Patents

Literature

121results about How to "Prevent unscrewing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

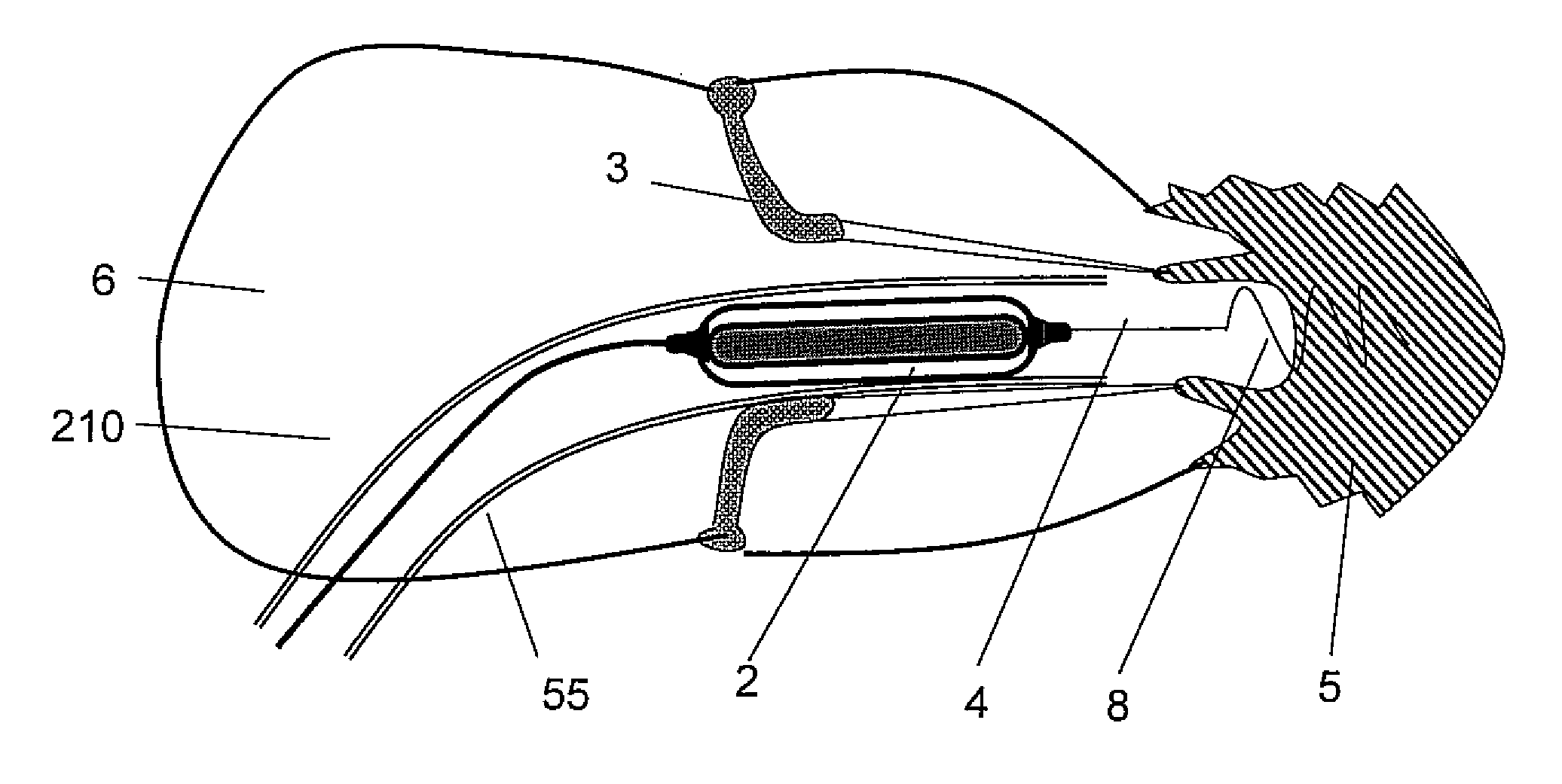

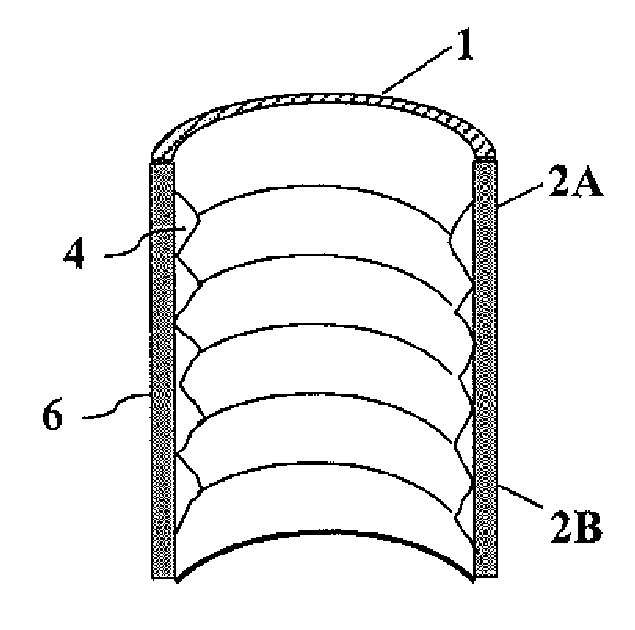

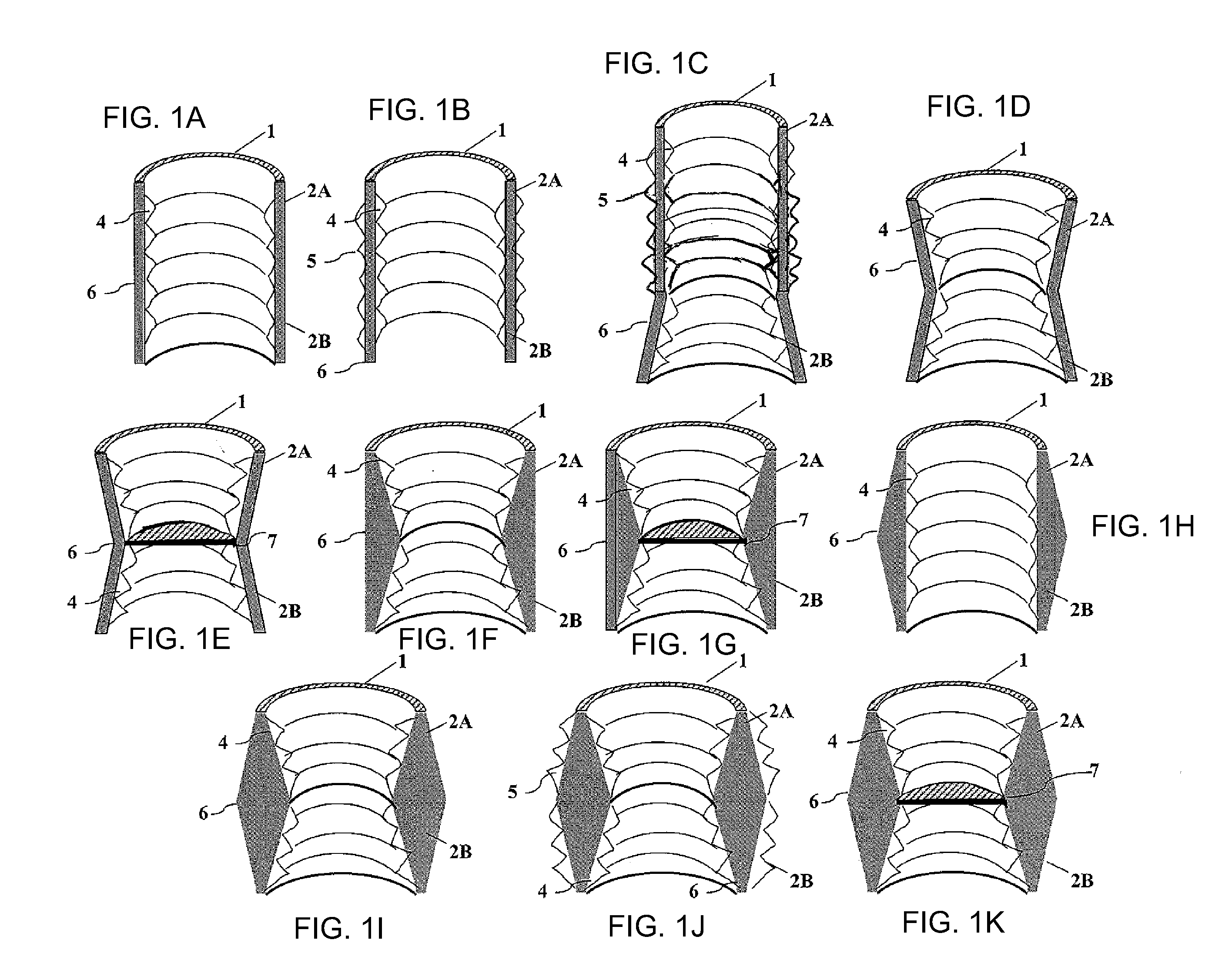

Medical device for use in treatment of a valve

InactiveUS20110022164A1Dampen rotational movementProfound clinical consequencesSuture equipmentsHeart valvesMedical deviceBiomedical engineering

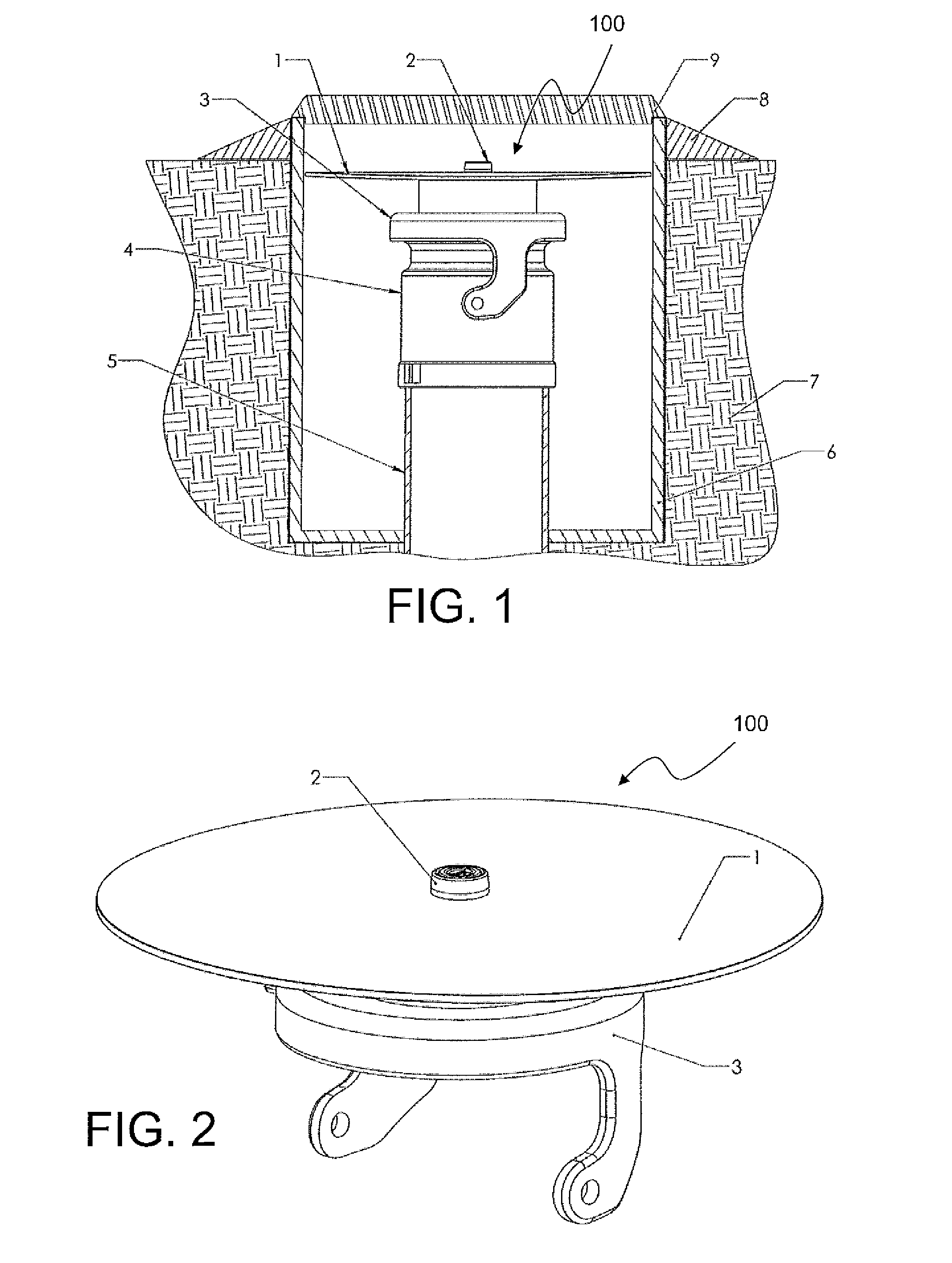

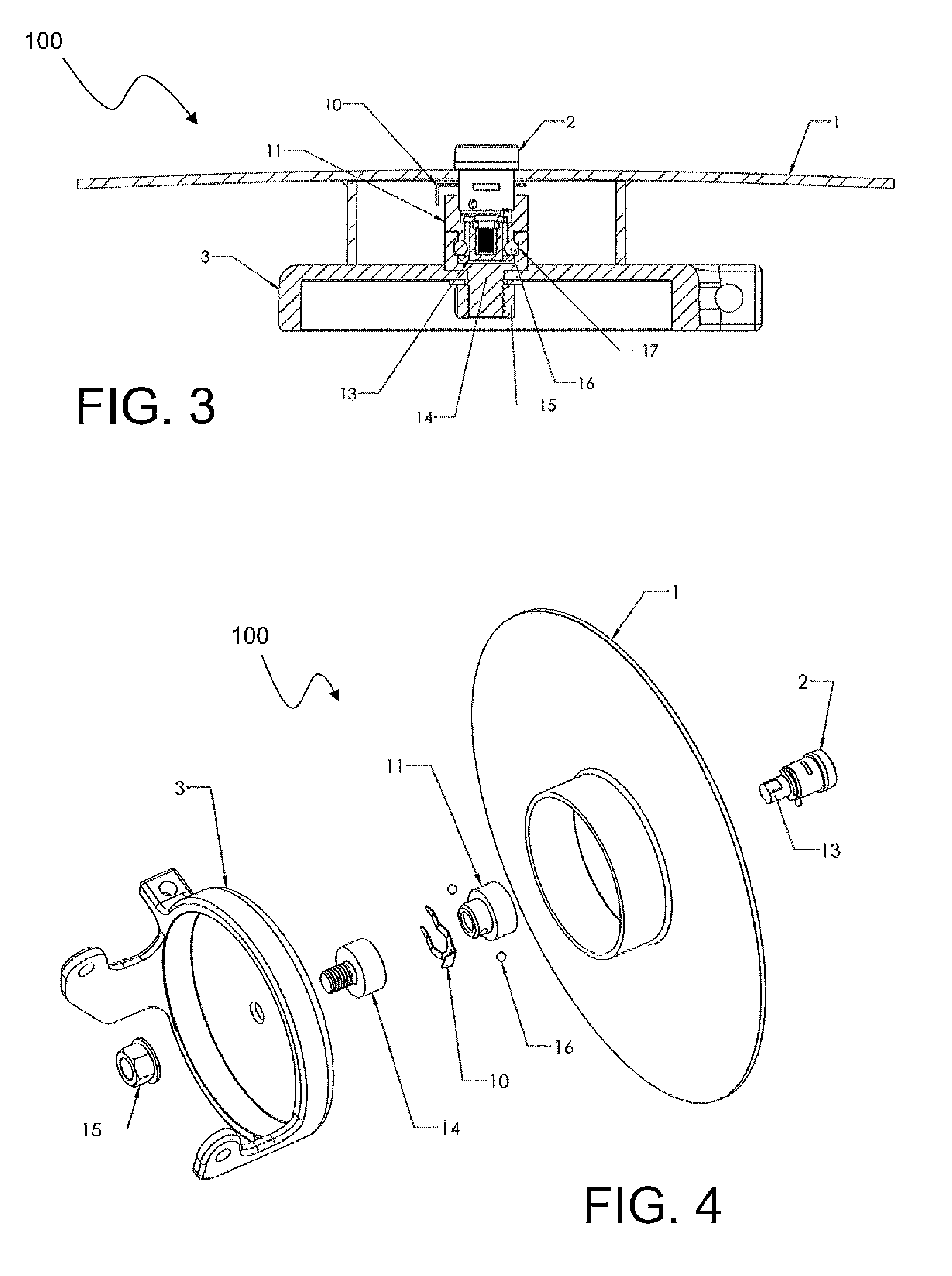

A medical device 1 for use in treatment of a valve comprises a treatment element 2 which is configured for location at a region of coaption of leaflets 3 of a valve to resist fluid flow in a retrograde direction through an opening 7 of the valve. The device also comprises a support 4 for the treatment element 2, and an anchor 8 for anchoring the support 4 to a heart wall. The treatment element 2 and / or at least a part of the support 4 comprises a hydrogel.

Owner:MEDNUA

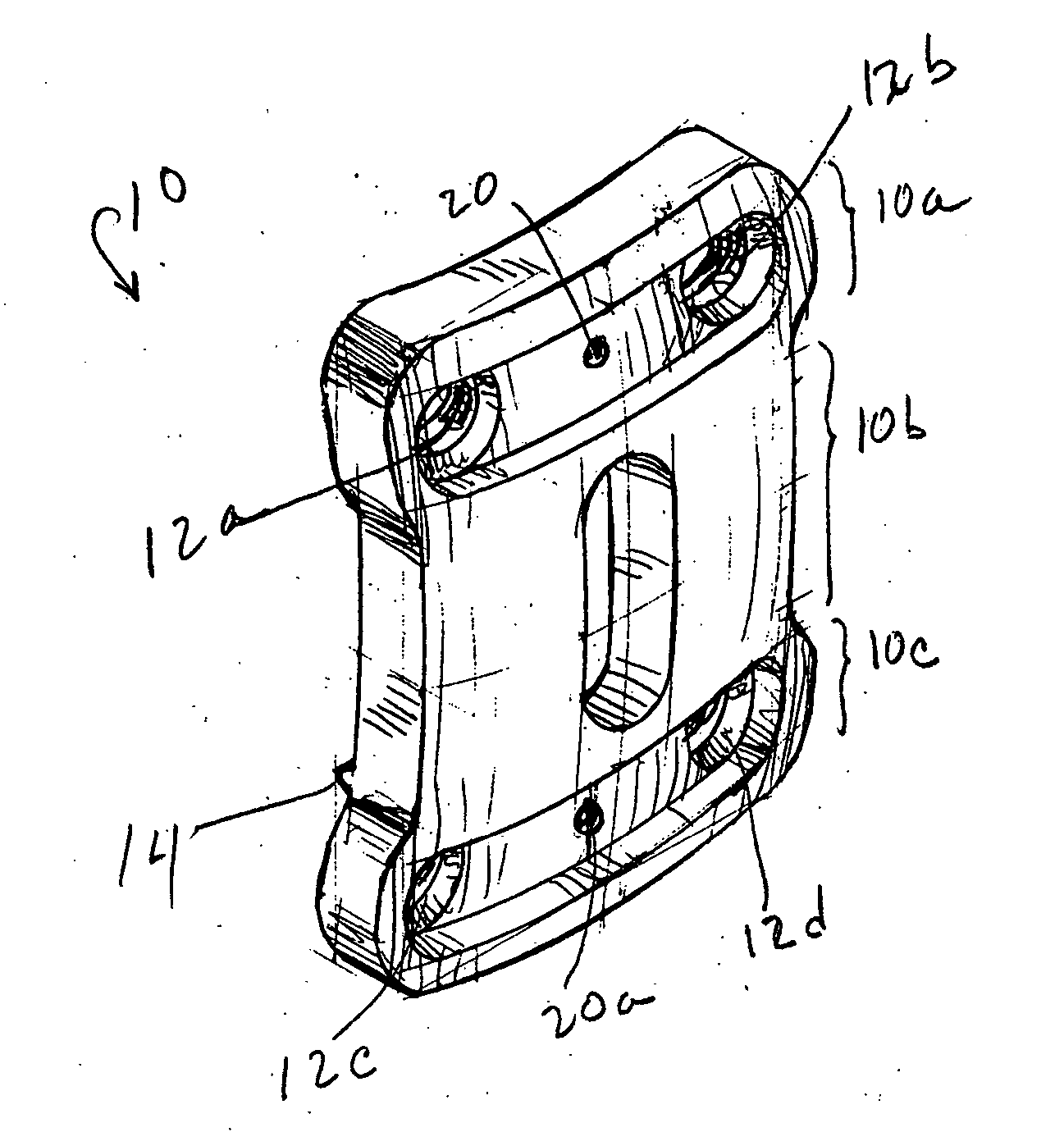

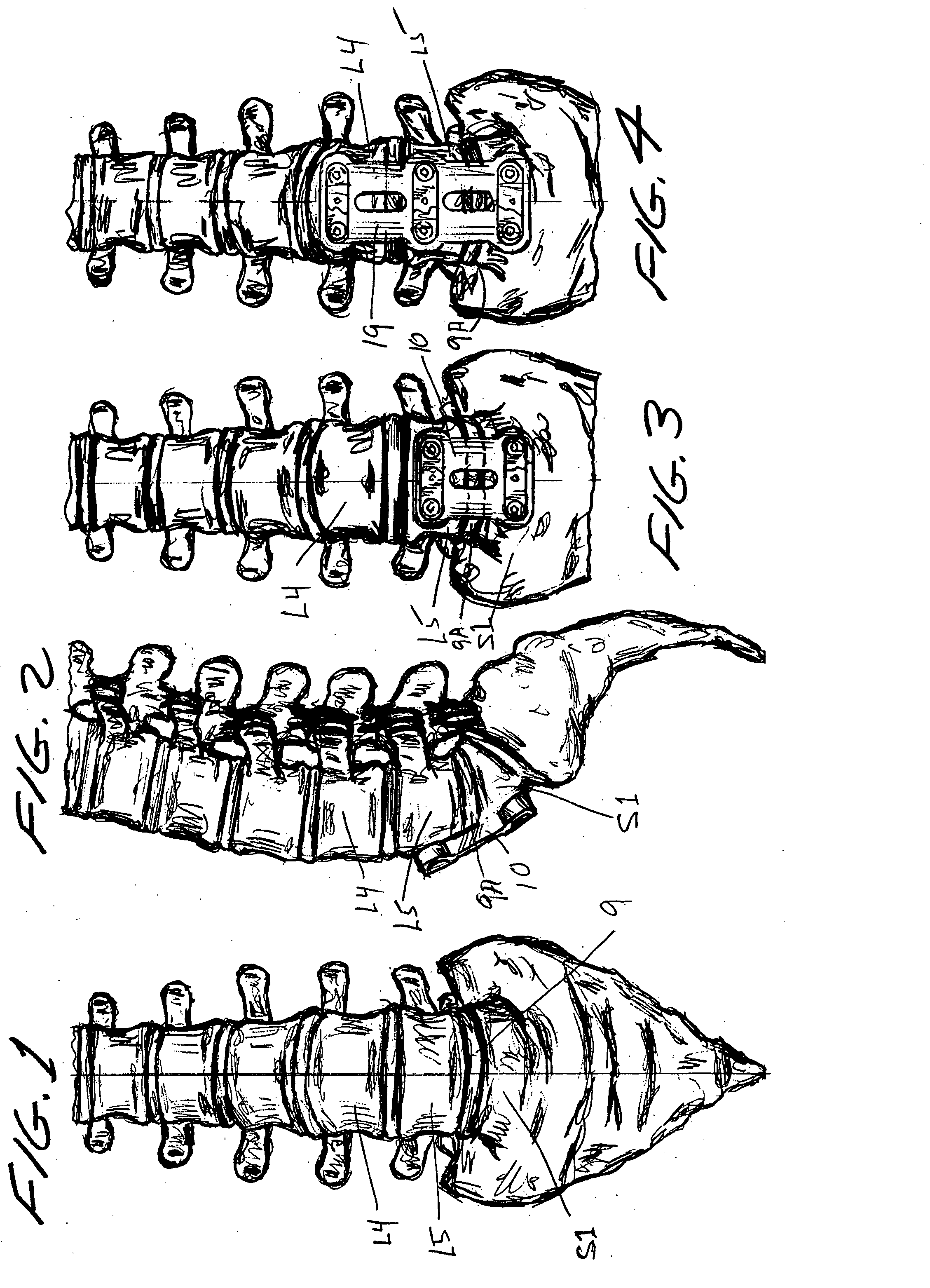

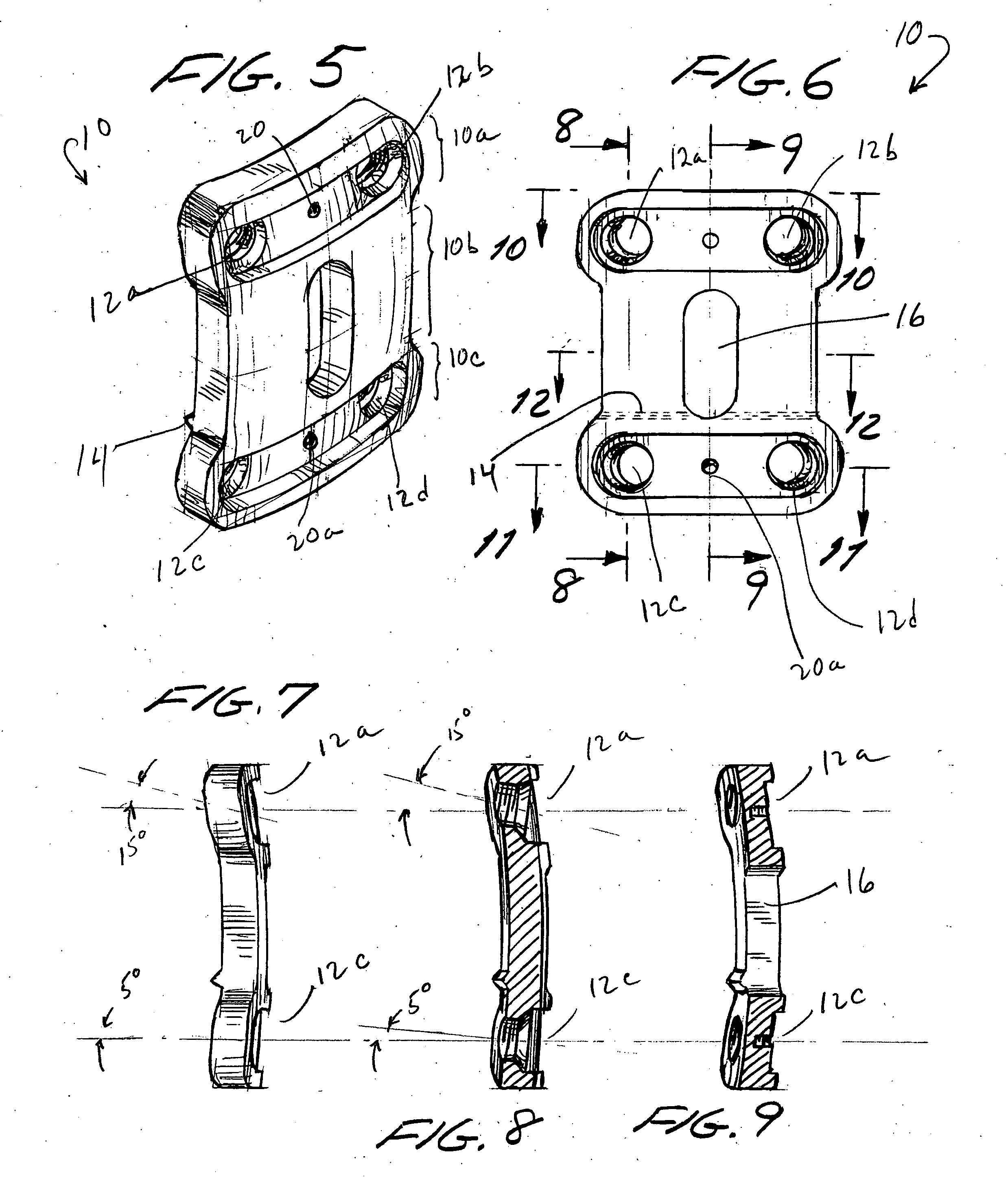

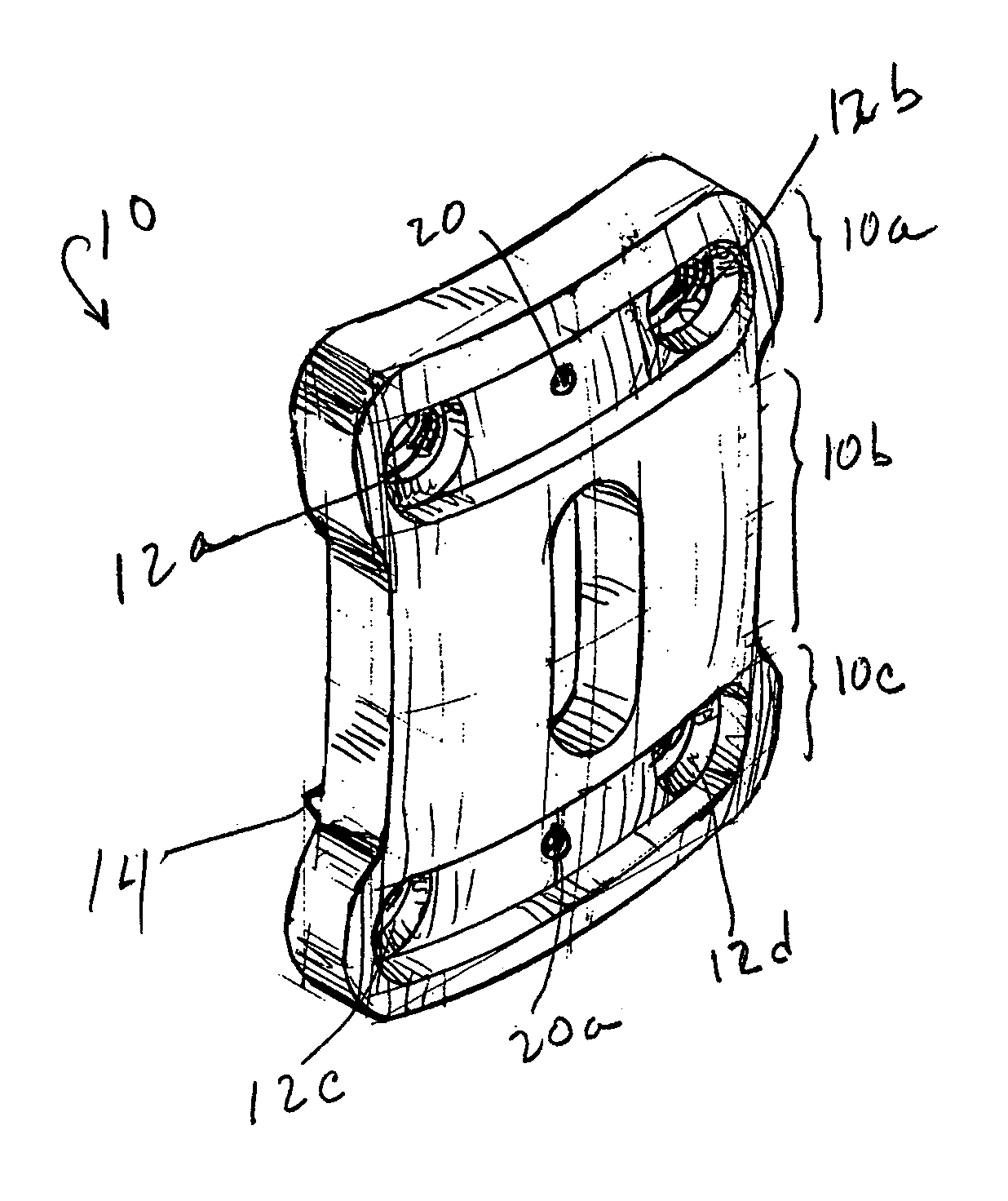

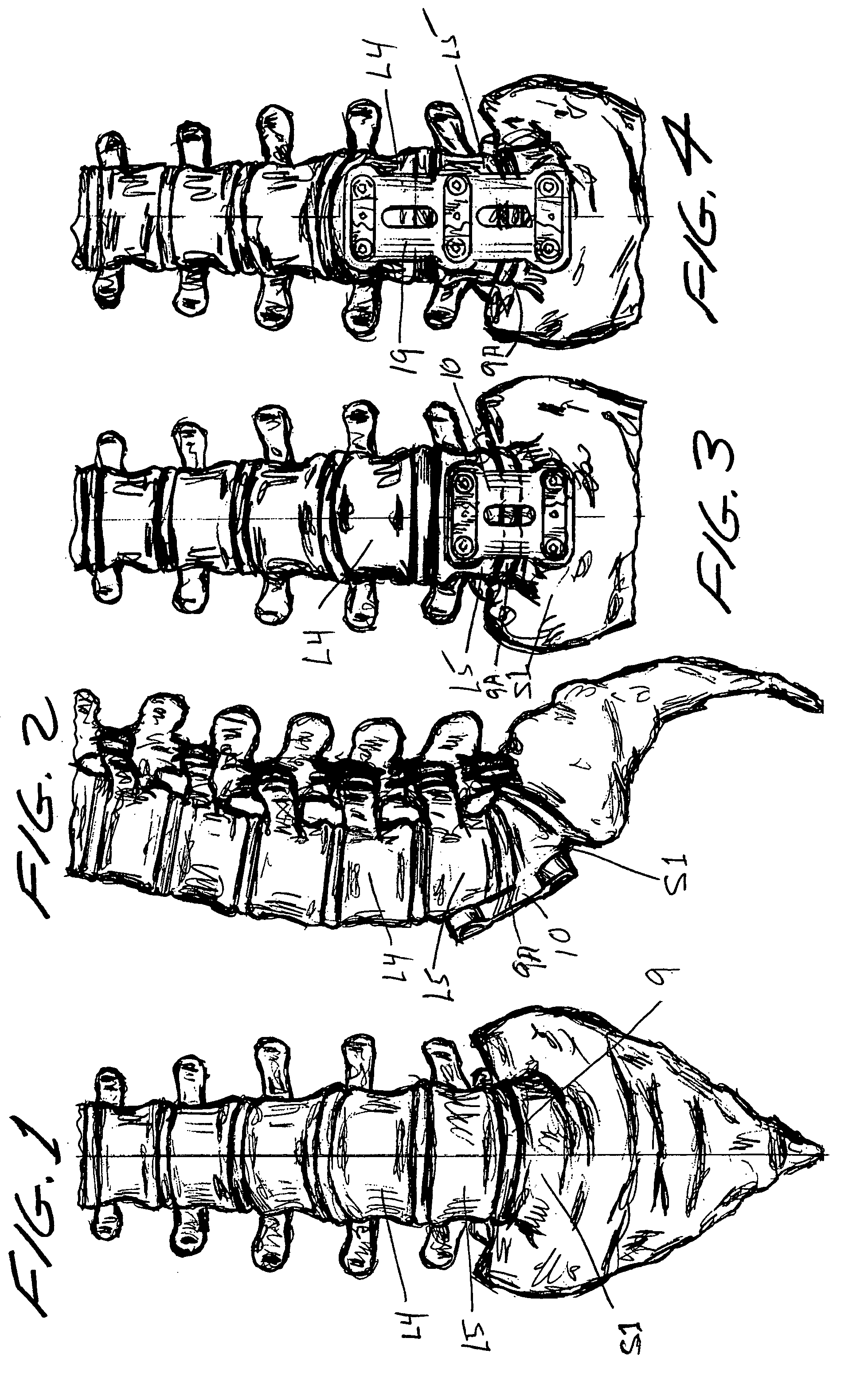

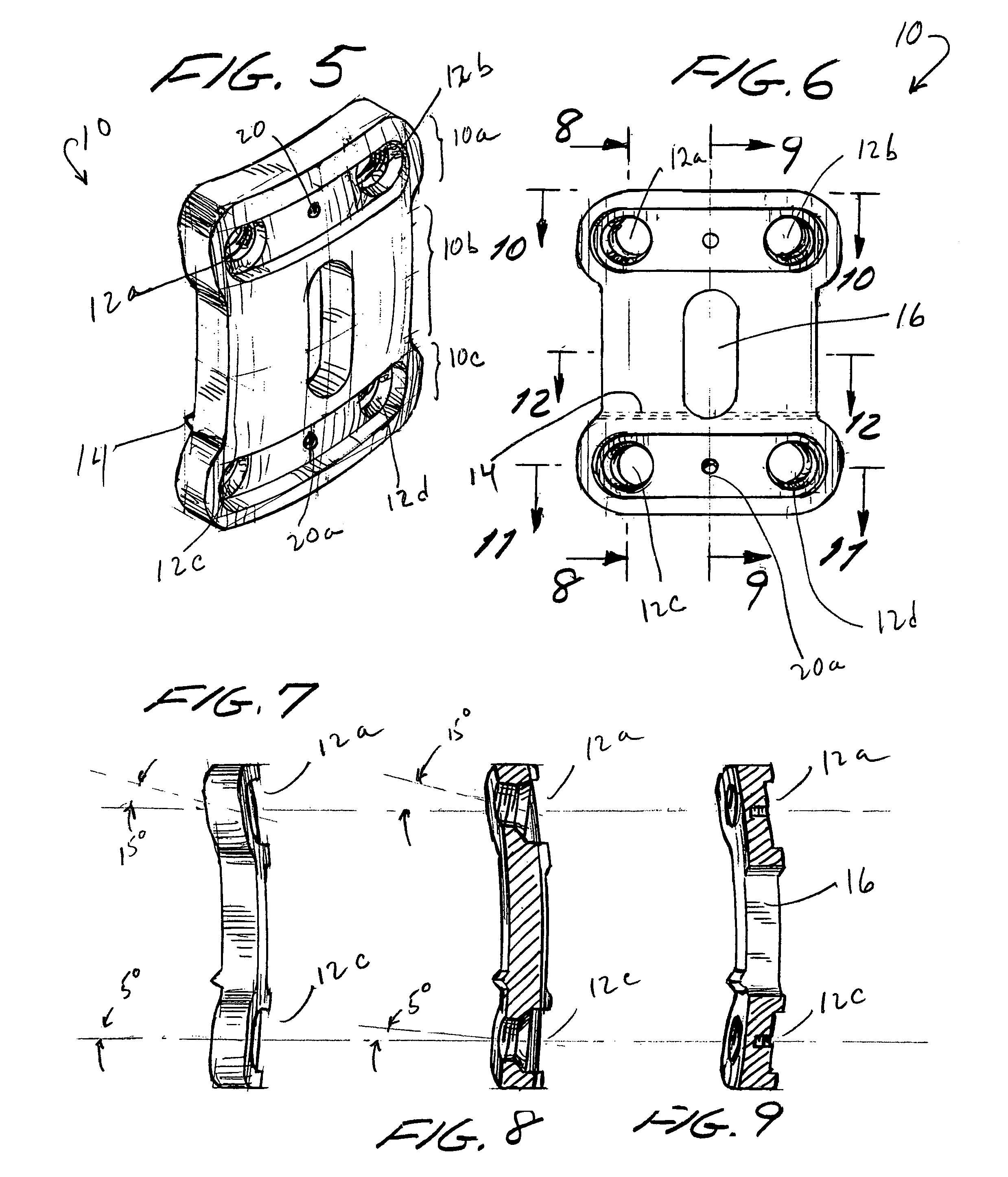

Anterior lumbar lag plate

InactiveUS20060229618A1Maximize effectivenessFusion wellInternal osteosythesisJoint implantsVertebraNuclear medicine

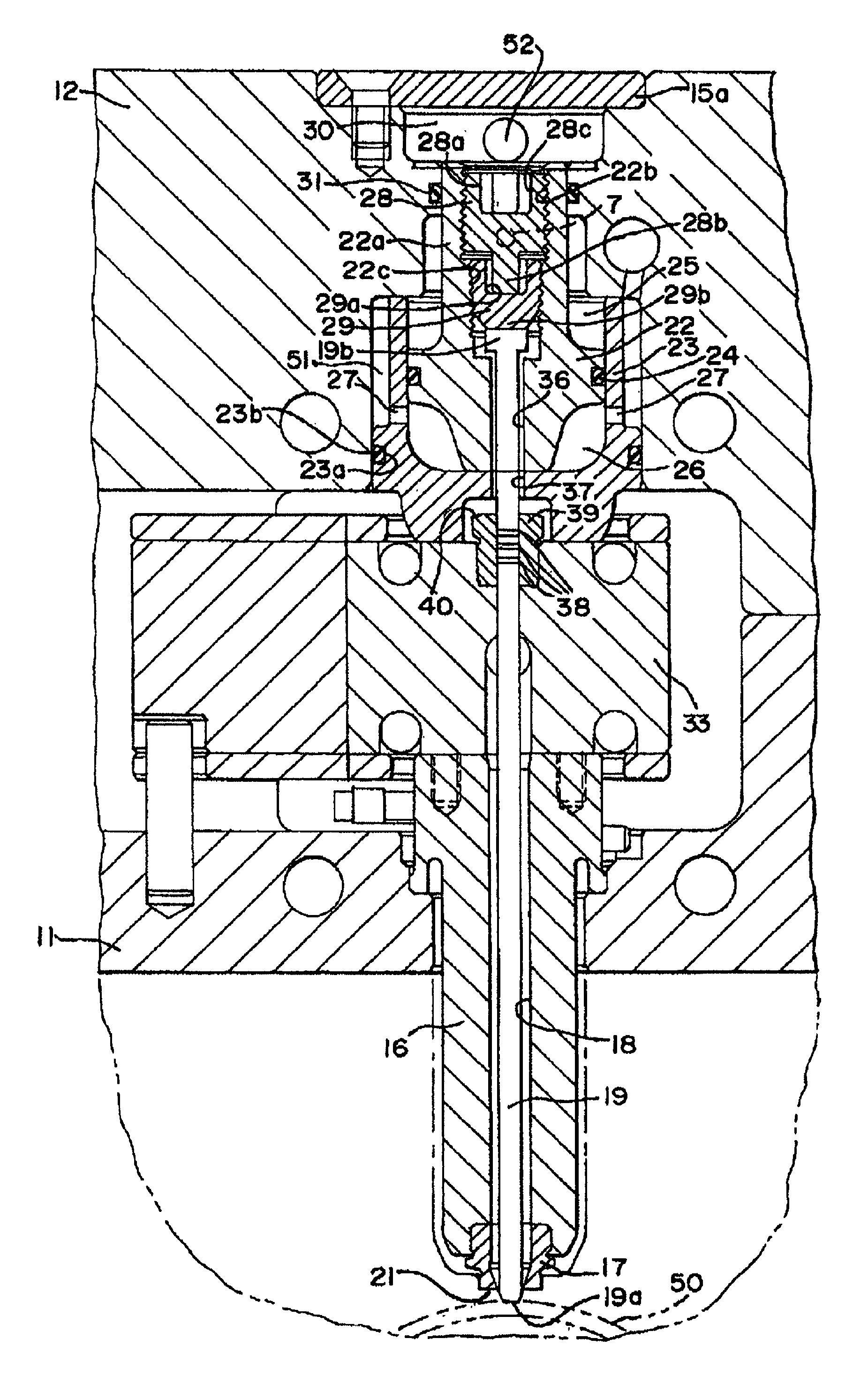

An anterior lumbar plate for attachment with bone screws to selected vertebrae of a person's spine is combined: (a) with separate L5 and S1 drill guides separately and removably attachable to the lumbar plate, and (b) with lock plates removably attachable to the lumbar plate to prevent unscrewing of installed bone screws. This invention further provides a method for implanting and locking in place the L5 and S1 bone screws. This invention is adaptable for L4-L5, L4-L5-S1, and L5-S1 lumbar plates.

Owner:STRYKER EURO OPERATIONS HLDG LLC

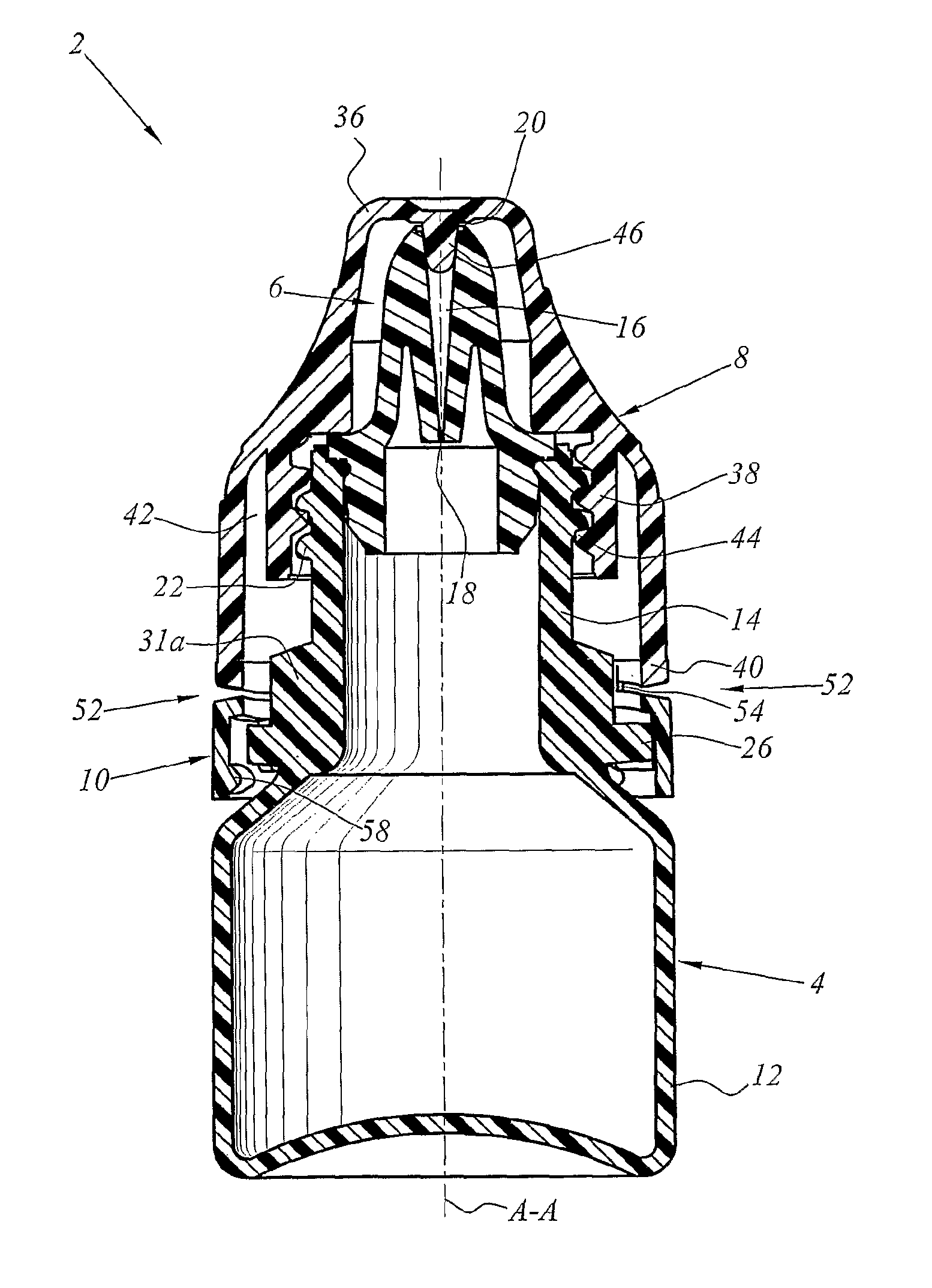

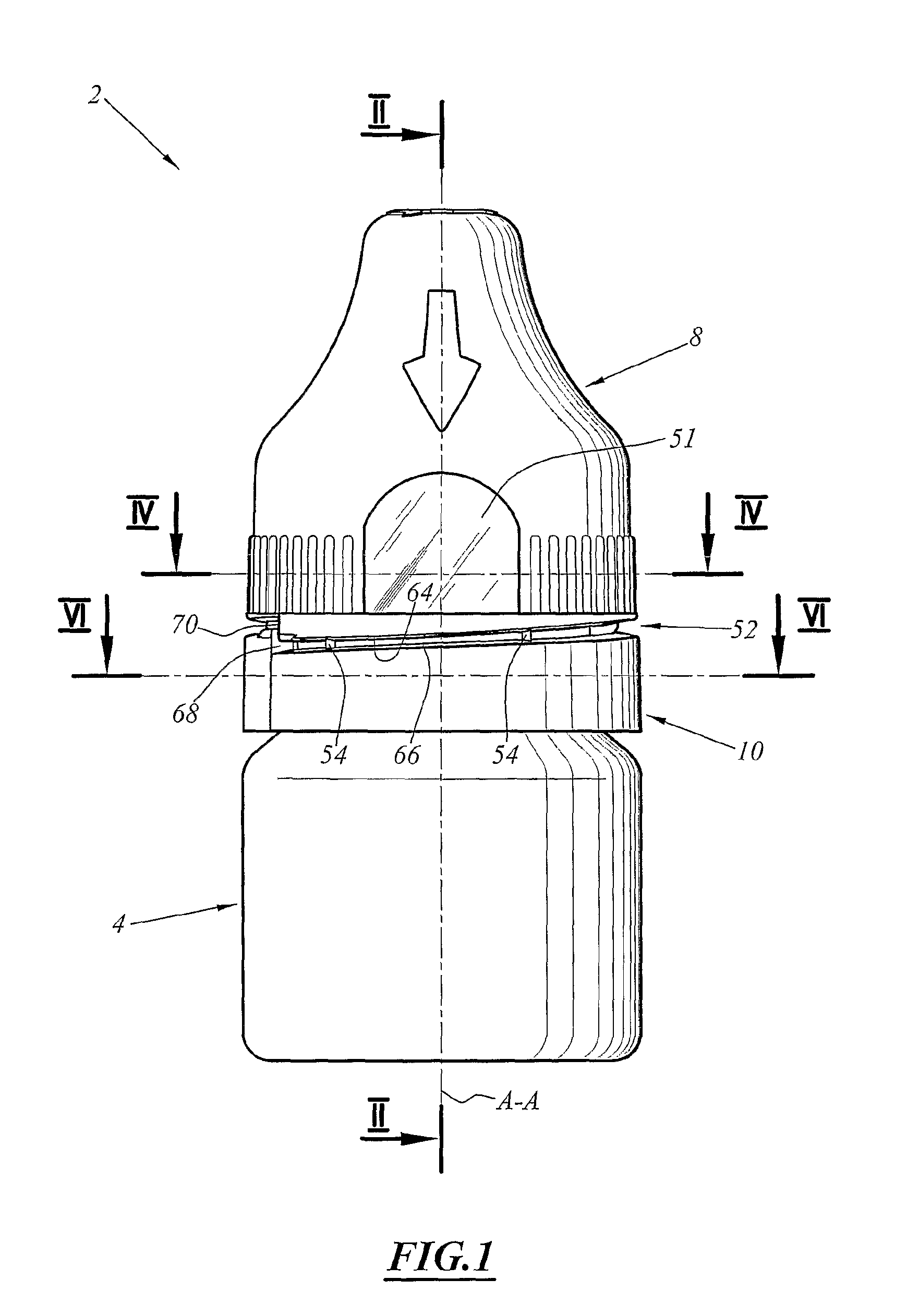

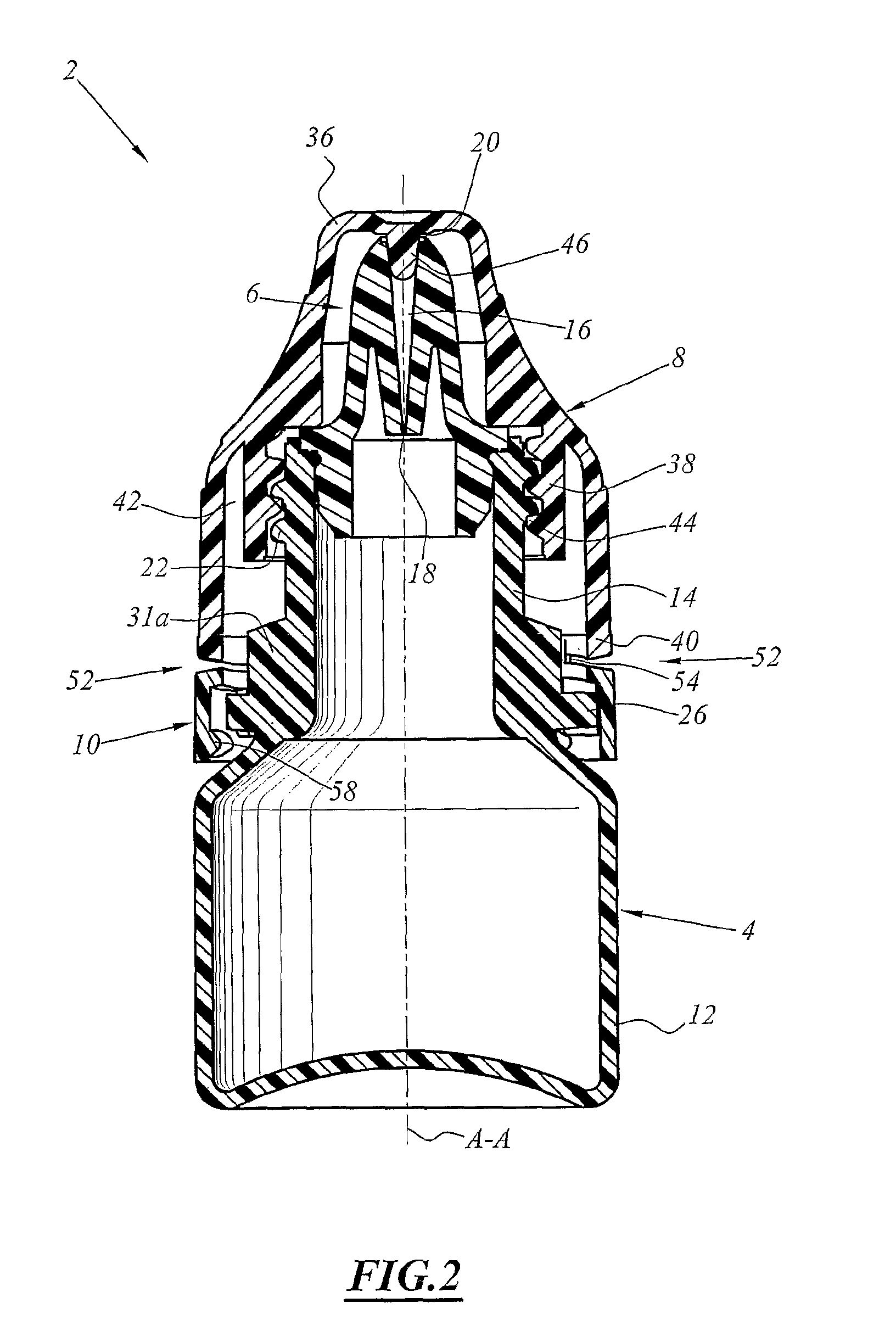

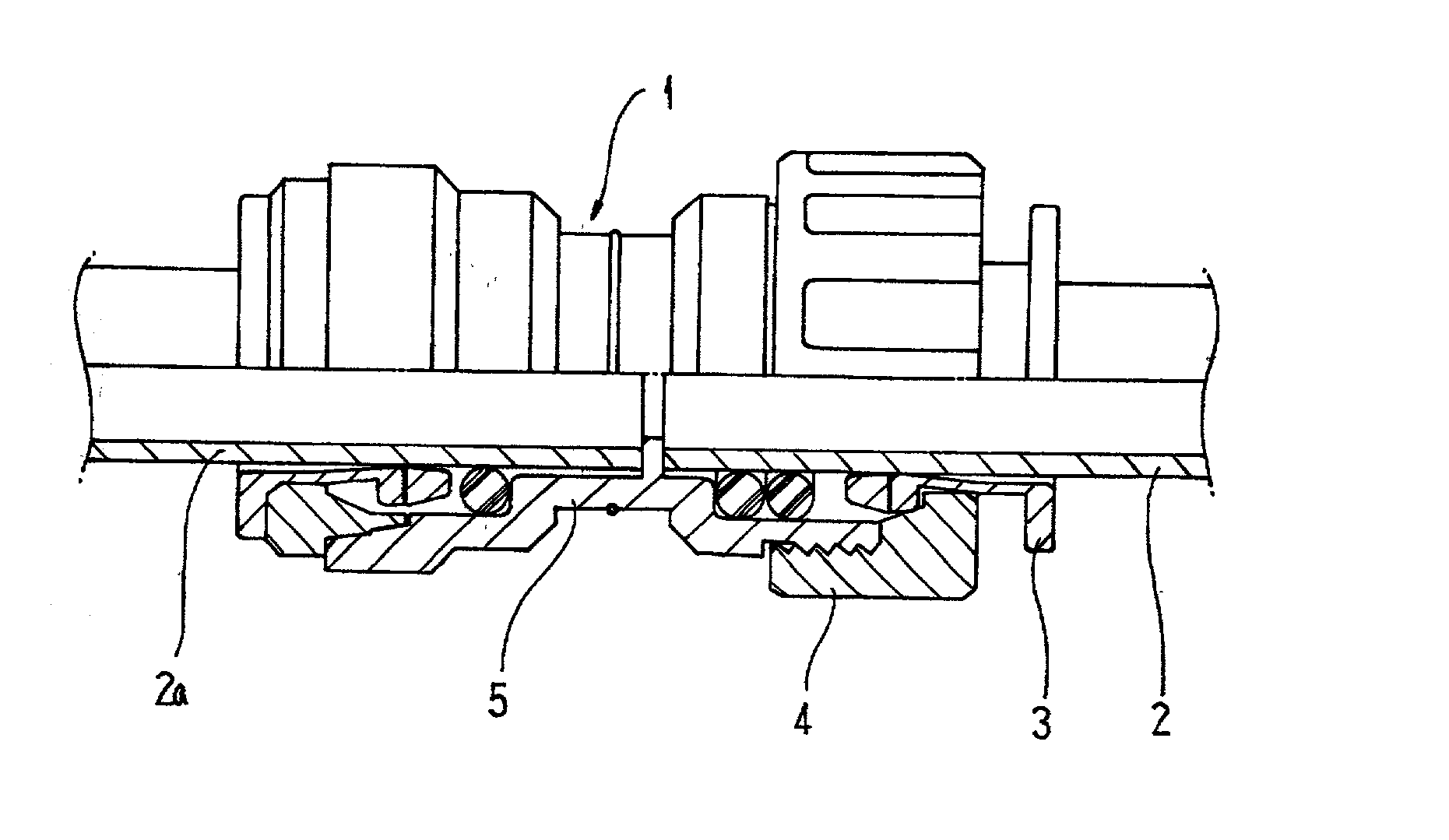

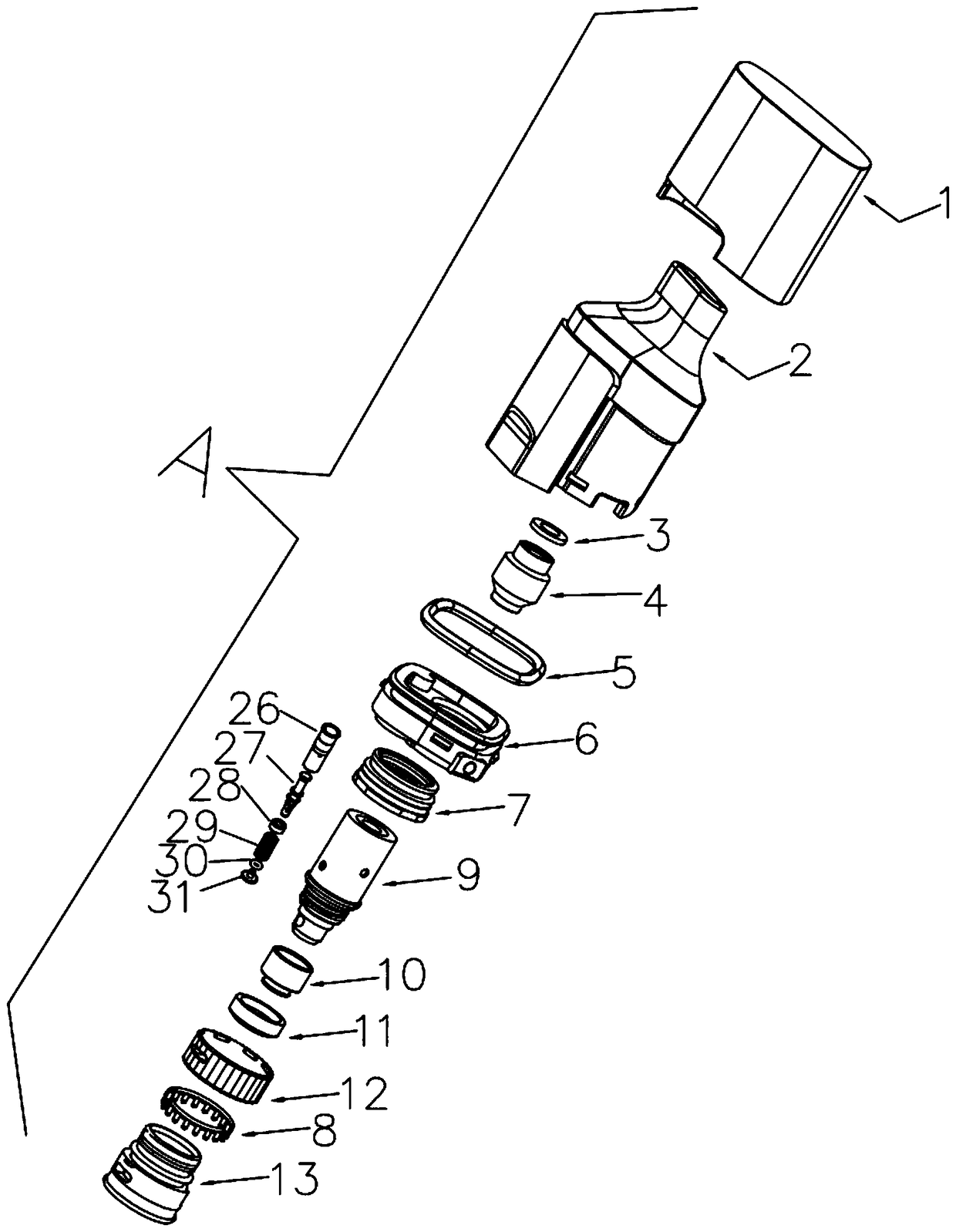

Assembly for conditioning and dispensing a medical liquid

ActiveUS8444610B2Controlling the riskPrevent unscrewingClosuresMedical applicatorsEngineeringMechanical engineering

This assembly is of the type including: a vessel (4) for containing liquid, the vessel (4) having a neck (14); a dispensing dropper end fitting (6) disposed at the end of the neck (14); and a cap (8) for closing the vessel (4), provided to be screwed onto the neck (14). In a preferred embodiment, the cap (8) and the neck (14) have safety element preventing the cap (8) from being unscrewed simply by applying an unscrewing torque, and allowing the cap (8) to be unscrewed when an additional action is applied together with the torque for unscrewing the cap (8).

Owner:REXAM PHARMA GMBH

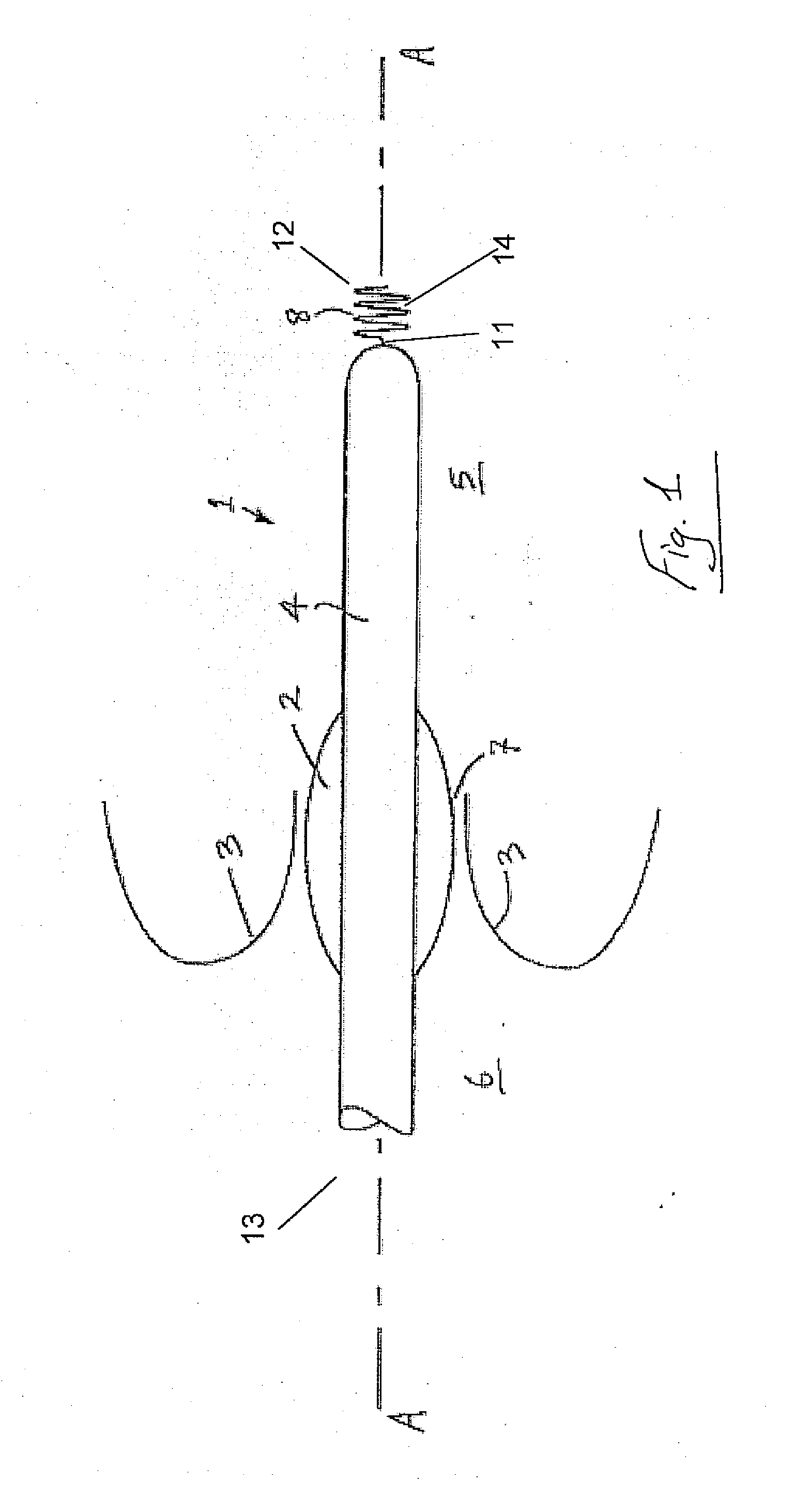

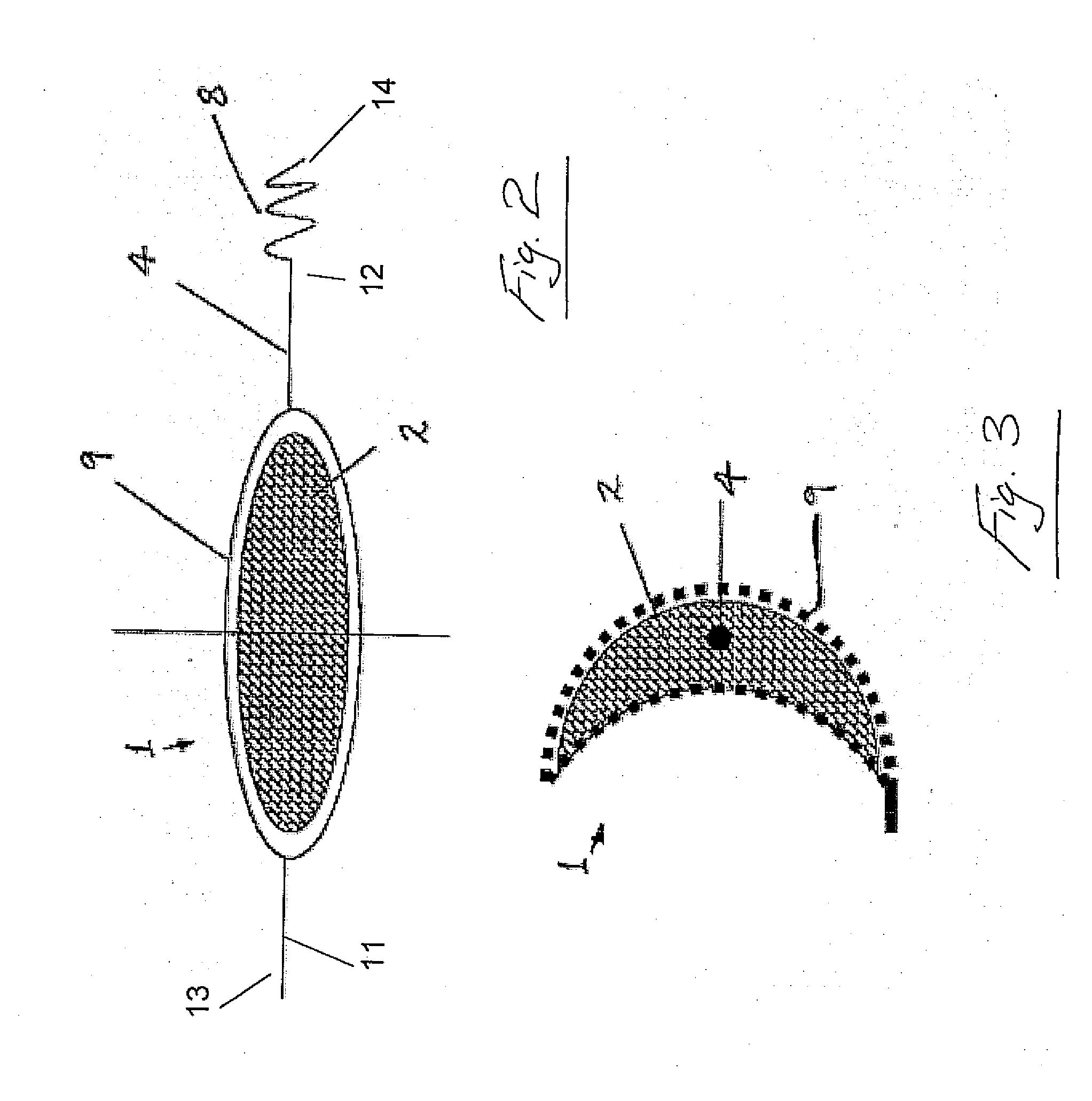

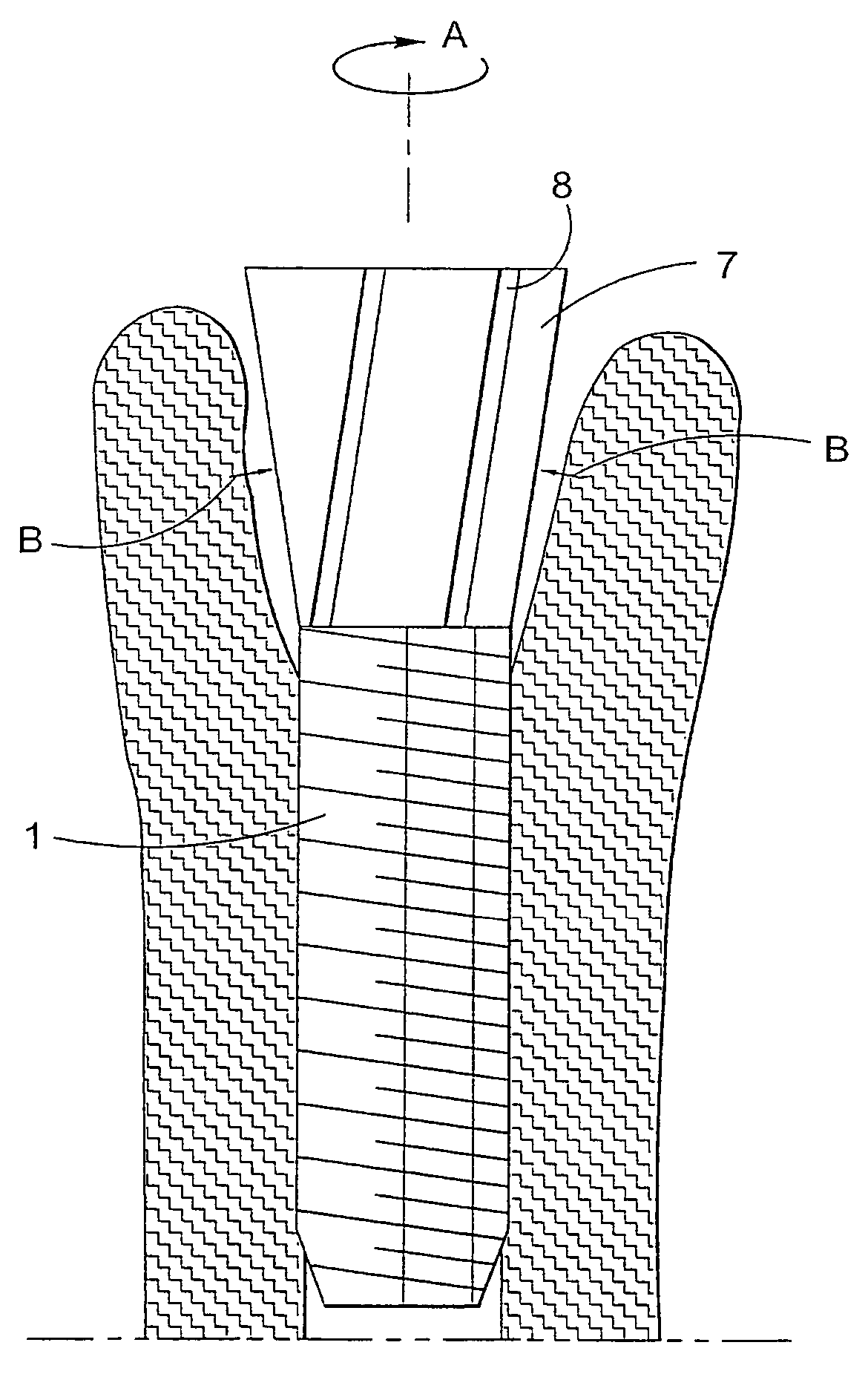

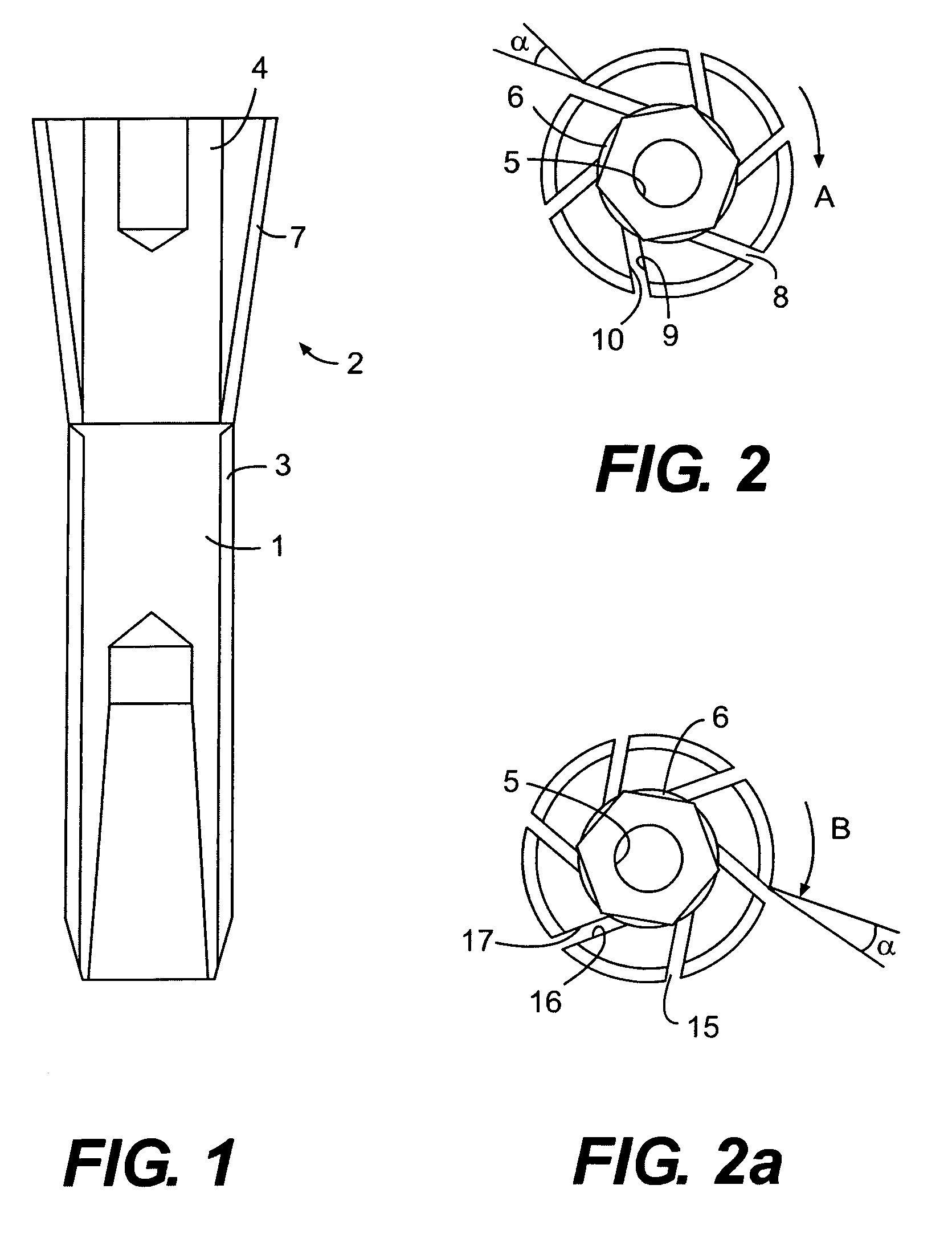

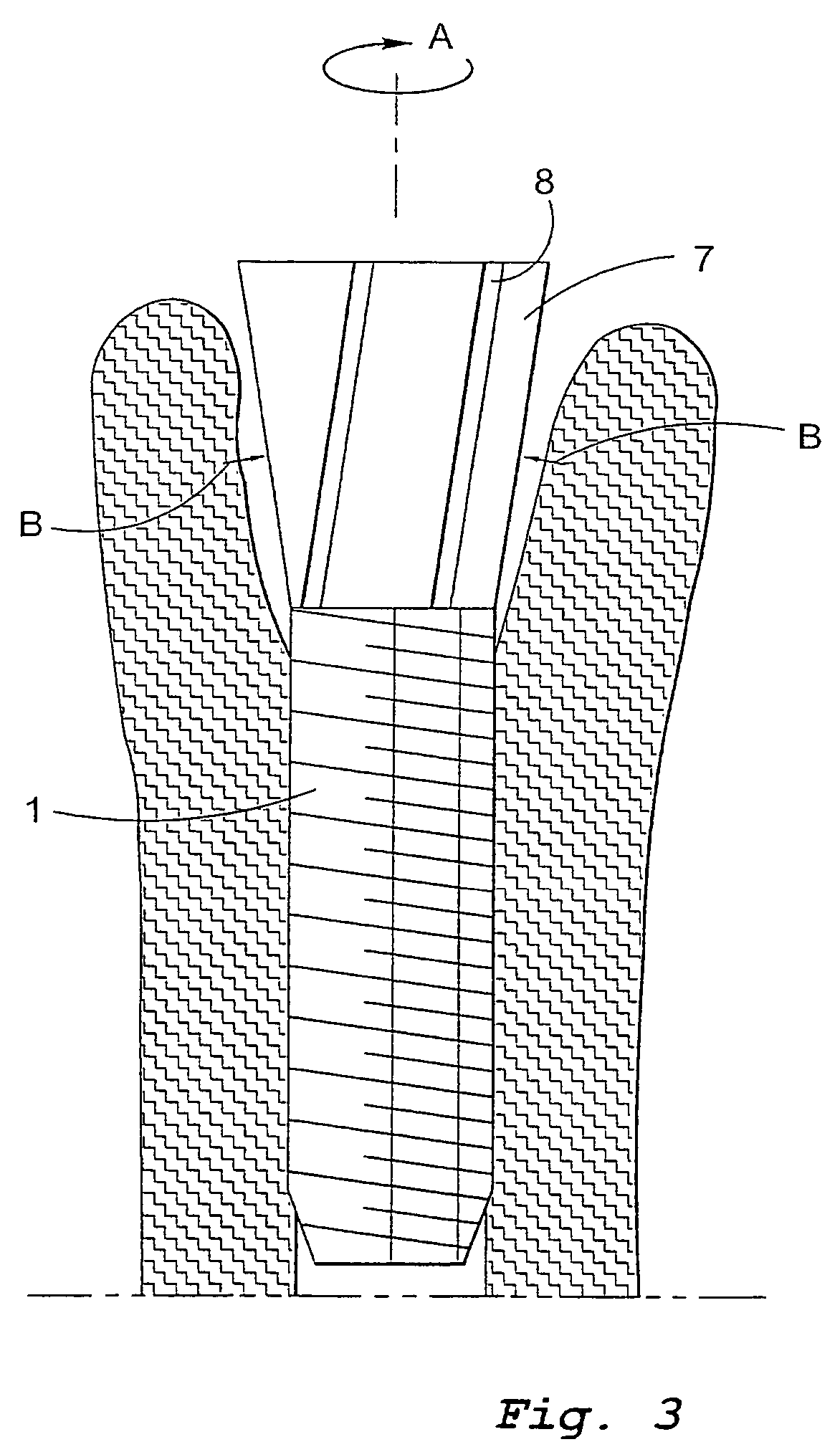

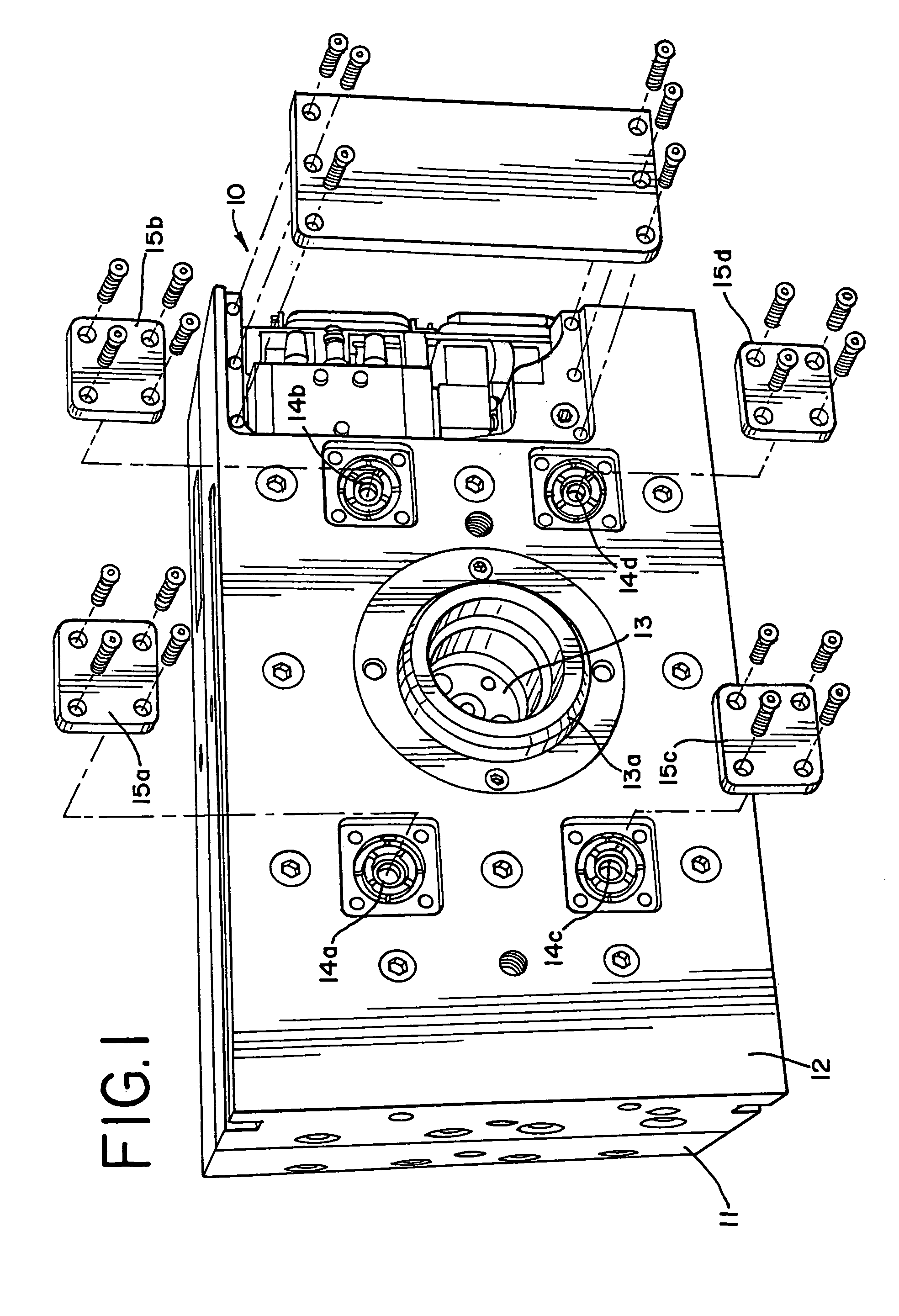

Fixture

A fixture having an anchoring portion and an application portion intended for connection to a prosthesis. The application portion has an outer end and an end connected to the anchoring portion. The application portion includes a flared part whose outer dimensions widen from the end of that part connected to the anchoring portion in a direction toward the outer end of the application portion. This flared part is elastically resilient transversely to the longitudinal direction of the fixture.

Owner:PIOS BIOTECH

Anterior lumbar lag plate

InactiveUS8052729B2Maximize effectivenessFusion wellInternal osteosythesisProsthesisLumbarIliac screw

An anterior lumbar plate for attachment with bone screws to selected vertebrae of a person's spine is combined: (a) with separate L5 and S1 drill guides separately and removably attachable to the lumbar plate, and (b) with lock plates removably attachable to the lumbar plate to prevent unscrewing of installed bone screws. This invention further provides a method for implanting and locking in place the L5 and S1 bone screws. This invention is adaptable for L4-L5, L4-L5-S1, and L5-S1 lumbar plates.

Owner:STRYKER EURO OPERATIONS HLDG LLC

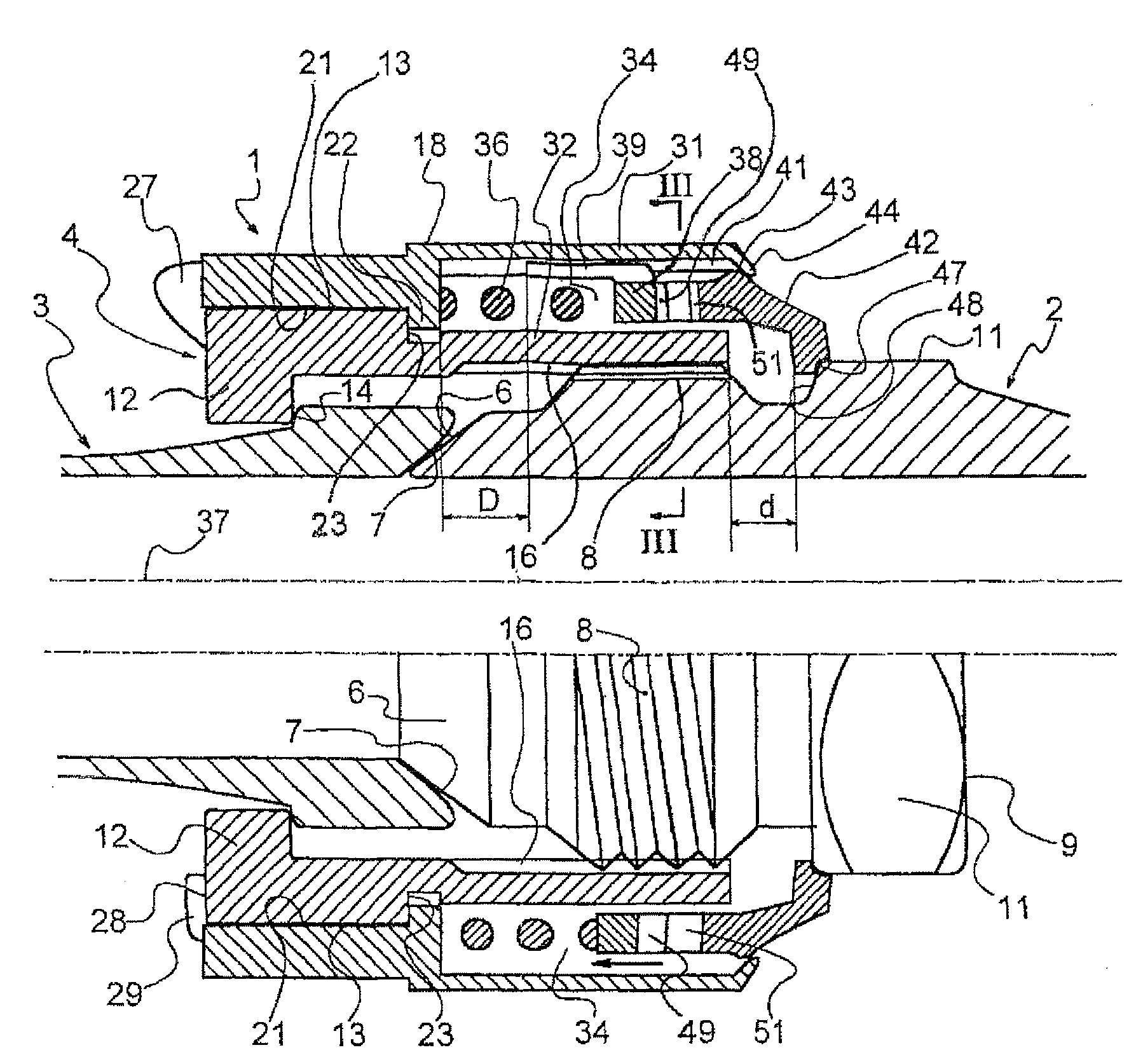

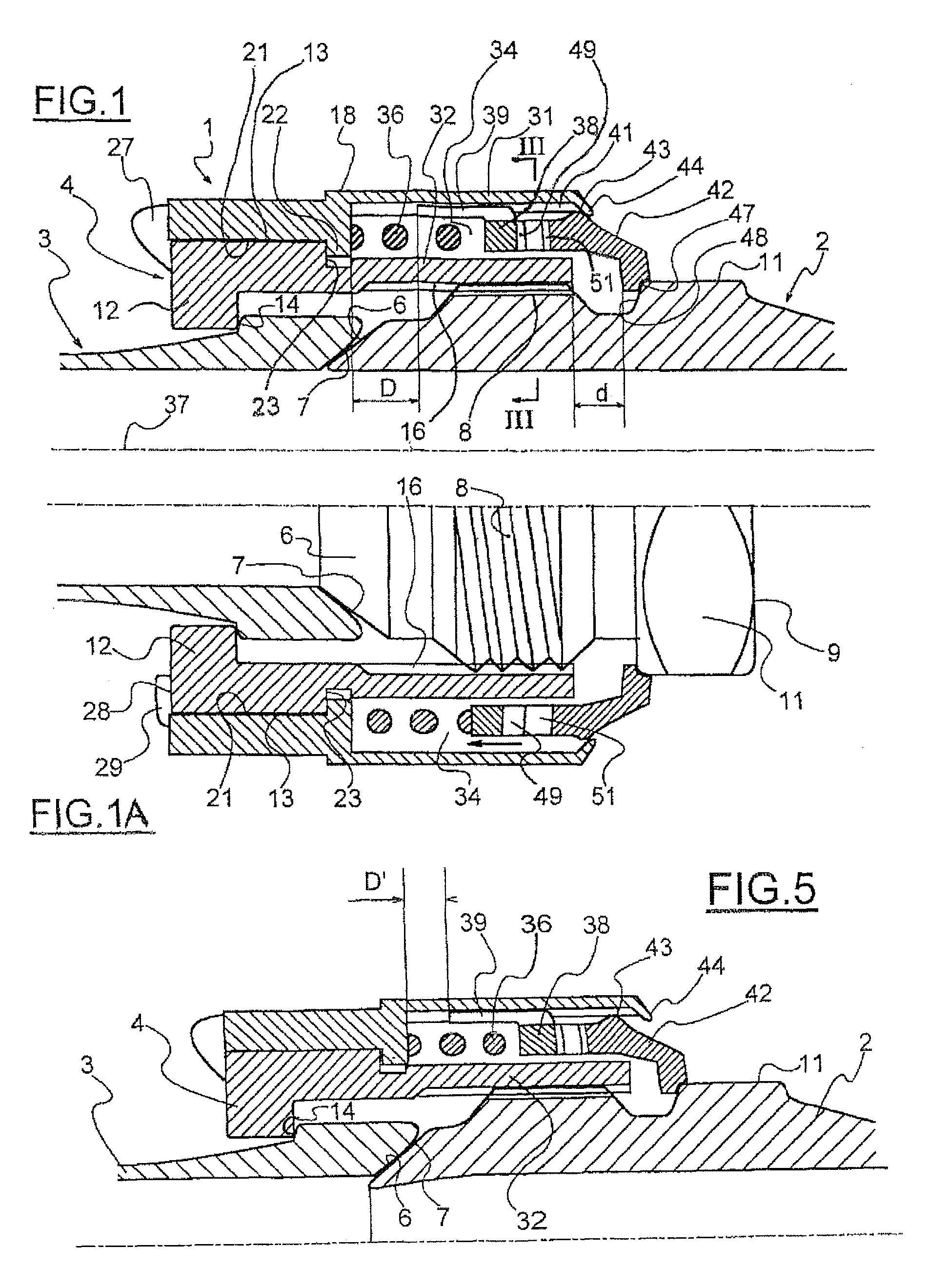

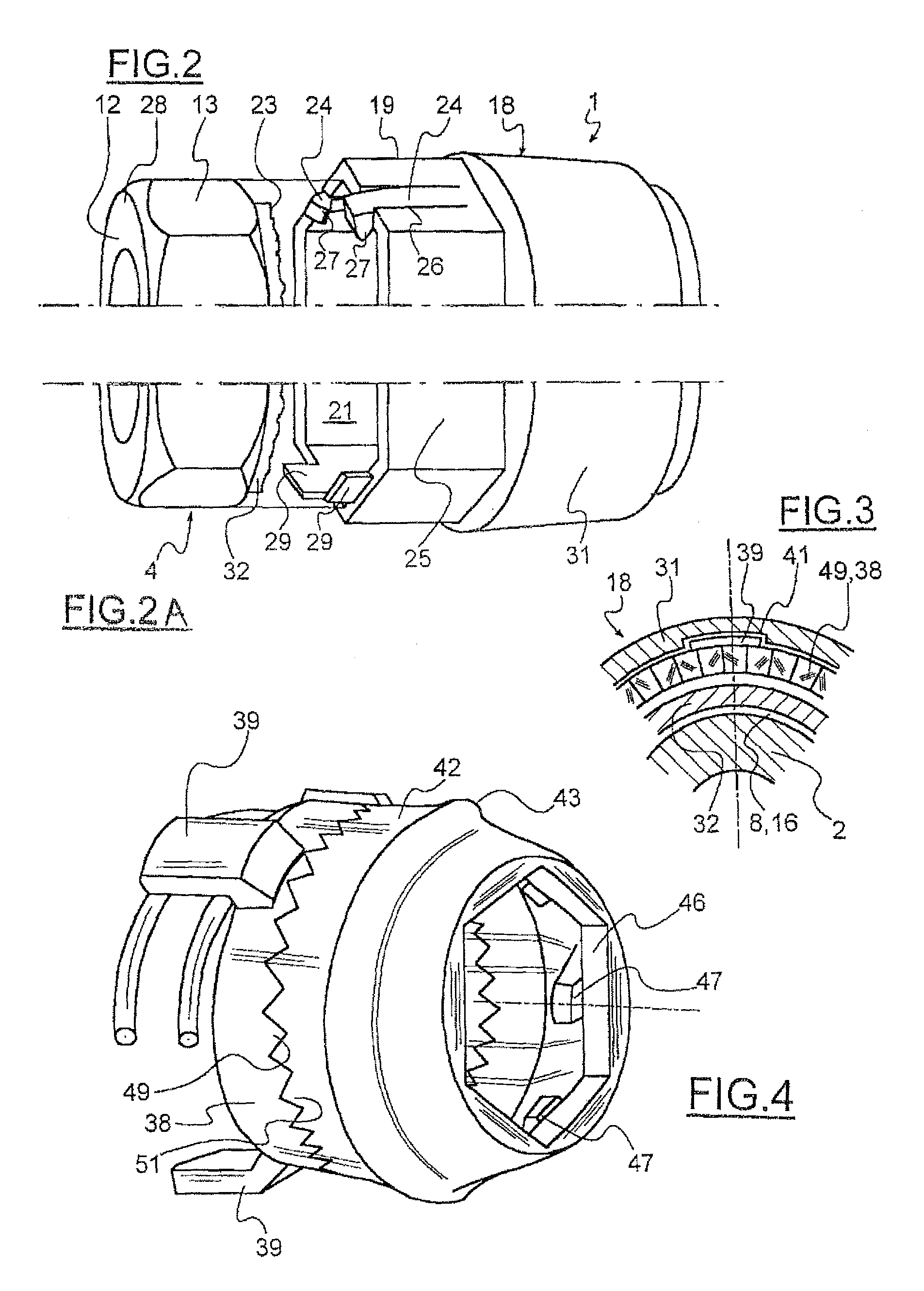

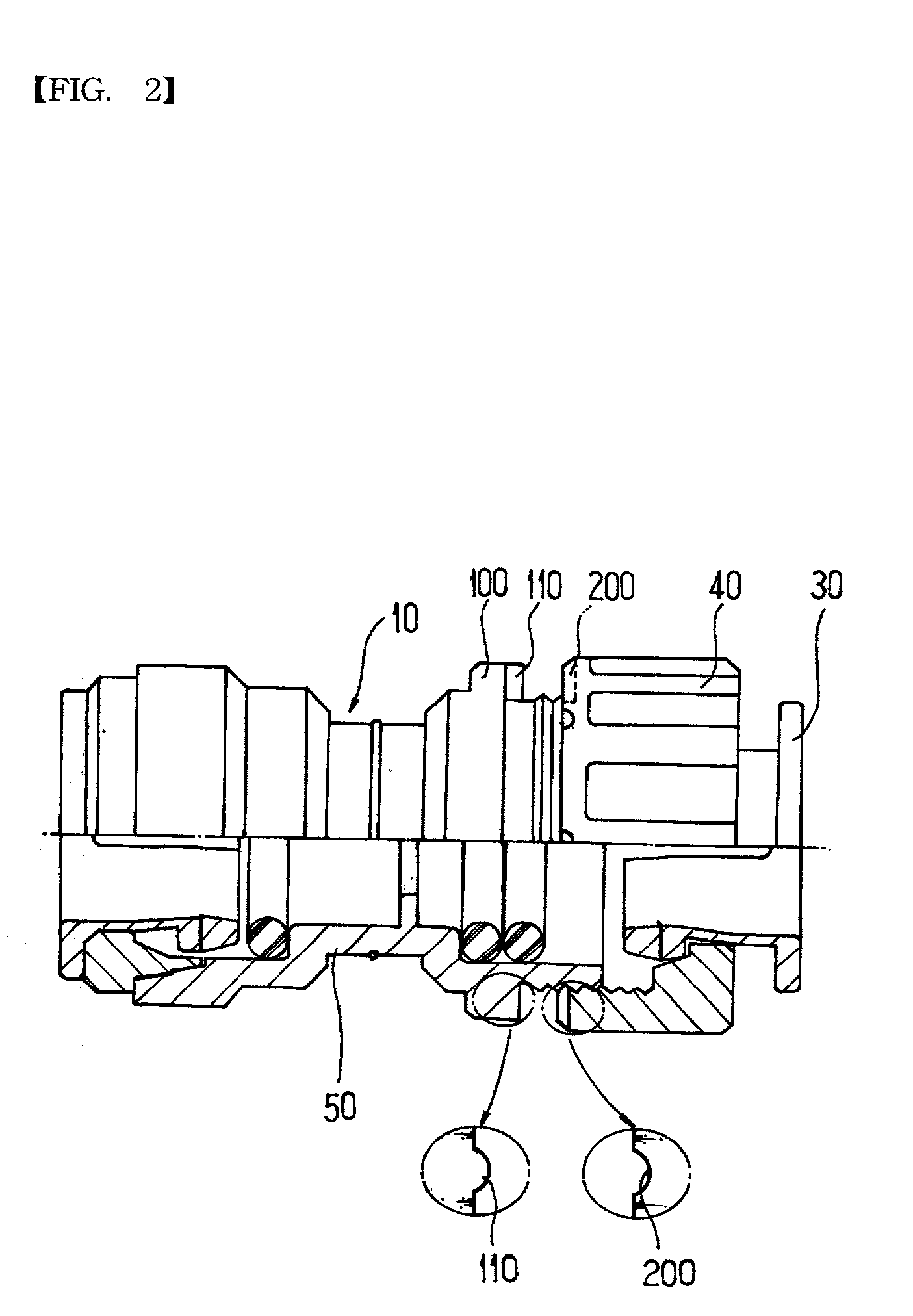

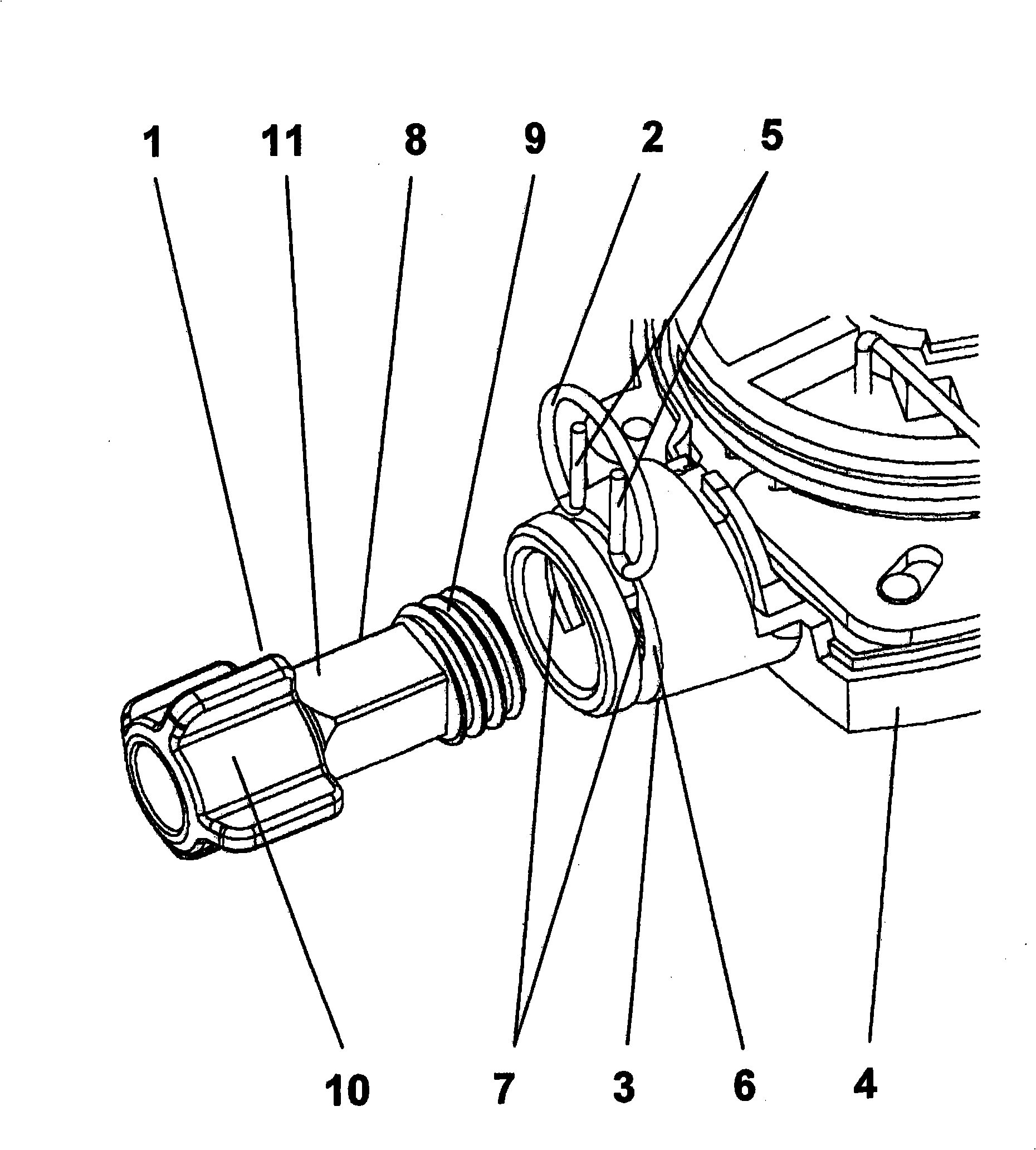

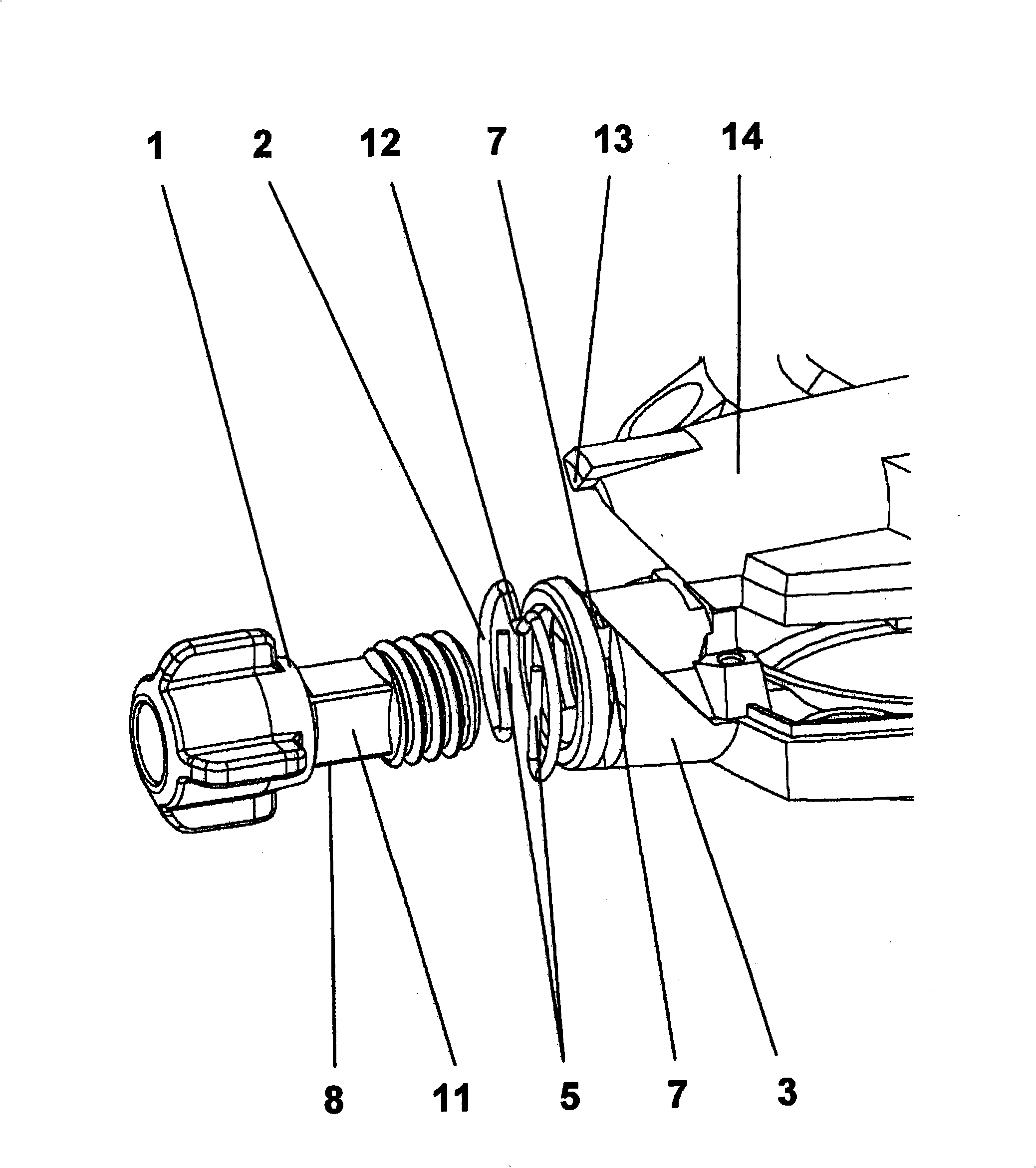

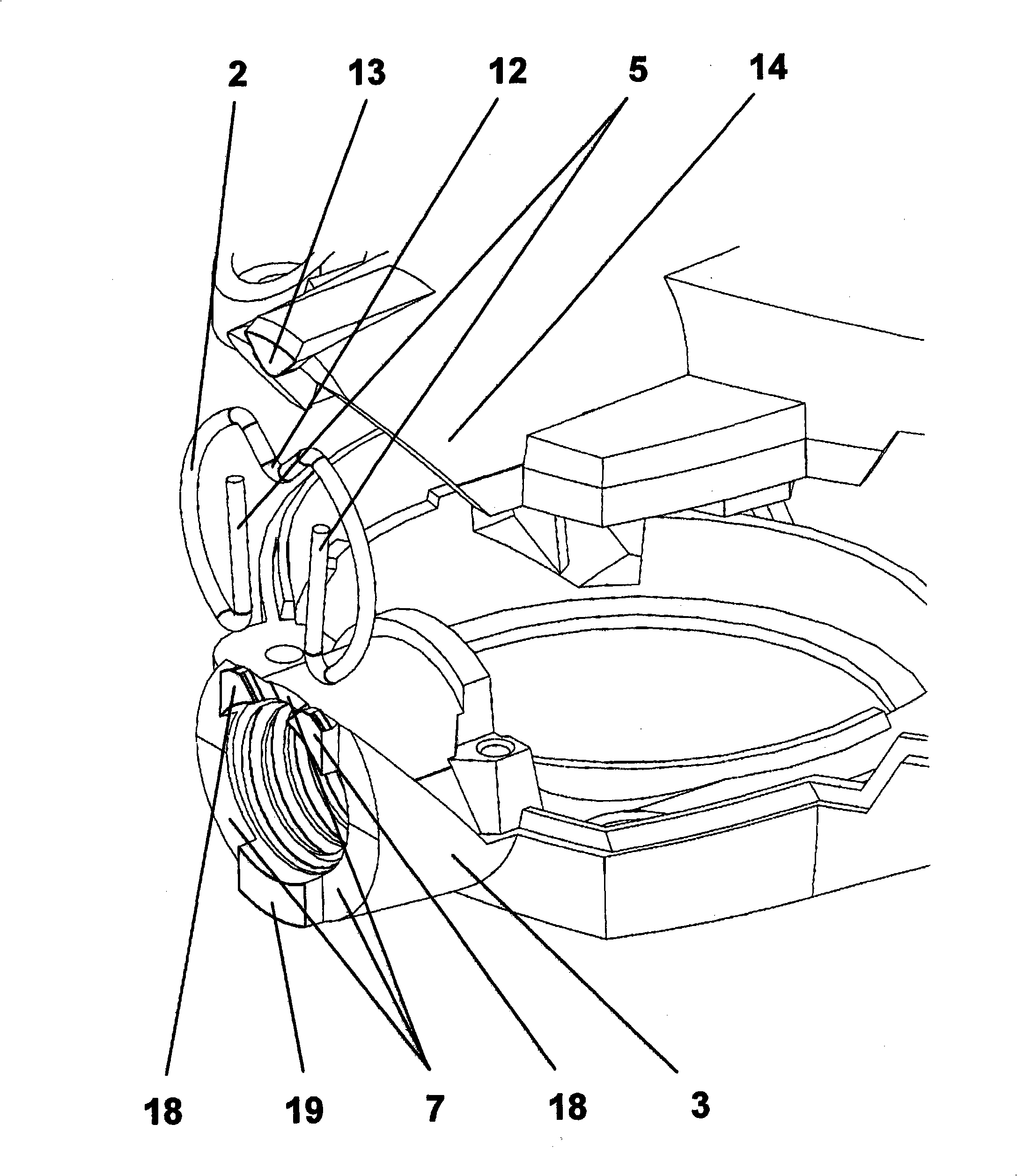

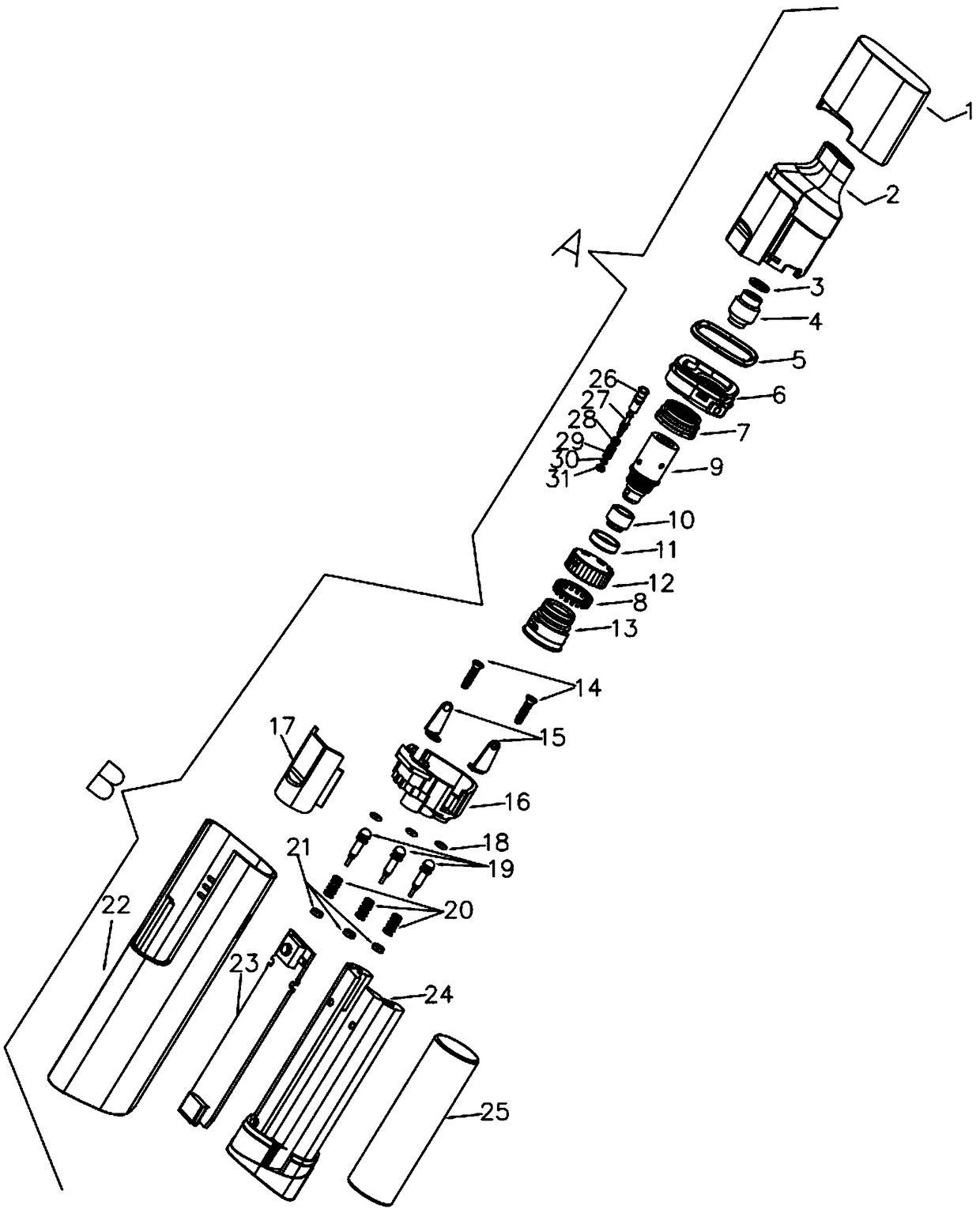

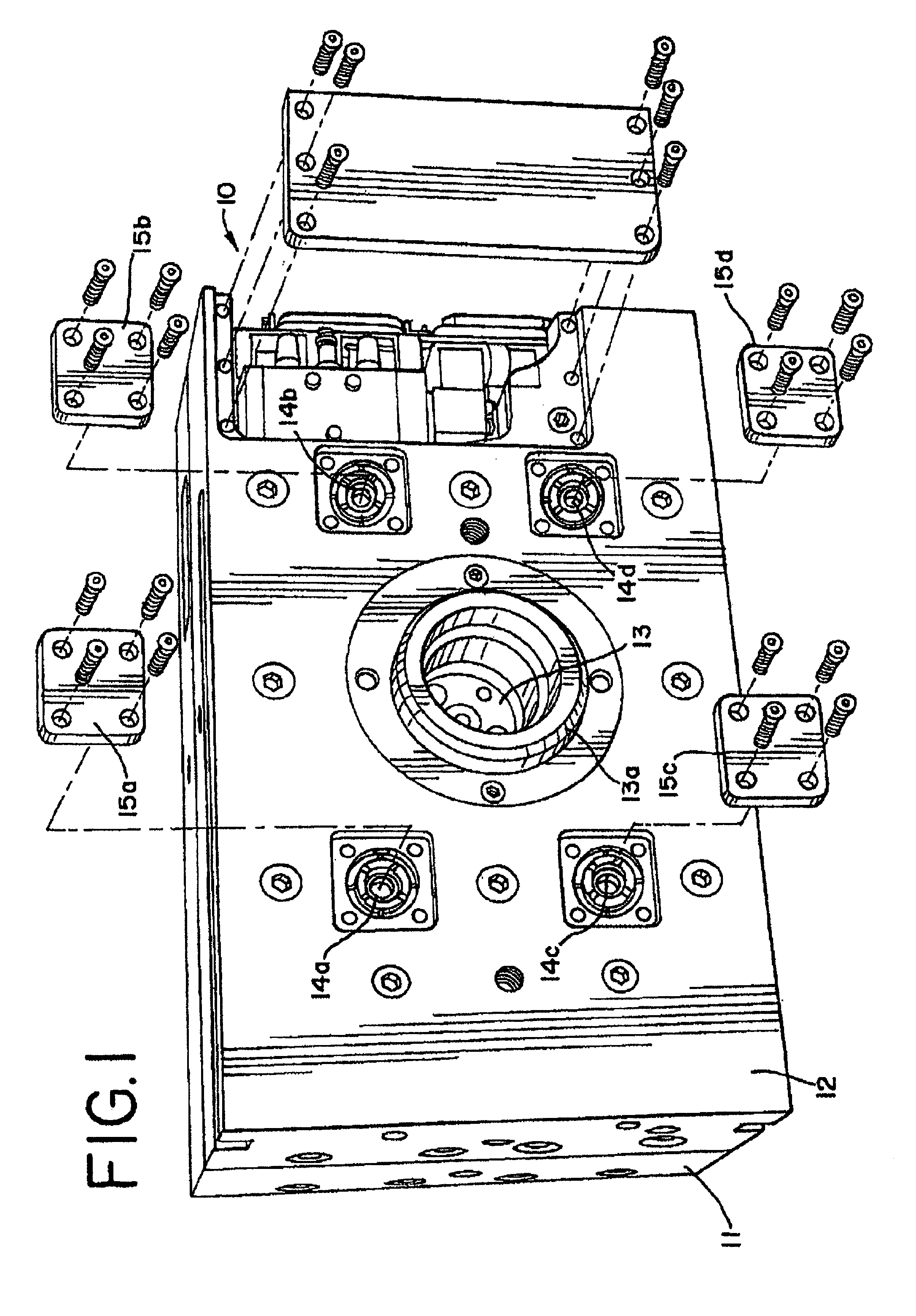

Locking device and a line fitting provided therewith

ActiveUS7883117B2Prevent unscrewingShort durationEngine sealsFluid pressure sealed jointsAxial distanceLine fitting

A locking device (1) is fixed to a nut (4) and includes a coupling unit (42) insertable into a hexagonal configuration (11) of a spigot end (2) at a reduced axial distance being coupled by mutually interpenetrable gears (49, 51) with a stop unit (38) which axially slides in a body (18) opposite to a compression spring (36). The gears (49, 51) are symmetric and are insertable into each other with a predetermined elastic resistance by the action of compression or loosing torque. The device is embodied in one piece which is mounted by assembling with the nut without affecting the spigot ends (2, 3).

Owner:JPB SYST

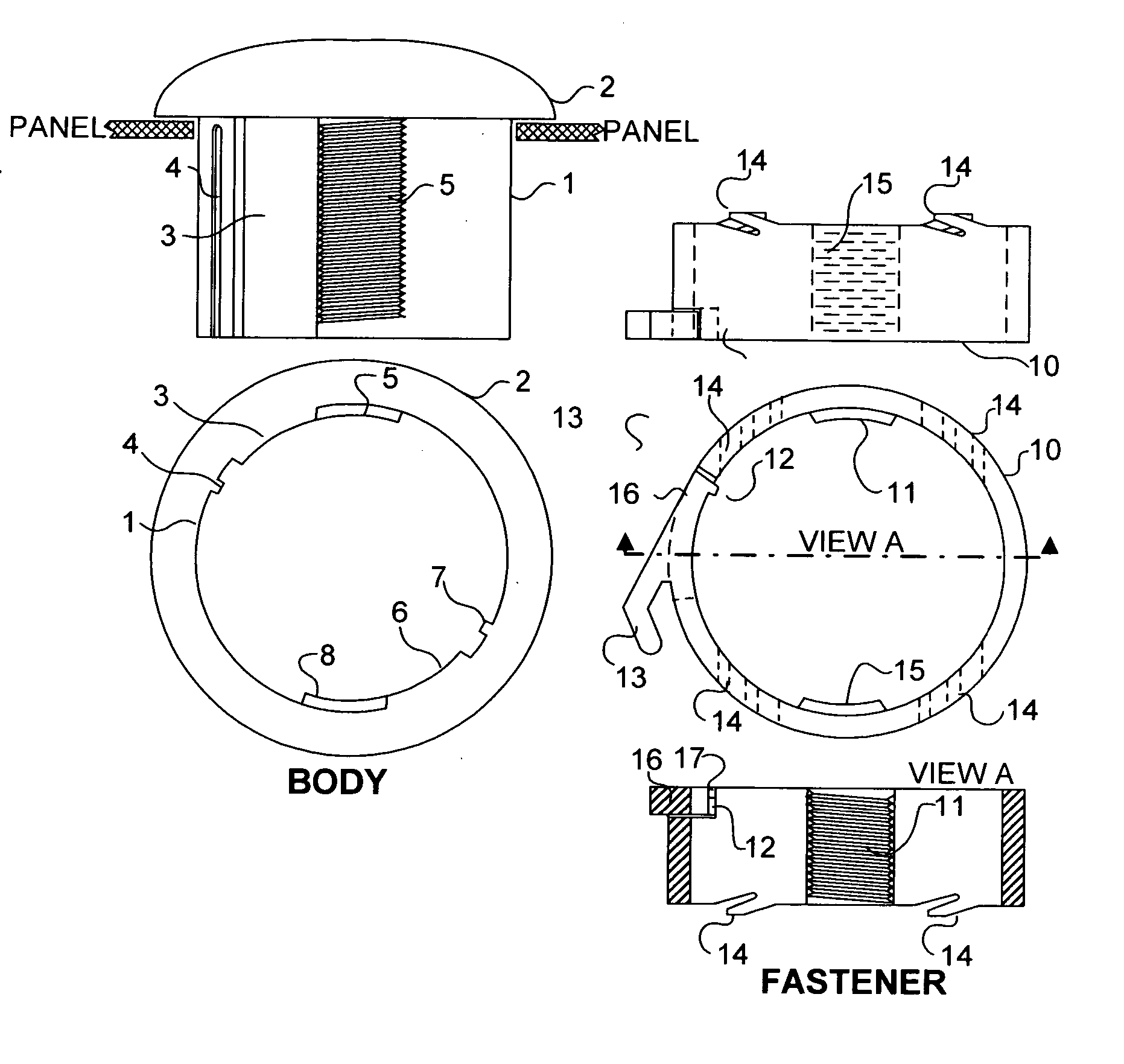

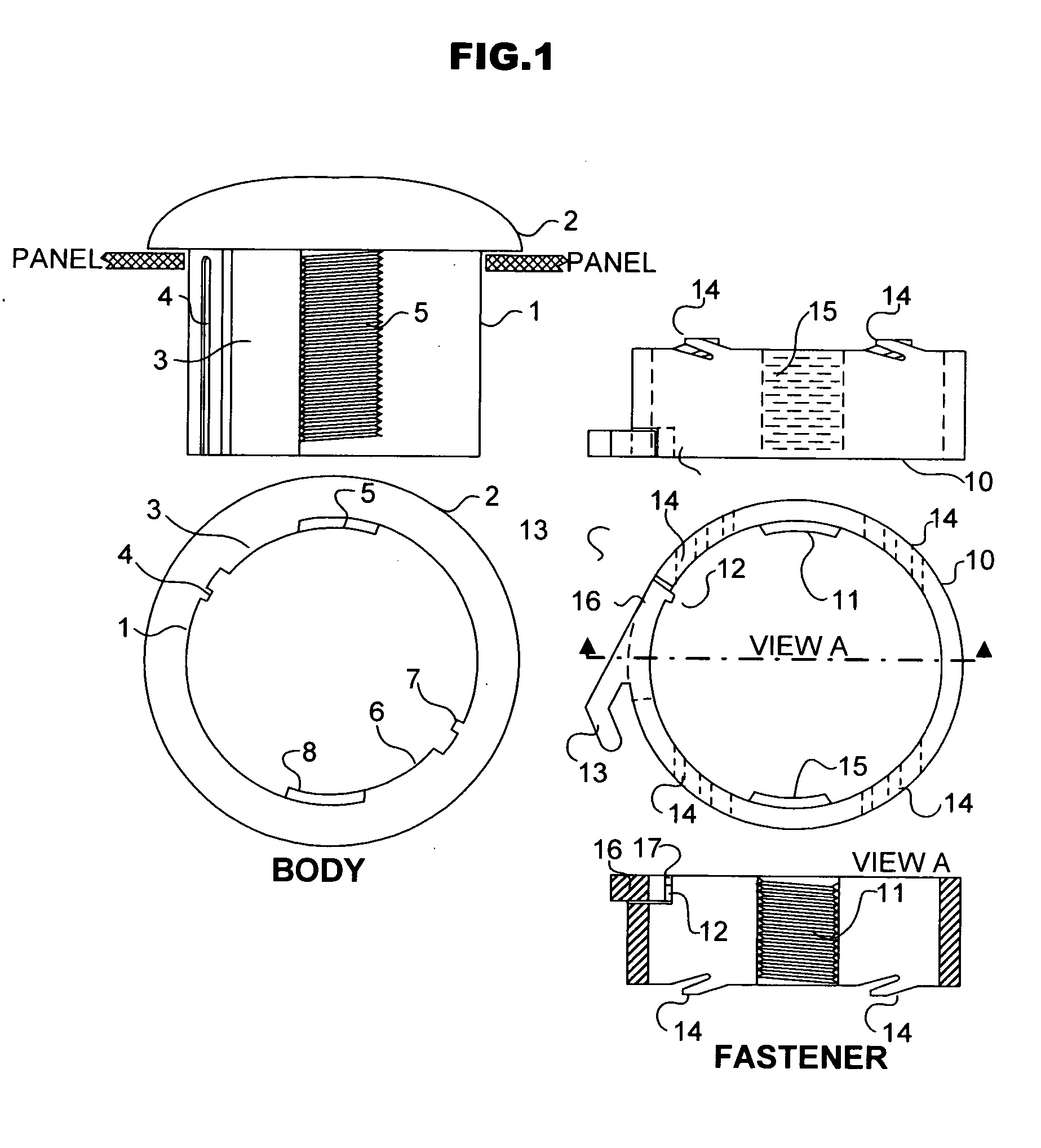

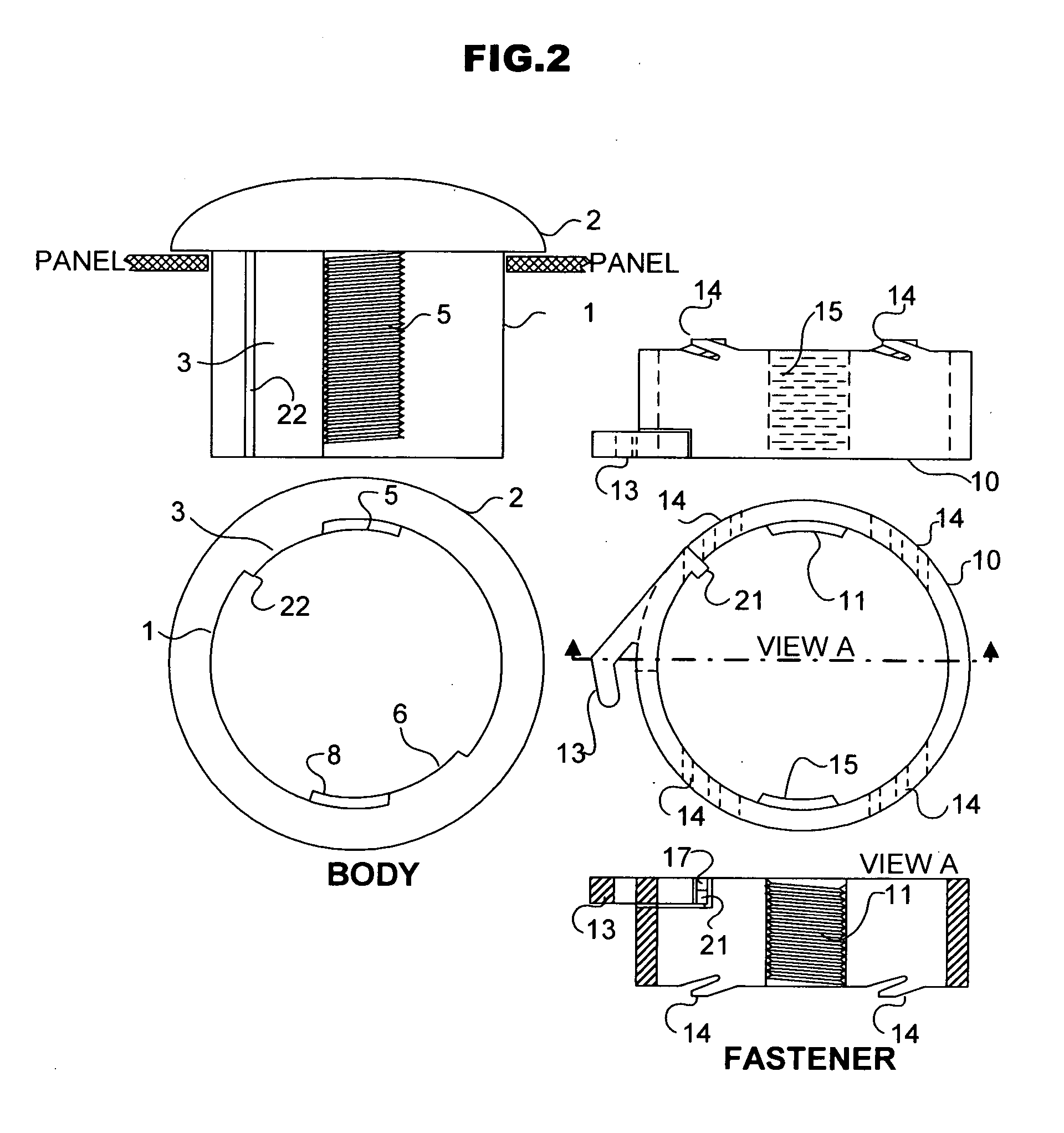

Latching quick-connect connector

InactiveUS20050220569A1Rapid and secure connectionFast and secure connectionNutsBoltsFastenerElectrical and Electronics engineering

A method is presented to allow a quick, positive attachment of a fastener to a module body. The module body and the fastener each have interrupted screw sections to connect with a partial turn. A latching mechanism, such as a pawl and cog arrangement, can provide a positive lock when the interrupted screw threads are fully engaged. A mechanism such as tab lever can be used to disengage the positive lock to easily remove the module. The controlled traverse over a known thread pitch allows the use of a compressible face on the fastener with a fixed compression and a repeatable, tight connection.

Owner:DRYER JOSEPH E

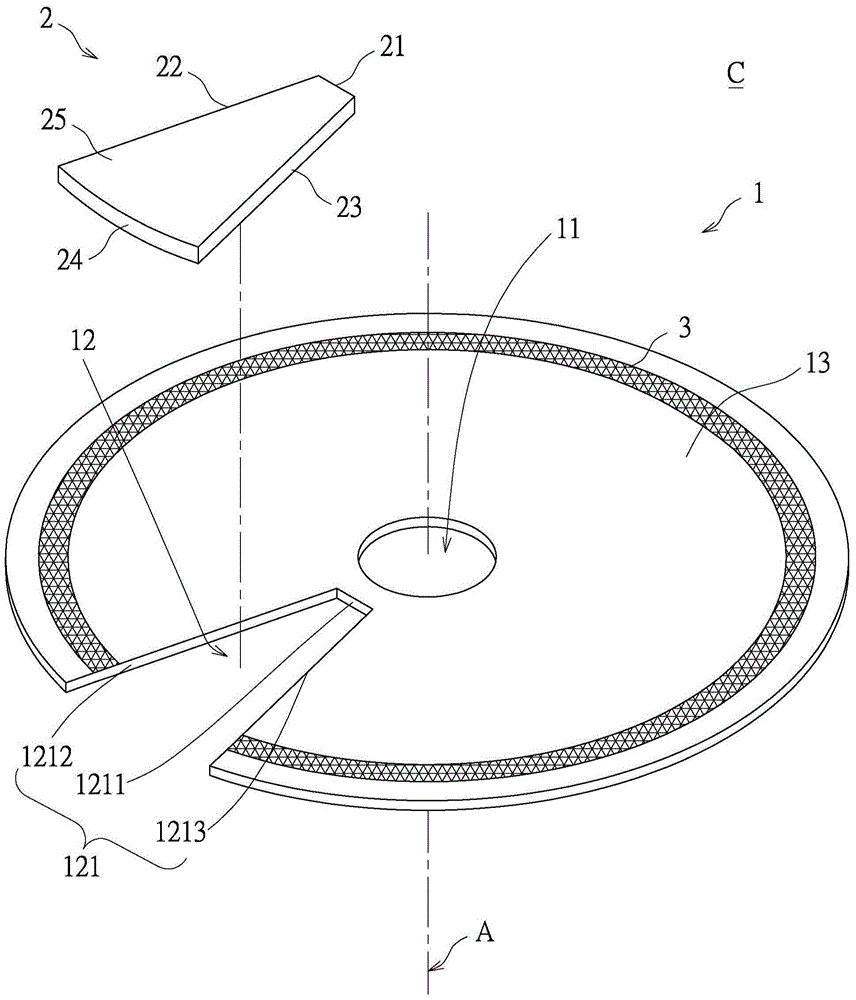

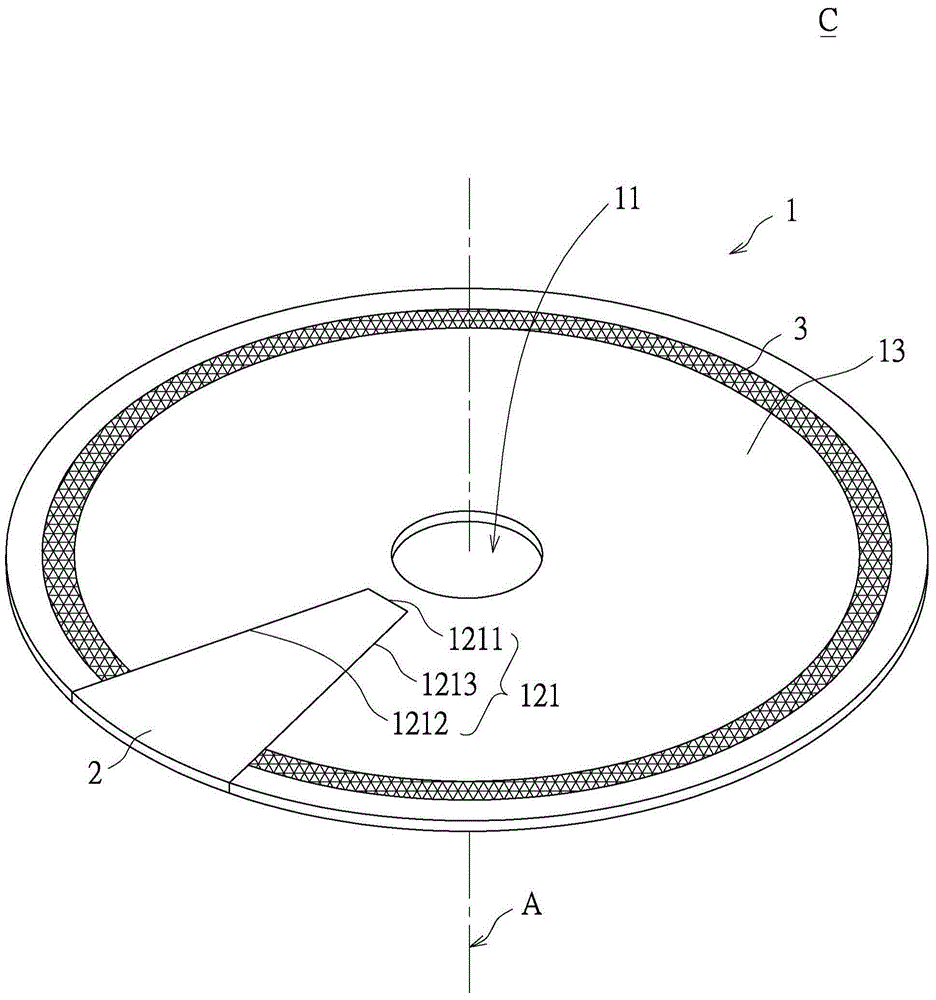

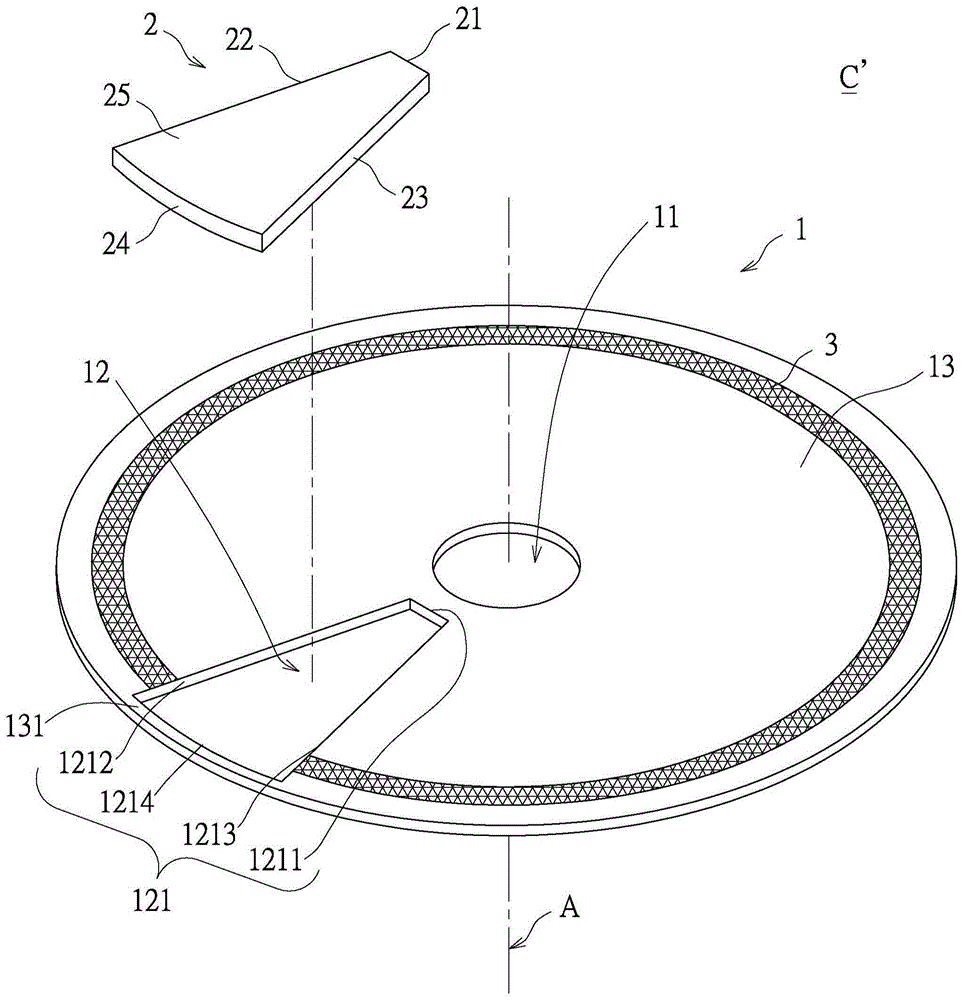

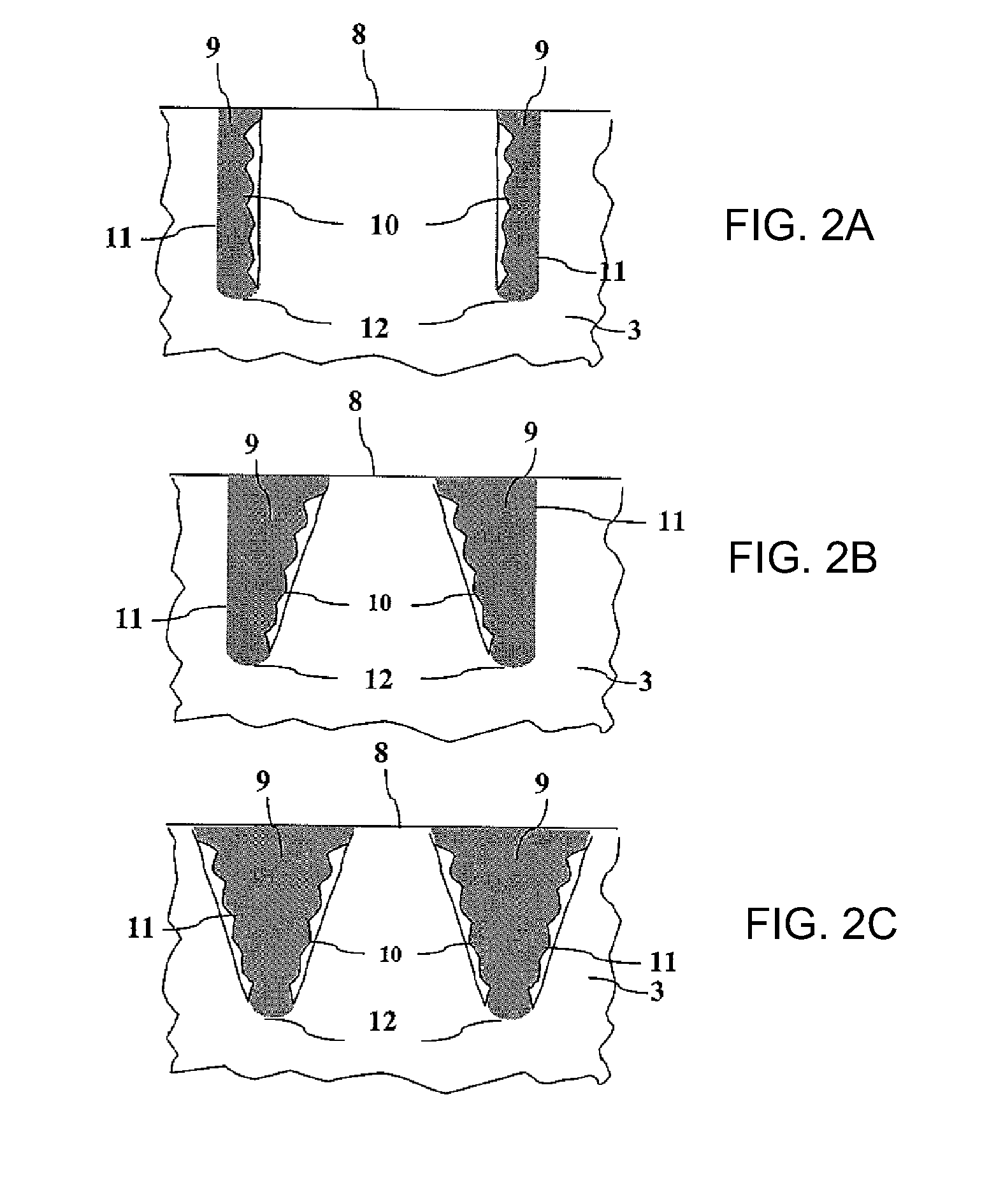

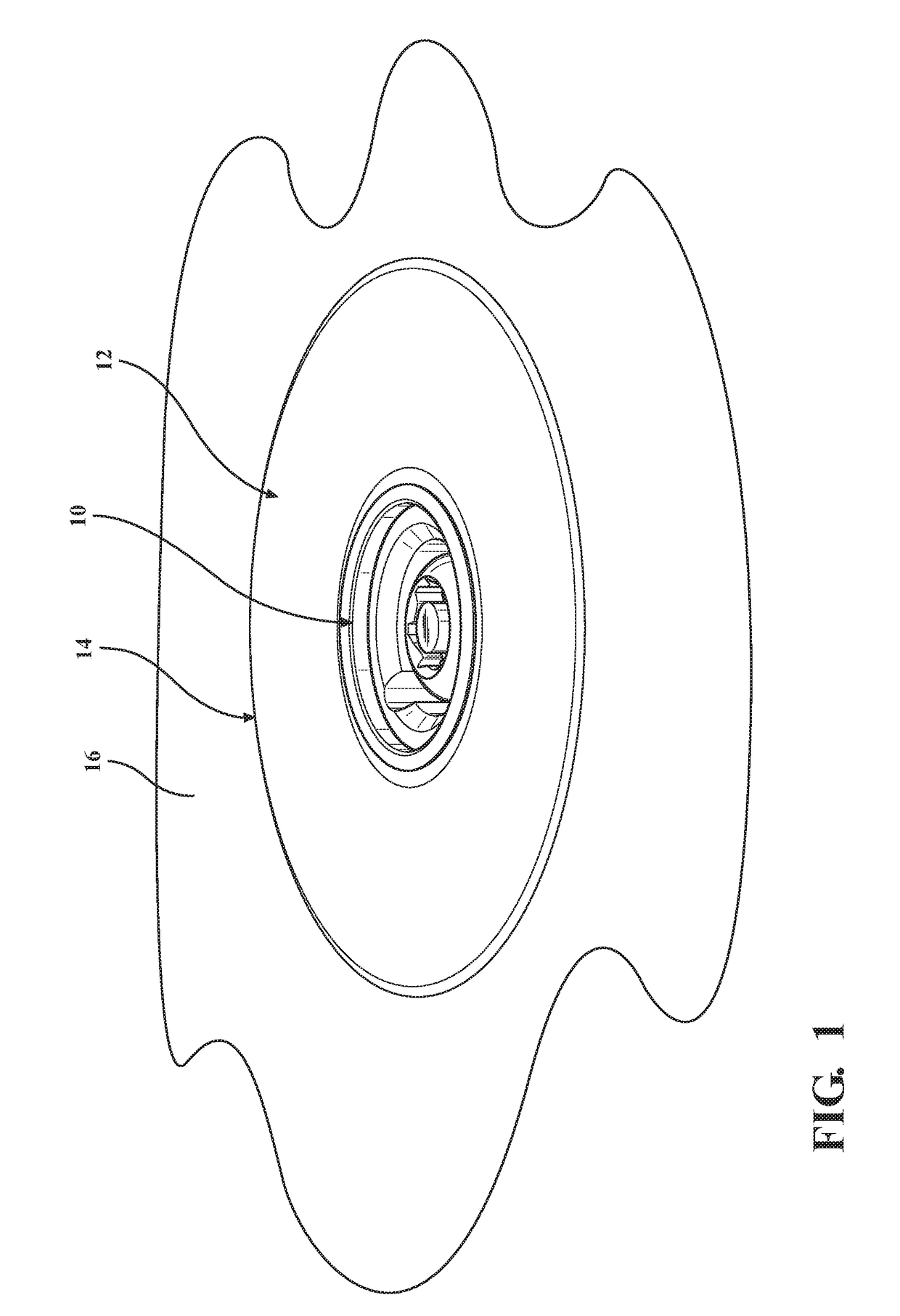

Optical color wheel component and optical color wheel thereof

The present invention provides an optical color wheel component and an optical color wheel thereof. The optical color wheel comprises a base unit, a light-transmitting unit, and a fluorescent unit. The base unit comprises a central hole, a central axis, a light-transmitting region, and a reflective region. The central hole is arranged along the central axis. The light-transmitting region and the reflective region are connected to go around the central axis. The light-transmitting region is provided with a through hole. The light-transmitting unit is arranged in the through hole and is surrounded by the through hole. The fluorescent unit is arranged on the reflective region and goes around the central axis. The invention also provides an optical color wheel component.

Owner:TAIWAN COLOR OPTICS

Method for preventing fastening nut from being stolen, anti-theft nut and special sleeve tool

The invention discloses a method for preventing a fastening nut from being stolen, an anti-theft nut and a special sleeve tool. A nut with internal threads is made into a cylindrical nut; when the cylindrical nut and a bolt are connected and fastened together, a washer sleeve with a cover sleeve is arranged on the bolt, and the cylindrical nut is connected to the bolt through the threads and is screwed on the bolt through the special sleeve tool with a one-way needle bearing, so that the cylindrical nut tightly presses the washer sleeve and is covered by the cover sleeve on the washer sleeve; and when the nut is needed to be loosened, another special sleeve tool with the one-way needle bearing in a different rotating direction stretches into an inner hole of the cover sleeve on the washer sleeve and is sleeved on the nut to loosen the nut. The invention has the advantages that: the anti-theft nut is difficult to steal, has a good anti-theft effect and reliable performance, and is convenient to install, maintain and disassemble.

Owner:贵州大正展业科技开发有限公司

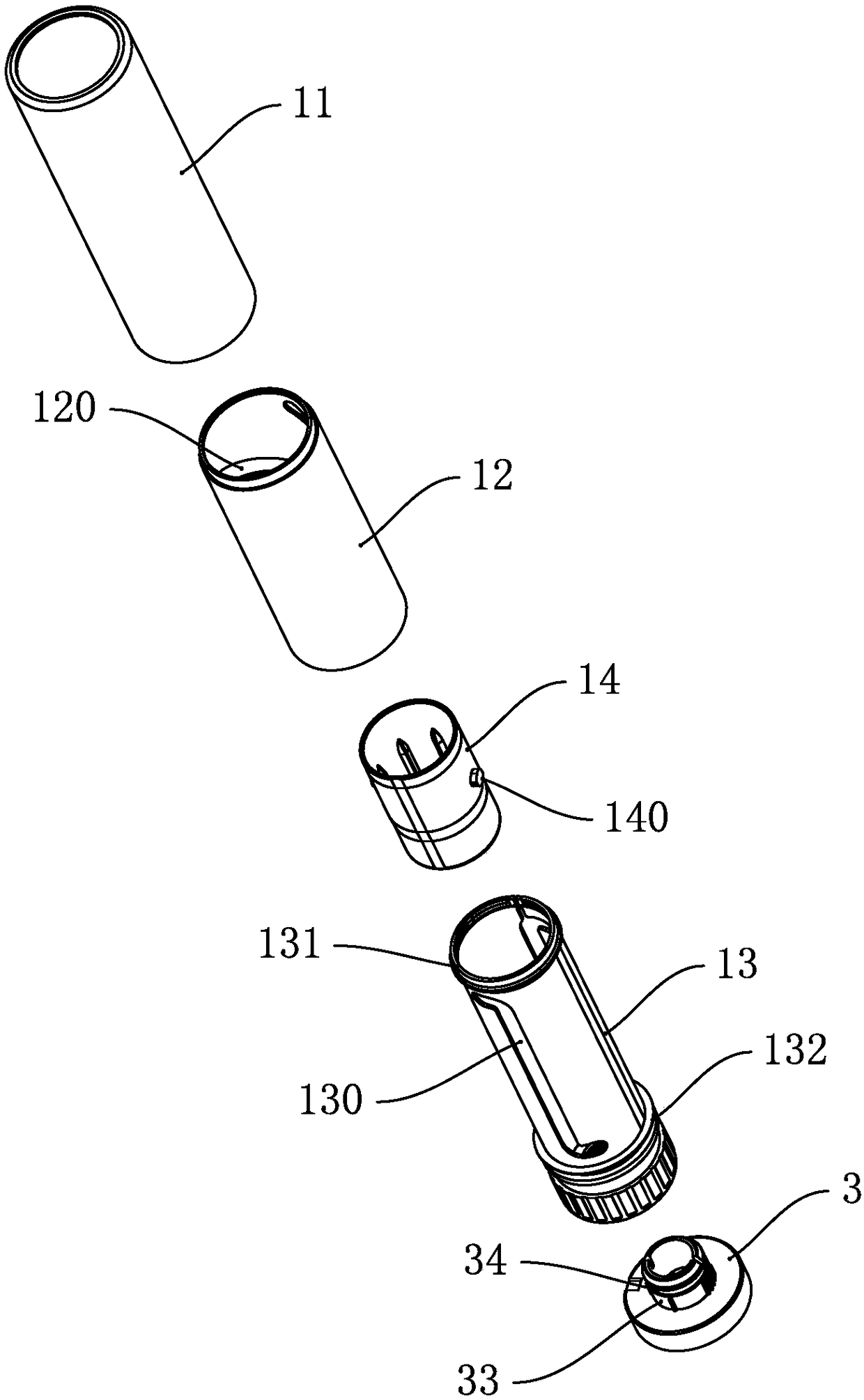

Median bundle core and packaging pipe

PendingCN108523378ANot easy to implementEasy to assemblePackaging toiletriesPackaging cosmeticsPackaging TubeHelix

The invention discloses a median bundle core and a packaging pipe. The median bundle core includes a bead, a fork, a spiral and a median bundle which are sequentially arranged from inside to outside.The bottom of the fork is provided with a connecting base, the bottom end face of the connecting base is provided with a groove, the inner side wall of the groove is provided with a clamping groove, the bottom surface of the groove is provided with a positioning hole, and the bottom of the median bundle extends in the axial direction and is close to the bottom edge of the connecting base or completely surrounds the connecting base. The packaging pipe includes a base and the median bundle core. During use, the bottom of the median bundle core is inserted in an inner chamber of the base, a connector matched with the clamping groove is disposed in the base, and the top surface of the connector is provided with a positioning block inserted in and matched with the positioning hole. The median bundle core and the base are clamped with each other, the connecting base is substantially hidden in the median bundle, the median bundle core cannot be used alone, but the median bundle core can be replaced, and the base is reused.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

Composite fastener for ceramic components

InactiveUS20100119299A1Prevent unscrewingHigh mechanical strengthYielding couplingCovering/liningsThermal shockMaterials science

A tubular composite member with two ends for connecting ceramic components made of a composite of an inorganic matrix reinforced with inorganic fibers is formed with an at least partially threaded internal surface and an external surface. A ceramic member has at least one surface formed with one or more annular grooves with an inner shell surface, an outer shell surface, and a root. The inner shell surface is at least partially threaded. A resulting ceramic member assembly includes at least two ceramic members connected by at least one tubular composite member. The ends of the tubular composite member are screwed into the corresponding annular groove of two adjacent ceramic members. The such fastened / joined ceramic members can be operated at high temperatures especially under thermal cycling and / or thermal shock conditions as well as dynamic mechanical load in different directions. Methods to manufacture tubular composite members according to this invention are described.

Owner:SGL CARBON SE

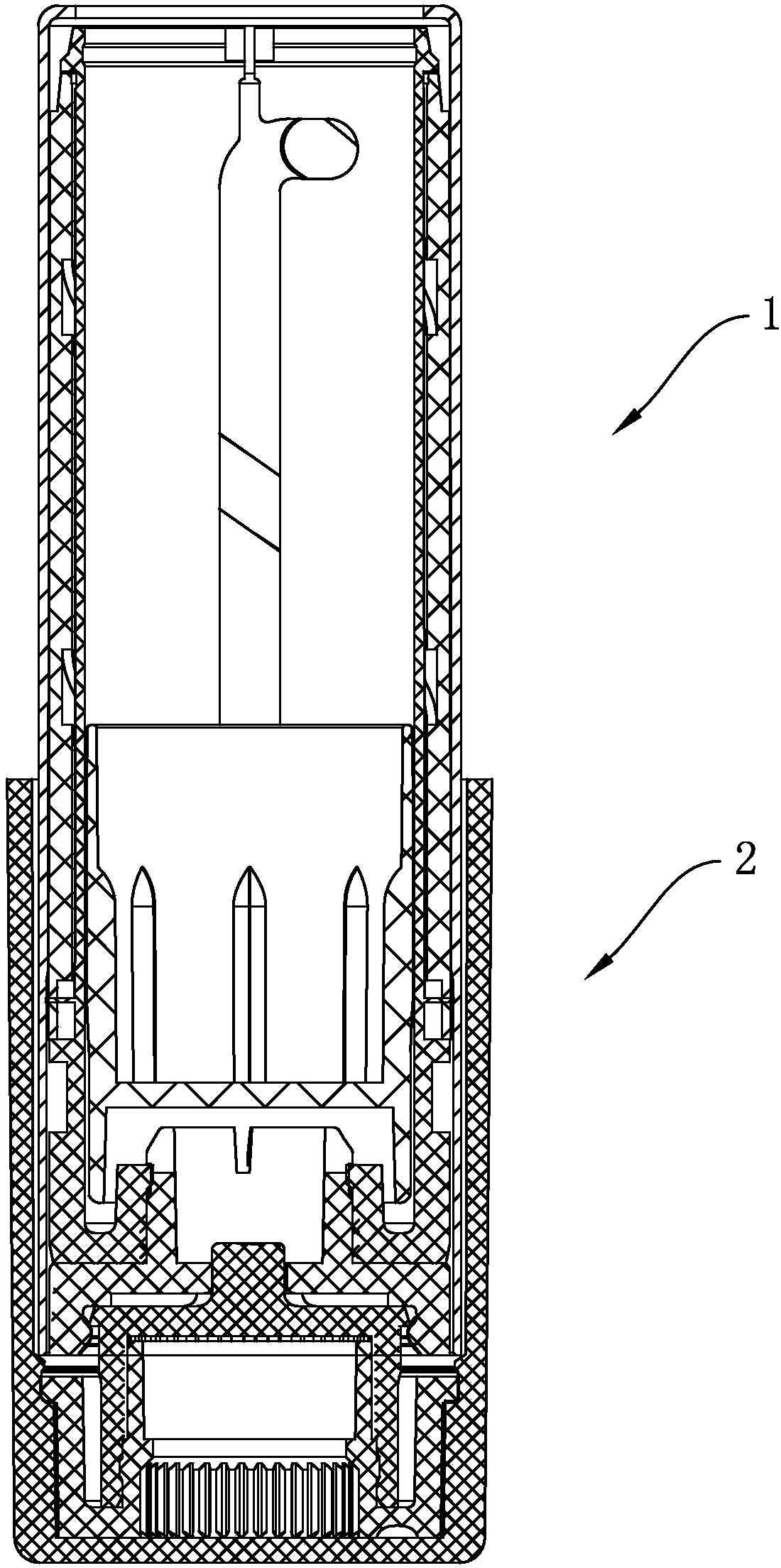

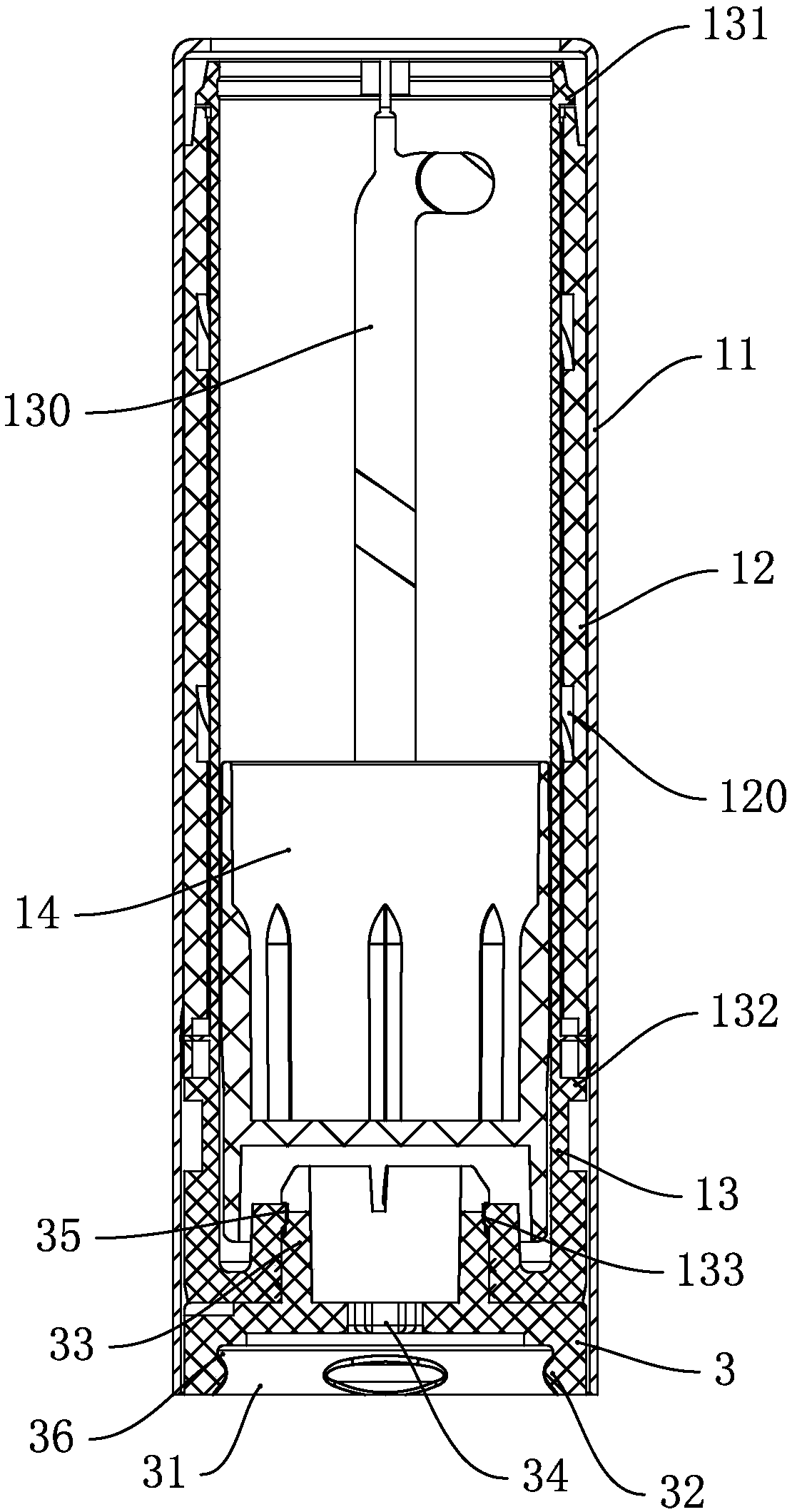

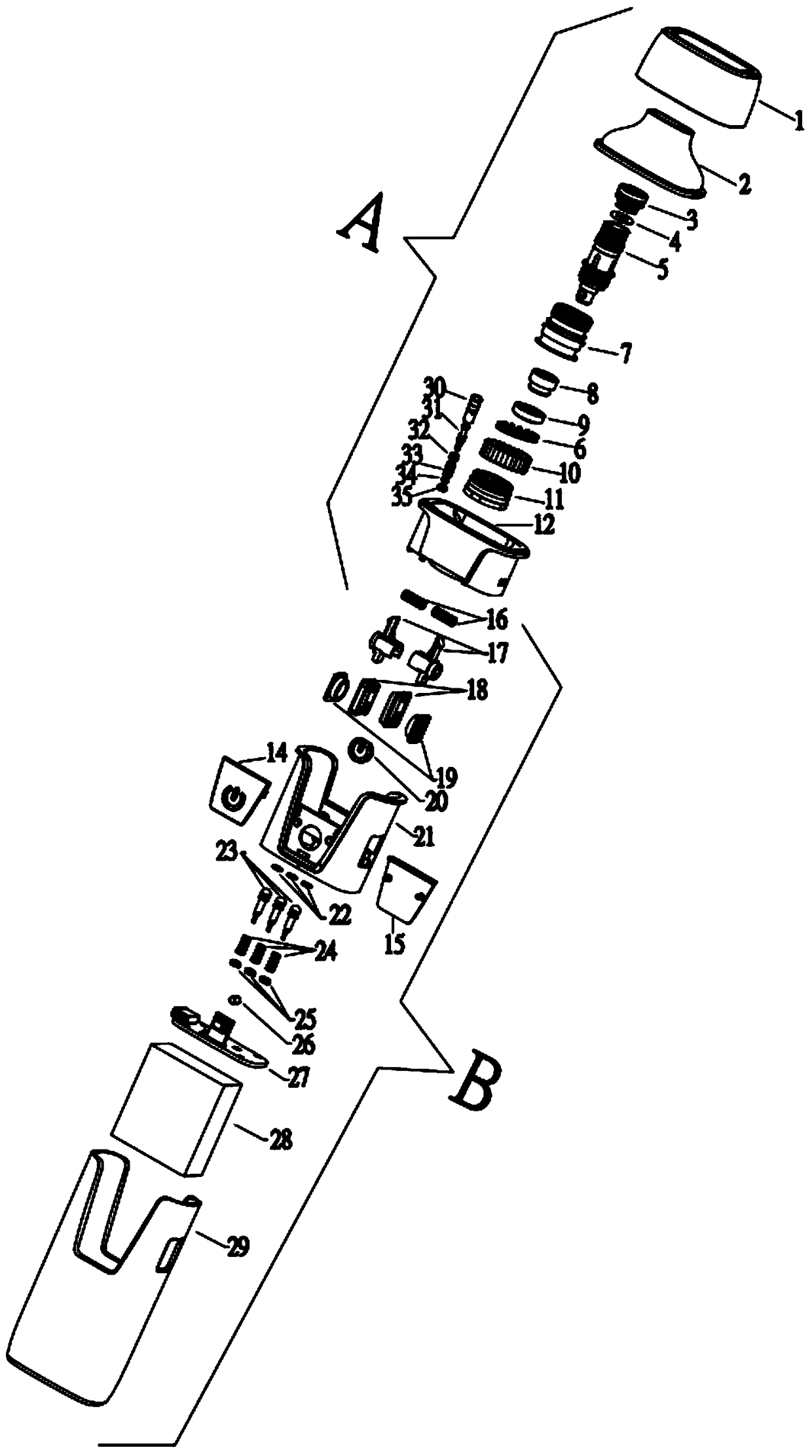

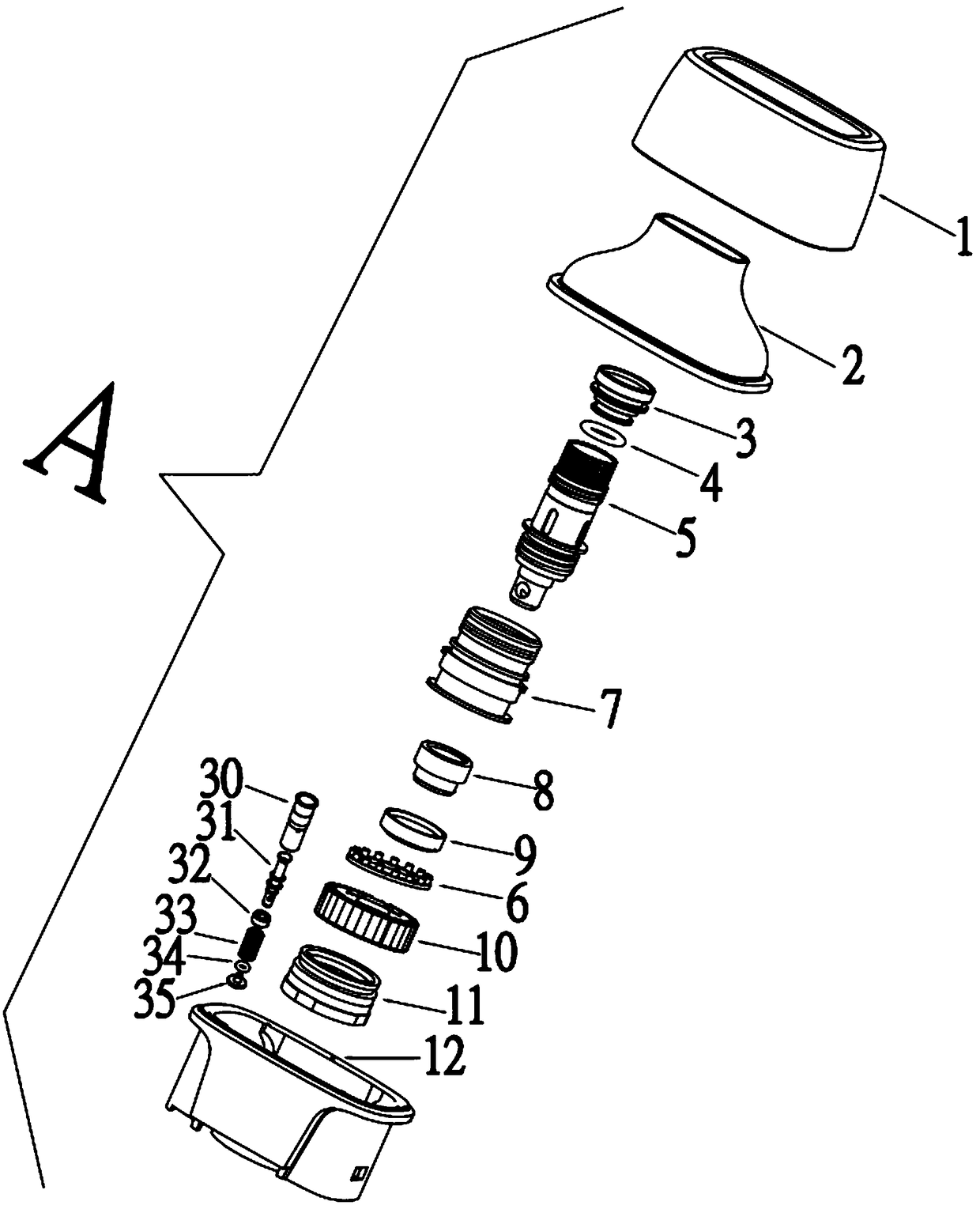

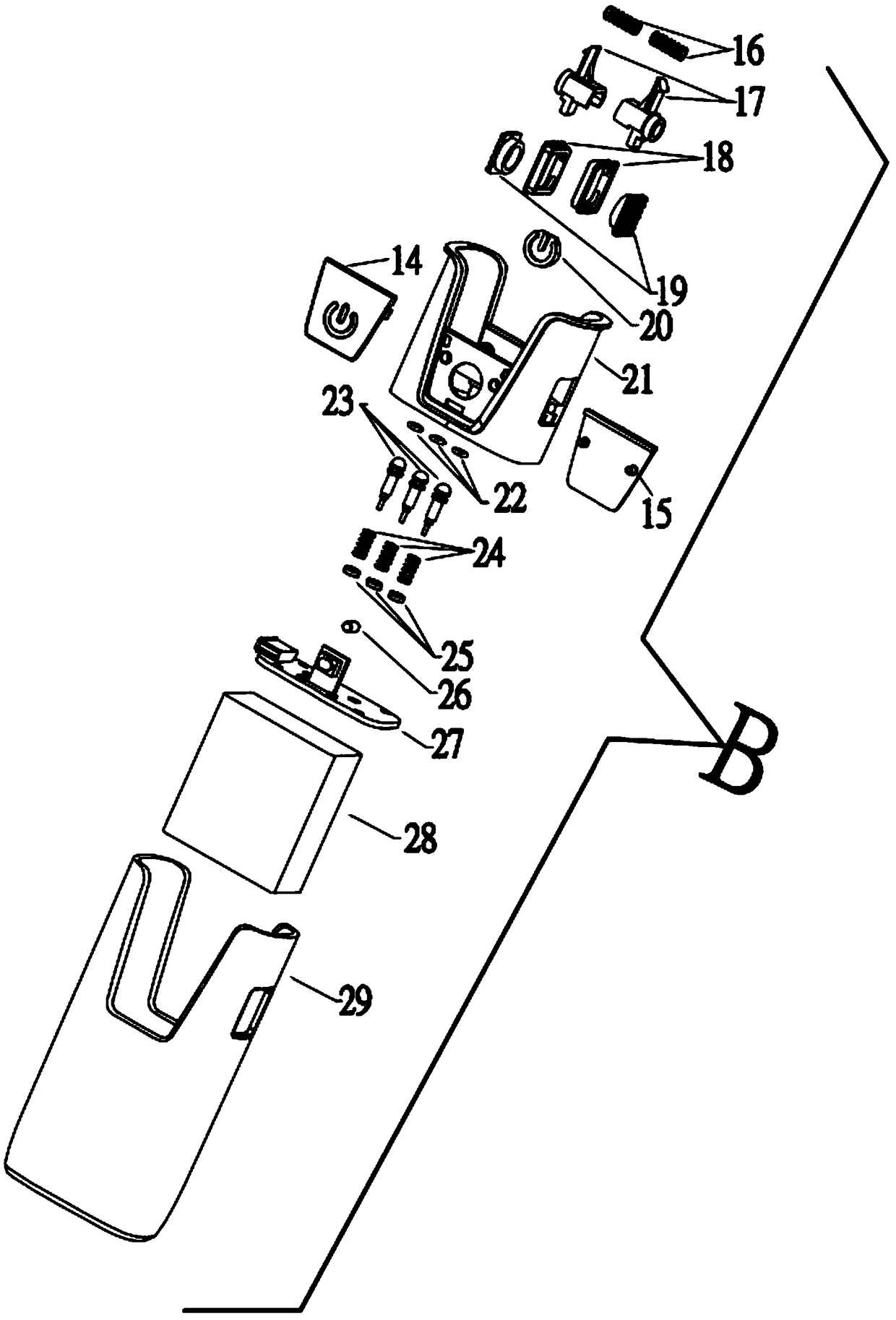

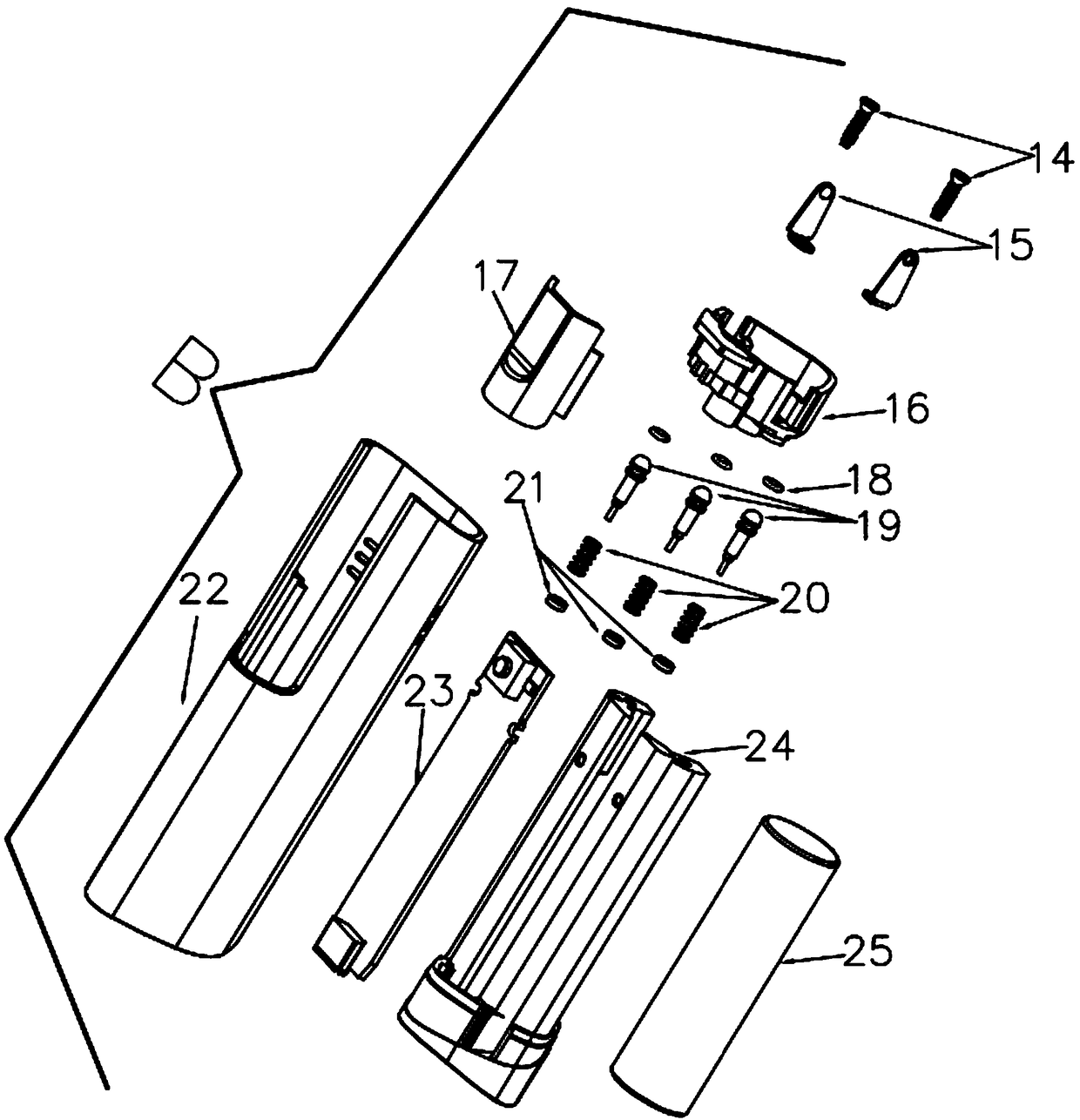

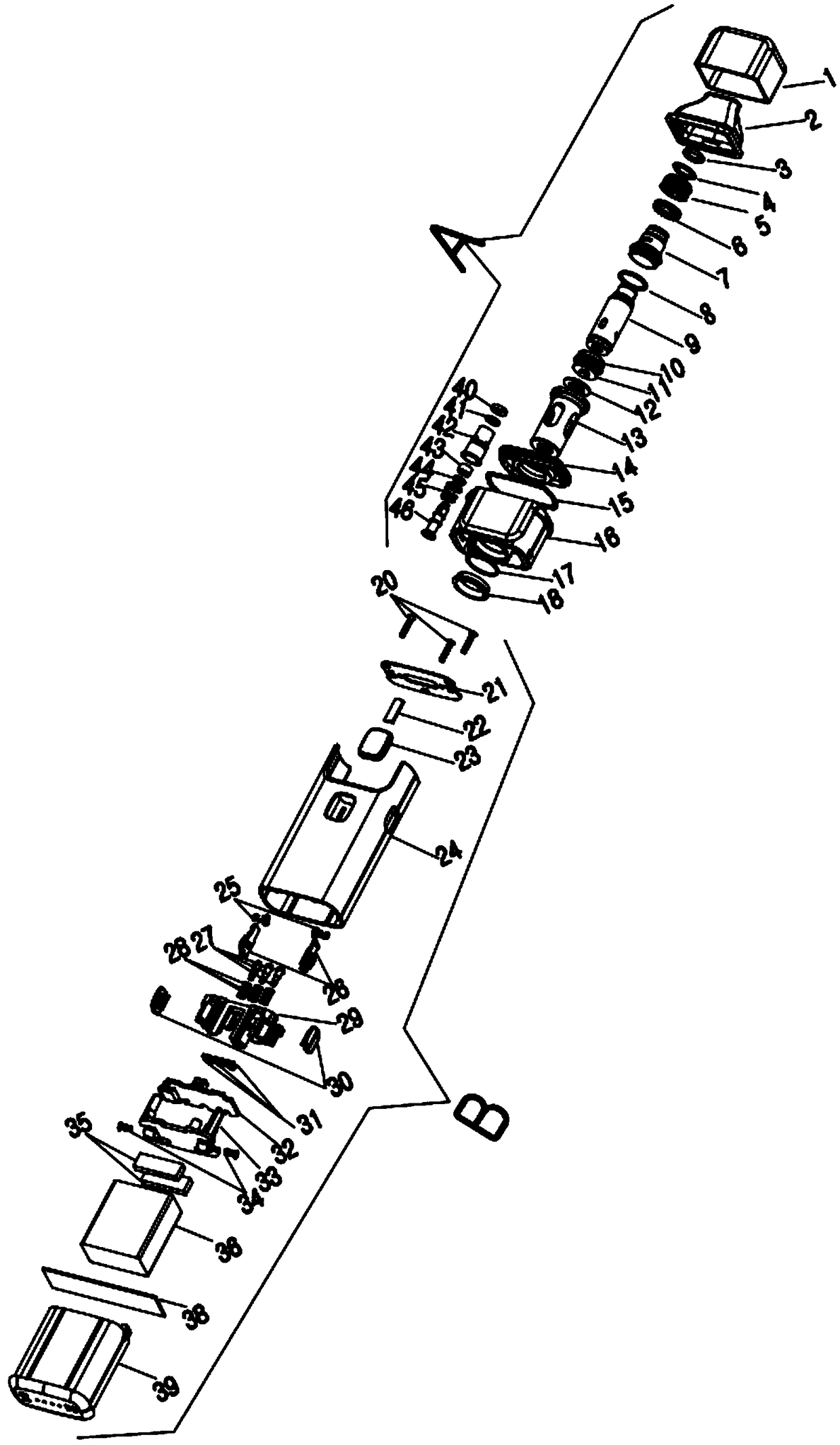

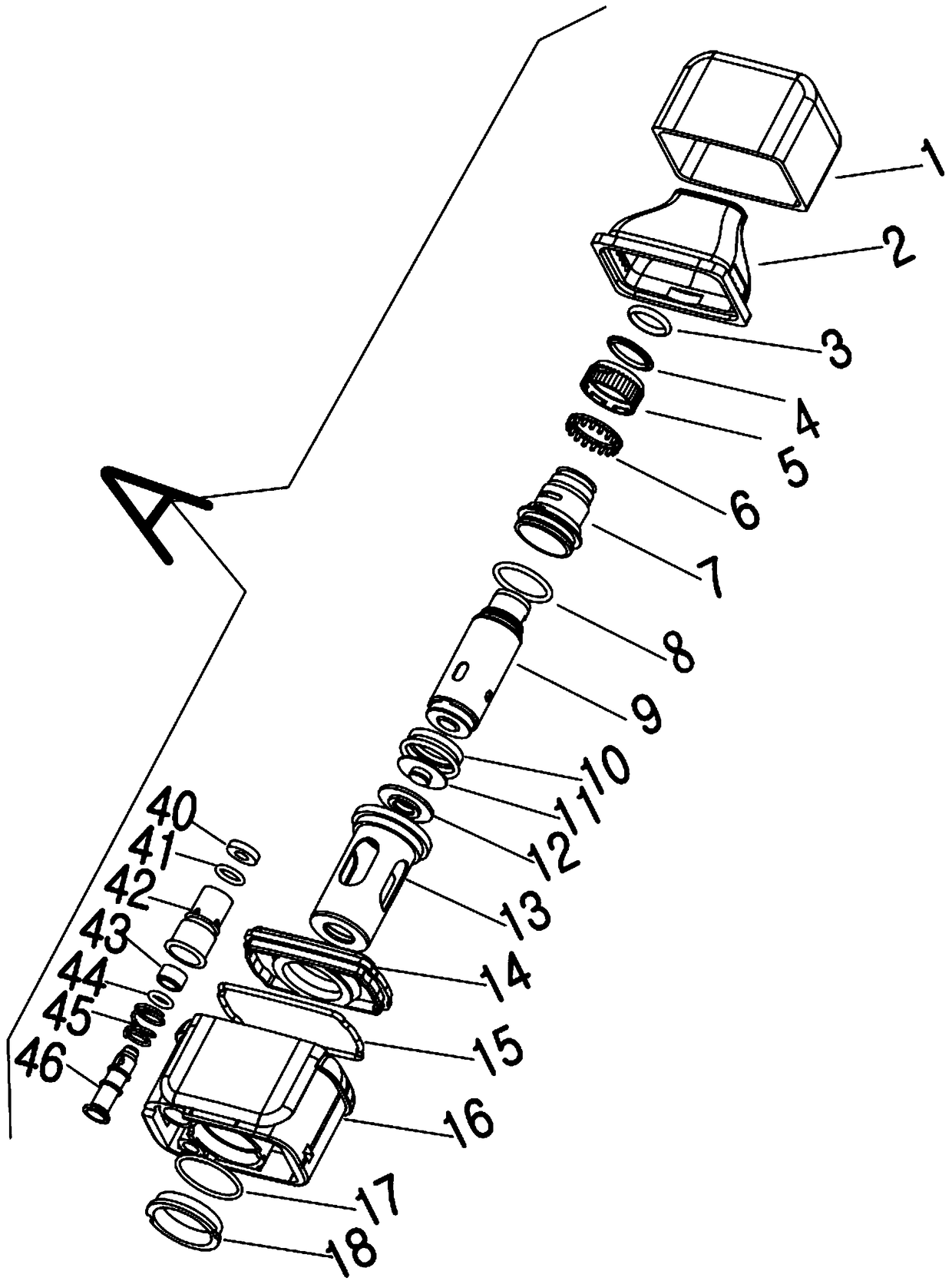

Electronic cigarette

InactiveCN109007991APrevent unscrewingEasy to separateTobacco devicesElectronic cigaretteEngineering

An electronic cigarette comprises an atomizer assembly (A) and a battery assembly (B), wherein the atomizer assembly is positioned above the battery assembly, and the atomizer assembly is tightly buckled with the battery assembly through the left and right switch keys (17) on the battery assembly, when the atomizer is detached, the press key caps (19) on the left and the right sides of the batteryassembly can be pressed at the same time, so that the atomizer can be ejected out and the atomizer can be separated from the battery, and the outer shape of the separated battery body is like a V shape. According to the invention, the battery and the atomizer can be separated from each other by pressing the key caps (19) on the left and right sides of the battery, and the opening and closing of the oil inlet hole and the child lock device are controlled by means of elastic force so as to prevent the heating core from being screwed out.

Owner:刘团芳

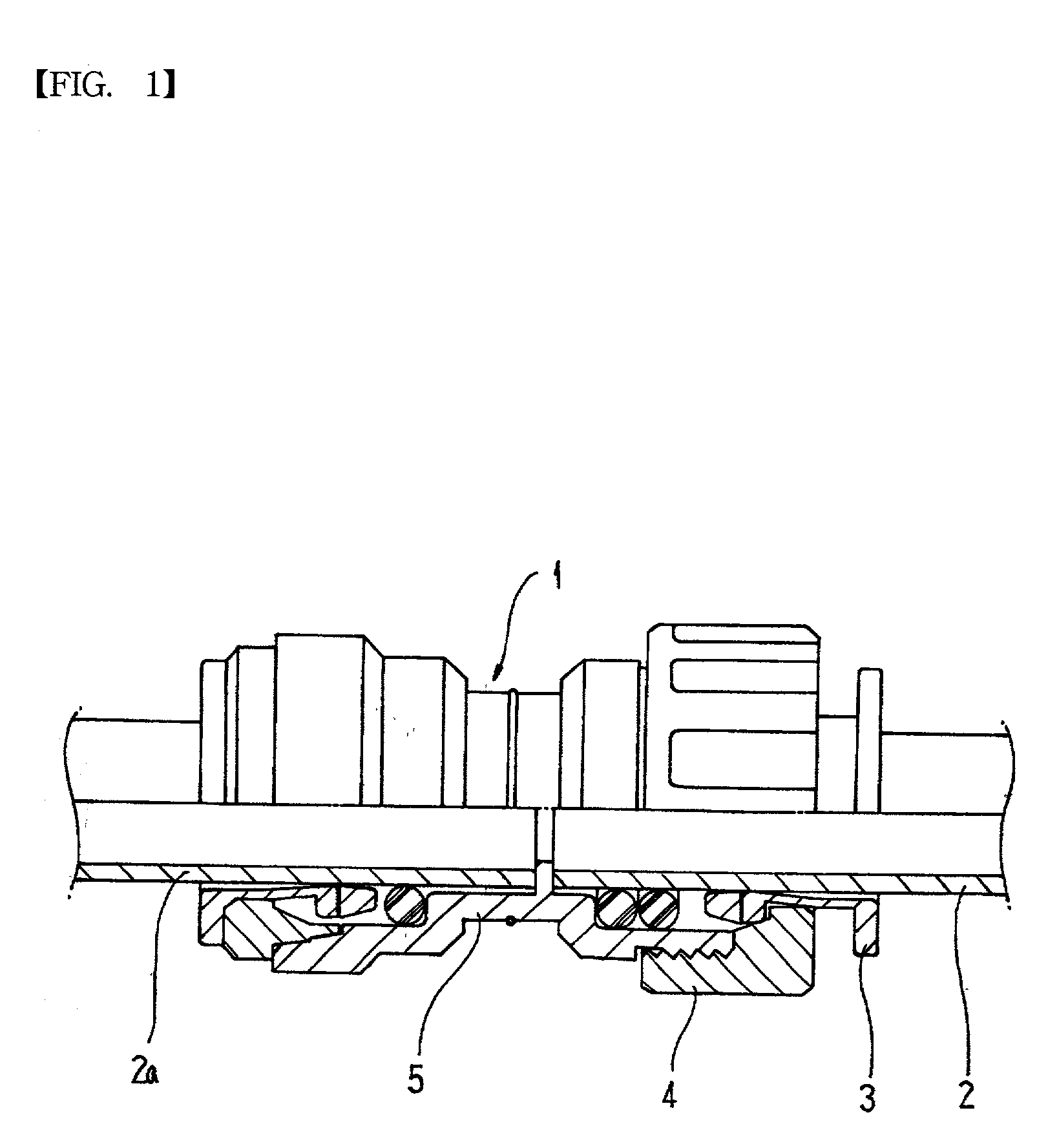

Device for locking cap nut for coupling

InactiveUS20030160449A1Inhibition releaseSmoothly assembled and disassembledSleeve/socket jointsEngine sealsEngineeringHooking

A device for locking a cap nut for a coupling includes a hooking plate 100 extended out of the body 50 connected to the metallic connecting pipe 21, a plurality of hooking protrusions 110 protruded from the hooking plate 100 at a regular space, and a plurality of hooking grooves 200 formed at a position facing the hooking protrusion 110 and engaged with the hooking protrusion 110 to prevent the cap nut 40 from being released when screwing the cap nut 40, so as to prevent the cap nut 40 from being released, so eventually securely assembling the connecting pipes 21 not to be separated from the coupling 10.

Owner:DEUTSCHE MONTAN TECHNOLOGIES GMBH

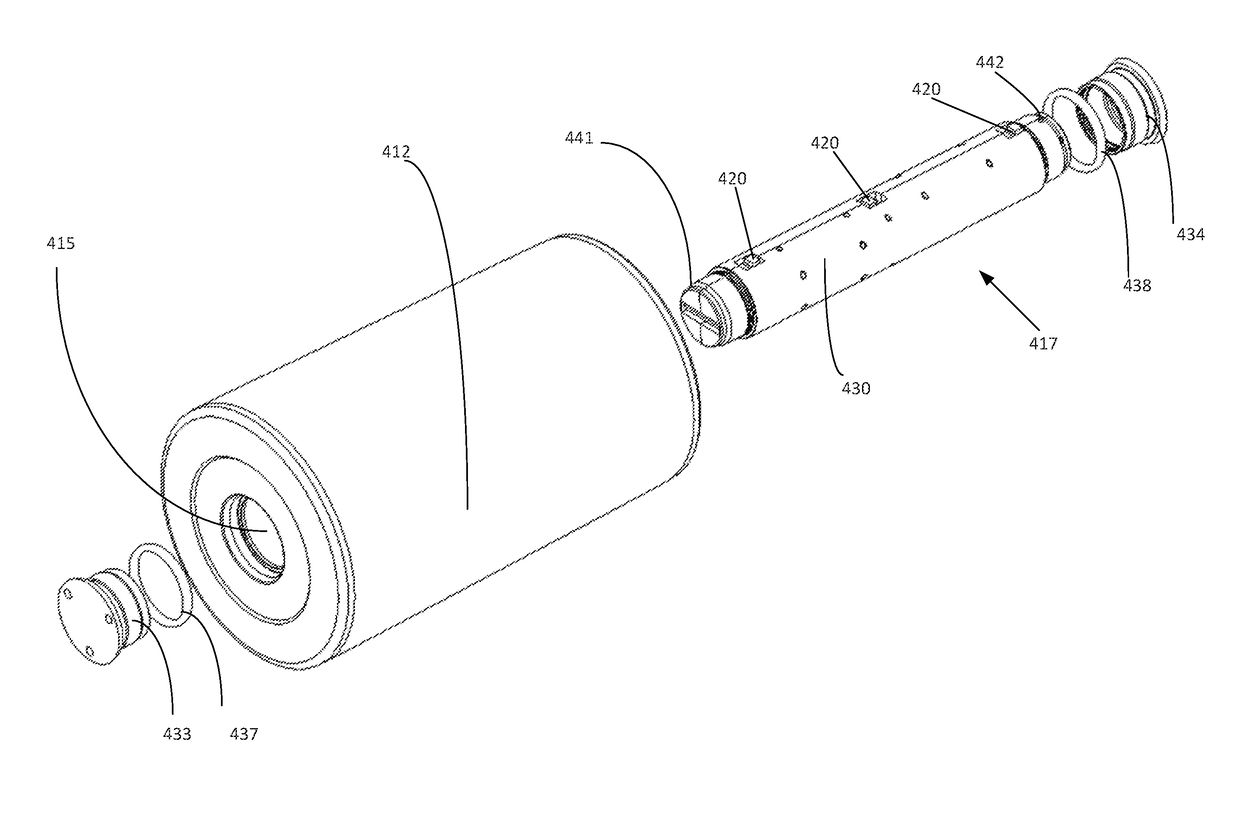

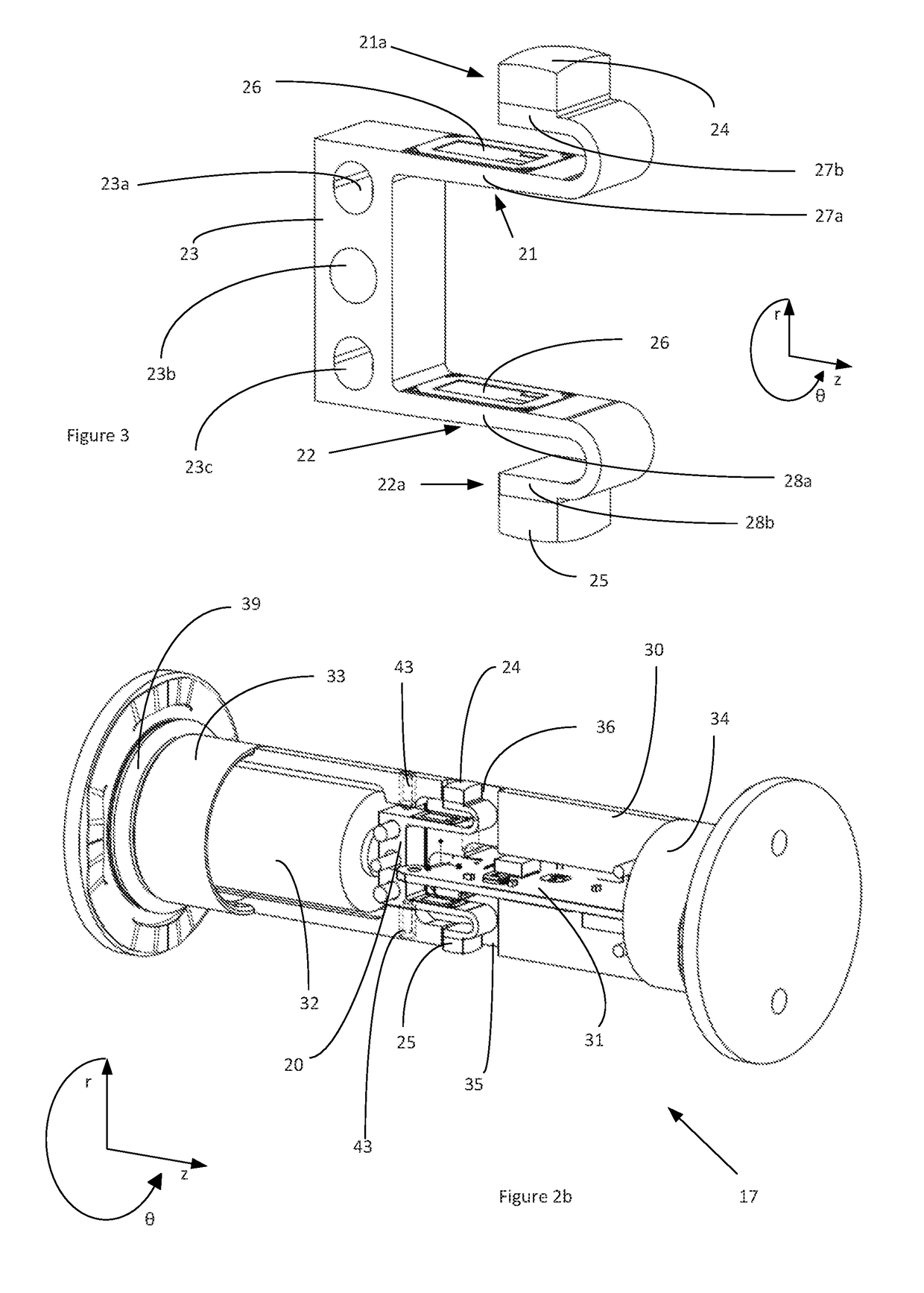

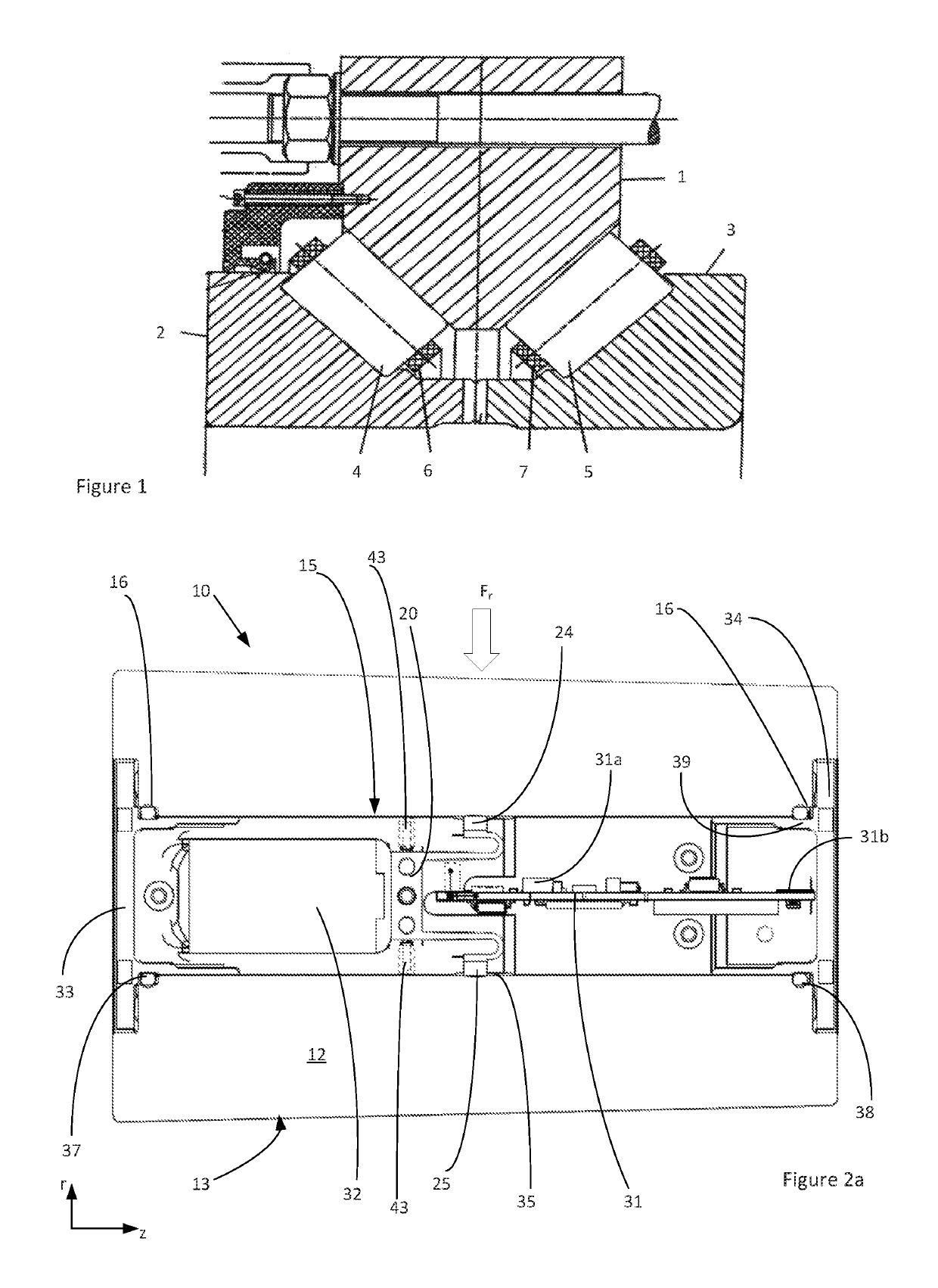

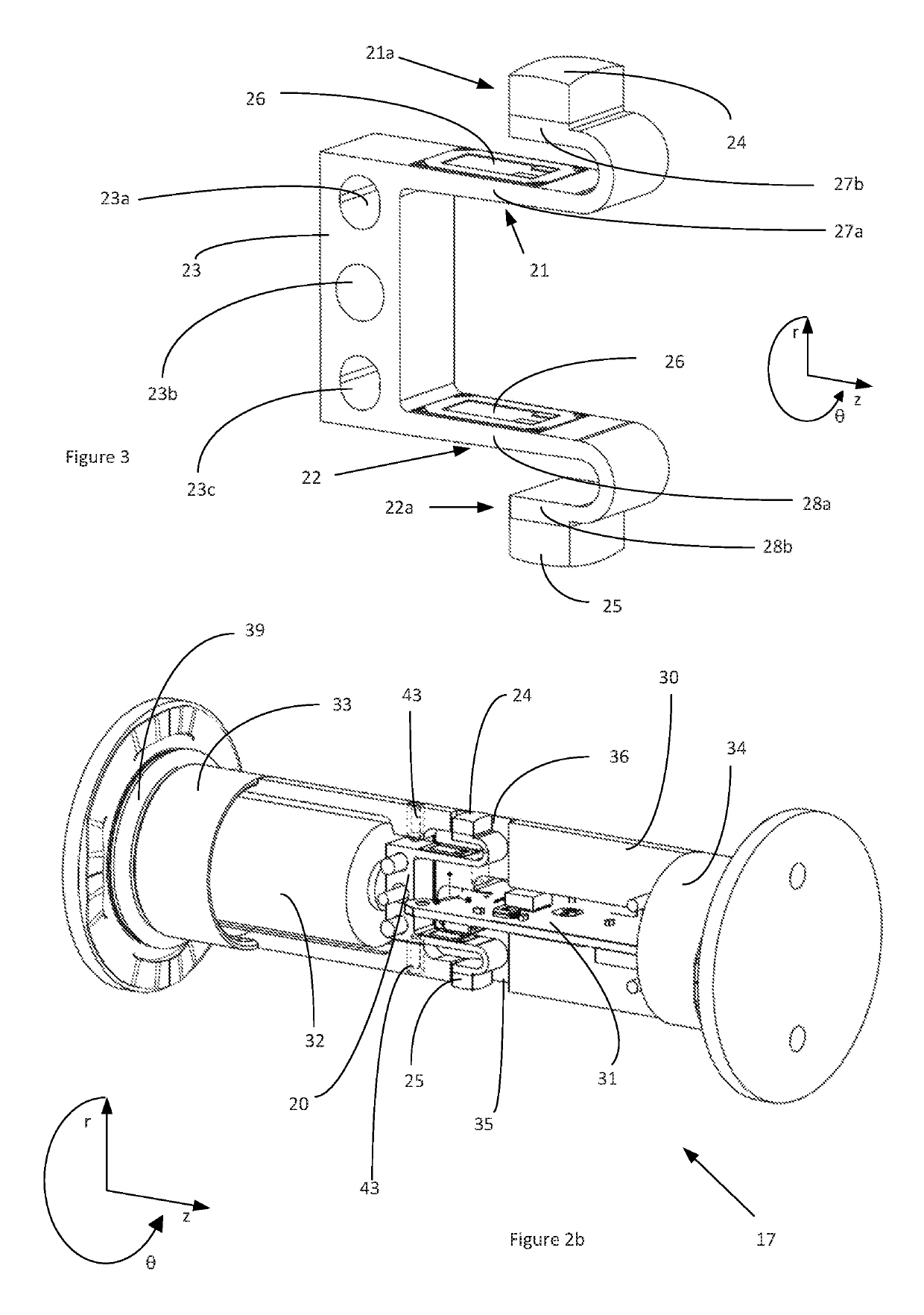

Sensorized roller

ActiveUS20180003492A1Prevent rotationEasily to dismountedRoller bearingsBearing assemblyEngineeringMechanical engineering

The present invention resides in a sensorized roller of a roller bearing. The sensorized roller includes a roller bore that accommodates a measuring device for measuring deformation of the roller bore and electronics for processing a deformation signal from the measuring device and wirelessly transmitting the processed deformation signal to an external receiver. According to the invention, the measuring device and electronics are mounted in a rigid housing that is shaped to fit within the roller bore. A radially outer surface of the housing includes at least one aperture associated with the measuring device. Furthermore, the rigid housing is resiliently mounted to the roller bore via first and second sealing elements that enclose a radial gap between a radially inner surface of the roller bore and a radially outer surface of the housing.

Owner:AB SKF

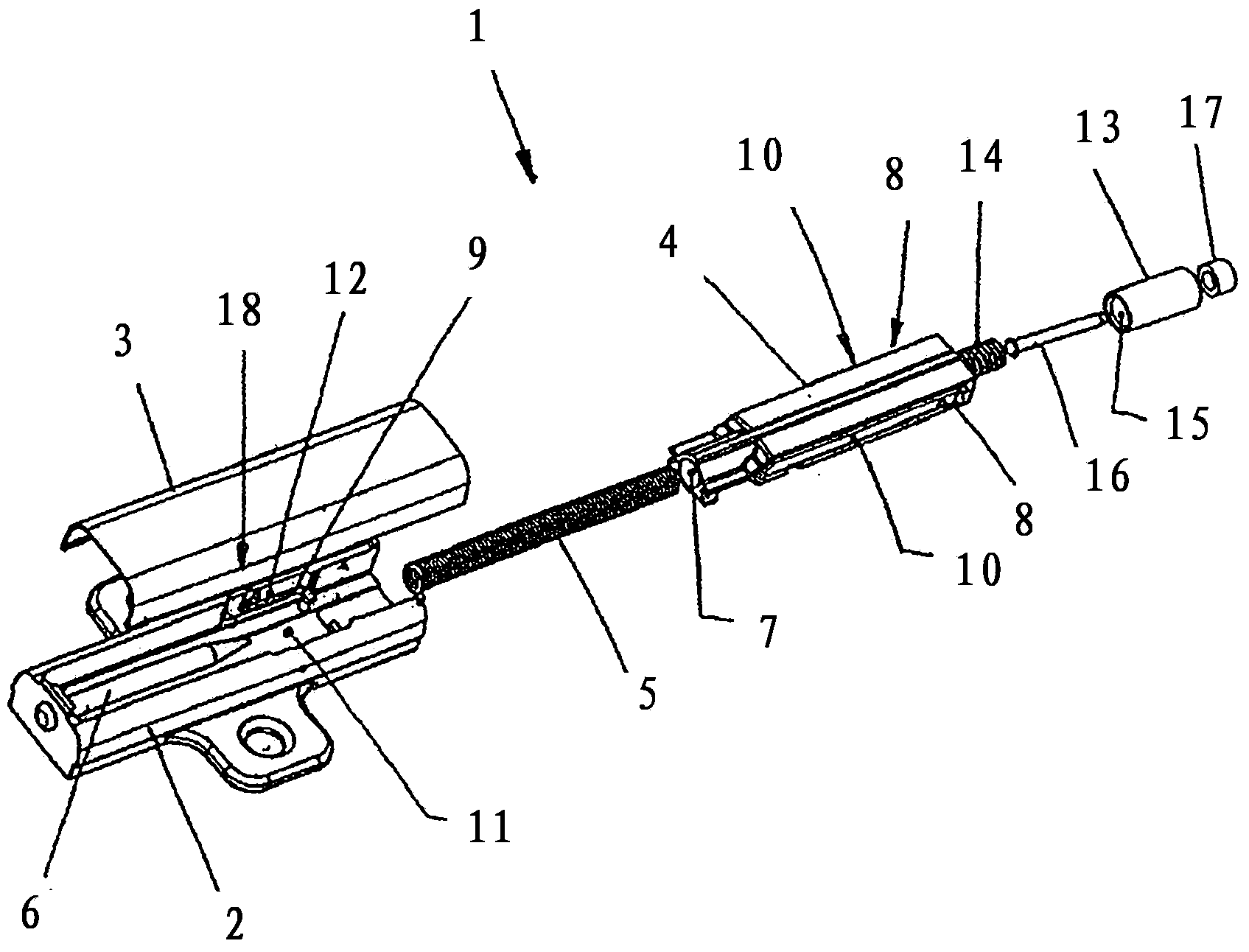

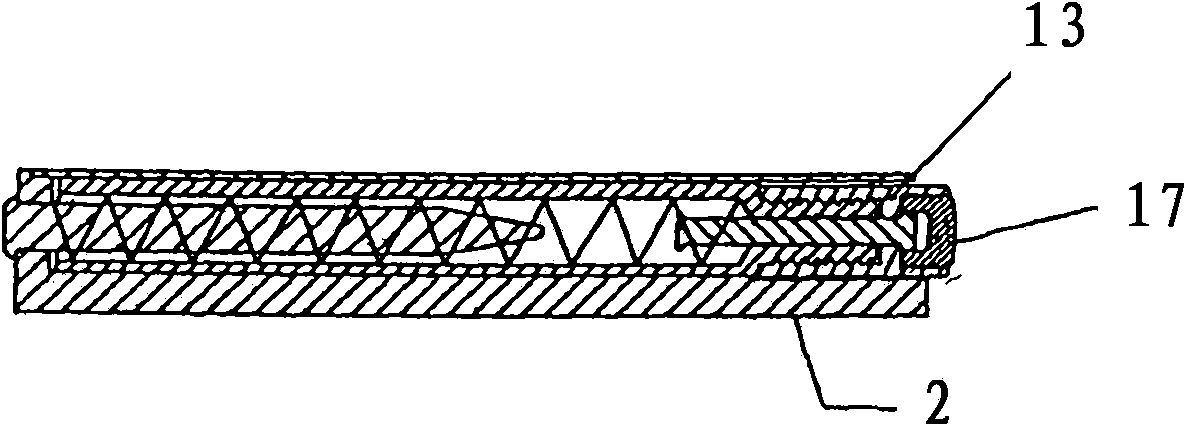

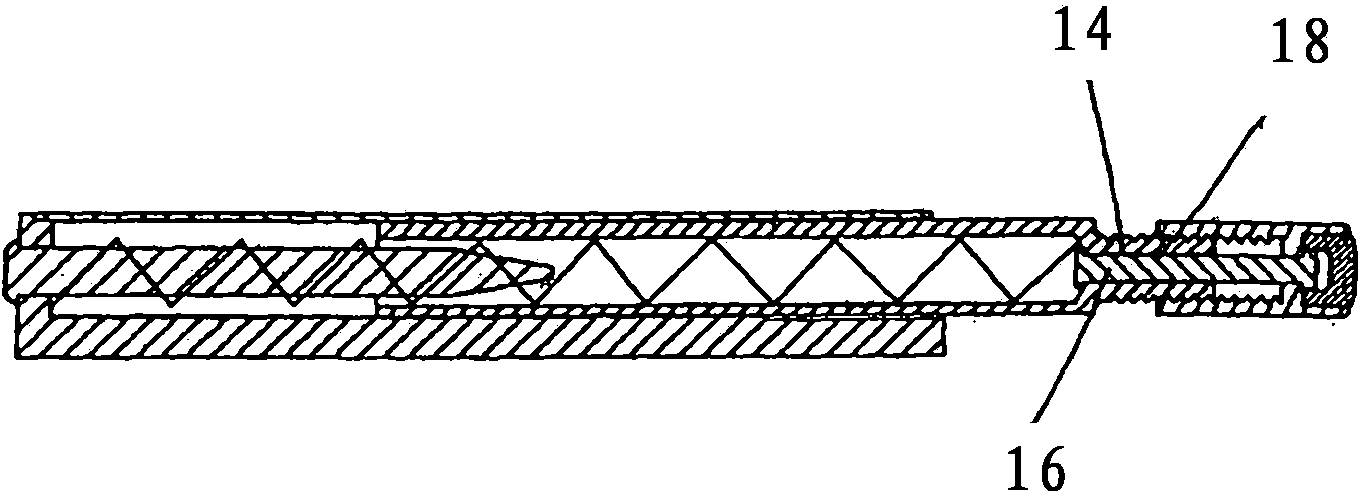

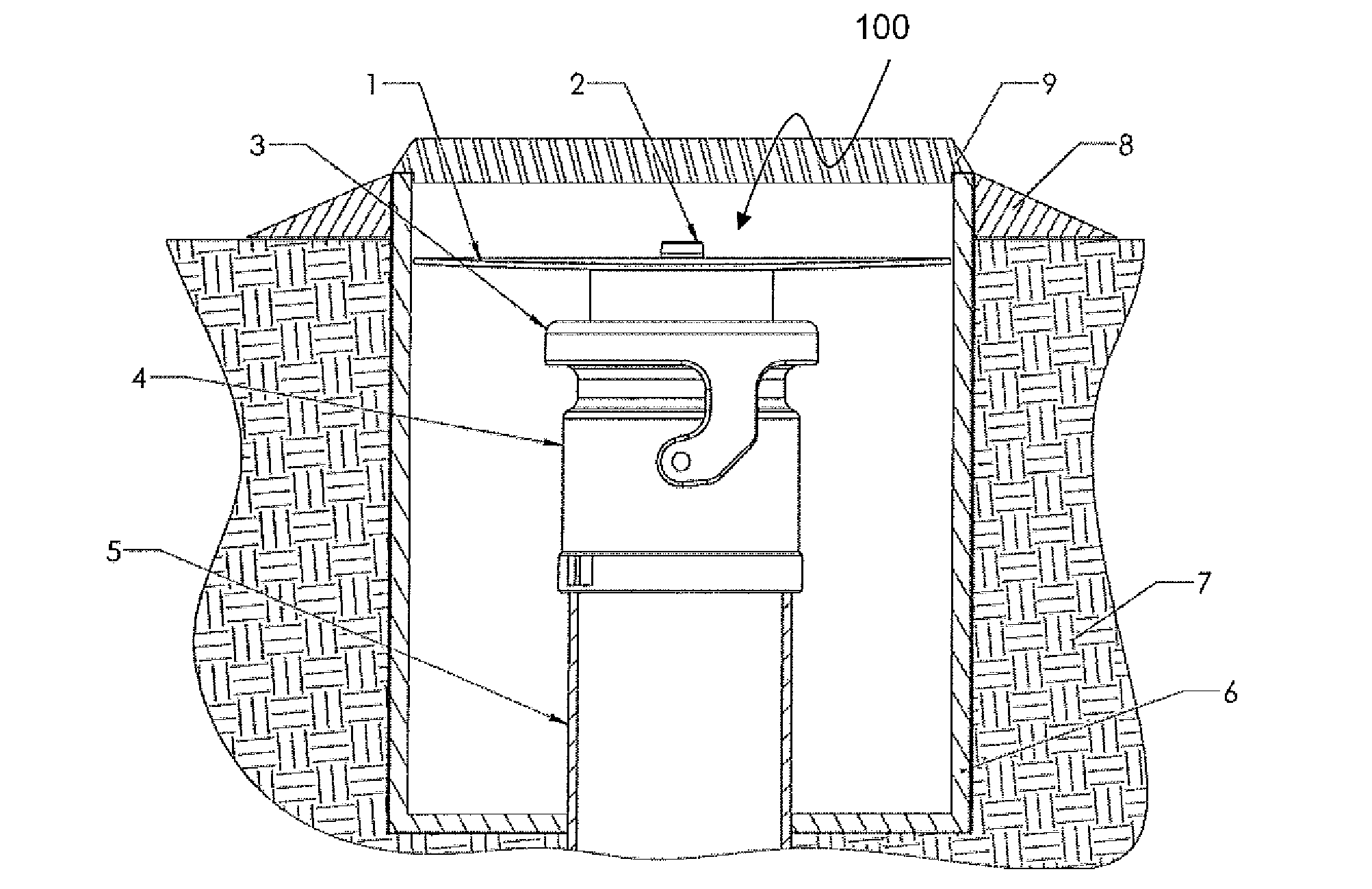

A touch-latch device for opening and holding a furniture opening component in a closed position

InactiveCN103459743AReduce the overall heightQuality improvementWing fastenersDrawersAxial displacementCoil spring

A touch-latch device used in furniture especially for initial opening of an opening furniture component, comprising a housing with an axially arranged groove, in which a push element is slidingly arranged, said element being actuated by a helical spring and controllable by a dual-position guide mechanism comprising a cam groove guide and an S-pin, wherein the device comprises a push element controlled by two dual-position guide mechanisms, wherein each cam groove guide of a dual-position guide mechanism is arranged on a lateral side of the push element and the S-pin is pivoted in the lateral wall of the groove of the housing, and that the push element is provided at its free end with a regulation plug arranged by means of a bolted joint, said plug being displaceable in axial direction, wherein the axial displacement of the regulation plug is limited by an arrester arranged therein.

Owner:TITOS DECANI LLC

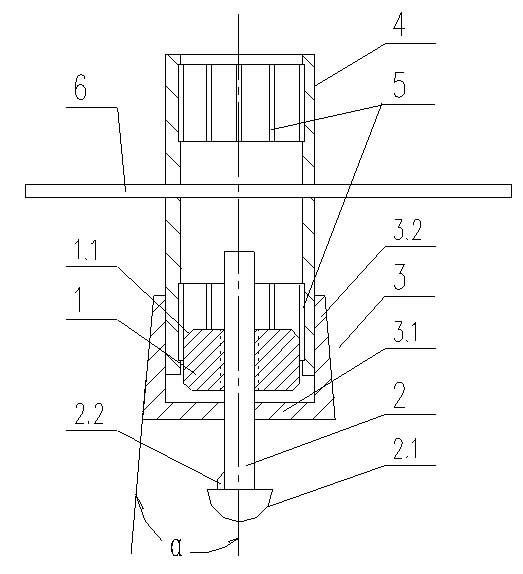

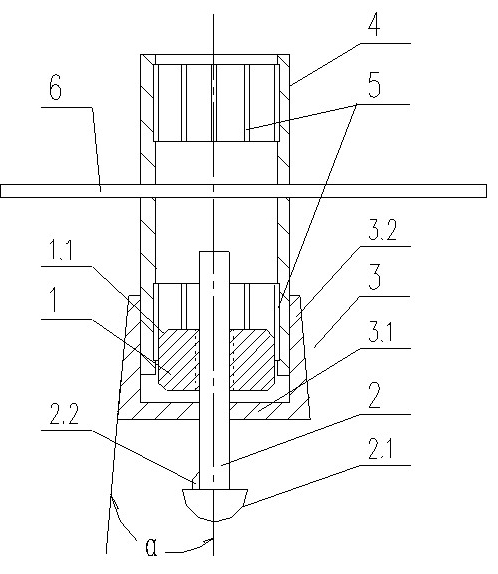

Setting device

ActiveCN101315097AAchieve fixationAvoid lossRoad vehiclesShaft for linear movementPre stressPre stressing

Owner:SRAM

Square electronic cigarette

The invention discloses a square electronic cigarette, comprising an atomizer assembly (A) and a battery assembly (B), wherein the atomizer assembly is positioned above the battery assembly, and the atomizer is fastened on an atomizing core fixing seat (6) of the atomizer through two elastic pieces (15) on the battery, so that the atomizer assembly and the battery assembly are connected together.When oil is injected into the atomizer, the upper oil inlet hole of the funnel (27) is controlled to move up and down by elastic force through pressing down the funnel (27) so as to control the opening and closing of the oil inlet hole, thereby forming a three-dimensional square shape of the electronic cigarette. The invention realizes the special shape of the square body and the purpose of controlling the opening and closing of the oil inlet hole by elastic force and preventing the heating core from being screwed out when the child locking device is used for regulating air.

Owner:刘团芳

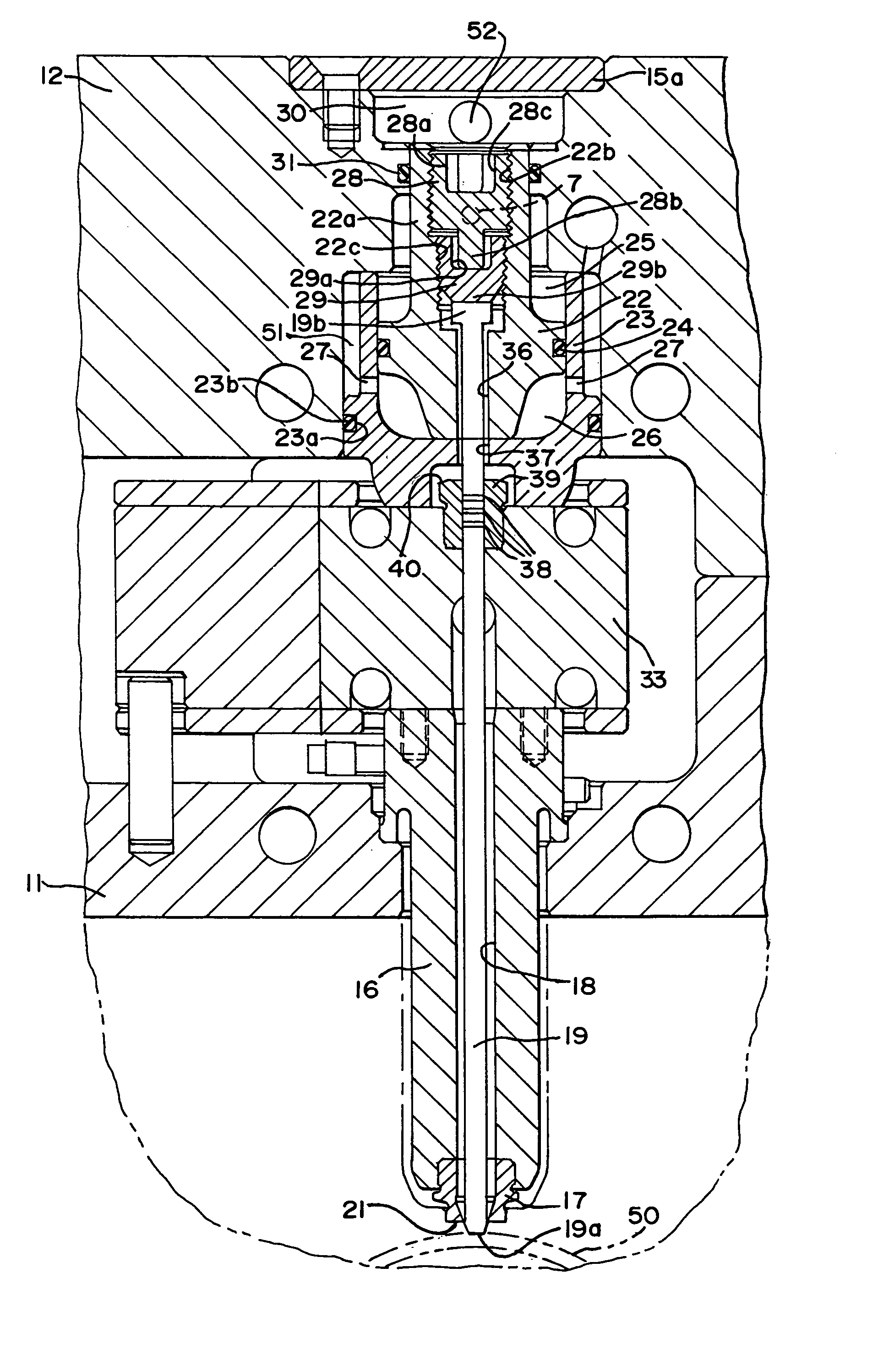

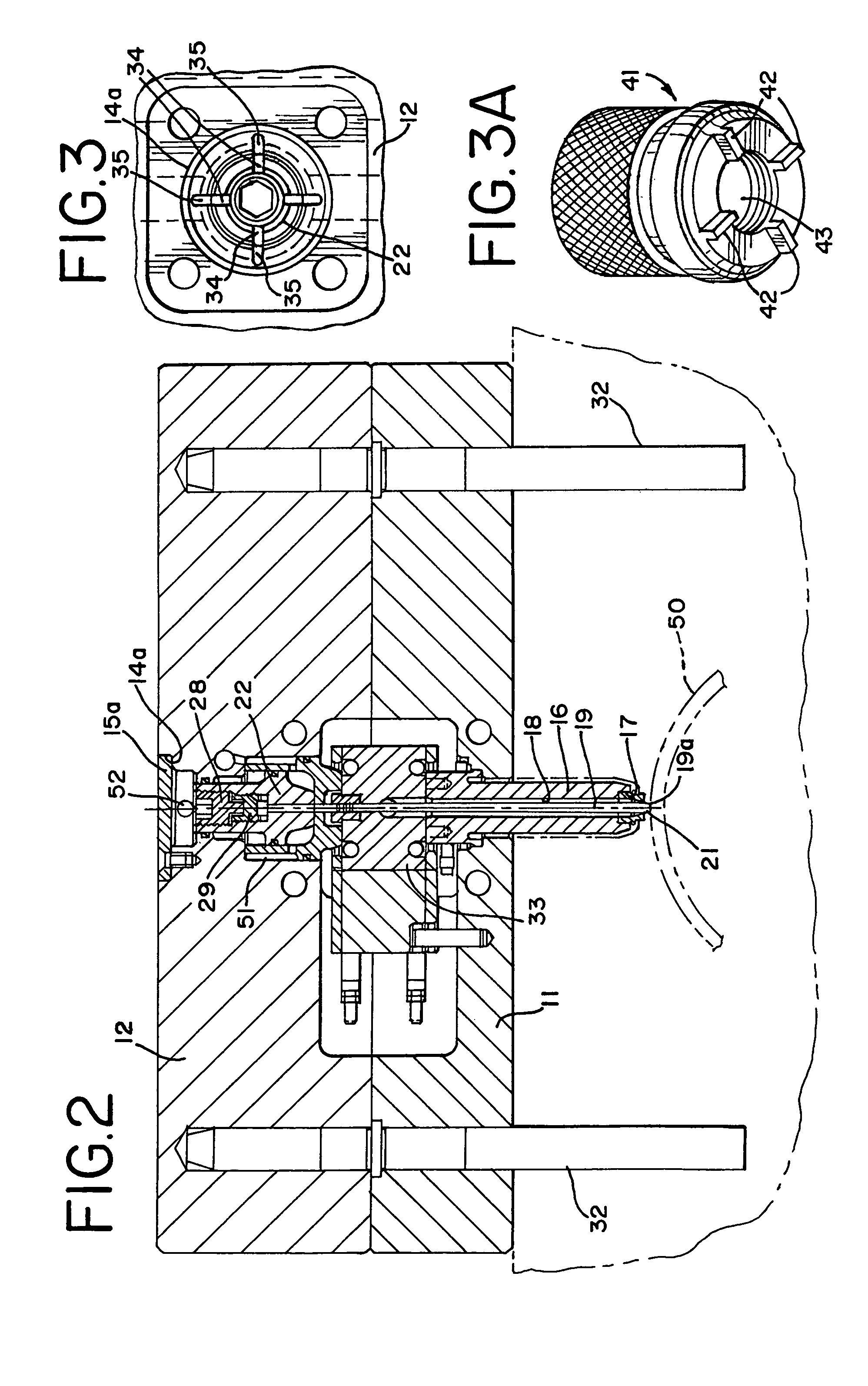

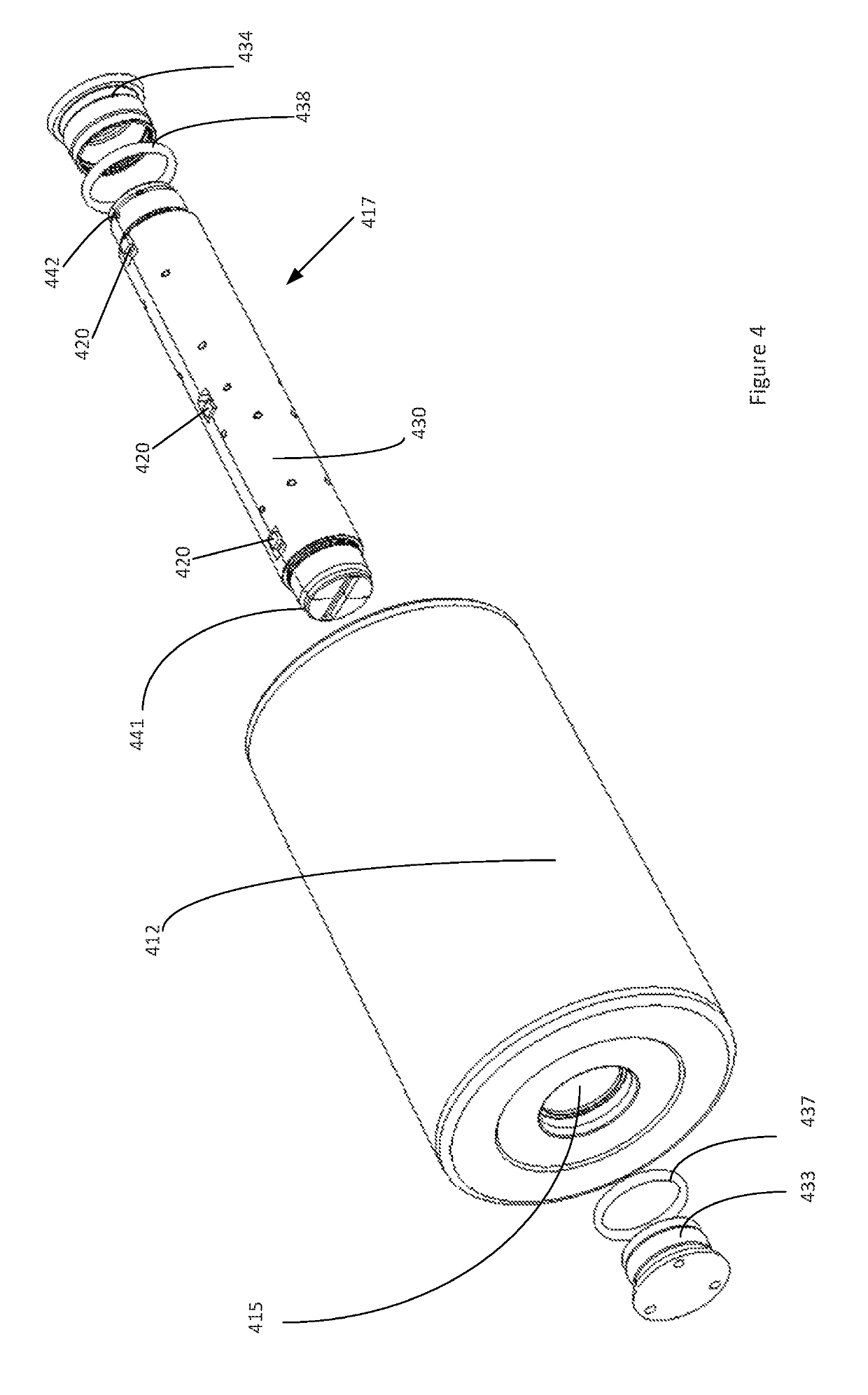

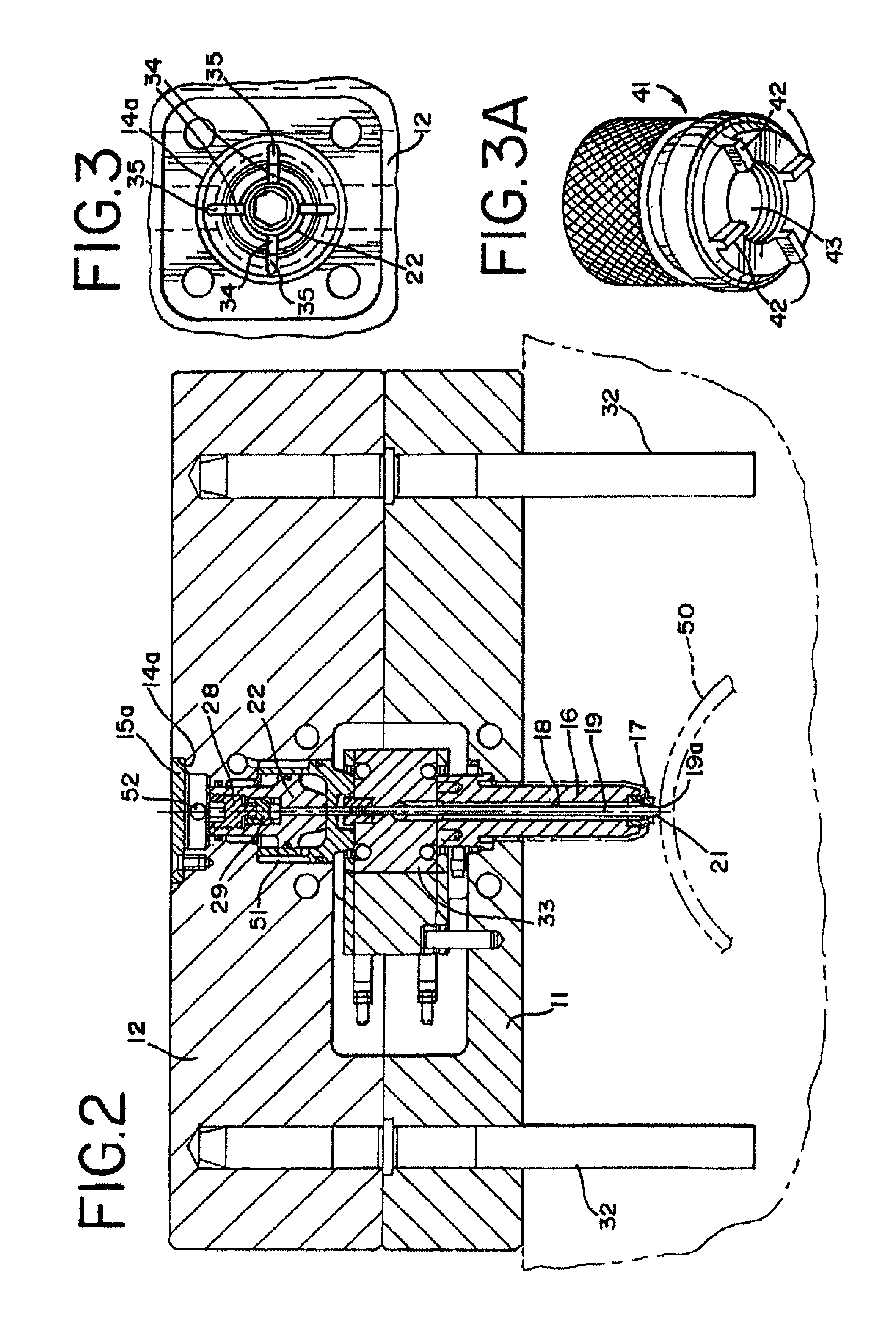

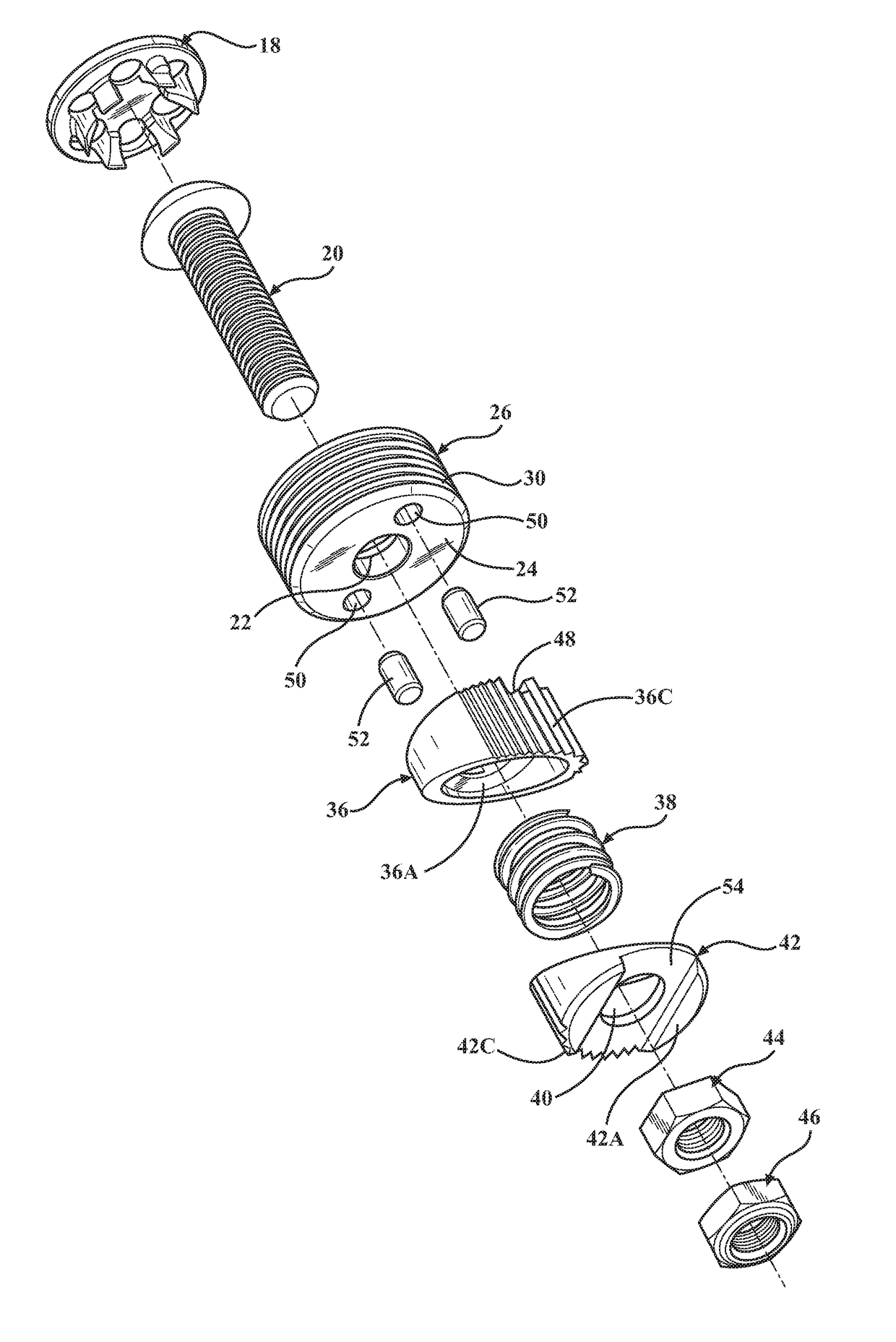

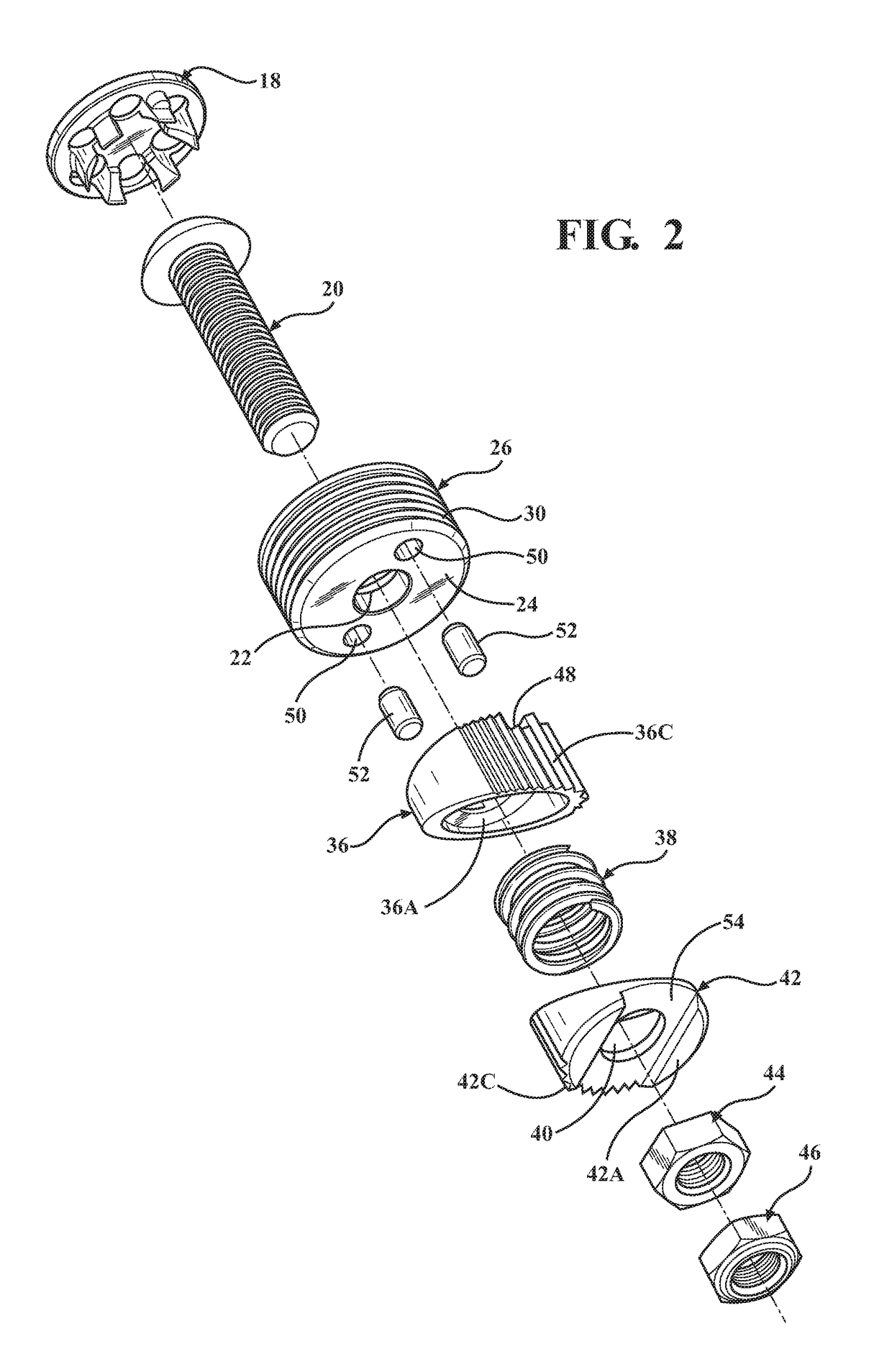

Adjustable valve pin assembly

A valve pin adjustment system is provided for use in valve gated injection molding applications which enables adjustments to the positioning of the valve pin without necessitating removal of the clamping plates and valve assembly components, including valve pins. A piston associated with the valve pin includes a cylindrical body having first and second co-axially aligned internally threaded bores of respective first and second diameters. Preferably, the threads formed in the first and second bores are of the opposite hand. First and second externally-threaded cylindrical valve pin positioning members are respectively received in the first and second bores. Each of the positioning members includes a head portion and a tip portion. The tip of the second positioning member is in contact with the head of the first positioning member to lock the first positioning member in place, and the tip of the first positioning member is in contact with a head portion on the valve pin to locate the valve pin.

Owner:TRAKAS PANOS

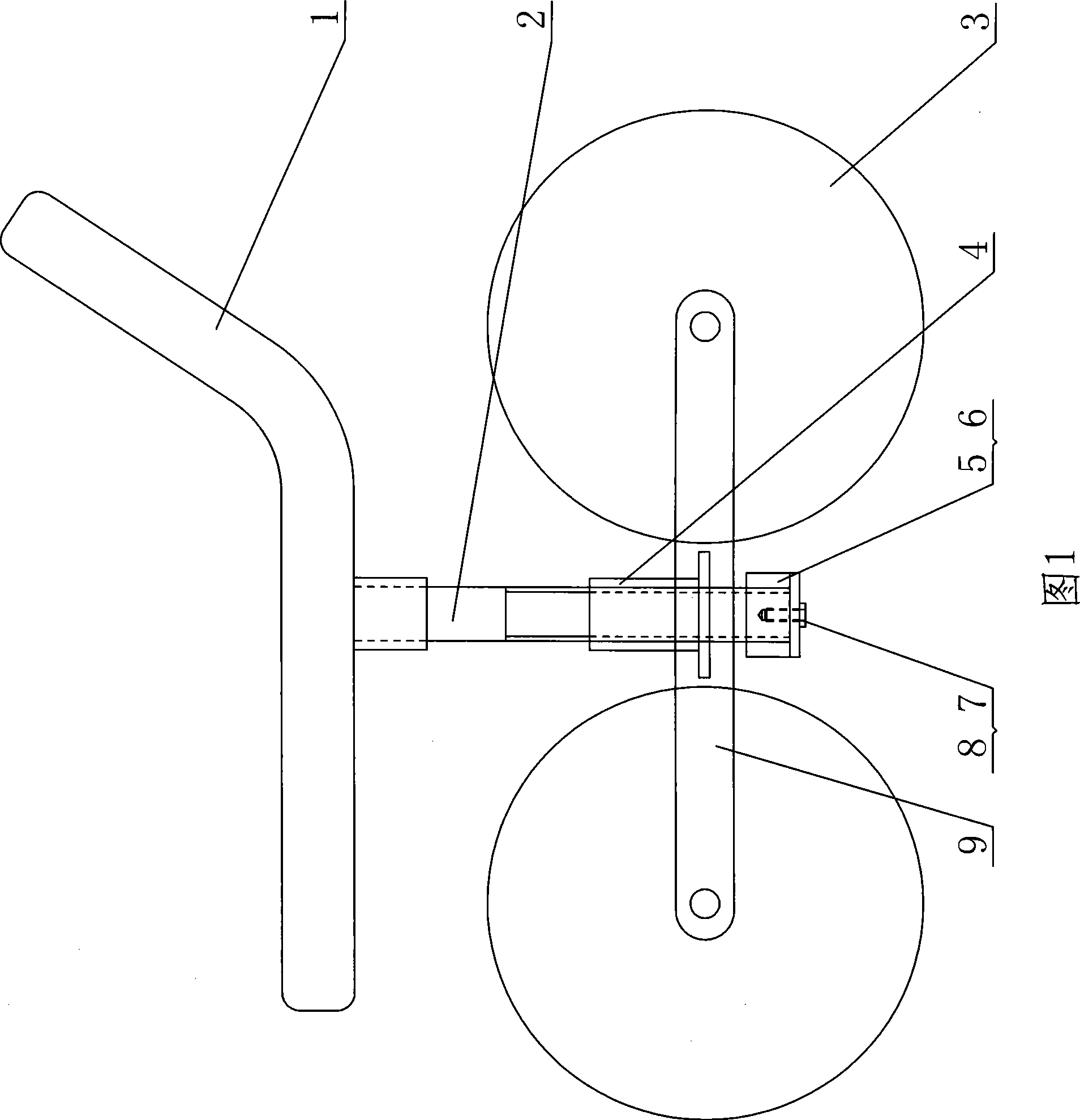

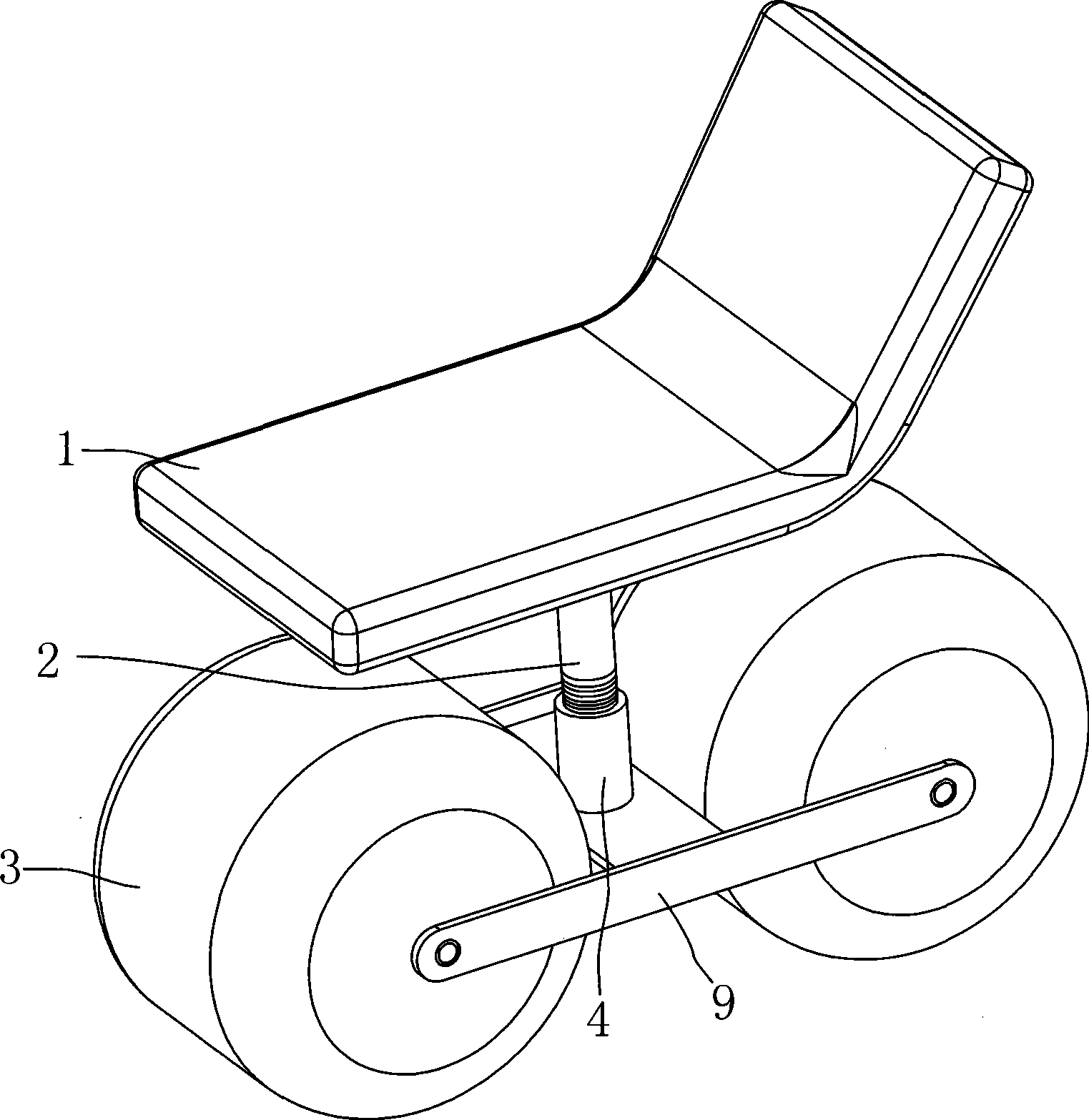

Agricultural trolley

The invention relates to a farm trolley. The farm trolley comprises a seat (1) a lifting rod (2), an 'H'-shaped chassis (9) and two trolley wheels, wherein the bottom of the seat is connected with the lifting rod, two trolley wheels are arranged on a front support and a rear support of the 'H'-shaped chassis, a threaded pipe (4) is arranged in the center of the 'H'-shaped chassis, the lower part of the lifting rod has threads matched with those of the threaded pipe arranged in the center of the 'H'-shaped chassis, a bottom end of the lifting rod is connected with a stopper, a bottom face of the lifting rod has a threaded hole (8), a screw (7) is fitted with the threaded hole to lock the stopper on the bottom face of the lifting rod and prevent the lifting rod from coming out of the threaded pipe. The farm trolley has the advantages of convenient adjustment, safe and stable use, compact structure, low cost and adaptability to various agricultural environments.

Owner:谢翠斌

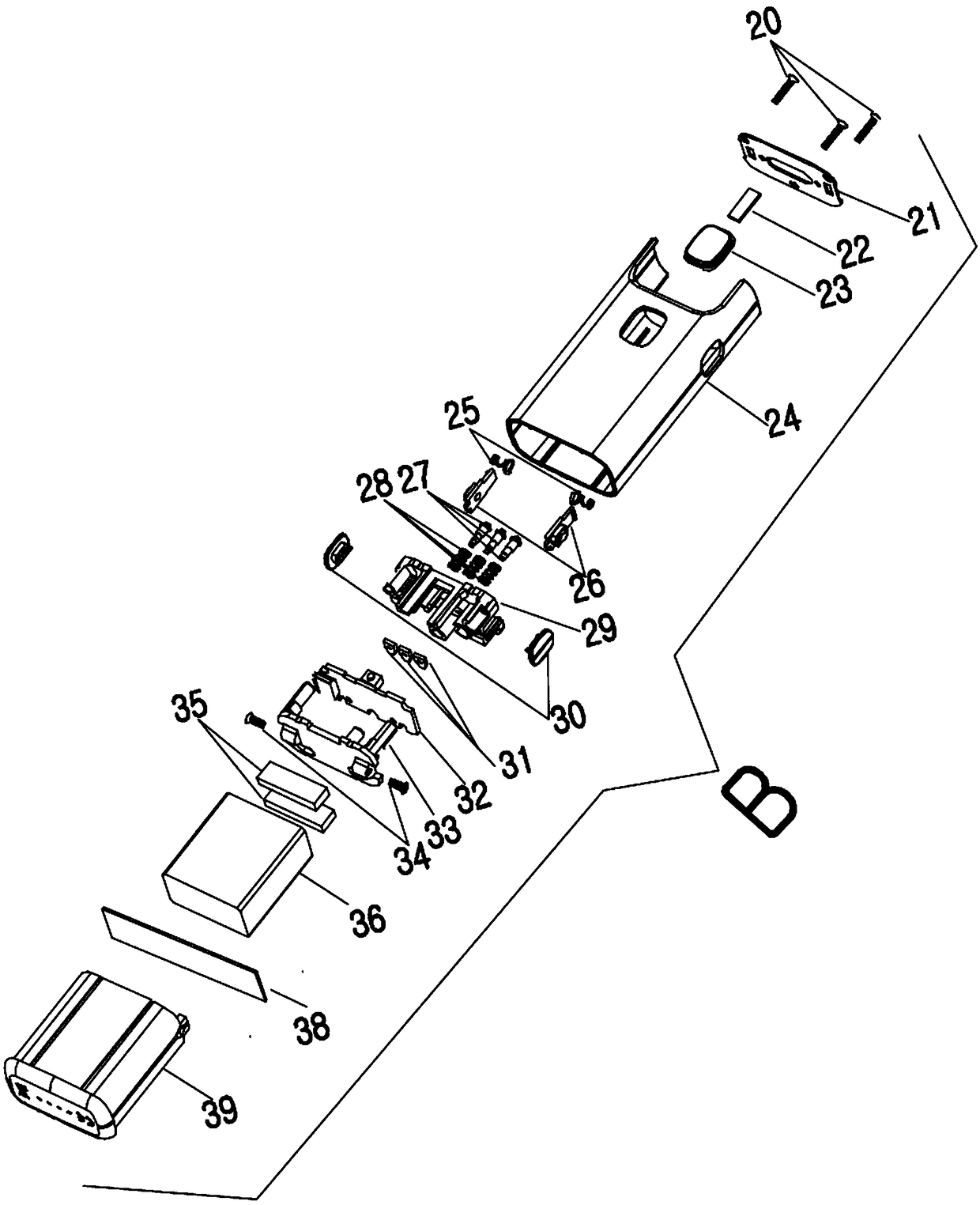

A detachable electronic cigarette of a snap-on battery atomizer

The invention discloses a detachable electronic cigarette of a snap-on battery atomizer, comprising an atomizer assembly (A) and a battery assembly (B), wherein the atomizer assembly is positioned above the battery assembly. The atomizer assembly is mounted on the battery assembly and closely connected to the battery through two bayonets (26) inside the battery. A bayonet button (30) is arranged on the battery, and the bayonet button (30) on both sides of the battery can be pressed to eject the atomizer and thereby separate the atomizer from the battery. A purpose of separating the battery andthe atomizer by pressing the button (30) on the left and right sides of the battery and controlling the opening and closing of the oil inlet hole by means of elastic force and preventing the heatingcore from being screwed out when the child lock device is used for regulating air is realized.

Owner:刘团芳

Sensorized roller

ActiveUS10371206B2Easily to dismountedPrevent unscrewingRoller bearingsBearing assemblyEngineeringMechanical engineering

Owner:AB SKF

Sample supporter for scanning electronic microscope

InactiveCN101127293AExtended service lifeHigh adjustment accuracyElectric discharge tubesMicroscopeEngineering

The utility model discloses a sample support for scanning electronic microscope, to prevent the sample support screw from turning out of the base and jamming on the platform. The sample support comprises a sample platform and a base with a plurality of threaded hole in the middle, and a screw mechanism; wherein, the screw used for adjusting height is arranged at the lower part of the screw mechanism. The screw is connected with the threaded hole; the lower part of the screw mechanism can screw into the base without exceeding the base thickness; the sample platform is connected with the top of the screw mechanism. The screw mechanism consists of two parts, the lower part is provided with the screw, and the top is provided with a replaceable module which is connected with the lower part of the screw mechanism and the sample platform respectively via a fast release device; the fast release device is of threaded screw structure; and the height of each replaceable module is determined according to the real need.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

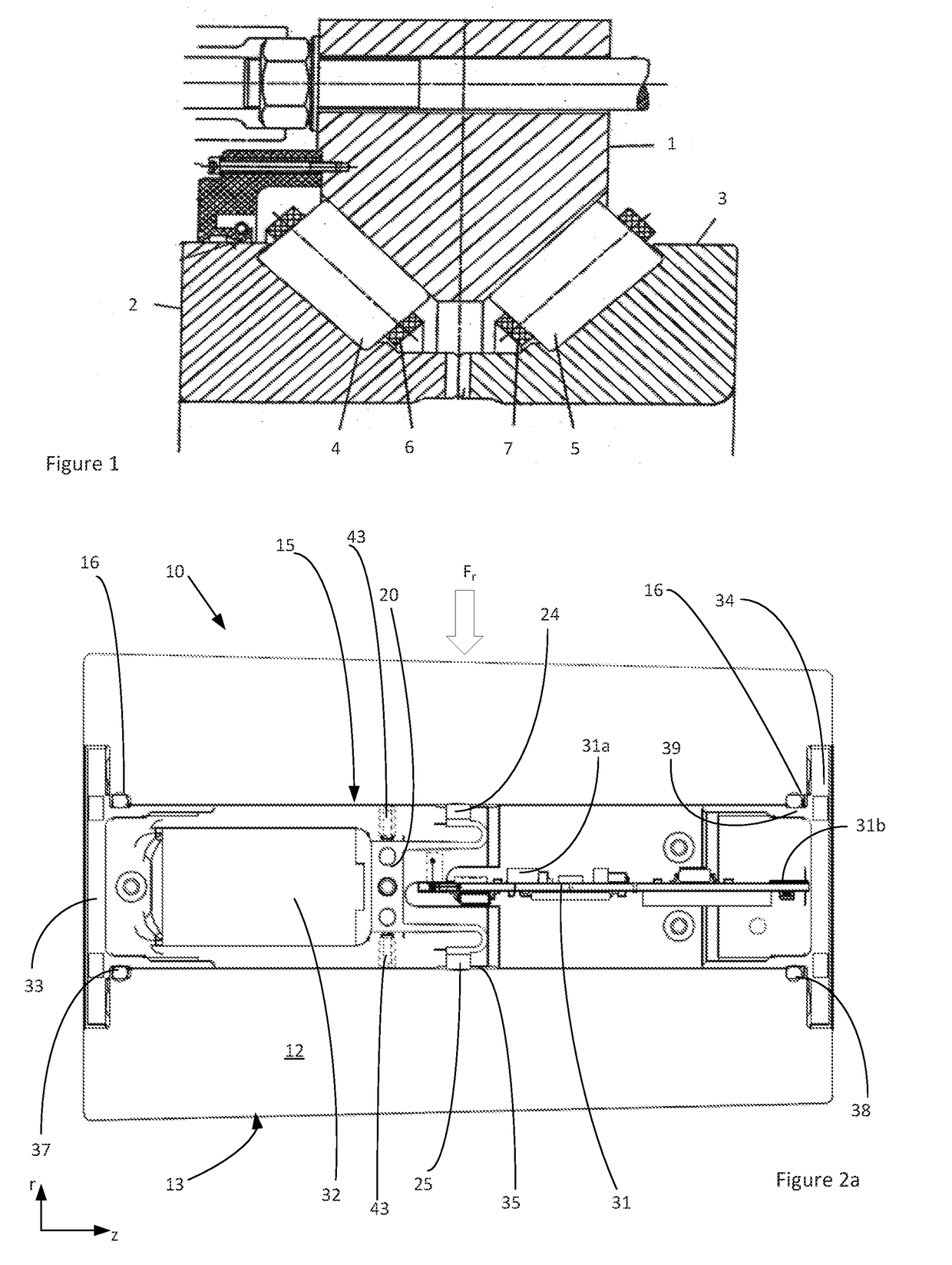

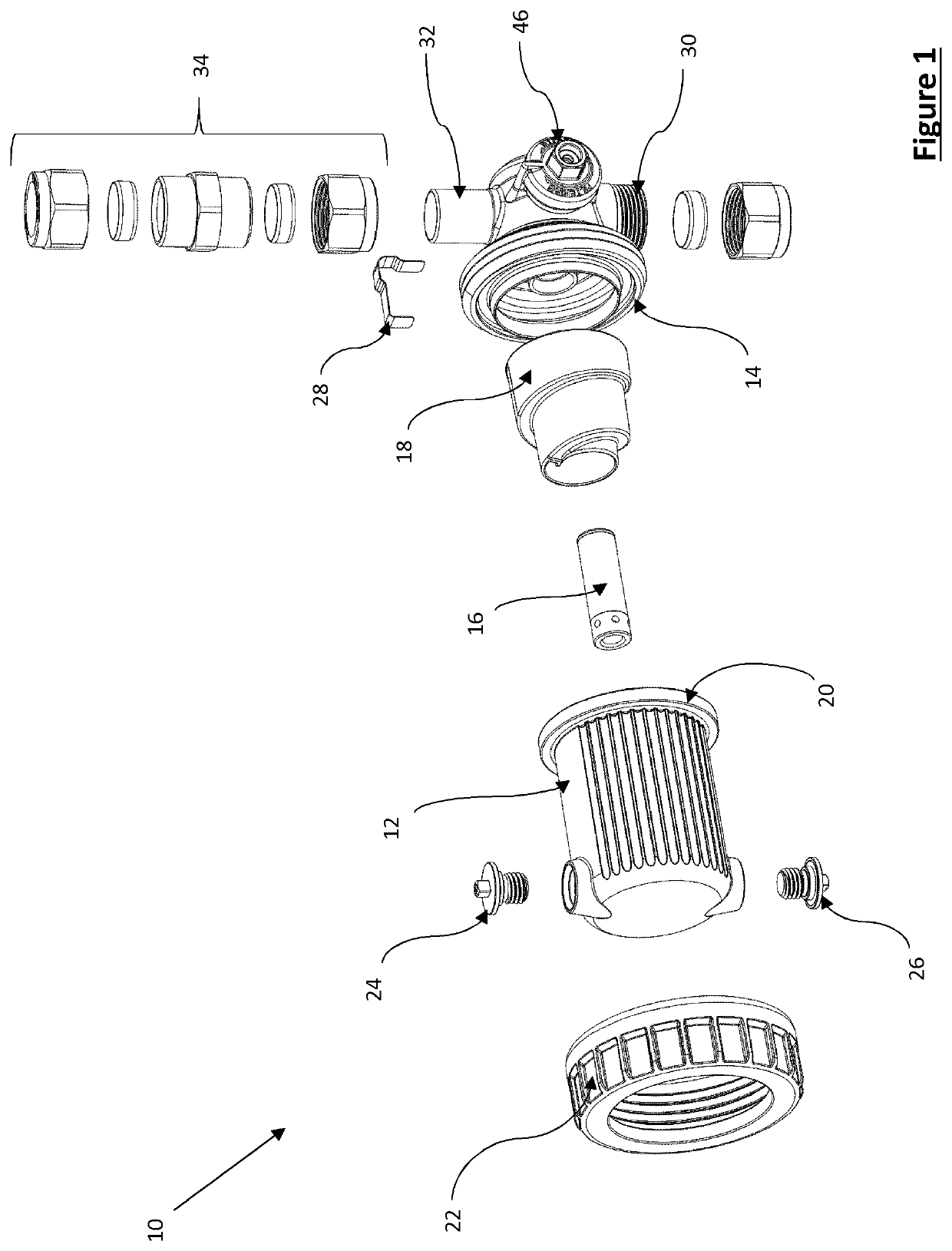

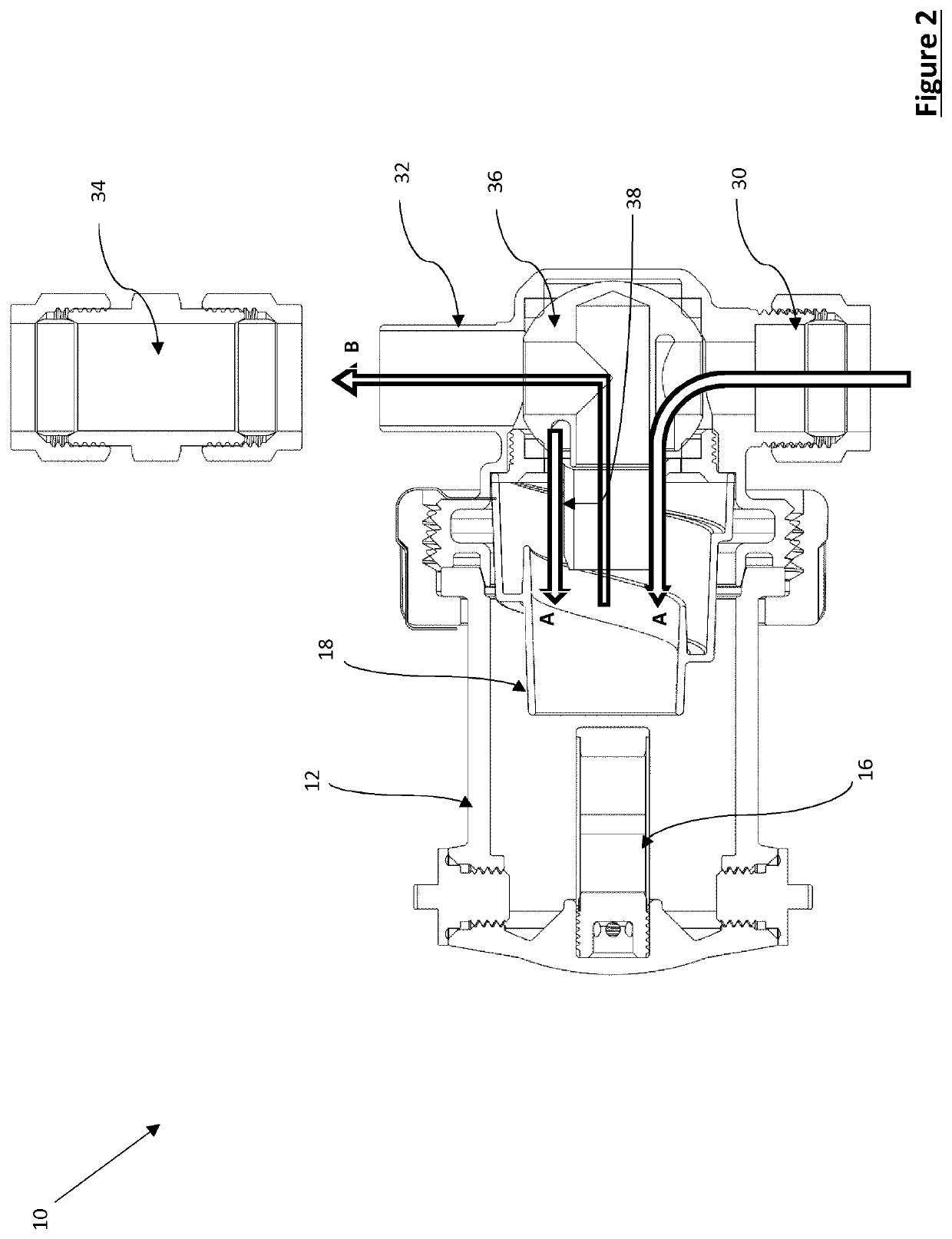

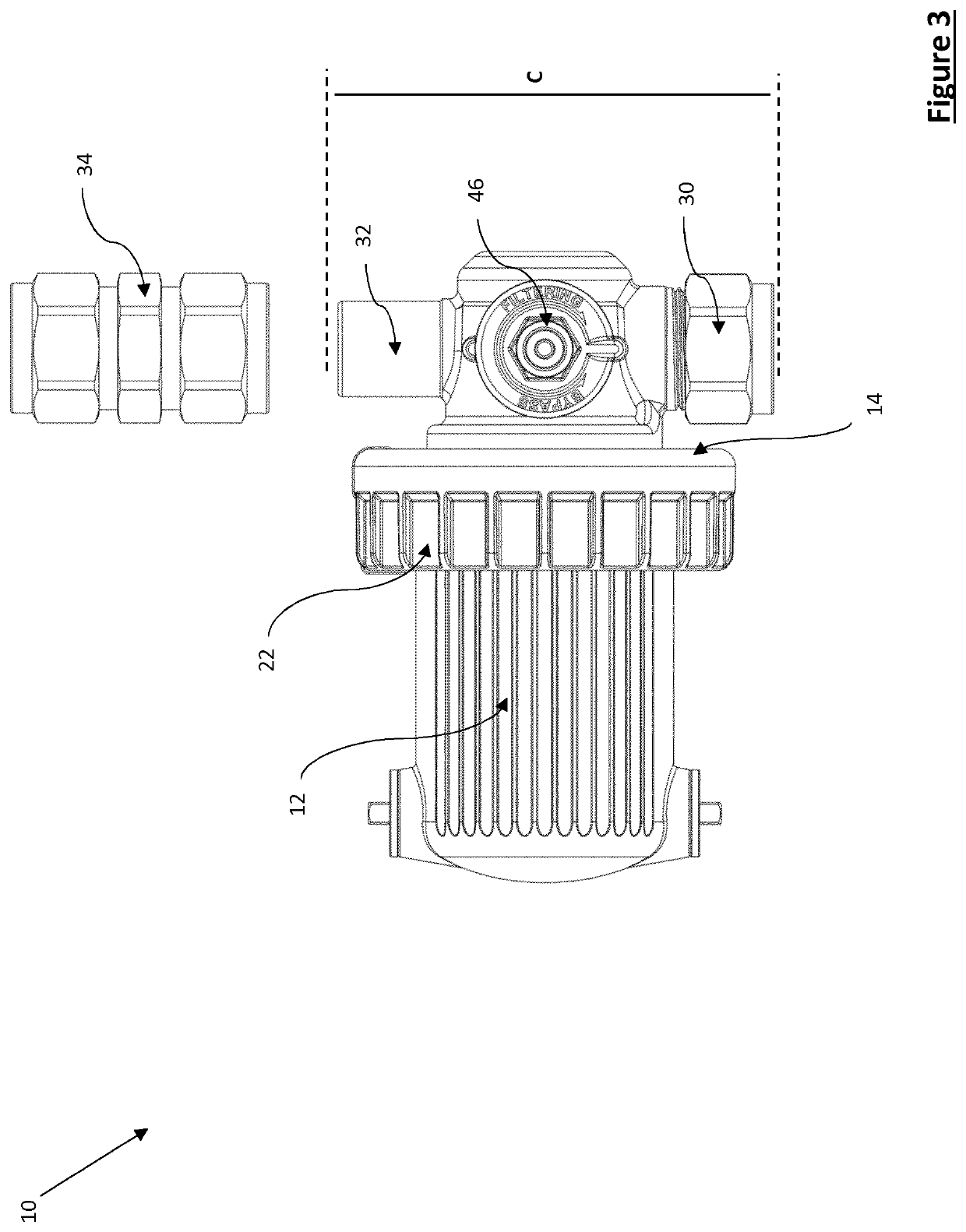

Magnetic filter for a central heating system

ActiveUS20200179943A1Resisting compressionAvoid over-tighteningLighting and heating apparatusElectrostatic separationEngineeringMechanics

A magnetic filter for a central heating system is disclosed, the filter including a separation chamber, a magnet for capturing magnetic particles within the separation chamber, an inlet for fluidly connecting to a central heating system circuit, an outlet for fluidly connecting to a central heating system circuit, and a single valve operable to select between at least two positions, the valve in a first position fluidly connecting the inlet to the separation chamber and fluidly connecting the outlet to the separation chamber and the valve in a second position isolating both the inlet and the outlet from the separation chamber.

Owner:ADEY HLDG

Underground tank lock

ActiveUS20100000999A1Prevent displacementPrevent unscrewingCapsBuilding locksEngineeringUnderground storage tank

Disclosed are apparatus and methodology for securing access to an underground device such as a storage tank. A lockable blocking plate is secured to a filler cap for an underground storage tank in a manner to inhibit access to the filler cap. The locking mechanism is configured such that the lock and blocking plate may freely rotate with respect to the filler cap. The blocking plate may include a side skirt extending to cover portions of the filler cap and, optionally, portions of a standpipe and coupling for the filler cap. Free rotation is enabled by way of an annular groove in a portion of the locking mechanism, and into which groove one or more locking portions may be inserted, or by way of a freely moving swivel boss attached to the filler cap.

Owner:COMPX INTERNATIONAL

Adjustable valve pin assembly

The valve pin adjustment system is provided for use in valve gated injection molding applications which enables adjustments to the positioning of the valve pin without necessitating removal of the clamping plates and valve assembly components, including valve pins. A piston associated with the valve pin includes a cylindrical body having first and second co-axially aligned internally threaded bores of respective first and second diameters. Preferably, the threads formed in the first and second bores are of the opposite hand. First and second externally-threaded cylindrical valve pin positioning members are respectively received in the first and second bores. Each of the positioning members includes a head portion and a tip portion. The tip of the second positioning member is in contact with the head of the first positioning member to lock the first positioning member in place, and the tip of the first positioning member is in contact with a head portion on the valve pin to locate the valve pin.

Owner:TRAKAS PANOS

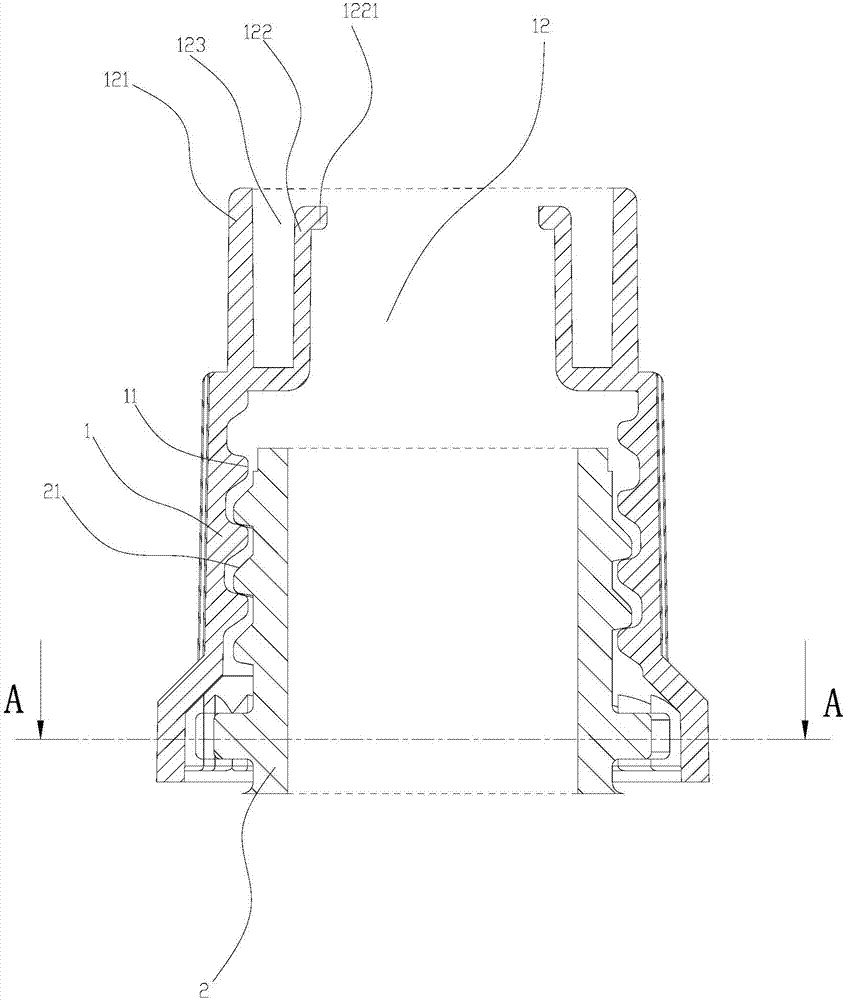

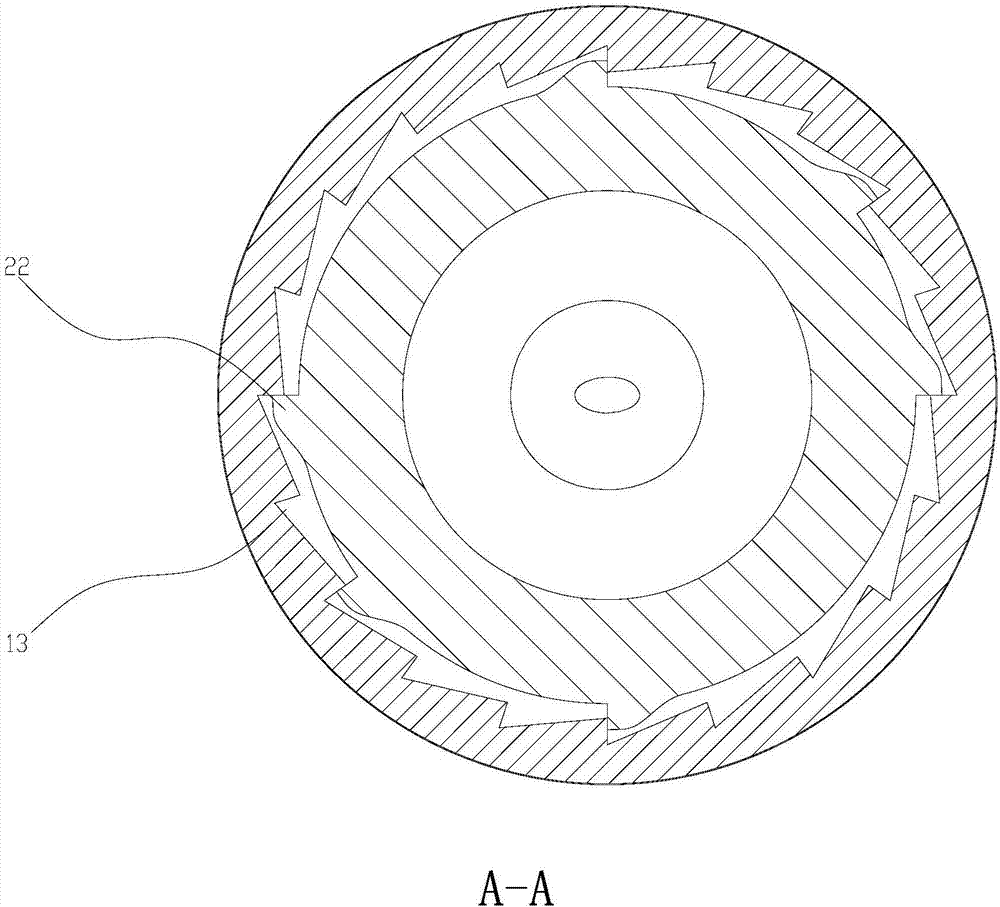

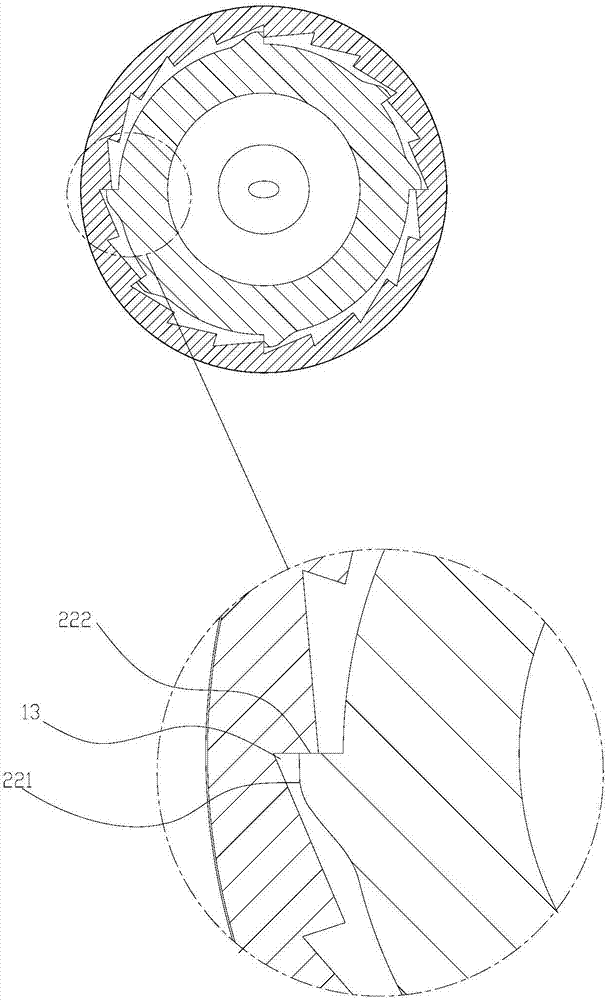

Inversion preventing structure and liquid bottle formed by same

The invention discloses an inversion preventing structure and a liquid bottle formed by the same. The inversion preventing structure comprises a fixed piece, and a movable piece rotationally connected with the outer periphery of the fixed piece; multiple projections are arranged at the outer periphery of the inner end of the fixed piece; a guide inclined surface is arranged on one sides of the projections, and a vertical or barb-shaped butting surface is arranged at the other sides of the projections; ratchets matched with the projections are arranged on the inner side of the outer end of the movable piece; the movable piece rotates; the movable piece and the fixed piece are in tight threaded connection; when the movable piece is suffered from reverse rotating force, the butting surface stops the ratchets to form inversion preventing fixed connection of the movable piece and the fixed piece; and the movable piece is a plastic piece. Through inversion preventing fixed connection of the movable piece and the fixed piece, the liquid bottle is prevented from randomly opening, the contact of liquid in the bottle with external air is prevented, and the preferable protecting effect on the liquid in the bottle is achieved; and in addition, a bottle bottom is downwards recessed below the bottle body, and a spraying pump is provided for spraying out the liquid in the bottle as far as possible, so that the liquid residue is reduced, and the waste is prevented.

Owner:SHENZHEN BONA MEDICINAL PACKAGING MATERIAL CO LTD

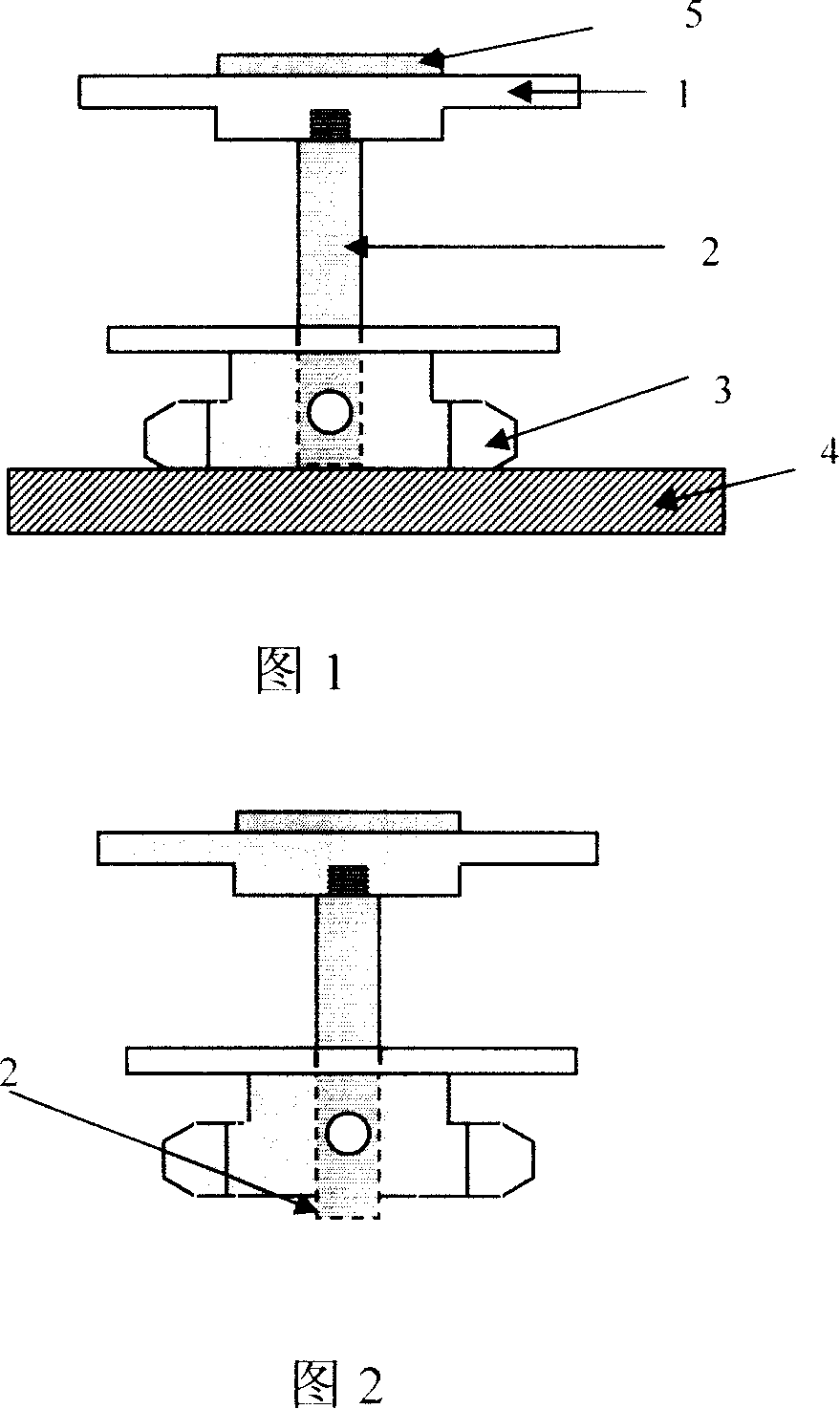

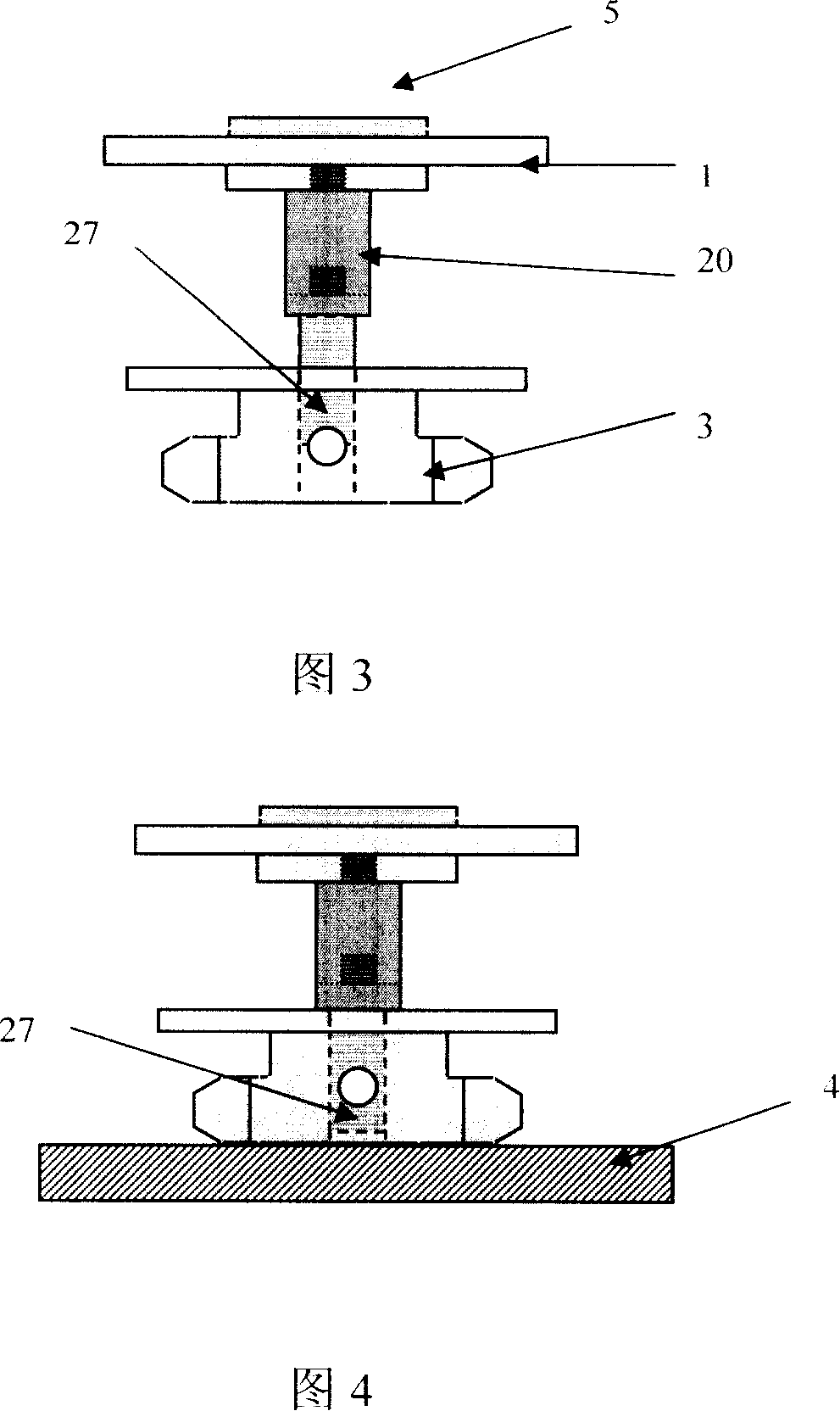

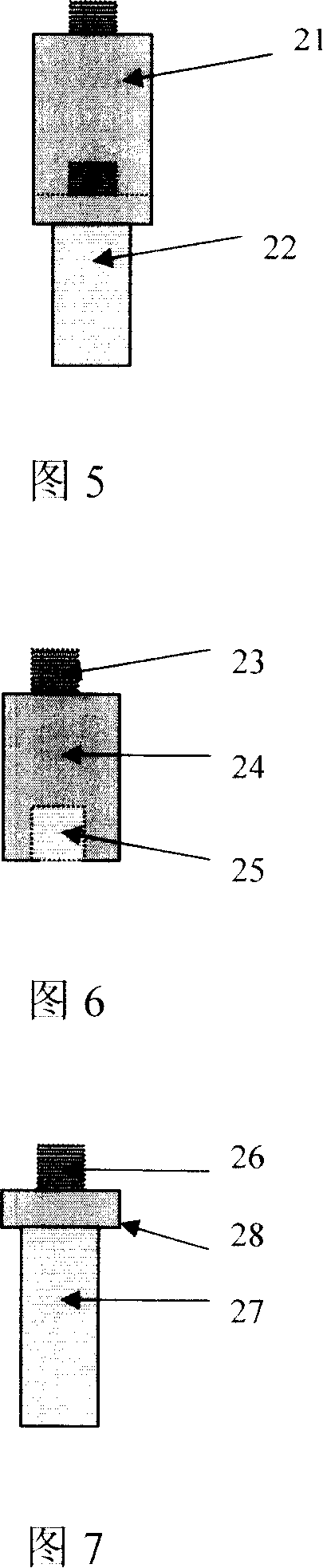

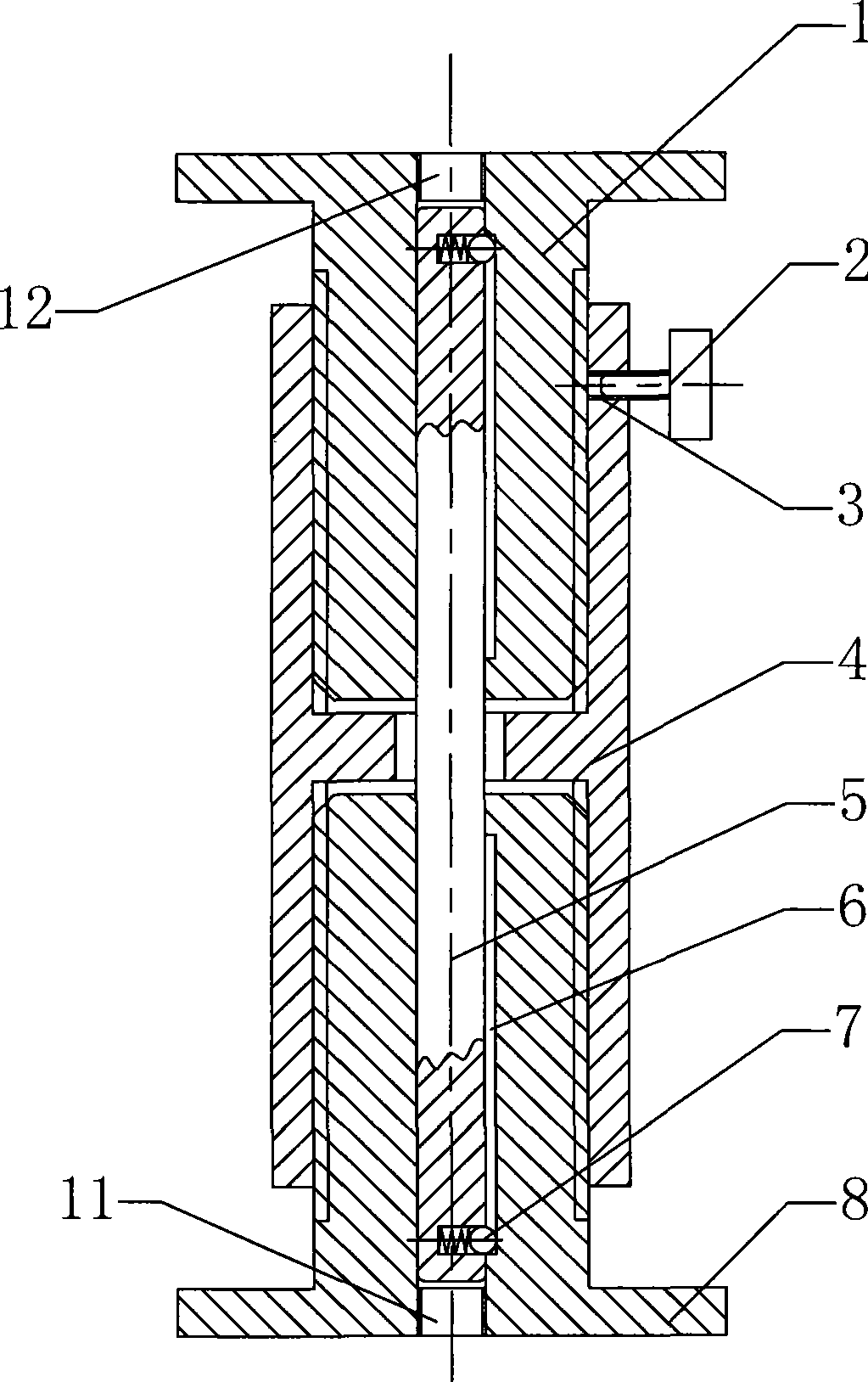

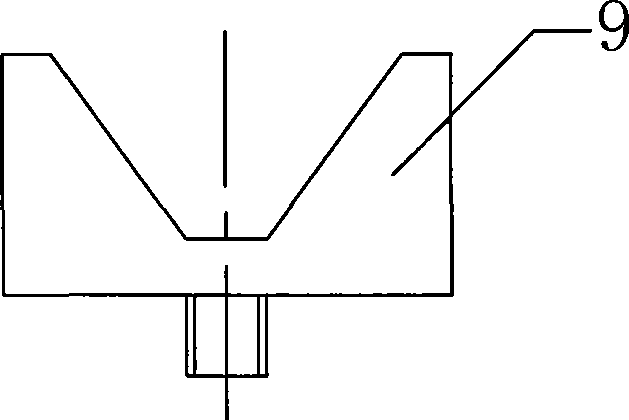

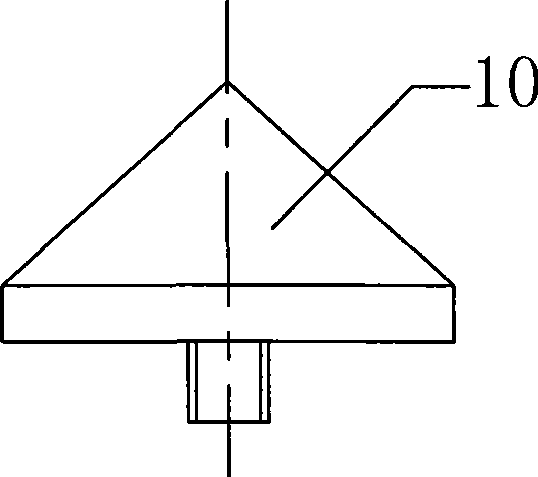

Stepless height-regulating support

ActiveCN101396794APrevent unscrewingPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention relates to a stepless height-adjusting supporter, comprising a spiral rotation body the two ends of which are respectively left-handed thread and right-handed thread; the two ends of the spiral rotation body are respectively provided with a left-handed thread cushion block and a right-handed thread cushion block which are matched with the spiral rotation body; a synchronizer which is arranged between the left-handed thread cushion block and the right-handed thread cushion block leads the left-handed thread cushion block and the right-handed thread cushion block to synchronously rotate correspondingly to the spiral rotation body. Owning to the synchronizer, the left-handed thread cushion block and the right-handed thread cushion block can be ensured to simultaneously move inwards or outwards along the axis line when the spiral rotation body rotates. According to different supporting requirements, different auxiliary transition supporters can be arranged on the left-handed thread cushion block and the right-handed thread cushion block, thus enlarging the application range of the stepless height-adjusting supporter. When the spiral structure is adopted to realize the stepless height adjustment, as the spiral structure has the characteristic that the spiral structure can only move in the axis line direction, the structure is compact and the stepless height-adjusting supporter can be convenient for use even in narrow space.

Owner:STATE GRID CORP OF CHINA +1

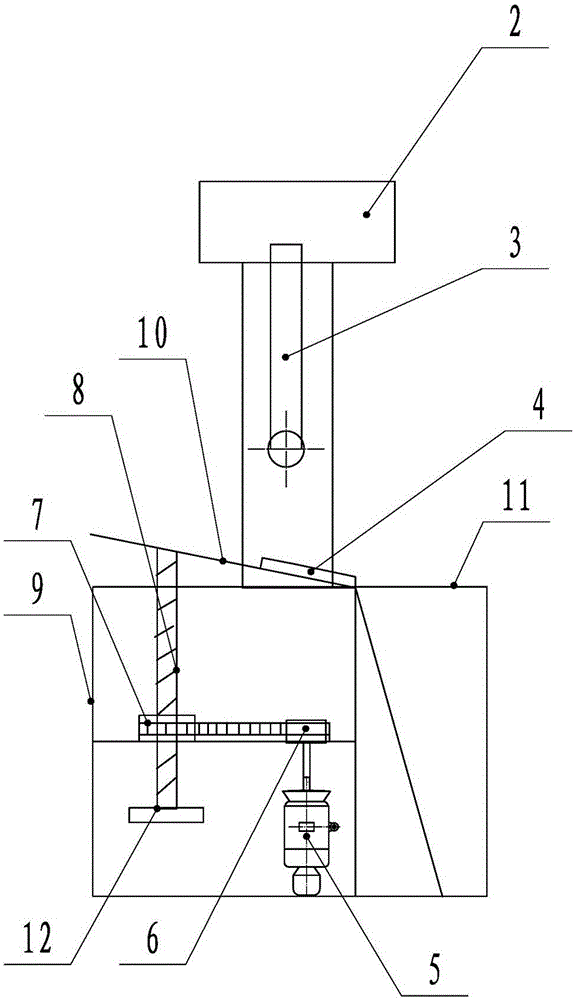

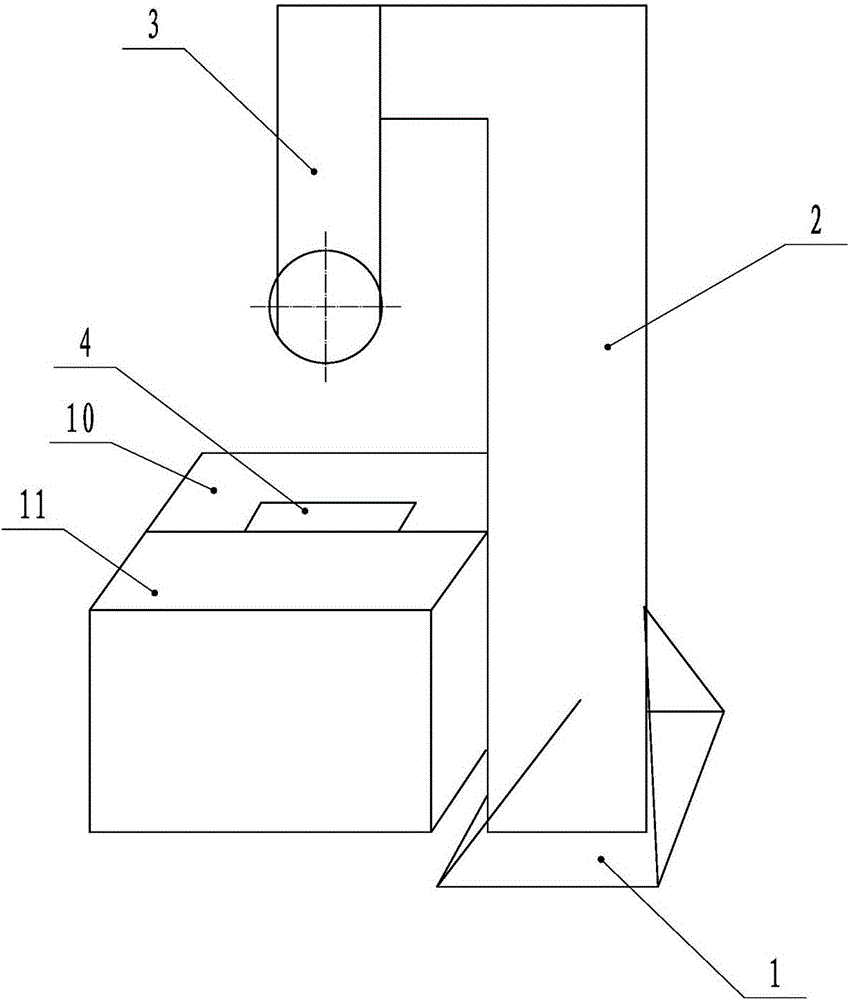

Impact testing apparatus with lifting workbench

InactiveCN106248334AThe rotation process is stableImprove work efficiencyWork benchesShock testingDrive motorImpact hammer

The invention discloses an impact test device with a lifting workbench, which includes a workbench, an impact mechanism and a lifting mechanism. The impact mechanism includes a base, a support frame, an impact hammer and a driving motor. The support frame is vertically arranged with the base, and the impact hammer is connected and supported. On the upper end of the frame, the drive motor drives the impact hammer to reciprocate up and down. The workbench is set close to the support frame and directly below the impact hammer. The workbench is a box structure surrounded by a top plate, side plates and bottom plates. Hinged, the top plate is provided with an impact pad at the position facing the impact hammer, and the lifting mechanism is located in the box of the workbench. The lifting mechanism connects the top plate to drive the top plate to rotate around the hinge point with the side plate. After the impact test is completed, the lifting mechanism drives the top plate to rise around the hinge point of the side plate, so that the sample to be impacted will slide off the top plate, and then the lifting mechanism drives the top plate to fall back to the level, and another sample to be impacted can be placed on the impact pad. This cycle realizes continuous impact test.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

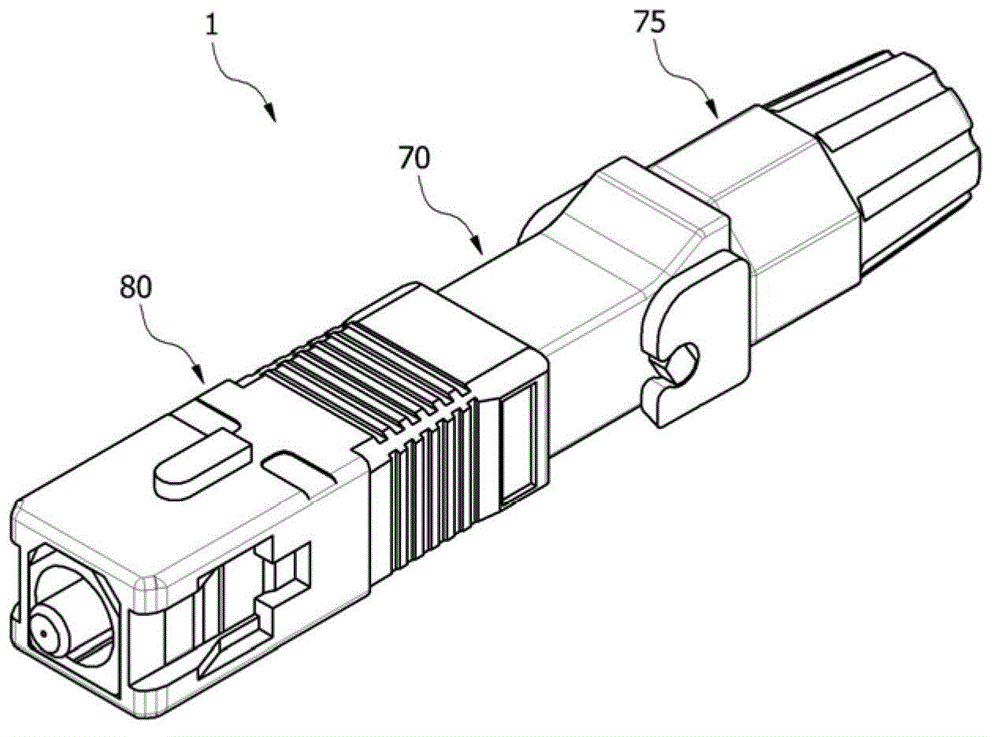

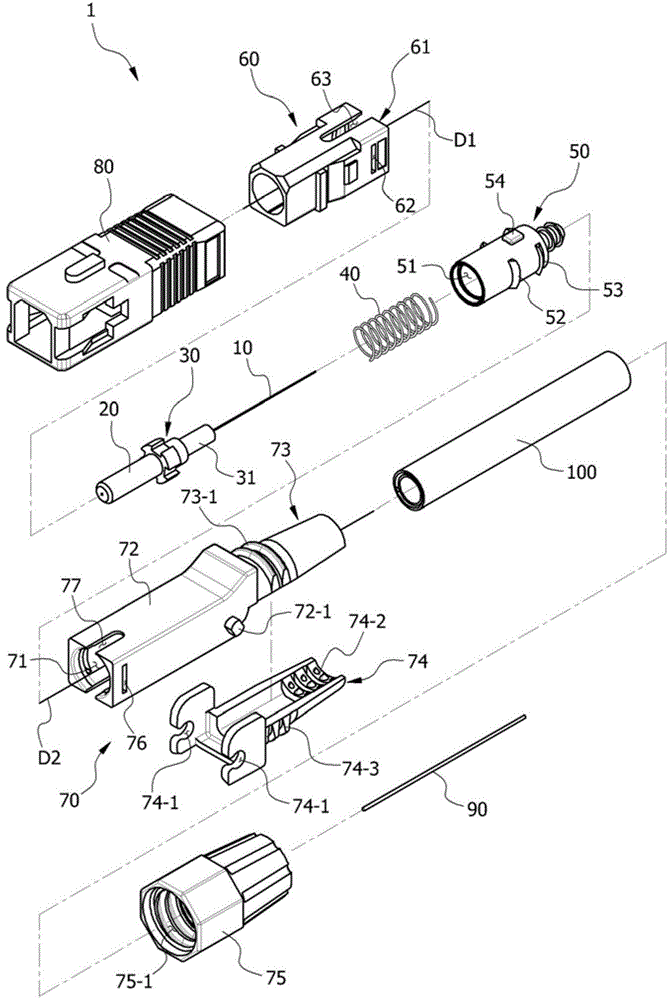

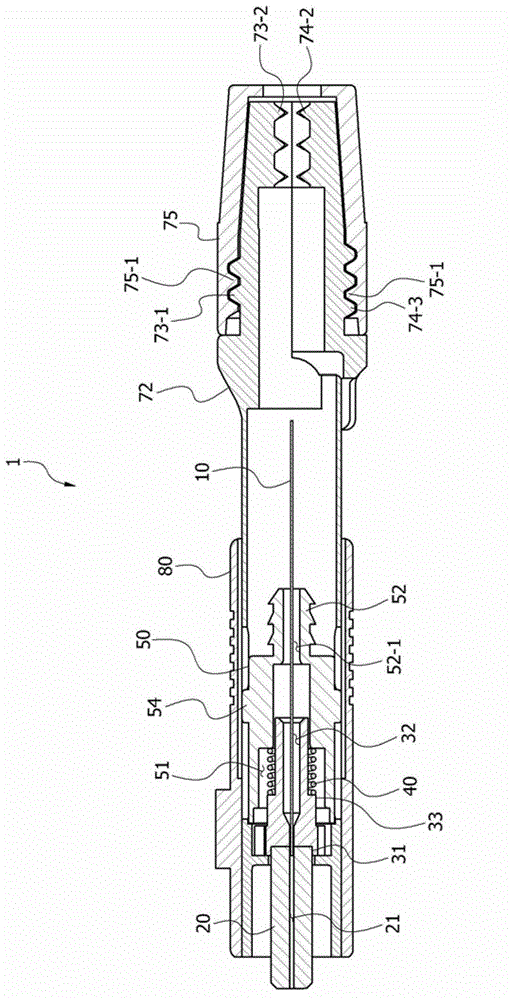

Fusion type optical connector

InactiveCN104020529APrevent rotationPrevent unscrewingCoupling light guidesFiberPlastic optical fiber

A fusion type optical connector is disclosed. The fusion type fiber connector comprises: a ferrule for supporting an optical fiber for the ferrule; a stopper for receiving the ferrule; a plug frame which is coupled to a part of the outer circumference of the stopper and has a groove formed at one end thereof; and a boot unit which supports a main optical fiber, is coupled with the other part of the outer circumference of the stopper, has a groove formed at one end thereof, and includes a first pressing part extending from the other end thereof and a second pressing part rotationally coupled with the other end thereof so as to cover the first pressing part.

Owner:A J WORLD CO LTD

High Security Flush Plug Assembly

InactiveUS20180335163A1Prevent unscrewingPrevent removalPreventing unauthorised/accidental actuationEngineeringFlange

A high security flush plug assembly includes a flush plug body threaded into a flush plug bore in a curb box flange, with a security bolt extending down through a hole in the flush plug body. The security bolt is received in a locking mechanism mounted thereto and extending below the flush plug body which when operated acts to engage the inside of the stand pipe to prevent any rotation of the flush plug body, preventing its removal until the locking mechanism is operated to release the engagement with the stand pipe.

Owner:STADLER DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com