Preparation method of concrete for building construction

A technology of concrete and construction, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high energy consumption, high equipment investment cost, high operating cost, etc., and achieve low energy consumption and high work efficiency , the effect of low workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

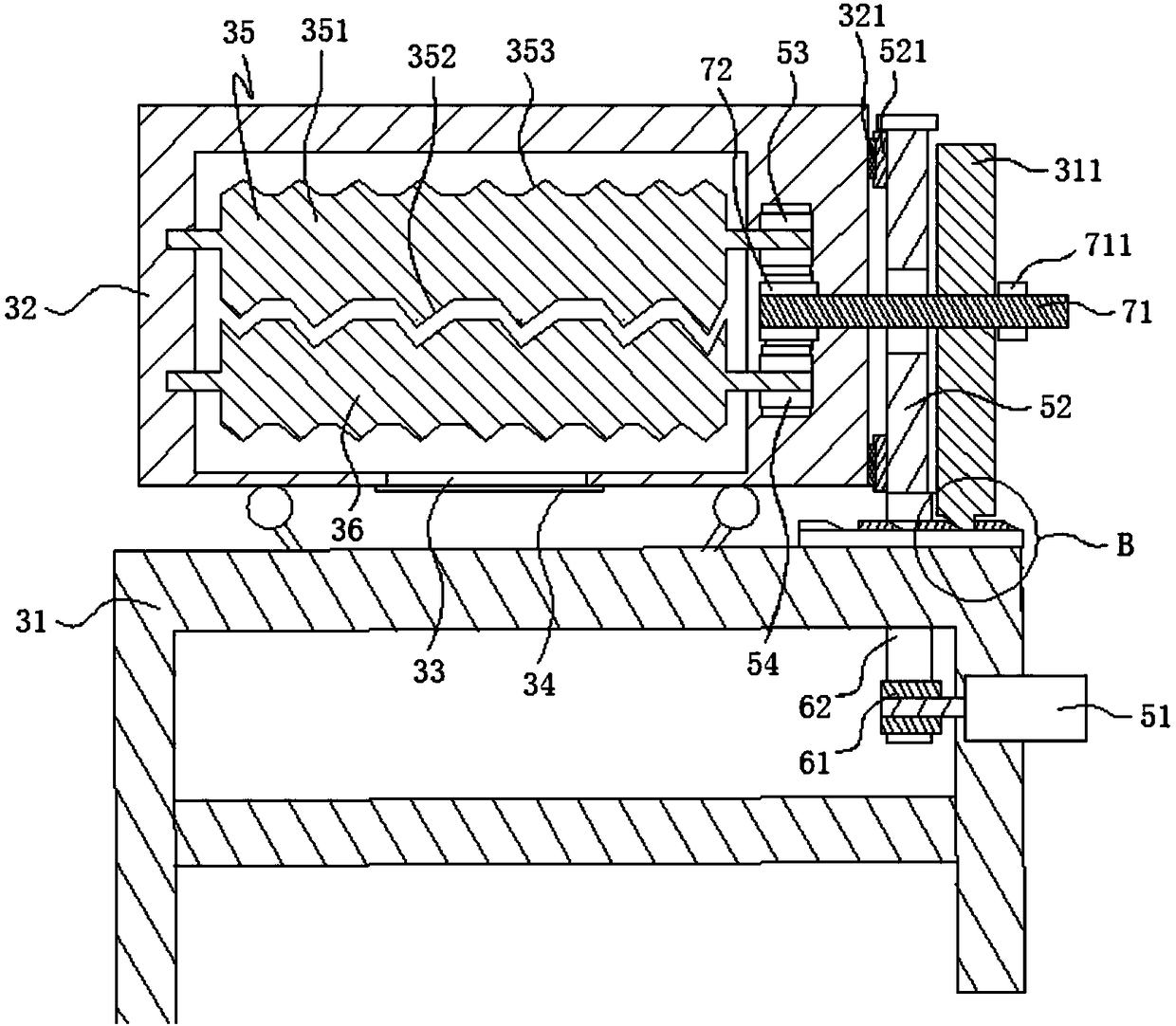

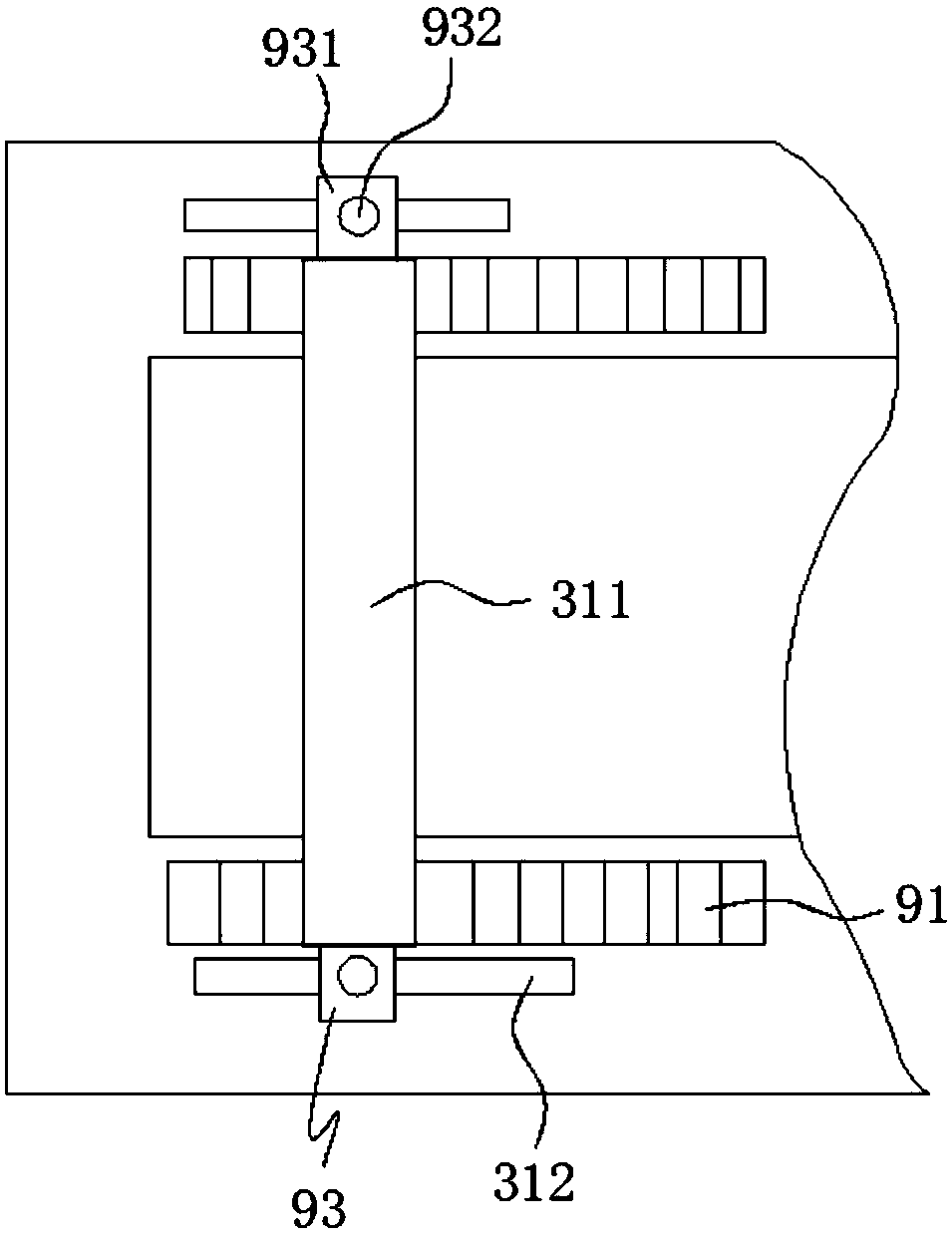

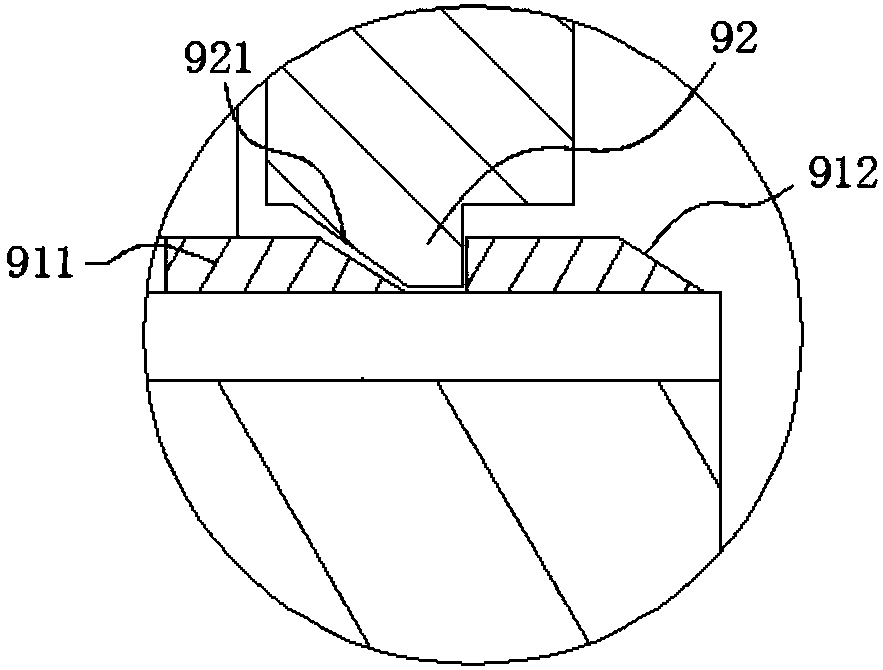

Embodiment 1

[0030] A method for preparing concrete for building construction, comprising the following steps: (1) Raw material preparation: take cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent Wherein sand and gravel and sand are obtained by crushing construction waste through a crushing device. After the crushing device is crushed once, 60% of the material is taken out to be sand and gravel; then the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, The particle size of the sand and gravel is 8 mm, and the particle size of the sand is 2 mm; the sludge is obtained by scraping mud at the bottom of the sedimentation tank by a mud scraper; the water reducing agent is composed of the following components in parts by weight: 40 parts of polycarboxylic acid mother liquor, 6 parts of slump-preserving agent, 2.5 parts of triethanolamine, 4 parts of acetone; sepiolite powder ...

Embodiment 2

[0039] A method for preparing concrete for building construction, comprising the following steps: (1) Raw material preparation: take cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent Wherein sand and gravel and sand are obtained by crushing construction waste through a crushing device. After the crushing device is crushed once, 60% of the material is taken out to be sand and gravel; then the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, The particle size of the sand is 10 mm, and the particle size of the sand is 3 mm; the sludge is obtained by scraping the sludge at the bottom of the sedimentation tank by a mud scraper; the water reducer is composed of the following components in parts by weight: 45 parts of polycarboxylic acid mother liquor, 10 parts of slump-preserving agent, 3.5 parts of triethanolamine, 6 parts of acetone; sepiolite powder obtaine...

Embodiment 3

[0042] A method for preparing concrete for building construction, comprising the following steps: (1) Raw material preparation: take cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent Wherein sand and gravel and sand are obtained by crushing construction waste through a crushing device. After the crushing device is crushed once, 60% of the material is taken out to be sand and gravel; then the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, The particle size of the sand is 10mm, and the particle size of the sand is 2mm; the sludge is obtained by scraping the sludge at the bottom of the sedimentation tank by a scraper; the water reducer is composed of the following components in parts by weight: 40 parts of polycarboxylic acid mother liquor, 10 parts of slump-preserving agent, 2.5 parts of triethanolamine, 4 parts of acetone; sepiolite powder obtained by g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com