Dual-purpose multi-model valve tightness detection pressing device

A multi-model, airtight technology, used in measuring devices, using liquid/vacuum for liquid tightness measurement, fluid tightness testing, etc. , easy to use, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

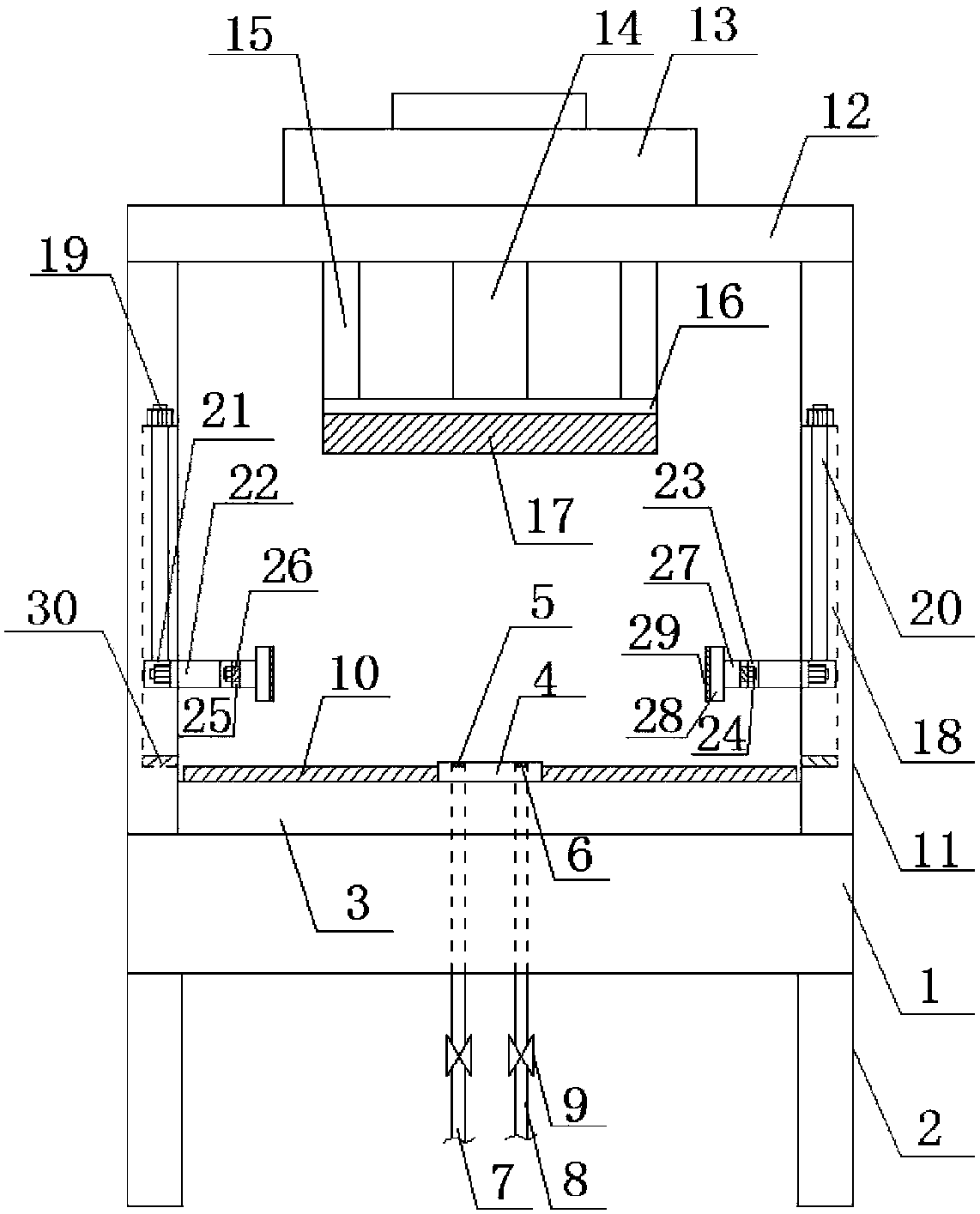

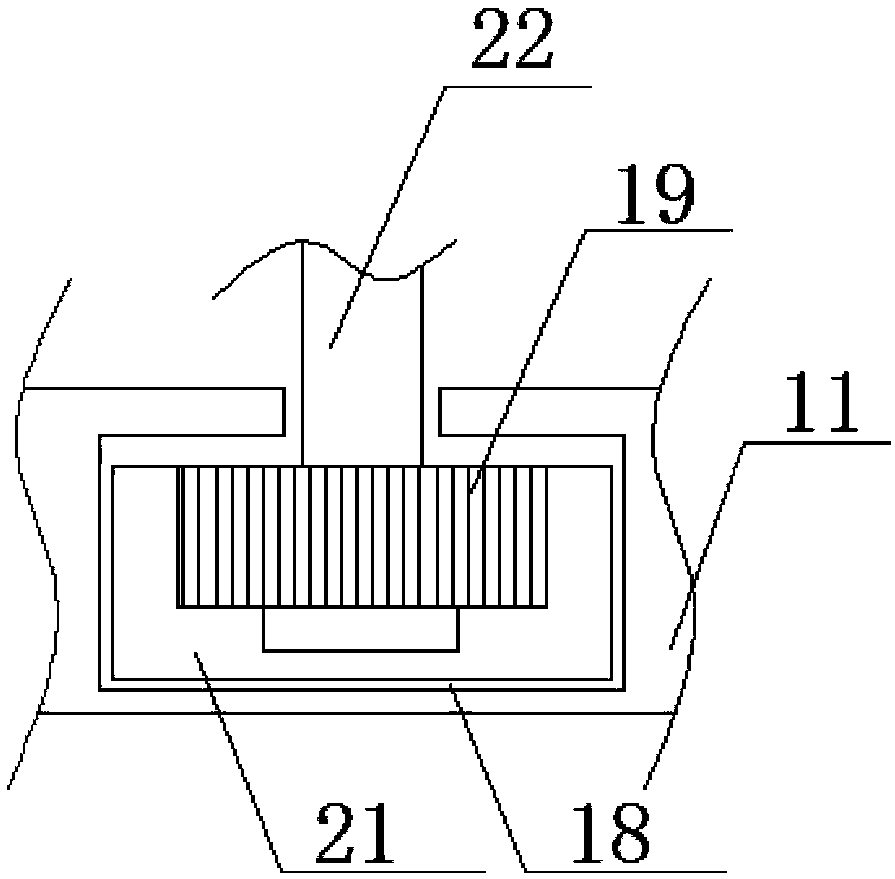

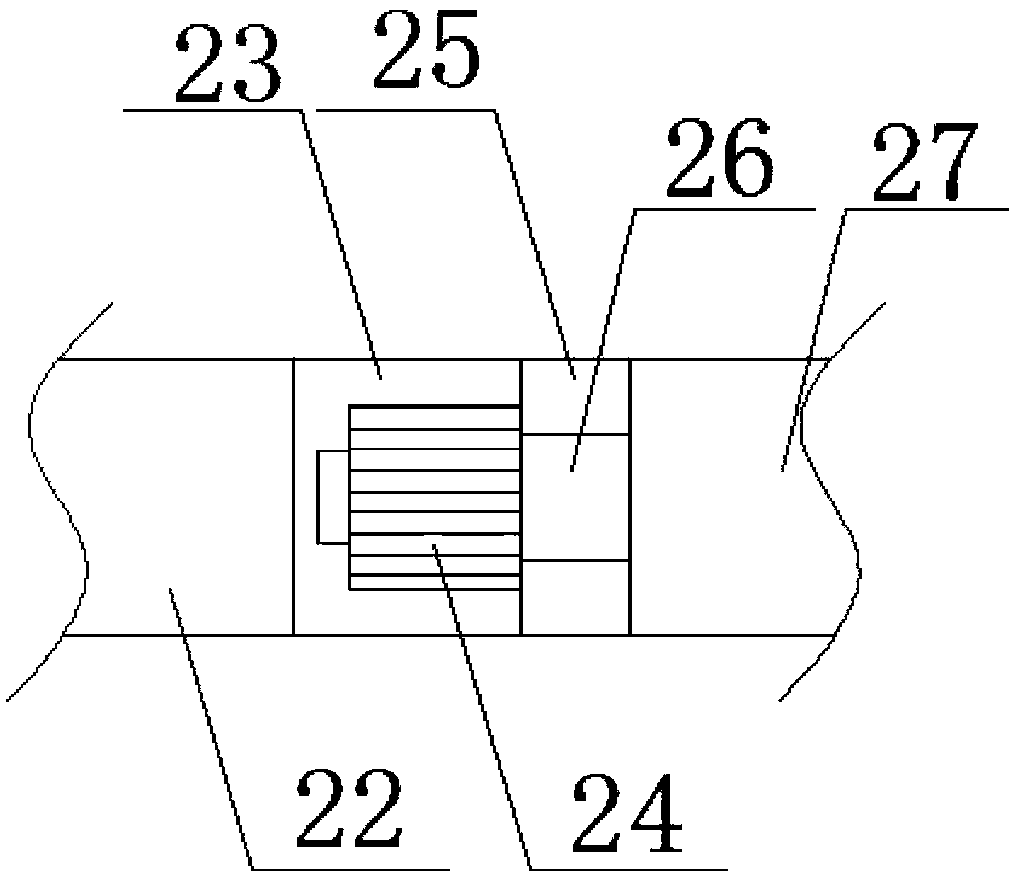

[0031] Such as Figure 1~6 As shown, a dual-purpose and multi-type valve airtightness detection and pressing device includes a workbench 1, the bottom of the workbench 1 is provided with a leg 2, and the top of the workbench 1 is provided with an upper sealing platform 3, and the upper seal The top of the table 3 is provided with an upper gasket 10, the center of the upper gasket 10 is provided with a test bearing platform 4, and both sides of the top of the workbench 1 are provided with supporting columns 11, and the tops of the two supporting columns 11 are fixedly connected. Fixed cross bar 12, below said fixed cross bar 12 is provided with an upper sealing table 16 connected with sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com