Optical color wheel component and optical color wheel thereof

A color wheel and optical technology, used in optics, instruments, projection devices, etc., can solve the problems of wind shear noise, up to 80 to 90 decibels, etc., to reduce noise and improve transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

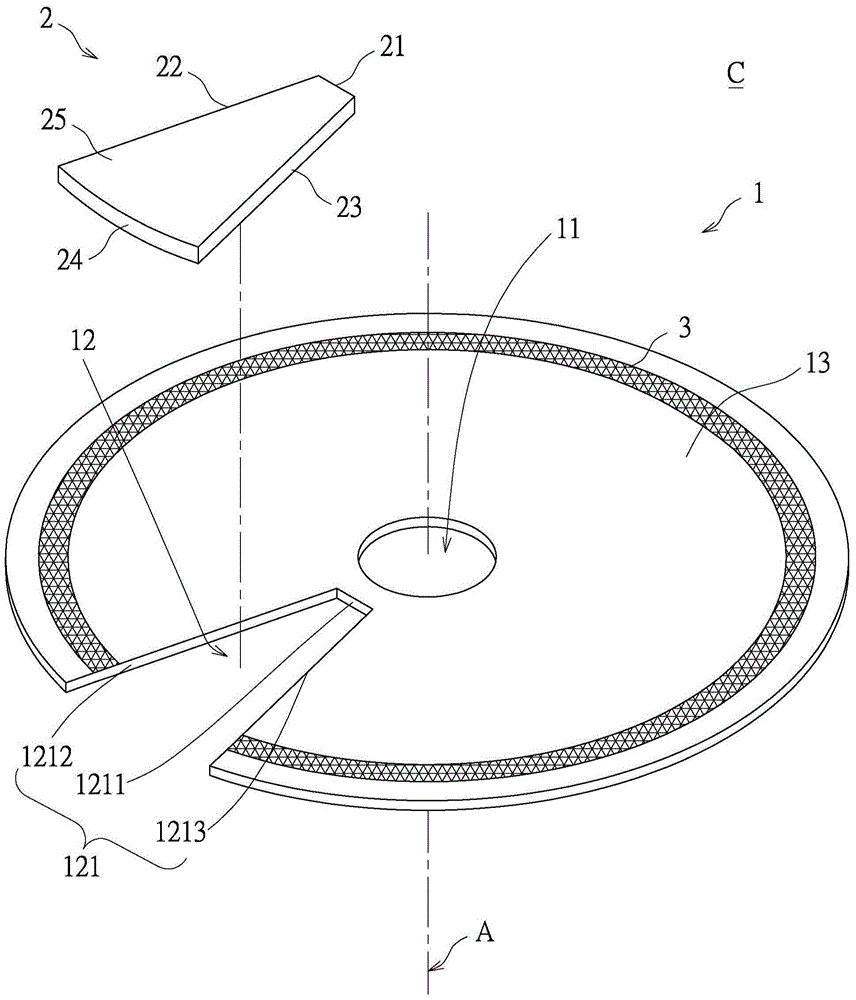

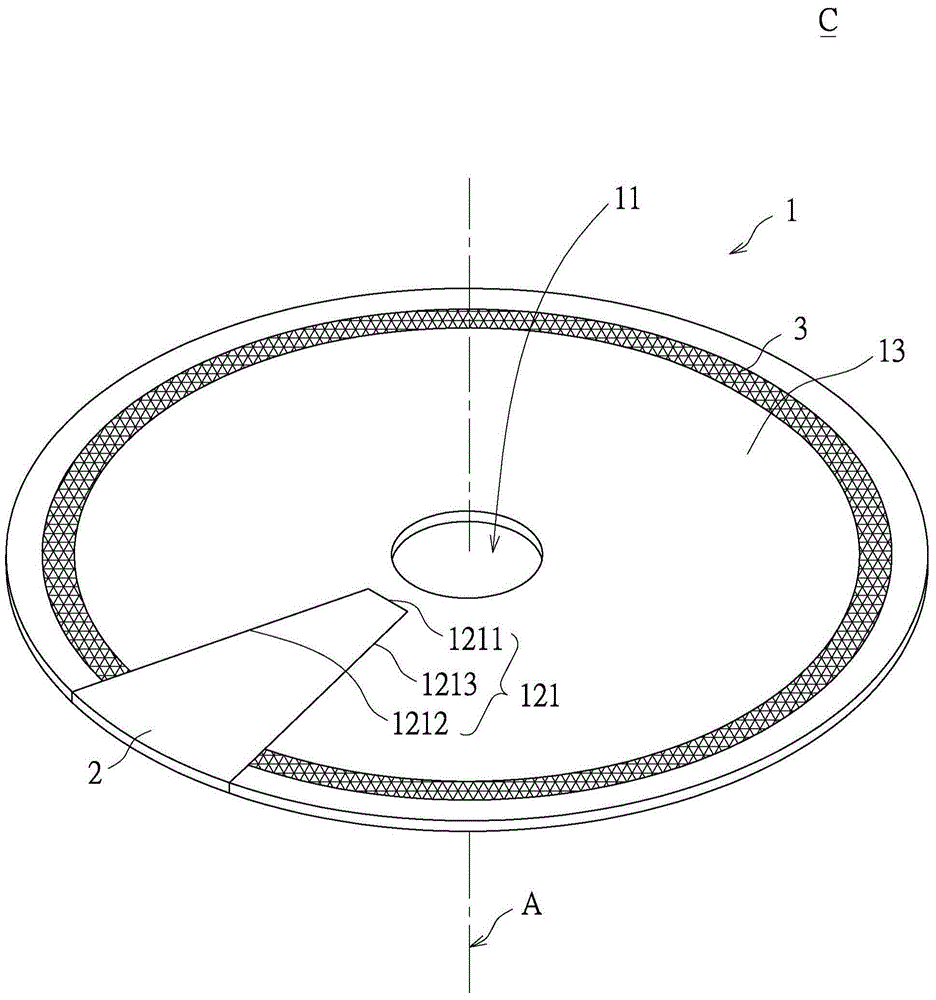

[0050] First, see Figure 1A to Figure 1B as shown, Figure 1A It is a three-dimensional exploded schematic view of the optical color wheel assembly and its optical color wheel according to the first embodiment of the present invention, Figure 1B It is a three-dimensional combined schematic view of the optical color wheel assembly and its optical color wheel according to the first embodiment of the present invention.

[0051] The first embodiment of the present invention provides an optical color wheel C, which includes a base unit 1, a light-transmitting unit 2, and a fluorescent unit 3. The base unit 1 includes a central hole 11, a central axis A, a transparent The light area 12 and a reflection area 13, the central hole 11 is arranged on the base unit 1, and is arranged along the central axis A, and the light transmission area 12 and the reflection area 13 are connected to each other to surround the central axis A, wherein the light transmission area 12 There is a through...

no. 2 example

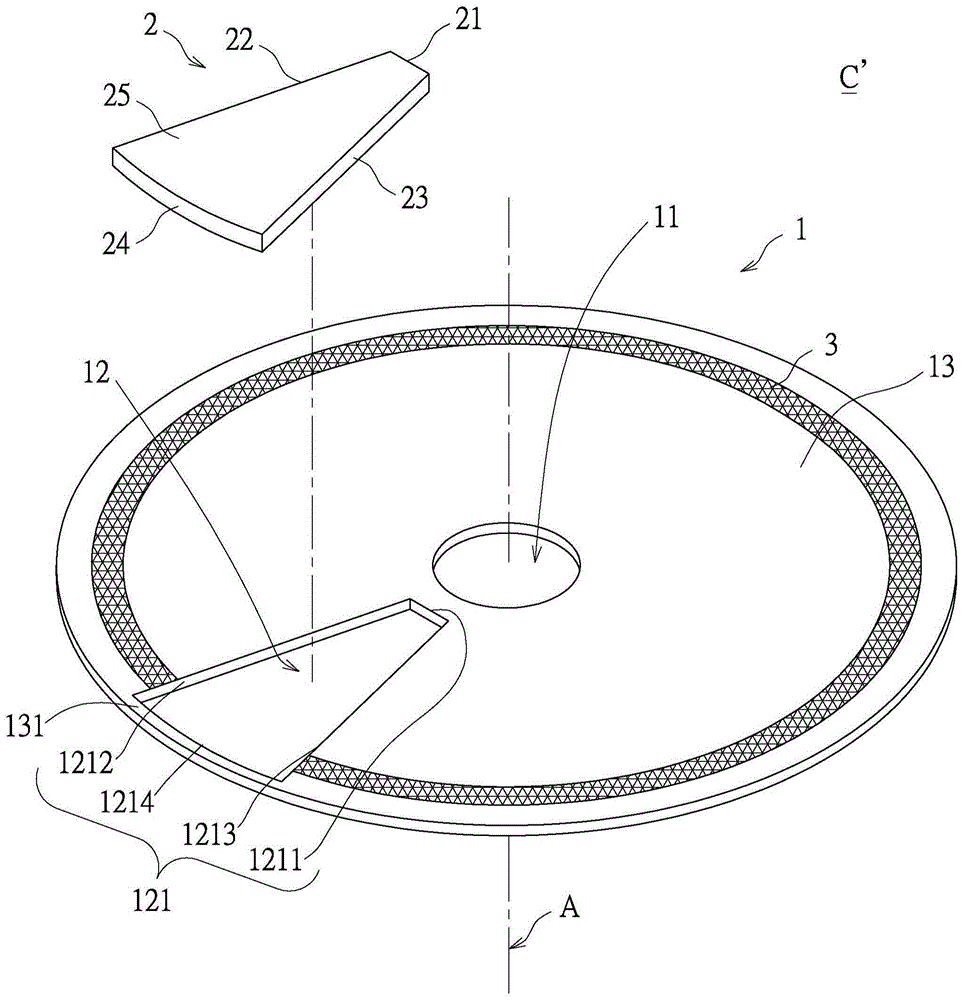

[0057] First, see Figure 2A to Figure 2B as shown, Figure 2A It is a perspective exploded view of the optical color wheel assembly and its optical color wheel according to the second embodiment of the present invention, Figure 2B It is a three-dimensional schematic diagram of the optical color wheel assembly and its optical color wheel according to the second embodiment of the present invention. Depend on Figure 1A and Figure 2A From the comparison, it can be seen that the biggest difference between the second embodiment and the first embodiment is that: the base unit 1 of the second embodiment further has a side end 131 . Through the design of the side end portion 131 , the light-transmitting unit can be tightly fitted in the through hole 121 more firmly.

[0058] Specifically, the second embodiment of the present invention provides an optical color wheel C', which includes a base unit 1, a light-transmitting unit 2, and a fluorescent unit 3. The base unit 1 includes ...

no. 3 example

[0067] First, see Figure 3A to Figure 3B as shown, Figure 3A It is a three-dimensional combination schematic diagram of the optical color wheel assembly and its optical color wheel according to the third embodiment of the present invention, Figure 3B It is a three-dimensional exploded schematic diagram of the optical color wheel assembly and the optical color wheel according to the third embodiment of the present invention. Depend on Figure 3A and Figure 2A It can be seen from the comparison that the biggest difference between the third embodiment and the second embodiment is that the optical color wheel (C', C") provided by the second embodiment of the present invention can be applied to the optical color wheel assembly of the projector On S. The third embodiment of the present invention provides an optical color wheel assembly S, which includes an optical color wheel C″, a driving element 4 and a spacer unit 5 .

[0068] As above, please also refer to Figure 2C As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com