Radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling

A catalytic reactor and oxalate technology, applied in the preparation of carbon monoxide or formate, chemical instruments and methods, organic chemistry, etc., can solve the problem of uneven temperature distribution in the bed, to eliminate temperature differences and improve uniformity performance and prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

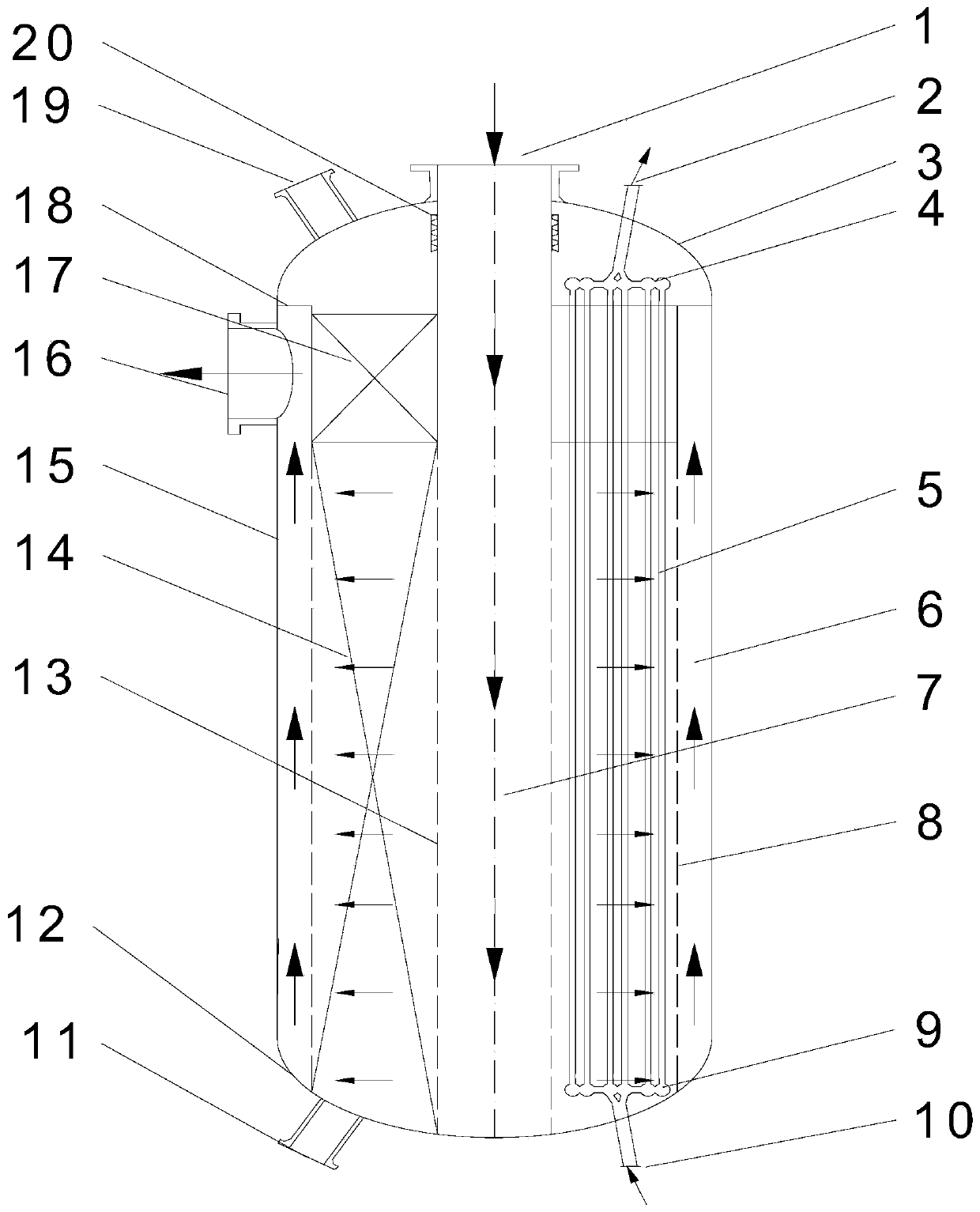

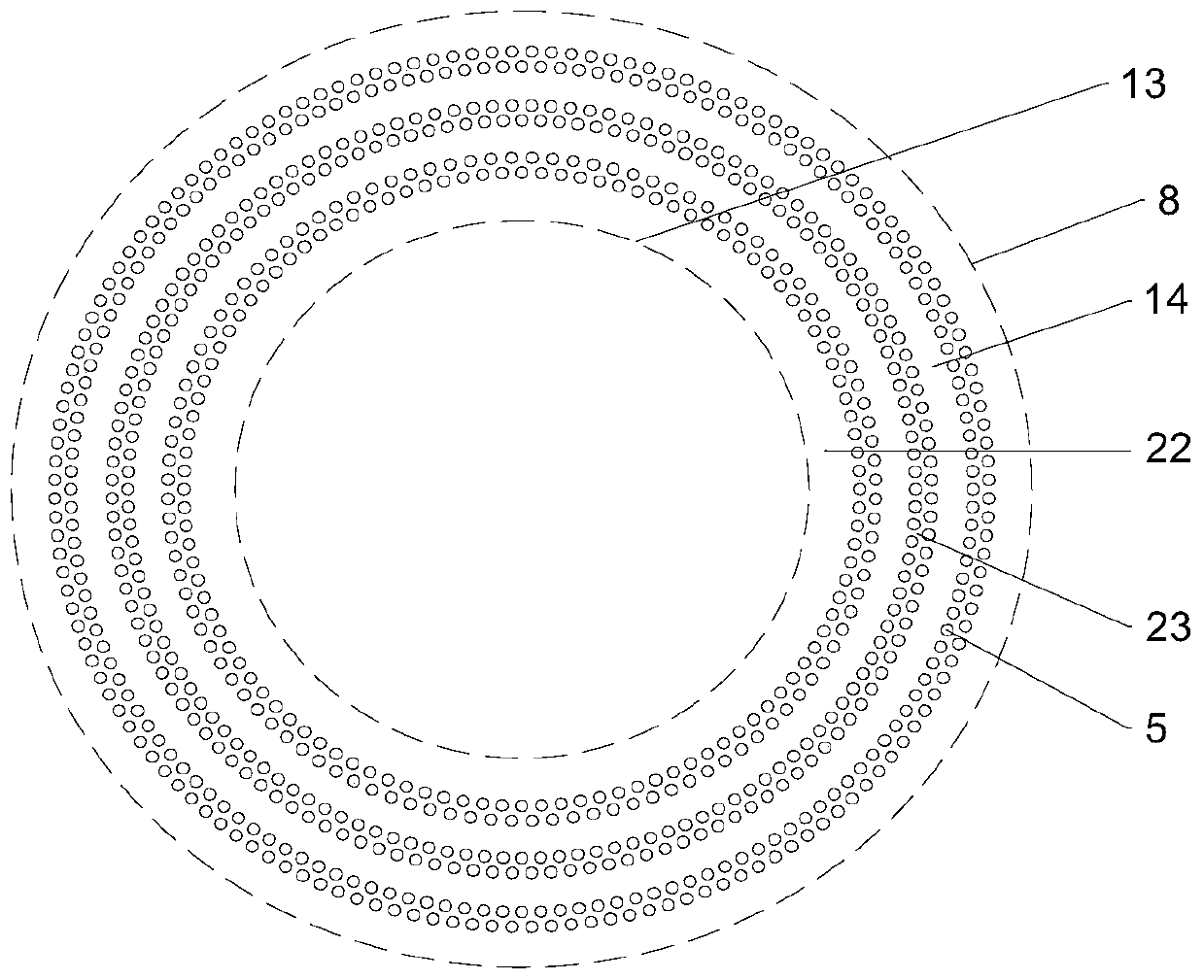

[0085] 100,000 tons / year methyl nitrite carbonylation to dimethyl oxalate plant, the reactor adopts such as figure 1 The structural form of the Π-type methyl nitrite carbonylation fixed-bed radial reactor is shown, and the feed gas is 11640Nm 3 / (m 3 h), the composition of raw gas is: CO20%, CH 3 ONO 10%, NO 1%, N 2 69%, the reaction feed temperature is 125°C, the heat exchange medium temperature is 118°C, the reaction temperature is less than 140°C, the pressure is 0.3MPa, the diameter of the reactor is 4000mm, the axial height of the catalyst bed is 6000mm, and the radial thickness of the bed is 700mm. The thickness is 160mm, and the thickness of the heat exchange area is 540mm. The arrangement of heat exchange tubes in the bed is as follows: image 3 As shown, there are 3 groups of 6 rows in total, the first group has 108 heat exchange tubes in the first row, and the tube center radius is 1.06m; the second row has 108 heat exchange tubes, and the tube center radius is ...

Embodiment 2

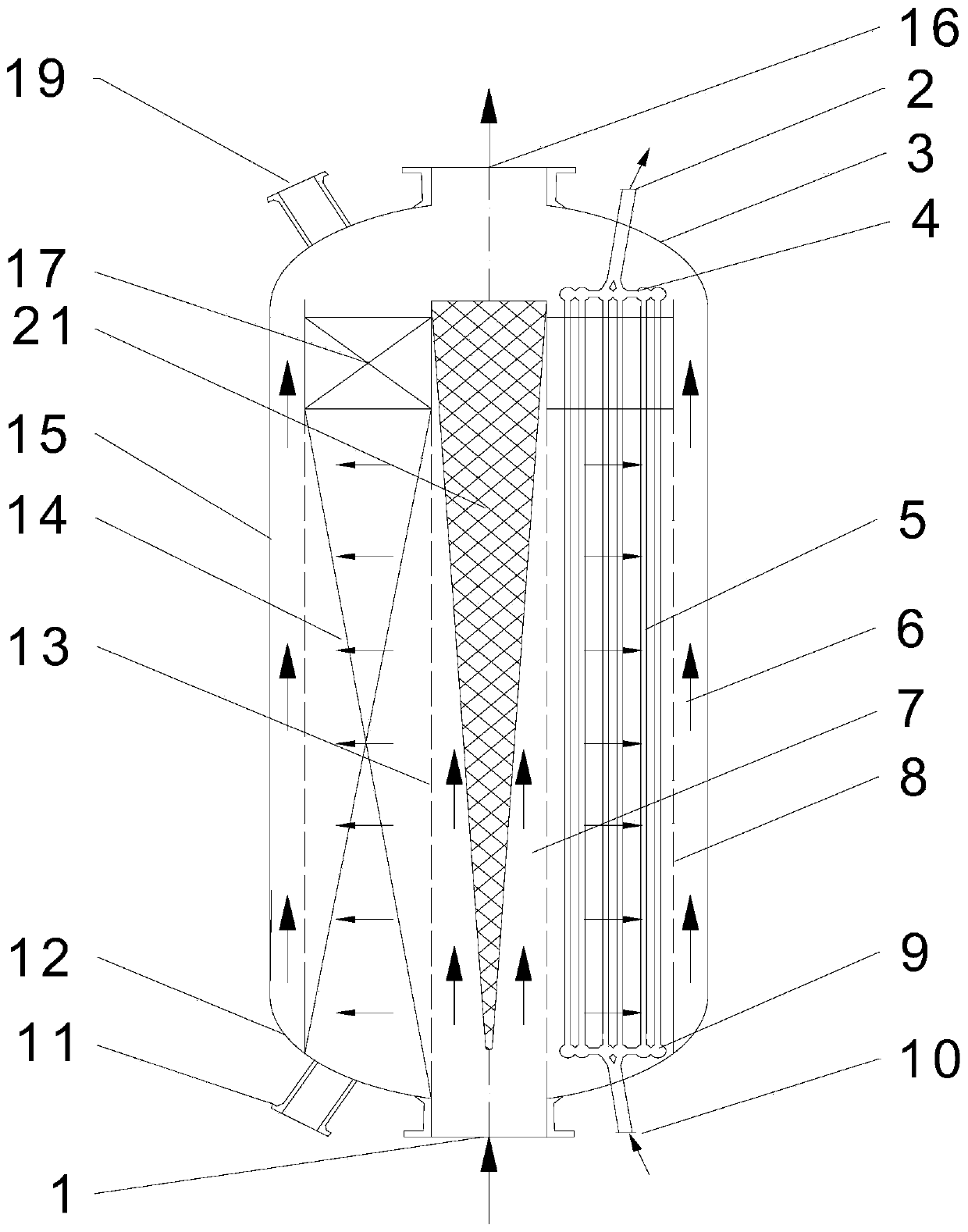

[0087] 100,000 tons / year methyl nitrite carbonylation to dimethyl oxalate plant, the reactor adopts such as figure 2 The structural form of the Z-type methyl nitrite carbonylation fixed-bed radial reactor is shown, and the feed gas is 11640Nm 3 / (m 3 h), the composition of raw gas is: CO20%, CH 3 ONO 10%, NO 1%, N 2 69%, the reaction feed temperature is 125°C, the heat exchange medium temperature is 118°C, the reaction temperature is less than 140°C, the pressure is 0.3MPa, the diameter of the reactor is 4000mm, the axial height of the catalyst bed is 6000mm, and the radial thickness of the bed is 700mm. The thickness is 160mm, and the thickness of the heat exchange area is 540mm. The arrangement of heat exchange tubes in the bed is as follows: image 3 As shown, there are 3 groups of 6 rows in total, the first group has 108 heat exchange tubes in the first row, and the tube center radius is 1.06m; the second row has 108 heat exchange tubes, and the tube center radius is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com