Sample supporter for scanning electronic microscope

A technology for electron microscopes and sample holders, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as parts falling in, not easy to find, and hidden dangers in the safe operation of scanning electron microscopes, so as to improve the adjustment accuracy and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

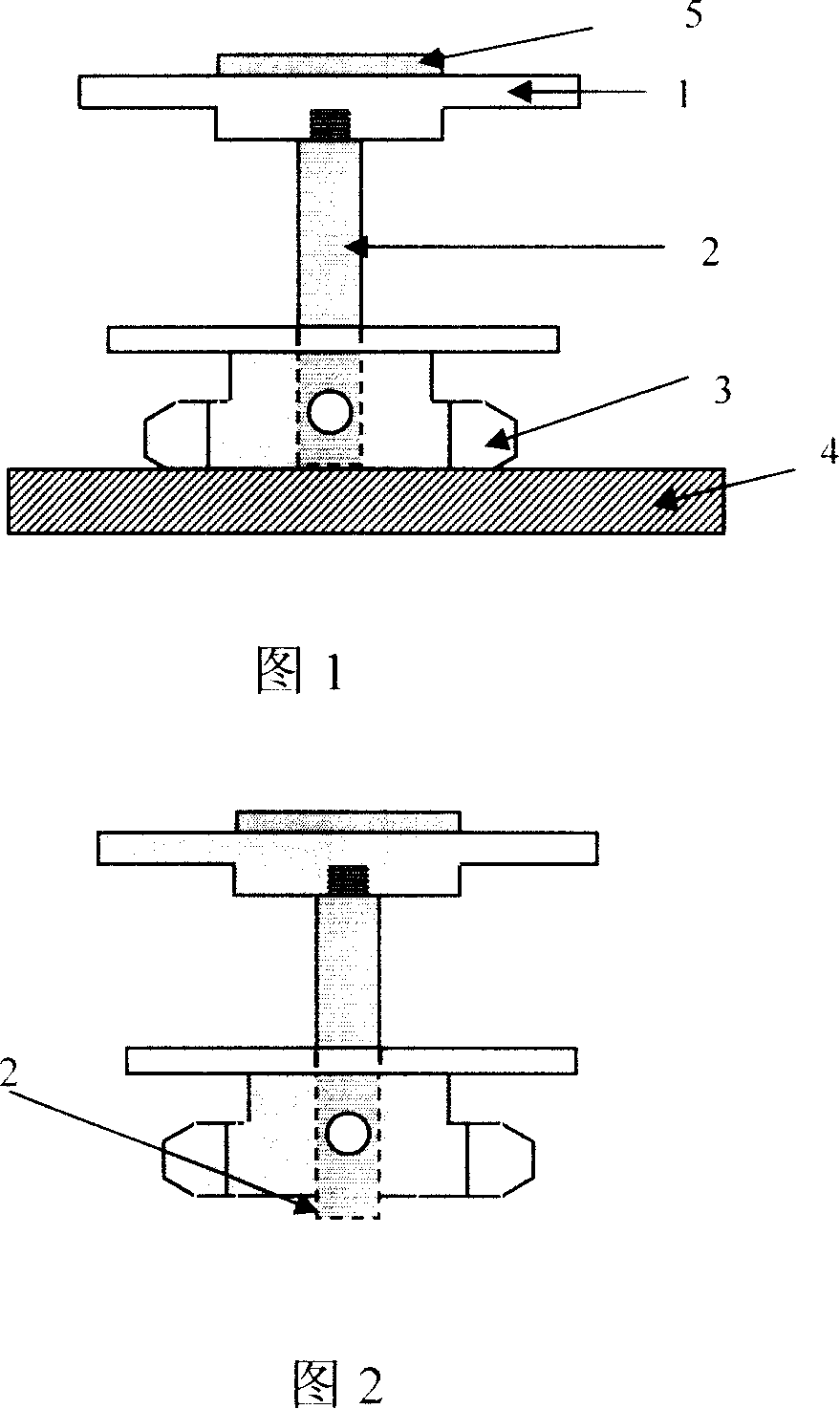

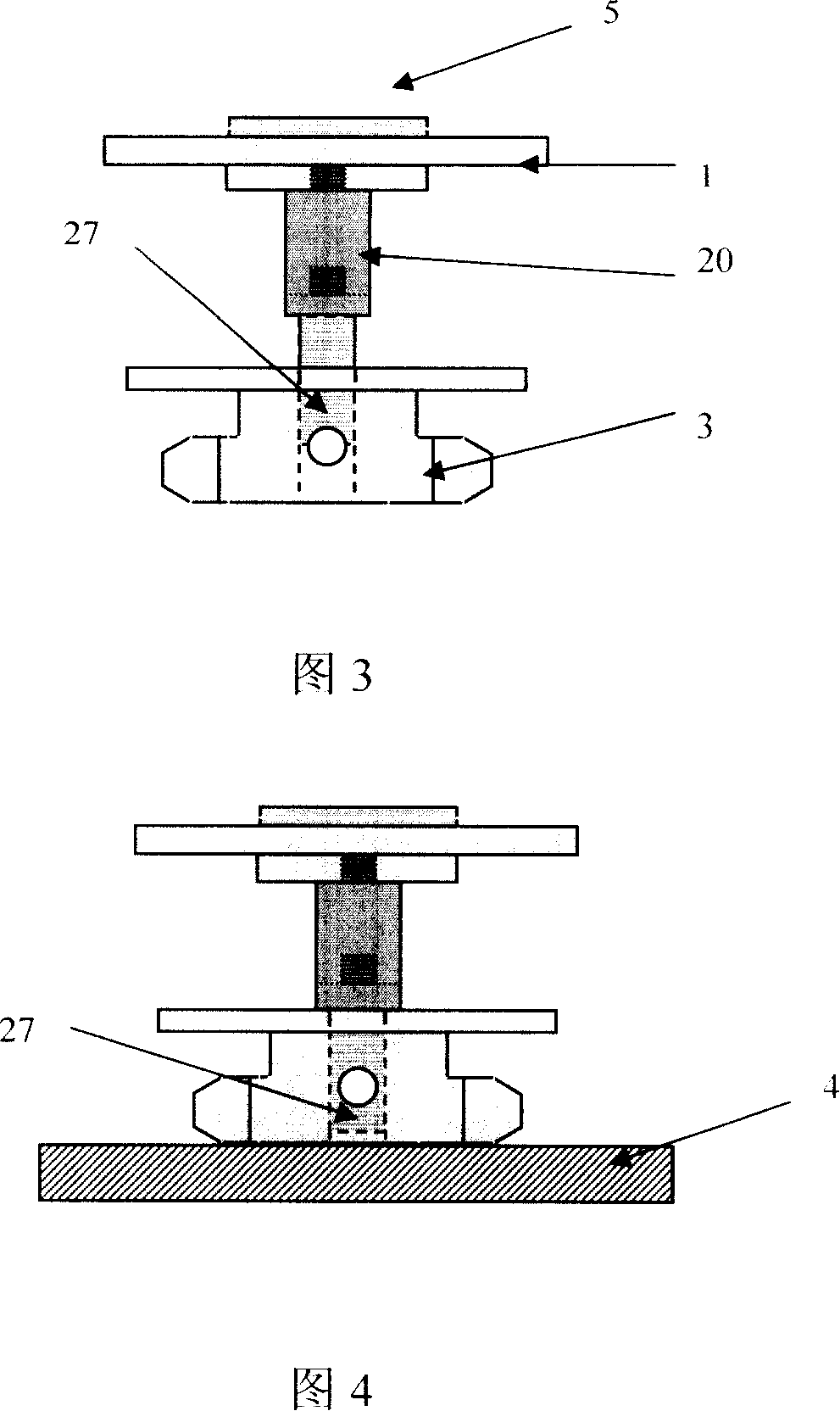

[0017] As shown in Fig. 3, it is a schematic diagram of the structure of the sample holder of the present invention. It includes a sample stage 1 , a screw mechanism 20 and a base 3 with a threaded hole in the middle, a sample 5 is placed on the sample stage 1 , and a screw 27 of the screw mechanism 20 is screwed into the base 3 .

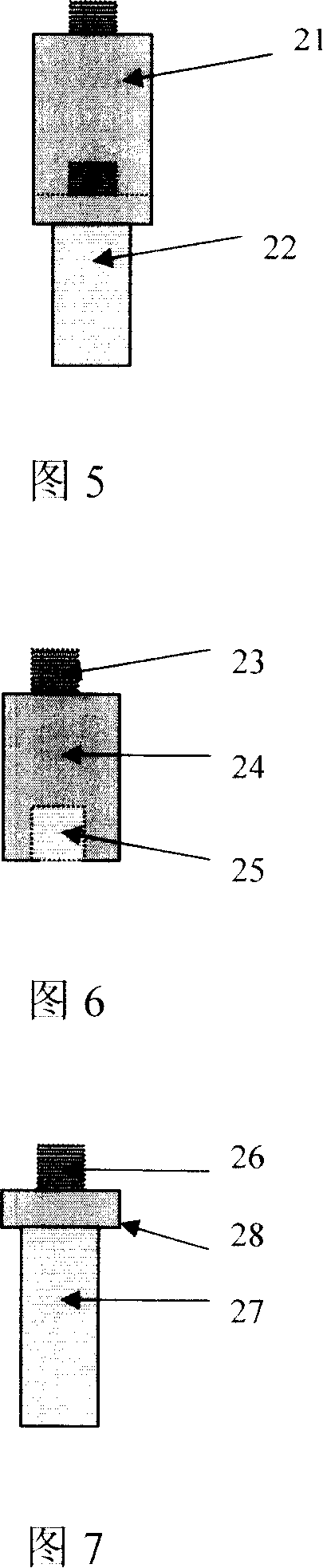

[0018] The specific structure of the screw mechanism 20 of the present invention can be as shown in Figures 5-7. As shown in FIG. 5 , the screw mechanism 20 consists of a replaceable module 21 and a lower part 22 . As shown in FIG. 6 , the replaceable module 21 is composed of a screw part 23 , a body 24 and a threaded hole 25 . As shown in FIG. 7 , the lower part 22 consists of a screw rod 27 , a stopper 28 and a connecting screw rod 26 . Wherein the connecting screw 25 and the threaded hole 25 are threaded screw mechanisms for realizing the connection between the replaceable module 21 and the lower part 22 . Of course, other forms of threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com