Patents

Literature

67results about How to "Suitable for large-scale processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery method for waste ferric trichloride etching liquid

ActiveCN104131285AImprove qualityLow operating costWater contaminantsWaste water treatment from metallurgical processElectrolysisIon-exchange membranes

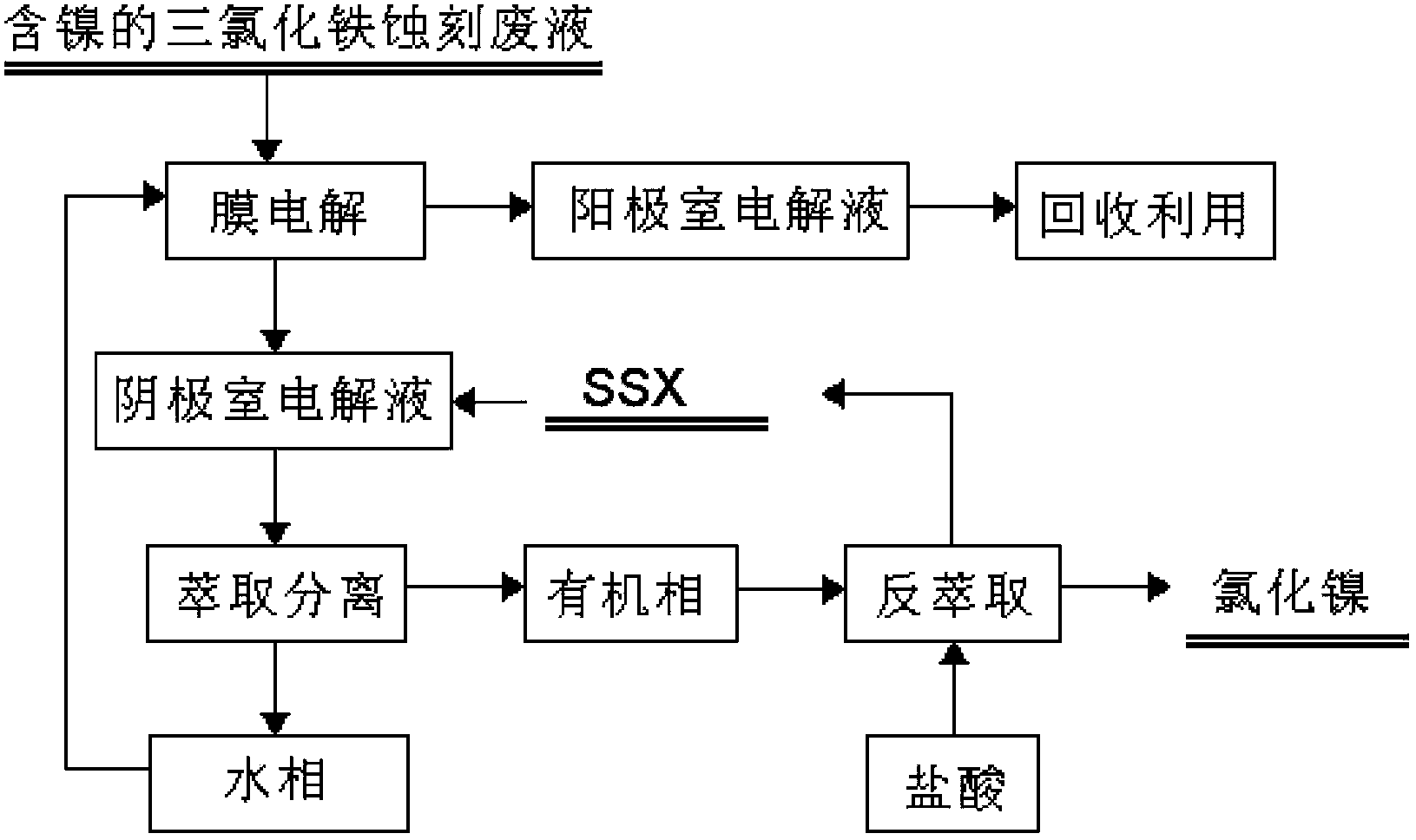

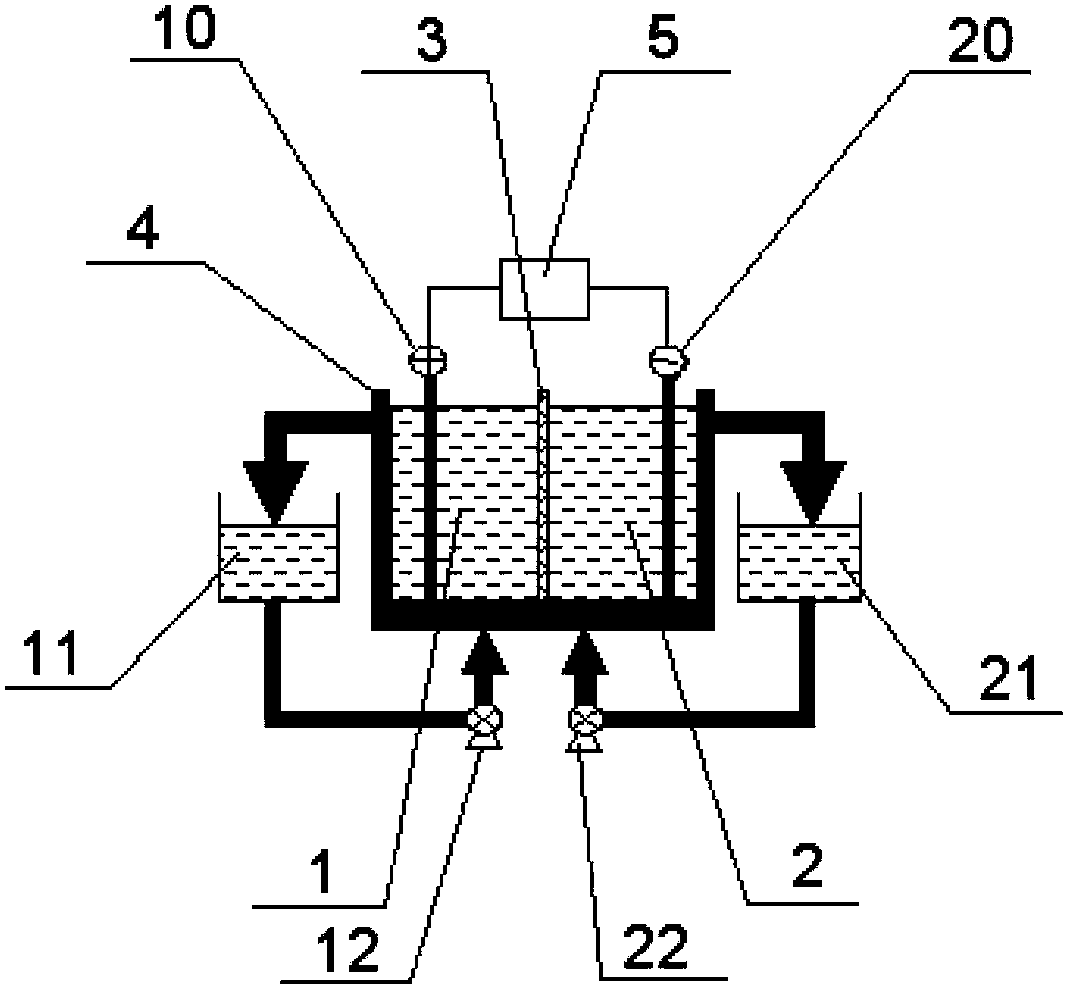

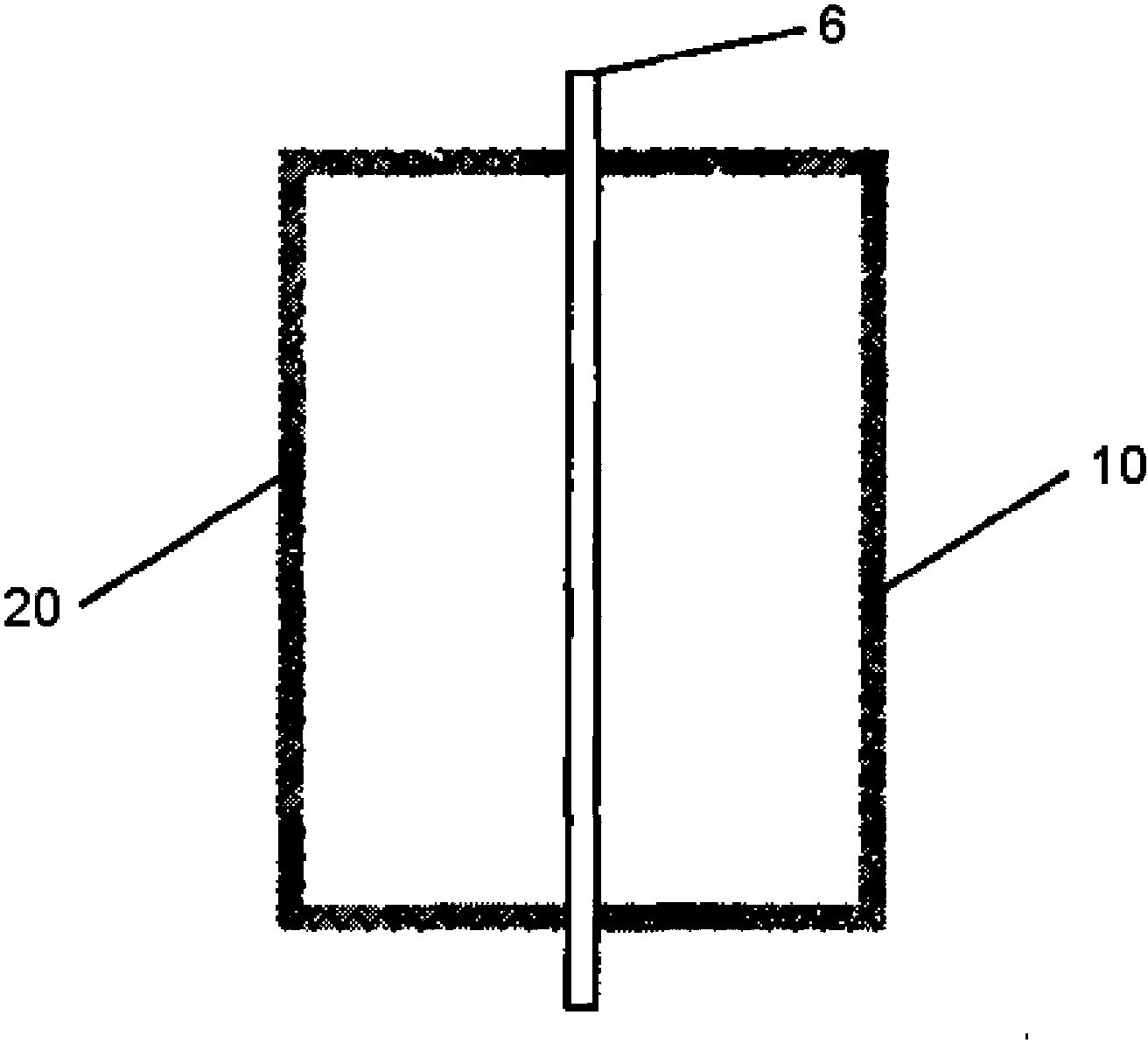

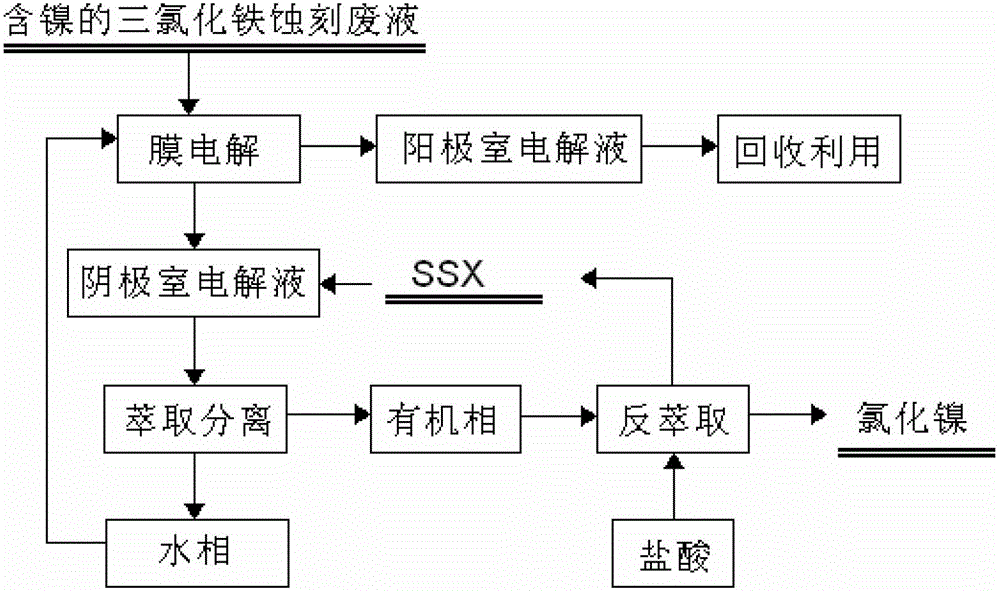

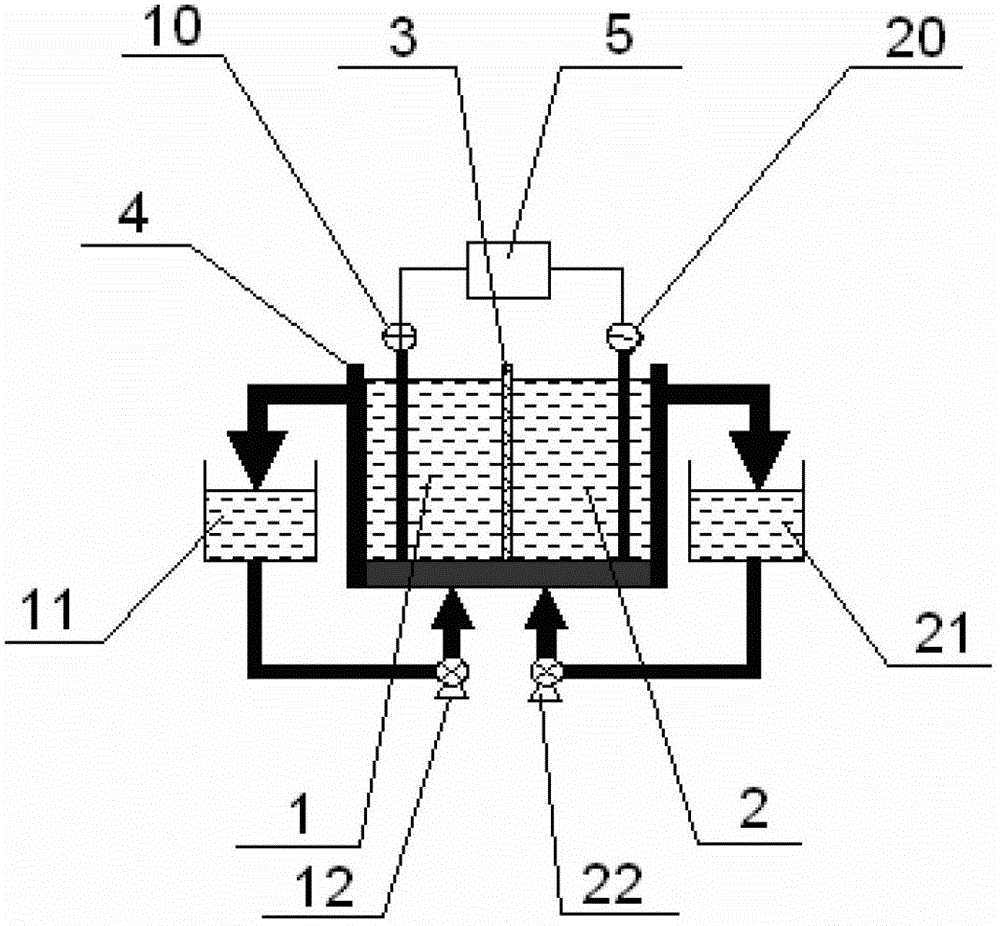

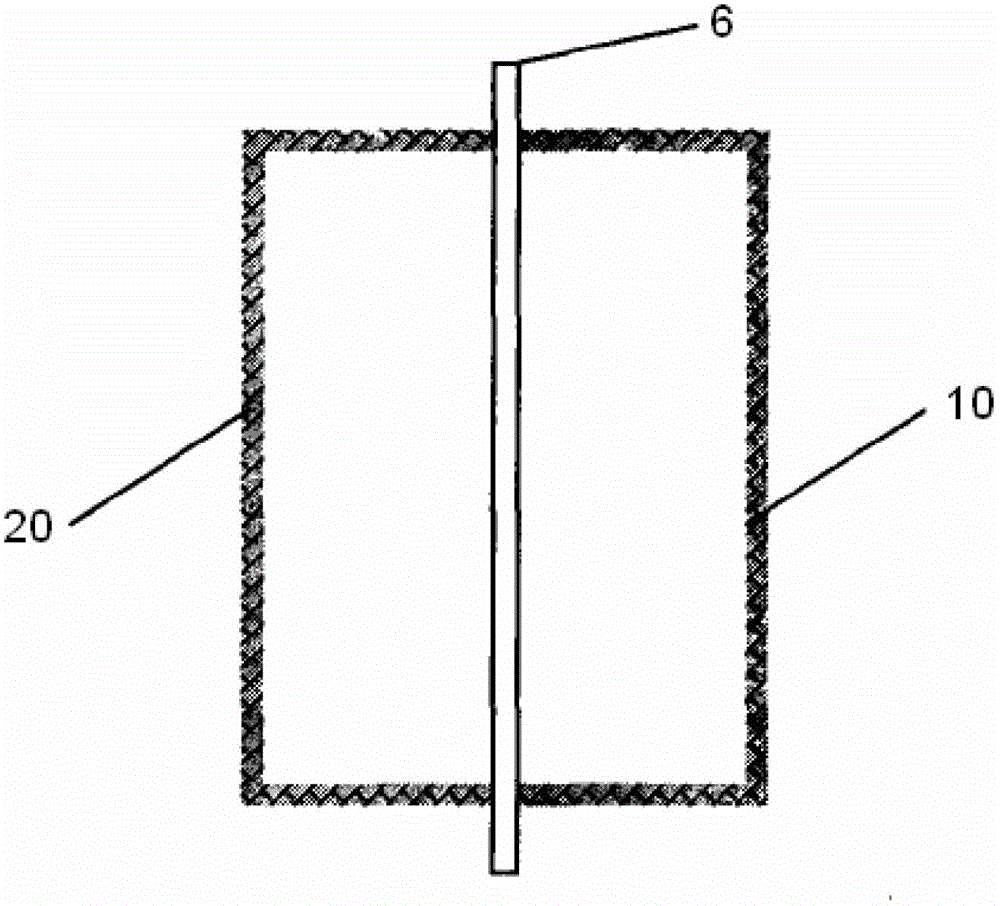

The invention provides a recovery method for a waste ferric trichloride etching liquid. The method adopts integrated membrane electrolysis and extraction technology and comprises the following steps: providing an electrolytic tank, wherein an ion exchange membrane is arranged in the electrolytic tank to divide the electrolytic tank into an anode chamber and a cathode chamber, and a cathode and an anode are respectively positioned in the cathode chamber and the anode chamber located at two sides of the ion exchange membrane; adding the waste ferric trichloride etching liquid into the cathode chamber and carrying out membrane electrolysis so as to reduce Fe3+ ions into Fe2+ ions; carrying out extraction on a solution obtained after electrolysis in the cathode chamber to remove impurity metals so as to obtain an extract phase solution and a metal impurity-removed phase solution and delivering the metal impurity-removed phase solution to the anode chamber for membrane electrolysis so as to oxidize Fe2+ ions into Fe3+ ions; and recovering a solution obtained after electrolysis in the anode chamber. Compared with conventional processing technology for the waste ferric trichloride etching liquid, the recovery method provided by the invention has the advantages of short and simple process flow, no generation of secondary pollution, no discharge of waste gas, waste water and industrial residue, low production cost, applicability to large-scale treatment, treating capacity of more than ten thousands every year and good environmental and economic benefits.

Owner:宁波东顺电子科技有限公司

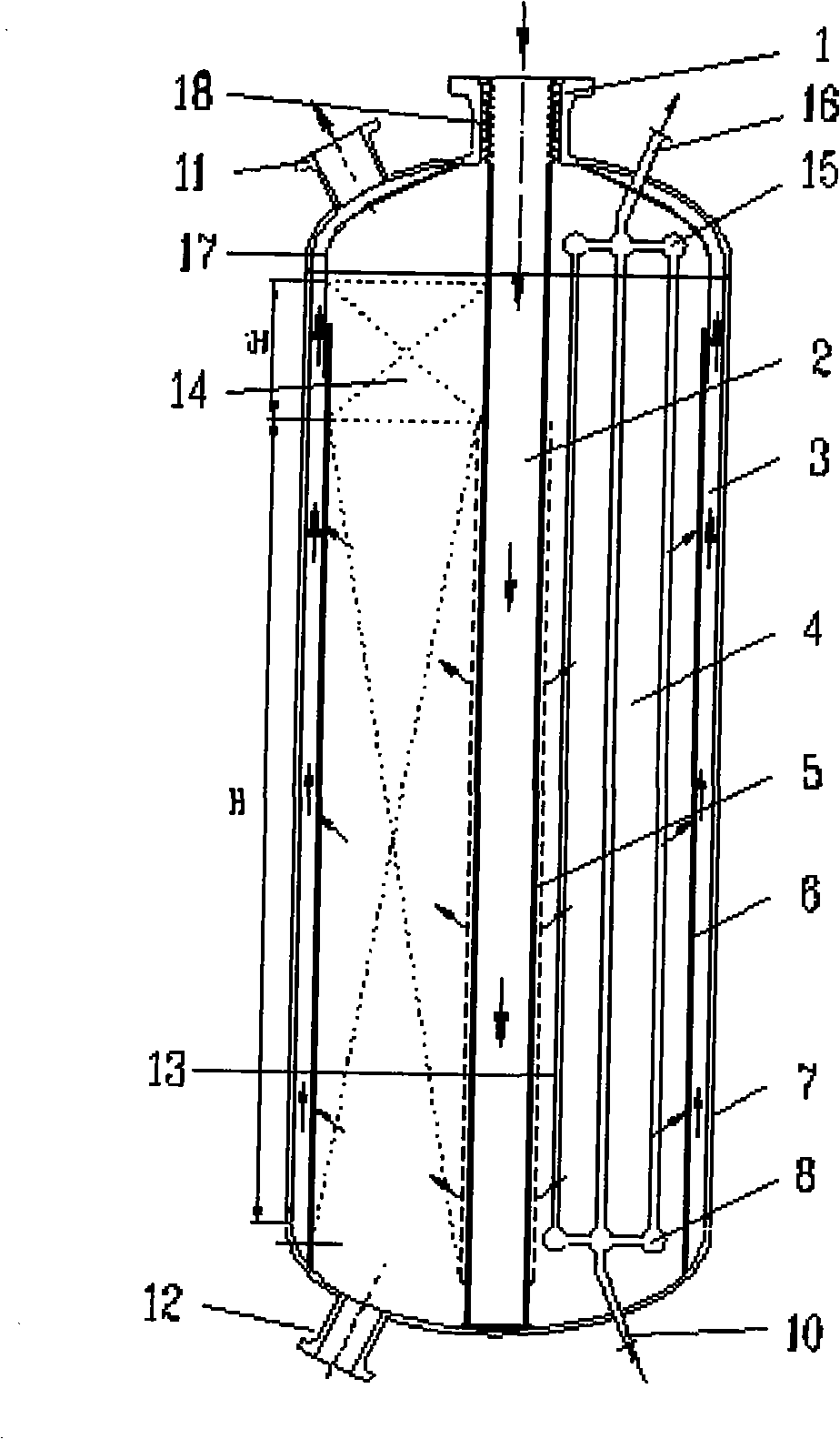

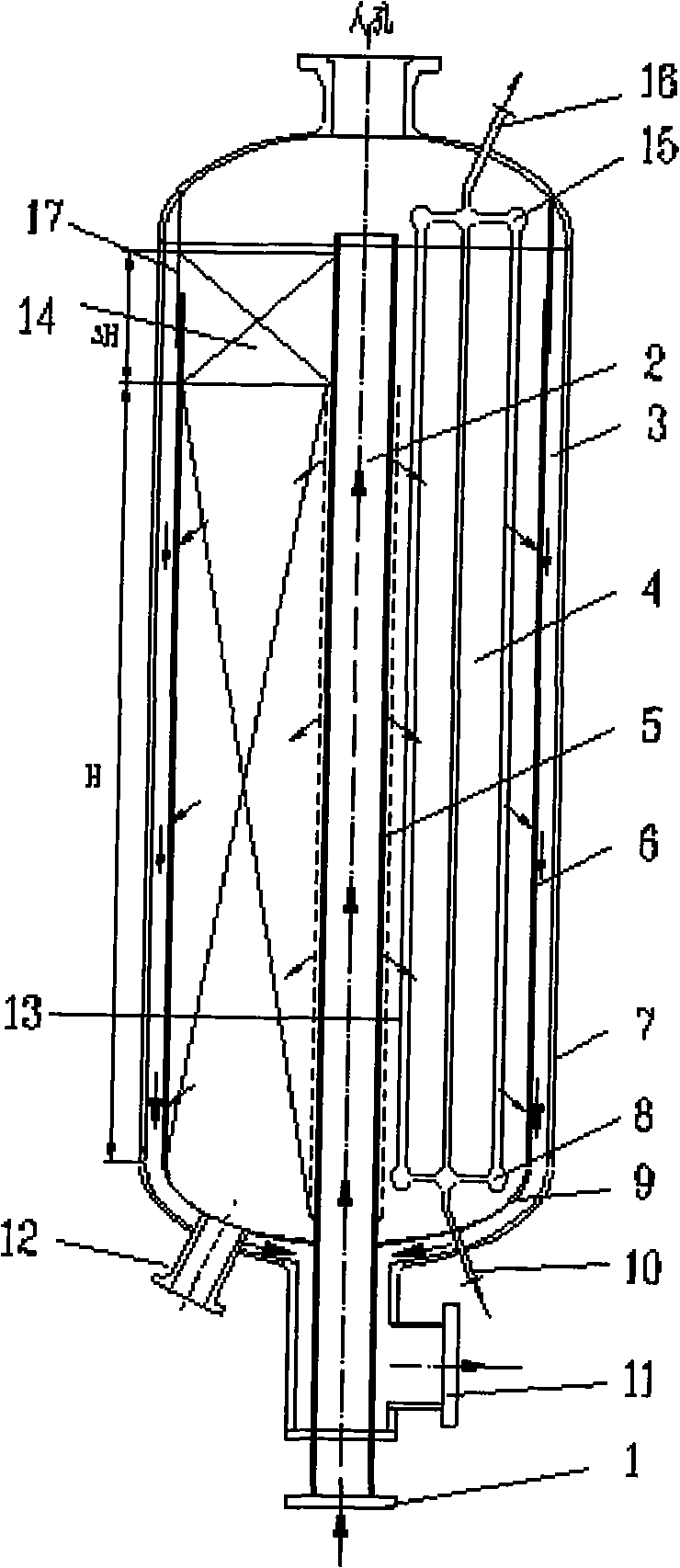

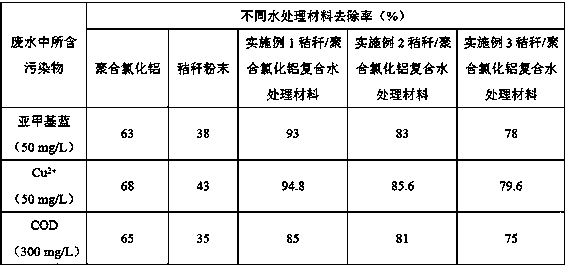

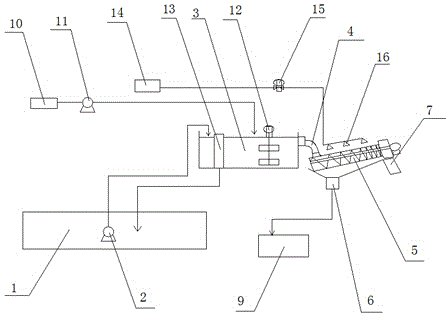

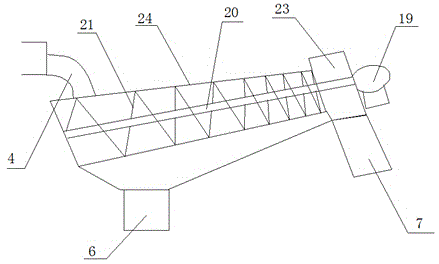

Method used for heat liberation pressurization catalytic reaction

InactiveCN101254442AImprove fill factorSuitable for large-scale processingStationary tubular conduit assembliesChemical/physical processesGas solidNuclear engineering

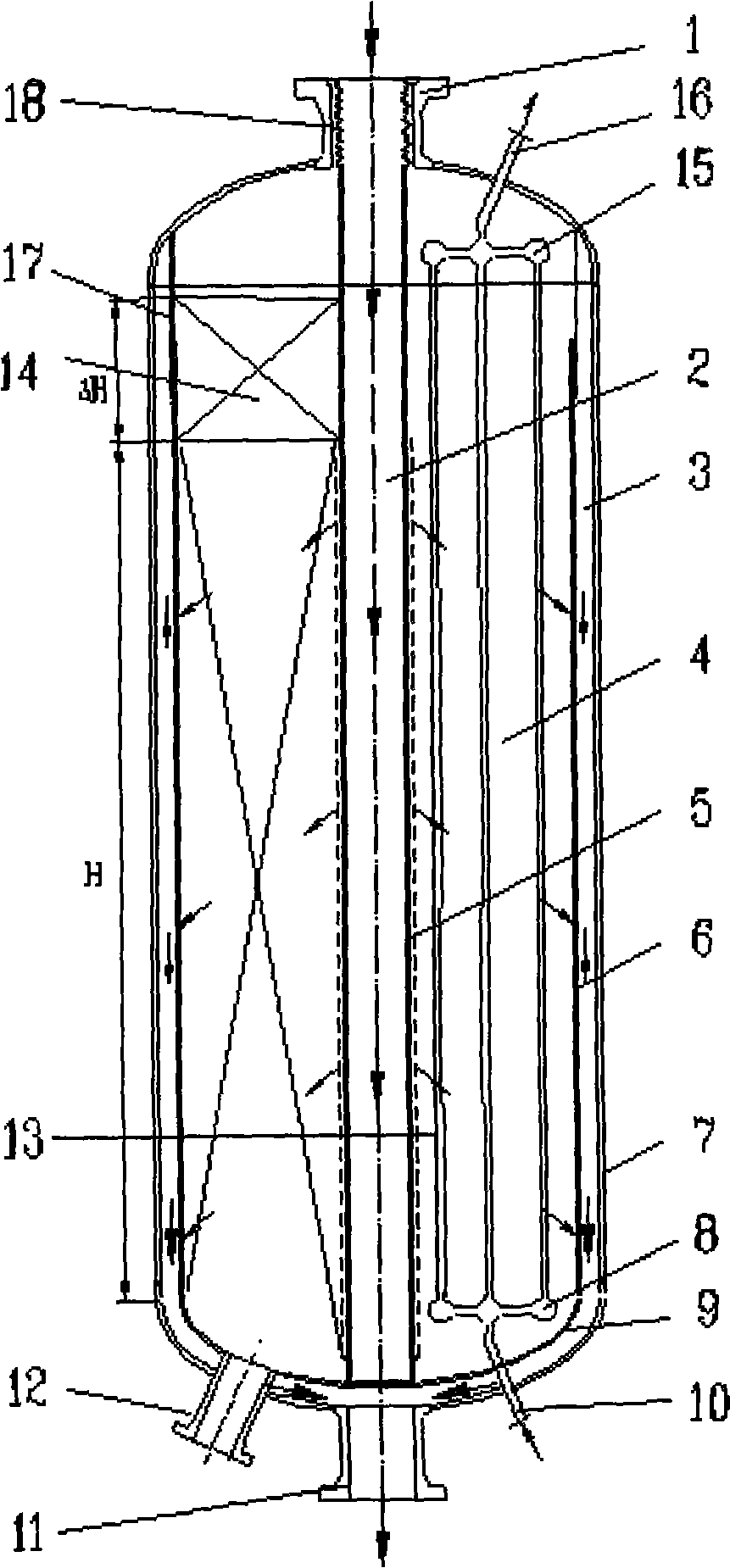

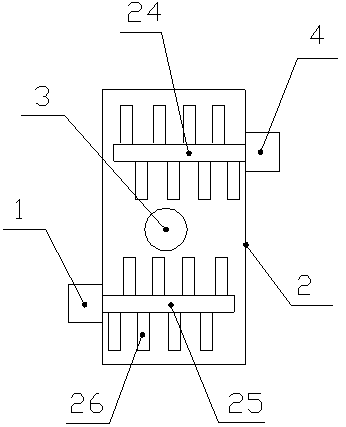

The invention provides a method for exothermic catalytic reaction under increased pressure and a reactor thereof. The method and the reactor are characterized in that: a round pressure vessel (7) with a catalytic bed (4) is used; a gas inlet (1) is positioned on an end cover of the vessel (7) and connected with an internal distribution drum (5) to form a shunt passage (2) for reacting gases; a gas outlet (11) is communicated with a space that is formed between the wall of the vessel (7) and an external distribution drum (6), to form a concentration passage (3) for the reacting gases, the catalytic bed (4) is defined between the external distribution drum (6) and the internal distribution drum (5) and is filled with catalysts; the reacting gases flow axially in a centrifugal manner from the internal distribution drum (5) to the external distribution drum (6). The method and the reactor have the advantages of axial and uniform distribution of the reaction gases, optimum distribution of bed temperature, high utilization rate of catalysts, and low pressure drop of fluids passing through the reactor. The invention is suitable for catalytic reactions in methanol, ammonia and dimethyl ether synthesis, as well as other exothermic gas-solid catalytic reactions under increased pressure.

Owner:EAST CHINA UNIV OF SCI & TECH

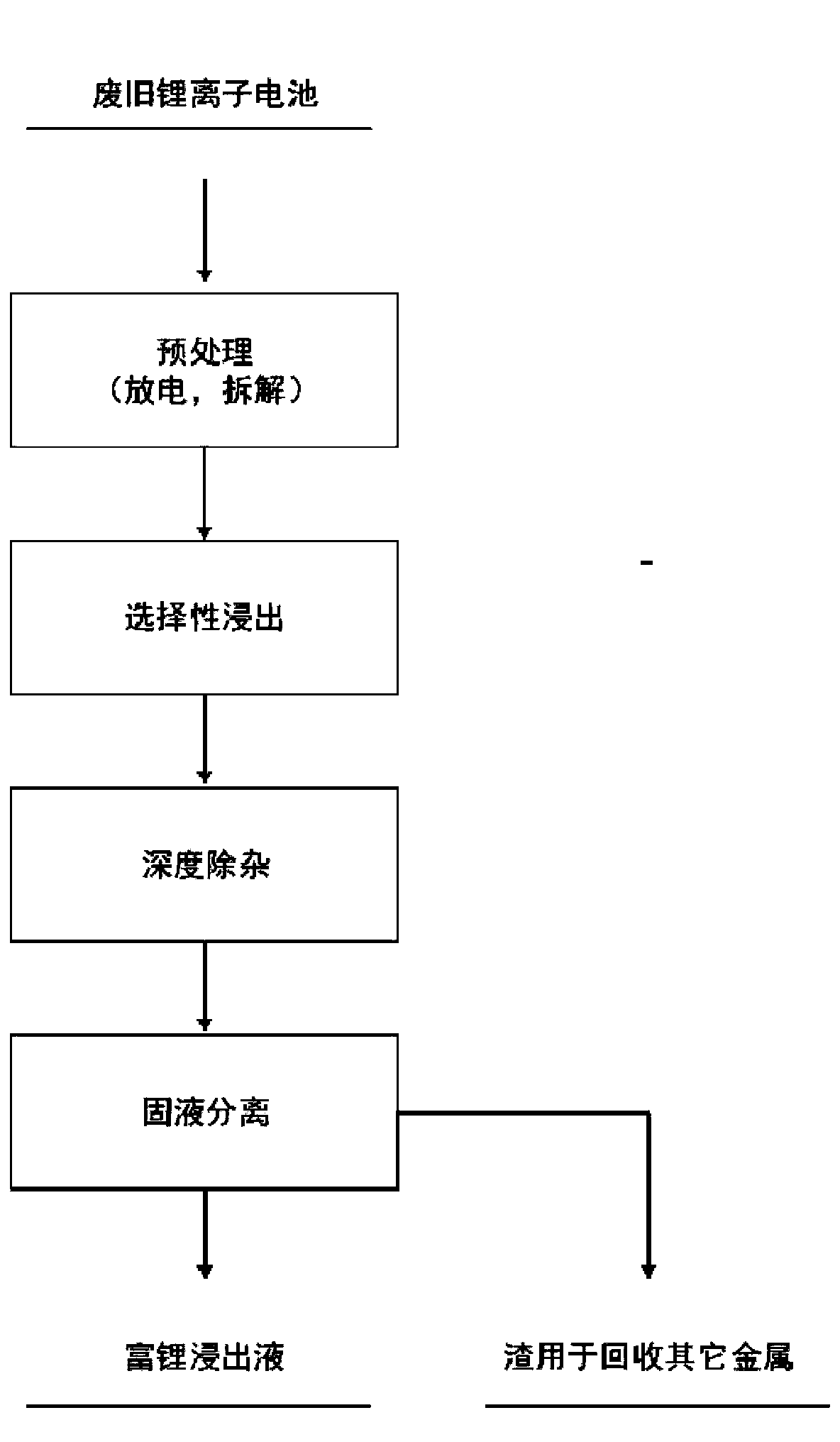

Method for extracting valuable metal from waste lithium ion battery material

InactiveCN110129571AHighly selective extractionAvoid leachingWaste accumulators reclaimingProcess efficiency improvementSlagEconomic benefits

The invention relates to a method for extracting valuable metals from waste lithium ion battery materials. The method comprises the following steps of (1) mixing the waste lithium ion battery materials with a leaching agent to obtain a mixed material, heating and pressurizing the mixed material, and carrying out solid-liquid separation to obtain a leachate and primary solid slag; and (2) adjustingthe pH value of the leachate prepared in step (1) to obtain secondary solid slag and a lithium-containing purification solution. According to the method, the lithium in the waste lithium ion batterycan enter the solution selectively, other metal components are mainly formed in the reacted liquid in the form of solid slag. After the leachate is subjected to deep impurity removal and solid-liquidseparation, the obtained lithium-rich filtrate is used for preparing a lithium product, the solid slag obtained in the two steps further recovers the valuable metals in the product through other methods. The method is very good for the selective extraction effect of lithium, meanwhile, the method has the advantages of being low in acid consumption, no other additives, environmental friendliness and high in economic benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

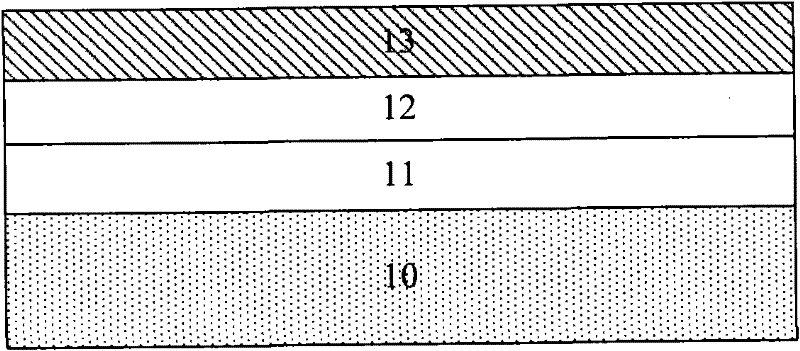

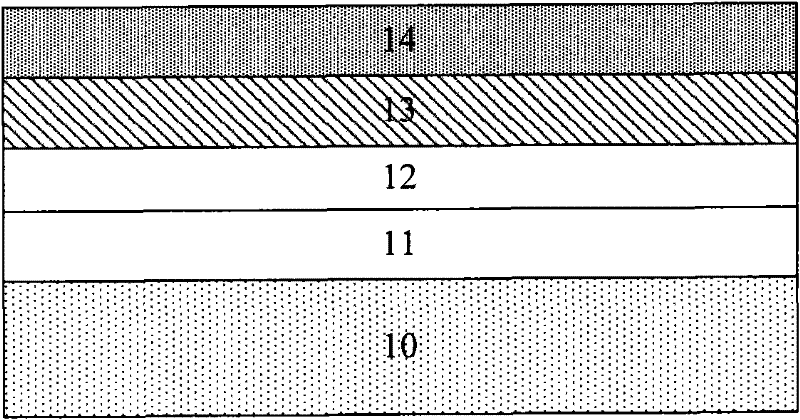

Method for manufacturing memory cell including resistor

InactiveCN102270738APrecise and controllable componentsImprove uniformityElectrical apparatusDigital storageMemory cellMaterials science

The present application discloses a manufacturing method of a memory cell including a resistor, comprising the following steps: a) forming a bottom electrode layer on an insulating substrate; b) forming a resistive material layer on the bottom electrode layer by MOCVD; c) forming a resistive material layer on the bottom electrode layer; forming a top electrode layer on the resistive material; and d) patterning the top electrode layer and the resistive material layer to form separated memory cells. The MOCVD method can be used to manufacture a resistive material layer with precise controllable thickness and composition and good uniformity, so that a memory cell of an RRAM with an MOM structure and excellent interface characteristics can be obtained.

Owner:PEKING UNIV

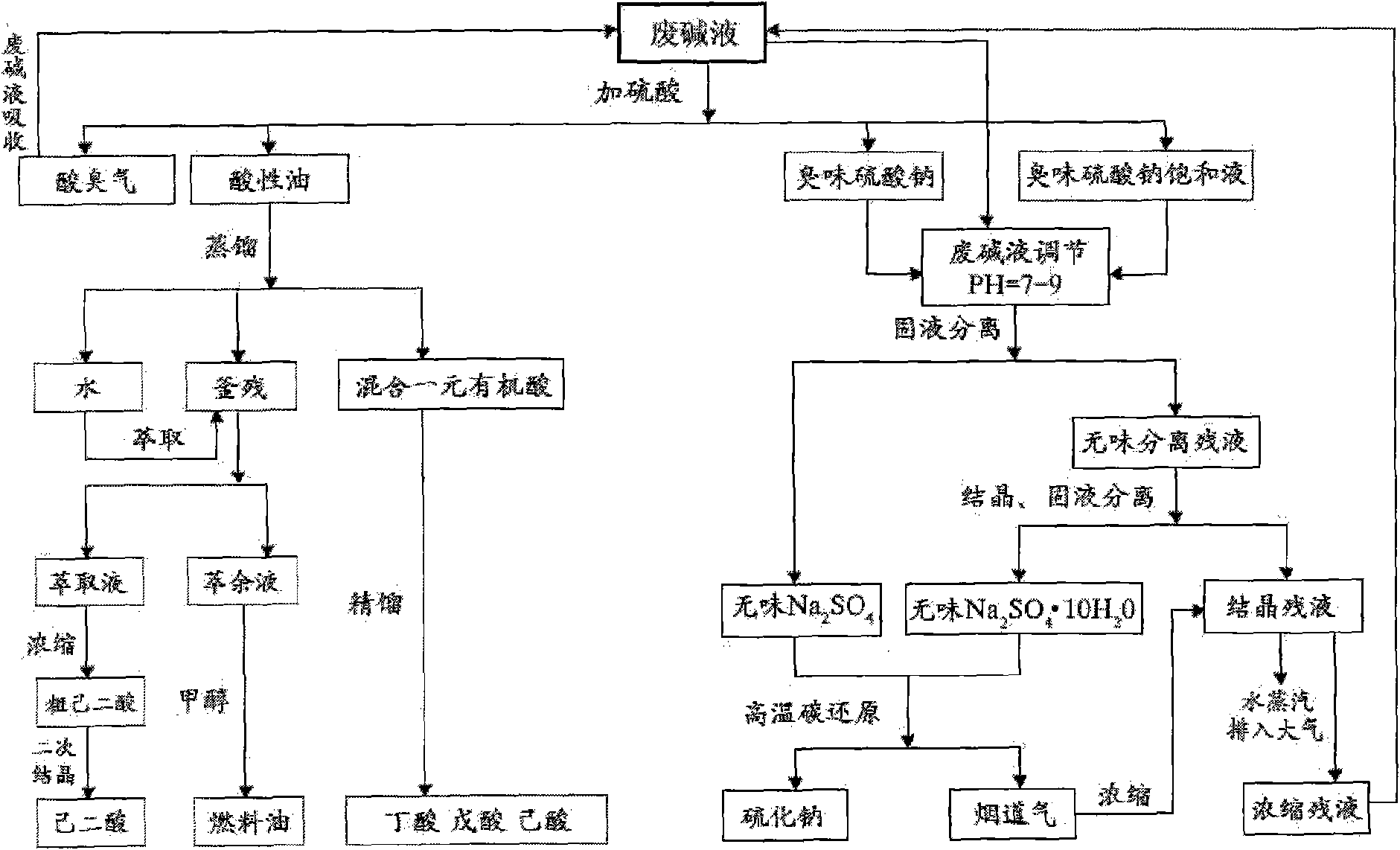

Method of recycling cyclohexanone waste lye

InactiveCN101560011AEliminate secondary pollutionGood social and environmental benefitsAlkali metal sulfides/polysulfidesNature of treatment waterCogenerationChemical products

The invention relates to a method of recycling cyclohexanone waste lye. The method comprises the following steps: 1) acid is used for neutralizing waste lye to extract acid oil, anhydrous sodium sulphate and sodium sulphate with water; acidulated sewage is processed; 2) acidic sour gas is processed; 3) anhydrous sodium sulphate and sodium sulphate with water are used for cogeneration of sodium sulfide; 4) acid oil is used for cogeneration of monocarboxylie acid, adipate and fuel oil. The technical route is reasonable and has the advantages that waste lye is used for processing the sewage acidulated by sodium sulfate solution immediately after neutralization with acid to eliminate acidic sour gas, so as to radically treat secondary pollution of acid neutralization method, achieve zero emission and improve environmental benefits obviously; sodium sulfide, monocarboxylie acid, adipate, clean fuel oil and other chemical products with high added-value are obtained, so that economic benefits are obvious; The method recycles waste resource, has low energy consumption and simple technique, which is applicable to scale treatment of cyclohexanone waste lye as well as industrial production of resource recovery.

Owner:赵志军

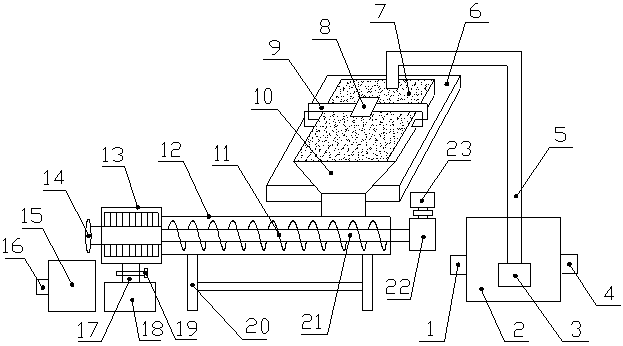

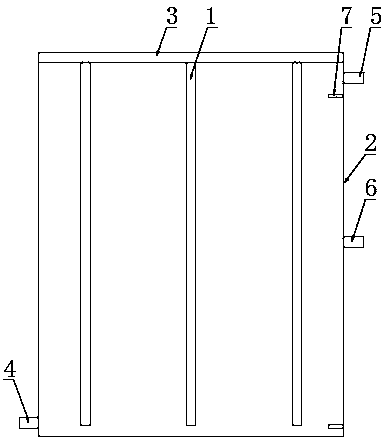

Solid-liquid separation processor

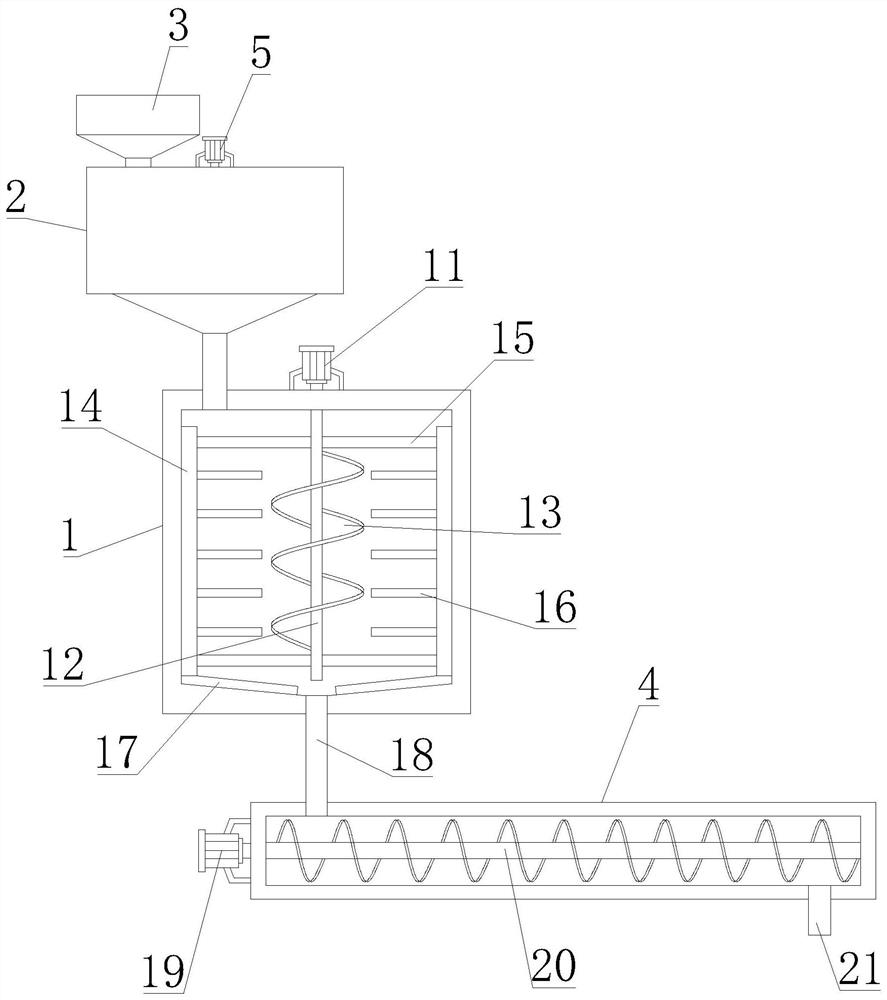

PendingCN109260806AWell mixedEasy to transportSludge treatmentTransportation and packagingSlagPulp and paper industry

The invention discloses a solid-liquid separation processor. The solid-liquid separation processor comprises a slag liquid storage box and an extrusion screw conveyor, a stirring motor A is connectedto the front part of the left side of the slag liquid storage box, a stirring shaft A is connected with the output shaft of the stirring motor A, a stirring motor B is connected with the rear part ofthe right side of the slag liquid storage box, and a stirring shaft B is connected with the output shaft of the stirring motor B; stirring blades are installed on the stirring shaft A and the stirringshaft B, a diving cutting pump is arranged in the middle of the slag liquid storage box, a discharging pipe is connected with the output end of the diving cutting pump, a filter sieve net is arrangedbelow the other end of the discharging pipe, and a feeding hopper is connected with the front end of the filter sieve net; and an extrusion drying box is connected with the left end of the extrusionscrew conveyor, the left side of the extrusion drying box is provided with a discharging port, and the lower end of the extrusion drying box is provided with a liquid outlet. The solid-liquid separation processor has the advantages that the operation is easy and convenient, the separation and collecting efficiency is high, the filter sieve net is not prone to being blocked, separation is even andthorough, the processing time is shortened, the processing cost is lowered, and the processor is suitable for large-scale processing.

Owner:禹州华德环保科技有限公司

Straw/polyferric sulfate composite water treatment material and preparation method thereof

ActiveCN104261541AGood adsorption and flocculation performanceSuitable for large-scale processingWater contaminantsWater/sewage treatment by flocculation/precipitationHigh concentrationHuman health

The invention discloses a straw / polyferric sulfate composite water treatment material and a preparation method thereof. A composite material with a good water treatment effect is prepared by using straw and polyferric sulfate as raw materials through a liquid phase method. The raw materials of the composite water treatment material are low in price, the composite water treatment material can be prepared under the conditions of normal temperature and normal pressure, reaction conditions are mild, the process is simple, and the preparation process is easy to control; the prepared composite material can play the advantages of a ferric salt polymer in the water treatment process, the iron content of treated water is reduced, the flocculating performance is good, the composite material has high wastewater treatment capacity, the negative effects caused by the fact that ferric ions enter the environment can be improved to the greatest extent, the problems that the water treated by a ferric salt flocculating agent is commonly colored and contains high-concentration high-valence state iron are solved, the injury to the human health is effectively avoided, and the composite material is applicable to large-scale wastewater treatment.

Owner:FUJIAN MELTS SPRINGS DTC CO LTD

Method for preparing high-activity alpha type hemihydrate gypsum cementing materials by using reaction of chlorine-alkali waste liquid treating ardealite

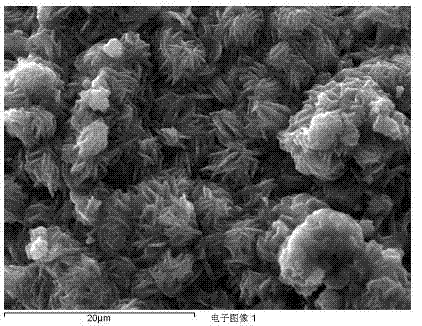

InactiveCN103011641AEliminate intermediate processesSuitable for large-scale processingPhosphogypsumHigh activity

The invention relates to a method for preparing high-activity alpha type hemihydrate gypsum cementing materials by using a reaction of chlorine-alkali waste liquid treating ardealite. The method comprises the following technique steps: (1) adding precipitator in the chlorine-alkali waste liquid for removing one part of ion impurities; (2) implementing the sedimentation and filtering technique; (3) implementing the concentration technique of calcium chloride solution; and (4) preparing high-activity hemihydrate gypsum cementing material through the normal pressure hydrothermal reaction. The method has the benefits that the problem of two wastes are synchronously solved, so that the environmental friendliness and the resource conservation are achieved; the waste liquid can be used by being concentrated to have the concentration of 15-45% without being prepared to crystals, so that the intermediate technique of preparing calcium chloride crystals can be avoided, and the energy consumption is reduced; the waste liquid can be recycled through disposing after the reaction; and the method is suitable for treating the chlorine-alkali waste liquid and the phosphating industrial wastes-ardealite in scale, and is also suitable for resource recycling industrial production.

Owner:WUHAN UNIV OF TECH

A method for removing heavy metals cadmium, lead and copper in water with Fred's salt

The invention discloses a method for removing heavy metals cadmium, lead and copper in water with Fred's salt. When the content of heavy metals Cd2+, Pb2+ and Cu2+ in water is on the order of mg / L, 20% of Fred's salt is taken The emulsion is added into the water body at a solid-liquid ratio of 1:10000 to 8:10000, and a mixed liquid is obtained after hydraulic stirring, and the mixed liquid is passed through an advection settling tank or an expansion upflow settling tank to collect heavy metal-containing sediments, and Collect clean water by way of water discharge along the way. The invention not only has the advantages of good water treatment effect, simple process and low cost, but also has the advantages of no secondary pollution, suitable for large-scale treatment of heavy metal-containing wastewater, and the like.

Owner:章兴华

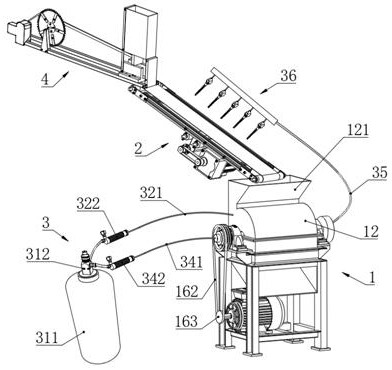

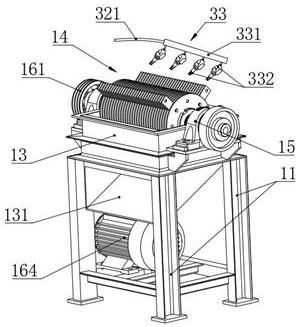

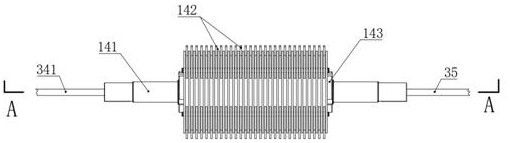

Brown sugar processing equipment and use method

ActiveCN112169948AIncrease temperatureIncrease the speed of crushingDomestic cooling apparatusLighting and heating apparatusEngineeringProcess engineering

The invention belongs to the technical field of brown sugar processing, and particularly relates to brown sugar processing equipment. The brown sugar processing equipment comprises a pulverizer, a conveying device and a cooling device, wherein the pulverizer is arranged on the back end of the conveying device, and a high-pressure tank of the cooling device is located on one side of the pulverizer.After the brown sugar processing equipment is operated for a long time, the temperature of cutters can be prevented from being increased, and brown sugar powder cannot be melted into blocks; and additionally, moisture in the brown sugar powder is condensed into ice crystals before processing, the brown sugar powder cannot be caked due to cooling of the cooling device, the crushing speed and the crushing quality are increased, and the influence on the processing efficiency is reduced. The invention further provides a use method of the equipment. The use method comprises the steps of preprocessing brown sugar blocks, cooling the brown sugar blocks, cooling the interiors of the cutters, and crushing the brown sugar blocks. According to the use method, the crushing operation can be performedwhen the water content of brown sugar is lower than 7%, the processing range is large, dehydration treatment is not needed, and the cost is reduced; and additionally, the use method has the advantagesof high degree of mechanization and high processing efficiency and processing quality and is suitable for large-scale processing.

Owner:湛江市金丰糖业有限公司

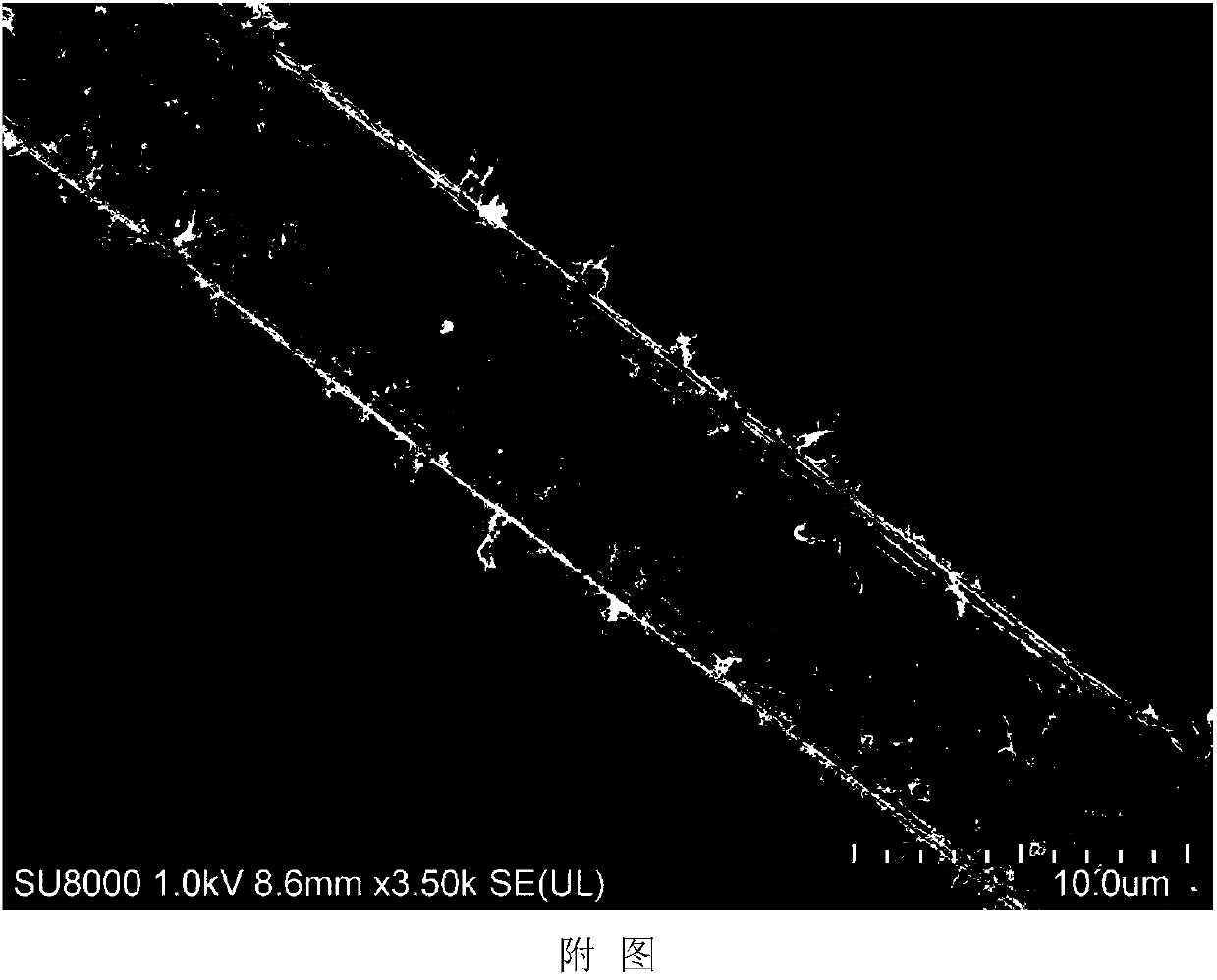

Treatment method for contact end of surface of oriented carbon nano tube-modified carbon fiber on the basis of gas-phase carbon nano tube dispersion mist

ActiveCN107604675AAvoid introducingSuitable for large-scale processingCarbon fibresFiberCarbon fibers

The invention discloses a treatment method for a contact end of a surface of an oriented carbon nano tube-modified carbon fiber on the basis of gas-phase carbon nano tube dispersion mist. The method includes the steps of: 1) uniformly mixing carbon nano tubes, a sizing agent and a diluting agent to form a semi-fluid; 2) dispersing the mixture to form gas-phase carbon nano tube mist with pulsed arc; 3) moving a carbon fiber close to a discharge point of the arc; 4) forming relative constant-speed movement between the discharge point of the pulsed arc and the carbon fiber; 5) baking the carbon fiber in a baking oven; and 6) after the carbon fiber is baked, cooling the carbon fiber to room temperature to finish the treatment for the contact end of the surface of the oriented carbon nano tube-modified carbon fiber.

Owner:QINGDAO UNIV OF SCI & TECH

Coal ash/magnetic straw composite material as well as preparation method and application thereof

ActiveCN107638872AImprove adsorption capacityEasy to separateOther chemical processesWater contaminantsTreated waterToxic industrial waste

The invention discloses a coal ash / magnetic straw composite material as well as a preparation method and application thereof. The coal ash / magnetic straw composite material is prepared through a liquid-phase method by taking agricultural waste oilseed rape straw and industrial waste coal ash as raw materials. The raw materials adopted by the composite material are all wastes, so that an effect oftreating waste by waste is realized, furthermore, the composite material can be prepared under normal temperature and normal pressure, has the advantages of mild reaction condition, simple process andeasily controllable preparation process; meanwhile, the coal ash / magnetic straw composite material not only can play the advantages of straw / coal ash on water treatment, has good adsorption and flocculation effects on wastewater, but also has better magnetic separation effects and good adsorptive capability, is capable of obviously improve the phenomenon that the conventional straw / coal ash is difficult to separate in the water treatment process, solves the problem that suspended solids usually exist in the coal ash treated water, and is suitable for large-scale treatment of wastewater.

Owner:FUJIAN MELTS SPRINGS DTC CO LTD

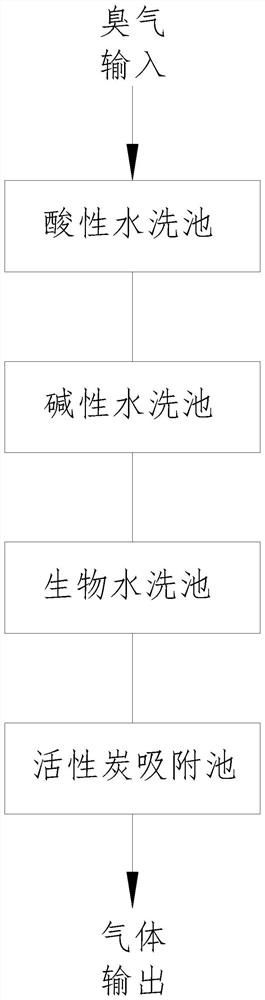

Desulfurated wastewater treatment method and device

PendingCN109205876AGuaranteed separation effectGuarantee the stable operation of the cycleTreatment involving filtrationWaste water treatment from gaseous effluentsFiltrationWastewater

The invention relates to the technical field of wastewater treatment, in particular to a desulfurated wastewater treatment method and device. The treatment method utilizes sodium sulfate and lime milkto remove hard matter, and the operation cost is reduced. The features of different nano filter membranes are utilized to conduct retention on various kinds of ions step by step, not only is separation of materials ensured, but also the safe stability of the system is guaranteed, the scaling risk in the nano filtration process is avoided, and a sodium chloride salt solution with the high purity is finally obtained on the water producing side; meanwhile, the reasonable backflowing process is conducted, the cyclic stable operation and the integral high recycling rate of the system are ensured;and low energy consumption is achieved while tap water is highly concentrated by using a combined technology of reverse osmosis concentration and electroosmosis concentration, and the reverse osmosisfresh water generated by the combined membrane system can be reused for production. The treatment device of desulfurated wastewater is reasonable in treatment unit configuration, operates stably, is high in automation degree, and is suitable for scale treatment of desulfurated wastewater.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

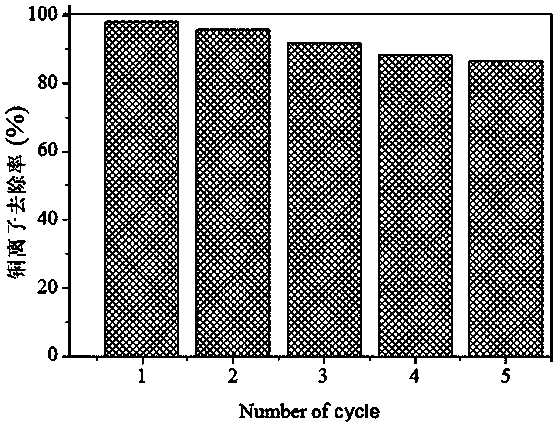

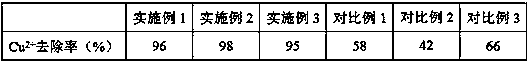

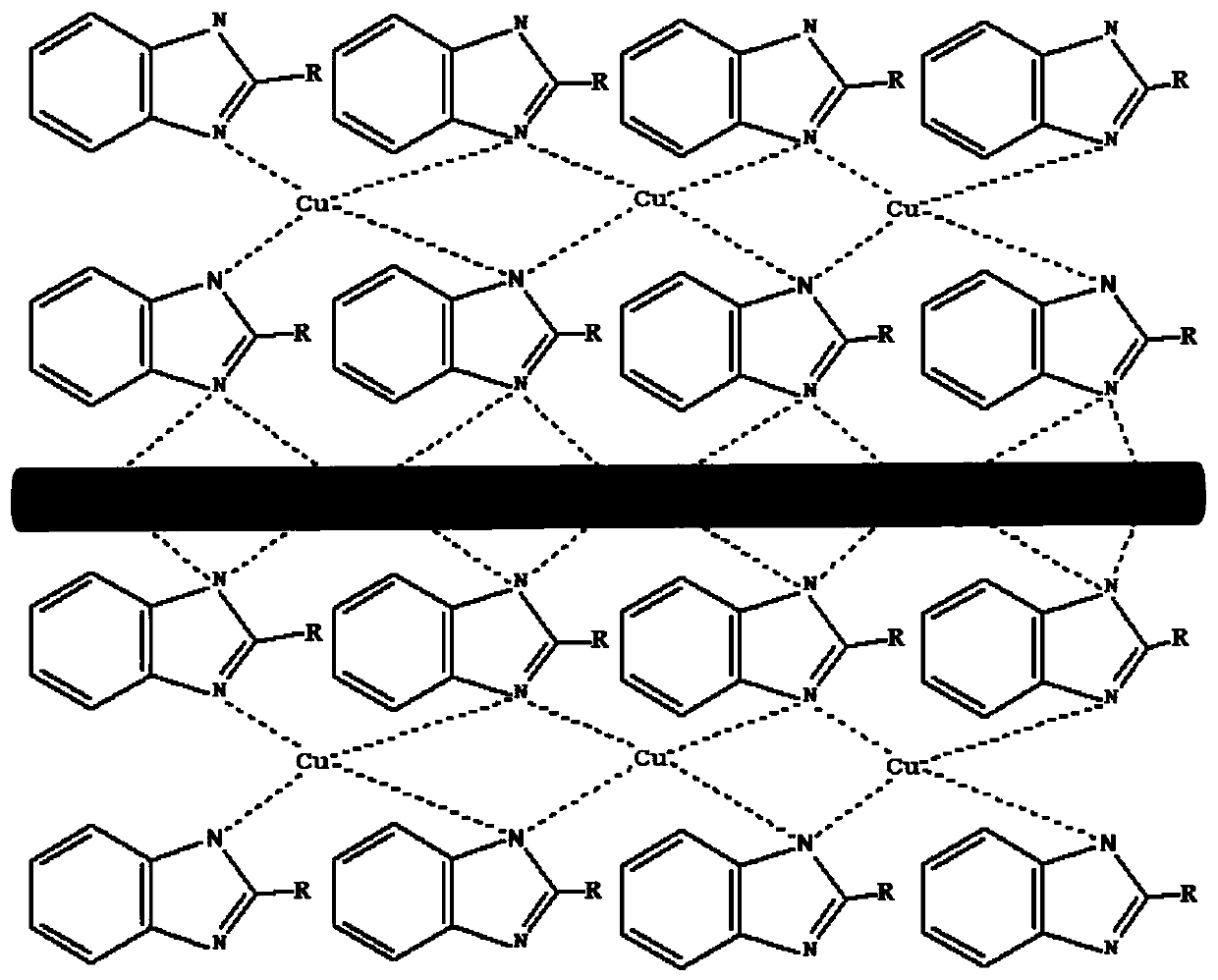

Antioxidant conductive copper nanowire film and preparation method and application thereof

ActiveCN110783025APrevent oxidationImprove antioxidant capacityMaterial nanotechnologyConductive layers on insulating-supportsReduction treatmentFormate

The invention discloses an antioxidant conductive copper nanowire film, and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly dispersingcopper nanowires in an organic solvent or an aqueous solution to prepare a copper nanowire film, and carrying out reduction treatment on the copper nanowire film, dissolving 2-methyl phenylimidazole or benzimidazole in a formic acid-copper formate water buffer solution, and adjusting the pH value until the 2-methyl phenylimidazole or benzimidazole is just completely dissolved to obtain an antioxidant solution, and immersing the copper nanowire film subjected to reduction treatment into a prepared antioxidant solution, carrying out antioxidant treatment, and blow-drying after treatment to obtain the antioxidant conductive copper nanowire film. The prepared antioxidant nanowire film does not influence the conductivity of the copper nanowire film, also does not influence the transparency of the copper nanowire film, has a very good antioxidant effect, solves the key problem of unstable conductivity of the copper nanowire film, and the possibility that the copper nanowire film replaces ITOto be applied to the field of transparent flexible electrodes is achieved.

Owner:JIANGSU UNIV OF SCI & TECH +1

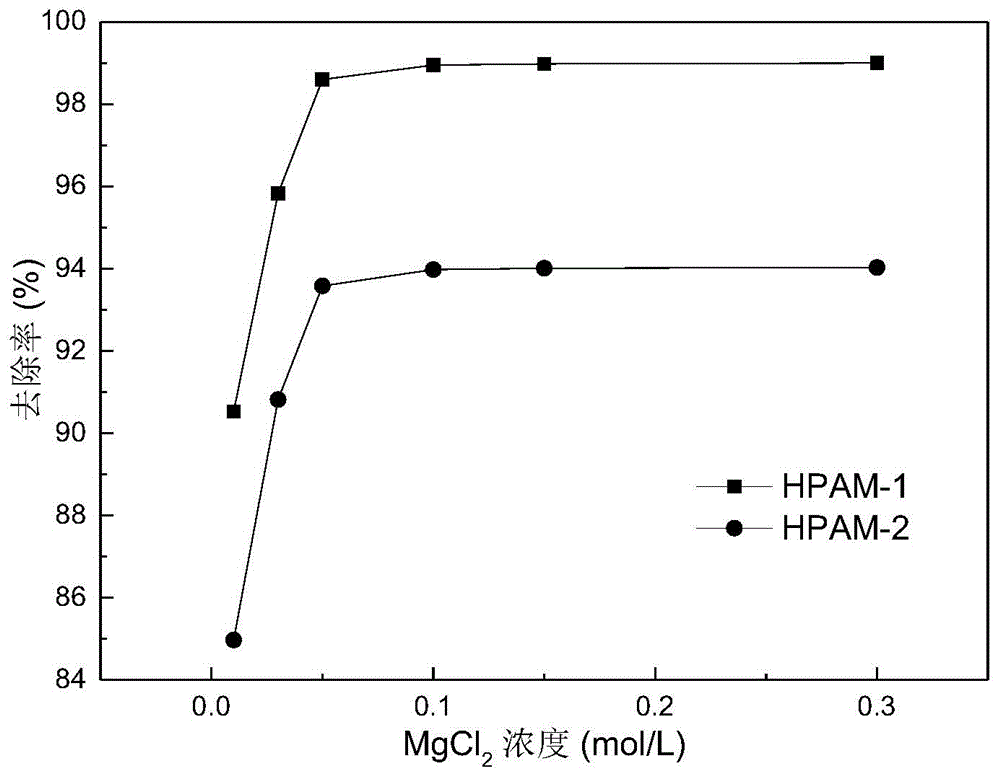

Method for treating water-soluble polymer containing wastewater

ActiveCN104944629ASuitable for large-scale processingImprove processing efficiencyMultistage water/sewage treatmentRoom temperatureWastewater

The invention discloses a method for treating water-soluble polymer containing wastewater, which comprises the following steps: (1) adjusting the pH value of the water-soluble polymer containing wastewater to 8-13.5; (2) putting a reactant MgCl2 into the water-soluble polymer containing wastewater with a concentration of 0.01-0.3 mol / L, and stirring for 30-40 minutes at room temperature, wherein in the process of stirring, the MgCl2 is completely dissociated into Mg<2+> and Cl<-> ions, and the Mg<2+> and HPAM are completely mixed and dissolved; and putting a reactant NaOH into the reaction system in a concentration of 0.02-0.6 mol / L, and continuing to stir for reaction so as to gradually form flocculent aggregates; (3) oscillating the water-soluble polymer containing wastewater for 10 minutes to 6 hours at an oscillating speed of 150-180 RPM, and carrying out centrifugal sedimentation for 10-20 minutes; and (4) after the standard is reached, discharging the obtained product. The method is simple, easy to operate, suitable for large-scale treatment, and high in treatment efficiency.

Owner:SHANDONG UNIV

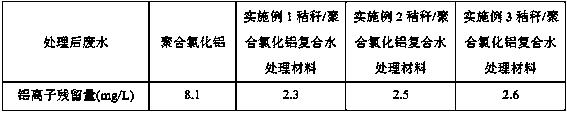

Straw/aluminium polychlorid composite water treatment material and preparation method thereof

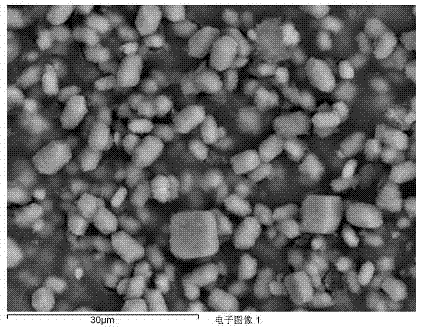

ActiveCN109231387ALarge specific surface areaGood adsorption and flocculation performanceWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chlorideHuman health

The invention discloses a straw / aluminium polychlorid composite water treatment material and a preparation method thereof. The method comprises the following steps: by adopting a liquid phase method,taking coal ash as a raw material to prepare aluminium chloride powder, mixing the aluminium chloride powder and rice straw to prepare a composite material with good water treatment effect. The composite material is prepared by taking industrial waste coal ash and agricultural waste straw as raw materials at normal temperature and under normal pressure, so that the price is cheap; the composite material has good flocculating performance, and good processing capacity for the waste water, the advantage of aluminium salt polymer in water treatment process is played, the residual amount of aluminium ions after processing the aluminium salt polymer is reduced, the negative effect caused by the entering of the aluminium ions to water environment can be maximumly improved, the problem of the toohigh concentration of aluminium ions in water processed by a traditional aluminium salt flocculant is solved, the harm to human health is effectively avoided and the material is suitable for processing the waste water in a large scale.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

High-hardness domestic drinking water softening device and method

InactiveCN106430733AGood dehardening effectReduce sedimentationMultistage water/sewage treatmentTreatment using complexing/solubilising chemicalsWater softeningSludge

The invention relates to a high-hardness domestic drinking water softening device and method. The high-hardness domestic drinking water softening device is characterized by comprising a liquid-solid fluidized-bed reactor, a water inlet and a chemical inlet are formed in the bottom of the liquid-solid fluidized-bed reactor, the bottom of the liquid-solid fluidized-bed reactor is filled with a crystal inducing material, the top face of the crystal inducing material is higher than the water inlet and the chemical inlet, a water outlet is formed in the top of the liquid-solid fluidized-bed reactor, the water inlet is connected with a water storage device for containing raw material to be softened through a pipeline, the chemical inlet is connected with a tank for containing a softening agent through a pipeline, and pumps are arranged at the position, between the water storage device and the water inlet, of the pipeline and the position, between the tank and the chemical inlet, of the pipeline respectively. The high-hardness domestic drinking water softening device is high in outlet water quality stability, small in sludge output and good in harness removal effect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

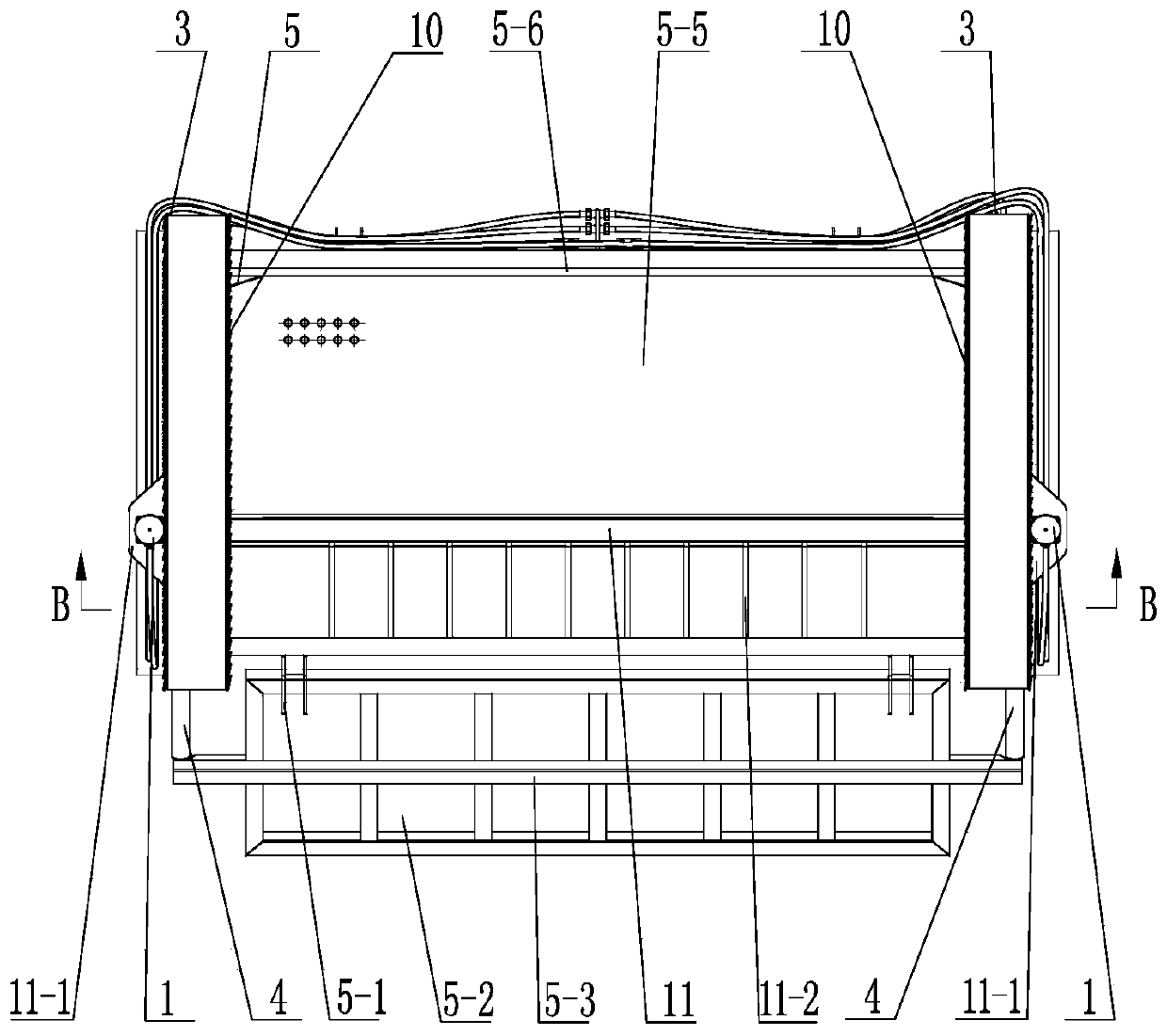

Guitar panel grinding machine

InactiveCN107717681ASmooth transmissionHigh degree of mechanizationGrinding drivesBelt grinding machinesSanderDrive shaft

The invention discloses a guitar panel grinding machine. Including the workbench, the workbench table is equipped with a transmission device, the transmission device is connected to the speaker positioning device, a pillar is connected to each side of the workbench, the two pillars are connected by a fixed rod, and two connecting rods are connected to the fixed rod. The connecting rods are all connected to the grinding device, and the grinding device is located directly above the speaker positioning device; the grinding device includes a double-headed motor, and two transmission shafts are arranged on the double-headed motor, and each of the two transmission shafts is connected to a connecting rod. There is a driving gear, the driving gear is connected to the chain, the chain is connected to the driven gear, and the two driven gears share the driven shaft, and each end of the driven shaft is connected to a connecting rod. Between the driven gears, a grinding belt is set on the roller. The invention has the advantages of fast processing speed, manpower saving, uniform quality of processed guitars and suitable for large-scale processing.

Owner:贵州贝加尔乐器有限公司

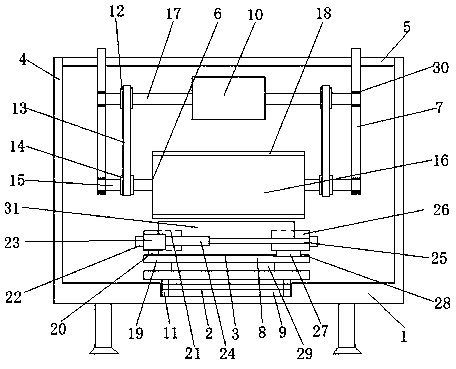

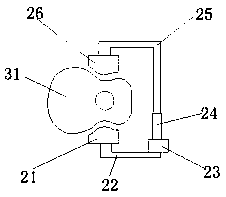

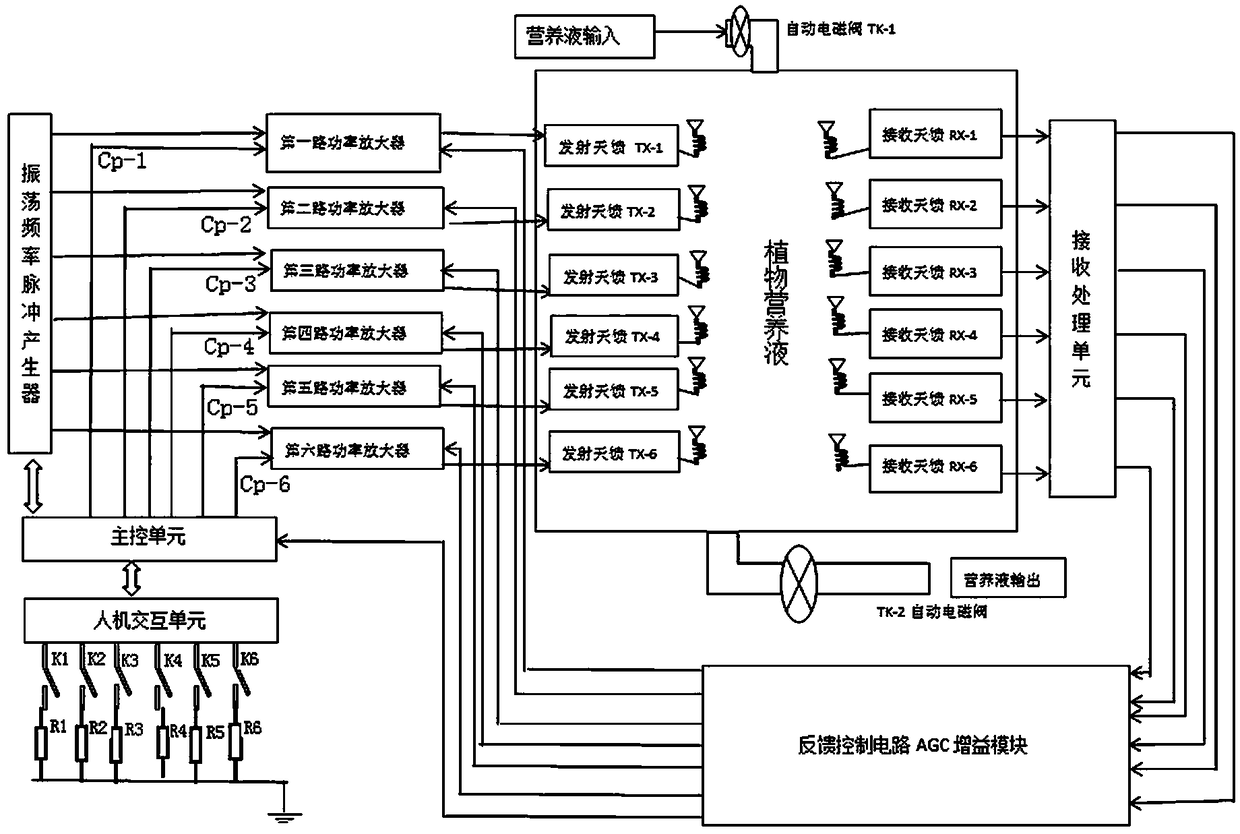

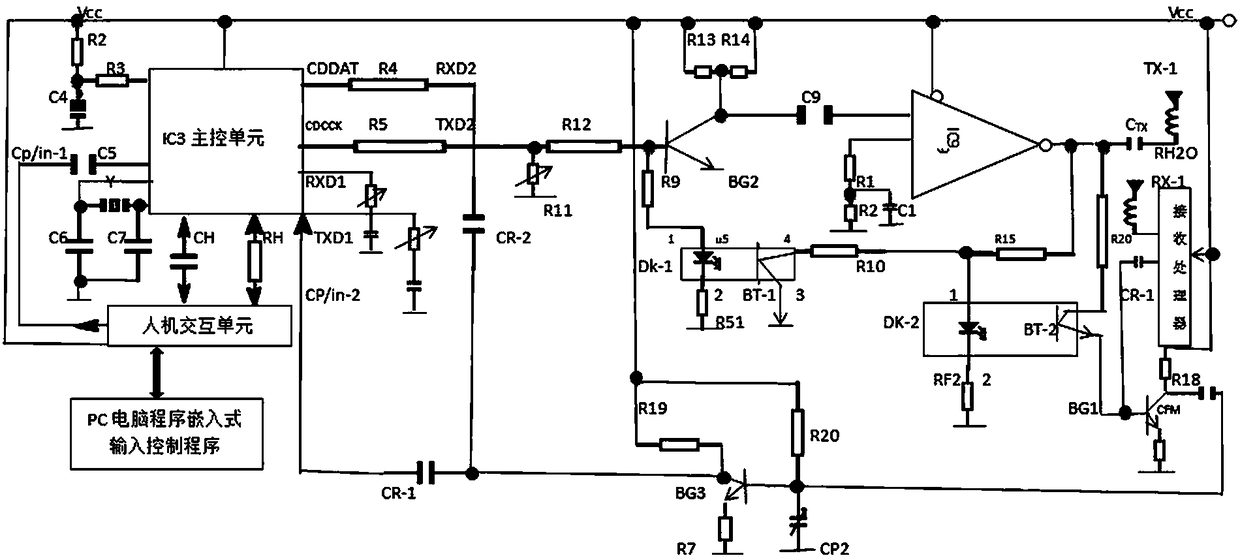

Negative hydrogen ion pulse radar equipment for hydrogen-state agriculture

PendingCN108594218APromote growthImprove nutritional qualityOscillations generatorsRadio wave reradiation/reflectionNutrient solutionAntenna feeder

The invention discloses negative hydrogen ion pulse radar equipment for hydrogen-state agriculture, and the equipment comprises an oscillation frequency pulse generator, a main control unit, a power amplifier, a slot antenna, a human-machine interaction unit, a receiving processing unit and a nutrient liquid container, wherein the slot antenna is fixed in the nutrient liquid container, and the slot antenna includes a transmitting antenna feed TX and a receiving antenna feeder RX. The oscillation frequency pulse generator is connected with the transmitting antenna feeder TX through the power amplifier, and the receiving processing unit is connected with the receiving antenna feeder RX. The main control unit is connected with the human-machine interaction unit, the oscillation frequency pulse generator, the power amplifier and the receiving processing unit, and the main control unit, the oscillation frequency pulse generator, the power amplifier, the slot antenna and the receiving processing unit form a closed cyclic pulsed electromagnetic oscillator circuit through the metal elements in nutrient solution. The equipment can enable the nutrient solution to be polarized into hydride mixed solution with negative hydrogen ions, thereby achieving the purpose of promoting the absorption of plant.

Owner:中亚民生科技发展有限公司

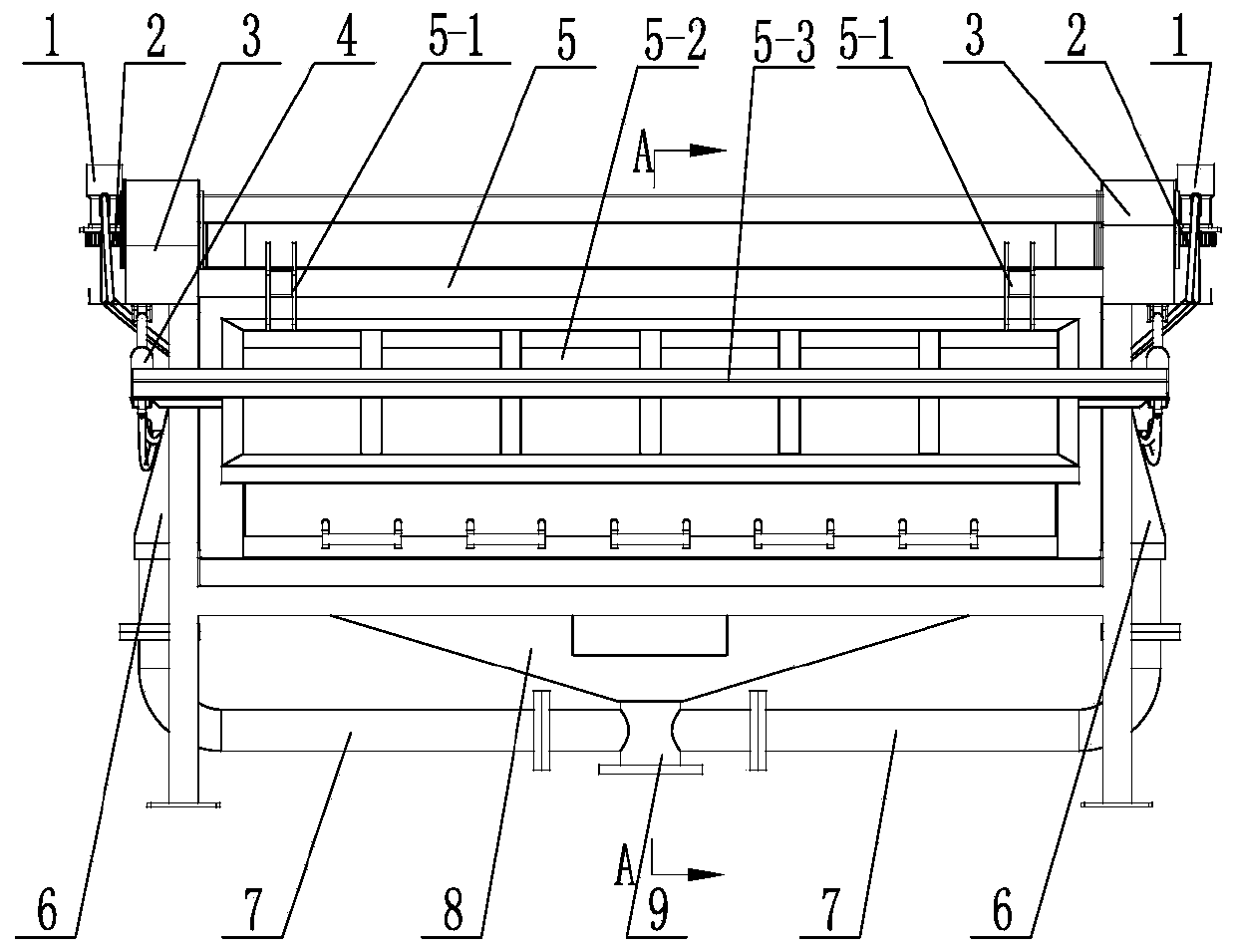

High-speed sludge treating system

InactiveCN105731759AContinuous high-efficiency processingReasonable structural designSludge treatment by de-watering/drying/thickeningSludge cakeFilter press

The invention discloses a high-speed sludge treating system, comprising a sludge pool, a sludge delivery pump, a sludge stirring tank, a sludge filter press and a filtrate pool, wherein the sludge delivery pump is arranged in the sludge pool and used for delivering sludge to the sludge stirring tank via a pipeline, the sludge stirring tank is connected with the sludge filter press via a sludge input, and the sludge filter press is provided with a filtrate outlet used for delivering filtrate to the filtrate pool and with a sludge cake outlet used for discharging a sludge cake. The high-speed sludge treating system is reasonable in structural design and convenient to use, can continuously and highly efficiently carry out sludge treatment and is applicable to a large water plant or sludge treatment unit.

Owner:陕西雅美环保科技有限公司

Preparation method and application of porous alginate membrane

ActiveCN113968993ASimple manufacturing methodImprove pore forming efficiencyCosmetic preparationsSurgical adhesivesWound dressingAlcohol ethyl

The invention discloses a preparation method and application of a porous alginate membrane, wherein the method comprises the following steps: freezing and solidifying a sodium alginate solution at low temperature, and injecting a low-melting-point unfreezing coagulator into the sodium alginate solution, the unfreezing coagulator comprises the following components in percentage by mass: 50-94% of absolute ethyl alcohol, 5-25% of anhydrous calcium chloride, 0.5-2% of glycerol and water; and the ice crystal structure of the sodium alginate macromolecules is gradually dissolved through ethanol permeation, meanwhile, the sodium alginate macromolecules during unfrozen are rapidly cross-linked and solidified through liquefied calcium ions, and the space structure of the frozen state of the sodium alginate macromolecules is reserved, so that a porous alginate film is formed. According to the preparation method, equipment and process conditions are simple, the pore-forming efficiency is greatly improved, the mechanical property of the porous alginate film is improved, and the preparation method is suitable for large-scale processing. In addition, the porous alginate film prepared by the invention can be used for facial masks, wound dressings, hemostatic sponges or cell scaffolds.

Owner:SOUTHWEST UNIV

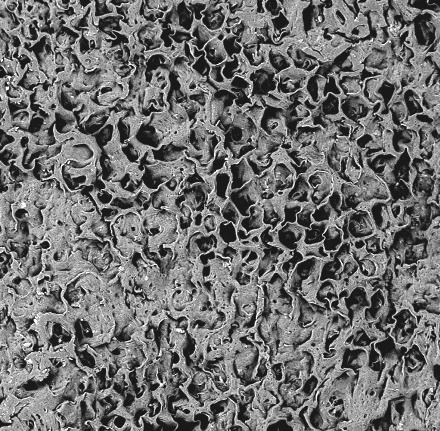

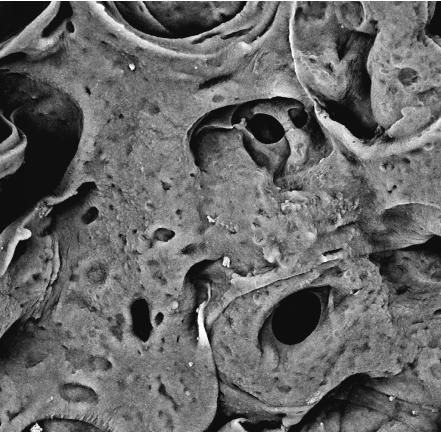

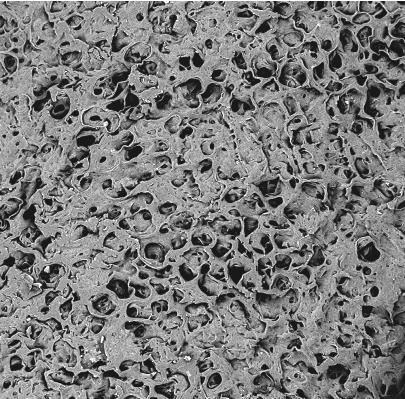

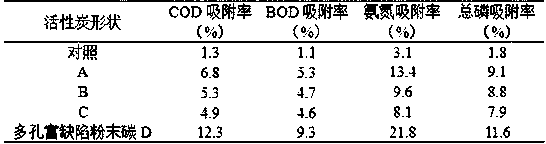

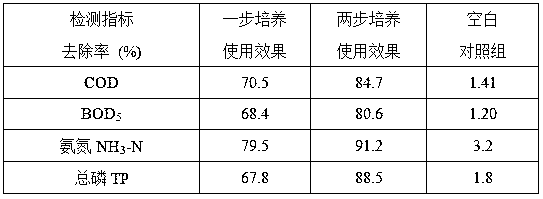

Biological active carbon with banyan leaves as carbon source carrier based on culture of high-sugar wastewater

ActiveCN109897869AGood dispersionOvercoming Hydrophobic ProblemsWater contaminantsMicroorganism based processesCarbon sourceBanyan

The invention belongs to the technical field of biological active carbon, and particularly relates to biological active carbon with banyan leaves as a carbon source carrier based on culture of high-sugar wastewater. The porous surface-defect-rich carbon carrier with the banyan leaves as a carbon source is placed in a culture medium, mixed strains are inoculated into the high-sugar wastewater in two steps, and through vibration and co-culture, the biological active carbon is prepared. Through culture in two steps, oligosaccharides or cellulose in the high-sugar wastewater are / or subjected to enzymolysis into low-molecular saccharides advantageously by the microbial strains added in the early stage, and produced mesostate can serve as the carbon source for growth and reproduction of the microbial strains added in the later period. Organic matter and pollutants adsorbed by the carrier carbon are efficiently utilized and synergistically degraded by microorganisms, and therefore a water purifying agent has the double purifying effects of carbon physical adsorption and bio-enzyme degradation, and is hydrophilic but easy to precipitate, and very suitable for scale treatment of the high-sugar wastewater.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

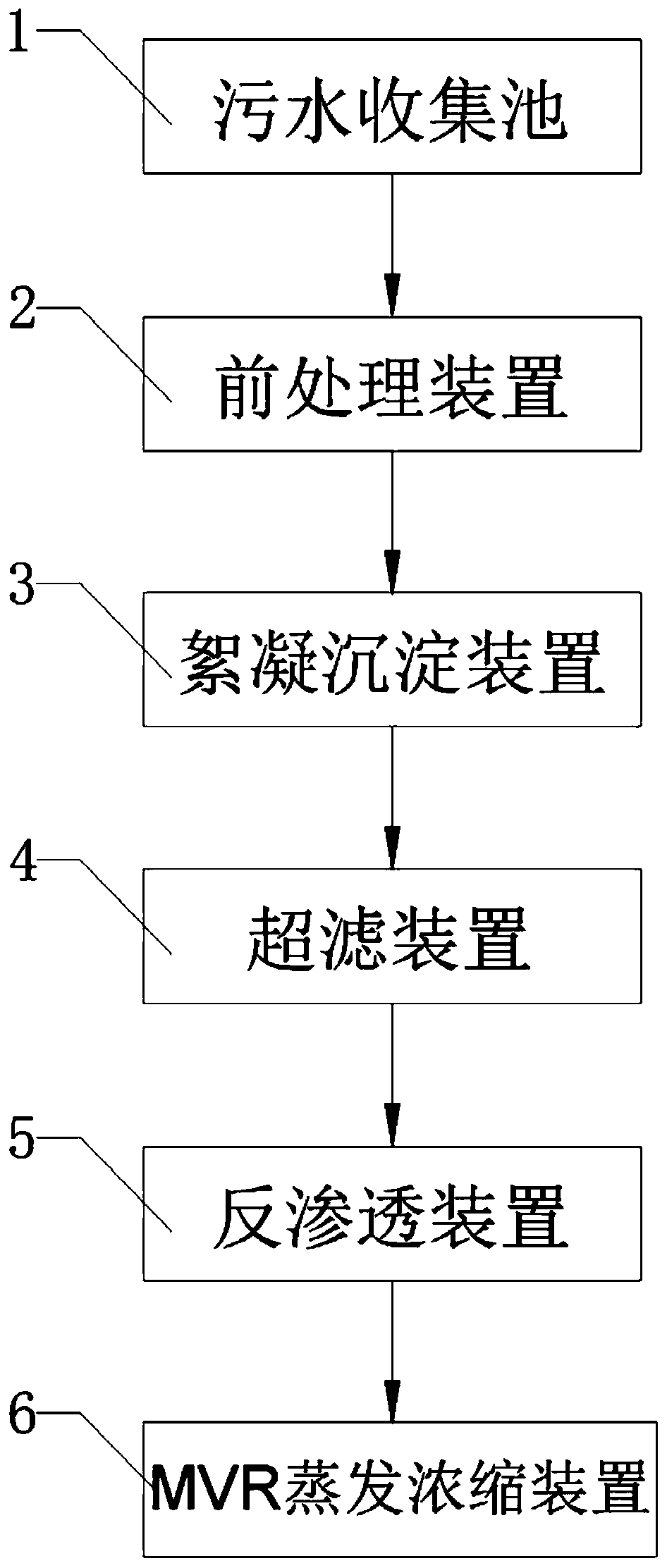

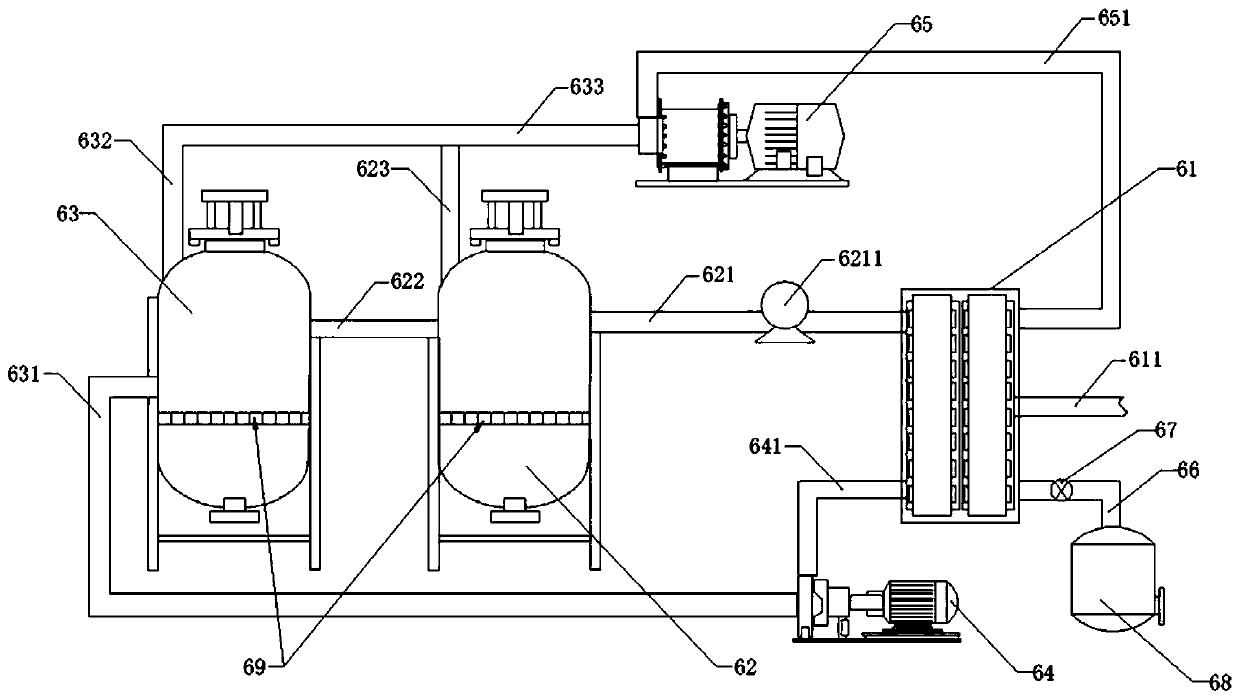

System and technology for concentration and crystallization treatment of high-salinity water

ActiveCN110723857AReduce energy consumptionAchieve recyclingWater treatment parameter controlFatty/oily/floating substances removal devicesSaline waterPlate heat exchanger

The invention relates to the technical field of sewage discharge, and concretely relates to a system and a technology for concentration and crystallization treatment of high-salinity water. The treatment system sequentially comprises a sewage collection tank, a pretreatment device, a flocculent precipitation device, an ultrafiltration device, a reverse osmosis device and an MVR evaporation concentration device according to the treatment use sequence, the MVR evaporation concentration device sequentially comprises a plate heat exchanger, a first precipitation and crystallization tank, a secondprecipitation and crystallization tank and a feed liquid circulating pump according to the treatment use sequence, and the steam outlet end of the first precipitation and crystallization tank and thesteam outlet end of the second precipitation and crystallization tank are communicated with the plate heat exchanger through a steam compressor; and the plate heat exchanger is provided with a feedingend, and the feeding end of the plate heat exchanger is communicated with the output end of the reverse osmosis device through a feeding pipeline. The system for concentration and crystallization treatment of high-salinity water has the advantages of novel structure, simplicity in operation, and ensuring of the integrity of crystals by precipitation, crystallization and growth of crystals of high-salinity water at the bottoms of the tank bodies of the first precipitation and crystallization tank and the second precipitation and crystallization tank.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

Rapid draining device for kitchen waste

PendingCN111267388AEasy to separateSuitable for large-scale processingPressesDrive wheelEnvironmental engineering

The invention relates to a rapid draining device for kitchen waste. A box body is provided with a front baffle capable of being opened downwards at a front side, and a rear baffle is fixed to the rearside of the box body; the box body is provided with draining meshes in a bottom plate and communicates with a liquid collection box on the lower part; the bottom of the liquid collection box is provided with a liquid drainage pipe at a liquid drainage port; the box body is provided with bearing seats at the tops of two side plates; a guide rail guiding a push plate is arranged on each bearing seat; each push plate is vertically arranged in the box body; movable seats at the two ends of the upper parts of the push plates are arranged on the guide rails and capable of moving to extrude the kitchen waste; a drive mechanism comprises two motors and transmission assemblies correspondingly converting rotational movement to linear movement; the two motors are installed on the movable seats of the push plates separately; each transmission assembly comprises a drive wheel and a driven element installed on the corresponding bearing seat and engaged with the corresponding drive wheel; each drivewheel is installed at the output side of the corresponding motor; and the two motors drive the transmission assemblies to drive the push plates to carry out linear movement simultaneously. The rapiddraining device for the kitchen waste is simple in structure, and capable of solving the problem of blockage on the draining meshes, and rapidly separating out free water in the kitchen waste.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

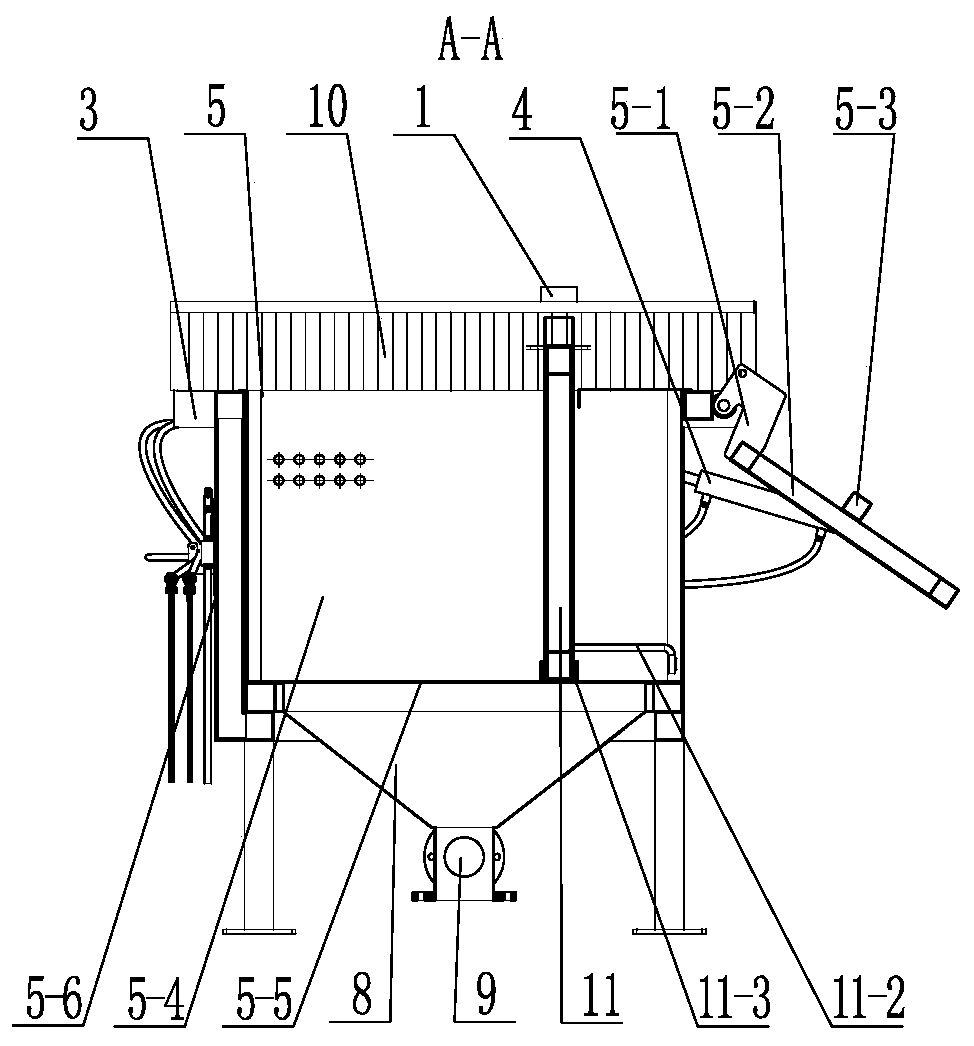

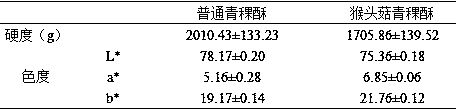

Preparation method of hericium erinaceus and highland barley shortbread

InactiveCN109769891AThe preparation method is scientific and safeCrispy tasteDough treatmentModified nutritive productsShortbread biscuitSesamum

The invention relates to a preparation method of a hericium erinaceus and highland barley shortbread, and belongs to the field of food processing. According to the method, a dried hericium erinaceus product and cleaned, washed and dried highland barley powder are pulverized and sieved, squeezed and puffed at 150-170 DEG C, and then ultra-finely pulverized; 300-400 parts of pre-gelatinized powder of the hericium erinaceus, 200-300 parts of wheat flour, 200-300 parts of butter, 180-200 parts of sugar powder, 60-80 parts of eggs, 4-6 parts of soda, 7-9 parts of ammonium hydrogen carbonate and 2-3parts of sesames are added by weight; the hericium erinaceus and highland barley shortbread is obtained through the steps of sugar and oil wipping, dough stirring, dividing and shaping, baking and cooling. The hericium erinaceus and highland barley shortbread prepared by the method has good taste, is very nutritious, is suitable for a wide range of people, is easy to digest, and has a certain effect in protecting the gastrointestinal function.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

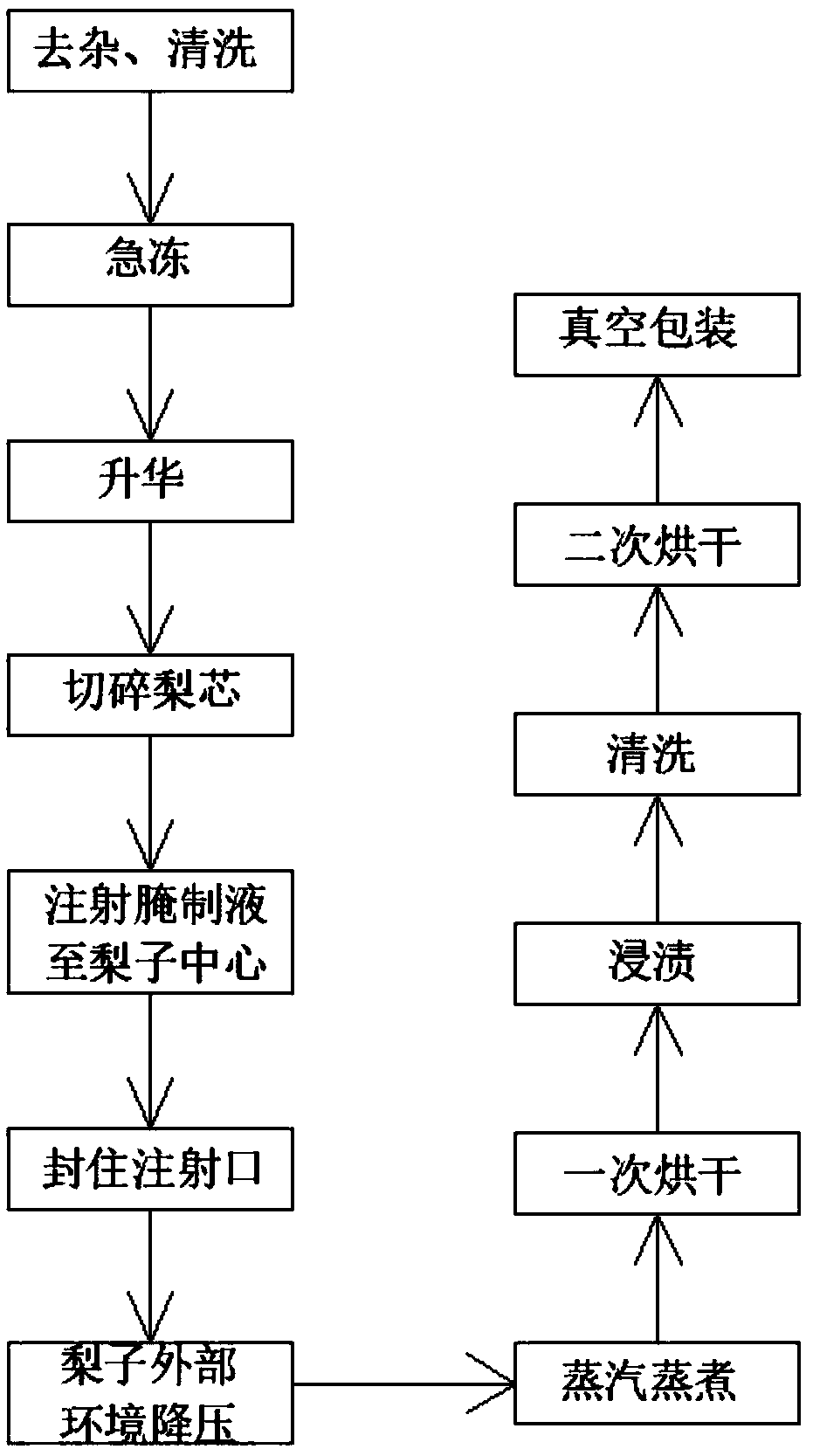

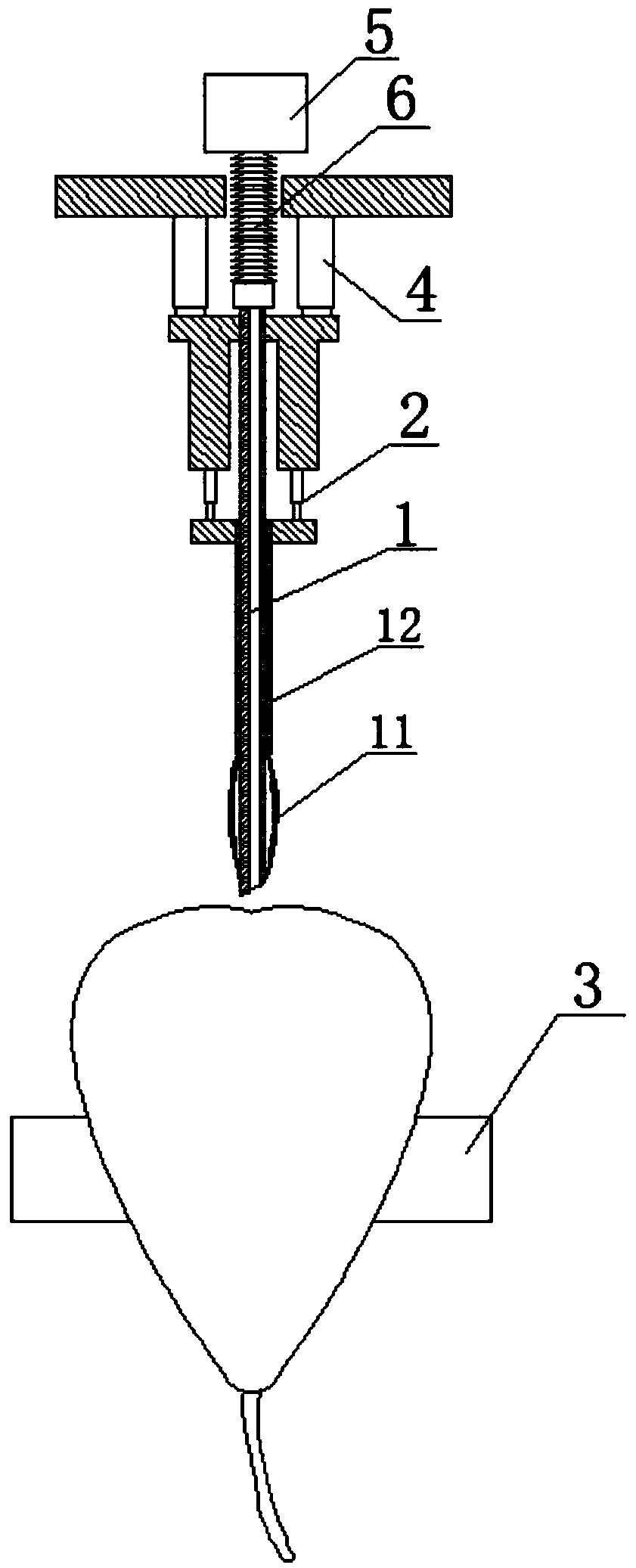

Pear pickling method for keeping pear appearance

The invention relates to a pear pickling method for keeping pear appearance. The method comprises the following steps in sequence: (1) subjecting fresh and incompletely mature pears to impurity removal and cleaning; (2) carrying out quick freezing on the pears, wherein the quick freezing temperature is -25 to -20 DEG C, the quick freezing time is 20-30min, and the pear cells are destroyed; (3) putting the quick-frozen pears into a vacuum container for vacuumizing, so that ice crystals frozen in the pears are directly sublimated and pores are generated, and meanwhile, the pear cells are furtherdestroyed; (4) chopping the pear core to form a cavity in the center of each pear while keeping the whole appearance of the pears, wherein broken fruit foam or fruit strips formed by the chopped pearcore is arranged in the cavity; (5) injecting a pickling solution into a cavity in the center of each pear; (6) using pectin to seal the injection hole in each pear; (7) placing the pears into a vacuum chamber, and slowly vacuumizing the chamber to 0.5MPa within 2-3h; and (8) conducting steaming: putting the pears into a steam room, carrying out steaming, and keeping the steam temperature at 100-130 DEG C by adjusting the pressure in the steam room, wherein the steaming time is 30-50 minutes.

Owner:任祐增

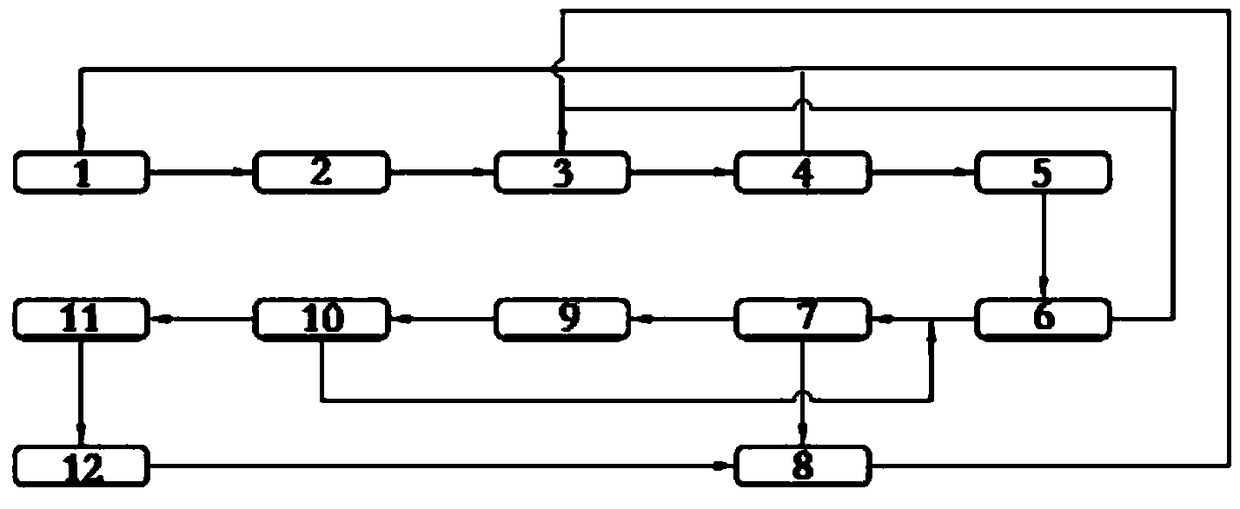

Recovery method of ferric chloride etching waste liquid

ActiveCN104131285BImprove qualityLow operating costWater contaminantsWaste water treatment from metallurgical processLiquid wasteRecovery method

The invention provides a method for recovering ferric chloride etching waste etching solution, which adopts membrane electrolysis and extraction integration technology, and an ion exchange membrane is set in the electrolytic cell to divide the electrolytic cell to form an anode chamber and a cathode chamber, and the cathode and the anode are respectively The cathode chamber and anode chamber located on both sides of the ion exchange membrane; ferric chloride etching waste solution is added into the cathode chamber for membrane electrolysis, and the Fe 3+ ion reduction to Fe 2+ Ions; the solution after electrolysis in the cathode chamber is extracted to remove impurity metals to obtain the extract phase solution and the demetallized impurity phase solution, and the demetallized impurity phase solution is sent to the anode chamber for membrane electrolysis, and the Fe 2+ Ions are oxidized to Fe 3+ Ions; the solution obtained by electrolysis in the anode chamber is recovered. Compared with the current ferric chloride etching waste liquid treatment technology, the technological process is short and simple, no secondary pollution occurs, no three wastes are discharged, the production cost is low, and it is suitable for large-scale treatment. The annual treatment capacity can be more than 10,000 tons. It has good environmental and economic benefits.

Owner:宁波东顺电子科技有限公司

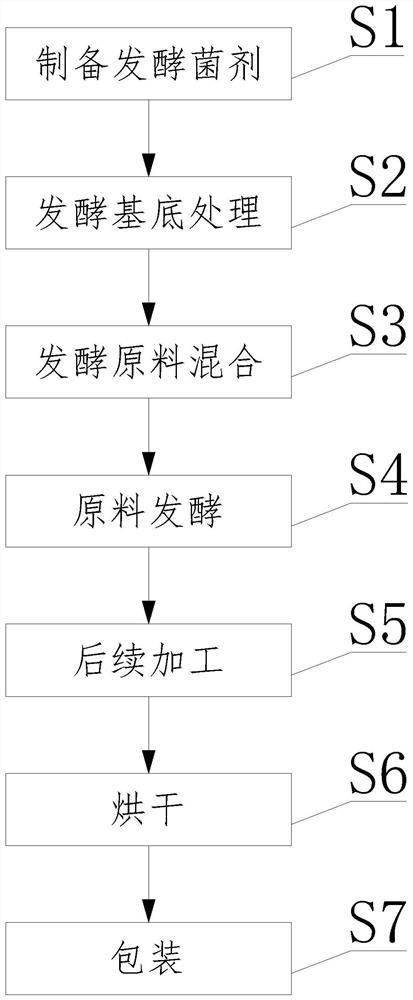

Organic fertilizer stack type fermentation method taking mushroom dregs as substrate

InactiveCN112409039AEfficient use ofEvenly distributedBio-organic fraction processingMicroorganism based treatmentBiotechnologyEngineering

The invention discloses an organic fertilizer stack type fermentation method taking mushroom dregs as a substrate. The method comprises the following steps: s1, preparing a fermentation microbial inoculum; s2, treating a fermentation substrate; s3, mixing the fermentation raw materials; s4, fermenting the raw materials: fermenting the fermentation raw materials, specifically, conveying the fermentation raw materials into a windrow type fermentation tank through conveying equipment to form compost, monitoring the compost temperature in the fermentation period, and turning the compost pile oncewhen the fermentation temperature is higher than 65 DEG C; when the fermentation temperature is always lower than 65 DEG C, turning the compost pile once every 5-6 days; when the fermentation temperature is reduced to 30 DEG C, ending the fermentation and preparing an organic fertilizer; s5, subsequent processing; s6, drying; and s7, packaging. According to the present invention, the raw materialscan be crushed and effectively mixed so as to uniformly distribute the fermentation substrate and the fermentation microbial inoculum, such that the fermentation effect is significantly improved, thewaste of the bacterial residue can be avoided, the nutrients in the bacterial residue can be effectively utilized, the quality of the organic fertilizer is significantly improved, the operation is simple, and the method is suitable for large-scale processing.

Owner:武汉达鑫源有机肥有限责任公司

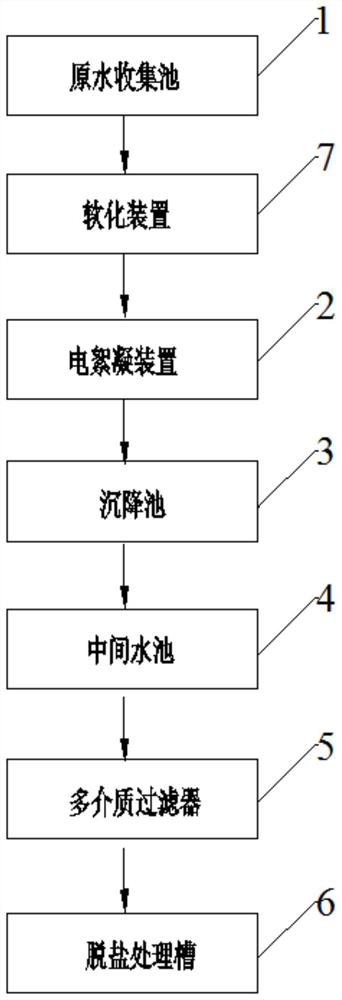

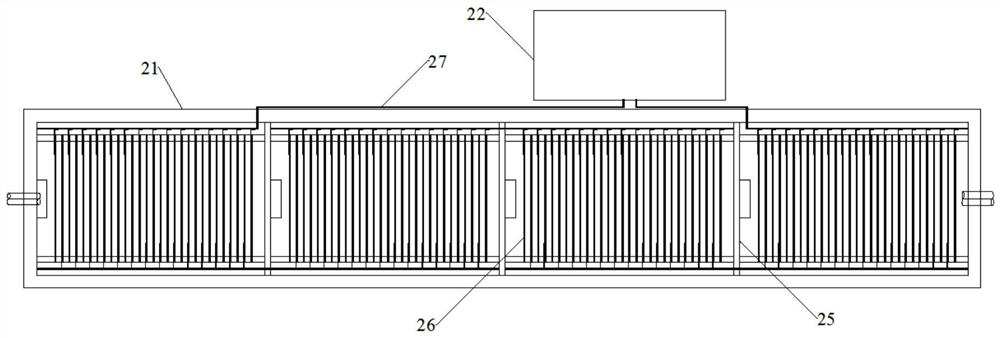

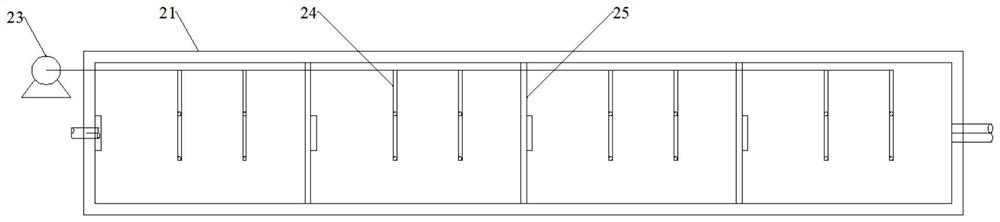

Electric flocculation silicon removal process and system for silicon-containing wastewater

PendingCN112499848AAvoid pollutionFacilitated DiffusionWater contaminantsScale removal and water softeningElectrolysisChemical agent

The invention relates to the technical field of silicon-containing wastewater treatment, in particular to an electric flocculation silicon removal process for silicon-containing wastewater. The process comprises the following steps: 1) collecting silicon-containing raw water into a raw water collecting tank, and pumping the silicon-containing raw water in the raw water collecting tank into an electric flocculation device through a gas-liquid mixing pump for electrolytic treatment, then feeding the electrolyzed water body into a sedimentation tank, and conducting standing for layering; (2) discharging lower-layer sediment settled and layered by the sedimentation tank in the step (1), and feeding supernatant liquid settled and layered by the sedimentation tank into a middle water pond for secondary settling; and (3) feeding the supernatant subjected to secondary sedimentation in the middle water pond in the step (2) into a multi-medium filter for filtering, and finally desalting the filtered filtrate for recycling. The electric flocculation silicon removal process for the silicon-containing wastewater is simple to operate, does not need to add chemical agents in the treatment process, avoids secondary pollution to the environment, can be suitable for large-scale treatment, and is high in practicability, and the silicon removal treatment rate is up to 99% or above.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

Processing technology of dried bamboo shoots

InactiveCN104839315AEvenly heatedSuitable for large-scale processingFruits/vegetable preservation by dehydrationAgricultural engineeringHealthful food

The invention discloses a processing technology of dried bamboo shoots, belonging to the technical field of food processing. The processing technology comprises the five specific steps of husking, poaching and carrying out fixation, cutting bamboo shoot flesh, spreading and airing, and drying. The problems that the baking time in the dried bamboo shoot treatment process is too long, furthermore, dried bamboo shoots can be easily hard and are not crisp, or, the dried bamboo shoots are red and black, appearance and flavor are influenced, and furthermore, the dried bamboo shoots go bad and cannot be eaten can be effectively solved. The processing technology of the dried bamboo shoots disclosed by the invention has the benefits that the color, the smell and the taste of the dried bamboo shoots are slightly different from fresh bamboo shoots; the dried bamboo shoots are crisp in texture and cannot go bad; furthermore, the process is simple and easy to operate; because of being cut, the bamboo shoots are heated uniformly; therefore, the baking time is greatly shortened; the baking time is only 20-24h; any additive is added in the production process; the processing technology accords with healthy food requirements; and therefore, the processing technology is not only applied to production of family workshops but also can be applied to large-scale processing of factories.

Owner:黄振忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com