Method for producing green ceramics matched with transparent dry frit pellets

A technology of transparent frit and production method, which is applied in the field of building materials and building materials of glass ceramics. It can solve the problems of no composition range requirements for ceramic green bodies, no standard specifications for ceramic green bodies, and inconsistent manufacturing processes, etc., so as to shorten the firing cycle. , The effect is stable and reliable, and the conception is scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

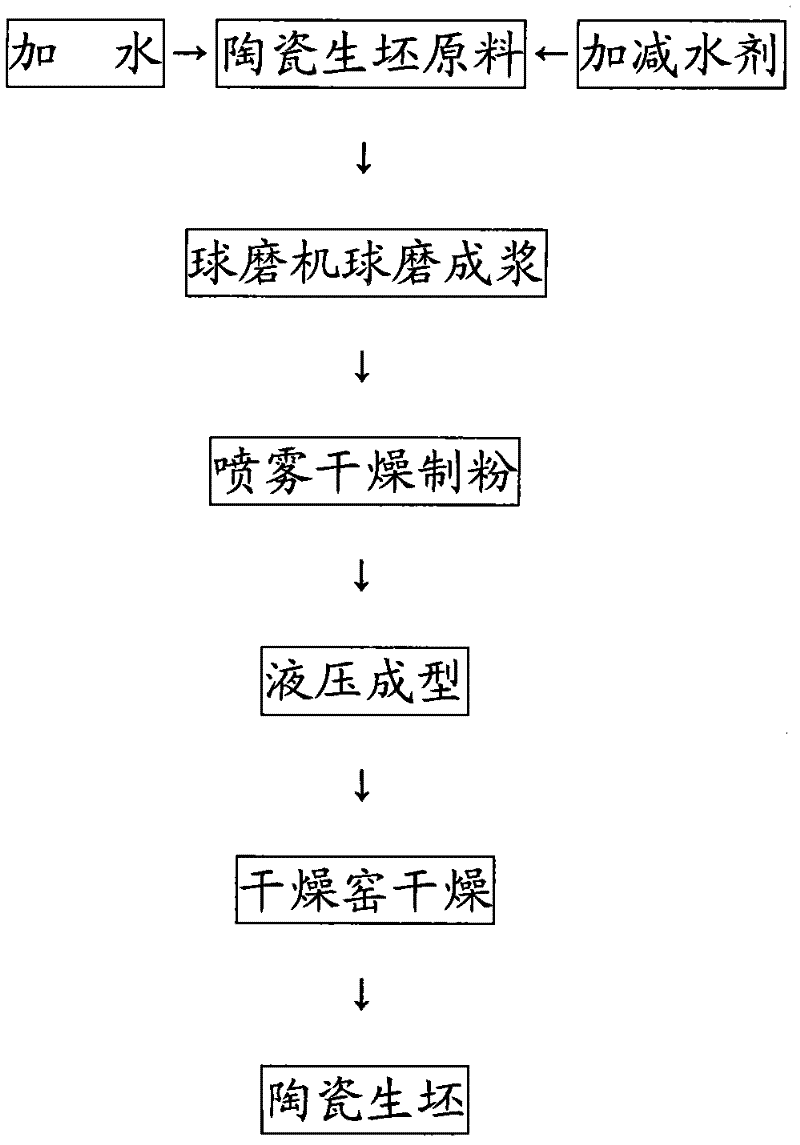

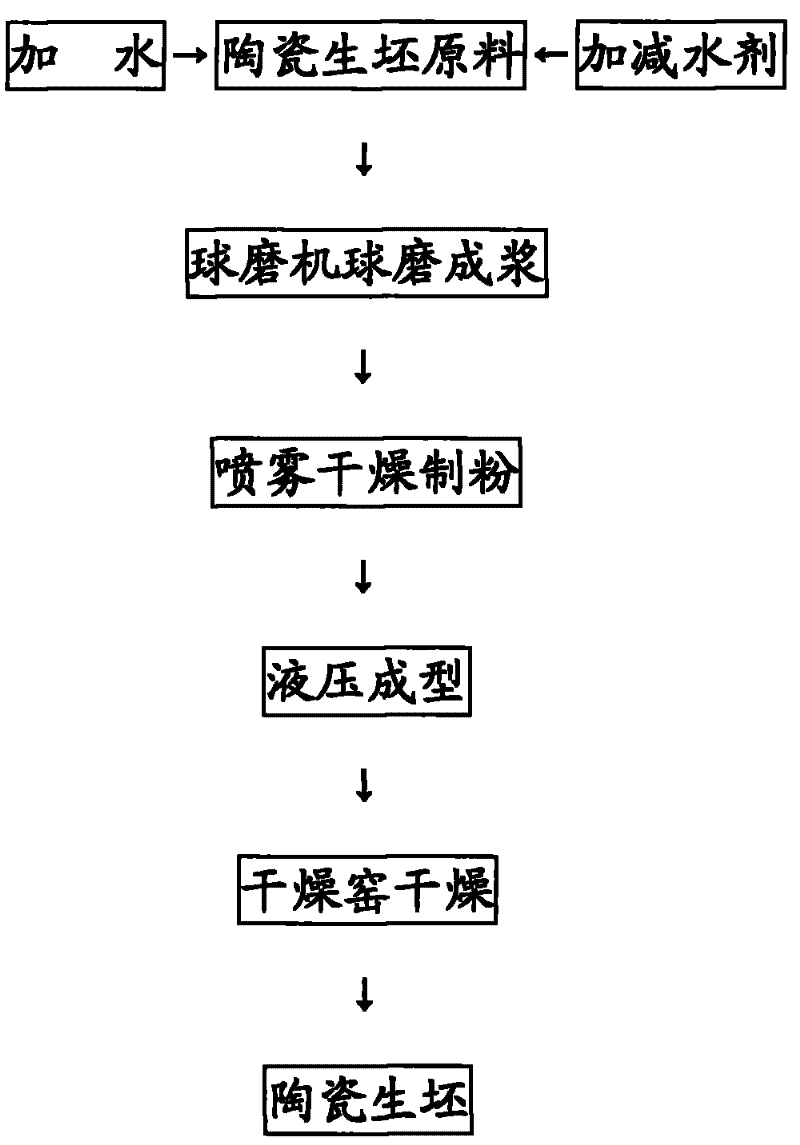

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0019] A ceramic green body production method matching transparent frit dry particles, using 385-12250 kg each of kaolin, clay, quartz, potassium feldspar, albite feldspar, and talc with a particle size of less than 1 mm as raw materials for ceramic green bodies. Add an appropriate amount of water to the ceramic green body raw material, and add alkali, water glass, and sodium tripolyphosphate equally as a water reducing agent, and the amount of the water reducing agent added is 0.3-0.5% of the ceramic green body raw material , after being ball-milled into a slurry by a ball mill, it is spray-dried to make powder, and the moisture after the spray-dried powder is 5.5-6.5%, and then hydraulically formed by an automatic hydraulic machine, and then dried in a drying kiln to obtain a composition range of SiO 2 66-75%, Al 2 o 3 15...

specific Embodiment approach 2

[0024]Carry out according to specific embodiment 1, just as shown in the accompanying drawing of description, just: this ceramic green body production method of matching transparent frit dry grain, with particle size less than 1 millimeter kaolin, clay, quartz, potassium feldspar, albite , Talc is mixed as ceramic green body raw material, in described ceramic green body raw material, add appropriate amount of water, and evenly add alkali, water glass, sodium tripolyphosphate as water reducing agent, the quantity of adding described water reducing agent is 0.3-0.5% of the ceramic green body raw material is ball milled into a slurry and then spray-dried to make powder. The moisture after the spray-dried powder is 5.5-6.5%, and then hydraulically formed by an automatic hydraulic machine, and then dried Kiln drying yields compositions ranging from SiO 2 66-75%, Al 2 o 3 15-25%, CaO+MgO 0.5-5%, K 2 O+Na 2 Ceramic green body with O 2-8%, water reducing agent 0-2%, and moisture ...

specific Embodiment approach 3

[0028] Carry out according to specific embodiment one, just as shown in the accompanying drawing of description, just: the ceramic green body production method of this matching transparent frit dry grain, the composition of ceramic green body is set as SiO 2 67.72%, Al 2 o 3 19.82%, CaO+MgO 2.62%, K 2 O+Na 2 O 5.37%, Fe 2 o 3 0.64%, TiO 2 0.21%, loss on ignition 3.62%, according to the composition of the ceramic green body, select black mud, kaolin, high-temperature sand, medium-temperature sand, low-temperature sand, potassium Sand and talc are used as raw materials for ceramic green bodies. Each batch weighs 35,000 kg. After mixing, add 0.4% sodium tripolyphosphate and 0.2% soda ash as water reducers, and add 0.55 times the weight of ceramic green body raw materials at the same time. The water is ball-milled in a ball mill into a slurry with a fineness of 0.5-1% of the sieve with ten thousand holes, and then sprayed and granulated to make a powder with a water cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com