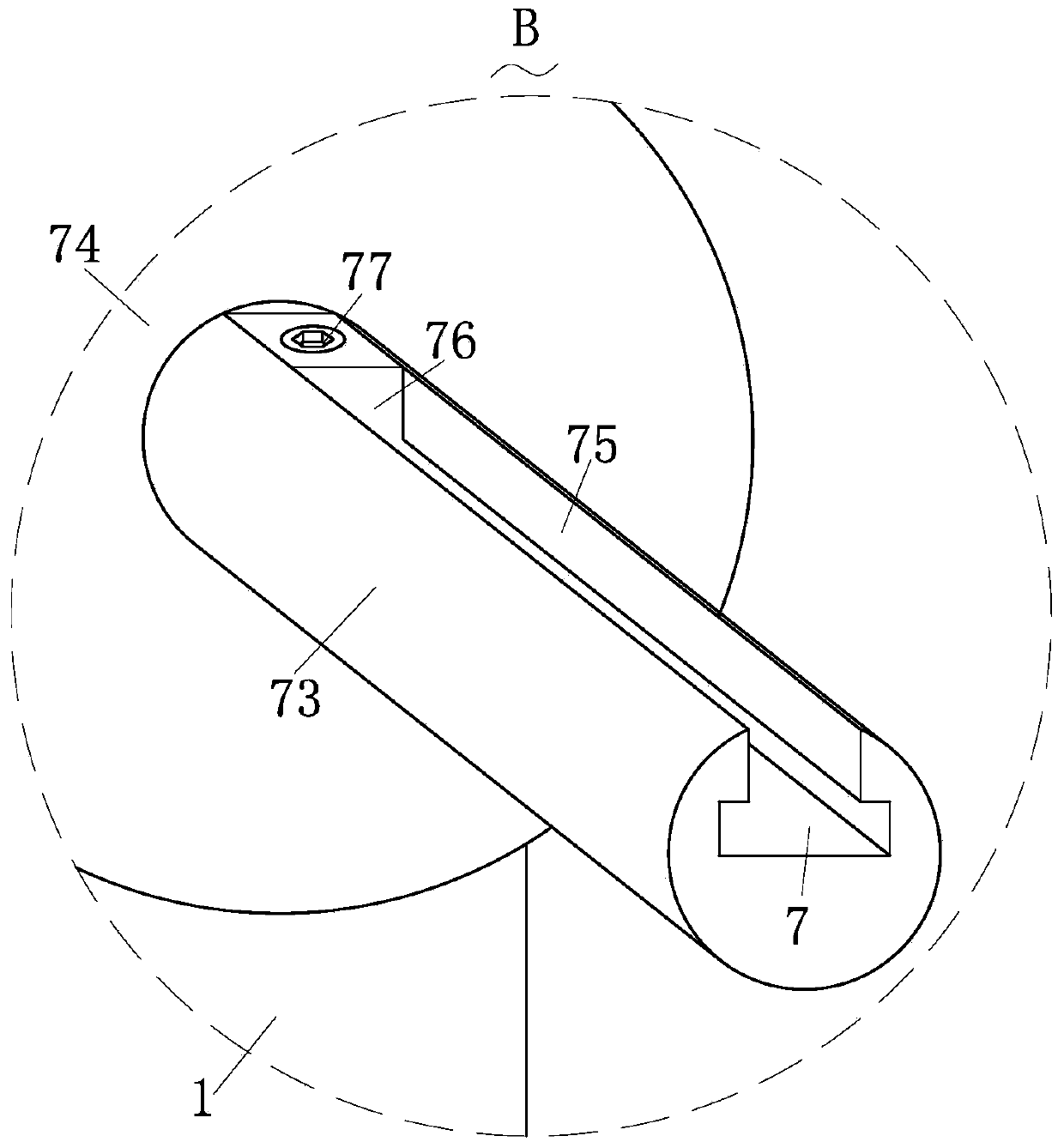

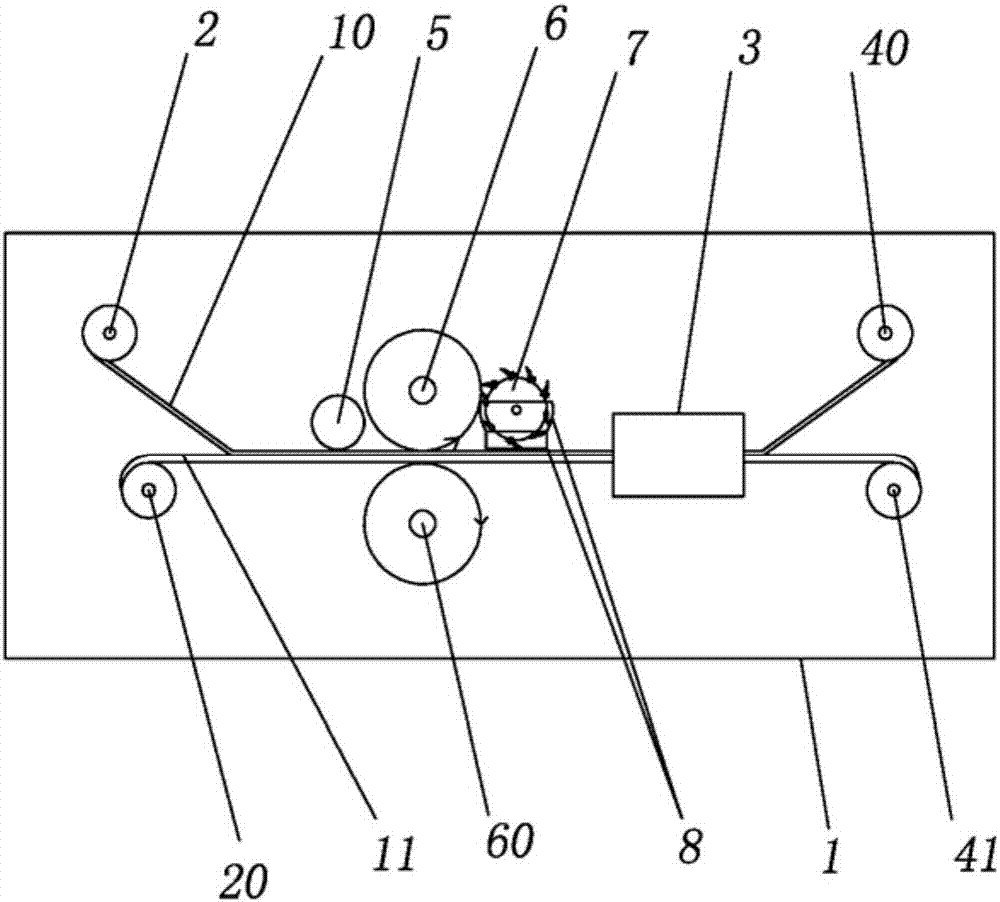

Cutting machine with guiding function for gauze element production and processing

ActiveCN110861132AAvoid creasesAvoid offsetMetal working apparatusWebs handlingMechanical engineeringIndustrial engineering

The invention relates to the field of gauze element production and processing devices, in particular to a cutting machine with a guiding function for gauze element production and processing. The cutting machine comprises a base, supporting legs, a discharge sleeve, a cutting structure, a feeding structure, a guiding structure and a discharging structure; the cutting structure can synchronously drive the feeding structure to work while the cutting structure is working, through the setting of the feeding structure, the feeding operation can be automatically conducted on a gauze element, the workintensity of manual feeding is reduced, the cut gauze element can further be leveled and limited, namely the wrinkle of the gauze element during cutting is avoided, the deviation of the gauze elementcaused by difficult fixation of the gauze element during cutting is also avoided, the guiding structure is arrange at the top end, close to one end of the feeding structure, of the base, the gauze element entering the feeding structure can be guided, the gauze element of the feeding structure is prevented from wrinkling and deviating, the guiding structure can be adjusted, and thus gauze elementswith different width can further be guided.

Owner:LIXIN FUYA GAUZE CO LTD

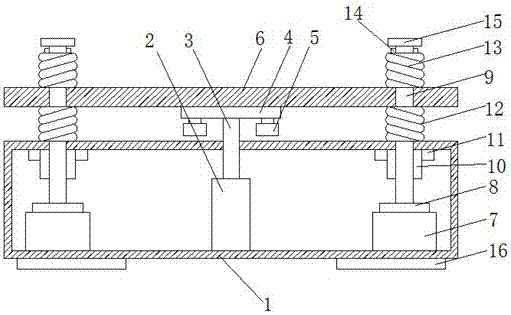

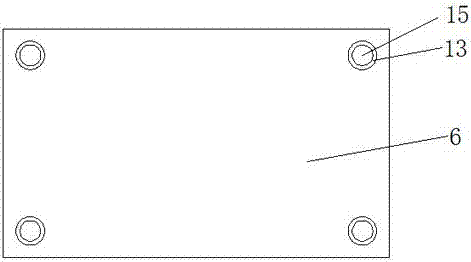

Electromechanical equipment damping device

PendingCN107327665AAvoid bouncingAvoid damageNon-rotating vibration suppressionEngine bedsEngineeringMachine

The invention provides an electromechanical equipment damping device, and relates to the field of equipment damping. The electromechanical equipment damping device comprises a damping base. The bottom of the inner wall of the damping base is fixedly connected with an air pressure barrel. An air pressure rod is movably connected in the air pressure barrel in an inserted manner. The end, away from the air pressure barrel, of the air pressure rod penetrates the damping base and extends to the outer portion of the damping base. A first fixed block is arranged above the damping base. The end, away from the air pressure barrel, of the air pressure rod penetrates the damping base to be fixedly connected with the first fixed block. The top of the first fixed block is fixedly connected with a damping platform. The positions, located on the two sides of the air pressure barrel, of the bottom of the inner wall of the damping base are fixedly connected with rubber damping blocks. According to the electromechanical equipment damping device, first damping springs, second damping springs and the air pressure barrel are arranged, and therefore the function of buffer damping can be effectively achieved when large machines work, and the situation that the ground is damaged due to bouncing of electromechanical equipment is effectively avoided.

Owner:刘兵

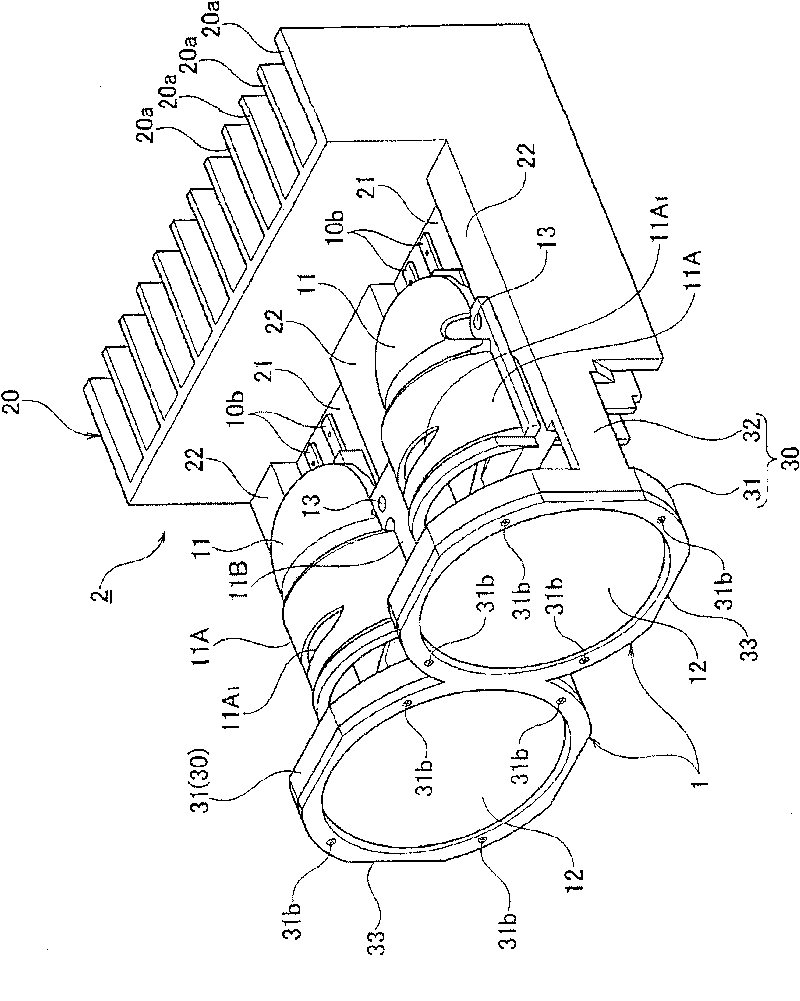

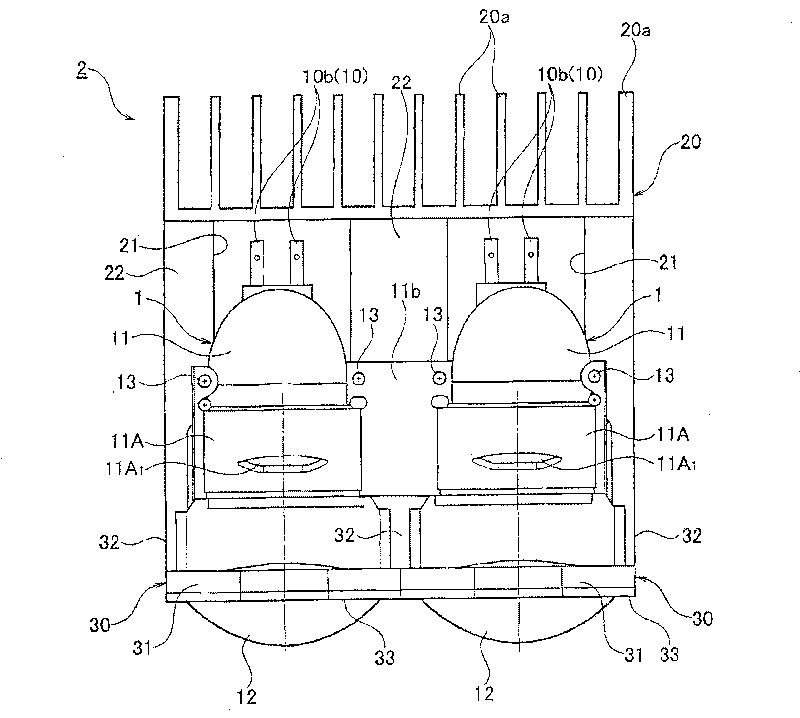

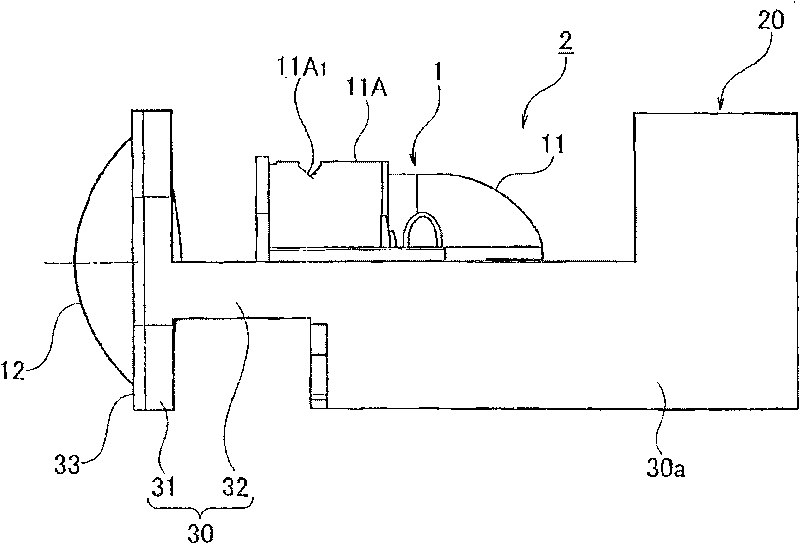

Vehicular lamp

InactiveCN101749617AEliminate temperature differencesNo slight position shiftPoint-like light sourceLighting heating/cooling arrangementsTemperature differenceOptoelectronics

The invention provides a projection-type vehicular lamp which can improve the whole radiation effect of a light source unit and can eliminate a temperature difference around a light source and a projection lens. The vehicular lamp is provided with a light source, a reflector, a projection lens and a radiating rib, wherein the reflector is provided with a cover part and reflects one part of emergent light of the light source to the front of the lamp; the periphery of the projection lens is kept fixed by a lens carrier; the projection lens converges the direct light of the light source and the reflecting light formed by the reflector and illuminates to the front of the lamp; and the radiating rib integrally arranges the light source, the reflector and the projection lens. The projection-type vehicular lamp is characterized in that the lens carrier and the radiating rib are integrally formed.

Owner:ICHIKOH IND LTD

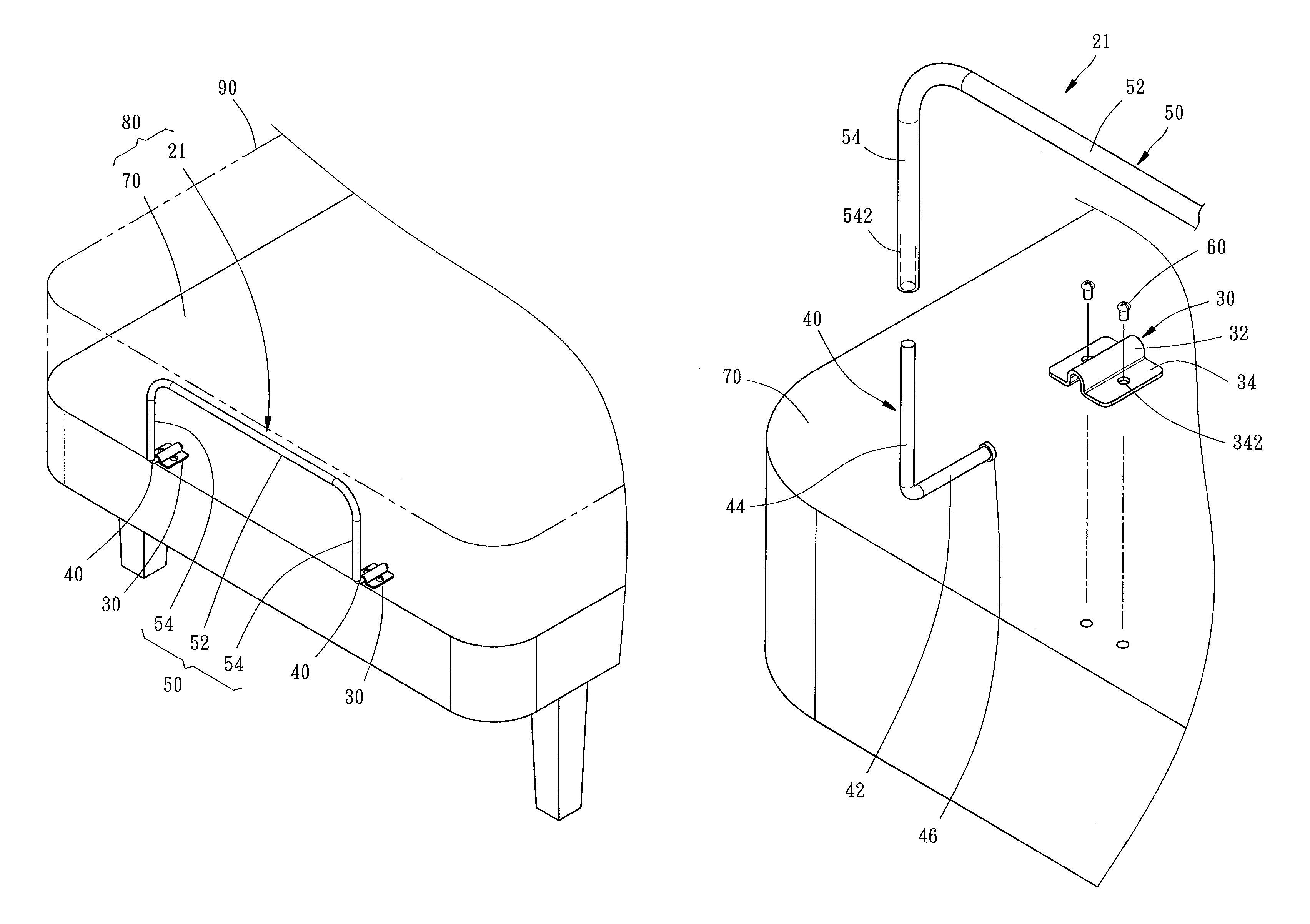

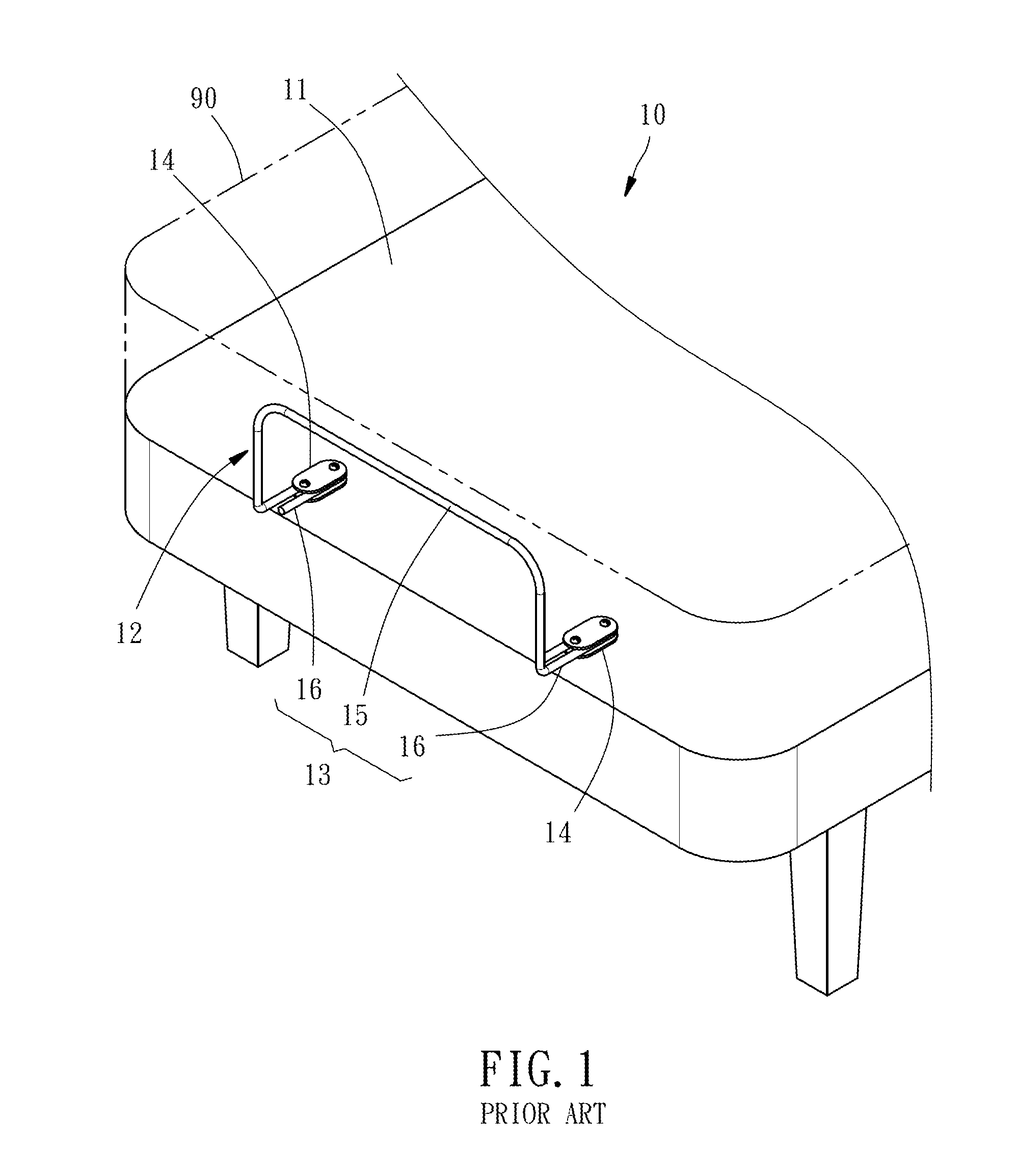

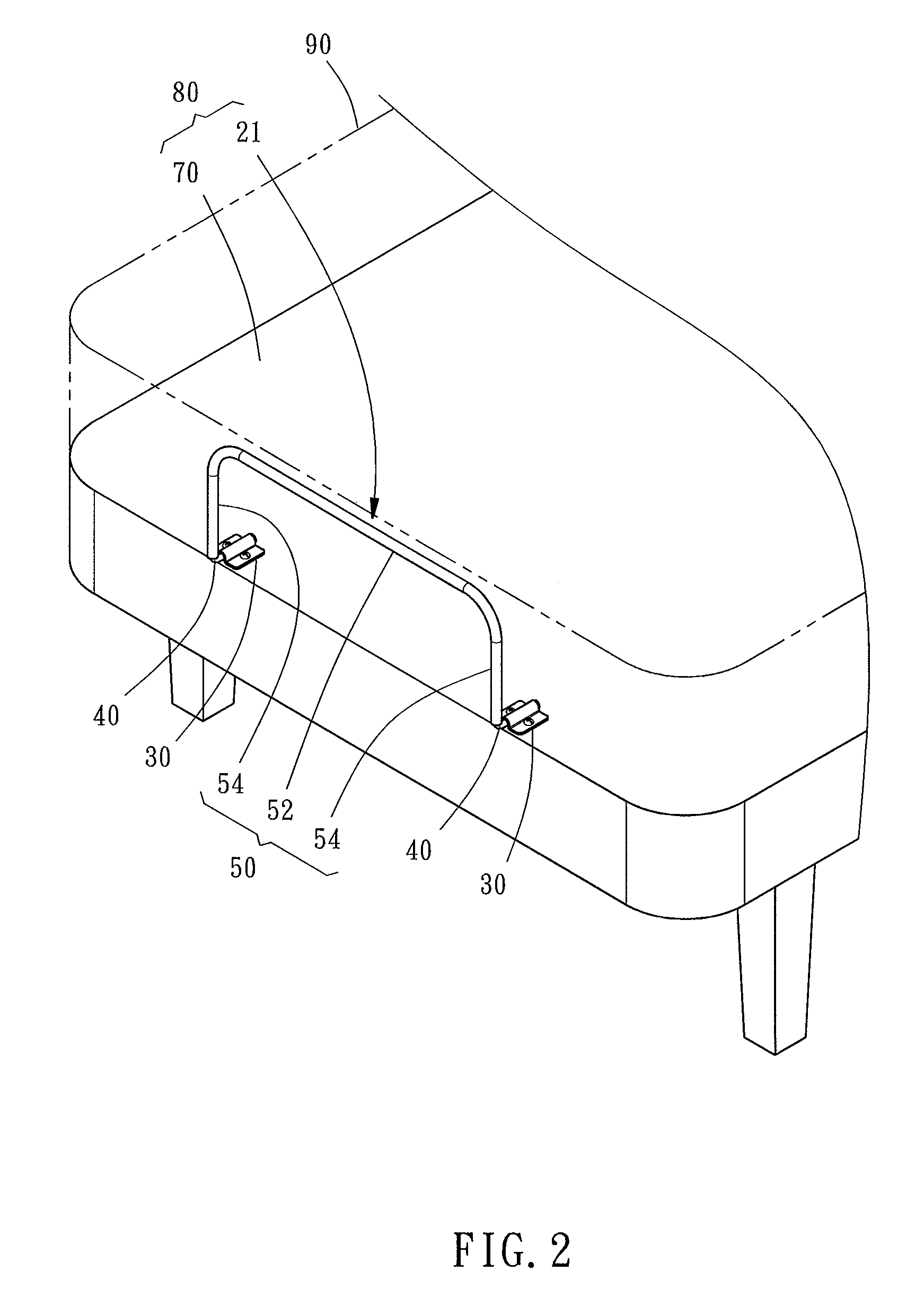

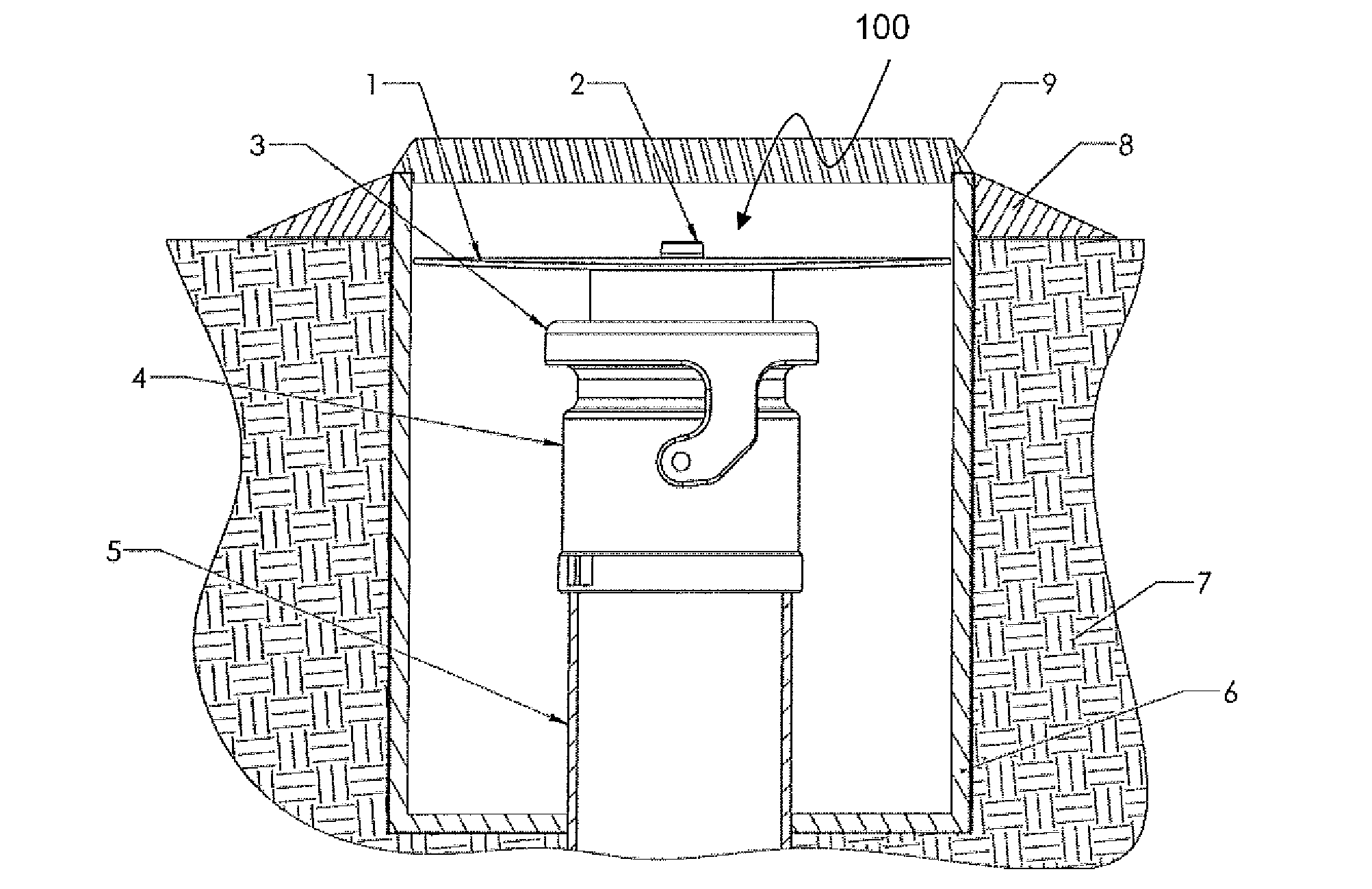

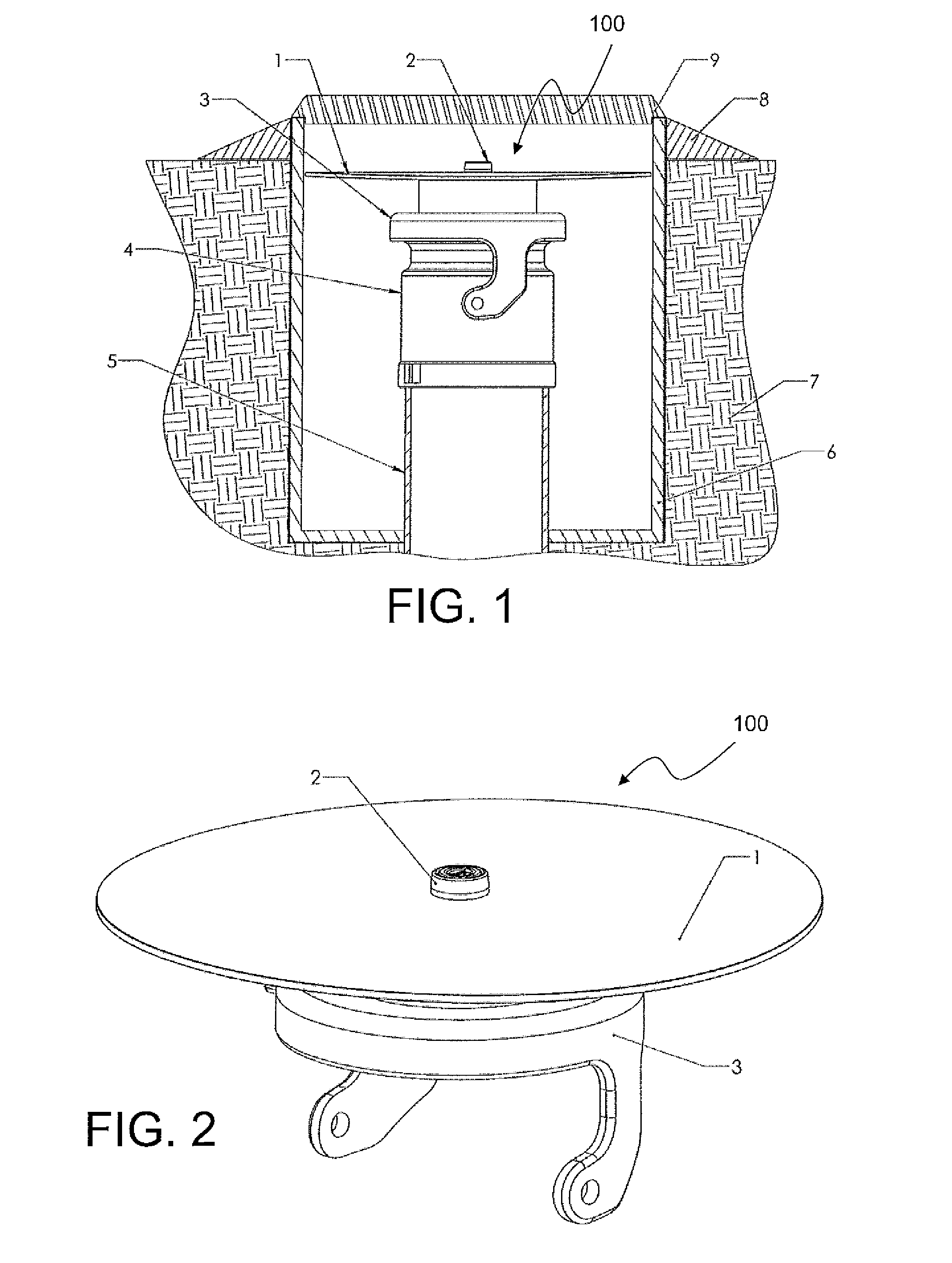

Bracket for retaining mattress

InactiveUS8776294B1Easily assemblePrevent displacementStuffed mattressesSpring mattressesHinge angleEngineering

A bracket, which is adapted for retaining a mattress, includes two hinge bases for being mounted on a bed frame, two rotating members and a connector. Each of the rotating members has a pivot and a first coupling portion extending from the pivot and being substantially perpendicular to the pivot. The pivots are respectively connected with the hinge bases rotatably. The connector has a transverse portion and two second coupling portions respectively provided at two ends of the transverse portion and coupled with the first coupling portions. As a result, the connector can be easily dismounted from and mounted to the rotating members. When the connector is dismounted from the rotating members, the bed frame is conveniently wrapped and transported.

Owner:MCCARTY PHILIP WOODS +3

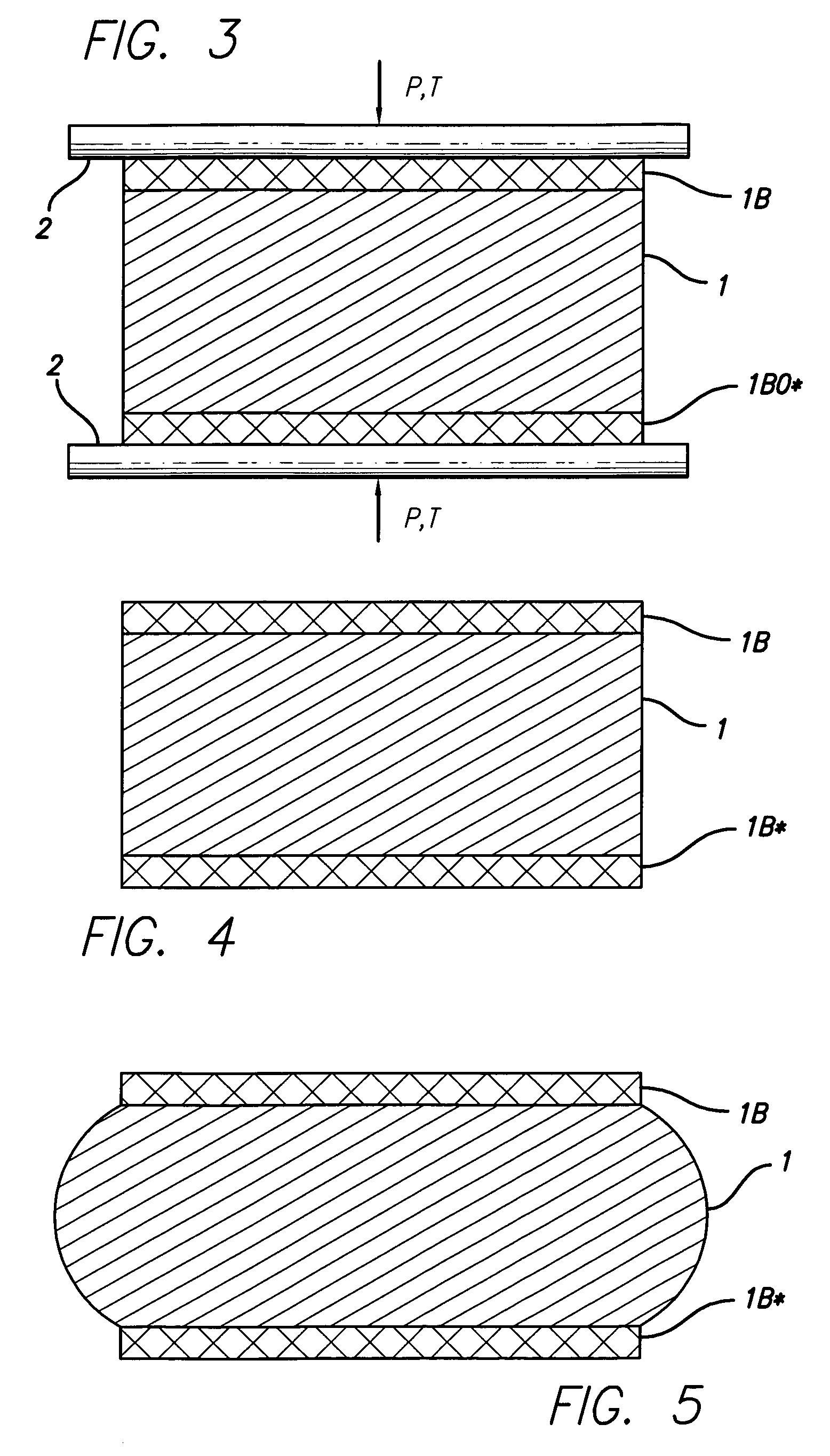

Snowboard binding

InactiveUS20050040624A1Increase coefficient of frictionPrevent displacementCarriage/perambulator accessoriesSki bindingsEngineeringMechanical engineering

Owner:SKIS ROSSIGNOL

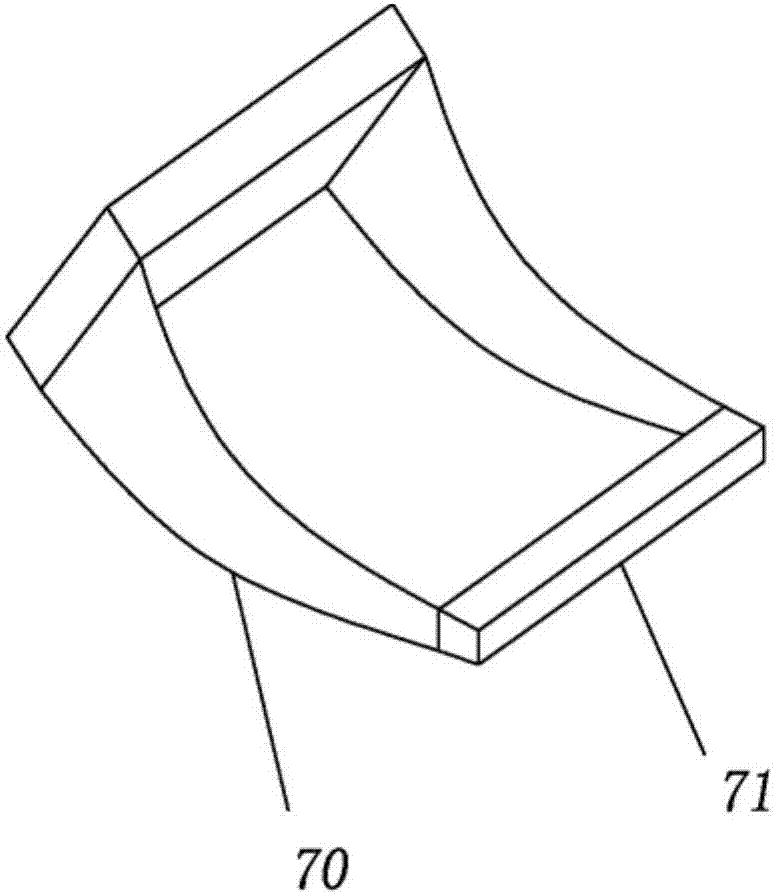

Dual-purpose cutting machine for steel tubes and steel plates

InactiveCN107627034AEasy to cutAchieve reductionLaser beam welding apparatusSheet steelArchitectural engineering

The invention provides a dual-purpose cutting machine for steel tubes and steel plates. Longitudinal support posts are respectively arranged on both sides of a support platform, a transverse support post is arranged on and connected to the top ends of the two longitudinal support posts, a first chute is formed in the bottom of the transverse support post, a first sliding block is arranged in the first chute, a fixed plate is connected to the first sliding block by virtue of a connecting rod, the fixed plate is connected with a placement platform by virtue of a pneumatic telescopic rod, a lasercutting head is arranged at the bottom of the placement platform, a fixed adjustment platform and a sliding adjustment platform which are connected by virtue of an adjusting rod are arranged on the top of the support platform, a second cutting table and a first cutting table are respectively connected to the tops of the fixed adjustment platform and the sliding adjustment platform by virtue of connecting posts, and clamping half rings are respectively arranged on the contact sides of the first cutting table and the second cutting table. According to the dual-purpose cutting machine for the steel tubes and the steel plates, the cutting tables and the clamping half rings are arranged at the same time, so that the steel plates and the steel tubes can be cut, and the distance between the first cutting table and the second cutting table can be adjusted, so that the steel plates or the steel tubes of different sizes can be cut.

Owner:天津澳普林特塑胶有限公司

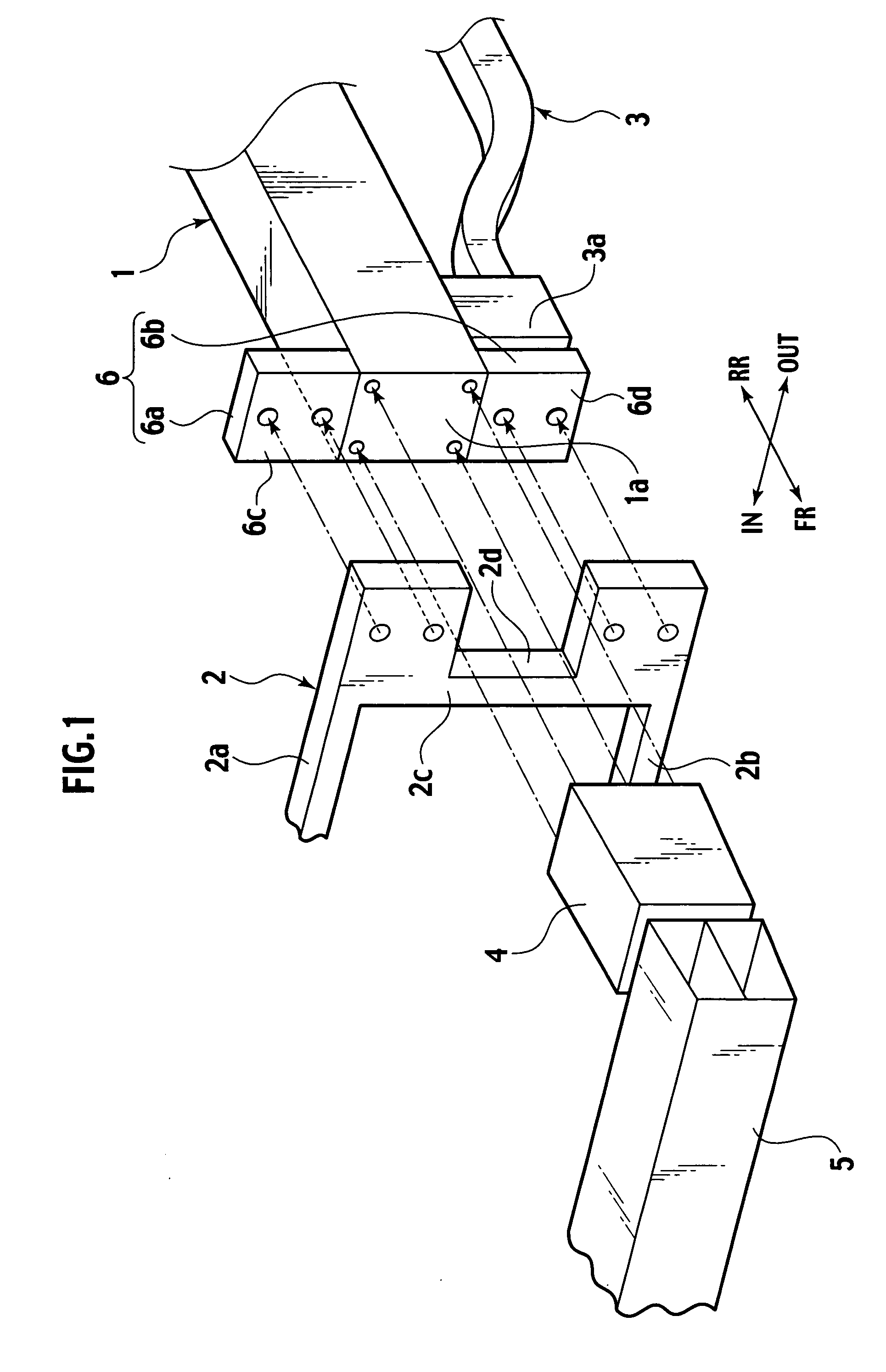

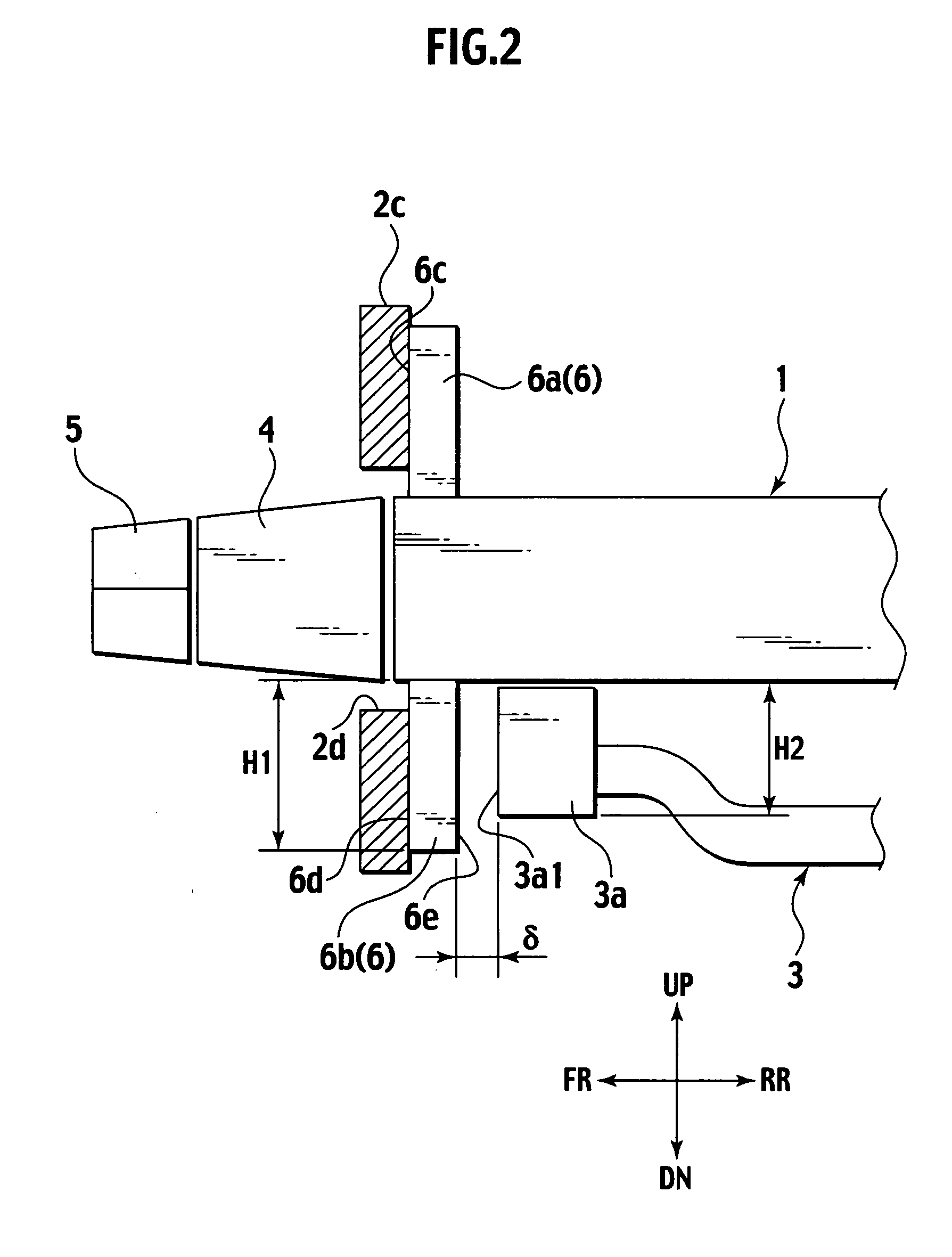

Vehicle front body structure

ActiveUS20050218645A1Prevent displacementPrevent forward movementSteering linkagesUnderstructuresStructural elementEngineering

Owner:NISSAN MOTOR CO LTD

Coating equipment

ActiveCN107983578AAvoid wrinklesEfficient removalLiquid surface applicatorsSpraying apparatusEngineeringSteel ball

The invention belongs to the technology for coating surfaces of objects through liquid or other fluid, and particularly relates to coating equipment. The coating equipment comprises a rack, a smoothening part, a bonding part, a cleaning part and a transmission mechanism, the rack is sequentially provided with a feeding unit, a bonding unit, a drying unit and a discharging unit, the smoothening part comprises a steel ball, a compressed spring and a cam for intermittently hitting the steel ball, the bonding part comprises an upper roller used for grinding base cloth and a lower roller used for supporting transfer paper, the cleaning part comprises a rotary barrel rotationally connected with the rack, the rotary barrel is rotationally provided with a cleaning piece used for cleaning the surface of the upper roller in a connected manner, and the transmission mechanism comprises a motor, a upper roller gear, a lower roller gear, a rotary barrel gear, a driving bevel gear and a driven bevelgear. According to the scheme, folding of the base cloth in the coating process can be effectively prevented.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

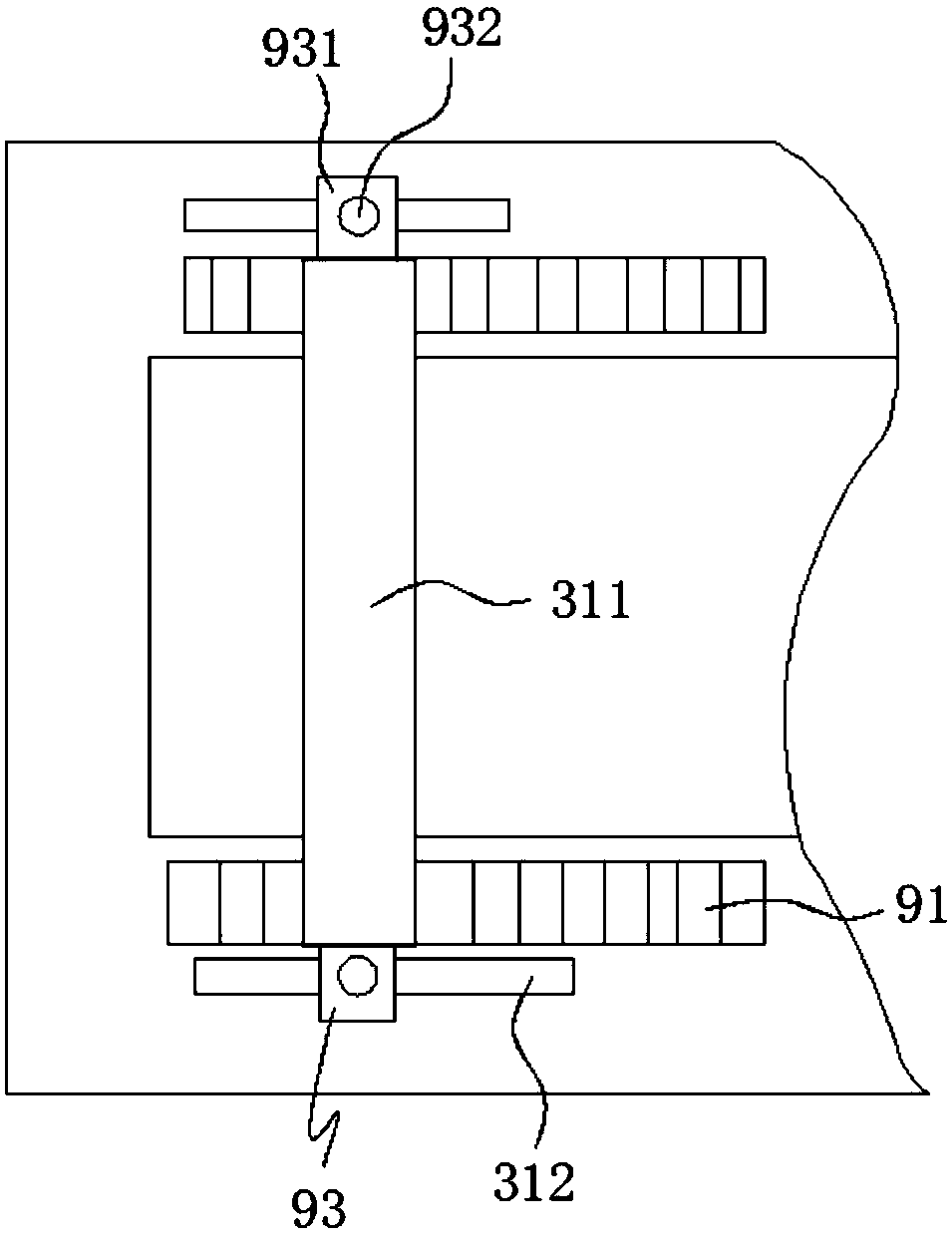

Dual-purpose multi-model valve tightness detection pressing device

InactiveCN109990959AEasy to usePrevent displacementMeasurement of fluid loss/gain rateEngineeringDual purpose

The invention provides a dual-purpose multi-model valve tightness detection pressing device, wherein an upper sealing bench is arranged at the top of a workbench, supporting upright posts are arrangedon two sides of the top of the workbench, the tops of the two supporting upright posts are fixedly connected with a fixed cross rod, the upper sealing bench connected with two pneumatic telescopic rods through a positioning telescopic rod is arranged below the fixed cross rod, sliding chutes are arranged in the two supporting upright posts, a first electric telescopic rod is fixed at the top endof the each sliding chute, a sliding block is arranged at the bottom end of the each first electric telescopic rod, the sliding block is connected with a second electric telescopic rod, a motor grooveis arranged at the tail end of the second electric telescopic rod, the motor groove is connected with a transition groove, a rotating rod is arranged in the transition groove, the tail end of the rotating rod is fixedly connected with a connecting rod, the tail end of the connecting rod is provided with a clamping piece. Through adoption of the dual-purpose multi-model valve tightness detection pressing device, valve tightness pressing operation can be performed on valves of different models, and the clamping piece is used for fixing the position of the valve to be pressed, thus the valve isprevented from being displaced in the pressing process.

Owner:天津市晓晖环保机械有限公司

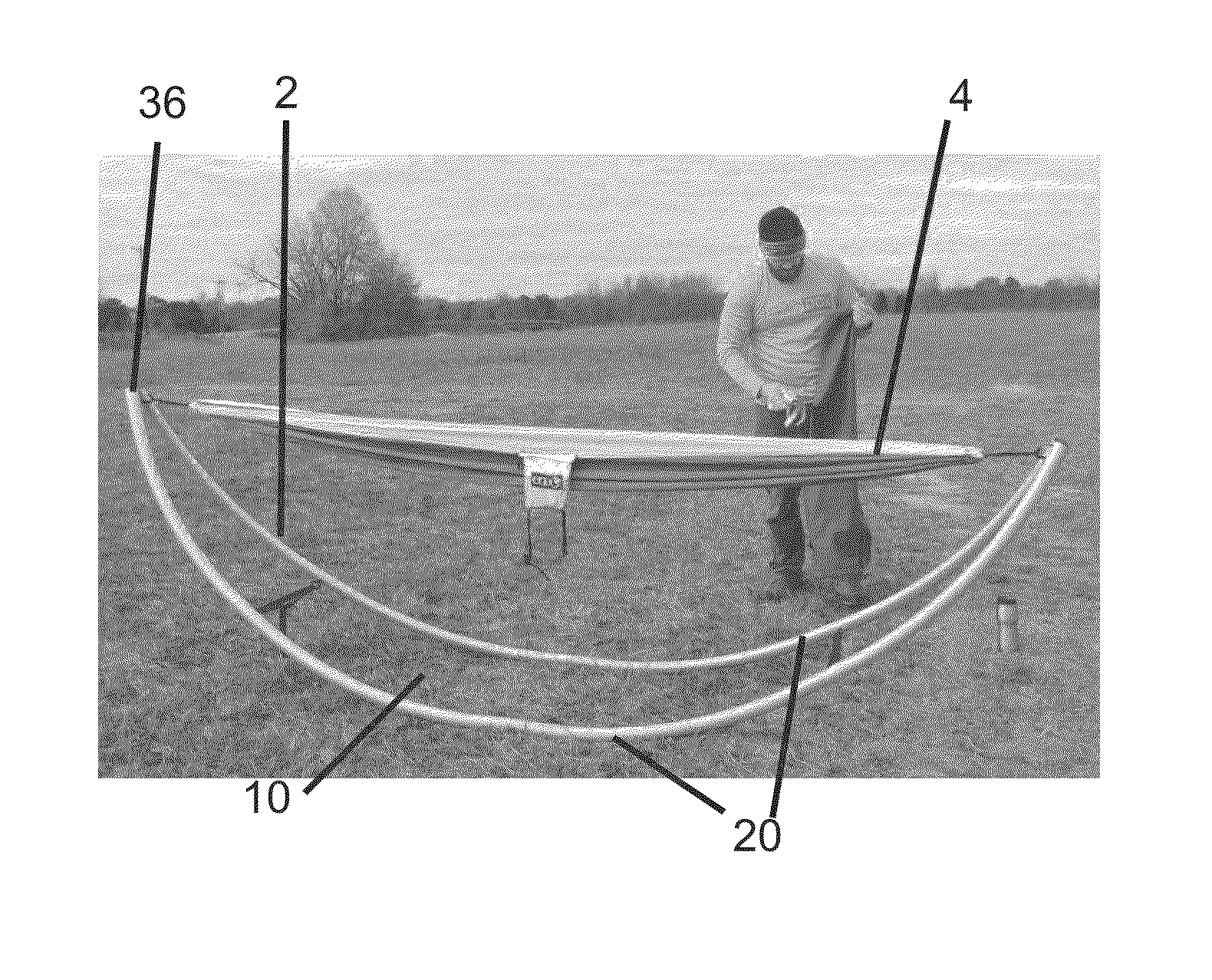

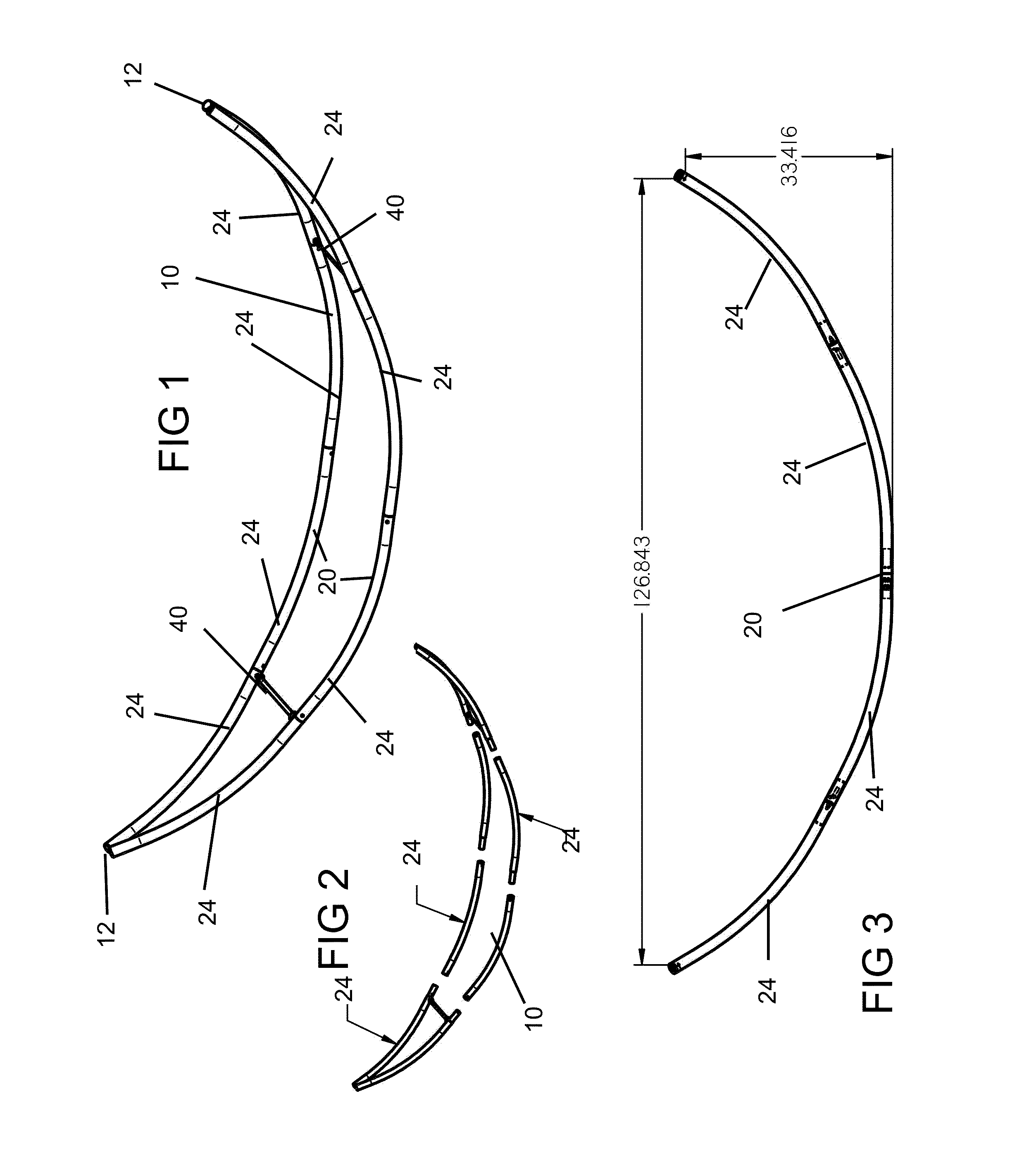

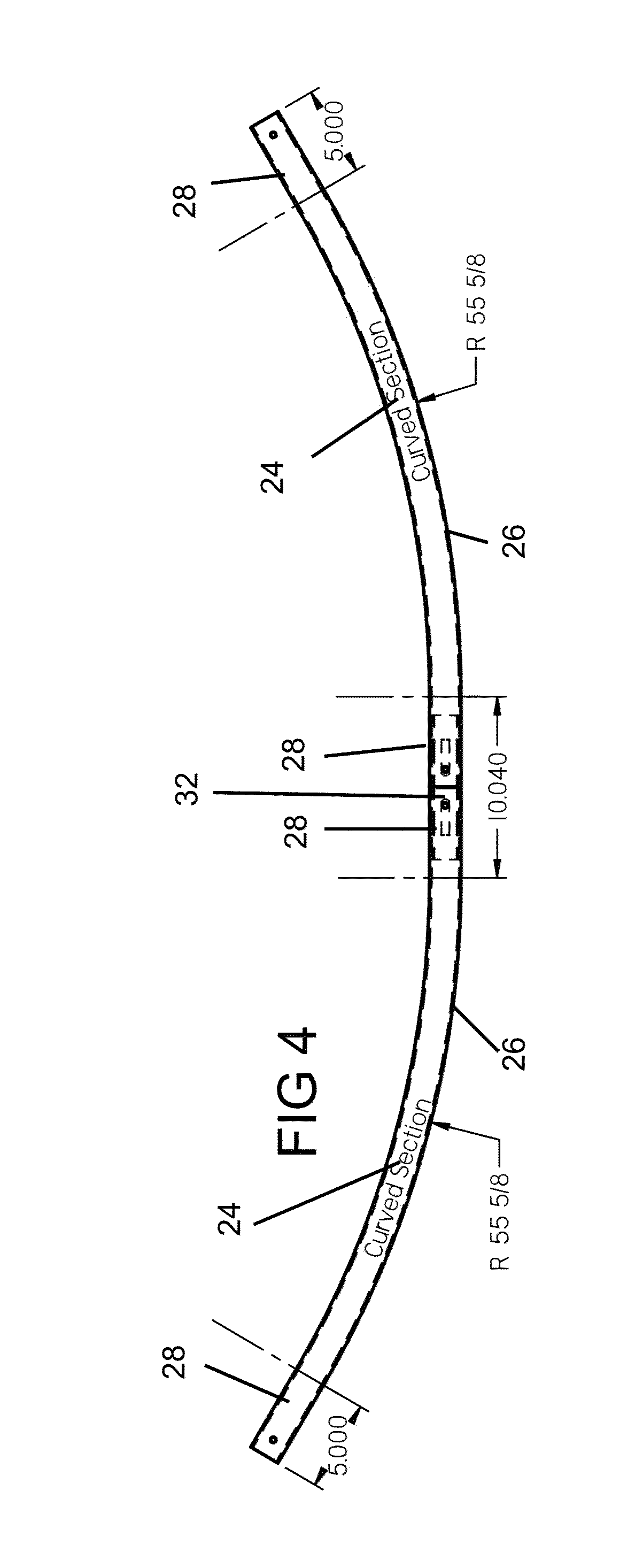

Portable Hammock Frame Shiftable Between Multiple Stable Positions

InactiveUS20160106200A1Prevent displacementAvoid lateral displacementTravelling sacksSofasEngineering

A hammock assembly comprises a conventional hammock on a hammock frame, which comprises two curved support members diverging from opposite ends at an angle. Each support member is formed of curved sections that are joined end to end to end. Disassembly of these curved sections or tube in the field provides portability. The hammock assembly will tilt when the occupant positions his or her center of gravity to the side of the center point of the hammock frame, so that the occupant can sit, partially recline or lie in a number of stable positions.

Owner:BRINKLEY CHADWICK CELEVATORON +1

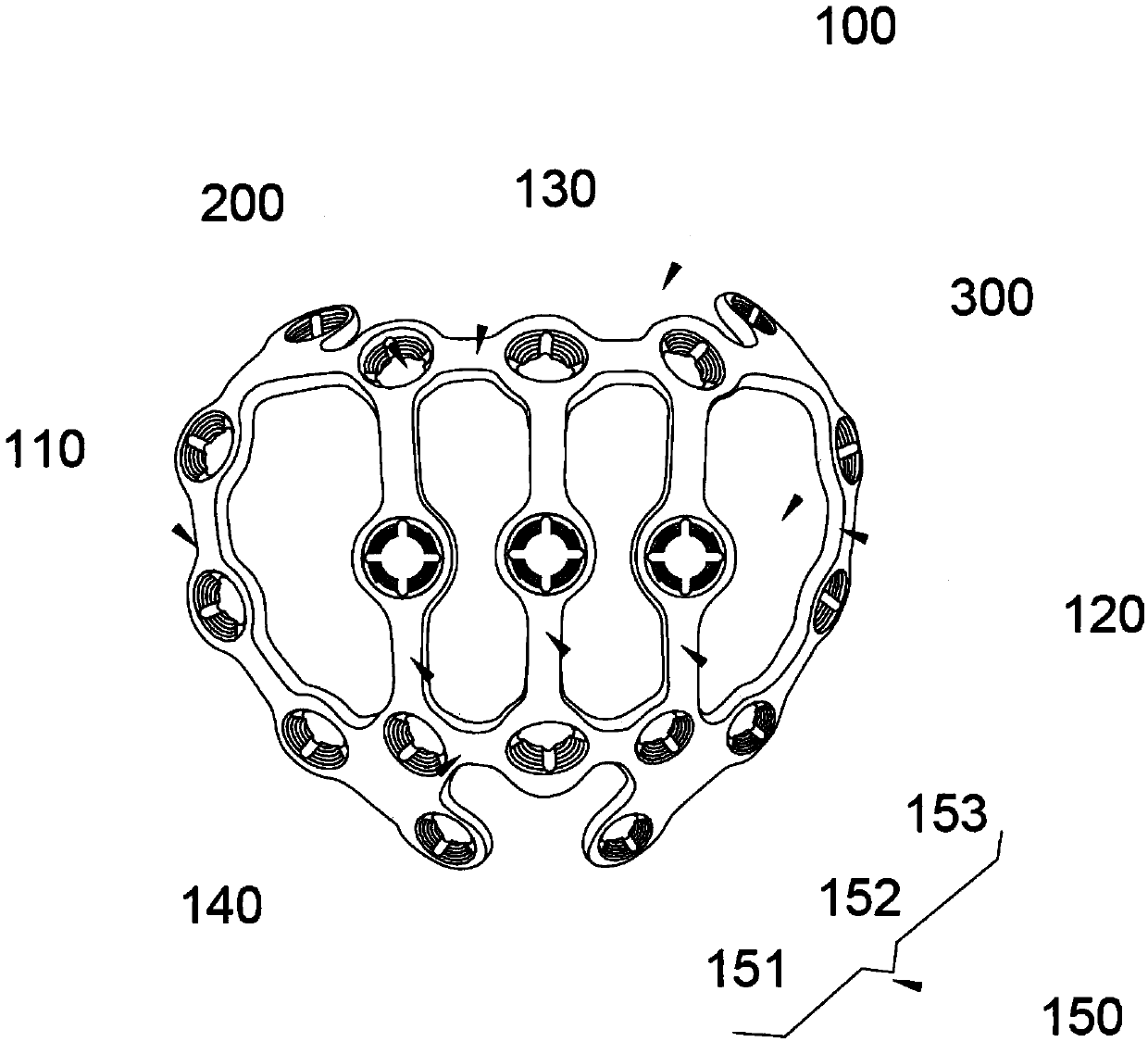

Multiaxial universal bonesetting plate for patellae

Owner:JIANGSU HOPE MEDICAL INSTR

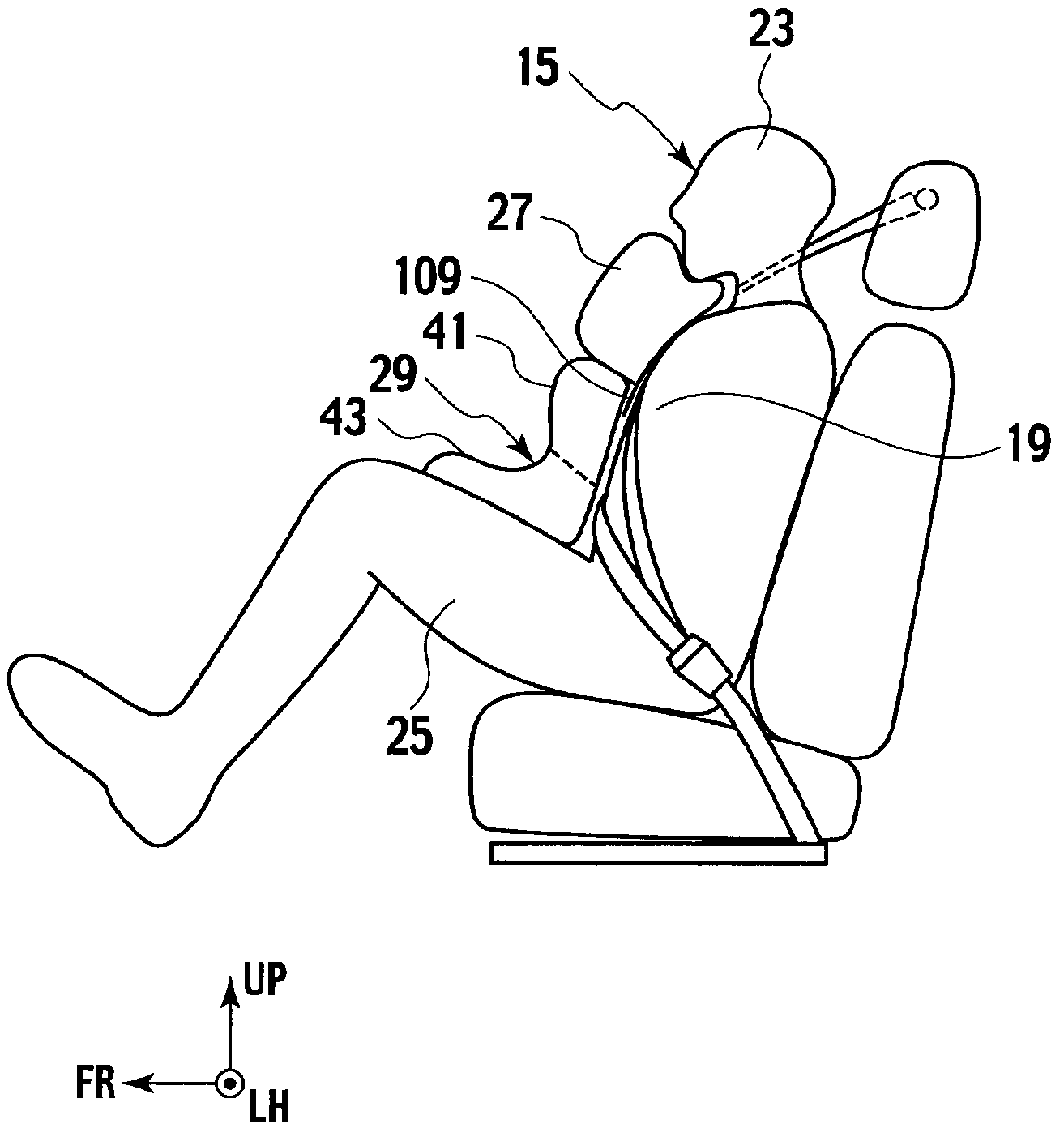

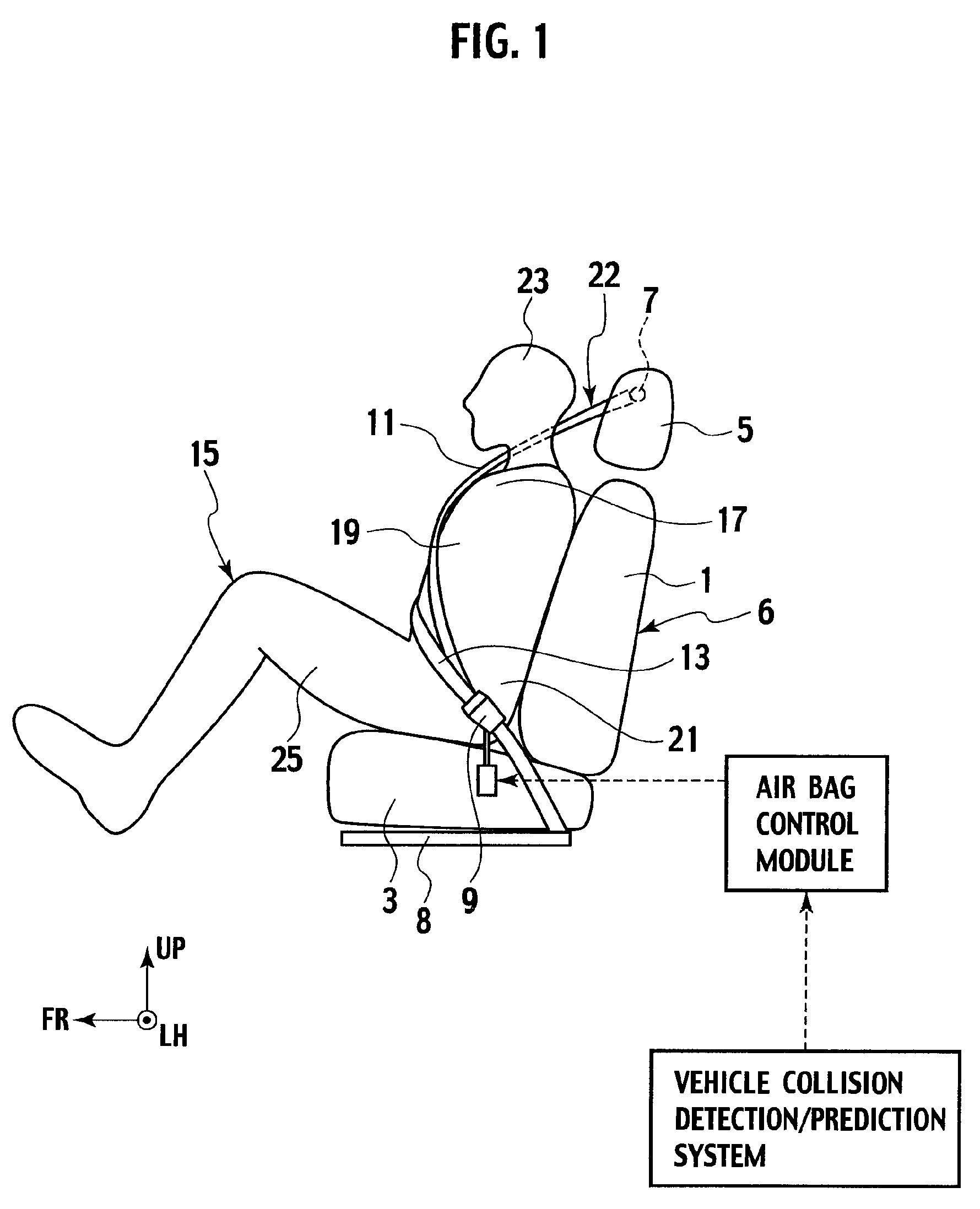

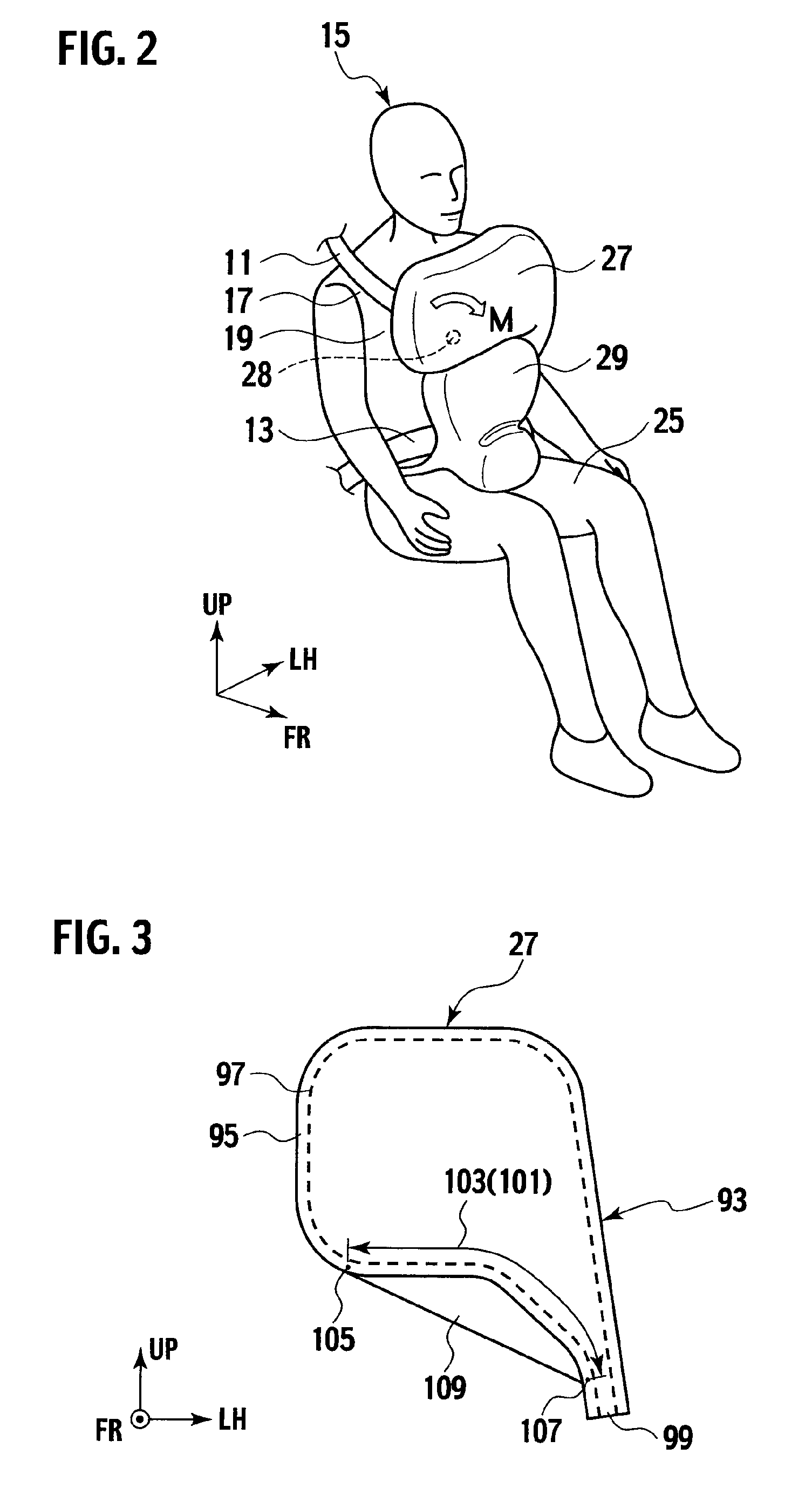

Vehicle occupant restraint system

ActiveUS20090278339A1Prevent displacementAvoid displacementPedestrian/occupant safety arrangementEnergy-absorbing device incorporationAirbag deploymentLumbar

A vehicle occupant restraint system including: a seatbelt device including a shoulder belt portion restraining a part of a vehicle occupant from one of shoulders to a chest, and a lap belt portion restraining a waist of the vehicle occupant; an upper airbag provided in the shoulder belt portion, and configured to be deployed forward from the shoulder belt portion; a lower airbag provided in the lap belt portion, and configured to be deployed forward from the lap belt portion, the deployed upper and lower airbags coming into contact with each other in a vertical direction; and a movement restraining portion restraining relative movement of the deployed upper and lower airbags in a front-rear direction, extending downward from a lower side of the deployed upper airbag, and positioned in the rear of the deployed lower airbag.

Owner:NISSAN MOTOR CO LTD +1

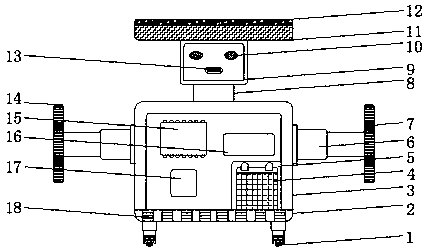

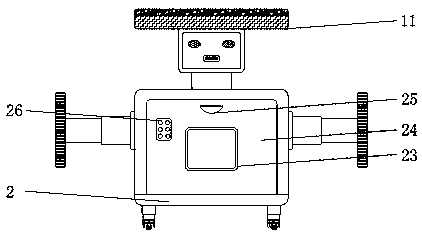

Novel traffic guidance robot

InactiveCN108326870AEasy maintenanceEnsure safetyArrangements for variable traffic instructionsManipulatorInformation storageInformation processing

The invention discloses a novel traffic guidance robot. The novel traffic guidance robot comprises a base, a shell, a storage battery, a head part and a solar panel, wherein the bottom of the shell isprovided with the base; universal wheels are arranged on the bottom of a connection plate; an information storage module is arranged in the shell on one side of a battery groove; an information collection module is arranged in the shell on one side of the information storage module; an information processing module is arranged in the shell on one side of the information collection module; a firstelectric telescopic rod and a third electric telescopic rod are separately arranged on one side of a connection shaft; a first LED traffic guidance rod is arranged on one side of the first electric telescopic rod, and a second LED traffic guidance rod is arranged on one side of the third electric telescopic rod; and the solar panel is arranged on the top end of the head part. According to the novel traffic guidance robot, the novel traffic guidance robot is convenient to move and regulate due to arrangement of a series of structures, and meanwhile traffic guidance is accurate; and labor is saved.

Owner:湖州慧斯顿机器人科技有限公司

Connector holding structure

InactiveUS6890211B2Prevent displacementPrevent occurrence of damageSubstation/switching arrangement detailsElectric discharge tubesElectrical and Electronics engineeringEngineering

Owner:MITSUBISHI MOTORS CORP +1

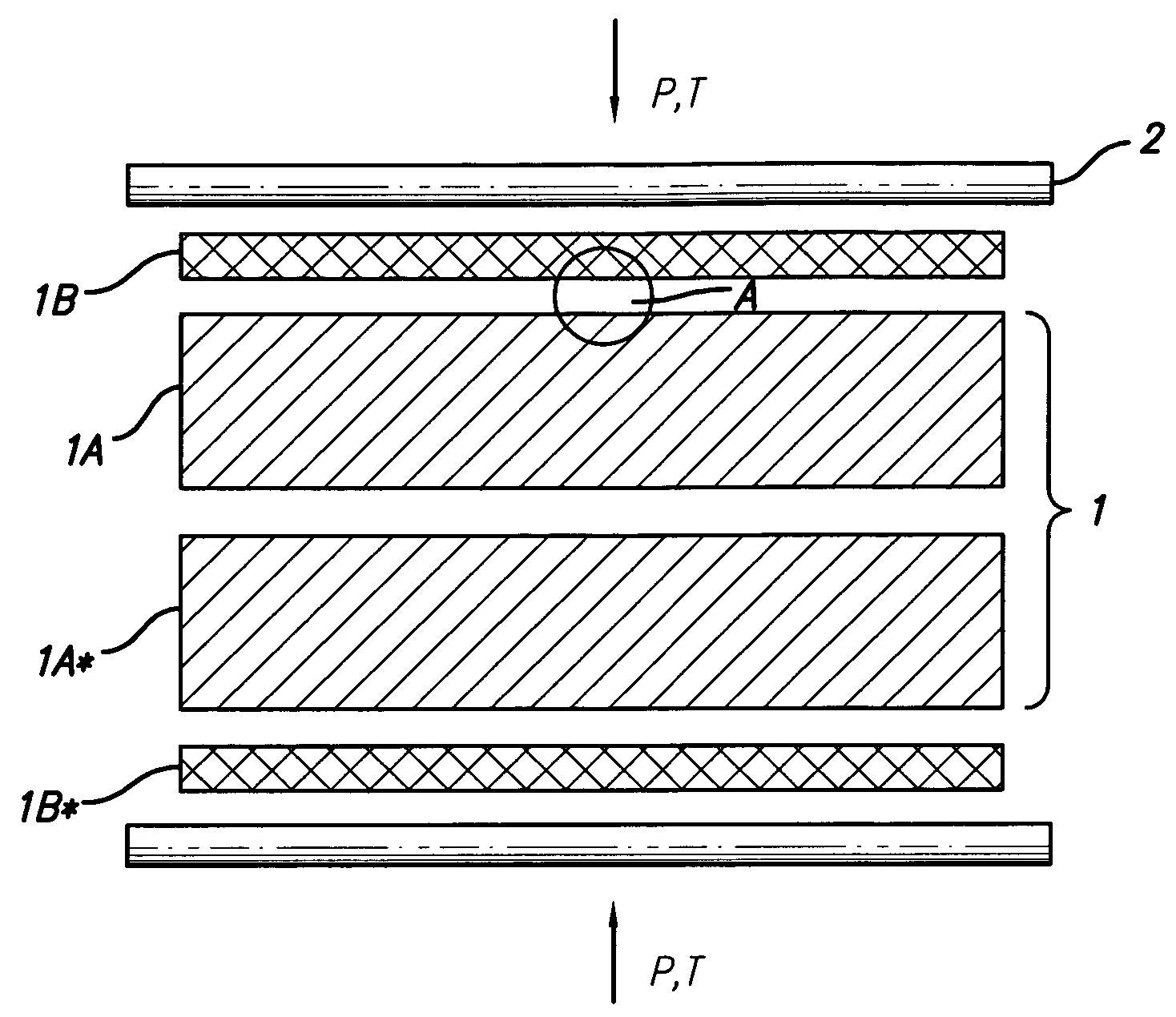

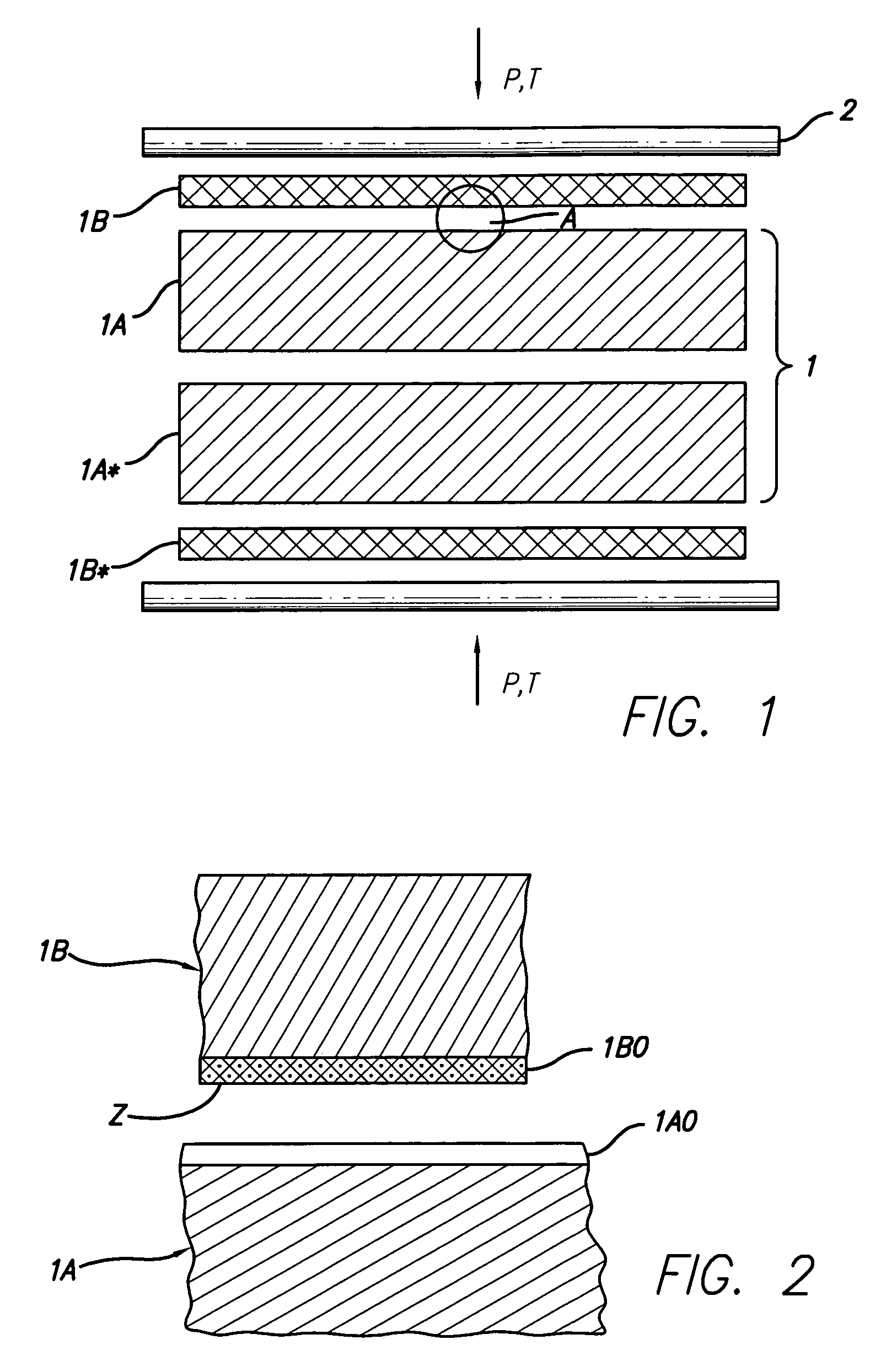

Method for the production of a multi-layer identity card of plastic

InactiveUS7201953B2High bonding strengthPrevent displacementDecorative surface effectsTraffic signalsEngineeringAdhesive

An improvement applicable to a method for the production of a multi-layer identity card of plastic wherein the card comprises one or more card core layers bonded under the action of pressure and heat and printed on either side or on opposite sides with a covering layer applied to the printed side or sides of the card core. In accordance with the improvement a thermoplastic polymer adhesive is applied between and in direct contact with each covering layer and the respective printed side of the card core, the thermoplastic adhesive coating possessing at least one additive that increases the friction between the covering layer and the printed card core during lamination so as to prevent displacement of the printed card core in relation to the covering layer or layers.

Owner:ORGA KARTENSYSTEME GMBH +1

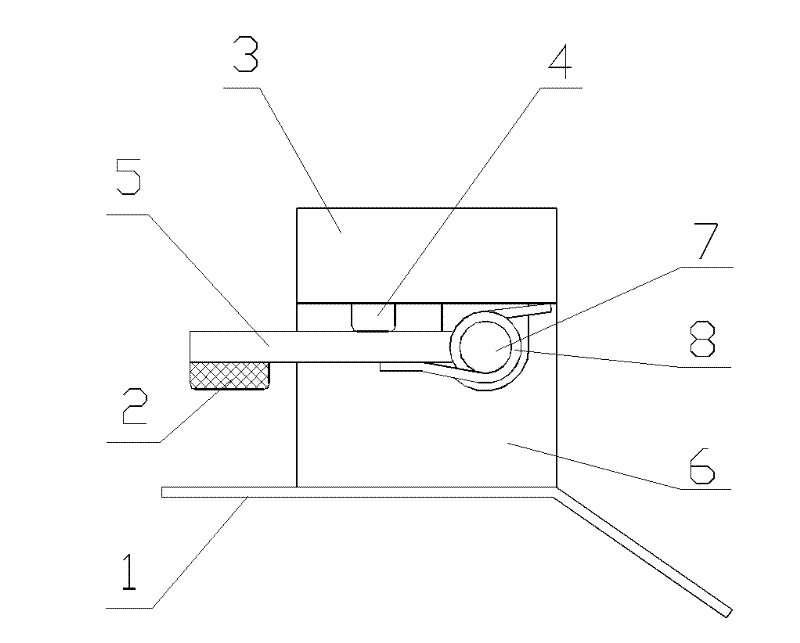

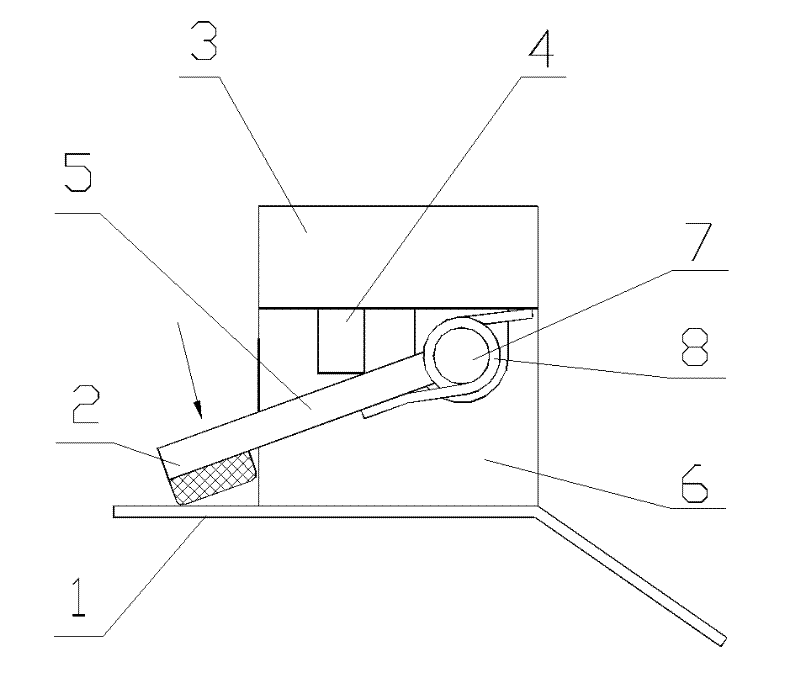

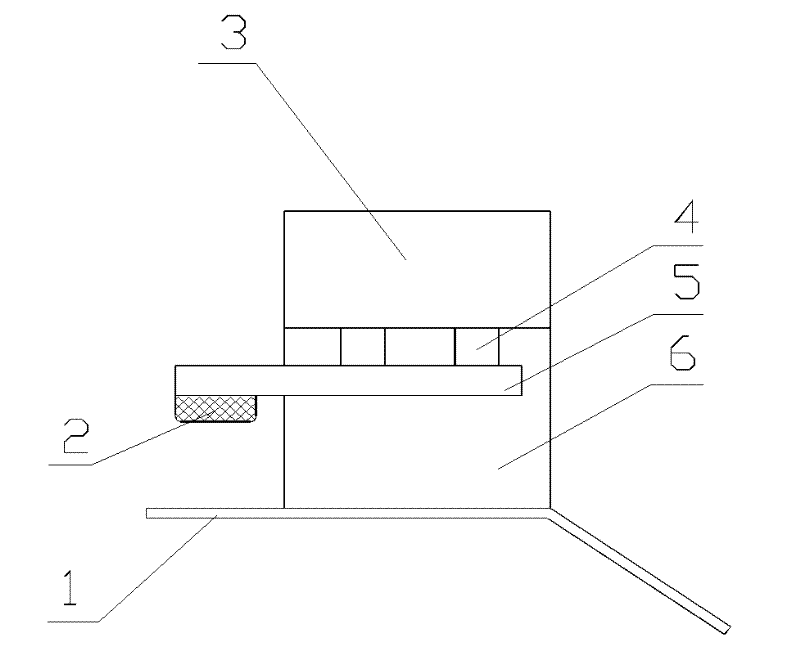

Improved upward and downward compression mechanism of keyhole machine tool

InactiveCN102358997AStable positioningReduce assembly requirements and debugging difficultiesPressersKeyholeMechanical construction

The invention discloses an improved upward and downward compression mechanism of a keyhole machine tool. An upward and downward compression structure of the keyhole machine tool comprises a retainer plate of which the lower part is fixed horizontally and a compression plate of which the upper side can be opened / closed; and the compression plate is horizontal, and moves vertically up and down in horizontal state under the driving action of a cylinder. When the upward and downward compression structure is pressed down vertically, the problem of displacement of cloth caused by shearing force of a rotary extrusion upward and downward compression structure in the conventional product is solved, the linearity of a shirt top fly keyhole is increased greatly, and the attractiveness of a shirt top fly is ensured; compared with the conventional rotary extrusion upward and downward compression structure, the vertically-pressed upward and downward compression structure has the advantages: the mechanical structure is simplified greatly, the assembling difficulty and debugging difficulty are lowered greatly, the mechanical assembling efficiency is increased, and the maintenance cost of a customer is lowered; and due to the adoption of the vertically-pressed upward and downward compression structure, a sufficient stress surface is ensured during compression of cloth is ensured, the stress is more uniform, and the compression effect is better.

Owner:SHANGHAI WEISHI MACHINERY

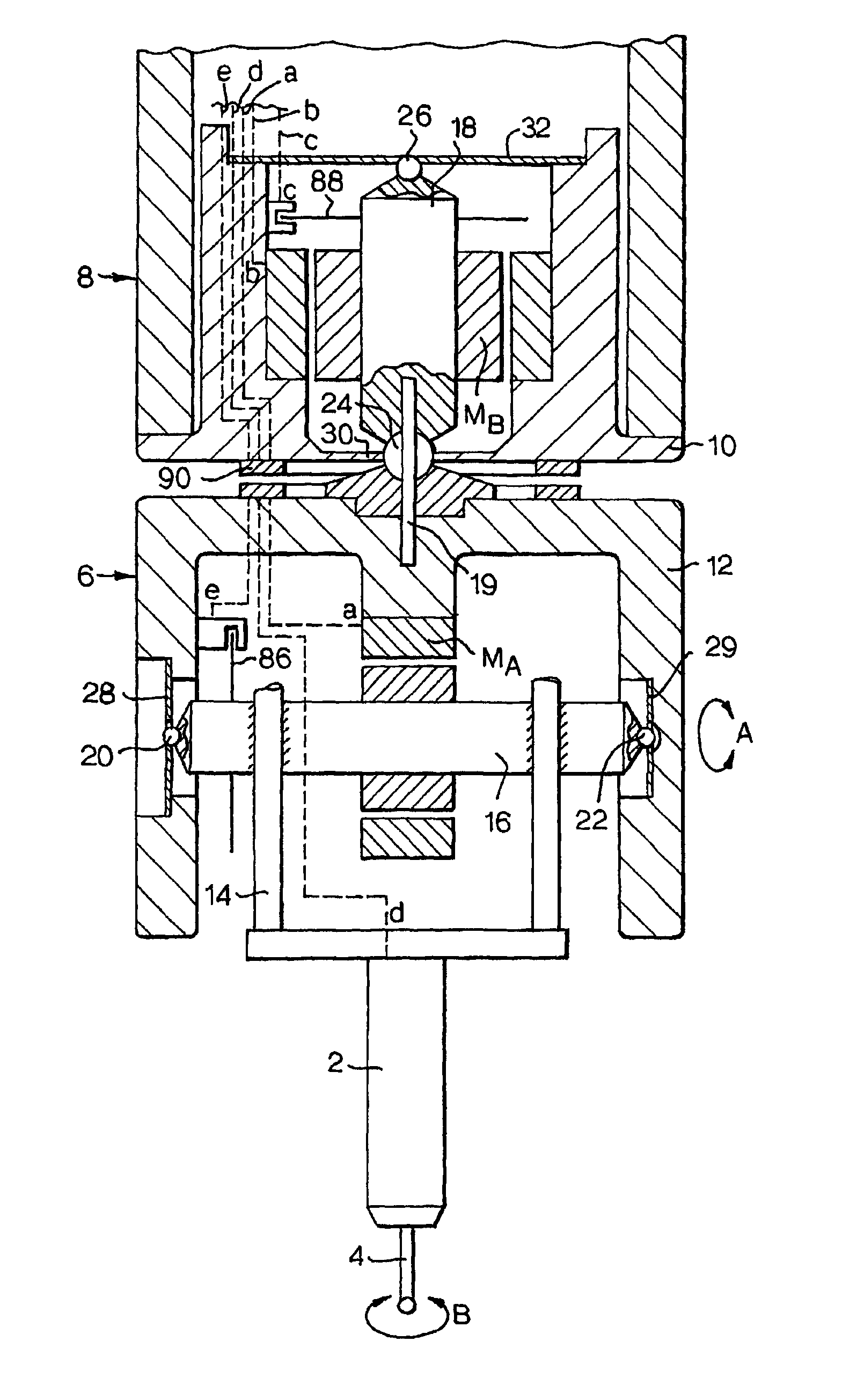

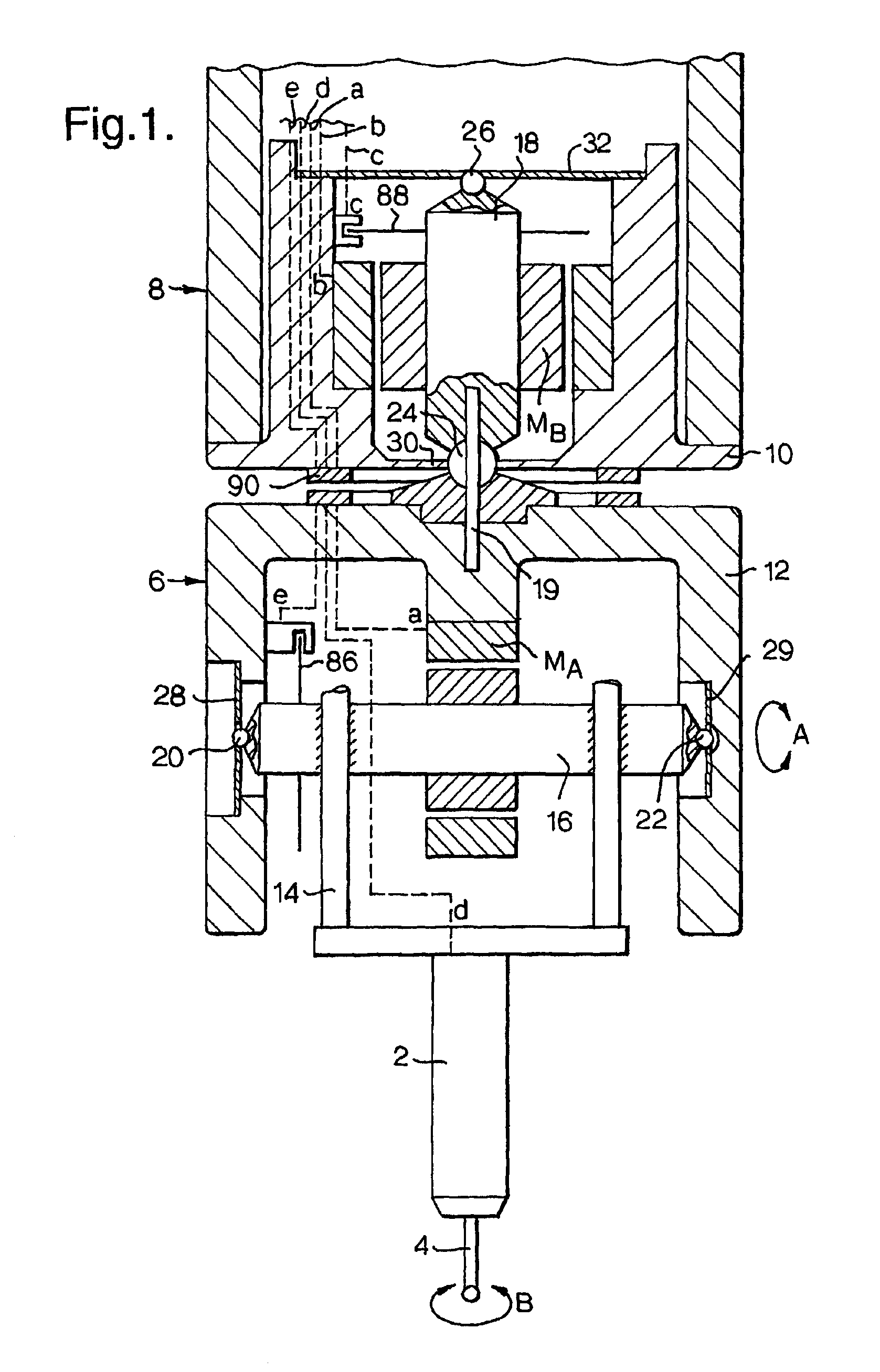

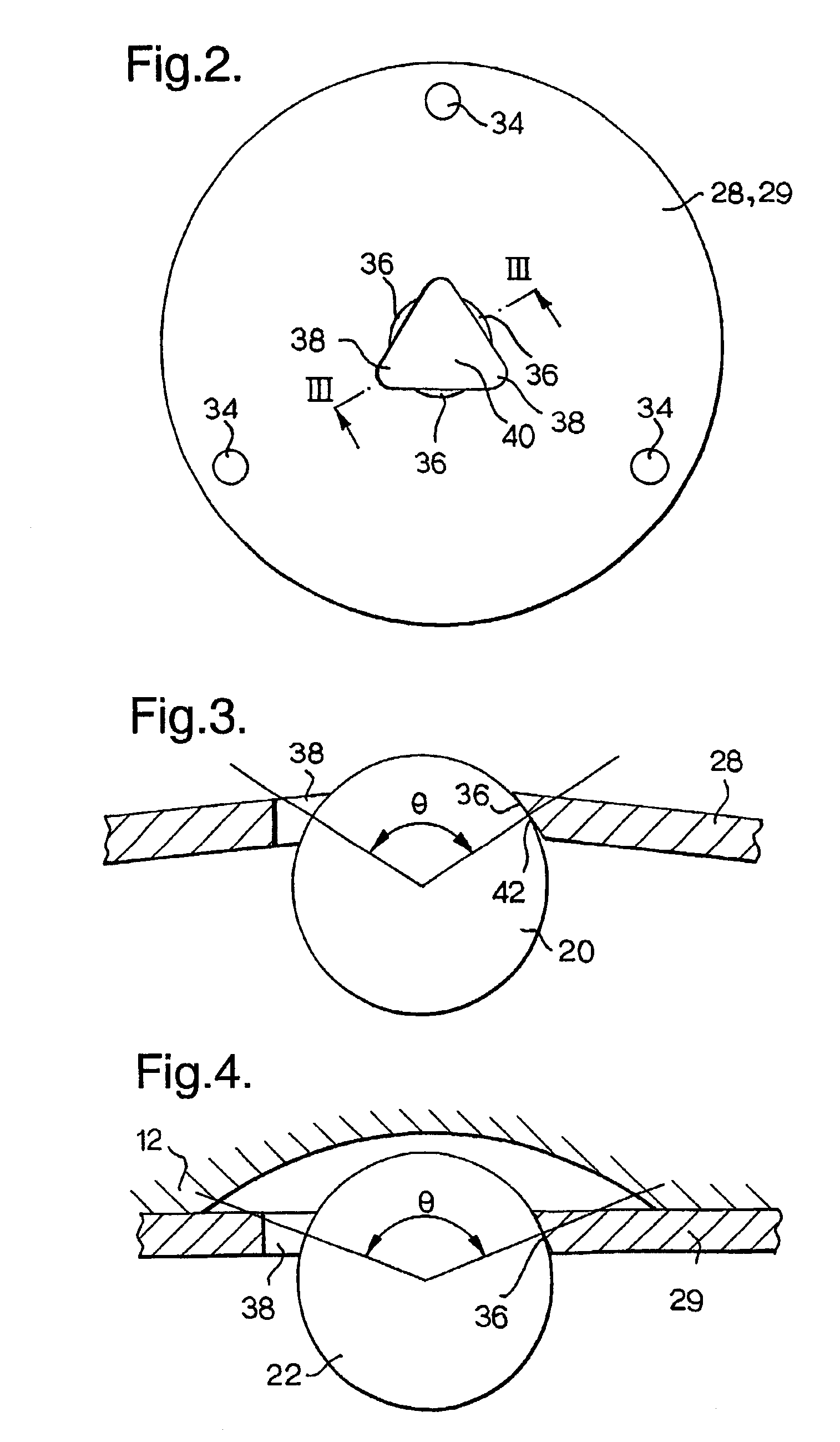

Bearing arrangement

A bearing arrangement for an articulatable support (6) comprises bearing assemblies (20 / 28, 22 / 29, 24 / 30 and 26 / 32). In one embodiment the assemblies comprise a ball (20, 22, 24, 26) and aperture (40 FIG. 2) having sliding contact at discrete areas (36) during relative rotation. In another embodiment the sliding contact may be formed at a ball (20,22,24,26) and a plastics e.g. P.T.F.E. support (84, 85 FIGS. 10 and 11). Resilient displacement of the bearing contact along a rotational axis (A and B) is provided by planar spring supports (28, 32) and rigid support is provided by supports (29 and 30).

Owner:RENISHAW PLC

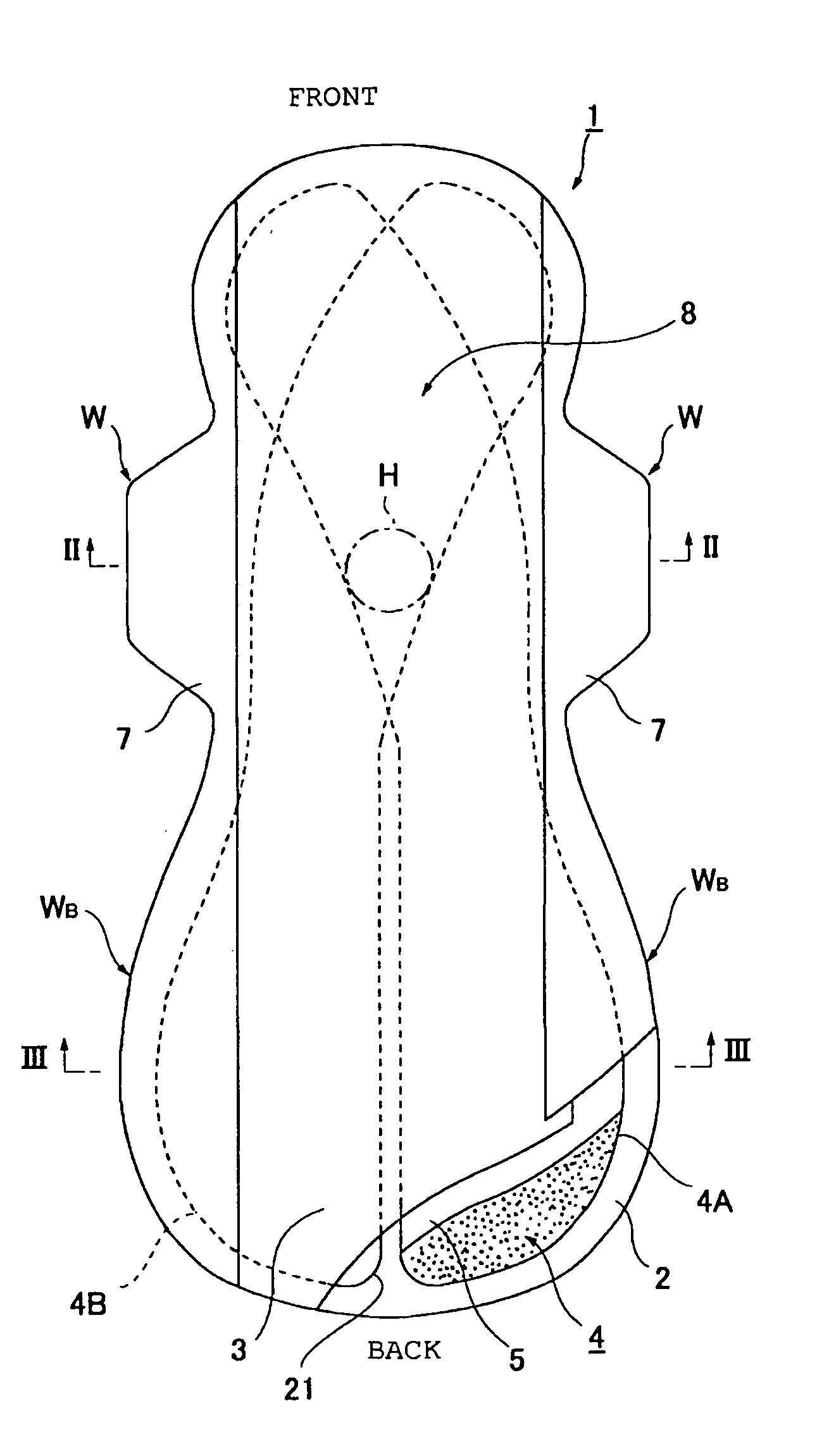

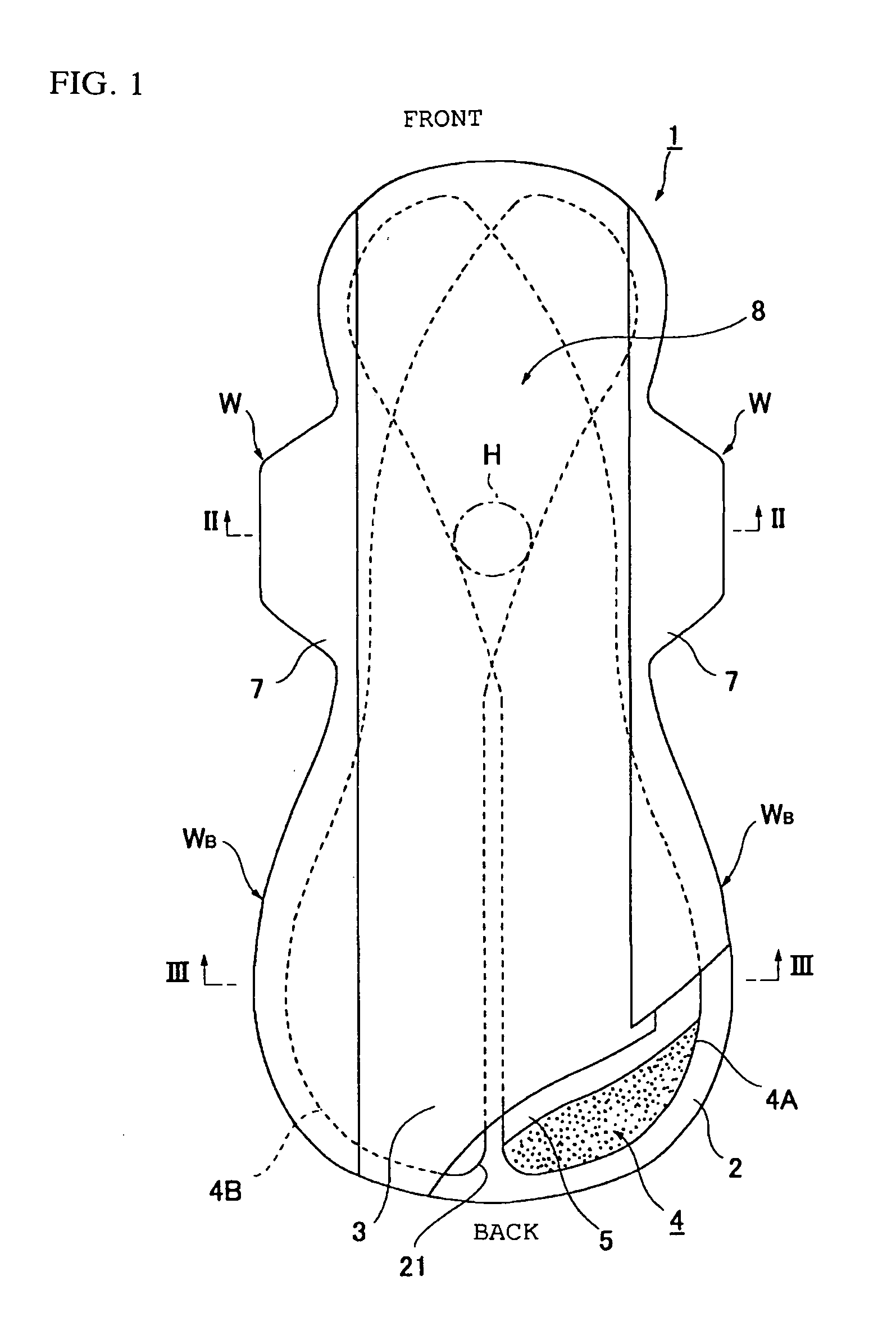

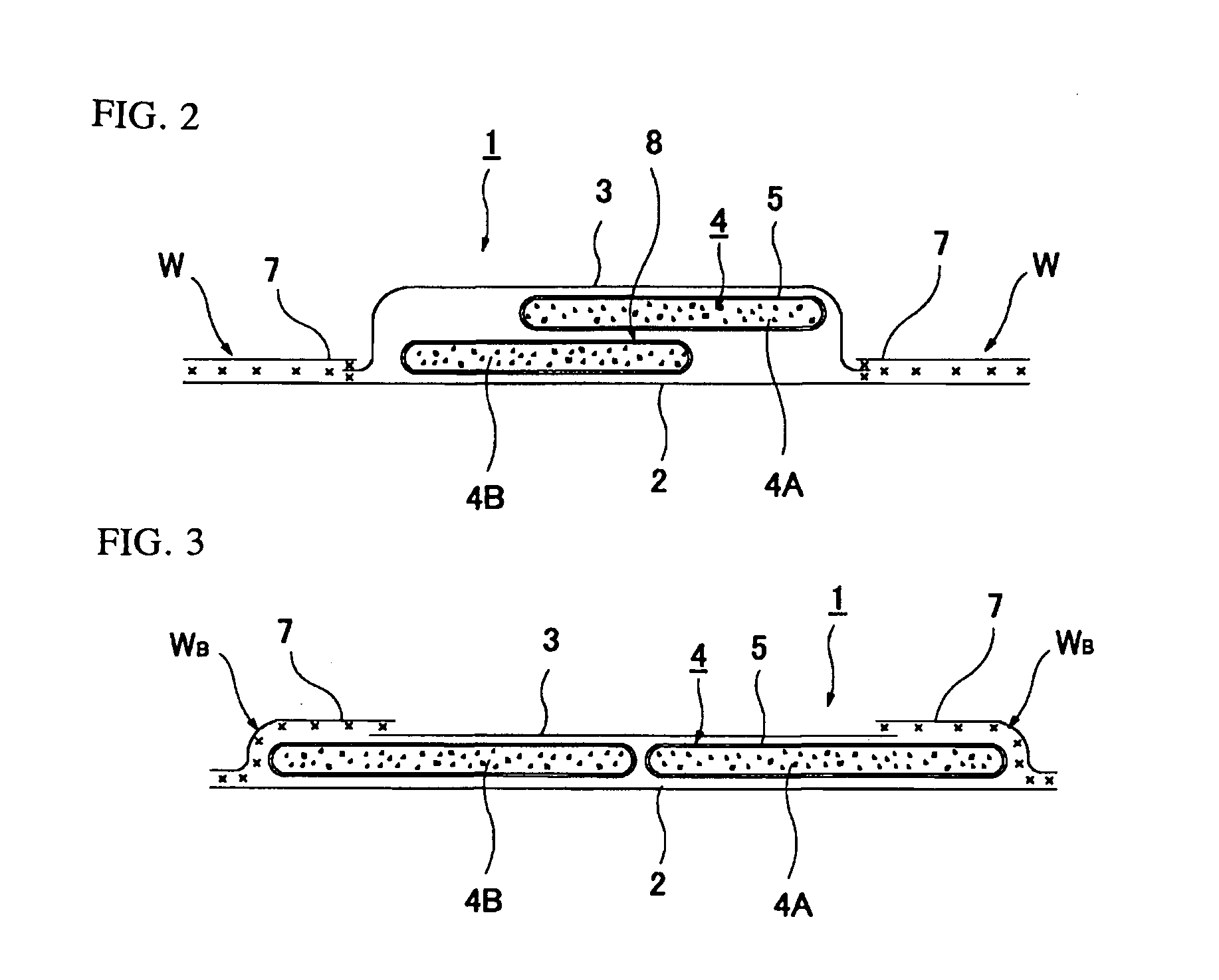

Absorbent article

ActiveUS20100030175A1Prevent displacementExcellent followabilitySanitary towelsBaby linensEngineeringMechanical engineering

An absorbent article comprises an absorbent interposed between a liquid-permeable surface sheet and a back sheet. The absorbent is constituted of a set of left and right absorbent elements arranged substantially along the longitudinal direction of the absorbent article. The absorbent element of one side is formed as a dogleg to the right in a top plan view whereas the absorbent element of the other side is formed as a dogleg to the left in a top plan view, so that the absorbent elements have an intersecting portion intersecting in at least the region containing the portion corresponding to the blood discharge opening of the wearer.

Owner:DAIO PAPER CORP

Preparation method of concrete for building construction

ActiveCN108117320APrevent displacementSimple and fast operationSolid waste managementGrain treatmentsFiberDry mixing

The invention discloses a preparation method of concrete for building construction. The preparation method comprises the following steps of: (1) raw material preparation: taking cement, sandstone, sand, gangue, meerschaum powder, a simulated steel fiber, an expanding agent, water and a water reducer, (2) dry mixing, and (3) wet mixing: putting a mixture B into a stirrer, and adding water into thestirrer for uniform stirring to form the grouted concrete, wherein the sandstone and the sand are prepared by crushing construction waste via a crushing device; 60% of a material taken out after primary crushing by the crushing device is the sandstone; and the rest 40% of the sandstone are continuously crushed to form the sand. The sand and the sandstone are prepared by crushing the construction waste; a resource is saved; the sand and the sandstone can be prepared by crushing via the single crushing device; and the equipment input cost is low.

Owner:广州市宏翰混凝土有限公司

Connector with a connection detecting function

InactiveUS20100304604A1Prevent displacementSimple constructionEngagement/disengagement of coupling partsEngineeringShort circuit

Owner:SUMITOMO WIRING SYST LTD

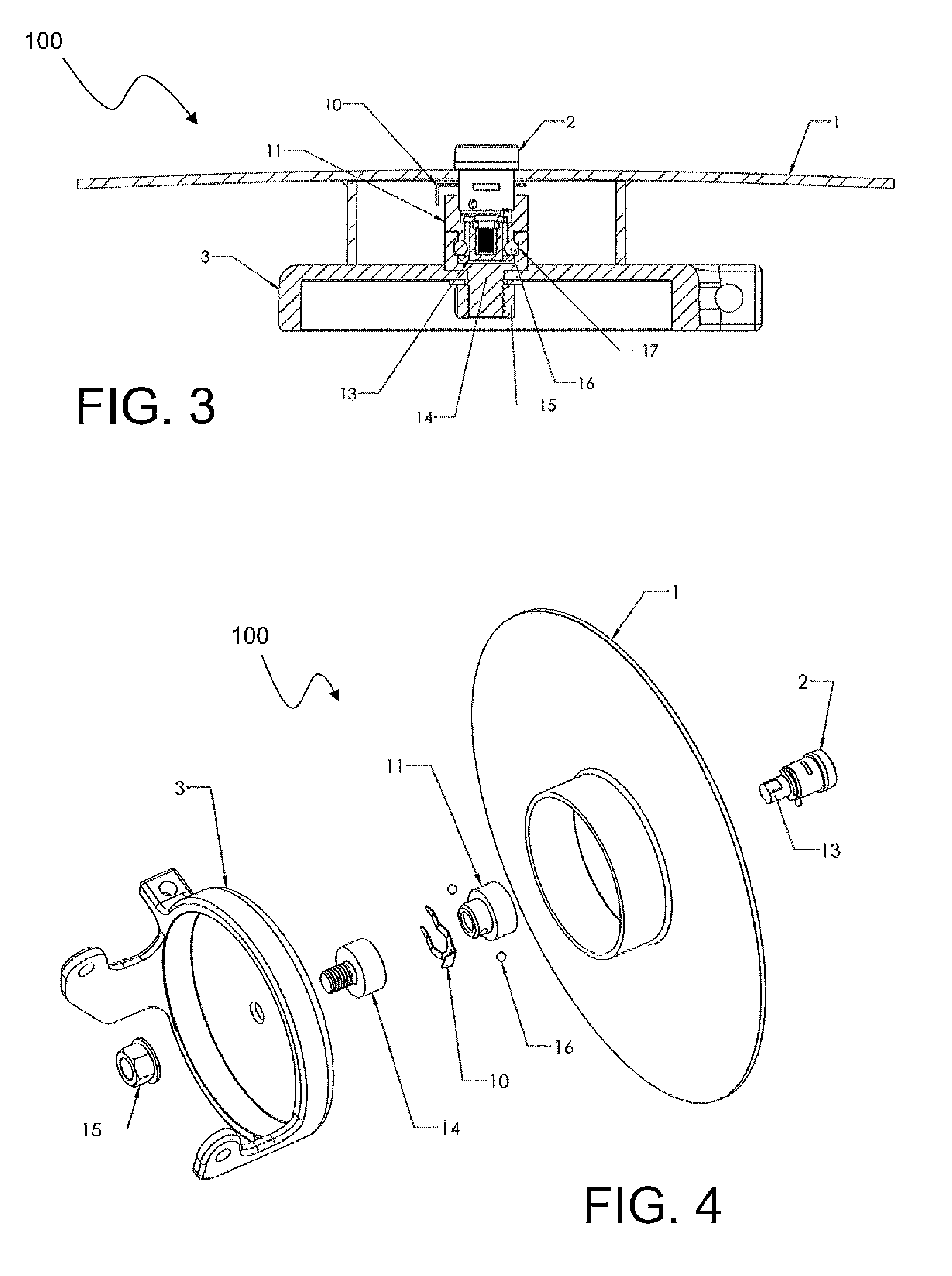

Underground tank lock

ActiveUS20100000999A1Prevent displacementPrevent unscrewingCapsBuilding locksEngineeringUnderground storage tank

Disclosed are apparatus and methodology for securing access to an underground device such as a storage tank. A lockable blocking plate is secured to a filler cap for an underground storage tank in a manner to inhibit access to the filler cap. The locking mechanism is configured such that the lock and blocking plate may freely rotate with respect to the filler cap. The blocking plate may include a side skirt extending to cover portions of the filler cap and, optionally, portions of a standpipe and coupling for the filler cap. Free rotation is enabled by way of an annular groove in a portion of the locking mechanism, and into which groove one or more locking portions may be inserted, or by way of a freely moving swivel boss attached to the filler cap.

Owner:COMPX INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com