Ceramic glaze, processing device and ceramic glaze processing method

A technology of ceramic glaze and processing device, applied in the field of ceramic glaze and processing, can solve the problems of affecting the quality of the glaze, cracking of the glaze, substandard, etc., so as to improve the utilization rate of resources, improve the gloss of the glaze, and reduce the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A ceramic glaze, which is composed of the following raw materials in parts by weight: 18 parts of waste porcelain powder, 16 parts of quartz, 10 parts of glass powder, 11 parts of clay, 7 parts of zinc oxide, 6 parts of quicklime, 5 parts of lithium china stone, oxidized 5 parts of boron, 4 parts of talc, 3 parts of alumina, 2 parts of petalite, 2 parts of calcium oxide, 1 part of sodium oxide, 1 part of strontium oxide, 0.5 parts of tin oxide, 0.3 parts of barium oxide, 0.2 parts of lead oxide, 0.1 part of zirconium oxide and 0.1 part of manganese oxide.

Embodiment 2

[0034] A ceramic glaze, which is composed of the following raw materials in parts by weight: 19 parts of waste porcelain powder, 21 parts of quartz, 11.5 parts of glass powder, 18.5 parts of clay, 9 parts of zinc oxide, 8.5 parts of quicklime, 7 parts of lithium china stone, oxide 6.5 parts of boron, 5 parts of talc, 5.5 parts of alumina, 3 parts of petalite, 3 parts of calcium oxide, 2 parts of sodium oxide, 1.5 parts of strontium oxide, 1 part of tin oxide, 0.5 parts of barium oxide, 0.3 parts of lead oxide, 0.5 parts of zirconia and 0.25 parts of manganese oxide.

Embodiment 3

[0036] A ceramic glaze, which is composed of the following raw materials in parts by weight: 26 parts of waste porcelain powder, 27 parts of quartz, 13 parts of glass powder, 25 parts of clay, 12 parts of zinc oxide, 11 parts of quicklime, 12 parts of lithium china stone, oxide 9 parts of boron, 7 parts of talc, 9 parts of alumina, 5 parts of lithium petalite, 4 parts of calcium oxide, 3 parts of sodium oxide, 2 parts of strontium oxide, 2 parts of tin oxide, 0.8 parts of barium oxide, 0.6 parts of lead oxide, 1 part of zirconia, 0.5 part of manganese oxide.

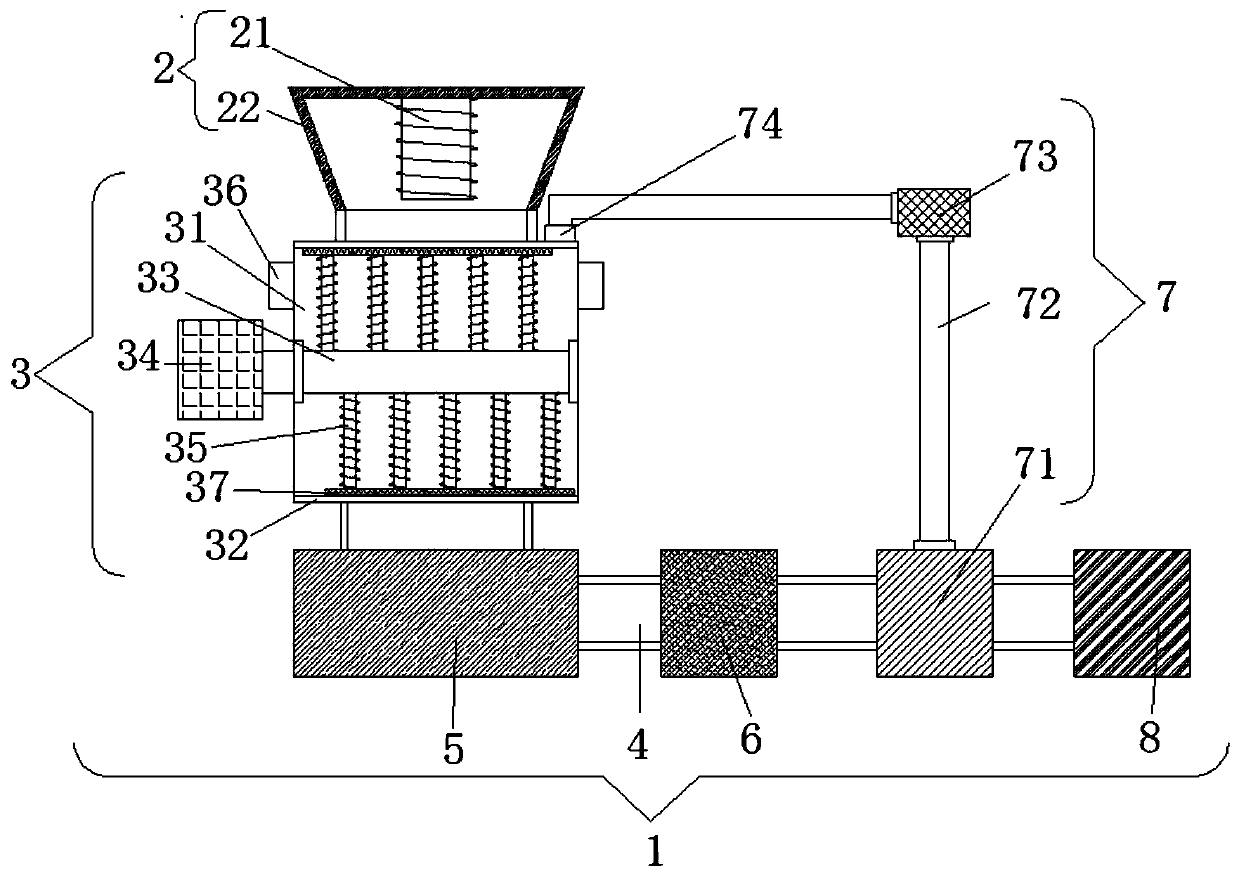

[0037] see figure 1, a ceramic glaze processing device, including a device body 1, the device body 1 includes a feeding device 2, a stirring heating device 3, a conveying device 4, a cooling device 5, a ball milling device 6, a drying and beating device 7, a packaging device 8, and feeding The device 2, the stirring heating device 3, the cooling device 5, the ball milling device 6, the drying and beating device 7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com