Preparation method of emerald ceramic

A technology of emerald porcelain and formula, which is applied to clay products, other household utensils, household utensils, etc., can solve the problems of reduced strength, high cost, and greater influence on the permeability of porcelain body, and achieve low production cost, low cost, Good effect of porcelain permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

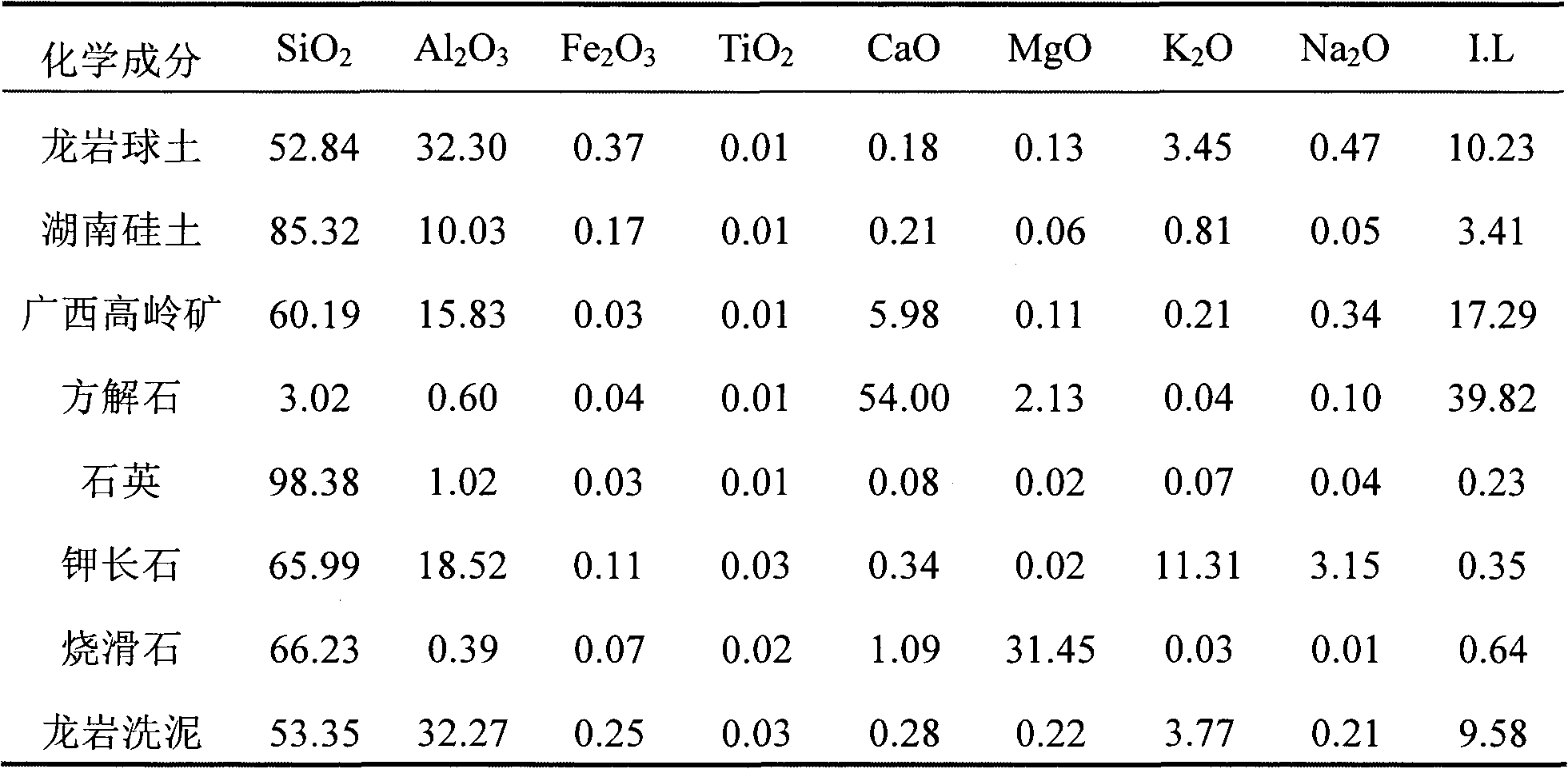

[0035] The raw material composition of the green body is as follows: 10% of Longyan ball clay (high plasticity clay), 5% of Hunan silica (low plasticity clay), 50% of Guangxi kaolin ore, 10% of calcite, and 25% of quartz. The composition of the enamel slurry is as follows: 24% potassium feldspar, 27% quartz, 15% calcite, 2% calcined talc, 30% Longyan washing mud, 2% zinc oxide, and 0.1% praseodymium oxide.

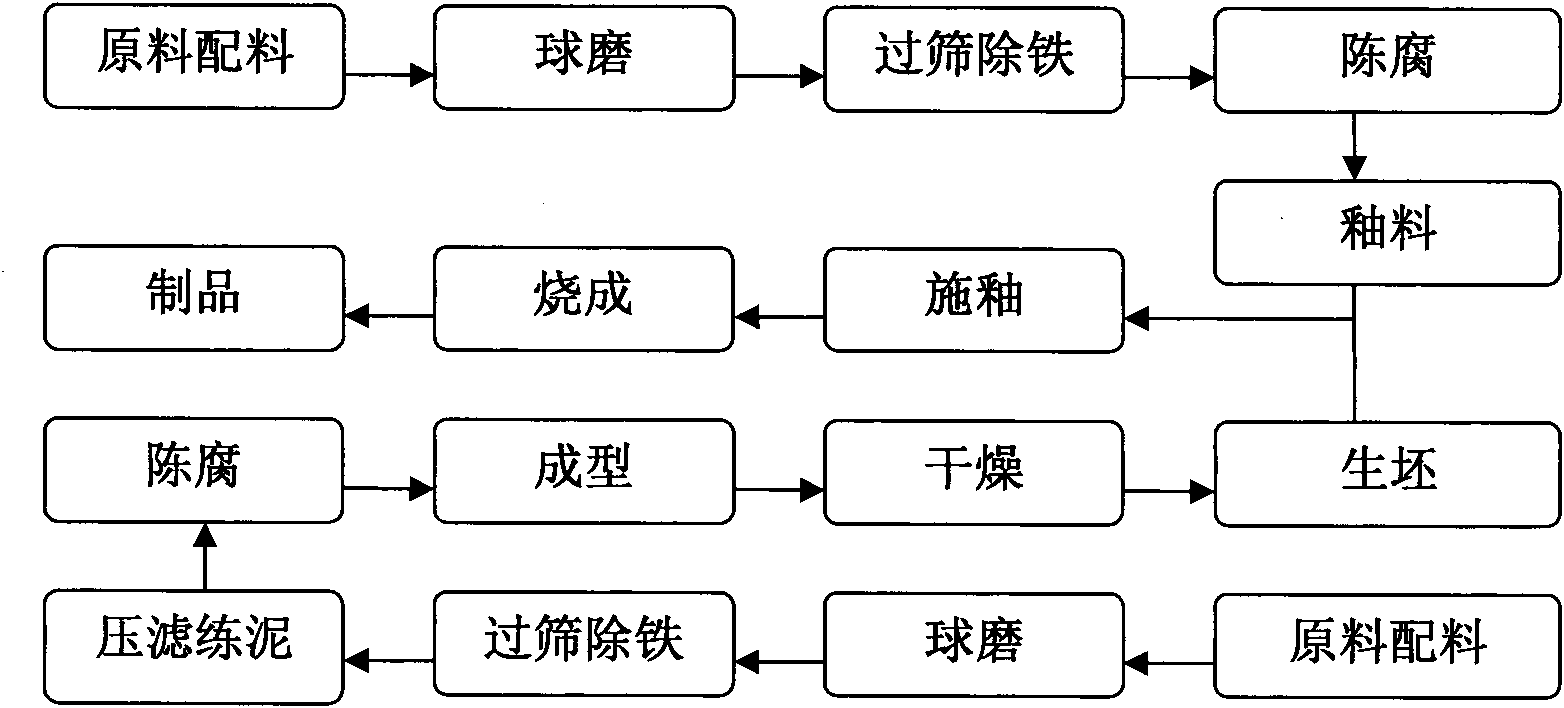

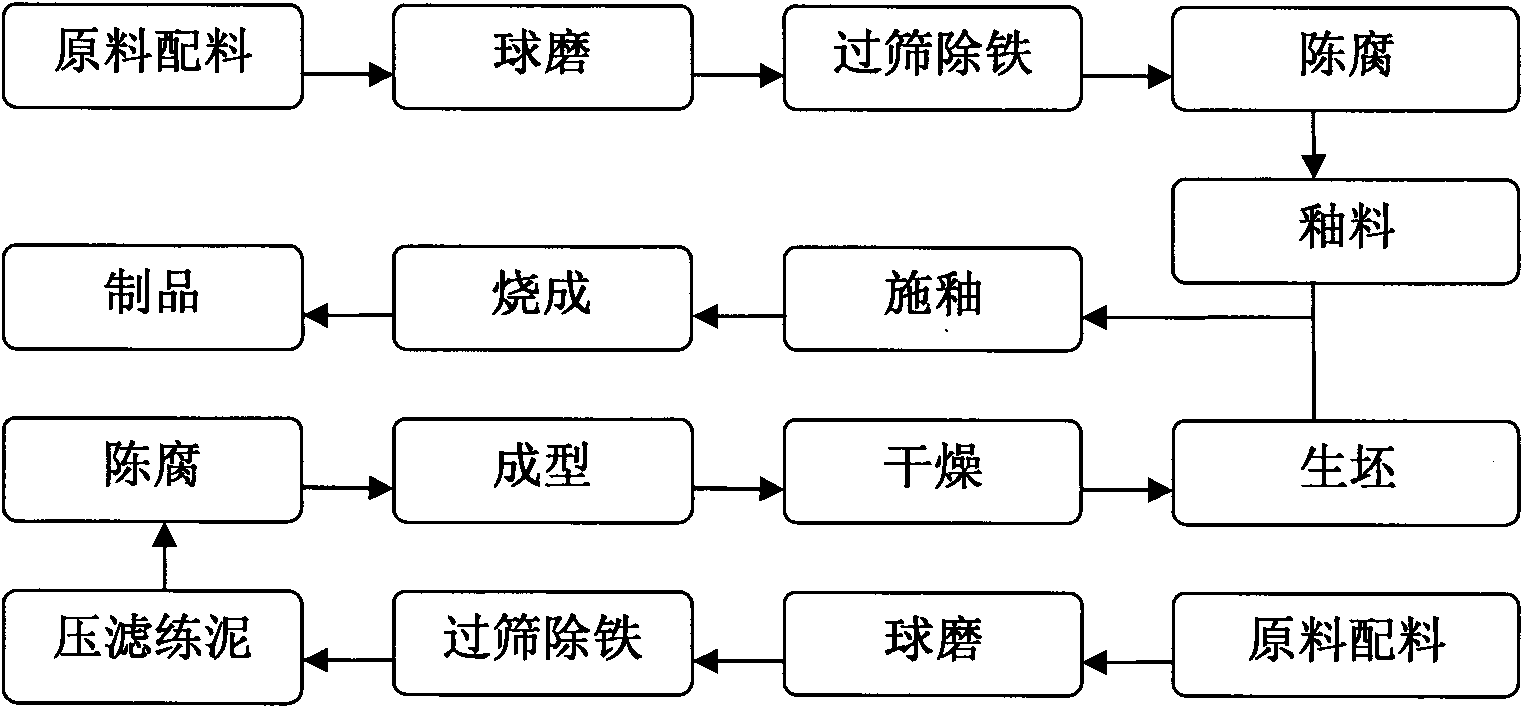

[0036] According to the above porcelain blank formula, according to figure 1 In the process shown, quartz, Guangxi kaolin ore and calcite are first mixed and ball milled, and then Longyan ball soil and Hunan silica are added together for ball milling to control the fineness of the slurry. Press filtration for dehydration, stale for 5 days, press molding, and dry the green body at 80°C for 12 hours. According to the above enamel formula, 0.3% carboxymethyl cellulose CMC is added, and the glaze slurry containing praseodymium oxide is prepared through ball milling, sieving, ...

Embodiment 2

[0041] The raw material composition of the green body is as follows: 15% of Longyan ball clay (high plasticity clay), 5% of Hunan silica (low plasticity clay), 38% of Guangxi kaolin ore, 10% of calcite, and 32% of quartz. The composition of the enamel slurry is as follows: 24% potassium feldspar, 27% quartz, 15% calcite, 2% calcined talc, 30% Longyan washing mud, 2% zinc oxide, and 0.1% praseodymium oxide.

[0042] According to the above porcelain blank formula, first mix quartz, Guangxi kaolin ore and calcite for ball milling, then add Longyan ball soil and Hunan silica into ball milling together to control the fineness of the slurry, and pass through a 250-mesh sieve with less than 0.5% of the slurry. Carry out dehydration by pressure filtration, stale for 6 days, press molding, and dry the body at 110°C for 12 hours. According to the above enamel formula, 0.3% carboxymethyl cellulose CMC is added, and the glaze slurry containing praseodymium oxide is prepared through ball m...

Embodiment 3

[0044]The raw material composition of the green body is as follows: 8% Longyan ball clay (high plasticity clay), 5% Hunan silica (low plasticity clay), 54% Guangxi kaolin ore, 15% calcite, and 18% quartz. The composition of the enamel slurry is as follows: 24% potassium feldspar, 27% quartz, 15% calcite, 2% calcined talc, 30% Longyan washing mud, 2% zinc oxide, and 0.1% praseodymium oxide.

[0045] According to the above porcelain blank formula, first mix quartz, Guangxi kaolin ore and calcite for ball milling, then add Longyan ball soil and Hunan silica into ball milling together to control the fineness of the slurry, and pass through a 250-mesh sieve with less than 0.5% of the slurry. Carry out dehydration by pressure filtration, stale for 6 days, press molding, and dry the body at 110°C for 12 hours. According to the above enamel formula, 0.3% carboxymethyl cellulose CMC is added, and the glaze slurry containing praseodymium oxide is prepared through ball milling, sieving, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com