Ceramic green body additive capable of reducing firing temperature as well as preparation method and application thereof

A ceramic body and firing temperature technology, which is applied in the field of ceramic body additives, can solve problems such as lowering the firing temperature, achieve the effects of reducing production costs, simple preparation process, and shortening the firing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Said formula:

[0033] Feldspar 35 parts

[0034] Quartz 30 parts

[0035] Kaolin 6.0 parts

[0036] Talc 6.0 parts

[0037] Lithium feldspar 25 parts

[0038] Lanthanum oxide 1.5 parts

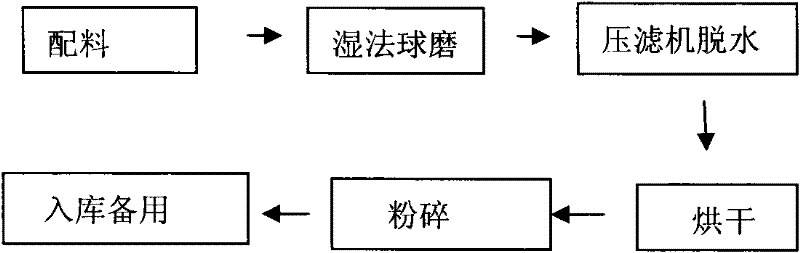

[0039] Such as process figure 1 As shown in the process flow diagram of the present invention, among the six kinds of raw materials used in the preparation of additives in this embodiment, five kinds of potassium feldspar, quartz, kaolin, talc, and lithium feldspar are natural raw materials, purchased in powder form, and one is chemical raw materials la 2 o 3 , with a purity of 99.99%. Raw material fineness passes through 160 mesh sieve. After accurately batching according to the formula, put it into a wet-process ball mill, grind until the fineness exceeds 300 mesh sieve, and discharge when the sieve balance is 0.5% wt. The slurry is pumped into a filter press for dehydration, and the dehydrated mud cake is dried to a moisture content of 1.0-2.0%wt, and then the dried mud ca...

Embodiment 2

[0044] Said formula:

[0045] Feldspar 45 parts

[0046] Quartz 36 parts

[0047] Kaolin 4.0 parts

[0048] Talc 2.0 parts

[0049] Lithium feldspar 18 parts

[0050] Lanthanum oxide 0.5 part.

[0051] Such as process figure 1 As shown in the process flow diagram of the present invention, among the six kinds of raw materials used in the preparation of additives in this embodiment, five kinds of potassium feldspar, quartz, kaolin, talc, and lithium feldspar are natural raw materials, purchased in powder form, and one is chemical raw materials la 2 o 3 , with a purity of 99.99%. Raw material fineness passes through 160 mesh sieve. After accurately proportioning according to the formula, put it into a wet-process ball mill, grind until the fineness exceeds 300 mesh sieve, and discharge when the sieve balance is 1% wt. The slurry is pumped into a filter press for dehydration, and the dehydrated mud cake is dried to a moisture content of 1.0-2.0%wt, and then the dried mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com