Control method for firing high-performance quartz ceramic

A technology of quartz ceramics and control methods, which is applied in the field of high-performance quartz ceramics, and can solve problems such as increased energy consumption during holding time, increased thermal expansion coefficient, and unreasonable gradation of quartz ceramic embryo particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

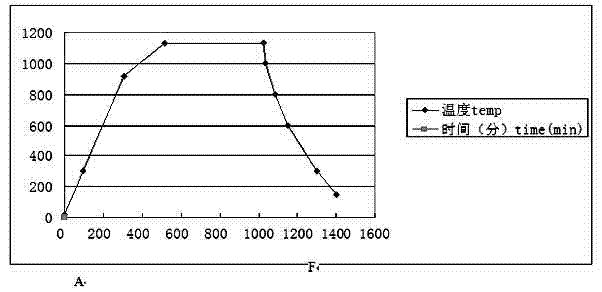

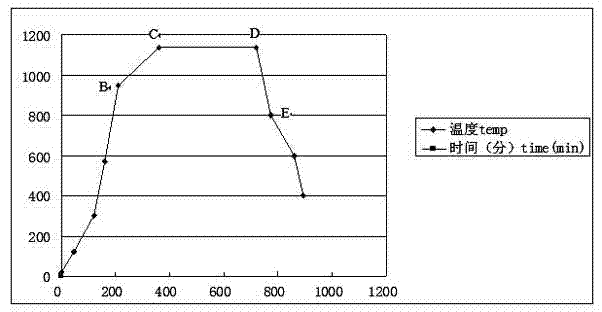

Image

Examples

Embodiment

[0014] Embodiment: A method for controlling the firing of high-performance quartz ceramics for polysilicon ingots, the main steps of which are:

[0015] Choose 1100Kg of bulk quartz sand raw materials with a silica content of 99.00%, and 2200Kg of high-purity quartz sand particles with a size of 0-60mm. Add 1000L of purified water for 12 hours of ball milling, and then transfer to a homogenization tank for homogenization. After 6 days of homogenization, it reaches the slurry design control range, the particle size diameter (D10%) is 1.47um, and the density is between 1825g / cm3. Viscosity 260cPs. Then carry out secondary granulation according to the ratio of 75% (weight percent) of slurry, 20% (weight percent) of 50-100 mesh high-purity quartz sand granules, and 5% (weight percent) of 100-200 mesh high-purity quartz sand granules. Gradation ratio, then add 0.1% (weight percent) glue for stirring, fast and slow stirring for 5 minutes respectively, the test viscosity value reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com