Synthesis method and applications of magnetic nano high-molecular polymer

A high-molecular polymer and magnetic nanotechnology, applied in the field of analytical chemistry, can solve problems such as insufficient hydrophobicity of the surface, influence of adsorption capacity, and separation difficulties, so as to ensure separation speed and separation effect, increase utilization rate, and enhance removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

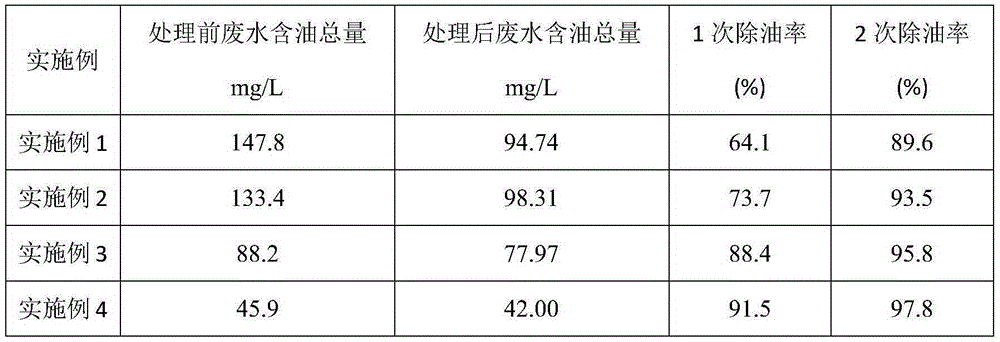

Examples

Embodiment 1

[0030] (1) The synthesis of sodium citrate modified magnetic nano-ferric oxide is as follows:

[0031] ① Weigh 9.80g (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O, 6.75 g FeCl 3 ·6H 2 O, dissolved in deionized water to prepare 50 mL of Fe-containing 2+ and Fe 3+ mixed solution;

[0032] ②Transfer the mixed solution prepared in step ① into a three-necked bottle, heat it in a water bath at 60°C under nitrogen protection, add concentrated ammonia water dropwise under mechanical stirring at a speed of 1000rpm, control the total volume of concentrated ammonia water at 12.5mL, and drop until the solution is Black precipitate, stop adding ammonia water, add 16.1g sodium citrate, continue to stir for 2 hours, add the remaining ammonia water dropwise;

[0033] ③The black solution obtained above was collected by an external magnetic field, washed three times with 50 mL of acetone, and dried in vacuum at 40°C for 48 hours to obtain sodium citrate-modified magnetic nano-ferric oxide powder.

[...

Embodiment 2

[0042] (1) The synthesis of sodium citrate modified magnetic nano-ferric oxide is as follows:

[0043] ①Weigh 5.96gFeCl 2 4H 2 O, 8.11 g FeCl 3 ·6H 2 O, dissolved in deionized water to prepare 50 mL of Fe-containing 2+ and Fe 3+ mixed solution;

[0044] ② Transfer the mixed solution prepared in step ① to a three-necked bottle, and heat it in a water bath at 70°C under nitrogen protection. Add concentrated ammonia water dropwise under mechanical stirring at a speed of 800rpm. The total volume of concentrated ammonia water is controlled at 20mL until the solution turns black. Precipitate, stop adding ammonia water, add 17.6g sodium citrate, continue to stir for 3h, add the remaining ammonia water dropwise;

[0045] ③The black solution obtained above was collected by an external magnetic field, washed with 70mL of acetone for 4 times, and then vacuum-dried at 45°C for 40h to obtain sodium citrate-modified magnetic nano-ferric oxide powder.

[0046] (2) The synthesis of fer...

Embodiment 3

[0054] (1) The synthesis of sodium citrate modified magnetic nano-ferric oxide is as follows:

[0055] ① Weigh 13.72g (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O, 19.66gFe 2 (SO 4 ) 3 9H 2 O, dissolved in deionized water to prepare 50 mL of Fe-containing 2+ and Fe 3+ mixed solution;

[0056] ② Transfer the mixed solution prepared in step ① to a three-necked bottle, heat it in a water bath at 70°C under the protection of nitrogen, and add concentrated ammonia water dropwise under mechanical stirring at a speed of 600rpm. The total volume of concentrated ammonia water is controlled at 22mL until the solution turns black Precipitate, stop adding ammonia water, add 24.7g sodium citrate, continue to stir for 4 hours, add the remaining ammonia water dropwise;

[0057] ③The black solution obtained above was collected by an external magnetic field, washed with 100 mL of acetone for 5 times, and dried in vacuum at 50°C for 24 hours to obtain sodium citrate-modified magnetic nano-ferric ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com