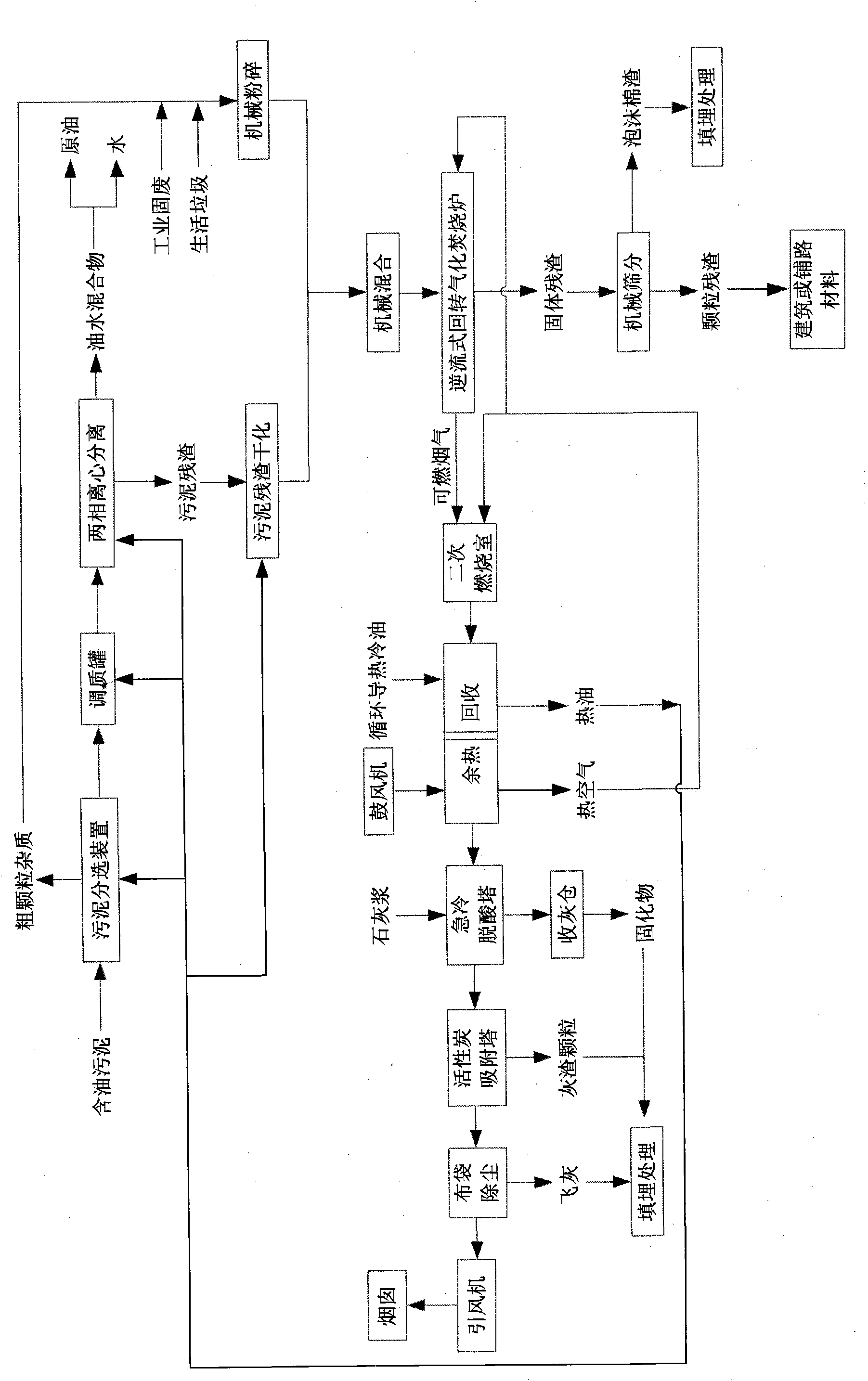

Combined treatment method for oilfield solid waste

A solid waste and combined treatment technology, applied in the field of resources and environment, can solve the problems of increasing oil field solid waste treatment costs, waste of resources, repeated purchase of equipment, etc., achieve good environmental and social benefits, save operating costs, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The annual production of oily sludge, industrial solid waste and domestic waste by an oilfield enterprise is 4800m 3 , 489 tons and 475 tons. Due to the low temperature during the freezing period in winter in the area where the oilfield is located, the heat loss of equipment operation is large and the economy is poor, so the regular operation mode is adopted (May 16th to September 15th every year, and the operation period is 120 days). According to the annual production data of oily sludge, the treatment volume of oily sludge is set at 1.7m 3 / h. After the oily sludge is sorted, water is added to the oily sludge pretreatment tank at a rate of 1020kg / h. At the same time, the oily sludge is stirred and kept warm, and the oily sludge becomes fluidized sludge. Then the fluidized sludge enters the oily sludge conditioning tank, and 1020kg / h of water is added to the tank, and sodium dodecylbenzenesulfonate is added to the oily sludge conditioning tank through the dosing dev...

Embodiment 2

[0042] The annual production of oily sludge, industrial solid waste and domestic waste by an oilfield company is 14500m3 3 , 1260 tons and 915 tons. The oilfield solid waste treatment plant adopts a regular operation mode (from May 1st to September 30th each year, the operation period is 150 days). According to the annual output data of oily sludge, the treatment volume of oily sludge is set at 4.1m 3 / h. After the oily sludge is sorted, water is added to the oily sludge pretreatment tank at a rate of 2460kg / h. At the same time, the oily sludge is stirred and kept warm, and the oily sludge becomes fluidized sludge. Then the fluidized sludge enters the oily sludge conditioning tank, and 2460kg / h of water is added to the tank, and polyoxyethylene lauryl ether is added to the oily sludge conditioning tank through the dosing device, and the addition amount is 0.02% of the weight of the oily sludge %, while stirring and heating the oily sludge to keep the temperature of the oily...

Embodiment 3

[0045] The annual output of oily sludge, industrial solid waste and domestic waste of an oilfield enterprise is 8600m 3 , 778 tons and 746 tons. The oilfield solid waste treatment plant adopts a regular operation mode (from May 16th to September 16th every year, the operation period is 120 days). According to the annual output data of oily sludge, the treatment volume of oily sludge is set at 3.0m 3 / h. After the oily sludge is sorted, water is added to the oily sludge pretreatment tank at a rate of 1800kg / h. At the same time, the oily sludge is stirred and kept warm, and the oily sludge becomes fluidized sludge. Then the fluidized sludge enters the oily sludge conditioning tank, and 1800kg / h of water is added to the tank, and sodium dodecylbenzenesulfonate and polyoxyethylene lauryl ether are added to the oily sludge conditioning tank through a dosing device. The mixture (the two each account for 50%) is added in an amount of 0.03% of the weight of the oily sludge, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com