Patents

Literature

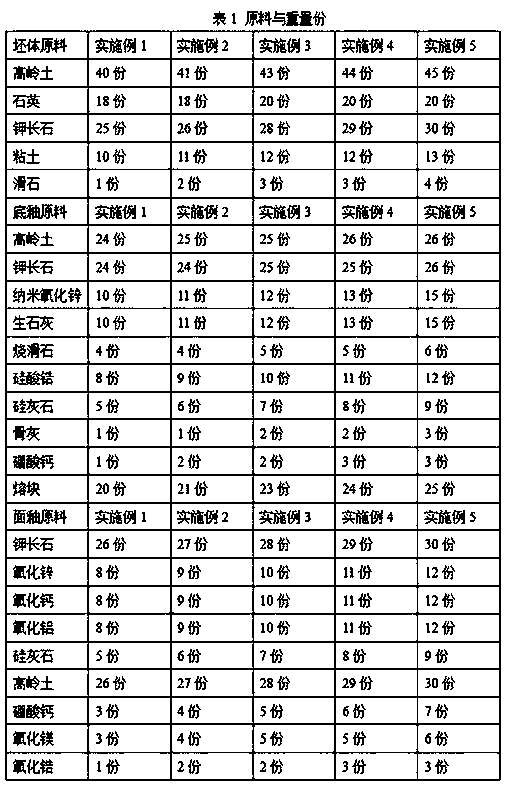

304 results about "Bone ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone ash is a white material produced by the calcination of bones. Typical bone ash consists of about 55.82% calcium oxide, 42.39% phosphorus pentoxide, and 1.79% water. The exact composition of these compounds varies depending upon the type of bones being used, but generally the formula for bone ash is: Ca₅(OH)(PO₄)₃. Bone ash usually has a density around 3.10 g/mL and a melting point of 1670 °C (3038 °F). Most bones retain their cellular structure through calcination.

Crystal glaze and its preparation method and use method

ActiveCN102659453AShorten the firing cycleTo achieve the purpose of industrialized mass productionBrickComposite ceramic

The invention discloses a crystal glaze and its preparation method and use method. The crystal glaze is prepared by uniformly mixing a basic crystal glaze and one or more coloring agents, wherein the weight of the one or more coloring agents is 0 to 10% of the total weight of the basic crystal glaze and the one or more coloring agents; and the basic crystal glaze mainly comprises 2 to 40 parts of spodumene, 5 to 20 parts of quartz, 5 to 25 parts of calcite, 5 to 25 parts of talcum, 5 to 20 parts of alumina, 1 to 5 parts of zinc oxide, 1 to 3 parts of sodium nitrate, 5 to 15 parts of zircon powder, 1 to 5 parts of bone ash, 1 to 5 parts of lithium carbonate and 5 to 15 parts of boric acid. In melting of the basic crystal glaze of the crystal glaze, the one or more coloring agents are used and thus a composite ceramic tile adopting the crystal glaze has a bright color and strong stereoscopic impression and produces crystal patterns having diameters of 3 to 4 centimeters. The preparation method greatly reduces a firing period of the traditional crystal glaze and realizes industrial production. An experiment proves that a crystal glaze surface with large crystal patterns can be obtained in a firing period of only 75 minutes.

Owner:JIANGSU BAIFU TECH CO LTD

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Copper red glaze formula and manufacturing process of copper red glaze porcelain

The invention belongs to the field of ceramic glazes, and in particular relates to a copper red glaze formula and a glazing process thereof, which can be widely applied to art ceramics or household ceramics. The copper red glaze formula comprises the following raw materials in percentage by weight: 40 to 50 percent of feldspar, 15 to 25 percent of quartz, 10 to 15 percent of limestone, 10 to 15 percent of grain ash, 1 to 5 percent of bone ash, 5 to 10 percent of tin, and 0.5 to 1.5 percent of copper. The porcelain prepared by using the copper red glaze is uniform in color and luster and thick in glaze surface; the overall glaze surface is white, and dark red floods from the white glaze surface; the porcelain has a unique artistic effect, and gives the impressions of deepness, steadiness, dignity and elegance.

Owner:福建省太古陶瓷有限责任公司

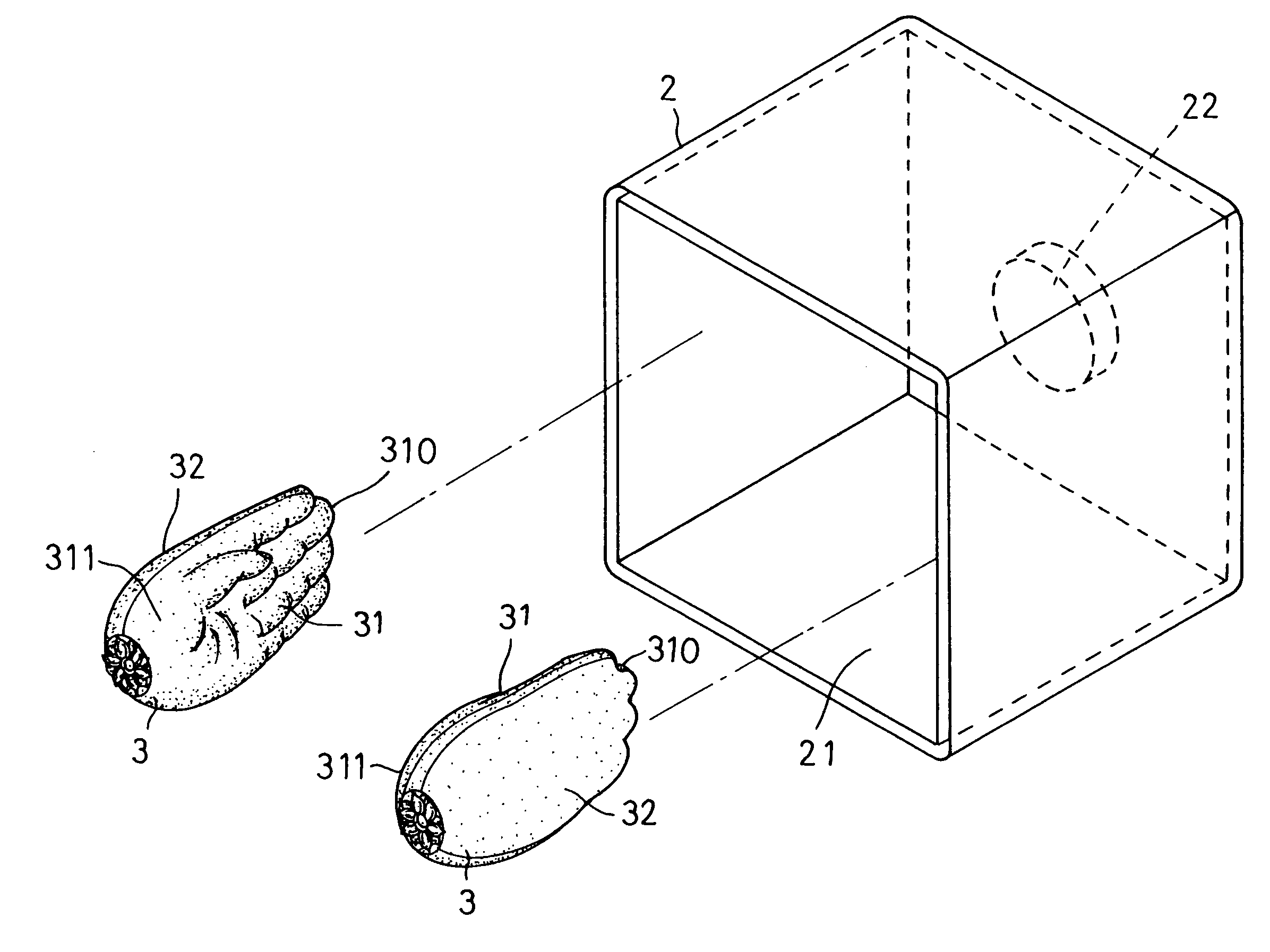

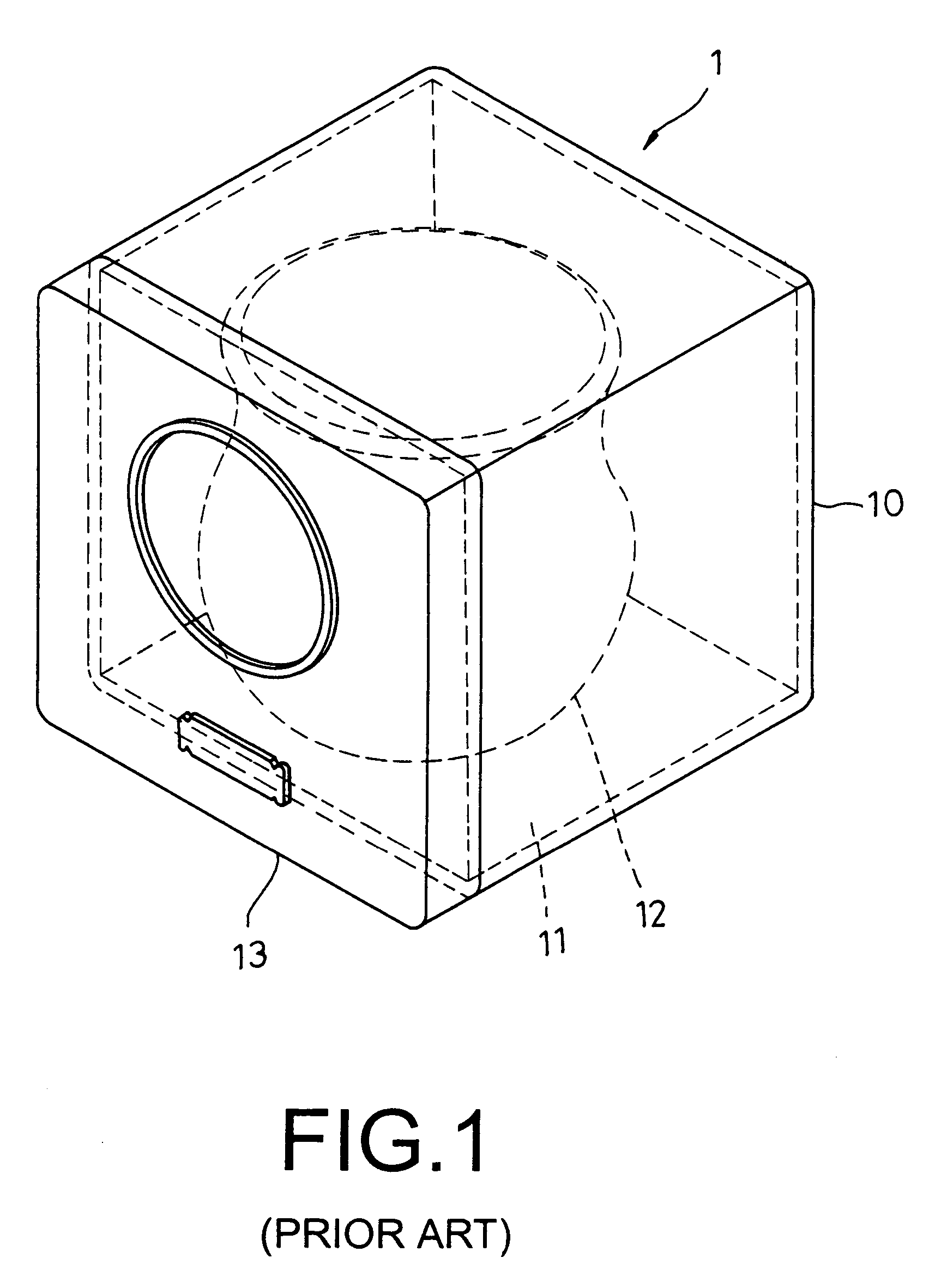

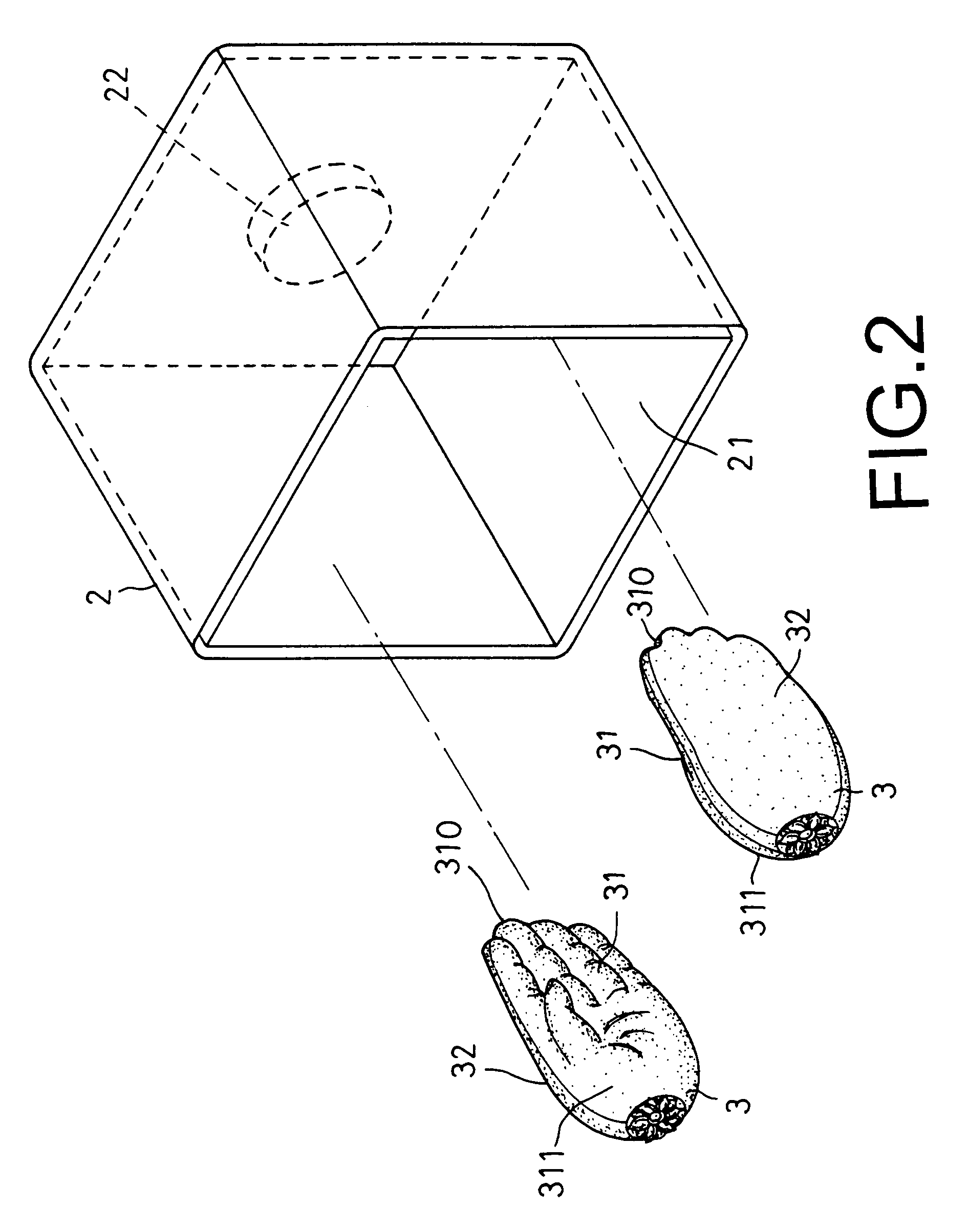

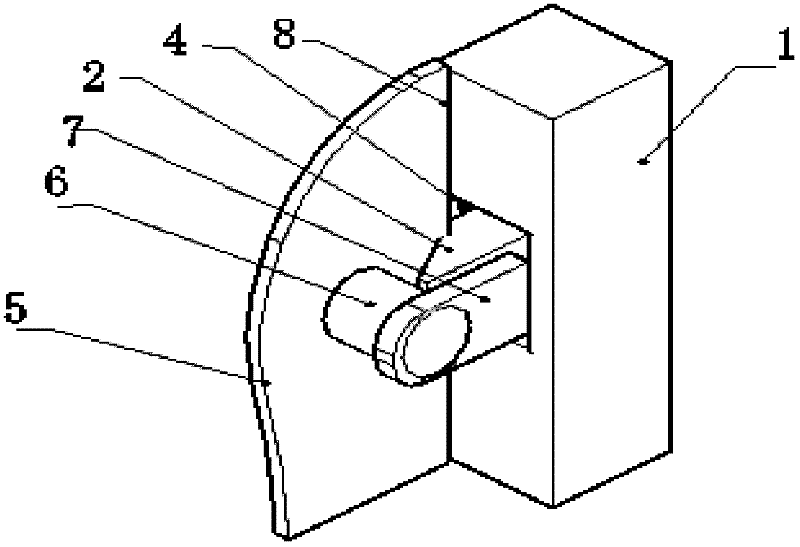

Bone-ashes urn preserving case

A bone-ashes urn preserving case includes a case body, a soft cushion and two positioning members. The case body has a chamber in its interior, and the soft cushion is attached on a rear wall of the case body, and the positioning members are respectively adhered on the inner surfaces of two opposite sidewalls of the case body. Each positioning members are made of soft plastic, shaped as a palm with five fingers, having an inner embrace surface for softly embracing two sides of a bone-ashes urn when it is placed in the chamber of the case body, with the soft cushion resting against the rear side of the urn. So the urn never sways or inclines in the case body even in case of an earthquake, always safely kept therein without possibility of getting any damage.

Owner:CHEN FENG KUEI

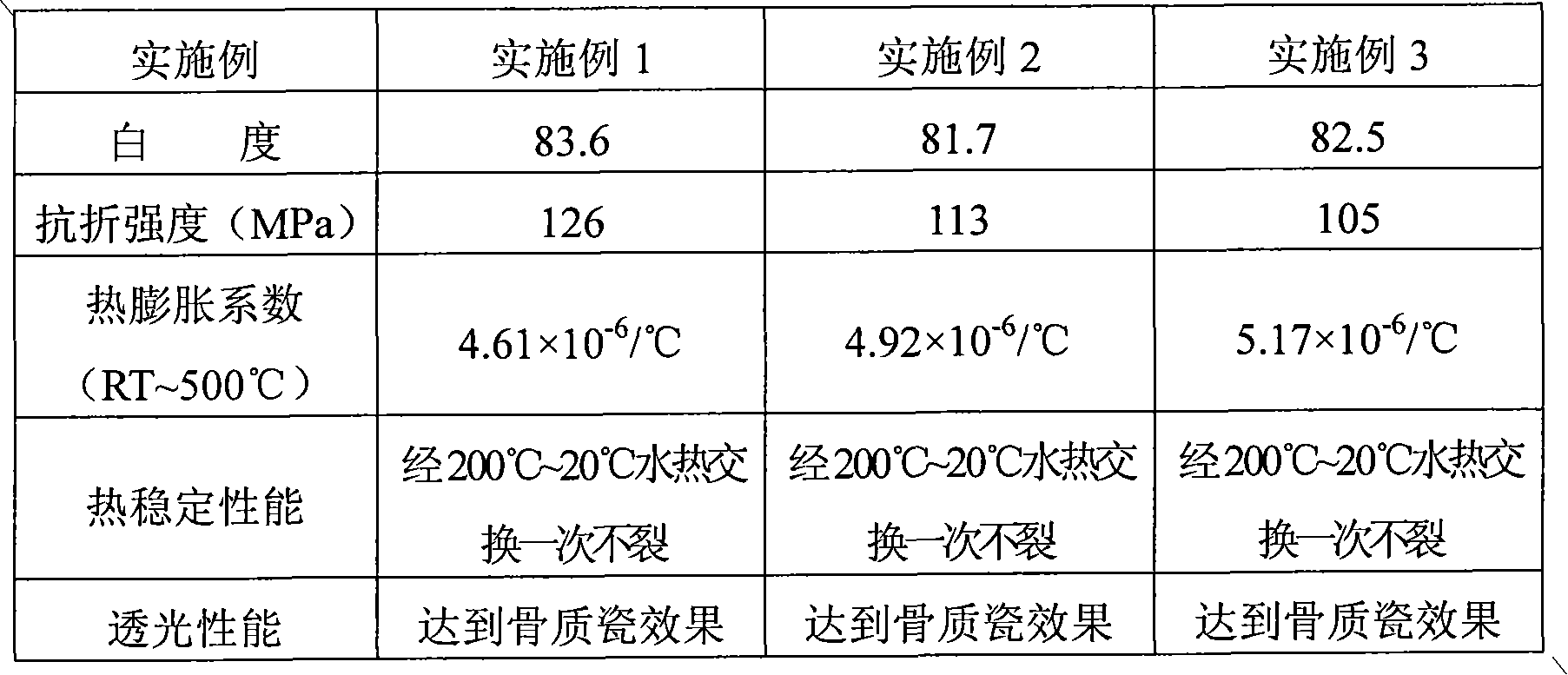

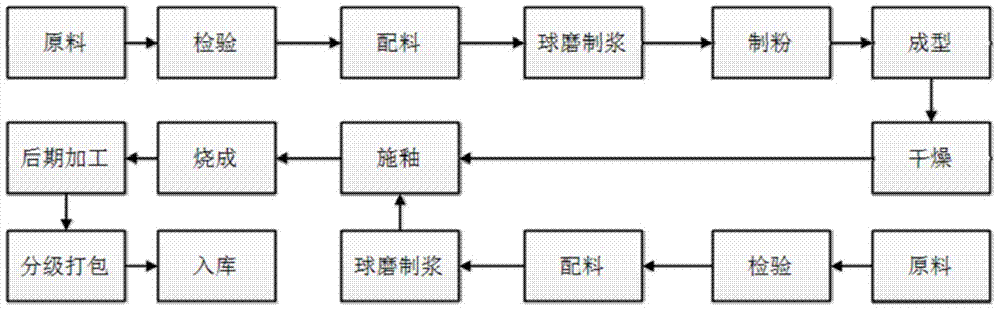

Middle-low temperature sintered fine bone china and production method thereof

ActiveCN101891455AReduced thermal stabilityImprove thermal stabilityCeramic materials productionClaywaresCoalBone china

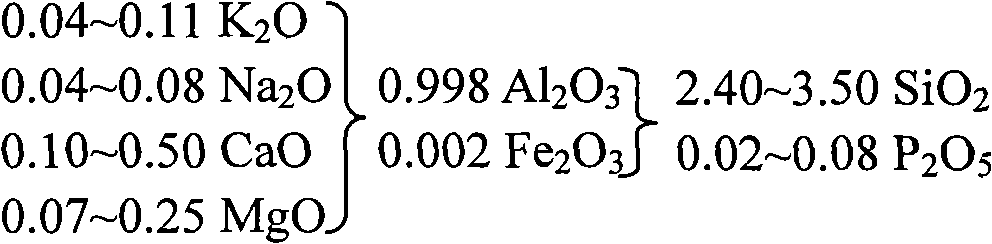

The invention relates to a middle-low temperature sintered fine bone china and a production method thereof. The china comprises the following chemical components in percentage by weight: 52 to 60 percent of SiO2, 28 to 37 percent of Al2O3, 1 to 4 percent of K2O, 1 to 2 percent of Na2O, 3 to 8 percent of CaO, 1 to 3 percent of MgO and 1 to 3 percent of P2O5; a used formula comprises the following raw materials in percentage by weight: 3 to 8 percent of bone ash, 32 to 45 percent of kaolin, 10 to 20 percent of aluminum oxide and 35 to 50 percent of fusion cake; the sintering temperature is between 1,170 and 1,250 DEG C; and not only a double-firing process of 'high-temperature biscuit firing and low-temperature glazed firing' or 'low-temperature biscuit firing and high-temperature glazed firing' can be adopted, but also a high-temperature single firing process can be applied. The fine bone china has an appearance effect of the conventional bone china, has physical and chemical properties superior to those of the bone china, has the significant advantages of low bone coal consumption and low sintering temperature, and is favorable for reducing the production cost and the energy consumption.

Owner:JINGDEZHEN CERAMIC UNIV

Image forming method by using bone ash

InactiveCN102627050AReduce wasteNo worries of crowded and noisyOrnamental structuresComputer printing3d image

Disclosed is an image forming method by using bone ash, comprising the following steps of: processing bone ash through impurity removing, disinfecting, bleaching, drying and grinding; processing a portrait with a computer to generate a three-dimensional image, using the ground bone ash as a material of a 3D printer and printing it into a statue; and coloring the statue by using the 3D printer or manually. The method provided by the invention has the positive effects that the method can avoid the problem that our country's limited land will be getting less and less due to the move of burial after cremation and protect arable lands. In addition, the image of a dead person can be preserved for good, which has real memorial significance.

Owner:闫如江

Production and using method of organic bio-fertilizer

InactiveCN101538177AImprove qualityIncrease profitFertiliser formsFertilizer mixturesHazardous substanceAnimal protein

The invention relates to a production method of organic bio-fertilizer. The method comprises the following steps: organic substances such as bean dregs, tobacco waste, scum, turf, animal protein, hoof meal, bone ash, pork skin, shell powder, and the like are prepared into powdery substances and evenly mixed, and then are fermented and decayed by using fermenting micro-organisms, after the content of the flora reaches 3 billion per gram, the inorganic elements such as N, P, K, and the like are added, the powdery substances are prepared into granular substances and dried, the dried granules together with bacteria strain, chitin and abamectin are mixed with water to form a package, and a product is formed after dehydration. The invention has the advantages that the method improves the quality of crops, reduces harmful substances and the content of heavy metal, improves the utilization ratio of the fertilizer, reduces the environmental pollution, improves the soil and cultivates the land capability.

Owner:段贺民

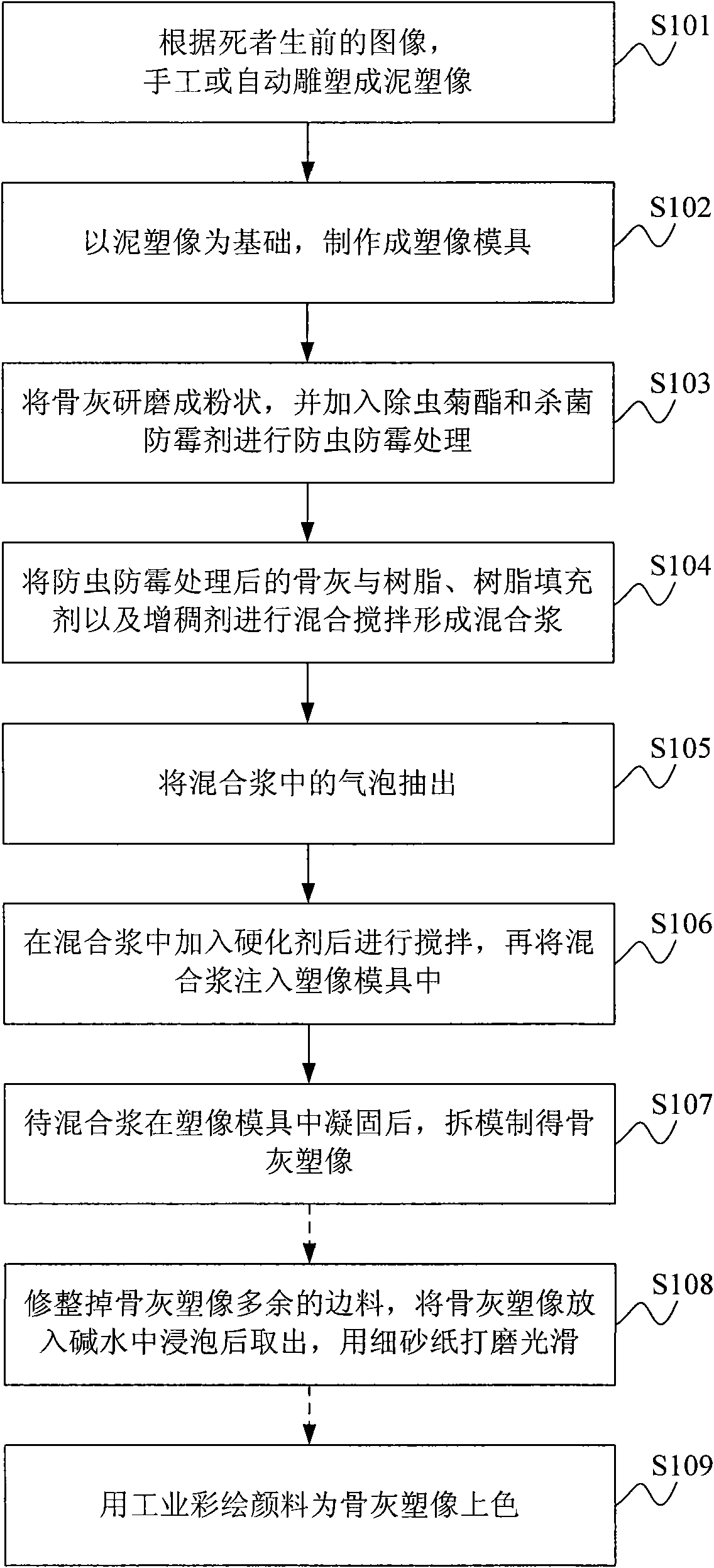

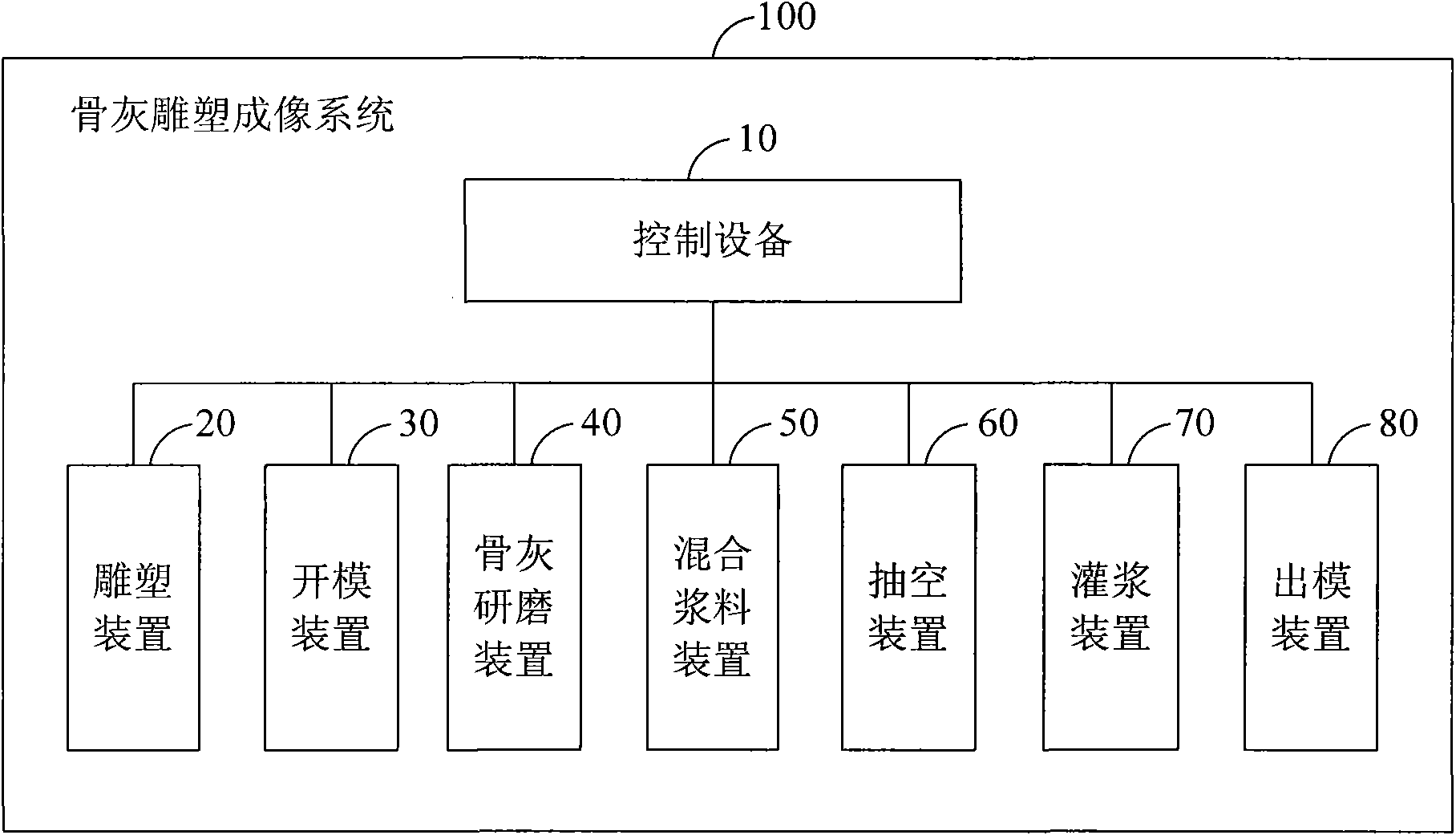

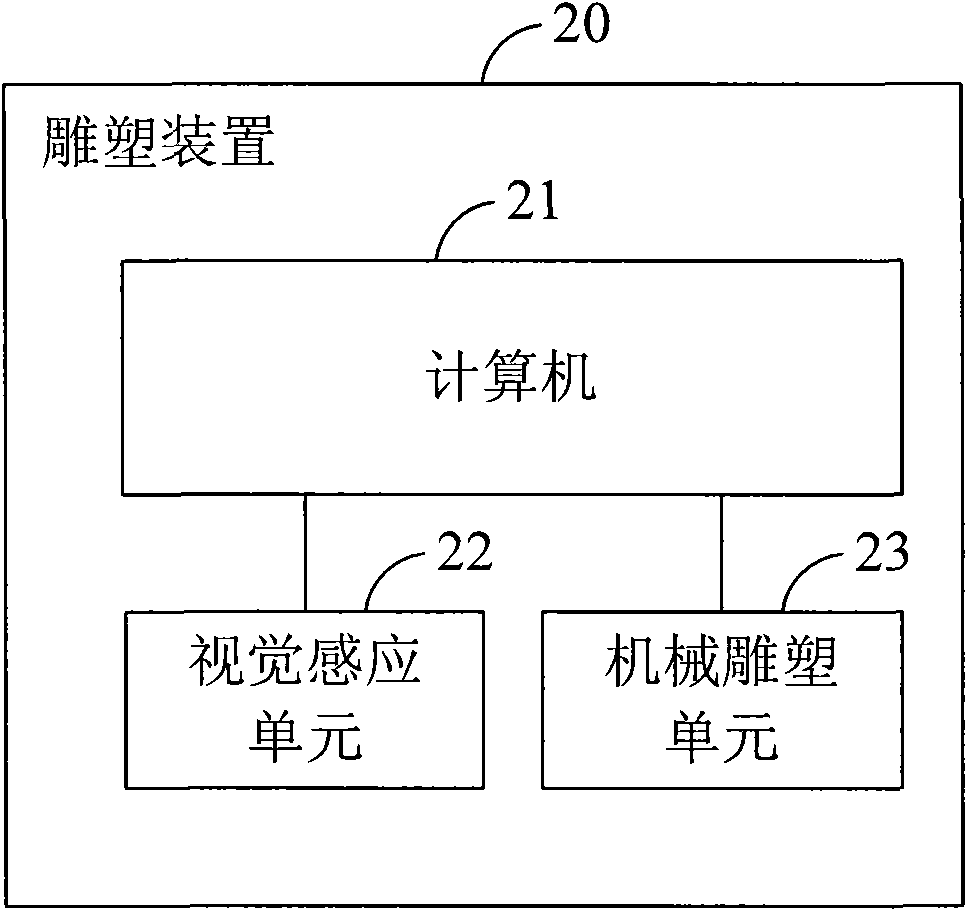

Bone ash sculpture imaging method and system

The invention discloses a bone ash sculpture imaging method. The sculpture imaging method comprises the following steps: sculpturing: manually or automatically sculpturing into a clay statue according to an image of a dead person while living; die sinking: making into a statue die based on the clay statue; grinding the bone ash: grinding the bone ash into powder and adding pyrethrin and a bactericidal mildew inhibitor to the bone ash for moth and mildew proofing; mixing slurry: mixing and stirring the moth and mildew-proofed bone ash with resin, a resin filler and a thickener into mixed slurry; exhausting: drawing air bubbles from the mixed slurry; grouting: mixing the mixed slurry after adding a hardener, and injecting the mixed slurry into the statue die; and demoulding: form stripping into the bone ash statue after the mixed slurry is solidified in the statue die. The invention further provides a bone ash sculpture imaging system. Whereby, the bone ash sculpture imaging method and the system can help create a more environmentally-friendly and cost-effective funeral mode while persisting in a humanization concept.

Owner:姜丰川 +1

Jade-like Ru porcelain and preparation method thereof

The invention relates to a jade-like Ru porcelain and a preparation method thereof. The jade-like Ru porcelain comprises a body and a glaze, wherein the preparation raw material of the body is of kaolin, and the preparation raw materials of the glaze comprises the following components in percentage by weight: 55%-80% of feldspar, 10%-25% of calcite, 5%-15% of cryptocrystalline quartz, 2%-10% of alkaline stone, 1%-8% of bone ash and 1%-8% of plant ash. According to the jade-like Ru porcelain disclosed by the invention, the Ru porcelain glaze with jade quality is combined with the body with thejade quality, a traditional Ru porcelain firing process is adopted for enabling the porcelain body to show the jade-like translucent state, color and luster are elegant, pale and graceful, a brand new visual impact and an artistic effect can be further generated, and the millenary Ru porcelain can further realize the historic breakthrough. A new species is added in the family of the Ru porcelain,the cultural connotation of the Ru porcelain is enriched, and the added value and the market share of Ru porcelain products are further improved.

Owner:河南弘宝汝瓷坊有限公司

Bone jade porcelain and method for manufacturing same

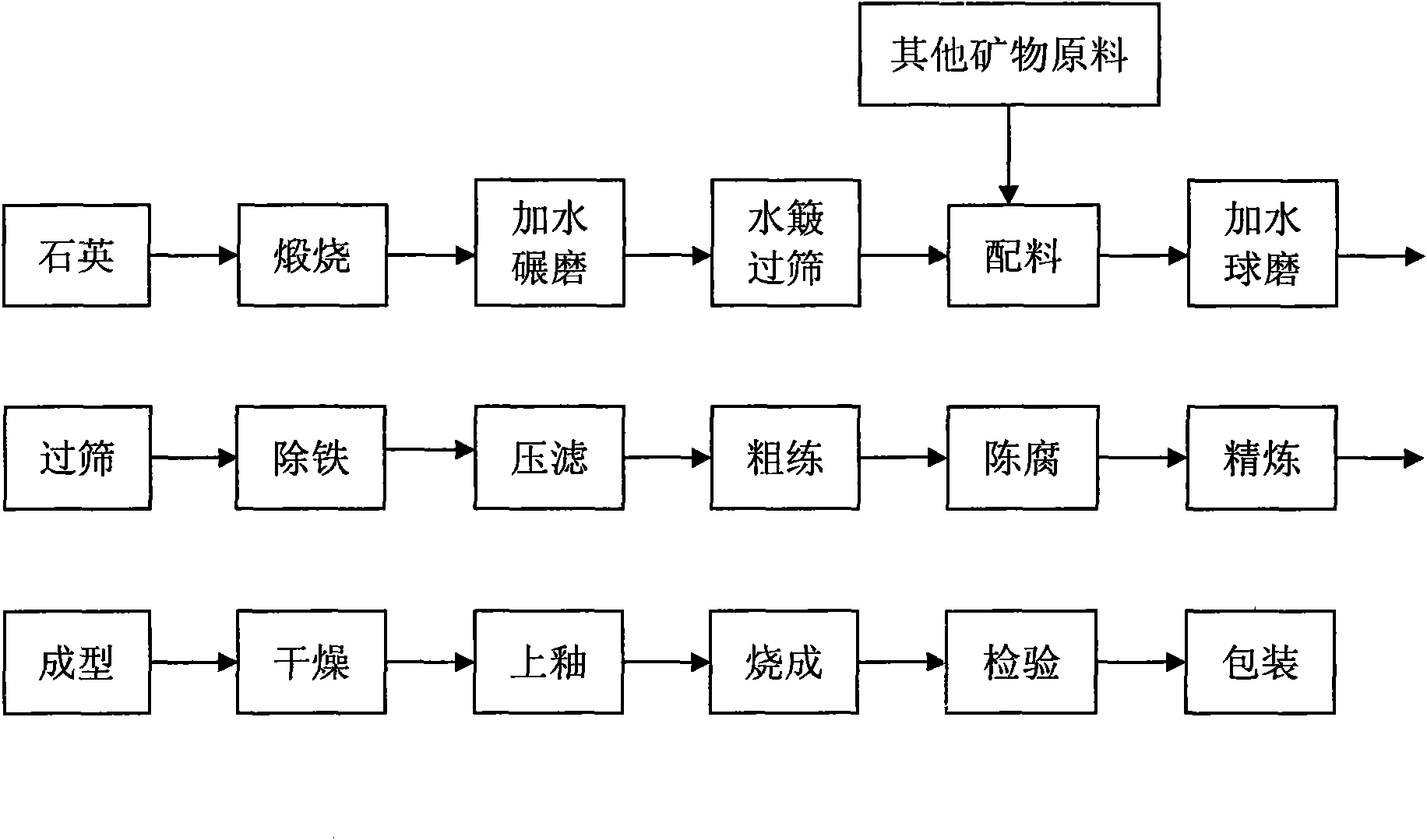

The invention relates to a household porcelain and a method for manufacturing the same, in particular to a bone jade porcelain and a method for manufacturing same. The bone jade porcelain body comprises quartz, petalite, Australian alumina, Guizhou clay, Longyan kaolin braying and Huidong kaolin braying. The method for manufacturing the bone jade porcelain comprises the following steps of: calcining the quartz, grinding with water, sieving with levigation and preparing into quartz grain, dosing according to formula, ball milling, sieving, removing iron, dehydrating in a way of filter pressing, primary smelting, aging, refining, shaping, drying, glazing and finally baking with a kiln. The invention has the tactile sensation of a bone ash porcelain, lower manufacturing cost compared with the bone ash porcelain, higher thermal stability, wider baking ranging and convenient control.

Owner:CHAOZHOU ZHONGXIA PORCELAIN FACTORY

Copper red reduction transmutation glaze, copper red reduction transmutation glaze ceramic product and preparation method thereof

The invention relates to copper red reduction transmutation glaze, a copper red reduction transmutation glaze ceramic product and a preparation method thereof, which belong to the technical field of ceramics. The copper red reduction transmutation glaze comprises the following components in parts by weight: 34 to 36 parts of nepheline syenite, 19 to 23 parts of light calcium carbonate, 2 to 5 parts of barium carbonate, 2 to 4 parts of zinc oxide, 1 to 2 parts of magnesium carbonate, 9 to 11 parts of kaolin, 14 to 18 parts of waste ceramic biscuit treatment material, 8.5 to 11 parts of quartz, 2 to 4 parts of bone ash, 1 to 4 parts of lithium carbonate and 2 to 5 parts of copper oxide. The copper red reduction transmutation glaze is uniformly in glaze surface color, has double color generation effect of being green in red and black in red and has strong classical atmosphere; and moreover, when a ceramic product is sintered according to the method, the rate of finished product is relatively high, and the method is suitable for ceramics for daily use and decorative ceramics.

Owner:FUJIAN QUANZHOU DESHENG GROUP

Low cost low expansion ceramic zirconium-free white glaze and preparation method thereof

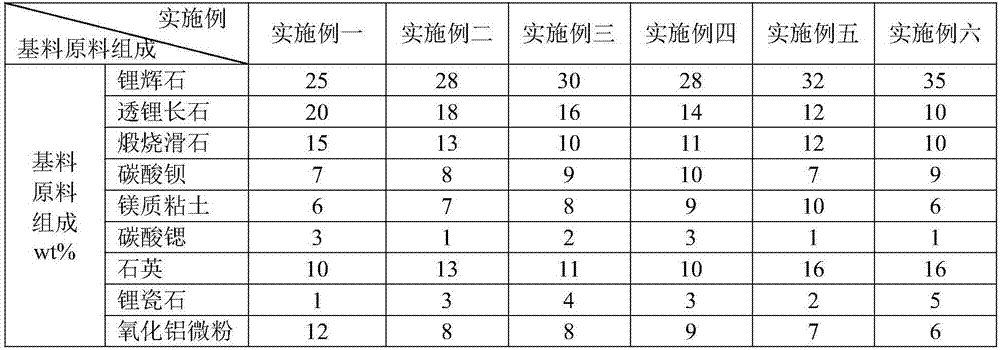

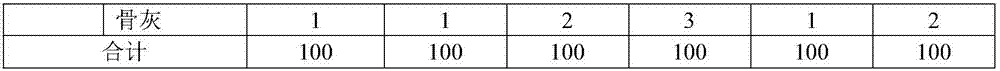

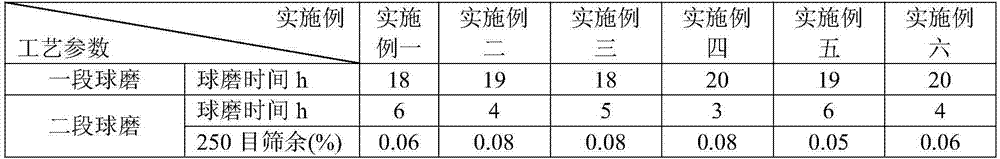

The invention discloses a low cost low expansion ceramic zirconium-free white glaze, which comprises a basic material and additives. The basic material is composed of the following raw materials in percentage by weight: 20 to 35 wt% of spodumene, 10 to 25 wt% of petalite, 10 to 15 wt% of calcined talcum, 7 to 10 wt% of barium carbonate, 6 to 10 wt% of magnesite clay, 1 to 3 wt% of strontium carbonate, 10 to 20 wt% of quartz, 1 to 5 wt% of lithium containing porcelain stone, 6 to 12 wt% of alumina micro powder, and 0 to 3 wt% of bone ash. The additives are hydroxypropyl methyl cellulose and sodium tripolyphosphate; wherein hydroxypropyl methyl cellulose accounts for 0.05 to 0.1 wt% of the basic material and sodium tripolyphosphate accounts for 0.20 to 0.30 wt% of the basic material. Furthermore, the invention also discloses a preparation method of the low cost low expansion ceramic zirconium-free white glaze. The low cost low expansion ceramic zirconium-free white glaze has the advantages of low production cost, safe application, no radiation, high whiteness, good melting performance, and adjustable expansion coefficient; can well meet the use requirements of various low expansion ceramic blanks, and is beneficial for the development of low expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

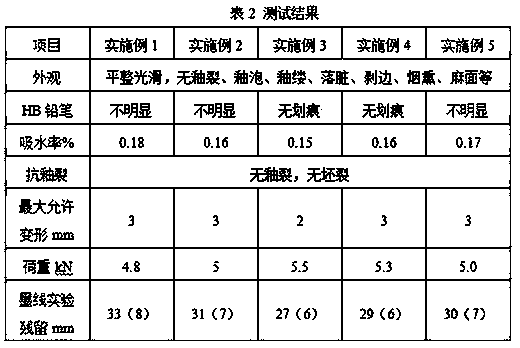

Ceramic product with self-cleaning glaze and making method thereof

The invention provides a ceramic product with self-cleaning glaze. The ceramic product comprises a tire material and the glaze, wherein the tire material comprises kaolin, quartz, potassium feldspar,clay and talc; the glaze comprises ground glaze and cover glaze, wherein the ground glaze comprises the following raw materials: potassium feldspar, nano zinc oxide, calcium oxide, burning talc, zirconium silicate, wollastonite, kaolin, bone ash, calcium borate and frit; the cover glaze comprises the following raw materials: potassium feldspar, kaolin, wollastonite, zinc oxide, calcium oxide, aluminum oxide, magnesium oxide, zirconium oxide and calcium borate. A making method of the ceramic product with the self-cleaning glaze comprises the following steps: (1) respectively mixing the tire material and the glaze, adding water, wet-milling with a ball mill and sieving to obtain tire material slurry and glaze slurry; (2) making a green body with the tire material slurry for biscuit firing; (3) applying the ground glaze; (4) applying the cover glaze; (4) firing. The ceramic product made of the making method provided by the invention is fine and bright in glazed surface and can effectivelyprevent the accumulation of dirt and the formation of black spots.

Owner:福建省德化龙辉陶瓷有限公司

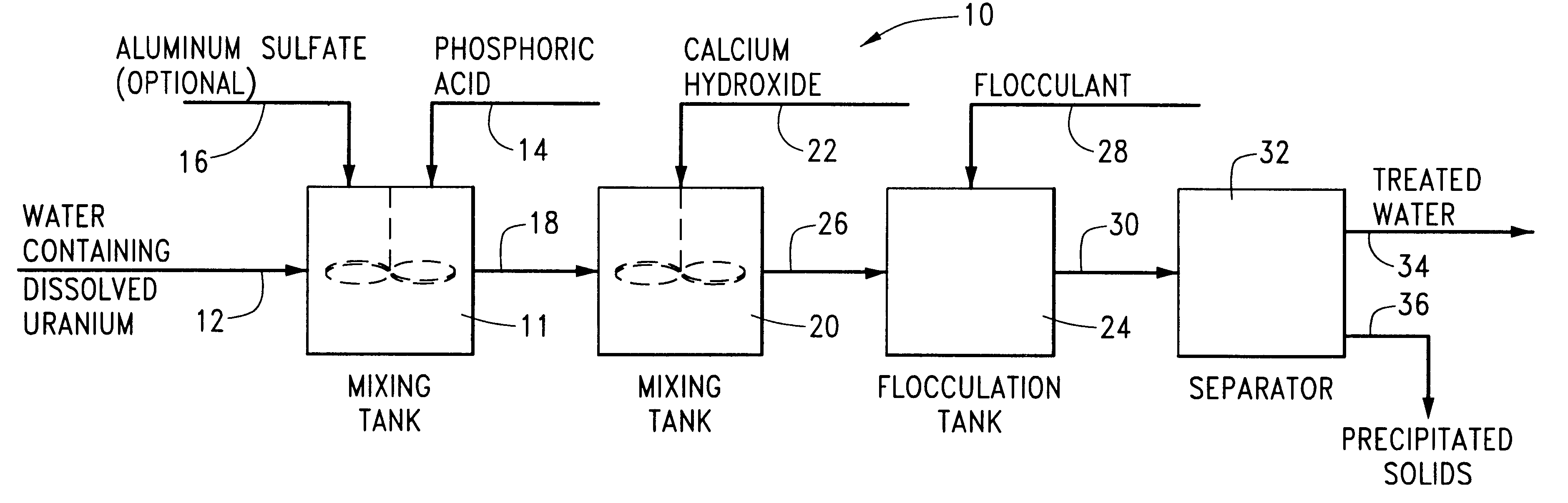

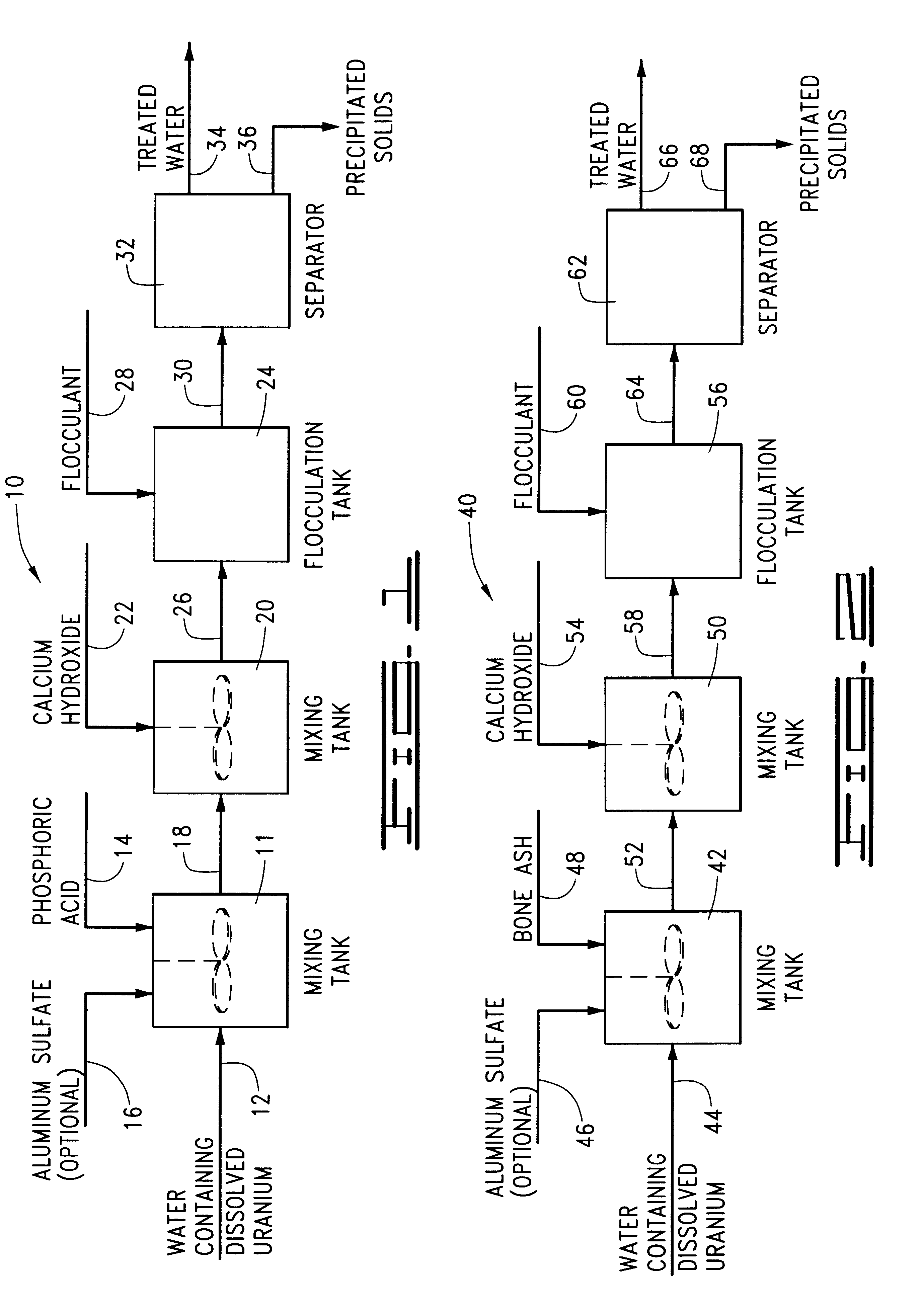

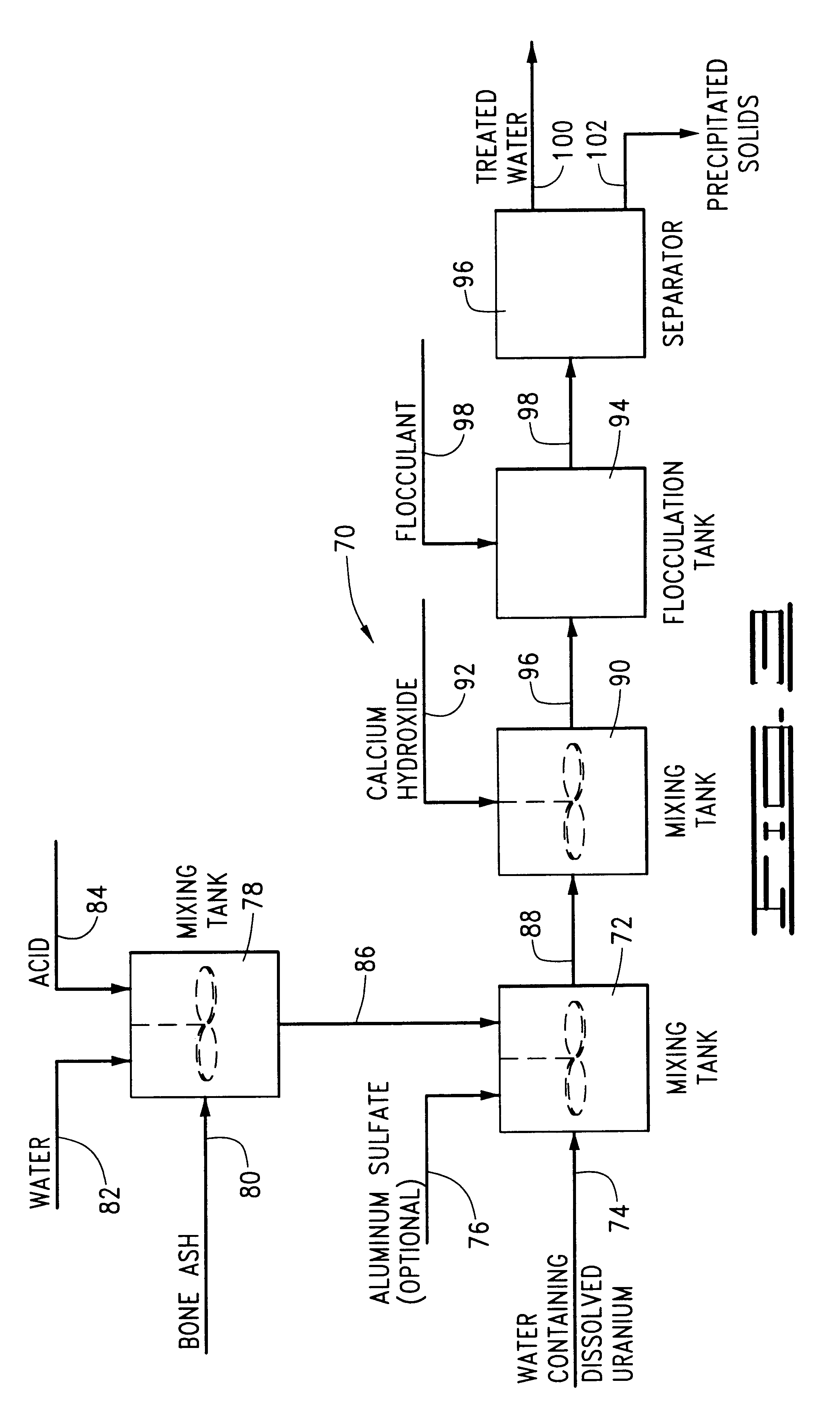

Process for removing dissolved uranium from water

InactiveUS6419832B1Transuranic element compoundsWater/sewage treatment by ion-exchangeCalcium hydroxidePhosphate

A process for removing dissolved uranium from water is provided. The process basically comprises (a) mixing phosphoric acid or particulate bone ash with the water, (b) mixing calcium hydroxide with the mixture produced in step (a) to thereby form calcium hydroxy phosphate or calcium hydroxy apatite which reacts with and complexes at least a portion of the uranium in the water to form a precipitate thereof, and (c) separating the precipitate from the water.

Owner:TRONOX LLC

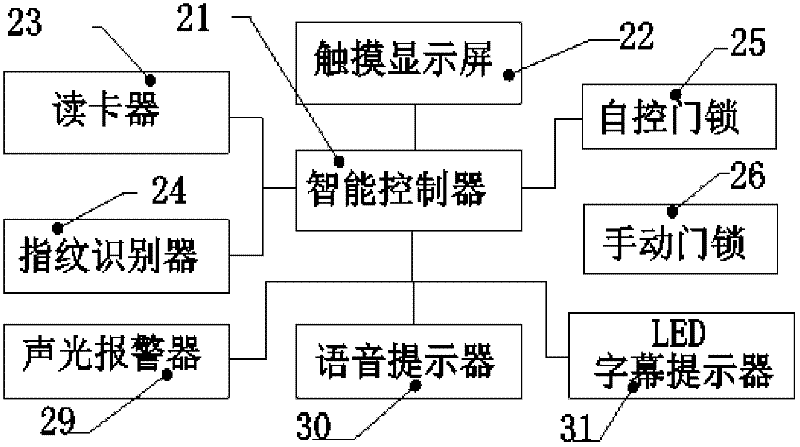

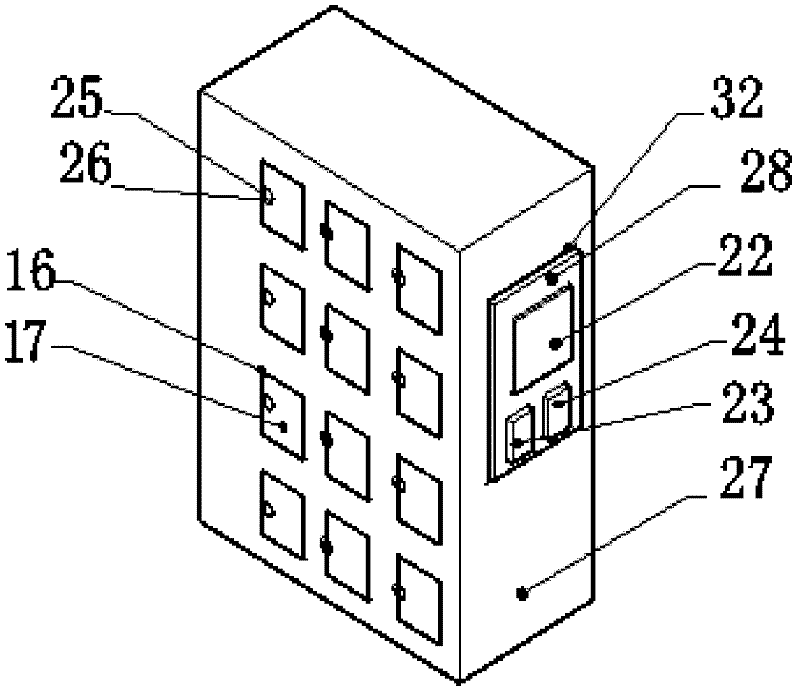

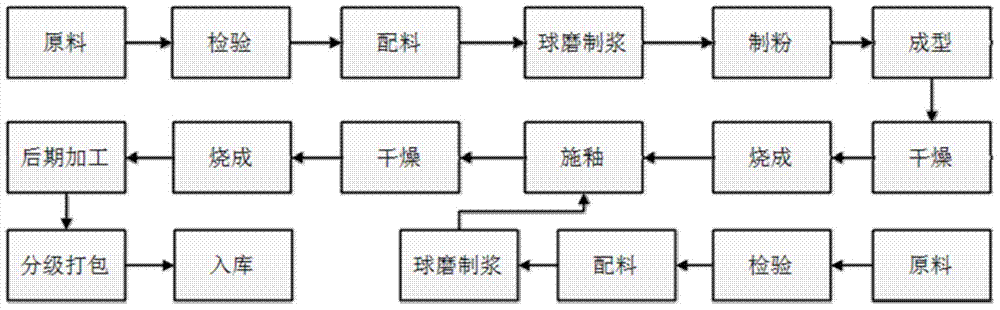

Automatic storage control method of bone ash storage rack and intelligent bone ash storage rack

The invention discloses an automatic storage control method of a bone ash storage rack, which is easy to implement, can realize automatic identification, control and management of depositing or withdrawing and is simple and convenient to perform depositing or withdrawing operation, as well as an intelligent bone ash storage rack. The method comprises the steps of performing automatic identification on a depositor by utilizing an intelligent card and / or a fingerprint through a control system and performing automatic storage control on a storage device. The intelligent bone ash storage rack comprises the storage device, the storage device is provided with an intelligent controller, the intelligent controller is respectively connected with an output device comprising a self-control door lock and a manual door lock and an output device comprising a card reader and a fingerprint reader, and the intelligent controller is further connected with a touch display screen.

Owner:江西天镜精藏科技有限公司

Green glaze and glazing process

The invention provides green glaze and a glazing process. The green glaze comprises following raw materials in parts by weight: 10 to 14 parts of quartz; 20-30 parts of melilite, 5-9 parts of modifiedtalcum, 6-8 parts of modified zinc oxide, 16-20 parts of kaolin, 5-7 parts of animal bone ash, 4-6 parts of plant ash, 11-15 parts of magnesian clay, 6-9 parts of copper ores, 12-14 parts of calcite,2-5 parts of glass powder, 1-3 parts of chromium oxide and 4-7 parts of iron ores. The prepared glazed porcelain is high in glossiness, smooth in surface and wide in market prospect.

Owner:福建省盛荣生态花卉研究院有限责任公司

Golden stripe tiger skin enameled container and manufacturing technology thereof

ActiveCN106396385AUnique artistic effectHigh economic valueTemperature controlManufacturing technology

The invention belongs to the technical field of ceramic production, and particularly relates to a golden stripe tiger skin enameled container and a manufacturing technology thereof. The golden stripe tiger skin enameled container is prepared from glaze materials comprising feldspar, calcinedtalc, quartz stone, kaoline, violet gold stone, low-temperature fusion cakes, barium carbonate, bone ash, iron sesquioxide, lapis lazuli, mellite and calcium. According to the golden stripe tiger skin enameled container, a burnt glazed surface is black or dark brown integrally, lumpy golden stripes are distributed on the black or dark brown glazed surface, the sizes and density of the stripes are changed according to the shape and the glazing thickness of the enameled container, and the golden stripe tiger skin enameled container has a unique artistic effect. Moreover, a furnace transformation glazing effect is formed by controlling accurate burning, the golden stripe tiger skin enameled container can be industrially produced in a large scale and quickly popularized for temperature control of the golden stripe tiger skin enameled container, and the golden stripe tiger skin enameled container has a relatively high economic value and has relatively high competitive power in the market.

Owner:福建德化县冠晟礼品有限公司

Ceramic for high strength cutting tool and preparation method of same

The invention relates to ceramic for a high strength cutting tool. The ceramic for the high strength cutting tool is prepared from the following raw materials in parts by weight: 1-2 parts of magnesite, 10-14 parts of aluminium oxide, 3-6 parts of barium oxide, 1-1.2 parts of bone ash, 3-4 parts of nano zinc oxide, 2-3 parts of calcium oxide, 47-55 parts of zirconium oxide, 20-25 parts of alpha-Al2O3 whisker, 15-18 parts of AlN whisker, right amount of ethyl alcohol, 0.3-0.4 part of carboxymethylcellulose, right amount of deionized water, 1-1.5 parts of polyacrylic acid, 1.2-1.6 parts of polyethylene glycol and 4-5 parts of anti-wear auxiliary. The ceramic for the high strength cutting tool has extremely high hardness, heat resistance and abrasion resistance of zirconium oxide ceramic; meanwhile, the alpha-Al2O3 whisker and AlN whisker are added, so that the ceramic for the high strength cutting tool has excellent toughness and is especially applicable to manufacturing of a cutting tool, service life is long, and relative cost is low; and abrasion resistance and heat resistance of the ceramic can be enhanced by adopting the anti-wear auxiliary.

Owner:HEFEI WANWEI ELECTRICAL EQUIP ENG

Method and apparatus for extracting carbon from biosome

The invention relates to a method for abstracting carbon from animal and plant bodies, which comprises the following steps: after gas generated by cremating the animal and the plant bodies is subject to liquid filtration and solid absorption, physically separating carbon oxide gas from the gas, and then obtaining solid carbon through chemical replacement. The solid obtained by cremating is formed into carbon oxide gas after being subject to pyrolysis at the temperature of 800 to 900 DEG C, and then the solid carbon is obtained through the chemical replacement. A device for abstracting the carbon from the animal and the plant bodies comprises an incinerator, a liquid filter and a solid absorber which are connected through a pipeline in sequence; the discharge outlet of the solid absorber is connected with a carbon oxide gas physical separator and a solid carbon chemical replacer through a pipeline in sequence; and an evacuation opening is also arranged on the carbon oxide gas physical separator. The device further comprises a bone ash pyrolysis oven; and the gas outlet of the bone ash pyrolysis oven is connected with the solid carbon chemical replacer. By adopting invention, the carbon can be abstracted form organisms (including human and animal remains and plant bodies) and is further made into a monumental diamond souvenir.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Novel human body bone china product and preparation method thereof

InactiveCN104944904AImprove textureImprove plasticityCeramic materials productionClaywaresHuman bodyPlasticizer

The invention discloses a novel human body bone china product and a preparation method thereof. The ceramic product comprises the following raw materials by weight percent: 45-50% of bone ash, 1-5% of clay, 8-15% of feldspar, 2-10% of quartz, 15-40% of kaolin, 5-10% of kibushi-clay, 1-3% of a plasticizer and 1-5% of sepiolite mineral nanofiber. The preparation method comprises the following steps: (1) preparing slurry agent; (2) forming; (3) firing; (4) coloring; (5) checking. Compared with the prior art, the ceramic product provided by the invention has the advantages of being good in bone-china texture, relatively high in plasticity in production process, not easy to deform, capable of being prepared into thinner bone-china products, relatively low in cost and relatively little in energy consumption, solving the problem that the land source is short at present, avoiding the problem that no place can be used for burying the dead in the future, and being a way of memorizing relatives.

Owner:邵国飞

A glaze material manufactured by utilization of tailings and a glazing process thereof

The invention discloses a glaze material manufactured by utilization of tailings. The glaze material comprises 40-65% of feldspar, 10-25% of quartz, 15-30% of iron ore mine tailings, 0-10% of limestone, 0-10% of kaolin and 0-10% of bone ash. The glaze material comprises following components by weight: 1-5 parts of K2O, 1-8 parts of Al2O3, 55-70 parts of SiO2, 1-5 parts of P2O5, 1-5 parts of Na2O, 1-8 parts of Fe2O3, 5-15 parts of CaO and 1-8 parts of MgO. The invention also discloses a glazing process of the glaze material manufactured by utilization of the tailings. The glazing process includes: adding the materials into a ball grinder and performing ball-milling, adding water, uniformly mixing, stirring and dissolving to obtain glaze slurry, with the fineness of the glaze slurry being controlled to be less than 0.01% of residue on sieve of a ten-thousand hole sieve; discharging the glaze slurry and stirring; sieving the glaze slurry with a sieve having a size of 200 meshes, applying the fully suspended glaze slurry onto the surface of a green body with the concentration being 38-46 baume degrees and the thickness of the glaze slurry on the surface of the green body being 0.2-1.2 mm; and subjecting the green body to high-temperature sintering, and cooling in furnace to room temperature after the sintering is finished to obtain a ceramic product. By adoption of a one-time sintering process, the product quality can reach that of secondary sintering and the product energy consumption is reduced.

Owner:苏友谊

Method for preparing positioning iron red crystal glaze

The present invention discloses a preparation method for positioning ferreous crystal; the preparation of the base glaze is that: potassic feldspar, quartz, kaoline, ocher, steatite, limestone and bone ash are mixed with ferric oxide for grilling; the proportion of the glaze slurry is 1.6-1.7 g / cm3; the preparation method of the crystal core is that: kaoline is mixed with ferric oxide for grilling and calcining and cooling to become grain powder; and then crystal core is pre-buried in the position for the blank body to form the crystal flower; the size Phi of the preburied hole is about 1mm; the quantity and distribution are adjusted according to the actual requirement; the base glaze is put on the ceramic blank body preburied with crystal core evenly; the thickness of the glaze level is controlled on 0.7-1.0mm; the semi finished product of the ceramic glaze is baked to the maximum temperature with oxidation blaze, and then is cooled into the room temperature. The present invention uses the common ceramic raw material and the positioning crystal measure to produce the positioning ferreous crystal glaze, which solves the shortcoming that the size and the distribution for the ferreous crystal flower is hard to be controlled; the method is a stable preparation method with simple process technical, wide baking temperature range, good stability, without needing middle temperature heat preservation; the produce cost is much lower.

Owner:SHAANXI UNIV OF SCI & TECH

Porcelain glaze and preparation and use method thereof

The invention belongs to the field of porcelain and in particular relates to a porcelain glaze and preparation and use methods thereof. The porcelain glaze is composed of the following raw materials in parts by weight: kaolin, potassium feldspar, calcite, quartz, plant ash, fluorite, ox bone ash, soda lime, frit and bentonite, wherein the frit is composed of the following raw materials in parts byweight: silica, aluminum oxide, boric acid, potassium carbonate and sodium carbonate. The preparation and use methods thereof comprise the following steps: preparing the glaze, firing a liquefied gaskiln and the like. The glaze has quenching resistance, gloss of the glaze is increased, the highly wear-resistant transparent microcrystalline frit glaze is obtained, the firing method is scientificand effective compared with the traditional firing manner, the firing time is long, and the transmutation effect is excellent.

Owner:张韶璞

Oil drop glaze preparation method

The invention provides a method for preparation of a drop glaze, which contains: mixing potash feldspar, terminus earth, talc, red lead oxide, vanadic anhydride, manganese oxide, ferric oxide and copper oxide; adding carboxymethyl cellulose as a paste regulator and grinding, sifting by 220 meshes sifter to prepare slip glaze; coating the surface of dry billet of pottery with the slip glaze, drying; putting the dried billet into a electric stove, keeping temperature for 0.5-2 hours in 1160-1220Deg. C in air oxidizing atmosphere or H2 and CO reducing atmosphere; cooling down naturally to the room temperature. The invention is characterized in that drop glaze can be prepared in a low temperature and a wide sintering temperature; the technique is simple to control, is repeatable and suitable for kinds of pottery billet; the usage of ferric oxide raw material, and there is no need of adding bone ash and P2O5; it can prepare golden and silver drop glaze, and the drop on the glaze has uniform size and distribution, and the glaze is smooth.

Owner:SHAANXI UNIV OF SCI & TECH

Artistic pottery fancy glaze and manufacturing method thereof

An artistic pottery fancy glaze mainly comprises 65 parts of sodium potassium feldspar, 3 parts of kaolin, 7 parts of lithium carbonate, 4 parts of bone ash, 4 parts of calcium carbonate, 11 parts of borax, 1 part of barium and 5 parts of quartz. Compared with the prior art, the method provided by the invention changes a formula of the glaze to reach changed fancy glaze effect, reduce expansion factor of the formula of the glaze, prevent glaze crack at low temperature and prolong utilization rate of the product; meanwhile, ceramic with the glaze has higher strength, brilliant glaze and good glossiness, compared with common ceramic.

Owner:德化县太阳鸟工艺品有限公司

Ru porcelain celeste blue glaze and preparation method thereof

The invention discloses a ru porcelain celeste blue glaze and a preparation method thereof. The ru porcelain celeste blue glaze is prepared from the following components in parts by weight: 11 to 18 parts of agate, 6 to 9 parts of purple and gold soil, 35 to 45 parts of feldspar powder, 9 to 15 parts of quartz powder, 16 to 25 parts of calcspar, 3 to 8 parts of bone ash, 6 to 15 parts of wood ash,10 to 16 parts of local glaze soil and 11 to 18 parts of home-made drug. The ru porcelain celeste blue glaze has the unique characteristics of lasting glaze color, natural accidental coloring into azure due to the adoption of agate, plain, elegance, smoothness, fineness, change along with light, brightness without dazzling, jade property, emulsion and ice property, green and elegant color, richness in water color, pure and fine glaze layer, jadeite color, high luster, softness, full glaze burning, dense glaze surface and texture like fish scales, cicada wings, crab claws, ice cracks and sesame blossoms.

Owner:马聚魁

Ru porcelain retro glaze and production method thereof

InactiveCN108483918AThe enamel is warm and moist like jadeImprove the status quo of strong glass textureClaywaresPotassiumCalcite

The invention provides Ru porcelain retro glaze and a production method thereof. The Ru porcelain retro glaze comprises the following components as raw materials in percent by weight: 18.8% of potassium feldspar, 5% of calcite, 12% of plant ash, 13.5% of melilite, 12% of black stone, 2% of bone ash, 5.7% of golden soil, 14% of dolomite, 3% of talc, 11% of agate and 3% of kaolin. The green glaze produced by the invention is as gentle as jade, dignified and restrained in texture, and improves the current situation of a strong glass texture of a modern Ru porcelain glaze layer; through a unique glaze formula, by a retro firing method, the glazed surface shows a crystallization effect, the Ru porcelain is as gentle as jade, dignified and restrained, and a retro effect is achieved; the green glaze restores the true color of the Ru porcelain blueish green glaze and is different from the current situation of the bluish color of the existing Ru porcelain glaze in the market, and the retro effect is achieved.

Owner:刘冬青

Transmutation glaze suitable for ceramic tile production and transmutation glaze ceramic tile

The invention discloses a transmutation glaze suitable for ceramic tile production and a transmutation glaze ceramic tile. The transmutation glaze comprises the following components in percentage by mass: 15-25% of potassium feldspar, 10-18% of frit, 5.0-18.0% of quartz, 2-15% of spodumene, 3-17% of bone ash, 1-9% of chromite, 4-16% of calcium carbonate, 1-12% of plant ash, 0-10% of ferrous manganese ores, 1-15% of calcium pyroborate, 3-16% of titanium dioxide, 0-8% of asbolite, 2-14% of dolomite, 0-9% of copper ores, 0.01-0.1% of sodium carboxymethylcellulose, 4-17% of zinc chloride, 1-8% of strontium carbonate and 0.2-1.6% of sodium carbonate. The transmutation glaze ceramic tile is obtained by firing after applying the transmutation glaze on a ceramic til green body. According to the transmutation glaze suitable for the ceramic tile production and the transmutation glaze ceramic tile, the transmutation glaze technology is applied to the production field of the ceramic tiles successfully, the products are attractive, elegant, luxury and artistic, and the quality and the additional value of the ceramic tile are improved.

Owner:HUBEI HANGRUI CERAMIC CO LTD

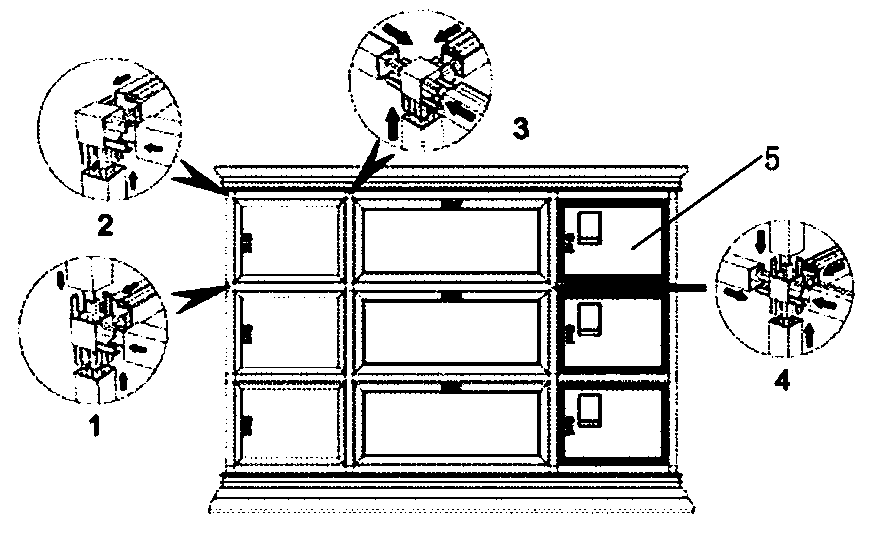

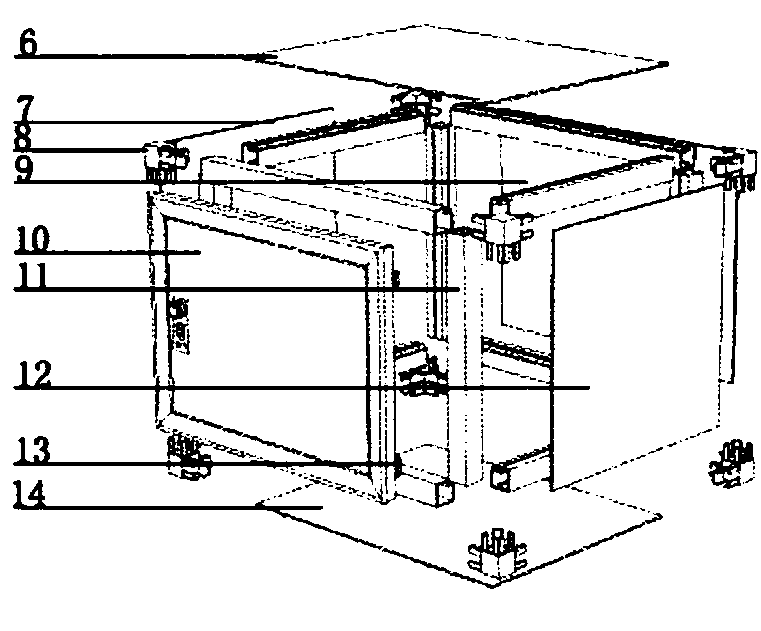

Metal storage rack used for placing bone ash box and combination method of same

InactiveCN103510743ANo pollution in the processEasy to assembleBurial vaultsMonumentsStructural engineeringMechanical engineering

The invention discloses a metal storage rack used for placing a bone ash box. The metal storage rack comprises two rows of unit cells. Each row of unit cells comprise two layers of unit cells. The unit cells are composed of cube connecting pieces, profiles and plates. Connectors composed of a plurality of edges are arranged on connecting surfaces of the connecting pieces. The profiles are hollow square pipes with grooves. The profiles are connected with the connecting pieces to form the frame structure of the storage rack. The plates are inserted into all surfaces of the frame structure respectively to isolate the unit cells and protect the bone ash box in the storage rack. Doors are arranged on the plates outside the two rows of unit cells of the storage rack and are provided with a door. The metal storage rack is easy to assemble, low in labor intensity and production cost, high in working efficiency, good in reliability, free of polluting the environment, and long in service life.

Owner:彭志龙

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com