Bone china paste and preparing technology thereof

A preparation process and bone china technology are applied in the field of bone china blanks and the preparation technology of bone china blanks, which can solve the problems of limited use, many ridge-containing raw materials, high price, etc. The effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

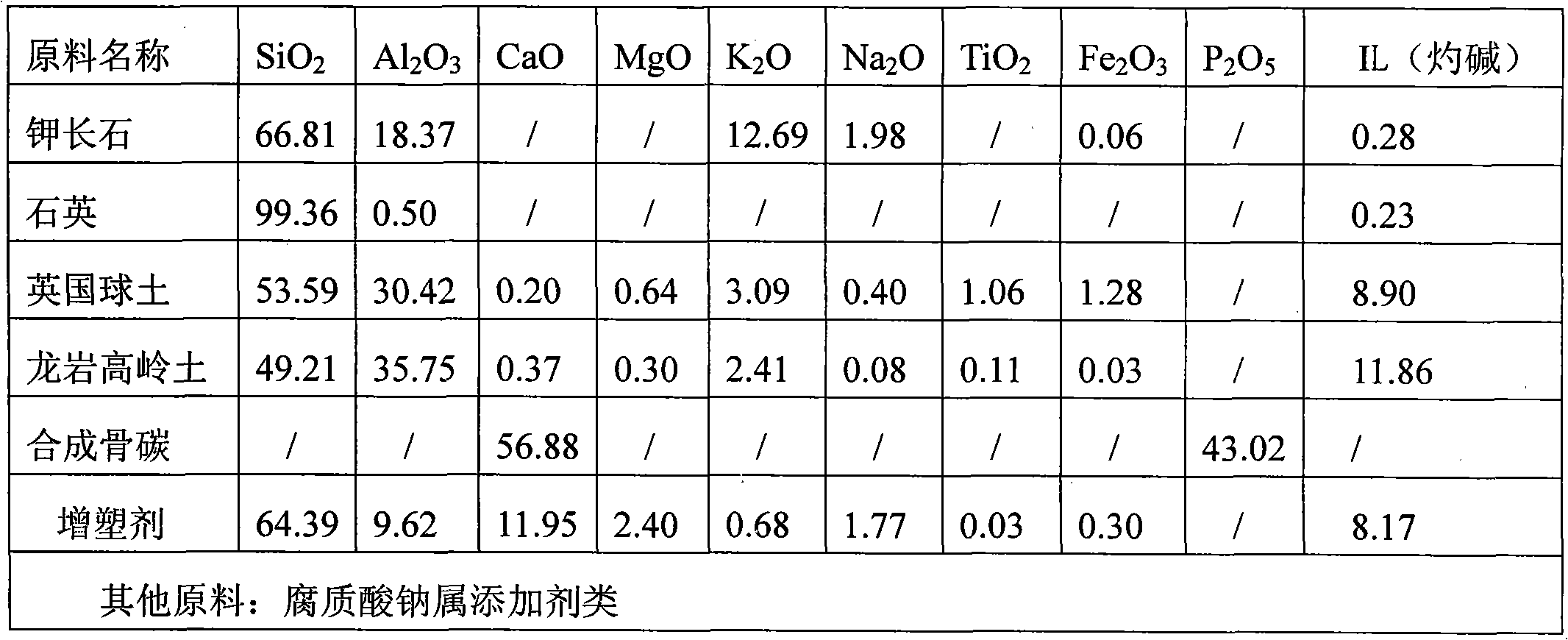

[0020] Embodiment 1: with 6 parts of quartz powder (325 orders), potassium feldspar powder (325 orders), 12 parts, 22 parts of Longyan kaolin (325 orders), 12 parts of British ball soil (250 orders), synthetic bone carbon (200 orders ) 45 parts, 3 parts of plasticizer, add sodium humate 0.3%, the above-mentioned raw material is carried out batching according to 3 tons of batching amount, and according to material: ball: water ratio=1: 2: 0.8, load into 3 tons of ball mills and ball mill for 13 hours Finally, let the slurry pass through a 250-mesh standard sieve, and then press filter for dehydration (press filter pressure 18Mpa, filter press time 60-80 minutes) to make a bone china mud cake with a moisture content of 22%, and then the bone china blank is prepared. It is used in the next process after the mud is refined or pulped.

Embodiment 2

[0021] Embodiment 2: 8 parts of quartz powder (325 orders), potassium feldspar powder (325 orders), 10 parts, 25 parts of Longyan kaolin (325 orders), 8 parts of British ball soil (250 orders), synthetic bone carbon (200 orders ) 47 parts, 2 parts of plasticizer, add sodium humate 0.25%, the above-mentioned raw material is carried out batching according to 3 tons of batching amount, and according to material: ball: water ratio=1: 2: 0.8, pack into 3 tons of ball mills and ball mill for 16 hours Finally, let the slurry pass through a 250-mesh standard sieve, and then press filter for dehydration (press filter pressure 18Mpa, filter press time 60-80 minutes) to make a bone china mud cake with a moisture content of 22%, and then the bone china blank is prepared. It is used in the next process after the mud is refined or pulped.

Embodiment 3

[0022] Embodiment 3: 10 parts of quartz powder (325 orders), potassium feldspar powder (325 orders), 14 parts, 20 parts of Longyan kaolin (325 orders), 10 parts of British ball soil (250 orders), synthetic bone char (200 orders ) 45 parts, 1 part of plasticizer, plus sodium humate 0.20%, the above-mentioned raw materials are batched according to the batching amount of 3 tons, and according to material: ball: water ratio = 1: 2: 0.8, put into 3 tons of ball mill ball mill for 16 hours Finally, let the slurry pass through a 250-mesh standard sieve, and then press filter for dehydration (press filter pressure 18Mpa, filter press time 60-80 minutes) to make a bone china mud cake with a moisture content of 22%, and then the bone china blank is prepared. It is used in the next process after the mud is refined or pulped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com