Patents

Literature

117results about How to "Shorten the firing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystal glaze and its preparation method and use method

ActiveCN102659453AShorten the firing cycleTo achieve the purpose of industrialized mass productionBrickComposite ceramic

The invention discloses a crystal glaze and its preparation method and use method. The crystal glaze is prepared by uniformly mixing a basic crystal glaze and one or more coloring agents, wherein the weight of the one or more coloring agents is 0 to 10% of the total weight of the basic crystal glaze and the one or more coloring agents; and the basic crystal glaze mainly comprises 2 to 40 parts of spodumene, 5 to 20 parts of quartz, 5 to 25 parts of calcite, 5 to 25 parts of talcum, 5 to 20 parts of alumina, 1 to 5 parts of zinc oxide, 1 to 3 parts of sodium nitrate, 5 to 15 parts of zircon powder, 1 to 5 parts of bone ash, 1 to 5 parts of lithium carbonate and 5 to 15 parts of boric acid. In melting of the basic crystal glaze of the crystal glaze, the one or more coloring agents are used and thus a composite ceramic tile adopting the crystal glaze has a bright color and strong stereoscopic impression and produces crystal patterns having diameters of 3 to 4 centimeters. The preparation method greatly reduces a firing period of the traditional crystal glaze and realizes industrial production. An experiment proves that a crystal glaze surface with large crystal patterns can be obtained in a firing period of only 75 minutes.

Owner:JIANGSU BAIFU TECH CO LTD

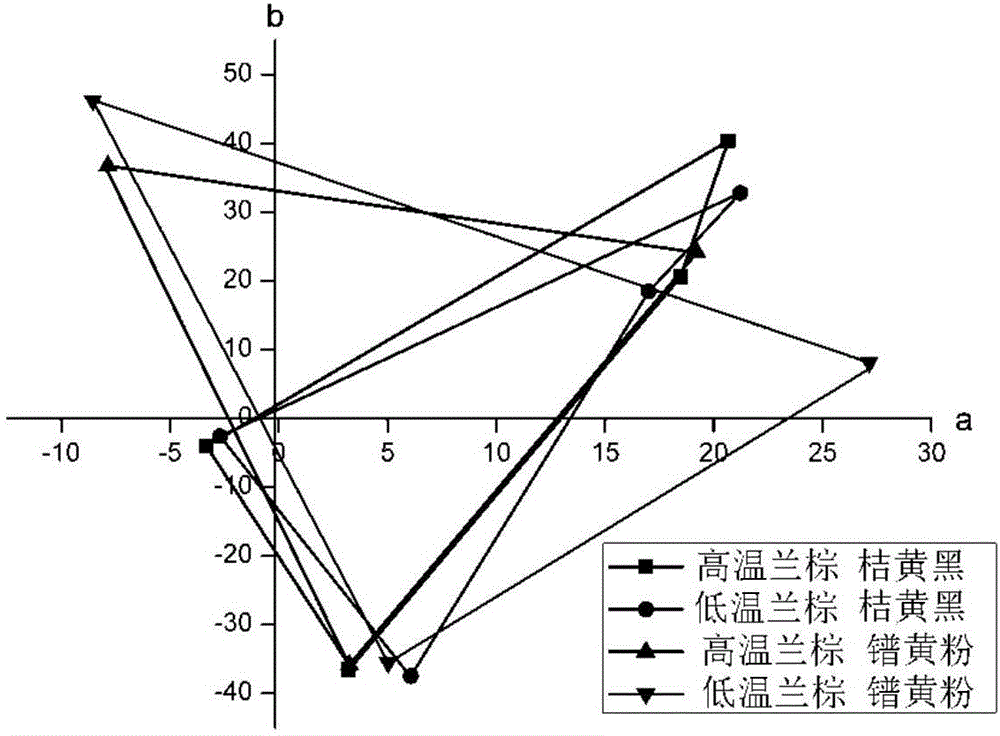

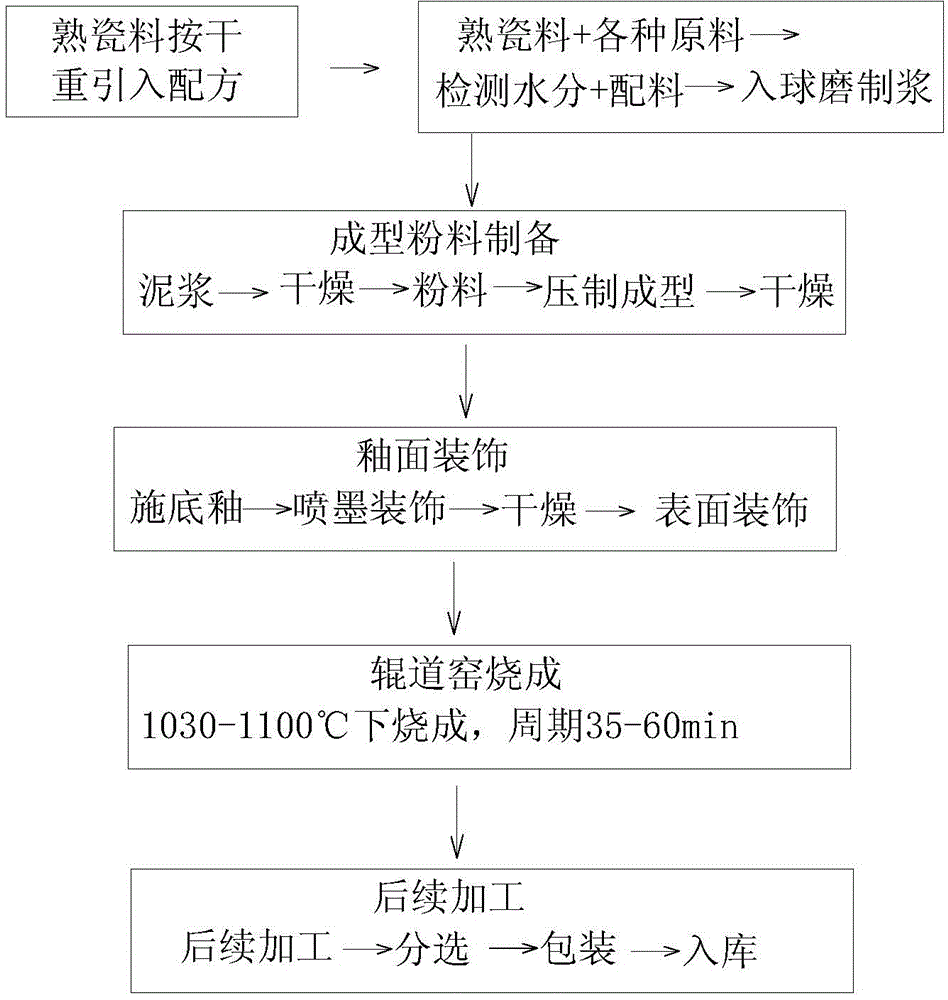

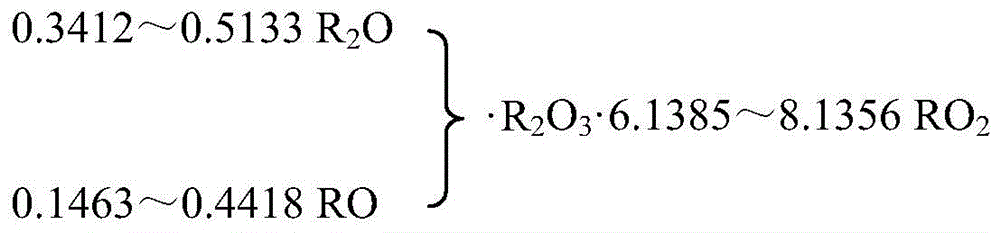

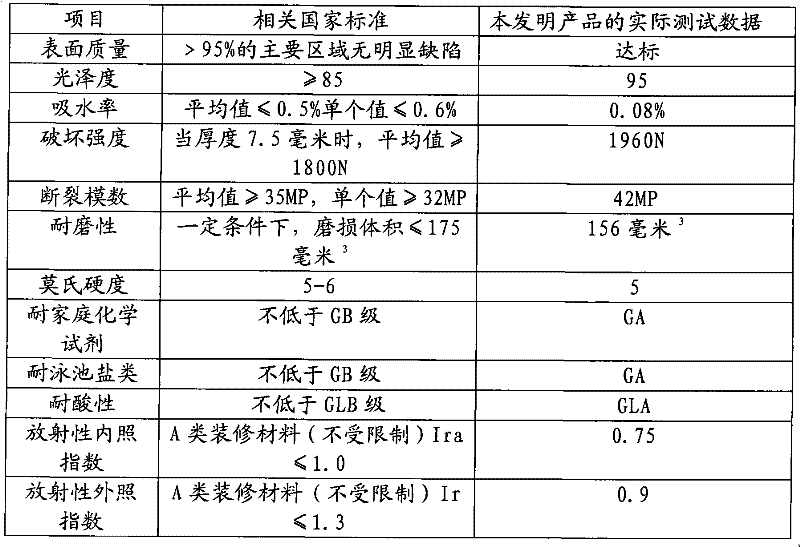

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

Preparation method of low-cost ultra-white porcelain tile

The invention relates to a preparation method of a low-cost ultra-white porcelain tile. The preparation method comprises the following steps of (1) weighing materials, mixing the materials, adding water, a bonding agent and a dispersing agent, carrying out ball milling to prepare slurry, wherein sieving the slurry by 250 meshes with the weight percent of residues being less than 0.5%; carrying out ageing for 24-72 hours for spare use, wherein the materials comprise the following components by weight percent: 25-40% of kaolin, 40-50% of low-cost whitening mineral, 9-15% of feldspar and 6-11% of quartz sand, and the low-cost whitening mineral is mixture of black talc and diopside; (2) feeding the slurry into a spraying and drying tower to carry out spraying granulation so as to obtain body powder; (3) pressing the body powder to obtain a green body, feeding the green body into a drying kiln for drying so as to obtain the dried green body; and (4) applying transparent glaze on the dried green body, entering a roller kiln for firing so as to obtain the low-cost ultra-white porcelain tile. The preparation method has the advantages that the cost is lower, the prepared porcelain tile is high in whiteness and good in mechanical property and thermal stability property.

Owner:WUHAN UNIV OF TECH +1

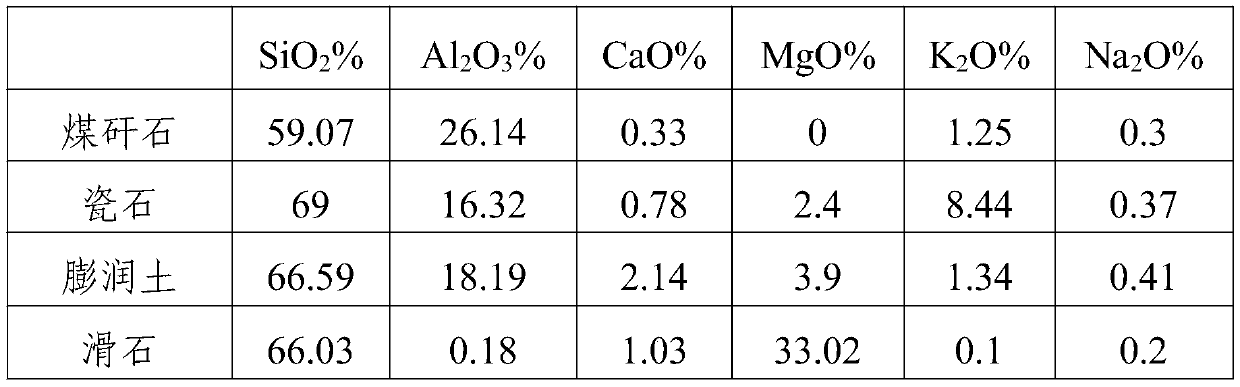

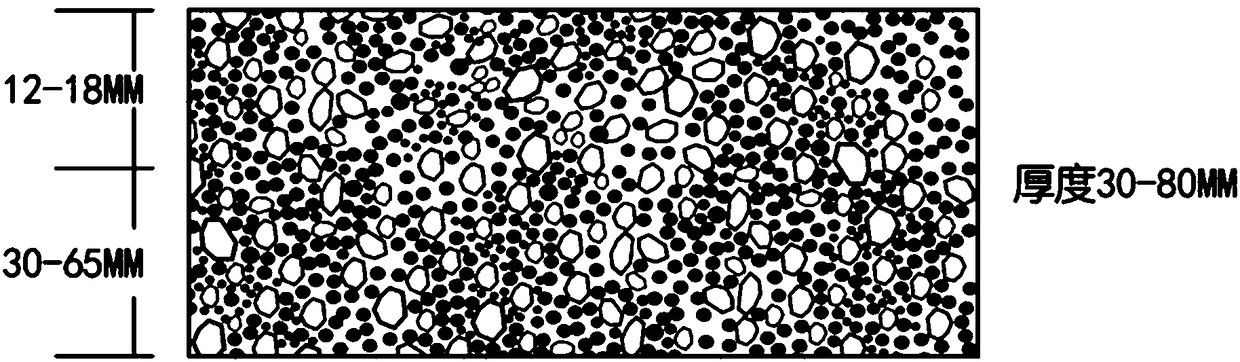

Method for preparing super-flat glaze-polished ceramic tile from coal gangue

ActiveCN106810206ALower melting temperatureGuaranteed wear resistanceCeramic materials productionClaywaresBrickResource utilization

The invention discloses a method for preparing a super-flat glaze-polished ceramic tile from coal gangue. By adopting a double-layer green body and reasonable green body formula and grain size gradation, the coal gangue is used as a main production raw material of the green body to the maximum extent; meanwhile, by raising the initial melting temperature of a ground coat layer, gas in the green body is exhausted as much as possible; in addition, a wear-resisting fritted glaze is adopted in a cover coat layer, so that the melting temperature of the glaze is reduced, and the abrasive hardness of the glaze is guaranteed; finally, the strength of a brick body and the flatness of the glaze are improved by adopting a high-temperature and heat-insulating mode. According to the method disclosed by the invention, by using the coal gangue as the main raw material and the wear-resisting fritted glaze, resource utilization of wastes is effectively realized, the sintering temperature is greatly lowered, the sintering period is shortened, and the production cost is remarkably reduced, so the method has a broad market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

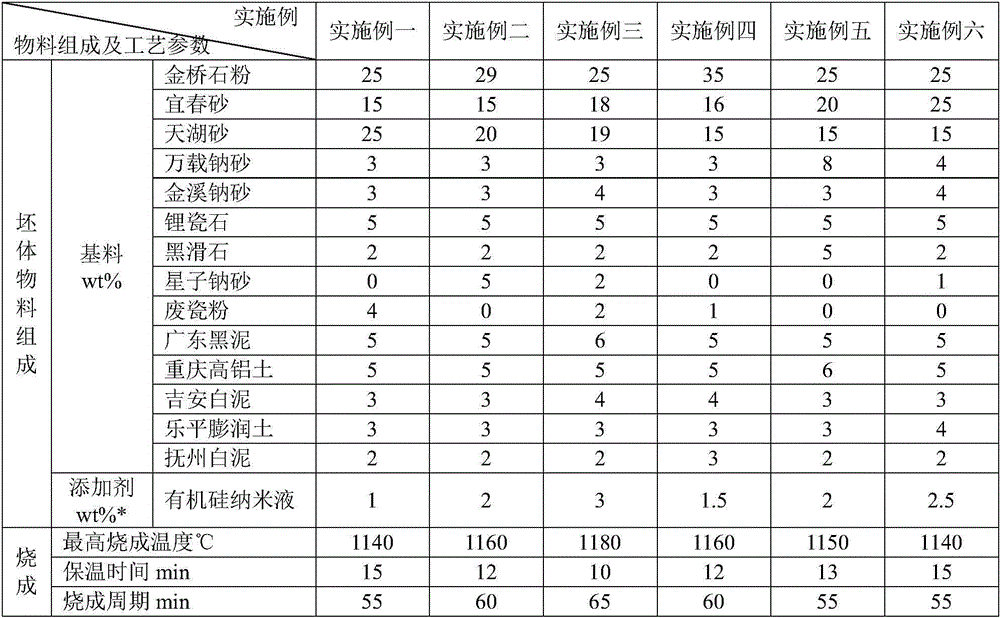

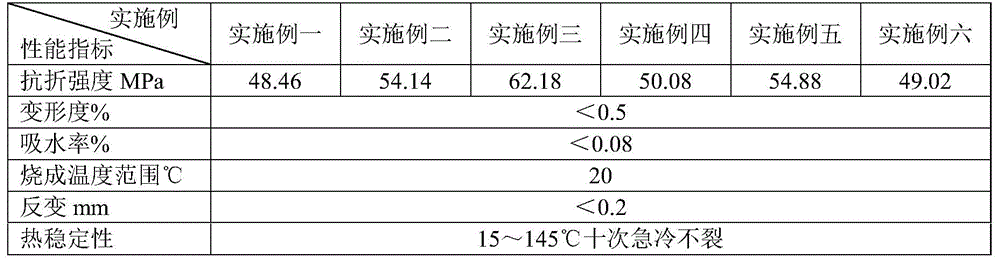

Ultralow-temperature low-deformation glazed green brick body and preparation method thereof

The invention discloses an ultralow-temperature low-deformation glazed green brick body which consists of a base stock and an additive, wherein the base stock is prepared from the following ingredients: 25-35wt% of Jinqiao limestone, 10-25wt% of Yichun sand, 10-25wt% of Tianhu sand, 3-8wt% of Wanzai sodium sand, 3-5wt% of Jinxi sodium sand, 5-10wt% of lithium chinastone, 2-5wt% of black talc, 0-5wt% of Xingzi sodium sand, 0-5wt% of waste porcelain powder, 5-8wt% of Guangdong black clay, 5-8wt% of Chongqing bauxite chamotte, 3-6wt% of Ji'an white mud, 3-8wt% of Leping bentonite and 2-5wt% of Fuzhou white mud; the additive refers to an organosilicone nano solution with solid content of 40% and accounts for 1-3wt% of the base stock. In addition, the invention also discloses a preparation method of the ultralow-temperature low-deformation glazed green brick body. The preparation method is easily available in raw material and low in price of raw materials, is capable of improving the product performance index, realizing decrease in sintering temperature, enlarging the sintering temperature range, ensuring the product quality and realizing energy consumption and consumption reduction, and is beneficial to promotion in sustainable development of industrial production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

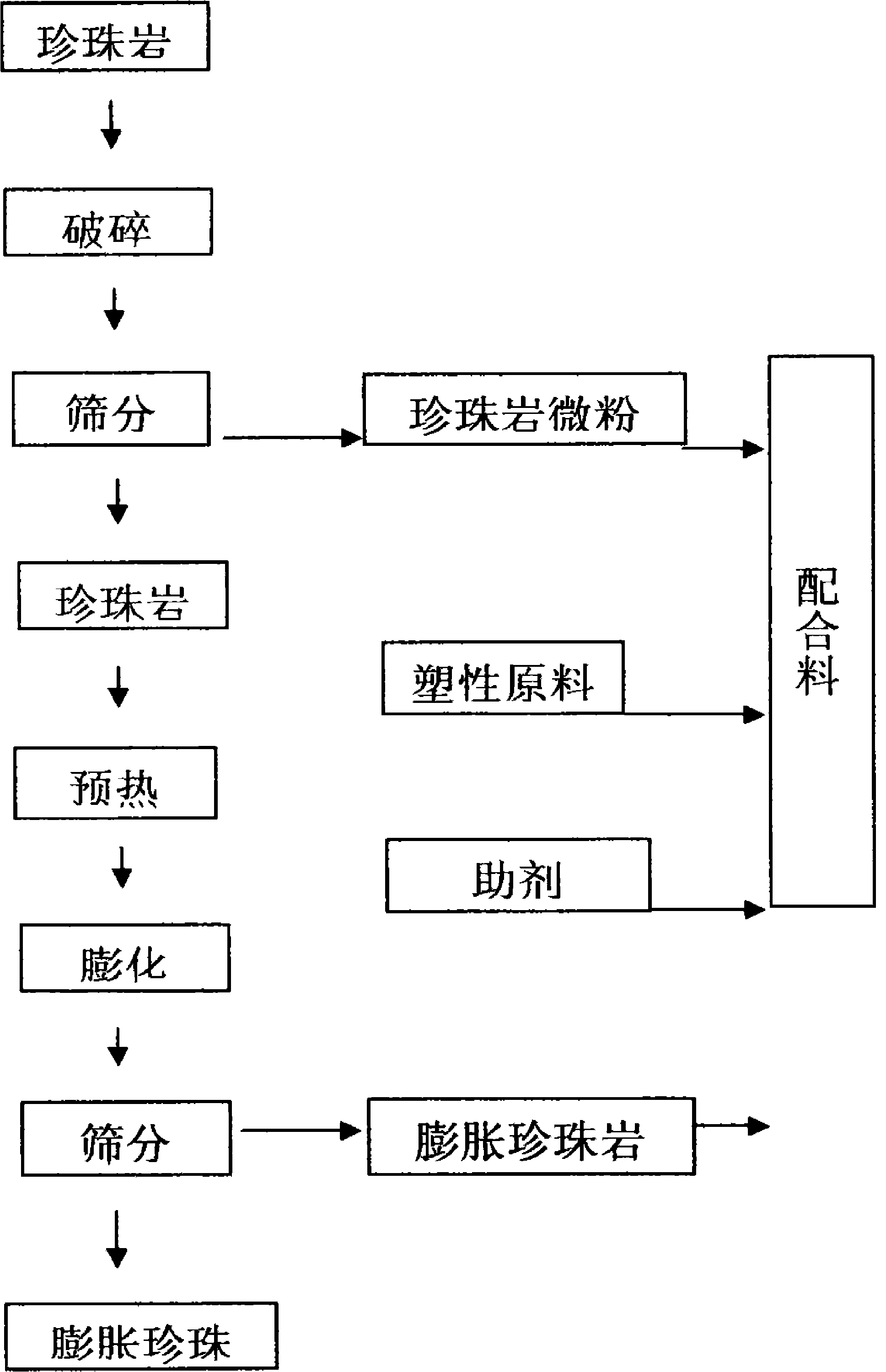

Method for producing light-weight heat-insulating decorative ceramic plate by using solid waste in production and processing course of expanded pearlite

InactiveCN103626476AIncreasing the thicknessLower firing temperatureCeramic materials productionCeramicwareSodium metasilicateSlurry

The invention provides a method for producing a light-weight heat-insulating decorative ceramic plate by using solid waste in the production and processing course of expanded pearlite. The light-weight heat-insulating decorative ceramic plate is prepared from the following materials: 25-100 percent of pearlite micro powder, 0-80 percent of expanded pearlite micro powder, 0-25 percent of Guangdong black clay, 0-10 percent of limestone, 0-5 percent of fluorite, 0.1-2 percent of black silicon carbide, 0-15 percent of bentonite, 0-5 percent of anhydrous sodium metasilicate, 0.1-0.5 percent of sodium humate and 0-1.0 percent of sodium tripolyphosphate. The batches are subjected to ball-milling and then slurry screening, slurry deironing, slurry aging, spray drying, powder aging, decorative distributing, dry-pressing forming, dry transporting and 900-1,050 DEG C oxidation burning are conducted to obtain the light-weight heat-insulating decorative integrated ceramic plate of which the water absorption is within 0.5%, the volume density is smaller than 500 kg / m<3>, the rupture modulus is more than 3.5 MPa, the heat conductivity is smaller than 0.08 / (m / k) and the burning level is A.

Owner:信阳方浩实业有限公司

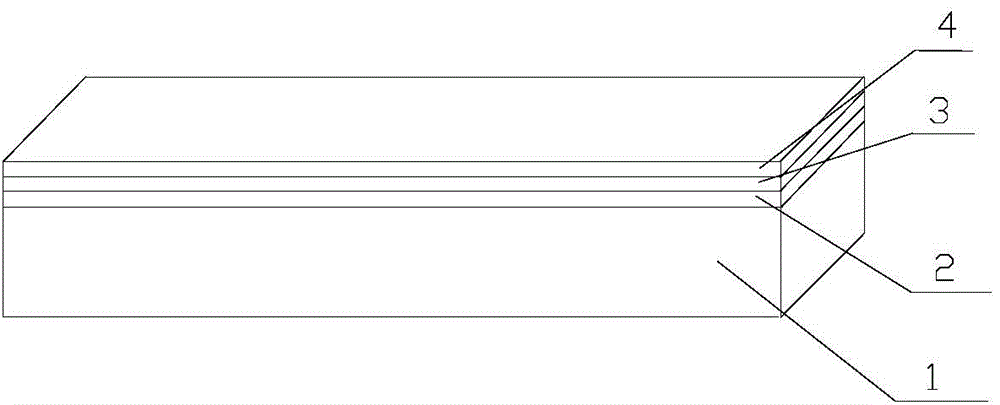

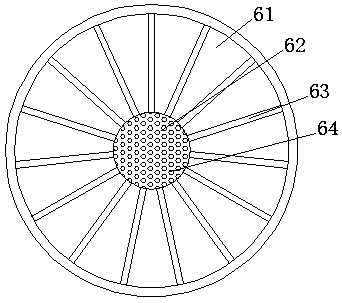

High-flux ceramic flat sheet membrane and preparation method thereof

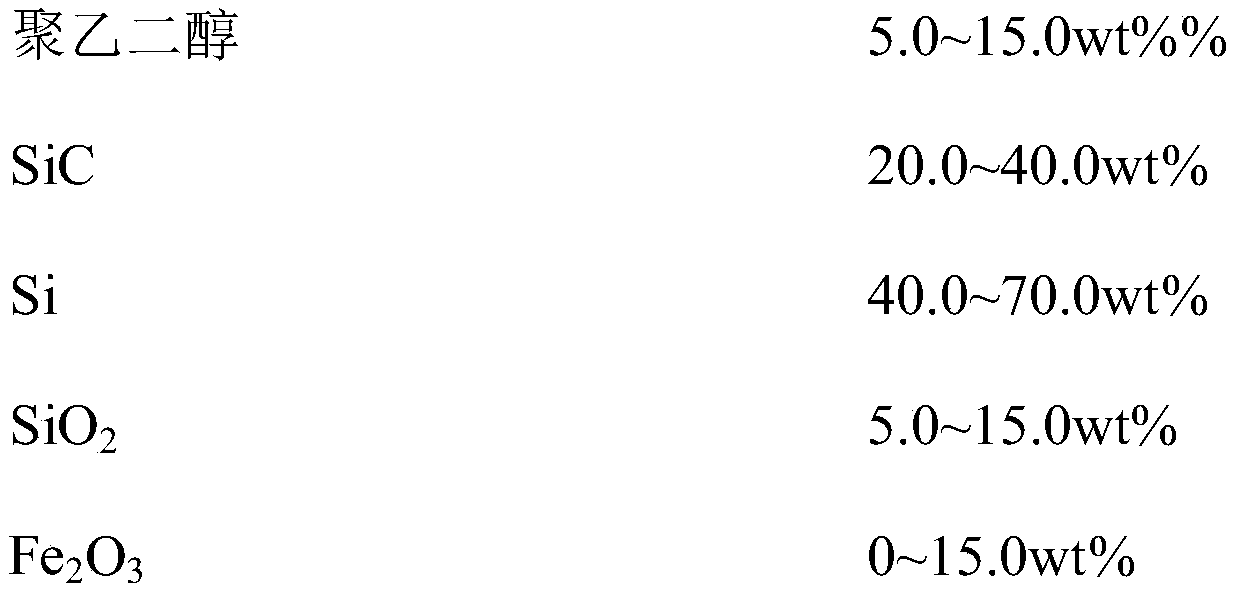

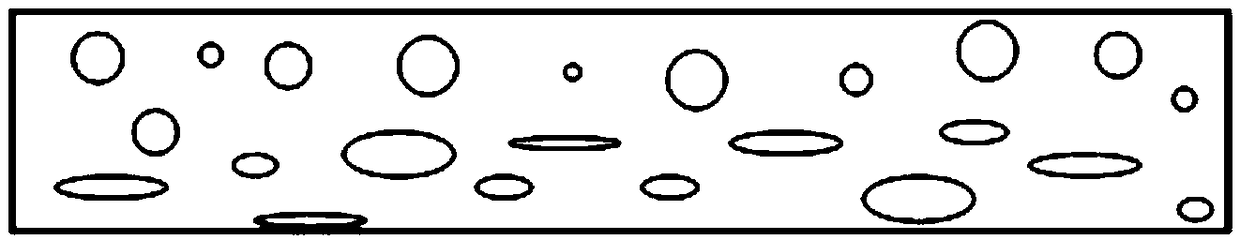

The invention relates to a high-flux ceramic flat sheet membrane and a preparation method thereof. The high-flux ceramic flat sheet membrane comprises a ceramic flat sheet membrane supporting body and a separation membrane layer wrapping the outer surface of the ceramic flat sheet membrane supporting body. The ceramic flat sheet membrane support body is prepared from the following raw materials in parts by mass: 40-57 parts of diatomite, 30-40 parts of alpha-alumina powder, 4-12 parts of a pore forming agent, 20-40 parts of a support body binding agent, 8-12 parts of a lubricant, 9-13 parts of a plasticizer and 12-18 parts of chopped fibers. The separation membrane layer is prepared from the following raw materials in parts by mass: 40-43 parts of ceramic powder particles, 4-6 parts of ethanol, 19-40 parts of a separation membrane layer binding agent and 9-12 parts of polyethylene glycol. The high-flux ceramic flat sheet membrane product is low in sintering temperature, low in production cost, high in product porosity, small in filtering resistance and high in water flux.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Low-temperature glaze-fired ceramic product and preparing method thereof

The invention provides a low-temperature glaze-fired ceramic product and a preparing method thereof, and relates to the technical field of ceramic products. The low-temperature glaze-fired ceramic product is obtained by coating a ceramic blank with low-temperature glaze and drying and firing the ceramic blank. The ceramic blank comprises, by mass, 30-40 parts of coal gangue, 40-50 parts of chinastone, 5-10 parts of bentonite, 3-8 parts of talc, 6-15 parts of wollastonite, 4-10 parts of clay, 1-3 parts of quartz and 0.2-0.6 part of sodium polyphosphate. The low-temperature glaze comprises, by mass, 5-15 parts of calcite, 30-40 parts of quartz, 10-20 parts of potassium feldspar, 9-15 parts of kaolin, 10-20 parts of talc, 15-25 parts of barium carbonate, 10-20 parts of borax, 5-10 parts of zinc oxide and 0.1-0.5 part of sodium carboxymethyl cellulose. The prepared ceramic product has high glaze surface hardness, color and luster and heat stability, the firing temperature is lowered, energy conservation and emission reduction are reduced, the adopted raw materials are easy to obtain and low in price, and production cost is reduced.

Owner:广东派陶科技有限公司

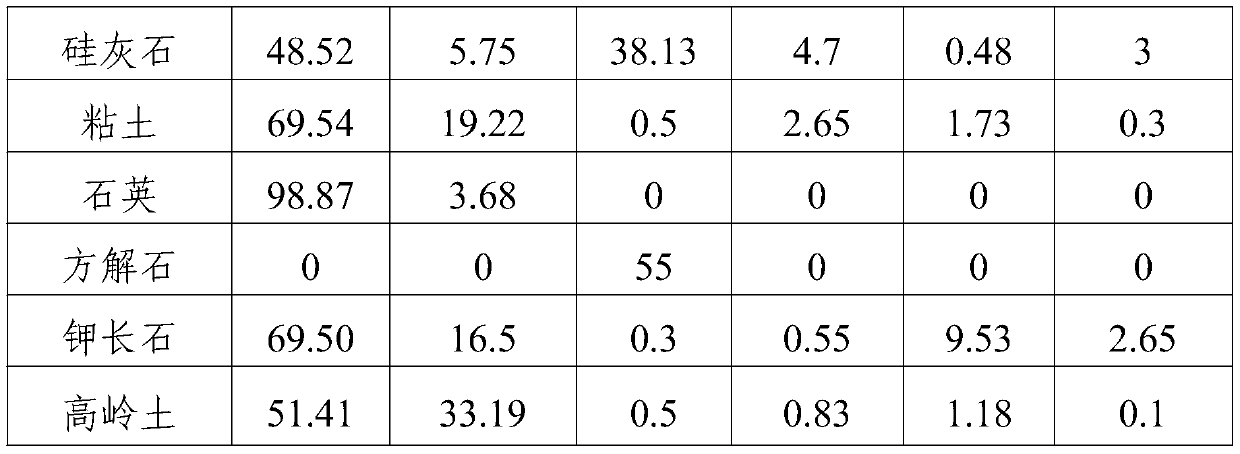

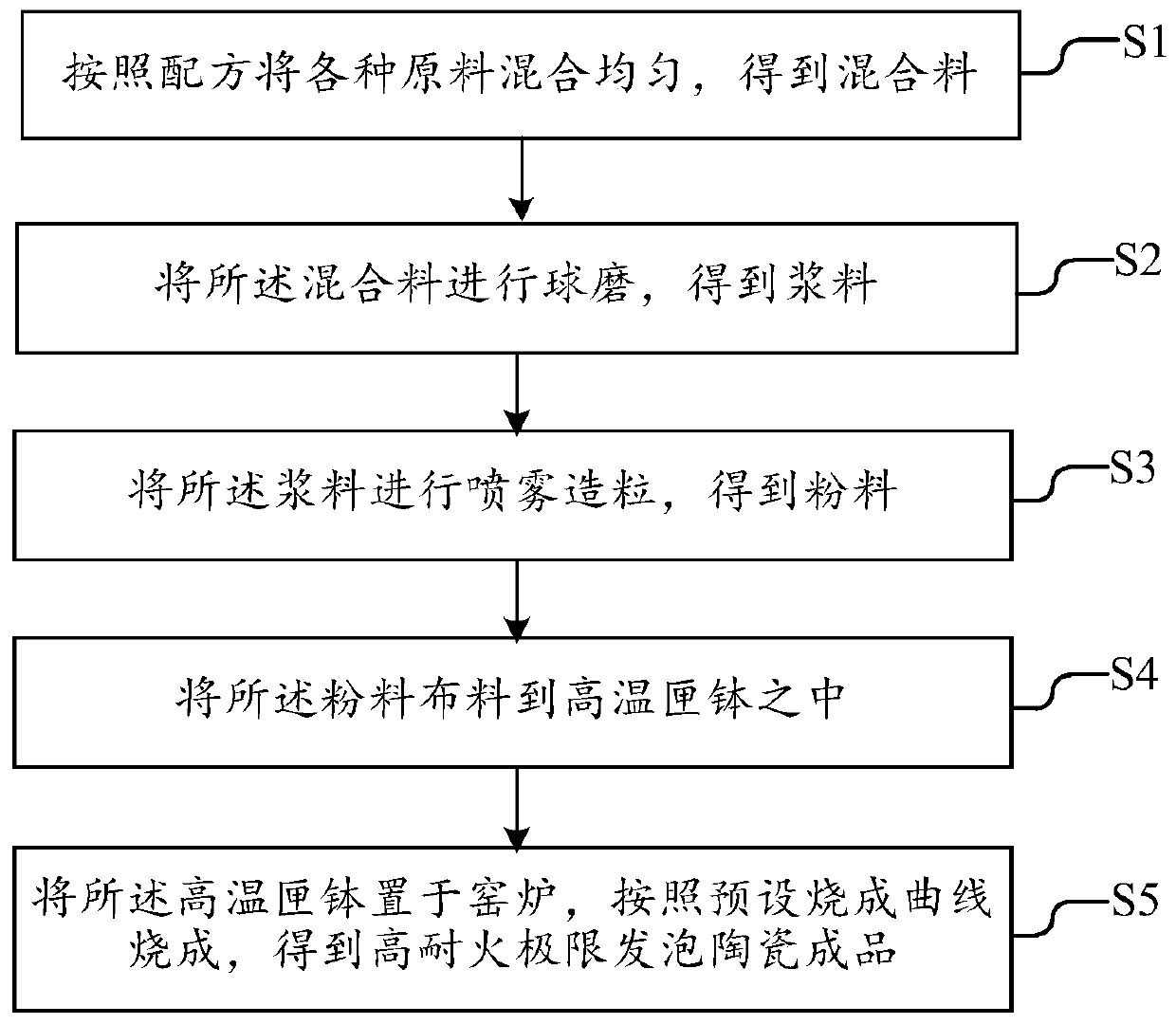

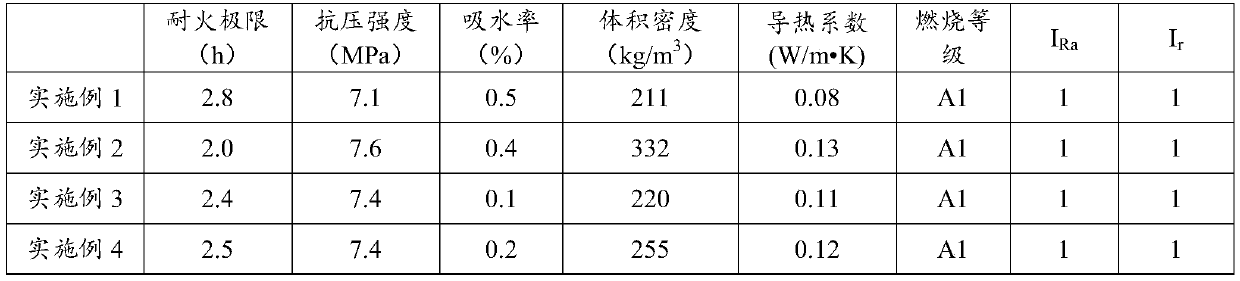

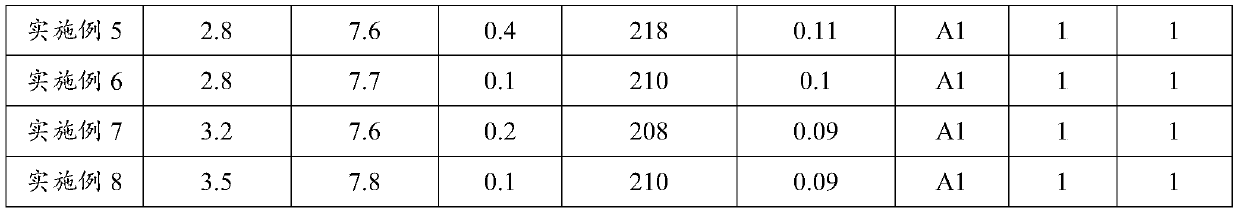

High fire resistance limit foamed ceramic and preparation method thereof

InactiveCN110526681AReduce crystallization tendencySmall coefficient of thermal expansionCeramic materials productionCeramicwareThermal expansionLithium compound

The invention discloses a high fire resistance limit foamed ceramic. The foamed ceramic is mainly prepared by the following raw materials in parts by weight: 90-95 parts of Luoyuan red tailings, 1-5 parts of a lithium compound, 1-3 parts of clay, 0.5-1 part of a foaming agent, and 0.2-1 part of a stabilizer, and the sum of parts by weight of each raw material component is 100 parts, wherein the lithium compound is one or more selected from spodumene, lithium porcelain stone, lithia mica, amblygonite, petalite, lithia mica, and zinnwaldite. The lithium-containing compound is added into the formula, the Li particle has a small radius and large electric field strength, so that the Li particle has the effect of strengthening a network, and thereby a thermal expansion coefficient of the foamedceramic can be reduced, crystallization tendency is reduced, fire resistance of the foamed ceramic can be improved, and application fields of the foamed ceramic is broadened.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

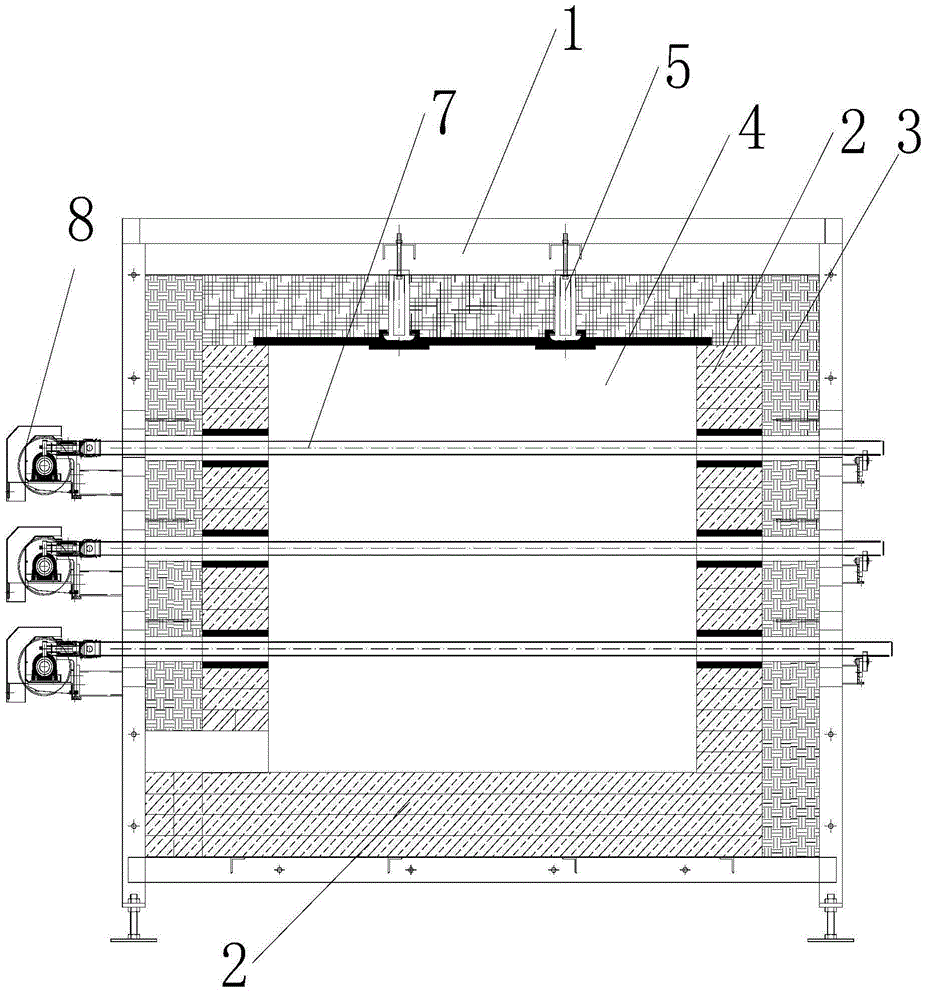

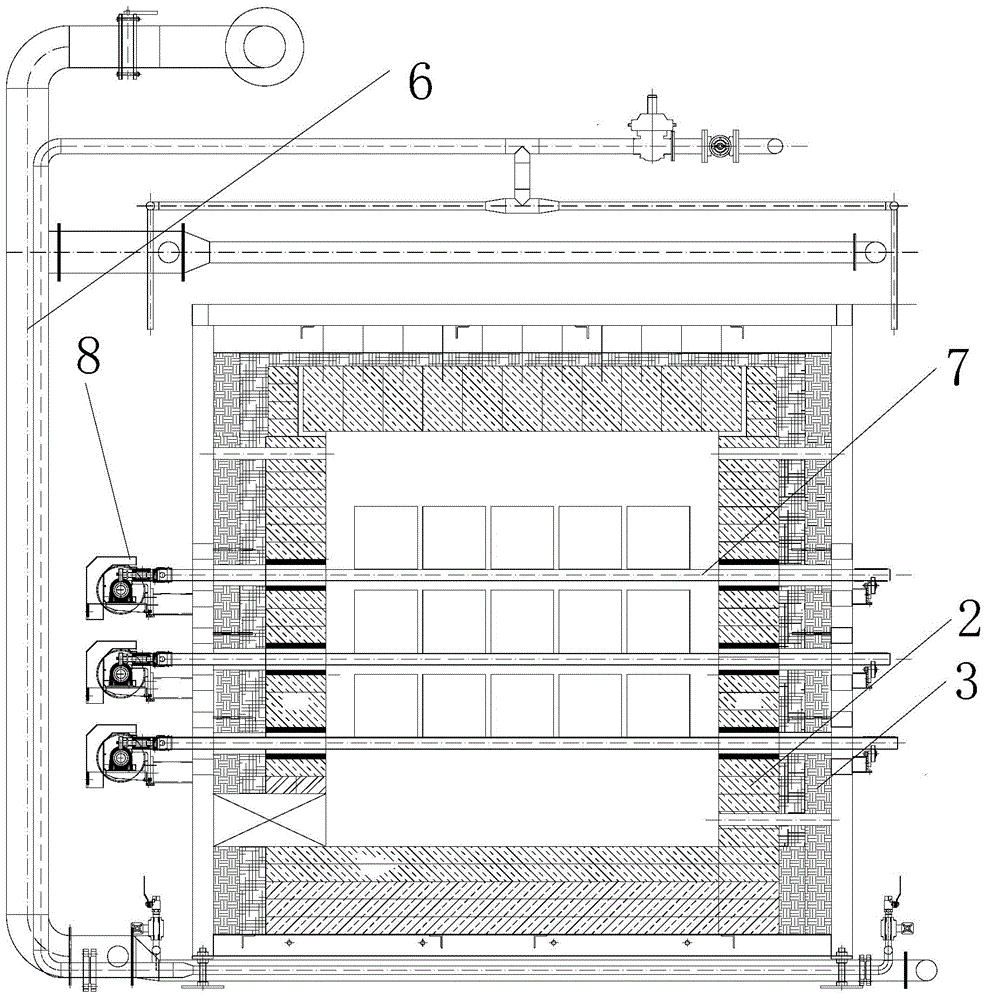

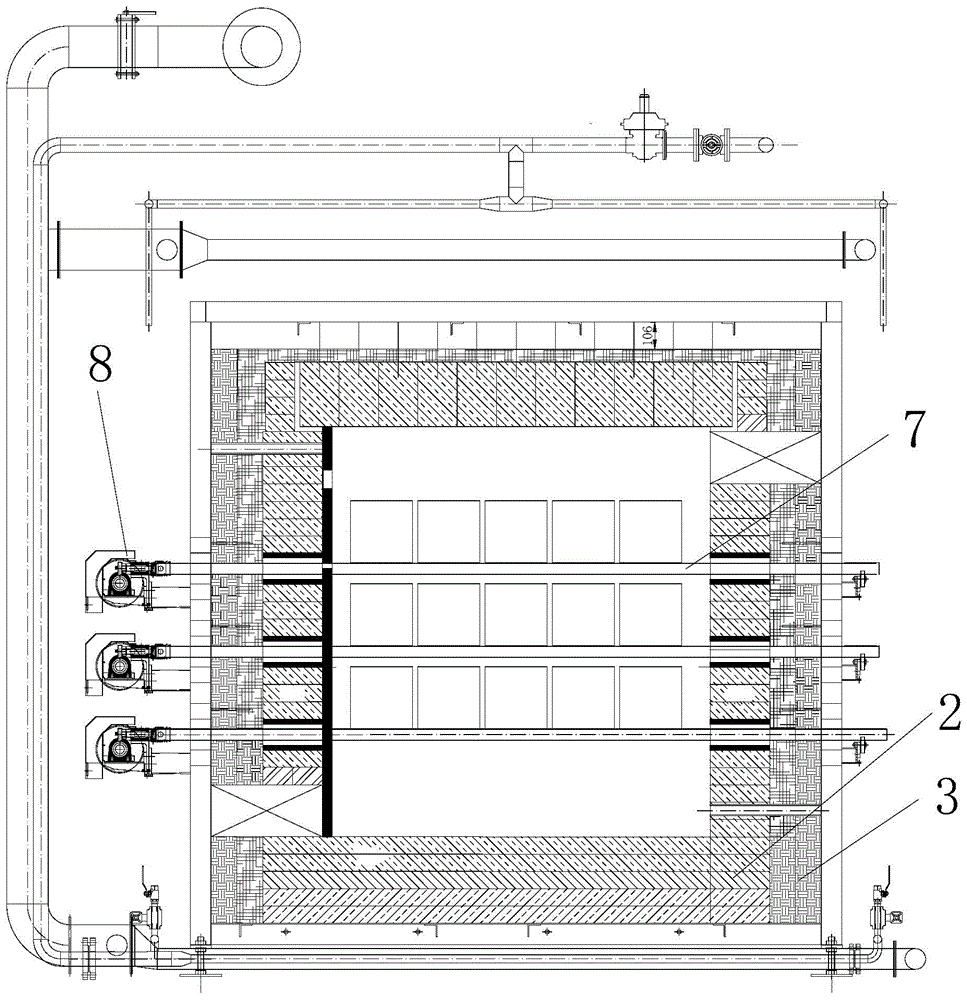

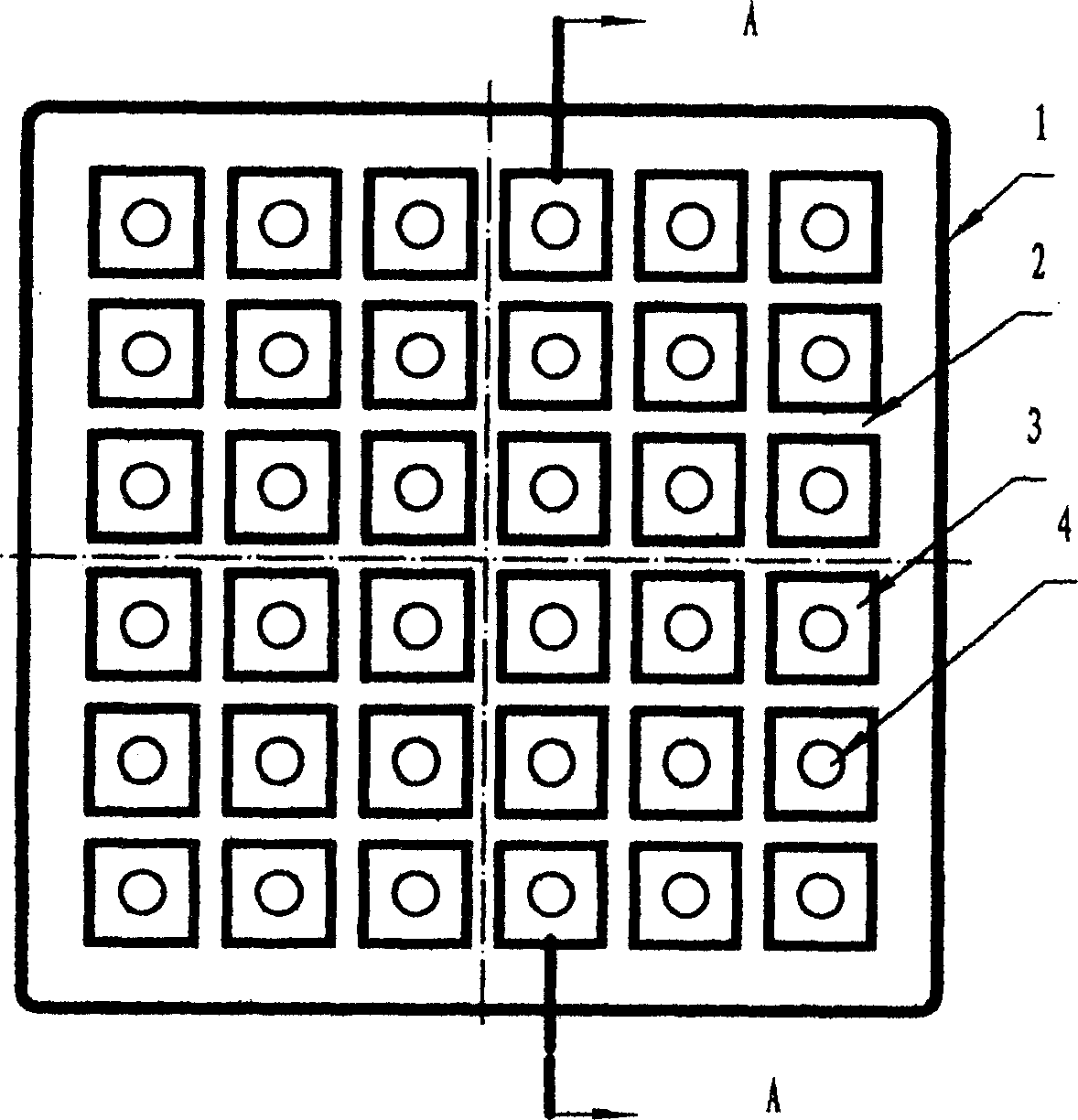

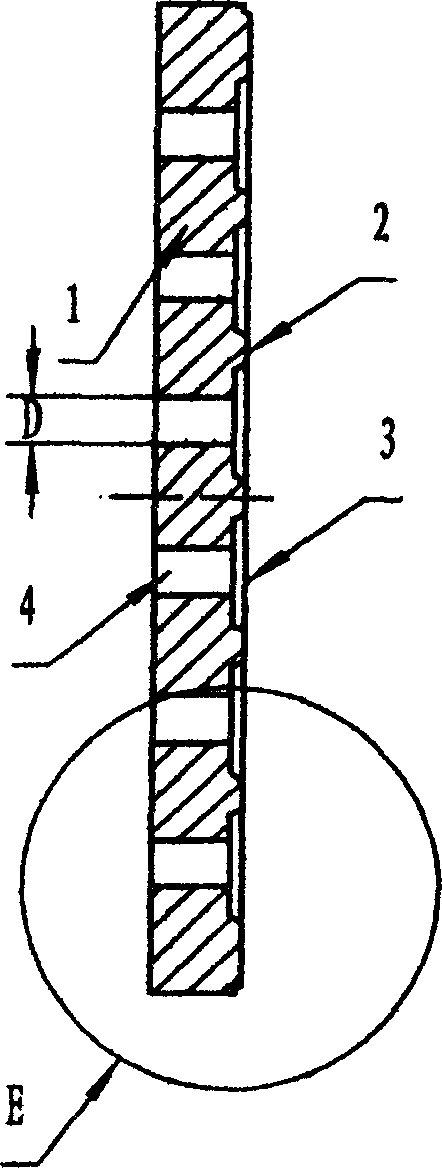

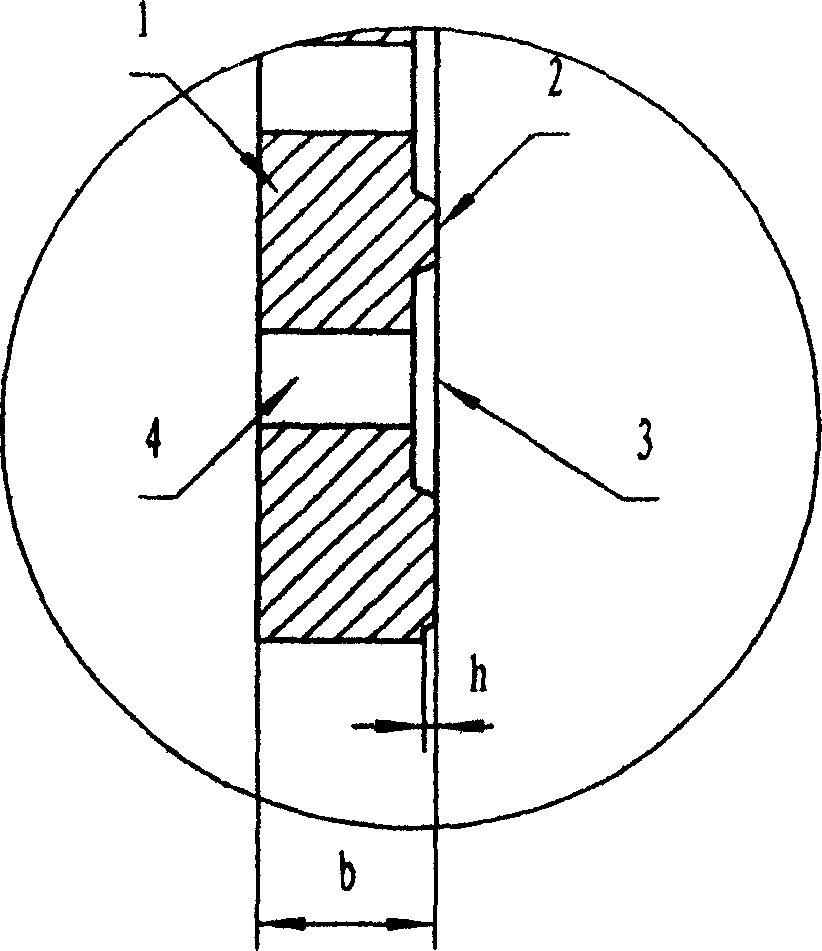

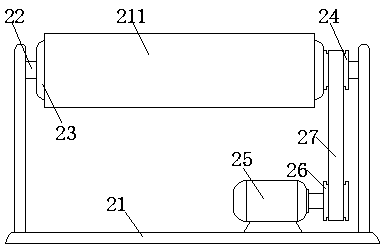

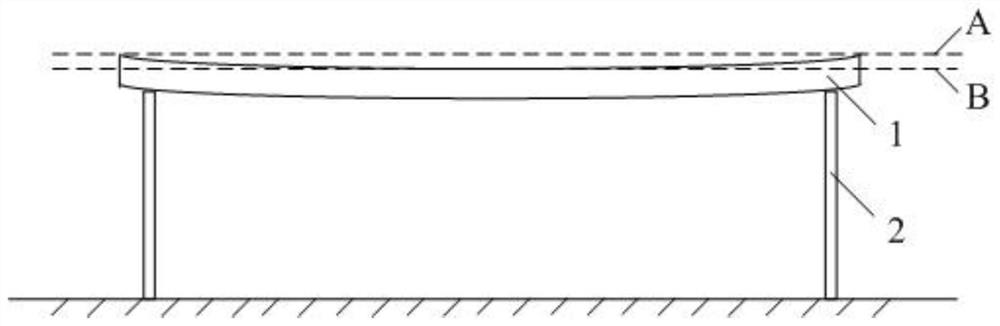

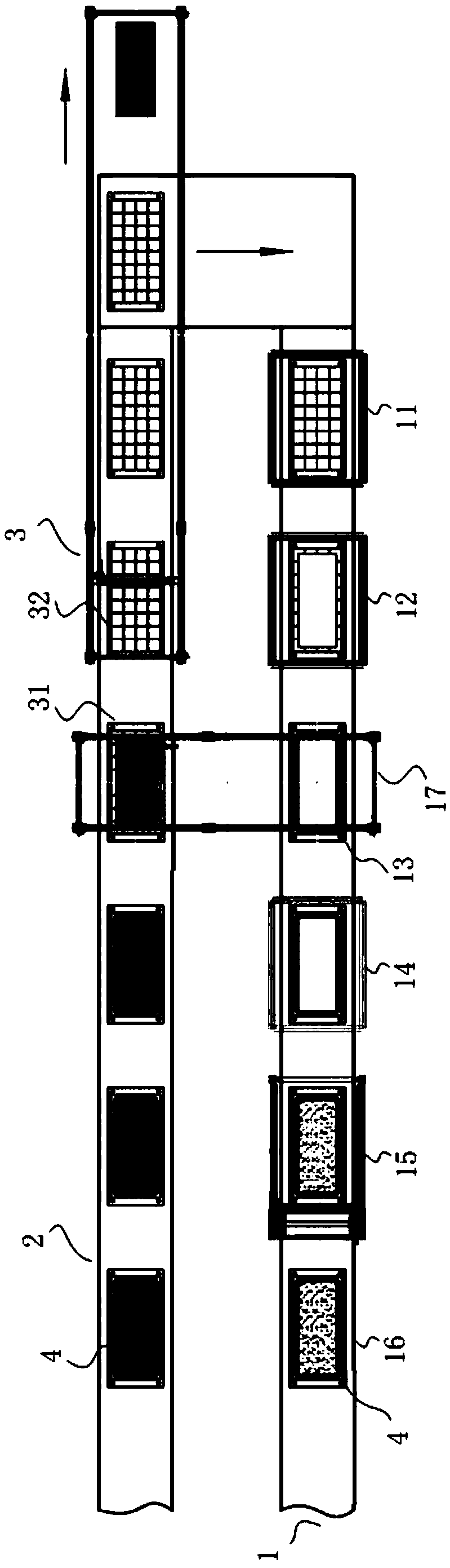

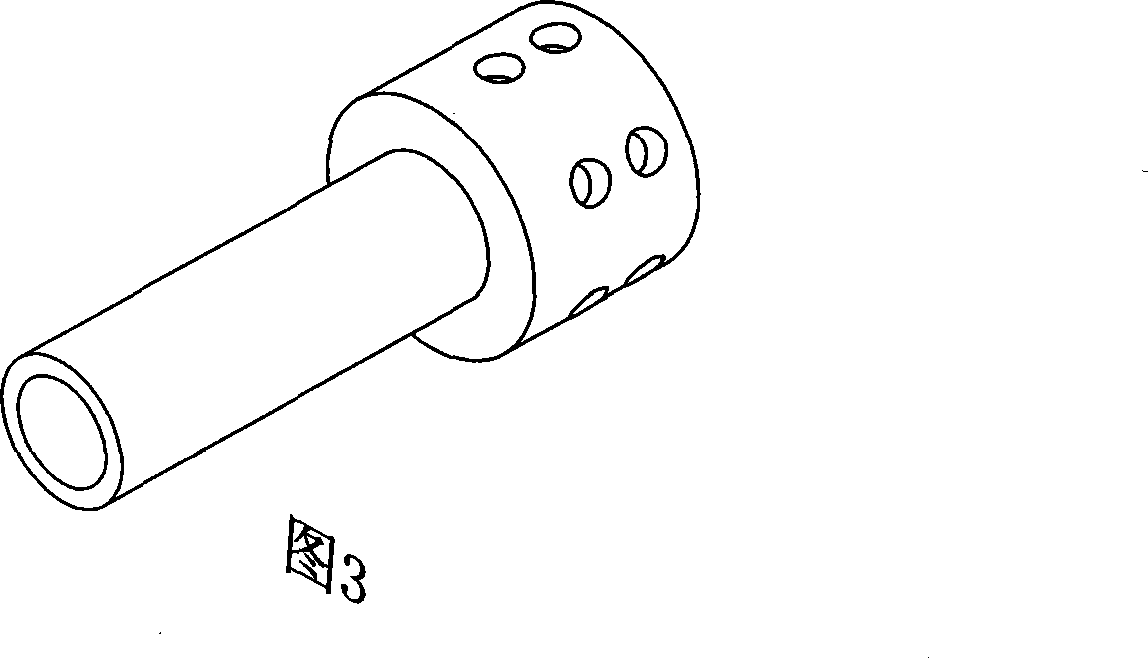

Roller kiln

The invention discloses a roller kiln. The roller kiln comprises a kiln body, the kiln body comprises a kiln top, an outer kiln framework connected in a detachable mode, light bricks made of clay or other materials, heat preservation components and a roller way transporting system, the outer kiln framework is a metal kiln framework, the light bricks are arranged on the kiln framework to form a kiln wall, the kiln wall combines with the kiln top to form a hearth, and the heat preservation components are arranged at the outer sides of the light bricks. The roller kiln has technical advantages of floor space saving, space saving, detachable structure, repeated use, low manufacturing cost, stepped variable-speed and variable-frequency transmission, short firing period, high product quality and the like.

Owner:广东中窑技术股份有限公司

Blue and white glazed porcelain

The invention discloses blue and white glazed porcelain. A porcelain blank consists of kaolin, natural clay, talc, feldspar, alumina micro-powder, silicon nitride, barium carbonate and wollastonite. A glaze for the porcelain consists of zinc oxide, cobalt oxide, quartz, limestone, lithium feldspar, ulexite, silicon carbonate, silicon nitride, iron sesquioxide, tin dioxide, zinc borate, montmorillonite, carboxymethylcellulose sodium and sodium humate. According to the blue and white glazed porcelain, the compositions of the porcelain blank and the glaze are optimized, so that the coloring effect and the physical and chemical performance such as hardness and stability of the porcelain are improved.

Owner:SUZHOU TUOKE INSTR EQUIP

Energy-saving ceramic fire resistant bearing board

InactiveCN1724964AChange the heating methodChange the state of heatingCharge supportsBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

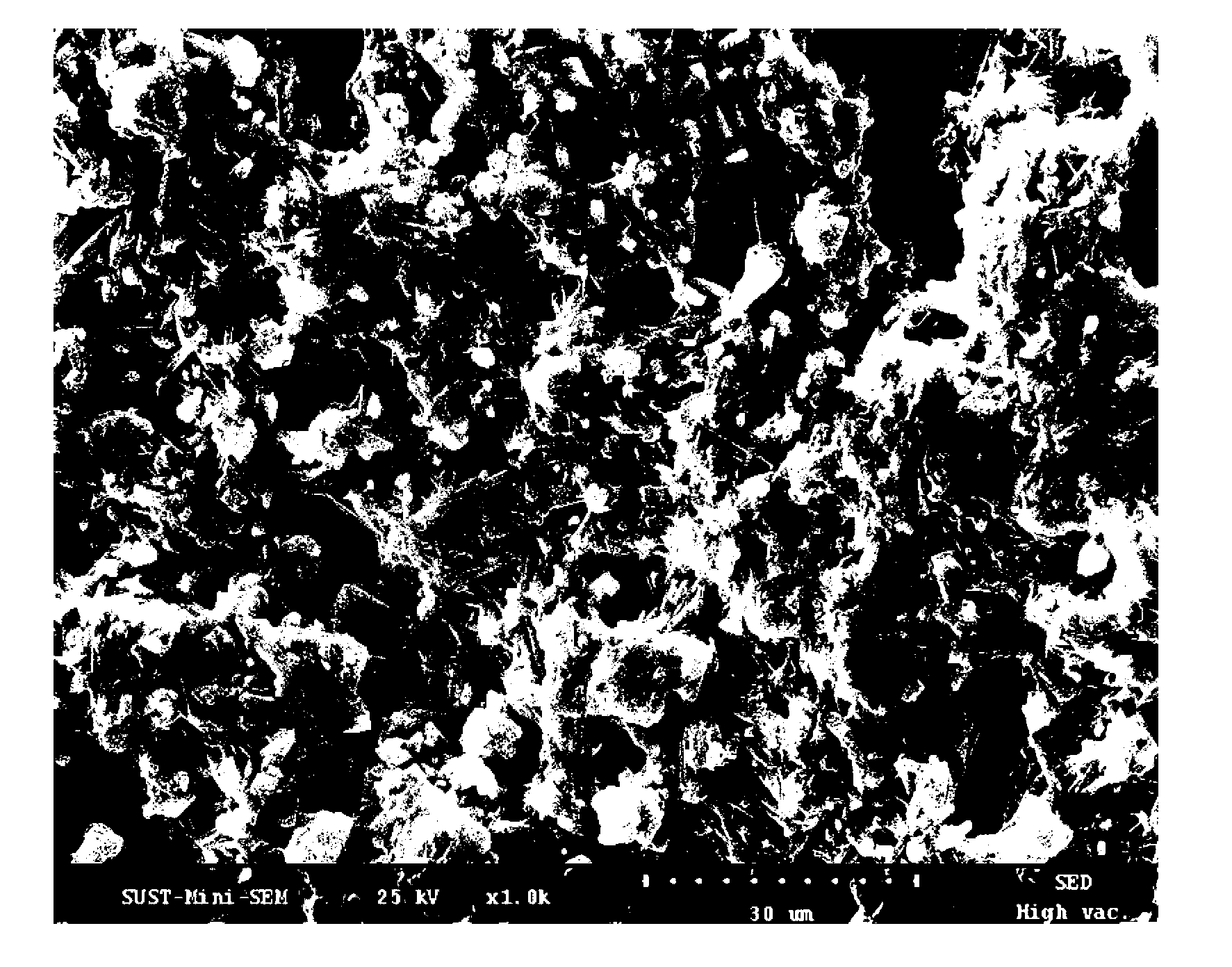

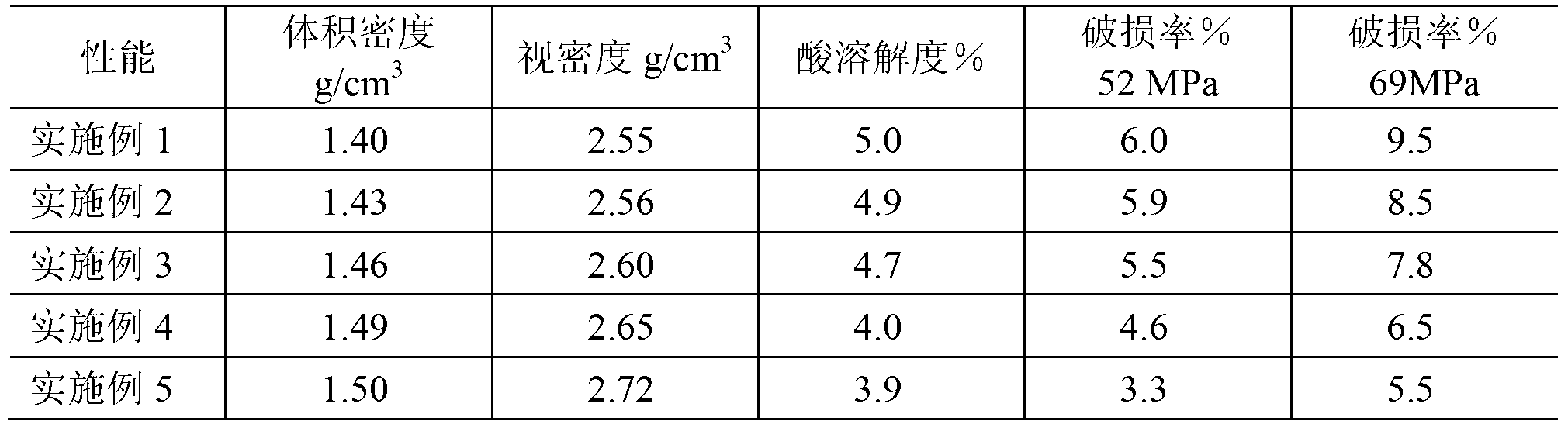

Method for preparing special fracturing propping agent for shale gas by utilizing low-carbon coal gangue

InactiveCN103288430AAchieve the purpose of sinteringReduce energy costsChemical industryFluid removalSlagManganese

The invention discloses a method for preparing a special fracturing propping agent for shale gas by utilizing low-carbon coal gangue. The method comprises the following steps of: ball milling the low-carbon coal gangue, sieving, taking the sieved coal gangue, placing the sieved coal gangue, coke, silicon micropowder and manganese slags in ball mill, wet grinding, and thus forming a mixed slurry, drying the mixed slurry by adopting a spray drying tower, scattering, taking coal gangue master batches as seeds, pelleting in a sugarcoating machine to form dense balls, forming by coating coke dust, placing the formed particles in a crucible, placing in an electric furnace, sintering at ultralow temperature by adopting a self-spreading manner, naturally cooling, and taking out, thus obtaining the special fracturing propping agent for the shale gas. The method provided by the invention has the advantages of being beneficial for saving high-quantity natural mineral resources, reducing firing temperature, shortening burning period, saving energy sources, and improving the combination property of a product; a secondary balling process is adopted for molding, the self spreading sintering advantage is displayed, the energy consumption is greatly reduced, the operation is convenient and easy to control, and the method is beneficial for industrialized large-scale production; the prepared propping agent has the good characteristics of low density, high intensity, high temperature resistance, high corrosion resistance and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Underglaze blue and underglaze red glaze ceramic

The invention discloses underglaze blue and underglaze red glaze ceramic. A ceramic body comprises the following components: kaolin, natural clay, talcum, feldspar, alumina micro powder, silicon nitride, barium carbonate and wollastonite; the ceramic glaze comprises the following components: cuprous oxide, zinc oxide, cobaltous oxide, quartz, limestone, lithium feldspar, ulexite, silicon carbide, silicon nitride, iron trioxide, stannic oxide, zinc borate, montmorillonite, carboxymethyl cellulose sodium and sodium humate. Through optimizing the components of the ceramic body and the glaze, the physical and chemical properties, such as the coloring effect, the hardness and the stability of the ceramic are improved.

Owner:SUZHOU TUOKE INSTR EQUIP

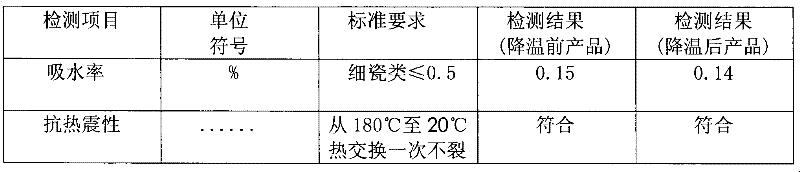

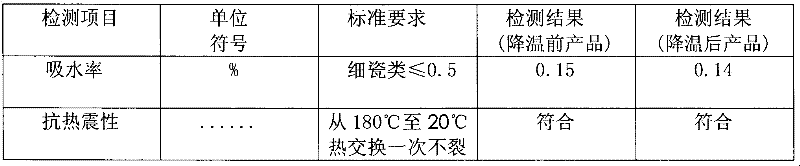

Ceramic green body additive capable of reducing firing temperature as well as preparation method and application thereof

The invention discloses a ceramic green body additive capable of reducing firing temperature as well as a preparation method and application thereof. The additive comprises the following components in parts by weight: 35-45 parts of potassium feldspar, 30-36 parts of quartz, 4.0-6.0 parts of kaolin, 2.0-6.0 parts of talc, 18-25 parts of lithium feldspar and 0.5-1.5 parts of lanthanum oxide. By adopting the additive, the firing temperature can be reduced by 50-70 DEG C, and the density and mullite crystalline phase quatity of the ceramic green body are basically constant; and under the condition that the glass phase content is slightly increased, the good thermal shock resistance of the product can be maintained. The additive provided by the invention is characterized in that the energy-saving effect is obvious, and the product can still have high quality and good application prospect.

Owner:广东宝丰陶瓷科技发展股份有限公司 +1

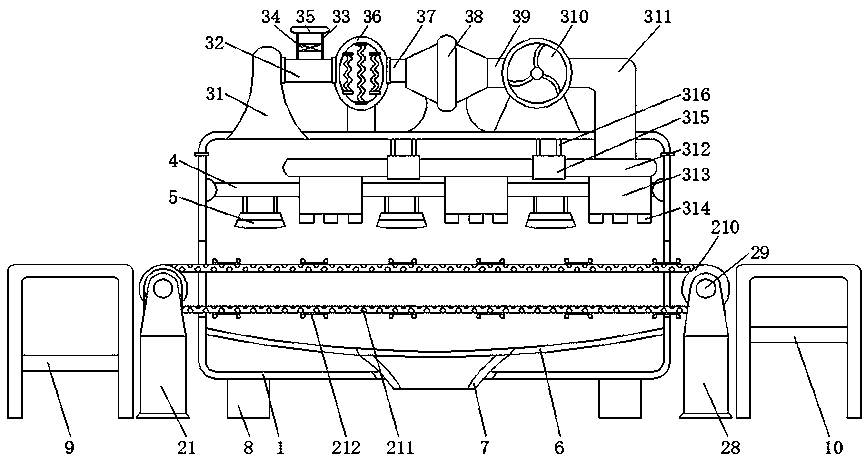

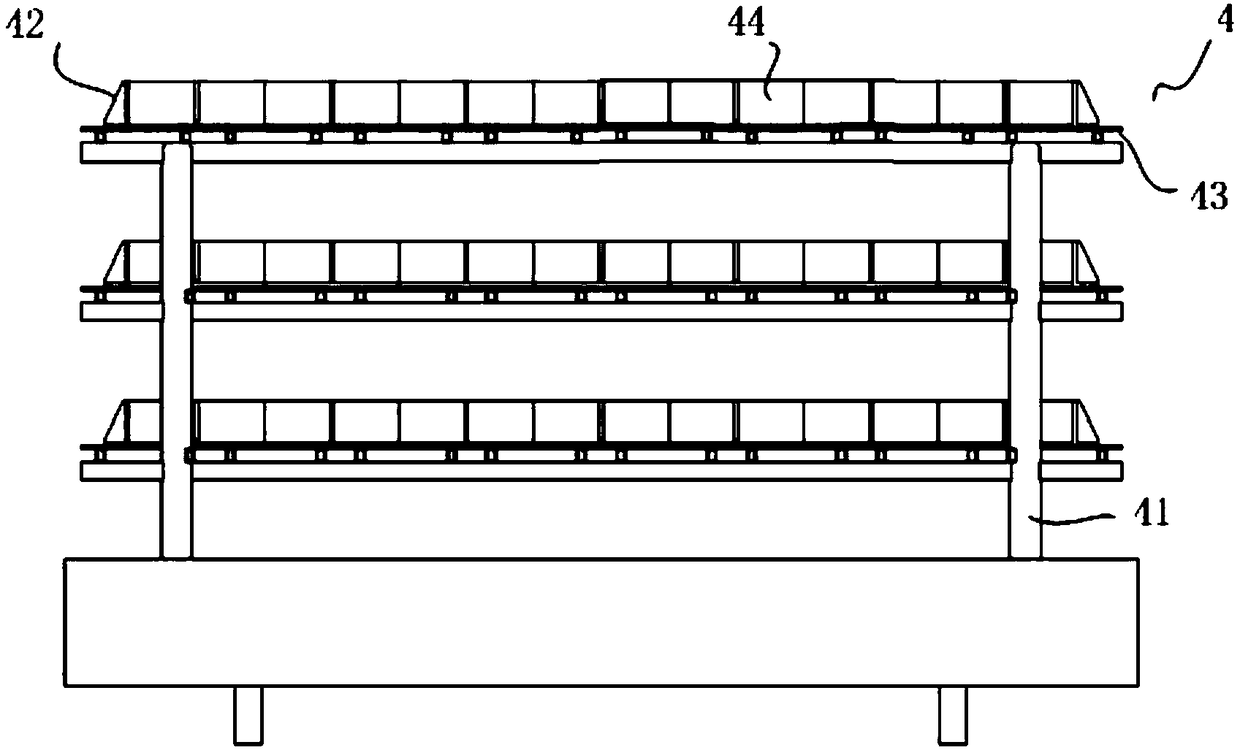

Drying device capable of adopting medium for discharging ceramic wet blank on basis of moisture balance

ActiveCN109269276APrevent deformation, bulging and crackingImprove the ability to absorb glazeDrying gas arrangementsDrying chambers/containersPulp and paper industryMoisture

The invention relates to the technical field of ceramic manufacturing and discloses a drying device capable of adopting a medium for discharging a ceramic wet blank on the basis of moisture balance. The device includes a drying chamber, a wet blank transmission mechanism is arranged in the drying chamber, a hot air drying mechanism is arranged on the top of the drying chamber, a mounting rod is fixedly mounted on the top between the inner walls of the drying chamber, and infrared radiators are fixedly mounted at the bottom of the mounting rod at equal intervals. Water in the ceramic wet blankabsorbs heat and is gasified, evaporated moisture spreads from the interior of the ceramic wet blank to the surface and then spreads from the surface of the ceramic wet blank to the outside, and whendamp air moves downward and passes through a condensation plate, the evaporated moisture condenses into small water drops; the small water drops move down from a condensation groove and enter a moisture exhaust pipe through guiding holes in a circular plate, so that the damp air is discharged. Moreover, deformation, expansion and cracking of the ceramic wet blank are effectively prevented, the glaze absorption capability of the ceramic wet blank is further improved, the ceramic firing cycle is shortened, and the energy consumption is reduced.

Owner:JINGDEZHEN CERAMIC INSTITUTE

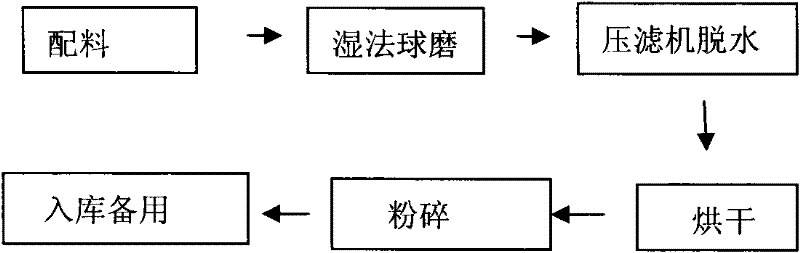

Novel medium-temperature sintered feldspathic porcelain and preparation method thereof

The invention discloses novel medium-temperature sintered feldspathic porcelain and a preparation method thereof. The porcelain is prepared from, by mass, 15-30% of feldspar, 30-50% of kaolin, 10-30% of quartz, 3% of calcinated talc, 3% of lithium chinastone and 5-10% of nanofibers with calcium sulfate additionally added; the preparation method comprises the steps of conducting raw material fine selection, pulverization, material matching, ball milling, fineness detection, slurry feeding and sieving for removing iron, adding the calcium sulfate nanofibers and stirring the mixture uniformly, conducting press filtering for extracting paste and pugging, then after the direct formation and drying procedures are completed and 11 hours later, conducting biscuit firing till the temperature reaches 1260 DEG C, preserving the temperature for 60 minutes, conducting cooling, and obtaining novel feldspathic porcelain pre-sintered billets. By means of the method, the defects of existing feldspathic porcelain that billet bodies are poor in strength and heat stability are overcome. The novel medium-temperature sintered feldspathic porcelain is scientific and reasonable in production method, easy to carry out, high in yield, good in product quality and capable of substantially shortening the sintering cycle and lowering the sintering temperature, the production cost is remarkably lowered, and the novel medium-temperature sintered feldspathic porcelain has a wide market prospect.

Owner:景德镇市大瓷庄瓷业有限公司

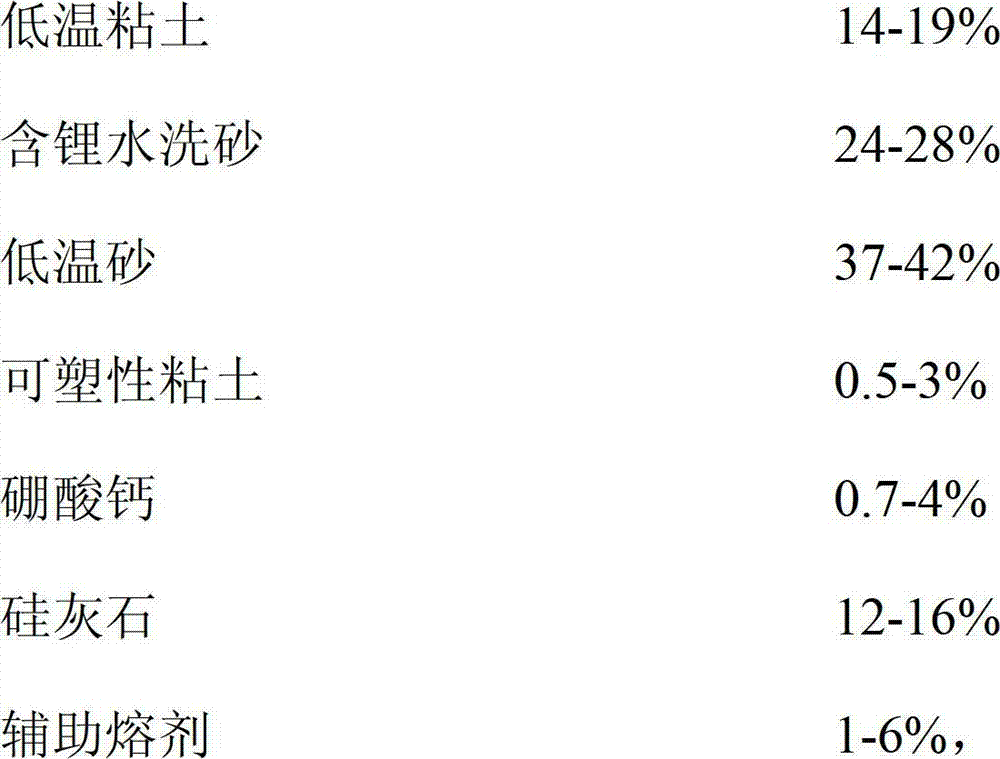

Preparation method of lithium tailing foam ceramic insulation board

InactiveCN109678553AImprove performanceSmall bulk densityCeramic materials productionCeramicwareTunnel kilnBall mill

The invention relates to a preparation method of a lithium tailing foam ceramic insulation board. The preparation method comprises the following steps: crushing lithium tailings, high-aluminum hard kaolin, shales and silicon carbide, removing impunities and controlling the particle size to 40-60 meshes; weighing the following basic materials in percentage by weight: 60-65% of the lithium tailings,20-30% of the high-aluminum hard kaolin and 15-20% of flux raw material shales; weighing a pore-forming agent silicon carbide which is 0.4% of the total weight of the basic materials; pouring the materials, spheres and water into a ball mill for wet milling at a ratio of 1:2:0.6 and controlling the fineness to below 1.5% as the sieve residue; performing spray granulation, controlling the particlesize to 60-120 meshes (greater than or equal to 80%) and the moisture content to below 1.5%; aging granulated powder for 24 hours and distributing the powder in a mould with a material distribution machine; sintering the powder into a finished product with a roller kiln or a tunnel kiln under the condition that a temperature curve is met, wherein under the temperature curve, the formula becomes aliquid phase, and the pore-forming agent is resolved. According to the preparation method, the ceramic insulation board of an outer wall, which is small in density, high in strength and low in heat conductivity coefficient, can be produced.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

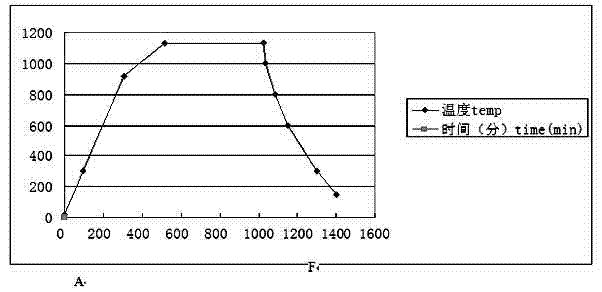

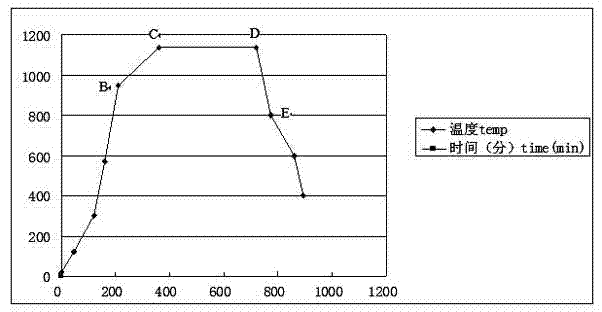

Control method for firing high-performance quartz ceramic

The invention provides a control method for firing high-performance quartz ceramic, which comprises the following steps: selecting high-purity (higher than 99.00%) quartz sand with reasonable grain size distribution, adding water, carrying out ball milling, homogenizing, adding the other two raw materials, carrying out secondary grain size distribution, stirring to injecting dynamic slurry into a mold, curing, and firing in a batch type kiln or progressive kiln through a six-step method, including low temperature stage, oxidative decomposition and crystal form transition stage, re-oxidative decomposition and firing stage, high temperature holding stage, cooling stage and recooling stage, thereby obtaining the high-performance quartz ceramic. The firing method provided by the invention saves the energy, promotes the development and utilization of high-performance quartz ceramic raw materials and natural gas, and effectively controls the firing temperature curve of the high-performance quartz ceramic; and the fired quartz ceramic has the advantages of uniform internal structure, excellent thermal shock stability and excellent rupture resistance. The operating process is stable, and implements low-carbon low-pollution emissions.

Owner:苏州先才新材料科技有限公司 +1

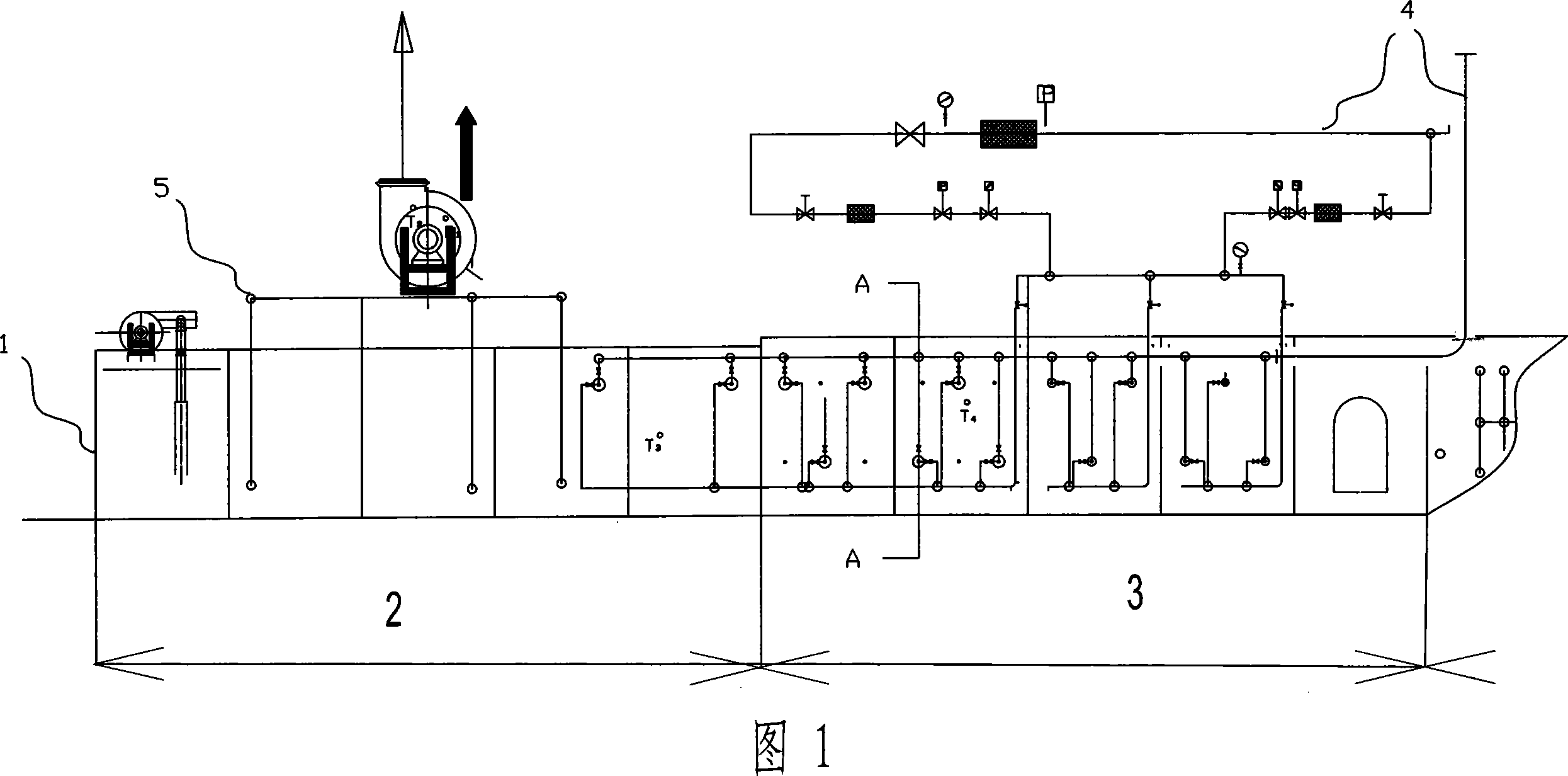

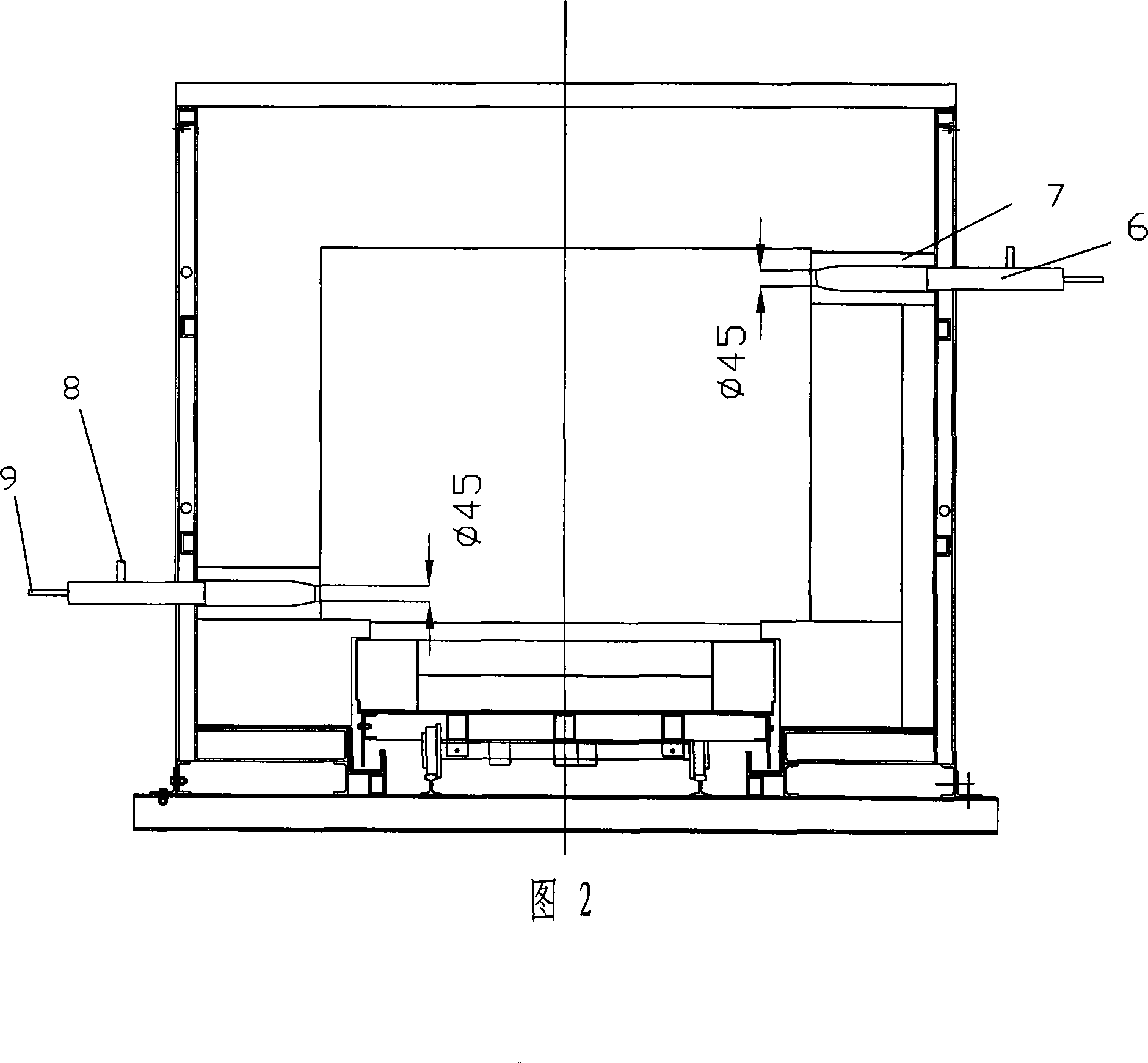

Rich-oxygen and pure oxygen burning tunnel kiln

InactiveCN101182218AReduce total powerEmission reductionFurnace typesCeramic materials productionTunnel kilnHigh concentration

The invention provides an oxygen-enriched and total-oxygen burning tunnel kiln, comprising a preheating area (2), a sintering area (3), a fuel and combustion-supporting medium feeding system (4), a smoke exhaust system (5), a quench area, a cooling area, a temperature control system, a burning system and a waste heat system. The tunnel kiln is used for a combustion-supporting medium with the volume concentration of at least 21 percent of oxygen and the fuel to burn together inside a burner (6), no air combustion-supporting fan is required, the burner (6) is installed at the position of a burner brick (7). In order to solve the problem that the exhaust emission quantity of a ceramic tunnel kiln is large, the invention adopts the high concentration oxygen burning tunnel kiln which has high thermal efficiency, so compared with the combustion which considers the air as the combustion-supporting medium, the burning product quantity is reduced more than 50 percent, the nitrogen oxide produced by the invention is reduced greatly, the invention can reduce the energy consumption more than 10 percent, and the harmful substance emission can be reduced to the minimum.

Owner:WUHAN UNIV OF TECH

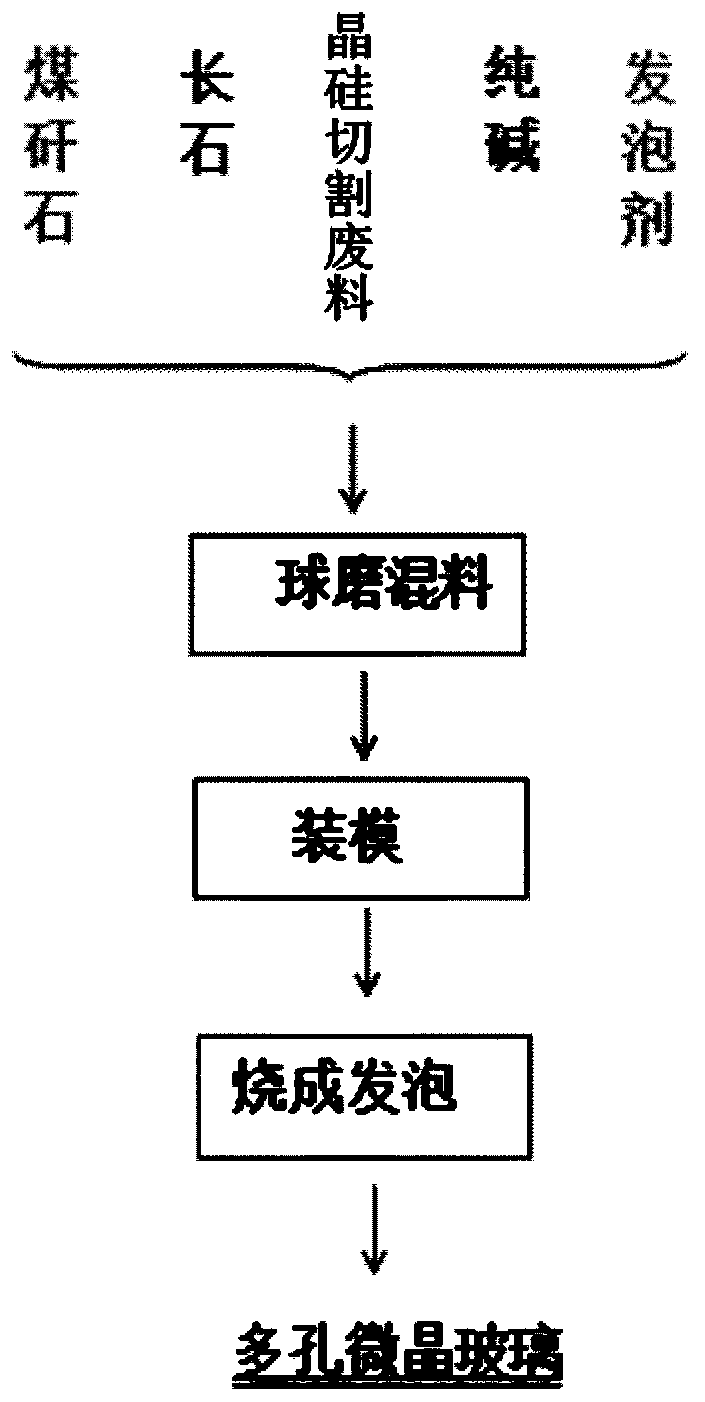

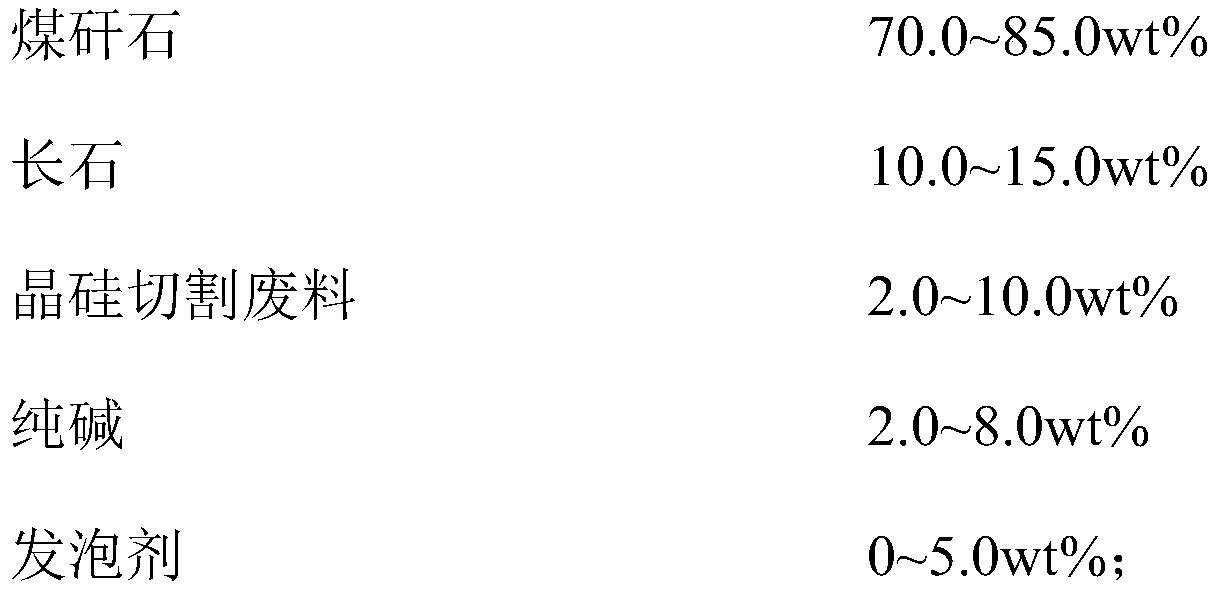

Method for preparing porous microcrystalline material from crystalline silicon cutting wastes in cooperation with coal gangue and application of porous microcrystalline material

ActiveCN110526584ALow costReduce manufacturing costGlass shaping apparatusThermal insulationNoise reduction

The invention relates to a method for preparing a porous microcrystalline material from crystalline silicon cutting wastes in cooperation with coal gangue and an application of the porous microcrystalline material. The porous microcrystalline material is prepared from the following raw materials in percentages by weight: 70.0 to 85.0 wt% of coal gangue, 10.0 to 15.0 wt% of feldspar, 2.0 to 10.0 wt% of crystalline silicon cutting wastes, 2.0 to 8.0 wt% of sodium carbonate and 0 to 5.0 wt% of a foaming agent. The porous microcrystalline material prepared by the method has the characteristics ofa light weight, wear resistance, acid and alkali corrosion resistance, good chemical stability, high strength, shock cooling and heating resistance, good thermal insulation property, sound insulation,easy cutting and the like, and has the advantages of low comprehensive costs, reusability and the like; and the material can be widely applied to key materials in the fields of building decoration, battery plates, heat insulation, noise reduction, shock prevention and the like, and heat insulation of pipelines, storage tanks and heat exchange systems in the mechanical field.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vitrification ceramic tile, preform body of the vitrification ceramic tile and preparation method of vitrification ceramic tile

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

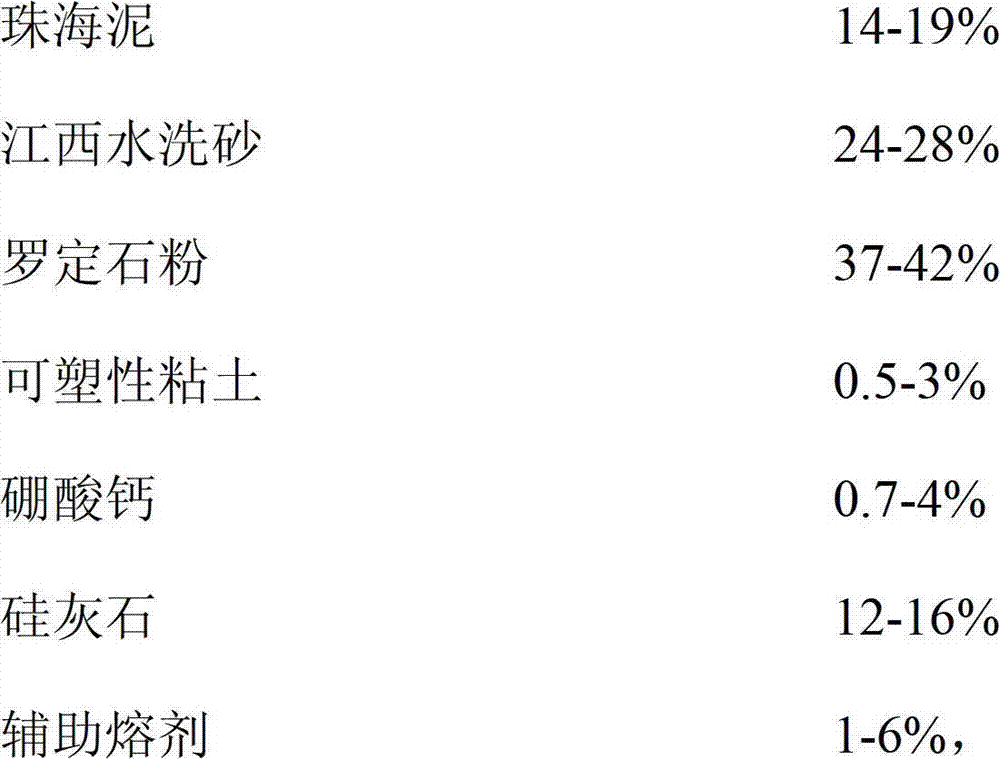

Building ceramic plate/brick and preparation method thereof

The invention discloses a building ceramic plate / brick, which is prepared from a base material and an additive, wherein the base material comprises 5-25 wt% of a plastic raw material, 40-60 wt% of a fluxing raw material, and 25-45 wt% of wollastonite and / or wollastonite fiber, and relative to the base material, the addition amount of the additive is 0.01-6 wt%, and the additive comprises one or a combination of an organic reinforcing agent and a water reducing agent. Correspondingly, the invention also discloses a preparation method of the building ceramic plate / brick. According to the invention, through formula design, wollastonite and / or wollastonite fibers are introduced into a green body for reinforcement and toughening while low-temperature fluxing raw materials are introduced to realize low-temperature firing and avoid high-temperature melting failure of inorganic fibers, so that the product performance is remarkably improved, and the energy consumption and the production cost are reduced.

Owner:况学成 +1

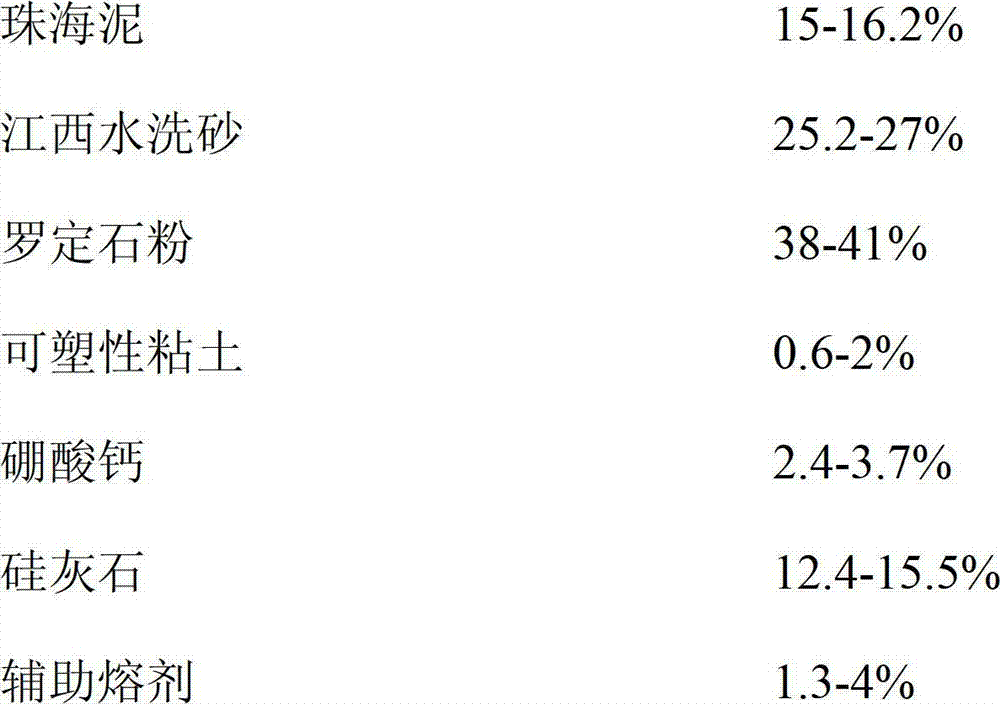

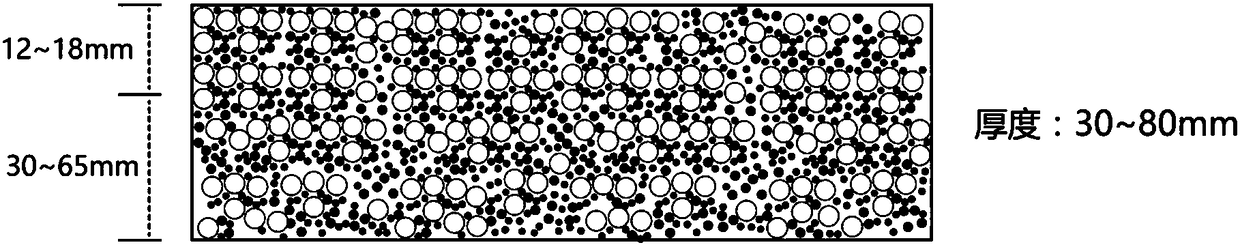

Method for preparing super-flat polished ceramic tiles by utilizing rare-earth tailings

ActiveCN106747296ALower melting temperatureGuaranteed wear resistanceCeramic materials productionClaywaresBrickFrit

The invention discloses a method for preparing super-flat polished ceramic tiles by utilizing rare-earth tailings. A double-layered blank body, a reasonable blank body formula and grain composition are adopted to maximally use the rare-earth tailings as main production raw materials of a blank body; meanwhile, gas in the blank body can be discharged as much as possible through improving an initial smelting temperature of a ground glaze layer; wear-resisting fritted glaze is adopted in a surface glaze layer so that the smelting temperature of a glaze surface is reduced and the wear-resisting rigidity of the glaze surface is also guaranteed; finally, a high-temperature heat-insulation manner is used for improving the strength of a brick body and the flatness of the glaze surface. The rare-earth tailings are used as the main raw material and the wear-resisting fritted glaze is adopted, so that the resource utilization of wastes is effectively improved; the firing temperature is greatly reduced, the firing period is shortened and the production cost is remarkably reduced, so that the method has wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material

The invention provides an isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material. The formula comprises the following components, by weight, 48%-55% of alumina, 18%-25% of feldspar flux, 15%-25% of calcined clay and 5%-15% of viscous agents. The formula takes chemically-synthesized viscous agents as viscous materials to replace plastic clay used in existing ingredients. Therefore, the non-plasticity clay can be used to replace scarce plastic clay raw materials. The cost of blank materials is reduced. The dependence of isostatic pressing electrical porcelain blanks on one-off resources is reduced.

Owner:CHINA XD ELECTRIC CO LTD

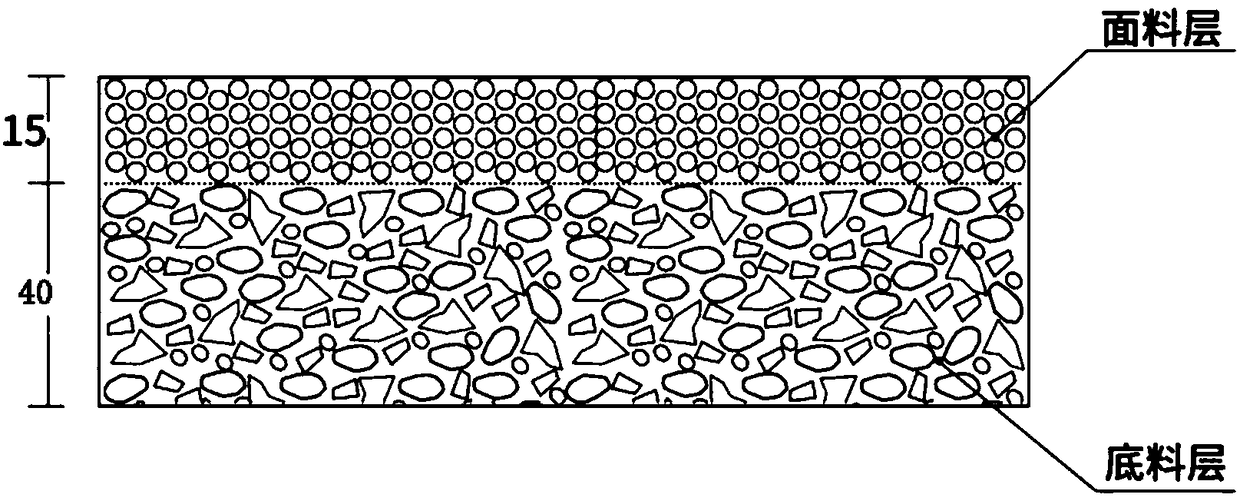

Open-type spontaneously generating negative oxygen ion multifunctional water permeable brick and preparation method thereof

ActiveCN108164281AImprove performanceEfficient methodCeramic materials productionCeramicwareBrickOxygen ions

The invention discloses an open-type spontaneously generating negative oxygen ion multifunctional water permeable brick. The open-type spontaneously generating negative oxygen ion multifunctional water permeable brick comprises a surface material layer and a bottom material layer, wherein the surface material layer comprises the following components in percentages by weight: 90-93% of wall floor tile waste particles A, and 7-10% of composite water soluble body A; the bottom material layer comprises the following components in percentages by weight: 90-93% of wall floor tile waste particles B,7-10% of composite water soluble body B; and the water absorption rate of the wall floor tile waste particles A and the wall floor tile waste particles B is less than 3%. According to the open-type spontaneously generating negative oxygen ion multifunctional permeable brick, rainwater can timely infiltrate into ground, and negative oxygen ions can be efficiently generated, so that air quality is improved, and smog pollution is reduced; and the brick deodorizes water body, reduces acidified rainwater, and has a sterilization function.

Owner:广东净雨环保科技有限公司

Medium temperature sintered cordierite heat-resistant porcelain and preparation method thereof

The invention discloses medium temperature sintered cordierite heat-resistant porcelain and a preparation method thereof. A heat-resistant porcelain rough body is prepared from, by mass, 35-40% of high-temperature sintered talc, 15-30% of alumina powder, 20-30% of clay, 10-20% of feldspar and 5-10% of calcium sulfate nanofiber additive. The preparation method comprises the steps that bisque firing is carried out to 1260 DEG C for 12 h after compounding, ball grinding, fineness detection, discharging, screening for removing iron, additive adding, even stirring, filter pressing and squeezing mud, pugging, aging, mud refining, forming, drying and fettling are carried out, the temperature is kept for 60 min, cooling is performed, and then a heat-resistant porcelain bisque can be obtained. The problems that existing cordierite heat-resistant porcelain is high in bisque synthesis temperature, long in sintering is long and poor in heat stability are solved. The production method is scientific, reasonable and easy to implement, the yield is high, product quality is good, the sintering period can be greatly shortened, the product heat stability is improved, and the market prospect is wide.

Owner:景德镇市大瓷庄瓷业有限公司

Tunnel kiln firing system of foamed ceramic light-weight board

InactiveCN108826967AAvoid Single Stack BurnsRealize automated productionFurnace typesCeramic materials productionTunnel kilnMaterial distribution

The invention discloses a tunnel kiln firing system of a foamed ceramic light-weight board. The tunnel kiln firing system comprises a feeding line, a tunnel kiln and a discharging line, wherein a kilncar comprises a support, the support is provided with a sagger, the sagger comprises a base plate, a surrounding plate and high-temperature-resistant paper, the surrounding plate is erected on the periphery of the base plate, and the base plate and the surrounding plate are both provided with the high-temperature-resistant paper. The feeding line comprises a cleaning unit for cleaning the base plate and the surrounding plate, a first laying unit for laying the high-temperature-resistant paper on the base plate, a surrounding plate erection unit for erecting the surrounding plate on the base plate, a second laying unit for laying the high-temperature-resistant paper on the surrounding plate, a material distribution unit for distributing a material on the sagger formed by the base plate, the surrounding plate and the high-temperature-resistant paper and a conveying unit for delivering the kiln car completing material distribution to the tunnel kiln. The tunnel kiln firing system achieves multi-layer firing, high automatic degree, high production efficiency and cost and space saving.

Owner:KEDA INDUSTRIAL GROUP CO LTD

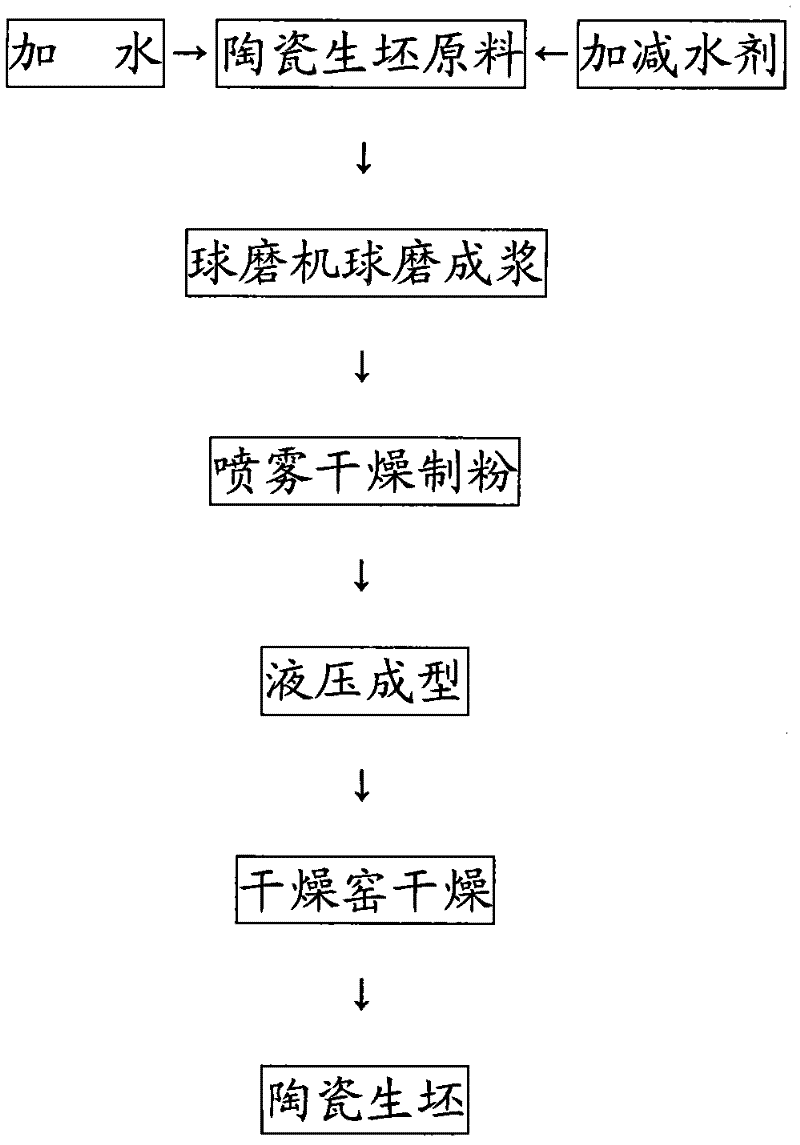

Method for producing green ceramics matched with transparent dry frit pellets

InactiveCN102501302AQuality assuranceAchieve normalizationCeramic shaping apparatusClaywaresPotassiumSlurry

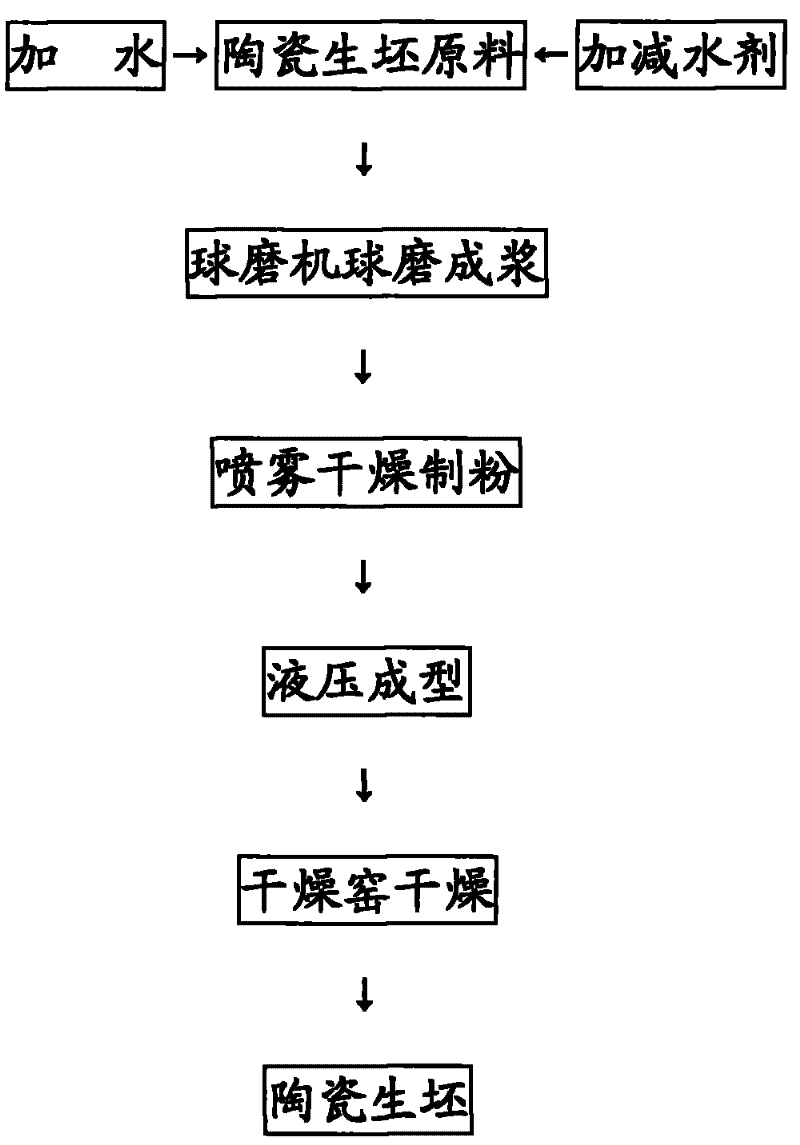

A method for producing green ceramics matched with transparent dry frit pellets relates to the technical field of building materials and includes the steps: selecting materials within the preset range of green ceramic components and standardizing process technology; mixing 385-12250 kilograms of kaolin, 385-12250 kilograms of clay, 385-12250 kilograms of quartz, 385-12250 kilograms of potassium feldspar, 385-12250 kilograms of soda feldspar and 385-12250 kilograms of soapstone which are smaller than 1 millimeter in granularity to form green ceramic raw materials; adding an appropriate amount of water into the green ceramic raw materials and equally adding water reducing agents comprising alkali, water glass and sodium tripolyphosphate, wherein the addition of the water reducing agents is 0.3-0.5% of that of the green ceramic raw materials; ball-milling the materials into slurry by the aid of a ball mill and then spraying and drying the slurry to form powder containing 5.5-6.5% of water; and performing hydraulic forming prior to drying to produce the green ceramics with the range of components including 66-75% of SiO2 (silicon dioxide), 15-25% of Al2O3 (aluminum oxide), 0.5-5% of CaO (calcium oxide)+MgO (magnesium oxide), 2-8% of K2O (potassium oxide)+Na2O (sodium oxide), 0-2% of water reducing agents and less than 0.5% of water. The method is used for producing the green ceramics matched with the transparent dry frit pellets.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

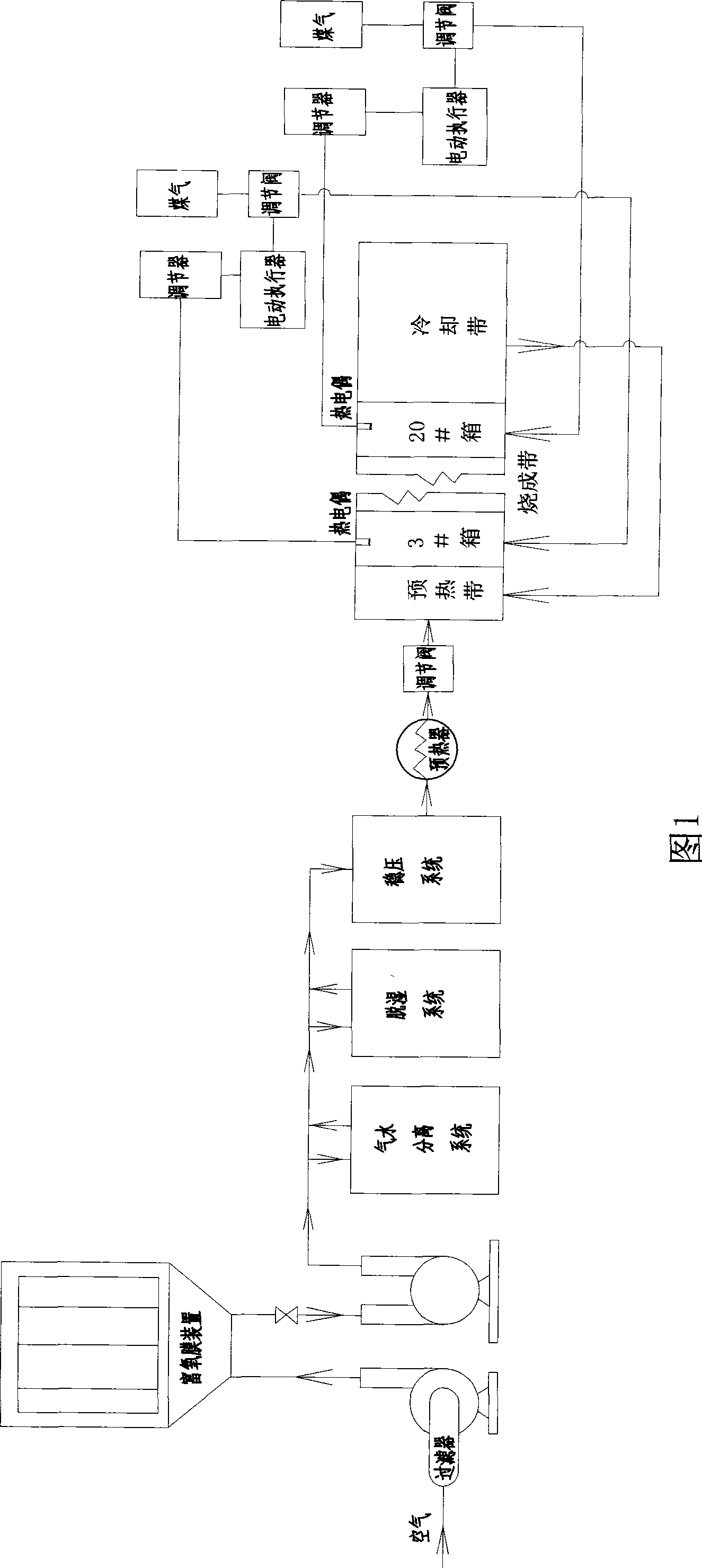

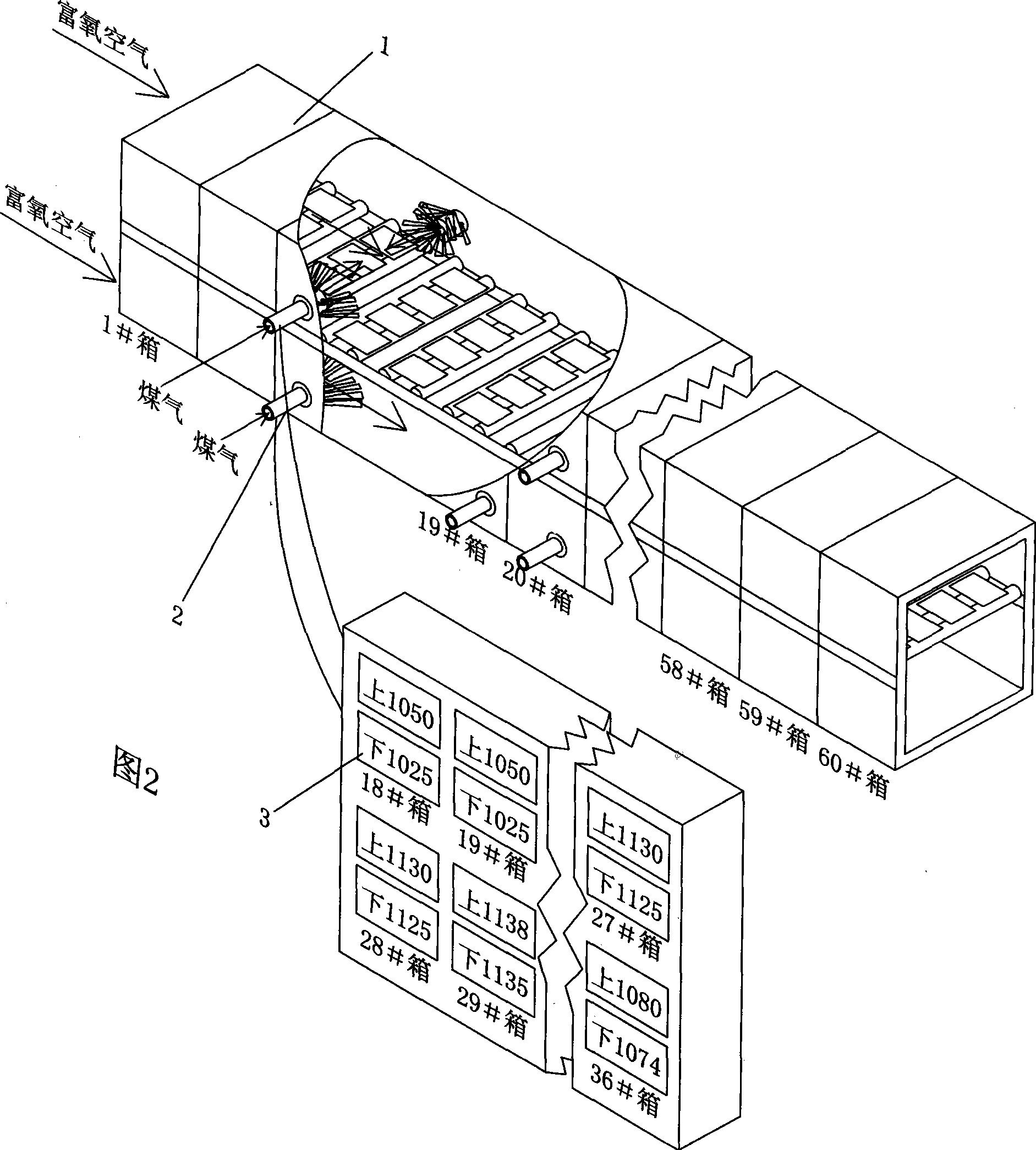

Method for applying membrane oxygen enrichment technology in roller kiln

The invention discloses a method for applying the membrane oxygen enrichment technology in a roller kiln, which is realized through the technical scheme: air is pumped by air input blower through a filter into an oxygen enrichment membrane device, and is transformed into oxygen enriched air under the action of pressure difference; the oxygen enriched air is sent by an air pump to a gas-water separation system and a dehumidification system, then enters a pressure stabilizing system, and finally after being preheated by a heater is sent by an oxygen enrichment nozzle to the upper layer and the lower layer of the manufactured ceramic tile; combustible gas is taken as fuel; the air input direction of the gas fuel is vertical to the air input direction of the oxygen enriched air; the gas fuel is distributed in burner high-speed injection kilns on two sides of the kiln body; and thermocouples distributed in different box bodies are used for testing the temperature in the kiln furnace when necessary, and sending signals to an adjustor which makes comparison between the signals and data set in advance, and issues instructions to an electric actuator to control the divergence of a combustible gas adjusting valve, thereby adjusting the feeding amount of the combustible gas to ensure that the temperature in the kiln remains at the required level.

Owner:王儒林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com