Patents

Literature

334 results about "Organic sulfide compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte for Li-S battery, preparation method thereof, and Li-S battery containing same

InactiveCN102983361AEasy to makeLow costCell electrodesSecondary cellsOrganosolvOrganic sulfide compound

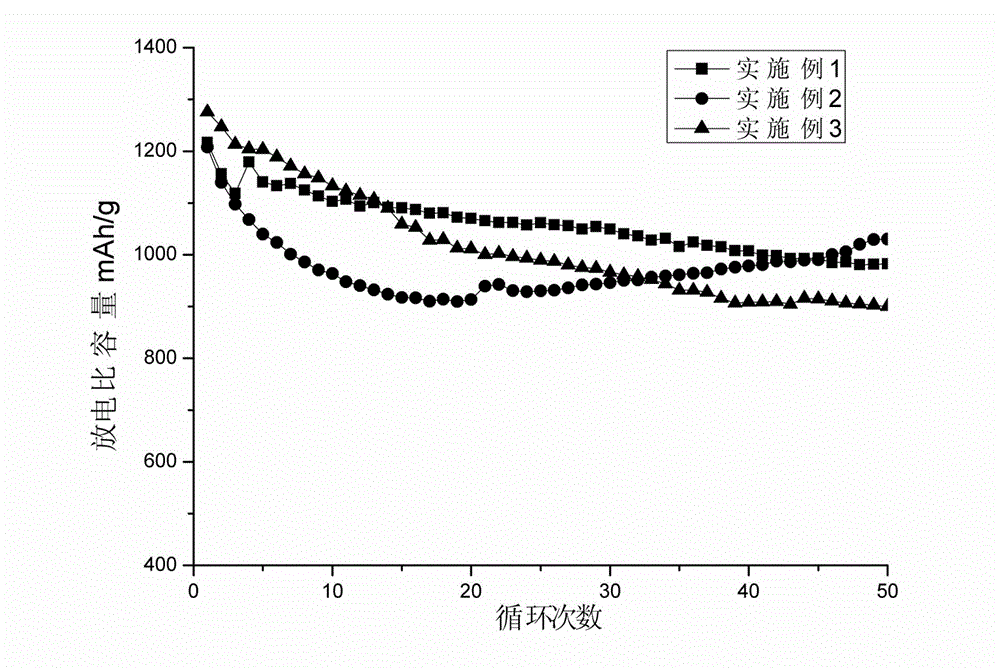

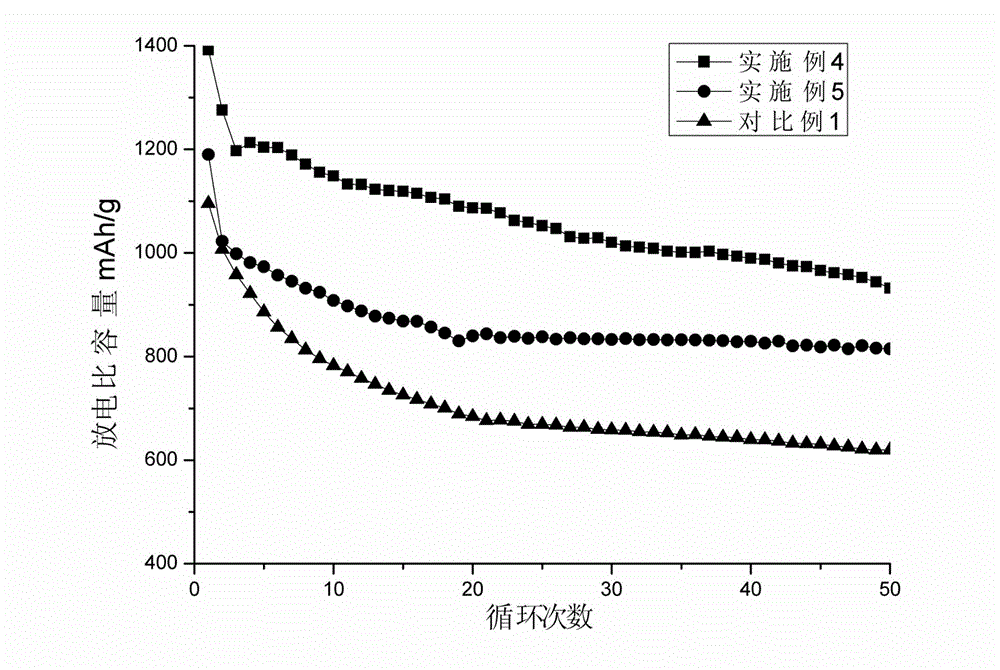

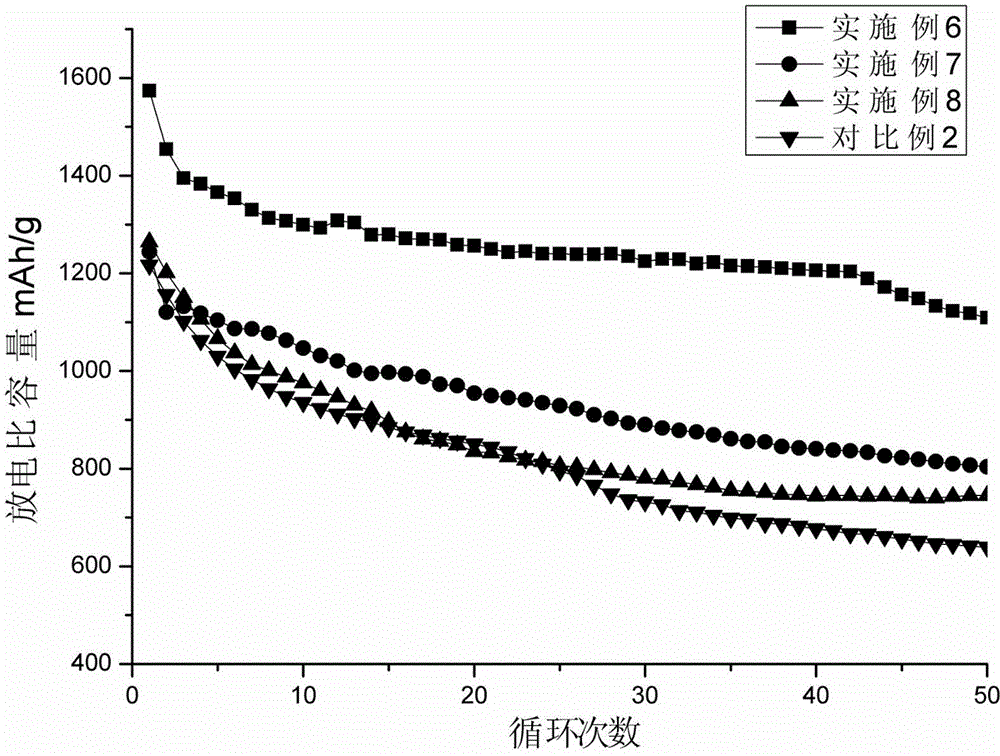

The invention discloses an electrolyte for a Li-S battery. The electrolyte mainly comprises electrolyte salts and an organic solvent, wherein the electrolyte salts contain lithium polysulfide, and the molecular formula of the lithium polysulfide is Li2Sn. A preparation method of the electrolyte comprises the following steps of adding lithium metal or Li2Sn and elemental sulfur into the organic solvent according to a molar ratio and carrying out reaction at room temperature and under the protection of an inert atmosphere to generate the electrolyte, wherein lithium salts, shuttle inhibitors and the like can be selectively added to the electrolyte. The invention further discloses a Li-S battery containing the electrolyte; a negative active material is the lithium metal or lithium-containing alloy; a positive active material is at least one of the elemental sulfur, organic sulfides and carbon-sulfur polymer, and the positive pole is composed of the positive active material, a conductive agent and a binding agent which are mixed in a certain mass ratio; and the dosage of the electrolyte is about 0.04 mL relative to every milligram of sulfur. The Li-S battery disclosed by the invention has the advantages that the sources of raw materials are broad, the energy density of the Li-S battery can be increased, and the cycle life of the Li-S battery can be prolonged.

Owner:NAT UNIV OF DEFENSE TECH

Three-piece solid golf ball

InactiveUS20010031669A1Excellent shot feelingImprove flight performanceGolf ballsSolid ballsOrganic sulfide compoundInter layer

The present invention provides a three-piece solid golf ball having good shot feel and excellent flight performance. The present invention relates to a three-piece solid golf ball comprising a core, an intermediate layer formed on the core, and a cover covering the intermediate layer, wherein the golf ball is obtained by adjusting a correlation between the amounts of organic sulfide compound, organic peroxide and co-crosslinking agent in a rubber composition for a core, and a correlation between surface hardness of the core, intermediate layer hardness, cover hardness, thickness of the intermediate layer and thickness of the cover, to a specified range.

Owner:SUMITOMO RUBBER IND LTD

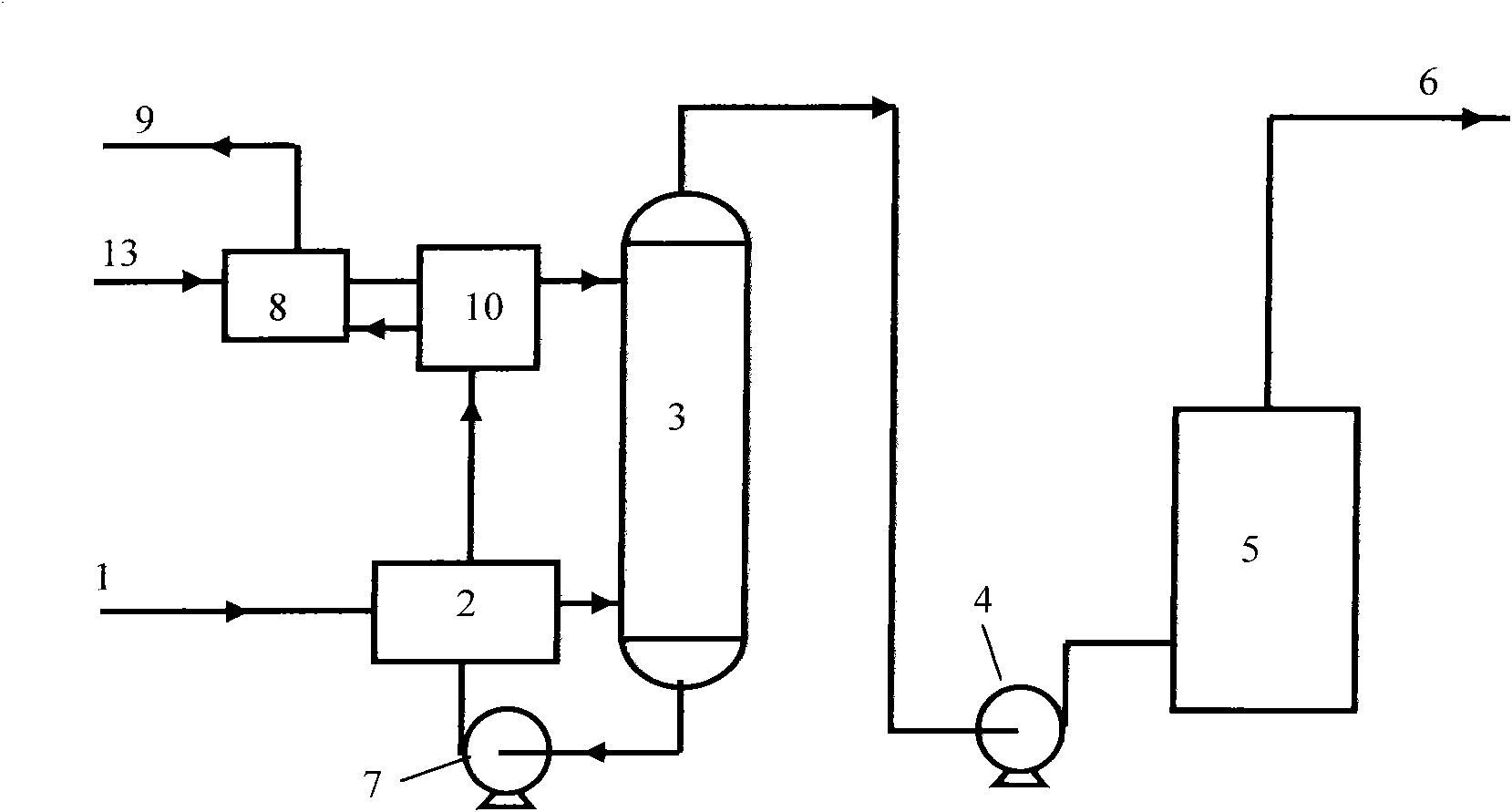

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

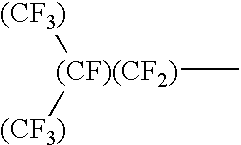

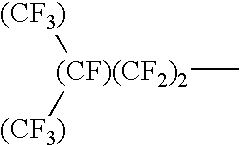

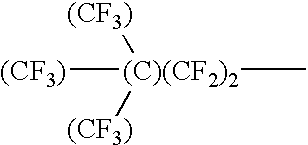

Mold for nano imprinting

InactiveUS6923930B2Avoid reactionSimplified representationMechanical working/deformationDecorative surface effectsOrganic sulfide compoundMetal mold

A metal mold for use in a nano-imprinting process comprises a firmly adhering monomolecular non-sticking layer. The layer was obtained by subjecting the mold to a reaction with a fluoroalkyl compound having a mercapto group. As a result of said reaction, the layer comprises an organic sulfide of said metal.

Owner:OBDUCAT AB SE

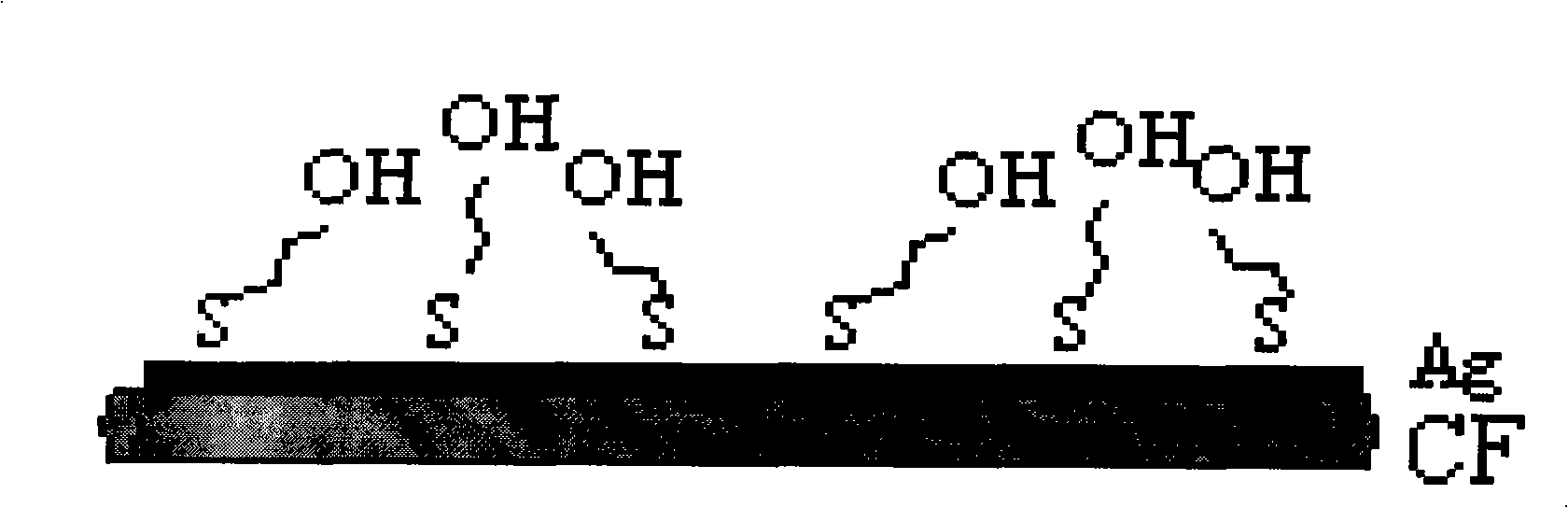

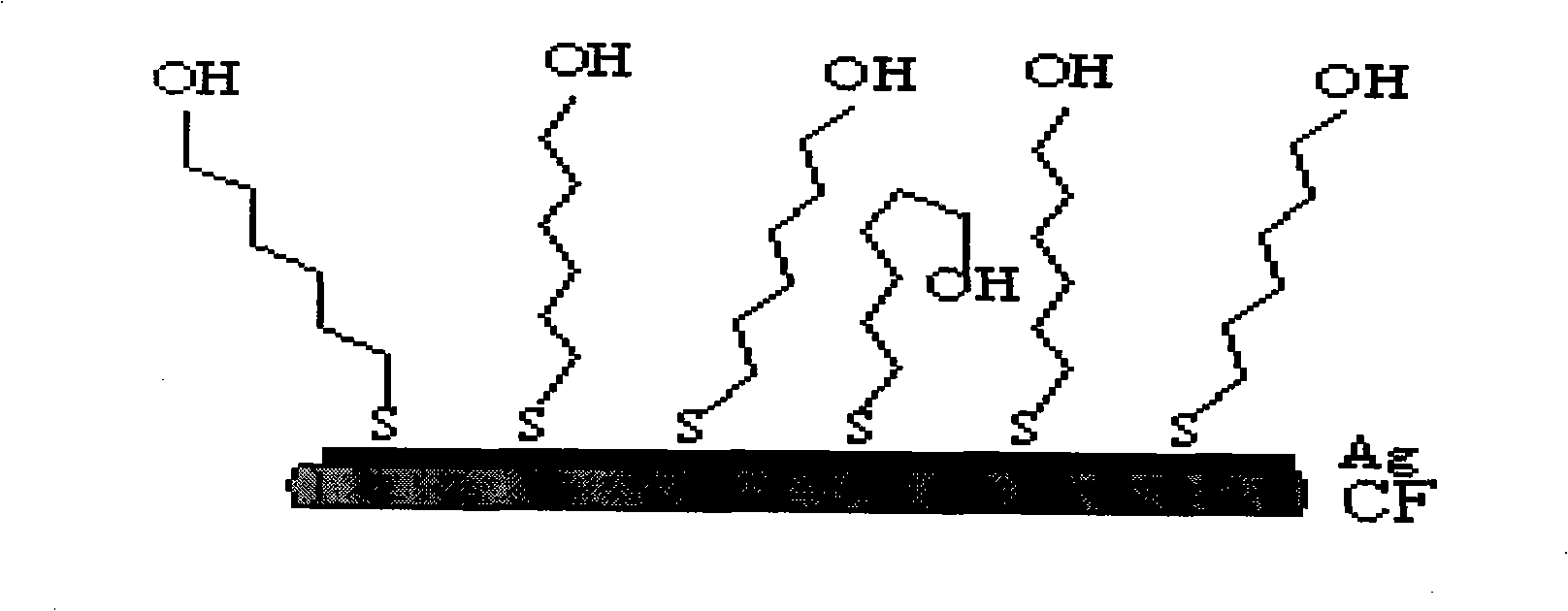

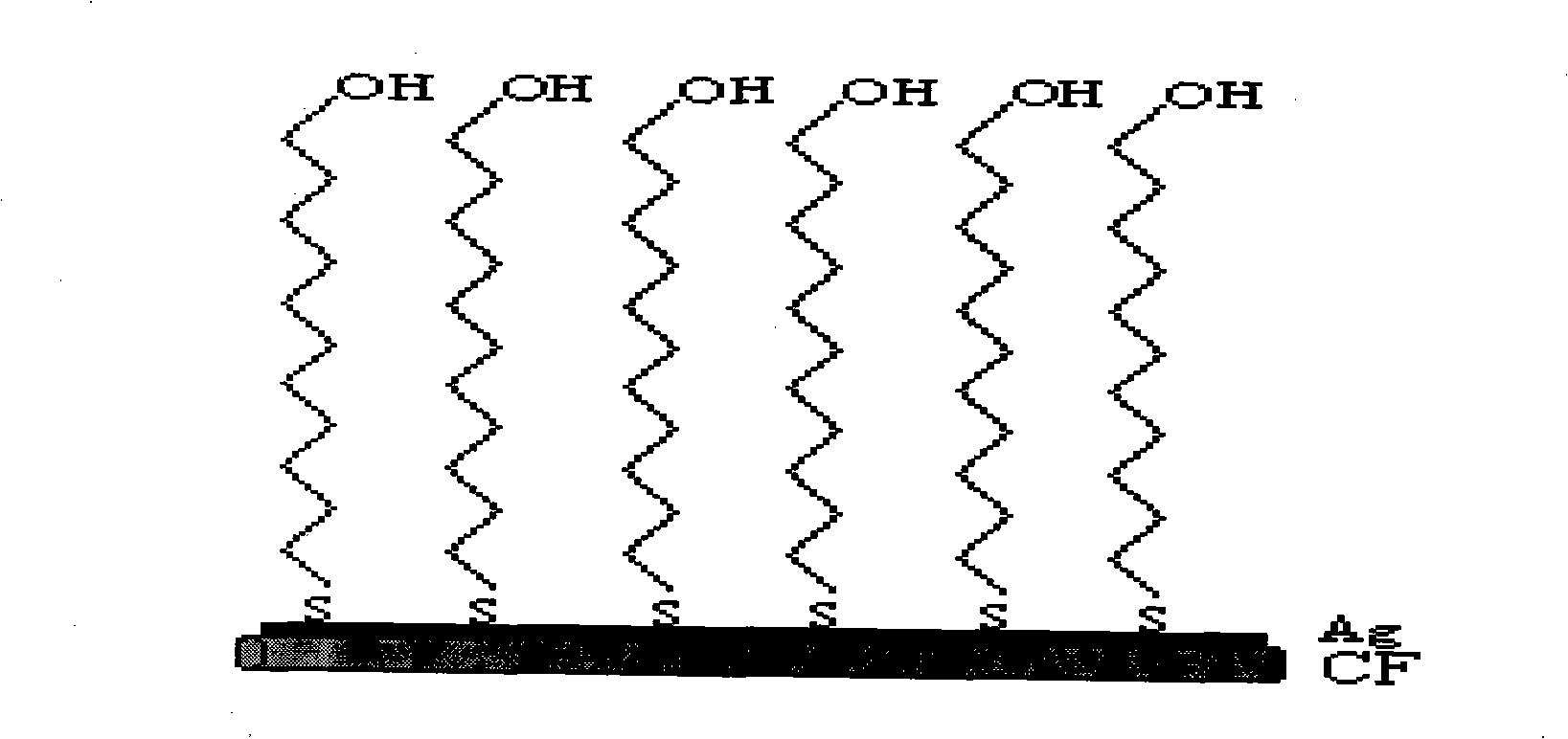

Carbon fiber surface modification method

The invention discloses a carbon fiber surface modification method, and relates to a carbon fiber modification method. The invention solves the problem of the uncontrollability of the distribution and arrangement of a carbon fiber surface functional group, which is not propitious to the study of the mechanism of a carbon fiber interface. The carbon fiber is plated with silver after surface pre-processing, then the carbon fiber with the silver-plated surface is infused in the dilute solution of thiol molecule containing sulfur element; depending on the coactions of the bonding reaction of sulfur atoms and metb and the force among self-assembly molecules, the thiol molecule has chemical absorption on the fiber surface and forms a closely arranged and ordered two-dimensional self-assembly single molecule membrane; two procedures are as follows: 1. the chemical plating of silver on the carbon fiber surface; and 2. the self assembly of molecules of organic sulfide on the silver-plating carbon fiber. The carbon fiber surface modification method has the advantages of realizing controllable, directional and ordered arrangement on the carbon fiber surface functional group from the molecule level, thus being beneficial to the study of the mechanism of the carbon fiber composite material interface.

Owner:HARBIN INST OF TECH

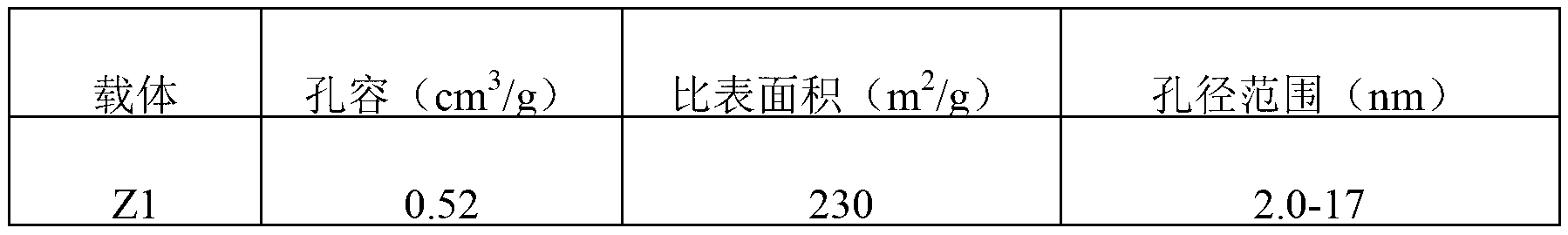

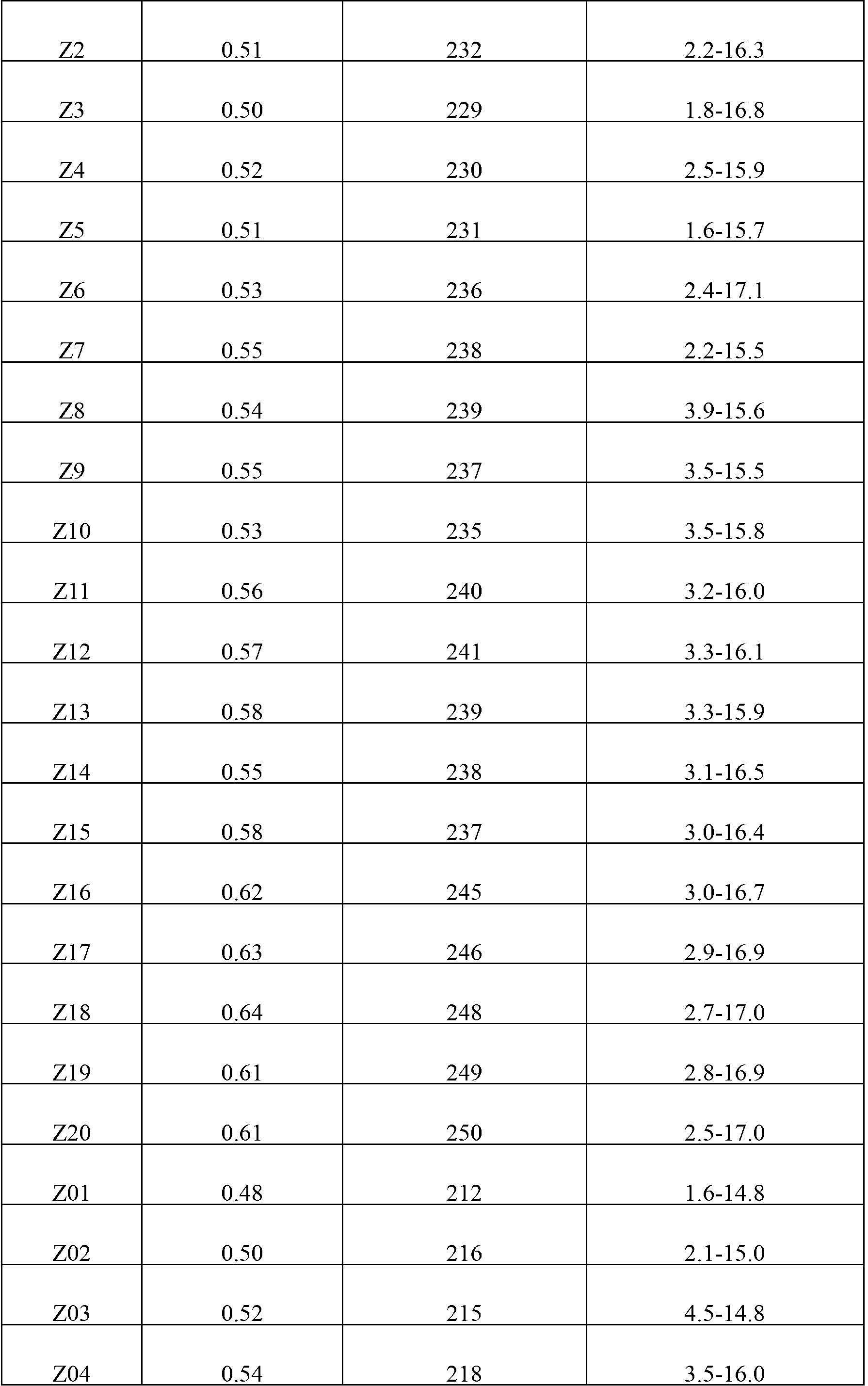

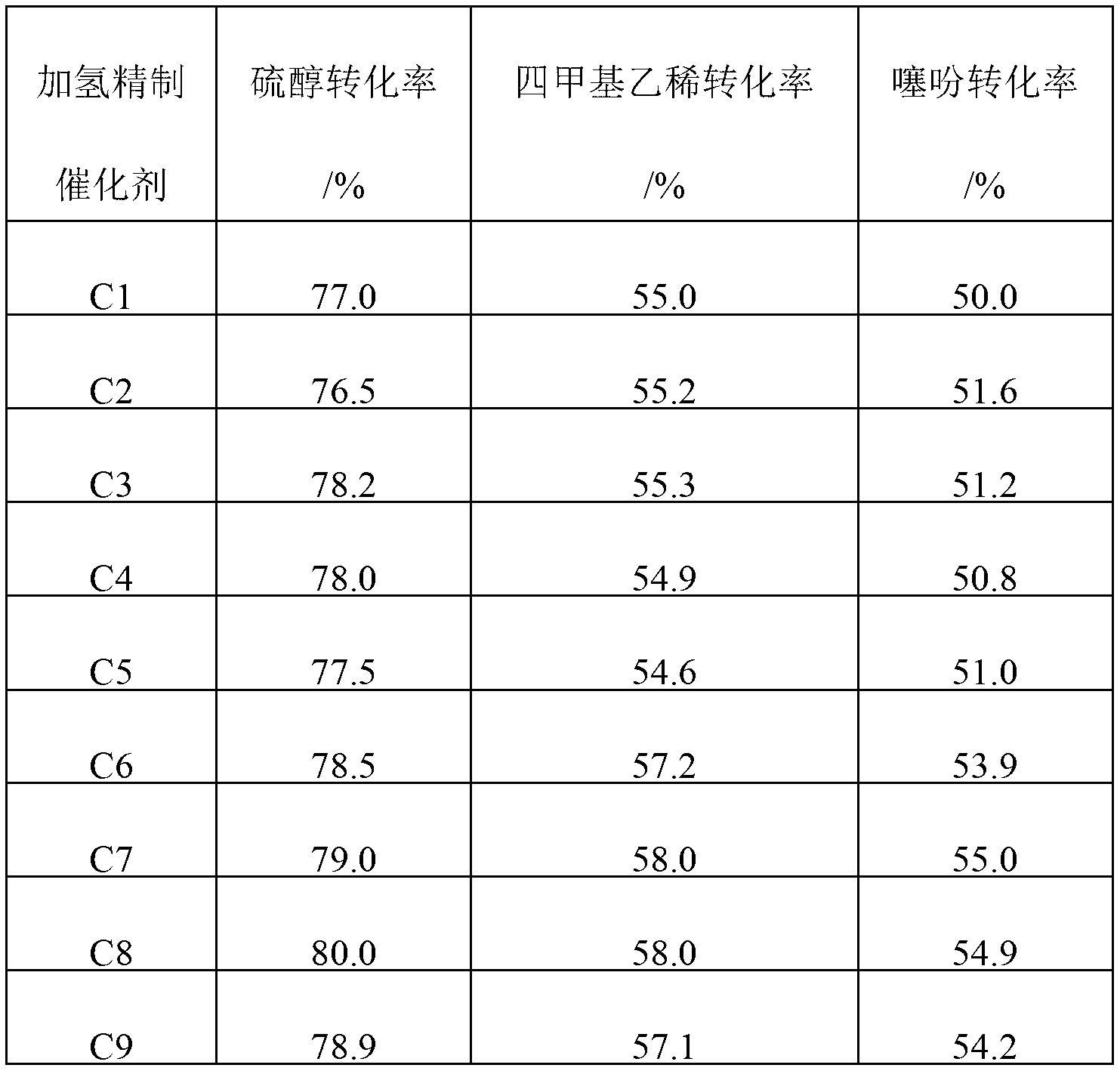

Hydrofining catalyst carrier and preparation method thereof as well as hydrofining catalyst using carrier and preparation method of hydrofining catalyst

ActiveCN103212449ALarge specific surface areaHigh porosityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsOrganic sulfide compoundNaphtha

The invention belongs to the technical field of hydrofining catalysts, and particularly relates to a hydrofining catalyst carrier and a preparation method thereof as well as a hydrofining catalyst using the carrier and a preparation method of the hydrofining catalyst. The preparation method of the carrier comprises the steps of: mixing modified diatomite, alumina powder, a bonding agent and a pore-enlarging agent, then kneading and forming, drying and roasting to obtain the carrier, and is characterized in that the modified diatomite is prepared by steeping diatomite in alkali liquor and neutralizing in acid liquor and then carrying out water washing and filter pressing, wherein the amount of impurities on the surface and in pore spaces can be greatly reduced, thereby being beneficial to load of active ingredients; and the hydrofining catalyst prepared by using the carrier is applicable to removal of organic sulfides and unsaturated hydrocarbons in light naphtha, liquefied gas, natural gas and oil refining dry gas.

Owner:SHENYANG SANJUKAITE CATALYST

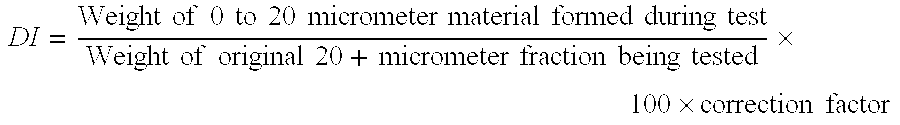

Desulfurization and sorbents for same

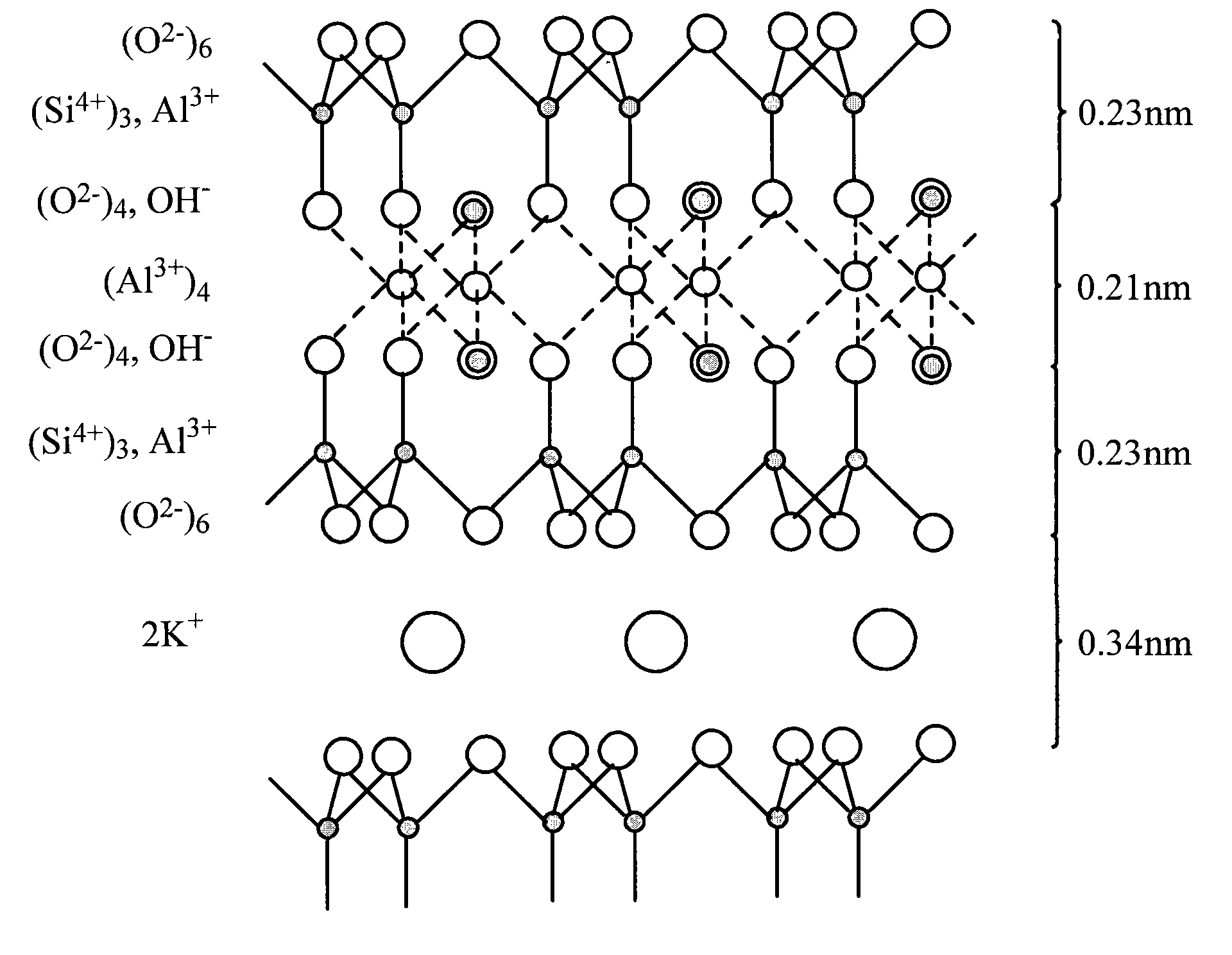

InactiveUS7241929B2Reduce componentsReduced valenceOther chemical processesAluminium silicatesOrganic sulfide compoundSorbent

Attrition resistant, sorbent compositions for the removal of elemental sulfur and sulfur compounds, such as hydrogen sulfide and organic sulfides, from cracked-gasoline and diesel fuels are prepared by the impregnation of a sorbent support comprising zinc oxide, expanded perlite, and alumina with a promoter such as nickel, nickel oxide or a precursor of nickel oxide followed by reduction of the valence of the promoter metal in the resulting promoter metal sorbent support composition. Also disclosed is a composition comprising desulfurized, cracked-gasoline wherein the desulfurized cracked-gasoline comprises less than about 1 ppmw thiol compounds and less than about 1 ppmw tetrahydrothiophene compounds.

Owner:CHINA PETROCHEMICAL CORP

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1718687AReduce saturation rateLow desulfurization activityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

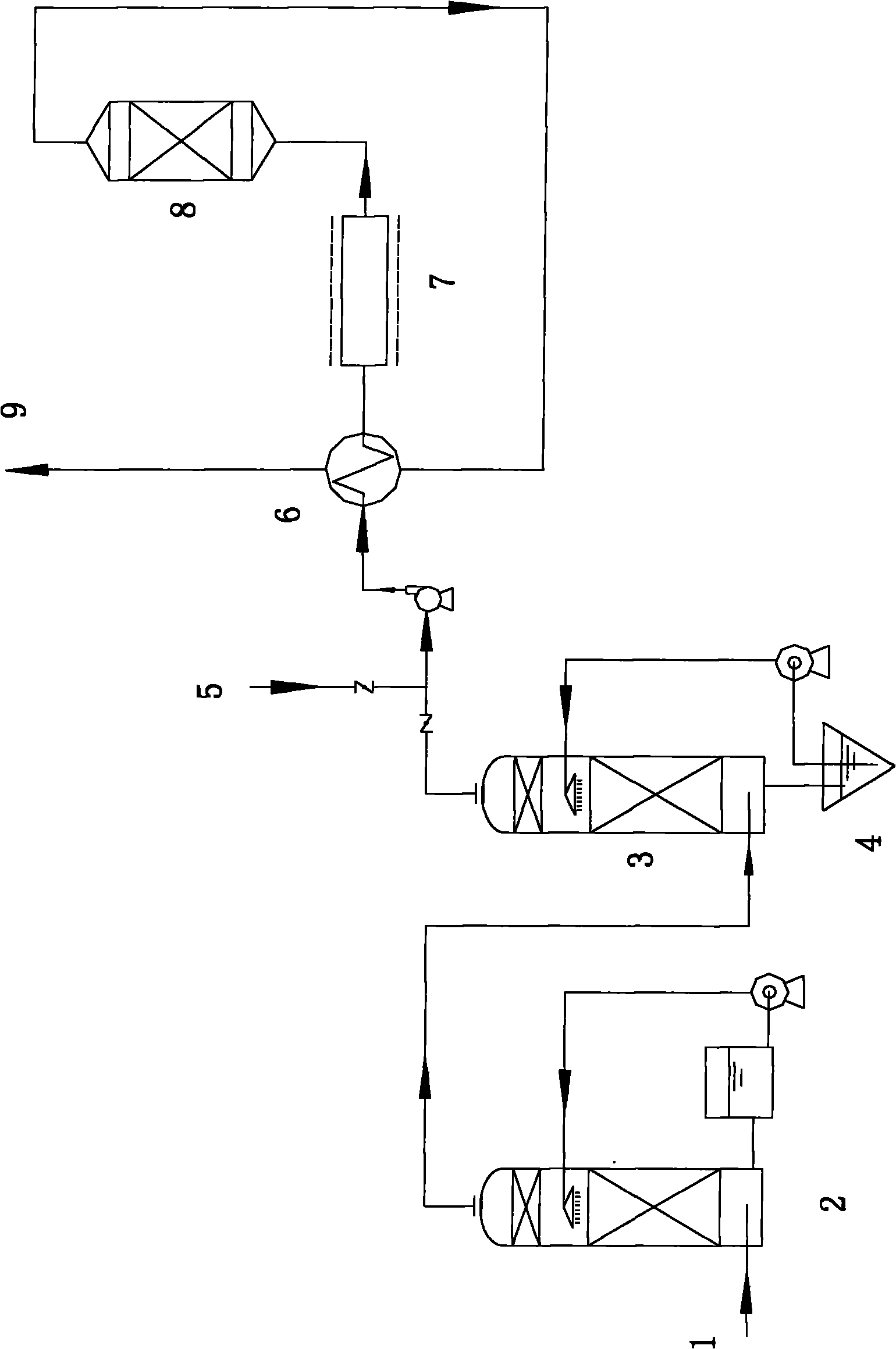

Treatment method for stinky waste gas containing sulfides and hydrocarbons

ActiveCN102309913APromote absorptionImprove economyDispersed particle separationOrganic sulfide compoundTreatment effect

The invention discloses a treatment method for stinky waste gas containing sulfides and hydrocarbons. The sulfides in the waste gas comprise hydrogen sulfide and organic sulfides. A combined treatment process of solvent absorption and alkali liquor absorption is adopted in the waste gas treatment; the absorption solvent adopted in the solvent absorption process is crude diesel oil fraction; the crude diesel oil fraction solvent is cooled to the temperature of between 10 DEG C below zero and 30 DEG C, then enters an absorption tower, and is in countercurrent contact with the stinky waste gas to absorb the hydrocarbons and the organic sulfides therein; the rich absorption solvent discharged from the absorption tower is not regenerated and directly enters a diesel oil hydro-treating device; and the gas phase discharged from the absorption tower enters an alkali liquor absorption device to absorb the hydrogen sulfide and the organic sulfides therein, and is finally emptied through an exhaust tube. The method has the advantages of simple flow, low cost, stable treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

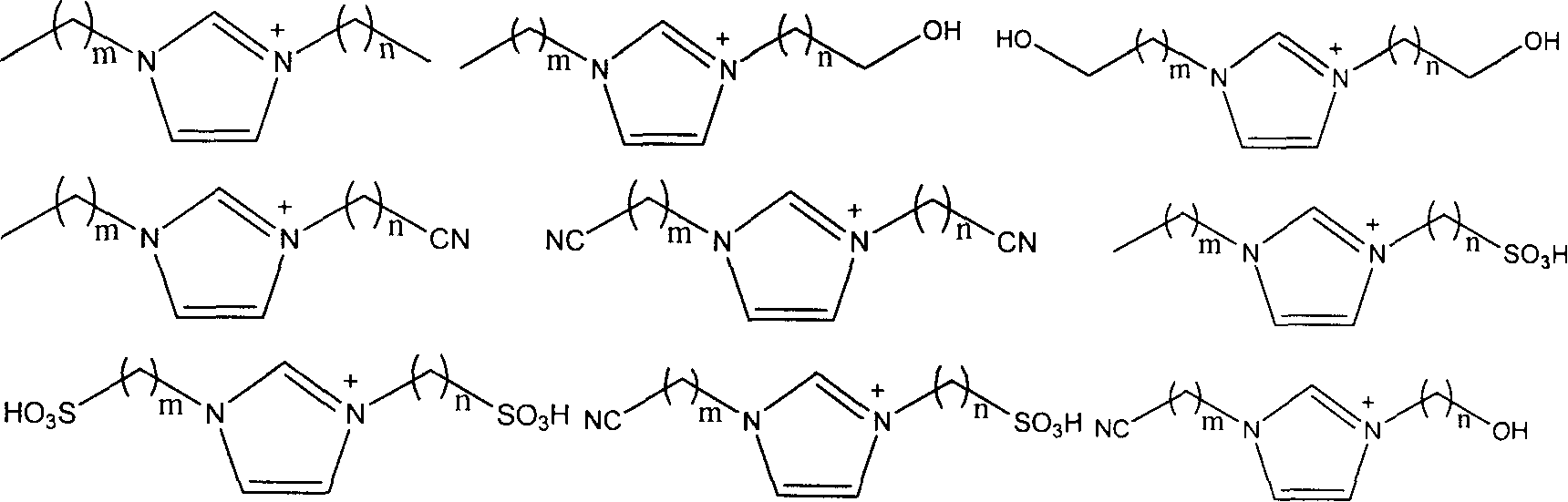

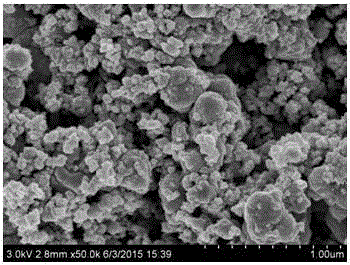

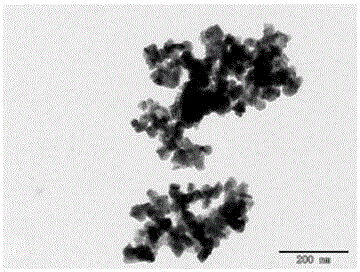

ZnIn2S4 nano materials and their synthesis method and application

InactiveCN1884090AImprove photoelectric performanceSimple methodGallium/indium/thallium compoundsZinc compoundsOrganic sulfide compoundIndium

The invention discloses a Znln2S4 nanometer material and synthesizing method and application, which is characterized by the following: adopting bivalent zinc salt, trivalent indium salt and organic sulfide as raw material; proceeding solvent heating or water heating reaction at 100-220 deg.c in the sealing reactor; setting surface activist as addictive; synthesizing Znln2S4 nanometer pipe, nanometer band and nanometer line selectively through controlling solvent kind, reacting temperature and reacting time. The invention belongs to layer-shaped hexagonal crystal phase with kind's direction of specific property, which is fit for relative domains of solar battery, optical catalyst, high-energy battery, and heat-conversion.

Owner:NANKAI UNIV

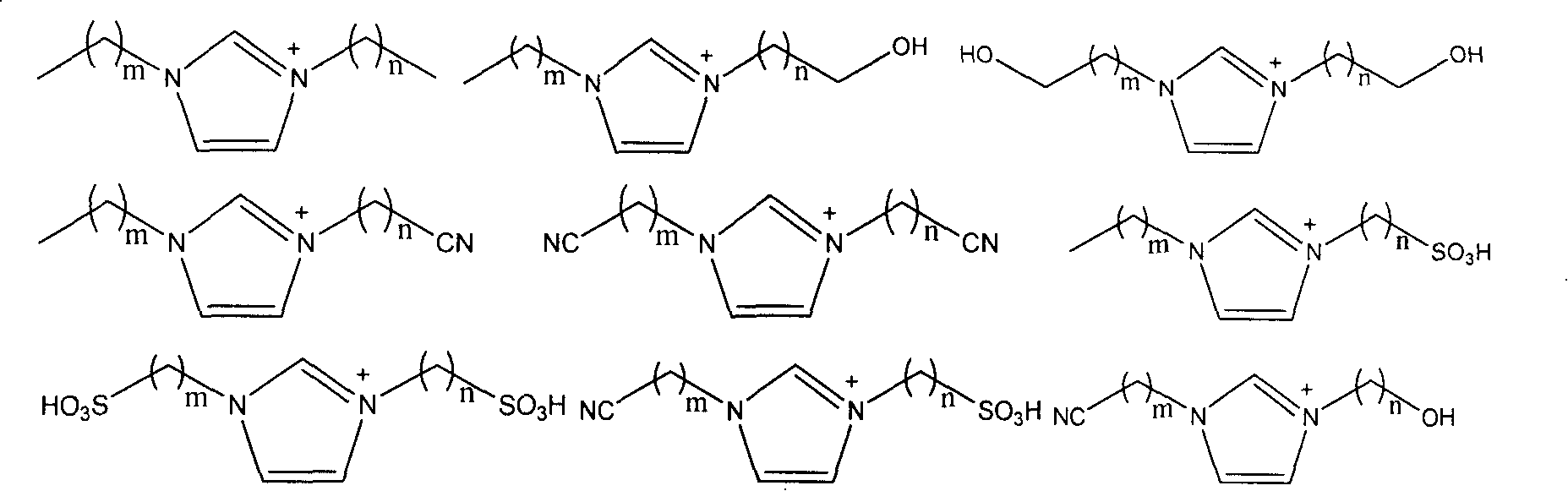

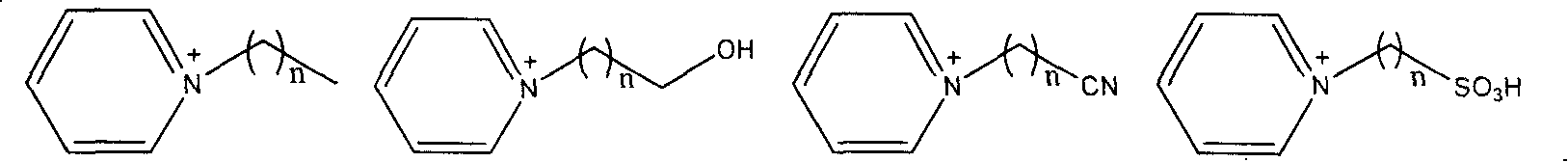

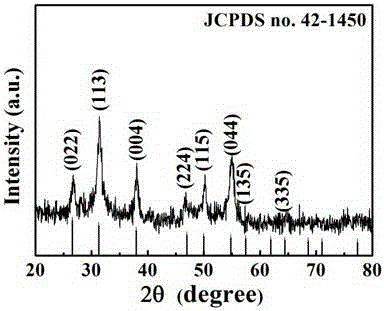

Polymer thin film containing ion liquid and preparing method thereof

The invention discloses a polymer membrane containing ionic liquid and a preparation method thereof. The polymer membrane is produced by membrane material and the ionic liquid absorbed and loaded on the membrane material, and the weight of the ionic liquid accounts for 0.1 to 70 percent of the weight of the polymer membrane. After homogeneous solution is formed by dissolving the ionic liquid into water solution of polyvinyl alcohol, a membrane is formed after the solution is dried at the ambient temperature, and the polymer membrane is obtained after the membrane is crosslinked with a crosslinking agent. The membrane of the invention has better thermal stability and mechanical stability, simple synthetic operation, potential application value in the processes of catalytic esterification, organic sulfide separation, aromatic hydrocarbon separation and alkane separation, etc, which has wide application on membrane catalysis, segregation analysis, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

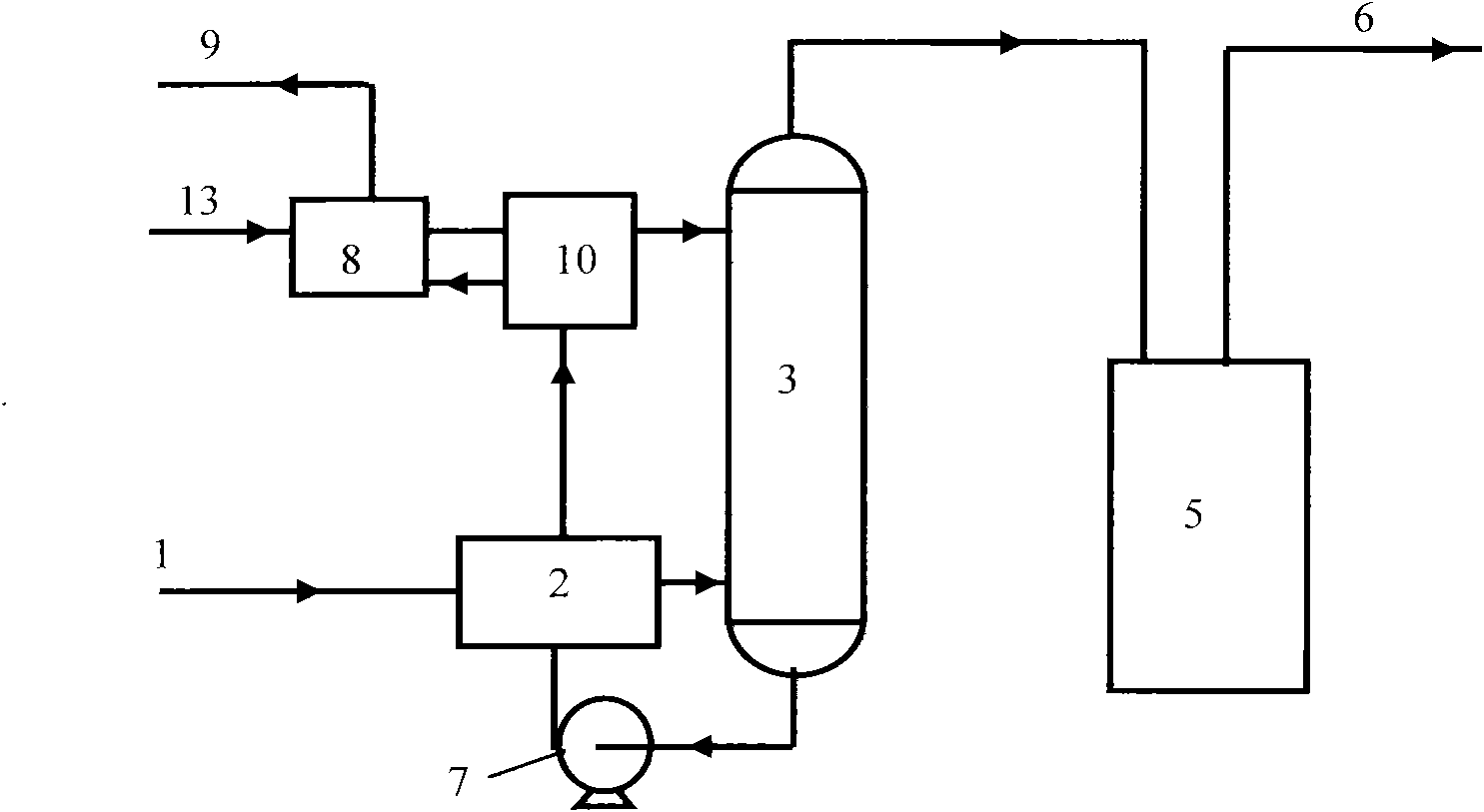

Hydrogenation modification method of faulty gasoline

ActiveCN1718688ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundHydrogen

A process for hydromodifying the poor-quality gasolinge(full-fraction FCC gasoline) features that under existence of H2 and in the condition that the temp is gradually raised, said gasoline is in contact with three catalysts to form 3 reaction regions. In the first low-temp region, the hydrorefining catalyst is used for removing biolefine. In the second higher-temp region, the modifying catalyst is used for increasing octane value and quality. In the third high-temp region, the selective hydrodesulfurizing catalyst is used for removing organic sulfide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel organic sulphur hydrogenation catalyst and preparation method thereof

ActiveCN103157481AHigh activityEasy to overflowGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsOrganic sulfide compoundPtru catalyst

The invention relates to an organic sulphur hydrogenation catalyst, comprising specific parts by weight of Al2O3 carrier, ZnO, iron oxide and molybdenum oxide. ZnO added in the hydrogenation catalyst disclosed by the invention is taken as an assistant, and has excellent synergistic effect together with active components of iron oxide and molybdenum oxide. Compared with the sulphur hydrogenation catalyst in the prior art, the organic sulphur hydrogenation catalyst has high thiofuran conversion and removal efficiency when used for removing organic sulfide such as thiophene in gas.

Owner:SHENYANG SANJUKAITE CATALYST

Aromatic adsorption desulfurizing method

InactiveCN1406914AReduce sulfur contentSimple processAbsorption purification/separationOrganic sulfide compoundActive component

An adsorption process for desulfurizing the C6-C11 arylhydrocarbon features that said arylhydrocarbon is contacted with an amorphous alloy adsorbent whose main active component is Ni the the fluidzed-bed or slurry bed reactor at ordinary temp-12 deg.C and ordinary pressure-1 MPa. It can reduce the sulfur content to less than 0.05 ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of copper, cobalt and sulfur micropowder

InactiveCN105355919AGood effectLarge reversible charge and discharge capacityCell electrodesSecondary cellsOrganic sulfide compoundCobalt salt

Owner:SOUTHWEST UNIVERSITY

Preparation method of super low sulfur diesel oil

InactiveCN1534082AHigh catalytic activityStrong catalytic selectivityTreatment with plural serial refining stagesOrganic sulfide compoundSorbent

A process for preparing ultralow-sulfur diesel oil includes mixing refined low-sulfur diesel oil with phase-transfer catalyst and aqueous solution of hydrogen peroxide, stirring, reaction for converting the organic sulfide to sulfone and / or sulfoxide, recovering phase-transfer catalyst, removing excessive hydrogen peroxide, selectively removing sulfone and / or sulfoxide by polar solvent, and adsorption. The final sulfur content is lower than 10 ppm (even up to 0 ppm).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sorbents for desulfurization

InactiveUS6864215B2Reduced valenceEfficient removalRefining with metalsOther chemical processesOrganic sulfide compoundSorbent

Attrition resistant, sorbent compositions for the removal of elemental sulfur and sulfur compounds, such as hydrogen sulfide and organic sulfides, from cracked-gasoline and diesel fuels are prepared by the impregnation of a sorbent support comprising zinc oxide, expanded perlite, and alumina with a promoter such as nickel, nickel oxide or a precursor of nickel oxide followed by reduction of the valence of the promoter metal in the resulting promoter metal sorbent support composition.

Owner:CHINA PETROCHEMICAL CORP

Absorption liquid for gas desulfurization and its application

ActiveCN1621133AGood choiceHigh selectivityDispersed particle separationOrganic sulfide compoundLight irradiation

The present invention discloses one kind of gas desulfurizing absorption liquid and its desulfurizing method. The gas desulfurizing absorption liquid has nanometer alpha- or gamma-ferric oxide and iron chelate as catalyst. In the presence of organic compound and alkali compound and light irradiation, air is introduced and the absorption liquid absorbed inorganic and / or organic sulfide are oxidized into simple substance sulfur. The gas desulfurizing method of the present invention has the advantages of low catalyst consumption, fast regeneration of catalyst, no jamming of the absorption tower, etc.

Owner:BEIJING BAIAONA HI TECH

Method for regenerating desulfurizing and denitrogenating adsorbant

InactiveCN101069839AAchieve recyclingDoes not affect the natureDispersed particle separationCombustible gas purificationOrganic sulfide compoundSorbent

The present invention relates to a regeneration method of desulfurizing denitrifying adsorbent. Said method includes the following steps: adding the adsorbent adsorbed organic sulfide and organic nitride into a mixed system formed from water phase and oil phase containing desulfurizing and denitrifying microbial cellulae, making regeneration reaction at 30deg.C, filtering, drying and roasting so as to obtain the regenerated adsorbent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Solvent for eliminating H2S from gas mixture

InactiveCN1887406APromote absorptionImprove the desorption effectDispersed particle separationSulfolaneOrganic sulfide compound

The present invention is method of adding one kind of secondary amine and one kind of organic amine with steric effect into water or sulfolane solution of N-methyl diethanolamine to obtain the activator for removing H2S from gas mixture with or without CO2. The present invention provides two solution recipes. The recipe I for the solution suitable for removing H2S from gas mixture containing no or less organic sulfide consists of N-methyl diethanolamine 30-50 wt%, secondary amine 1-10 wt%, steric amine 1-15 wt% and water for the rest. The recipe II for the solution suitable for removing H2S from gas mixture containing organic sulfide consists of N-methyl diethanolamine 30-40 wt%, secondary amine 1-5 wt%, steric amine 1-15 wt%, water 5 wt% and sulfolane for the rest.

Owner:HUAXI CHEM INST CHENGDU CITY

Rechargeable aluminum-sulfur battery and preparation method thereof

InactiveCN101764255AIncrease the effective reaction areaWide variety of sourcesFinal product manufactureElectrolyte accumulators manufactureOrganic sulfide compoundMetallic aluminum

The invention discloses a rechargeable aluminum-sulfur battery and a preparation method thereof. The rechargeable aluminum-sulfur battery is prepared by adopting metallic aluminum or aluminum alloy, preferably foamed aluminum as cathode, polymeric organosulfides as anode active substances, and halogenated aluminic acid ionic liquid formed by halogenated aluminum with any one of quaternary ammonium salt, quaternary phosphor salt or quaternary sulfosalt as electrolyte. The rechargeable aluminum-sulfur battery has high energy density, good circulation performance, safety and environmental protection, no pollution in preparation process, low cost and simple technique, thus having good application prospect.

Owner:无锡欧力达新能源电力科技有限公司

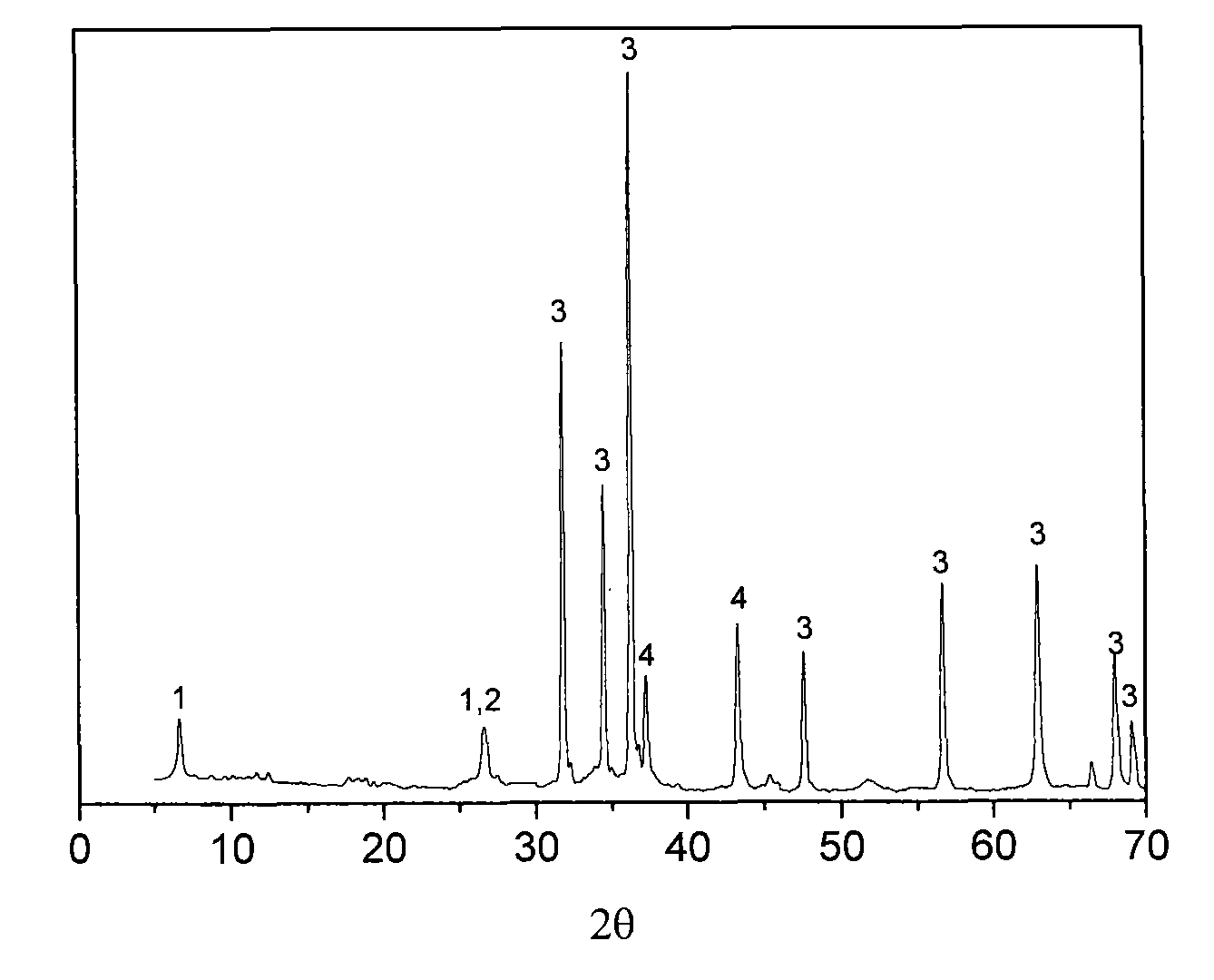

Tin-containing desulfurization adsorbent and preparation method and application thereof

ActiveCN102114407AHigh strengthHigh desulfurization activityOther chemical processesHydrocarbon oils refiningTin dioxideOrganic sulfide compound

The invention discloses an adsorbent for removing sulfur from cracked gasoline and diesel fuel. The adsorbent comprises the following components: 1) a silicon oxide source which at least contains mica, 2) a stannic oxide adhesive, 3) oxide(s) of one or more metals selected from IIB, VB and VIB, and 4) at least one accelerator metal selected from cobalt, nickel, iron and manganese. The adsorbent has good wear-resistant strength and desulfurization activity, and can be used for removing elemental sulfur and sulfides such as hydrogen sulfide and organic sulfide from the cracked gasoline and the diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

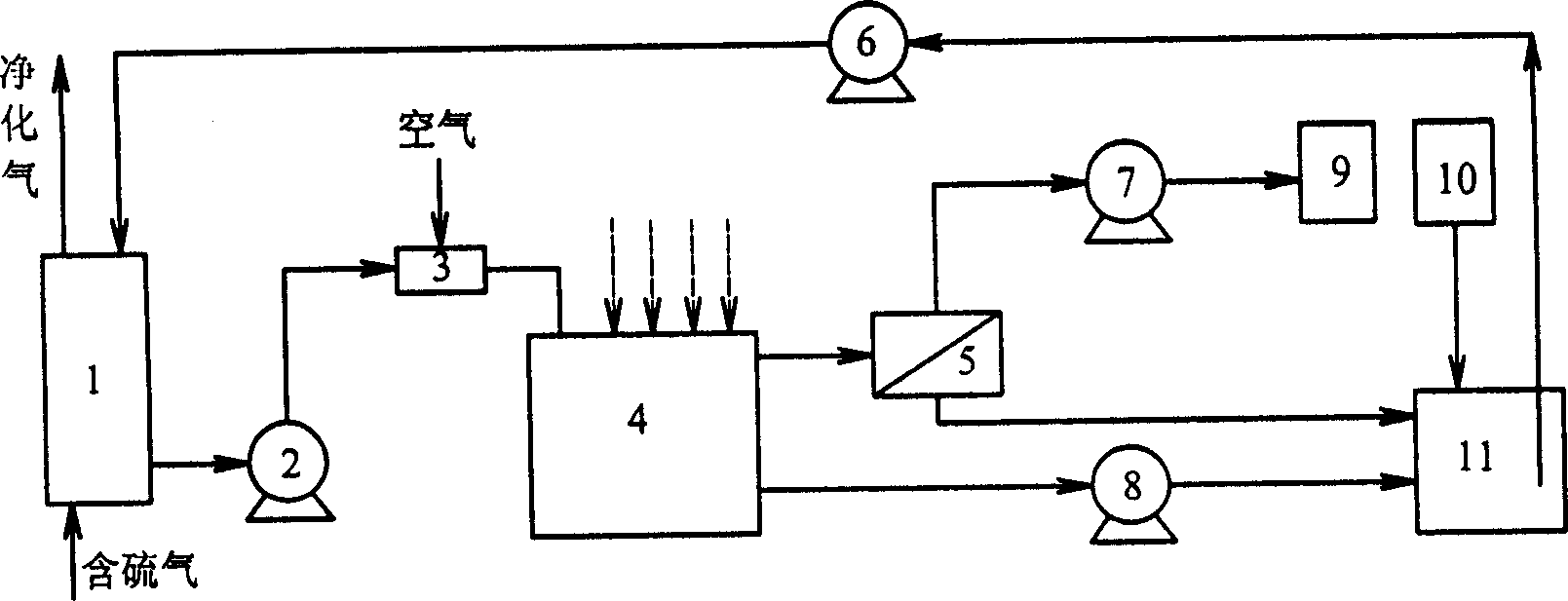

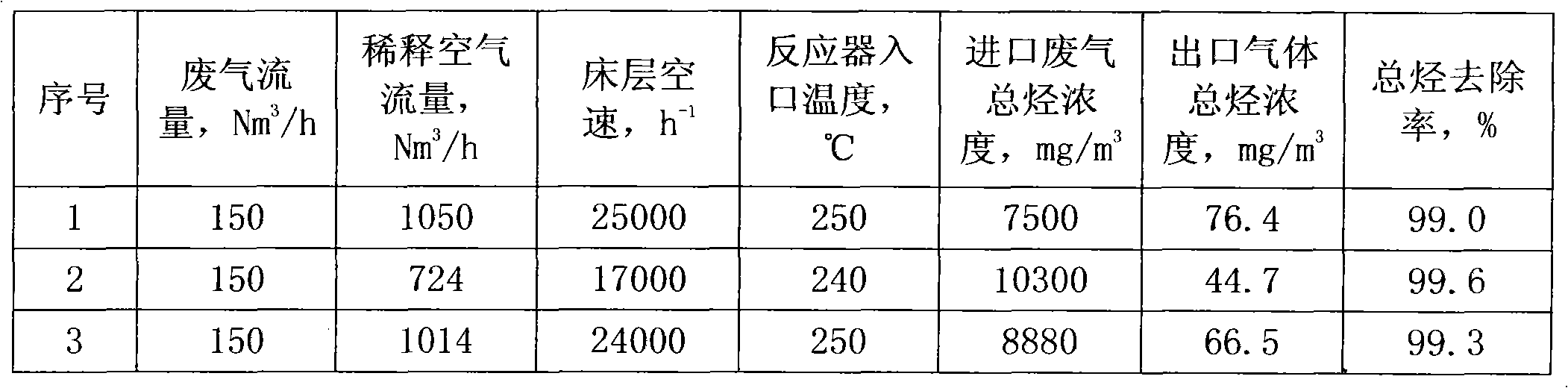

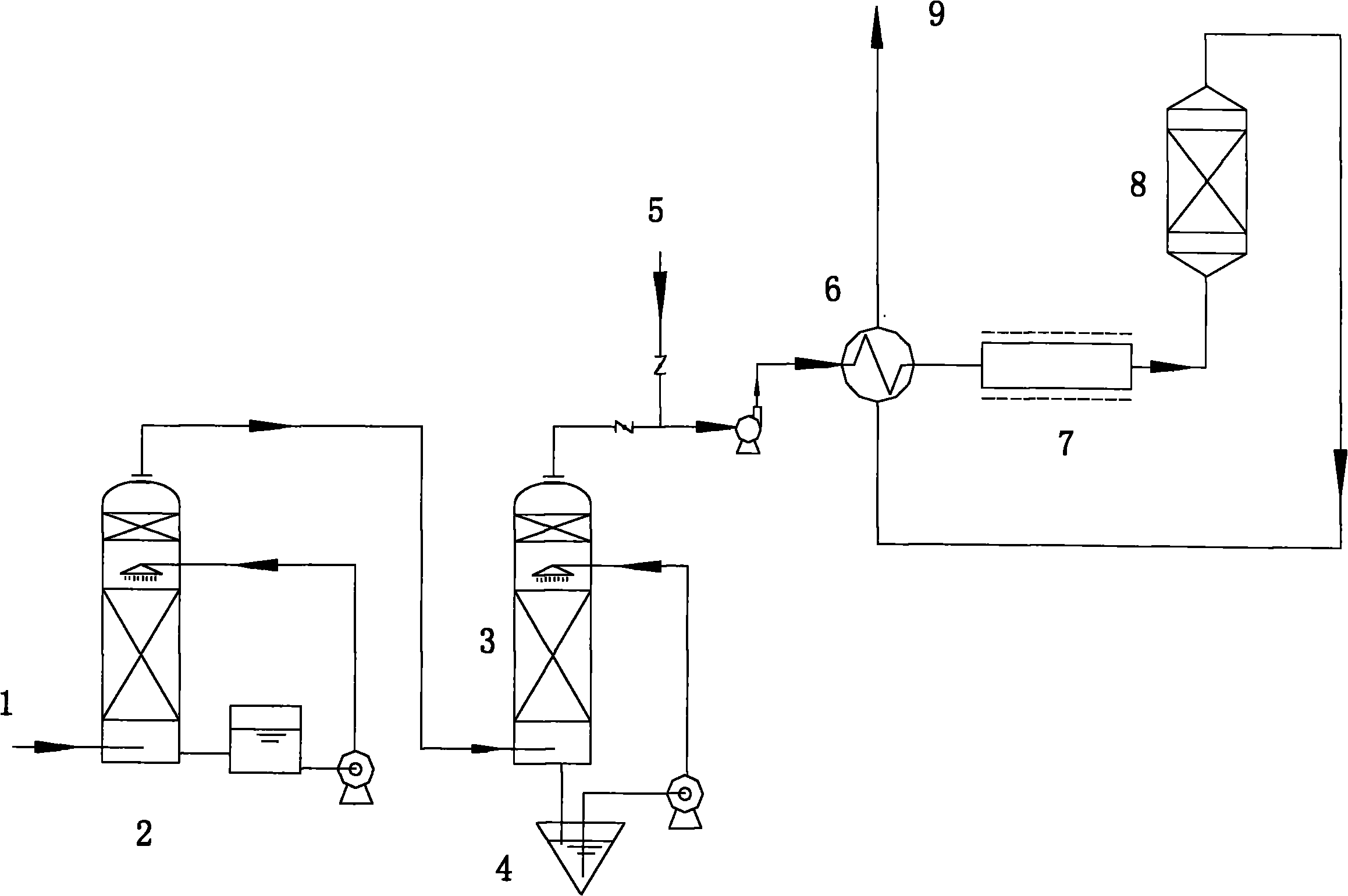

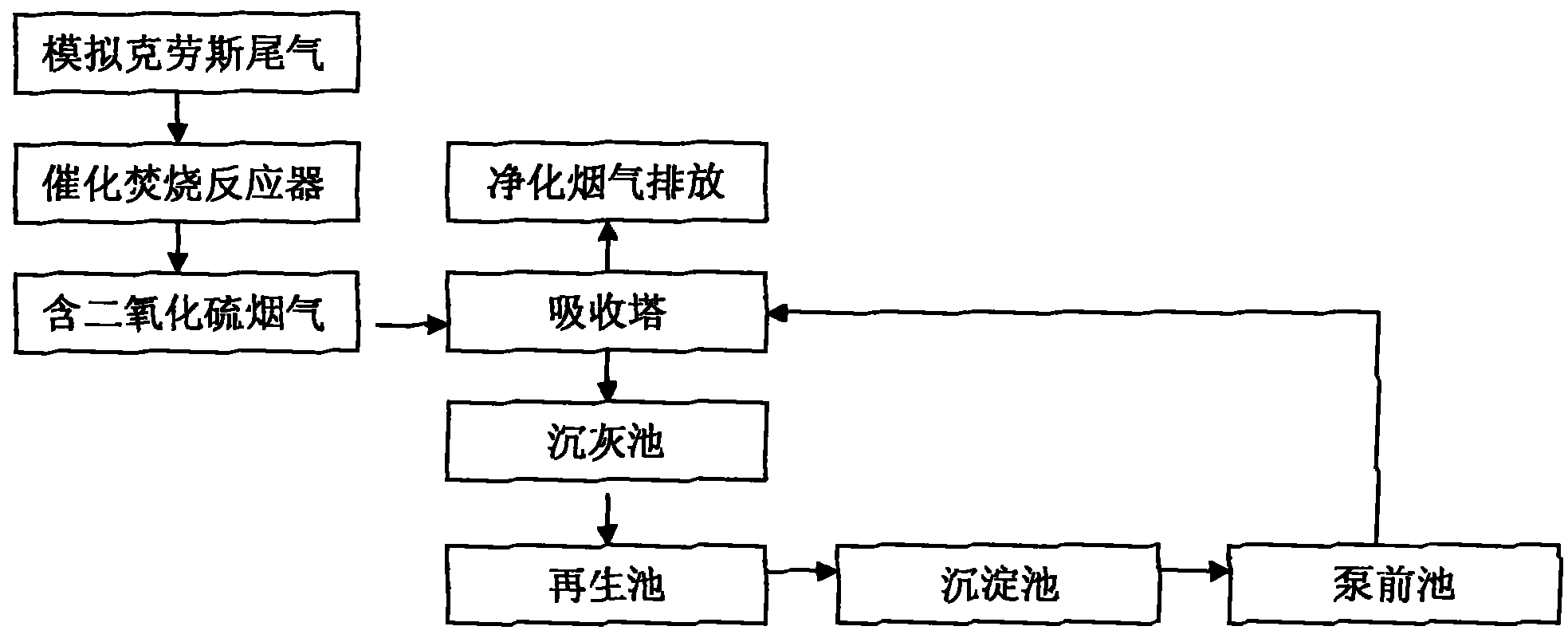

Purification method of sulfur-containing organic waste gas

ActiveCN102049181AStable operation impactGood processing effectDispersed particle separationOrganic sulfide compoundPurification methods

The invention discloses a purification method of a sulfur-containing organic waste gas. The method comprises the following steps: firstly, washing and pre-treating the waste gas with alkali liquor so as to remove hydrogen sulfide in the waste gas; secondly, washing with sump oil to remove organic sulfide and hydrocarbon contaminants in the waste gas; and finally, performing catalytic combustion to completely remove hydrocarbon contaminants in the waste gas, thereby ensuring that the waste gas meets the emission standard. The waste gas is the organic waste gas which is high in sulfur content and is discharged from a sour water tank or alkaline residue tank of a petrochemical enterprise. The method provided by the invention is economical and can be used for removing various harmful substances in the waste gas; and the method has the advantages of short process flow, simplicity, lower equipment investment and operating cost, complete removal of contaminants, no secondary pollution and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

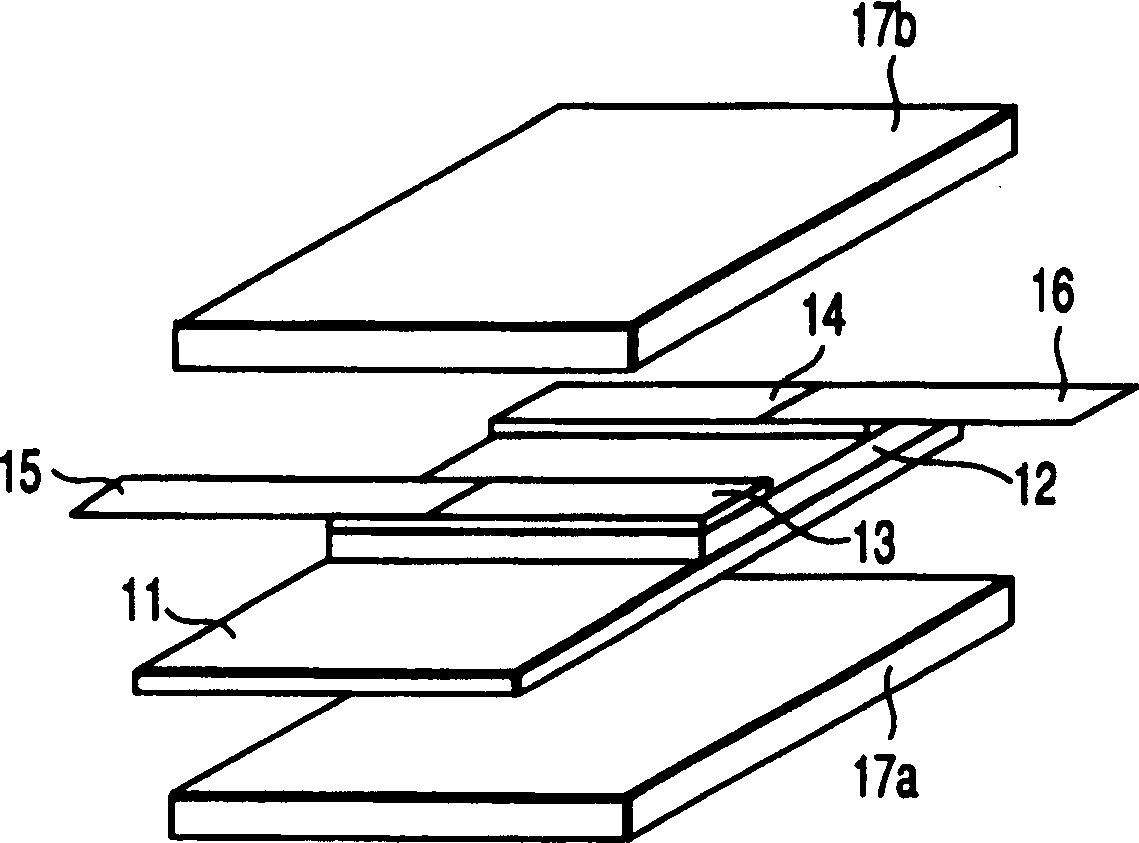

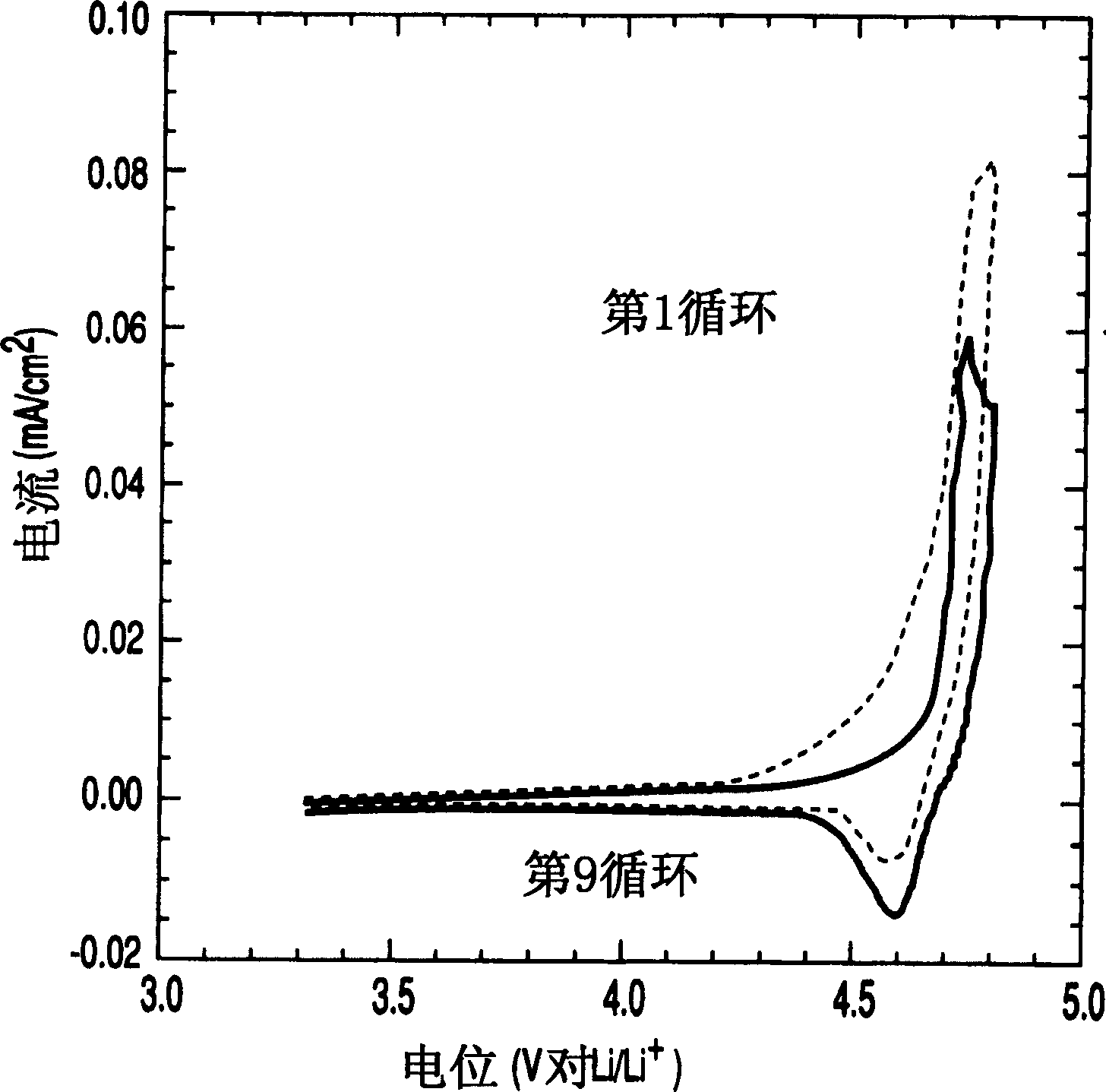

Anode for lithium secondary battery and lithium secondary battery

InactiveCN1463473AIncrease energy densityIncrease capacityElectrode carriers/collectorsPositive electrodesLithiumOrganic sulfide compound

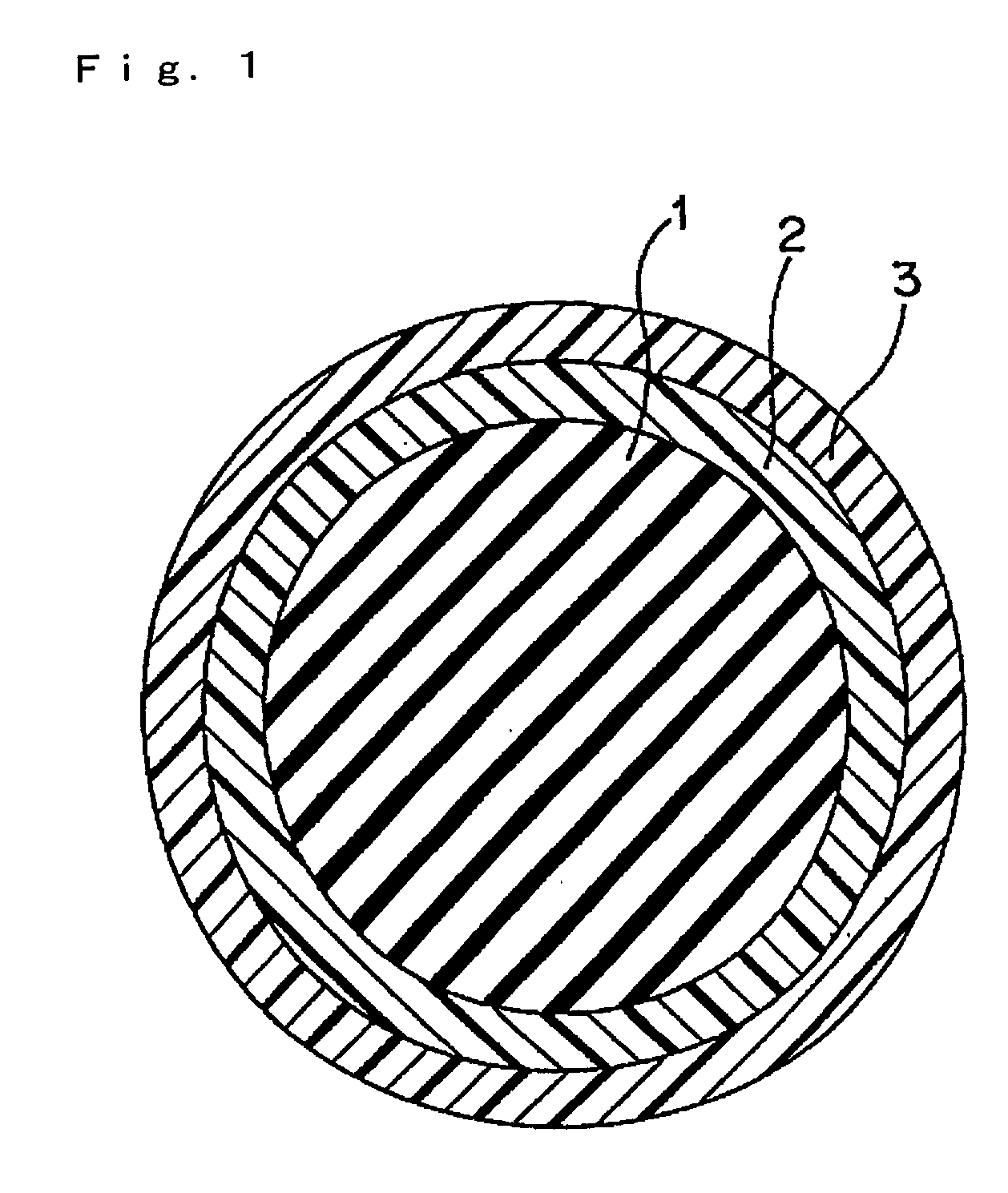

A positive electrode for lithium secondary battery includes a collector obtained by forming a carbonaceous material film on the surface of a conductive substrate, and a positive electrode material layer carried on the carbonaceous material film side of the collector and containing an organic sulfide compound as a main active material.

Owner:SUBARU CORP +1

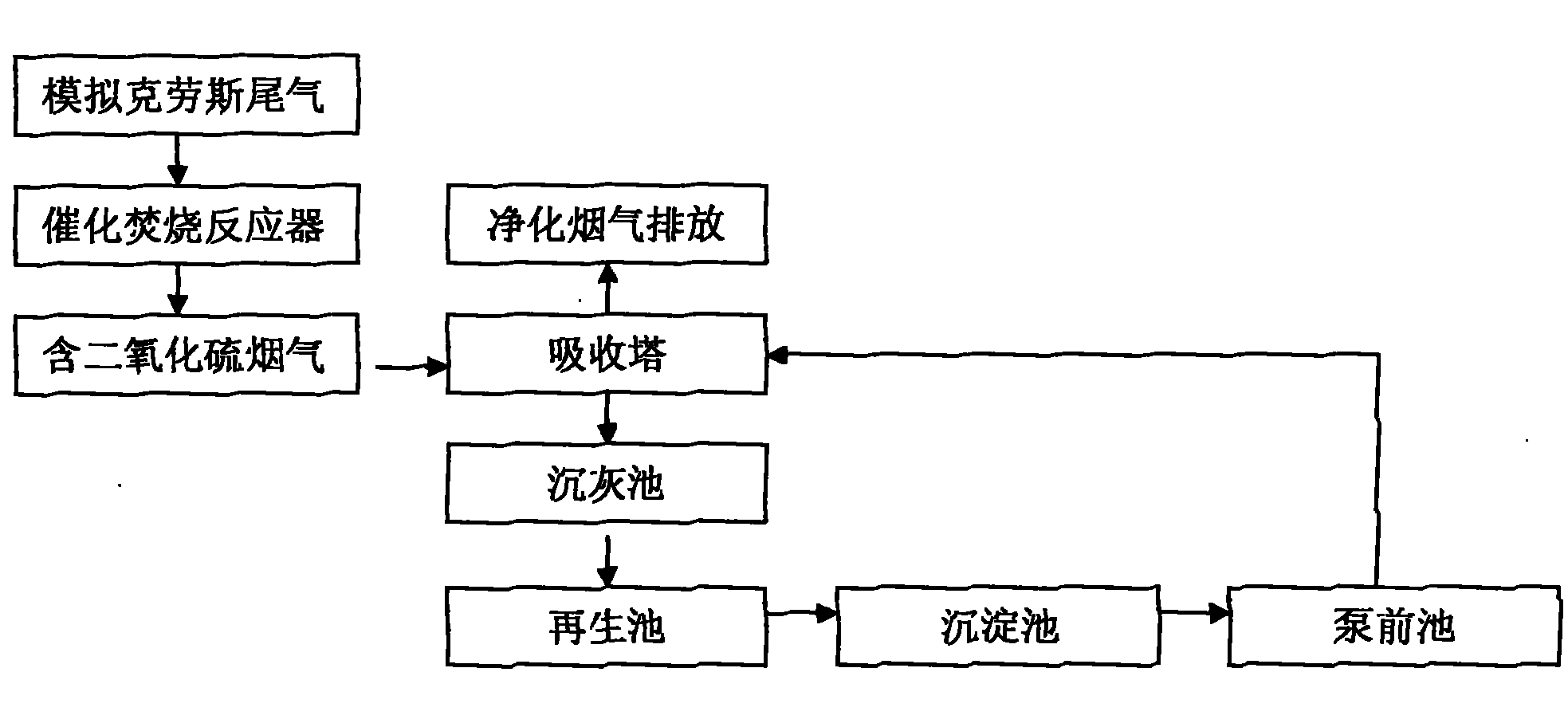

Combined treatment method for waste gas containing sulfur compounds

The invention discloses a combined treatment method for waste gas containing sulfur compounds. The method comprises the following steps of: mixing the waste gas containing the sulfur compounds and air, delivering the preheated gas to a catalytic incineration reactor, and performing catalytic incineration operation at the temperature of between 150 and 450 DEG C under the conditions that the space velocity is 1,000 to 35,000h<-1> and the peroxide coefficient is 0.5 to 8.0; delivering the flue gas formed after catalytic incineration to an absorption tower after heat exchange and cooling, discharging the desulfurized and washed purified flue gas, delivering the desulfurized and washed slurry to a regeneration tank provided with a stirring device, performing regeneration reaction on the slurry and regeneration alkali, delivering the reaction product to a sedimentation tank, overflowing the clarified liquid in the sedimentation tank to a pre-pumping tank, recycling the alkali supplemented clarified liquid to a desulfurization tower, and regularly clearing the settled calcium sulfite, calcium sulfate and calcium carbonate. By the method, hydrogen sulfide and organic sulfides in the waste gas containing the sulfur compounds can be efficiently converted into sulfur dioxide, and the sulfur dioxide is recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

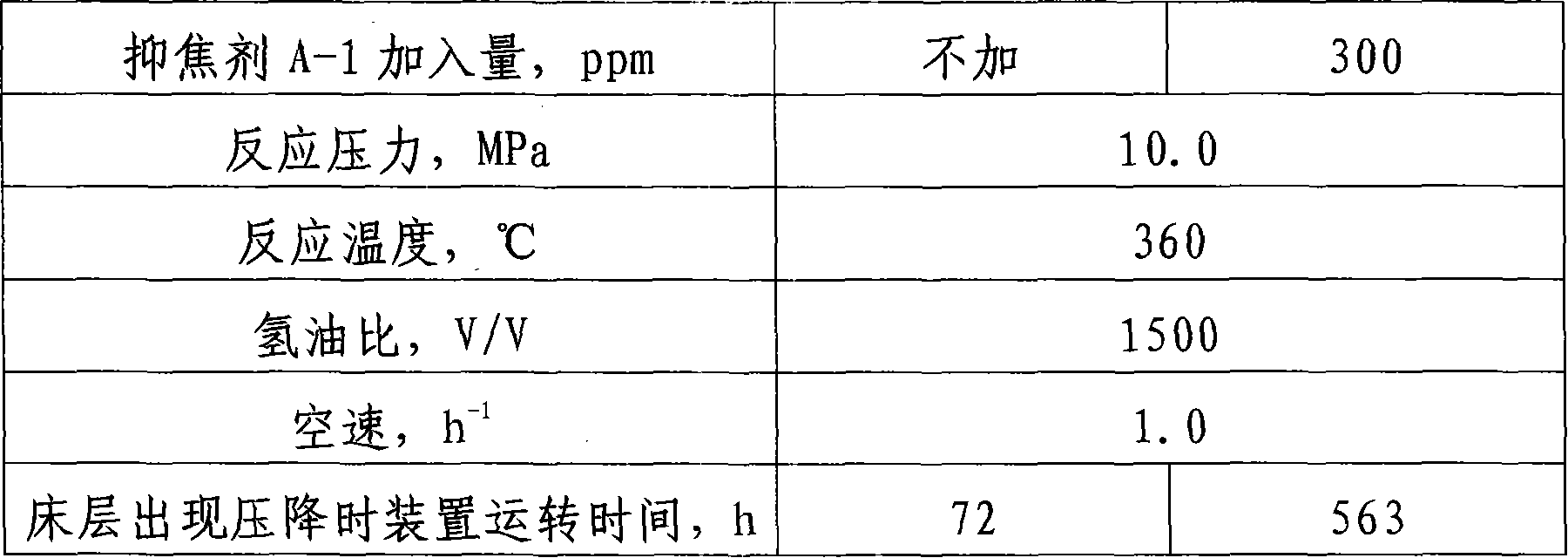

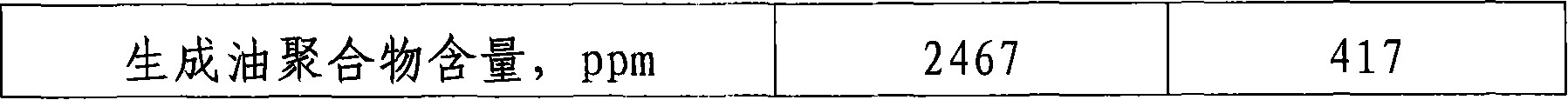

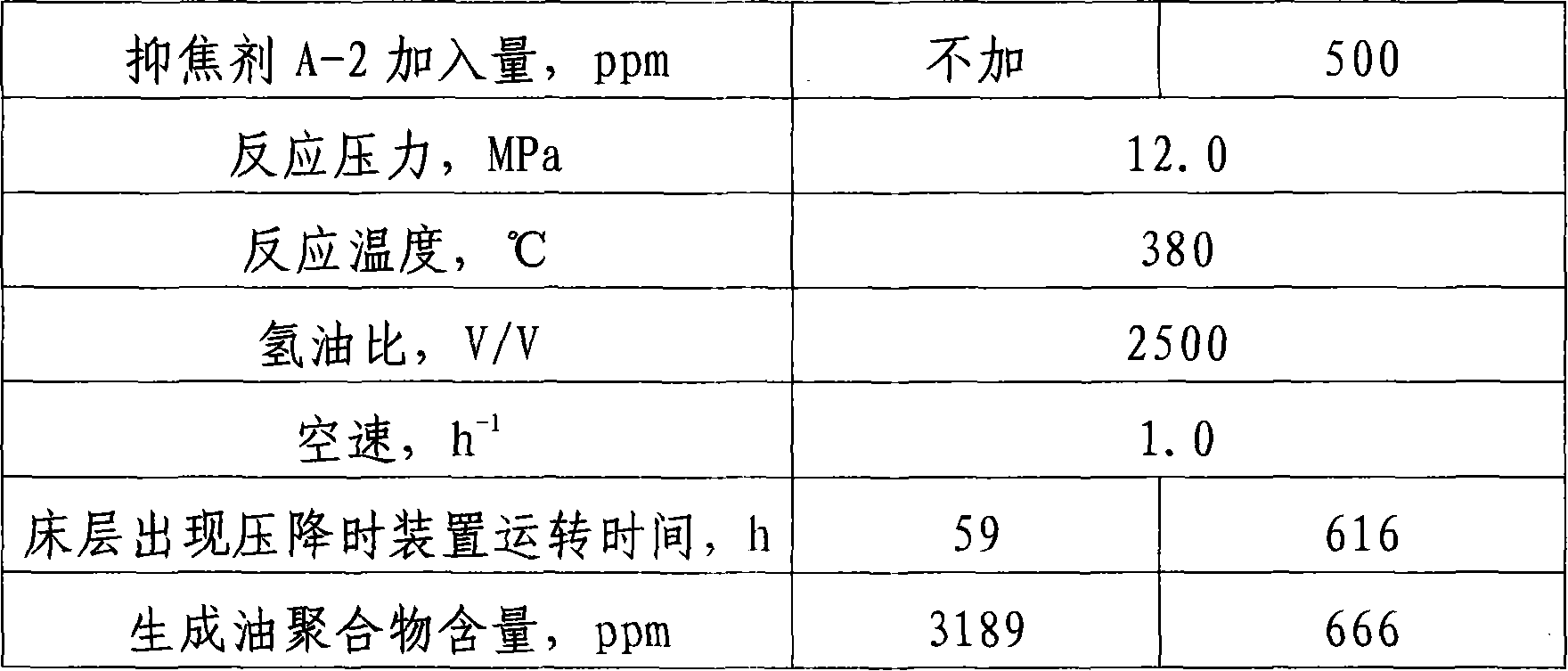

Coke inhibitor as well as preparation method and use thereof

InactiveCN101250437ADoes not affect product qualityGood effectThermal non-catalytic crackingTreatment apparatus corrosion/fouling inhibitionOrganic sulfide compoundOrganic solvent

The invention discloses a coke inhibitor and the process for preparation and the application, the coke inhibitor is the mixture which is formed by organophosphorus compound, phenolic compound, amine compound, high molecular weight polymerization amine, organo-sulfur compound and organic solvent. The weight percentage contents are respectively 5-15%, 10-30%, 10-30%, 10-40%, 5-10% and 20-30%. The process for preparing coke inhibitor has the advantages of simple process for preparation, lower production cost, excellent coke inhibiting property, bigger flexibility and wide application scope.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Zirconic desulphurization adsorbent, preparation method and application thereof

The invention relates to an adsorbent which is used for removing sulfur from being cracked gasoline and diesel engine fuel. The adsorbent comprises the following components: (1) silicon oxide source containing at lease mica; (2) zirconium dioxide binder; (3) oxides of one or more metals selected from groups IIB, VB and VIB; (4) at least one promoter metal selected from cobalt, iron and manganese.The adsorbent has good wear resistance and good desulphurization activity, and can be used for removing elemental sulfur and sulfide from being cracked gasoline and diesel oil fuel, such as hydrogen sulfide and organic sulfur compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

Garlic oil cyclodextrin or cyclodextrin derivate inclusion compound and preparation method

InactiveCN101485446AGood water solubilityImprove stabilityAntipyreticAnalgesicsSolubilityOrganic sulfide compound

The invention relates to a garlic oil cyclodextrin or cyclodextrin derivative inclusion compound, and a preparation method thereof. Garlic oil is an organic sulfide extracted from garlic and has the functions of resisting bacteria, diminishing inflammation, improving organism immunity, preventing and treating cardiovascular system diseases, and the like. Garlic oil has aroma and hot taste similar to fresh garlic, is integral in flavor, pure natural, safe and healthy, and is widely applied to salty food additives, health-care food, edible blend oil and the like, but as the garlic oil is unstable in properties, strong in volatility and acrimony and difficult to dissolve in water, the application of the garlic oil to food is greatly limited. The preparation method applies cyclodextrin and cyclodextrin derivatives to the inclusion of garlic oil so as to prepare the garlic oil cyclodextrin or cyclodextrin derivative inclusion compound, solves the problems that the garlic oil is low in water solubility, strong in acrimony and the like, and enables the garlic oil to be directly applied to food and health care products.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

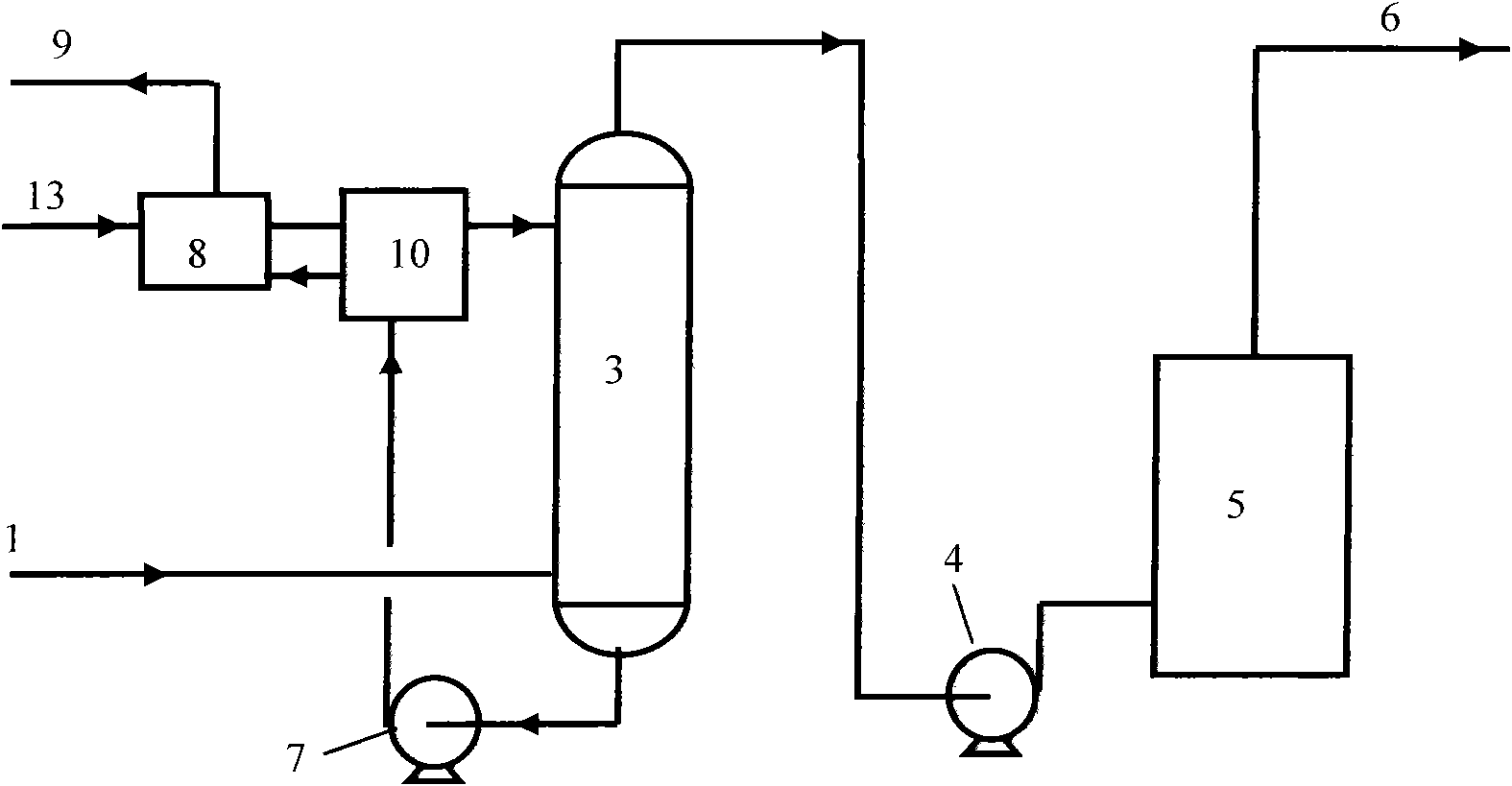

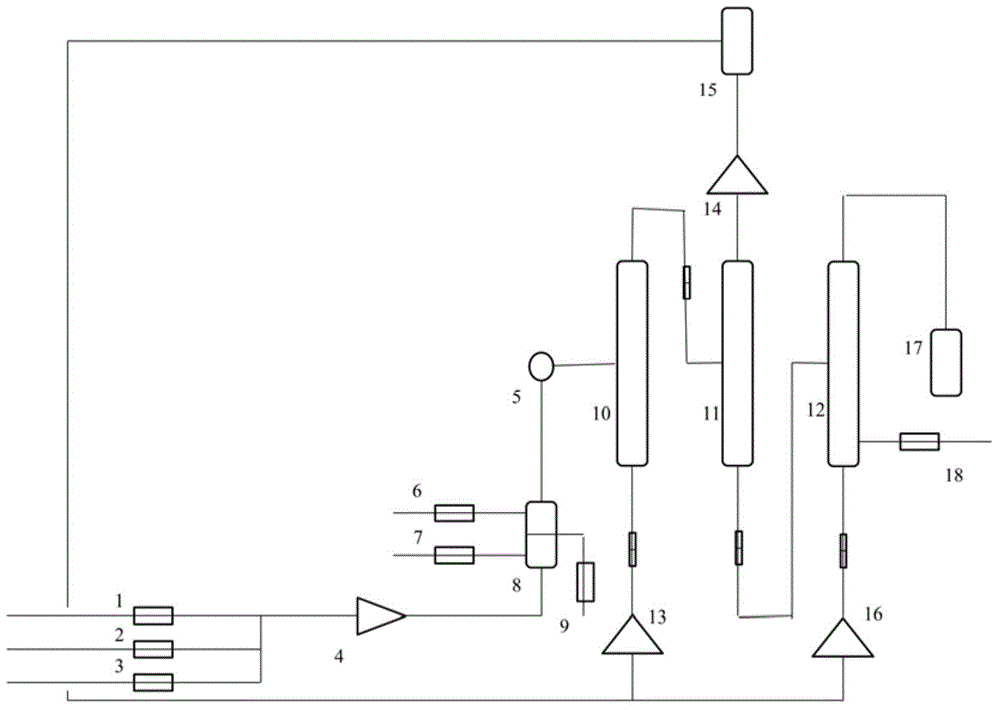

Technique and system for preparing propylene oxide by directly oxidizing propylene with oxygen and hydrogen

ActiveCN104650008AAvoid damageAvoid pollutionOrganic chemistryBulk chemical productionEnvironmental resistanceOrganic sulfide compound

The invention provides a technique and a system for preparing propylene oxide by directly oxidizing propylene with oxygen and hydrogen. The technique comprises the following steps that: (1) propylene, circulation propylene, and high-boiling-point organic sulfide are added to a mixed solvent of methanol and hydrazine hydrate, hydrogen and oxygen are accessed, and raw propylene oxide is produced; (2) raw propylene oxide is cooled and pumped into a rough separation tower by a pump, and organic sulfide and a few of high-boiling-point by-products in raw propylene oxide are removed; (3) a balance mixture of propylene and propylene oxide enters a propylene stripping tower, and unreacted propylene and a little propylene oxide in the mixture are removed; and (4) balance propylene oxide mixed liquor enters an extraction purification tower containing cumin and an alkaline solution, and is further extracted and rectified to form propylene oxide with high purity. The technique and the system are energy-saving and environmentally friendly, can increase the purity and the yield of propylene oxide significantly, reduce the losses of propylene oxide, and are suitable for industrialized production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

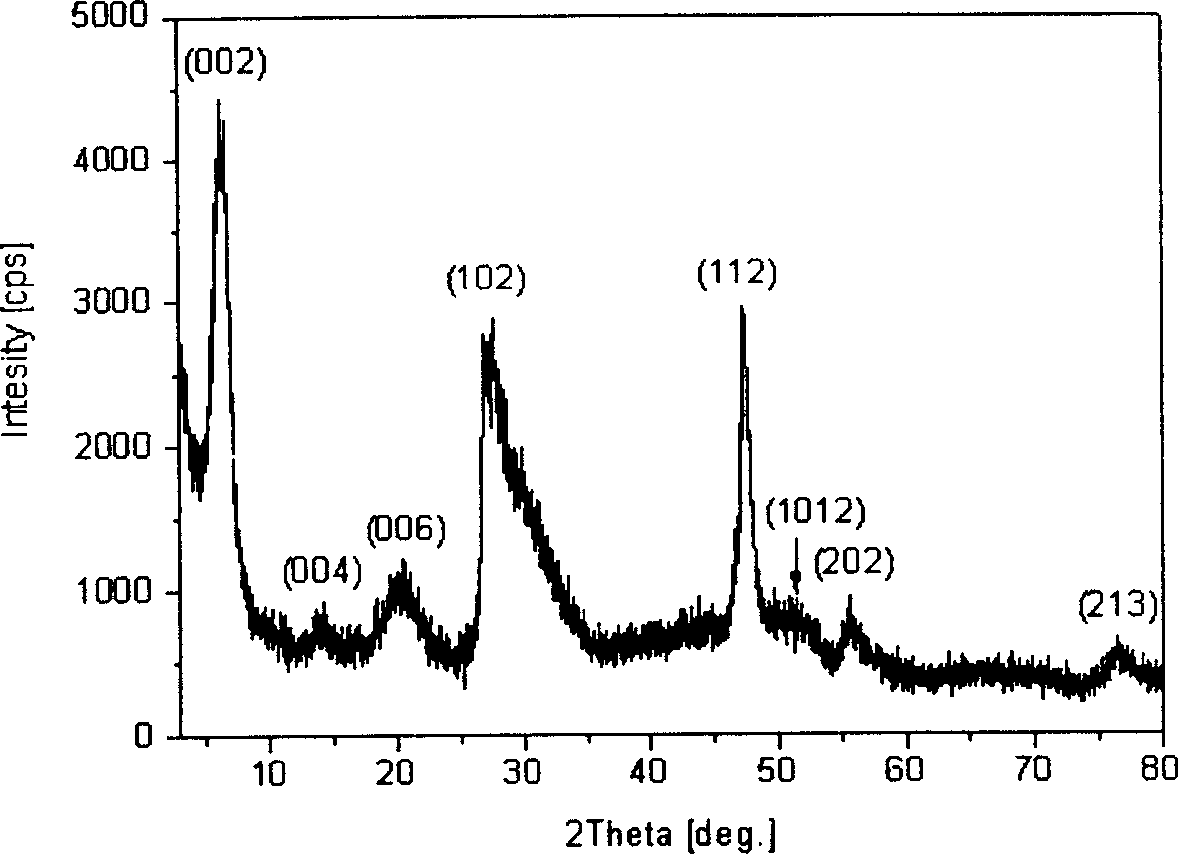

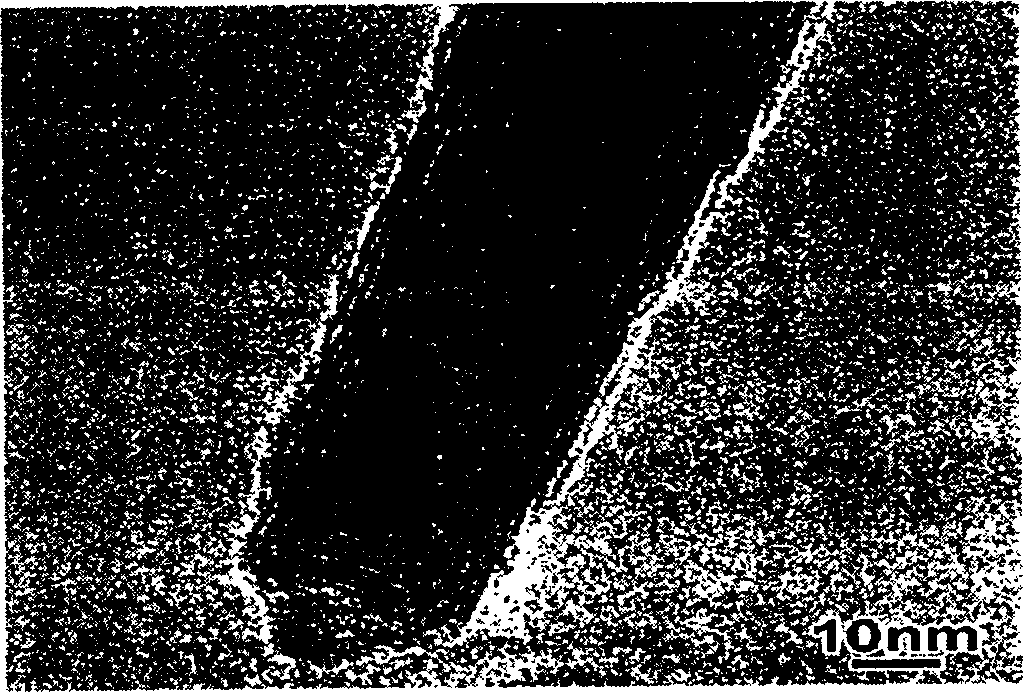

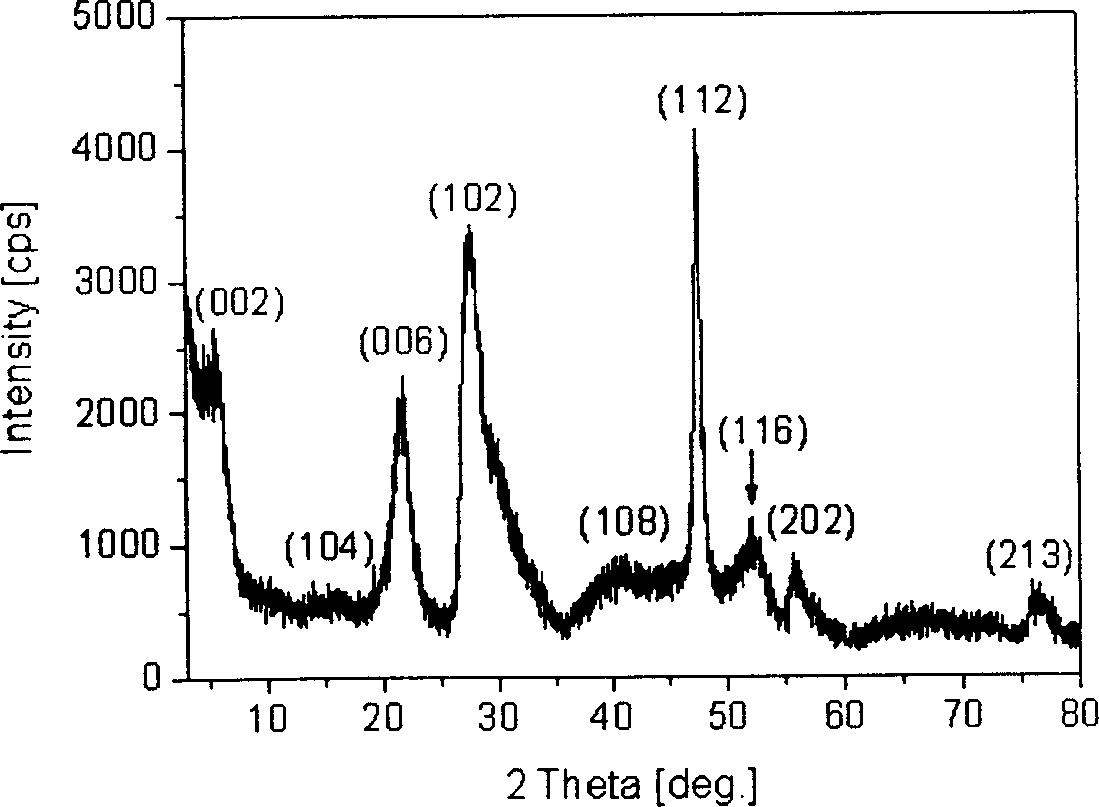

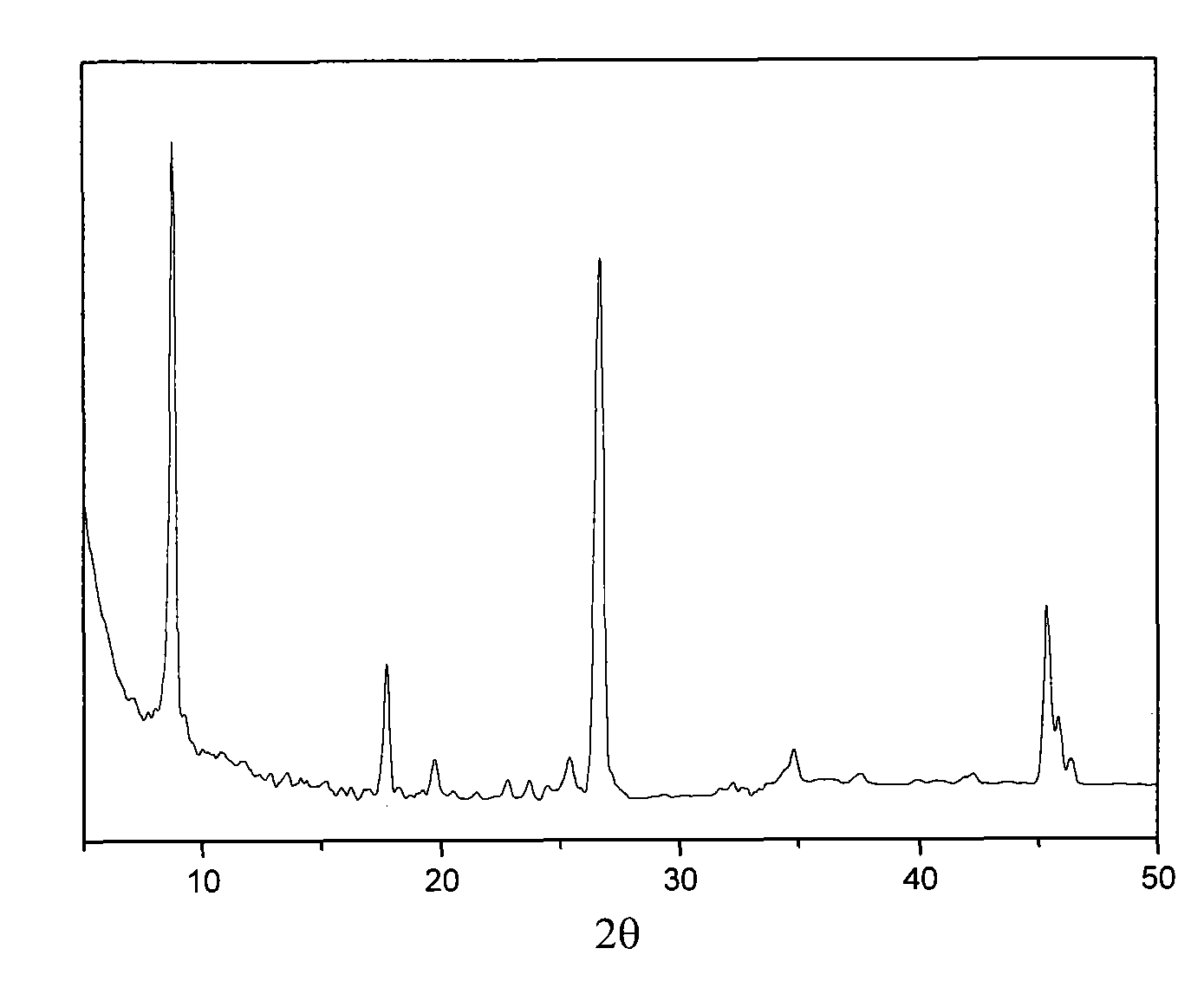

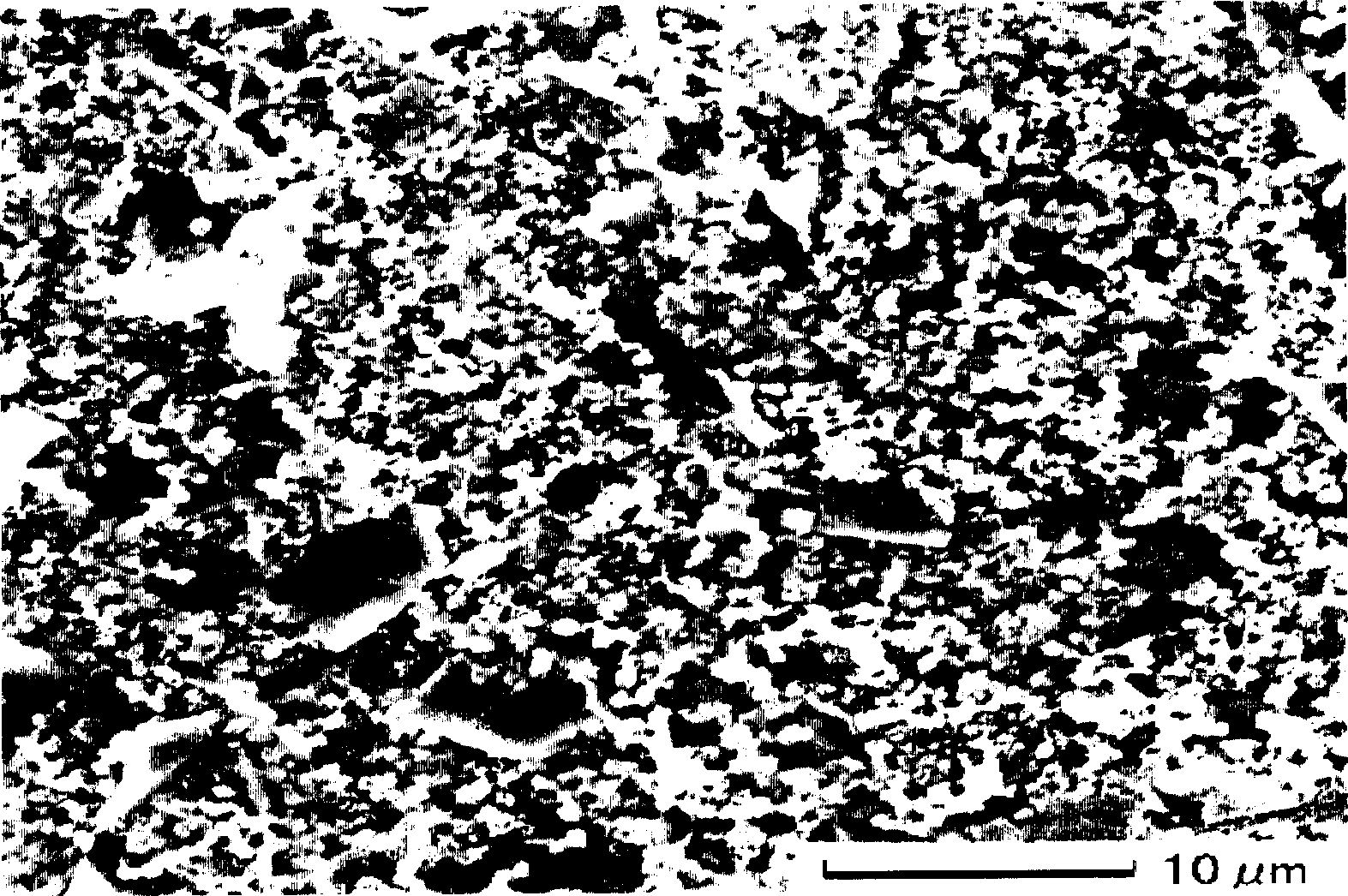

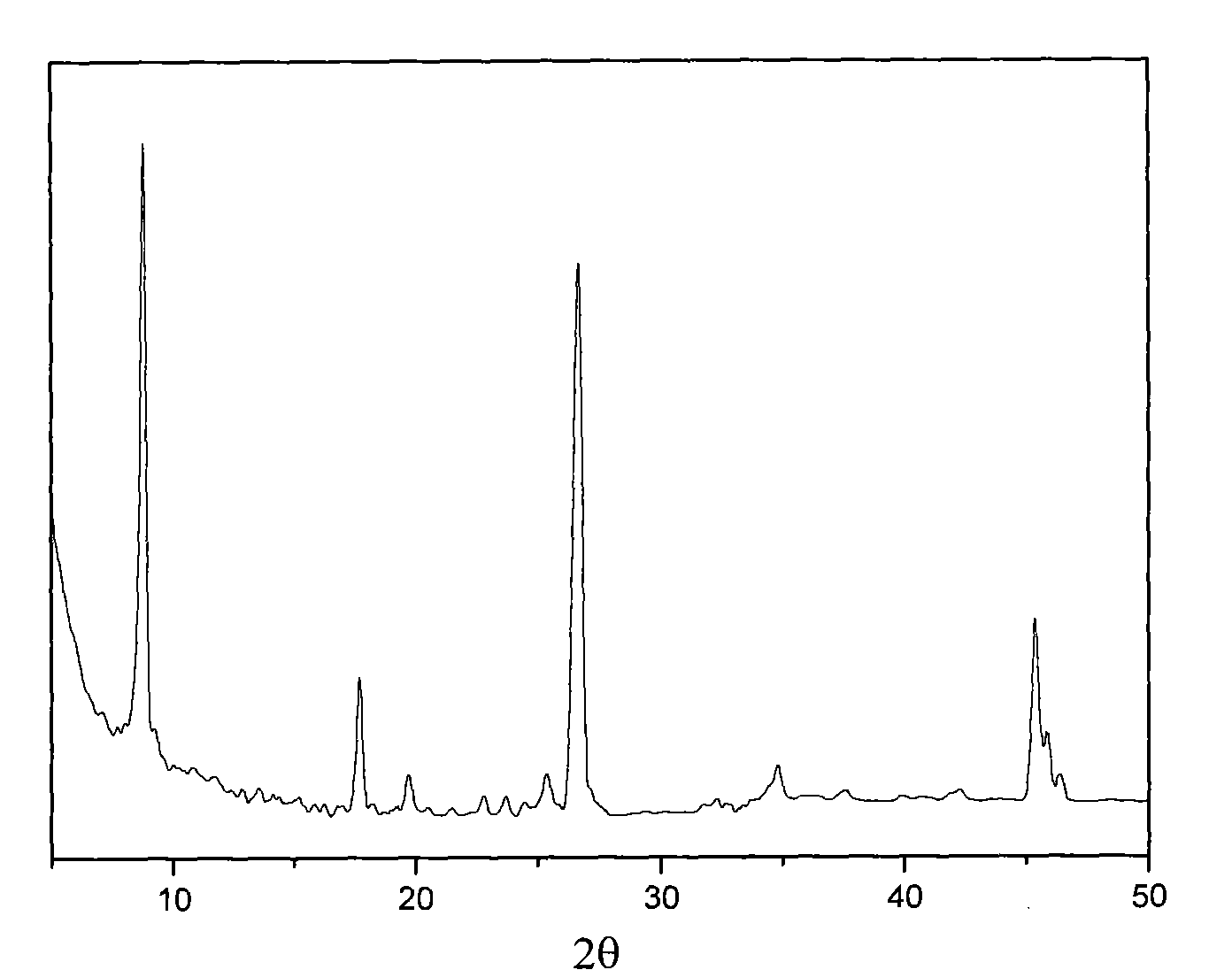

Process for adsorptive desulfurization of light oil distillates

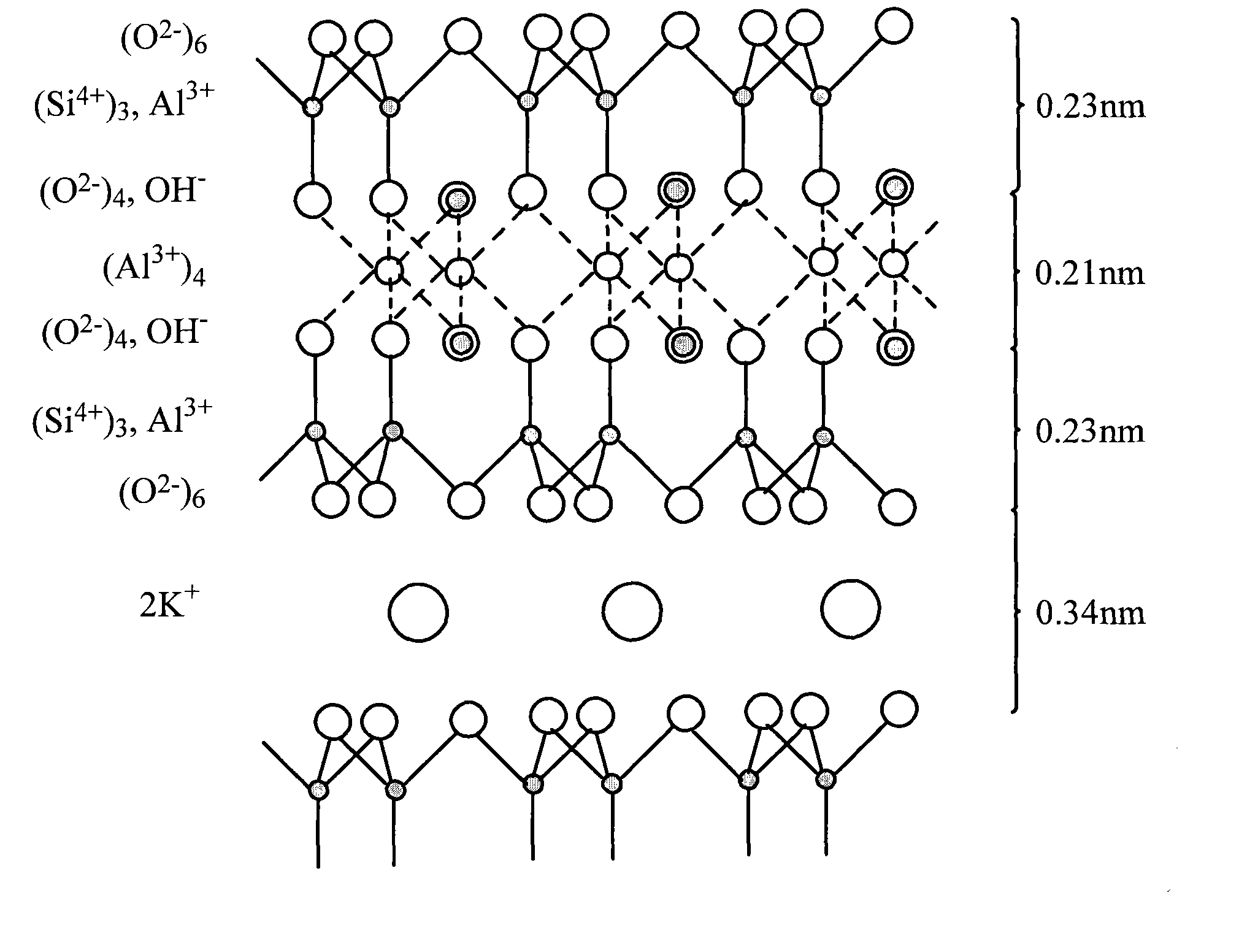

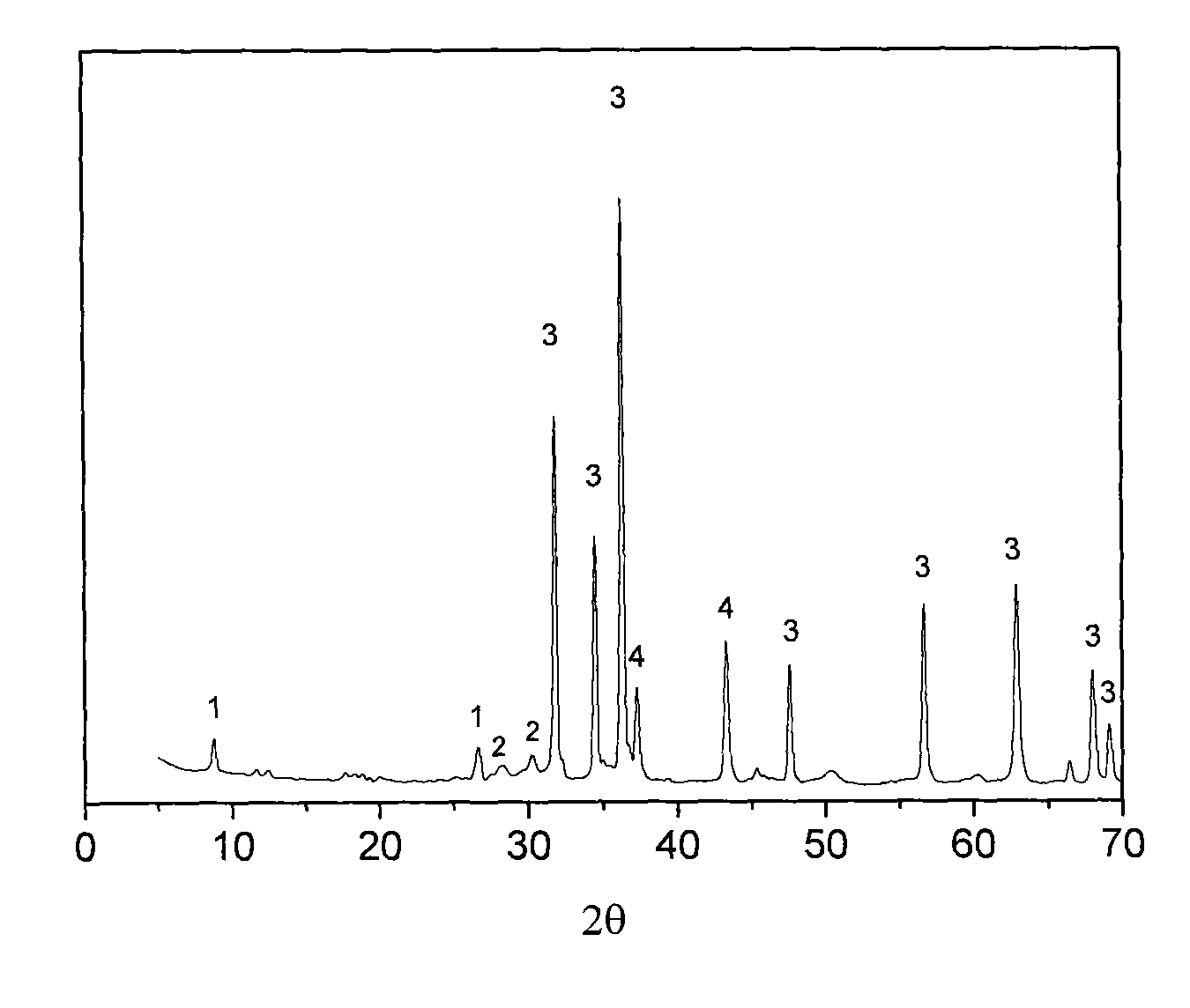

InactiveUS6875340B2Improve abilitiesSimple technologyRefining with metalsOther chemical processesOrganic sulfide compoundX-ray

A process for adsorptive desulfurization of gasoline or diesel oil or aromatics lower than C12 containing organic sulfide impurities, wherein these feedstocks contact an amorphous alloy adsorbent comprising nickel as a major active component in a fluidized bed reactor or a magnetic-stabilized fluidized bed reactor or a slurry bed reactor. There is only a single diffuse peak at 2θ=45° in the 2θ range from 20° to 80° in the X-ray diffraction (XRD) pattern of the adsorbent. The adsorbent consists of 50-95 wt % of nickel, 1-30 wt % of aluminum, 0-35 wt % of iron, and 0-10 wt % of one or more metals selected from copper, zinc, molybdenum, chromium, and cobalt.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com