Patents

Literature

49results about How to "Eliminate temperature differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

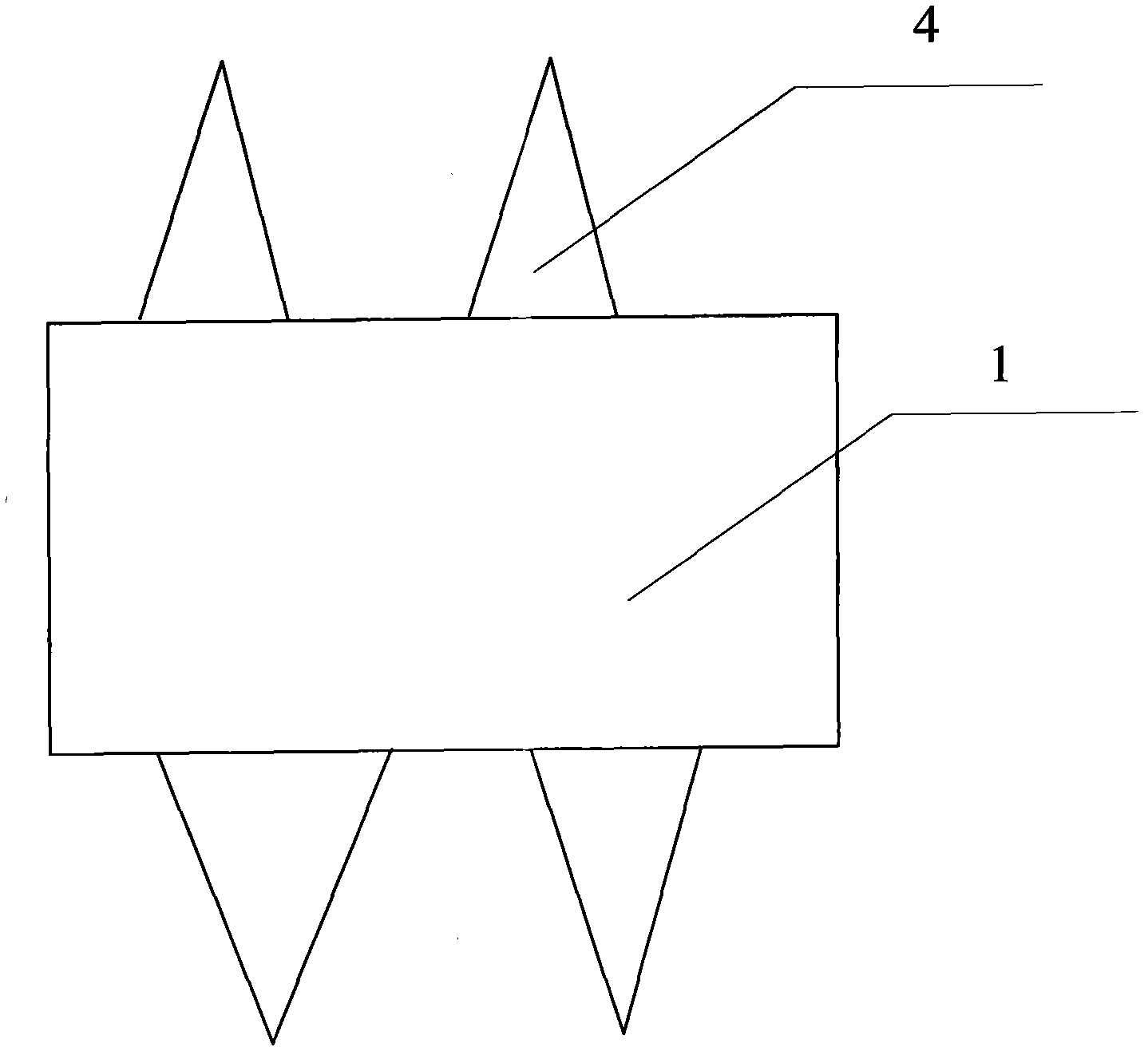

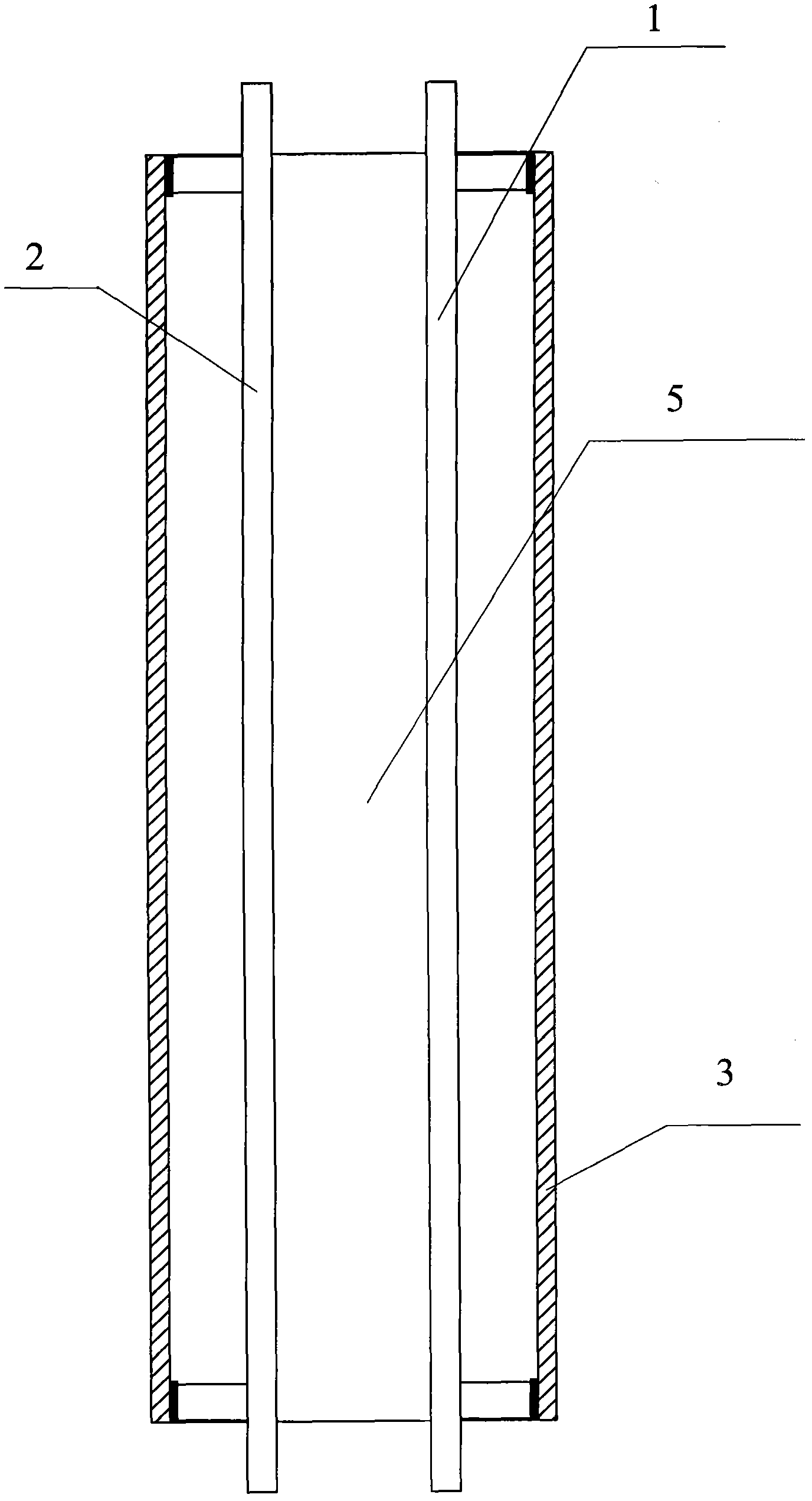

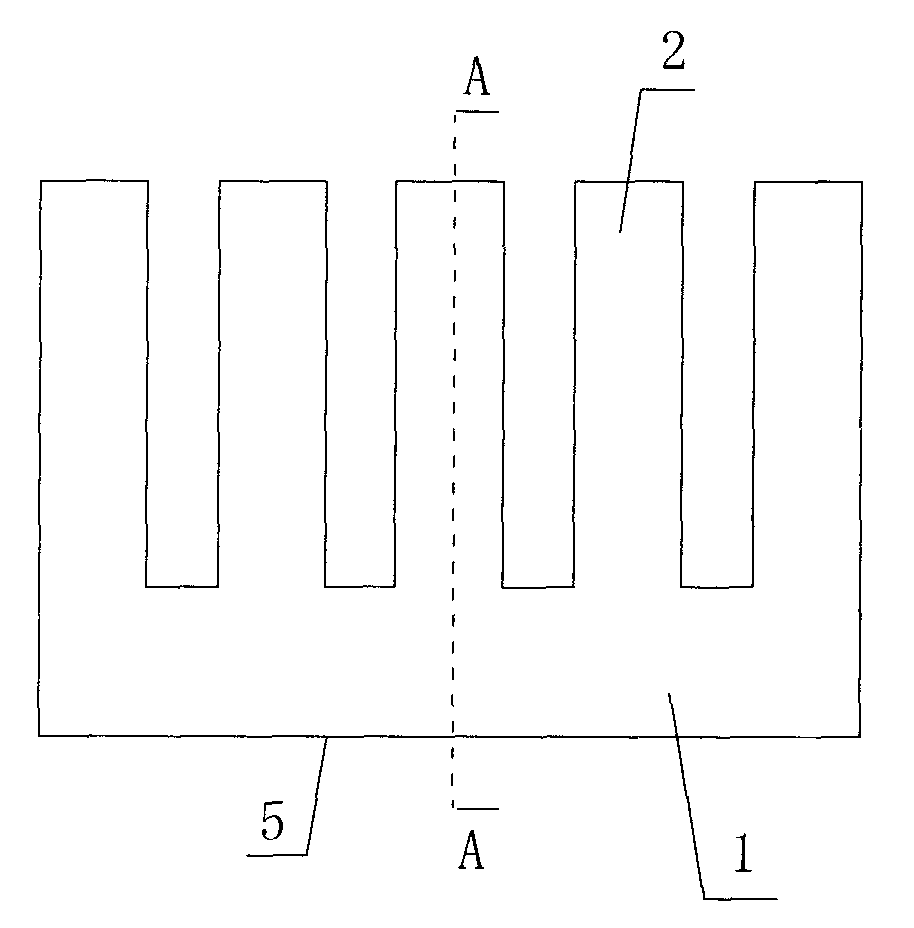

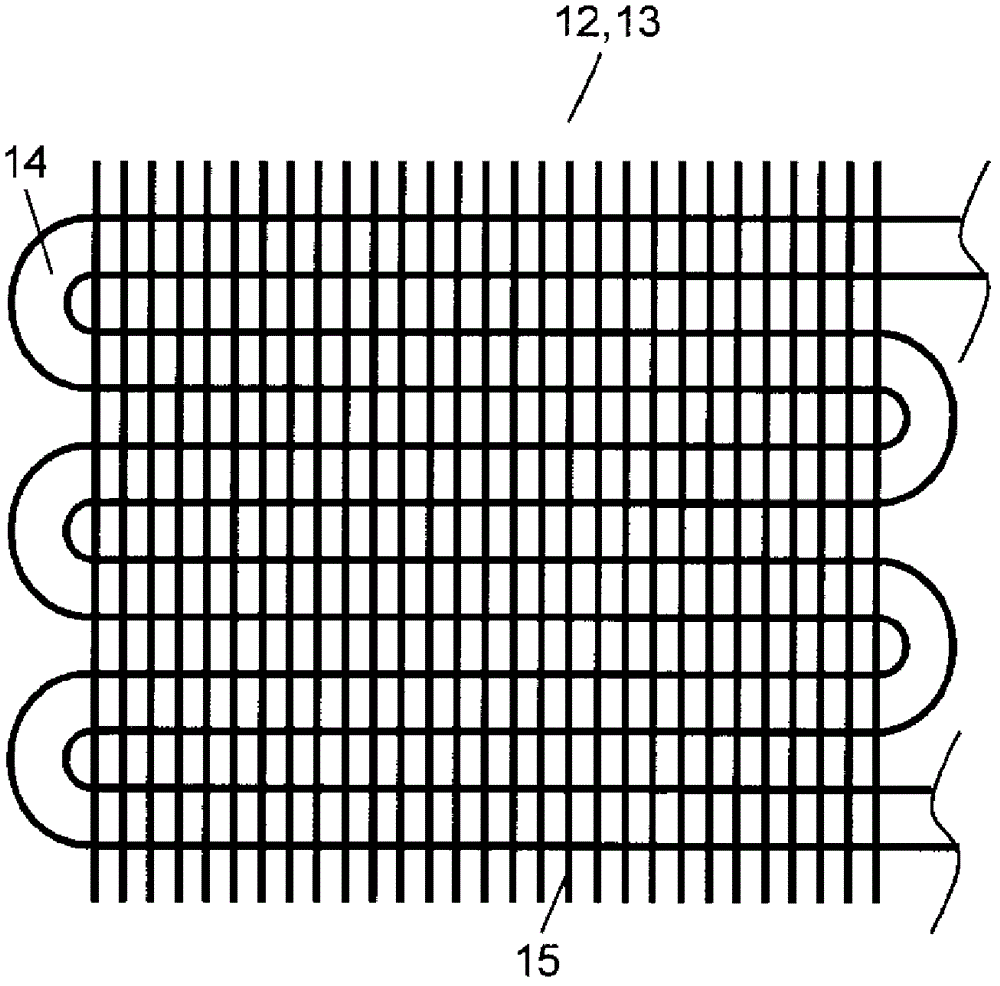

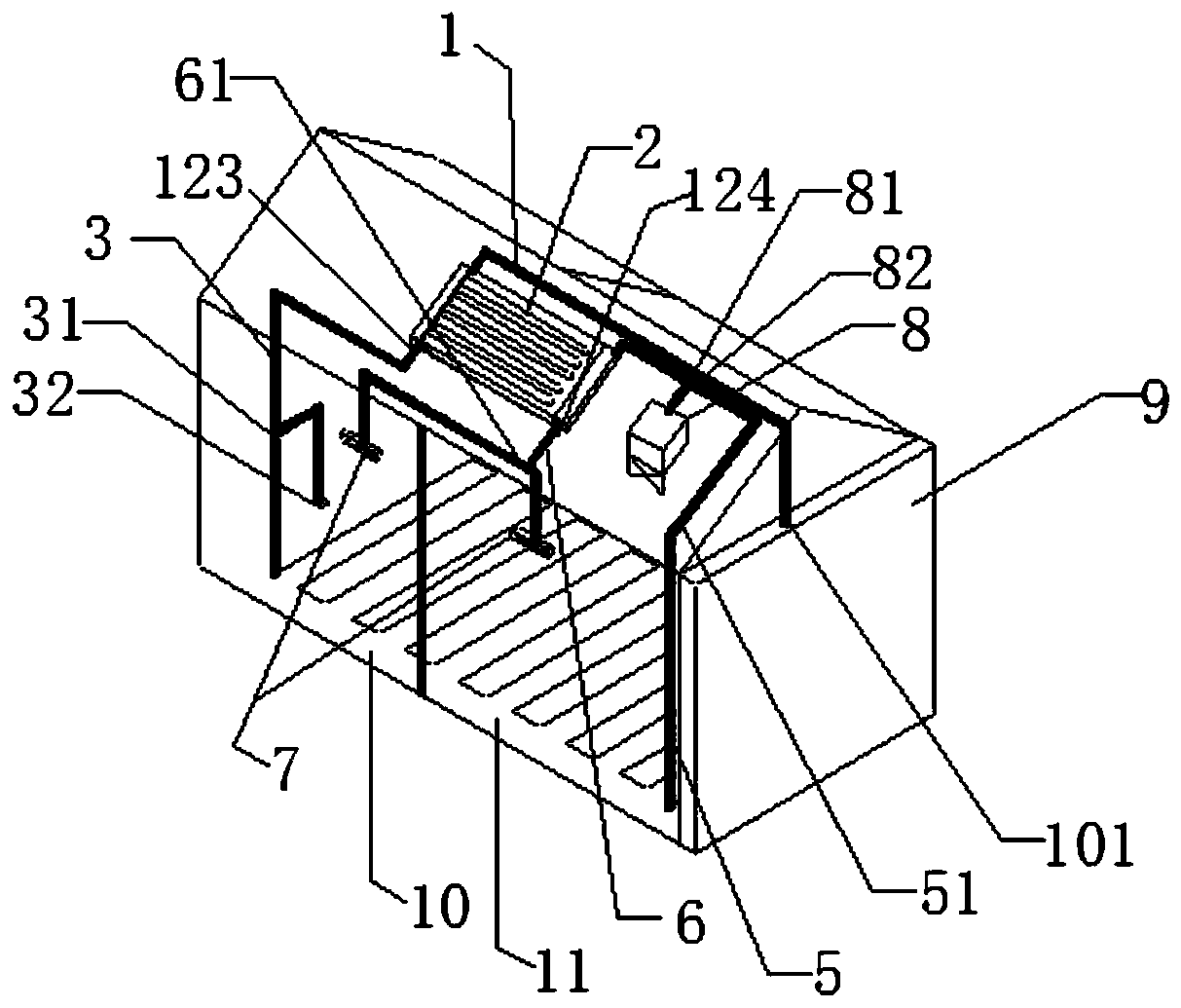

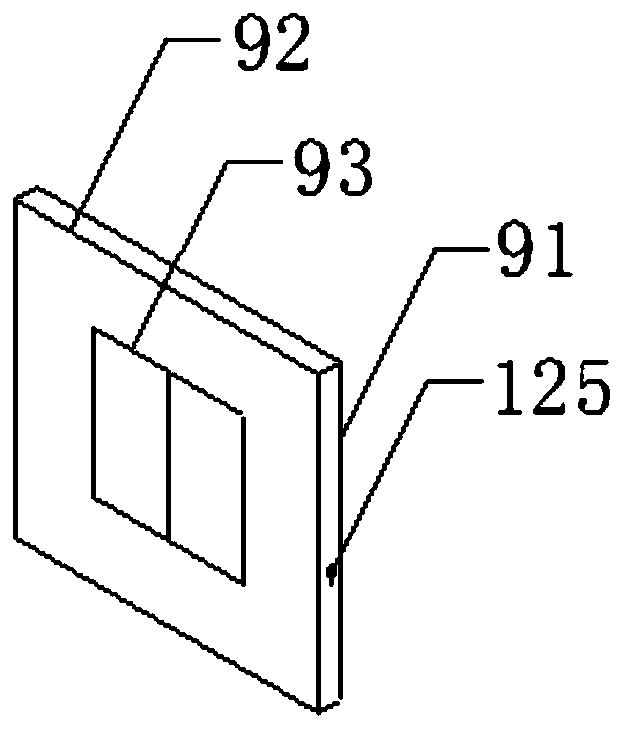

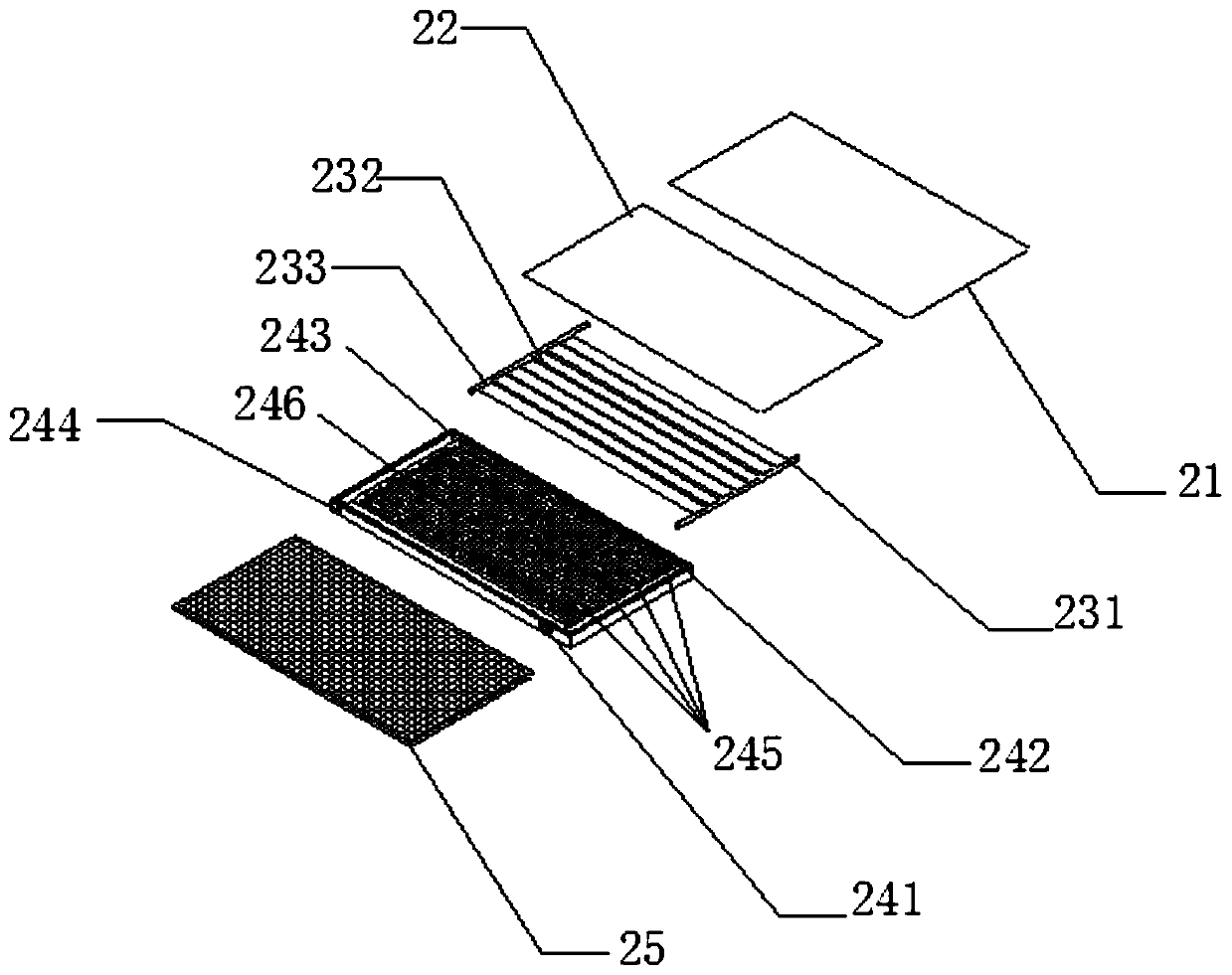

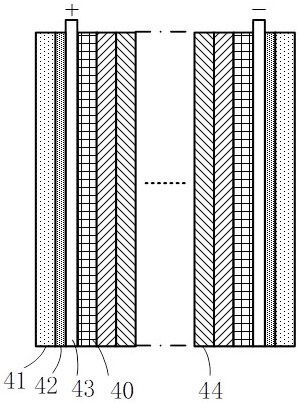

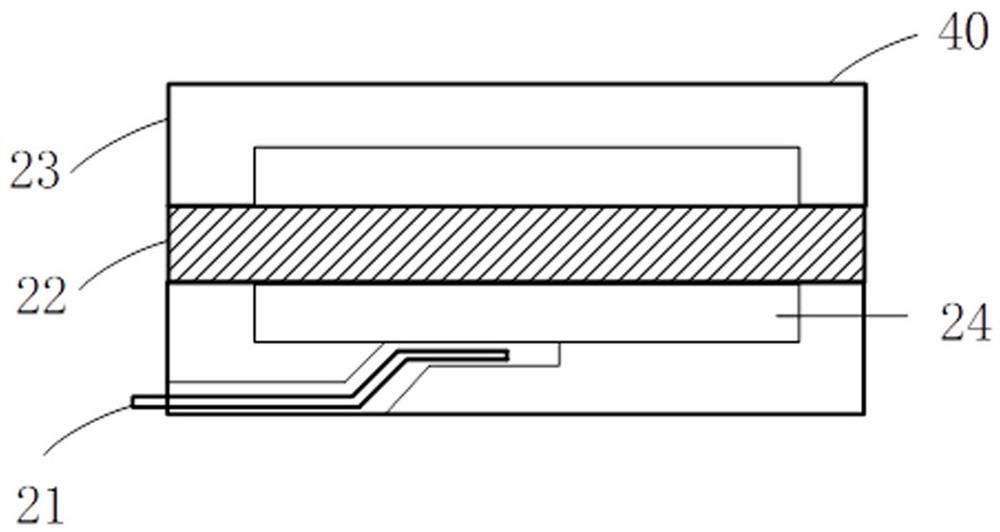

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

Large-power LED lamp heat radiator with fins having functions of heat pipes

InactiveCN101806441AMeet the needs of useSimple structurePoint-like light sourceLighting heating/cooling arrangementsLED lampHeat pipe

The invention discloses a large-power LED lamp heat radiator with fins having functions of heat pipes, which comprises a metallic heat radiating body and at least one metallic heat radiating fin, wherein the metallic heat radiating body and the metallic heat radiating fin are both in a hollow structure; a first hollow cavity in the interior of the metallic heat radiating body is communicated with a second hollow cavity in the interior of the metallic heat radiating fin to form an intercommunicated closed type inner cavity body; a heat pipe fluid absorbing core is arranged on the inner wall of the closed type inner cavity body, and operating fluid is filled in the heat pipe fluid absorbing core; the heat radiating body and the metallic heat radiating fin correspondingly form an integrated heat pipe for heat exchange; the inner wall of the heat radiating body and the inner wall of the metallic heat radiating fin form a pipe shell of the integrated heat pipe; and the heat radiating body and the metallic heat radiating fin have functions of heat pipes. The invention has the advantages of simple and reasonable structure, small volume, convenient processing, manufacture, installation and arrangement, large heat radiating area, high heat conduction coefficient and good heat radiating performance, and can effectively solve the heat radiating problem of large-power LED lamps.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

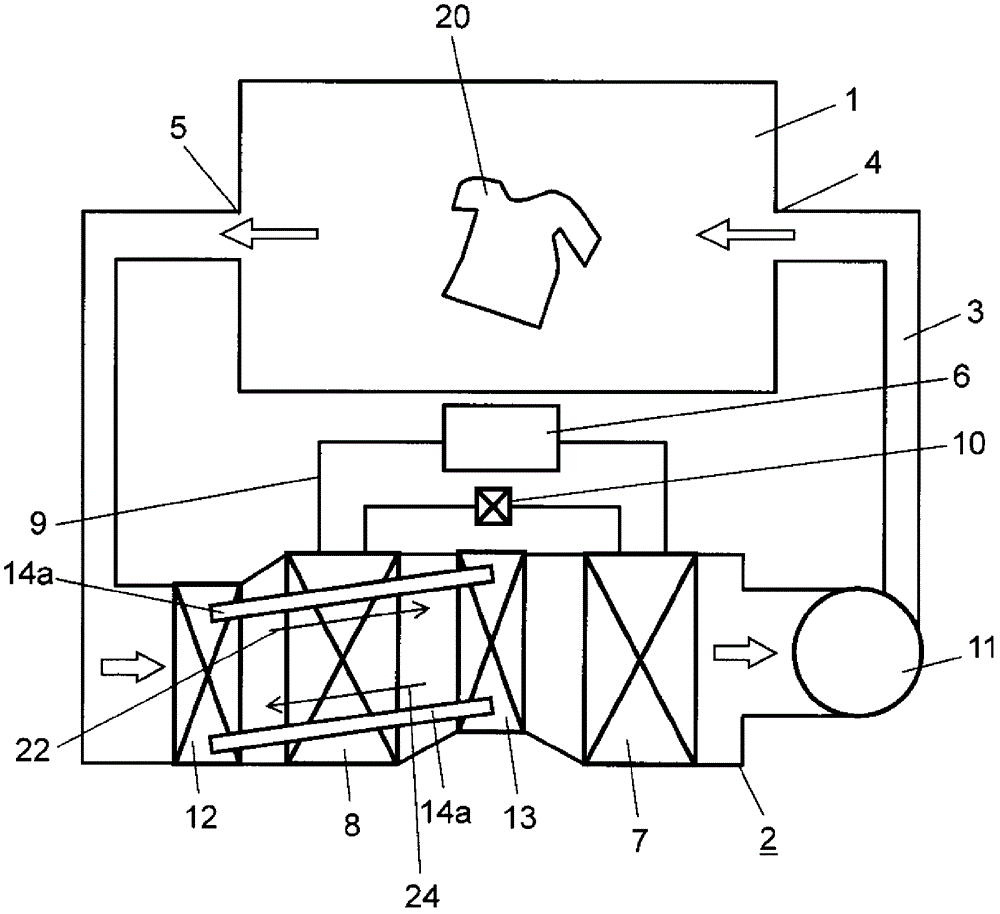

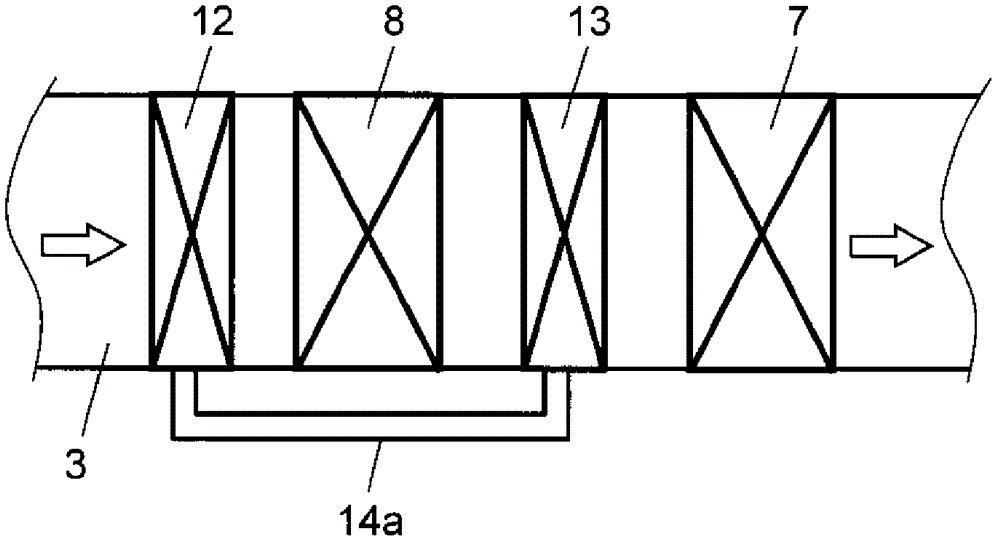

Drying device

InactiveCN102803882AReduce the burden onImprove energy efficiencyHeat recovery systemsCompression machines with non-reversible cyclePlate heat exchangerEngineering

A drying device comprising a drying chamber, a fan, a circulation flow path, and a heat pump. The heat pump comprises a compressor, an evaporator, a condenser, a pressure reducing valve, a pipe path, an upstream heat exchanger provided in the circulation flow path at a position between the drying chamber and the evaporator and exchanging heat with air for drying, a downstream heat exchanger provided between the evaporator and the condenser and exchanging heat with the air for drying, and a heat moving section for circulating a heat medium to the upstream heat exchanger and the downstream heat exchanger. The drying device is configured so that the heat of the air for drying is moved from the upstream heat exchanger to the downstream heat exchanger through the heat medium.

Owner:PANASONIC CORP

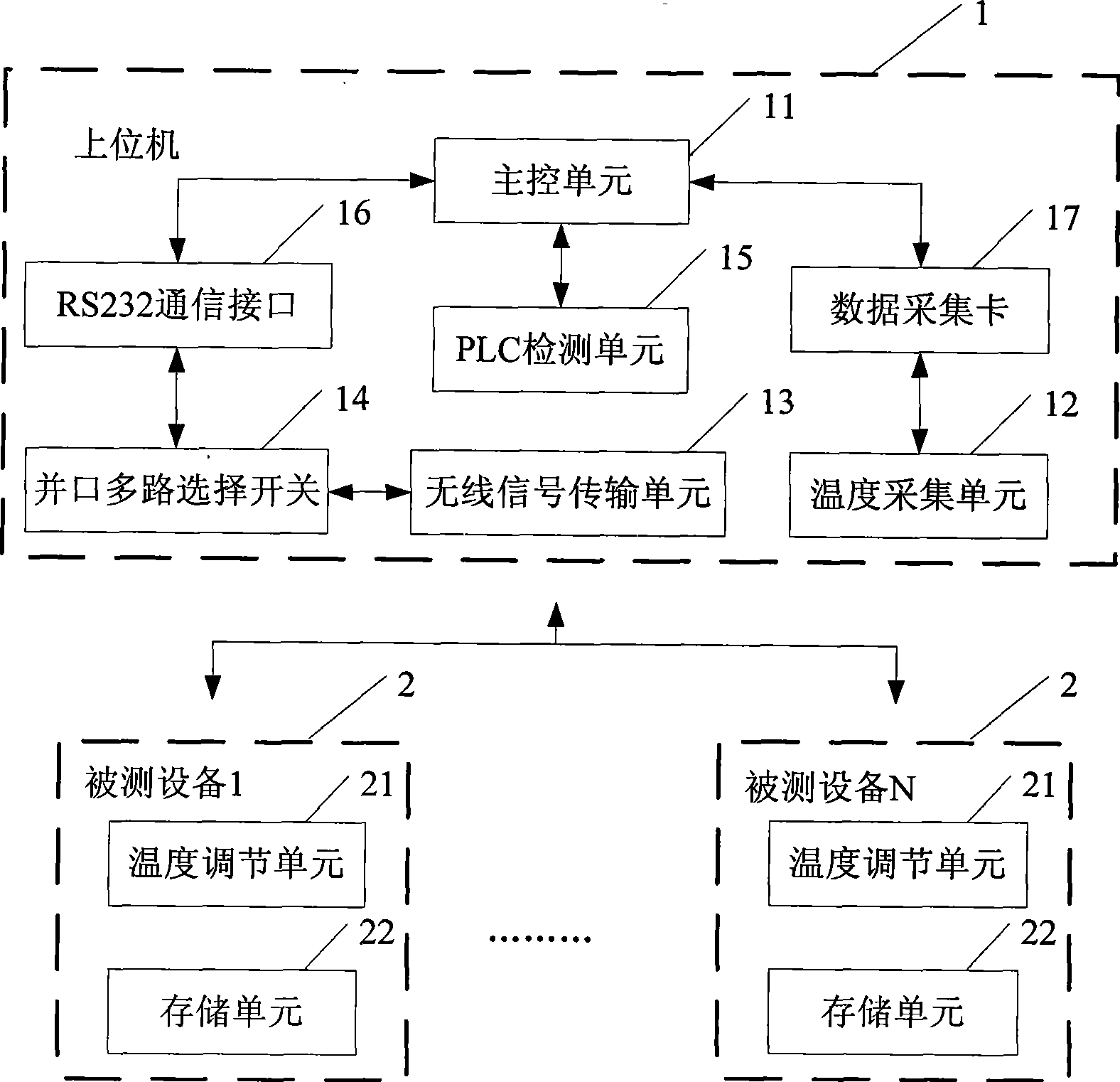

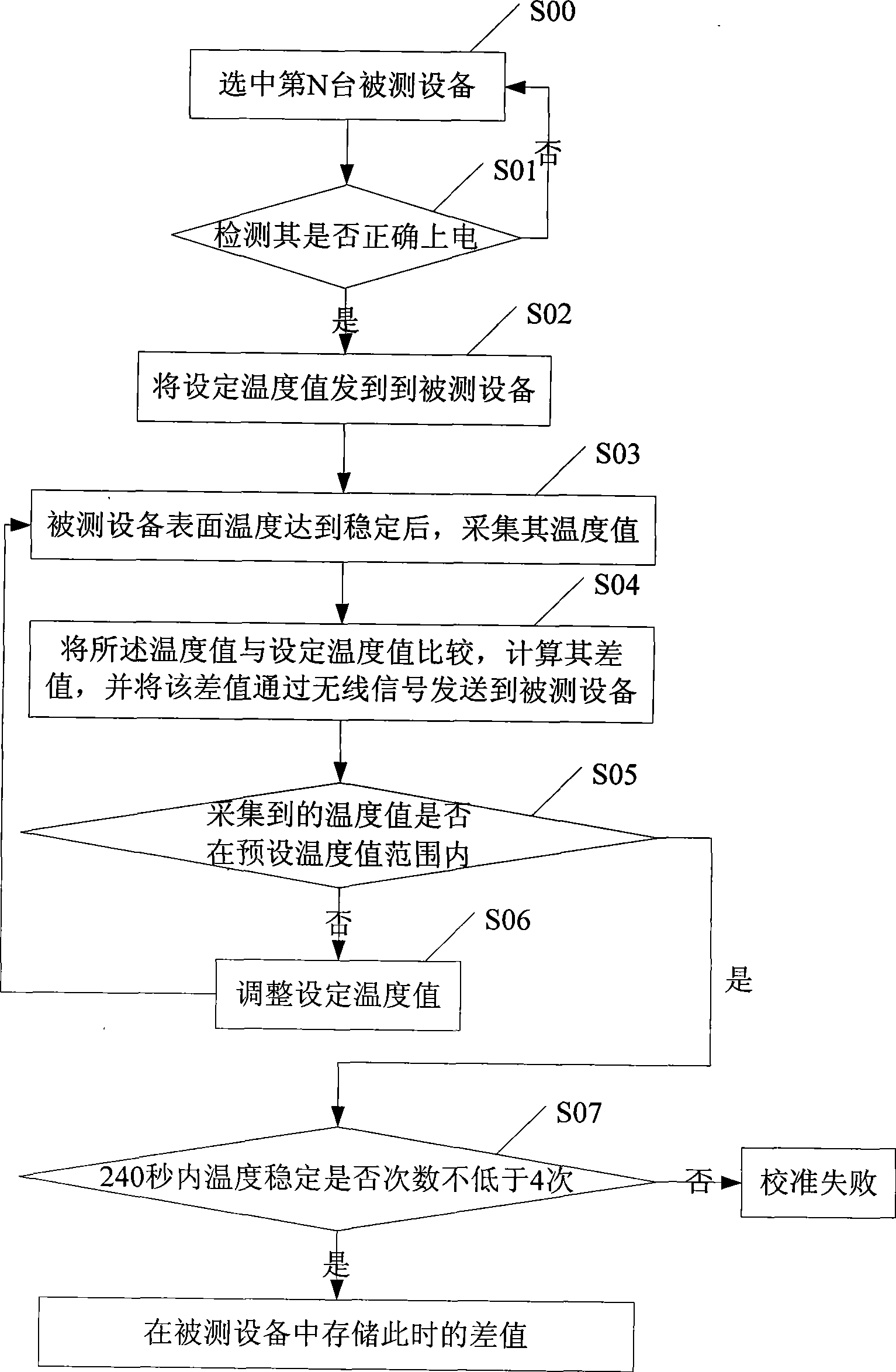

Temperature calibration system and method

InactiveCN101504552AEliminate the influence of parameter errorsEliminate temperature differencesRadiation pyrometryTemperature control using electric meansTemperature differenceHeating power

The invention discloses a temperature correction system and method. The system comprises a host computer and one or more tested devices. The host computer is provided with a main control unit for sending a set temperature value to one tested device, calculating the difference value of the actual temperature value of the surface of the test device and the set temperature value and sending the difference value to the tested device, a temperature acquisition unit, namely an infrared temperature sensor, for acquiring the temperature value of the tested device when the surface temperature of the tested device is stable and sending the temperature value to the main control unit, and a wireless signal transmission unit for transmitting the set temperature value of the main control unit and the difference value to the tested device. The tested device is provided with a temperature adjusting unit for adjusting the heating power according to the set temperature value from a host computer so that the surface temperature reaches a stable value, and a storage unit for storing the difference value of the set temperature and the surface actual value. The temperature correction system and the method can eliminate the temperature differences for small household appliances caused by the influences of parameter errors of parts of a controlled panel and the errors of assembling factors and the resistance value of a heating element.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

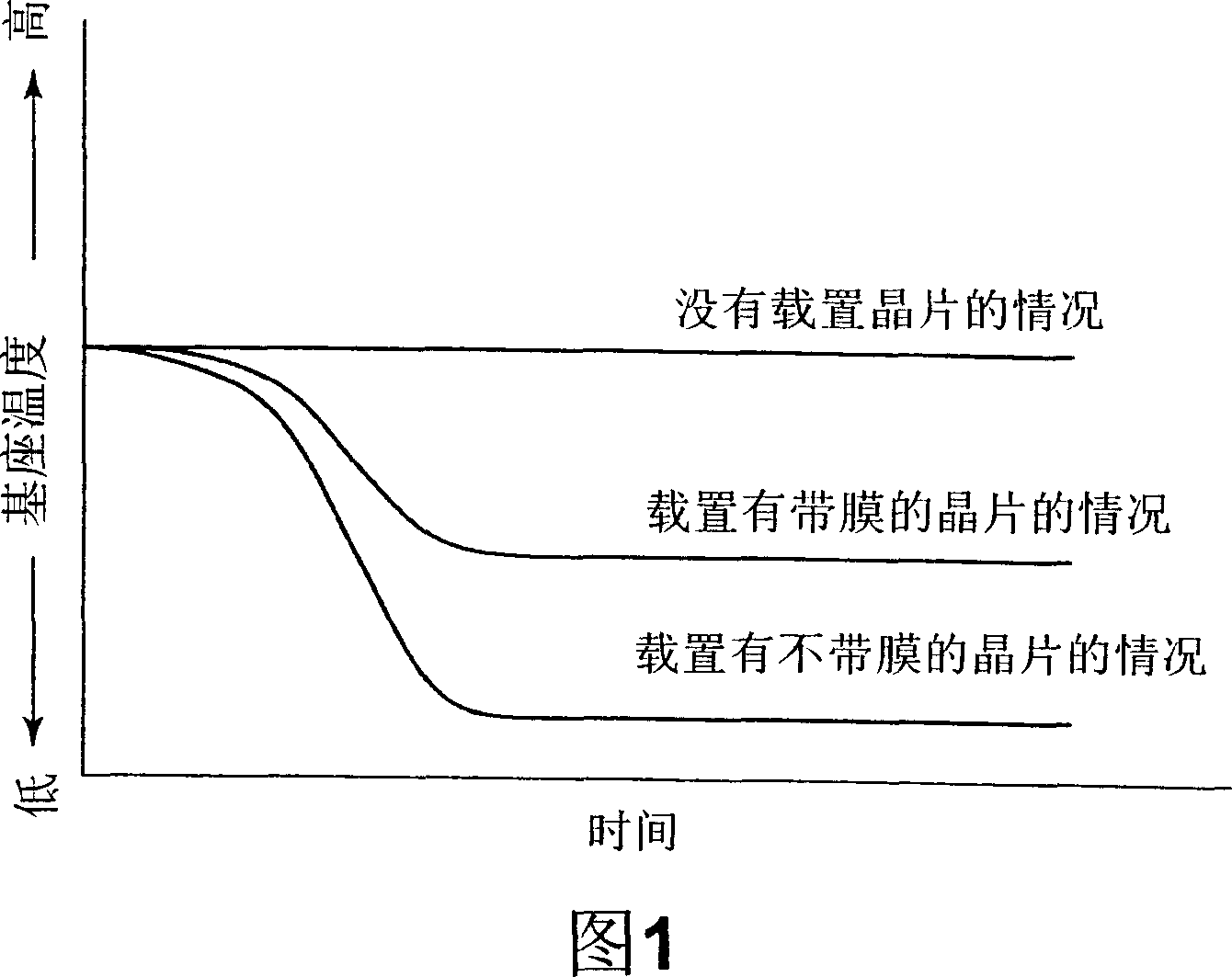

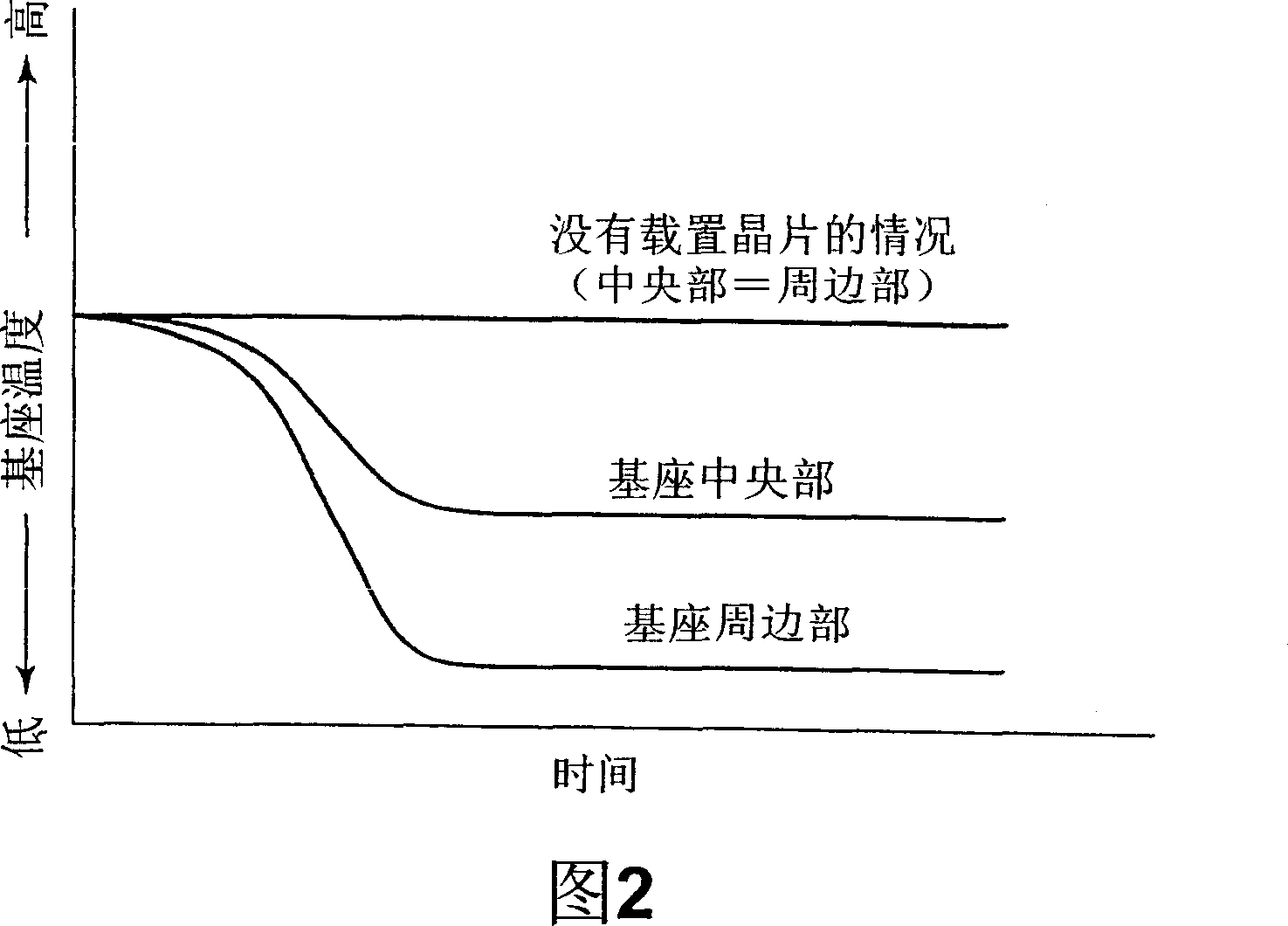

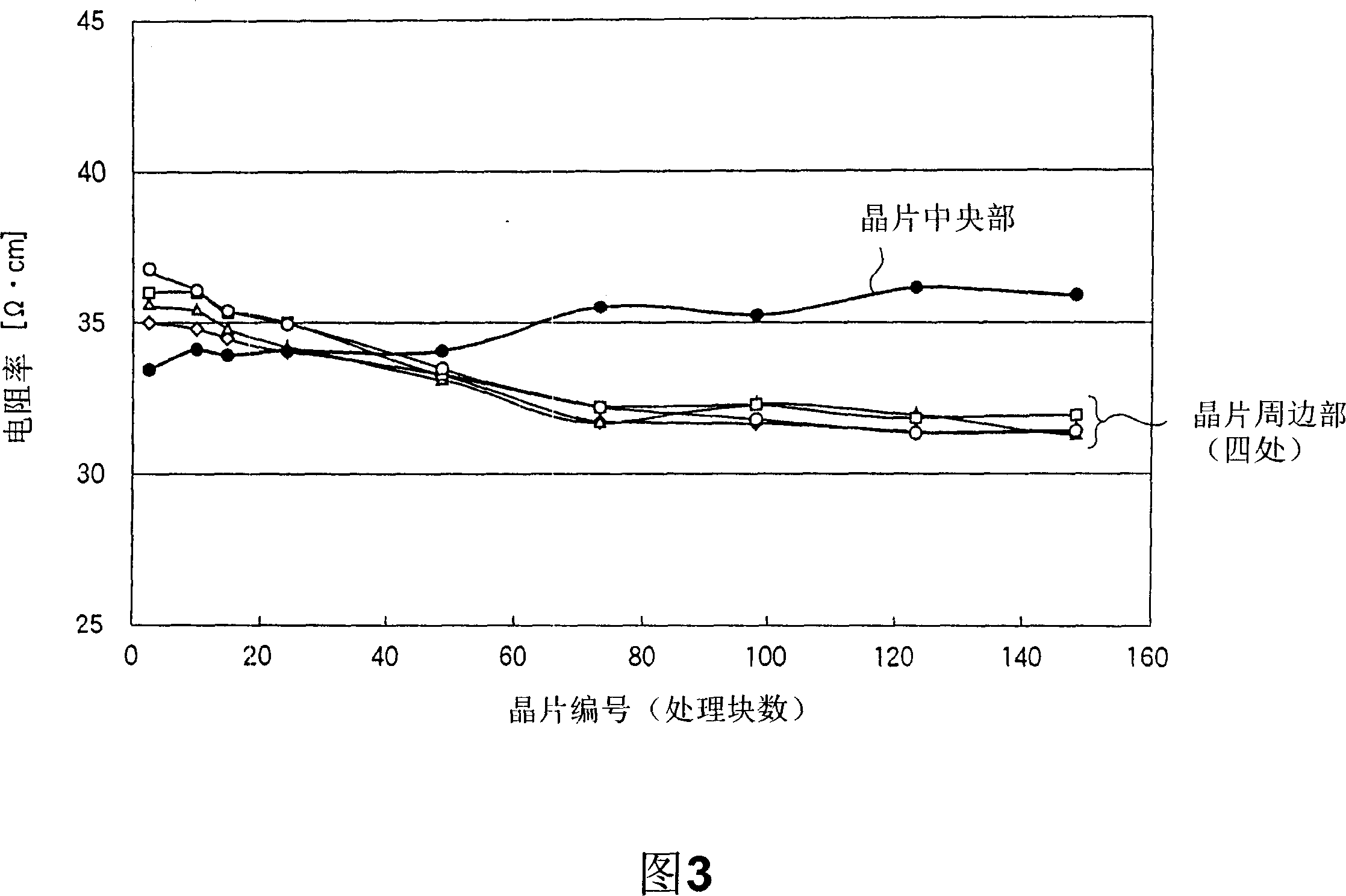

Substrate processing method and substrate processing apparatus

InactiveCN1969059AGood reproducibilityImprove treatment uniformitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTemperature controlAbsorptance

Disclosed is a substrate processing method wherein the infrared absorptance or infrared transmittance of a substrate to be processed is measured in advance, and the substrate is processed according to the measured value while independently controlling temperatures at least in a first region located in the central part of the substrate and in a second region around the first region using temperature control means which are respectively provided for the first region and the second region and can be controlled independently from each other.

Owner:TOKYO ELECTRON LTD

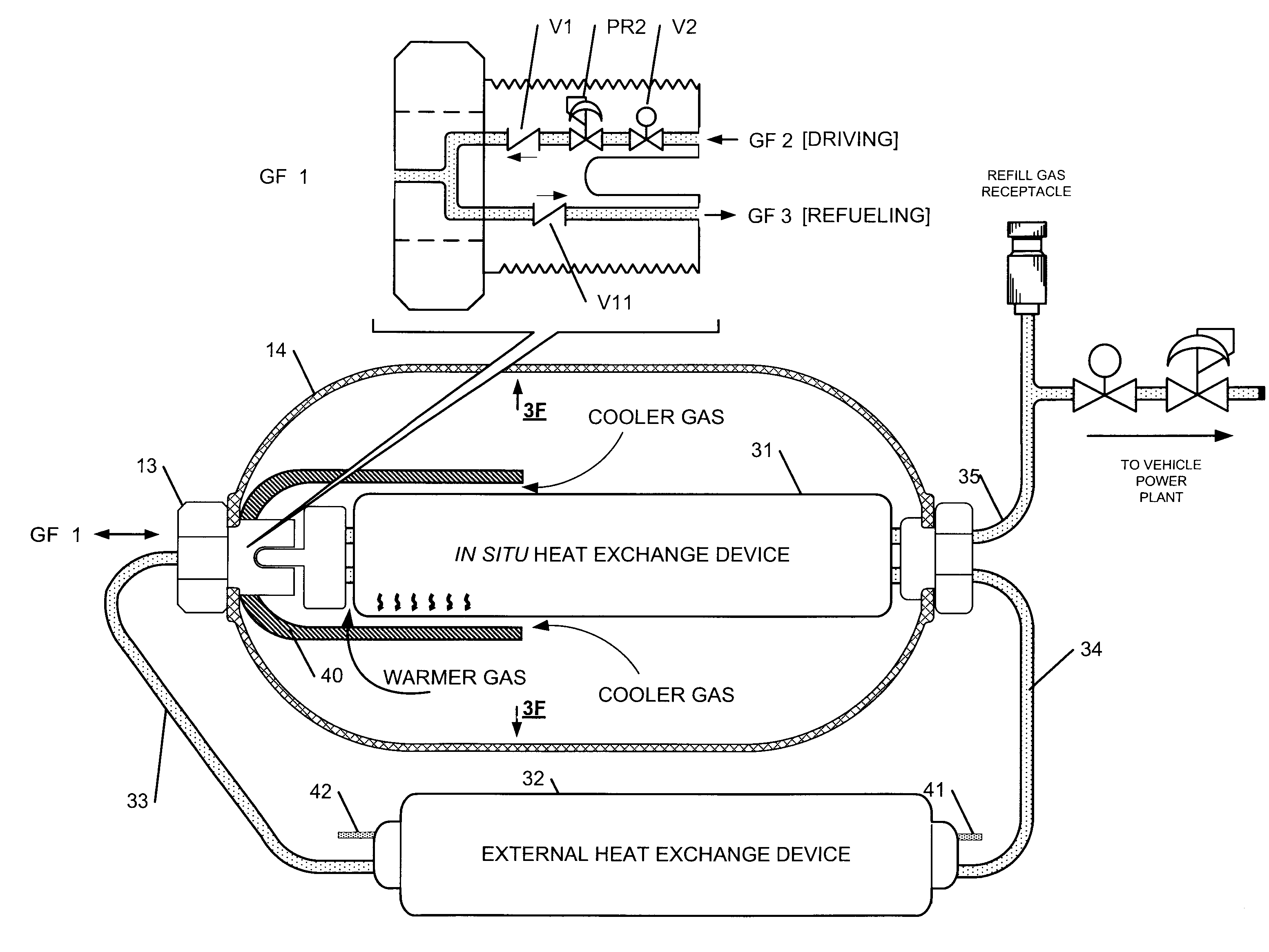

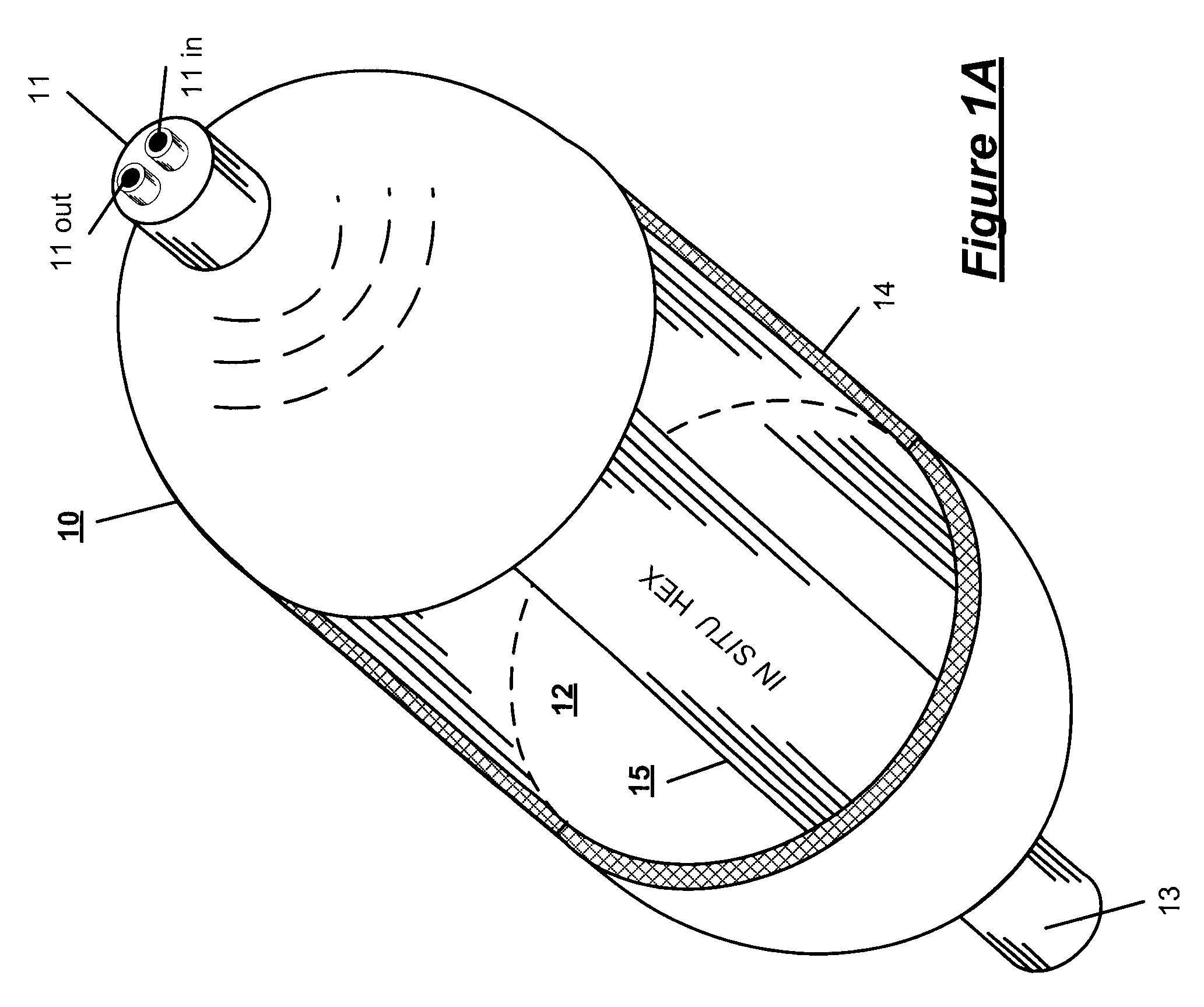

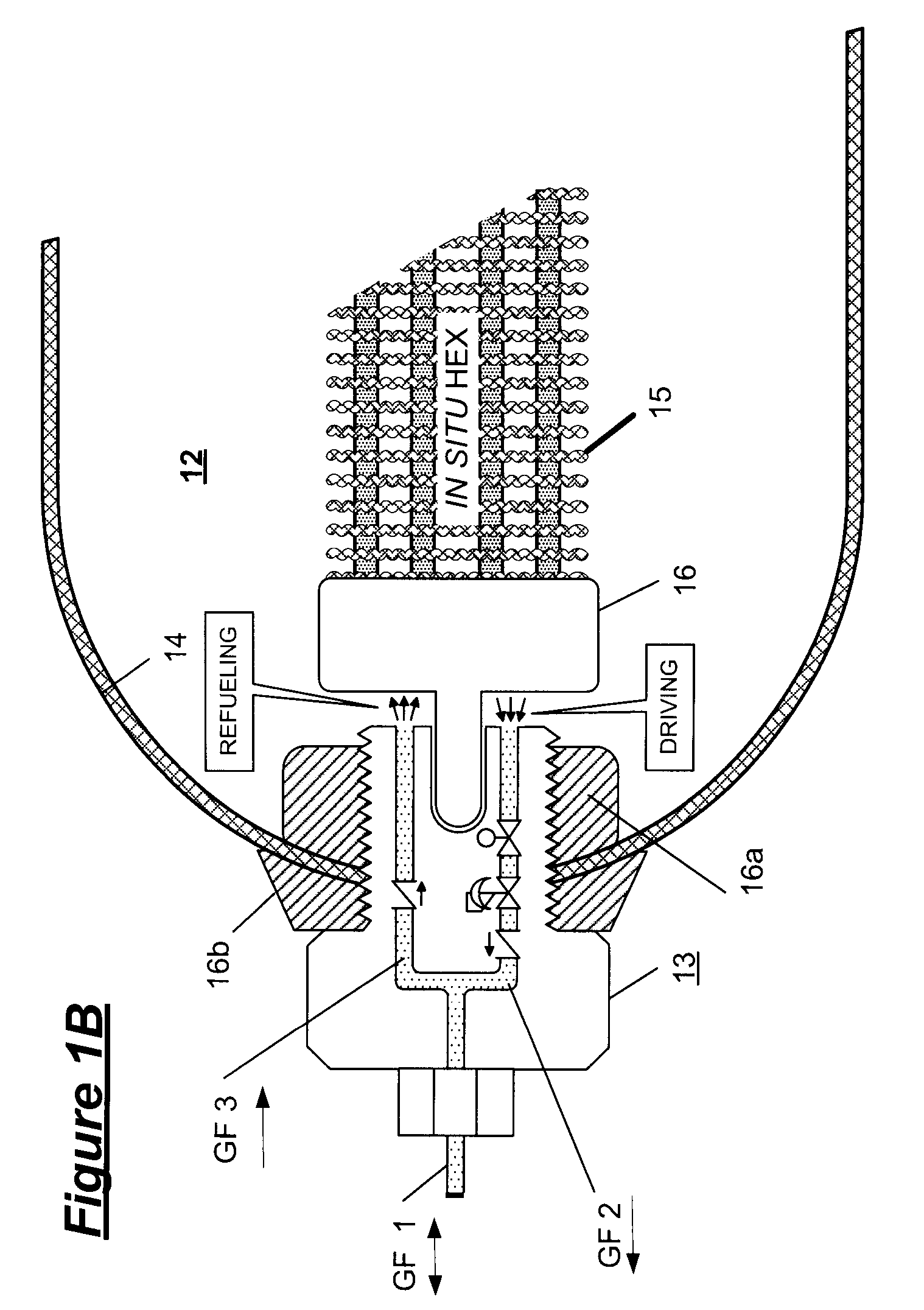

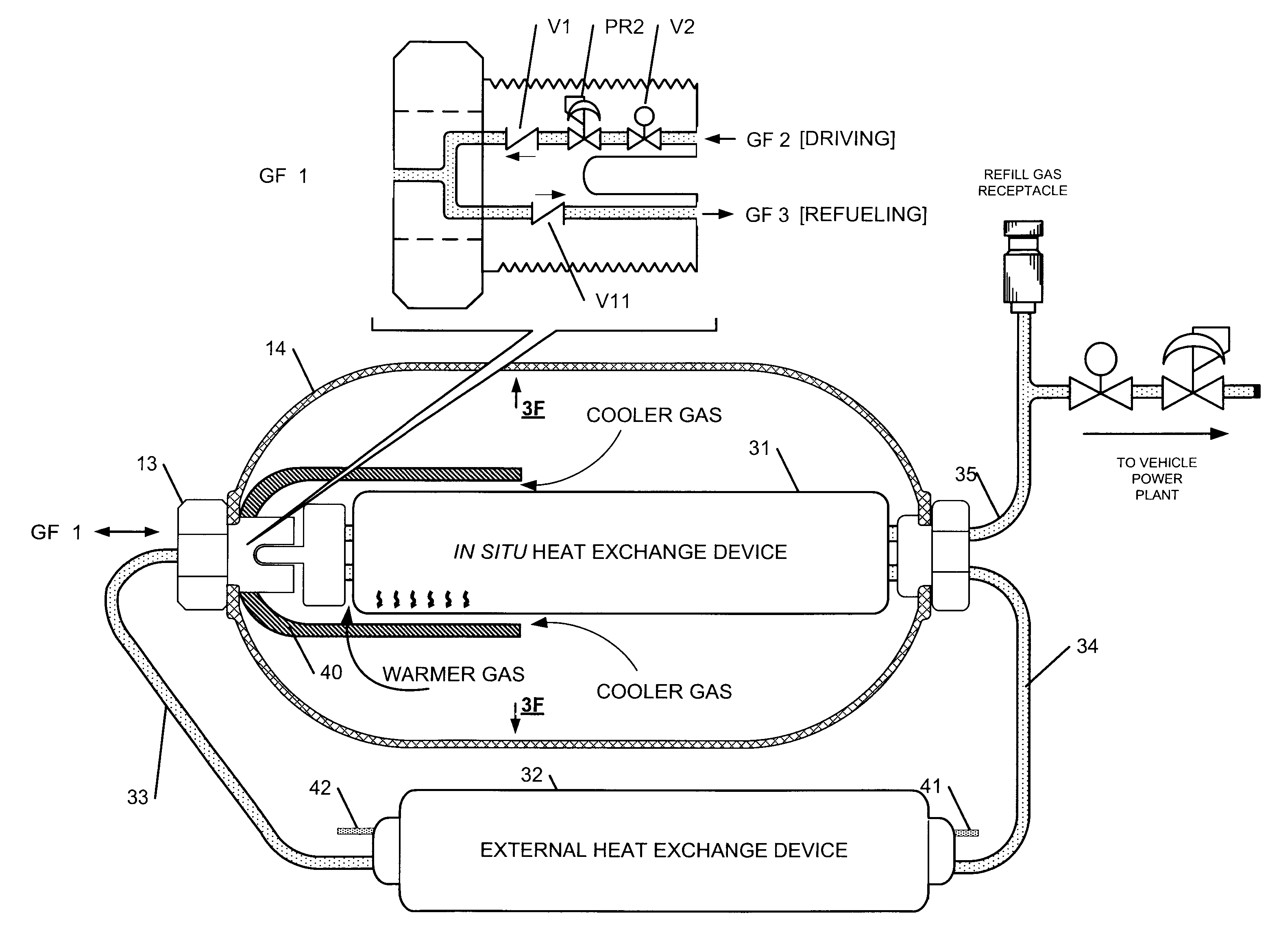

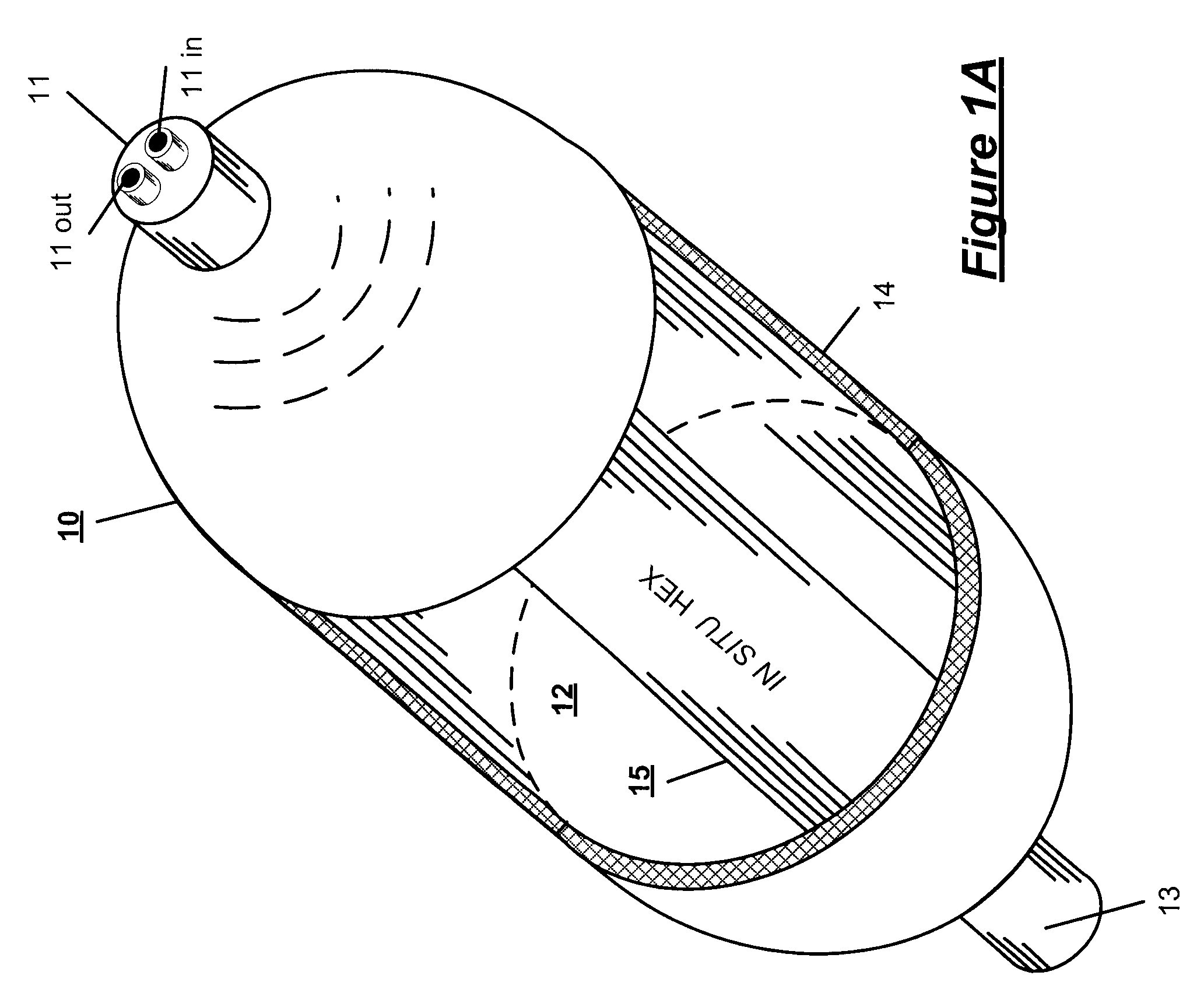

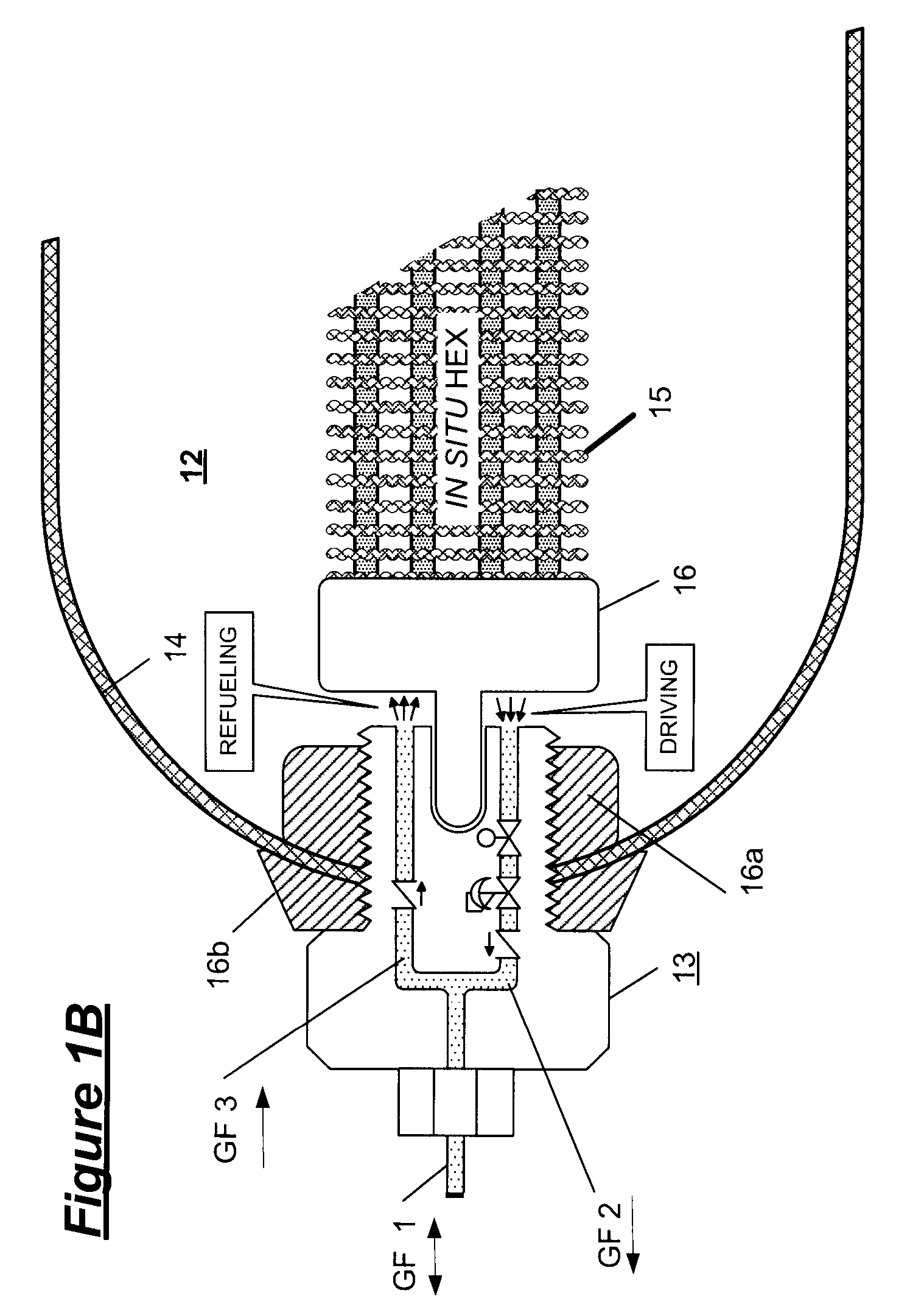

Selective Warming and Heat Isolation For On Board High Pressure Storage Tanks Installed on Gas Fueled Vehicles

ActiveUS20090114367A1Eliminate thermally induced leakReduce riskSpace heating and ventilationPipe heating/coolingOn boardControl system

A thermal management system for gas flow from an on board high pressure vehicle gas storage tank comprising an on board heat source operatively interconnected with a heater disposed in proximity to the metal component gas outlet flow control system of the on board tank; a thermostat regulating the flow of heat to the heater such that the thermostat regulates the temperature of the metal component outlet flow control system of the tank to a temperature corresponding to at least the minimum lower limit temperature permitted by the temperature tolerance range of metal component outlet flow control system of the tank; and an optional insulating shroud circumferentially disposed surrounding the gas flow heater installed in the system.

Owner:HONDA MOTOR CO LTD

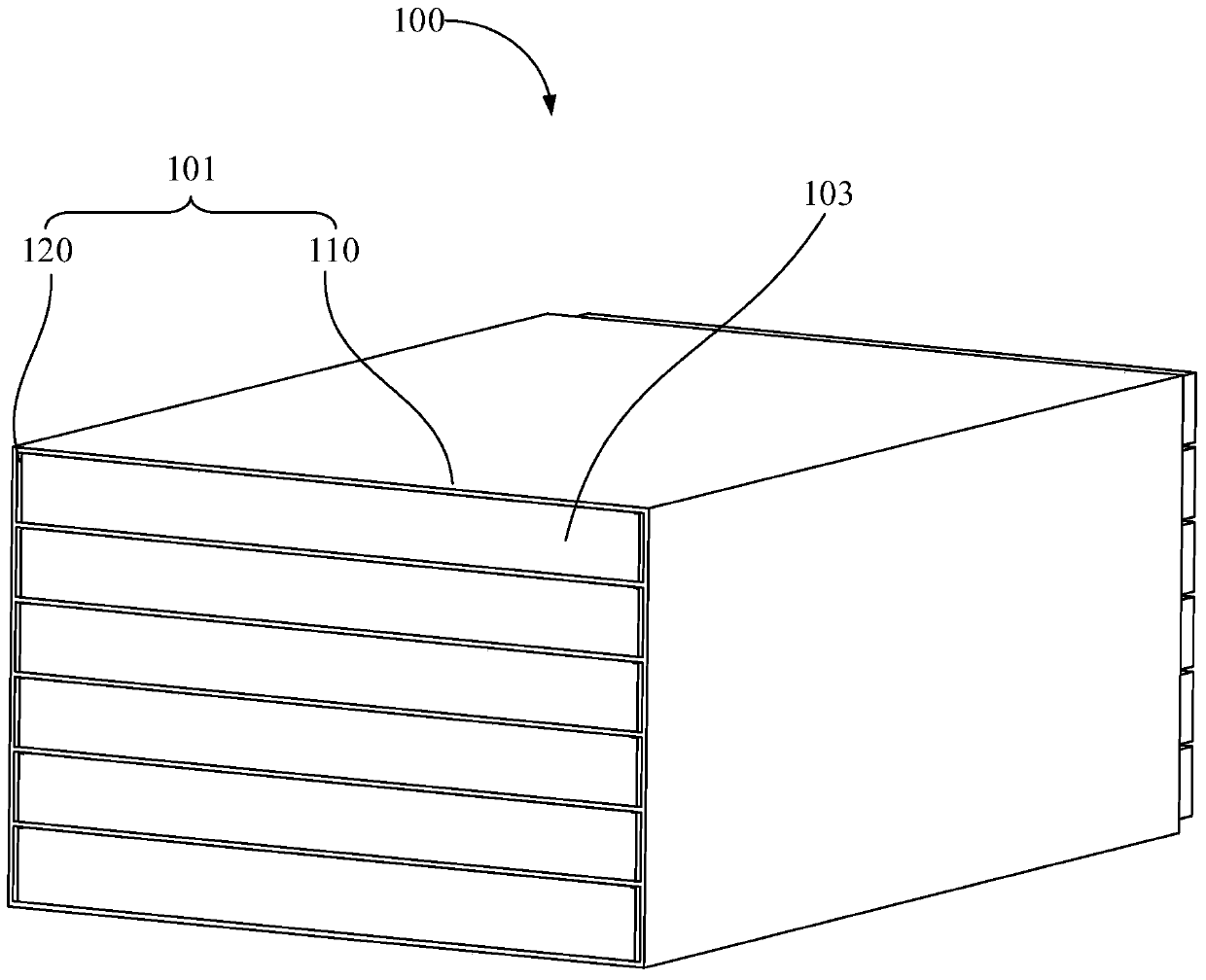

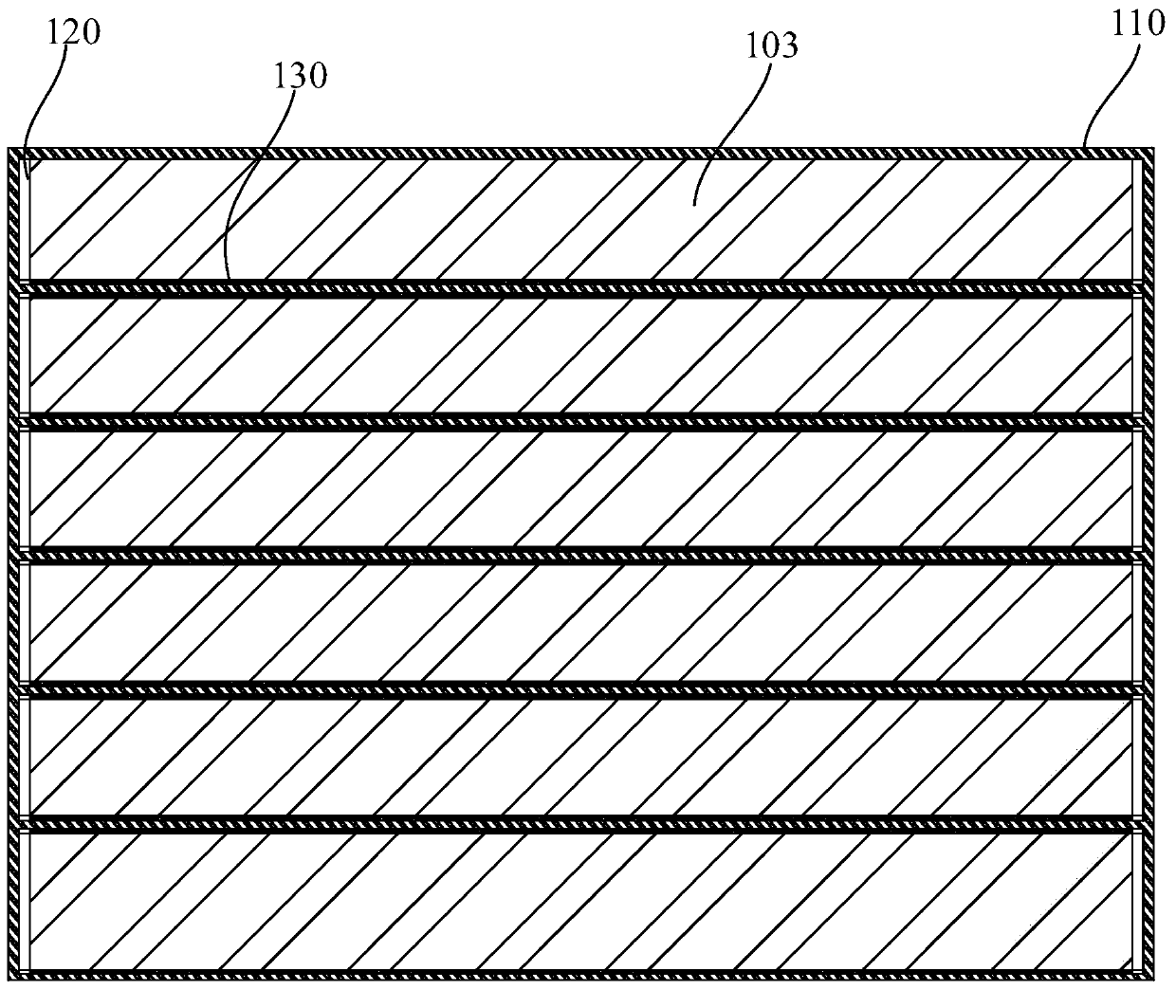

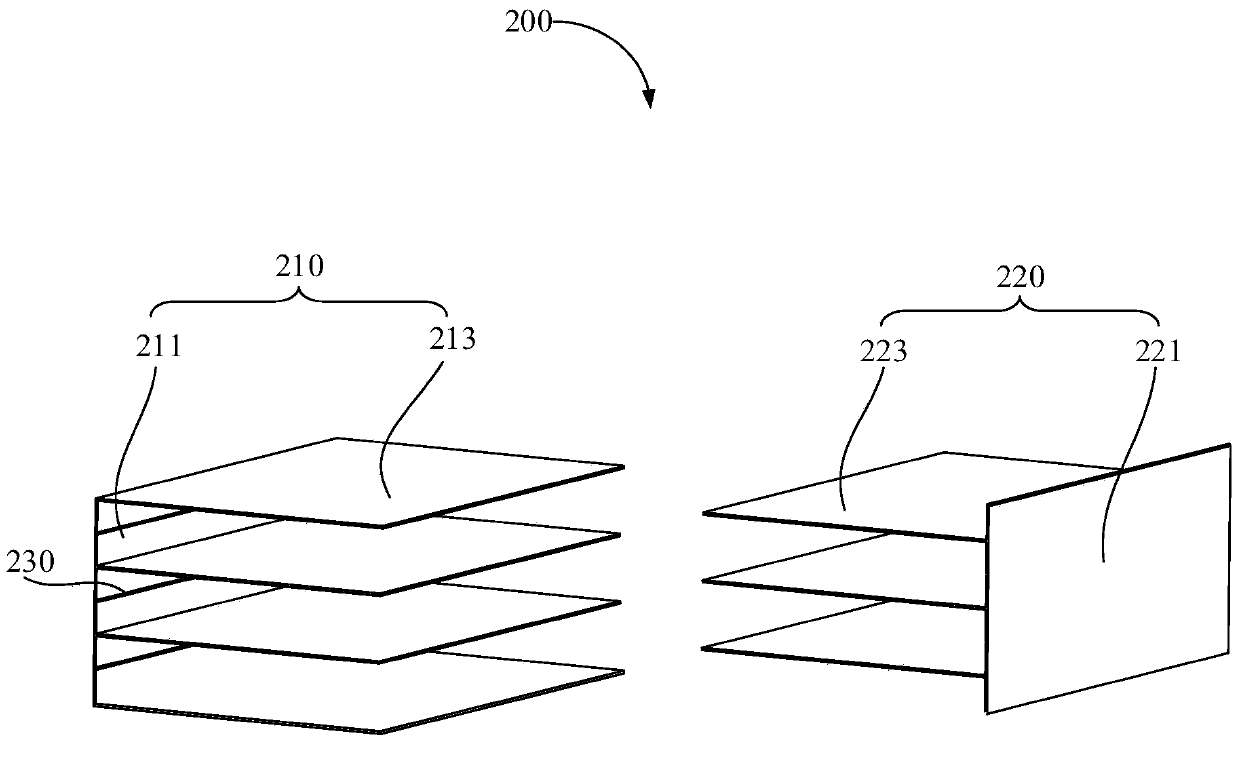

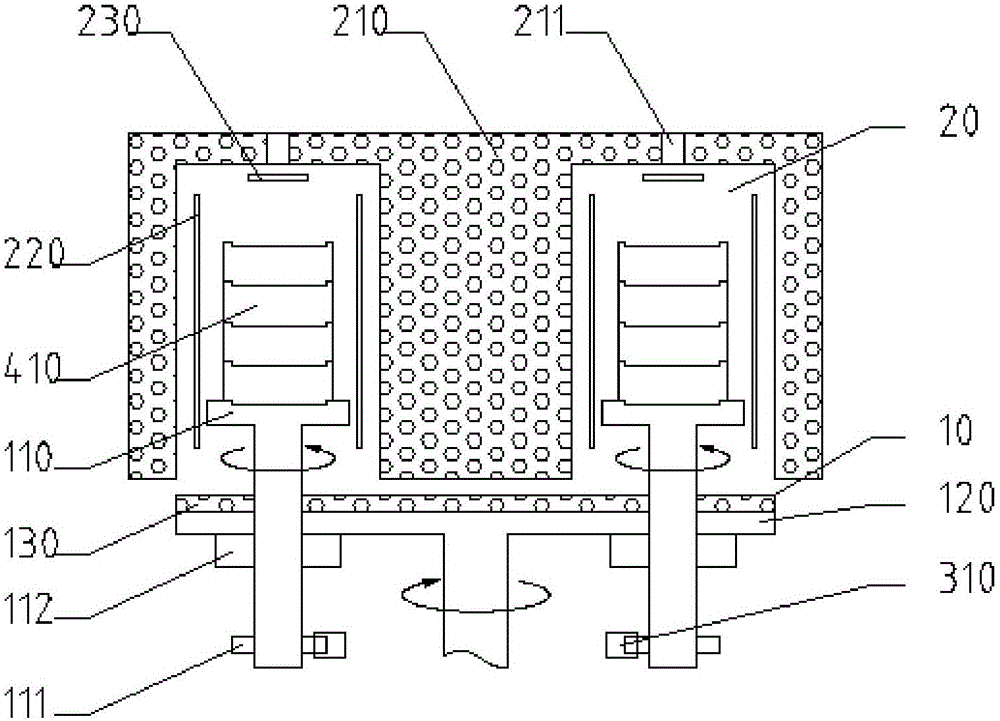

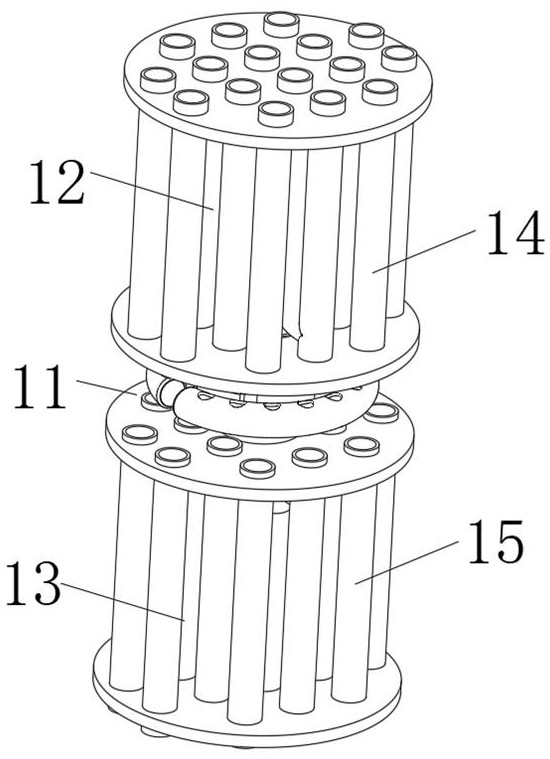

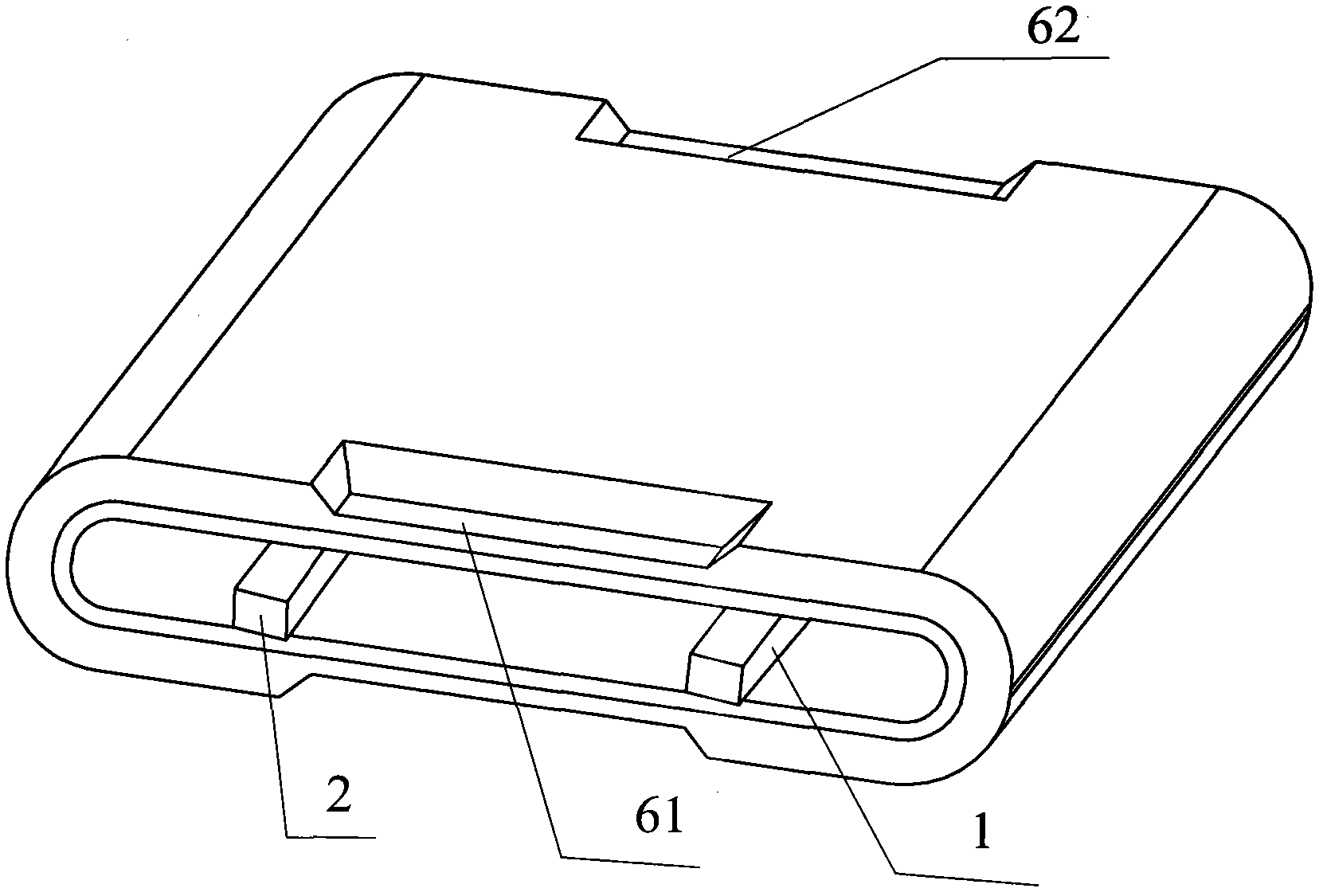

Battery, heat management apparatus thereof and uav having battery

ActiveCN105518928AReduce temperature riseExtended service lifeCell temperature controlRemote controlled aircraftHeat managementHeat conducting

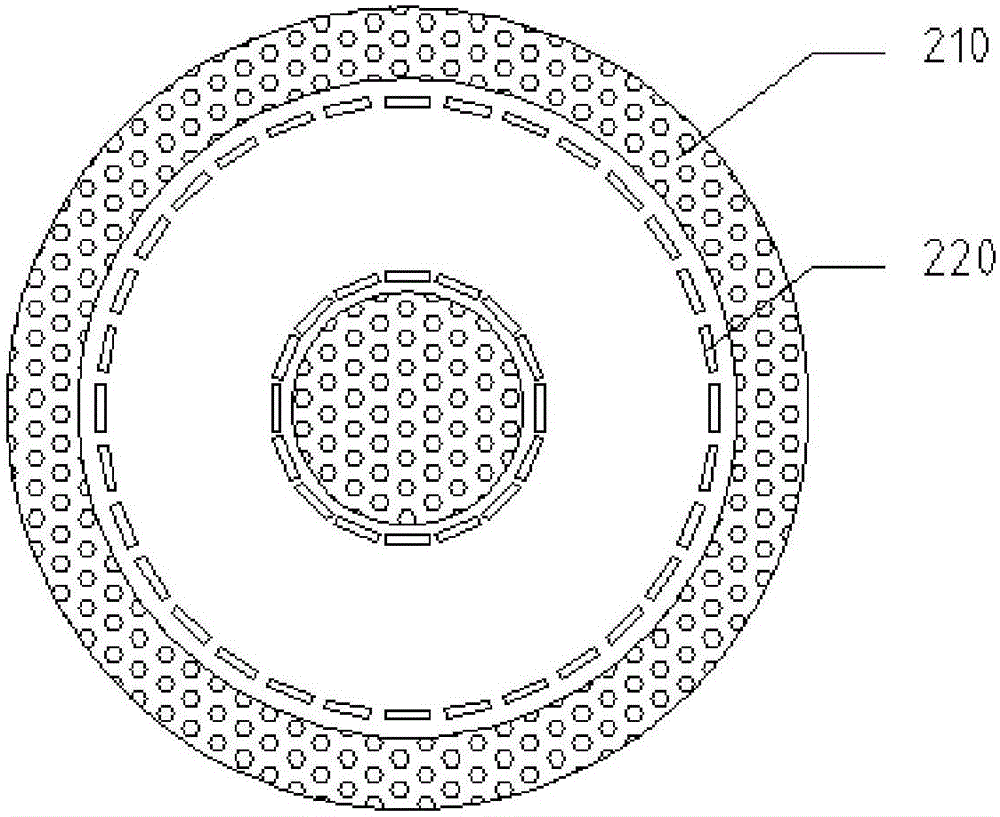

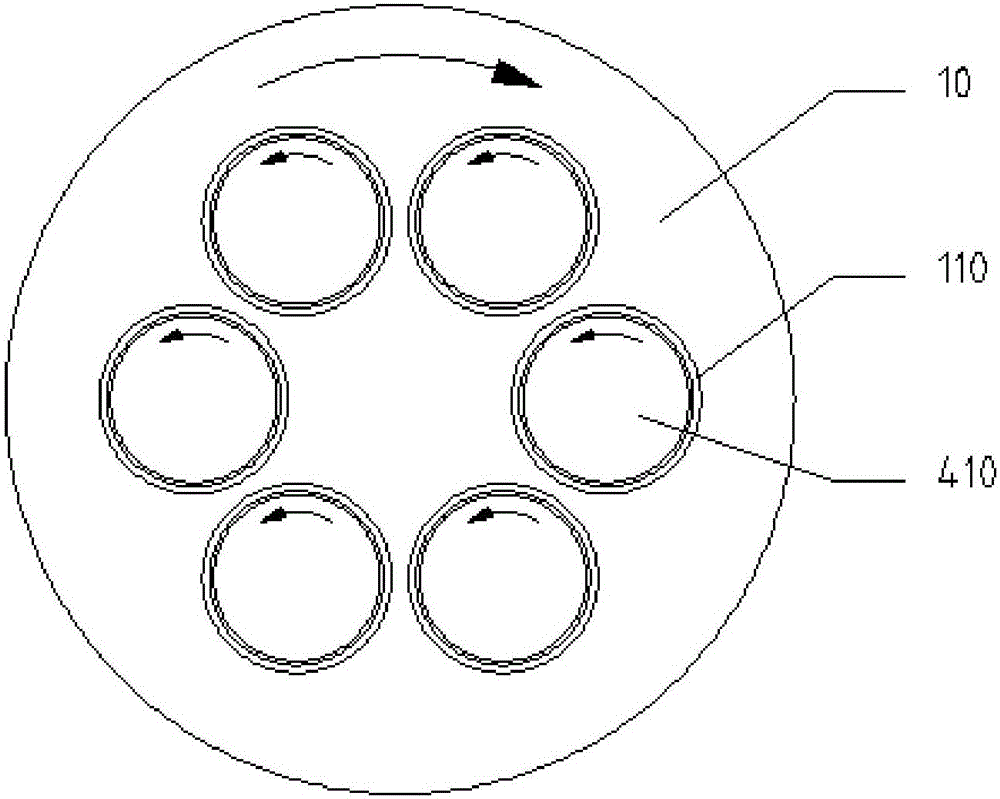

A battery (100, 200, 300), a heat management apparatus (101, 301) thereof and a UAV (10) having the battery. The heat management apparatus (101, 301) comprises: a heat conduction shell (110, 210, 220, 310) having an accommodation cavity (311), and at least one heat conduction frame (320) mounted inside the accommodation cavity (311), wherein the heat conduction frame (320) is connected to an inner wall of the accommodation cavity (311) in a heat-conducting manner, so that the heat of the heat conduction frame (320) can be conducted to the heat conduction shell (110, 210, 220, 310); the heat conduction frame (320) divides the accommodation cavity (311) into multiple battery cell bin positions (120, 330) for accommodating battery cells (103, 303); and the heat conduction frame (320) can be in contact with the battery cells (103, 303) so as to conduct the heat generated by the battery cells (103, 303). The above-mentioned heat management apparatus (101, 301) has the advantages of being able to improve the service life of a battery and eliminate a temperature difference between two adjacent battery cells (103, 303), a smaller volume, a lighter weight, a lower cost and less limitation on the selection of a battery.

Owner:SZ DJI TECH CO LTD

Selective warming and heat isolation for on board high pressure storage tanks installed on gas fueled vehicles

ActiveUS8256449B2Eliminate thermally induced leakReduce riskExhaust apparatusPipe heating/coolingLower limitControl system

A thermal management system for gas flow from an on board high pressure vehicle gas storage tank comprising an on board heat source operatively interconnected with a heater disposed in proximity to the metal component gas outlet flow control system of the on board tank; a thermostat regulating the flow of heat to the heater such that the thermostat regulates the temperature of the metal component outlet flow control system of the tank to a temperature corresponding to at least the minimum lower limit temperature permitted by the temperature tolerance range of metal component outlet flow control system of the tank; and an optional insulating shroud circumferentially disposed surrounding the gas flow heater installed in the system.

Owner:HONDA MOTOR CO LTD

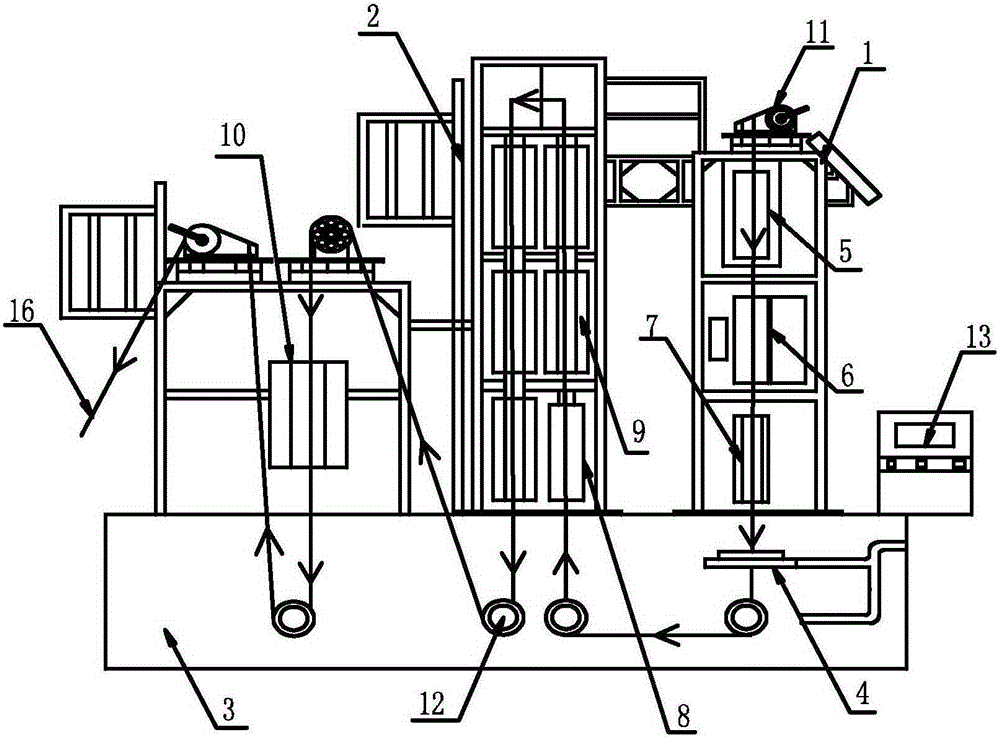

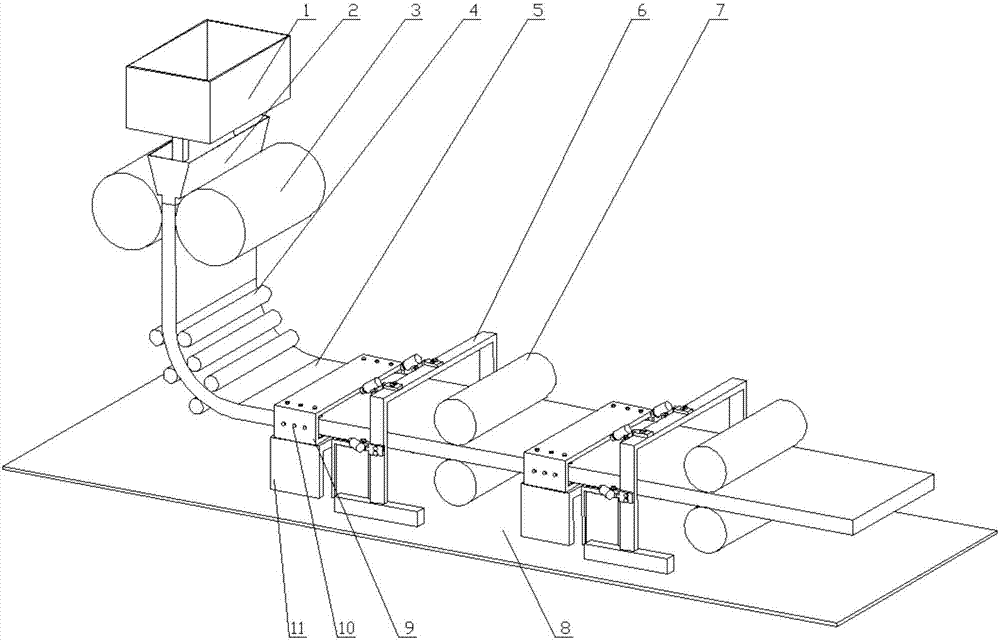

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Heat collection and storage wall and air-water heat collector combined heating system

ActiveCN109737486AIncrease profitMeet heat load demandsLighting and heating apparatusSpace heating and ventilation detailsSuper coolingEngineering

A heat collection and storage wall and air-water heat collector combined heating system comprises a heat collection and storage wall. The heat collection and storage wall is arranged on the outer sideface of a house. Air in the heat collection and storage wall is connected with an air inlet of an air-water heat collector through an air inlet pipeline under the effect of a draught fan. The air-water heat collector comprises a water outlet. The water outlet is connected with a coil pipe of a phase change heat storage floor through a water outlet pipeline, wherein the phase change heat storage floor is arranged on a bottom plate. The water outlet pipeline is provided with a first electric three-way joint. The first electric three-way joint is connected with a domestic hot water device through a pipeline. Temperature sensors used for sensing temperature are arranged in rooms. The air-water heat collector is connected with the first electric three-way joint. The heat collection and storagewall and air-water heat collector combined heating system can store heat and has all-day heating capacity, temperature differences between the south rooms and the north rooms are eliminated, and by means of the heat collection and storage wall and air-water heat collector combined heating system, the heat collector is protected against super-cooling and overheating.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

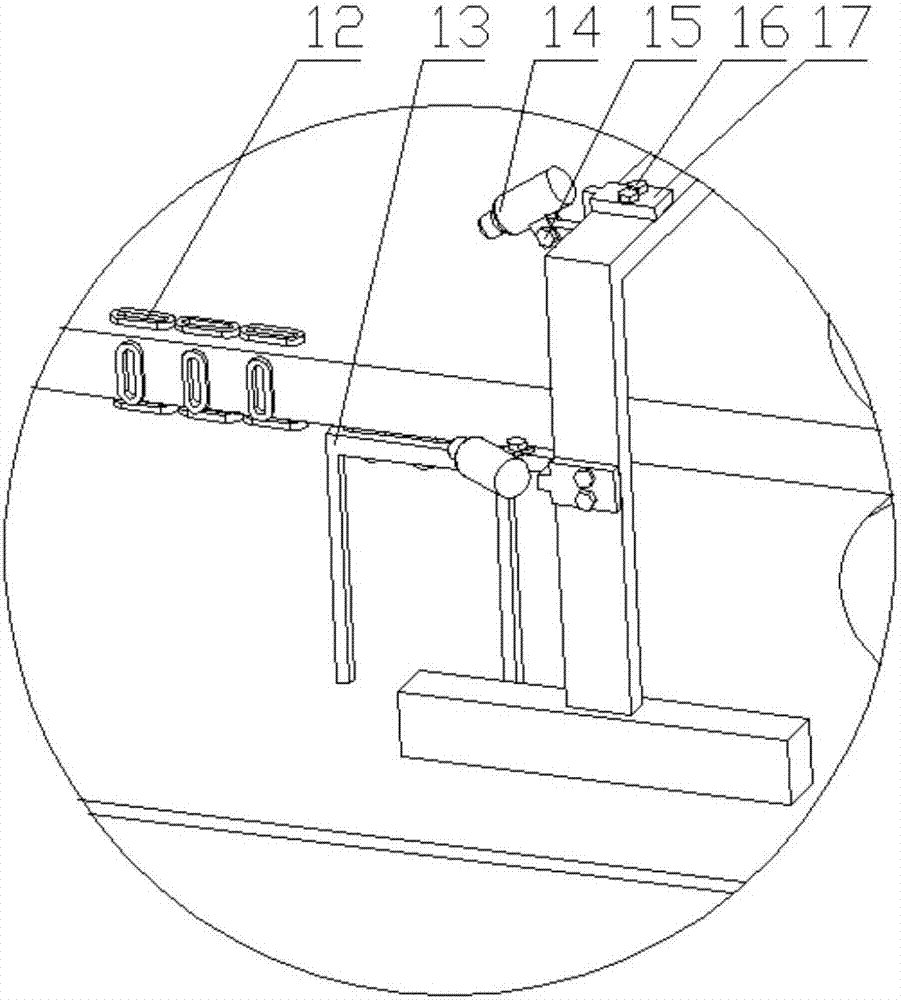

Titanium-alloy-plate tandem-rolling temperature controlling device and temperature controlling tandem-rolling method

ActiveCN107159719APrecise temperature controlAvoid warpingTemperature control deviceTemperature controlEngineering

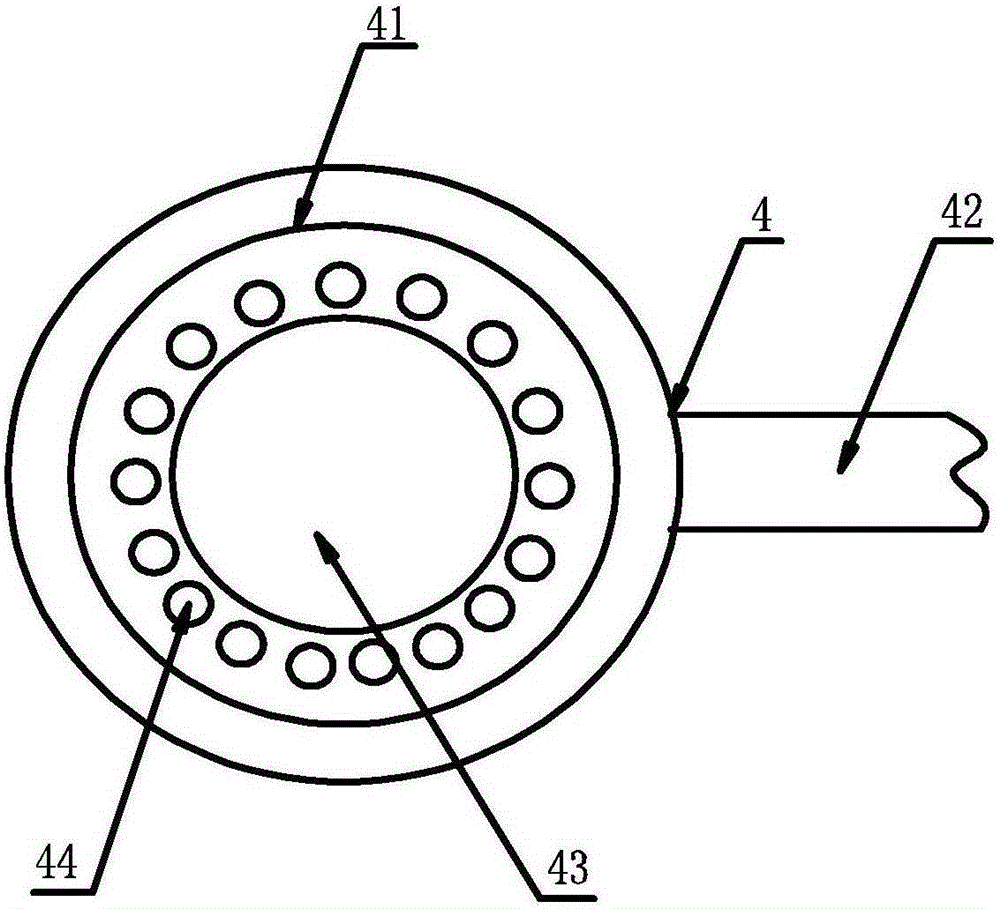

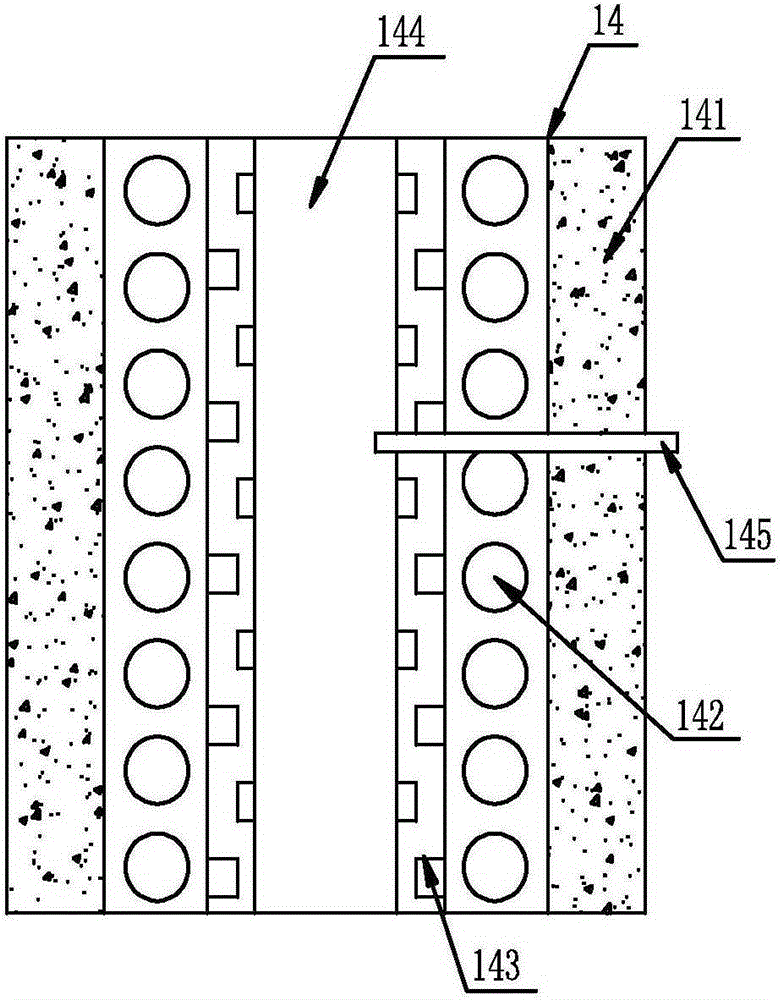

A titanium-alloy-plate tandem-rolling temperature controlling device comprises annular induction coils, supporting frames, stone boxes, trusses, supports and colorimetric pyrometers. The trusses are arranged in front of rolling rollers correspondingly, each two colorimetric pyrometers are arranged on a cross beam of the corresponding truss, each colorimetric pyrometer is arranged on a vertical beam of one side of the corresponding truss, and the included angle of each colorimetric pyrometer and the titanium-alloy-plate surface can be adjusted; the supporting frames are arranged on the positions which are away from the trusses for 2 meters correspondingly, the stone boxes are fixed on the supporting frames, a rolled titanium-alloy plate passes from the inner portions of the stone boxes, and annular induction coil sets are arranged on the upper surfaces, the lower surfaces and the side surfaces of the two sides of the inner portion of each stone box; and the annular induction coil sets are all away from the surface of the titanium-alloy plate for 2 centimeters, each set of the annular induction coil sets comprises 3 annular induction coils, and the annular induction coils can heat the plate edge of the titanium-alloy plate after being electrified. According to the titanium-alloy-plate tandem-rolling temperature controlling device, the temperature difference in the titanium-alloy plate in the whole tandem-rolling process can be eliminated, the temperature of the titanium-alloy plate in the rolling process can be accurately controlled, and warping of panels is avoided.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

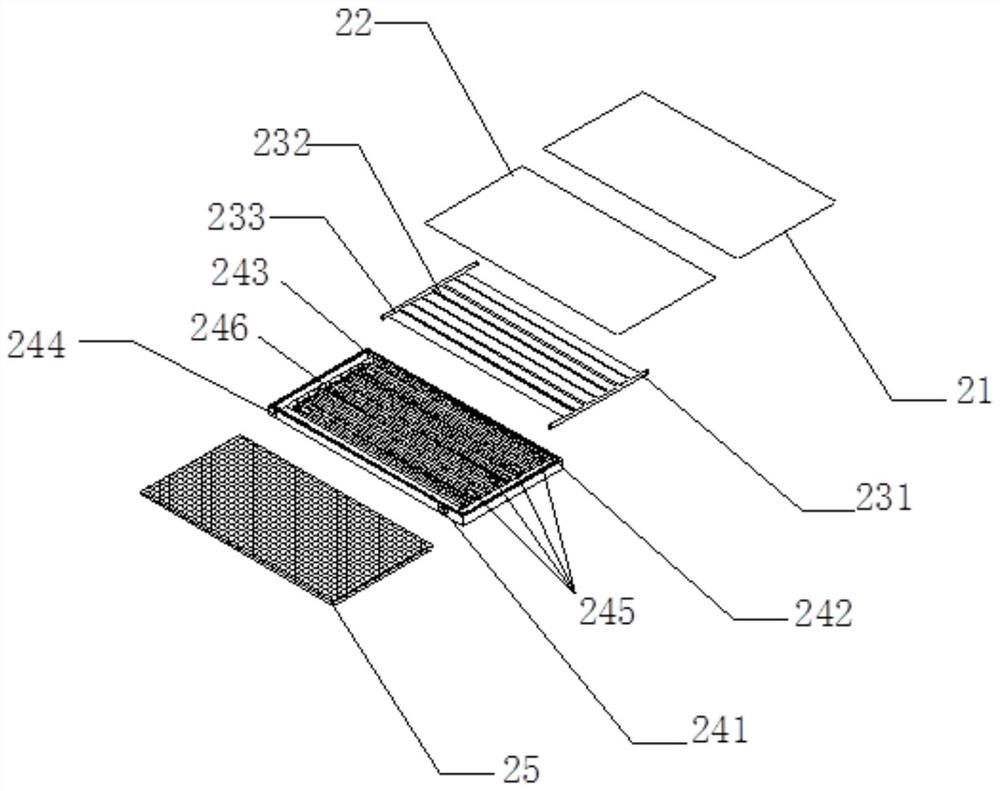

Permeation device and method

ActiveCN105063550AEliminate temperature differencesImprove consistencyVacuum evaporation coatingSputtering coatingVacuum pumpingSintered magnets

The invention discloses a permeation device and method. The permeation device comprises a heating chamber, a rotary tray, rotary brackets, material boxes, a lifting mechanism and a transmission device, wherein the heating chamber is provided with an annular groove, and the rotary tray is arranged below the opening end of the lower end of the heating chamber; the rotary brackets are mounted on the rotary tray; the material boxes are arranged on the rotary brackets; the rotary brackets and the material boxes can ascend and descend under the action of the lifting mechanism; the rotary brackets can rotate in the annular groove under the action of the transmission device and revolve around the center axis of the rotary tray. The permeation method comprises the steps of material charging, vacuum pumping, high-temperature permeation, cooling, material taking and other steps. By means of the permeation device and method, the condition equality of the magnet positions and the condition equality of the heating environment are both achieved, so that the uniformity of the temperature condition required by sintered magnets in the high-temperature permeation and air cooling process is satisfied, and the consistency of properties of products is guaranteed.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD +1

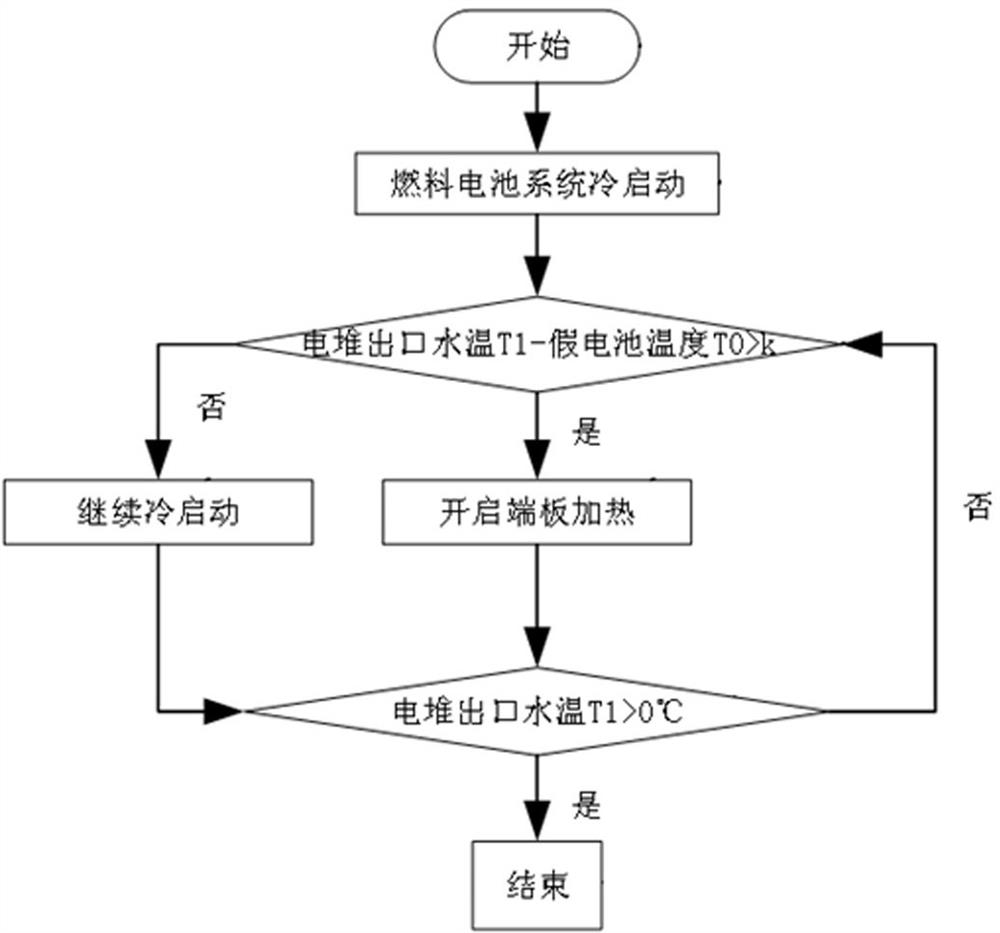

Fuel cell stack device

PendingCN114824405ARealize integrated functional designDoes not affect consistencyReactant parameters controlMotive system fuel cellsFuel cellsPtru catalyst

The invention provides a fuel cell stack device, belongs to the technical field of fuel cells, and solves the problem that the use performance and the service life of a stack are affected due to overlarge working state difference of single cells at different positions in the prior art. The device comprises a plurality of single batteries which are stacked into a whole, and a false battery, a collector plate, an insulating plate and an end plate which are sequentially stacked on the outer sides of the first battery and the last battery respectively. Wherein the false battery adopts a sheet structure and comprises a bipolar plate, a membrane electrode without a catalyst, a cathode and an anode gas flow channel. And in the false battery, the membrane electrode is arranged in the middle of the bipolar plate so as to isolate the cathode gas flow channel and the anode gas flow channel on the two sides of the bipolar plate. And a cathode gas flow channel, an anode gas flow channel and a water flow channel are arranged in the bipolar plate in the false battery. And a state detection sensor for measuring the internal state of the false battery is arranged in the cathode and anode gas flow channel or the water flow channel. According to the device, the integrated function design of condensed water removal and inter-sheet working difference adjustment can be realized.

Owner:BEIJING SINOHYTEC

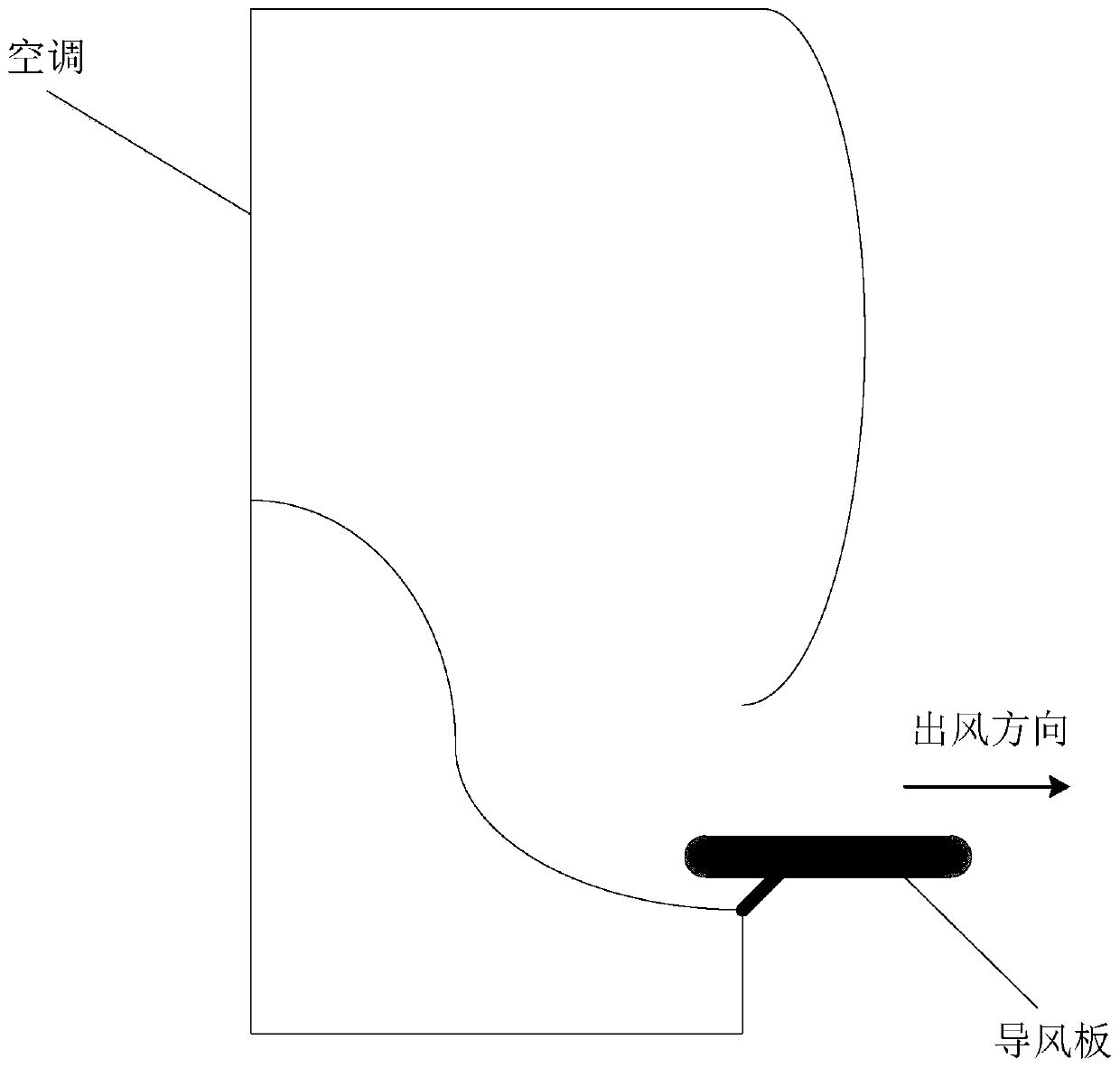

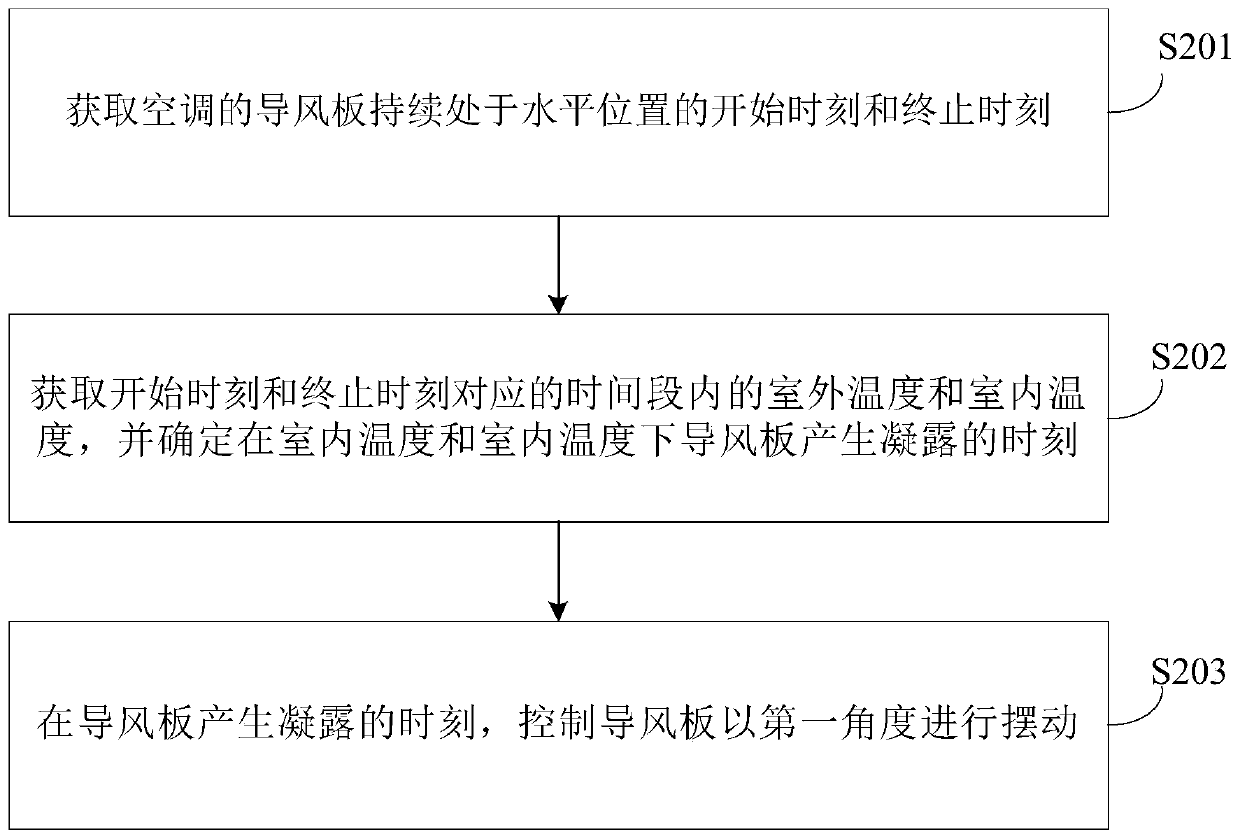

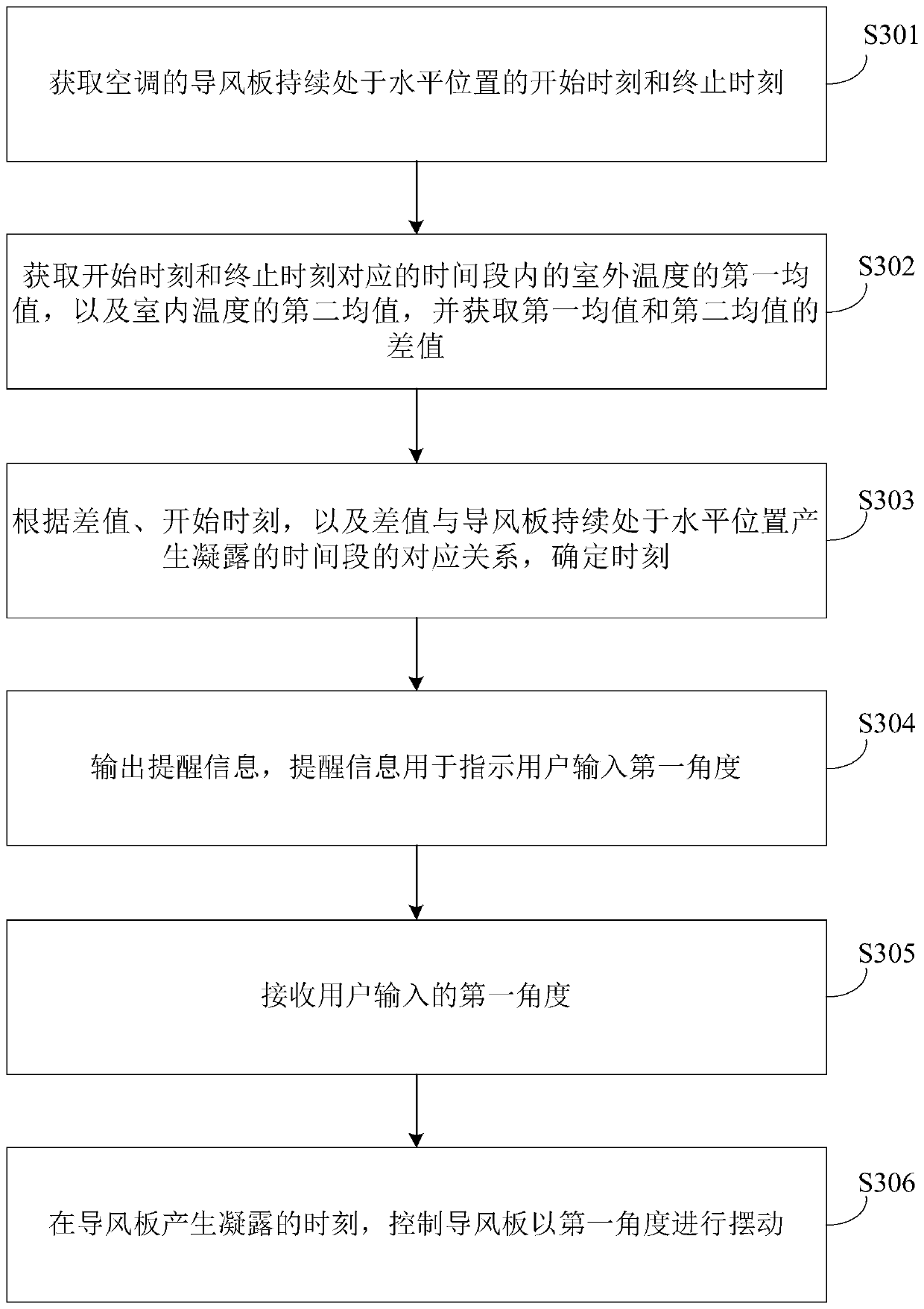

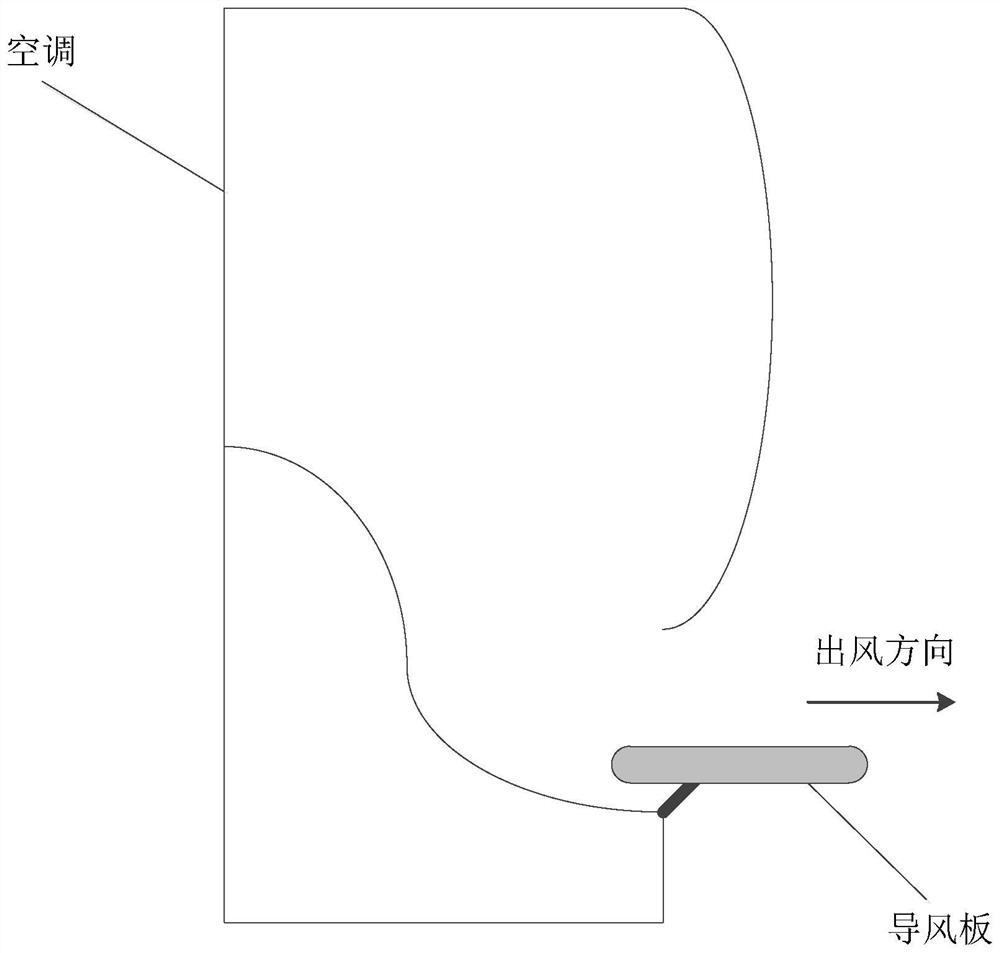

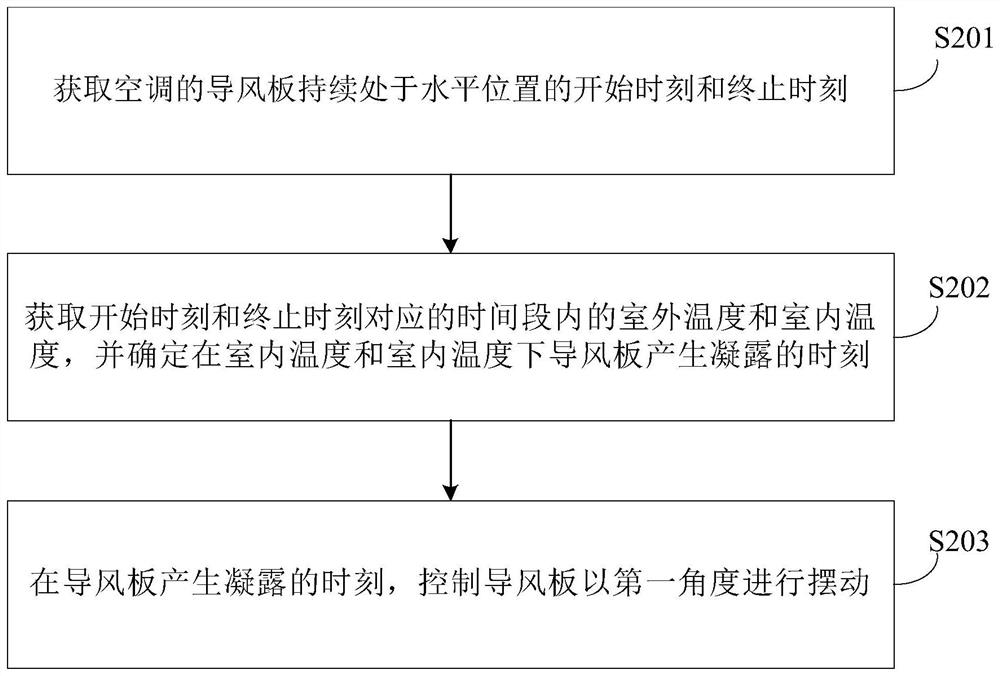

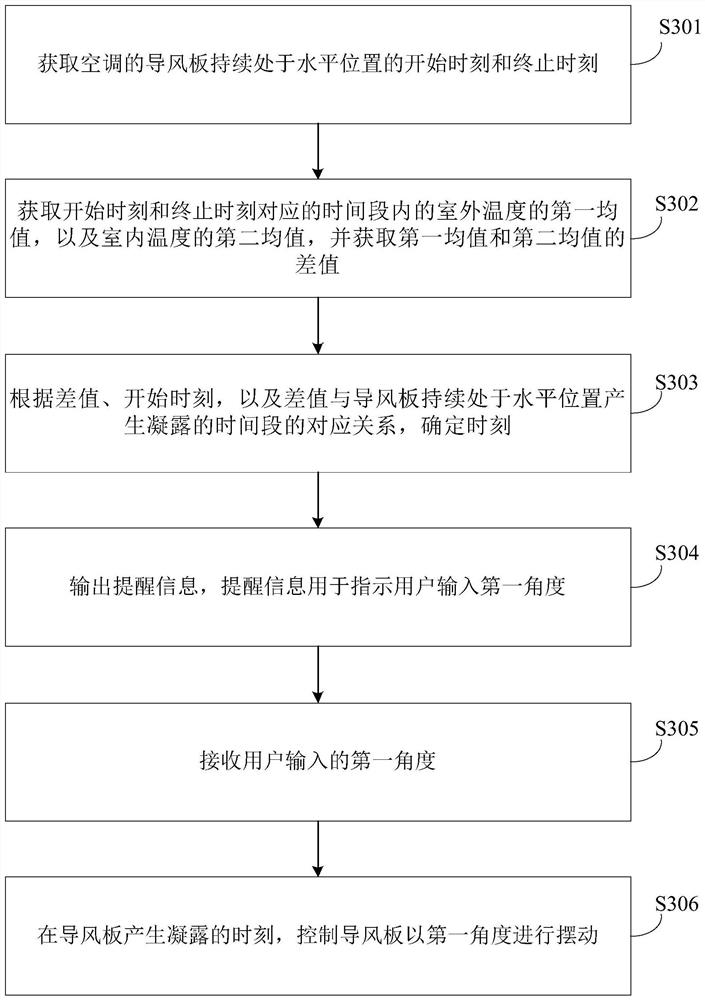

Anti-condensation method and device, electronic device and storage medium

ActiveCN110608524ADoes not affect cooling and heating efficiencyEliminate temperature differencesMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceEngineering

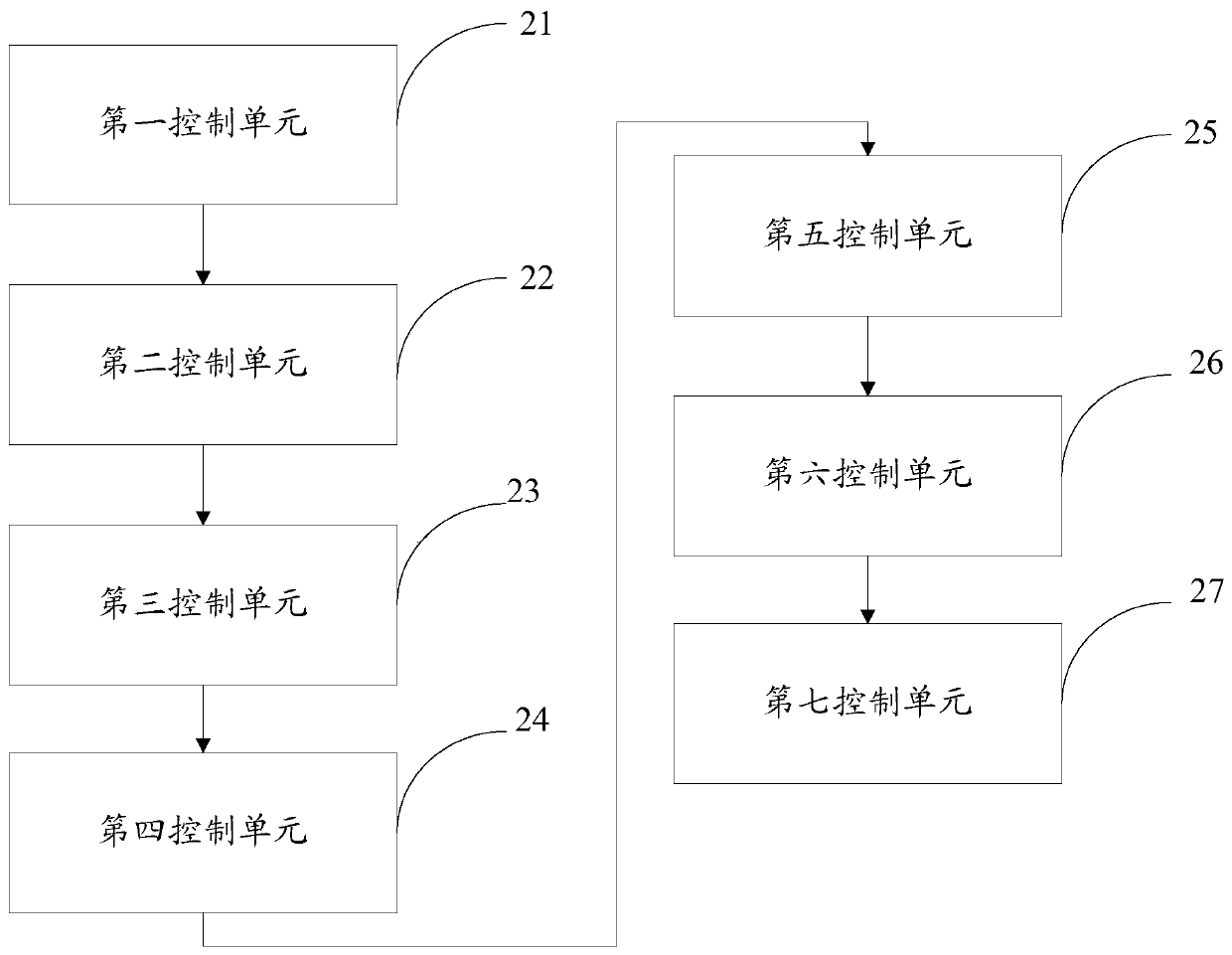

The invention provides an anti-condensation method and device, an electronic device and a storage medium. The method comprises the following steps that a starting moment and an ending moment of an airdeflector of an air conditioner continuously in a horizontal position are acquired; an outdoor temperature and an indoor temperature in the time period corresponding to the starting moment and the ending moment are acquired, and the moment when condensation is generated on the air deflector at the outdoor temperature and the indoor temperature is determined; and the air deflector is controlled toswing at the first angle when the condensation is generated on the air deflector. According to the anti-condensation method, according to the outdoor temperature and the indoor temperature in the time period when the air deflector of the air conditioner is continuously in the horizontal position, the moment when the condensation is generated is pre-determined, and the air deflector is controlledto swing at the moment, so that the temperature difference at the air deflector is eliminated, and the purpose of avoiding generation of condensation is achieved on the premise that the refrigerationand heating efficiency of the air conditioner is not affected.

Owner:ZHENGZHOU HAIER AIR CONDITIONER CO LTD

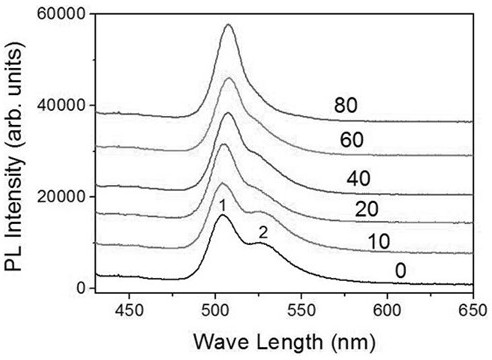

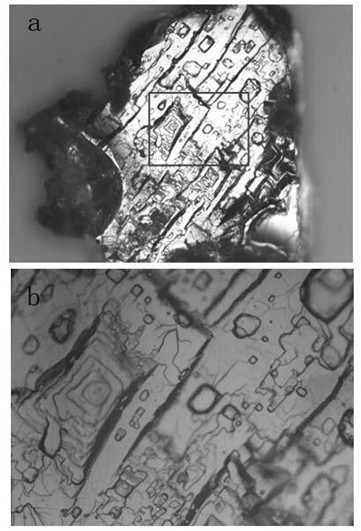

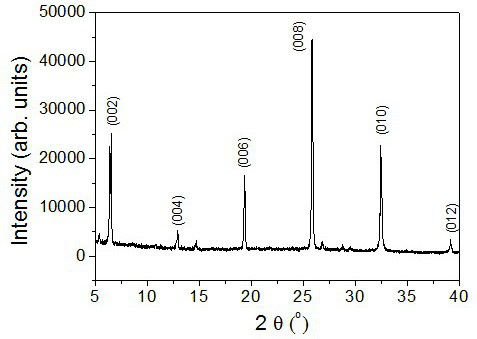

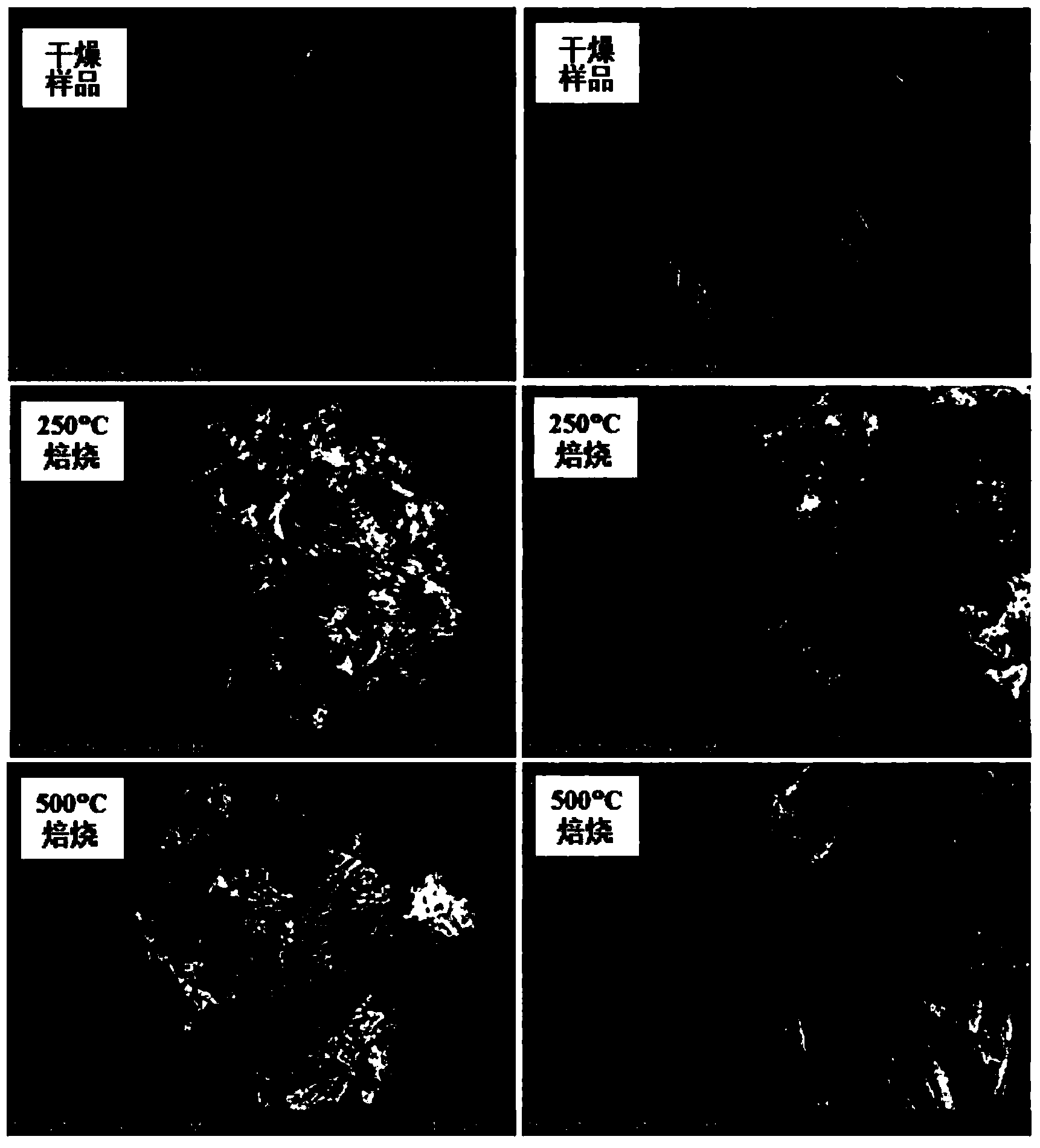

Preparation method of two-dimensional perovskite single crystal with high luminous purity

InactiveCN112064104AElimination of double photoluminescenceAvoid accumulationPolycrystalline material growthFrom normal temperature solutionsOctahedronPhotoluminescence

The invention discloses a preparation method of a two-dimensional perovskite single crystal with high luminescence purity. A hydrothermal technology is introduced into a solution cooling method to prepare a (BA) 2PbI4 single crystal. As the temperature in the hydrothermal kettle is uniform, the temperature difference between the inside and the outside of the crystal can be eliminated; in the growth process of the (BA) 2PbI4 single crystal, BA organic cations tend to be arranged in order due to the fact that the BA 2PbI4 single crystal bears gas pressure, accumulation of the cations is avoided,and thus the double photoluminescence phenomenon of the two-dimensional (BA) 2PbI4 single crystal is eliminated, and the luminescence purity of the two-dimensional (BA) 2PbI4 single crystal is improved. The (BA) 2PbI4 crystal prepared by adopting a hydrothermal auxiliary solution cooling method is a lamellar lamellar single crystal. The structure of the [PbI6] 4-octahedron is an orthogonal crystal structure. Compared with a (BA) 2PbI4 crystal prepared by a solution cooling method in the prior art, the luminescence purity of the sample prepared by the method is obviously improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

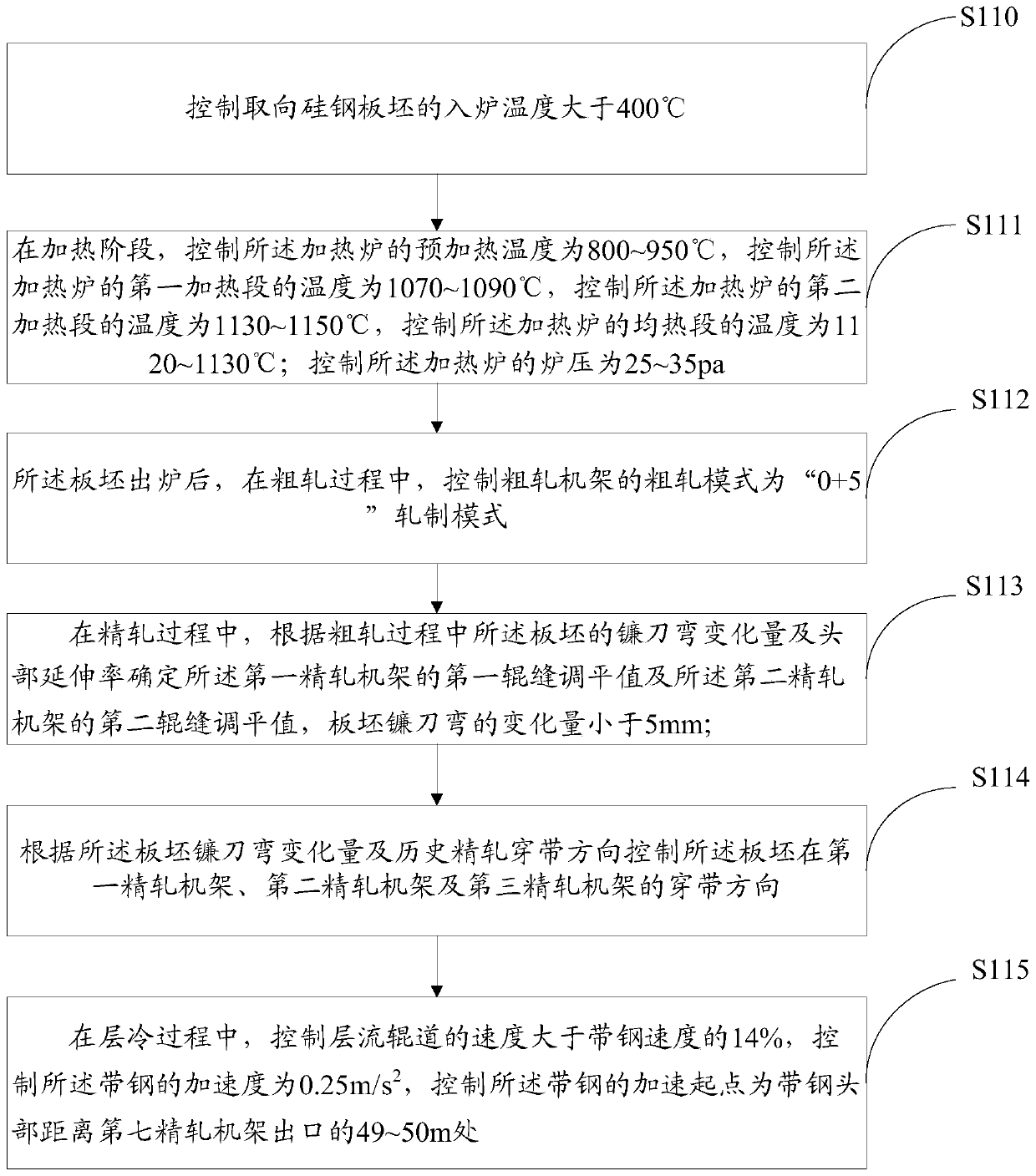

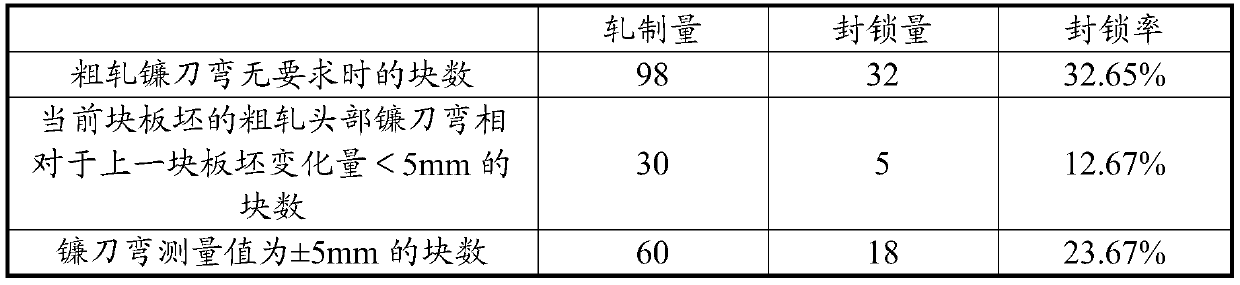

Method and device for controlling asymmetric flatness of oriented silicon steel

ActiveCN110586659AImprove asymmetric straightnessAvoid wavyRoll force/gap control deviceMetal rolling arrangementsStrip steelSilicon

The invention provides a method for controlling asymmetric flatness of oriented silicon steel. The method comprises the steps of controlling charging temperature of an oriented silicon steel slab to be greater than 350 DEG C, controlling preheating temperature to be 800-950 DEG C, controlling temperature of a first heating zone to be 1070-1090 DEG C, controlling temperature of a second heating zone to be 1130-1150 DEG C, and controlling temperature of a soaking zone to be 1120-1130 DEG C; controlling furnace pressure to be 25-35 pa; controlling a rough rolling mode to be a '0+5' rolling mode;determining roll gap leveling values of a first finish rolling rack and a second finish rolling rack, wherein variation amount of slab camber is less than 5 mm; controlling threading directions of theslab on the first finish rolling rack, the second finish rolling rack and a third finish rolling rack; and in the layer cooling process, controlling speed of a laminar flow roller table to be greaterthan 14% that of strip steel, controlling accelerated speed of the strip steel to be 0.25 m / s<2>, and controlling acceleration starting point of the strip steel to be located in the position where ahead of the strip steel is 49-50 m away from an outlet of a seventh finish rolling rack.

Owner:BEIJING SHOUGANG CO LTD

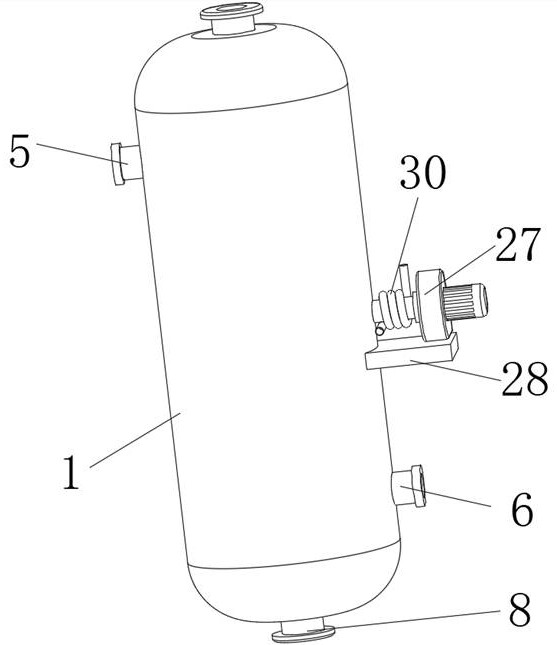

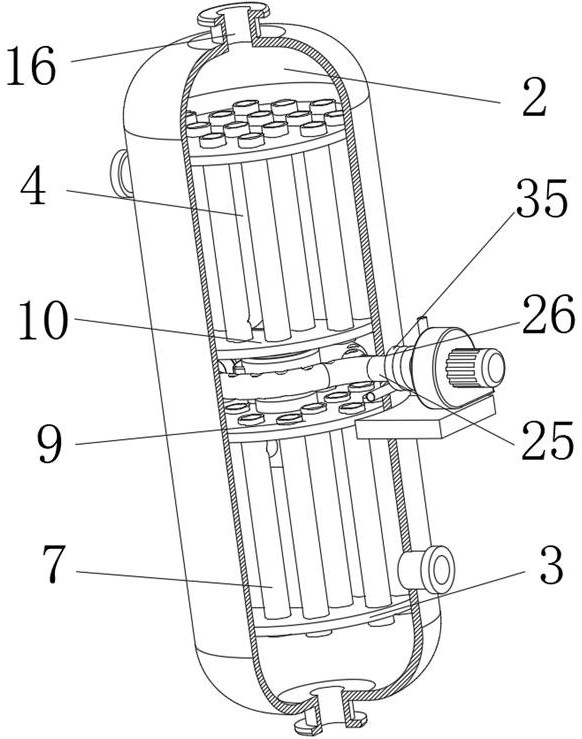

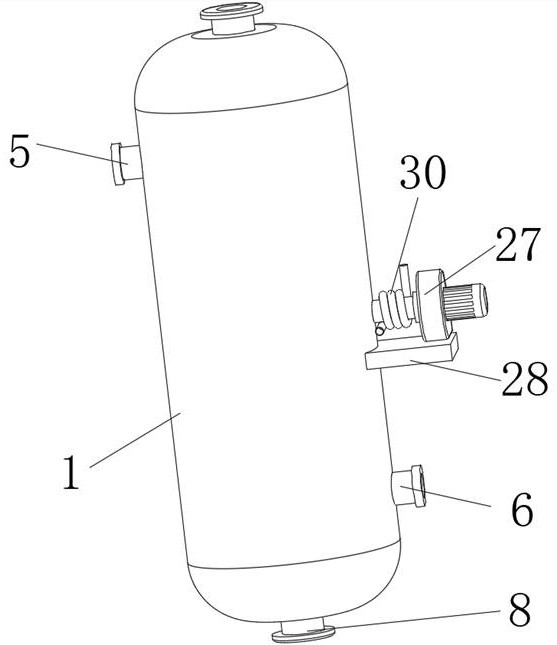

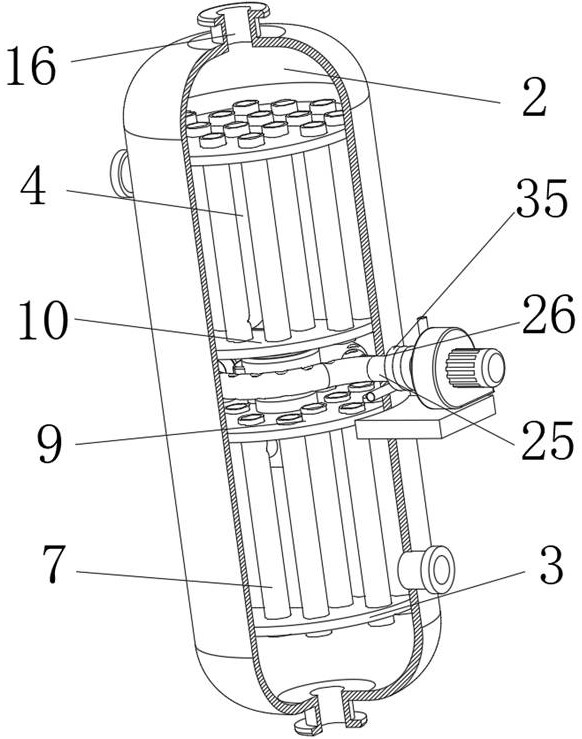

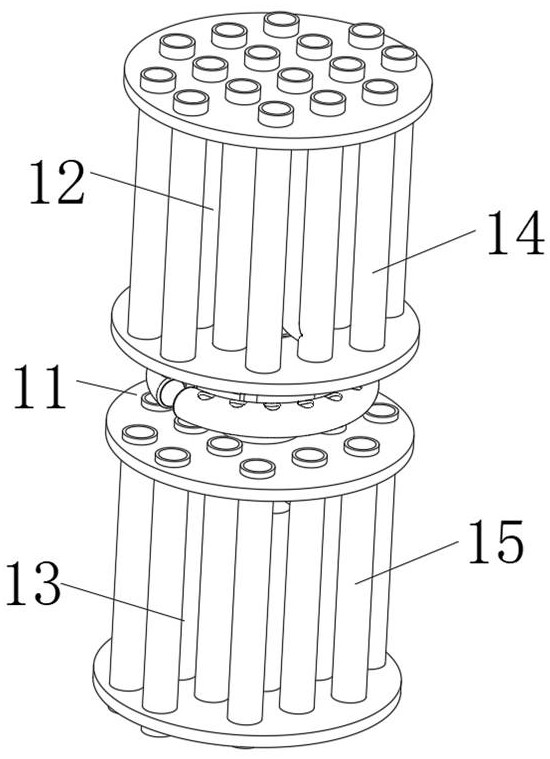

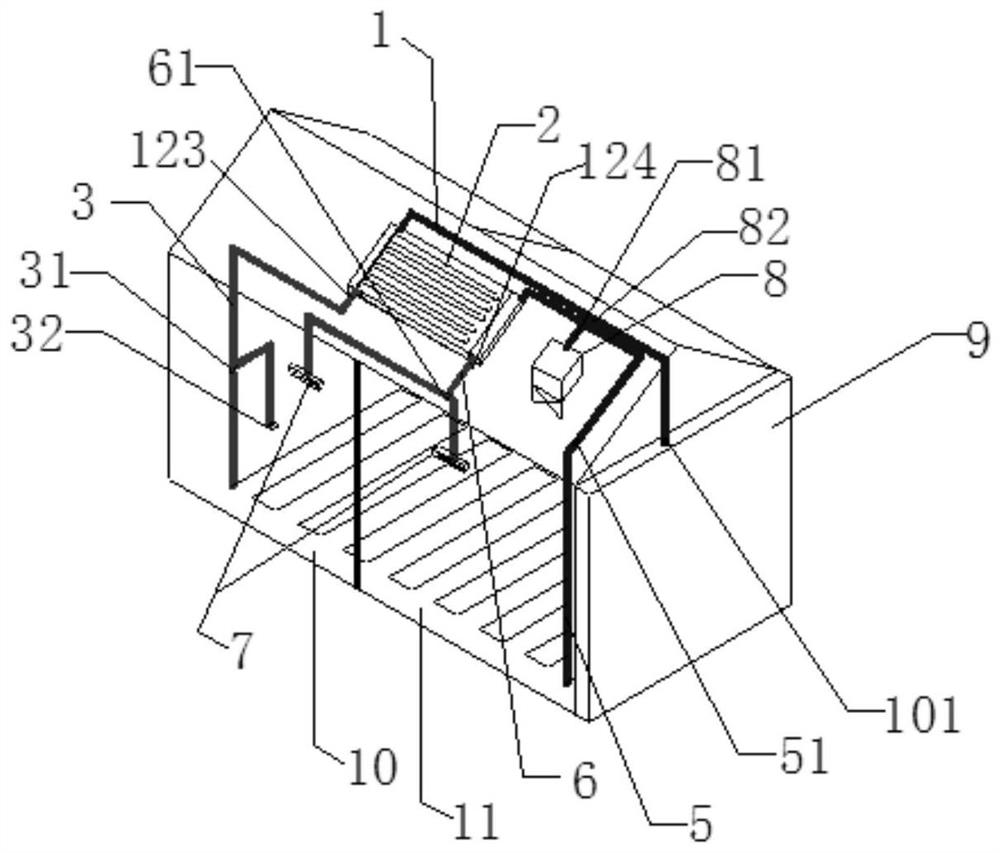

Perturbator structure for gas-phase aldehyde hydrogenation reactor

ActiveCN111701538AOptimize existing technologyEliminate temperature differencesChemical/physical processesPhysicsHeat carrier

The invention discloses a perturbator structure for a gas-phase aldehyde hydrogenation reactor. The structure comprises a pipe body; a cavity is formed in the pipe body; first partition plates are arranged in the cavity; an air inlet is formed in one side of the upper part of the pipe body; air outlet is formed in one side of the lower part of the pipe body, and the air inlet and the air outlet are both located between the two first partition plates. A plurality of tiny pipes are fixedly arranged between two first partition plates in a penetrating manner; and the upper part and the lower partof the pipe body are both provided with a through opening used for enabling a heat carrier to circulate inside and outside the pipe body. A disturbance structure is arranged on the pipe body; throughthe perturbator structure for a gas-phase aldehyde hydrogenation reactor, the disturbance structure is adopted; a conventional technology is optimized, the heat carrier can enter the cavity from the two ends of the pipe body at the same time; furthermore, the heat removed from the upper part of the pipe body is the same as the heat removed from the lower part of the pipe body, the temperature difference between the upper part and the lower part of the pipe body is eliminated, the selectivity of a catalyst in the upper part of the pipe body is guaranteed, the service life of the catalyst is ensured, the excess temperature of the upper part of the pipe body is prevented, and thus the production of alcohol is guaranteed.

Owner:NINGBO JUHUA CHEM TECH CO LTD

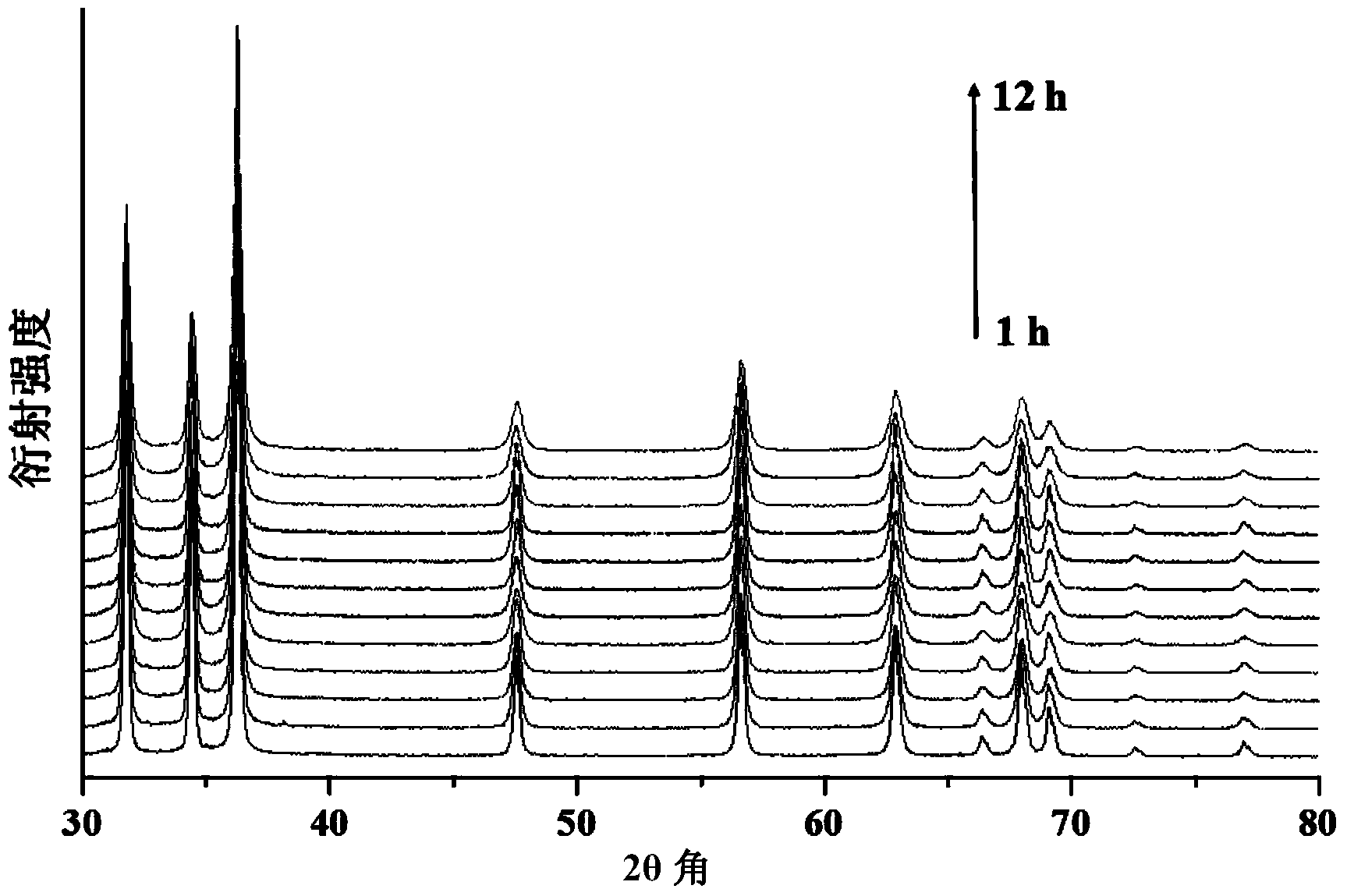

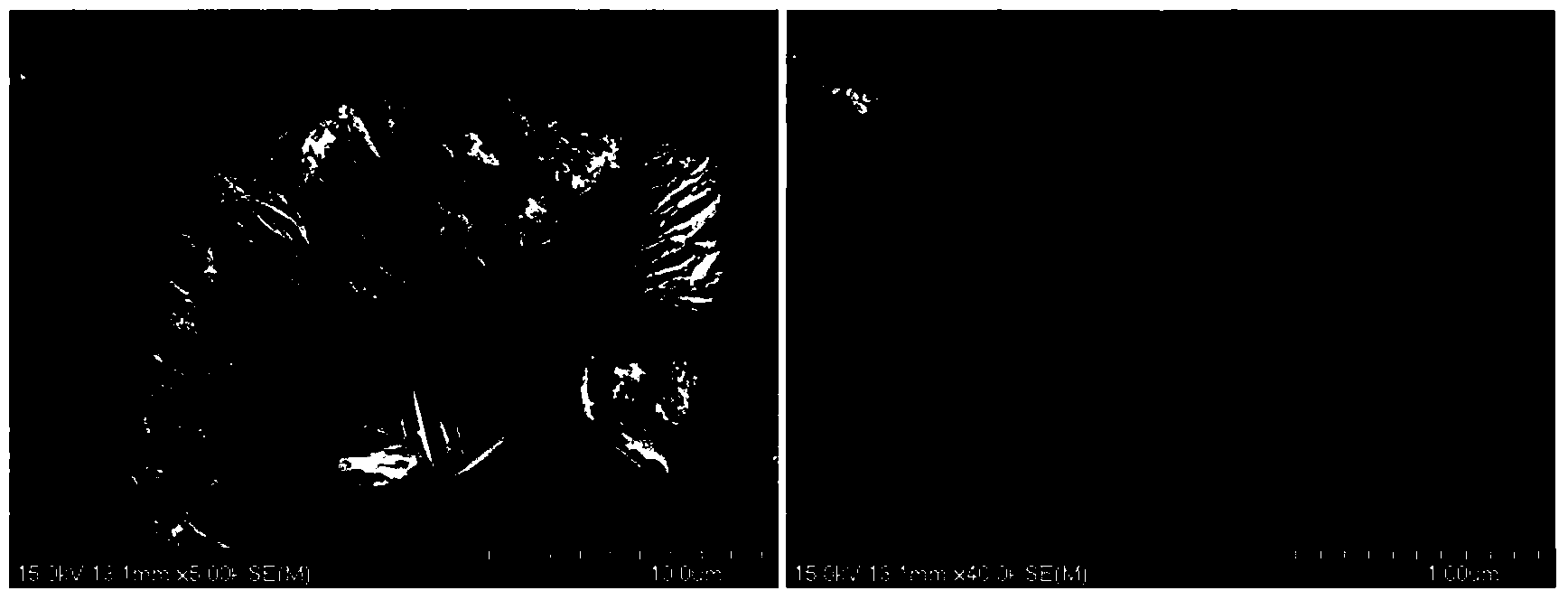

Preparation method of ZnO nano porous sheet cluster

ActiveCN104229866AReduce the volatile surface areaUniform shapeZinc oxides/hydroxidesZinc nitrateZinc nitrate hexahydrate

The invention discloses a preparation method of a ZnO nano porous sheet cluster. The reparation method comprises the steps of mixing raw materials, namely zinc nitrate and urea, with water, adding the mixture to a cylindrical container having the inner diameter of 10-50mm, sealing, heating to the range of 80-100 DEG C for reacting under normal pressure for 1-15h, and finally, performing filtering, drying and roasting treatment to obtain the ZnO nano porous sheet cluster. The cylindrical reactor with the special inner diameter is adopted for the preparation method of the ZnO nano porous sheet cluster so that the ZnO nano porous sheet cluster can be prepared by reacting the zinc nitrate with the urea under the condition of a high Zn<2+> concentration, and therefore, the production efficiency of ZnO can be improved.

Owner:嘉善县国创新能源研究院

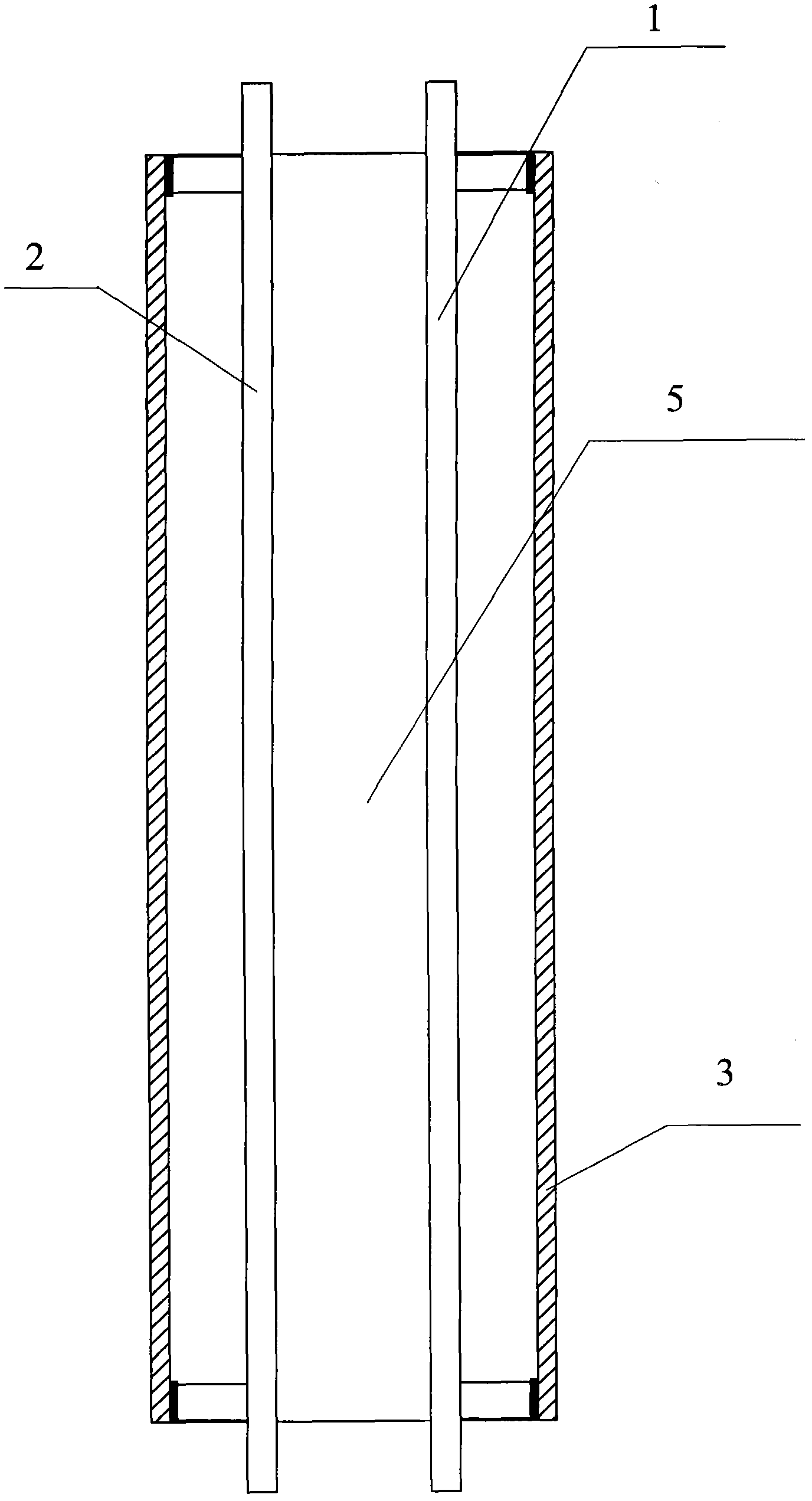

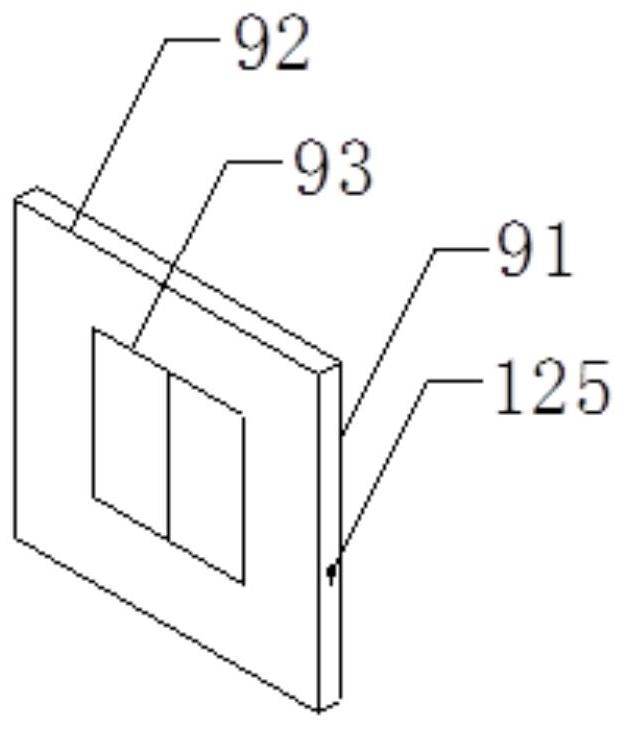

Battery

InactiveCN102569866BStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingEngineering

A battery may be provided. The battery may comprise: a battery housing (90) having at least an opening end; a battery cover sealing the opening end; an electric core received in the battery housing (90) which comprises a positive heat-conducting member (1) and a negative heat-conducting member (2) that are electrically insulated from each other, the positive heat-conducting member (1) and the negative heat-conducting member (2) each having at least an end penetrating through the battery cover respectively; and an electrolyte filled in a space formed by the battery housing (90) with the battery cover.

Owner:BYD CO LTD

A lithium battery filler

ActiveCN103840223BEffective coolingImprove cooling effectSecondary cells servicing/maintenanceBatteriesCombustionWorking temperature

The invention relates to a lithium battery filling agent. The lithium battery filing agent is used for filling a gap of a lithium battery pack and comprises the following components in percentage by mass: 25%-90% of paraffin, 5%-70% of a flame retardant and 3%-20% of a cooling agent. The lithium battery can be efficiently cooled, the technology is simple, and no peripheral cooling device is needed; as the flame retardant is added, heat produced in a using process of the battery pack can be absorbed, and when the temperature of a battery is too high and is close to or higher than a combustion value of paraffin, a flame retardant effect can be realized and potential safety hazards, such as outbreak of a fire and explosion, of the lithium battery can be eliminated; cooling is carried out from interior of the battery pack by adding the cooling agent, the cooling capacity of the lithium battery is further improved, the working temperature of the lithium battery is reduced, the temperature of the battery pack is uniform, the temperature difference among batteries in the battery pack is eliminated, and accidents that the batteries are soft and bulged as local temperature is too high owning to nonuniform cooling of the battery pack can be effectively prevented.

Owner:河南平原众创知识产权运营管理有限公司

Pretreatment refining method for broad width silk fabric

ActiveCN109056310AResolve uneven diffusionSolve the temperature differenceBiochemical treatment with enzymes/microorganismsGrip property fibresMetallurgyThermal water

The invention discloses a pretreatment refining method for a broad width silk fabric and belongs to the technical field of silk product pretreatment. The pretreatment refining method is characterizedby comprising the following treatment steps of charging water in a dyeing groove on a vehicle, performing heating to 58-63 DEG C, performing running for 2 passes, and draining off water; after preheating a large shaft, adding hot water with the temperature being 96-99 DEG C in the dyeing groove, and adding a refining additive; sealing a cover, performing running for 4 passes, and draining off thewater; performing washing for 3 passes with the hot water at the temperature of 96-99 DEG C, and then pouring the shaft with cold water; adding water in the dyeing groove, adding baking soda and desizing powder ZS-20 to prepare a refined solution, performing crystal form refining, performing running for 5-6 passes, and performing 4 cycles of back vehicles; and performing washing for 2 passes withthe hot water at the temperature of 96-99 DEG C, and then pouring the shaft with the cold water. The invention provides the pretreatment refining method aiming to the broad width silk fabric and mainly solves the defects of hard hand feeling of a head and a tail and different hand feelings at the left part and the right part of degumming of a silk fabric on a jig dyeing machine.

Owner:ZIBO DARANFANG SILK GRP

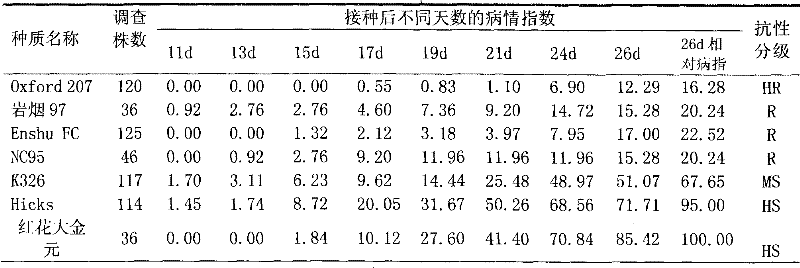

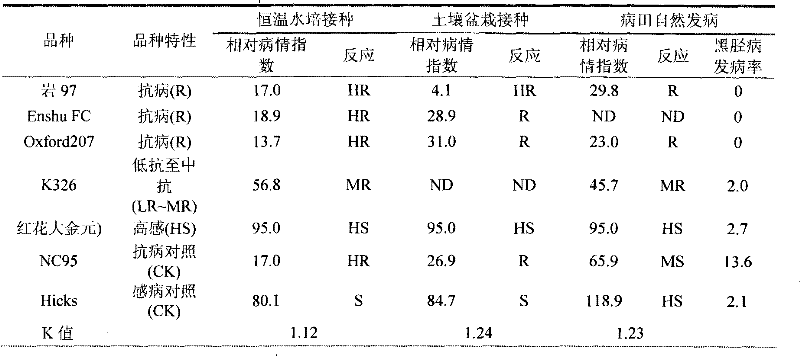

Method for identifying resistance to tobacco bacterial wilt during seedling stage

InactiveCN101496481BHigh densityLow costBacteriaAgriculture gas emission reductionDiseaseNicotiana tabacum

The invention relates to a seedling stage identification method for the resistance of tobacco to the bacterial wilt. The seedling stage identification method comprises the steps of heat preservation pool construction, pool water heating and circulation, wilt bacterium inoculation, tobacco seedling, disease state investigation and grading. The method replaces a conventional field identification result with a seedling stage identification result, identifies a great amount of material in a smaller area, carries out the identification a plurality of times annually, improves the reliability of theresult, shortens the identification cycle, saves the site and test cost, and covers little floor space. The seedling stage identification method for the resistance of tobacco to the bacterial wilt ischaracterized by rapid disease development, good result repeatability, and the like. The seedling stage identification method for the resistance of tobacco to the bacterial wilt can effectively remove the interference on the resistance result caused by soil temperature difference, strain pathogenicity difference, strain quantity difference and other diseases, thereby benefiting the recurrence andcomparison of results from different years and different labs. The difference between the attack rates of infection resistant varieties and the disease indexes is obvious; and the appraisal result ofthe resistance of the variety is basically consistent with the perennial resistance appraisal result obtained by others. The method has greater application potential in the resistance identification and resistance heredity rule study of disease resistant resources and breeding medium materials.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Infrared radiation temperature measurement calibration device and calibration method for chemical vapor deposition equipment

ActiveCN103712695BEliminate temperature differencesRelative temperature is accurateRadiation pyrometryFiberGas phase

The invention discloses an infrared radiation temperature measurement calibrating device for chemical vapor deposition equipment, and a calibration method thereof. The optical detection holes capable of light transmission, of the calibrating device are arranged in a spraying disc; infrared radiation temperature testers are arranged to be corresponding to the optical detection holes in the spraying disc; and fibers or light beams are fixed through a black-body furnace end clamp and a detection hole end clamp and are connected between a black-body furnace and the optical detection holes. Through the fibers or the light beams, infrared radiation of the black-body furnace is introduced to the optical detection openings of the spraying disc of the metal organic chemical vapor deposition equipment, and on-line calibration can be performed on the infrared radiation temperature testers above the spraying disc. The advantages are as follows: the structure is simple, temperature differences caused by system errors and assembling factors of an infrared radiation temperature tester system itself can be eliminated, the relative temperature tested by each infrared radiation temperature tester is more accurate, and the uniformity adjustment of the surface temperature of a substrate bearing plate is facilitated, thus the problem of temperature calibration of the metal organic chemical vapor deposition equipment is solved.

Owner:甘志银

Anti-condensation method, device, electronic equipment and storage medium

ActiveCN110608524BDoes not affect cooling and heating efficiencyEliminate temperature differencesMechanical apparatusSpace heating and ventilation safety systemsStart timeOutdoor temperature

The present application provides an anti-condensation method, device, electronic equipment, and storage medium, the method including: obtaining the start time and end time when the wind deflector of the air conditioner is continuously in a horizontal position; obtaining the time period corresponding to the start time and end time The outdoor temperature and the indoor temperature inside, and determine the moment when the air deflector produces condensation under the indoor temperature and the indoor temperature; when the air deflector produces condensation, control the air deflector to swing at the first angle. The anti-condensation method provided in this embodiment can predetermine the moment when condensation occurs according to the outdoor temperature and indoor temperature during the time period when the wind deflector of the air conditioner is continuously in a horizontal position, and control the swing of the wind deflector at this moment, In order to eliminate the temperature difference at the air deflector, and then achieve the purpose of preventing condensation without affecting the cooling and heating efficiency of the air conditioner.

Owner:ZHENGZHOU HAIER AIR CONDITIONER CO LTD

Disruptor structure for gas-phase aldehyde hydrogenation reactor

ActiveCN111701538BEliminate temperature differencesIncrease temperatureChemical/physical processesPtru catalystHeat carrier

The invention discloses a perturbator structure for a gas-phase aldehyde hydrogenation reactor. The structure comprises a pipe body; a cavity is formed in the pipe body; first partition plates are arranged in the cavity; an air inlet is formed in one side of the upper part of the pipe body; air outlet is formed in one side of the lower part of the pipe body, and the air inlet and the air outlet are both located between the two first partition plates. A plurality of tiny pipes are fixedly arranged between two first partition plates in a penetrating manner; and the upper part and the lower partof the pipe body are both provided with a through opening used for enabling a heat carrier to circulate inside and outside the pipe body. A disturbance structure is arranged on the pipe body; throughthe perturbator structure for a gas-phase aldehyde hydrogenation reactor, the disturbance structure is adopted; a conventional technology is optimized, the heat carrier can enter the cavity from the two ends of the pipe body at the same time; furthermore, the heat removed from the upper part of the pipe body is the same as the heat removed from the lower part of the pipe body, the temperature difference between the upper part and the lower part of the pipe body is eliminated, the selectivity of a catalyst in the upper part of the pipe body is guaranteed, the service life of the catalyst is ensured, the excess temperature of the upper part of the pipe body is prevented, and thus the production of alcohol is guaranteed.

Owner:NINGBO JUHUA CHEM TECH CO LTD

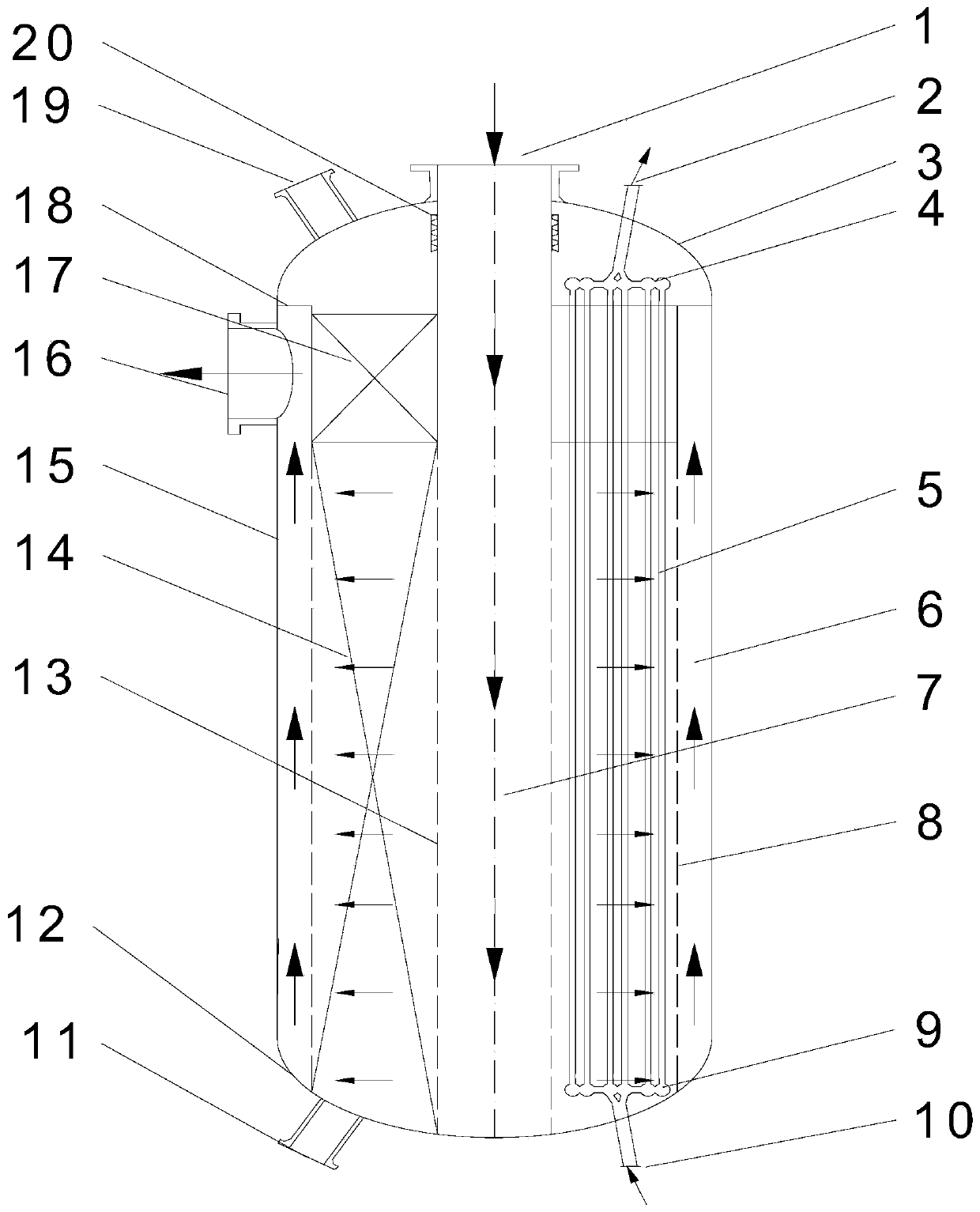

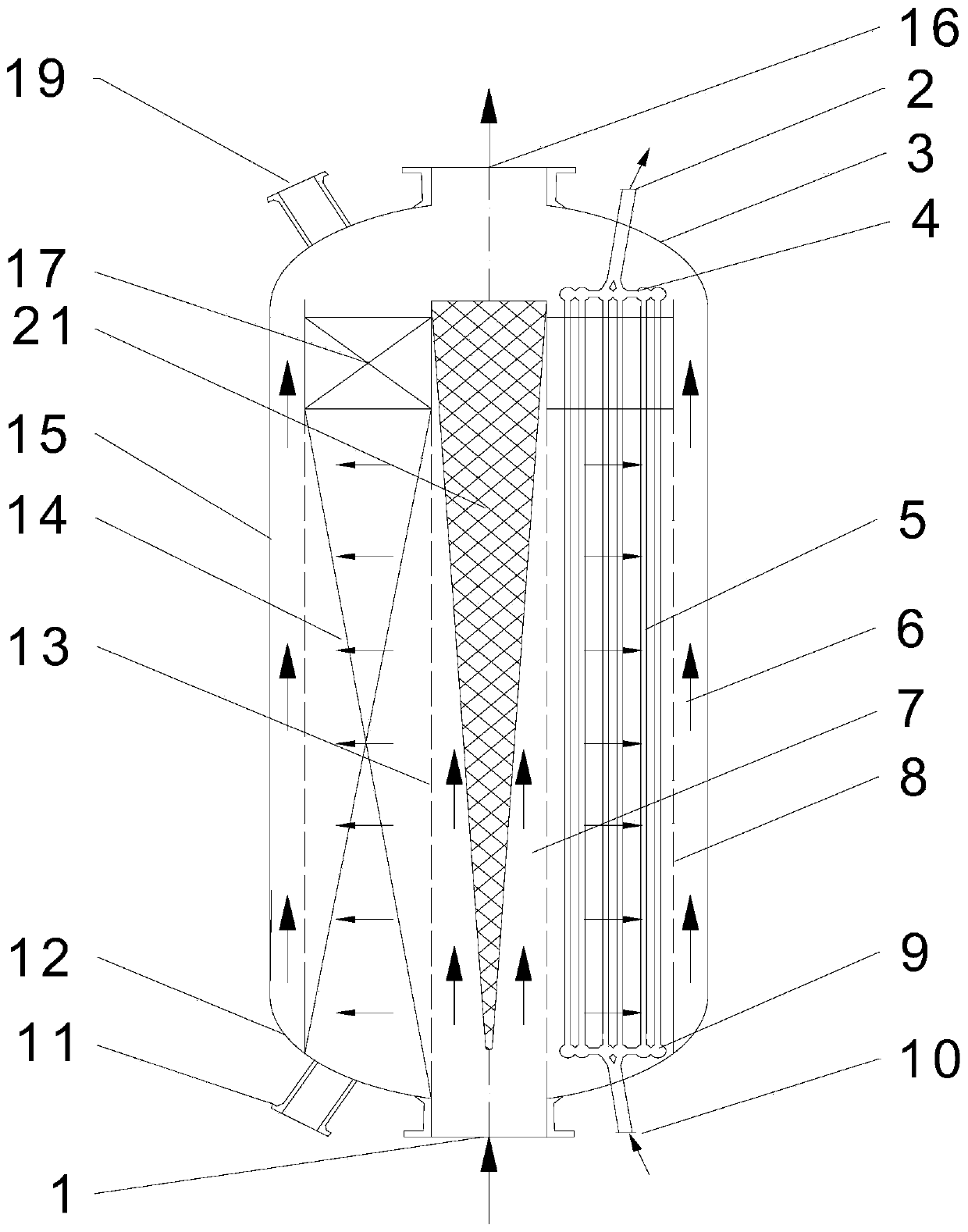

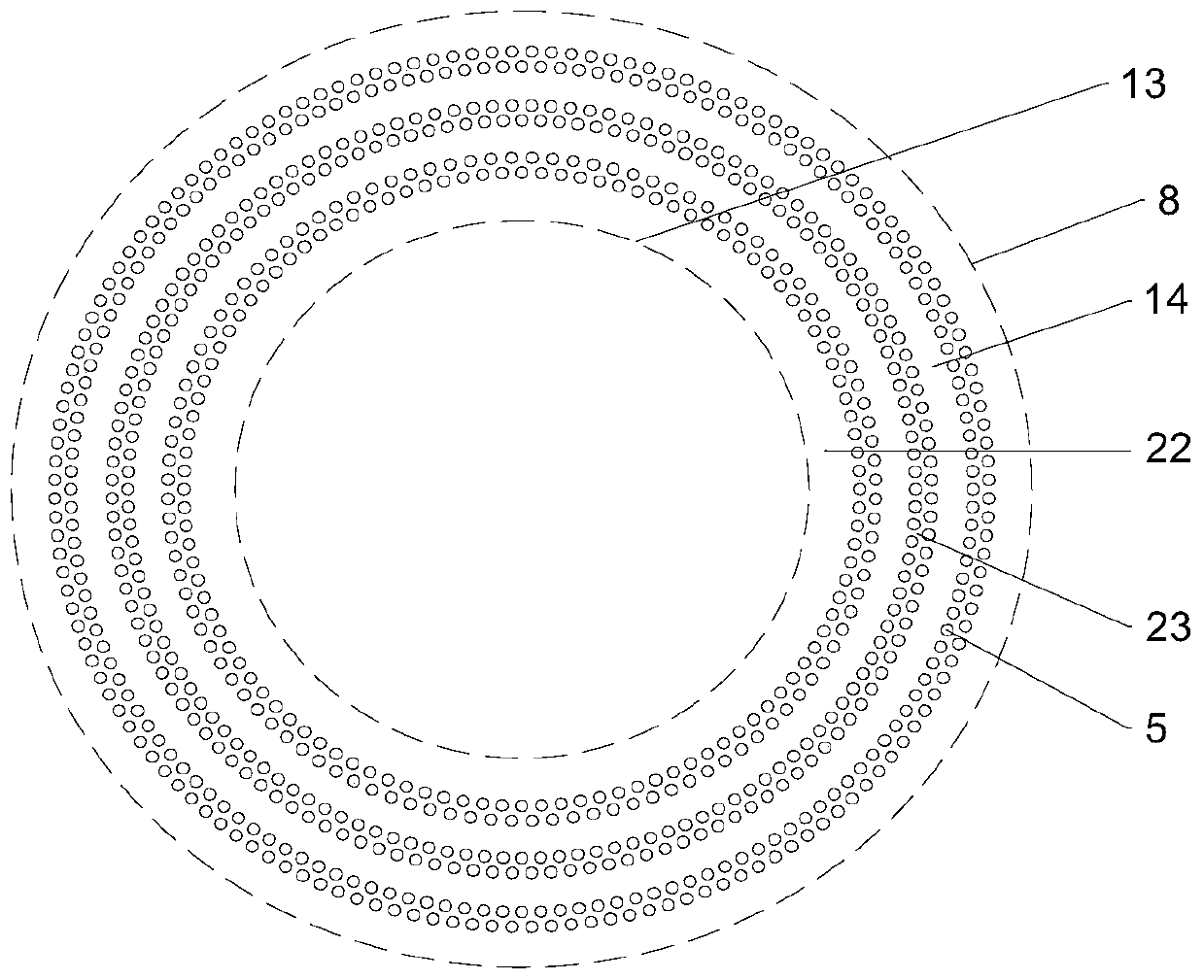

Radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling

PendingCN111589378AEliminate temperature differencesAvoid overheatingPreparation by carbon monoxide or formate reactionChemical/physical processesCarbonylationFixed bed

The invention discloses a radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling. The reactor comprises a cylindrical vessel composed of an upper end socket, acylindrical barrel and a lower end socket in sequence from top to bottom. A reaction gas feeding port, a reaction gas discharging port, a heat exchange medium inlet, a heat exchange medium outlet, acatalyst feeding port and a catalyst discharging port are formed in the outer portion of the cylindrical vessel. The catalytic bed layer is divided into a heat insulation area and a heat exchange areafrom inside to outside, and the heat exchange area is provided with multiple groups of heat exchange tubes which are concentrically arranged in two rows as a group. The radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling has the characteristics of uniform distribution of reaction gas along the axial direction, reasonable bed layer temperature distribution, high catalyst utilization rate, small reactor pressure drop and the like, is suitable for a reaction for producing oxalate through carbonylation coupling, and is also suitable for other exothermicgas-solid phase catalytic reactions.

Owner:EAST CHINA UNIV OF SCI & TECH

A combined heating system of heat-collecting heat-storage wall and air-water heat collector

ActiveCN109737486BIncrease profitMeet heat load demandsLighting and heating apparatusSpace heating and ventilation detailsCollector deviceAtmospheric sciences

A combined heating system of a heat collecting and storing wall and an air-water heat collector, including a heat collecting and storing wall, the heat collecting and storing wall is arranged on the outer side of a house, and the air in the heat collecting and storing wall is blown by a fan The air inlet pipe is connected with the air inlet of the air-water heat collector. The air-water heat collector includes a water outlet. Three-way one, electric three-way one is connected with domestic hot water equipment through pipes, a temperature sensor for sensing temperature is installed inside the room, and the air-water collector is connected with electric three-way one. The invention can store heat, has the ability to provide heating throughout the day, eliminates the temperature difference between the north and the south, and protects the combined heating system of the air-water collector and the heat-collecting heat-storage wall from overcooling and overheating of the heat collector.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

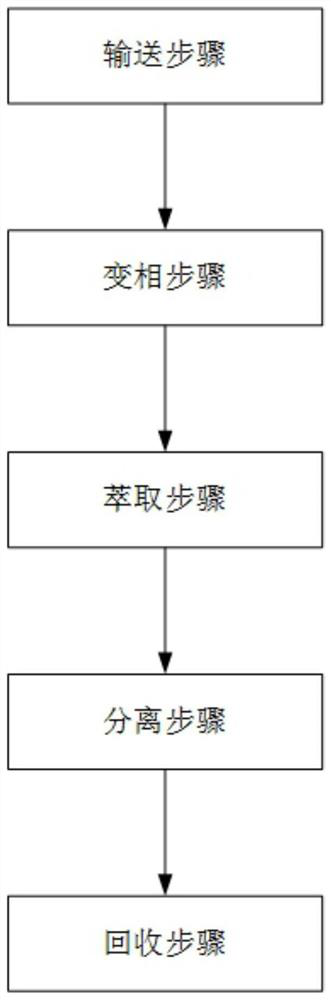

Supercritical CO2 extraction method of black tea

PendingCN114159826AImprove solubilityReduce extraction costsSolid solvent extractionPhysical chemistryProcess engineering

The invention relates to the technical field of extraction, in particular to a supercritical CO2 extraction method of black tea, which comprises the following steps: a phase change step: pressurizing and heating liquid CO2 to change the liquid CO2 phase into a supercritical state; an extraction step: carrying out mixed extraction on the black tea by using CO2 in a supercritical state in a first preset pressure environment; a separation step: in a second preset pressure environment, performing multi-stage heating depressurization separation on the CO2 containing the black tea extract; and a recovery step: collecting the separated black tea extract, and filtering and condensing the separated gas CO2 to recover the gas CO2 into liquid CO2. According to the scheme, the solubility of the extract in supercritical CO2 can be increased, and CO2 is recycled, so that the extraction effect is improved, and the extraction cost is reduced.

Owner:李志军

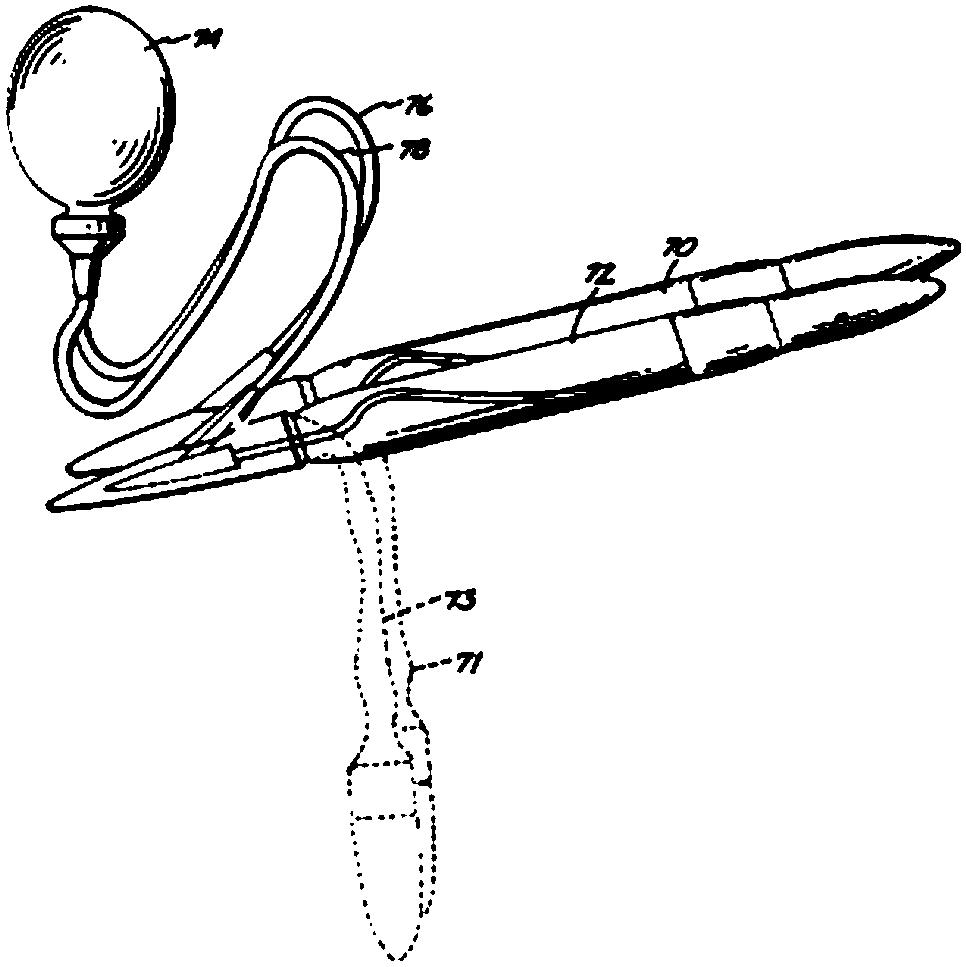

Penis pacemaker and control method thereof

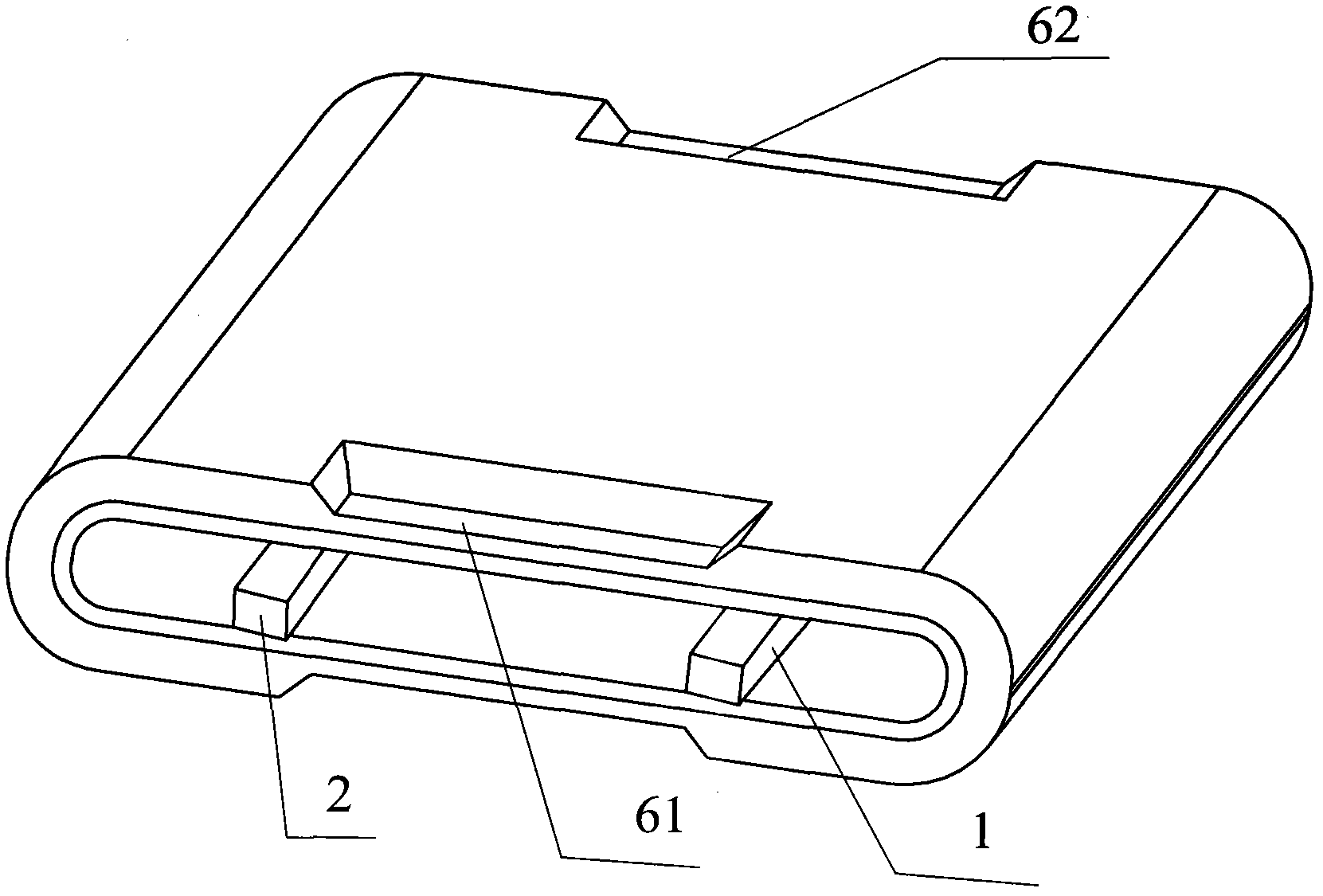

ActiveCN108338855AAnatomical injuryNot easy to shiftPenis implantsTherapeutic coolingPenisCardiac pacemaker electrode

The embodiment of the invention provides a penis pacemaker and a control method of the penis pacemaker. The penis pacemaker provided by the embodiment of the invention comprises a penis implantation mechanism, a liquid storage chamber, catheters and a pump, wherein the penis implantation mechanism is used between the subcutaneous part of the penis and the cavernous body, and the penis implantationmechanism is provided with a hollow cavity, and is fixed to the near end of the penis in a manner of being capable of stretching out and contracting axially; liquid is stored in the liquid storage chamber, and the liquid storage chamber communicates with the cavity of the penis implantation mechanism through at least one catheter; the pump is coupled to the liquid storage chamber and the penis implantation mechanism, and the pump is used for providing power for the transmission of liquid between the liquid storage chamber and the penis implantation mechanism.

Owner:SHANGHAI CLINICAL ENGINE TECH DEV CO LTD

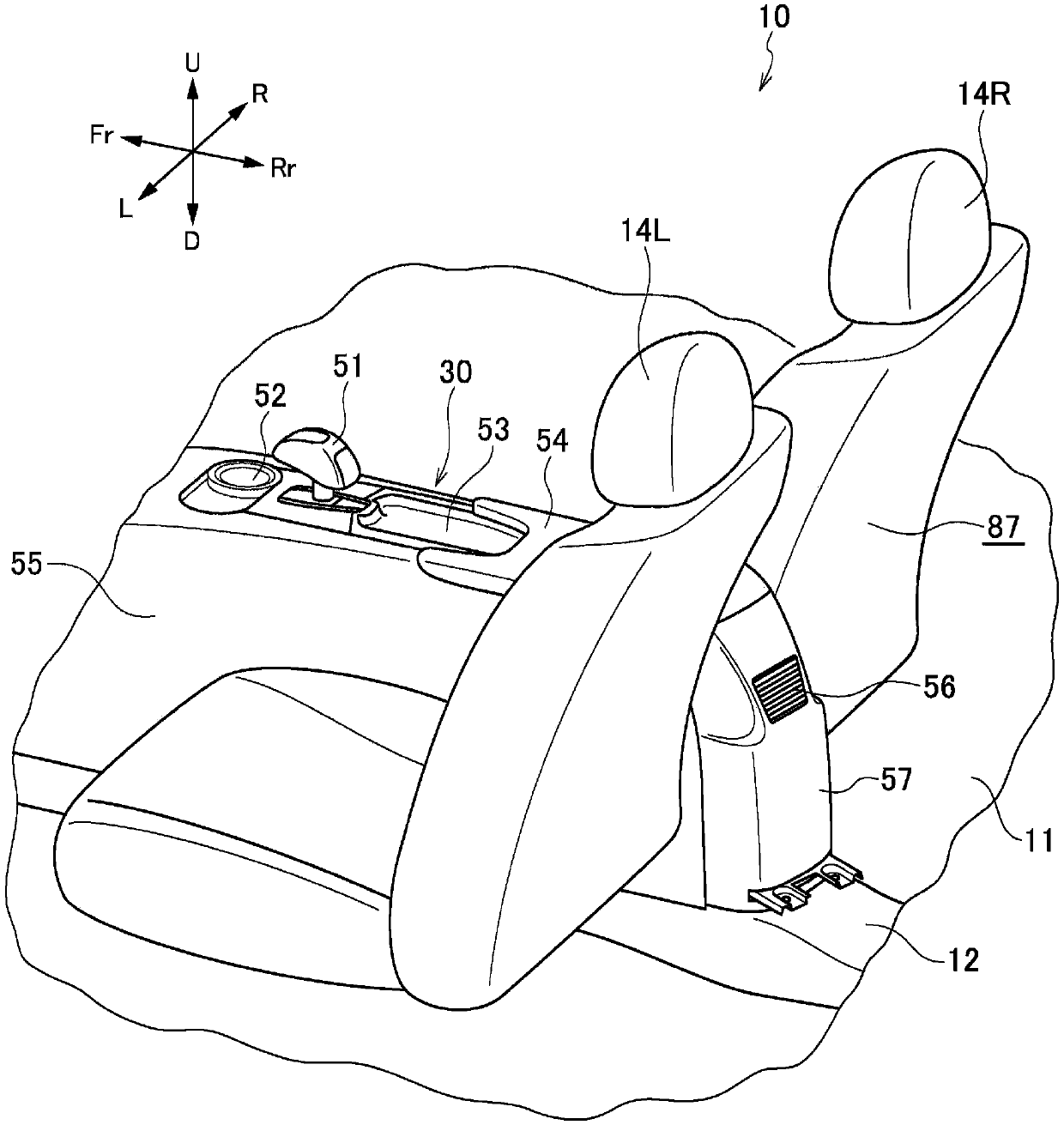

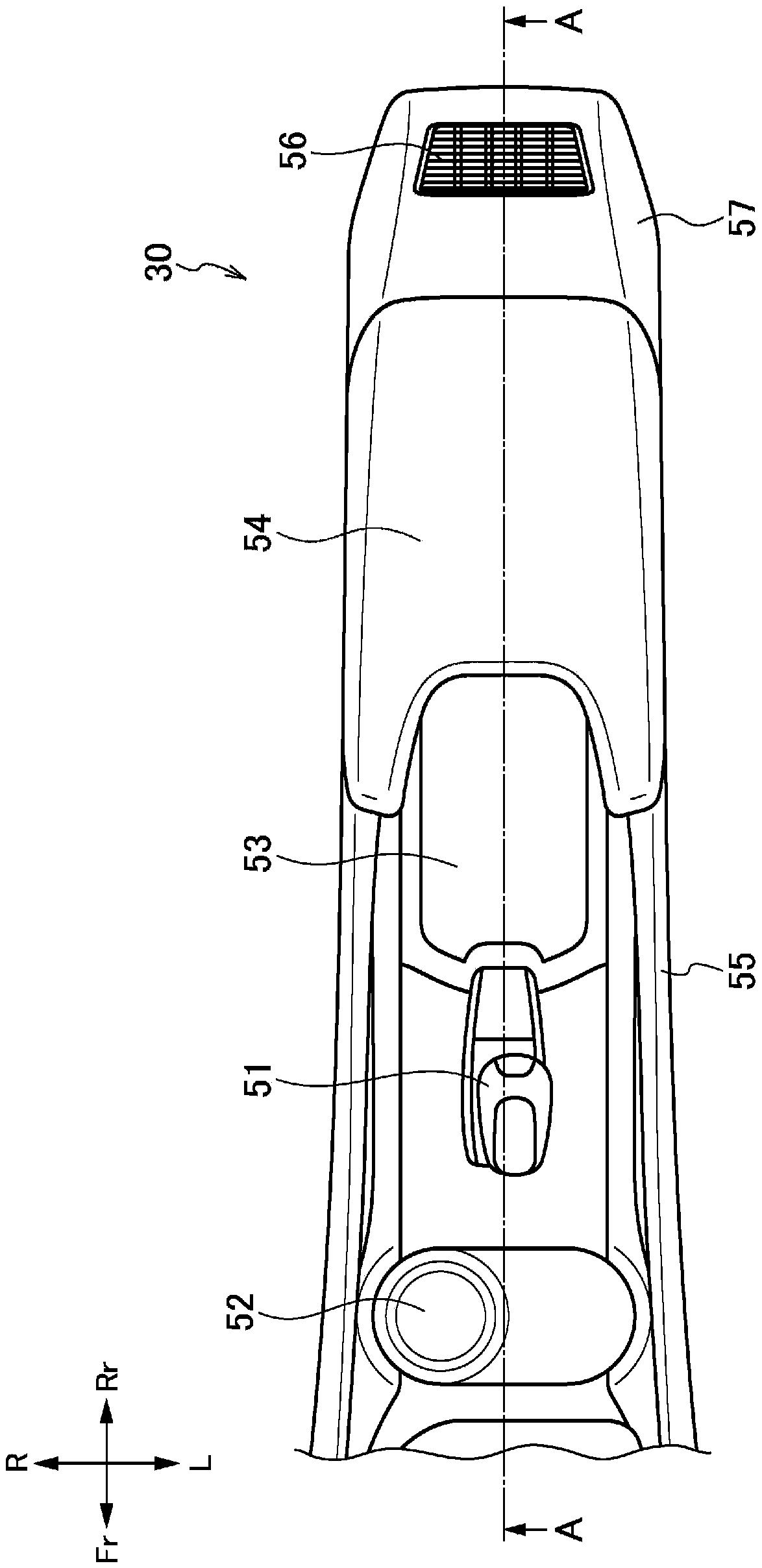

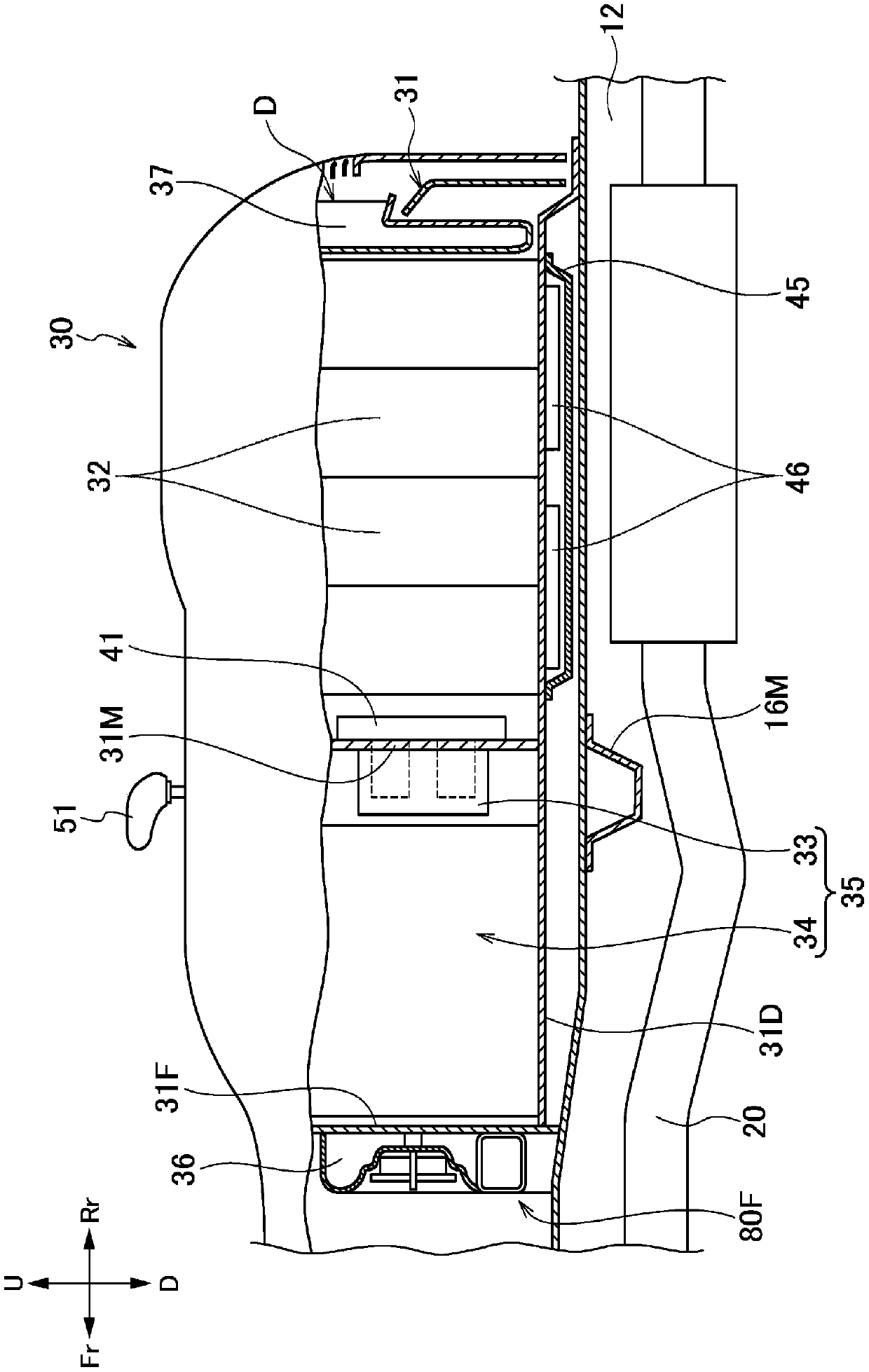

vehicle

ActiveCN107074096BSuppress discomfortThe environment in the car is comfortableElectric propulsion mountingSecondary cellsWaste management

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com