Method for extracting copper from organic silicon chemical waste residue leaching liquid of chloride and mixed salts containing copper

A technology of leaching liquid and organosilicon, which is applied in the direction of copper oxide/copper hydroxide, improvement of process efficiency, photography process, etc., and can solve problems such as difficult handling of liquid after replacement, high anode requirements, and chlorine gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

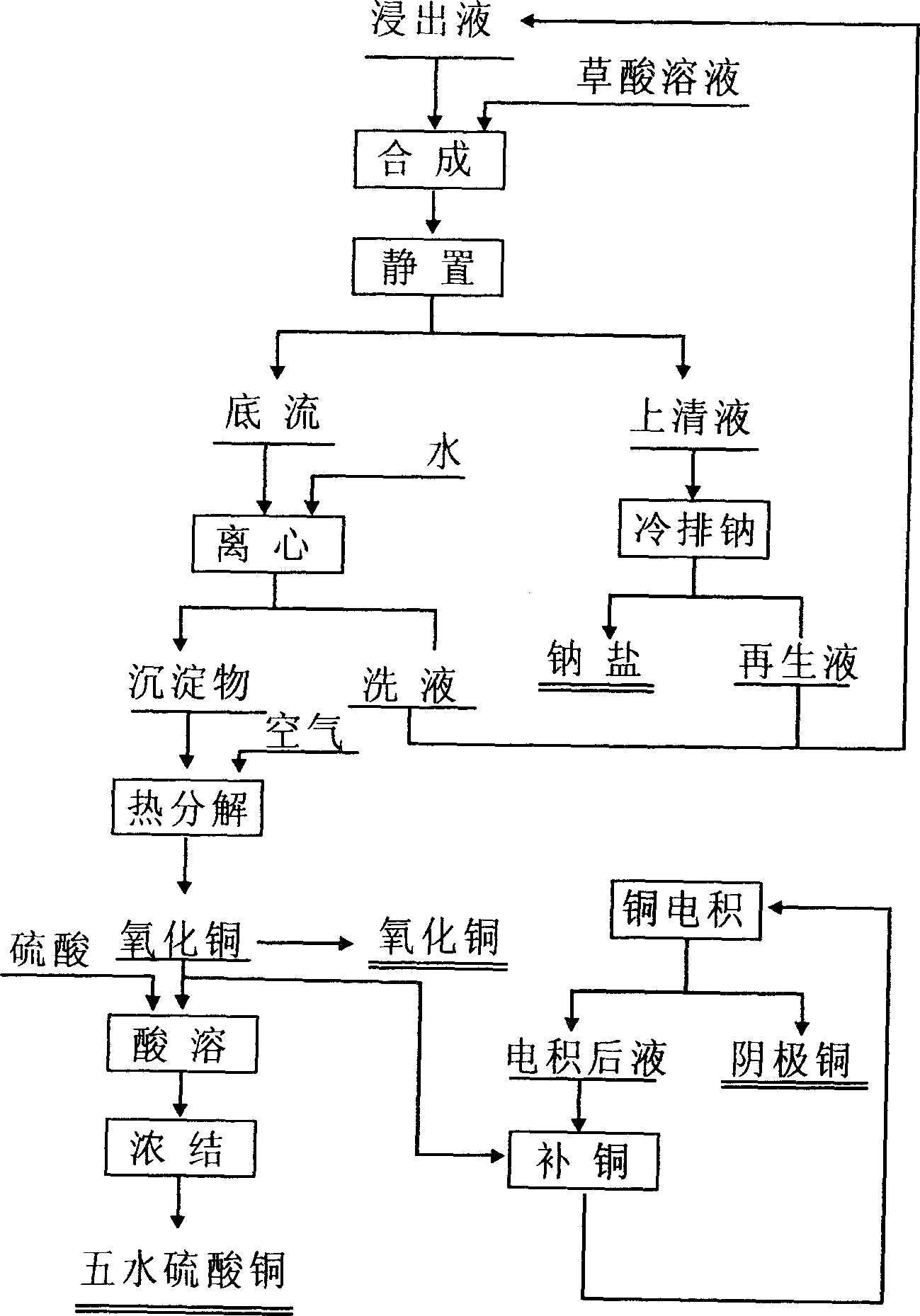

Image

Examples

Embodiment

[0014] 1. Using sodium hypochlorite as oxidant, leaching organic silicon "waste residue slurry" with hydrochloric acid solution greater than 60°C to obtain acidic copper chloride salt system leaching solution, put the solution into the reaction kettle and heat it above 70°C to start stirring, and at the same time add a small stream to prepare nearly Saturated oxalic acid solution is used for precipitation reaction, and the residual copper in the supernatant of process control is 0.5-2 g / L as the end point of precipitation. After the end of the precipitation reaction, put it into the sedimentation tank and let it stand still. The sediment is put into the centrifuge for dehydration and washing, and then after the second slurry washing and drying, the sediment is put into the stainless steel pyrolysis pot for air thermal decomposition, and the pyrolysis temperature is controlled at 500 ~900℃, the end point of pyrolysis is copper oxide product. Leave the supernatant liquid as a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com