Patents

Literature

235 results about "Bone china" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone china is a type of porcelain that is composed of bone ash, feldspathic material, and kaolin. It has been defined as "ware with a translucent body" containing a minimum of 30% of phosphate derived from animal bone and calculated calcium phosphate. Bone china is the strongest of the porcelain or china ceramics, having very high mechanical and physical strength and chip resistance, and is known for its high levels of whiteness and translucency. Its high strength allows it to be produced in thinner cross-sections than other types of porcelain. Like stoneware it is vitrified, but is translucent due to differing mineral properties.

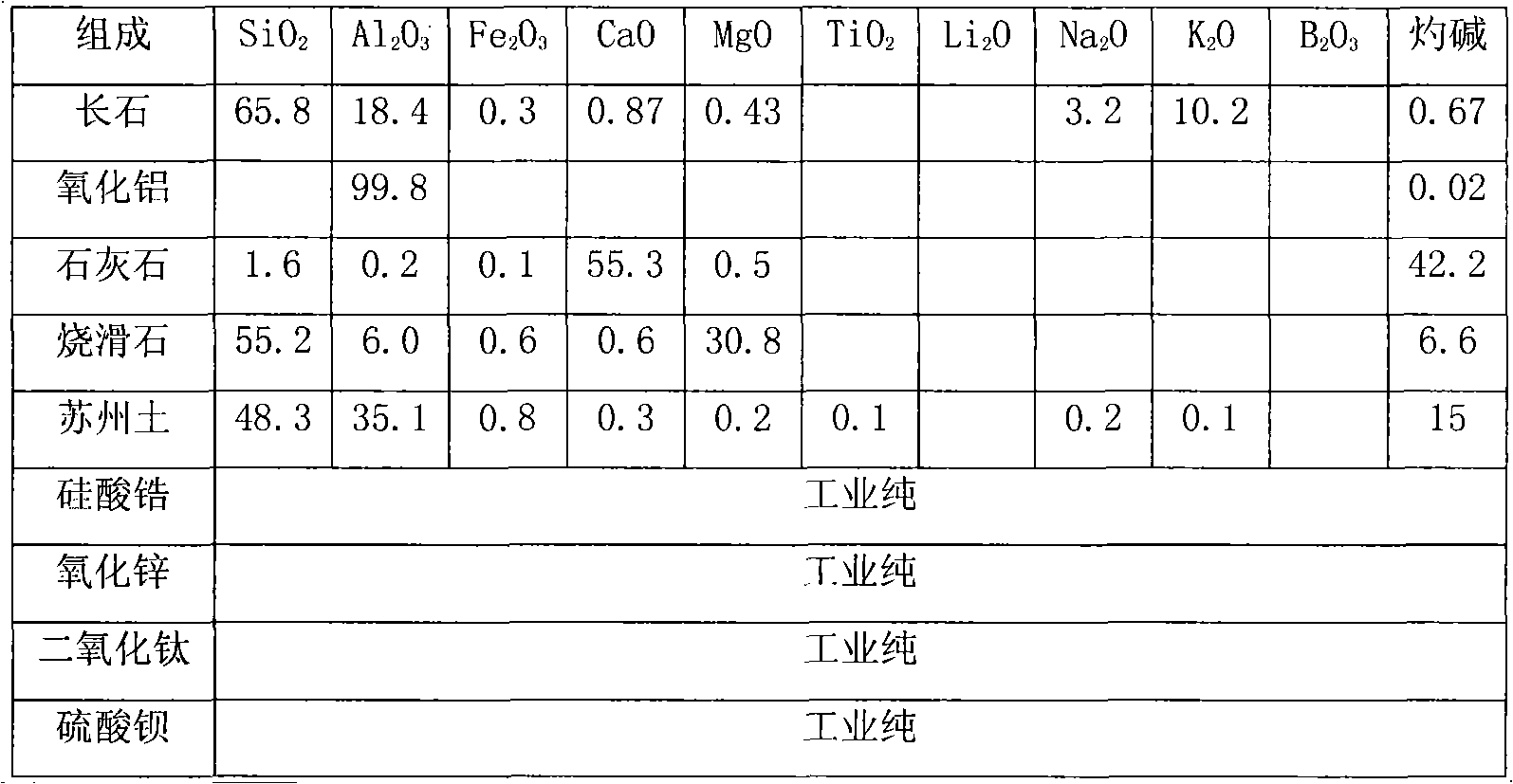

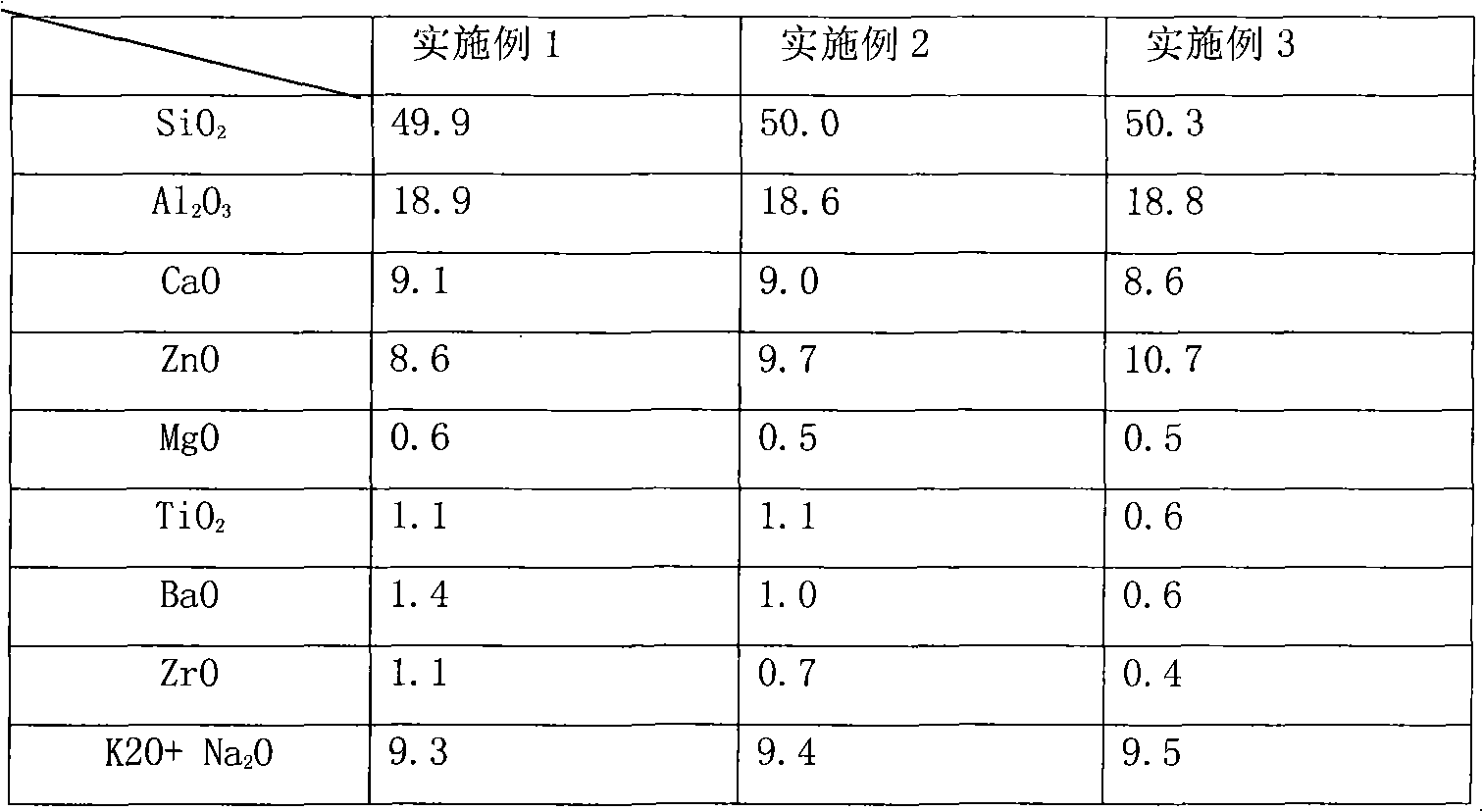

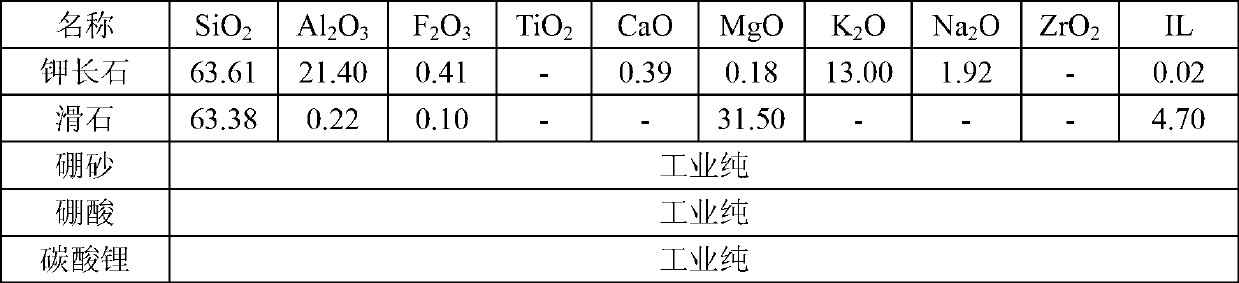

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

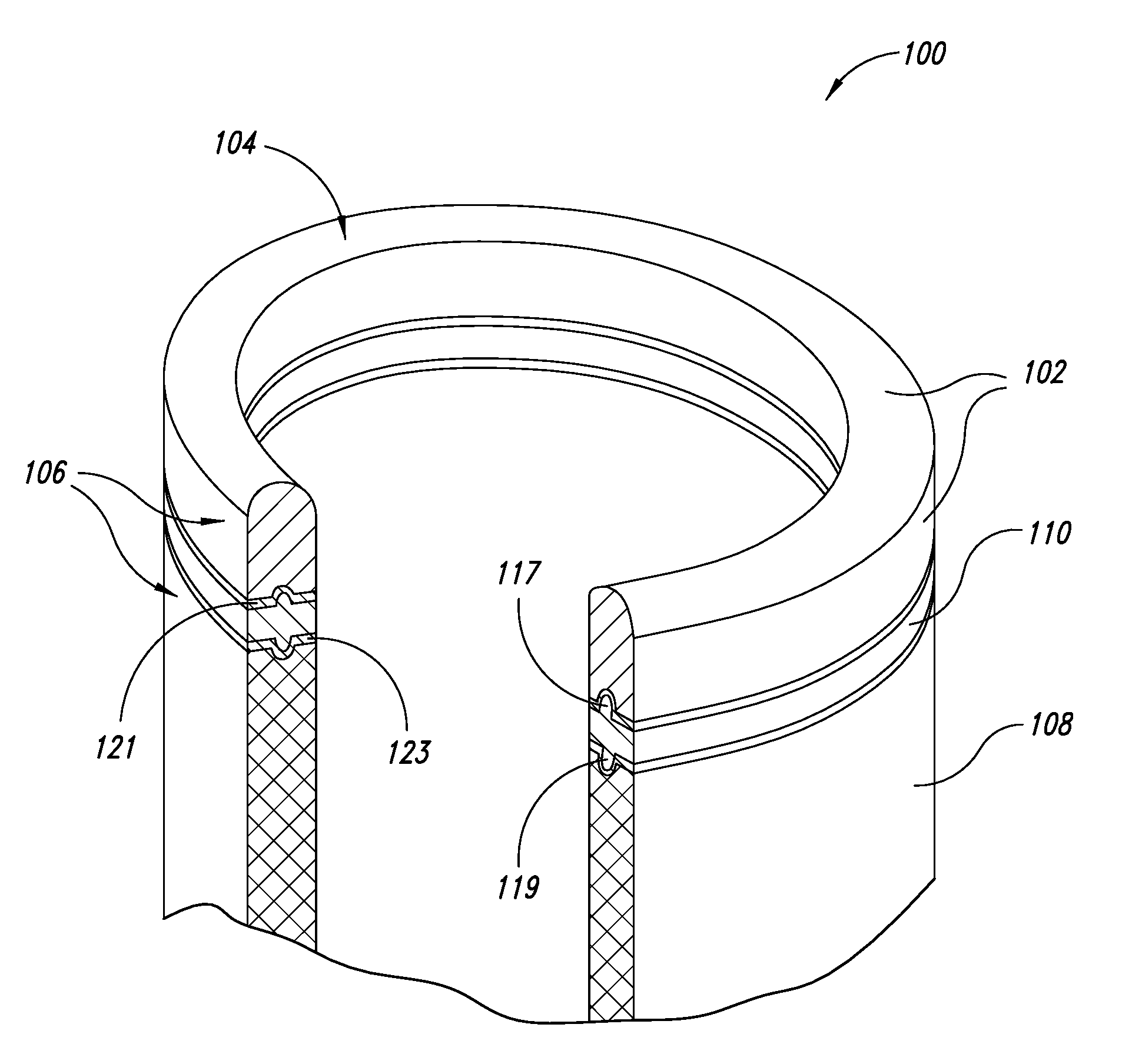

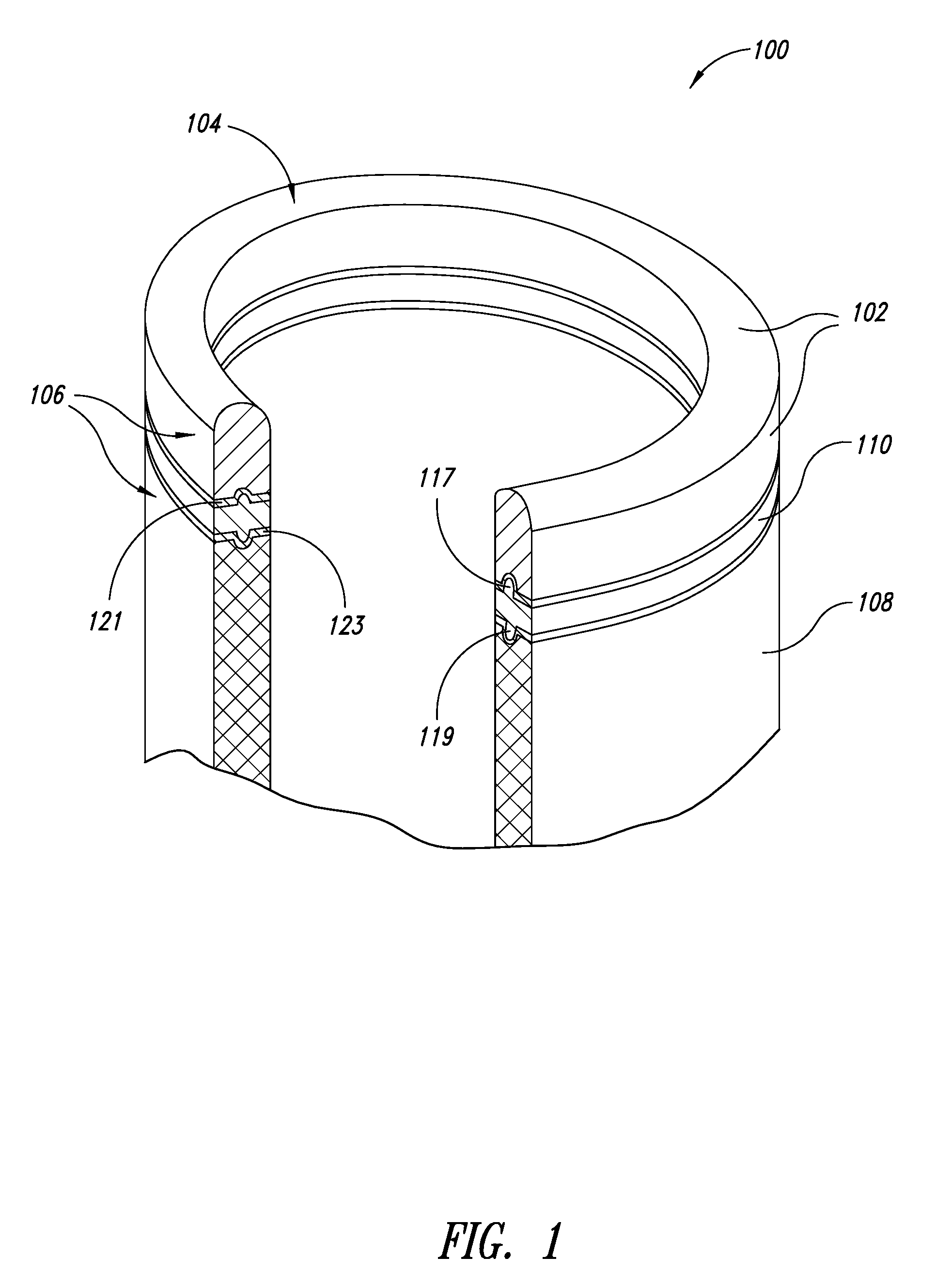

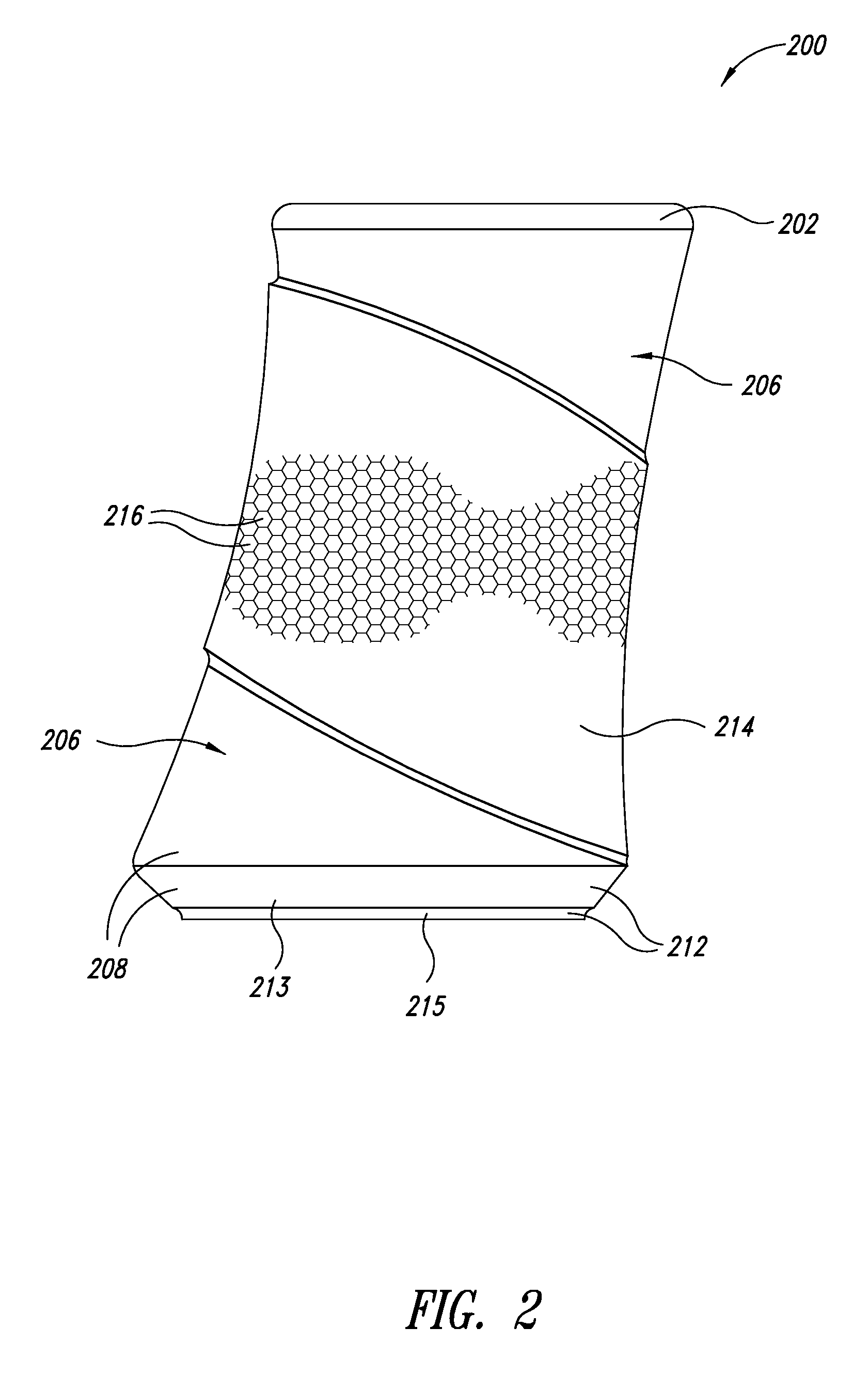

Portable beverage container

InactiveUS20070056964A1Improve overall sensePrevent escapeDrinking vesselsRigid containersEngineeringBone china

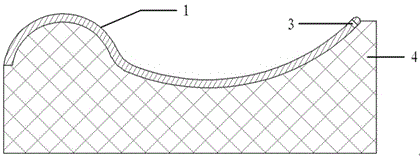

A portable beverage container comprises a base portion having a seat adapted to support the beverage container on a surface and / or in a holder, the base portion being fabricated from a first material such as plastics, rubbers, metals, and / or silicone. The portable beverage container further comprises a lip, which a user contacts when consuming a beverage, sealingly and rigidly attached to the base and fabricated from a second material, different from the first, the second material being adapted to enhance a drinking sensation of the user. The second material can for example comprise ceramic, bone china, stones, and / or glass. In other embodiments, the beverage container may include a bone china handle with a silicone over-mold.

Owner:CHEFN

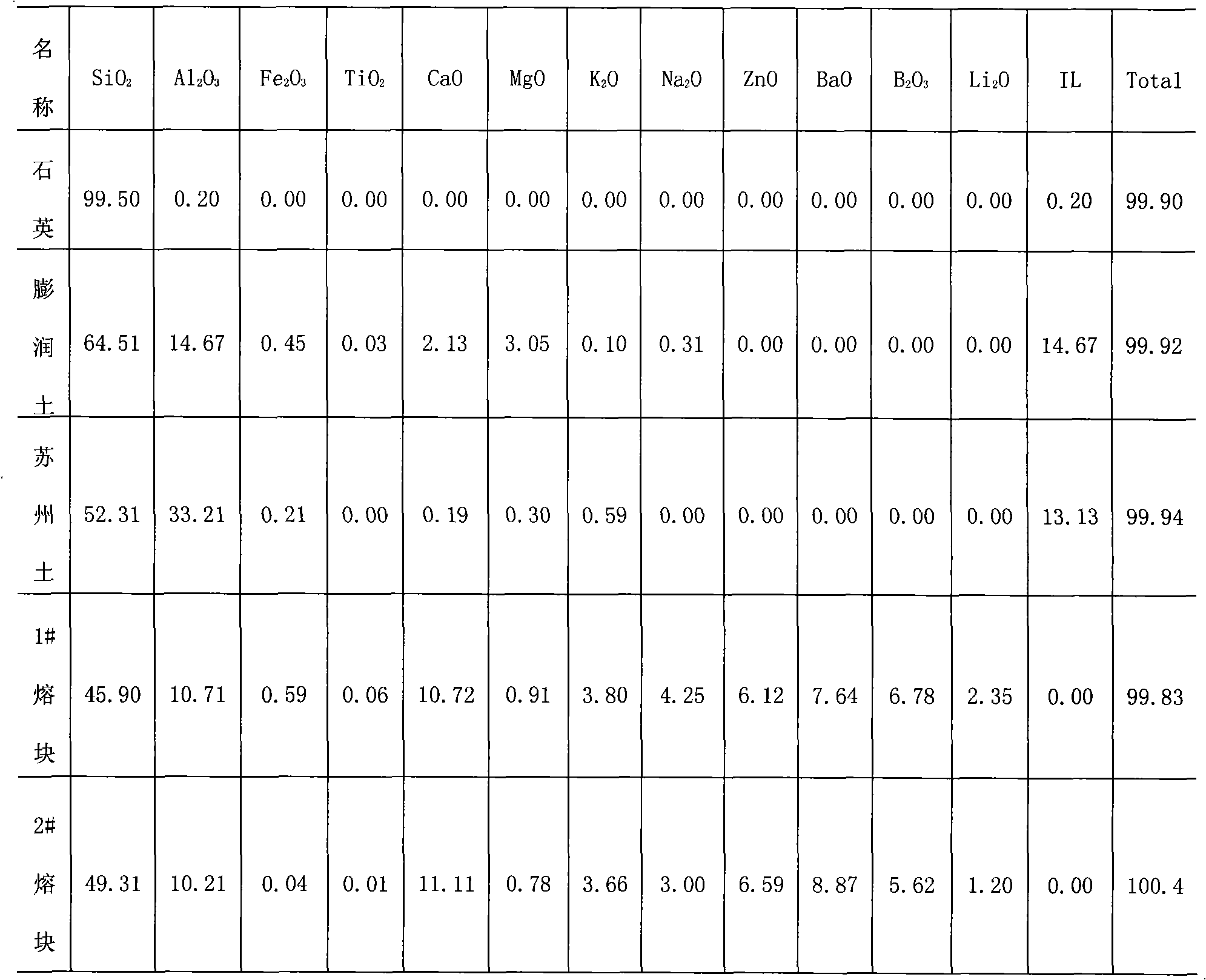

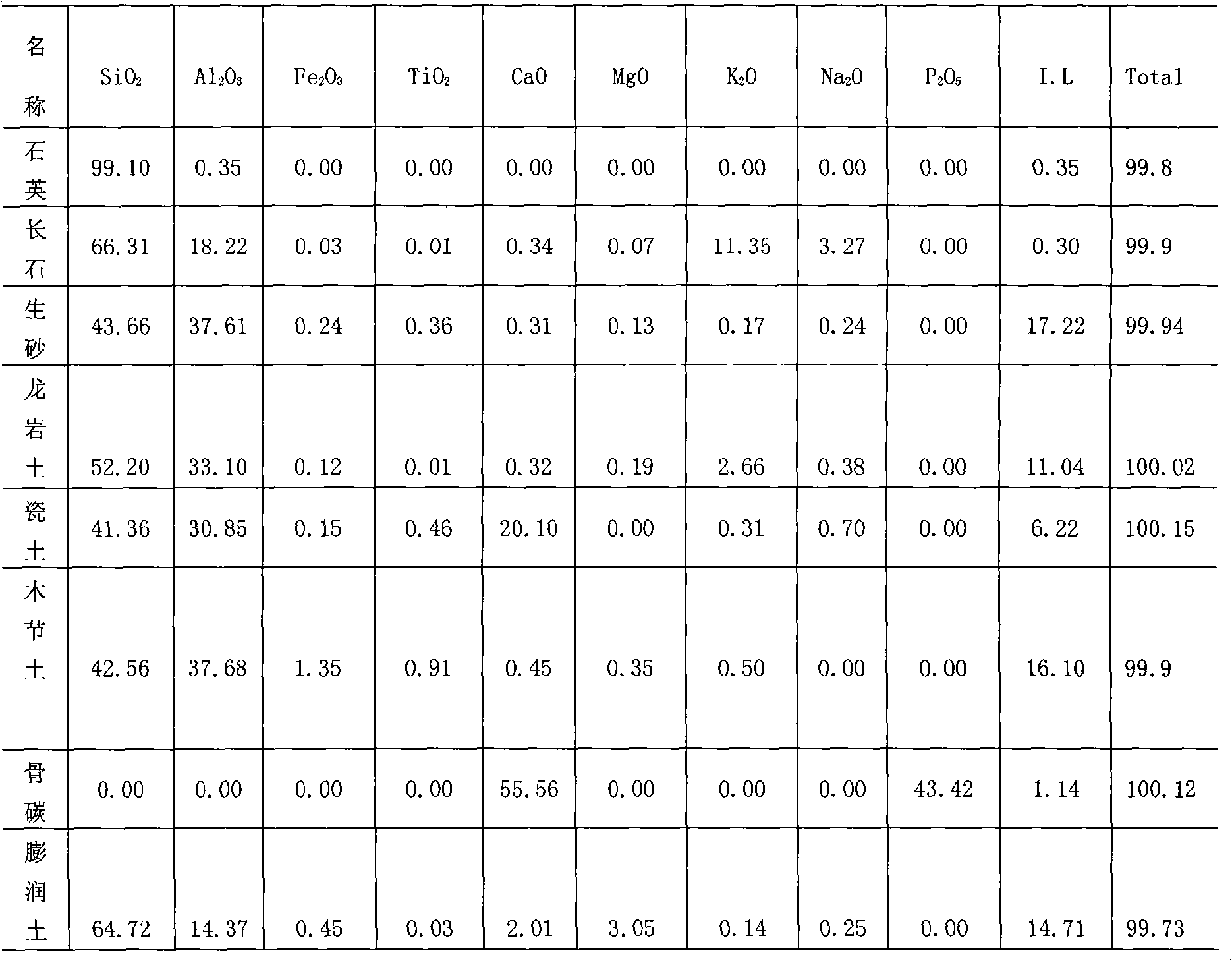

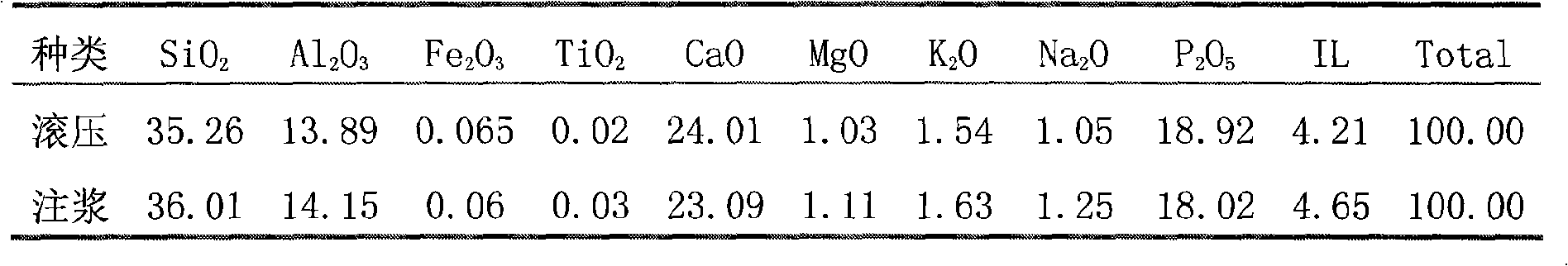

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

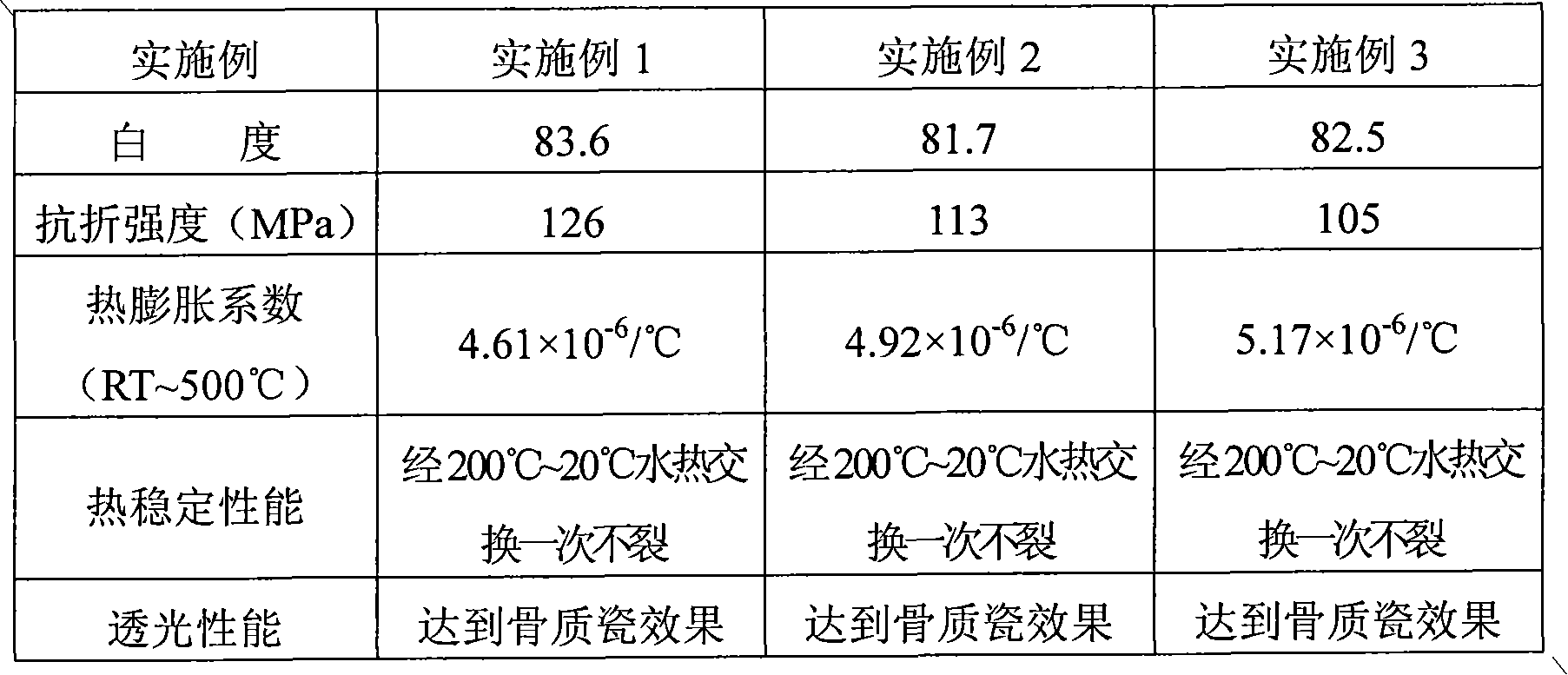

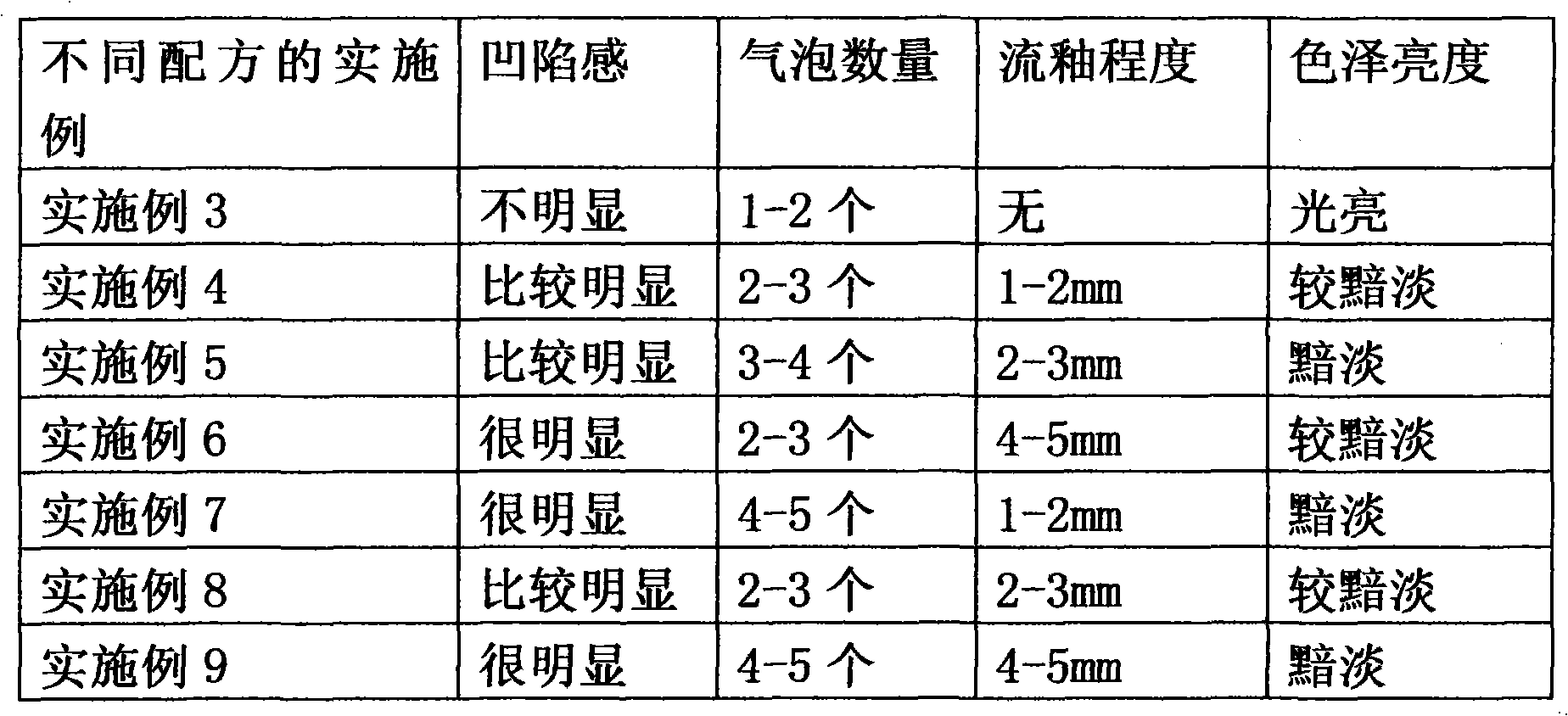

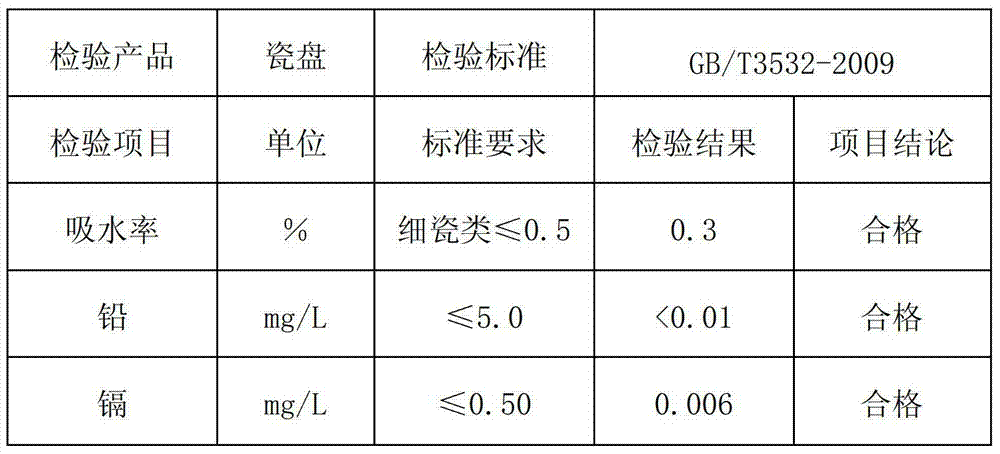

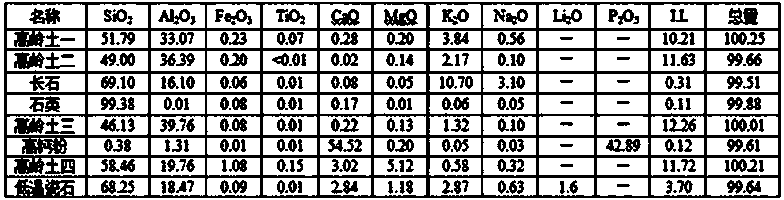

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

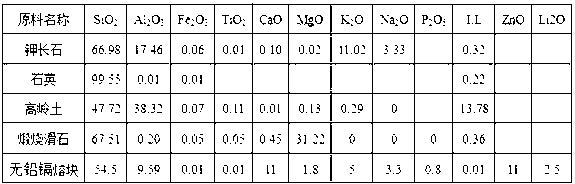

Daily-used fine porcelain with high property and preparation method thereof

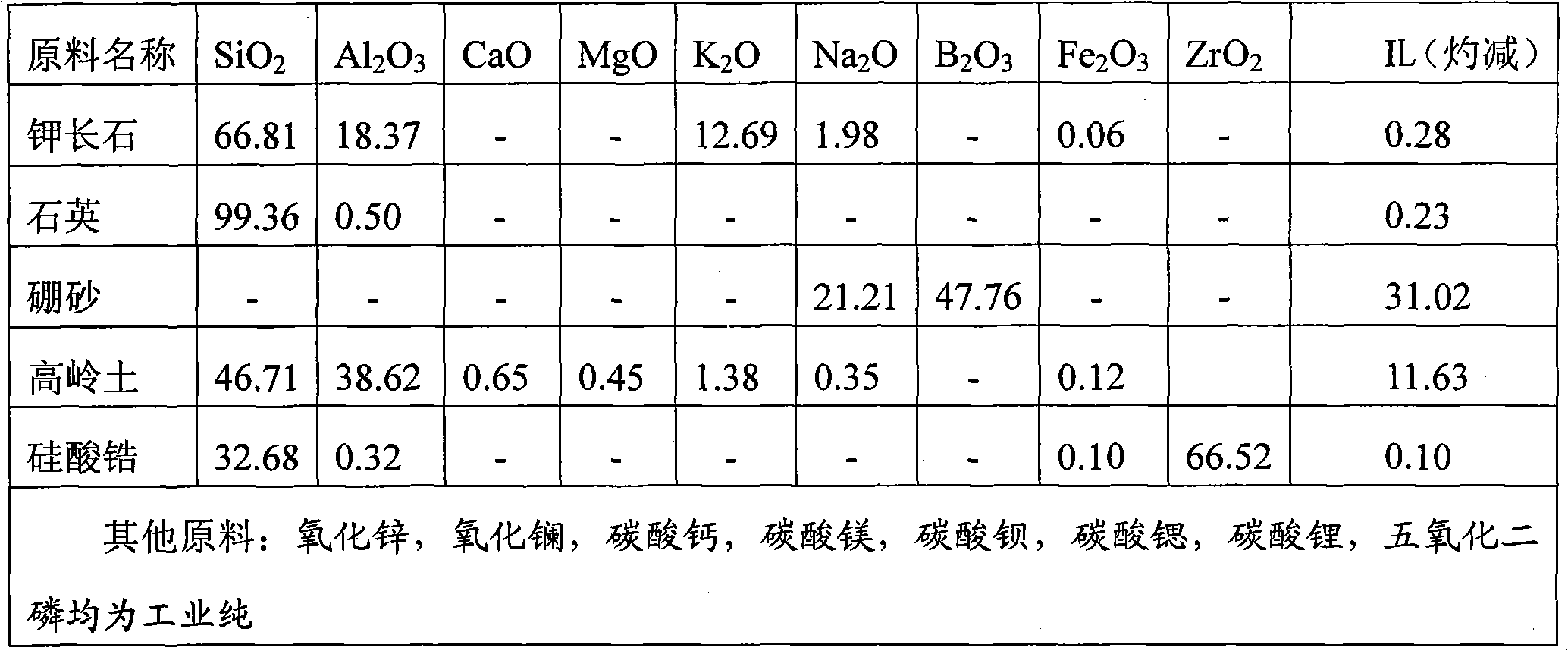

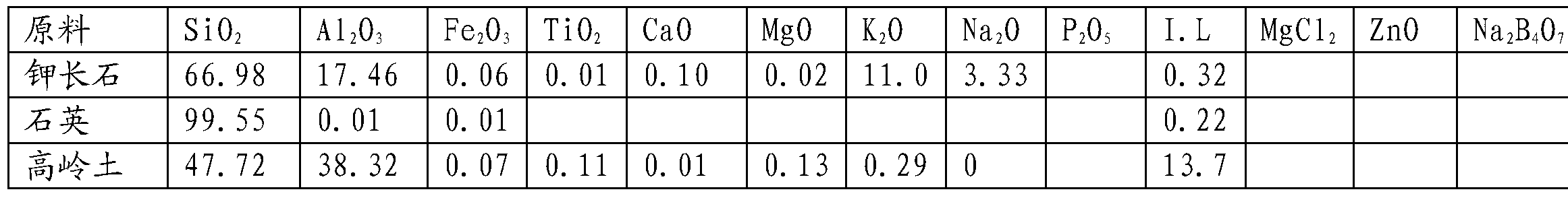

The invention belongs to the technical field of daily-used ceramics, relating to daily-used fine porcelain with high property and a preparation method thereof. The chemical constituents of the daily-used fine porcelain are 52-60% of SiO2, 32-40% of Al2O3, 1-3% of K2O, 1-3% OF Na2O, 1.5-3.5% of CaO, 0.5-1.5% of MgO and 1-2% of P2O5. The adopted raw material formulation is as follows: 40-45% of kaoline, 15-25% of quartz, 10-15% of potassium feldspar, 10-20% of alumina and 8-15% of antireflective agent. The daily-used fine porcelain of the invention integrates three characteristics of high strength, high white and high transparence, and has the characteristics of good molding property, wide sintering arrange and high thermal stability and the like, thereby overcoming the defect of bad light transmittance of normal strengthened porcelain, and solving the problems of uneasy molding and narrow sintering arrange of high-grade porcelain such as steatite porcelain and bone porcelain. The porcelain is sintered at the temperature of 1270-1320 DEG C, is easy to be produced and promoted, and is hopeful to become novel high-grade daily-used fine porcelain after bone porcelain and steatite porcelain.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Microcrystal-reinforced transparent leadless fritted glaze and preparation method thereof

The invention discloses a microcrystal-reinforced transparent leadless fritted glaze and a preparation method thereof, belonging to the field of ceramic glaze processing. The microcrystal-reinforced transparent leadless fritted glaze, prepared by the invention, comprises the chemical components in percentage by weight: 45.0-55.0% of SiO2, 5.0-7.0% of Al2O3, 0.1-0.2% of Fe2O3, 2.0-11.0% of CaO, 1.0-1.5% of MgO, 2.0-4.0% of K2O, 0.5-2.0% of Na2O, 0-3.0% of Li2O, 7.0-9.0% of ZnO, 3.0-5.0% of BaO, 2.0-2.6% of SrO, 5.0-10.0% of B2O3, 3.0-6.0% of ZrO2, and 0-1.0% of La2O3. The lead element in the fritted glaze is replaced with a composite solvent of alkali metal, alkaline-earth metal and a small amount of rare earth elements, the lead release is zero, thus the damage of the lead element in high-grade household porcelains represented by fine-bone china to a human body is thoroughly eliminated; and the prepared product is good in glaze glossiness and thermal stability, and high in transparency.

Owner:SHAANXI UNIV OF SCI & TECH

Lead-free and cadmium-free bone china glaze and preparation process thereof

The invention discloses a lead-free and cadmium -free bone china glaze and a preparation process thereof. The lead-free and cadmium-free bone china glaze comprises the following compositions in percentage by weight: 50.0 to 62.0 percent of SiO2, 6.0 to 10.0 percent of Al2O3, 6.0 to 10.0 percent of CaO, 0.5 to 4 percent of MgO, 0.0 to 2.0 percent of BaO, 0.5 to 3.0 percent of SrO, 6.0 to 10.0 percent of ZnO, 2.0 to 6.5 percent of K2O, 1.0 to 5.0 percent of Na2O, 0.2 to 3.0 percent of Li2O, 1.0 to 3.0 percent of B2O3, 1.0 to 3.5 percent of ZrO2, 0.2 to 1.0 percent of La2O3, and 0.1 to 2.0 percent of P2O5. By optimizing the glaze formula, the glaze has no lead and cadmium, so the glaze is non-toxic and environment-friendly. The lead-free and cadmium-free bone china glaze and the preparation process thereof have the advantages of reducing the consumption of zinc oxide, overcoming the defects of soft glaze, easy scratching and color disadvantage caused by high zinc oxide content, and improving the hardness of the glaze by optimizing the chemical compositions of the glaze.

Owner:SHENZHEN YONG FENG YUAN IND

Leadless bone porcelain and method for preparing same

The invention discloses leadless bone china and a preparation method thereof. The leadless bone china consists of cattle bone coal, pig bone coal, sandstone in Datong, quartz, feldspar, kaolin, calcined kaolin, and bentonite. The preparation method is as follows: leadless bone china is sorted manually, pulverized and processed; b. calcining, ball milling and alkaline cleaning process equipment and process are adopted for the bone coal; c. wet process is adopted for preparing semi-finished china and glaze; d. roll forming process and chain-type dryness are adopted for flat products and products in regular shape; e. high temperature biscuit firing with natural gas and medium and low temperature glaze firing are adopted; f. machine and manual spraying glazing are adopted for glazing; g. a roller hearth furnace is adopted for enamel firing in the environment of natural gases. The leadless bone china is primarily prepared with sandstone in Datong; the molding ratio of the product is as high as 96 percent; the product is transparent, light, fine and hard; the china is harder, whiter and more transparent than the ordinary china.

Owner:SHANXI MINGHE CERAMIC

Middle-low temperature sintered fine bone china and production method thereof

ActiveCN101891455AReduced thermal stabilityImprove thermal stabilityCeramic materials productionClaywaresCoalBone china

The invention relates to a middle-low temperature sintered fine bone china and a production method thereof. The china comprises the following chemical components in percentage by weight: 52 to 60 percent of SiO2, 28 to 37 percent of Al2O3, 1 to 4 percent of K2O, 1 to 2 percent of Na2O, 3 to 8 percent of CaO, 1 to 3 percent of MgO and 1 to 3 percent of P2O5; a used formula comprises the following raw materials in percentage by weight: 3 to 8 percent of bone ash, 32 to 45 percent of kaolin, 10 to 20 percent of aluminum oxide and 35 to 50 percent of fusion cake; the sintering temperature is between 1,170 and 1,250 DEG C; and not only a double-firing process of 'high-temperature biscuit firing and low-temperature glazed firing' or 'low-temperature biscuit firing and high-temperature glazed firing' can be adopted, but also a high-temperature single firing process can be applied. The fine bone china has an appearance effect of the conventional bone china, has physical and chemical properties superior to those of the bone china, has the significant advantages of low bone coal consumption and low sintering temperature, and is favorable for reducing the production cost and the energy consumption.

Owner:JINGDEZHEN CERAMIC UNIV

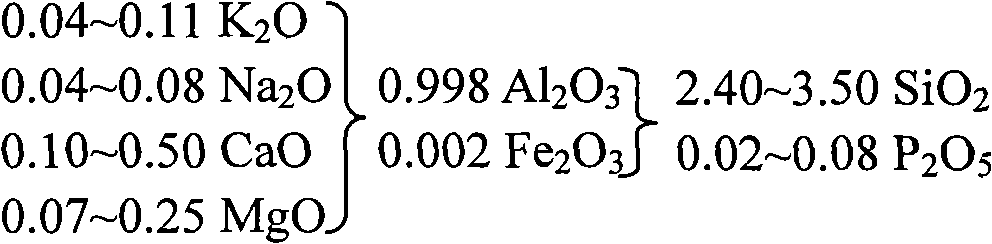

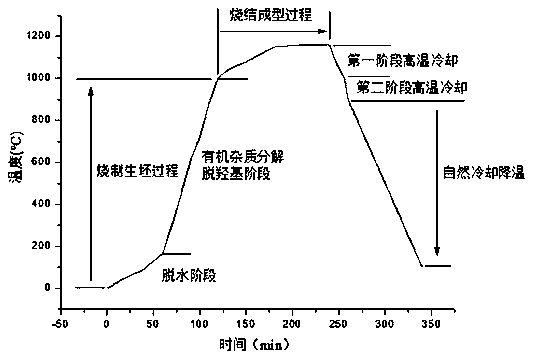

Bone-china exquisite glaze and method for fabricating bone-china exquisite products by using bone-china exquisite glaze

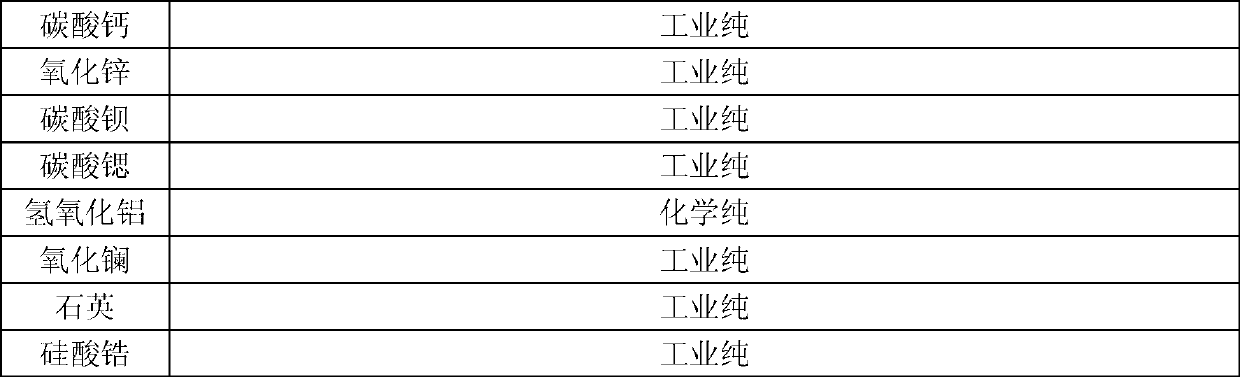

The invention relates to a bone-china exquisite glaze. The glaze comprises the following components in parts by weight: 16-24 parts of silica, 0-8 parts of clay, 28-38 parts of feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 10-17 parts of barium carbonate, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 2-12 parts of zinc oxide, 0-6 parts of aluminum hydroxide, 0-3 parts of talc, 0-12 parts of calcite and 0-1 part zirconium silicate. The glaze has the advantages of good transmittance and no opaque phenomenon and is exquisitely carved and glittering and translucent like jewels; the invention also provides a method for fabricating bone-china exquisite products from bone-china exquisite glaze, according to the method, residual bubbles can be eliminated, at the same time, the expansion coefficients of the glaze and the bone china are matched, quick heating and cooling resistance of products are improved and the cracking problem is avoided.

Owner:潮州市雅森陶瓷实业有限公司

Blue-and-white bone jewelry delicate porcelain

The invention relates to a blue-and-white bone jewelry delicate porcelain, which is a material belonging to chemical industry and capable of being directly applied to bone porcelain decoration. The preparation process of the blue-and-white bone jewelry delicate porcelain comprises the procedures of raw material processing, blank compacting, band model drying, demouding, drying, blank grinding, water supplement, inspection of a fine blank, placing in a low-temperature kiln, biscuiting at a low temperature, applique, sand blasting, glazing, glaze washing, placing in a high-temperature kiln, biscuiting at a high temperature, examination, polishing, glaze spraying, placing in a glost kiln, glost firing, kiln opening, inspection, applique, decoration firing, sole polishing, inspection, and placing in a finished product storage, and moreover, related conditions of temperature and time range in the steps of placing in the low-temperature biscuiting kiln, biscuiting at a low temperature and the like are required to be controlled. The invention has the advantages that the jewelry delicate porcelain is prepared by a special prescription and a special process method in bone porcelain, and a material similar to jewelry is embedded in the bone porcelain. Compared with other jewelry materials, the jewelry delicate porcelain has higher rich and honorable, decent and graceful features.

Owner:SHENZHEN BRIGHT FUTURE IND CO LTD

Bone matte glaze and method for manufacturing bone china product by using same

The invention relates to bone matte glaze. The bone matte glaze comprises, by weight, 100 parts of frits, 3-8 parts of clay, 2-12 parts of aedelforsite, 3-6 parts of aluminum oxide, 6-15 parts of zinc oxide and 6 parts of stannic oxide. The frits comprise, by weight, 16-24 parts of quartz, 28-38 parts of potash feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 0-10 parts of zinc oxide, 0-3 parts of talcum, 0-12 parts of calcite and 0-0.5 part of zirconium silicate. The glaze surface of a product using the glaze is fine, smooth, resistant to pollution, resistant to acid and alkali, easy to wash and suitable for the decoration means such as decal. The invention further provides a method for manufacturing the bone china product by using the bone matte glaze. The method is simple in firing process, stable in production and good in benefit.

Owner:GUANGDONG SONGFA CERAMICS

Middle-temperature high-grade daily tableware porcelain and preparation method thereof

ActiveCN105967643ALower firing temperatureFine and transparent porcelainClaywaresPotassiumBarium carbonate

The invention relates to the technical field of porcelain manufacture and concretely relates to a middle-temperature high-grade daily tableware porcelain and a preparation method thereof. Blank materials of the middle-temperature high-grade daily tableware porcelain comprise kaolin, potassium feldspar, wollastonite, quartz, lithionite, dolomite and calcinedtalc. Glaze materials of the middle-temperature high-grade daily tableware porcelain comprise low temperature transparent frit, feldspar, kaolin, waste glass, fluorite, quartz, zinc oxide, barium carbonate and lithionite. Through adjustment of the blank materials and glaze materials and use of a reasonable formula and specially-produced frit, a sintering temperature is reduced to 1050-1150 DEG C so that a sintering temperature is low, fuel is saved, product stability is high and a production cost is reduced. The glaze materials improve blank whiteness. The middle-temperature high-grade daily tableware porcelain has fine and transparent texture, good light transmittance and a gentle color, has qualitative sense close to that of bone-china, does not release lead and cadmium in a test, is safe for use and has good social and economic benefits.

Owner:德化县如瓷生活文化有限公司

Under-glaze colored decoration method of bone china

The invention relates to an under-glaze colored decoration method of bone china. The method includes an under-glaze colored decoration firing process and a pigment preparation technology, which includes transferring figures through pigment paint or labels for porcelain to a biscuit after lower temperature biscuit firing at a temperature of 700-800 DEG C, covering a protective layer, buckling a decorated ware on a profiling kiln furniture, performing firing at a temperature of 1250-1290 DEG C, wherein figure surfaces cannot be bruised, performing polishing on figure bases after firing, spraying fritted glaze slip, and performing glaze firing at a temperature of 1170-1200 DEG C. The figure surfaces are arranged under a glaze layer completely, and the method is a novel color decoration different from bone china over-glaze color figure for in-glaze decoration. Blanks are performed biscuit firing at a low temperature, the figure bases are fired through oxidizing flames at a high temperature (1250-1290 DEG C), and vitreous enamels are fired through oxidizing flames at an intermediate temperature (1170-1200 DEG C). Compared with once-firing of under-glaze color figure through reducing flames at a high temperature, the method is a firing method in which the temperature and the flame property are completely different. Bottoms of high range gift porcelain products are glazed through lowtemperature glazes, and smooth and non-discoloring forever after firing at a temperature of about 800-850 DEG C.

Owner:湖南丰德利瓷业有限公司

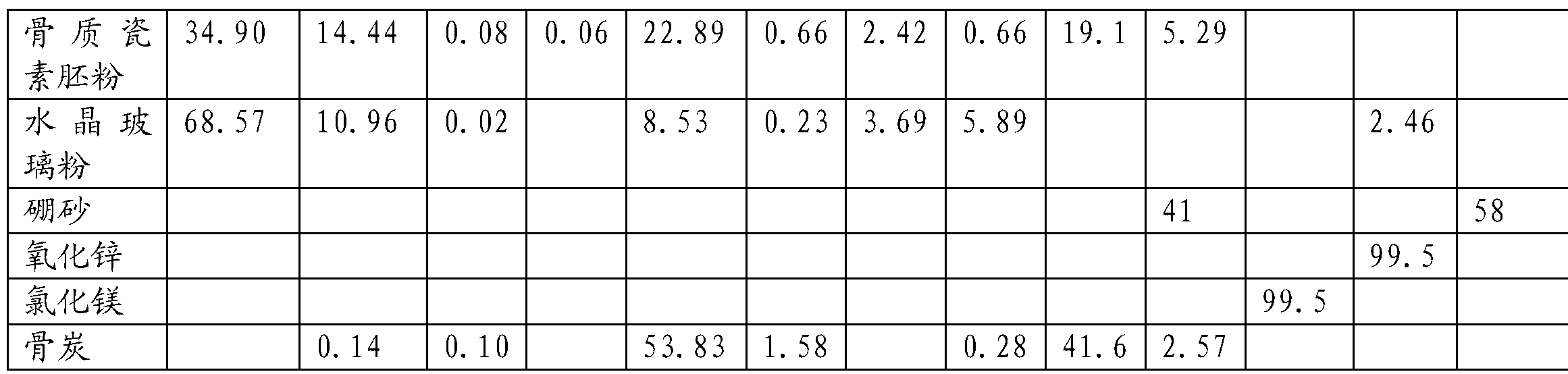

Processing craft of new bone china blank and glaze

The invention belongs to the technical field of ceramic product manufacturing methods, particularly relates to a new bone china blank and glaze craft, and mainly solves the problem that the production processes in the bone china are complex, the heat stability of a product is poor, the glaze hardness is low, and the production cost is high. According to the technical scheme, the new bone china blank and glaze craft comprises the following steps of preparing pug, preparing glaze, and producing a blank. The processing craft provided by the invention has the advantages that the heat stability of a once-firing product is good, the glaze hardness is high, the production cost is low, the boneblack content is less and the like.

Owner:YING COUNTY SHENGFU CERAMICS IND CO LTD

Ivory ceramic and production technology thereof

InactiveCN103288424AHigh whitenessGlaze surface hardness is highClaywaresUltimate tensile strengthBone china

The invention relates to an ivory ceramic and a production technology thereof, and belongs to the technical field of ceramics. A technical scheme adopted in the invention is characterized in that the ivory ceramic is prepared through calcining 5-30mass% of quartz, 5-30mass% of feldspar, 20-50mass% of kaolin, 1-20mass% of ceramic powder, 1-15mass% of alumina and 1-20mass% of bone black; and the ceramic powder is obtained after crushing bone china wastes or is obtained after crushing ivory ceramic wastes. The ivory ceramic has a high whiteness, a good transparency, a fine ceramic texture and a shining and smooth glaze, has the advantages possessed by the bone china, also has the advantages of good molding stability, high glaze hardness, high overall strength, reasonable technology and high molding rate, overcomes the disadvantages of the bone china, is a substitute product of the bone china, is called as the ivory ceramic because of the ivory color, and has a high grade and a low cost; the bone chain wastes are afresh used, so energy saving and environmental protection are realized.

Owner:TANGSHAN PERMANENT AUSPICIOUS PORCELAIN IND LIMITED

Production technology for producing spontaneous glaze bone china by efficient utilization of desert material

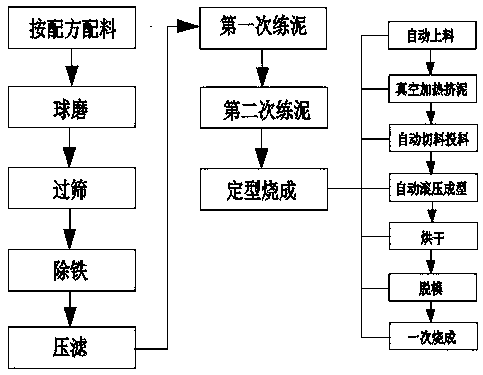

The invention relates to a production technology for producing spontaneous glaze bone china by efficient utilization of a desert material. The spontaneous glaze bone china is prepared from the following raw materials in percentage by weight: 50-60% of sand grains from desert, 15-25% of halloysite, 15-20% of feldspar, 2-9% of hydroxyl calcium phosphate, 2-3% of nanoscale spodumene, 1-3% of talc and1-1.5% of nanoscale zircon sand; the production technology of the bone china comprises the following steps: dosing according to the formula, ball milling, sieving, iron removal, filter pressing, first pugging, second pugging and setting firing; the setting firing comprises the following steps: preparation of ceramic pug, automatic charging, vacuum heating and pug squeezing, automatic blanking andfeeding, automatic moulding by rolling, drying, demoulding and once firing. According to the production technology provided by the invention, the sand grains in desert are introduced into the Dehua jade china pug to partially replace the raw materials, and the ceramic firing energy consumption and production cost are reduced by the once firing technology; meanwhile, in combination with the intelligent production technology, traditional Dehua jade chain preparation technology is integrated with intelligent production.

Owner:温克仁

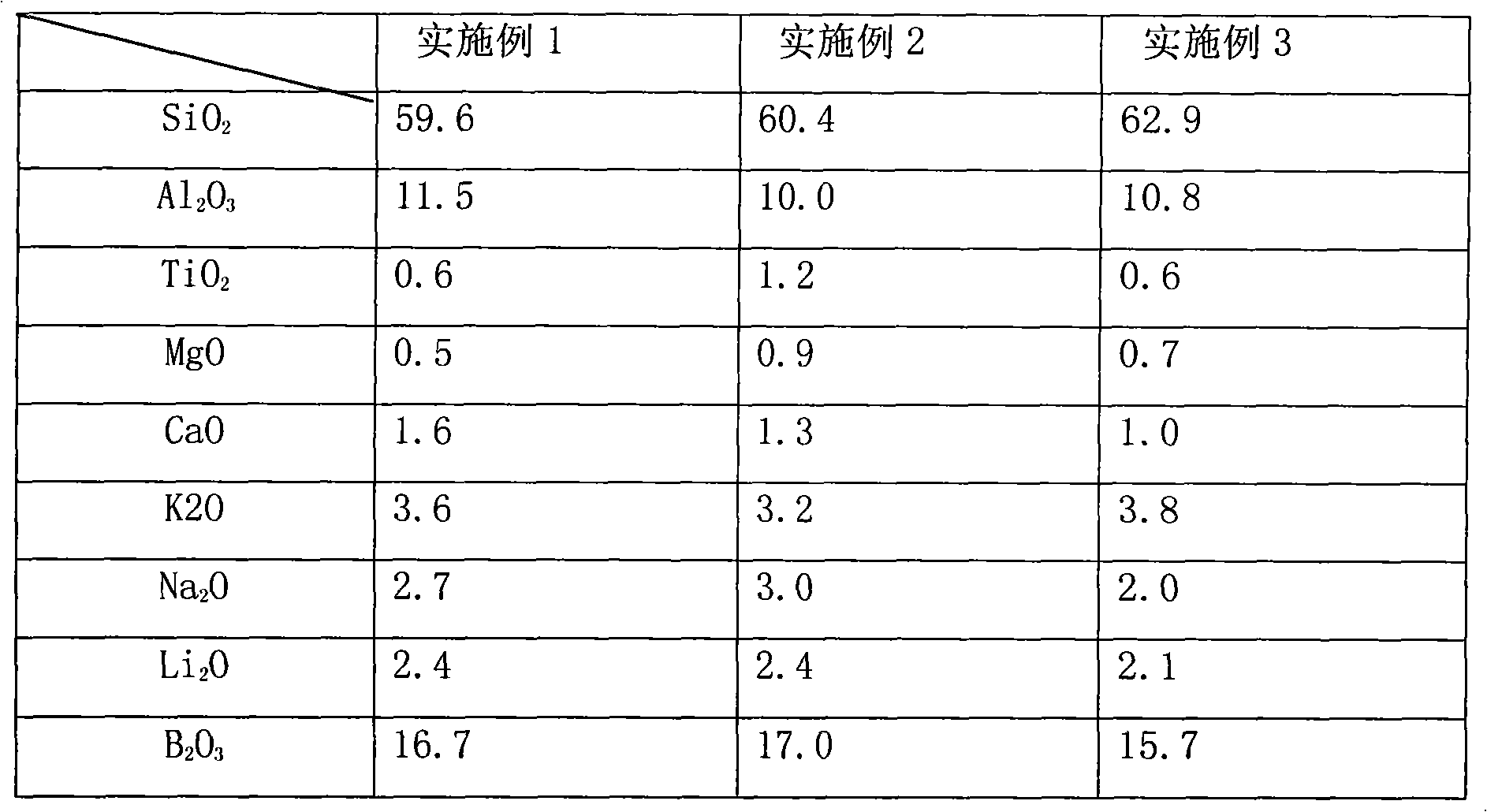

Lead and cadmium free fritted glaze for bone China with high acid resistance and alkali resistance

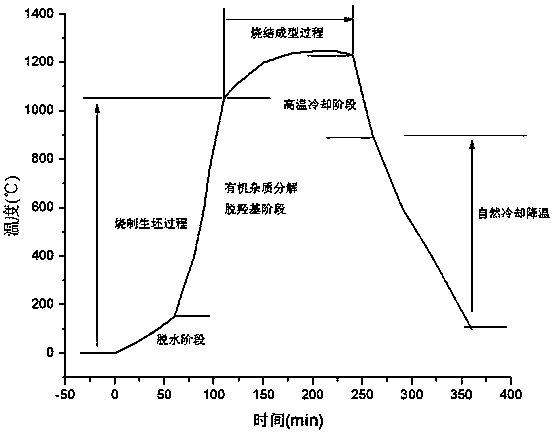

The invention relates to a ceramic glaze, particularly a lead free fritted glaze for a bone China with high acid resistance and alkali resistance to produce the lead free bone China products with the high quality. The lead free fritted glaze with the high acid resistance and alkali resistance has the components by weight: 58.0-66.0% of SiO2, 10.0-15.0% of Al2O3, 0.0-1.0% of TiO2, 0.5-2.0% of CaO, 0.0-1.0% of MgO, 2.0-6.0% of K2O, 2.0-6.0% of Na2O2, 2.0-6.0% of Li2O2 and 15.0-25.0% of B2O3. The lead free fritted glaze with the acid resistance and alkali resistance does not contain the metal components of lead, cadmium, zinc, barium and the like, adds with a certain alkali metal oxide, TiO2 and boracic acid with simple composition, scientific and reasonable application. The glaze has good application adaptability and is especially for the excessive furnace temperature. The burned finished ceramic has smooth glaze and good gloss. The glaze has good corrosion resistance and has high adaptability to the decal paper. The glaze is especially for the tableware washer due to high mechanical strength and thermal shock stability.

Owner:张垠

Preparation method of bright red glaze bone china

The invention discloses a preparation method of bright red glaze bone china, wherein the bone china is prepared by the bright red glaze, the bone china comprises a bright red pigment glaze layer and a transparent glaze layer, the bright red pigment glaze layer is prepared by the following steps of: using 10-20 parts of BF242 clinker, 20-32 parts of DF-02 clinker, 6-14 parts of Suzhou soil and 42-56 parts of bright red coating pigment as raw materials, burning the raw materials to entire-clinker, adding water therein and ball milling the same, adjusting the specific gravity of the glaze slip to 1.85-1.95 g / m3 if the glaze slip fineness reaches to such a condition that the screen residue of a sieve with 325 meshes is 0.01-0.04% after the deironization procedure, coating the bright red pigment glaze on a bone china bisque body by a glaze spraying method, wherein the thickness of the glaze layer is 0.6-1.0 mm, and drying; coating the transparent glaze on the dry bisque body with bright red pigment glaze, and drying the bisque body; and sintering the bone china under an oxidizing flame atmosphere, wherein the highest sintering temperature is 1090+ / -1 DEG C. The prepared product has the advantages of moist and uniform glaze surface, brilliant and fadeless color, good thermal stability and non harmful lead and cadmium dissolution.

Owner:山西高陶瓷业有限责任公司 +1

High-whiteness bone china for daily use and preparation method thereof

InactiveCN107140948AImprove qualityImprove performanceCeramic materials productionClaywaresFiberBrucite

The invention provides a high-whiteness bone china for daily use, and a preparation method thereof. The high-whiteness bone china for daily use is prepared from the following components in percentage content: 21 to 24 percent of kaolin, 7 to 11 percent of feldspar, 10 to 15 percent of quartz, 1.3 to 2.6 percent of sepiolite fiber, 0.3 to 1.2 percent of brucite, 2 to 5 percent of diatomite, 0.48 to 0.65 percent of sodium alginate, 0.15 to 0.25 percent of a dispersing agent and the balance of bone ash powder, through the steps of mixing, heating, precalcining, crushing, ball-milling, sintering and the like. The high-whiteness bone china for daily use has high thermoplasticity, high heat stability and high processability; and the prepared product has flat and smooth appearance, the mechanical strength and the light-transmitting property are remarkably improved, the whiteness can reach 82 percent, the rate of finished products can reach above 95 percent, and the comprehensive quality of the china for daily use is effectively improved.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

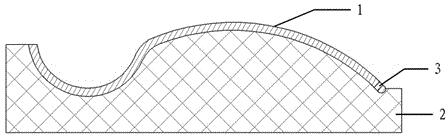

Preparation method of portable bone-china soup ladle

ActiveCN105645926AThe appearance is regular and unchangedHigh light transmittanceCeramic materials productionTablewaresMetallurgyBone quality

The invention discloses a preparation method of a portable bone-china soup ladle. The preparation method is characterized by comprising the following production steps of 1, blank preparation, 2, glaze preparation, 3, slip casting, 4, fettling, 5, biscuiting, 6, glazing and 7, firing. The obtained portable bone-china soup ladle is neat in appearance and free of deformation, the product light transmission is good, and the glaze layer is smooth; the product is attractive and portable, and the impact resistance strength is higher than 1.5 J / cm<2>. The product quality meets the standard requests of GB / T13522 Bone China.

Owner:广东金鹿陶瓷实业有限公司

Method for preparing high-strength, high-whiteness, high- thermal-shock-resistance petuntse

The present invention provides a method for preparing high-strength, high-whiteness, high-thermal-shock-resistance petuntse. The preparation method comprises the following production steps of (1) mechanically beating pyrophyllite, washing to remove mud and removing iron by magnetic separator and sieving; (2) mechanically beating kaolin, washing to remove mud and removing iron by magnetic separator and sieving; (3) according to the percentage by weight, weighting 28% of potassium feldspar, 12% of aluminum oxide, 10% of illite, 10% of montmorillonite and 30% of kaolin, mixing with 10% of pyrophyllite, ball milling, removing iron by magnetic separator and sieving to obtain petuntse materials; (4) press filtering the above sieved petuntse materials to obtain petuntse. The petuntse prepared by the invention is suitable for the production of ceramic products for daily use, product qualification rate is high. The strength, whiteness and thermal shock resistance of the product are superior to that of bone china, porcelain and highly siliceous magnesia porcelain, production cost is low, products are particularly applied in dishwashers, microwaves, refrigerators and sterilized cupboard.

Owner:CHAOZHOU RONGCHANG CERAMIC IND CO LTD

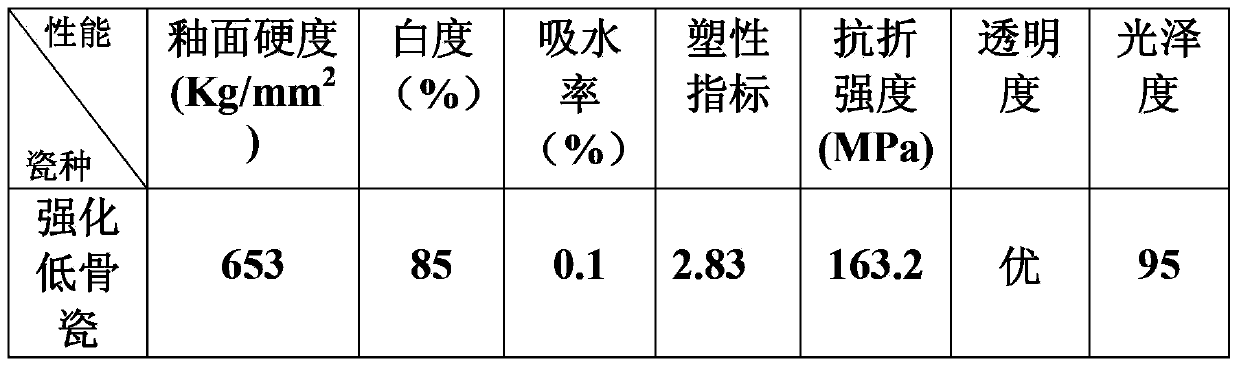

Preparation method of reinforced bone china and product prepared therefrom

The invention relates to a preparation method of reinforced bone china and a product prepared therefrom. According to the preparation method, a green body formula comprises the following components in percentage by weight: 15 to 20% of kaolin I, 15 to 20% of kaolin II, 10 to 15% of feldspar, 5 to 10% of quartz, 8 to 10% of kaolin III, 2 to 5% of kaolin IV, 35 to 40% of high calcium powder, and 5 to 10% of low-temperature cornish stone; a glaze formula comprises the following components in percentage by weight: 10 to 15% of kaolin I, 30 to 40% of feldspar, 5 to 10% of quartz, 8 to 13% of borax, 5 to 10% of zinc oxide, 10 to 15% of cornish stone, 3 to 6% of dolomite, 8 to 12% of calcite, and 5 to 8% of barium carbonate. The production method is scientific and reasonable, advanced in process technology, high in rate of finished products, and high in product quality, realizes firing at medium and low temperatures and has the advantages that a lot of gas and fuel is saved, the defect rate caused by the glaze firing at high temperature is greatly reduced, the production cost is remarkably reduced, and thus a wide market prospect is brought.

Owner:景德镇恩达陶瓷有限公司

Ordinary fine procelain

ActiveCN101928132ALower firing temperatureHigh whitenessSolid waste disposalClaywaresBall millBone china

The invention relates to procelain production and aims to provide an ordinary fine procelain featuring low firing temperature and reduced production cost. The ordinary fine procelain of the invention comprises the following components in percentage by weight: 9-12% of Guangxi soil, 5-10% of Jingxing soil, 2-6% of Shanyin soil, 2-7% of Yusi soil, 2-8% of Tang county soil, 8-14% of Longyan soil, 22-28% of quartz, 24-30% of Datong soil, 8-14% of feldspar and 6-8% of fine bone china waste powder. Blank is crushed, processed into fine powder of 100 meshes and ball-milled in a wet-type ball mill while being added with water, blank: ball: water=1:2.5:1; the mixture is levigated for 18-20 hours; the mixture passes through a sieve of 250 meshes, the fineness of the mixture is 0.8%, the mixture is dehydrated by a mud press to have a water content of 21% and then vacuum pugging is carried out on the mixture for twice at a vacuum degree more than or equal to 0.09MPa.In the invention, the fine bone china waste powder is added to the production of the ordinary fine procelain, therefore the firing temperature of the ordinary fine porcelain in the invention is reduced by about 30 DEG C compared with the firing temperature of the traditional ordinary fine porcelain.

Owner:PINGDING YINGYU PORCELAIN

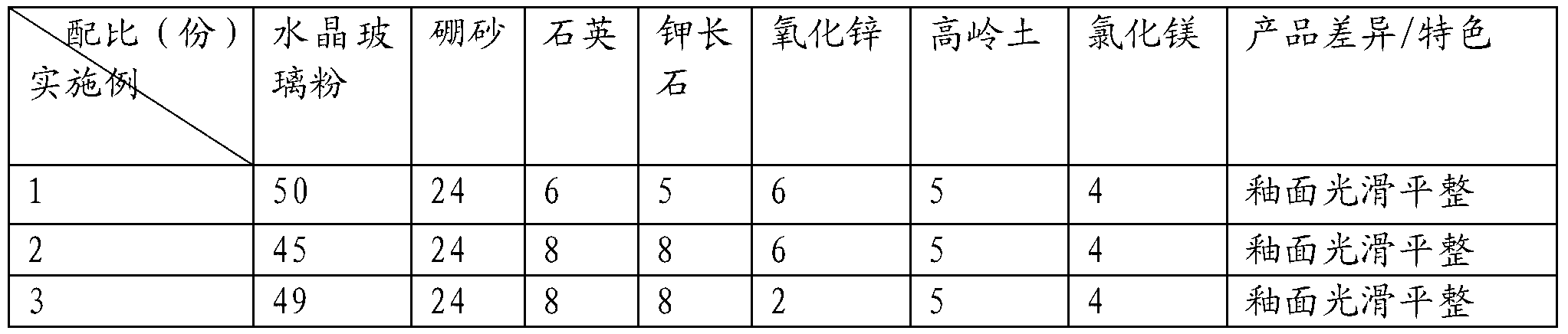

Manufacturing process of crystal frit-containing exquisite glazes and exquisite products

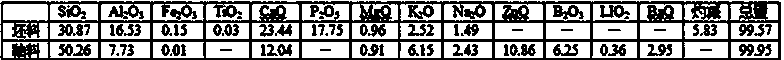

The invention provides a manufacturing process of crystal frit-containing exquisite glazes and exquisite products and relates to a formula and a preparation method of a crystal frit and the manufacturing process of the crystal frit-containing exquisite glazes and bone-china exquisite products. The crystal frit comprises the following components in percentage by weight: 40-55% of crystal glass powder, 20-24% of borax, 6-10% of potassium feldspar, 5-10% of quartz, 5-6% of zinc oxide, 5-8% of kaoline and 4-6% of magnesium chloride and particularly comprises the following components in percentage by weight: 40-62% of SiO2, 6.4-11% of Al2O3, 3.4-4.8% of CaO, 2.0-3.2% of K2O, 2.5-3.7% of Na2O, 6-7.9% of ZnO, 3.7-5.6% of MgCl2 and 11.6-14.0% of Na2B4O7. By adopting the technical scheme, the crystal exquisite frit can serve as the exquisite glazes in exquisite products and can also serve as cover glazes.

Owner:SHENZHEN YONGFENGYUAN PORCELAIN

Blue-and-white pigment used in bone china and fabricating technology for blue-and-white bone china

The invention relates to a blue-and-white pigment used in a bone china and a fabricating technology for the blue-and-white bone china. The blue-and-white pigment used in the bone china is prepared by mixing following components in percentage by weight: 30%-70% of the pigment, 10%-30% of a bone china blank, 10%-40% of glaze and 1%-3% of methylcellulose. The fabricating technology of the blue-and-white bone china comprises the steps that a bone biscuit which is subjected to biscuit firing is coated with the blue-and-white pigment which is prepared in a ratio and used in the bone china, and then the bon biscuit is placed in a kiln for color baking. According to the invention, the pigment is matched with the bone china blank and the glaze for usage, a mixture with the pigment is drawn on the biscuit and subjected to high temperature color baking, and the combination degree of bone china blank components in the mixture and the bone china biscuit is good, so that the pigment in the mixture is attached to the bone china biscuit excellently; meanwhile, contained components of the glaze enhance the fusion degree with sizing glaze; and consequently, the defect of permeation of the blue-and-white on the bone china in conventional processing and formulas is overcome excellently.

Owner:SHENZHEN YONGFENGYUAN PORCELAIN

Strengthened low-bone china porcelain and production method thereof

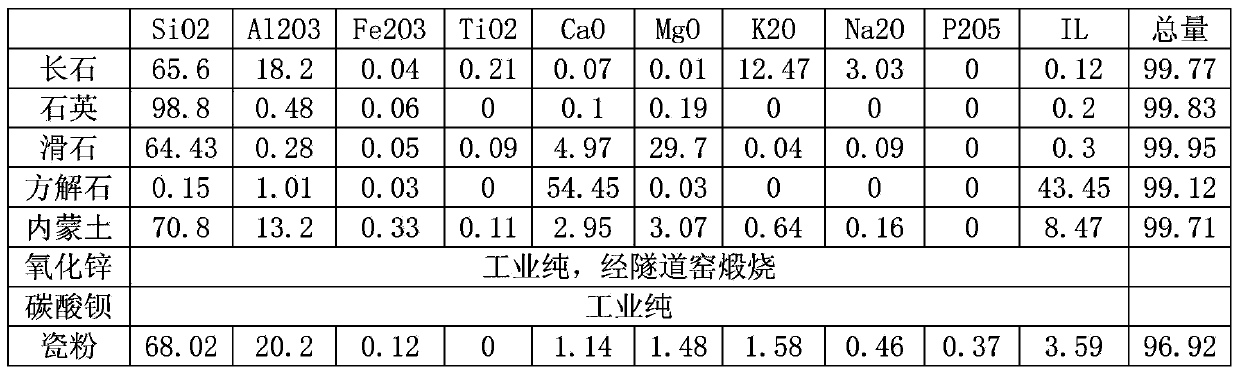

The invention relates to strengthened low-bone china porcelain and a production method thereof, and mainly overcomes technical difficulties that the conventional bone chain is low in strength, is easily scratched by a knife and fork and difficult to clean. The invention adopts the technical scheme as follows: the strengthened low-bone china porcelain is prepared from a blank material and a glaze material, wherein the blank material is prepared from the following components in parts by weight: 25-33 parts of quartz, 20-25 parts of Datong soil, 3-5 parts of talc, 10-15 parts of Fujian soil, 5-10 parts of Hunan soil, 2-5 parts of alumina, 4-10 parts of bone powder, 8-10 parts of feldspar and 3-5 parts of Inner Mongolia soil; and the glaze material is prepared from the following components in parts by weight: 8-10 parts of quartz, 35-40 parts of feldspar, 4-6 parts of talc, 4-6 parts of Inner Mongolia soil, 10-13 parts of calcite, 3-5 parts of zinc oxide, 2-4 parts of barium oxide and 15-20 parts of porcelain powder. The production method comprises the following steps: 1) preparing the blank material; 2) preparing the glaze material; 3) preparing a blank; 4) glazing; and 5) firing.

Owner:阳城县侨枫瓷业有限公司

Bone China and preparation method thereof

InactiveCN101723649AImprove liquiditySolve the problems of instability, low strength and easy crackingInstabilityTransmittance

The invention discloses a bone china and a preparation method thereof, relates to a bone china and provides a bone china with better performance and a preparation method thereof. The blank raw materials of the bone china are 45-55 percent of bone powder, 255-34 percent of clay, 85-14 percent of feldspar and 85-12 percent of quartz. The preparation method comprises the following steps of: drying and calcinating the bone powder, cooling along with a furnace, ball milling and washing and then drying; carrying out ball milling on the clay, the feldspar and the quartz; mixing bone powder, clay powder, feldspar powder and quartz power which are subjected to ball milling; adding a dispersant and grinding to obtain a bone china sizing agent; pouring the bone china sizing agent into a mold and molding, then demolding and drying to obtain a blank; and repairing the bland, pouring the blank into the furnace and sintering to obtain the bone china. The invention solves the problems that the sizing agent molded by grouting has instability, low strength, easy crack and the like, caused by overhigh viscosity of the bone china sizing agent, improves the mechanical strength and the transmittance of the bone china, enables the comprehensive performance index of a bone body to reach an optimal balance by adopting a proper sintering system, avoids the production problem of higher production cost and has considerable market prospect.

Owner:XIAMEN UNIV

Bone china paste and preparing technology thereof

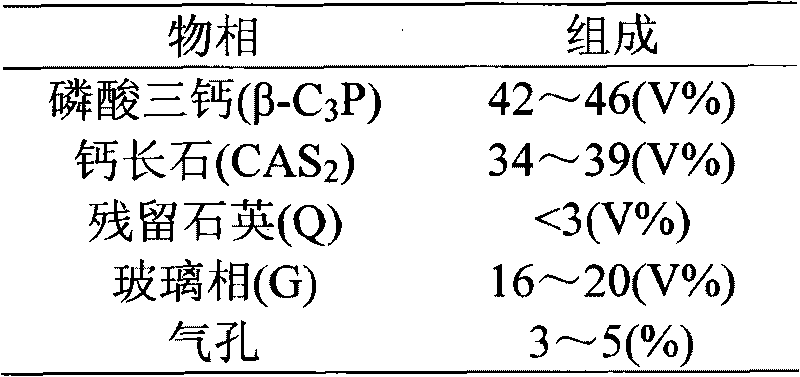

The invention discloses a bone china paste and a preparing technology thereof. The bone china paste comprises the following components by weight percent: 34.0-38.0% of SiO2, 12.0-16.0% of Al2O3, 0.2-0.4% of Fe2O3, 0.05-0.2% of TiO2, 24.5-27.0% of CaO, 0.5-1.5% of MgO, 18.0-21.0% of P2O5 and 0-4.0% of K2O and Na2O2, wherein the sum of the weight percent of the compounds is 100%. Ball clay is introduced in the bone china paste to increase the plasticity of the paste; and synthetic bone char is used to replace natural bone char, thus the dependence of the mass production of the bone china paste to natural bone char can be lowered and the paste can have reasonable chemical composition and better physical performance indexes; and the formability of paste can be improved, the production technology difficulty of bone china can be reduced, the qualification rate of products can be greatly increased, and technical supports can be provided for the batch production of bone china.

Owner:SHENZHEN YONG FENG YUAN IND

Method for preparing underglaze bone china

The invention discloses a method for preparing underglaze bone china, which comprises the following production steps: preparing a bone china material into a blank; performing high temperature biscuit firing on the blank, wherein the temperature of the biscuit firing is between 1,250 and 1,280 DEG C; performing color painting on a product after the biscuit firing, wherein the pigment used by the color painting is prepared from the following compositions by weight percentage: 65 to 75 percent of colorradical and 25 to 35 percent of glaze; performing high temperature color firing on the product after the color painting, and the temperature of the color firing is between 1,200 and 1,250 DEG C; and glazing the product after the high temperature color firing with the same glaze in the pigment, and performing medium temperature glaze firing to prepare a finished product, wherein the temperature of the glaze firing is between 1,050 and 1,150 DEG C. The underglaze bone china prepared by the method has clear color painting patterns, strong stereovision, and rich, fresh and bright color of the color painting patterns, smooth, neat and delicate glaze and high firing rate.

Owner:李永生 +1

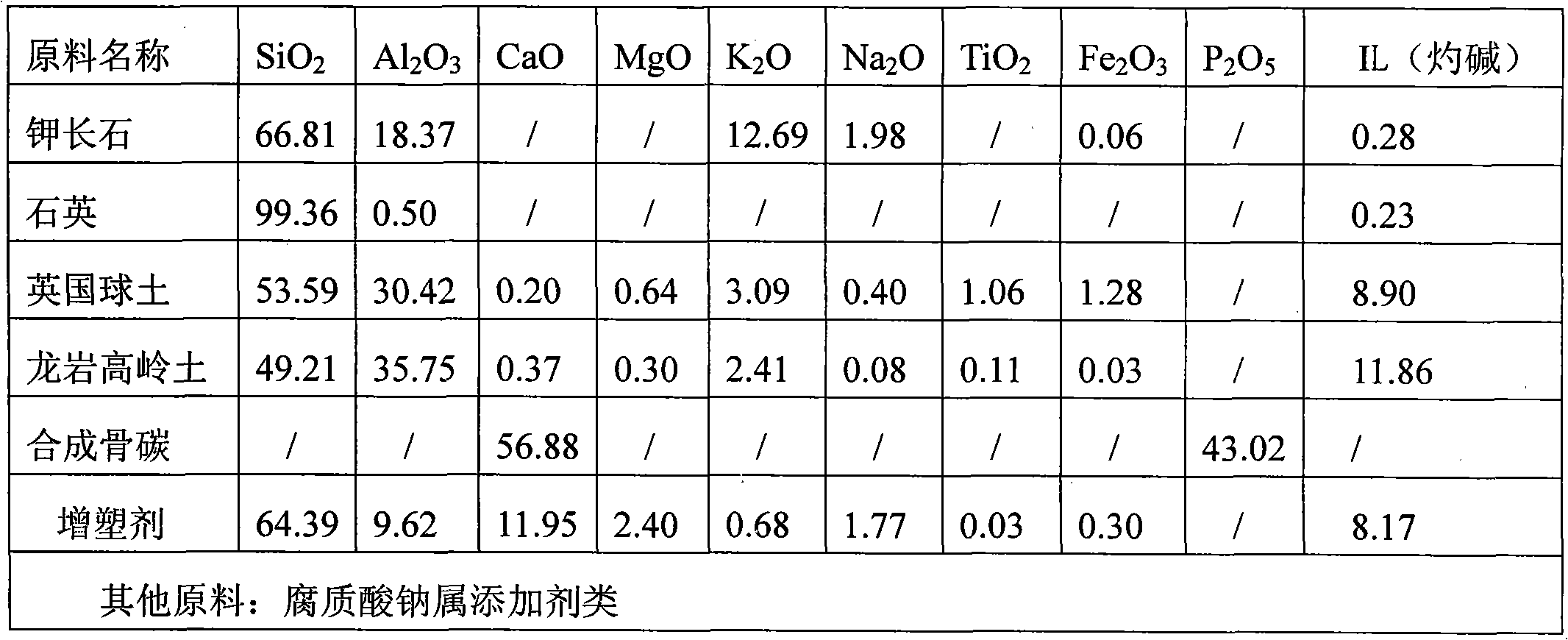

Novel human body bone china product and preparation method thereof

InactiveCN104944904AImprove textureImprove plasticityCeramic materials productionClaywaresHuman bodyPlasticizer

The invention discloses a novel human body bone china product and a preparation method thereof. The ceramic product comprises the following raw materials by weight percent: 45-50% of bone ash, 1-5% of clay, 8-15% of feldspar, 2-10% of quartz, 15-40% of kaolin, 5-10% of kibushi-clay, 1-3% of a plasticizer and 1-5% of sepiolite mineral nanofiber. The preparation method comprises the following steps: (1) preparing slurry agent; (2) forming; (3) firing; (4) coloring; (5) checking. Compared with the prior art, the ceramic product provided by the invention has the advantages of being good in bone-china texture, relatively high in plasticity in production process, not easy to deform, capable of being prepared into thinner bone-china products, relatively low in cost and relatively little in energy consumption, solving the problem that the land source is short at present, avoiding the problem that no place can be used for burying the dead in the future, and being a way of memorizing relatives.

Owner:邵国飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com