Combined treatment method for waste gas containing sulfur compounds

A treatment method and compound technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of large air resistance in the catalytic incineration reactor bed, complex catalyst components, complex process, etc., and reach the service life Long life, excellent performance and low catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

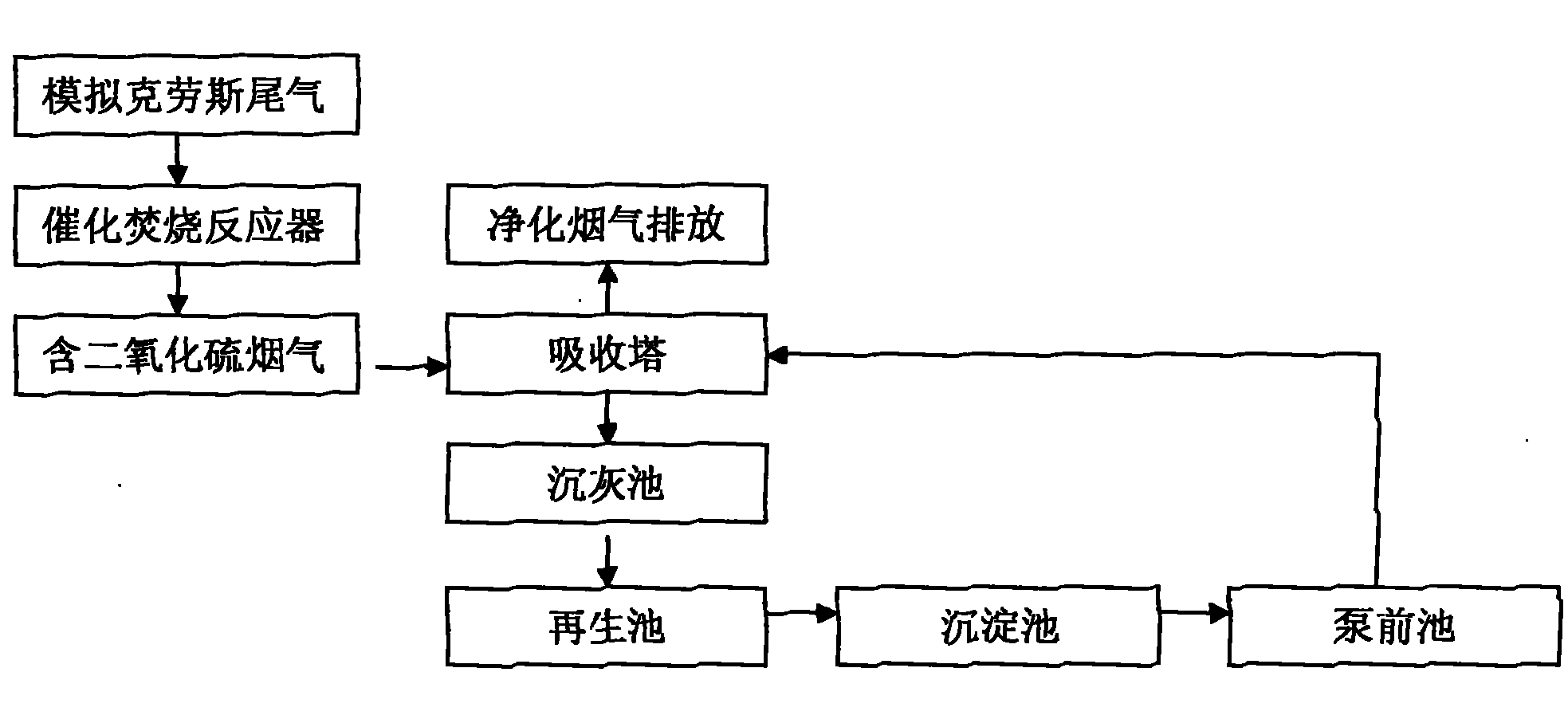

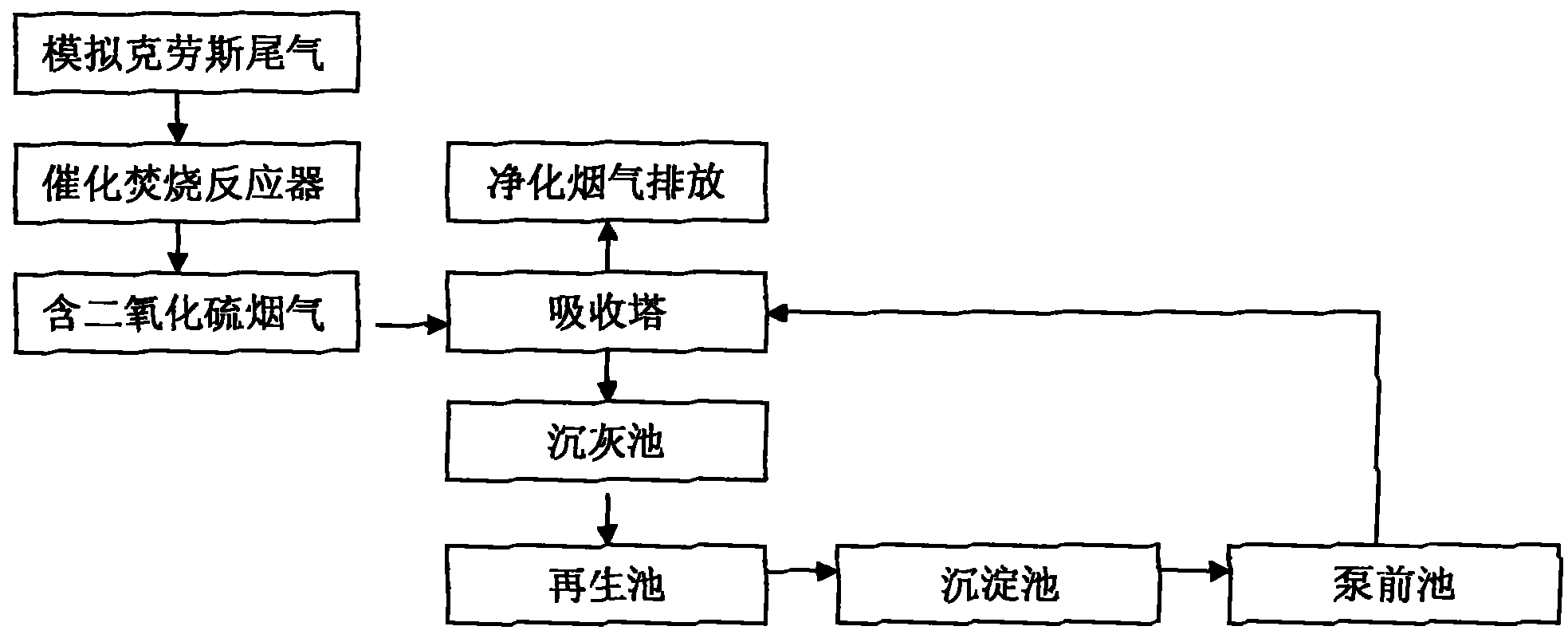

[0027] Such as figure 1 As shown, the exhaust gas of sulfur-containing compounds is mixed with air, and enters the catalytic incineration reactor after preheating. The feed gas composition is 0.2% (v / v) of hydrogen sulfide, 0.05% (v / v) of carbonyl sulfide, and 3.0% of water vapor (v / v), oxygen 0.75% (v / v), and the rest is nitrogen. The catalyst used in catalytic incineration uses honeycomb ceramics as the carrier, and the active component weight content is Bi 2.5%, Cu 1.5%, TiO 2 3.0%, the Cu / Bi molar ratio is about 2:1, and the specific surface area is 1900m 2 / m 3 , the average pore size is 4.6nm, the reaction temperature is 350°C, and the space velocity is 6000h -1 , the flue gas formed after catalytic incineration enters the absorption tower after heat exchange and cooling. The pH of the absorption liquid used in the absorption tower is 8, the concentration of sodium ions is 2 mol / liter, and the liquid-gas ratio to the flue gas is 3L / m 3 , the reflux ratio (i.e. the per...

Embodiment 2

[0029] Such as figure 1 As shown, the exhaust gas of sulfur-containing compounds is mixed with air, and enters the catalytic incineration reactor after preheating. The feed gas composition is 0.24% (v / v) of hydrogen sulfide, 0.06% (v / v) of carbonyl sulfide, and 3.0% of water vapor (v / v), oxygen 0.90% (v / v), and all the other being nitrogen, the composition of catalyst used by catalytic incineration is La 2 o 3 3.2% (La 2.7%), Bi 2 o 3 4.5% (Bi 4.0%), TiO 2 92.8%, the La / Bi molar ratio is about 1:1, the reaction temperature is 350°C, and the space velocity is 6000h -1 , the flue gas formed after catalytic incineration enters the absorption tower after heat exchange and cooling. The pH of the absorption liquid used in the absorption tower is 9, the concentration of sodium ions is 0.5 mol / liter, and the liquid-gas ratio to the flue gas is 5L / m 3 , the reflux ratio (i.e. the percentage of the regeneration circulation amount to the total circulation amount) of the absorption l...

Embodiment 3

[0031] Such as figure 1 As shown, the exhaust gas of sulfur-containing compounds is mixed with air, and enters the catalytic incineration reactor after preheating. The feed gas composition is 0.21% (v / v) of hydrogen sulfide, 0.07% (v / v) of carbonyl sulfide, and 3.0% of water vapor. (v / v), oxygen 0.84% (v / v), the rest is nitrogen, the composition of the catalyst used for catalytic incineration is CuO 2.9%, Bi 2 o 3 8.6%, TiO 2 88.5%, the Cu / Bi molar ratio is about 1:1, the reaction temperature is 320°C, and the space velocity is 6000h -1 , the flue gas formed after catalytic incineration enters the absorption tower after heat exchange and cooling. The pH of the absorption liquid used in the absorption tower is 8, the concentration of sodium ions is 3 mol / liter, and the liquid-gas ratio to the flue gas is 4L / m 3 , the reflux ratio (i.e. the percentage of the regeneration circulation amount to the total circulation amount) of the absorption liquid entering the regeneration t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com