Preparation method of organic/inorganic composite luminous silica gel with integrated functions of luminescence and encapsulation and application of silica gel on LED light source

An inorganic composite and functional technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

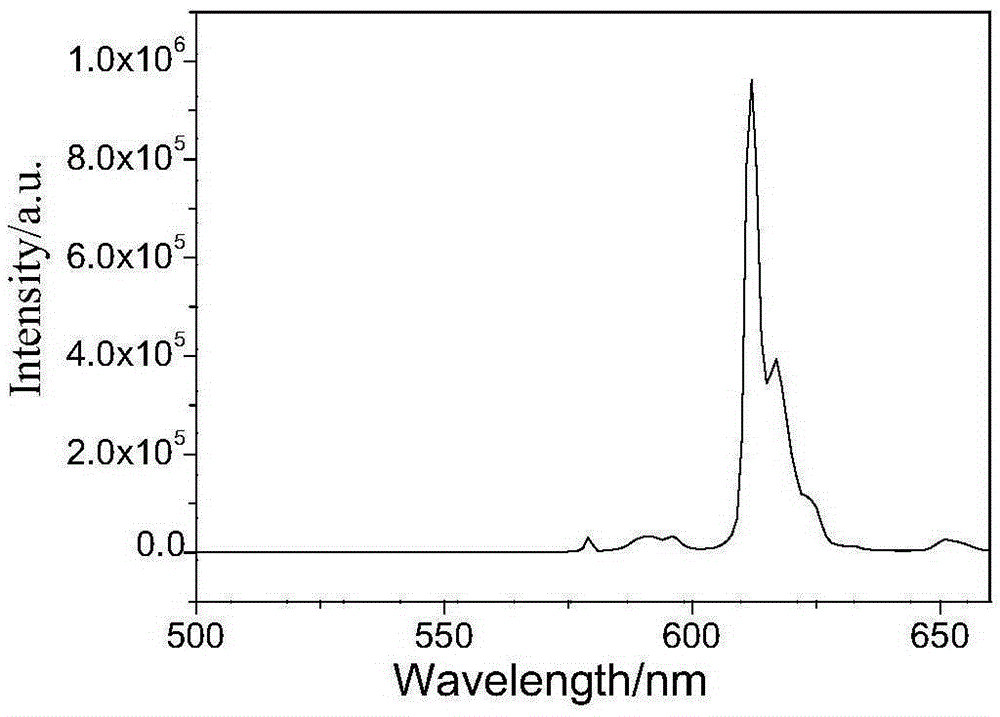

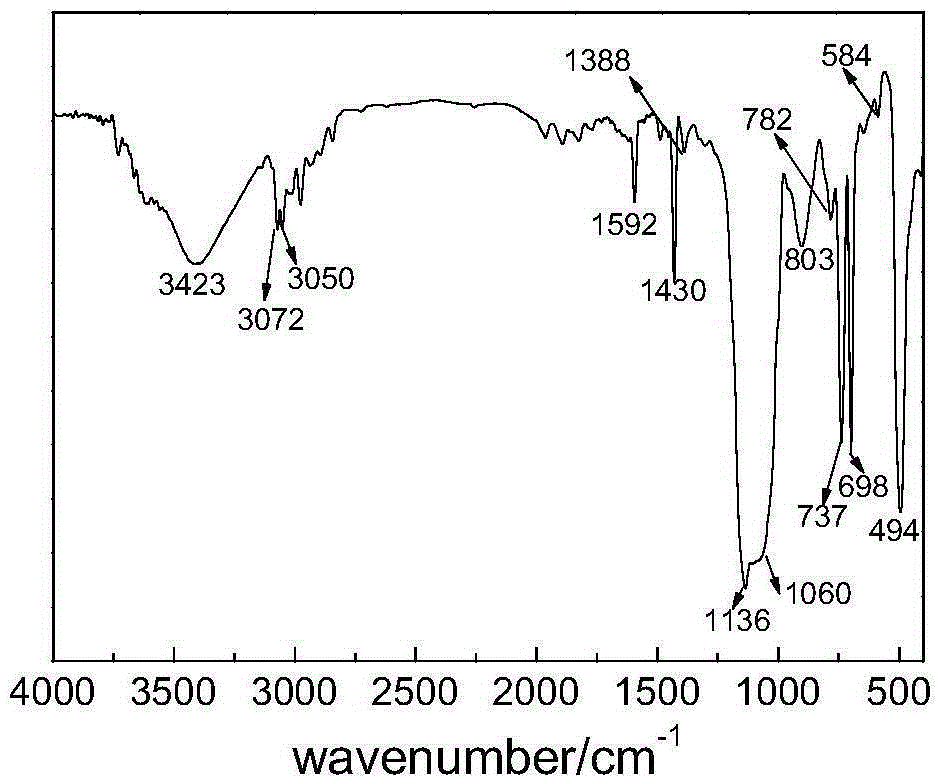

[0054] 1. Preparation of surface-modified europium-containing hydrotalcite:

[0055] 1) will contain 0.006molMgCl 2 Aqueous solution and containing 0.002molAlCl 3 The aqueous solution is prepared as a binary mixed solution A, in which Mg 2+ The concentration is 0.12M;

[0056] 2) Dissolve europium oxide with dilute hydrochloric acid and pour it into A to prepare solution B, in which Mg 2+ :Eu 3+ The molar ratio is 1:0.086;

[0057] 3) Mix 0.001 mol of thienoyltrifluoroacetone and 0.0005 mol of 1,10-phenanthroline in 0.003 mol of sodium stearate at a concentration of 0.1M to prepare mixed slurry C;

[0058] 4) Under strong stirring, add solution B dropwise to mixed slurry C, and after 10 minutes of reaction, add 2.88mL of silane coupling agent KH-550. Use 20% sodium hydroxide aqueous solution to adjust the reaction mixed slurry to pH = 9, age at 80°C for 12 hours, filter with suction, wash the filter cake with water until pH = 7, and filter with suction after precipitatio...

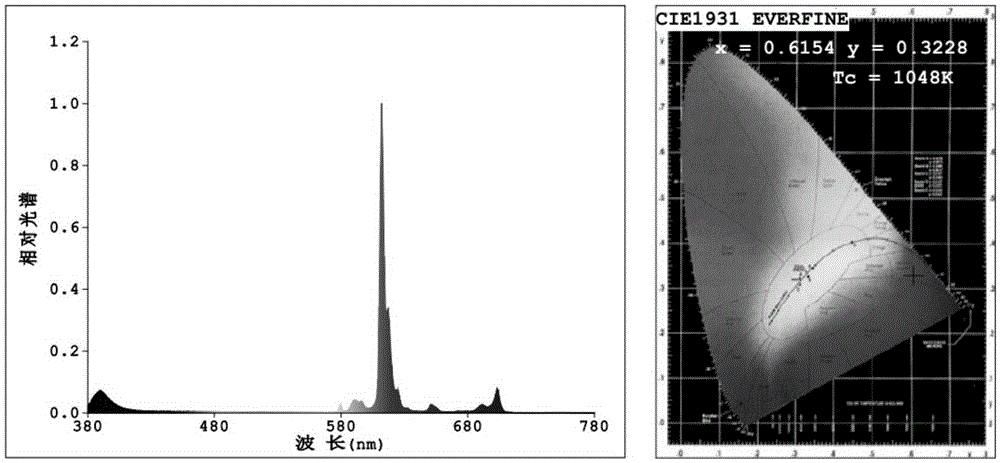

Embodiment 2

[0076] 1. Preparation of surface-modified europium-containing hydrotalcite:

[0077] 1) will contain 0.008molZnCl 2 Aqueous solution and containing 0.003molFeCl 3 The aqueous solution is prepared as a binary mixed solution A, in which Zn 2+ The concentration is 0.16M;

[0078] 2) Dissolve europium oxide with dilute hydrochloric acid and pour it into A to prepare solution B, in which Zn 2+ :Eu 3+ The molar ratio is 1:0.092;

[0079] 3) Pre-mix 0.0022mol of acetylacetone and 0.0007mol of bipyridyl in 0.003mol of sodium dodecylbenzoate with a concentration of 0.12M to prepare mixed slurry C;

[0080]4) Under strong stirring, add solution B dropwise to mixed slurry C, and after reacting for 10 minutes, add 2.56 mL of silane coupling agent KH-570. Use 20% sodium hydroxide aqueous solution to adjust the reaction mixture slurry to pH = 10, age at 75°C for 10 hours, filter with suction, wash the filter cake with water until pH = 8, and filter with suction after precipitation. T...

Embodiment 3

[0098] 1. Preparation of surface-modified terbium-containing hydrotalcite:

[0099] 1) will contain 0.01molCuCl 2 Aqueous solution containing 0.008molCrCl 3 The aqueous solution is prepared as a binary mixed solution A, in which Cu 2+ The concentration is 0.40M;

[0100] 2) Dissolve terbium oxide with dilute hydrochloric acid and pour it into A to prepare solution B, in which Cu 2+ :Tb 3+ The molar ratio is 1:0.12;

[0101] 3) Pre-mix 0.035mol of terephthalic acid and 0.012mol of 2,2-bipyridine in 0.004mol of sodium dodecylbenzenesulfonate with a concentration of 0.26M to prepare mixed slurry C;

[0102] 4) Add solution B dropwise to mixed slurry C, and after microwave reaction for 10 minutes, add silane coupling agent KH-1712.5mL. Use 20% sodium hydroxide aqueous solution to adjust the reaction mixed slurry to pH = 11, age at 70°C for 6 hours, filter with suction, wash the filter cake with water until pH = 7, and filter with suction after precipitation. The cake was dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com