Patents

Literature

492 results about "Polyoxyethylene lauryl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of rapid molding powder material used for three dimensional printing

InactiveCN103936428ASmall median diameterNarrow particle size distributionMaterials preparationPolyvinyl alcohol

The invention discloses a preparation method of a rapid molding powder material used for three dimensional printing. The method is characterized in that the method comprises the following steps: 1, powder material pretreatment: mixing 88-96% of a powder material with 4-12% of 3-aminopropyltriethoxysilane, and grinding at a rotating speed of 500-1000rpm for 2-6h to obtain a pretreated powder material; and 2, molding material preparation: adding 50-70% by mass of water, adding 0.5-1.0% of polyethylene glycol monooleyl ether, stirring for dissolving, adding 2-10% of polyvinyl alcohol, heating for dissolving, adding 25-40% of the pretreated powder material, stirring for uniform mixing, putting the obtained mixture in a grinder, carrying out normal temperature mixing grinding for 10-15h, and carrying out spray drying to obtain the rapid molding powder material. The rapid molding powder material can be directly molded at a temperature of 85-100DEG C under a pressure of 1-10MPa without sprinkling a binder, and has the advantages of simple preparation technology, easy condition control, low production cost and easy industrialized production.

Owner:UNIV OF JINAN

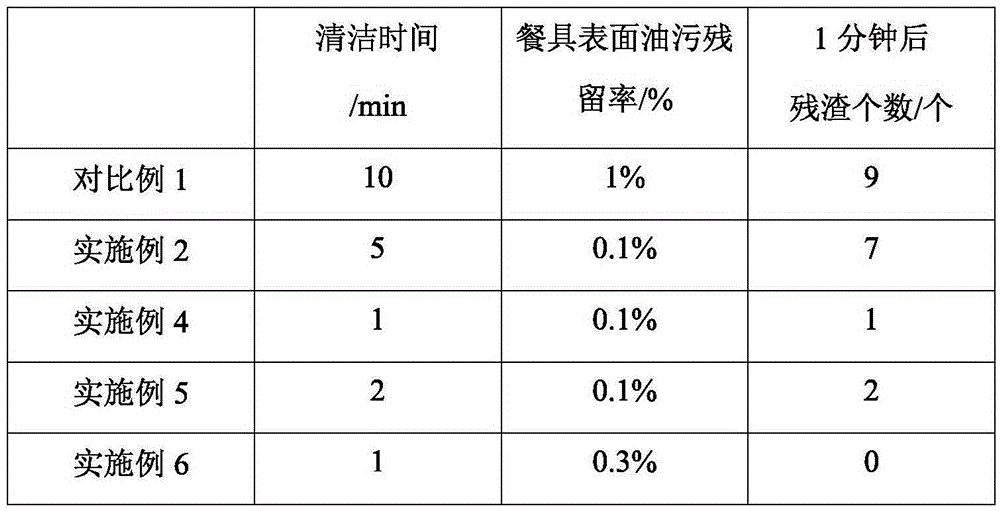

Coconut oil fruit and vegetable cleaning agent

ActiveCN105255601AReduce intensityReduced Chances of ContaminationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCocamidopropyl betaineCleansing Agents

The invention discloses a coconut oil fruit and vegetable cleaning agent. The coconut oil fruit and vegetable cleaning agent is prepared from, by weight, 58-96 parts of deionized water, 1-15 parts of fatty alcohol polyoxyethylene lauryl ether sulfate sodium, 0.1-0.5 part of caustic soda flakes, 0.1-0.5 part of ethylene diamine tetraacetic acid tetrasodium, 1-10 parts of alkyl polyglucoside, 1-10 parts of calkyl polyglucosides, 1-5 parts of sodium chloride, 0.01-0.5 part of Casson and 0.1-0.5 part of coconut oil essence. The coconut oil fruit and vegetable cleaning agent is high in dirt removing capacity compared with existing detergent, granulate grease dirt and residues dried on and fixed to the surface of utensil can be immediately removed, residues dried on the surface of utensil through air cannot be removed by the existing detergent, soaking needs to be performed for a period of time in clean water, common soaking at least needs to be performed for 10 min, time is wasted, lotus leaf powder is added, and the residues can be removed through clean water without being soaked.

Owner:HUBEI MULAN TONGDA TECH

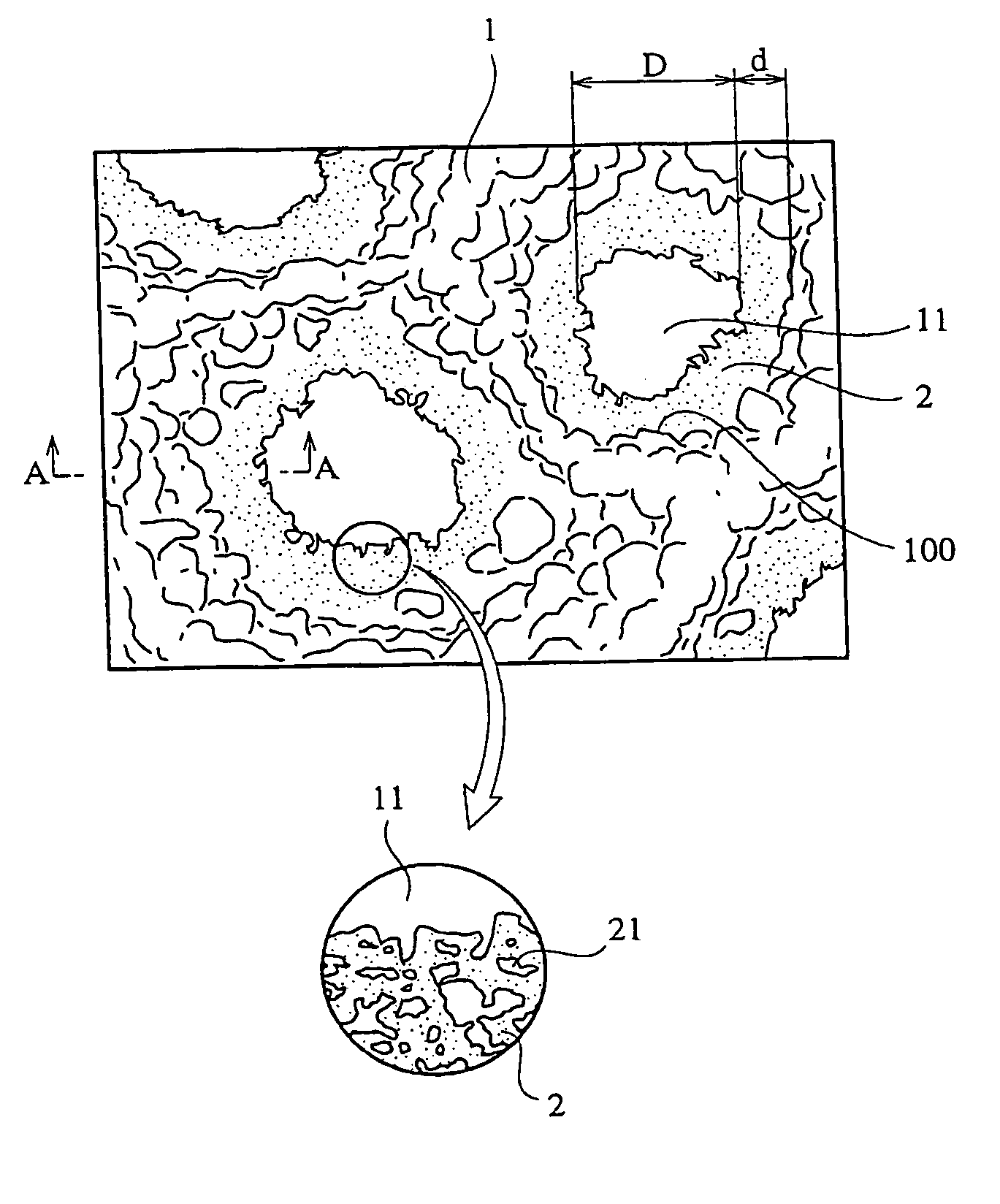

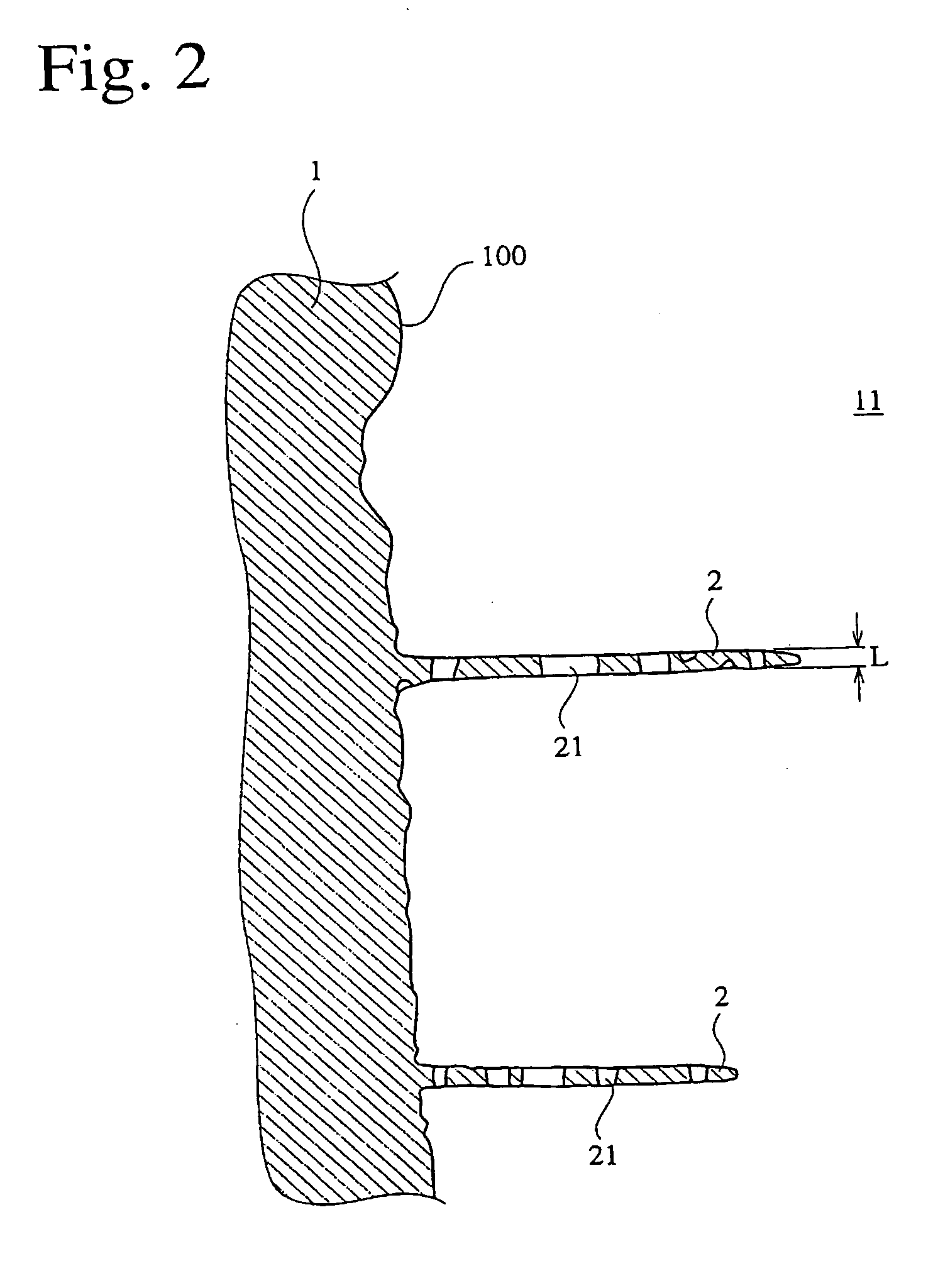

Porous calcium phosphate ceramic and method for producing same

InactiveUS20050119761A1Excellent new-bone-forming capabilityHigh mechanical strengthImpression capsBone implantCalcium biphosphateNetwork structure

A porous calcium phosphate ceramic comprising a support portion having pores, and ring-shaped portions formed in the pores, the ring-shaped portions having pluralities of fine pores so that they have a network structure. A method for producing a porous calcium phosphate ceramic comprising stirring a slurry containing coarse calcium phosphate particles, fine calcium phosphate particles, a nonionic surfactant and a water-soluble high-molecular compound to foam the slurry; gelling the foamed slurry; and then drying the resultant get to obtain a sintered porous calcium phosphate ceramic; the nonionic surfactant being malamide and / or polyoxyethylene lauryl ether.

Owner:HOYA CORP

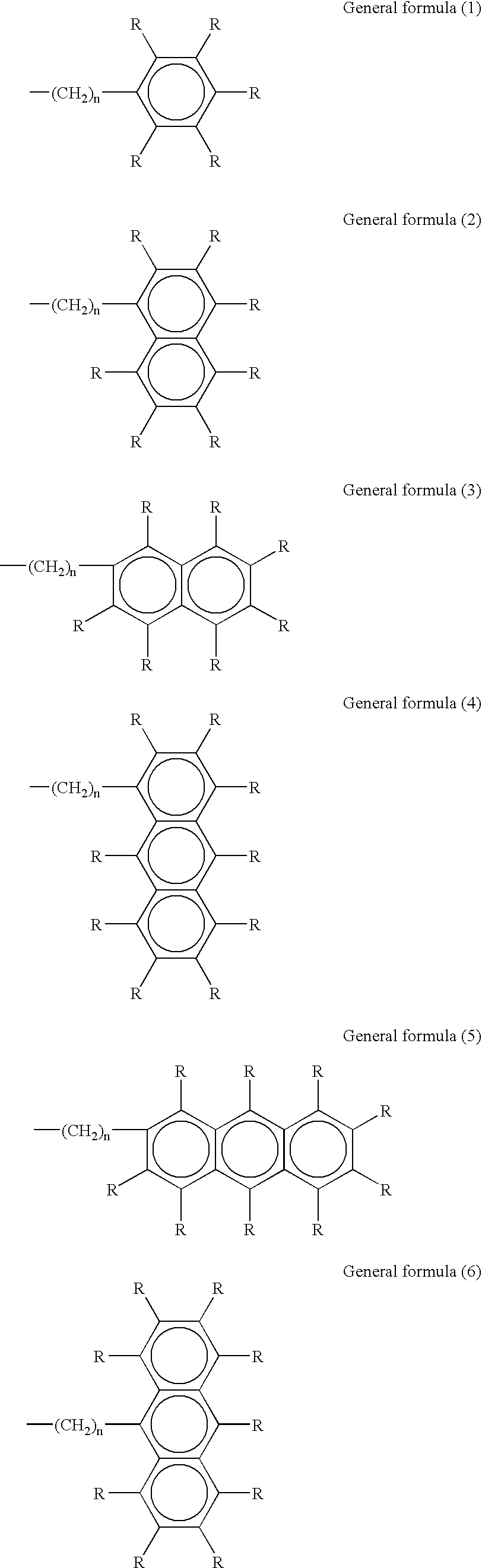

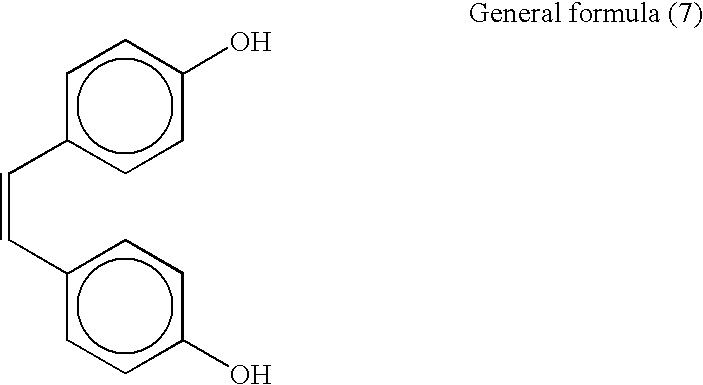

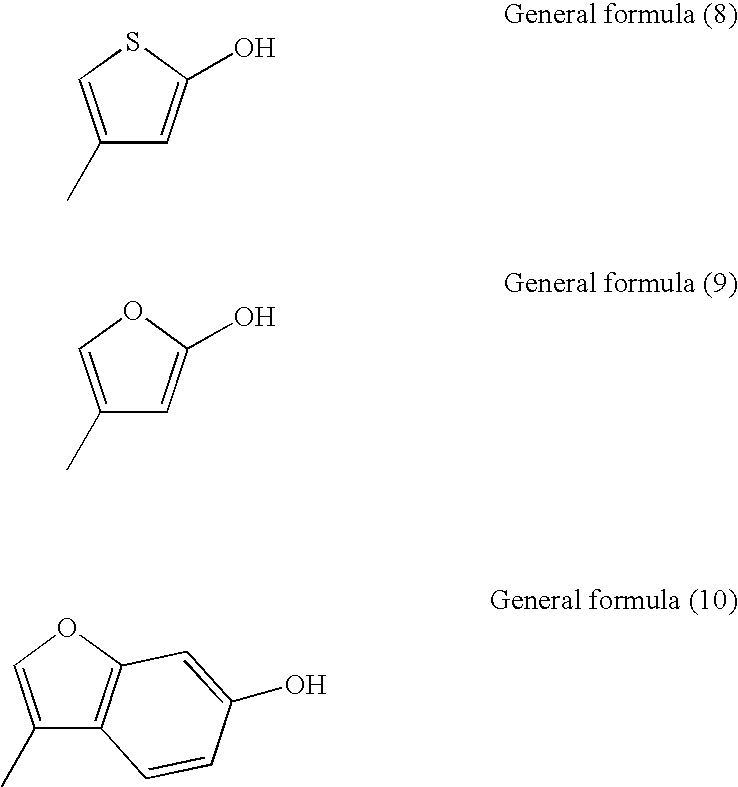

Allergen-inhibiting method, allergen-inhibiting fiber and allergen-inhibiting sheet

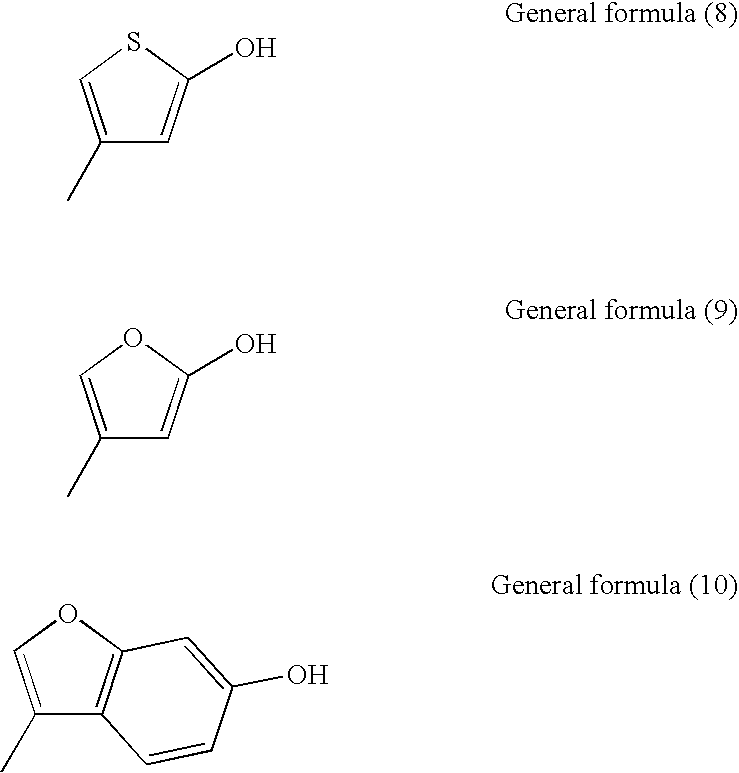

The allergen inhibitor of this invention comprises at least one compound selected from the group consisting of an aromatic hydroxy compound, an alkali metal carbonate, alum, lauryl benzene sulfonate, lauryl sulfate, polyoxyethylene lauryl ether sulfate, and a divalent or more sulfate having either or both of a polyoxyethylene chain and a polyethylene chain in the molecule thereof.

Owner:SUZUKI TARO +2

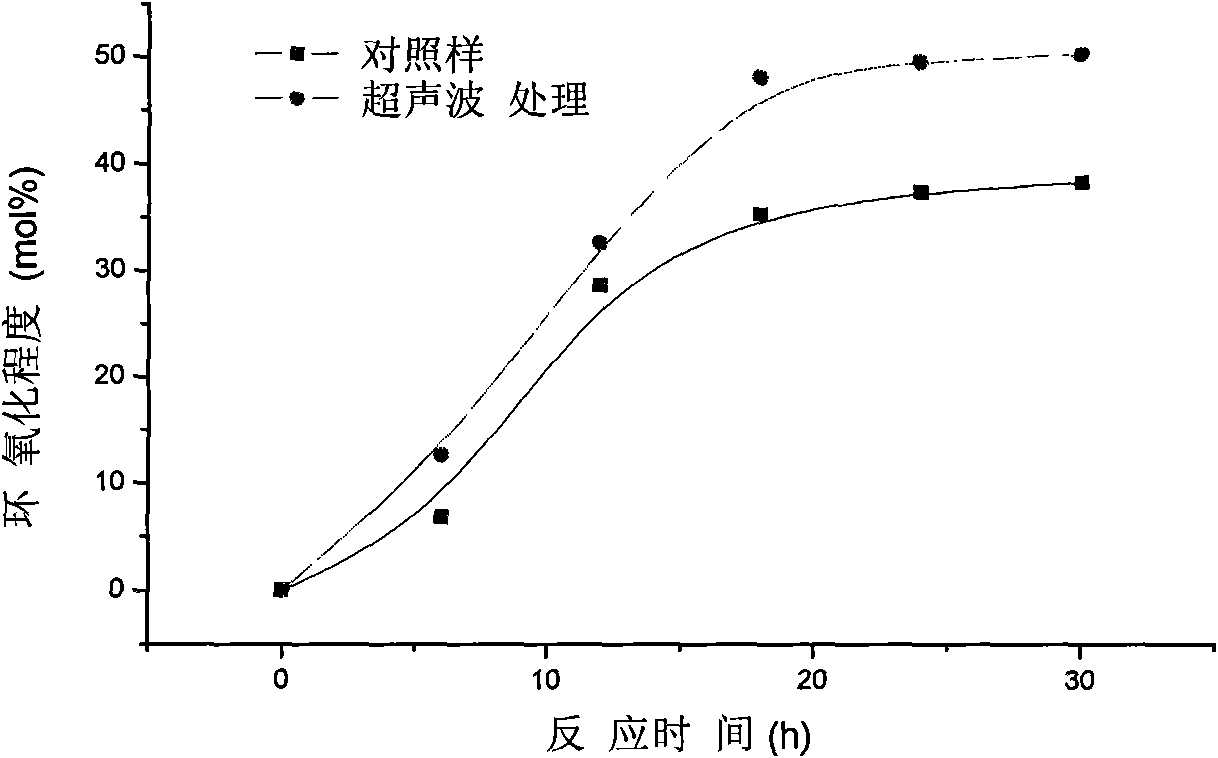

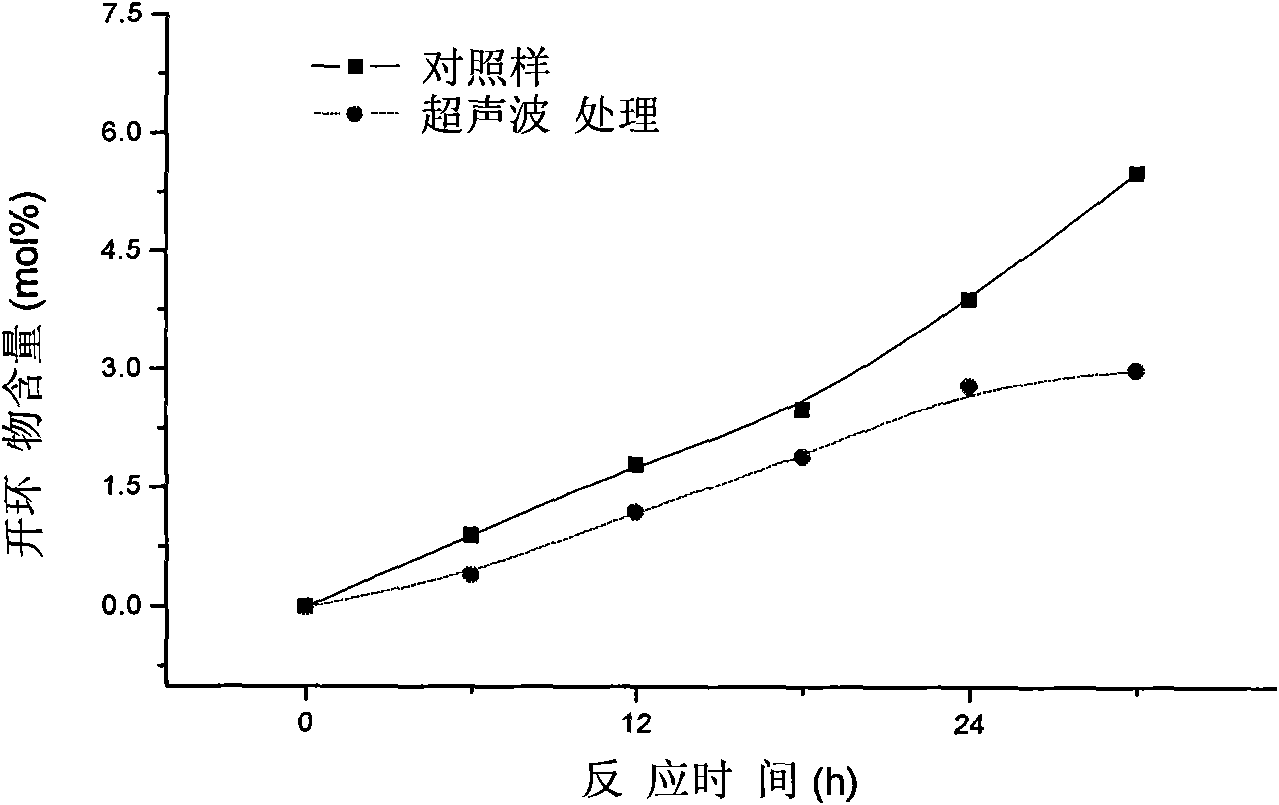

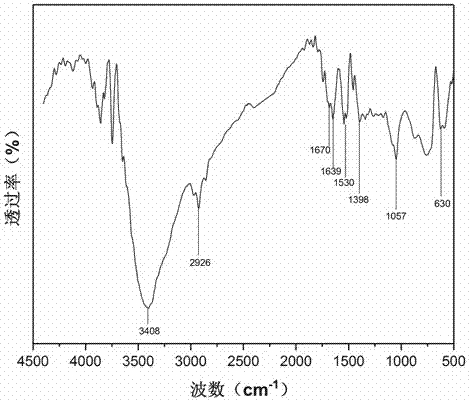

Method for preparing epoxidized natural rubber

InactiveCN101942043AGood effectPrecise control of the degree of epoxidationTotal solid contentReaction temperature

The invention discloses a method for preparing epoxidized natural rubber, which comprises the following steps of: diluting 100 parts of condensed natural rubber latex with the total solid content of 60 percent with deionized water until the total solid content is 30 percent, adding 1 to 3 parts of 20 percent polyoxyethylene lauryl ether with stirring, stabilizing the mixed solution for 2 hours, slowly adding 16 to 24 parts of 86 percent formic acid and 35 to 45 parts of 30 percent hydrogen peroxide, finishing reaction at certain reaction temperature, for a certain reaction time and in an ultrasonic treatment way, adjusting a pH value to 8 to 9 with ammonia water, and performing coagulation, dehydration, rinsing, granulation and drying to prepare the epoxidized natural rubber with the epoxidization degree of 10 to 50 percent, the ring-opening substance content of less than 3.0 percent, relatively higher quality consistency and capability of satisfying needs in application performance.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Water-based metal cleaner

The invention provides a water-based metal cleaner, relating to a technology of pretreatment of processes of metal coating, electroplating, hot dipping coating and the like, in particular to a technology of cleaning the pretreatment surface of carbon steel. The water-based metal cleaner provided by the method comprises the following components of: 190 to 220 g / L of industrial hydrochloric acid, 1.7 to 8.5 g / L of phosphoric acid, 1 to 5 g / L of oxalic acid or 1 to 5 g / L of tartaric acid, 1 to 2.2 g / L of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES or 1.5 to 2 g / L of sodium dodecyl sulfate, 0.6 to 1.6 g / L of peregal 0-15, and 2 to 2.3 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The cleaner can fast, effectively and synchronously complete two processes of deoiling and derusting on the metal pretreatment surface, can effectively prevent acid mist from volatilizing, prolongs the service life of equipment and improves the working environment of labor workers.

Owner:BEIJING JJRS TECH DEV +1

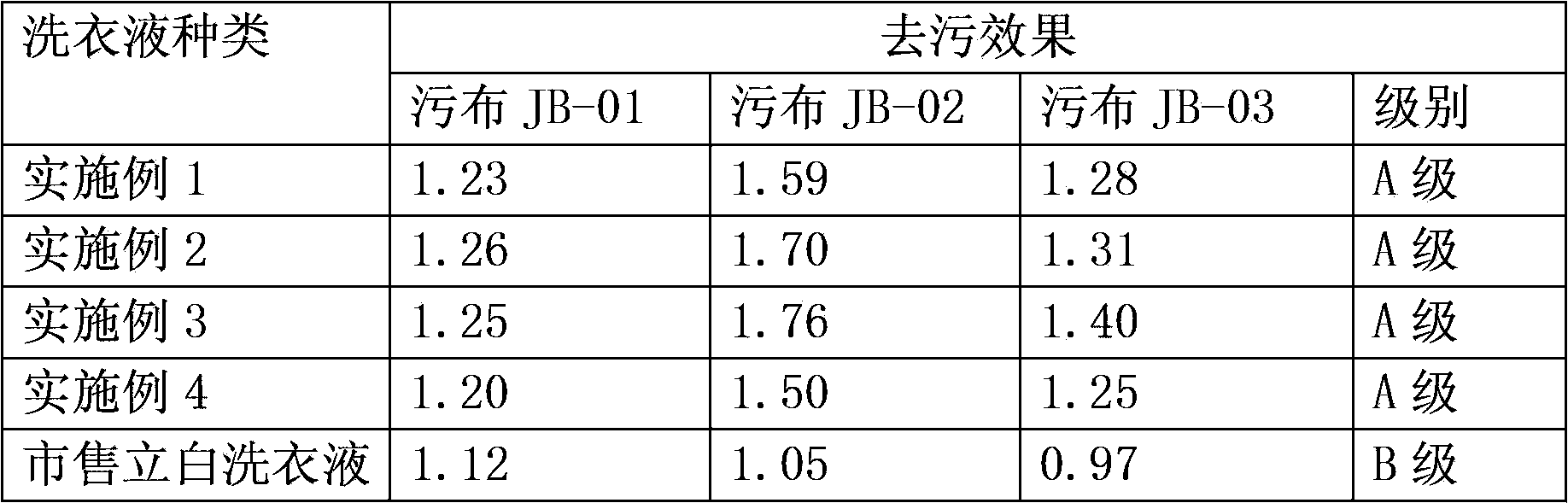

Liquid detergent

InactiveCN103773622AEfficient removalBright as newAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsAlpha-olefinFatty alcohol

The invention discloses a liquid detergent. The liquid detergent comprises the following components in percentage by weight: 10-20 percent of fatty alcohol-polyoxyethylene ether, 5-8 percent of fatty alcohol polyoxyethylene lauryl ether sulfate sodium, 1-6 percent of alpha-olefin sulfonate, 1-5 percent of sec-alkyl sodium sulfate, 5-10 percent of coconut oil fatty acid diethanolamine, 0.5-1 percent of protease, 1-5 percent of an enzyme stabilizer, 0.1-1 percent of a builder, 0.05-0.5 percent of a fluorescent brightening agent, 0.05-0.5 percent of essence, and the balance of deionized water. The liquid detergent has a good stain removal effect, can effectively remove various intractable dirts on the surface of fabric, meanwhile can prevent secondary sedimentation of the dirt, has a better capacity of modifying the color on the surface of the fabric, and can ensure that the fabric is bright in color as a new one after washing.

Owner:阳紫威

Preparation method of nano-composite PTFE (polytetrafluoroethylene) anti-dripping agent

The invention discloses a preparation method of a nano-composite PTFE (polytetrafluoroethylene) anti-dripping agent. The preparation method comprises the following steps: 1), preparing an initiator solution; 2), preparing a nano-hydrotalcite solution; 3), adding 7 parts of maleic anhydride, 55 parts of maleic anhydride, 8 parts of butyl methacrylate, 2 parts of calcium carbonate, 8 parts of superfine silicon dioxide powder, 2 parts of primary alcobol ethoxylate, 1 part of alkylphenol ethoxylates, 1 part of dodecyl trimethyl ammonium bromide, 2 parts of dodecyl trimethyl ammonium sulfate, 4 parts of polyoxyethylene lauryl ether and 5 parts of kaolin into a reaction kettle and stirring uniformly, raising the temperature to 85 DEG C at 5 DEG C / min, and adding 15 parts of initiator solutions for one hour of a seed reaction; 4), obtaining polymer emulsion; 5), obtaining precipitate; and 6), performing centrifugal separation on the precipitate, washing an emulsifier in a system with hot water at the temperature of 75 DEG C, performing centrifugal separation again, and performing drying and grinding to obtain the anti-dripping agent. The nano-composite PTFE anti-dripping agent prepared with the method has good stability.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

Foaming composite material with high thermal conductivity

ActiveCN103818075AOvercoming thermal conductivityOvercome functionNon-macromolecular adhesive additivesSynthetic resin layered productsAntioxidantPlasticizer

The invention relates to a resin foaming composite material, especially to a foaming composite material with high thermal conductivity. The foaming composite material is prepared by the following steps: primary mixing: 8-12 parts by weight of a heat conduction material is added into 40-100 parts by weight of matrix resin to obtain a primary mixed object; plasticization and granulation: 2-8 parts by weight of a fire retardant, 6-10 parts by weight of a softening plasticizer, 3-7 parts by weight of a flexibilizer, 1-4 parts by weight of a coupling agent and 0.6-1.2 parts by weight of an antioxidant are added into the primary mixed object for blending modification and plasticization, and extrusion and granulation are carried out to obtain a first granule; remixing and foaming: 15-25 parts by weight of one or more selected from fatty alcohol polyoxyethylene lauryl ether sulfate sodium or an azo-compound are mixed with one or more selected from the first granule and 30-70 parts by weight of the matrix resin, extrusion and foaming are conducted to prepare a foaming material, and a full-open foaming material layer is compounded on the foaming material through glue to form the foaming composite material with high thermal conductivity. The material provided by the invention has high thermal conductivity and is waterproof and shock-absorbing.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Emulsifying agent having stabilizing effect in clethodim emulsifiable concentrates and preparation method thereof

InactiveCN102318602ASolve the problem of high decomposition rate after storageDilution stability qualifiedBiocideAnimal repellantsEpoxyPhenyl Ethers

The invention discloses an emulsifying agent having a stabilizing effect, which is one or a mixture of several of polyoxyethylene lauryl ether, polyoxyethylene nonyl phenyl ether, alkylaryl polyethenoxy ether, polyoxyethylated fatty acid, epoxy chloropropane, PO-EO block polyether, alkylphenol polyoxyethylene formaldehyde condensation product, calcium dodecyl benzene sulfonate, dodecyl benzenesulfonic acid, 2,6-di-tert-butyl-4-methyl phenol and tween-80. By adopting a method of combining a particular stabilizer with a reasonable formula, the problem of high decomposition rate after the clethodim is stored can be solved; and the characteristics are stable, the clethodim is free from having the layering and precipitation problems during the storage process, and the dilution stabilization of the emulsifible concentrates is qualified. The emulsifying agent is particularly suitable for preparing clethodim emulsifiable concentrates. By utilizing the clethodim emulsifiable concentrates which is prepared by the emulsifying agent having the stabilizing effect, the resource can be saved, so the clethodim can be maximally used; and the clethodim emulsifiable concentrates which is prepared by the emulsifying agent having the stabilizing effect have an excellent effect on preventing the gramineous weed, have no residual influence on the aftercrop crops and have good safety.

Owner:南京扬子鸿利源化学品有限责任公司

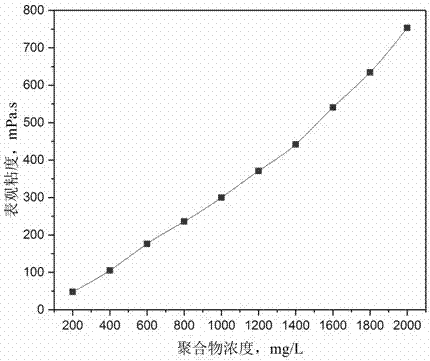

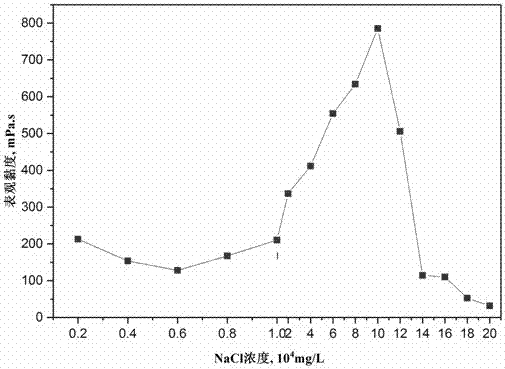

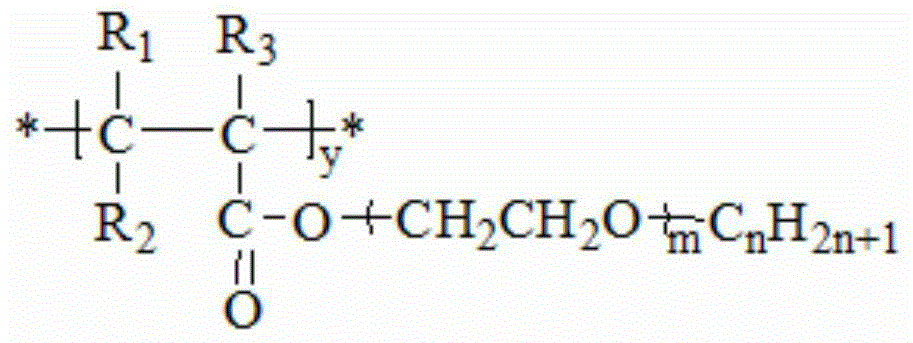

Surface-active two-tailed hydrophobic associated polymer and preparation method thereof

ActiveCN107033293AAvoid hydrolysisImprove rigidityDrilling compositionPolymer scienceTemperature resistance

The invention discloses a surface-active two-tailed hydrophobic associated polymer and a preparation method thereof; the surface-active two-tailed hydrophobic associated polymer is prepared via micellar free radical copolymerization: adding a surfactant, sodium lauryl sulfate, and a hydrophobic monomer, N-phenethyl-N-alkyl (methyl) acrylamide or N-benzyl-N-alkyl (methyl) acrylamide into the aqueous solution of acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, and surface-active macromonomer polyoxyethylene lauryl ether (methyl) acrylate, using the surfactant to solubilize the hydrophobic monomer in the formed micelle, using sodium hydroxide to adjust pH to 6-8, and copolymerizing the hydrophobic monomer and a water-soluble monomer by means of photo-initiation. The properties, such as tackifying performance, temperature resistance, salt resistance and hydrolysis resistance, of the polymer can be effectively improved, the preparation method and principle of the polymer are reliable, and the preparation method is simple to perform and has a promising application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

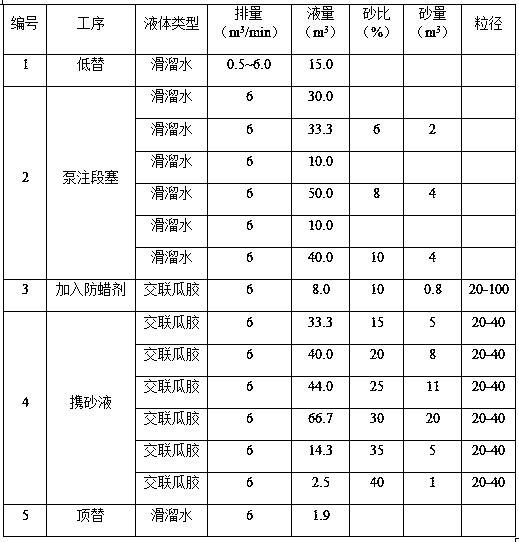

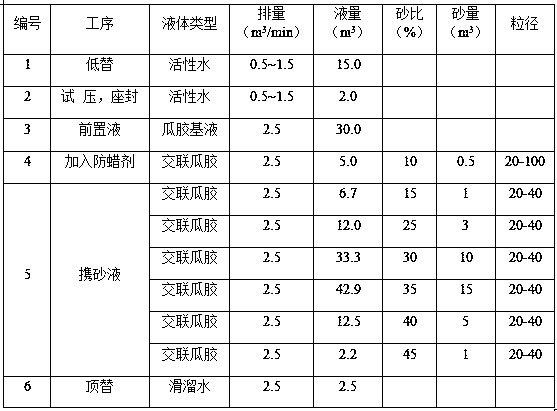

Wax inhibitor added during fracturing construction and preparation method and application thereof

ActiveCN108915637AExpand the scope of actionTo preventCleaning apparatusFluid removalROSIN POWDERSodium stearate

The invention provides a wax inhibitor added during fracturing construction. The wax inhibitor is prepared from the following raw materials in percentage by weight: 10%-20% of sodium stearate, 10%-20%of peregal O-25, 10%-15% of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES, 5%-10% of sodium dodecyl benzene sulfonate ABS, 0.5%-1% of ethylenediamine traacetic acid, 1%-2% of rosin powder, and the balance of quartz sand. Meanwhile, the invention also provides a preparation method and application of the wax inhibitor. The wax inhibitor provided by the invention does not need separate construction, is added during fracturing construction and can penetrate through the distal end of stratum, so that the action range of the wax inhibitor in the stratum is enlarged, the effective time is long, and the wax inhibitor can be slowly released in the stratum at 30 DEG C for about 2 years; wax inhibition is carried out before crude oil production, so that the source of wax production is directly cut off, and the generation of wax is fundamentally prevented; construction is convenient and construction cost is reduced.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

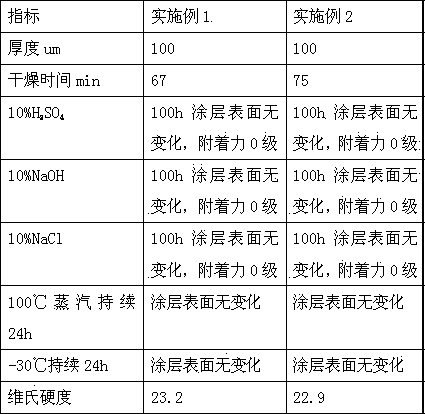

Paint for electrical equipment and preparation process of paint

The invention discloses paint for electrical equipment. The paint is prepared from the following raw materials in parts by weight: 30-40 parts of polyvinylpyrrolidone, 25-28 parts of vinyl trimethoxy silane, 18-22 parts of silicone oil emulsion, 15-20 parts of polyoxyethylene lauryl ether, 12-14 parts of phthalate, 8-10 parts of silicon carbide, 6-8 parts of lithium-based bentonite, 2-3 parts of nanosize silica and 1-2 parts of nano titanium dioxide. The invention further discloses a preparation process of the paint. The paint can be used for effectively preventing corrosion of acid-base slats, prolonging the service life of a cable material and reducing occurrence of potential safety hazards.

Owner:CHONGQING RYAN PAINT CO LTD

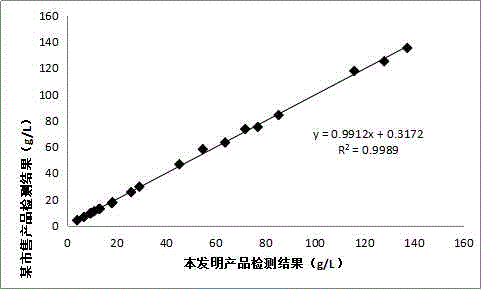

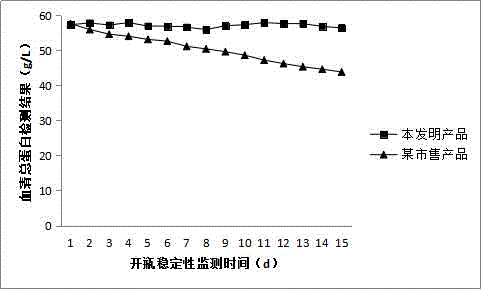

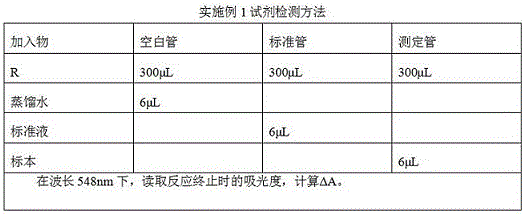

Total serum protein detection kit with strong anti-interference capability

InactiveCN106442352AImprove anti-interference abilityGood repeatabilityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsSolubilityPotassium hydroxide

The invention discloses a total serum protein detection reagent. By virtue of improvement on the basis of a biuret determination method, potassium hydroxide is used for replacing sodium hydroxide, and interference of dextran on detection result is eliminated; two non-ionic surfactants, namely polyoxyethylene laurel ether and Tween-20, are used, so that solubility of the reagent is enhanced, and process of reaction can be more benefited. The reagent has good accuracy and repeatability as well as good detection range and is beneficial to clinically popularization and application of the reagent.

Owner:济南中安生物技术服务有限公司

Water-based environment-friendly cleaning agent for circuit boards

ActiveCN104232344AEasy to prepareEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsDiethylene glycol monobutyl etherIsobutanol

The invention belongs to the field of a circuit board cleaning agent, and discloses a water-based environment-friendly cleaning agent for circuit boards. The cleaning agent is prepared from the following raw materials in parts by weight: 1-2 parts of potassium polyoxyethylene lauryl ether phosphate, 1-2 parts of sodium sulfate, 1-2 parts of tetrafluoropropanol, 1-2 parts of sodium citrate, 2-3 parts of benzotriazole, 3-5 parts of isobutanol, 3-5 parts of triethanolamine, 3-5 parts of polyoxyethylene ether, 4-6 parts of diethylene glycol monobutyl ether, 10-15 parts of coco fatty acid diethanol amide and 30-40 parts of de-ionized water. The cleaning agent disclosed by the invention has no problem of stratification, and is good in stability and free from corrosion to metal; and in addition, the cleaning agent is good in compound removal effect.

Owner:南通旭德科技有限公司

Silk fabric cold pad-batch pretreatment auxiliary

The invention discloses a silk fabric cold pad-batch pretreatment auxiliary. The silk fabric cold pad-batch pretreatment auxiliary comprises the following components in parts by weight: 10-25 parts of 8.5% hydrogen peroxide, 10-25 parts of sodium carbonate, 7.5-15 parts of sodium silicate, 40-46 parts of sodium dodecyl benzene sulfonate, 3-5 parts of polyoxyethylene lauryl ether sodium sulfate and 5-10 parts of sodium dodecyl sulfonate. Aiming at the particularity of the silk fabric, the invention provides a cold pad-batch pretreatment auxiliary which is more suitable for the silk fabric. By utilizing the silk fabric cold pad-batch pretreatment auxiliary, the silk fiber damage rate can be reduced to less than 0.6% simultaneously when various sericin impurities are effectively removed.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

Leather cleaning agent

InactiveCN103666795AStay softEffective waterproof and decontaminationSurface-active detergent compositionsLeather/skins/hides/pelt chemical treatment apparatusSodium metasilicateDioxyethylene Ether

The invention relates to a leather cleaning agent and belongs to the technical field of fine chemicals. The leather cleaning agent comprises the following components in parts by weight: 1 to 3 parts of vitamin E, 20 to 25 parts of neats-foot oil, 0.1 to 0.5 part of lipase, 2 to 5 parts of polyoxyethylene lauryl ether, 0.2 to 0.5 part of pine needle essential oil, 20 to 25 parts of isopropyl alcohol, 2 to 6 parts of sodium metasilicate, 1 to 2 parts of preservative, 1 to 2 parts of foaming agent and 100 to 130 parts of water. The leather cleaning agent disclosed by the invention uses the water as a solvent, does not contain stearate and is environmental-friendly; when the product disclosed by the invention is adopted to clean leather, a layer of protective film can be formed on the leather, water can be effectively prevented, dirt can be effectively removed and the leather is kept soft; in addition, the product disclosed by the invention has a wide application range and can be used for cleaning leather sofas, leather shoes, leather bags and the like.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

High efficiency oil stain removal cleaning agent and preparation method thereof

InactiveCN106566663AEasy to cleanEasy to prepareInorganic/elemental detergent compounding agentsPolymeric surface-active compoundsSodium metasilicateCleansing Agents

Belonging to the technical field of cleaning agents, the invention in particular relates to a high efficiency oil stain removal cleaning agent. The cleaning agent comprises the following components by mass: 6.3-9.6 parts of sodium dodecyl benzene sulfonate, 3.6-5.3 parts of fatty alcohol polyoxyethylene ether sulfate, 1.5-2.4 parts of polyoxyethylene lauryl ether, 2.7-3.2 parts of anhydrous sodium metasilicate, 3.5-4.2 parts of bentonite, 2.4-3.1 parts of sodium carbonate, 0.4-0.7 part of an anti-redeposition agent, 1.5-1.8 parts of a bleaching agent, and 55-68 parts of water. The oil stain cleaning agent provided by the invention cannot cause damage to an oil stain adhered surface. At the same time, the oil stain cleaning agent provided by the invention has good cleaning effect, and the preparation method is simple and is easy for industrialized production.

Owner:重庆市品鑫新材料科技有限公司

Plant hand sanitizer

InactiveCN103027877ALow costSimple recipeCosmetic preparationsToilet preparationsHand sanitizerStearic acid

The invention discloses a plant hand sanitizer. The plant hand sanitizer comprises the following components in part by weight: 20-23 parts of aloe juice, 10-12 parts of castor oil, 10 parts of rose extract, 6 parts of vitamin A, 50-55 parts of deionized water, 6-8 parts of citric acid, 8-10 parts of tea tree oil and 3-5 parts of polyoxyethylene lauryl ether and stearic acid. Natural plant extract is added into the plant hand sanitizer, so that the plant hand sanitizer does not hurt hands and has a hand skin protecting function; and the plant hand sanitizer is simple in formulation, low in raw material cost and simple in preparation process.

Owner:WUJIANG DEZUO DAILY CHEM PROD

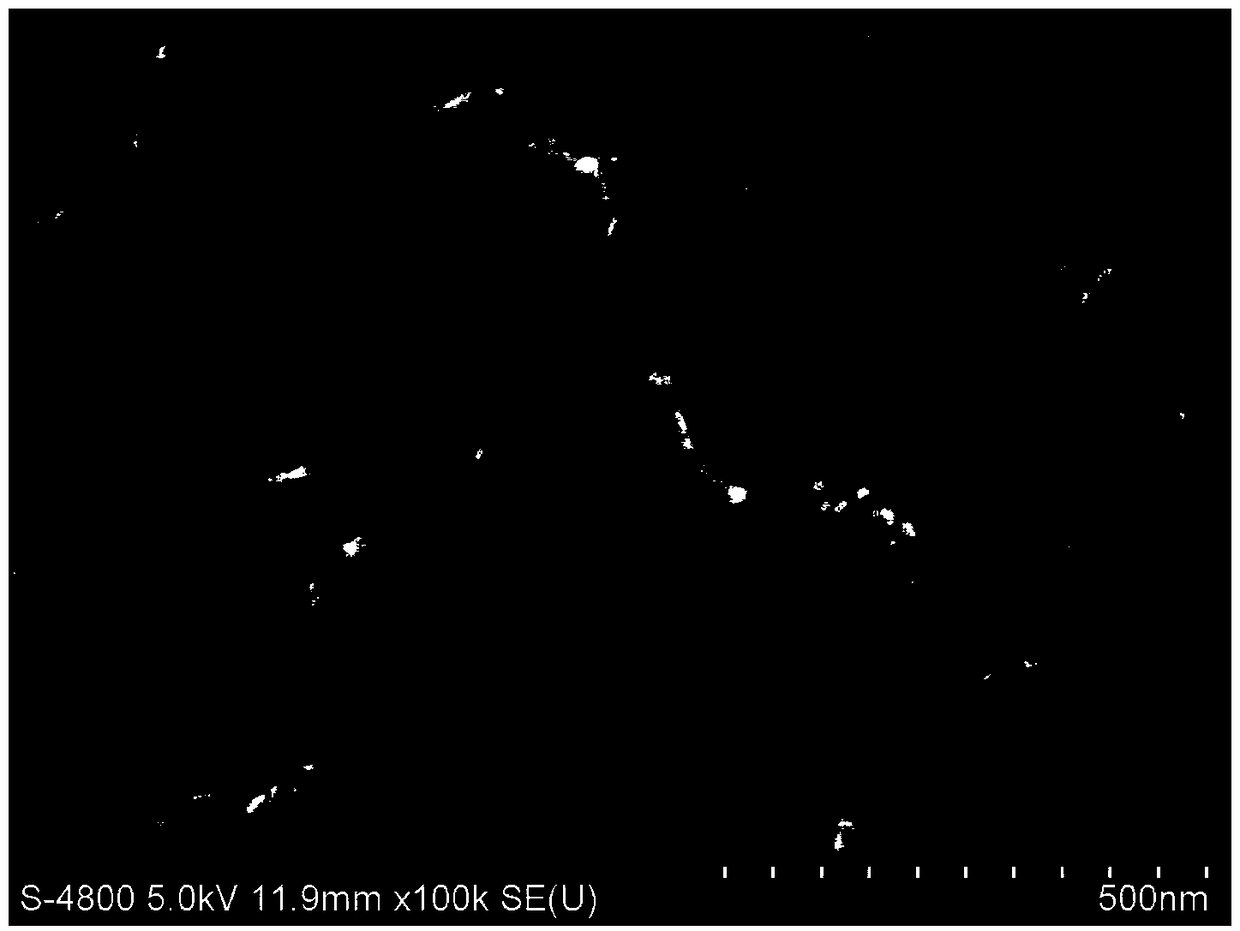

Freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder

The invention provides a freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder. According to the freeze drying preparation method, a surface-active agent polyethylene glycol (PEG), polyvinylpyrrolidone (PVP) or polyoxyethylene lauryl ether are added on the basis of freeze drying for in-situ preparing of about 10 nm of ultra-fine nanometer W-Y2O3 composite powder. The freeze drying preparation method comprises the steps that ammonium meta-tungstate, yttrium nitrate hexahydrate and a surface-active agent are dissolved into water and are fully dispersed anddissolved through ultrasonic treatment; then a mixture is placed in a refrigerator to be pre-frozen for a period of time; after being pre-frozen, the mixture is put into a freeze dryer to be subjected to freeze drying; a freeze-dried loose structure is ground and calcined in air so as to remove the surface-active agent, and thus WO3-Y2O3 composite powder is obtained; and finally, two-step reduction is conducted through hydrogen, and thus the ultra-fine tungsten-doped yttrium oxide composite powder is obtained. The powder, with the surface-active agent being added, prepared through the freezedrying method is small in particle aggregation, the average grain size reaches about 10 nm, granularity distribution of grains is extremely narrow, and second-phase Y2O3 is distributed quite evenly.

Owner:TIANJIN UNIV

Allergen inhibitor, allergen-inhibiting method, allergen-inhibiting fiber and allergen-inhibiting sheet

InactiveUS20050095222A1Excellent allergen-inhibiting effectInhibition is effectiveBiocideAnimal repellantsSulfateCompound (substance)

The allergen inhibitor of this invention comprises at least one compound selected from the group consisting of an aromatic hydroxy compound, an alkali metal carbonate, alum, lauryl benzene sulfonate, lauryl sulfate, polyoxyethylene lauryl ether sulfate, and a divalent or more sulfate having either or both of a polyoxyethylene chain and a polyethylene chain in the molecule thereof.

Owner:SEKISUI CHEM CO LTD

Reeling agent for automatic silk reeling production

InactiveCN104480536AIncrease release rateFull penetrationSilk reelingCocamidopropyl betaineBright-white

The invention relates to the technical field of silk production and discloses a reeling agent for automatic silk reeling production. The reeling agent comprises the following raw materials of, by weight, 5 to 10 parts of castor oil polyoxyethylene ether, 6 to 9 parts of lauryl sodium sulfate, 6 to 9 parts of polyoxyethylene lauryl ether, 5 to 10 parts of polyoxyethylene fatty alcohol sodium sulfate, 5 to 8 parts of cocamidopropyl betaine, 10 to 15 parts of hydrogen peroxide, and 10 to 15 parts of sodium silicate. The reeling agent is reasonable in formula, capable of effectively increasing the reelability rate of raw silk, improving product quality, fully permeating cocoon shells, performing uniform reeling, and reducing the influence of cocoon quality differences on silk reeling quality, low in production cost, and small in use amount, silk produced through subsequent processes is bright white and soft and smooth in touch, and the use amount of the reeling agent is easy to control.

Owner:安徽省广德新丰丝绸有限公司

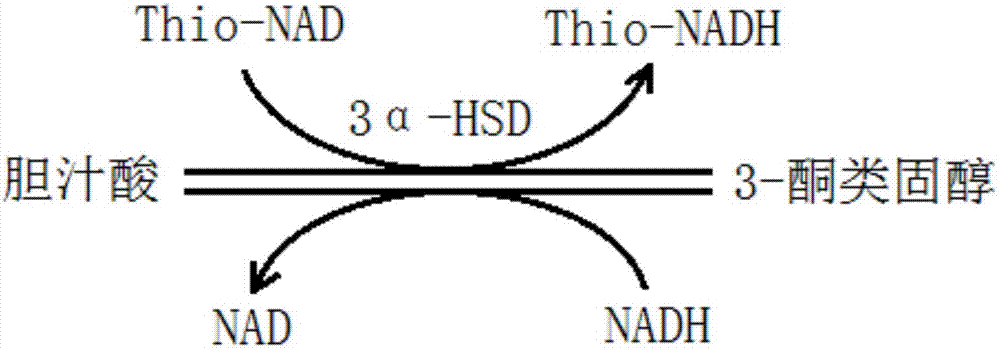

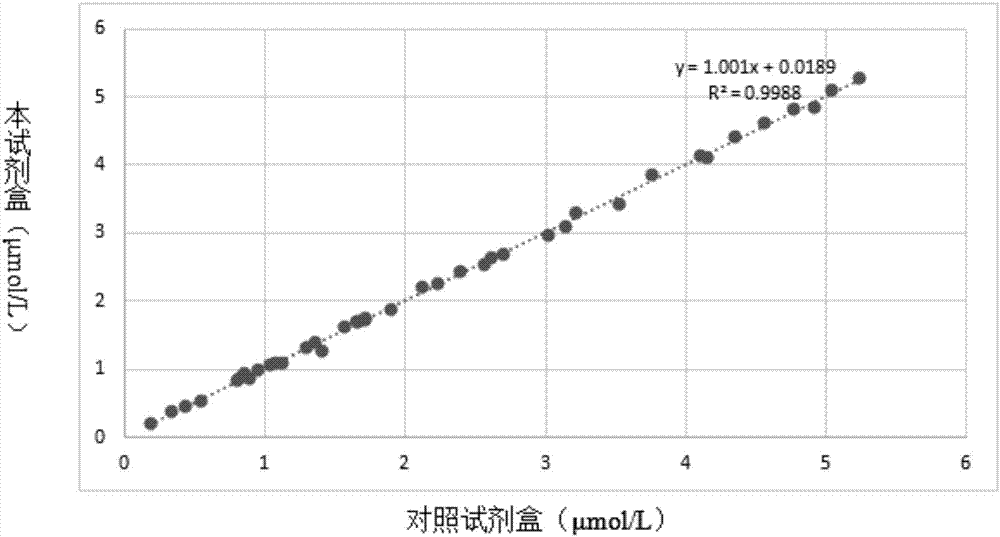

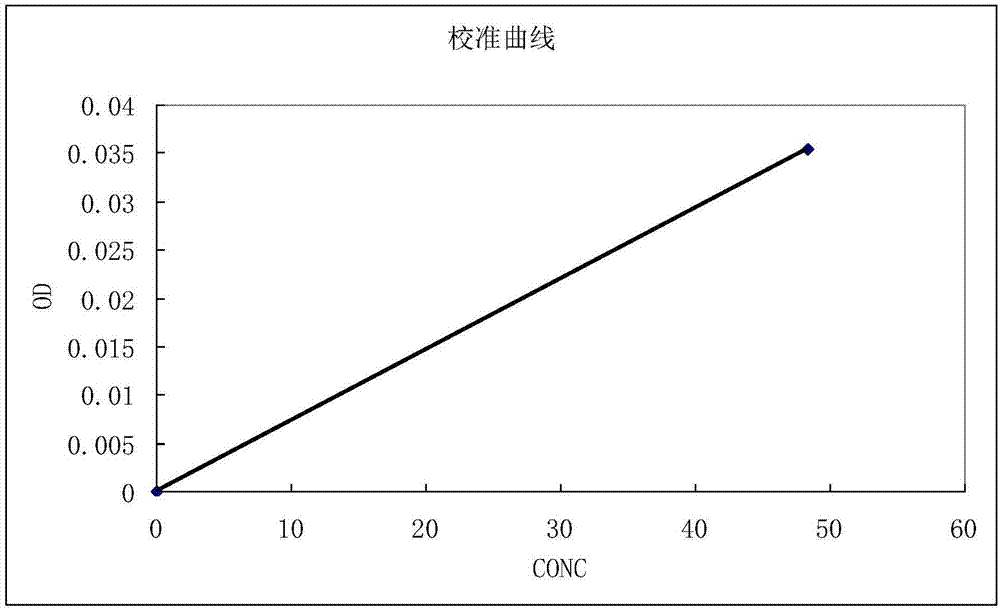

Kit for measuring content of total bile acid of blood serum and use method of kit

InactiveCN107505273AImprove accuracyImprove stabilityPreparing sample for investigationBiological material analysisSucroseBovine serum albumin

The invention discloses a kit for measuring content of total bile acid of blood serum and a use method of the kit, relates to the field of biochemical detection and aims to provide a high-stability, high-accuracy and non-interfering kit for measuring the content of total bile acid of blood serum and a use method of the kit. The kit comprises a reagent 1 and a reagent 2, wherein the reagent 1 comprises a GOOD'S buffer solution, thionicotinamide adenine dinucleotide, polyoxyethylene ether of nonylphenol, polyoxyethylene lauryl ether, ADP.2Na, EDTA (ethylene diamine tetraacetic acid), bovine serum albumin, mannitol and a preservative (proclin series); the reagent 2 comprises a GOOD'S buffer solution, 3 alpha-hydroxysteroid dehydrogenase, reduced coenzyme and the like. Due to addition of ethylene glycol, sucrose and multiple compound stabilizers, the stability of the reagents is improved; due to addition of EDTA, the interference effect of metal ions can be reduced and the test result accuracy can be improved.

Owner:WHITMAN BIOTECH NANJING

Glass detergent

InactiveCN102876514ADoes not affect light transmissionDoes not affect reflectivitySurface-active non-soap compounds and soap mixture detergentsDichlorodifluoromethanePhotochemistry

The invention discloses a glass detergent. The glass detergent consists of the following components: 18 to 20 parts of absolute ethanol, 8 to 10 parts of dichlorodifluoromethane, 3 to 5 parts of sodium hydroxide, 6 to 8 parts of polyoxyethylene lauryl ether and 40 to 50 parts of water. The glass detergent has a remarkable decontamination effect, is noncorrosive and nonflammable, does not pollute and affect the environment, does not affect the light transmission property and light reflectivity of glass, can be safely used, and meets the requirements of people.

Owner:QIDONG DONGZHOU INSTR

Multifunctional cutting fluid and preparation method thereof

InactiveCN104403769AImprove the lubrication effectImprove corrosion resistanceLubricant compositionHydrogenLubrication

The invention relates to a multifunctional cutting fluid and a preparation method thereof. The multifunctional cutting fluid comprises the following constituents by weight percent: 30 to 40 percent of mineral oil, 5 to 12 percent of triethanolamine, 3 to 8 percent of polyoxyethylene lauryl ether, 10 to 15 percent of an antirust agent, 1 to 5 percent of a lubricant, 1 to 3 percent of a bactericidal agent, 0.5 to 1 percent of a corrosion inhibitor, 1 to 3 percent of a pH (potential of hydrogen) regulator, and water for the surplus. The preparation method comprises the steps of putting the water into a container, weighing the mineral oil, the triethanolamine and the polyoxyethylene lauryl ether according to a formula, stirring the raw materials to be dissolved, sequentially adding the antirust agent, the lubricant, the bactericidal agent and the corrosion inhibitor, stirring the solution for 10 minutes, and then regulating the pH value of the solution through the pH regulator. The multifunctional cutting fluid has good antirust, anti-corrosion and lubrication effects and good stability, and has low probability of deterioration.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

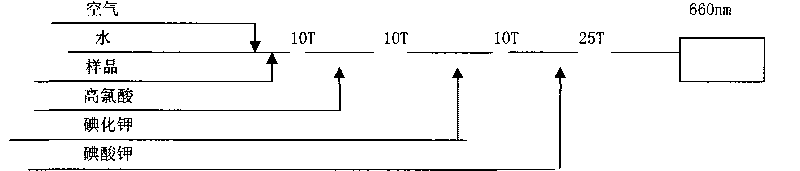

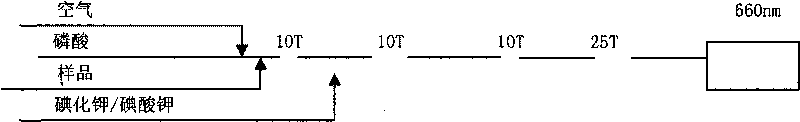

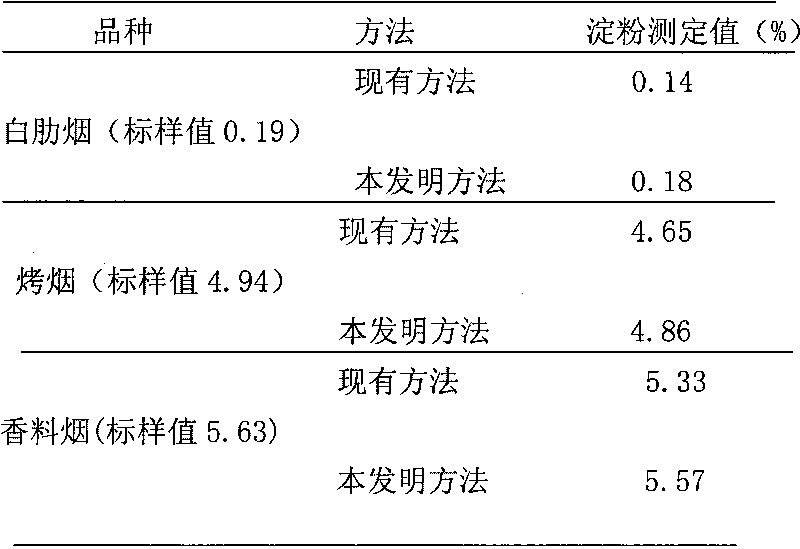

Method for determining starch content in tobacco

ActiveCN101750411AStarch content close toThe starch content is close to the real valueMaterial analysis by observing effect on chemical indicatorShake upPhosphoric acid

The invention relates to a method for determining the starch content in tobacco, which comprises the following steps: weighing a dried and smashed tobacco sample, placing in a beaker, adding distilled water for boiling, cooling, then setting the volume by using the distilled water, shaking up, filtering and preparing a sample reagent; setting the volume of 75-85% phosphoric acid by using the distillated water, adding a 22% polyoxyethylene lauryl ether reagent, and preparing a phosphoric acid reagent; weighing potassium iodate and potassium iodide, setting the volume by using the distilled water, adding the 22% polyoxyethylene lauryl ether reagent, and preparing a potassium iodate / potassium iodide reagent; weighing amylase and amylopectin, commonly dissolving in the distilled water, setting the volume and preparing a standard stock solution reagent; and sequentially carrying out sample injection on all the reagents through the program run of a continuous flow analyzer, and determining the starch content in the sample at a certain wavelength. The method can save the reagents, eliminate the potential safety hazard of experimental staff, protect the instrument and lead the determined starch content in the tobacco to be closer to the true value.

Owner:CHINA TOBACCO ANHUI IND CO LTD

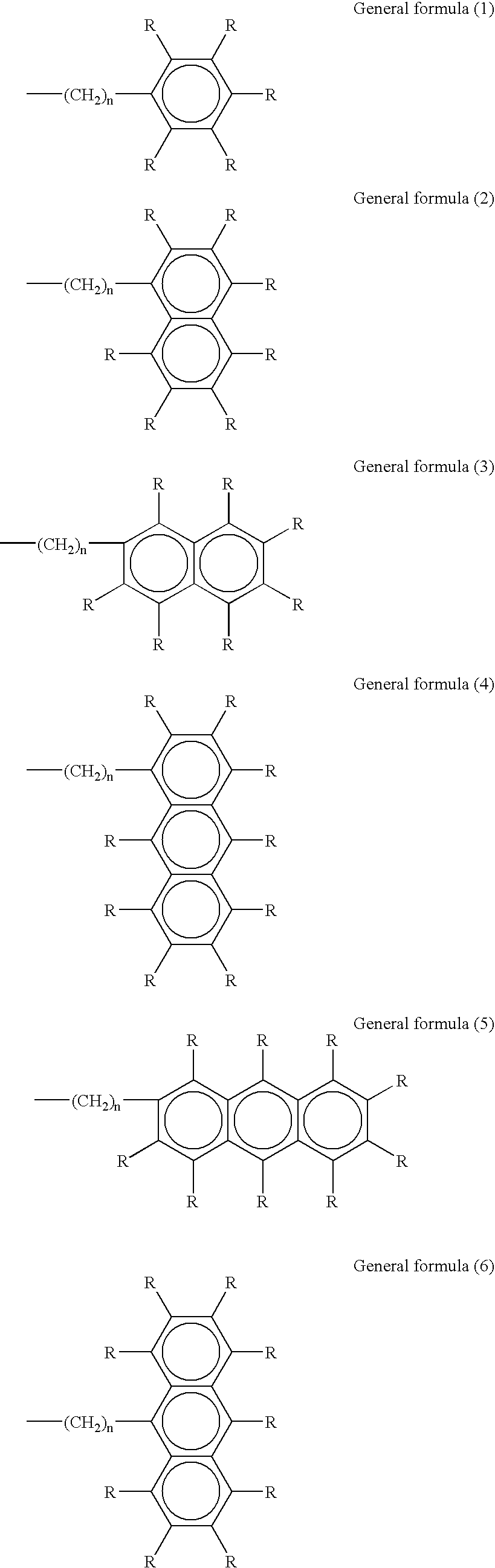

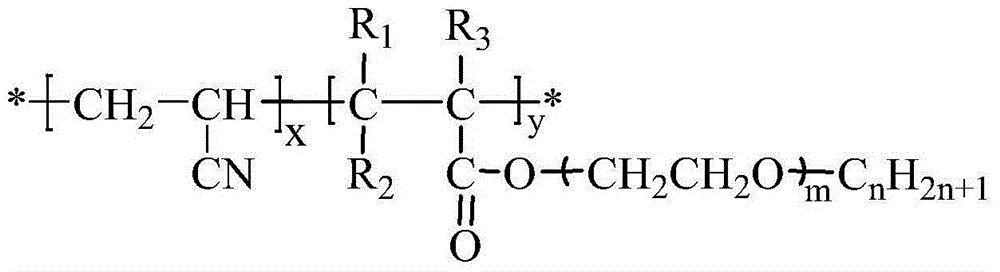

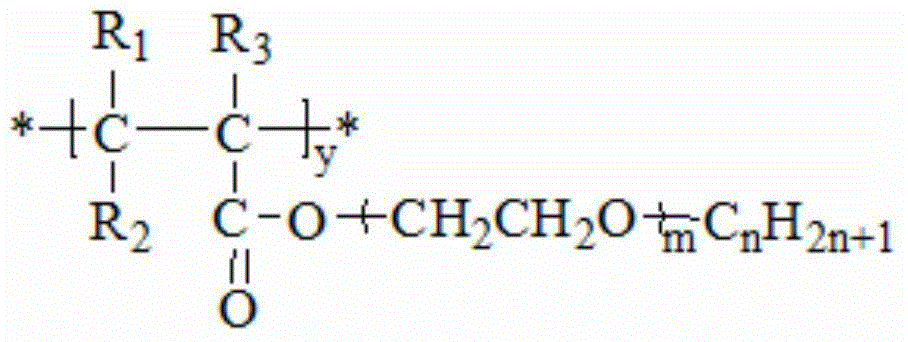

Second monomer of acrylonitrile copolymer solid-solid phase change material and preparation method and use of second monomer

InactiveCN103980482AHas the function of heat storage and temperature adjustmentWeaken the dipole forcePreparation by ester-hydroxy reactionHeat-exchange elementsPolymer scienceDecomposition

The invention discloses a second monomer of an acrylonitrile copolymer solid-solid phase change material and a preparation method of the second monomer, a method for preparing the acrylonitrile copolymer solid-solid phase change material from the second monomer, and a method for preparing a thermo-regulated fiber / film from the prepared phase change material. The second monomer is prepared from polyoxyethylene lauryl ether reacting with ester monomers containing unsaturated double bonds in the presence of a catalyst and a polymerization inhibitor. The acrylonitrile copolymer solid-solid phase change material is prepared from the second monomer, the melting point of the material can be lower than the decomposition temperature, and the acrylonitrile copolymer solid-solid phase change material is applicable to melt spinning. The phase change material is spun and filmed under the melting condition after being mixed with a thermal stabilizer, so as to prepare the fiber / film with good energy storage and temperature adjustment performances.

Owner:TIANJIN POLYTECHNIC UNIV

Color material for low-temperature glaze coloring

InactiveCN105860585APure colorModerate viscosityPigment treatment with macromolecular organic compoundsPigment physical treatmentManufacturing technologyLow temperature curing

The invention discloses a color material for low-temperature glaze coloring and relates to the technical field of ceramic production. The color material is prepared from the following raw materials in parts by weight: 25-30 parts of pigment, 10-13 parts of mineral powder, 8-11 parts of polyoxyethylene, 6-9 parts of gelatin, 5-8 parts of hydroxyethyl cellulose, 4-6 parts of polyoxyethylene lauryl ether, 4-6 parts of sodium polyacrylate, 3-5 parts of glass fiber powder, 2-3 parts of bone black powder, 2-3 parts of urea, 1-2 parts of sodium citrate, 1-2 parts of nano zirconia, 15-20 parts of turpentine oil and 100-120 parts of water. The color material disclosed by the invention has pure color and moderate viscosity and can be effectively adhered to the glaze surface of porcelain; the formed color patterns are bright and beautiful with smooth surfaces; through low-temperature curing, the color patterns have excellent corrosion resistance, wear resistance and weather resistance; and moreover, the effects of the color patterns are always consistent, and thus the ornamental value of the ceramic product is greatly improved.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

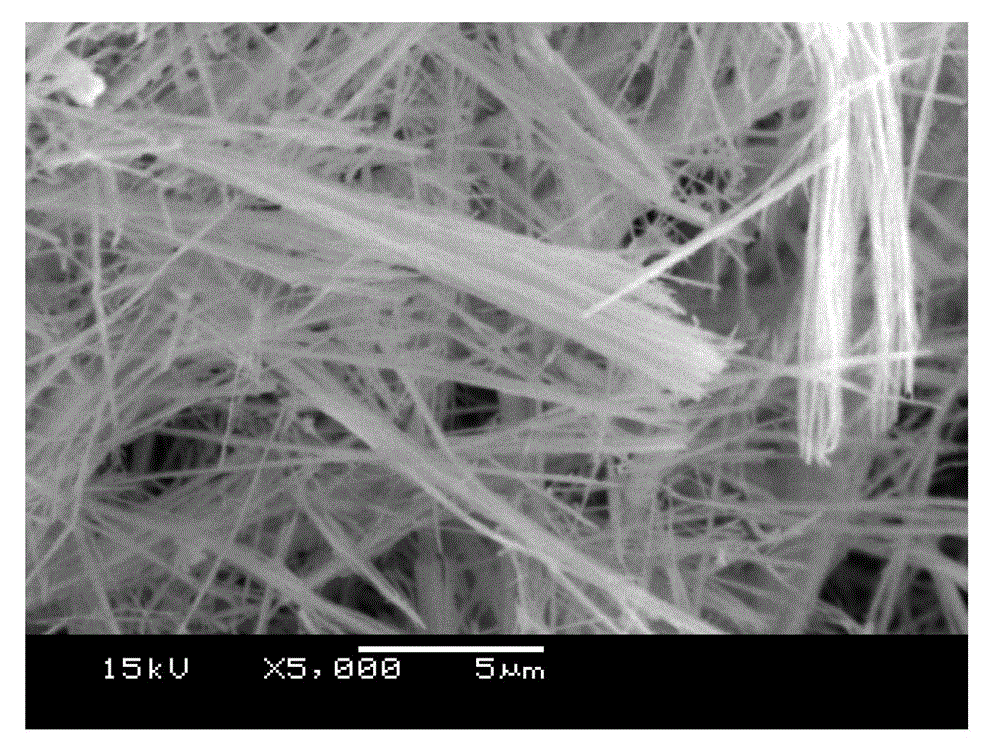

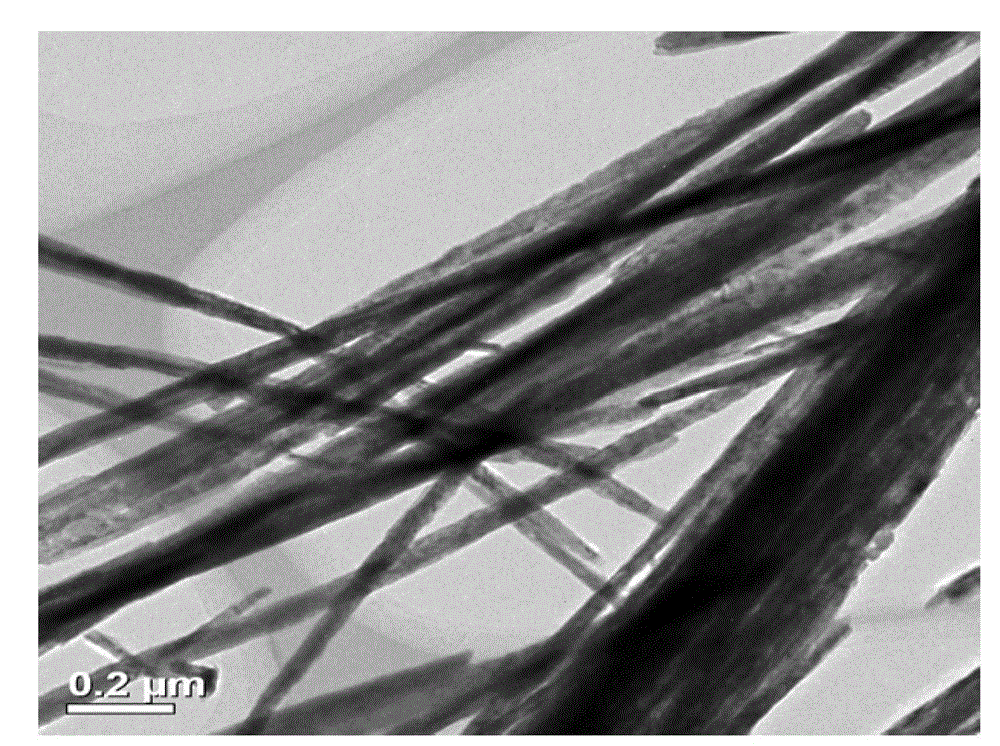

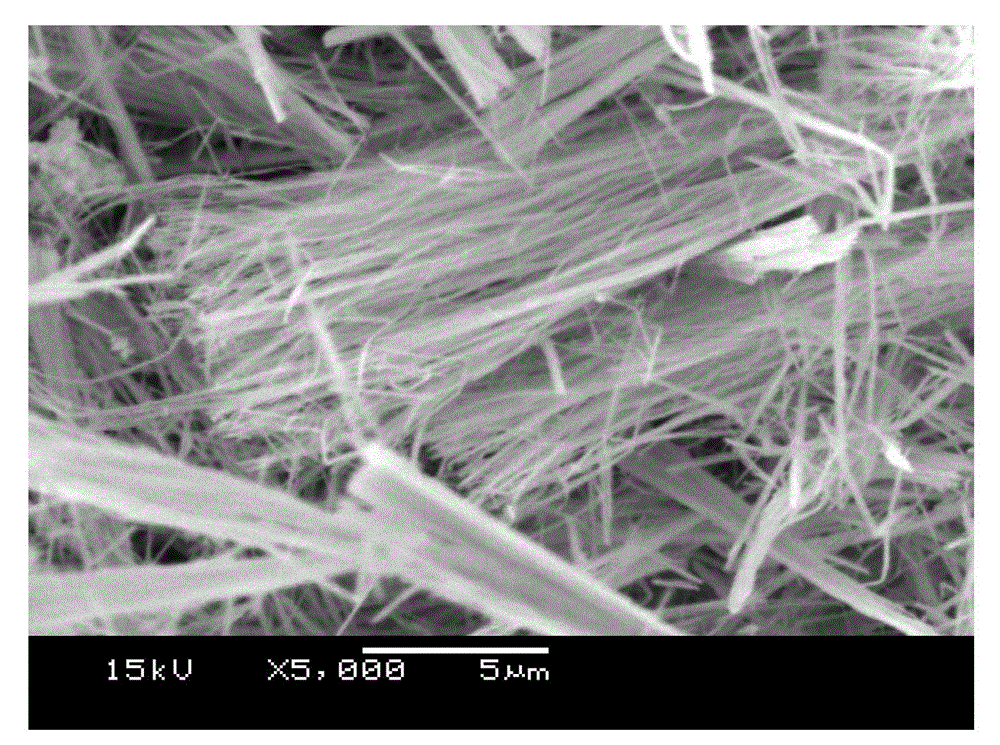

Solvothermal preparation method of cobalt nano-fibers

The invention discloses a solvothermal preparation method of cobalt nano-fibers, which belongs to the technical field of metal materials. The solvothermal preparation method is characterized by adopting a solvothermal method, taking glycol as a solvent and ethidene diamine as a reducing agent and reducing cobalt salt to the cobalt nano-fibers with the help of surfactants including polyvinylpyrrolidone and polyethylene glycol monooleyl ether. The generated cobalt nano-fibers are subjected to centrifugal separation, washed twice or three times by absolute ethyl alcohol, dried and collected. The cobalt nano-fibers range from fifty to one hundred nanometers in diameter and ten to dozens of micrometers in length, the length-diameter ratio of the cobalt nano-fibers is very large, and the cobalt nano-fibers grow in a bundle form. The solvothermal preparation method has the effects and benefits that under the combined action of the two surfactants and the ethidene diamine, reduced cobalt grows linearly in a direction (001) to form the cobalt nano-fibers with even diameters and good flexibility; and the solvothermal preparation method has the advantages of simple process and low cost.

Owner:DALIAN UNIV OF TECH

Grafting survival promoter and application thereof to plant grafting stock

InactiveCN106417323AImprove survival rateRaw materials are easy to getBiocidePlant growth regulatorsDisinfectant8-Hydroxyquinoline

The invention discloses a grafting survival promoter. A preparation method of the grafting survival promoter comprises the following steps of dissolving gibberellin or auxin in 75-percent ethyl alcohol to obtain a first moxture, diluting the mixture for 30 to 50 times by using water, afterwards, adding glucose or fructose, 8-hydroxyquinoline or thiabendazole and polyoxyethylene lauryl ether into an obtained second mixture respectively, and finally, regulating the pH (potential of Hydrogen) of a system to be 3 to 5, so that the grafting survival promoter is obtained. The invention also discloses application of the grafting survival promoter to the grafting of a plant. According to the grafting survival promoter and the application of the grafting survival promoter, through adding a growth promoter, a disinfectant, a surfactant and a nutrient substance, a scion and a stock are enabled to heal as quickly as possible in a germfree condition; the survival rate of the grafted plant is improved. The grafting survival promoter has the advantages that raw materials are easily obtained; the cost is low; the preparation method is simple.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com