Desulfurated wastewater treatment method and device

A desulfurization wastewater and treatment method technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high hardness of desulfurization wastewater, inability to reuse, environmental hazards, etc., to ensure circulation The effects of stable operation, reduced operating costs, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

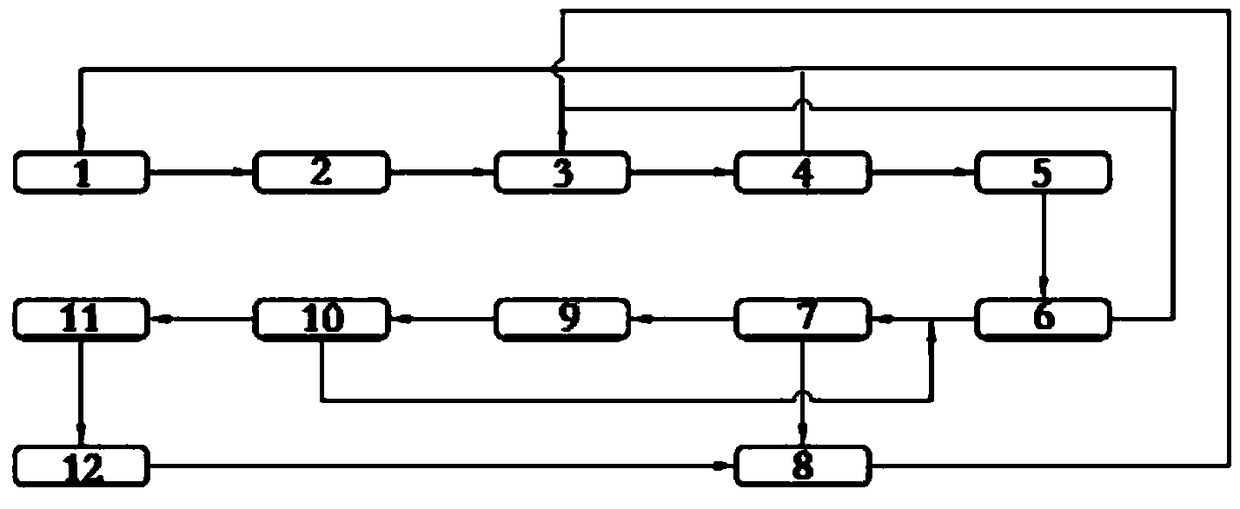

[0093] At present, a thermal power plant in Shaoxing has about 25 tons of desulfurization wastewater per hour that needs advanced treatment. Now with the processing capacity of every batch of 0.5t to the desulfurization wastewater treatment device provided by the invention (as figure 1 shown) to design, install and debug, and then carry out a pilot test on the desulfurization wastewater of the plant, as follows:

[0094] The salt content in the effluent of the three-box desulfurization wastewater of the plant is about 27000ppm, the calcium ion content is about 4500ppm, and the magnesium ion content is about 700ppm;

[0095] 0.5t of the triple box effluent of the above-mentioned desulfurization waste water enters the dosing reaction sedimentation tank 1 through a submersible pump, and adds 15kg of sodium sulfate, 2kg of milk of lime (concentration is 4wt%) and flocculant (to ensure that the content of flocculant in the system is about 5ppm) , stirred and mixed for 30min, and t...

Embodiment 2

[0103] Carry out pilot test to desulfurization waste water in embodiment 1 equally, specifically as follows:

[0104] The salt content in the effluent of the three-box desulfurization wastewater of the plant is about 27000ppm, the calcium ion content is about 4500ppm, and the magnesium ion content is about 700ppm;

[0105] 0.5t of the three-box effluent of the above-mentioned desulfurization wastewater is entered into the dosing reaction sedimentation tank 1 through a submersible pump, and 15kg of sodium sulfate, 2kg of milk of lime (concentration is 5wt%) and flocculant (to ensure that the content of flocculant in the system is about 5ppm) is added. , stirred and mixed for 30min, and then carried out precipitation treatment for 4h; after the precipitation treatment was completed, the resulting supernatant (calcium ion content was about 2000ppm) entered the filtration unit 2 for filtration treatment (specifically, ultrafiltration treatment was adopted, during which the Produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com