Patents

Literature

153results about How to "Does not affect light transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar cell packaging adhesive film with high light conversion efficiency

ActiveCN104927686AImprove utilization efficiencyGood light stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesLight conversion efficiencySemiconductor

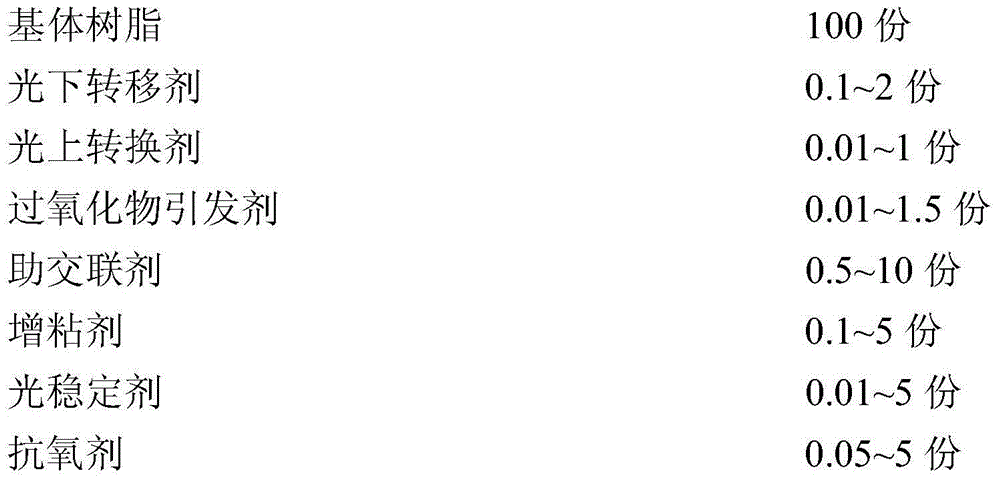

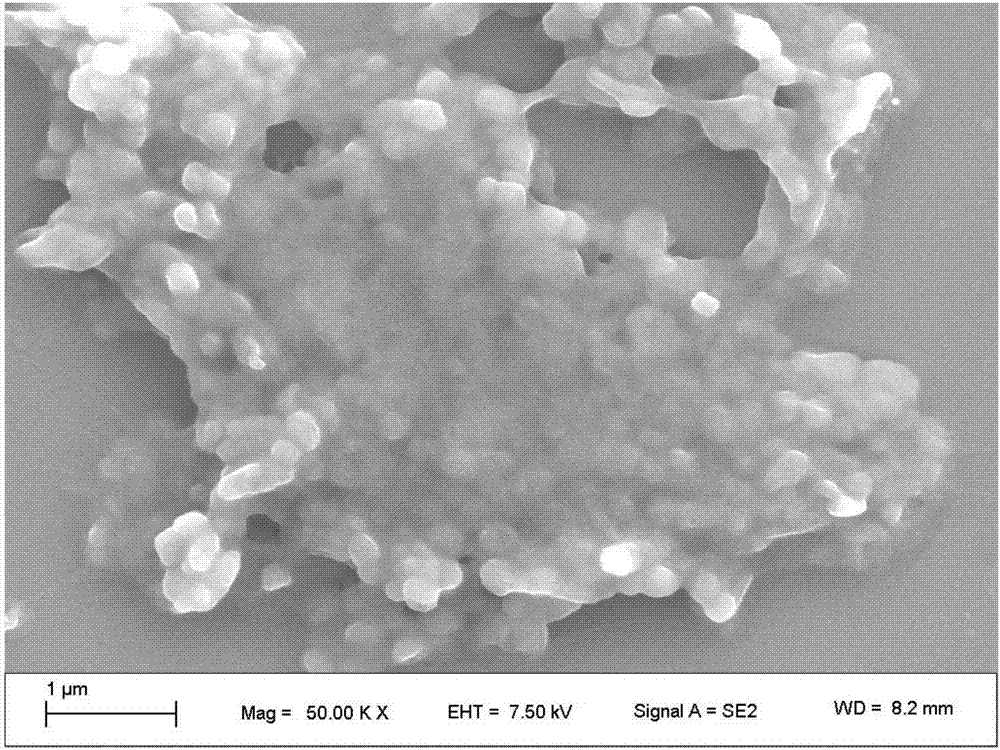

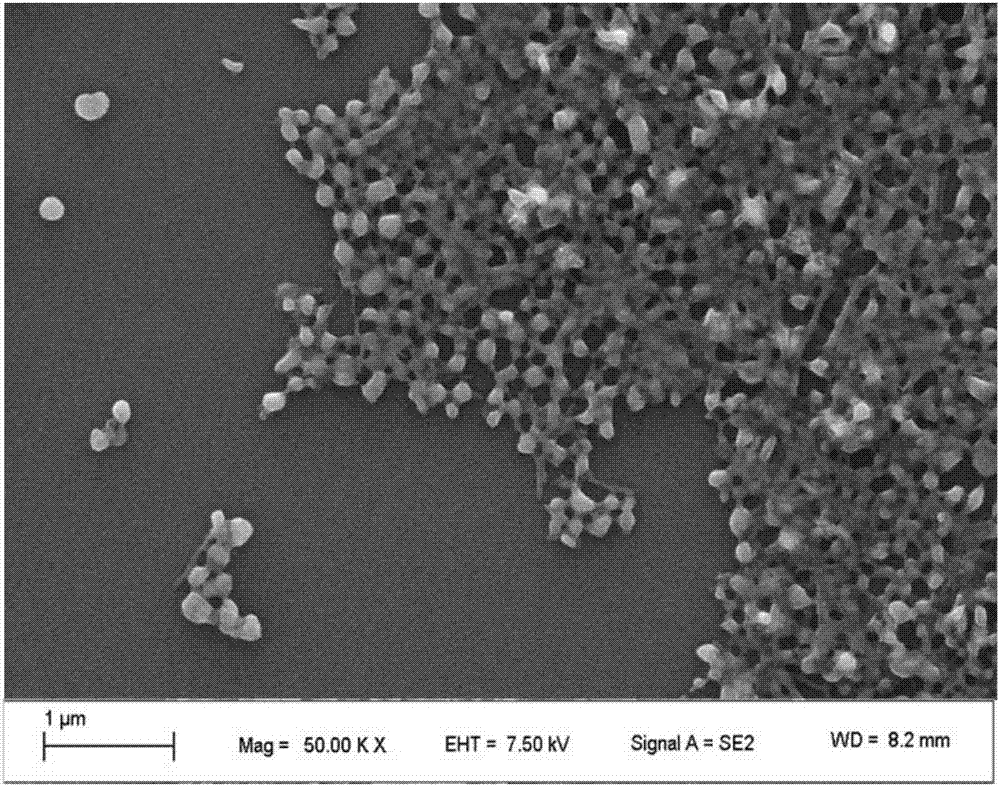

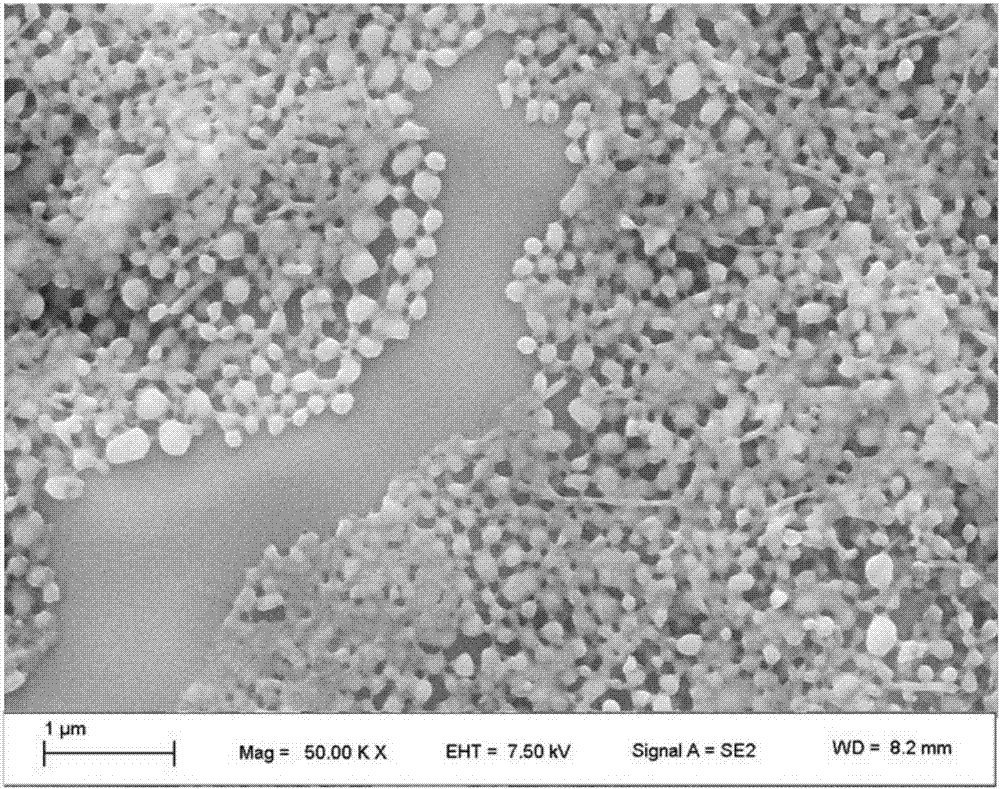

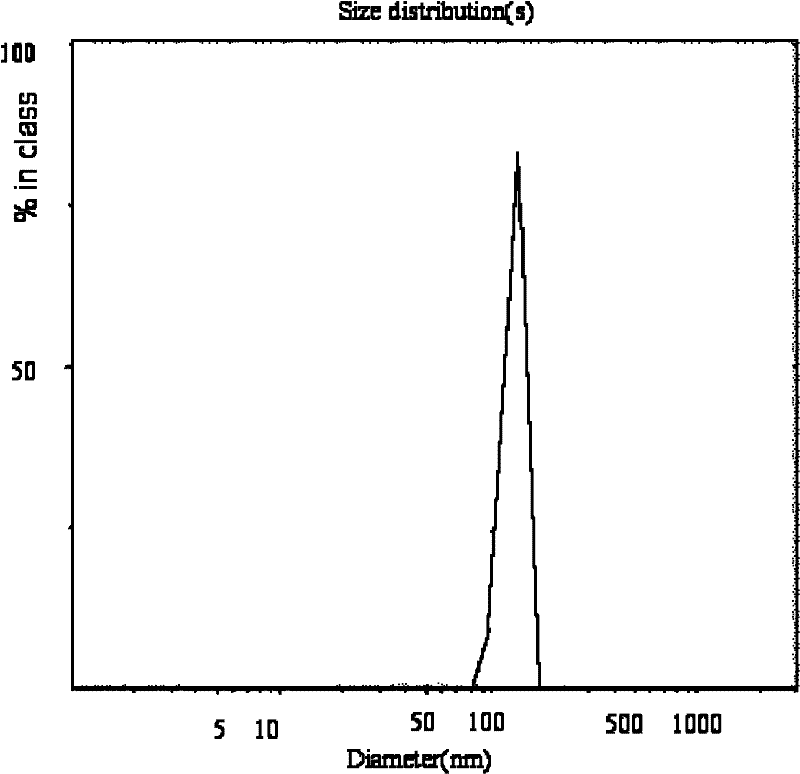

The invention discloses a solar cell packaging adhesive film with high light conversion efficiency. According to the adhesive film, a heavy rare earth ion doped inorganic fluorophor is adopted as a light up-conversion agent (two or more incident photons with the wavelength greater than 1,100 nm can be converted into a photo with the wavelength being 500 nm to 1,100 nm); a semiconductor quantum dot with a certain size distribution is adopted as a light down-conversion agent (an incident photon with the wavelength being 300 nm to 500 nm can be converted into a photo with the wavelength being 500 nm to 1,100 nm); the utilization rate of solar spectrum is effectively increased; and the photoelectric conversion efficiency of photovoltaic modules is improved. The conversion agents in the adhesive film do not contain organic ligands, so that the adhesive film is good in light stability and long in service life. In addition, the adhesive film is formed by premixing basic resin, the light down-conversion agent, the light up-conversion agent and the like and then performing extrusion casting or calendering by an extruder, so that the industrialized production can be realized.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Method for preparing pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and product thereof

InactiveCN101649065AImprove the effect of graftingDoes not affect light transmissionAlcoholPolyvinylidene difluoride

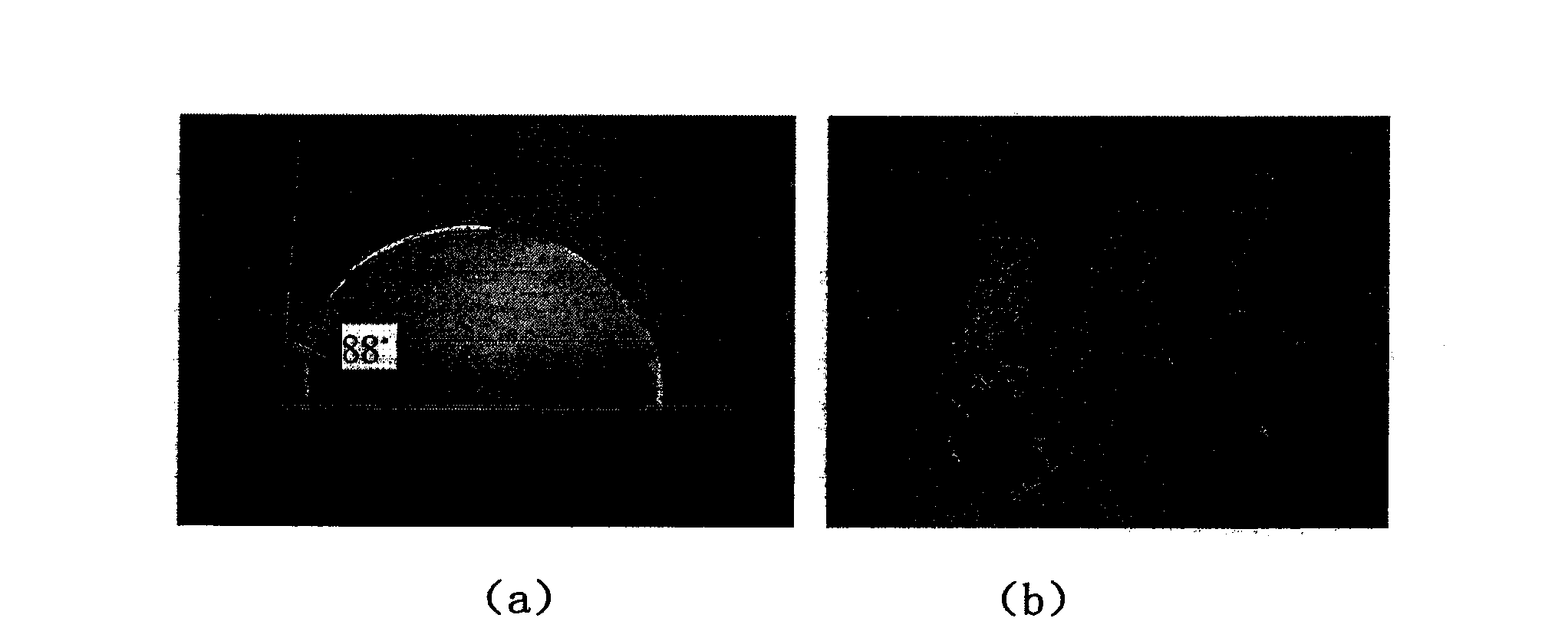

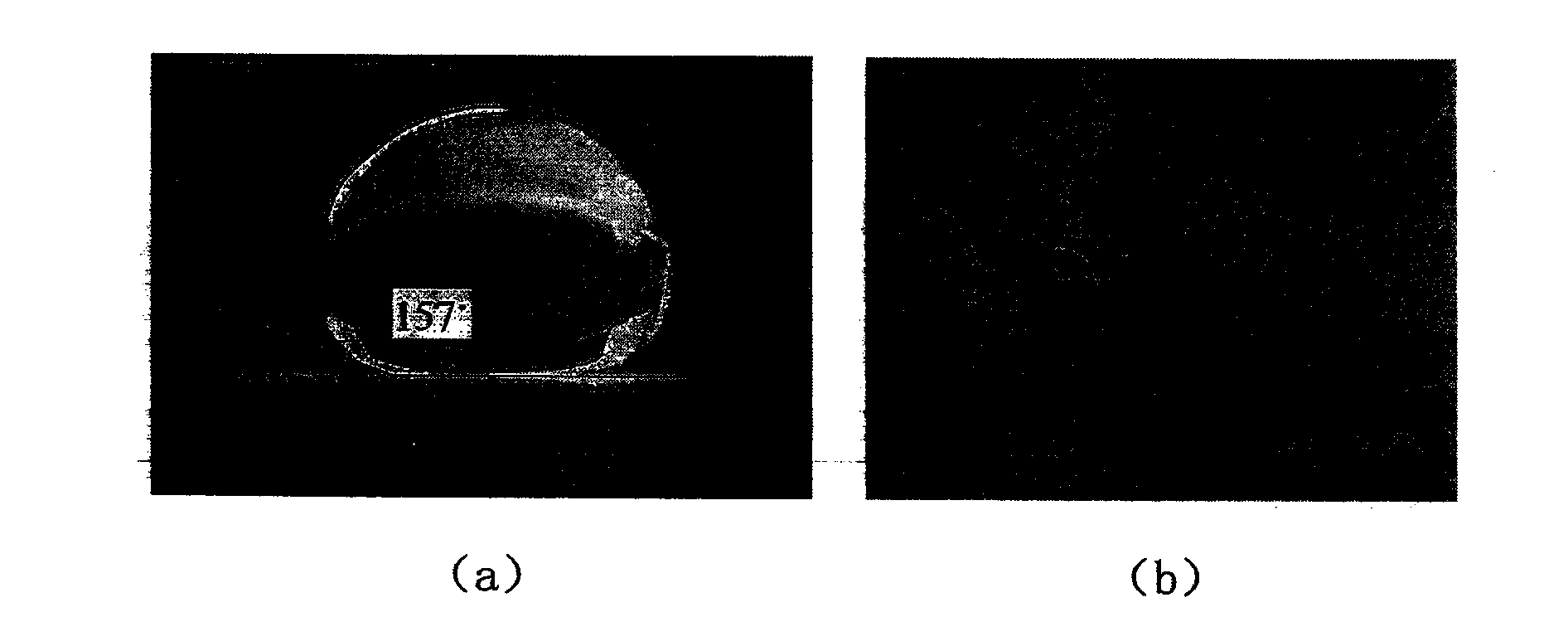

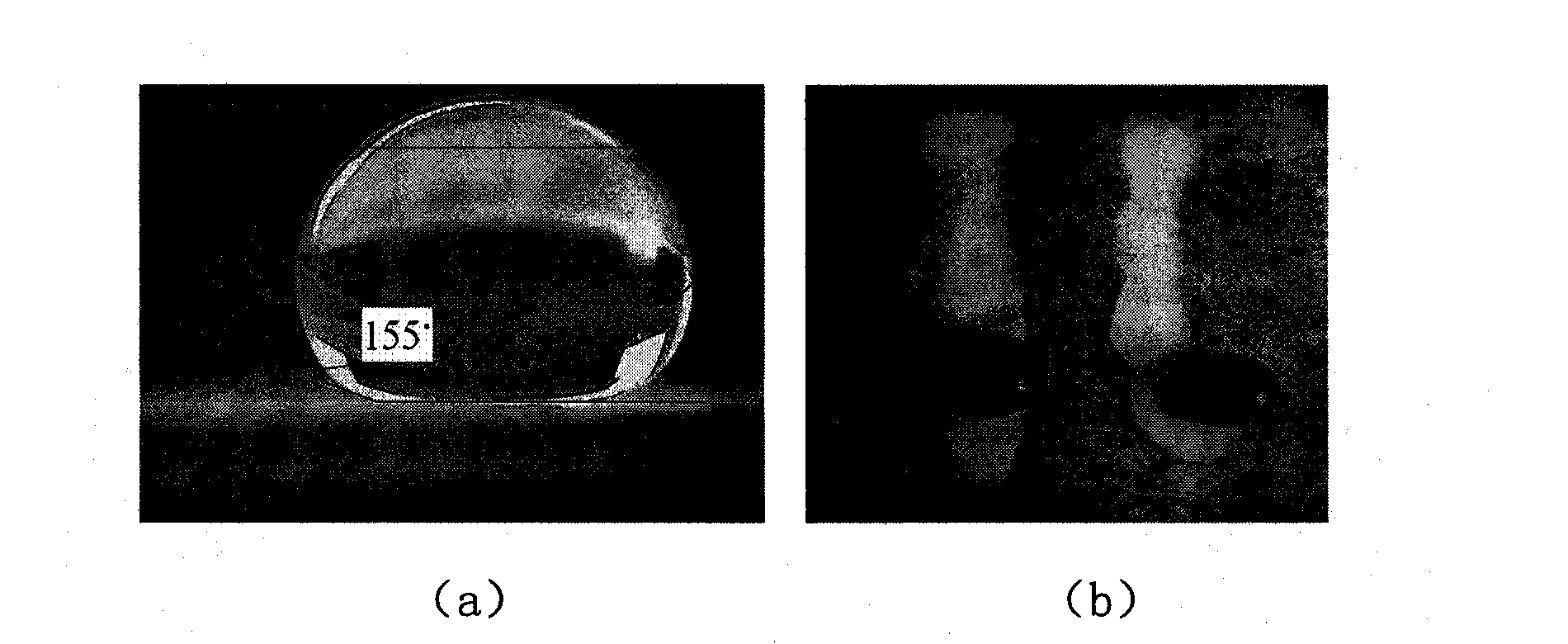

The invention relates to a method for preparing a pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and a product thereof. The method comprises the following processes: (1) PVDF film preparation; and (2) PVDF film processing with alkali liquor, including an alkali-water solution processing process and an alkali-alcohol solution processing process, wherein the alkali-water solution processing process comprises the following steps: soaking the PVDF film in alkali-water solution with the mass concentration of 20-40 percent; processing at 60-80 DEG C for 2-3 hours and then taking out to wash with water; drying and obtaining the PVDF film; the alkali-alcohol solution processing process comprises the following steps: soaking the PVDF film in alkali-alcohol solution with themass concentration of 2-10 percent; processing at 25-40 DEG C for 3-5 minutes and then taking the film out; washing with water and drying; soaking the PVDF film in proper solution to react at 25-60 DEG C for 3-10 minutes; then taking out and fully washing with water; drying and then obtaining the PVDF film; (3) decorating the surface of the PVDF film by organosilane and preparing the pollution preventing self-cleaning polyvinylidene fluoride film. The pollution preventing self-cleaning PVDF film product is prepared by the method.

Owner:TIANJIN POLYTECHNIC UNIV

High-gloss PTFE (polytetrafluoroethylene) anti-drop agent and preparation method thereof

The invention relates to a high-gloss PTFE (polytetrafluoroethylene) anti-drop agent and a preparation method thereof. The preparation method includes: 1), adding a small amount of an emulsified monomer A solution to a PTFE emulsion and performing irradiation treatment on the PTFE emulsion in high energy ray, and grafting a small number of monomers on the surface of PTFE particles; 2), in the absence of oxygen, initiating monomer B to perform polymerization reaction in the treated PTFE emulsion by the aid of an initiator and adding a cross-linking agent at a later stage to form nuclear-shell nano PTFE composite particles with PTFE particles as nuclears and a polymer as a shell; 3), filtering the modified PTFE emulsion and subjecting a filtrate to spray drying to obtain the high-gloss PTFE anti-drop agent. With the method, under the condition that no dispersants or compatibility agents are added, the anti-drop agent can be well-dispersed in thermoplastic resin with good compatibility, and light transmission, glossiness and the like of matrix resin are unaffected by the anti-drop agent dispersed in engineering plastics of PA, PC and the like.

Owner:安徽申嘉聚合物科技有限公司

Graphene protection method and graphene film containing protective layer

InactiveCN104692362ADoes not affect light transmissionDoes not affect processing performanceCarbon compoundsCarbon-silicon compound conductorsPolymethyl methacrylateSilicon dioxide

The invention relates to a method for protection of grapheme with a protective solution. The method comprises the steps of: 1) coating the graphene surface with the protective solution; and 2) curing the protective solution by heating or illumination to form a graphene film containing the protective layer. Specifically, the protective solution for forming the protective layer can be an acrylic acid based light curable glue, acrylic acid based heat curable glue, an epoxy light curable glue, an epoxy heat curable glue, a silicon based heat curable glue, a silicon based light curable glue, a silicon dioxide hardening liquid, a polyurethane based light curable glue, a polyurethane based heat curable glue, a polymethyl methacrylate heat curable glue or polymethyl methacrylate light curable glue. The invention also relates to the protective layer containing graphene film prepared according to the method.

Owner:2D CARBON CHANGZHOU TECH INC

Agent for dirt-removing and antifogging

InactiveCN1418787ANo pollution in the processNo pollutionOther chemical processesVehicle cleaningSolventSURFACTANT BLEND

The detersive antifogging agent for glass is made of (wt%) 10-20% of anhydrous ethanol as solvent, 5-15% of propylene glycol 5-15% of isopropanol as dispersing agent, 5-20% of cocoanut oil fatty acid diethanol acylamide as non-ionic surfactant, 1-1.5% of essence and 40-60% of pure clean water as raw material through the processes of uniformly stirring them and filling. It is simple in productionprocess and is obvious in detersive antifogging effect, and has extensive application.

Owner:崔长安

A kind of polymer type optical lens antifogging agent and preparation method thereof

InactiveCN102260482ADoes not affect light transmissionNot corrosiveOther chemical processesAnhydrous ethanolDistilled water

The invention relates to the field of material chemistry and mainly provides a polymer type antifogging agent for an optical lens and a preparation method thereof. The technical scheme in the invention comprises the following steps: mixing 1-2 parts by weight of colorless transparent secoctylphenol polyoxyethylene ether liquid which is abbreviated to TX-10, 8-12 parts by weight of isopropanol, 28-32 parts by weight of anhydrous ethanol and 45-50 parts by weight of double distilled water so as to form 100mL of basic liquid; and then adding about 100 parts by weight of double distilled water in 2-6 parts by weight of weighed white sodium dodecyl benzene sulfonate solid powder which is abbreviated to SDBS so as to prepare a 4.0% aqueous solution serving as an additive, and evenly mixing the additive with the basic liquid in a volume ratio of 1:1 (100mL:100mL), so that the antifogging agent is obtained.

Owner:中南大学肝胆肠外科研究中心 +1

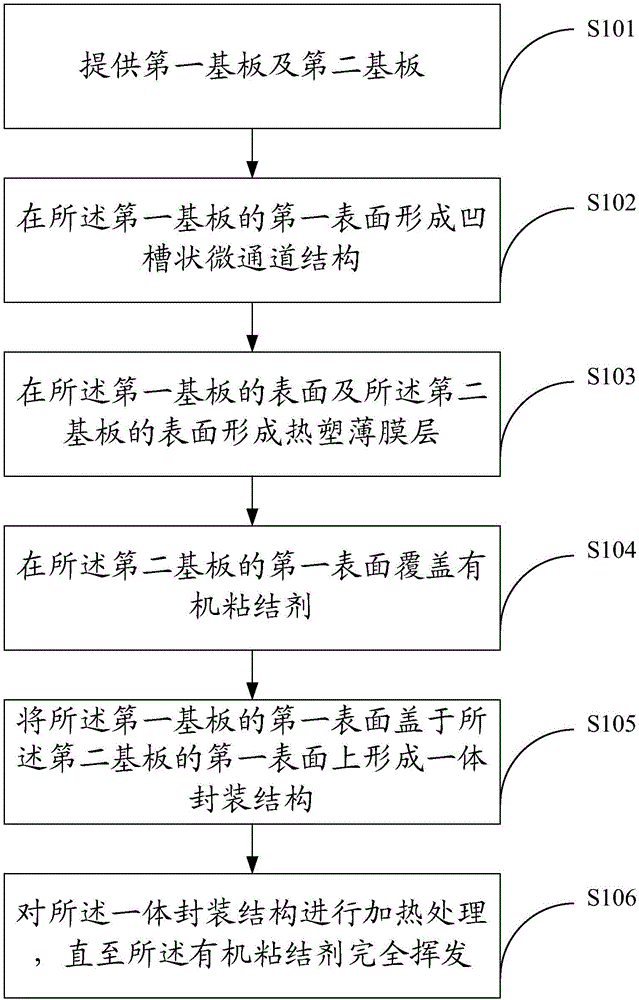

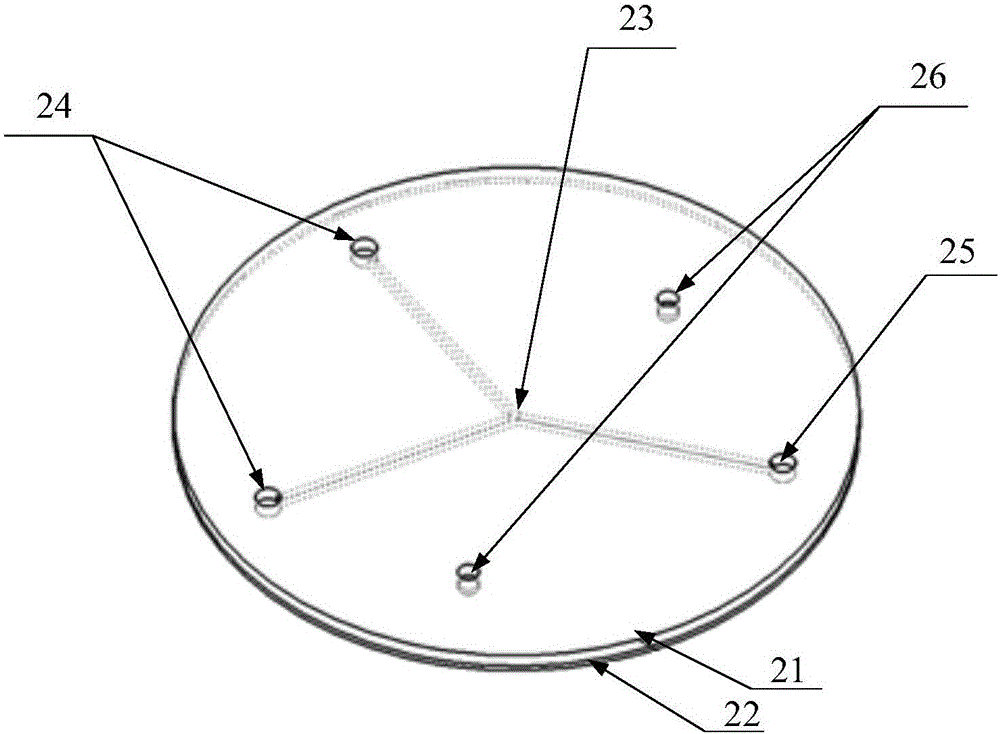

Method for packaging microfluidic chip

ActiveCN106531646AAccelerate evaporationImprove strength propertiesSemiconductor/solid-state device manufacturingLaboratory glasswaresAdhesiveEngineering

The invention provides a method for packaging a microfluidic chip. The method comprises the following steps: providing a first substrate and a second substrate; forming a groove-shaped micro channel structure on a first surface of the first substrate; forming a thermoplastic film layer on the surface of the first substrate and the surface of the second substrate; covering an organic adhesive on the first surface of the second substrate; covering the first surface of the first substrate on the first surface of the second substrate to form an integrated packaging structure; and performing heat treatment on the integrated packaging structure until the organic adhesive is completely volatilized. By adoption of the method, the problem of fracturing of a microfluidic structure in the microfluidic chip is solved, and the high strength, high reliability and light transmission of the microfluidic chip are guaranteed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

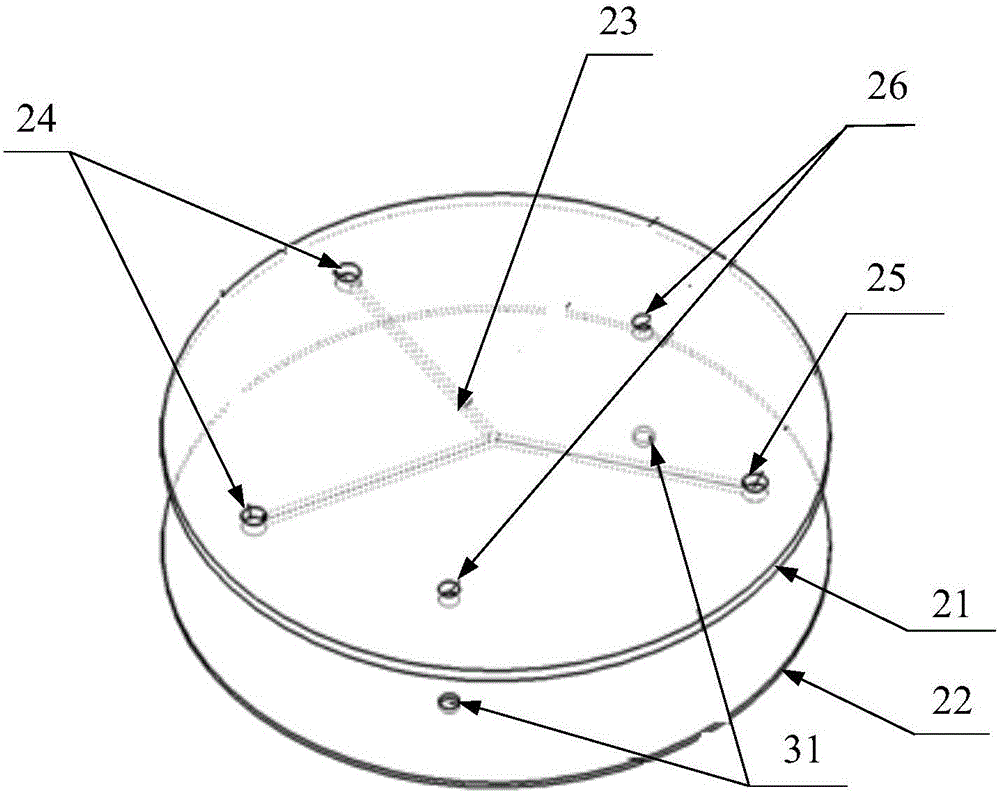

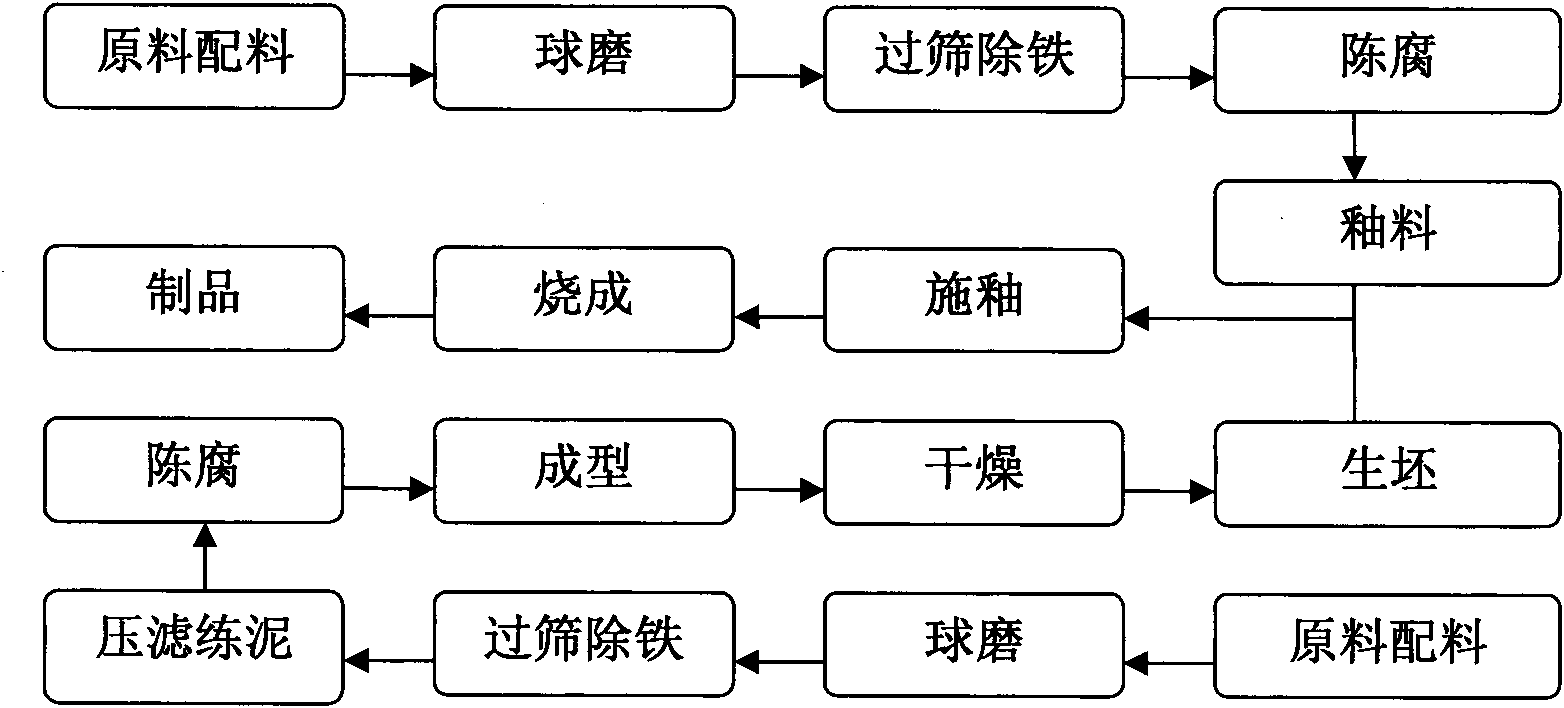

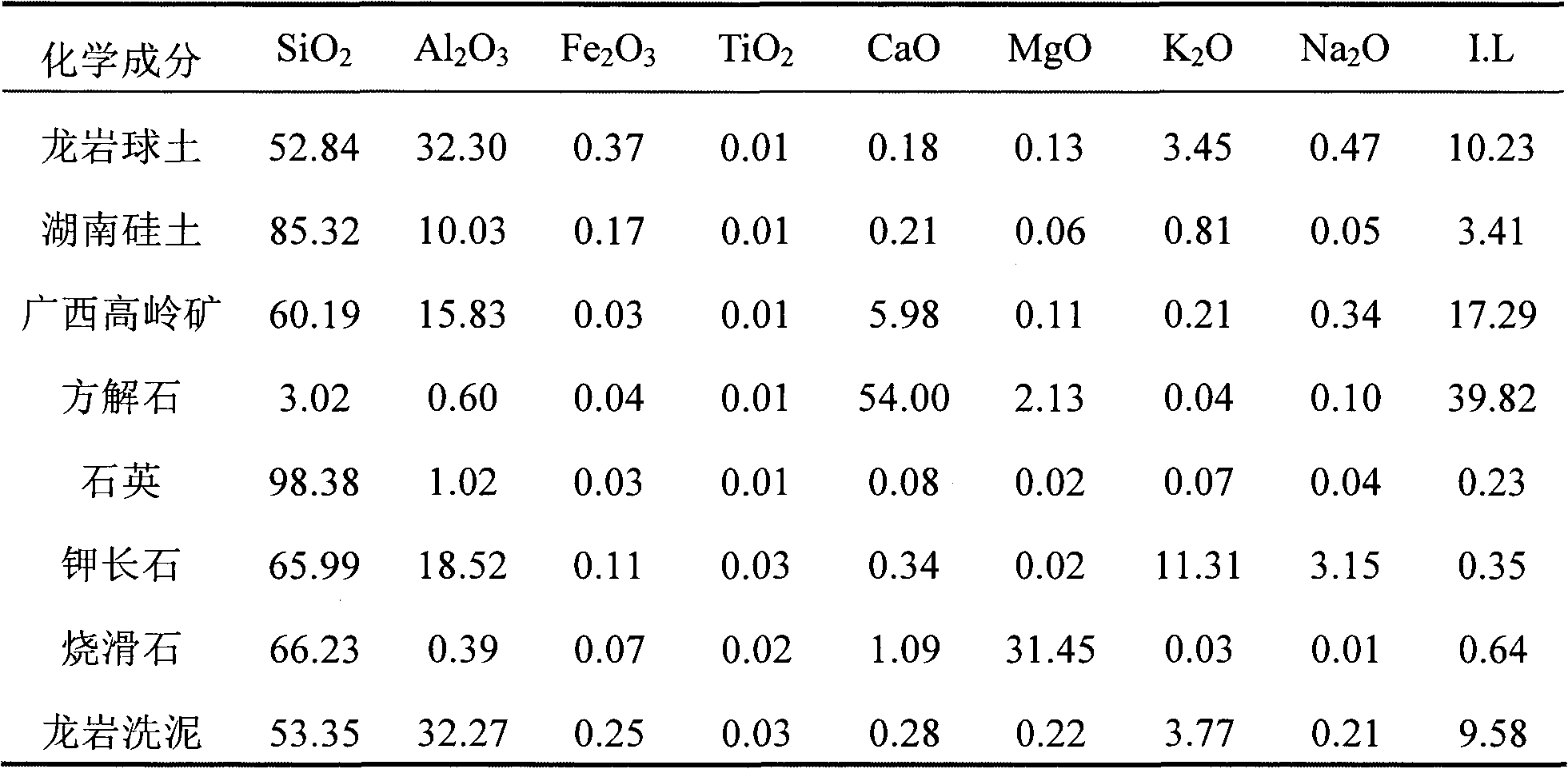

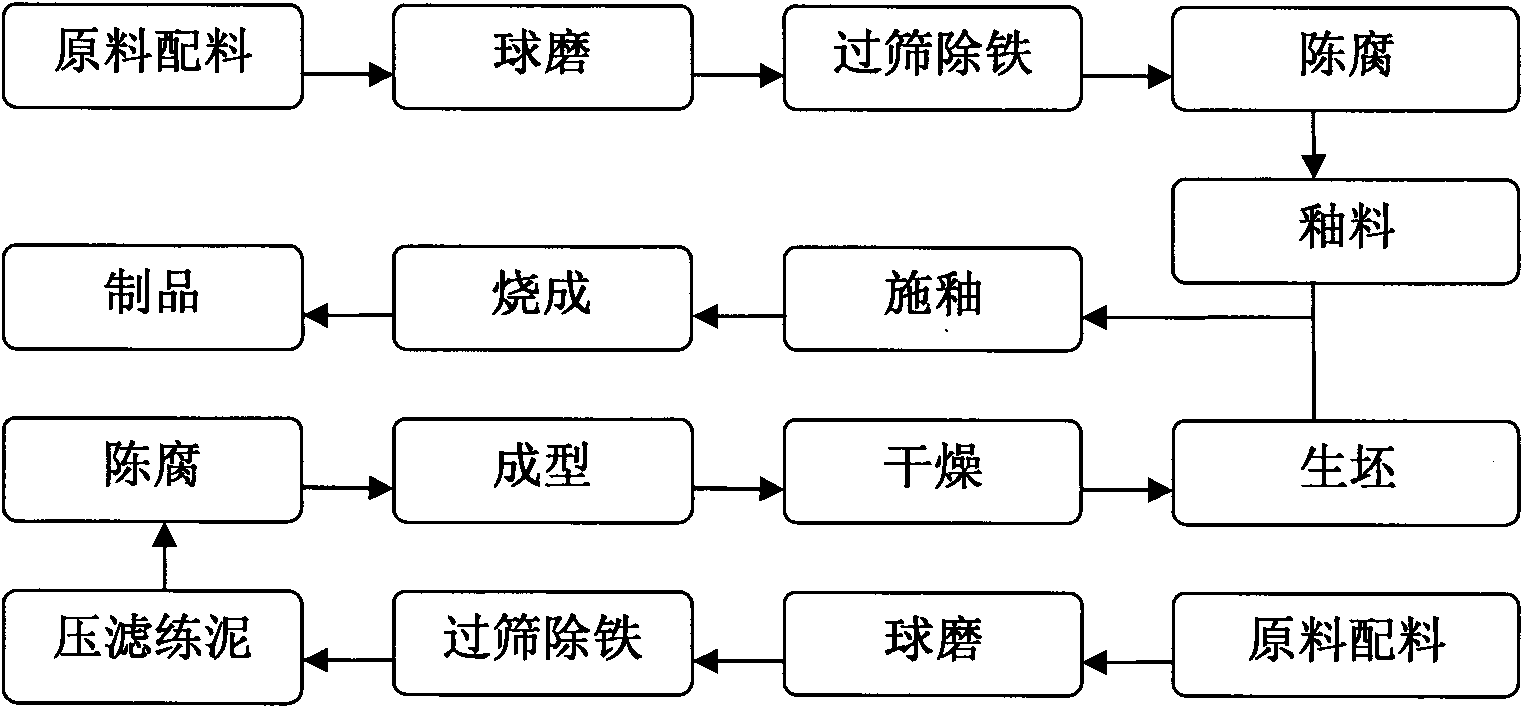

Preparation method of emerald ceramic

The invention discloses a preparation method of emerald ceramic, which comprises the steps of: (1) weighing raw materials according to a formula, mixing quartz, Guangxi Kaolinite and calcite for carrying wet-method ball-grinding, adding high-plasticity clay and low-plasticity clay for carrying out wet-method ball-grinding; (2) sieving and dewatering, ageing mud for 4-6 days, drying at a temperature of 80-110 DEG C after carrying out plastic forming; and (3) glazing, insulating the temperature at a temperature of 1240-1280 DEG C for 1-1.5h in an oxidizing atmosphere, and then cooling. The prepared emerald ceramic has the advantages of better permeability, light green color, emerald texture, high strength, good heat stability, lower production cost and better application value.

Owner:SOUTH CHINA UNIV OF TECH

Filling master batch capable of increasing strength and toughness of plastic product and preparation method of filling master batch

The invention belongs to the technical field of preparing a plastic product, and particularly relates to filling master batch capable of increasing strength and toughness of the plastic product and a preparation method of the filling master batch. The filling master batch is prepared by inorganic powder, a dispersing agent, a lubricating agent, a coupling agent, a heat stabilizer and carrier resin, and the inorganic powder is a mixture which is compounded by talcum powder and mica powder, of which the average grain diameters are 6-8 mum, in 1 : 1 mass ratio by passing through a 1800-2000 mesh screen. The filling master batch provided by the invention is mainly used for replacing part of synthetic resin in raw materials of an existing plastic product. Compared with the prior art, according to the filling master batch provided by the invention, the cost is low, and the production cost can be reduced to a large extent after part of the synthetic resin is replaced; and meanwhile, the filling master batch provided by the invention has the advantages of increasing the production efficiency, improving the product mechanical performance, increasing the heat-resisting temperature of the plastic product and the like, the plastic product, particularly a thin film product, which is prepared by adding the filling master batch is suitable for printing and is suitable for food and medical packaging industry.

Owner:河南惠强新能源材料科技股份有限公司

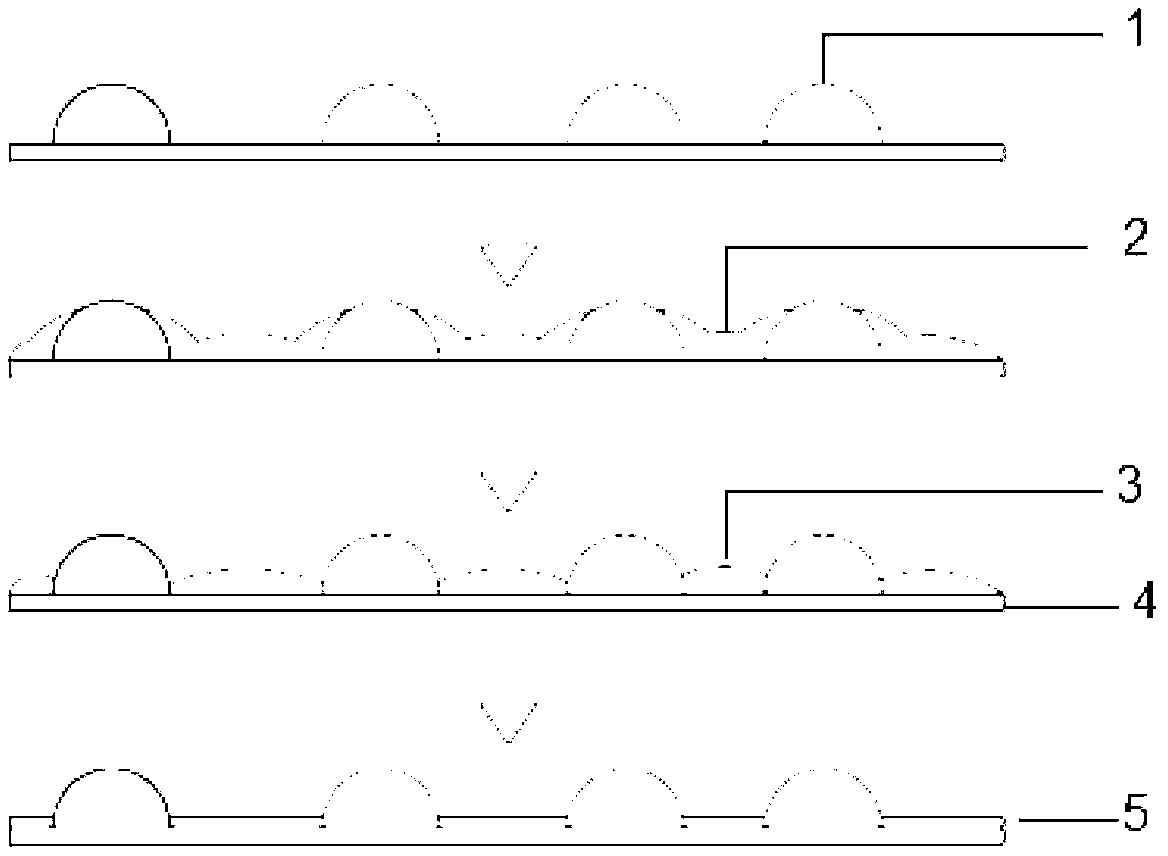

Chromatism-free patterning carbon nanotube transparent conductive film and preparation method thereof

ActiveCN103280255AImprove conductivityHigh light transmittanceConductive layers on insulating-supportsCable/conductor manufactureTransmittanceElectric properties

The invention discloses a chromatism-free patterning carbon nanotube transparent conductive film and a preparation method of the chromatism-free patterning carbon nanotube transparent conductive film. The chromatism-free patterning carbon nanotube transparent conductive film comprises a transparent substrate, a patterning carbon nanotube film which is at least distributed in a visible area on the surface of the transparent substrate, and a patterning insulating material layer distributed on the surface of the transparent substrate, the insulating material layer and the carbon nanotube film are staggered and complemented at least in the visible area, and the light transmittance of the insulating material layer and the light transmittance of the carbon nanotube film are also fundamentally consistent. The preparation method includes the steps of forming the patterning insulating material layer on the surface of the transparent substrate, and forming the patterning carbon nanotube film at least in the visible area on the surface of the transparent substrate. Preferably, the insulating material layer can be mainly made of hydrophobic insulating material, and paint can be further mixed. According to the chromatism-free patterning carbon nanotube transparent conductive film and the preparation method of the chromatism-free patterning carbon nanotube transparent conductive film, high-efficiency, large-area and continual preparation of the chromatism-free patterning carbon nanotube transparent conductive film can be achieved, the technology is easy and controllable, needed equipment is simple, cost is low, optical and electric properties of products are good, and the chromatism-free patterning carbon nanotube transparent conductive film has wide application prospects.

Owner:SUZHOU HANANO MATERIALS TECH LTD

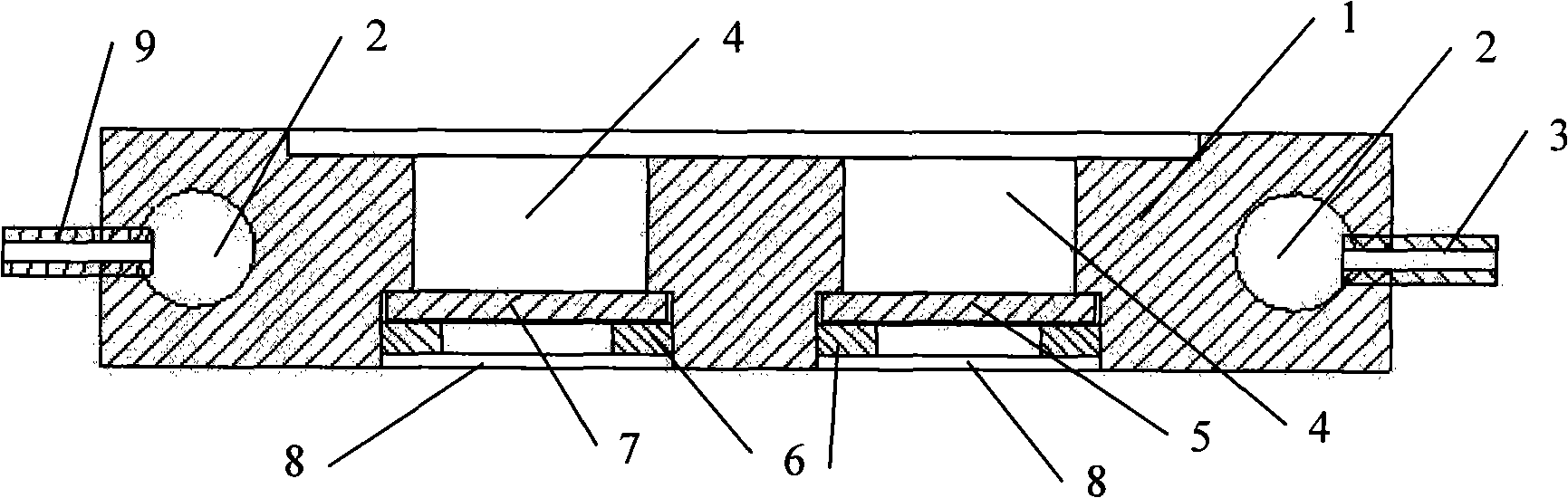

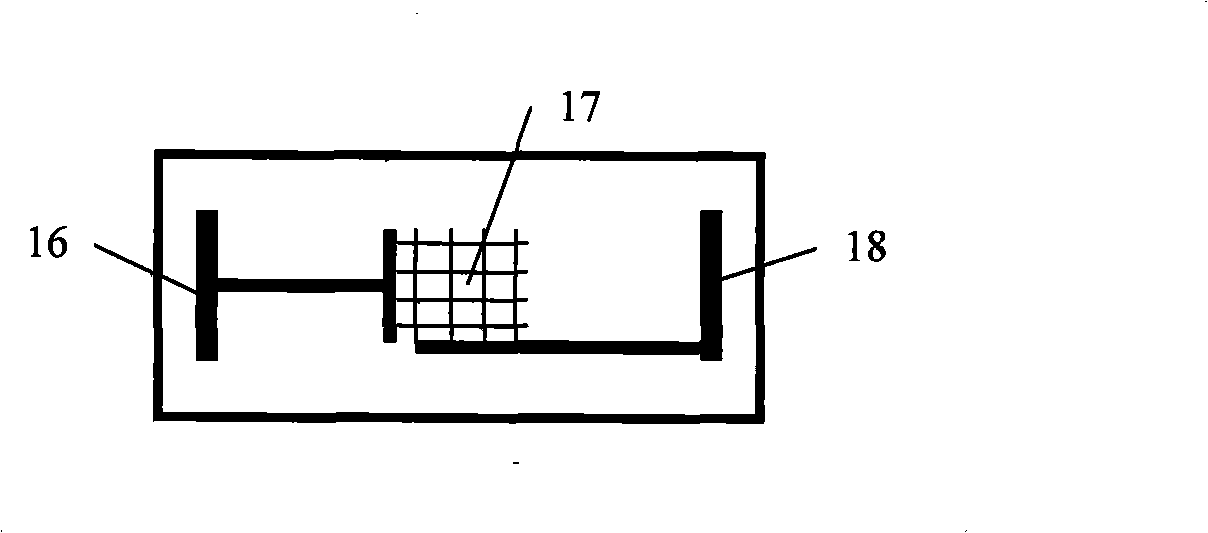

Low-temperature microscopic differential scanning calorimetry system body apparatus

InactiveCN101334398AUnbreakableExcellent optical propertiesMicrobiological testing/measurementMaterial analysis by optical meansNitrogen gasEngineering

The invention discloses a main device of a cryogenic micro-differential scanning calorimetry system which comprises a cryostage, a sample support and a reference support; the cryostage is a cylinder, an annular nitrogen channel is arranged inside the cryostage, and the cyrostage is provided with a cold nitrogen inlet and a cold nitrogen outlet; two symmetrical cavities are opened along the central axis line of the cryostage, the upper half part of each cavity is cylindrical, the lower half part of each is rectangular, the sample support or the reference support is arranged in the rectangular cavities and fixed by a rectangular brass ring; cold nitrogen carries out the heat exchange with the cryostage after entering the annular channel, the cold energy is transferred to the sample and the reference support, thereby completing the cooling of the sample and a reference substance; the sample and the reference support adopt quartz glass as substrates, grid-shaped thin-film thermocouples are sputtered on the quartz substrates; the back surfaces of the quartz substrates are plated with transparent tin oxide heating thin films; the outsides of the thin-film thermocouples and the tin oxide heating thin films are respectively plated with SiO2 protective layers; the sample and the reference support are geometrically symmetrical and same in weight. The main device of the cryogenic micro-differential scanning calorimetry system can simultaneously obtain micro-images of the sample and various physical and chemical parameters during the temperature increase and the temperature decrease processes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

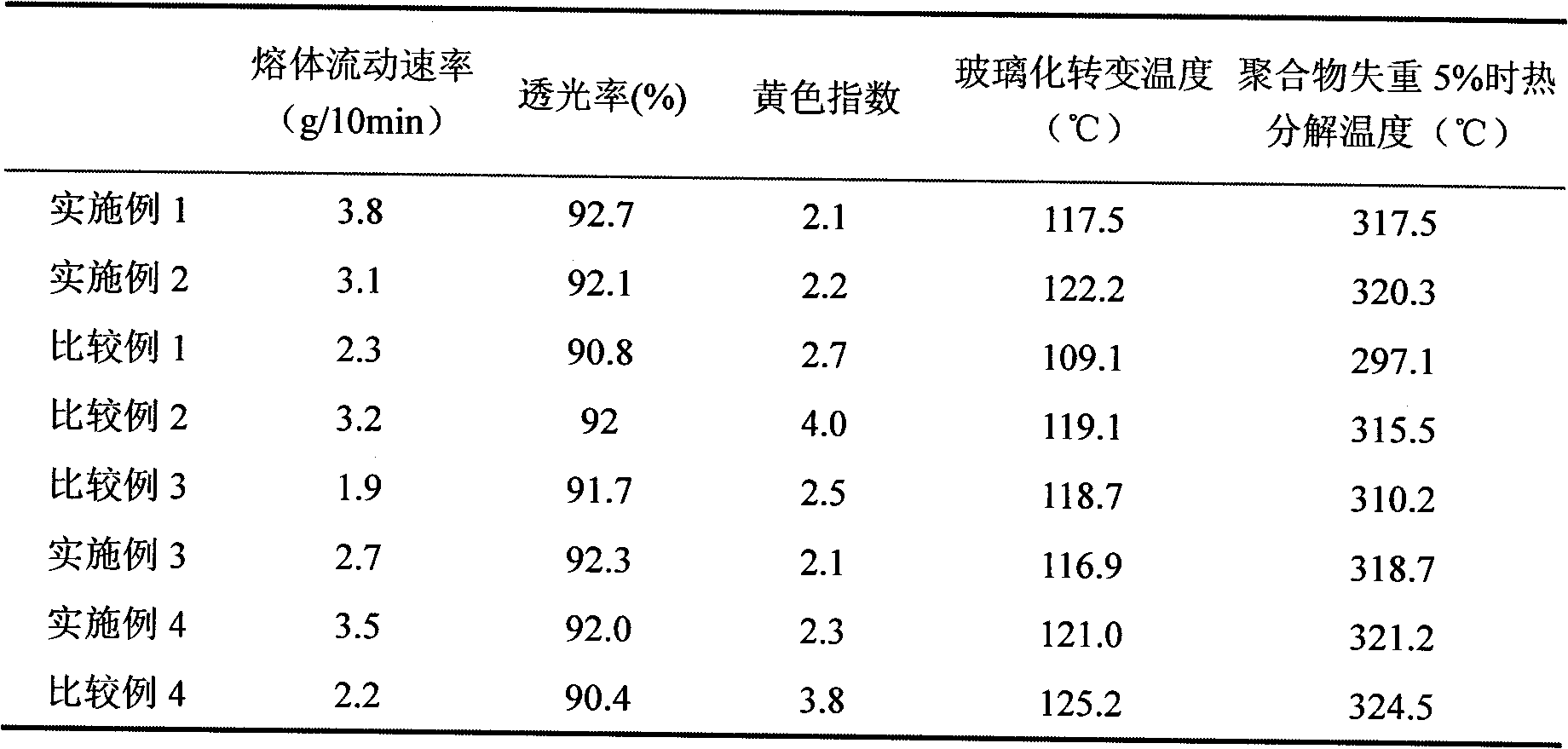

Method for preparing (methyl) acrylate polymer

ActiveCN102311518AHigh glass transition temperatureIncrease the initial thermal decomposition temperaturePolymer scienceReaction temperature

The invention relates to a method for preparing a (methyl) acrylate polymer. In the method, high-temperature continuous bulk polymerization is performed or less than or equal to 5 percent of atent solvent is added so as to perform solution polymerization in a circulating tube type reactor and a straight tube type reactor, and an N-alkyl maleimide monomer and a vinyl monomer are introduced into a (methyl) acrylate monomer and are copolymerized with the (methyl) acrylate monomer so as to prepare the (methyl) acrylate polymer with good heat resistant performance. The method comprises the following steps of: reducing the content of oxygen dissolved in a comonomer to 1 to 3 ppm by nitrogen; supplying the (methyl) acrylate monomer, the N-alkyl maleimide monomer and the vinyl monomer to the circulating tube type reactor continuously, and controlling the conversion rate to be 45 to 60 percent, wherein the polymerization temperature is between 130 and 150 DEG C; and conveying a reaction mixture to the straight tube type reactor continuously, wherein the reaction temperature is controlled to be 140 to 160 DEG C, and the polymerization conversion rate is controlled to be 55 to 90 percent. Bythe method, the glass transition temperature and initial thermal decomposition temperature of the polymer are improved obviously.

Owner:PETROCHINA CO LTD

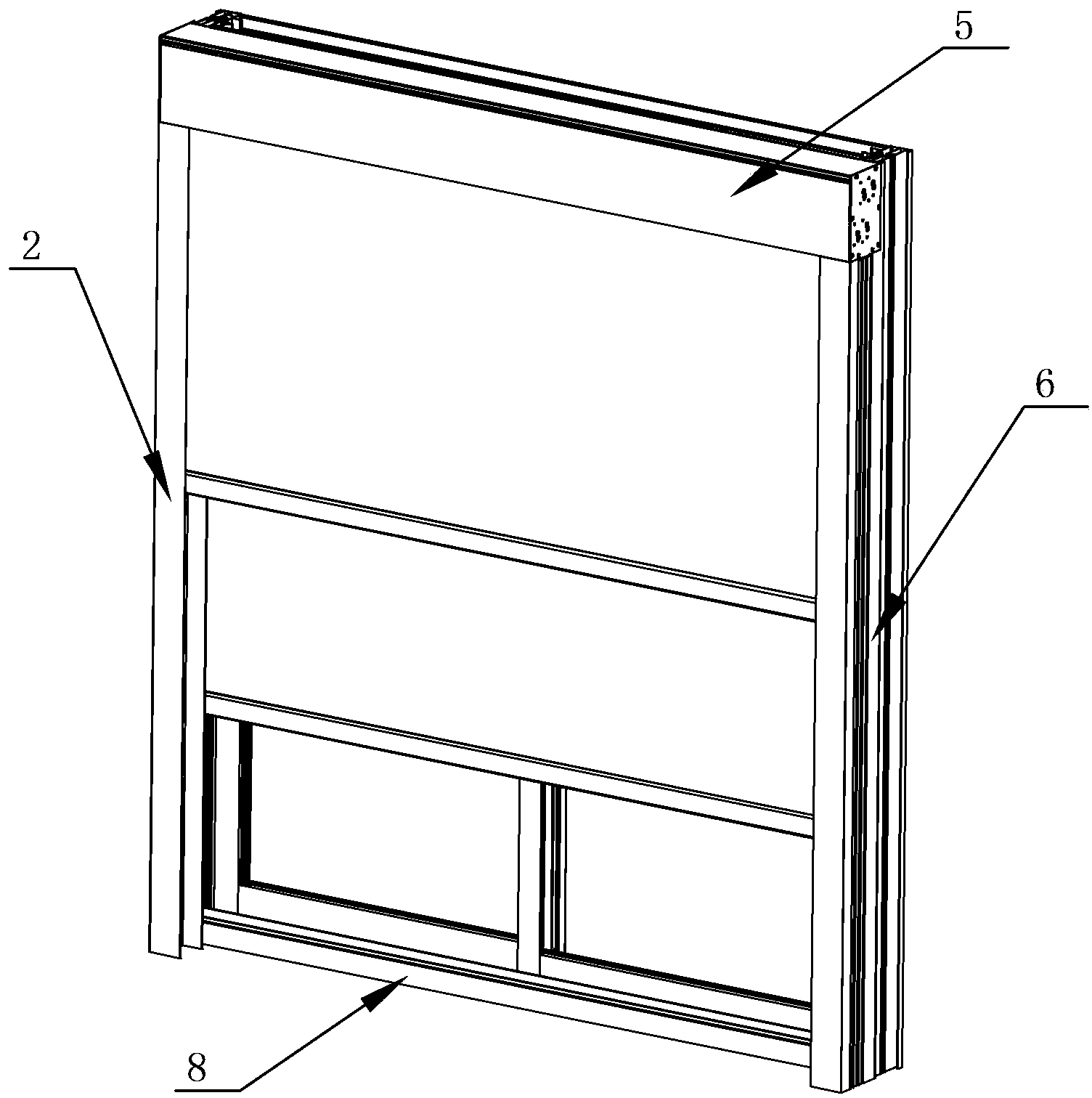

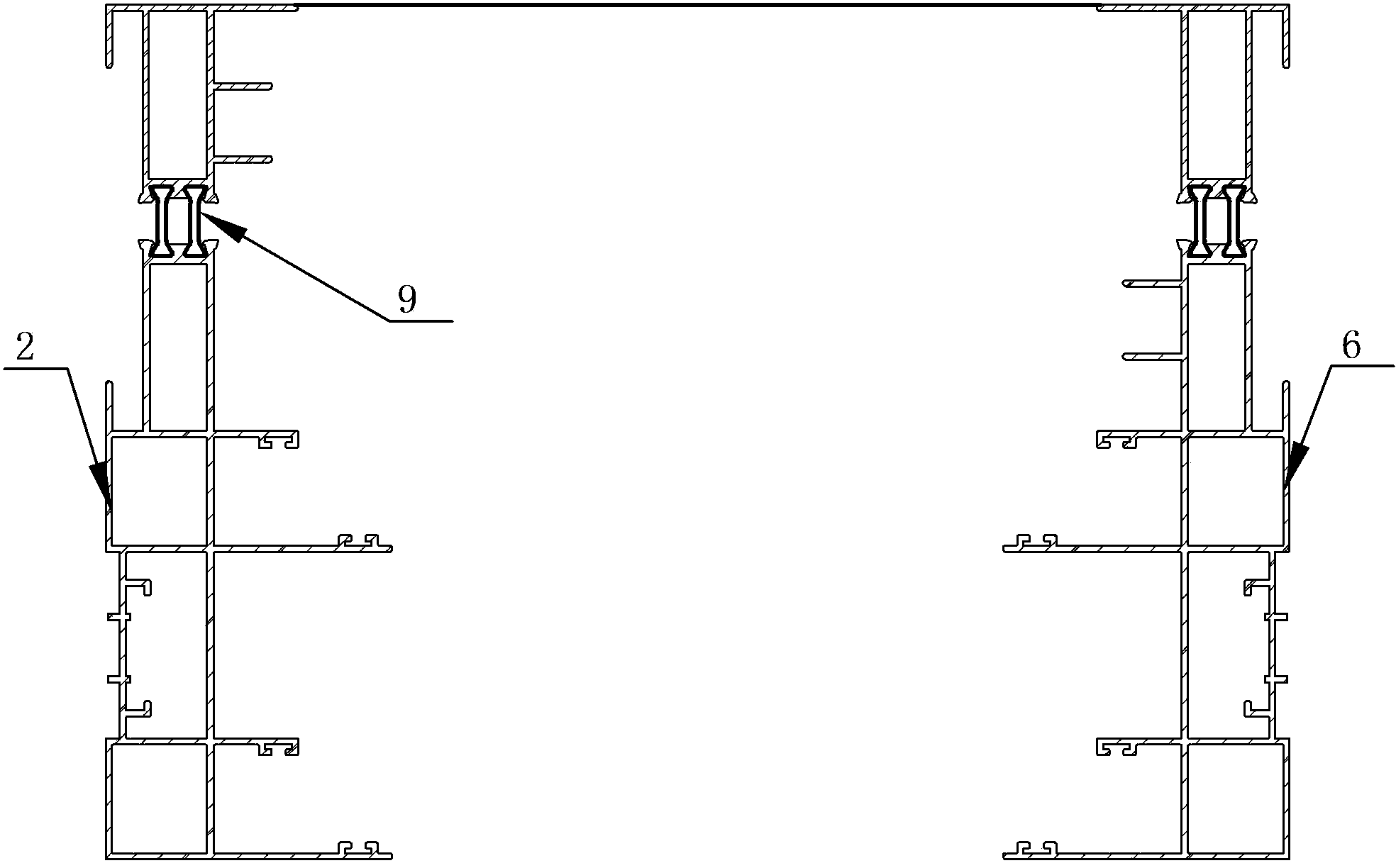

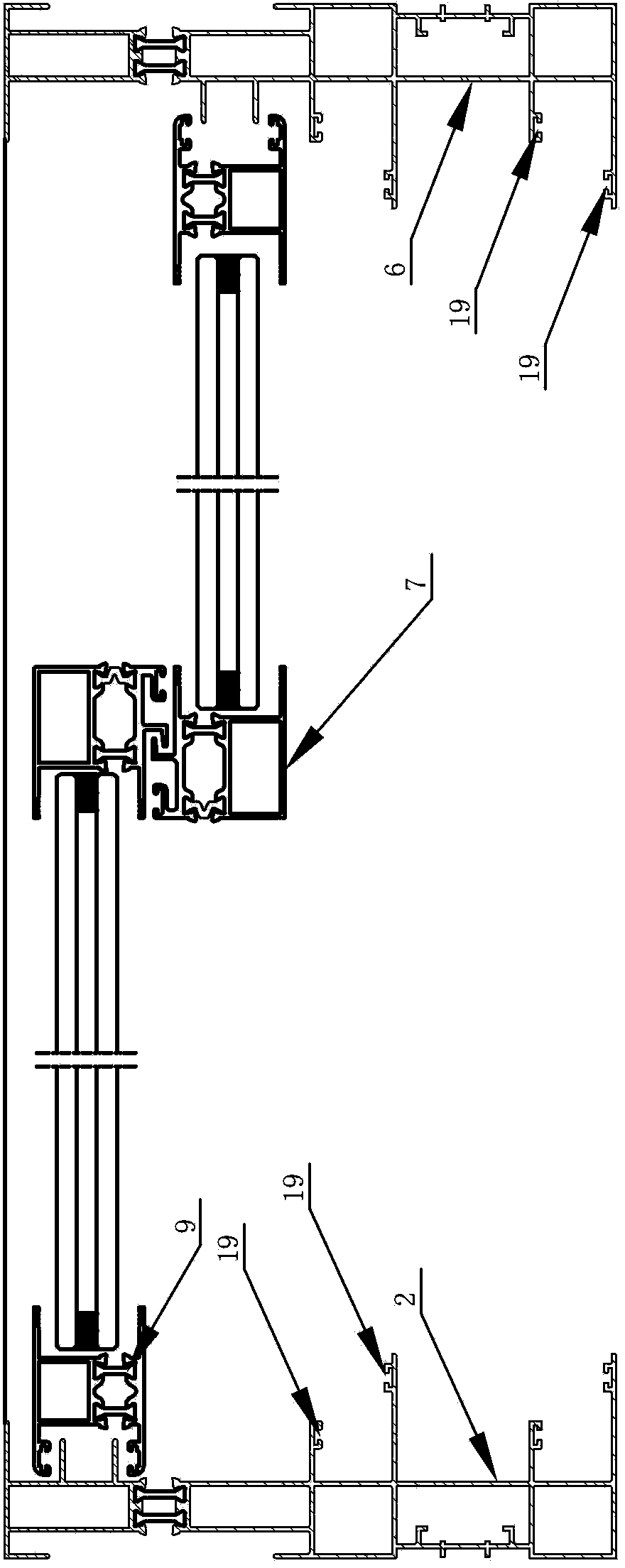

Integrated window

ActiveCN103352638ADoes not affect strengthDoes not affect light transmissionLight protection screensWing arrangementsSash windowEngineering

The invention provides an integrated window, and belongs to the field of building components. The integrated window solves the problem that a curtain cannot be conveniently installed on an external window of an existing building. The integrated window comprises a window frame, wherein sash grooves which are used for installation of sashes are formed in the window frame, a curtain cover is installed on the top of the window frame, and curtain fabric is hung on the curtain cover. According to the integrated window, the structure of the curtain is added in the condition that the requirements for strength, light transmission and ventilation of the integrated window are not influenced, construction operation of installing the curtain of a user is omitted, time and manpower are saved, and cost of materials can also be reduced due to the fact that batch production is carried out on both components such as the curtain cover, and the window frame.

Owner:NINGBO XIANFENG NEW MATERIAL

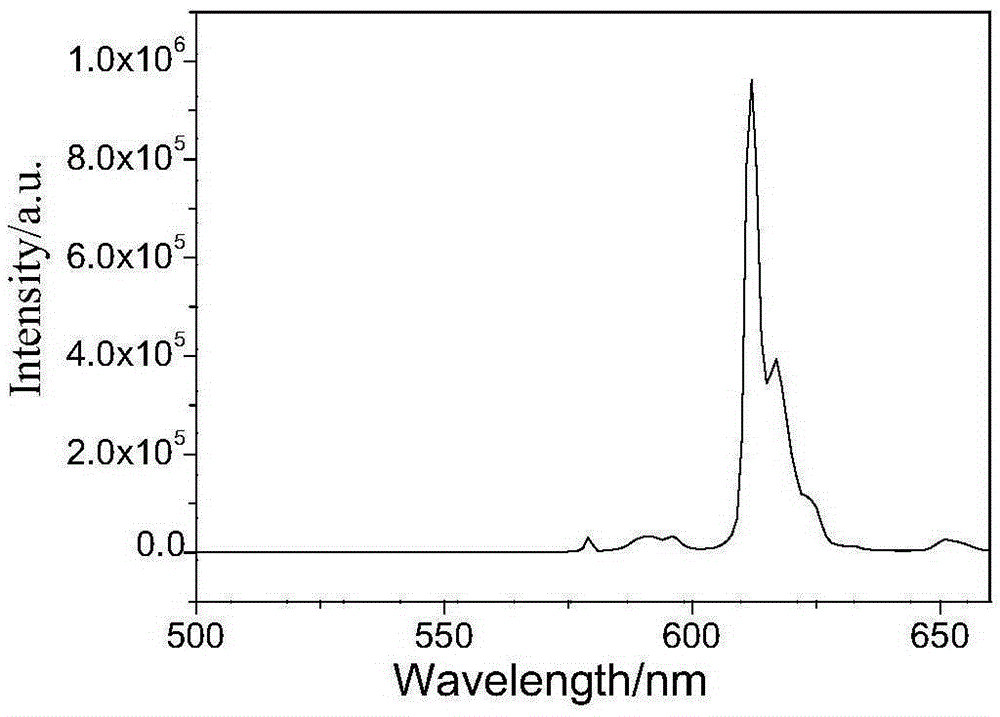

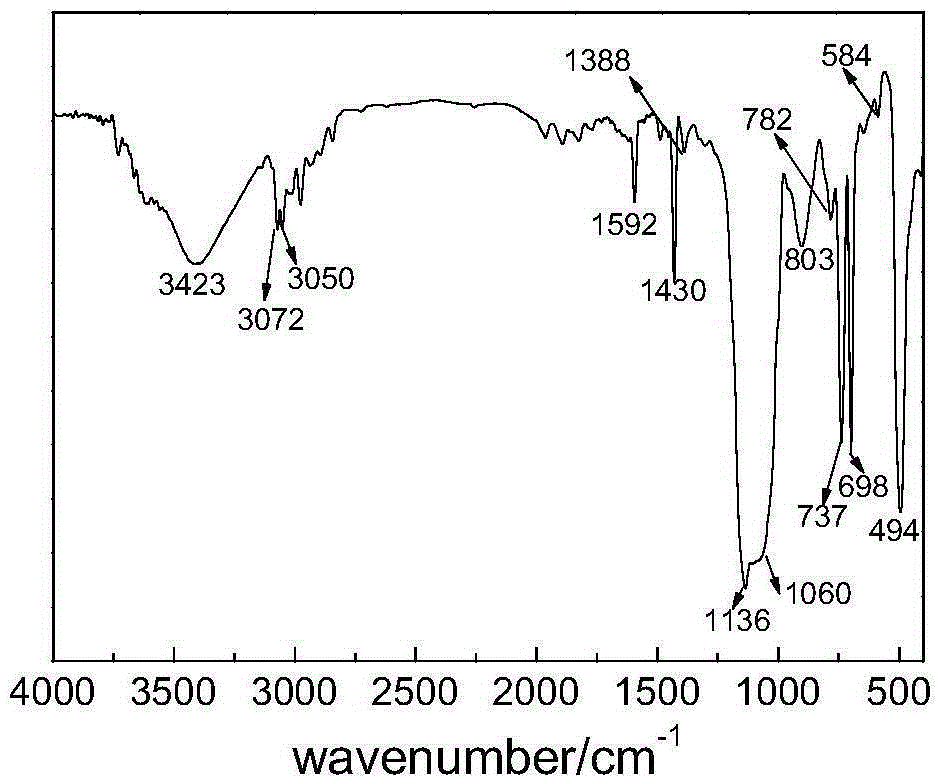

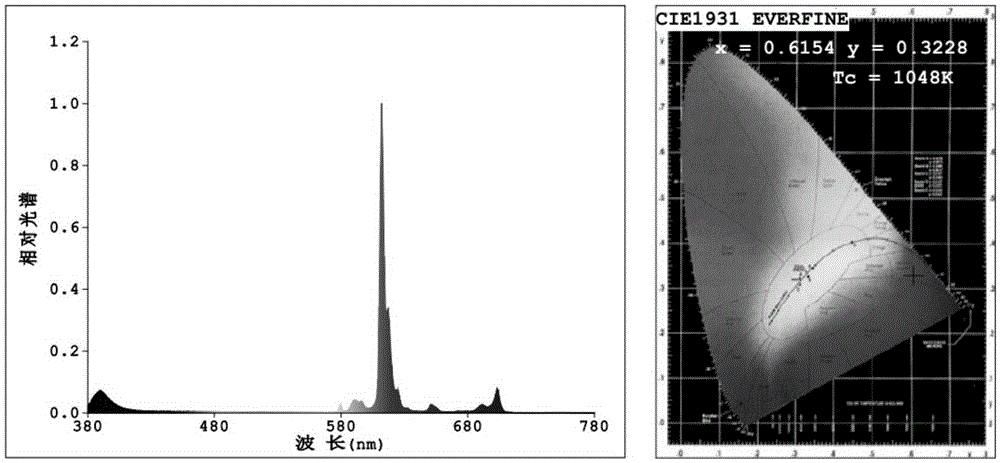

Preparation method of organic/inorganic composite luminous silica gel with integrated functions of luminescence and encapsulation and application of silica gel on LED light source

ActiveCN105295387AImprove performanceImprove Optical UniformityLuminescent compositionsSemiconductor devicesFluorescenceElectric light

The invention specifically relates to an organic / inorganic composite luminous silica gel with integrated functions of luminescence and encapsulation and a preparation method thereof, and also relates to an application of the silica gel on LED electric light source. The preparation method comprises the following steps: carrying out supermolecular assembly on hydrotalcite and rare earth organic luminous complex, wherein the region isolation effect of nano sheet layers of rigid hydrotalcite can be utilized to inhibit the concentration quench of rare earth complex so as to improve the thermal stability; then introducing fluorescent hydrotalcite is individually introduced into methyl phenyl vinyl silicon resin and methyl phenyl hydrogen-containing silicon resin through a peeling reassembly method to evenly disperse rare earth organic complex into the silicon resin matrix in the molecular level so as to produce luminous methyl phenyl vinyl silicon resin and luminous methyl phenyl hydrogen-containing silicon resin; and finally carrying out silicon-hydrogen addition reactions to produce the luminous silica gel with an encapsulation function. The prepared luminous silica gel can replace the conventional fluorescent powder and encapsulation material in the LED production. The produced LED has better optical homogeneity, and the luminous efficiency of single bulb is also improved.

Owner:FUJIAN NORMAL UNIV

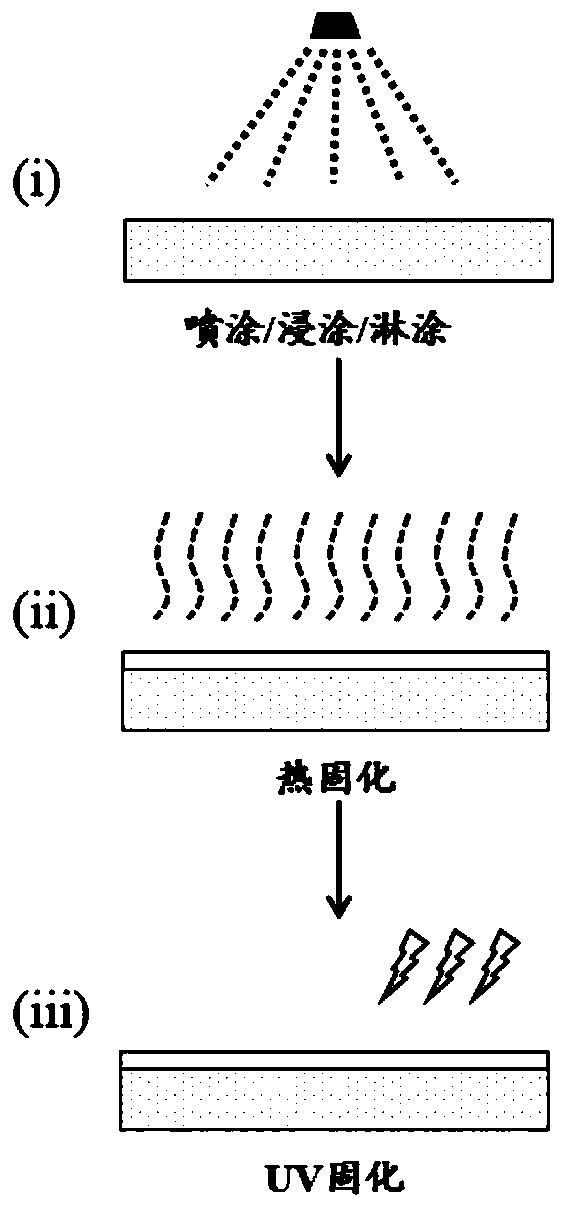

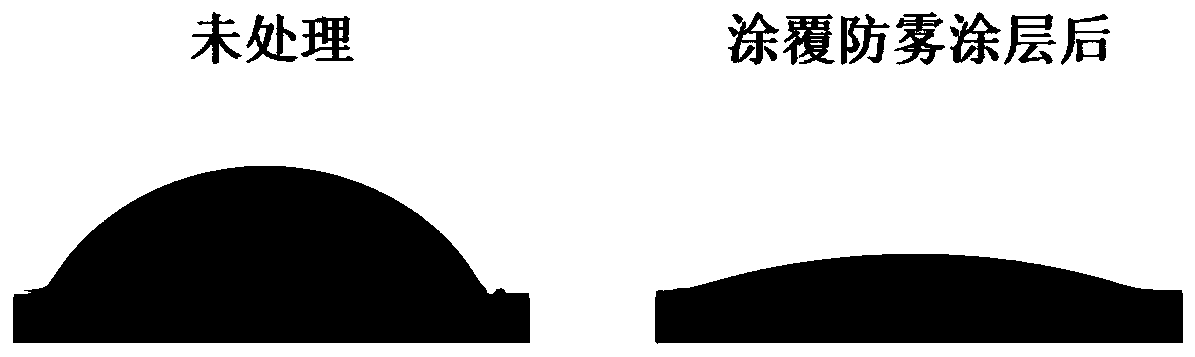

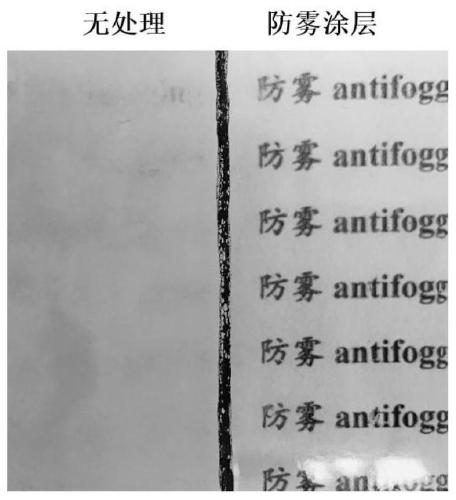

Wear-resistant anti-fog resin and preparation method thereof, and anti-fog coating

The invention relates to the technical field of functional materials, and provides wear-resistant anti-fog resin and a preparation method thereof, and an anti-fog coating. According to the invention,the types of monomers are optimized; the wear-resistant anti-fog resin which can be self-crosslinked under the conditions of heat and UV is synthesized; the anti-fog resin can be dissolved in a low-toxicity organic solvent, a long-acting wear-resistant anti-fog coating can be prepared on planar and curved glass, PC, PMMA and PET, other initiators or cross-linking agents do not need to be added inthe curing process, and use and residues of toxic small molecules are reduced. The anti-fog coating provided by the invention has the advantages of lasting anti-fog effect, environment-friendly construction process, good wear resistance and higher safety to a human body, and the light transmission performance of the base material is not influenced.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid self-cleaning glass film, preparation method of self-cleaning glass and product obtained through preparation method

The invention discloses a liquid self-cleaning glass film, a preparation method of self-cleaning glass and a product obtained through the preparation method. The preparation method comprises the preparation steps of mixing butyl titanate, alkoxysilane and ethanol, and performing stirring until the butyl titanate and the alkoxysilane are uniformly and sufficiently mixed so as to obtain a clear solution; adding water and acid, performing continuous stirring until the butyl titanate and the alkoxysilane are sufficiently hydrolyzed; after sufficient hydrolyzing, concentrating the obtained solution, obtaining a liquid self-cleaning glass film, coating the surface of the glass with the glass film, and drying so as to obtain the self-cleaning glass. The method is performed at the room temperature, and simple in technology; the glass film and a glass base material are firmly combined, so that the self-cleaning capacity is high, the hydrophilicity is good, the photodegradation organic pollutant is good in effect, and the service life is long. Compared with a conventional method, the preparation method disclosed by the invention has the advantages that the technology is simple, the cost is low, the industrialized production is facilitated, and the liquid self-cleaning glass film can be widely applied in the fields of glass curtain walls, window glass, solar power plants and the like.

Owner:UNIV OF JINAN

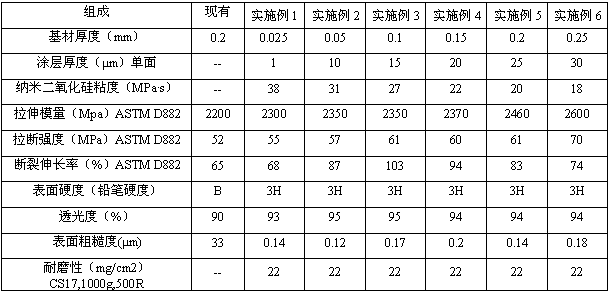

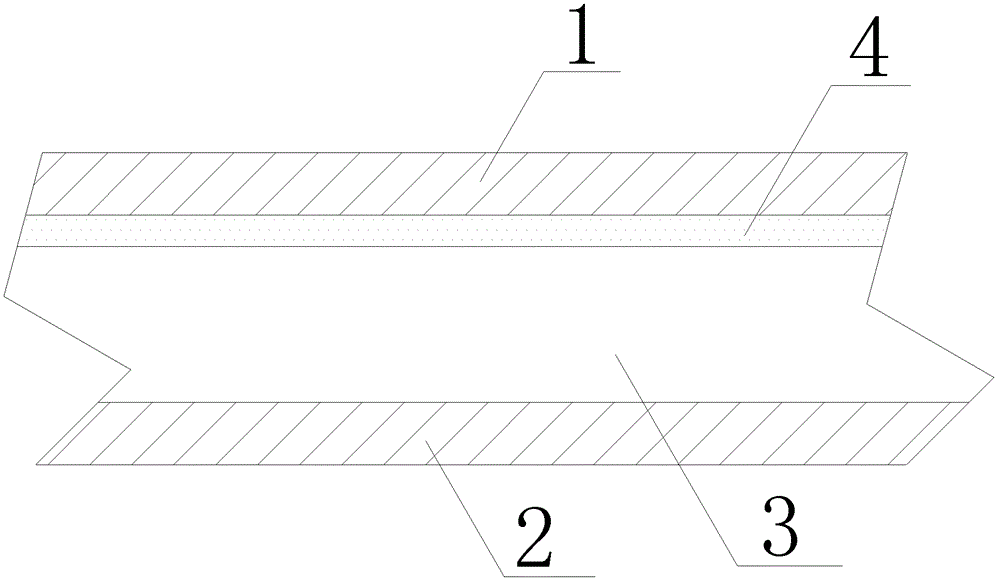

High-strength wear-resistant high-transmission polycarbonate film

InactiveCN103214687ADoes not affect light transmissionHigh strengthSynthetic resin layered productsCoatingsWear resistantUltraviolet

The invention relates to the field of polycarbonate resin, in particular relates to a high-strength wear-resistant high-transmission polycarbonate film. The high-strength wear-resistant high-transmission polycarbonate film comprises a base material made from polycarbonate, wherein the base material is a sheet or a film with the thickness of 0.025-25mm, a layer of nano silicon dioxide dried and cured by ultraviolet rays is sprayed on at least one of an upper surface and a lower surface of the sheet or film, the average spraying thickness of the single surface is 1-100mum, the viscosity of the nano silicon dioxide is 18-38MPa.s, the split particles with particle size distribution of 0.1-0.5mum are more than 99%, and the specific surface area is 25-100m<2> / g. According to invention, the high-strength wear-resistant high-transmission polycarbonate film is sprayed on the surface of the polycarbonate, and one layer of nano silicon dioxide is dried and cured by ultraviolet rays, so that on the premise that the transmission of the film is not influenced, the strength and tensile ductility of the film can be improved, the wear resistance and finishing can be enhanced, the applications of the film are wide. Thus, the high-strength wear-resistant high-transmission polycarbonate film is a novel environment-friendly multifunctional film.

Owner:上海冠旗电子新材料股份有限公司

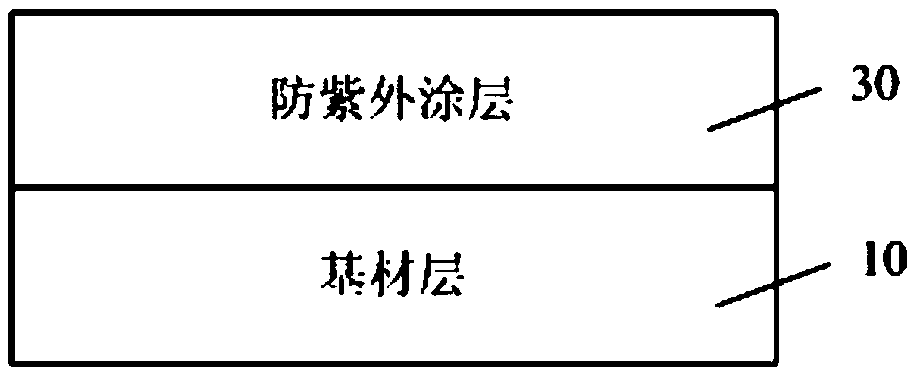

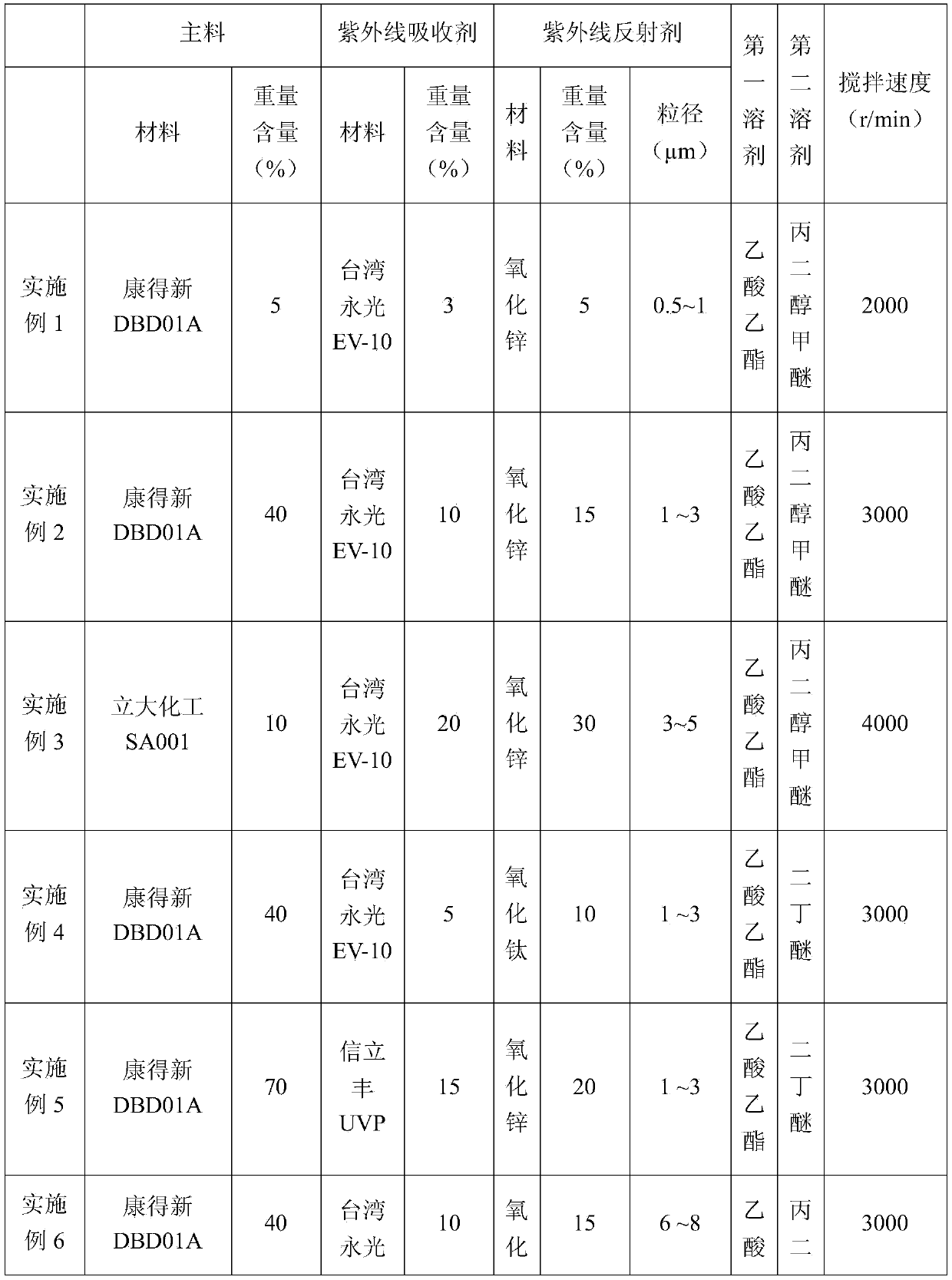

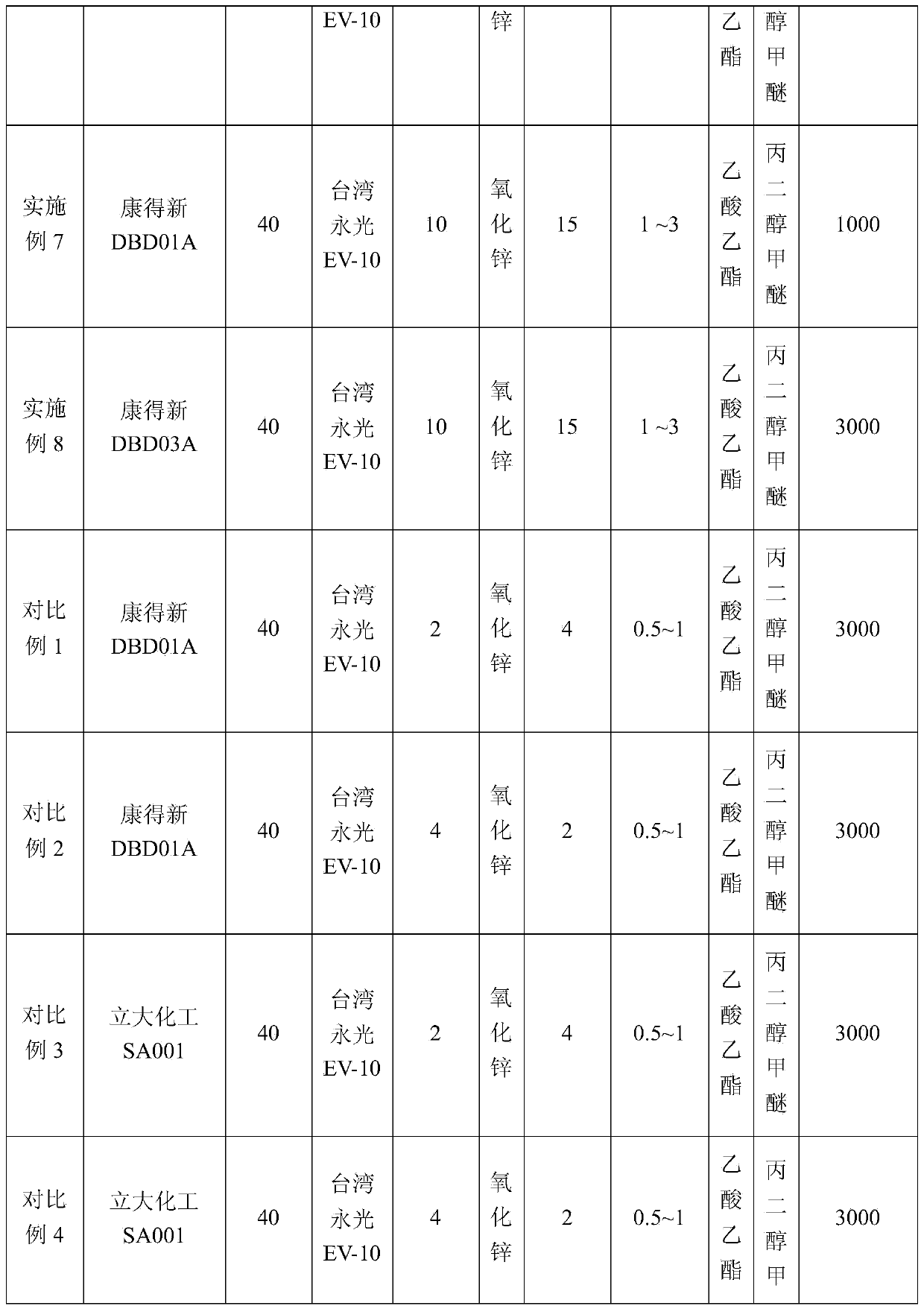

Anti-ultraviolet material, anti-ultraviolet film and preparation method of film

ActiveCN105368116AHigh UV reflectivityHigh yieldPolyurea/polyurethane coatingsRadiation-absorbing paintsCost ControlsUv absorber

The invention provides an anti-ultraviolet material, an anti-ultraviolet film and a preparation method of the film. The anti-ultraviolet material comprises a hardening coating, an ultraviolet absorber and an ultraviolet reflection agent, and in the above material compositions, the ultraviolet absorber weight content is in the scope of 3-20%, and the ultraviolet reflection agent weight content is in the scope of 5-30%. The anti-ultraviolet material is capable of relatively well guaranteeing relatively high ultraviolet reflectivity and absorptivity without influencing the light transmission performance, and also is in favor for cost control.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Visible-light response self-cleaning coating and preparation method thereof

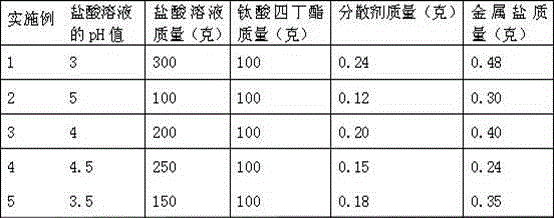

ActiveCN103555010ABroaden applicationDoes not affect light transmissionCoatingsPolyethylene glycolMaterials science

The invention discloses a visible-light response self-cleaning coating and a preparation method thereof. The self-cleaning coating comprises the following components in percentage by mass: 5-10.5% of titanium dioxide doped with metal ions and added with a dispersing agent, 0.5-1% of polysiloxane and the balance of solvent and impurities, wherein the metal ions are one of W<6+> and V<4+> or a mixture of the two; the dispersing agent is PEG (polyethylene glycol). The preparation method comprises the following steps: A) preparing a titanium dioxide sol doped with metal ions and added with the dispersing agent; B) preparing polysiloxane; C) preparing the self-cleaning coating: mixing the titanium dioxide sol doped with metal ions and added with the dispersing agent with the polysiloxane sol at a proportion of (9-19):1 to obtain the visible-light response self-cleaning coating. The self-cleaning coating disclosed by the invention can respond to catalysis at the visible light band, and is convenient to coat without influencing the light transmission of glass; the preparation method has the characteristics of simple process, low production cost and the like.

Owner:SHANGYU JIEHUA CHEM

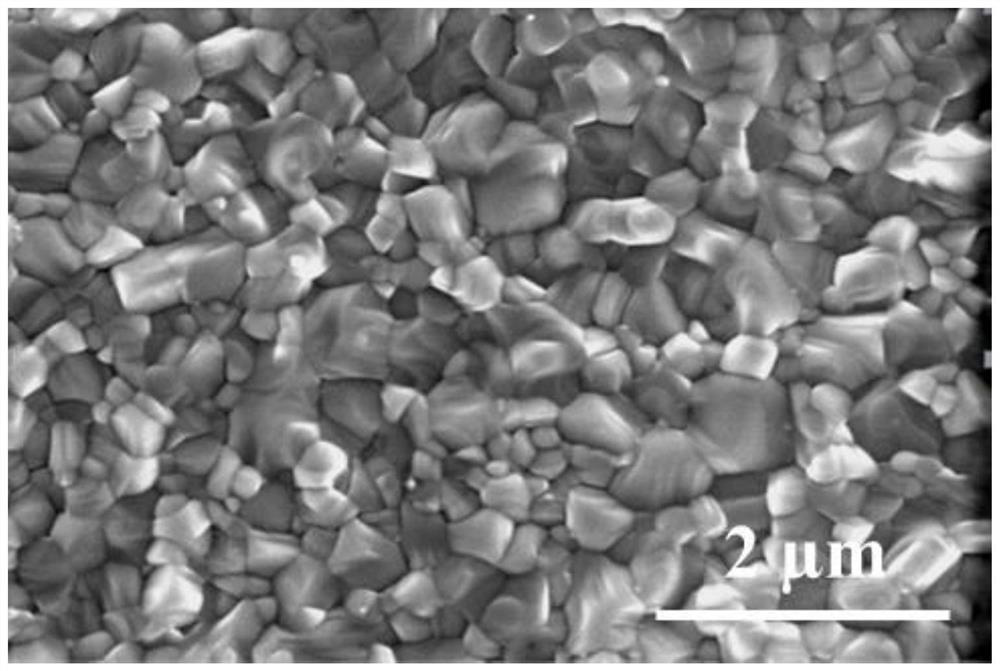

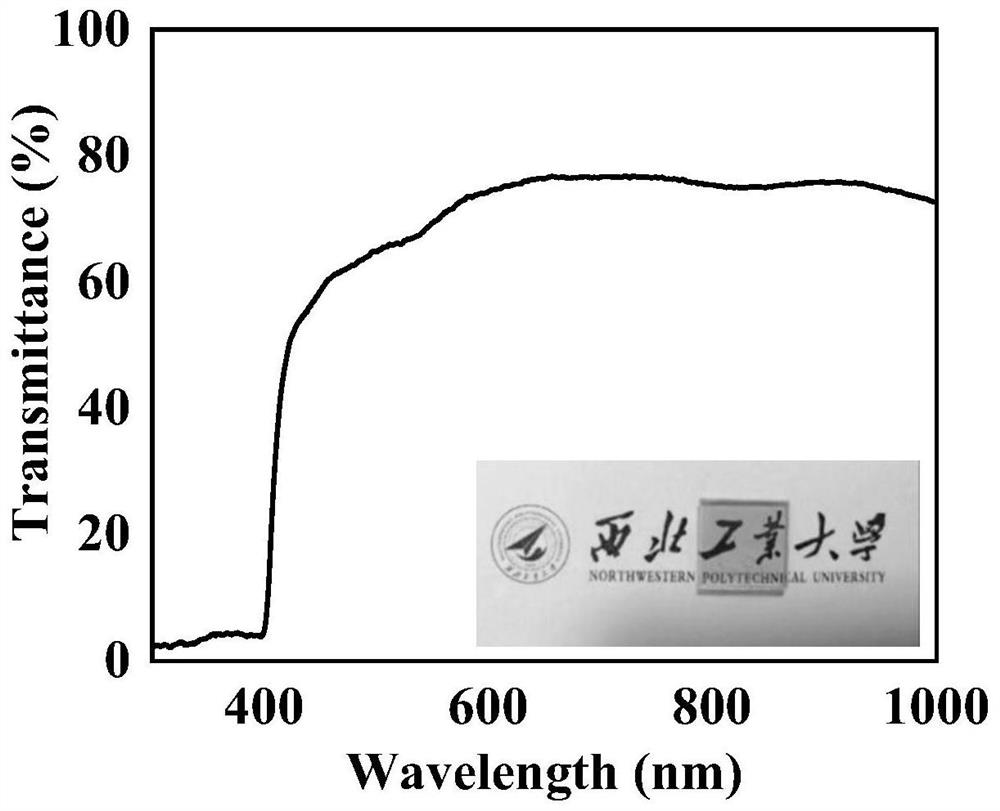

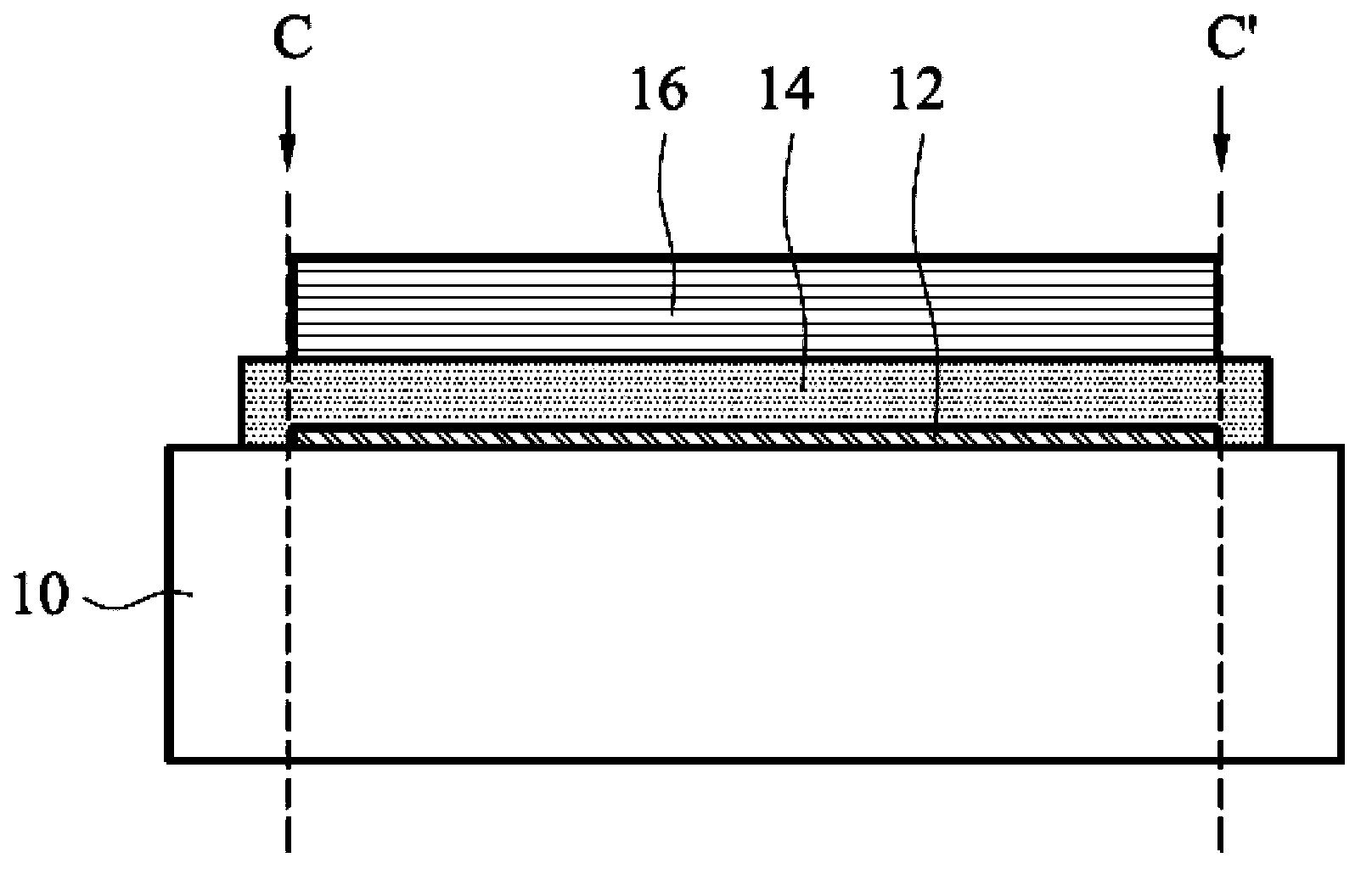

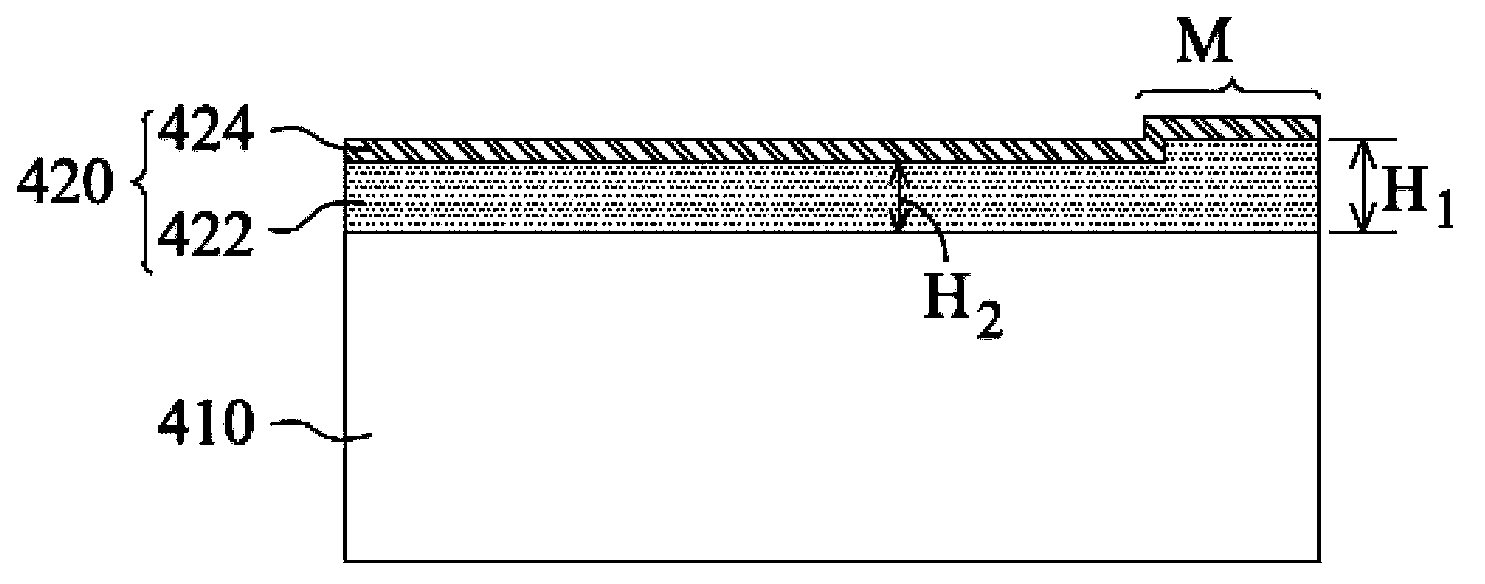

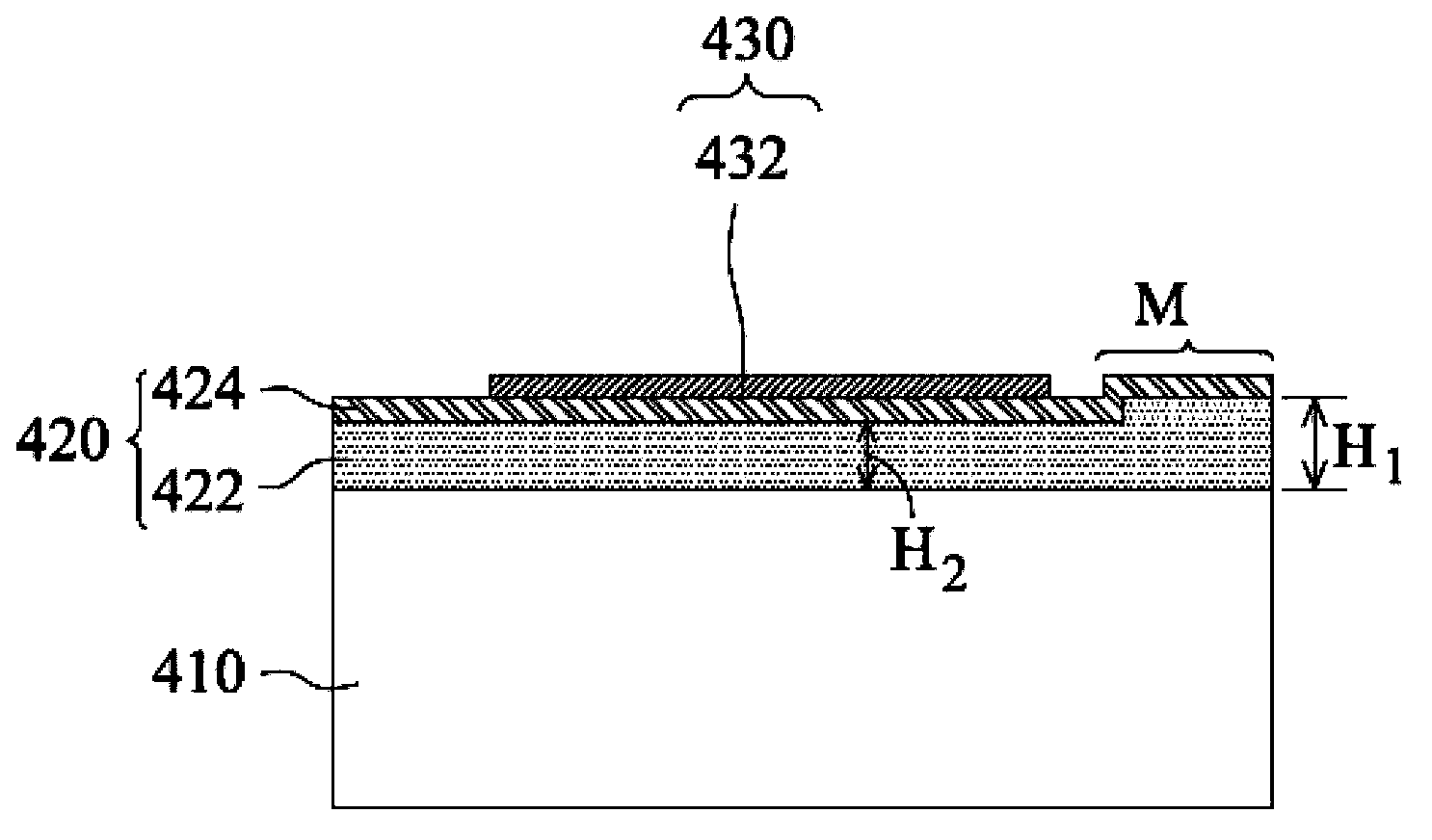

Perovskite transparent photovoltaic glass and preparation method thereof

InactiveCN112838165AImprove transmittanceBarrierSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsElectrochromism

The presesnt invention relates to perovskite transparent photovoltaic glass and the preparation method thereof, a wide bandgap perovskite material is adopted as a light absorption layer, ultraviolet light can be absorbed for power generation, meanwhile, visible light can penetrate through the perovskite transparent photovoltaic glass, and the light transmission of the glass is not affected. The absorption layer of the photovoltaic cell is wide bandgap perovskite which is prepared by a two-step deposition method and contains Cl and Br, and the transparent electrode is an ultrathin metal or transparent conductive oxide film. The method is simple in process and easy to operate, the visible light region transmittance of the obtained photovoltaic cell is larger than 60%, the photoelectric conversion efficiency is larger than 1%, and the method is expected to be applied to building curtain walls and car windows. The transparent photovoltaic cell can also be integrated with an electrochromic device to form self-powered intelligent photochromic glass which is expected to be applied to the fields of flight goggles, intelligent windows and the like. The transparent photovoltaic cell can be laminated with a common solar cell panel to reduce the damage of ultraviolet rays, improve the photoelectric conversion efficiency and improve the stability of the cell.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

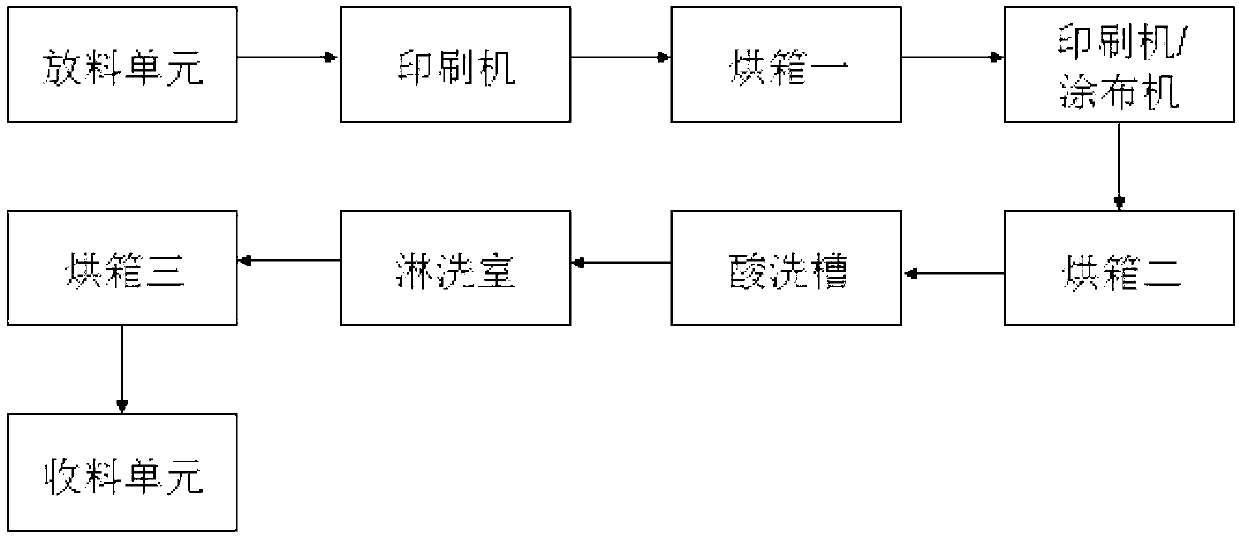

Technology for producing color gradually-changed mobile phone rear cover

InactiveCN109895429AGood flexibilityGood revengeDomestic articlesTelephone set constructionsEngineeringPrinting ink

The invention relates to the technical field of mobile phone rear covers, in particular to a technology for producing a color gradually-changed mobile phone rear cover. The technology includes the following steps that (1) cutting is conducted; (2) LOGO printing is performed; (3) UV transfer printing is carried out; (4) dip dyeing is conducted, colorful printing ink is used for dip dyeing of a pattern layer to form a color gradually-changed layer, and the dip dyeing temperature is 80-90 DEG C; (5) electroplating is performed; (6) a cover bottom is printed; (7) high-pressure treatment is carriedout; (8) strengthening is performed and (9) CNC cutting is executed. Dip dyeing is also called exhaustion dyeing, belongs to a dye application term and involves a method in which a dyed material is dipped into a dye bath containing dye and required auxiliaries and the dyed material is gradually dyed by the dye through dye bath circulation or dyed material movement. The method is also a dyeing method of repeatedly dipping the material into dye liquor to make the material and the dye liquor be relatively moved continuously. By adoption of the technology for achieving color gradual changing withdip dyeing, dip-dyed products are evenly colored, and the gradual changing effect is good; and moreover, various colors can be dip-dyed at the same time.

Owner:SHENZHEN ATES SCI & TECH CO LTD

Single-glass touchpad and manufacturing method thereof

ActiveCN103838407ADoes not affect light transmissionReduce sheddingInput/output processes for data processingAdhesiveTouchpad

The invention provides a single-glass touchpad. The single-glass touchpad comprises a covering plate, a bearing layer, a signal conductor and bonding adhesives, wherein a patterned conductive layer is formed on the bearing layer and comprises a sensing electrode, the signal conductor is electrically connected to the sensing electrode and is gathered in at least one bonding region, the bonding region or the bonding regions are located in at least one outer side edge of the sensing electrode, the thickness of the bonding region or the bonding regions is larger than the thickness of the bearing layer in a non-bonding region, and the bonding adhesives are arranged between the covering plate and the bearing layer and used for bonding the covering plate and the bearing layer. The invention further provides a manufacturing method of the single-glass touchpad. By means of the single-glass touchpad, the problem that a touch structure at the edge area of the bearing layer in the bonding region falls off easily or is damaged easily in the manufacturing process can be relieved, and further the yield of the single-glass touchpad is improved.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Anti-mildew photocurable waterborne stone protective agent for stone surface and preparation method of anti-mildew photocurable waterborne stone protective agent

ActiveCN108203559AImprove film forming speedImprove the protective effectAntifouling/underwater paintsPaints with biocidesHigh humiditySolvent

The invention discloses an anti-mildew photocurable waterborne stone protective agent for a stone surface and a preparation method of the anti-mildew photocurable waterborne stone protective agent. The protective agent comprises the following components: UV-curable film forming resin, a photoinitiator, a polyphosphoric acid dispersant, an organic silicon defoaming agent, a film forming auxiliary,a slow-release broad-spectrum anti-mildew bactericide and solvent water. Due to a synergistic effect of a light-curable resin technology and a nano-adsorbent carrier slow release technology, the filmforming speed and protective effect of the waterborne stone protective agent are greatly improved, and the curing effect exerting time is greatly shortened while the original advantage of a waterborneprotective agent is retained, so that the construction efficiency can be remarkably increased; and meanwhile, the protective construction operation can also be realized under a low-temperature or high-humidity environment, so that the adaptability of the waterborne stone protective agent in the prior art is widened, and the antibacterial and anti-mildew properties of the waterborne stone protective agent are remarkably improved while the color, glossiness and light transmitting property of a coating are not affected.

Owner:云浮华云创新设计有限公司

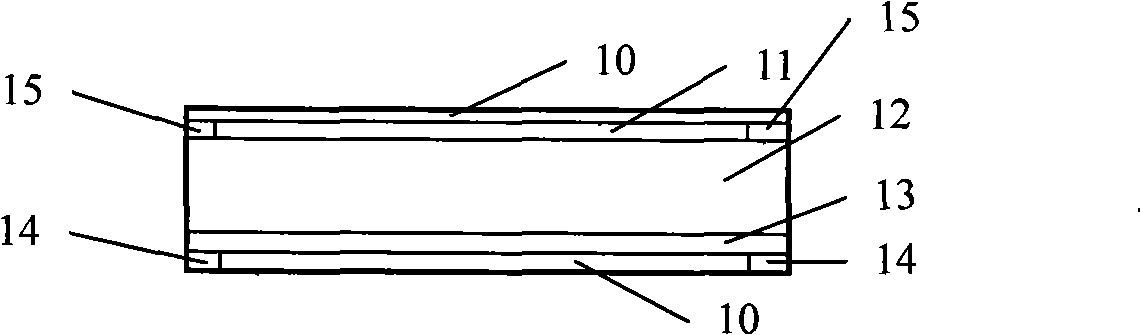

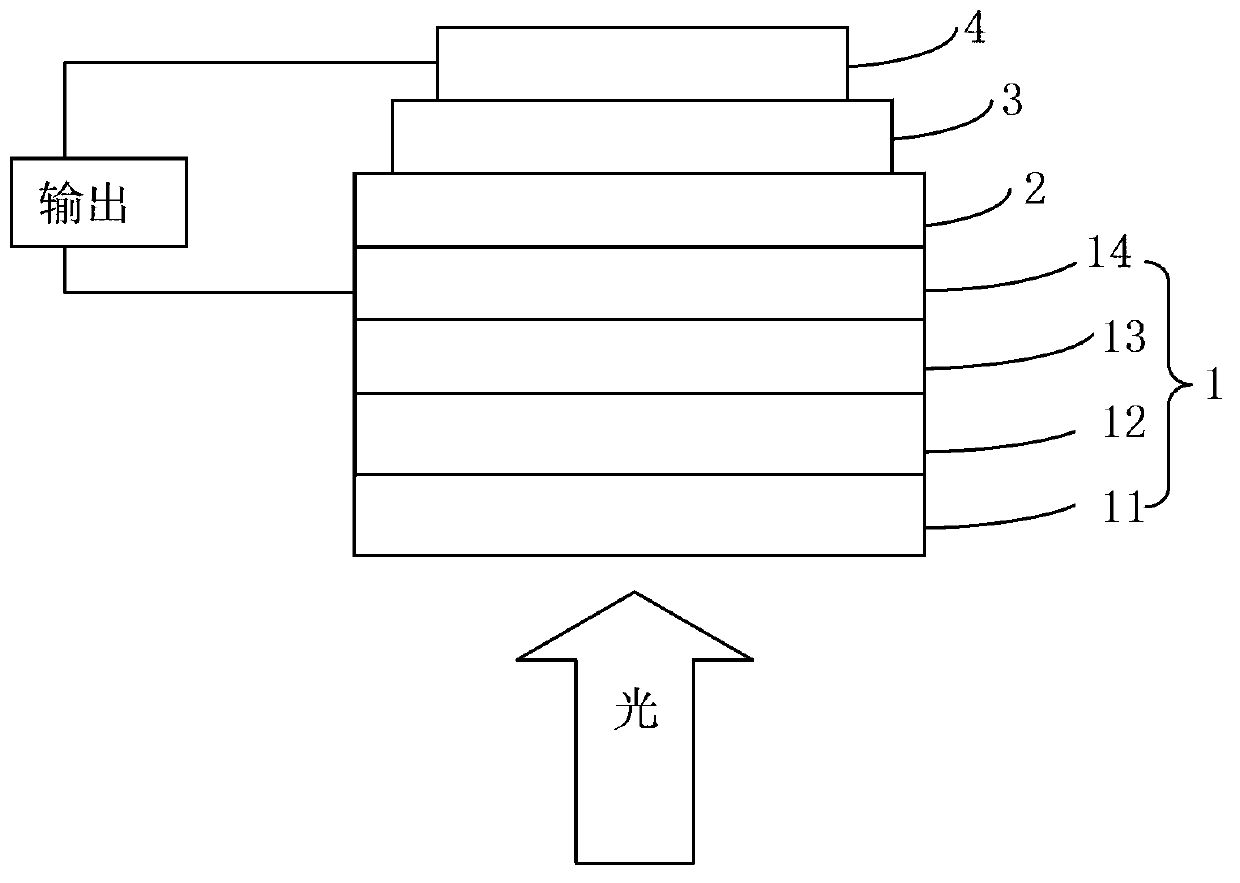

Flexible transparent conductive graphene film and manufacturing method and application thereof

InactiveCN104183700AImprove conductivityHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceGraphene

The invention provides a flexible transparent conductive graphene film and a manufacturing method and application thereof. The flexible transparent conductive graphene film comprises a glass substrate and graphene layers and metal layers sequentially stacked on the glass substrate in a staggered mode. The metal layers are arranged between two adjacent graphene layers. Layers of the metal layers are one to four. The flexible transparent conductive graphene film has high conductivity and light transmittance and good flexibility. The flexible transparent conductive graphene film manufacturing method comprises steps: the graphene layer is firstly manufactured on the glass substrate; the metal layer is then manufactured on the graphene layer; manufacturing of the graphene layer and the metal layer is repeated, and the repeated times of the metal layer is one to four, the graphene layer is finally manufactured, and the flexible transparent conductive graphene film is manufactured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

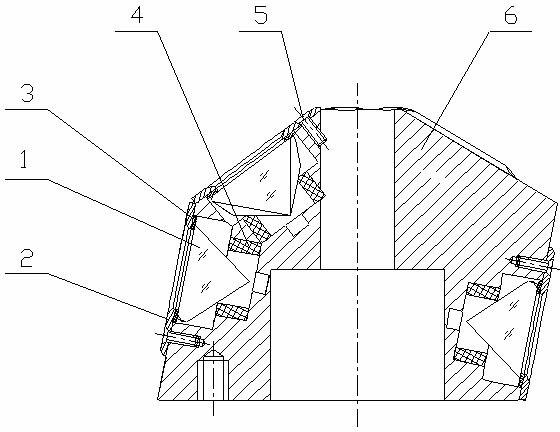

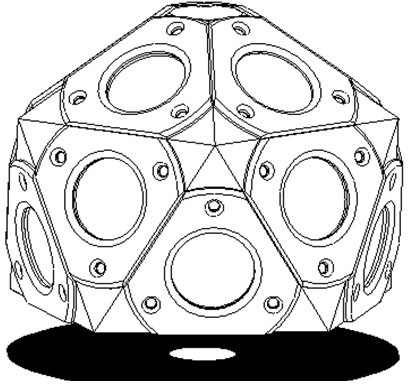

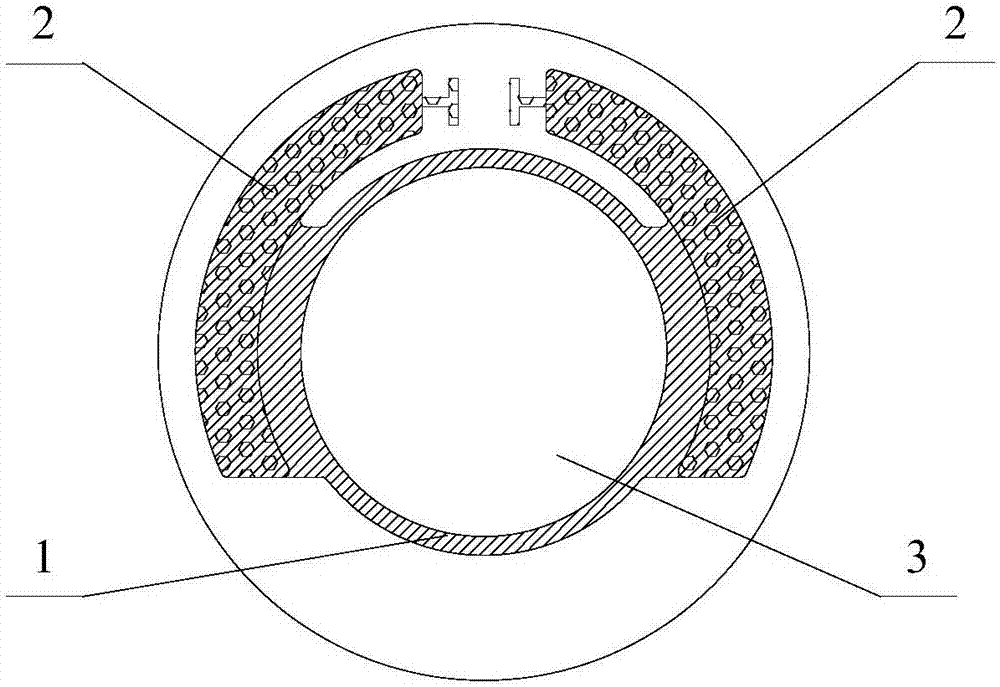

All-sky laser airborne three-layer multi-channel reflectarray

InactiveCN102279392AIncrease reflective areaExpand field of viewWave based measurement systemsHigh volume manufacturingBlind zone

The invention relates to a full horizon laser airborne three-layer multi-channel reflective array. A prior art has the disadvantages of a small remote angle and a large range finding blind area. A technical scheme of the invention is as follows: the full horizon laser airborne three-layer multi-channel reflective array comprises pyramid prisms, prism covers, gaskets, and reflective array shells with a similarly semispherical shape, a number of the pyramid prisms is 15, undersurfaces of the 15 pyramid prisms are parallel to 15 regular triangle planes respectively, and the pyramid prisms are placed in the reflective array shells respectively; the 15 regular triangle planes take hemisphere crowns as vertexes, one plane connects with other one, thus adjacent 5 planes form a regular five pyramid configuration, and the 15 regular triangle planes are distributed on 3 different latitudes in appearance, wherein each latitude has 5 planes. The full horizon laser airborne three-layer multi-channel reflective array has the advantages of full horizon, no blind area, all-weather and high reflection efficacies, wide suitable range, simple production and easiness of mass production.

Owner:XIAN TECHNOLOGICAL UNIV

Sodium bismuthate/epoxy resin/glass fiber composite material, preparation method thereof, and application method for composite material in degradation of organic waste water

ActiveCN103623868AImprove stress shock resistancePromote absorptionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyUltrasonic dispersion

The invention discloses a sodium bismuthate / epoxy resin / glass fiber composite material, a preparation method thereof and an application method for the composite material in degradation of organic waste water. The preparation method comprises the following steps: soaking sodium bismuthate powder in an aqueous solution of a silane coupling agent for treatment, then taking out the sodium bismuthate powder and drying the sodium bismuthate powder for subsequent usage; adding methyl tetrahydrophthalic anhydride into an epoxy resin and carrying out uniform mixing so as to obtain an epoxy resin glue solution; and mixing the treated sodium bismuthate with the epoxy resin glue solution, carrying out ultrasonic dispersion, coating an obtained mixture on glass fiber cloth, folding the glass fiber cloth three to five times in a die, carrying out curing, cooling and demolding and cutting the glass fiber cloth to a certain shape and a certain size. The application method comprises the following steps: uniformly putting the composite material with an appropriate shape and an appropriate size between jacket layers of a glass tube reactor and installing a visible light lamp at the center of an inner tube; allowing organic waste water to enter into a glass jacket, pass through the composite material and undergo a visible light catalytic degradation reaction with sodium bismuthate under irradiation by visible light. The preparation method has the advantages of low requirements on equipment, simple procedures, low energy consumption and convenience in operation; and the composite material is capable of degrading organic waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Washable anti-counterfeiting hot stamping film and preparation method thereof

ActiveCN114407547AGood weather resistanceImprove acid and alkali corrosion resistancePackage recyclingPattern printingHot stampingStructural engineering

The washable anti-counterfeiting hot stamping film comprises a base material layer, a release layer, an imaging layer, a metal reflecting layer and an adhesive layer which are arranged in sequence, a wear-resistant protective layer is arranged between the release layer and the imaging layer; a wear-resistant protective layer is arranged between the imaging layer and the release layer, and a buffer layer is arranged between the wear-resistant protective layer and the imaging layer, so that the wear-resistant protective layer has good wear-resistant, waterproof, weather-resistant and acid and alkali corrosion-resistant effects, and can protect the imaging layer; according to the anti-counterfeiting hot stamping film, the anti-counterfeiting layer is arranged on the anti-counterfeiting hot stamping film, so that the imaging layer can effectively express patterns in a longer time, the buffer layer has good elasticity and plays a role in blocking and buffering, and the phenomenon that the anti-counterfeiting hot stamping film is subjected to negative influence on the release effect and the wear-resisting effect of the finished anti-counterfeiting hot stamping film due to deformation damage of the anti-counterfeiting hot stamping film and the release layer in the imaging process is avoided; and the imaging effect of the finished hot stamping film can be improved.

Owner:江苏泰佳新材料科技有限公司

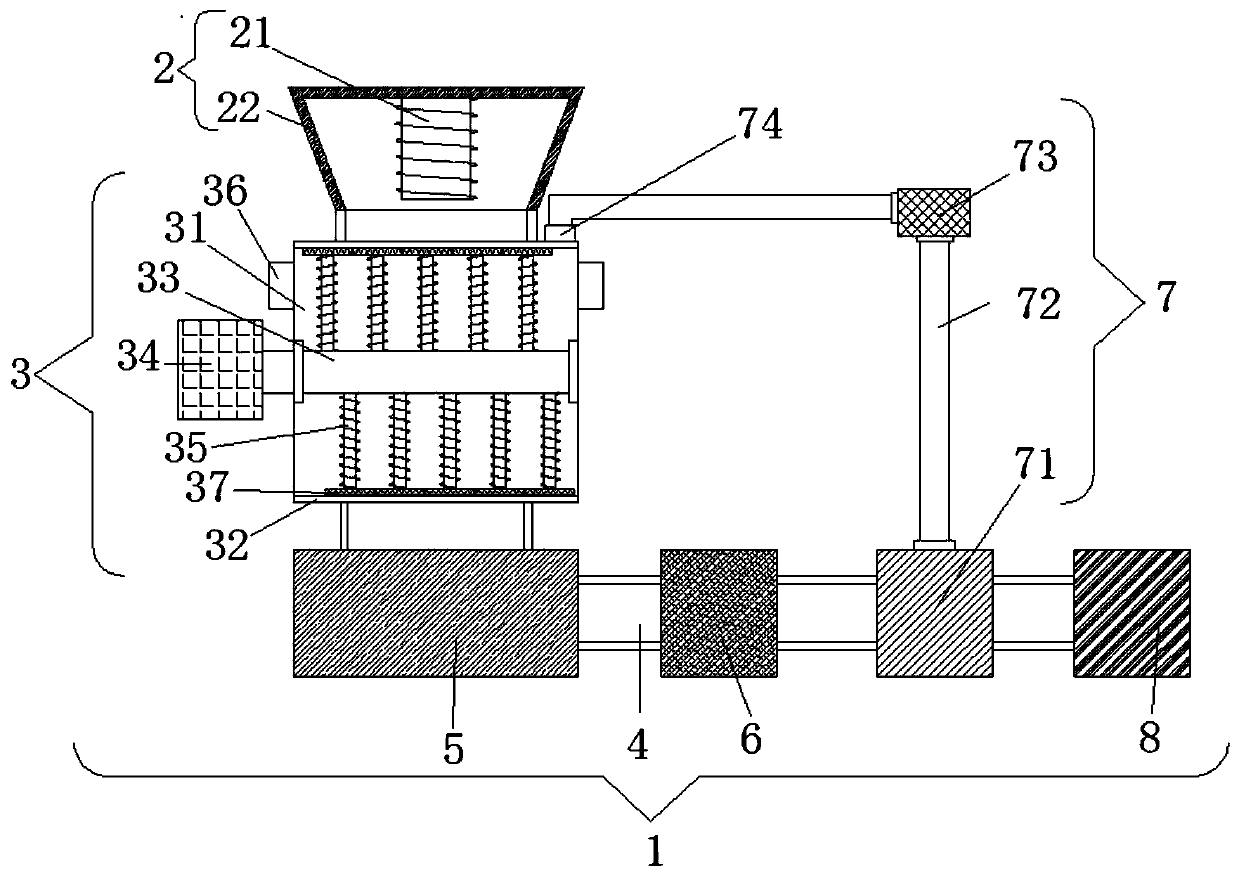

Ceramic glaze, processing device and ceramic glaze processing method

The invention provides a ceramic glaze material, a processing device and a ceramic glaze material processing method, and belongs to the technical field of glaze materials and processing. The ceramic glaze material comprises the components of: waste ceramic powder, quartz, glass powder, clay, zinc oxide, lithium chinastone, boron oxide, talc, alumina, strontium oxide, tin oxide and other formula raw materials; a feeding device and a heating and stirring device are adopted. According to the ceramic glaze, the processing device and the ceramic glaze processing method, a certain amount of waste ceramic powder and a small amount of tin oxide and strontium oxide are added to achieve the effect of improving the glossiness of a glaze surface. The feeding device and the heating and stirring deviceare arranged; in a glaze processing process, the formula raw materials are separately heated, stirred and then mixed for processing, and the formula raw materials are fully stirred and heated, and therefore, the formula raw materials can be heated more uniformly and stirred more sufficiently, and high-quality glaze is produced, so that the glossiness of the glaze surface is improved, the conditions of the cracking of the glaze surface and the like are reduced, and the quality of the produced glaze is greatly improved.

Owner:景德镇澐知味陶瓷文化有限公司

Heat insulation glass

InactiveCN103057197AGood heat insulationDoes not affect light transmission performanceGlass/slag layered productsScale sizeNanometre

The invention relates to a heat insulation glass, which comprises a first glass layer and a second glass layer. An interlayer between the first glass layer and the second glass layers is provided with a transparent insulation board; one side of the transparent insulation board is coated with a metal particle layer comprising titanium dioxide or cobalt dioxide; and metal particles on the metal particles layer have nanometer scale size, and thickness of nanometer scale or approximately to nanometer scale. As the transparent insulation board has heat insulation function itself, and the nano metal layer reflects solar radiation, the heat insulation effect is excellent; and the nano metal layer has barely no influence on light transmitting properties, so transmission effect of the glass itself can be guaranteed at the same time.

Owner:SHAANXI LONGHAI ENG CONSTR

Camera cover plate and camera

PendingCN107181902ADoes not affect appearanceDoes not affect light transmissionTelevision system detailsColor television detailsOptical transparencyIndium tin oxide

The present invention discloses a camera cover plate and a camera. The camera cover plate comprises an indium tin oxide layer and two conductive layers; the indium tin oxide layer is arranged in a non-image pick-up area of the camera cover plate; and the two conductive layers are arranged in the non-image pick-up area and are both communicated with the indium tin oxide layer. When the camera cover plate is used, a direct-current voltage is applied between the two conductive layers; since the conductive layers are communicated with the indium tin oxide layer, the indium tin oxide layer has an electrical conductivity characteristic and an optical transparency characteristic, after the voltage is applied, the indium tin oxide layer will be heated, and the temperature of the camera cover plate will rise, and therefore, an anti-fog effect can be realized, and the overall appearance of the camera will not be affected; and the indium tin oxide layer avoids an image pick-up area, and therefore, the light transmission performance of the camera cover plate will not be affected. Therefore, the light transmission performance of the camera cover plate provided by the present invention can be ensured, the camera cover plate can realize the anti-fog effect, the overall appearance of the camera will not be affected, and problems in the field at present can be solved.

Owner:TRULY OPTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com