Patents

Literature

339 results about "Combined treatment method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

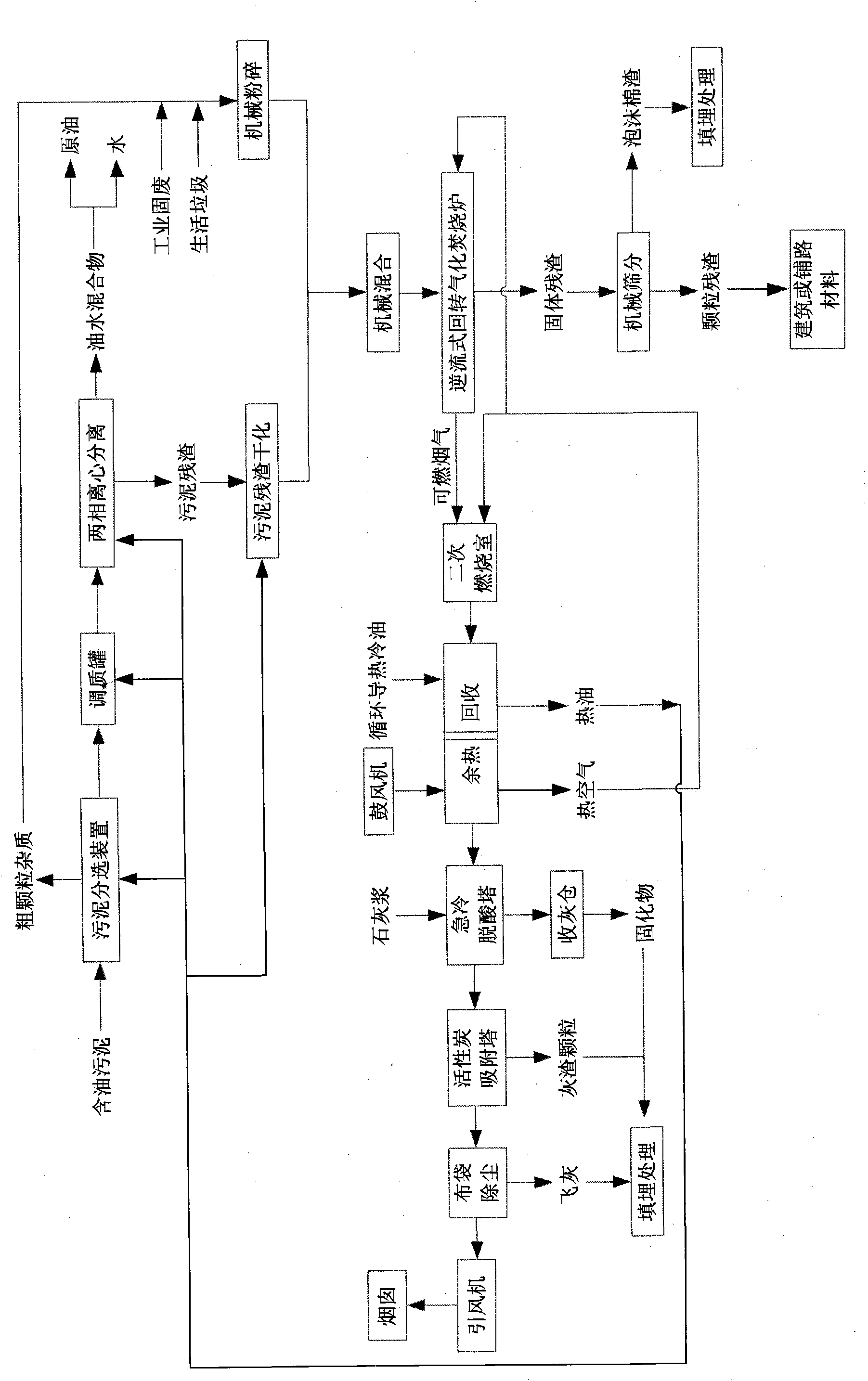

Combined treatment method for oilfield solid waste

InactiveCN101963358AHigh recovery rateLess investmentIncinerator apparatusCombustion chamberOil sludge

The invention provides a new combined treatment process for oilfield solid waste (oil sludge, industrial solid waste and household garbage). In the process, liquid-solid separation is performed on the oil sludge of an oilfield by adopting a conditioning-centrifugal separation process; the separated liquid enters oil-water separation equipment constructed on the oilfield for recovering crude oil; the oil recovery rate is up to 65 to 90 percent; after drying separated solid residue, the separated solid residue and pre-crushed industrial solid waste and household garbage are mixed and enter a countercurrent-type rotary gasification incinerator; combustible components in the oilfield solid waste are decomposed and gasified into combustible gases which are combusted partially in the incinerator; the combustible gases are combusted completely in a secondary combustion chamber; high-temperature smoke gas afterheat is recovered by a conduction oil afterheat boiler and air preheating equipment; and low-temperature smoke gas of which the afterheat is recovered is harmlessly exhausted after being treated by a sharp-quenching deacidification tower, an activated carbon adsorption tower and a bag-type dust remover. The process realizes the purposes of decrement, harmlessness and resources of oilfield solid waste treatment.

Owner:KUNMING UNIV OF SCI & TECH

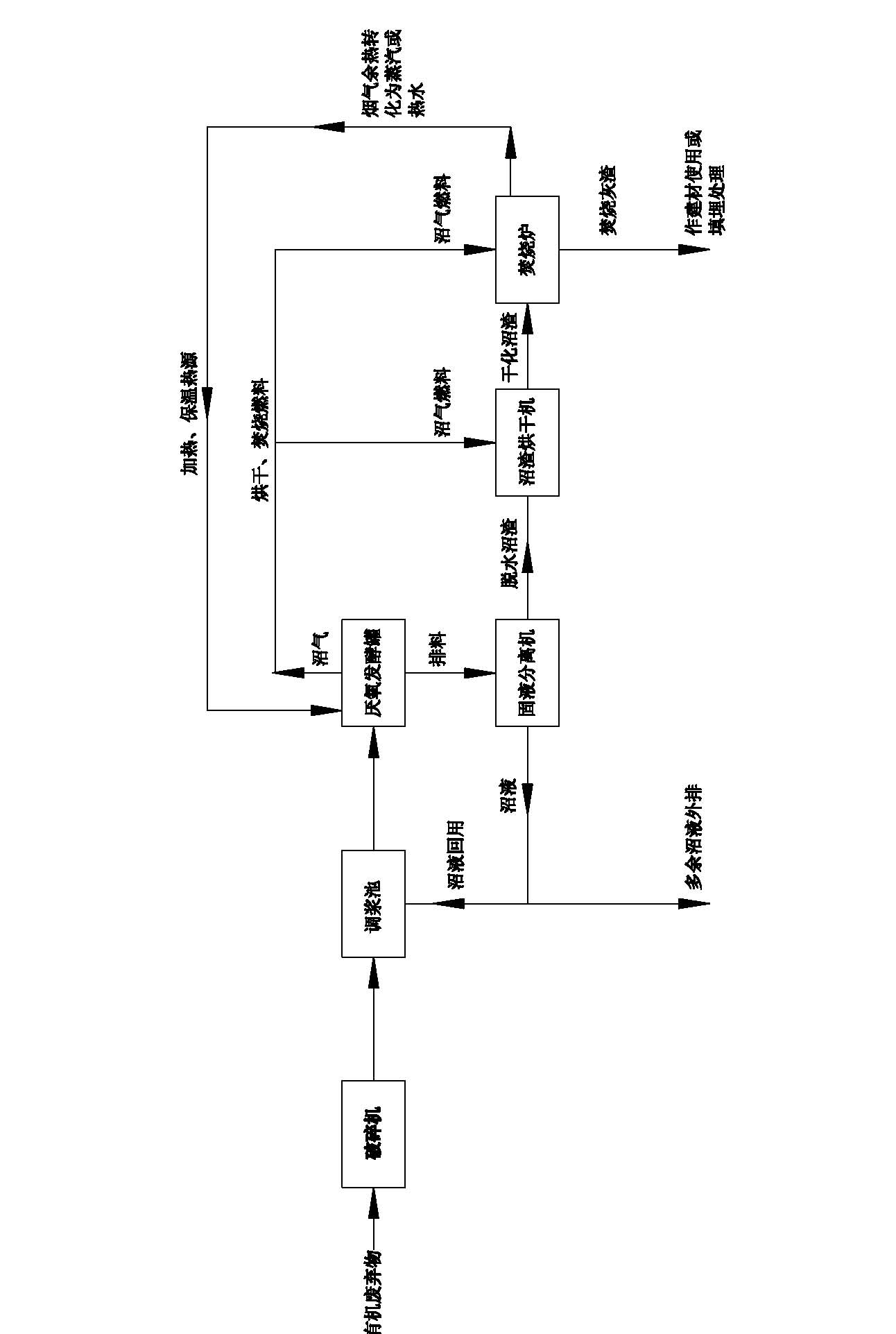

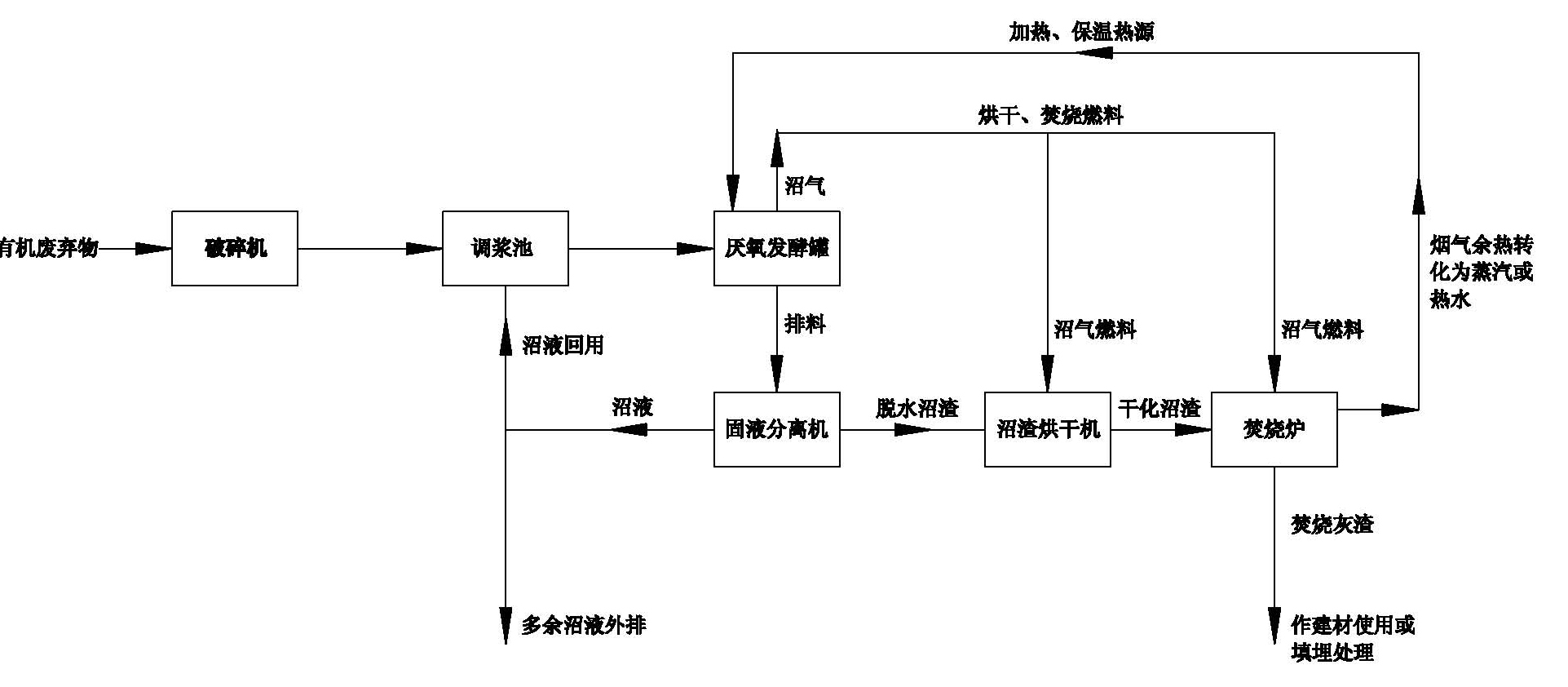

Anaerobic fermentation-incineration combined treatment method for organic wastes

InactiveCN102374543AAchieve reductionHarmlessGas production bioreactorsLiquid production bioreactorsSlagSlurry

The invention discloses an anaerobic fermentation-incineration combined treatment method for organic wastes. The anaerobic fermentation-incineration combined treatment method is characterized by comprising the following steps of: firstly, crushing the organic wastes, feeding the crushed organic wastes into a slurry mixing pool to be mixed with water or a methane solution to form a fermentation raw material, and feeding the fermentation raw material into an anaerobic fermentation tank for anaerobic fermentation treatment; secondly, performing solid-liquid separation treatment on residual slurry to form the methane solution and dehydrated methane slag; thirdly, making partial methane solution flow back to the slurry mixing pool, discharging surplus methane solution outwards to a sewage treatment facility; fourthly, feeding the dehydrated methane slag into a methane slag drying machine by taking methane generated by the anaerobic fermentation tank as fuel for heating, wherein the moisture content of the dried methane slag is made lower than 40%; fifthly, incinerating the dried methane slag subjected to drying treatment by using the methane collected from the anaerobic fermentation tank as auxiliary fuel for methane slag combustion; and sixthly, producing steam or hot water by a waste heat boiler by using high-temperature flue gas discharged from a methane slag incineration furnace, and supplying the steam or the hot water to the fermentation tank to serve as a hot source for heating or heat insulating. According to the invention, the anaerobic fermentation and the incineration treatment are organically combined, the advantages of the anaerobic fermentation and the incineration treatment are fully exerted, and the reduction, harmlessness and the recycling of rubbish are facilitated.

Owner:NANJING UNIV

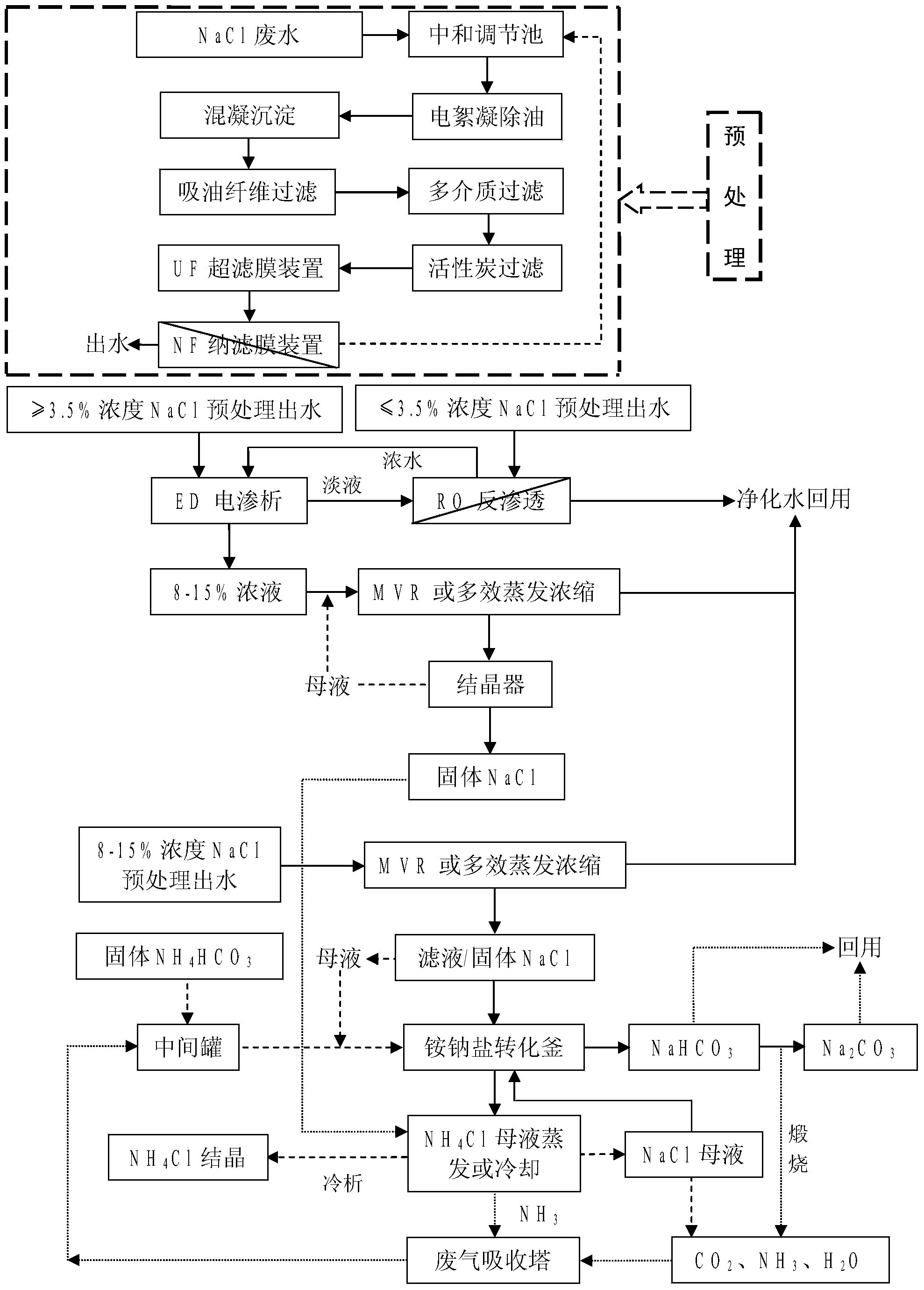

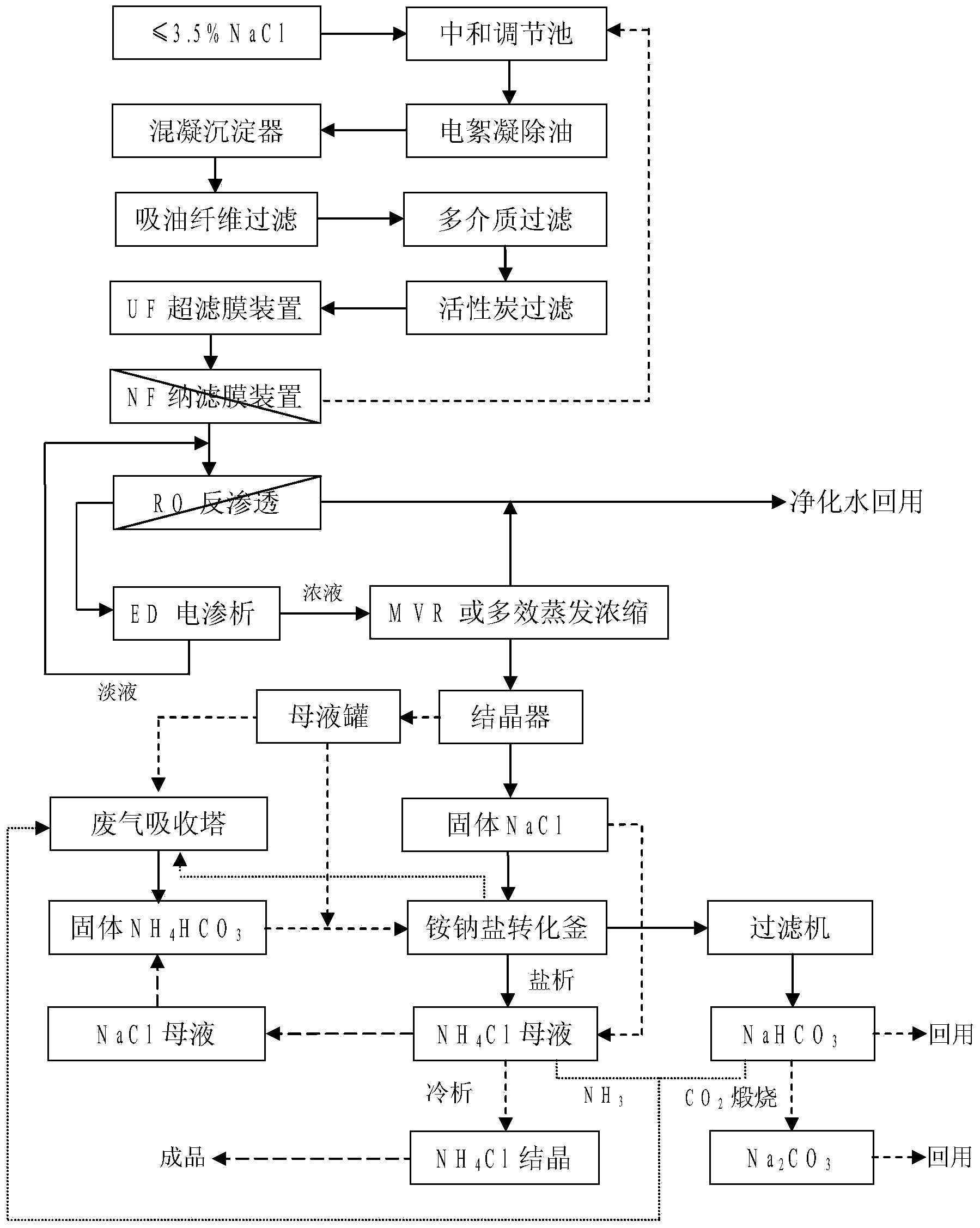

Combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth

InactiveCN103449653AImprove environmental protection measuresAvoid volatile lossGeneral water supply conservationMultistage water/sewage treatmentSodium bicarbonateUltrafiltration

The invention relates to a combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth. According to the method, a series of desalination and concentration treatments such as deoiling, neutralizing, homogenizing, aeration, flocculation, ultrafiltration, nanofiltration, reverse osmosis, electroosmosis and MVR (mitral valve replacement) concentration are carried out on the wastewater, so that recyclable purified water is obtained; ammonium bicarbonate is added into the sodium chloride extracted from the wastewater, so that the sodium salt can be converted and regenerated into sodium bicarbonate, sodium carbonate and ammonium chloride products for dressing and smelting of the rare earth. According to the method, the recovery rate of the wastewater is high, the effluent quality is stable, the conversion rate of the sodium salt is high, and no three wastes are discharged; production equipment is compact, simple to operate, and easy to realize automation control; the problem that the sodium chloride-containing wastewater and other similar industrial wastewater generated in dressing and smelting of rare earth are difficult to recycle is solved.

Owner:YANSHAN UNIV

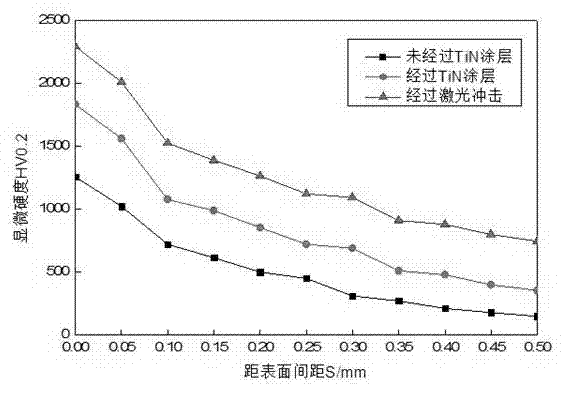

Combined treatment method for prolonging life of oversized shearing equipment tool

InactiveCN103668171AHigh hardnessImprove wear resistanceHeat inorganic powder coatingHardnessWear resistance

The invention discloses a combined treatment method for prolonging the life of an oversized shearing equipment tool, and relates to the technical field of application of machine manufacturing and material treatment processing. According to the invention, a TiN surface coating is utilized to improve the hardness, abrasive resistance and high-temperature resistance of the oversized shearing equipment tool, and the high-amplitude residual compressive stress layer generated by laser shock is utilized to effectively improve the mechanical property of the oversized shearing equipment tool, and particularly the fatigue life of the material is greatly increased.

Owner:JIANGSU WANLI MACHINERY +1

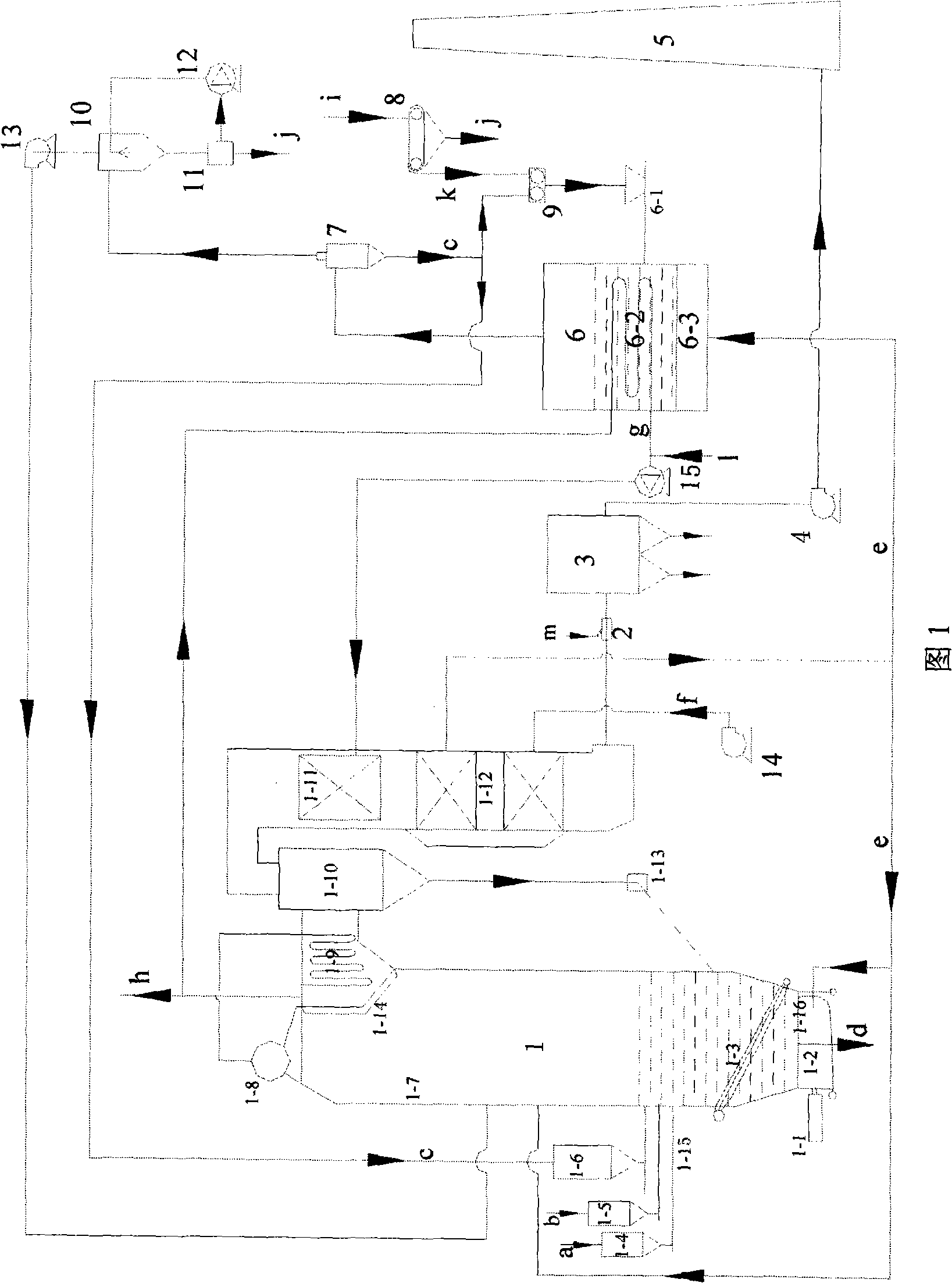

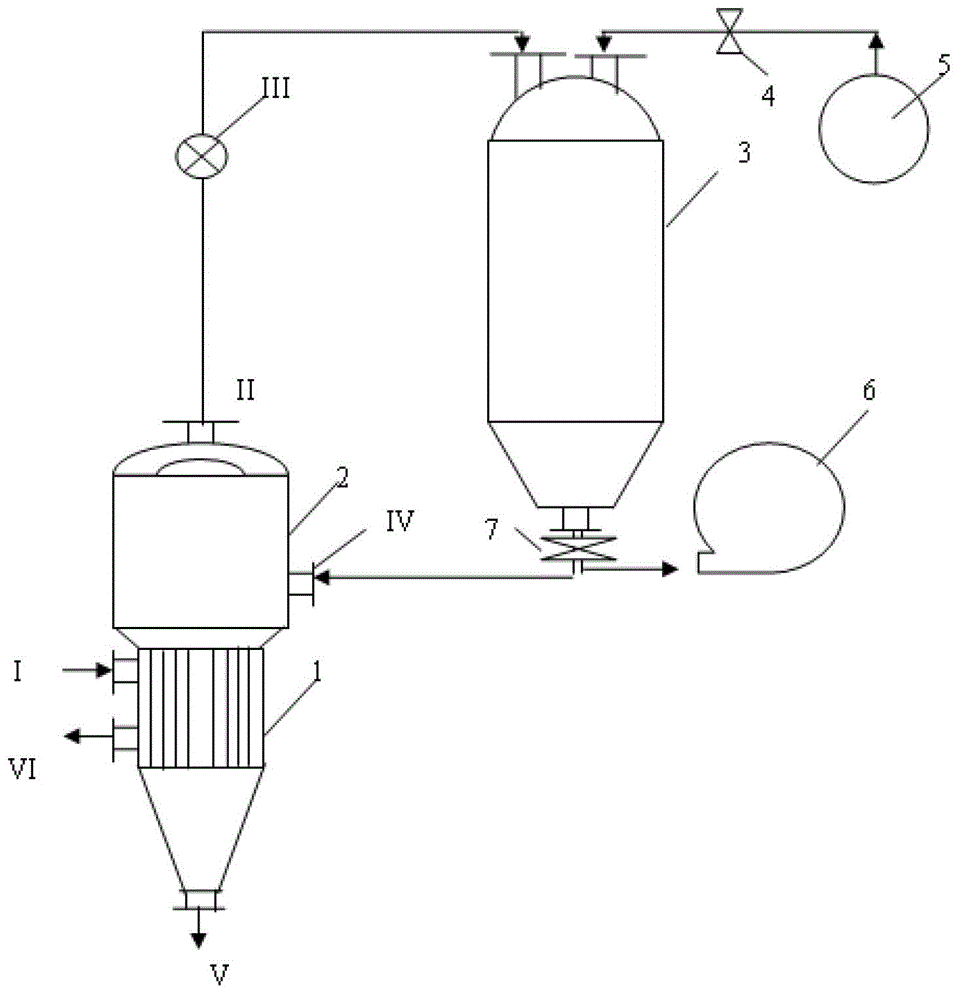

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

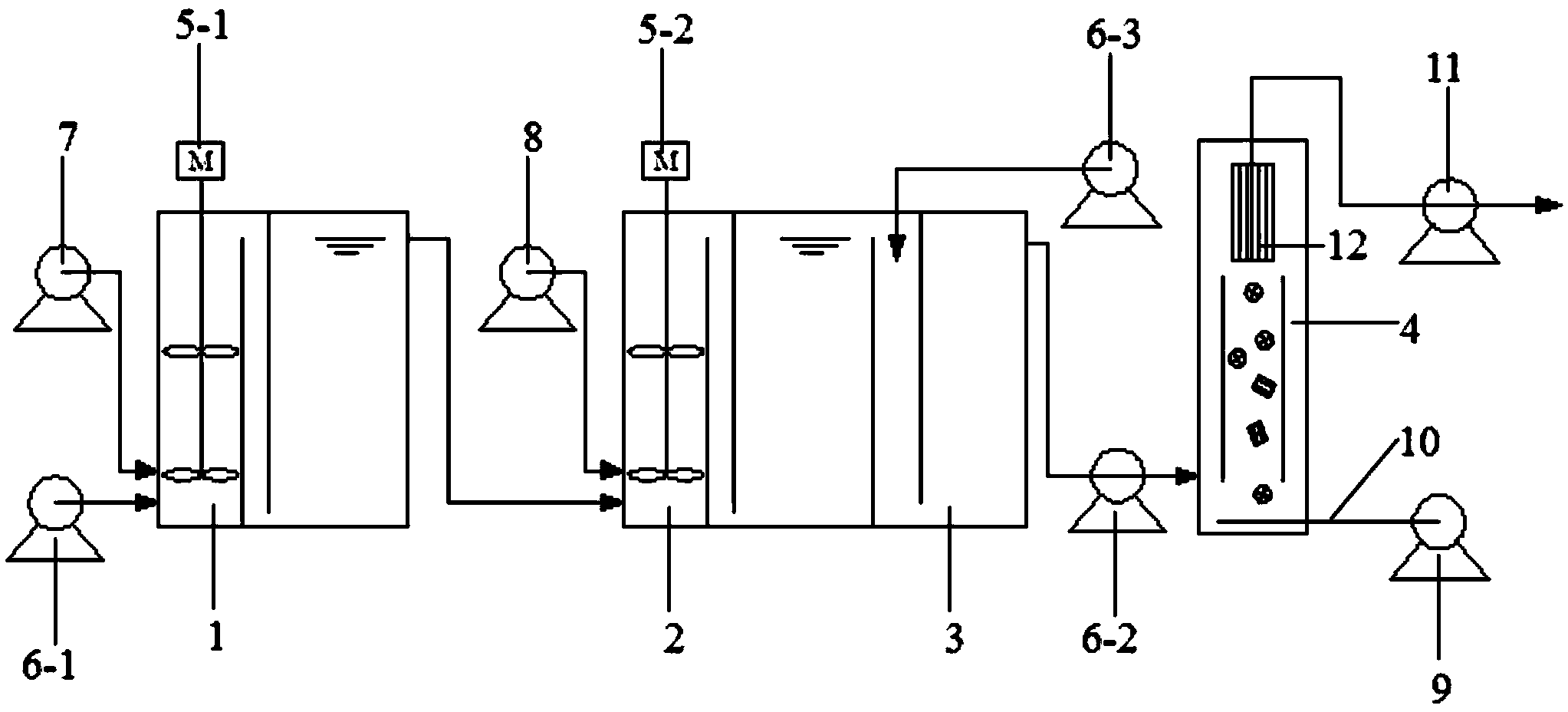

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

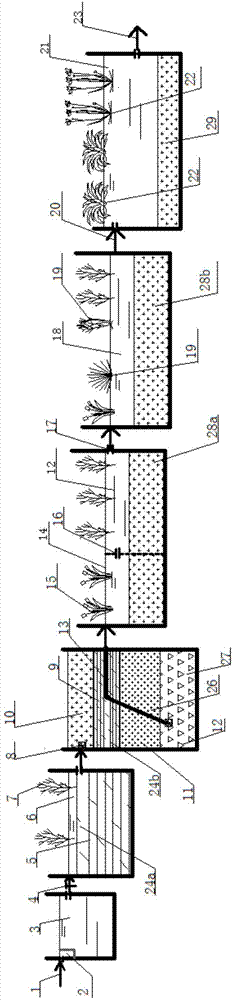

Ecological combined treatment method and device for rural distributed sewage

InactiveCN103880257AEfficient purificationImprove processing efficiencyMultistage water/sewage treatmentConstructed wetlandBiological filter

The invention discloses an ecological combined treatment method and device for rural distributed sewage. The method comprises the steps of A) rural sewage collection and pretreatment; B) treatment by a biological filter; C) treatment by an artificial wetland and a stabilization pond; D) ecological landscape configuration. The device is characterized in that a main water inlet pipeline is respectively connected with a lattice pool and a regulation pool, the regulation pool is connected with a horizontal flow biological filter through a water distribution pipe, the horizontal flow biological filter is connected with a vertical flow biological filter through a filter screen-water distribution pipe, the vertical flow biological filter is connected with a first-level artificial wetland via a perforated water collection pipe which is horizontally arranged, the first-level artificial wetland is connected with a second-level artificial wetland through an overflow weir, the second-level artificial wetland is connected with the stabilization pond through a straight flow water drain pipe, and a main water drain pipe is arranged at the tail end of the stabilization pond. According to the method, energy consumption is not required, the operation and the maintenance are simple and convenient, and the method further has the advantages of landscape effect, economic benefits, simple structure and low investment; high-efficient purification of rural distributed domestic and farming sewage is realized, and the removal rate of nitrogen, phosphorus, COD and the like in sewage is above 80% after treatment.

Owner:大长江环境工程技术有限责任公司

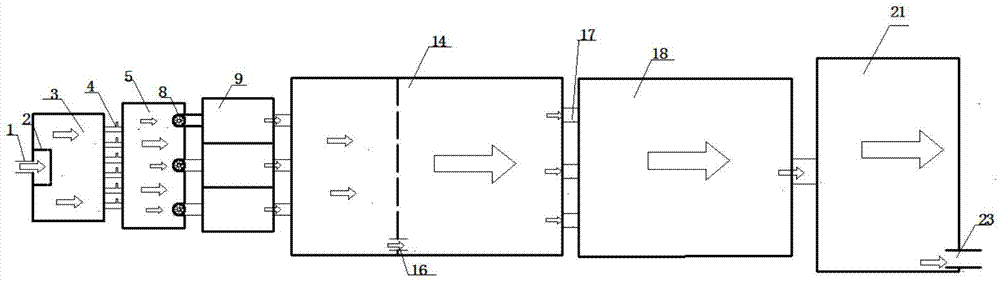

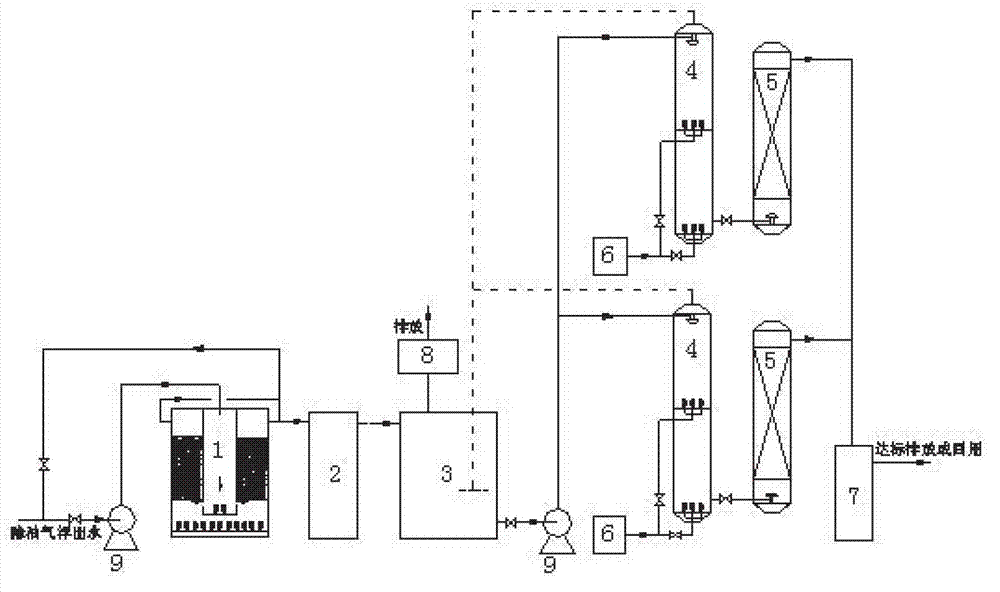

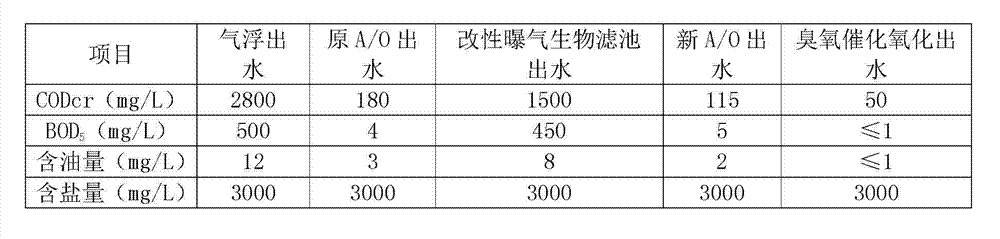

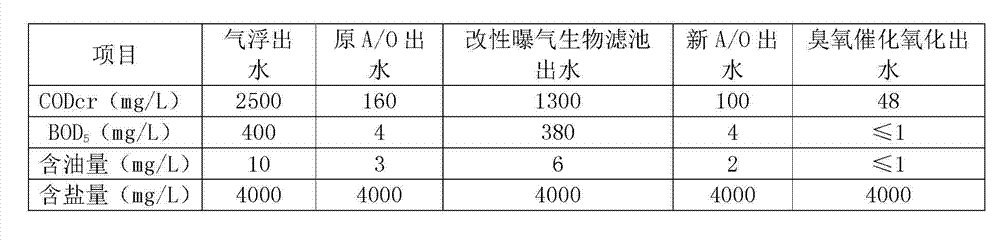

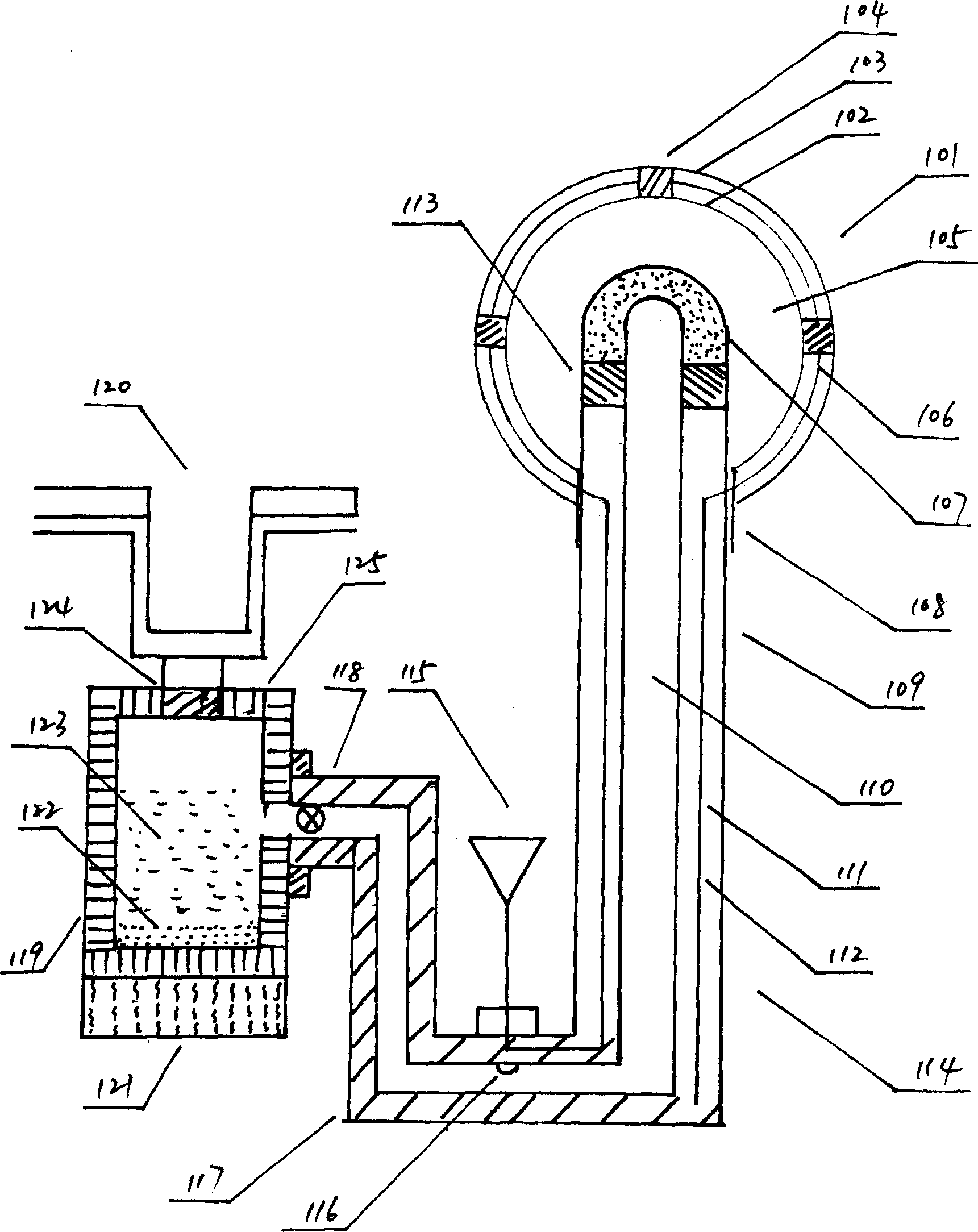

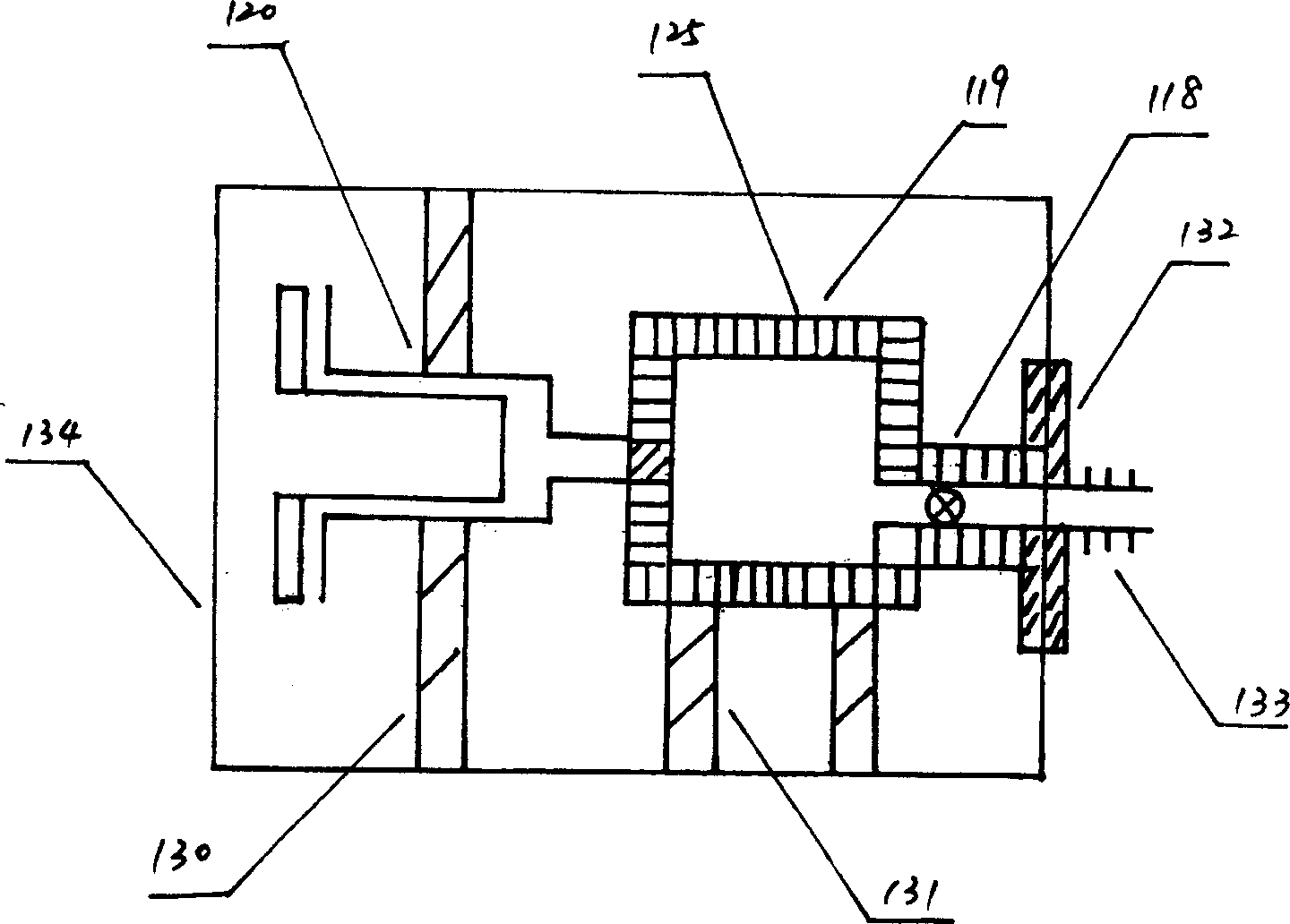

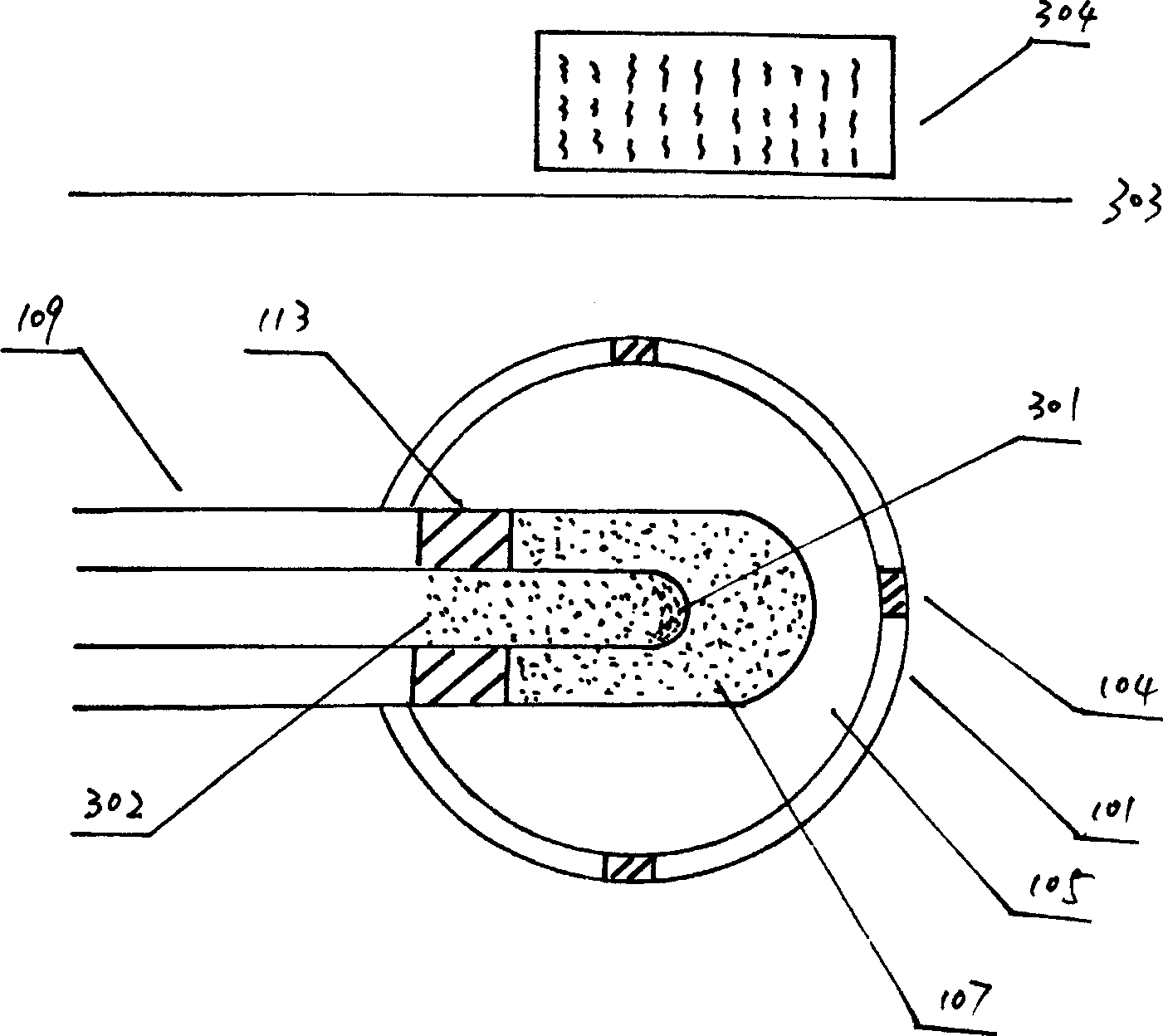

Combined treatment method of oil-refining wastewater containing naphthenic acid

ActiveCN102923913AImprove ozone utilizationEnhance the role of adsorption and enrichment of organic matterWater contaminantsMultistage water/sewage treatmentChemical oxygen demandCatalytic oxidation

The invention relates to a combined treatment method of oil-refining wastewater containing naphthenic acid. The combined treatment method of the oil-refining wastewater containing naphthenic acid is characterized in that a pre-treatment technology is added at the front end of an 'anoxic / oxic' ('A / O') step of an oil removing + A / O process, and an advanced treatment process is added at the back end of the 'A / O' step. Air-floatation oil removing effluent enters a modified biological aerated filter to be pre-treated, a filler is subjected to modification treatment, and the combined treatment method adopts upstream continuous operation. Hydraulic loading is controlled in a range of 1.0-3.0 m<3> / m<2>-h, the temperature is controlled in a range of 25-35 DEG C, the reflux ratio is controlled to be 100-150%, the gas-water ratio is controlled to be 3:1-5:1, and an automatic back washing period is controlled to be 48-72 hours. The effluent of the modified biological aerated filter is subjected to treatment of an 'A / O' biochemical system, enters an intermediate reaction tank and then enters a pre-mixing tower in parallel. The effluent of the pre-mixing tower enters a catalytic oxidation tower to quickly oxidize difficultly-biodegradable organic matter in sewage and reduce chemical oxygen demand (COD) of the sewage, and finally treated effluent enters a clean water pond.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Tumour local comprehensive therepy method and device

InactiveCN1537646ALow temperatureSmall rangeElectrotherapyMedical devicesAbnormal tissue growthMicrosphere

A comprehensive localized therapy method and equipment for tumor features that various endoscopes are used to inject the magnetic immune microspheres carrying biologic medicine and the antineoplastic magnetic chemical medicine into tumor focus, the liquid radioactive source is poured in the inner cavity of catheter, and an alternative magnetic field is generated around the tumor focus to induce the microspheres to generate heat and adsorbing the antineoplastic medicine to round the tumor focus. Its advantage is the combination of biotherapy, chemicotherapy, radiotherapy and thermotherapy.

Owner:高春平

Combined treatment method for oil-containing sludge

ActiveCN103241913AReduce lossesImprove economySludge treatment by de-watering/drying/thickeningResource utilizationPetrochemical

The invention relates to a combined treatment technology for oil-containing sludge, which is particularly suitable for oil-containing sludge which is generated in sewage treatment processes of petrochemical plants. The method comprises: adding a texturizer into the oil-containing sludge for texturizing treatment, adding an oil displacement agent for uniformly mixing, mechanically dehydrating the oil-containing sludge to reduce a water content to 50-90%, then sending the oil-containing sludge into squeezing equipment for squeezing, mixing mud cakes after squeezing with a mixed extractant, uniformly stirring for extraction, sending a mixture into a solid-liquid separator after extraction, introducing a separated liquid into a rectifying tower for regenerating the extractant, and mixing separated solid residue after dried with coal to used as a fuel. The treatment technology of the invention has advantages of low energy consumption for oil-containing sludge treatment, and fast extraction speed, can recover oil in the oil-containing sludge, and can implement resource utilization and harmlessness treatment of the oil-containing sludge.

Owner:PETROCHINA CO LTD

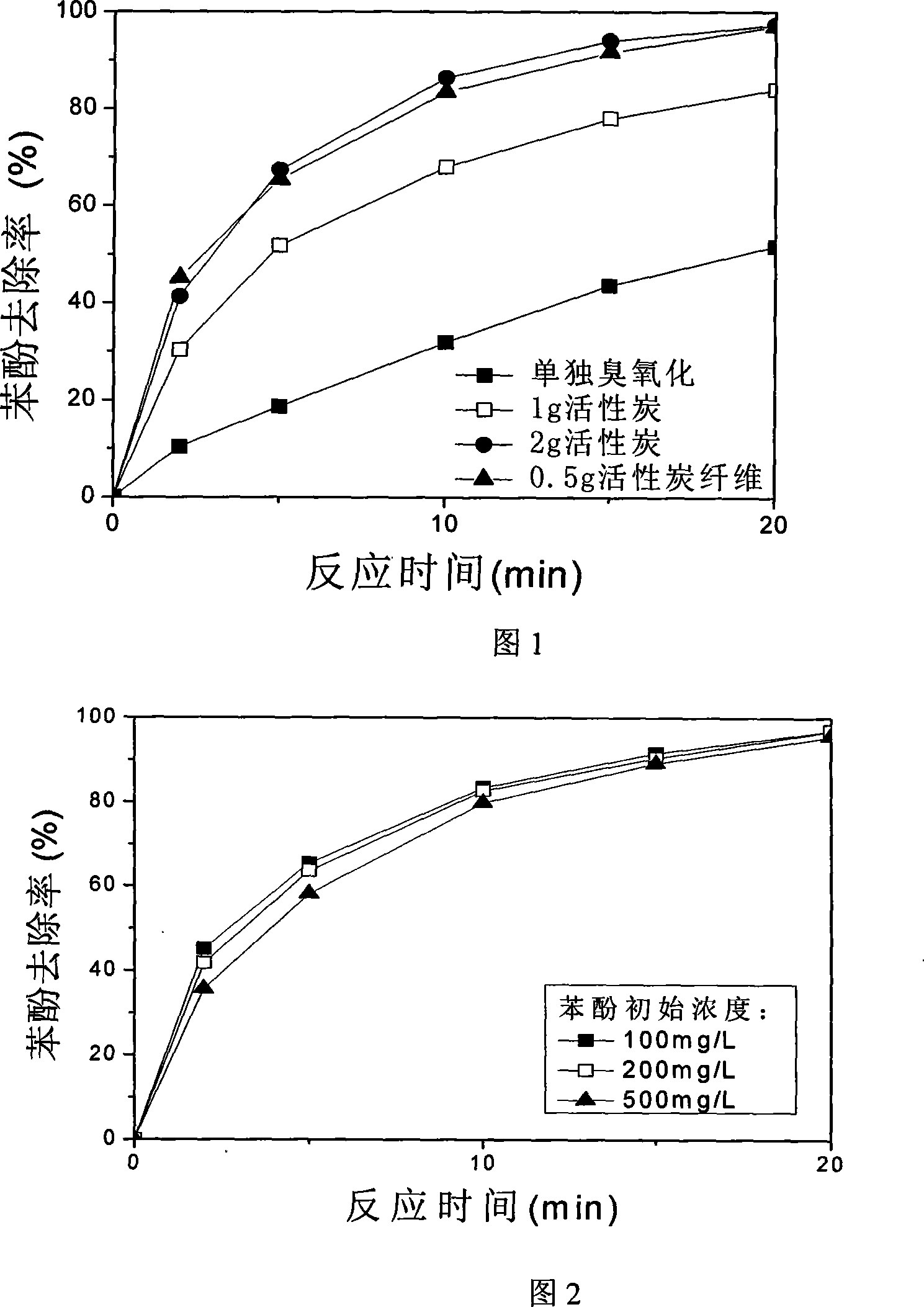

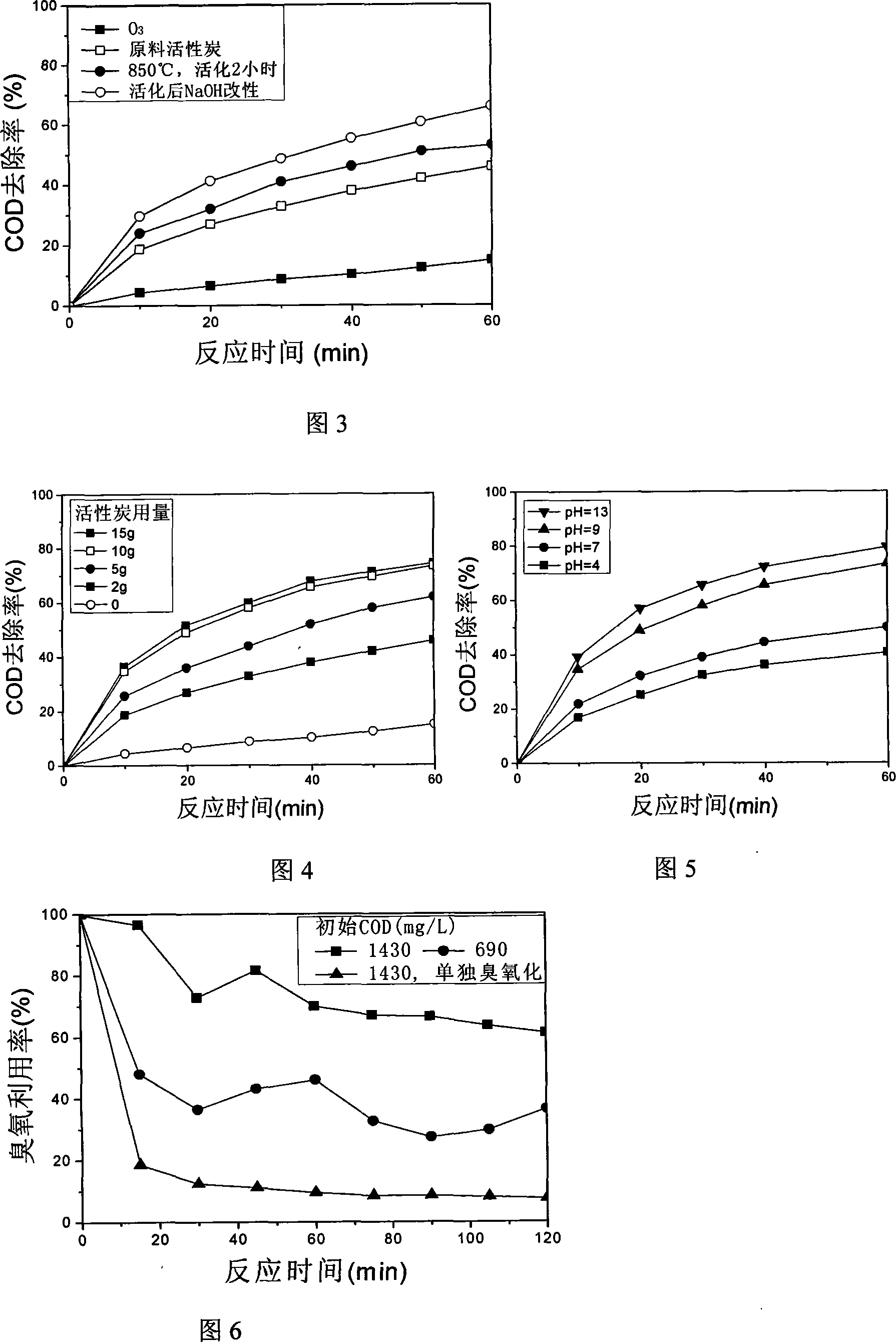

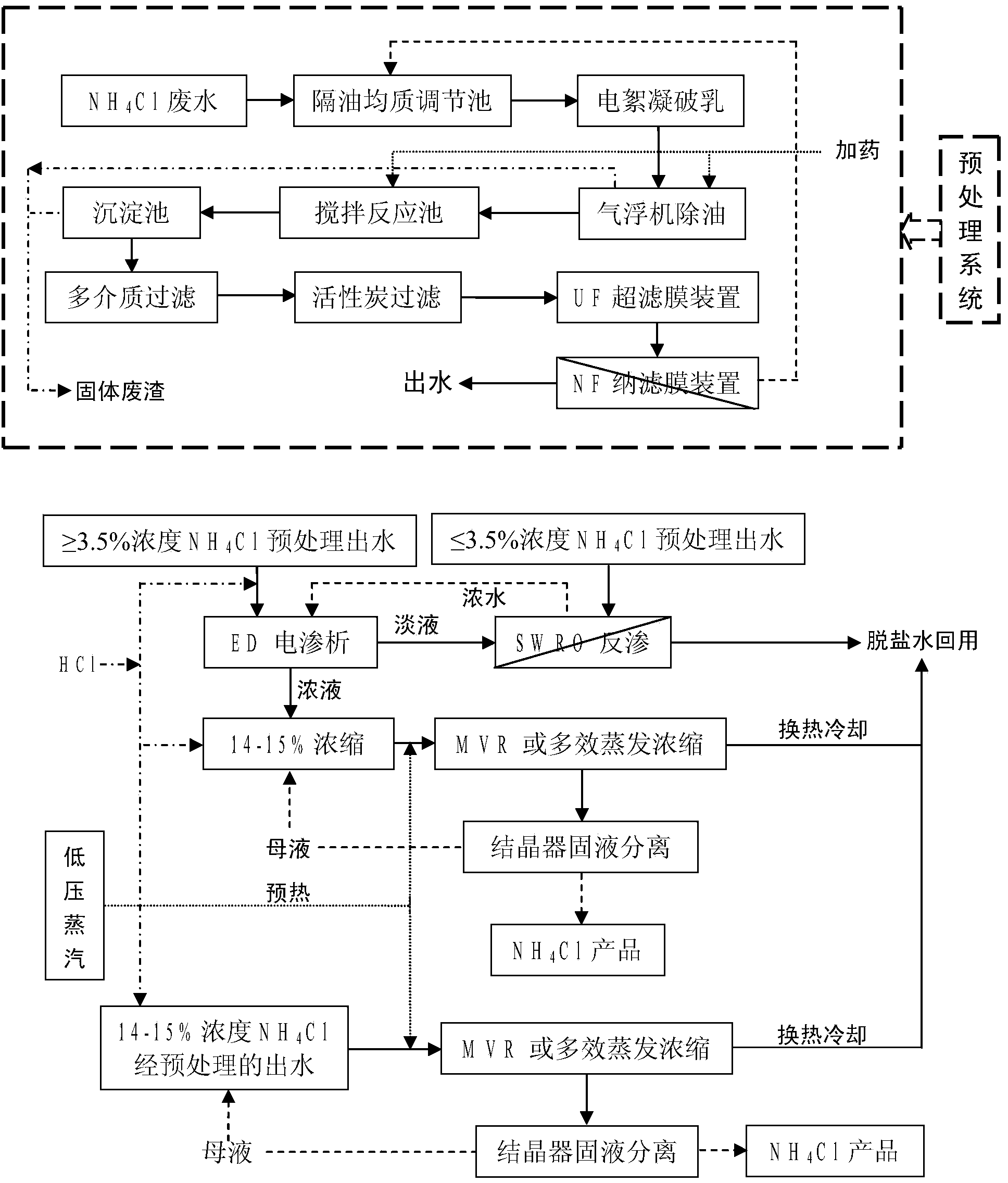

Method for carrying water treatment by active carbon fiber-ozone oxidization combination

InactiveCN101125691AIncrease profitIncrease total removalWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFiberWater vapor

The invention relates to a water combined treatment method of activated carbon fiber and ozone oxidation in water treatment field. The technic proposal is that: the bottom of a reactor is provided with an air distribution board which is connected with an ozonizer and the upper part of the air distribution board is provided with single layer or multi-layer modified activated carbon fiber; activated carbon fiber in the reactor accounting for the amount of waster water is 1-50g / L, ozonization gas concentration is 5-12mg / L and the treatment time is 5-90min; the modification of activated carbon fiber is to put active carbon into a charing activation furnace to be activated secondarily. During the activation process, apart from vapor, carbon dioxide, alkaline gas and one or two sorts of metal salts are chosen as activating agent to increase the ratio of aperture of larger than 0.7-2.5nm on the active carbon surface. The invention can degrade the organic contaminant into carbon dioxide, water and nontoxic byproducts and has the advantages of high efficiency, low cost, simple process, easy operation and no secondary pollution towards the environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

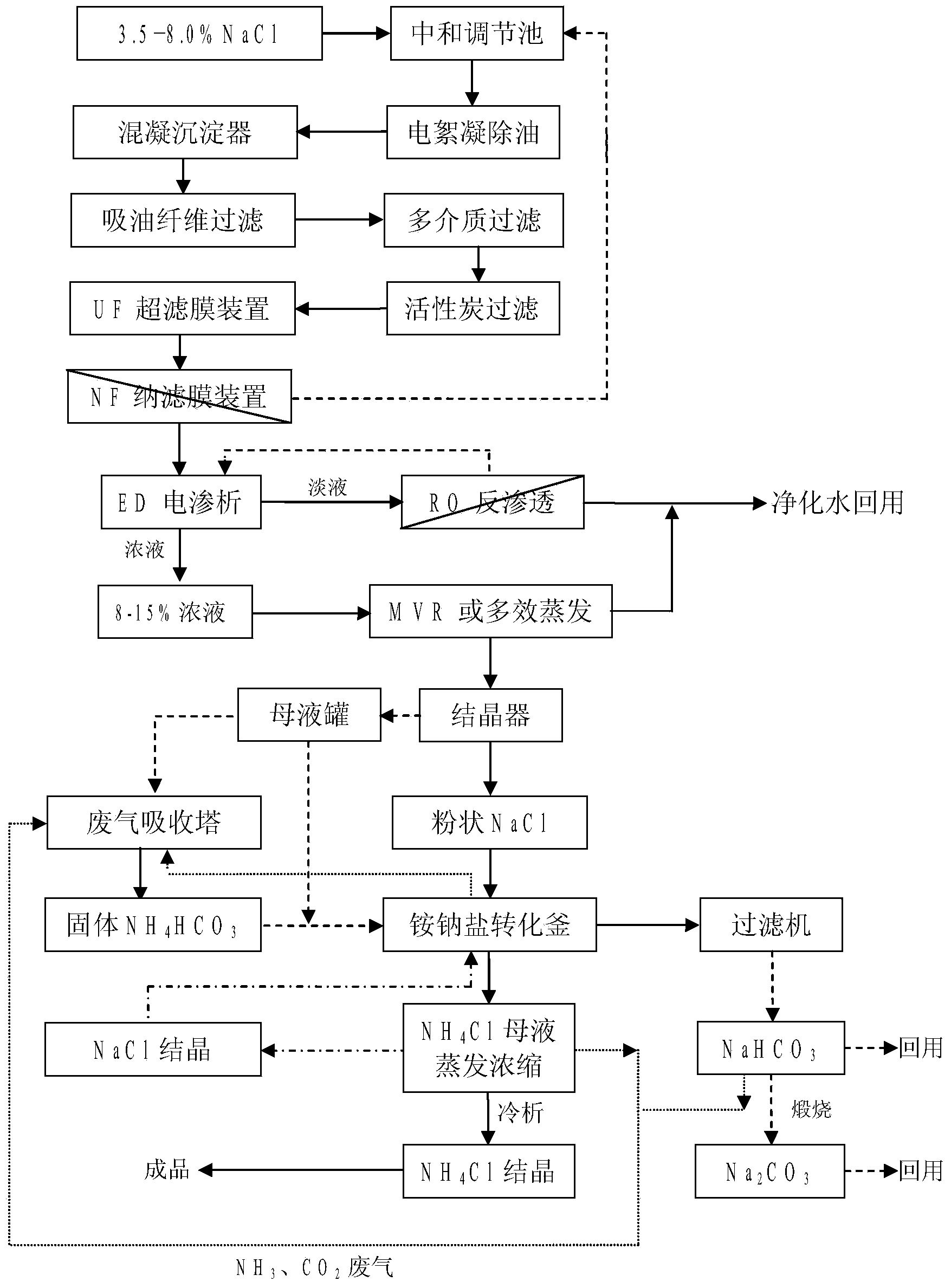

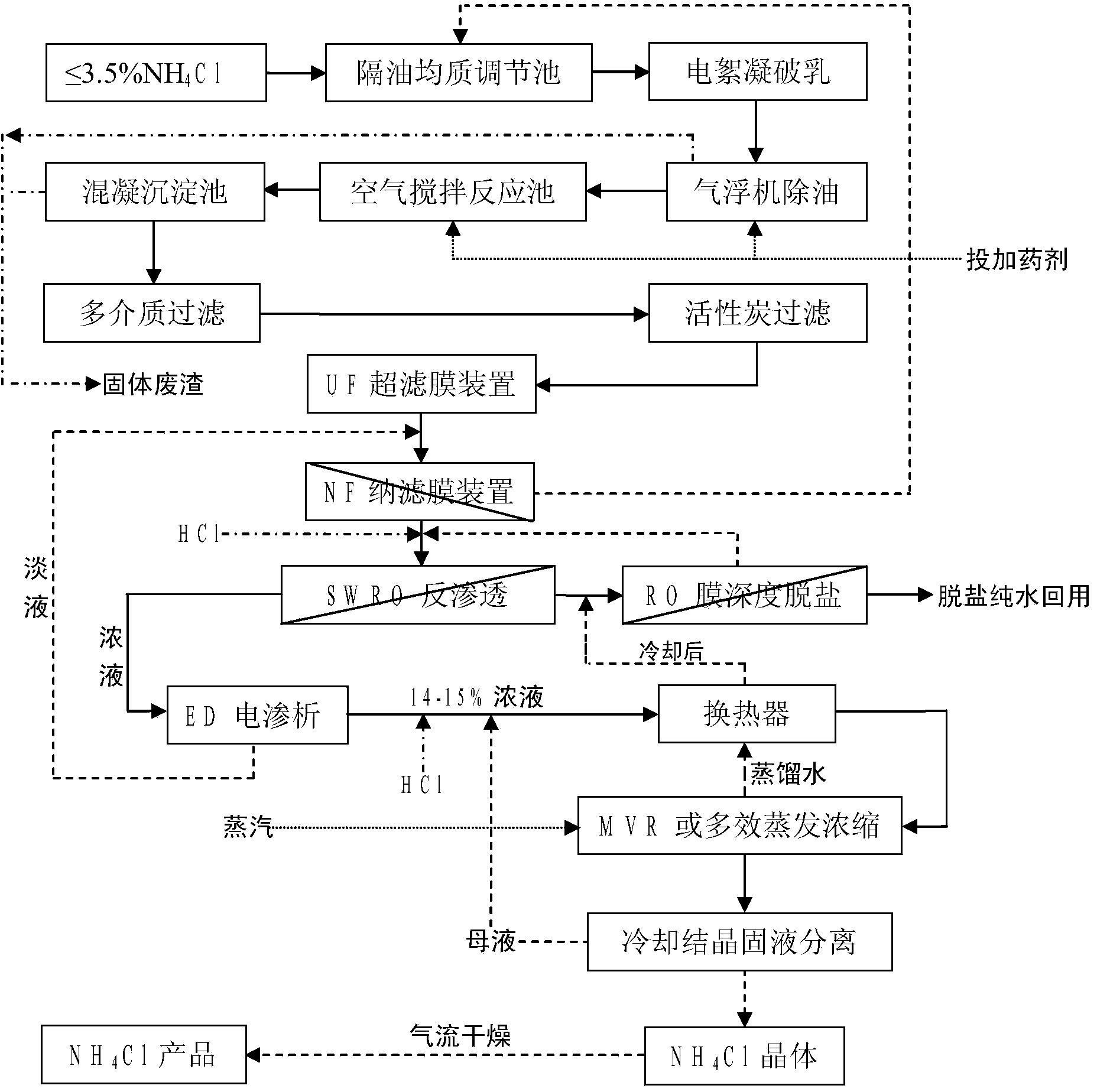

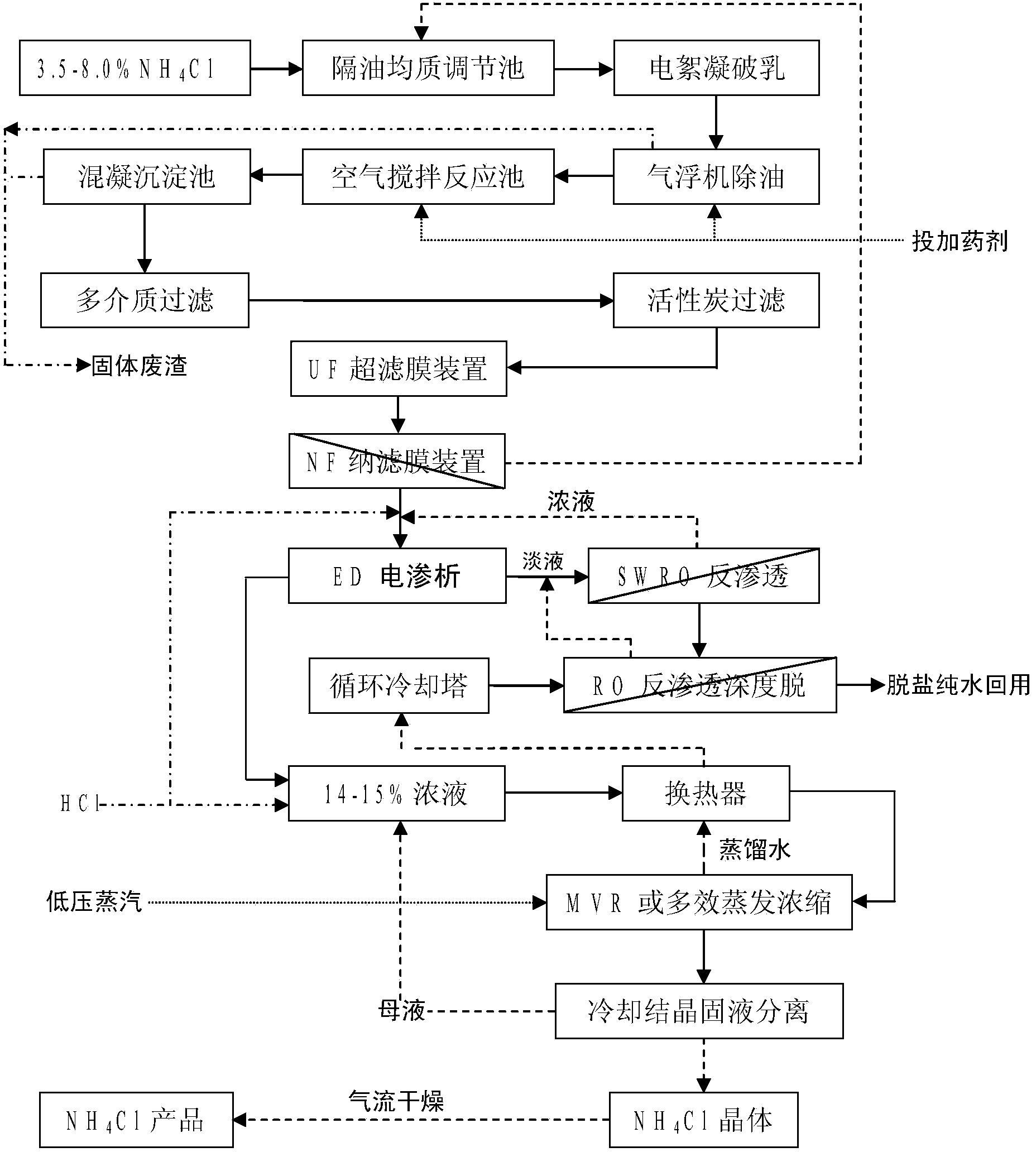

Combined treatment method for ammonia chloride waste water through rare earth extraction separation

InactiveCN104140174AReduce processing costsProduction unit is compactGeneral water supply conservationMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention provides a combined treatment method for ammonia chloride waste water through rare earth extraction separation. The method mainly comprises the steps that the waste water is subjected to a series of desalting and concentration treatment through oil separation, homogenizing, aerating, electric flocculation demulsification, degreasing through an air floating machine, precipitation of calcium, magnesium and heavy metal ions through chemical feeding, microfiltration, ultrafiltration, nanofiltration, reverse osmosis, electrodialysis, evaporation, concentration and the other processes, and then desalted and purified water capable of being utilized cyclically and ammonia chloride products conforming to agricultural standards are obtained. The waste water treatment process is mature, stable and low in treatment cost; production equipment is complete and easy to operate, and automatic industrial control can be easily achieved; zero emission and resource utilization in the treatment process of the ammonia chloride waste water, with different concentrations, generated through rare earth extraction separation are well achieved.

Owner:YANSHAN UNIV

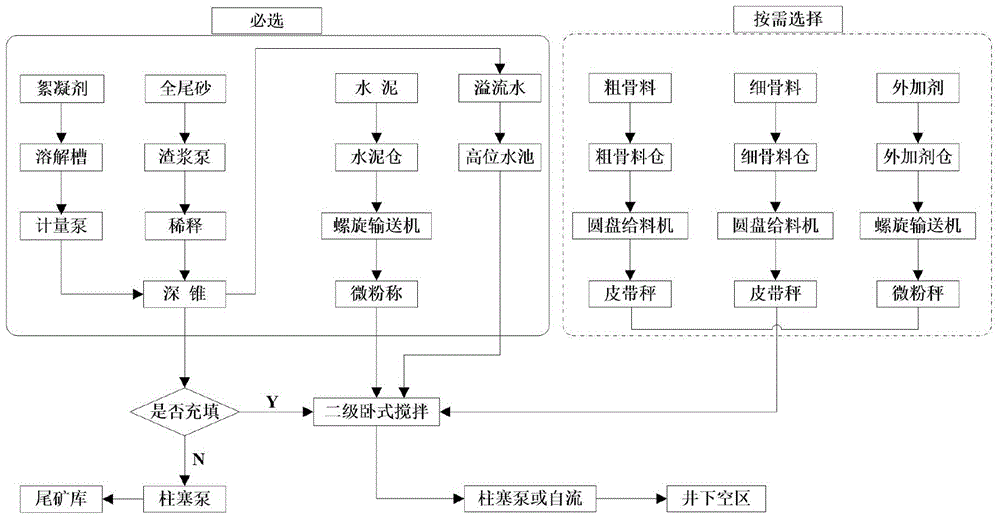

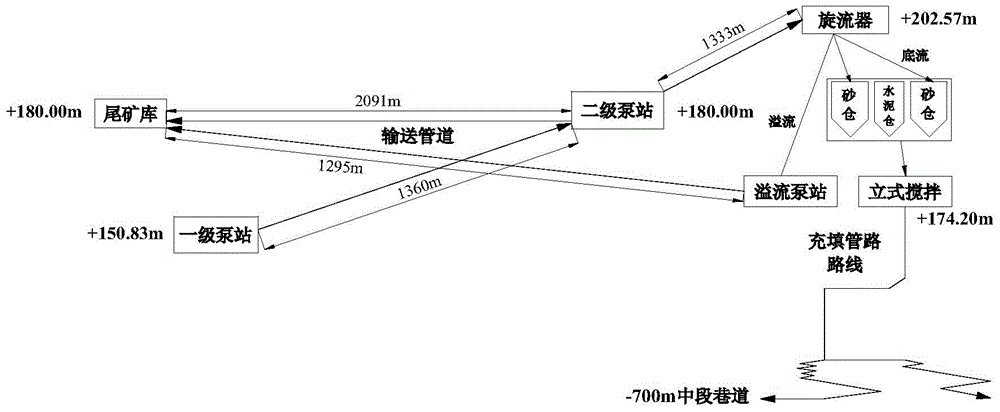

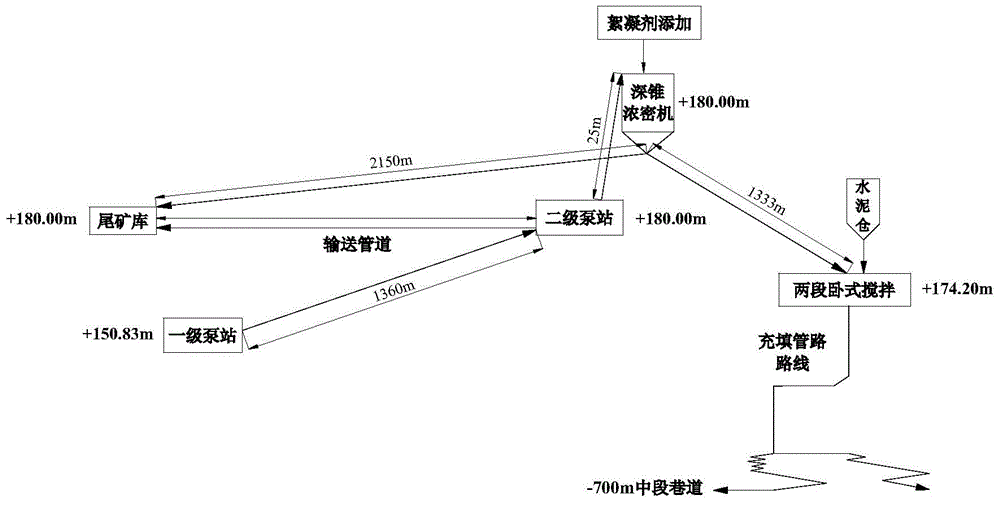

Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

ActiveCN104929683AHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

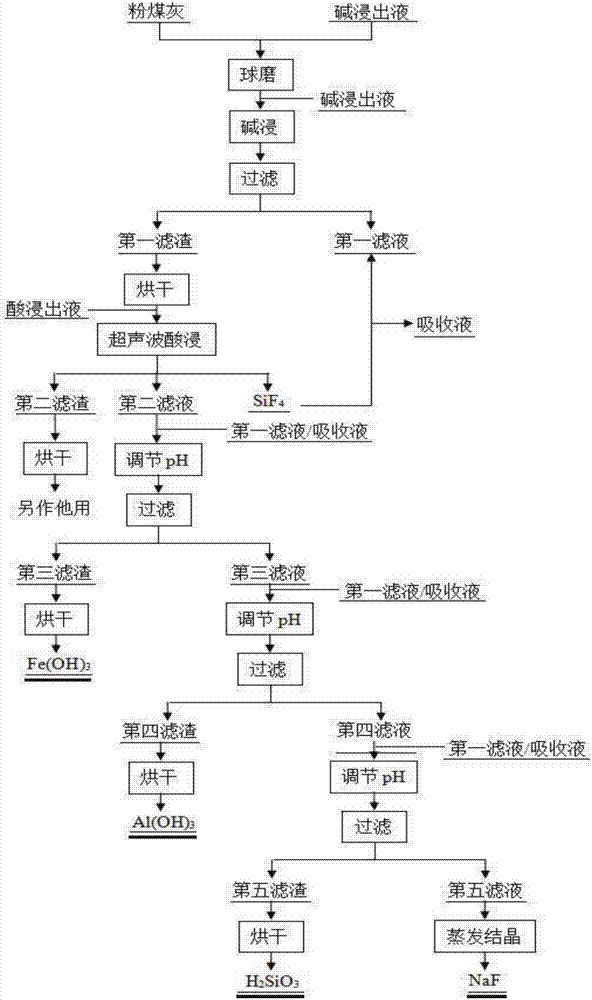

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

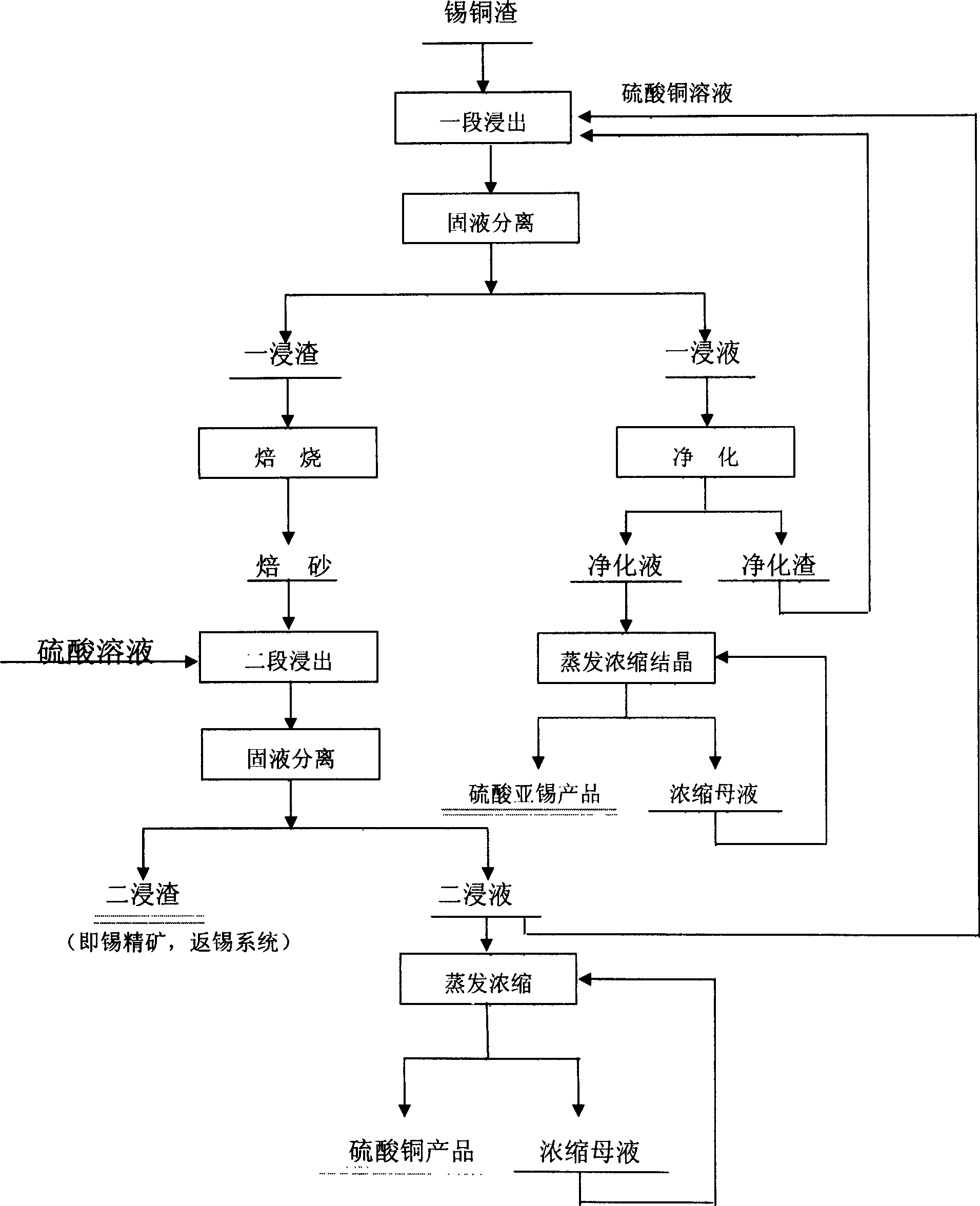

Trentment method of tin copper slag

InactiveCN1786226ASimple processReduce manufacturing costProcess efficiency improvementSulfuric acidCombined treatment method

The invention relates to a tin copper scale fire wet method combining treatment method. It can use simple technique to produce top stannous sulfate product. The tin copper scale is a high tin low copper middle material, packed by tin and copper. The invention combines tin copper scale treatment and stannous sulfate preparing, adopts respectively two segment atmospheric pressure leaching method for copper sulfate test and sulfuric acid solution to effectively separate copper from the tin copper scale, and gain high quality tin fine mineral product, copper sulfate product and stannous sulfate product.

Owner:云南锡业集团有限责任公司

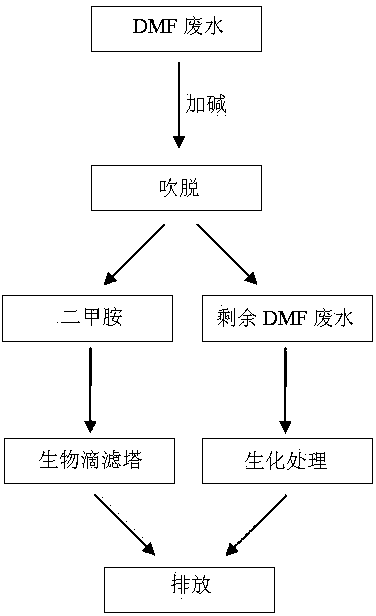

Combined treatment method of N, N-dimethylformamide (DMF) wastewater

InactiveCN103449662AAvoid secondary pollutionImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentN dimethylformamideExisting Treatment

The invention discloses a combined treatment method of N, N-dimethylformamide (DMF) wastewater, relates to the field of environment protection and water pollution treatment, and in particular relates to a combined treatment method for treating the N, N-DMF wastewater. The method specifically comprises the following steps: firstly decomposing the DMF wastewater into dimethylamine and formate under an alkali condition, then carrying out air stripping, introducing the dimethylamine waste gas generated in the air stripping into a bio-trickling tower for treatment, and directly carrying out biochemical treatment on the air-stripped wastewater. According to the combined treatment method disclosed by the invention, a physic-chemical method and a biological method are combined, a feasible process for treating the DMF wastewater is provided, the toxicity of the DMF wastewater is reduced by means of the physical-chemical method, the biodegradability of the DMF wastewater is improved, and the generated dimethylamine organic waste gas and wastewater are subjected to advanced treatment by means of the bio-chemical method. By adopting the combined treatment method disclosed by the invention, the effective and economical treatment of the DMF wastewater is achieved, and the problems of secondary pollution, difficult regeneration, low efficiency and the like easily caused by the existing treatment methods of adsorption, extraction, chemical oxidization and the like are solved.

Owner:NANJING TECH UNIV

A method of lime-fly ash joint treatment of high-concentration fluorine-containing wastewater

InactiveCN102267768APores increasedIncrease in sizeMultistage water/sewage treatmentWater/sewage treatment by sorptionSolution treatmentHigh concentration

The invention discloses a lime-fly ash joint treatment method for high-concentration fluorine-containing wastewater, which comprises the following steps: lime primary precipitation treatment stage: the temperature is 10°C, the amount of lime added is 0.1-0.2g per 50mL of fluorine-containing wastewater, Adsorption time is 30-60min, pH is 5.0-8.0; fly ash secondary adsorption treatment stage: temperature is 15°C-45°C, fly ash addition is 5.0-15.0g per 50mL fluorine-containing wastewater, adsorption time is 60- 120 minutes, pH is 5.0-7.0, and the fly ash has been modified by acid solution in advance. The modified fly ash is used for industrial wastewater treatment to improve the utilization rate and effect of the fly ash, and the fly ash is a renewable material, which can be recycled through pickling and other processes.

Owner:NORTHWEST A & F UNIV +1

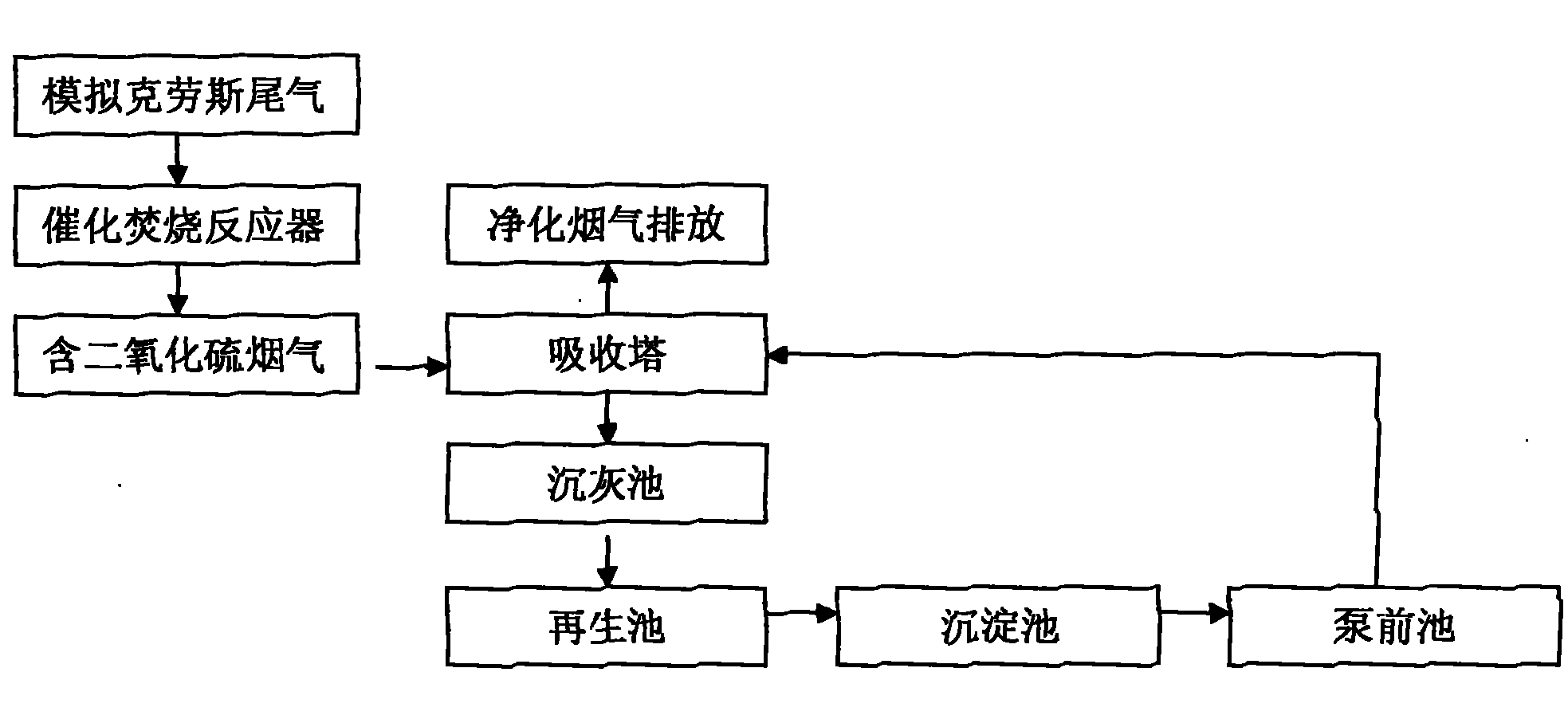

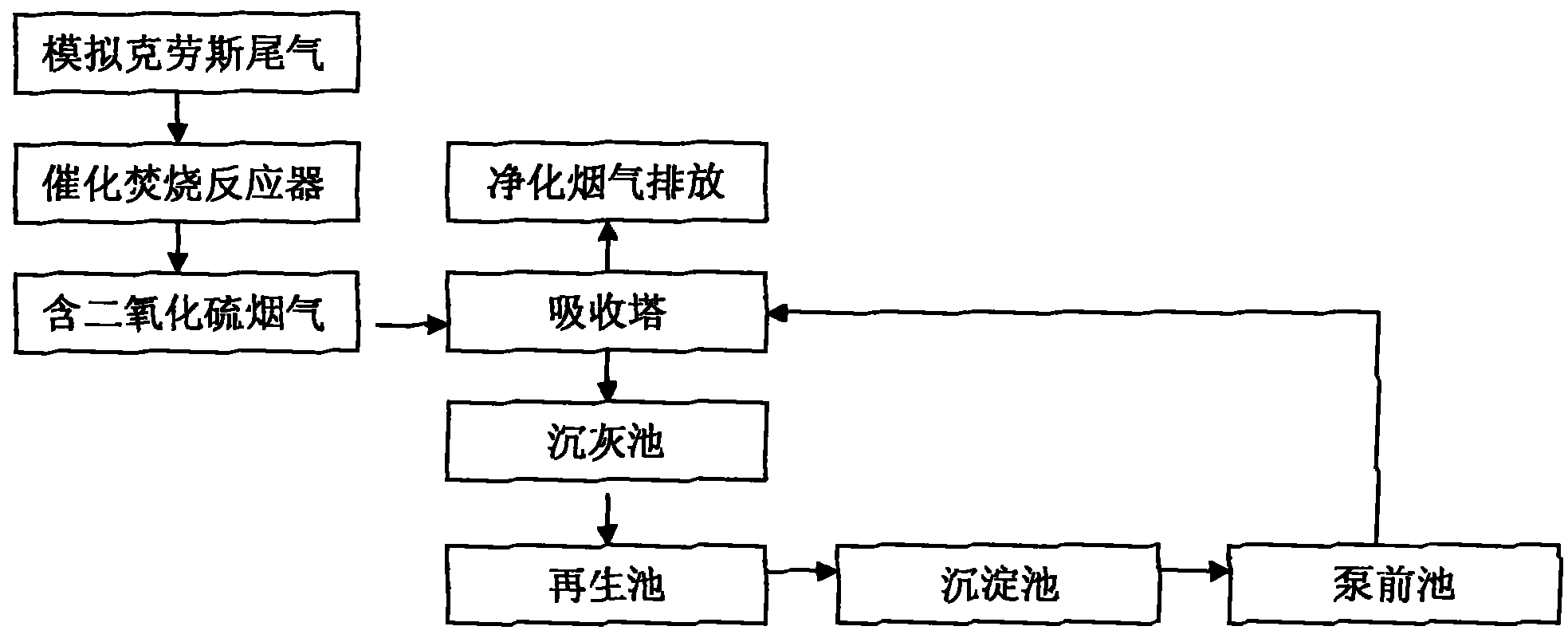

Combined treatment method for waste gas containing sulfur compounds

The invention discloses a combined treatment method for waste gas containing sulfur compounds. The method comprises the following steps of: mixing the waste gas containing the sulfur compounds and air, delivering the preheated gas to a catalytic incineration reactor, and performing catalytic incineration operation at the temperature of between 150 and 450 DEG C under the conditions that the space velocity is 1,000 to 35,000h<-1> and the peroxide coefficient is 0.5 to 8.0; delivering the flue gas formed after catalytic incineration to an absorption tower after heat exchange and cooling, discharging the desulfurized and washed purified flue gas, delivering the desulfurized and washed slurry to a regeneration tank provided with a stirring device, performing regeneration reaction on the slurry and regeneration alkali, delivering the reaction product to a sedimentation tank, overflowing the clarified liquid in the sedimentation tank to a pre-pumping tank, recycling the alkali supplemented clarified liquid to a desulfurization tower, and regularly clearing the settled calcium sulfite, calcium sulfate and calcium carbonate. By the method, hydrogen sulfide and organic sulfides in the waste gas containing the sulfur compounds can be efficiently converted into sulfur dioxide, and the sulfur dioxide is recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

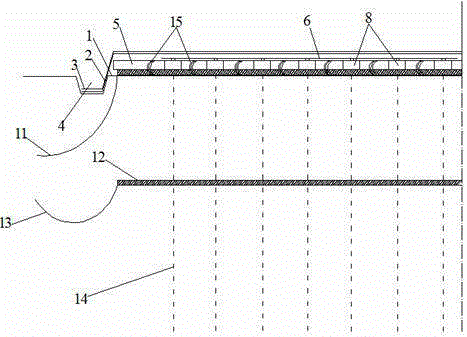

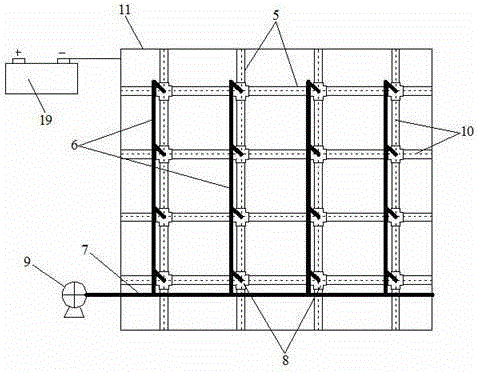

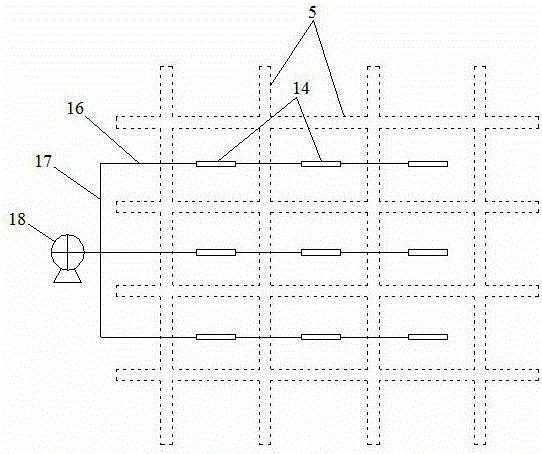

Saturated dredger soft soil foundation reinforcing treatment system and grid-type vacuum preloading and electroosmosis-method combined treatment method

ActiveCN105256788AConsistent seepage pathImprove processing efficiencySoil preservationCombined methodEngineering

The invention discloses a saturated dredger soft soil foundation reinforcing treatment system and a grid-type vacuum preloading and electroosmosis-method combined treatment method. The problems that when a saturated dredger soft soil foundation is treated with an existing vacuum preloading and electroosmosis combined method, the water content of saturated dredger soft soil in the construction initial stage is large, strength is quite low, and therefore workers and machines can not enter a site easily are solved. According to the treatment system and the treatment method, superficial-layer foundation treatment is carried out through a transverse water draining system and an electroosmosis system in the earlier construction stage, and deep-layer foundation reinforcing is carried out through a vertical water draining system in the later stage. Electrodes are vertically arranged, the electroosmosis flow direction of pore water and the vacuum osmosis flow direction of the transverse water draining system are overlapped accordingly, and the treatment efficiency of the vacuum preloading and electroosmosis combined method is improved to the maximum degree; and the superficial layer and the deep layer of the foundation can be reinforced through the arranging manner of the water draining systems. The treatment system and the treatment method have the beneficial effects of being convenient to construct, efficient in treatment and the like, electroosmosis and vacuum preloading are subjected to beneficial effect complementing, and the treatment system and the treatment method are suitable for reinforcing large-area saturated dredger soft soil foundations.

Owner:SHANGHAI UNIV

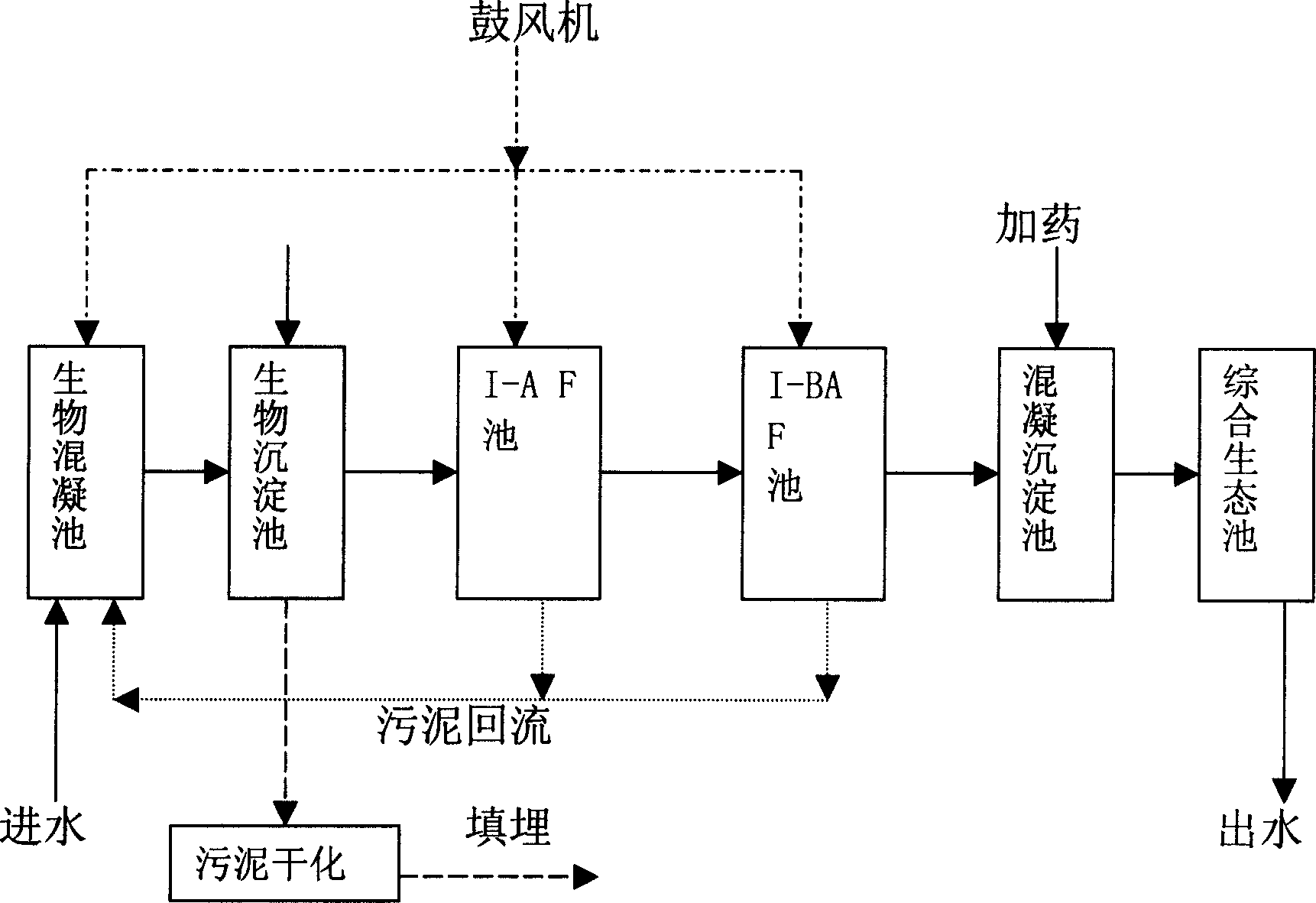

Combined treatment method and system for landfill leachate

InactiveCN1631820AEasy to handleStabilizationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiltrationWater quality

Disclosed are a method for processing rubbish percolating water and its system. The processing technique realizes the procession by combining the procession, biological processing technology and ecological procession. The system mainly comprises of adjusting pool, biological coagulation pool, high effective biological filtration pool, comprehensive ecological pool and so on. Compared with the present technology, it has rapid processing speed, high quality of water processed which can reach the first-class drainage standard, and can realize naugh drainage of waste water in rubbish processing factory.

Owner:PEKING UNIV

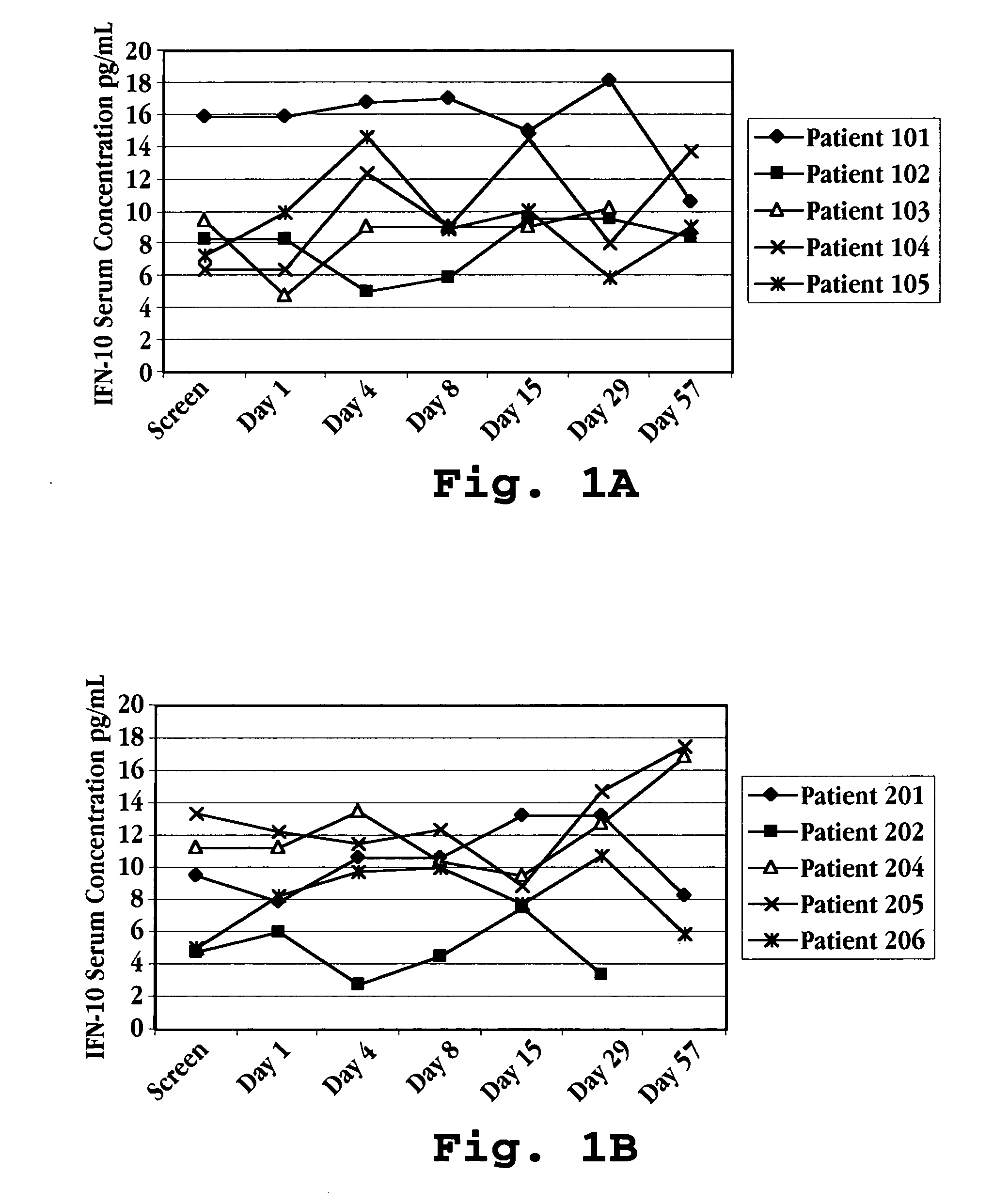

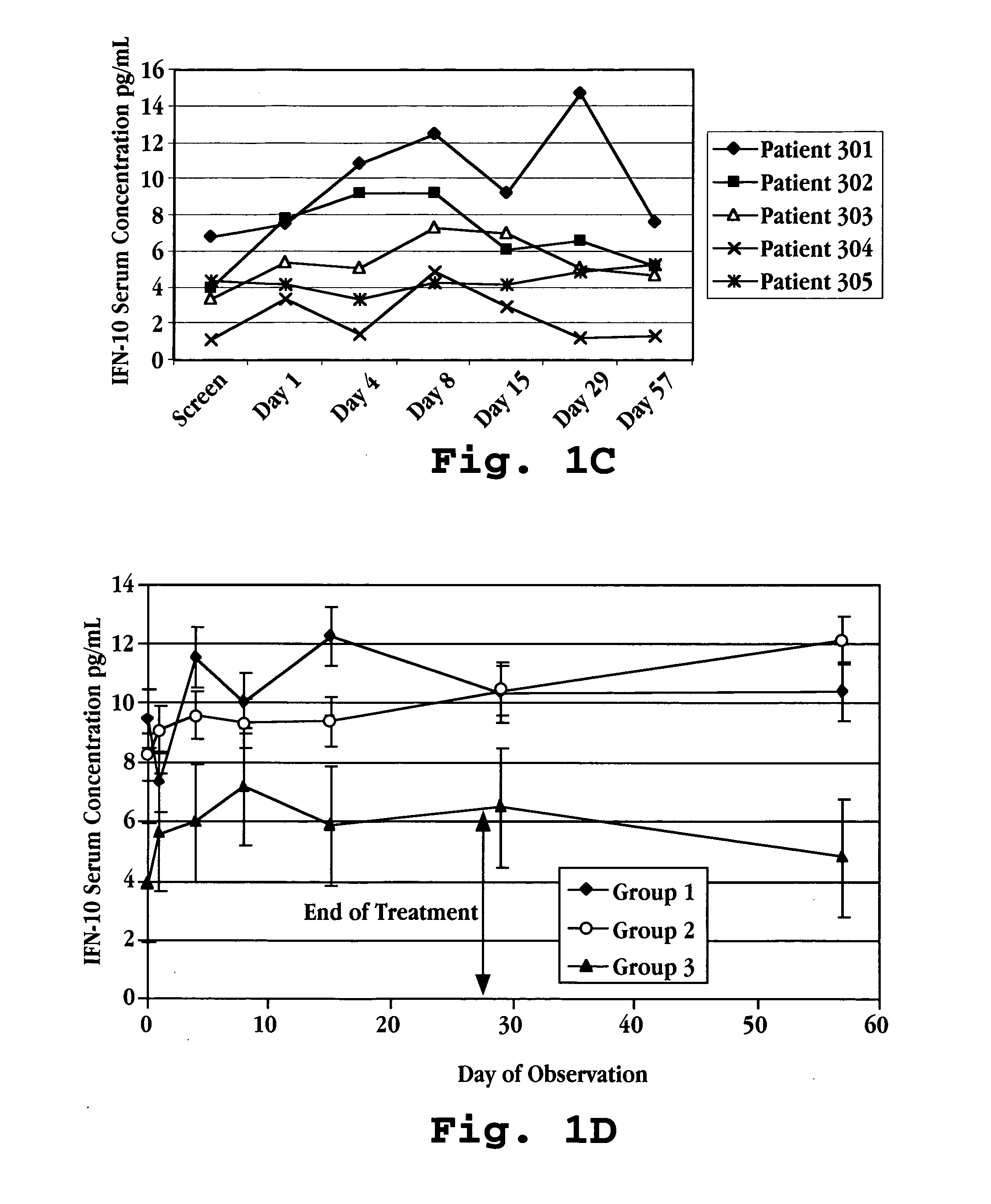

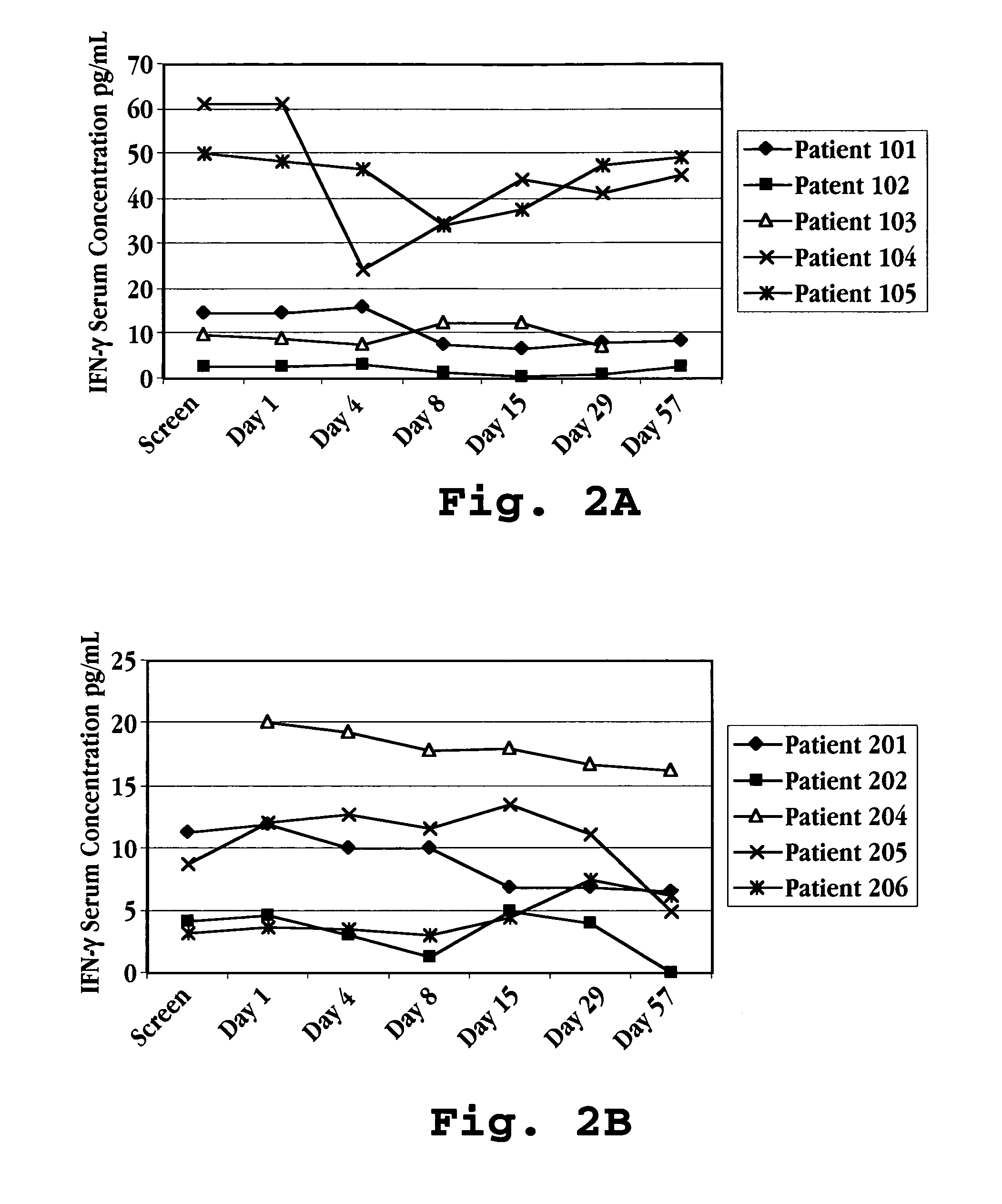

Combination therapy using interferon-tau

InactiveUS20050084478A1Relieve symptomsInhibit progressBiocidePeptide/protein ingredientsAutoimmune conditionRegimen

Methods of treatment comprised of a combination treatment regimen of interferon-tau (IFNτ) and one or more additional agents are described. In the combined treatment method, IFNτ is orally administered to the patient. One or more additional treatment agents are administered prior to, concurrent with, or subsequent to oral administration of IFNτ. In one embodiment, the combined treatment regimen is for treatment of an autoimmune condition, such as multiple sclerosis, and interferon-tau is administered in combination with a second therapeutic, autoimmune treatment agent. In another embodiment, the combined treatment regimen involves administering an agent that protects or stabilizes interferon-tau after oral administration, optionally in combination with another treatment agent.

Owner:PEPGEN CORP

Physicochemical and biochemical combined treatment method of fracturing backflow liquid

ActiveCN104108833AReduce processing costsSimple processWaste water treatment from quariesMultistage water/sewage treatmentSuspended particlesAluminium chlorohydrate

The invention provides a physicochemical and biochemical combined treatment method of fracturing backflow liquid. The physicochemical and biochemical combined treatment method comprises the following steps of: (1) introducing the fracturing backflow liquid into a regulating sedimentation tank, and controlling the pH value of the fracturing backflow liquid to 6-8, wherein the hydraulic retention time of the fracturing backflow liquid is 2-4 hours in the regulating sedimentation tank; (2) introducing a supernatant from the regulating sedimentation tank into a coagulation sedimentation tank, adding a polyaluminium chloride water solution and a polyacrylamide water solution to the coagulation sedimentation tank, depositing to remove suspended particles out of waste water inside the coagulation sedimentation tank, introducing the supernatant from the coagulation sedimentation tank into an intermediate tank, and regulating the CODconcentration of the waste water inside the intermediate tank to 800-1200mg / L; (3) treating the waste water from the intermediate tank into an aerobic fluidized bed membrane bioreactor in which biological membrane culture is completed, wherein the aerobic fluidized bed membrane bioreactor operates in a way of a continuous water feeding and continuous drainage under the condition of aeration, and the treated waste water is discharged after passing through the membrane assembly of the aerobic fluidized bed membrane bioreactor.

Owner:SICHUAN UNIV

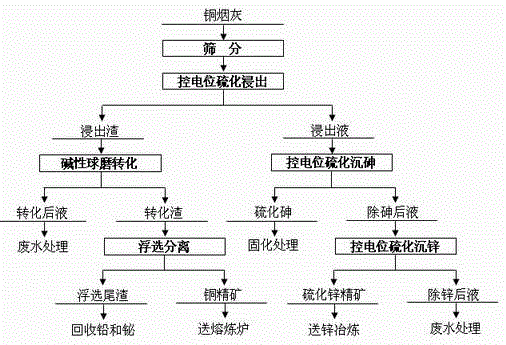

Copper soot smelting and separation combined treatment method

InactiveCN105624412AEasy to separateEasy to controlProcess efficiency improvementArsenic compoundsSlagFiltration

The invention discloses a copper soot smelting and separation combined treatment method. Copper soot is leached in water solution after ball milling to a requested particle size; sodium sulfide is added to control the metal ion mixed potential of whole pulp at a requested numerical value; meanwhile, sulfuric acid is added to adjust the pH value of the pulp to keep at a requested numerical value; after the solution potential is stabilized, and the stirring is continued by a period of time, the filtration is performed; the leaching liquid controls the metal ion mixed potential and the pH value; arsenic sulfide and zinc sulfide precipitates are respectively prepared to send to waste water for treatment; and leaching slag directly performs flotation to prepare copper concentrate and flotation tailing after alkaline ball milling conversion. The method recovers valuable metal step by step by using a control potential vulcanization leaching and beneficiation combined method; the processes are tightly associated; and single process cannot achieve the desired effect of selection and separation of the valuable metal in copper soot. The leaching rates of arsenic and zinc both reach above 95.0%; and the direct recovery rate of copper reaches above 98.0%.

Owner:CENT SOUTH UNIV

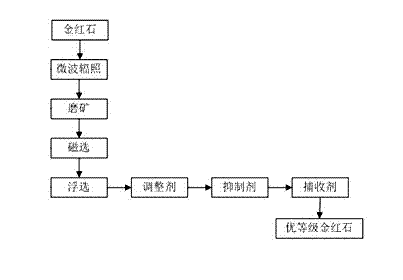

Method for raising grade of rutile by adopting microwave irradiation-magnetic separation-floatation combined process

InactiveCN102357404ANo pollution in the processSimple processing methodFlotationWet separationPhysical chemistryMineralogy

The invention discloses a method for raising the grade of rutile by adopting a microwave irradiation-magnetic separation-floatation combined process, belonging to the field of ore processing. The method comprises the following steps of: putting dried rutile ore into microwave equipment for radiating for 20-60 seconds, quickly cooling with water 20-60 seconds later, performing ore grinding for 40-60 minutes, and magnetically separating the ground rutile ore to obtain iron concentrated ore and enriched rutile ore; and adding a regulating agent into the enriched rutile ore, adjusting the pH value of the rutile ore to 2-3, and adding an inhibiting agent and a collecting agent for floating for 3-8 minutes. Due to the adoption of the microwave irradiation-magnetic separation-floatation combined treatment method, impurities in the rutile ore can be removed, TiO2 in the rutile ore is enriched, the grade of the rutile ore is raised, and rutile ore meeting the industrial premium grade standard can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

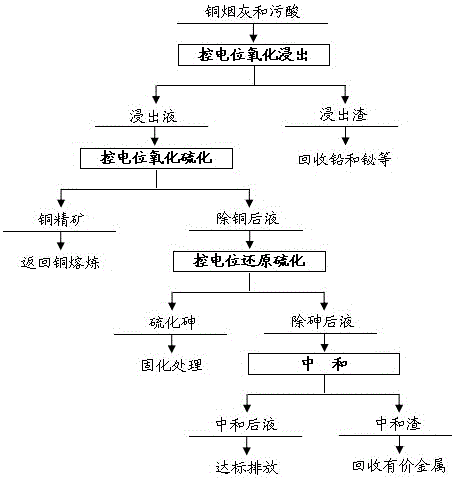

Combined treatment method for copper smelting soot and polluted acid

InactiveCN105950874AEasy to separateAvoid consumptionProcess efficiency improvementCopper sulfideSoot

The invention discloses a combined treatment method for copper smelting soot and polluted acid. The method includes the steps that after the copper smelting soot and the polluted acid are mixed for pulp conditioning, an oxidizing agent is added for controlled-potential oxidization leaching, so that copper, arsenic, zinc and other metal in the copper soot are dissolved to enter leachate, and lead, bismuth and other metal are precipitated to enter a reaching residue; then an oxidizing agent is added into the leachate so that As(III) in the solution can be completely oxidized into As(V); afterwards, sodium sulphide is added, so that the copper in the solution is precipitated in the form of copper sulphide to produce copper concentrate, and a reducing agent is added into the copper-removed solution so that the As(V) in the solution can be completely reduced into As (III); then sodium sulphide is added so that the arsenic in the solution can be precipitated in the form of arsenic sulfide; and finally the arsenic-removed solution is neutralized with alkaline and then is discharged after reaching the standard. By the adoption of the combined treatment method, controlled-potential oxidization leaching, controlled-potential oxidization sulfurization and reduction sulfurization are simultaneously combined to be used for step-by-step separation and recovery of valuable metal in the copper smelting soot and polluted acid, and therefore waste in the system can be recycled, and the purpose of using waste to treat waste is achieved.

Owner:CENT SOUTH UNIV

Combined treatment method for used water glass sand reclamation and reclamation treating liquid concentration

ActiveCN102974757AHigh removal rateEasy to handleMould handling/dressing devicesSoil scienceWater vapor

The invention relates to a combined treatment method for used water glass sand reclamation and reclamation treating liquid concentration. The combined treatment method comprises the steps of: adding used water glass sand reclamation treating liquid into a concentration device, and placing used water glass sand into a used water glass sand reclamation device; leading in water vapor being 100 DEG C or water vapor being above g 100 DEG C to the concentration device, heating, evaporating and concentrating the used water glass sand reclamation treating liquid; discharging secondary vapor from the concentration device to lead into the used water glass sand reclamation device; and spraying and leaching the used water glass sand with the led-in vapor, so as to obtain the reclaimed water glass sand. According to the combined treatment method for the used water glass sand reclamation and liquid concentration treatment, the removal rate on the residual adhesive films of the used sand is high, and the treating effect is good, the reclaimed sand subjected to dewatering and drying treatment can meet the casting requirement; and the water consumption is little, concentrated waste water is simply and feasibly utilized, the energy consumption is little, and the water glass sand can be effectively reclaimed and utilized, thereby saving resources and lowering the cost.

Owner:WUHAN TEXTILE UNIV

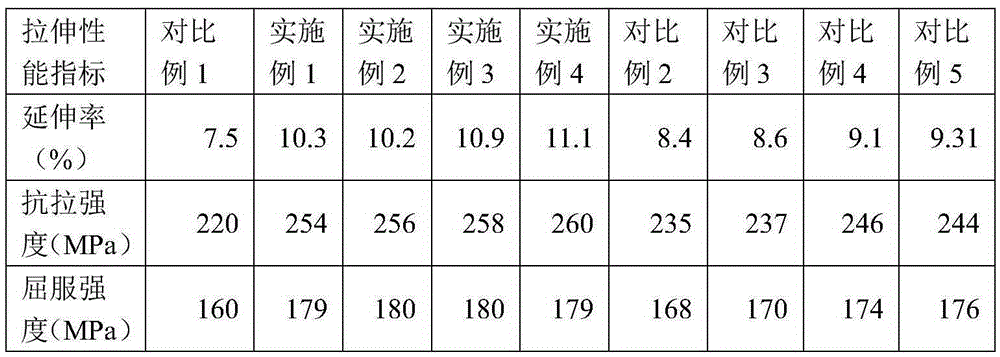

Copious cooling and magnetic field treating method for improving plastic processing performance of magnesium alloy

The invention provides a copious cooling and magnetic field treating method for improving the plastic processing performance of magnesium alloy. A magnesium alloy sample undergoes magnetic field treatment at constant low temperature after being cooled to ultralow temperature through liquid nitrogen according to a certain cooling speed, keeps insulated for a certain period of time at the constant low temperature, is heated to tempering temperature after recovering to indoor temperature according to a certain warming speed and finally is naturally cooled to the indoor temperature with a furnace when the tempering insulation time is up. According to the invention, the indoor temperature plastic processing performance of the magnesium alloy can be improved by weakening the basal texture of the magnesium alloy through special copious cooling treatment and the magnetic field combined treatment method under the copious cooling condition, especially the copious cooling and magnetic field coupling effect. The copious cooling and magnetic field treating method has the advantages of being low in investment and remarkable in effect.

Owner:常熟市麻先生服饰贸易有限公司

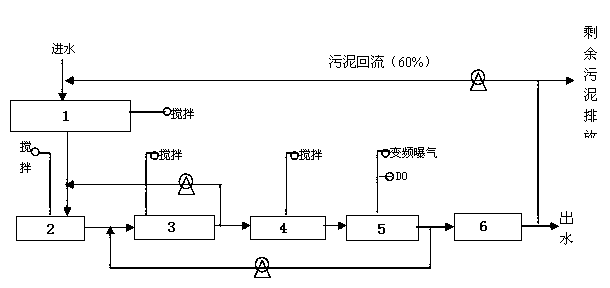

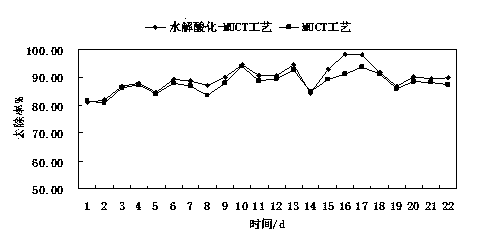

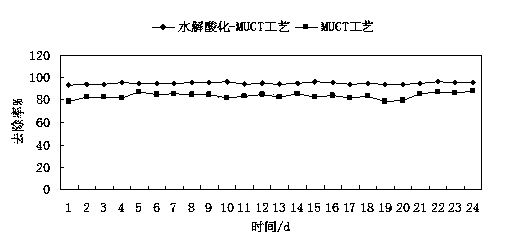

Hydrolytic acidification-MUCT combined treatment apparatus and method for high-concentration organic waste water

InactiveCN103992006AEasy to handleReduce organic contentWater contaminantsMultistage water/sewage treatmentSludgeHydrolysis

The invention discloses a hydrolytic acidification-MUCT combined treatment apparatus and method for high-concentration organic waste water, which belongs to the technical fields of waste water treatment and environmental protection. The hydrolytic acidification-MUCT combined treatment method is an improvement of a traditional MUCT treatment method for waste water, carries out hydrolytic acidification before MUCT treatment and allows sludge in a sedimentation basin to partially return to a hydrolytic acidification tank according to a designed sludge return quantity, thereby improving waste water treatment efficiency, reducing residual sludge amount and effectively saving treatment and disposal cost for residual sludge.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

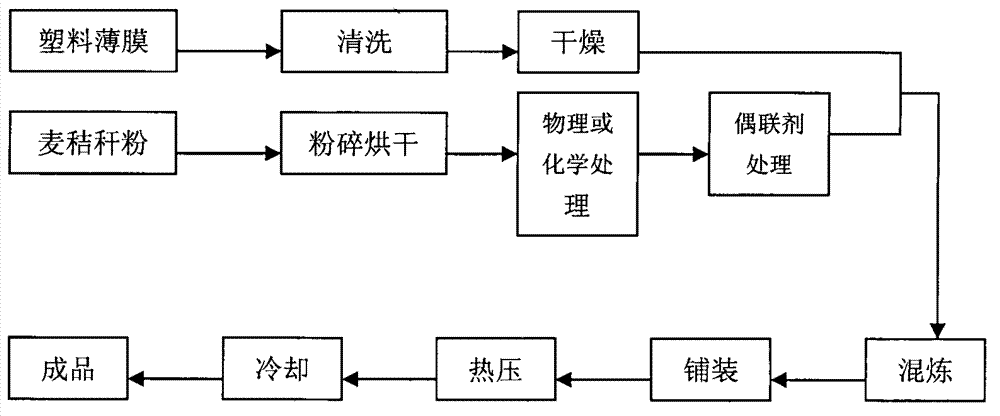

Process for preparing wheat straw/plastic film composite material

InactiveCN102863693AHigh market cost performanceSolve the shortcomings of not easy to bondRaw material divisionFiberCompression molding

The invention relates to a process for preparing a wheat straw / plastic film composite material. According to the process, a plastic film of the composite material is reinforced through wheat straw fibers, a combined treatment method (that is, wheat straw is treated through a physical or chemical method, and then a combined coupling agent is used) is used for conducting surface treatment on wheat straw fibers, the interface bonding strength between wheat straw fibers and a plastic matrix is improved, and the wheat straw / plastic film composite material can be manufactured through technologies such as melt blending and compression molding. The process has the advantages that compared with wheat straw / plastic film composite materials which are treated by a coupling agent merely, the mechanical property and the moisture-absorption water-absorption resistance of the composite material which is subjected to combined treatment are greatly improved, the frictional wear performance of the composite material is better than that of composite materials which are prepared by wheat straw and treated by the coupling agent merely. The composite material is prepared for packaging plastic films and agricultural waste and has significant realistic meaning in terms of environmental protection and resource recycling.

Owner:NANJING AGRICULTURAL UNIVERSITY

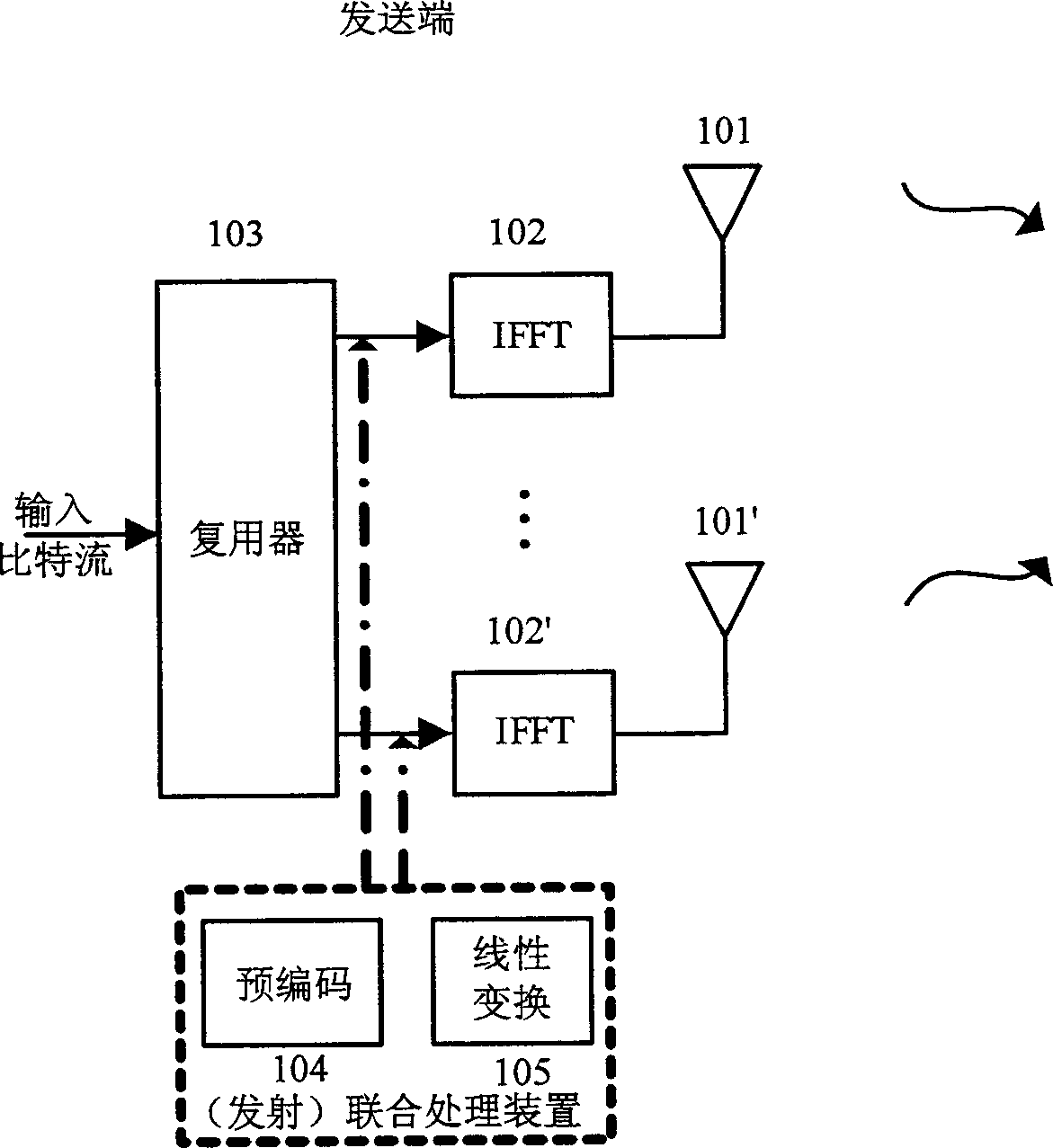

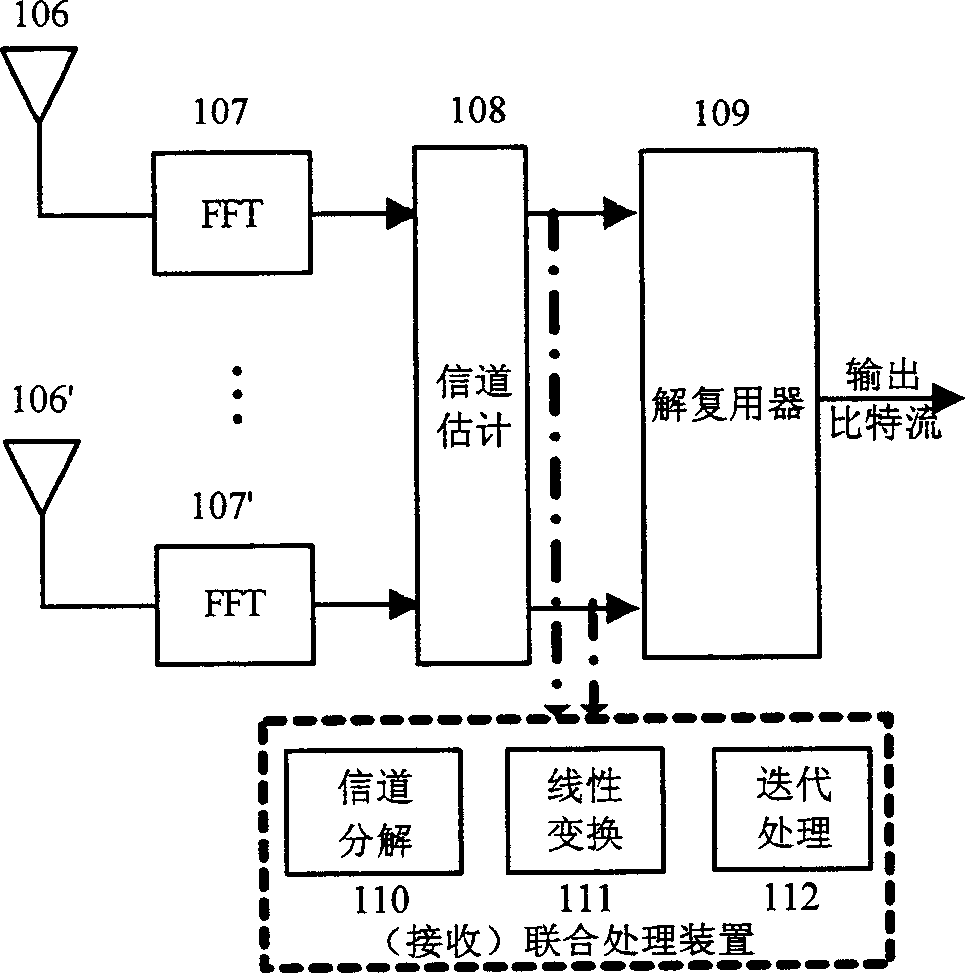

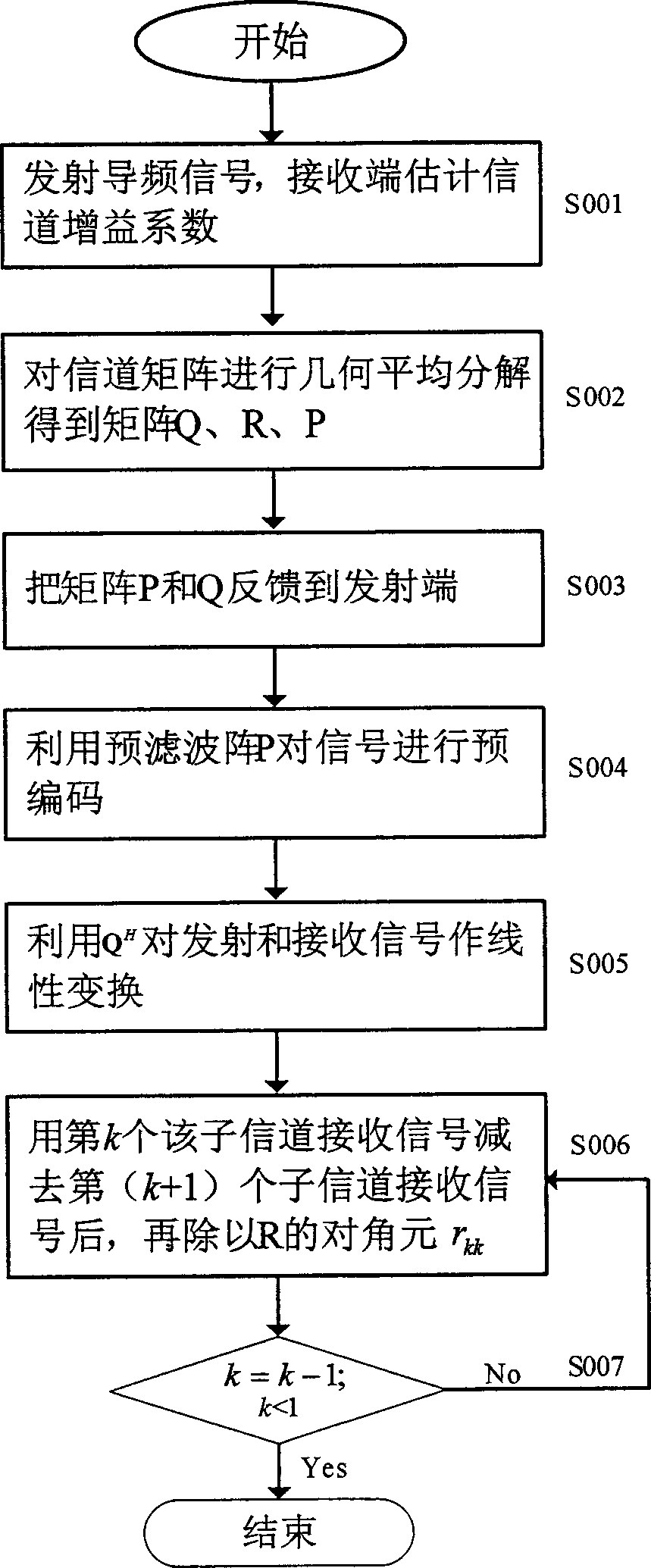

Multi-antenna wireless communication system, transmit/receive processing unit and its combined treatment method

InactiveCN1838578ANo bit error rate performance degradationReduce bit error rateMulti-frequency code systemsError prevention/detection by diversity receptionCommunications systemSignal on

The invention provides a combined treatment method in multi-antenna wireless communicating system, which comprises a receiving end used to do geometric average dissociation to the channel matrix to obtain the linear transformation matrix Q, the upper triangular matrix R and the pre-filtering matrix P with their dimensionality K*K, it feedbacks the pre-filtering matrix P and the linear transformation matrix Q to the sending end and uses QH to do linear transformation to the signals; it uses the pre-filtering matrix P to do linear pre-coding to the signals and uses QH to do the linear transformation to the signals on the sending end; it testes the serial disturbance delete signals and recoveries the corresponding antenna end sending signals on the receiving end.

Owner:PANASONIC CORP

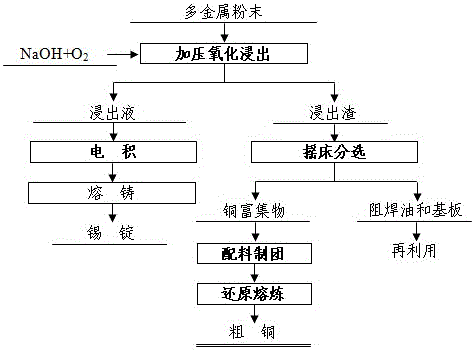

Dressing-metallurgy combined treatment method for waste printed circuit board multi-metal powder

ActiveCN106381391AEfficient removalAvoid pollutionProcess efficiency improvementSmelting processOxygen

The invention provides a dressing-metallurgy combined treatment method for waste printed circuit board multi-metal powder. According to the dressing-metallurgy combined treatment method for the waste printed circuit board multi-metal powder, oxidizing leaching of the multi-metal powder is conducted in an alkaline system containing a catalyst through feeding of oxygen, tin is dissolved into a leaching solution in a sodium stannate form, and meanwhile copper is separated from a residual plastic matrix; a copper-enriched object and waste plastic are generated from the leaching solution in a shaking table separation manner, and the copper-enriched object generates crude copper through reduction smelting after material blending. The essence of the dressing-metallurgy combined treatment method for the waste printed circuit board multi-metal powder is that the waste printed circuit board multi-metal powder is treated in a chemical dressing and thermometallurgy combined manner. It is effectively avoided that the tin is reduced and mixed with the crude copper, the environmental pollution problem caused in the smelting process of the waste plastic is eliminated, and the environmental pollution caused in the process of recycling the copper from the multi-metal powder is completely eradicated through the source treatment measure.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com