Patents

Literature

2581 results about "Potassium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium oxide (K₂O) or Kalium oxide is an ionic compound of potassium and oxygen. This pale yellow solid, the simplest oxide of potassium, is a rarely encountered, highly reactive compound. Some materials of commerce, such as fertilizers and cements, are assayed assuming the percent composition that would be equivalent to the chemical compound mixture K₂O.

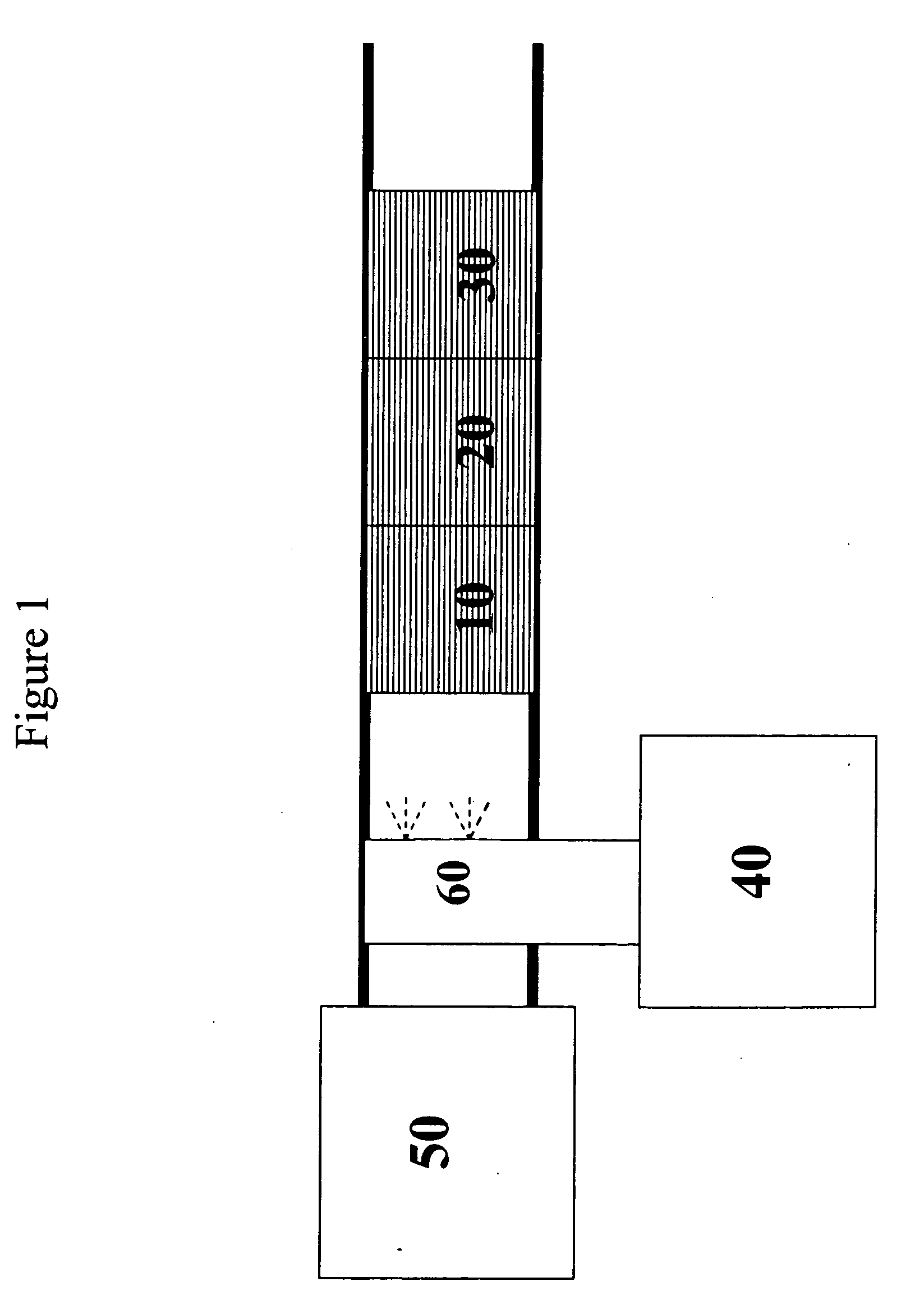

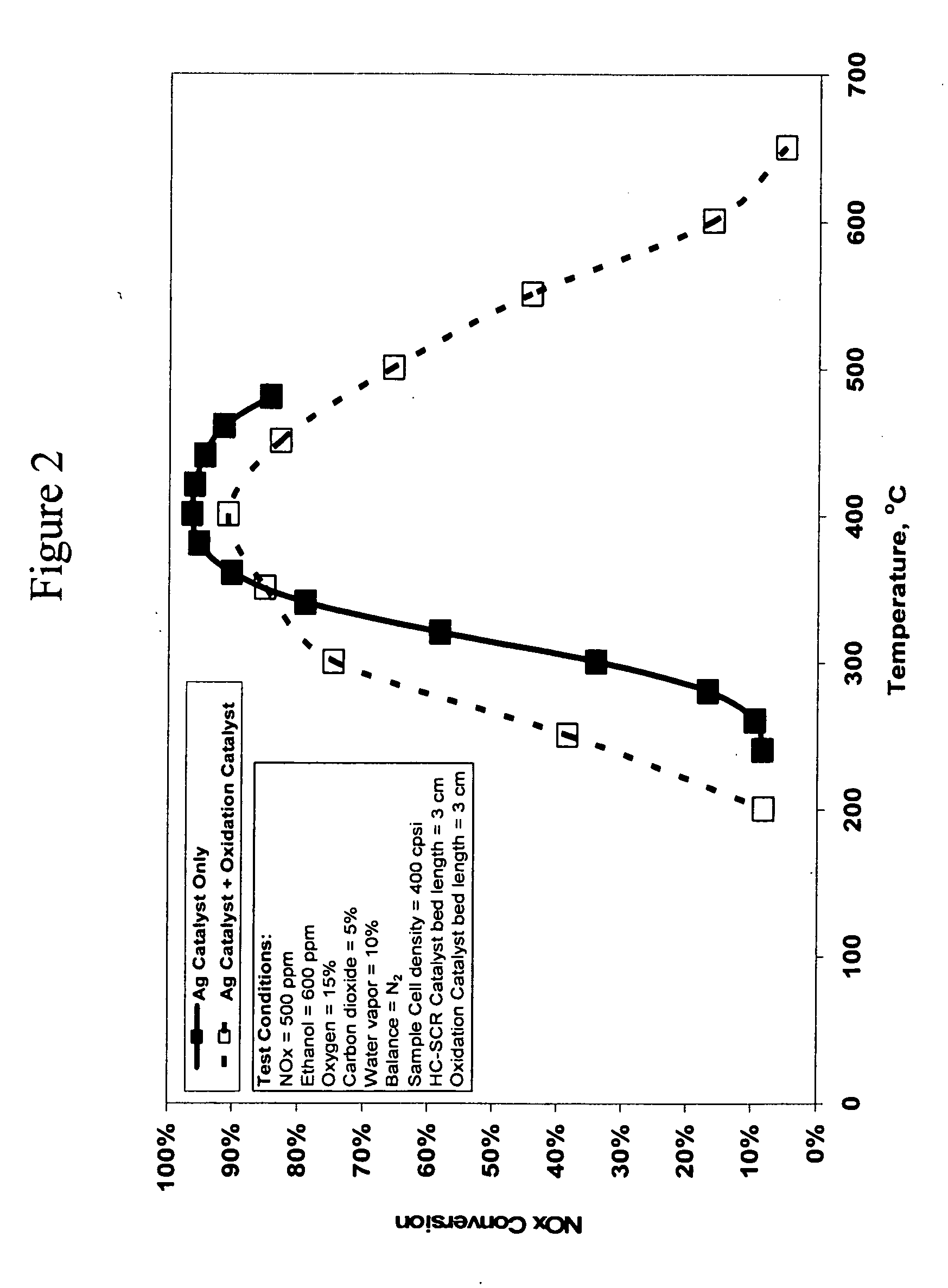

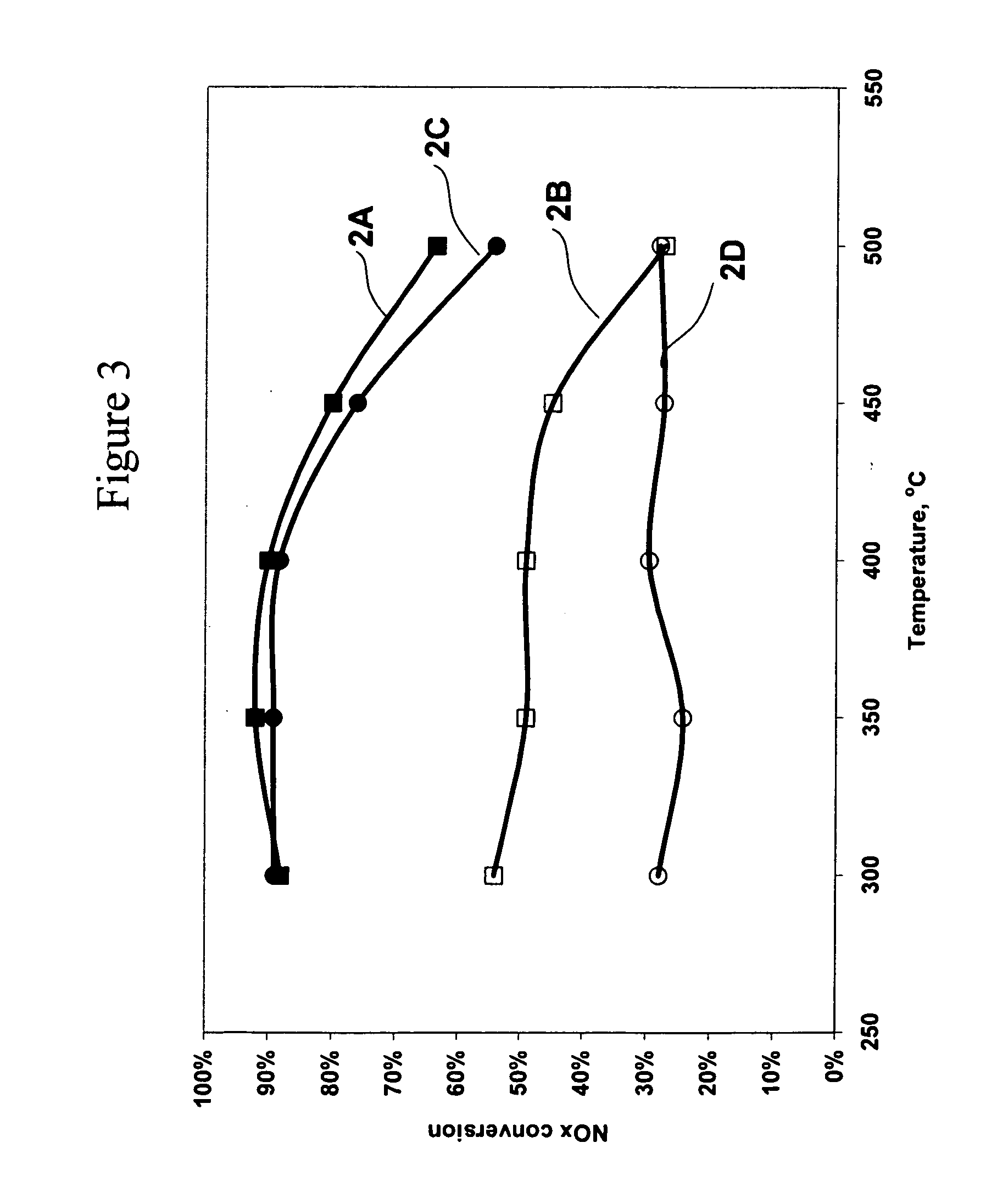

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

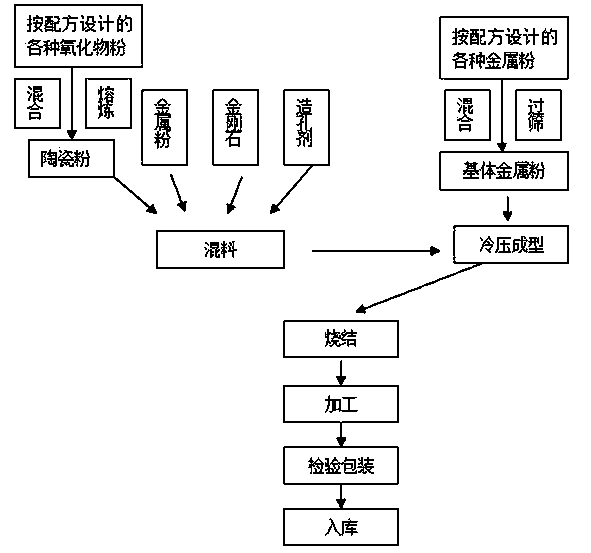

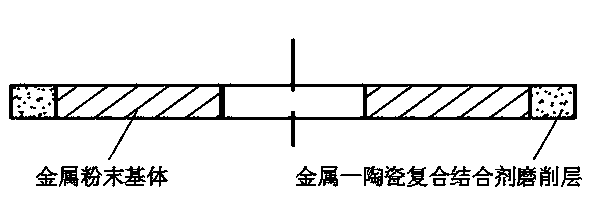

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

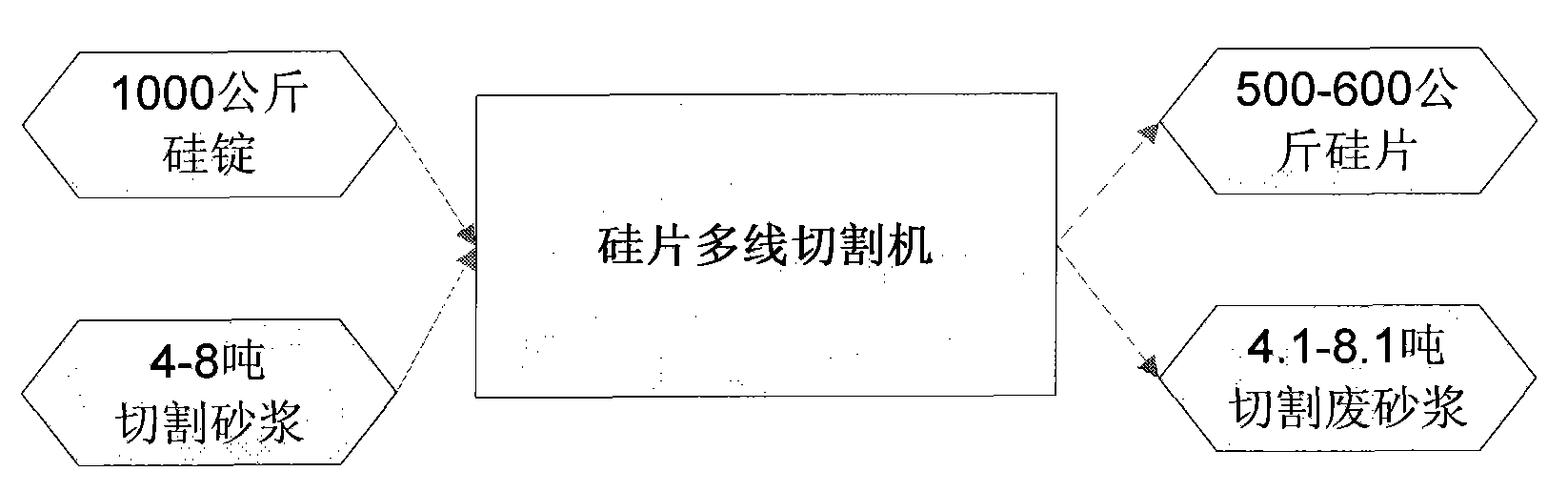

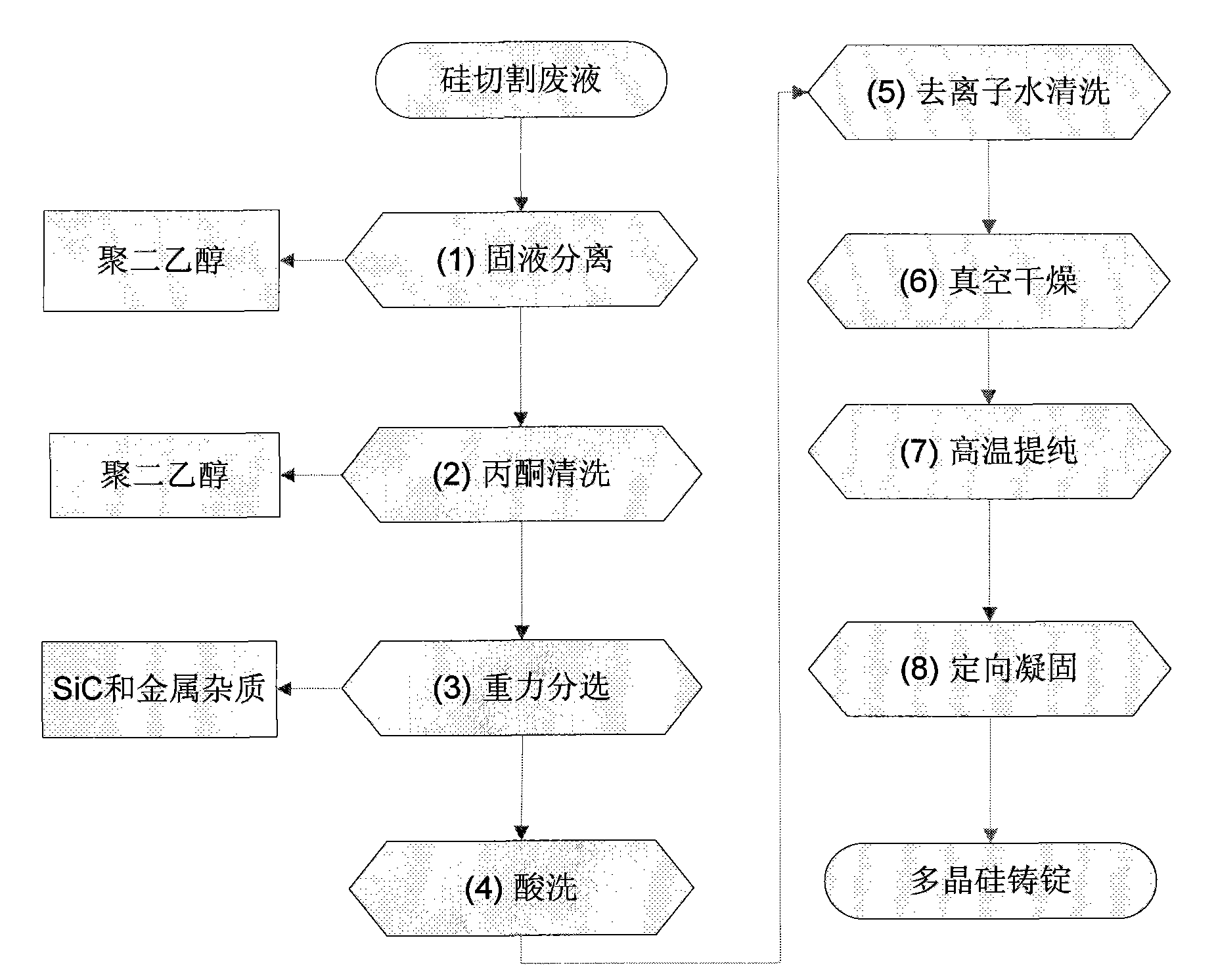

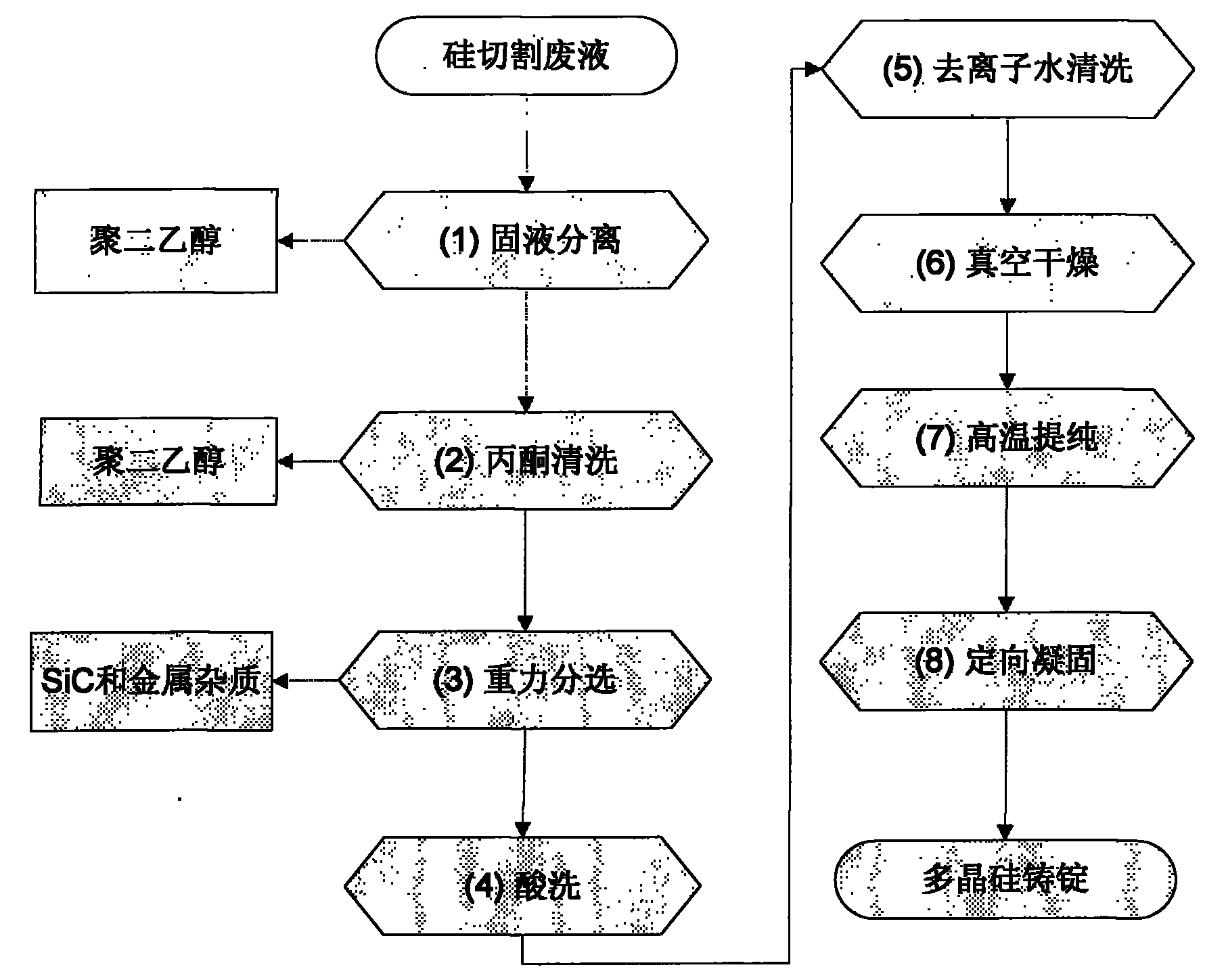

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

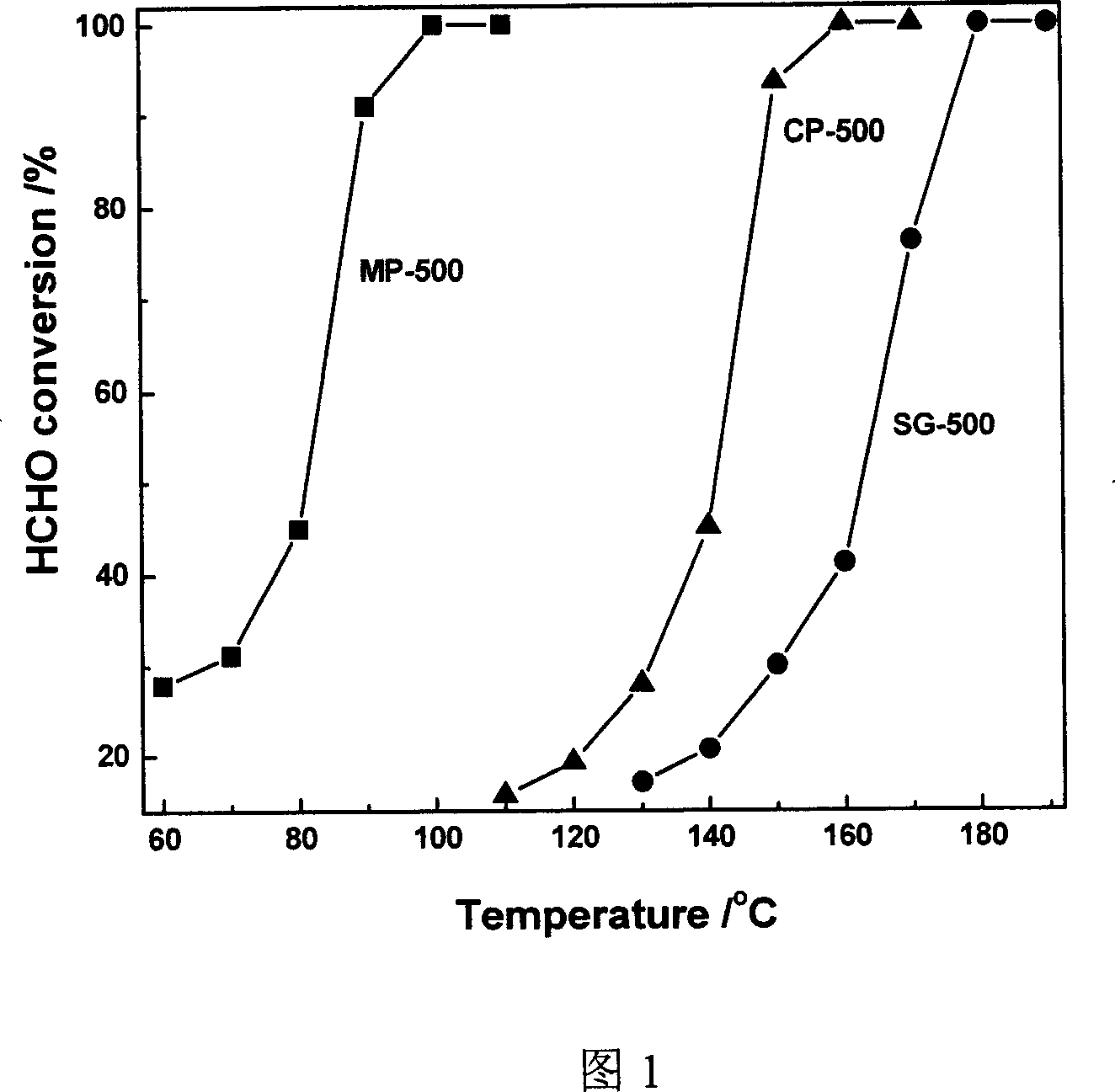

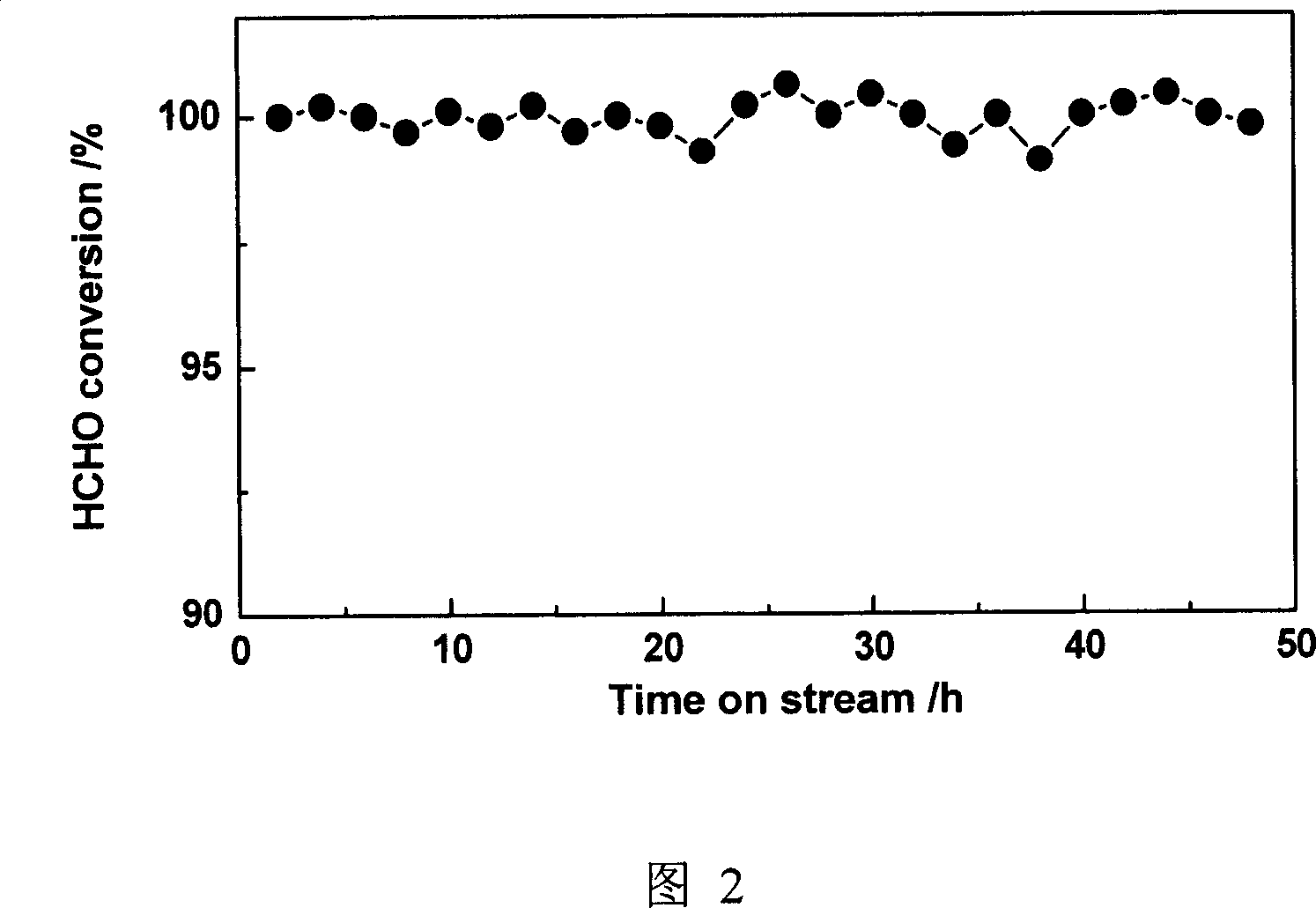

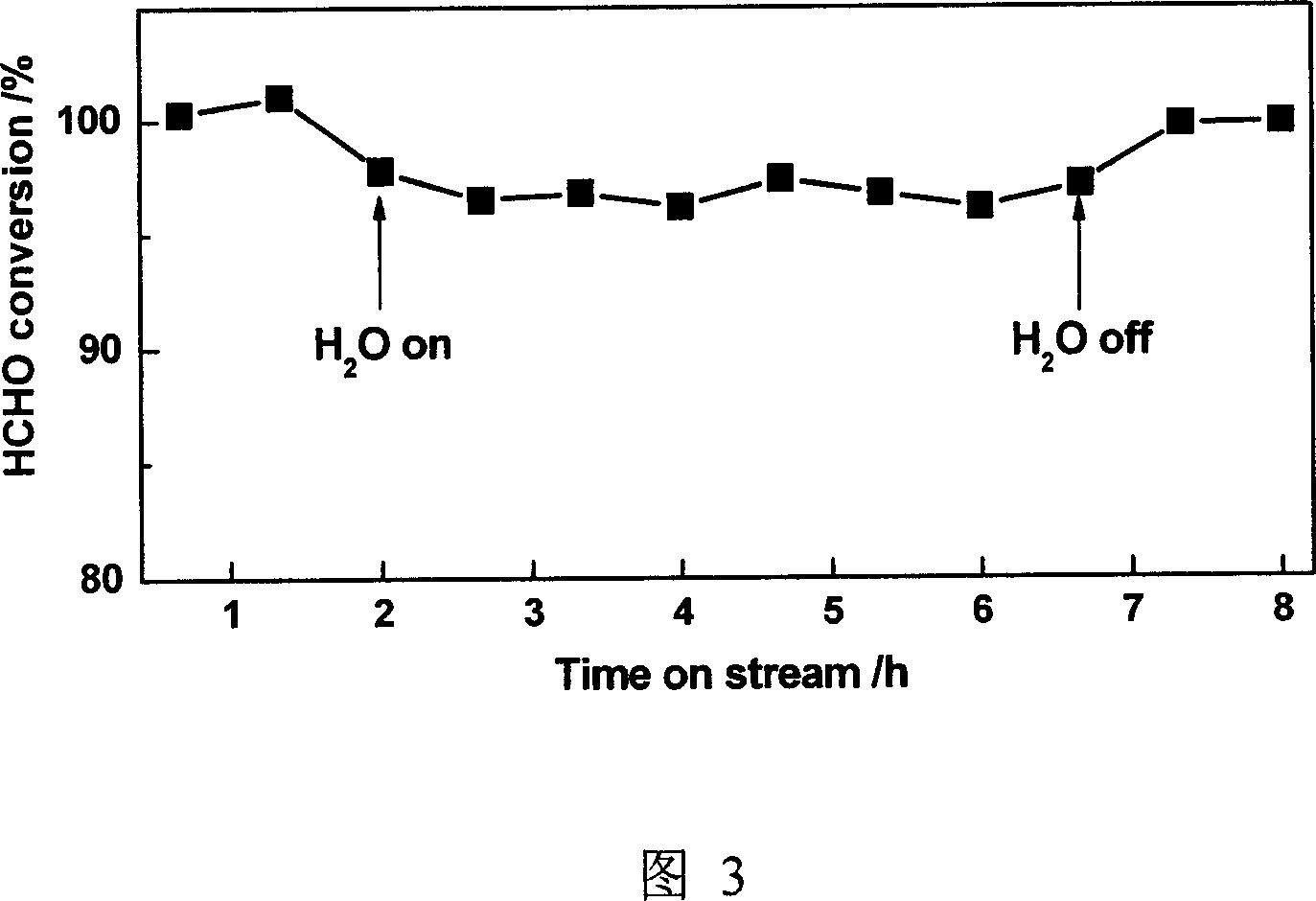

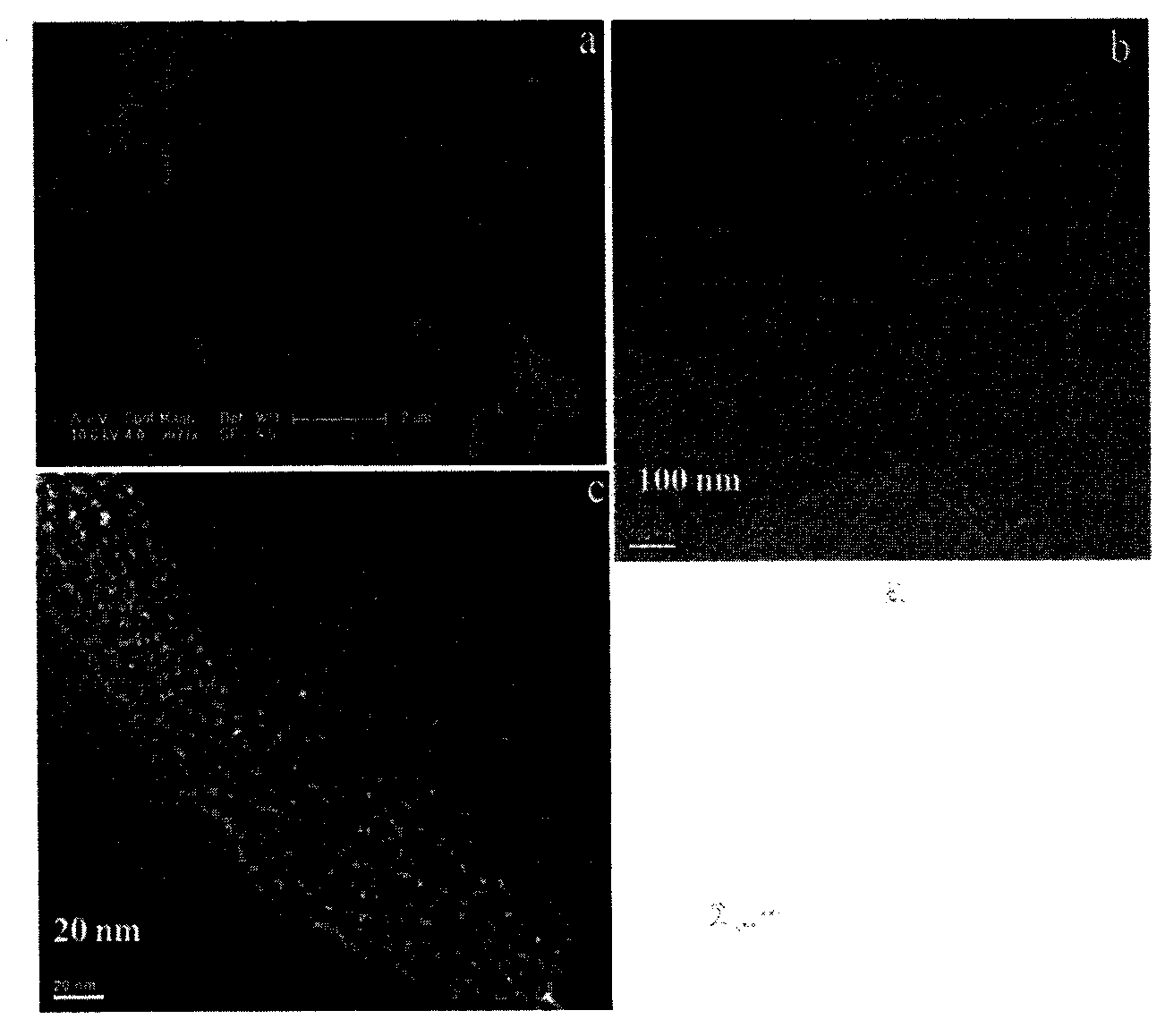

Manganese cerium composite oxide catalyst, its production and use

InactiveCN101028595AStrong interactionHigh activityDispersed particle separationCatalyst activation/preparationNitrateManganese

A composite Mn-Ce oxide catalyst for oxidizing the form-aldehyde into CO2 and H2O is prepared through adding soluble manganese nitrate in the solution of potassium permanganate and cerium ammonium nitrate while stirring, adding potassium hydroxide, stirring to obtain deposit, filtering, washing, drying at 80-120 deg.C and calcining.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preferred materials for pigmented ink jet ink

InactiveUS6866379B2Measurement apparatus componentsDuplicating/marking methodsAddition polymerLithium hydroxide

An ink jet ink composition including from 40.0 to 99.0% by weight of water; from 0.1 to 20.0% by weight of a pigment dispersed with an oleoyl methyl taurine salt dispersant from 0 to 70.0% by weight of a water miscible co-solvent; and from 0.1 to 20.0% by weight of a water-reducible addition polymer; wherein the weight average molecular weight of the polymer is from 2,000 to 100,000; the acid number is from 50 to 400; and the acid group on the polymer is neutralized by an alkaline metal hydroxide such as lithium hydroxide, sodium hydroxide potassium hydroxide, or a mixture thereof; and wherein all weight percentages are based on the total weight of the ink composition. An ink jet printing method is also disclosed.

Owner:EASTMAN KODAK CO

Biological multi-effect fertilizer

ActiveCN101492324AEffective controlReduce reproductive rateOrganic fertilisersFertilizer mixturesMedicinal herbsPins needles

The invention discloses a multi-effect biofertilizer, comprising sarcandra glabra, cortex fraxini, radix stemonae, lightyellow sophora root, pin needles, isatis root, phellodendron, aloe, humic acid and inorganic fertilizers of nitrogen, phosphorus and potassium; the weight percentages of the components are as follows: 1-2.5% of sarcandra glabra extract, 1-2.5% of radix stemonae extract, 1-2.5% of phellodendron extract, 5-10% of aloe extract, 10-15% of pin needles, 7-10% of isatis root, 7-10% of cortex fraxini, 10-15% of lightyellow sophora root, 15-20% of humic acid, 10-20% of available nitrogen, 5-10% of phosphorus pentoxide and 5-10% of potassium oxide. The Chinese medicinal herbs of the invention have the advantages of sterilization and disinfestation, safety without pollution, combined herbs and fertilizers, compound multielements, comprehensive nutrition, long-acting slow release and improved utilization rate. The multi-effect biofertilizer can be widely applied to such cash crops as corn, cotton, rapeseed plants, peanuts, legume, silkworm and mulberry, tea forests, fruit grove and various vegetables.

Owner:何同林

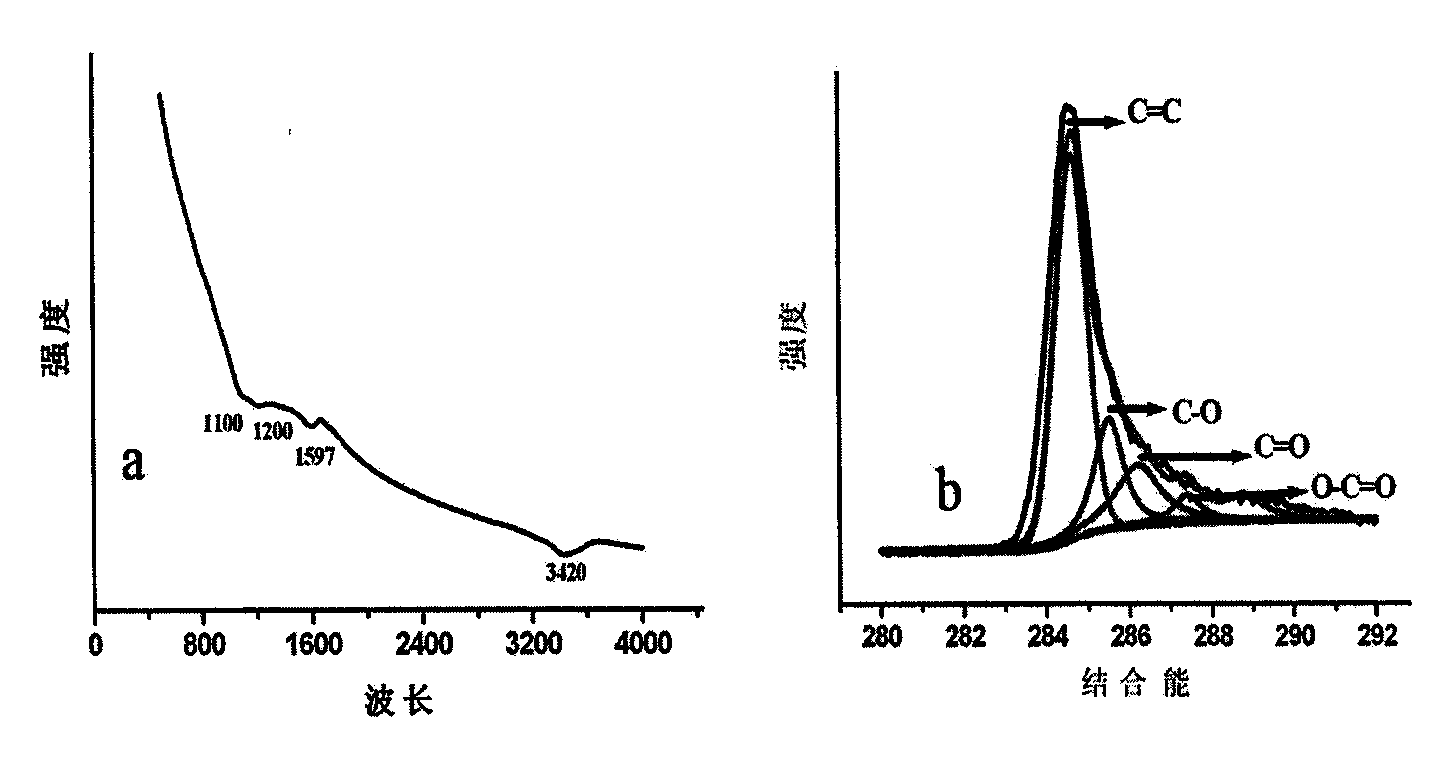

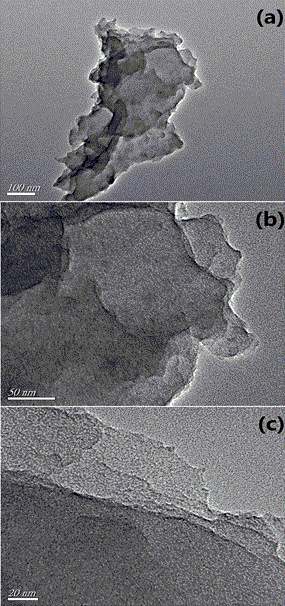

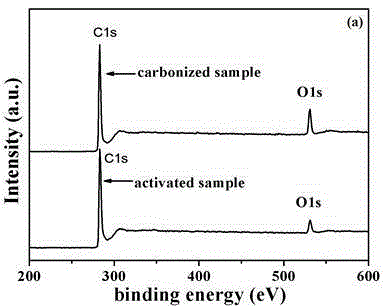

Method for preparing activated carbon material with humic acid as raw material and application of activated carbon material

InactiveCN103641117ALarge reservesLarge specific surface areaCarbon compoundsOther chemical processesCapacitancePotassium hydroxide

The invention relates to a method for preparing activated carbon with humic acid as a raw material and an application of the activated carbon. The method comprises the steps of mixing industrial humic acid with an activating agent which is potassium hydroxide, sodium hydroxide, zinc chloride, potassium carbonate or phosphoric acid uniformly to react under inert atmosphere protection for 1-5 hours; then cooling the product, washing the product in an acid solution until the pH value is 6-7 and drying the product, thus obtaining the activated carbon. The method is convenient to operate, is relatively low in energy consumption and is suitable for large-scale industrial production. The humic acid porous activated carbon material obtained by the method has a rich porous structure and a relatively big specific surface area, is used for preparing water purifiers or electrode materials of supercapacitors, and has methylene blue dye adsorption value of 600mg / g. Besides, the humic acid porous activated carbon material is used as the electrode material of a supercapacitor to assemble a high-performance supercapacitor. The specific capacitance of the activated carbon single electrode is 351Fg<-1>. Various test results show that the activated carbon is microporous-mesoporous composite carbon and has specific surface area of about 3200m<2> / g, the pore size distribution of the activated carbon is 1-5nm, and the pore volume of the activated carbon is about 2cm<3> / g.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

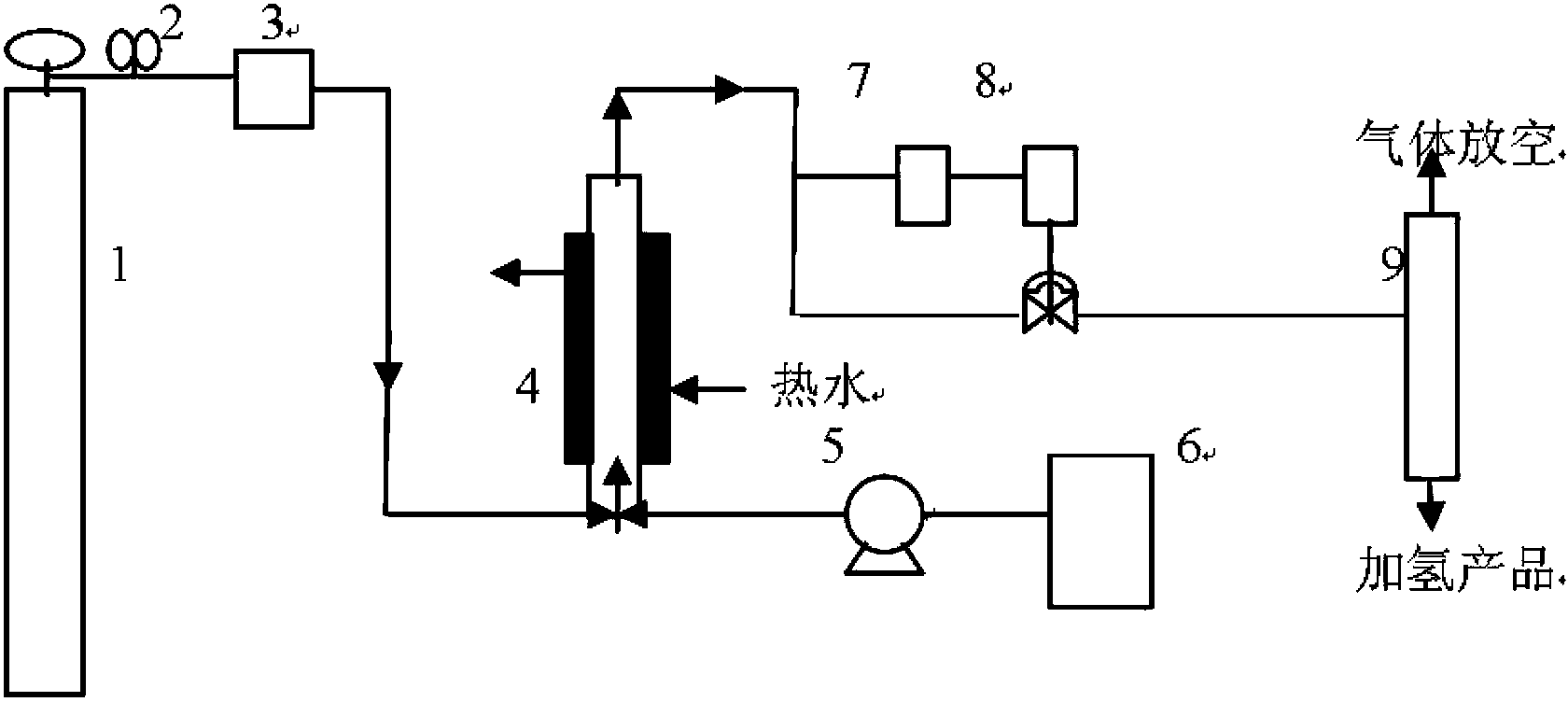

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

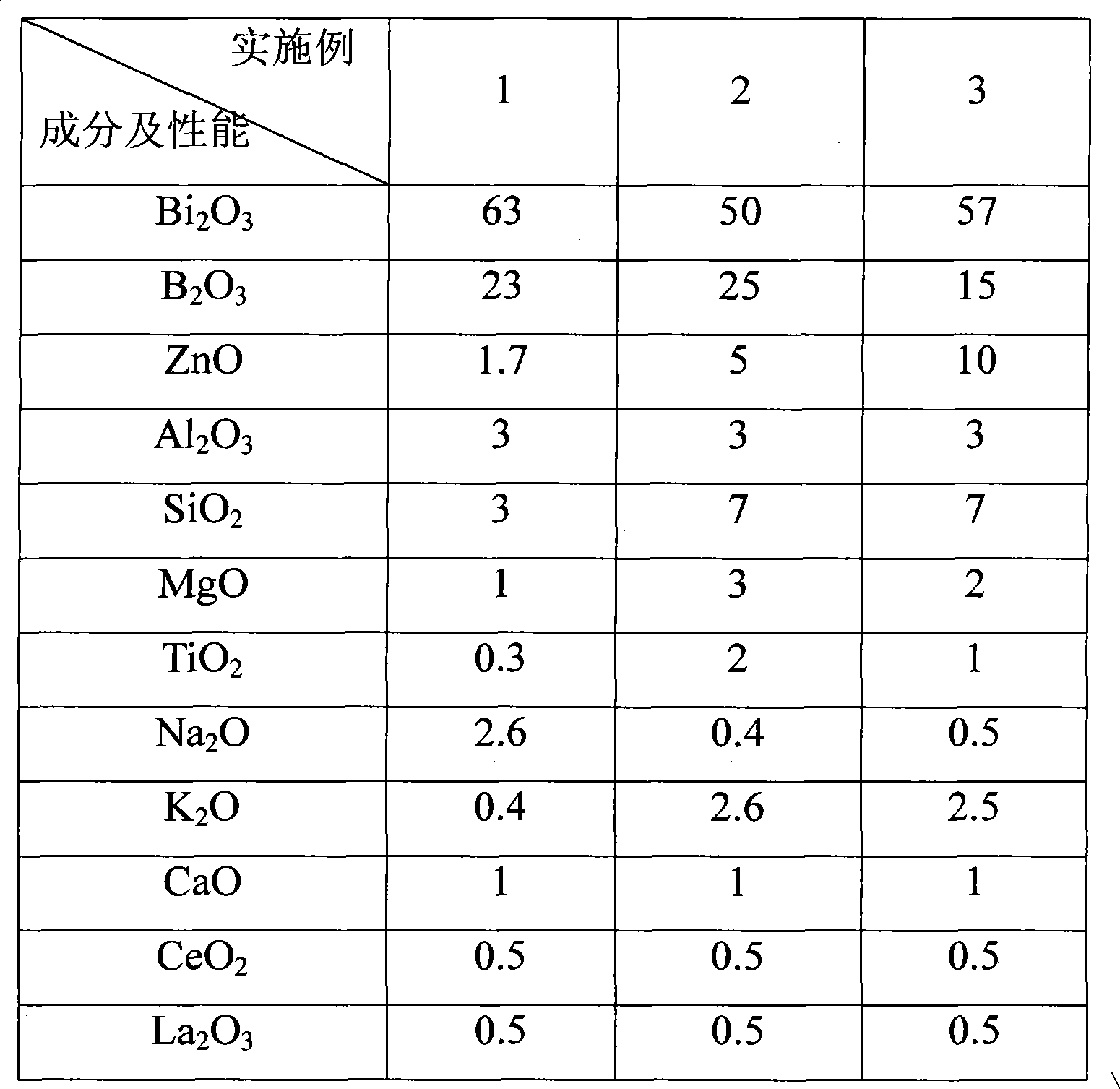

Low-melting point lead-less glasses powder for frit slurry, and preparation and use thereof

The invention discloses lead-free glass dust with low melting point used for glass frit slurry, as well as the preparation method and the application thereof. The lead-free glass dust is characterized in that the compositions have the following weight percentages: 50%-70% of bismuth oxide, 0.1%-30% of boric oxide, 0.1%-30% of zinc oxide, 0.1%-10% of aluminium oxide, 0.1%-10% of silicon oxide, 0.1%-10% of magnesia magnesium oxide, 0.1%-10% of titania titanium dioxide, 0.1%-5% of sodium monoxide, 0.1%-5% of potassium oxide, 0.1%-5% of calcium oxide, 0.1%-2% of cerium oxide, and 0.1%-2% of cerium oxide. The preparation method comprises the following steps: all raw materials are fully mixed; the mixed mixture is put into a crucible, and is then put into an electric furnace at the furnace temperature of 1200-1450 DEG C; the melted glass slurry is poured into a tablet machine for being pressed into sheets or poured into cold water; the flaky or granule glass and dye are put into a ball mill together for ball milling; the glass dust after the ball milling process is screened and bagged; and the glass dust is applicable to the glass frit slurry field of the dielectric layers of plasma displays, fluorescent displays and the like. The invention has the advantages that the glass dust has good insulation and high dielectric constant, and is applicable to screen printing.

Owner:陈培

Method for conversion of atmospheric carbon dioxide into useful materials

A method for converting carbon dioxide in a gaseous environment, including air into useful materials by use of renewable energy sources which comprises:(1) extracting carbon dioxide from a gaseous source using a sorbent such as sodium hydroxide, calcium hydroxide, or potassium hydroxide;(2) utilizing wind power, solar power, or other renewable energy sources to regenerate said sorbent by membrane cell electrolysis or other similar method, simultaneously producing hydrogen (H2) gas;(3) releasing carbon dioxide from said sorbent; and(4) utilizing the Fischer Tropsch process, Mobil process, ICI process, or related or similar processes to convert carbon oxides to a hydrocarbon concomittantly with or after effecting the reverse water-gas shift reaction to convert said CO2 and H2 gas into carbon monoxide for reaction in said Fischer Tropsch process, Mobil process or ICI process.

Owner:KAPLAN THOMAS PROGER

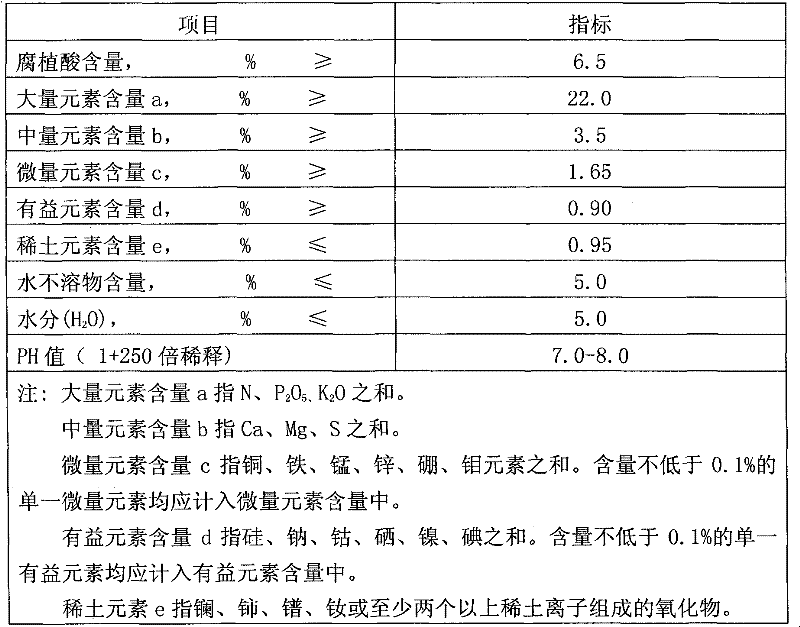

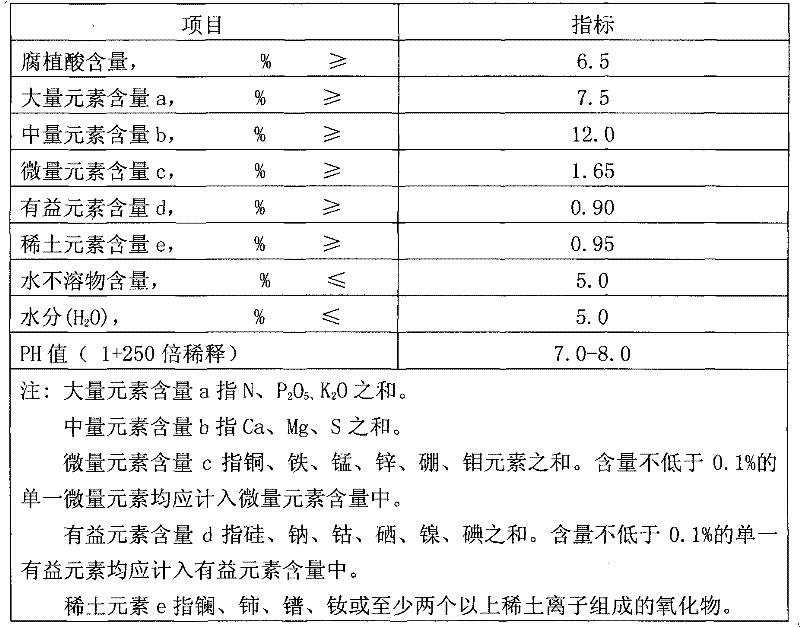

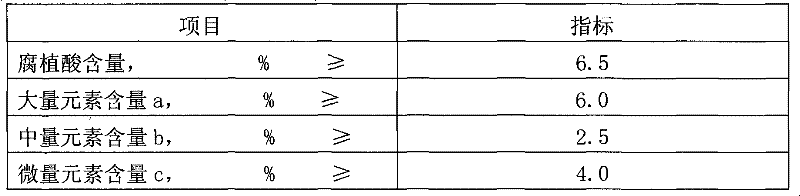

Water-soluble fertilizer containing humic acid chelating multielement and preparation method thereof

InactiveCN102190521AAvoid antagonismPromote absorptionFertilizer mixturesRare-earth elementHigh absorption

The invention, belonging to the technical filed of agriculture, relates to a water-soluble fertilizer containing humic acid chelating multielement and a preparation method thereof. The water-soluble fertilizer is formed through a chelating process of raw materials, and the component of the raw materials comprises (by weight parts): 10 potassium humate powder containing more than 50 wt% humic acid, more than 50 wt% kali and no more than 3wt% water insolubles, 48-52 water, 7-24 macroelement compound, 4-18 mediumelement compound, 7.5-23.5 microelement compound, 2.5 beneficial element compound, 2rare earth element compound and 1.3-1.7 auxiliary agent. The preparation method includes seven steps. The water-soluble fertilizer has the advantages of complete nutrients, good compatibleness of nutrient elements, and high absorption and utilization of nutrient elements.

Owner:BEIJING ZHONGYAN MEIHUA BIOCHEM INST

High-toughness enamel glaze

InactiveCN108658462AImprove toughnessOvercome the defect of porcelain crackLithium oxideSilicon dioxide

The invention discloses high-toughness enamel glaze. The enamel glaze is prepared from the following components in parts by weight: 40-50 parts of silicon dioxide, 15-25 parts of titanium dioxide, 5-15 parts of potassium oxide, 10-20 parts of sodium oxide, 1-5 parts of lithium oxide, 2-4 parts of calcium fluoride, 6-12 parts of vanadium pentoxide, 1-3 parts of tungsten carbide and 5-10 parts of aluminum oxide and zirconium dioxide. According to the enamel glaze, by means of the composition, the toughness of the enamel glaze can be greatly improved, meanwhile, the defect that ceramic cracks arecaused due to collision can be overcome, and therefore, the enamel glaze has a wide application prospect.

Owner:沙冰娟

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

Fused iron catalyst for producing light olefins from syngas and preparation method and application thereof

ActiveCN101757925APreparation raw materials are cheapRaw materials are readily availableHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasFluidized bed

The invention provides fused iron catalyst for producing light olefins from syngas and a preparation method and application thereof. The fused iron catalyst includes iron oxide and cocatalyst and the proportion of the components is as follows by weight percent: 0.1-5 alumina, 0.1-6 potassium oxide, 0.1-4.0 calcium oxide and 0.01-8.5 other oxides, and balance iron oxide. The fused iron catalyst has the beneficial effects that (1) the materials of the fused iron catalyst are cheap and easy to get, the preparation process is simple, and the fused iron catalyst is low in cost and is suitable for industrial production; (2) the fused iron catalyst is of high mechanical strength as well as good pressure resistance and abrasion resistance and is suitable for a fixed bed, a fluidized bed and a slurry bed reactor; and (3) the fused iron catalyst has high Fischer-Tropsch synthesis activity and selectivity, the conversion per pass can be more than 95%, the selectivity of the methane is less than 10% and the content of the light olefins can reach 80-90%.

Owner:ZHEJIANG UNIV OF TECH

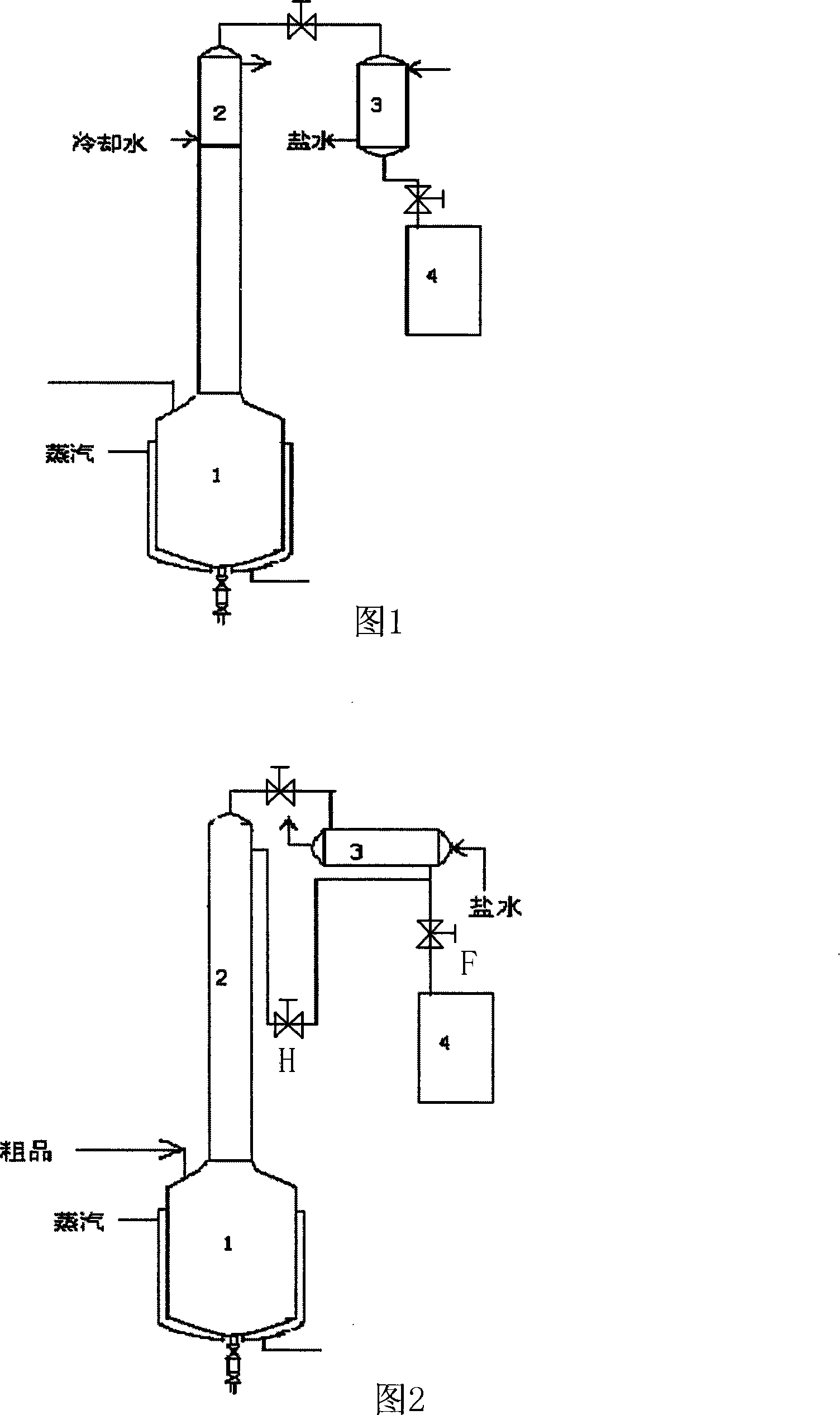

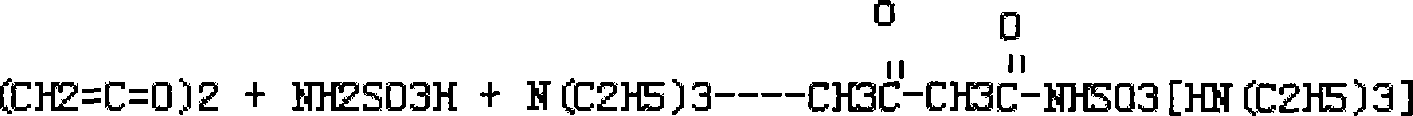

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

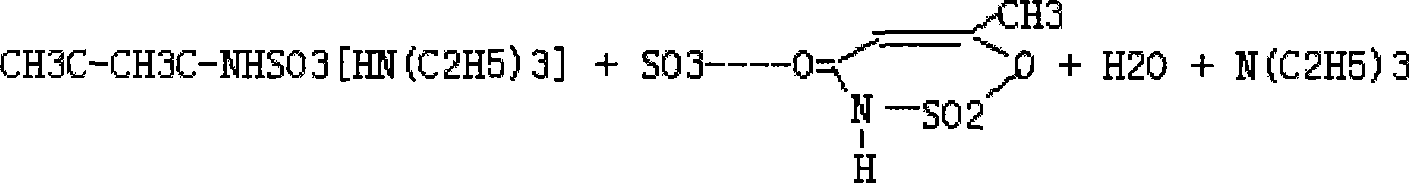

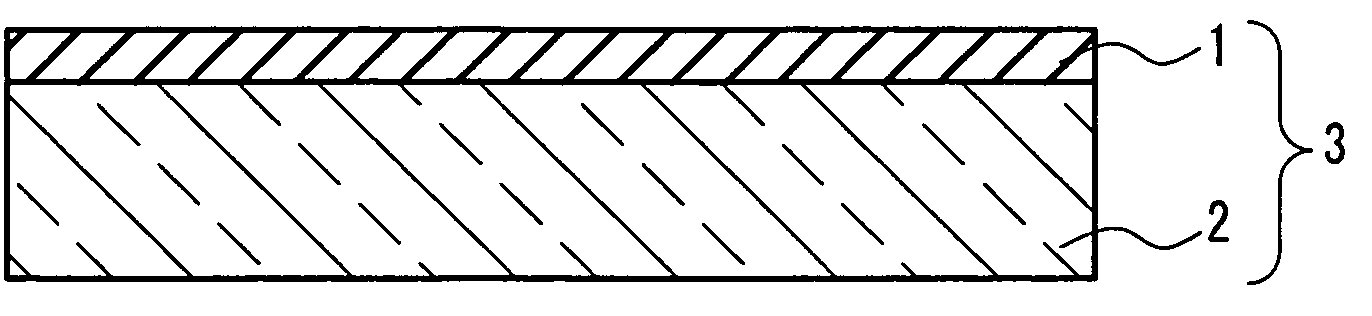

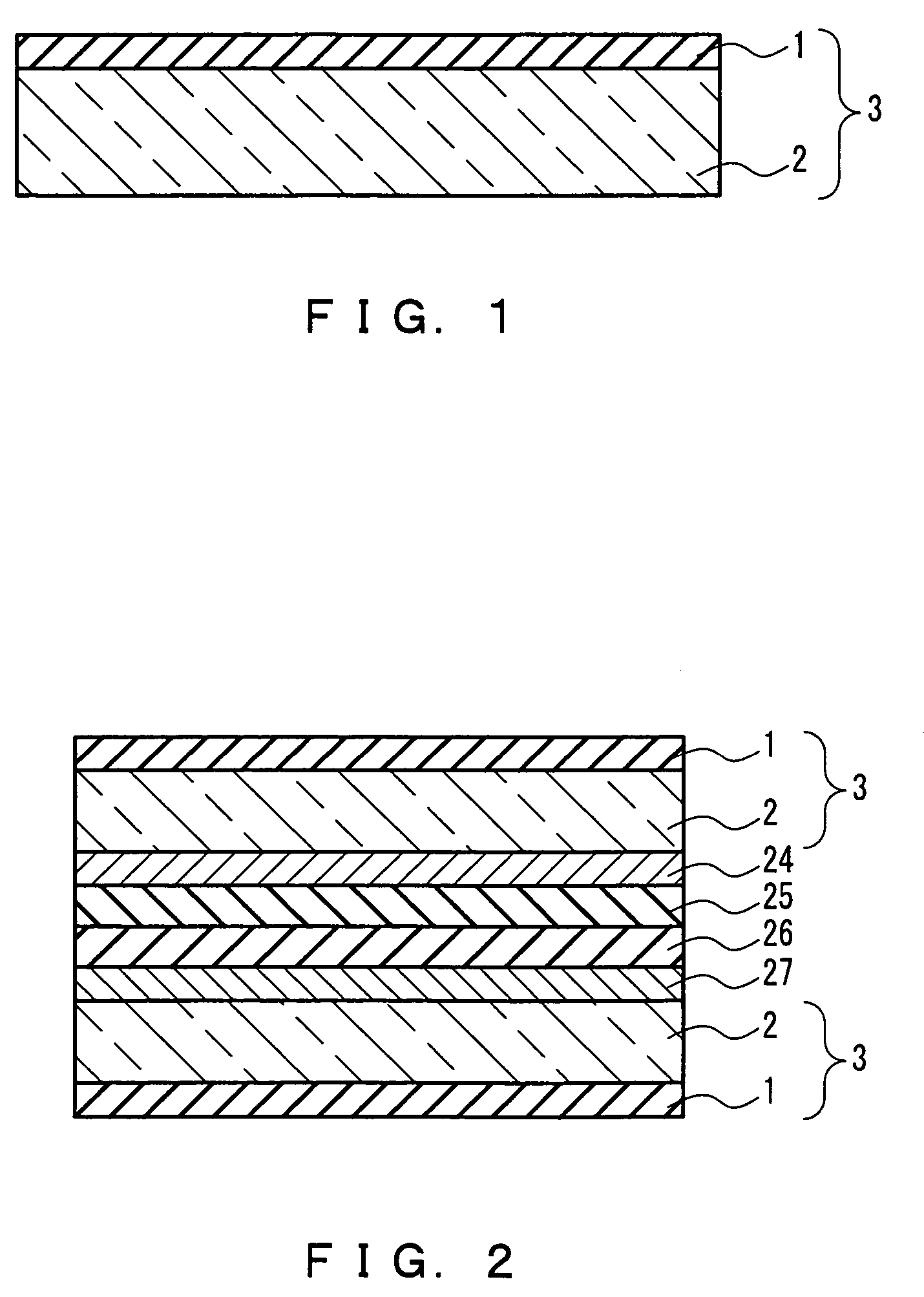

Organic luminescence device and its production method

InactiveUS20050122039A1Excellent gas barrier propertiesDischarge tube luminescnet screensLayered productsWater vaporOxygen

An organic luminescence device uses a substrate with a gas-barrier film in which a gas-barrier film containing an amorphous oxide and at least two kinds of oxides selected from the group consisting of boron oxide, phosphorus oxide, sodium oxide, potassium oxide, lead oxide, titanium oxide, magnesium oxide, and barium oxide is formed on a substrate. The selected two kinds of oxides are a combination of an oxide of an element having a large atomic radius and an oxide of an element having a small atomic radius. The substrate is made of glass or plastic. As a result, the organic luminescence device using a substrate excellent in gas-barrier capability to prevent the infiltration of oxygen, water vapor, etc. from outside is provided.

Owner:PANASONIC CORP

Long-acting slow-release corn special blending fertilizer and preparation method thereof

InactiveCN101618987ANo pollution in the processSimple processFertilizer mixturesPhosphorus utilizationNitrification inhibitors

The invention relates to a soil fertilizer technique, in particular to a long-acting slow-release corn special blending fertilizer and a preparation method thereof to solve the problems that the nitrogen and phosphorus utilization rate of the fertilizer is low, the after manuring in the corn growth period consumes a large amount of time and labor and the like. The blending fertilizer comprises the following components in percentage by weight: 45 to 58 percent of nitrogen fertilizer, 16 to 25 percent of phosphate fertilizer, 16 to 25 percent of potassium fertilizer, and 4 to 14 percent of nitrogen phosphorus fertilizer synergist; and nutritive substances of the blending fertilizer comprise the following components in percentage by weight: 24 to 28 percent of pure nitrogen, 8 to 12 percent of diphosphorus pentanitride, and 10 to 15 percent of potassium oxide. The preparation method comprises the following steps: adding the granular nitrogen fertilizer, phosphate fertilizer, potassium fertilizer and the nitrogen phosphorus fertilizer synergist into a mixing and stirring machine according to the weight ratio, mixing and stirring the materials evenly to obtain the long-acting slow-release corn special blending fertilizer, and performing sub-package to obtain the finished product; or selecting a urease inhibitor, a nitrification inhibitor and a phosphate fertilizer synergist to granulate by mixing so as to obtain the granular nitrogen phosphorus fertilizer synergist, and then blending the granular nitrogen phosphorus fertilizer synergist with the granular nitrogen fertilizer, phosphate fertilizer and potassium fertilizer to obtain the finished product. The long-acting slow-release corn special blending fertilizer and the preparation method have simple process and easy implementation, are suitable for one-step basal application without after manuring for corn production in the Northeast, and reduce the usage amount by 10 to 20 percent without reducing the yield.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Organic acid potassium nutritional agent

ActiveCN101555177AHigh in potassiumPromote absorptionOrganic fertilisersPotassium fertilisersDry weightPollen

The invention discloses an organic acid potassium nutritional agent which comprises potassium-containing compound counted by potassium oxide, trace elements, organic acid, carbohydrates, deep-sea algal counted by dry weight, enzyme, alkyl polyuronide surfactant, and fat-soluble pollen extracts, and the allowance water. Potassium ions can be chelated with the organic acid to prevent the potassium from being fixed by soil, thereby improving the potassium utilization rate and the potassium efficiency of plants; auxogen contained in the trace elements, the enzyme and the deep-sea algal can provide perfect conditions for the growth of the plants. The organic acid potassium nutritional agent of the invention can be directionally applied to various crops, using 30-300g / acre in the leaf surface application and 1.5-4.5kg / acre in the soil application. The organic acid potassium nutritional agent prepared via the technical scheme of the invention has the advantages of high potassium content, easy absorption, small corresponding production equipment investment, simple process and low cost and can be widely applied to the industrial production.

Owner:袁磊

Amorphous polyamide resin composition and molded product

Provided are an amorphous polyamide resin composition having high transparency, and is excellent in heat resistance and stiffness, and a molded product thereof. The glass filler contains, expressed in terms of oxides by mass %, 68 to 74% of silicon dioxide (SiO2), to 5% of aluminum oxide (Al2O3), 2 to 5% of boron oxide (B2O3), 2 to 10% of calcium oxide (CaO), 0 to 5% of zinc oxide (ZnO), 0 to 5% of strontium oxide (SrO), 0 to 1% of barium oxide (BaO), 1 to 5% of magnesium oxide (MgO), 0 to 5% of lithium oxide (Li2O), 5 to 12% of sodium oxide (Na2O), and 0 to 10% of potassium oxide (K2O), where a total amount of lithium oxide (Li2O), sodium oxide (Na2O), and potassium oxide (K2O) is 8 to 12%.

Owner:ASAHI FIBER GLASS CO LTD

Foam drainage gas recovery method for natural gas horizontal well

InactiveCN102587865AThe effect of drainage and gas recovery is obviousSimple and safe operationFluid removalDrilling compositionRecovery methodPolyethylene glycol

The invention relates to a foam drainage gas recovery method used for a natural gas horizontal well. The method is capable of injecting a foam scrubbing agent into the bottommost end of a gas well shaft, so that the whole shaft is filled with foam fluid and optimal drainage gas recovery effect is achieved. The technical scheme of the method comprises the following steps: firstly, manufacturing a dynamical underground foam scrubbing bar which consists of a gas nozzle, a tail wing, a boosting agent, a shell and a protection head sleeve, wherein the material for manufacturing the tail wing, the shell and the protection head sleeve is the solid foam scrubbing agent which consists of polyoxyethylene alkyl ethers, polyethylene glycol, urea, imidazoline, sodium dodecyl benzene sulfonate and saturated alcohol sulfate; and the boosting agent is one of dry ice, sodium hydride or potassium oxide; and secondly, throwing the dynamical underground foam scrubbing bar to the bottom of the well, wherein the boosting agent is in contact with water to generate a large amount of gas, so that the foam scrubbing bar is pushed to the bottommost end; and as the foam scrubbing agent is dissolved, a large amount of foam is formed to achieve the optimal effect of drainage gas recovery. The method disclosed by the invention has a wide application range without any wellhead equipment and energy, is simpleand safe in operation, low in cost and has no pollution to the environment.

Owner:SOUTHWEST PETROLEUM UNIV

Water-soluble fertilizer by complexing humic acid with plurality of nutrient elements and preparation method thereof

ActiveCN101798246AAvoid fixationFacilitate the operation of transmissionFertilizer mixturesWater insolublePotassium

The invention belongs to the technical field of agriculture, in particular relates to a water-soluble fertilizer by complexing humic acid with a plurality of nutrient elements and a preparation method thereof. The water-soluble fertilizer is prepared by complexing the following raw materials by weight parts: 8 parts of potassium humic acid powder containing more than or equal to 50 percent of humic acid component, more than or equal to 10 percent of potassium oxide component and less than or equal to 2 percent of water-insoluble substances, 42-46 parts of water, 33-38 parts of major element compound, 10 parts of trace element compound, 1.3-1.5 parts of additives and 1.8-2.5 parts of plant growth regulator. The preparation method comprises six steps. The water-soluble fertilizer has the advantages of complete nutrient elements, higher crop absorption utilization rate and stronger directivity.

Owner:陕西赛恩农业科技股份有限公司

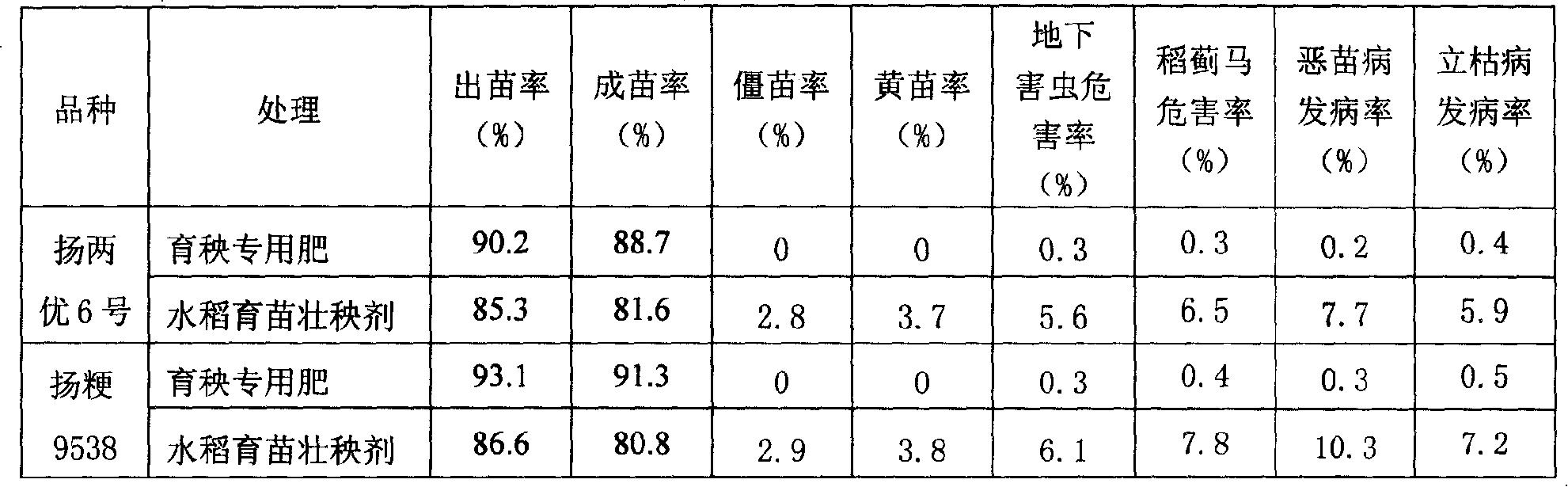

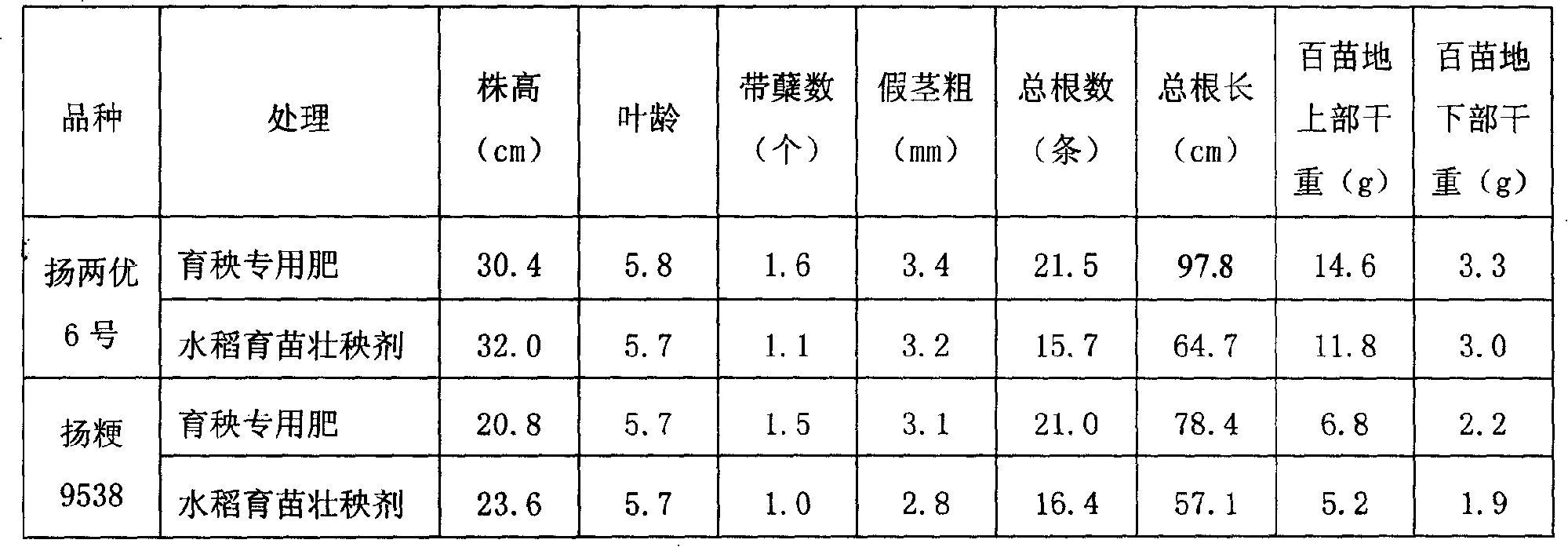

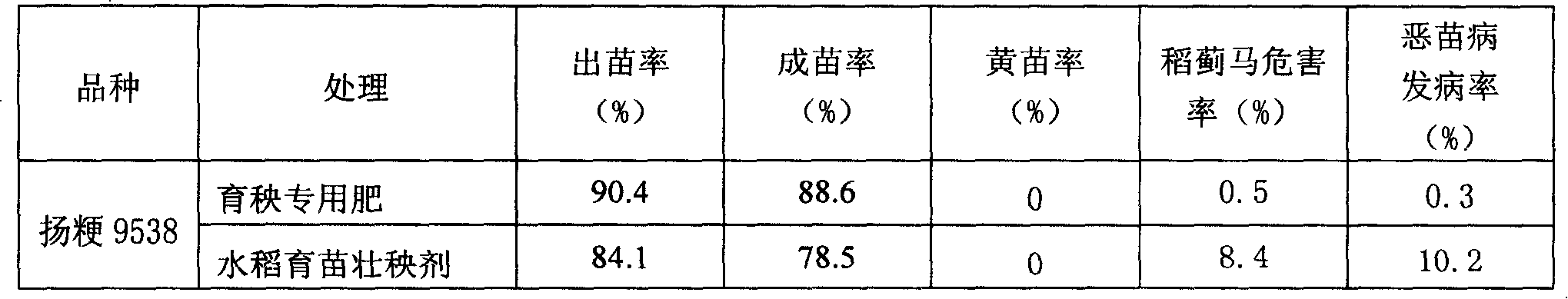

Special-purpose slow release fertilizer for water-retention sprout-cultivation

ActiveCN101209938AIncreased supply bufferReduce water consumptionFertilizer mixturesRoot growthAdditive ingredient

The invention discloses a special fertilizer with medical fertilizer slowly released and water conserved for seedlings growth which is characterized in that the fertilizer mainly consists of the following ingredients according to weight propotion: 5-10 percent of super-absorbent resin, 8-20 percent of nitrogen (N), 5-12 percent of phosphorus pentoxide (P2O5), 3-7 percent of potassium oxide (K2O), 1-3 percent of zinc (Zn), 1-3 percent of ferrite (Fe), 1-5 percent of ingredients of boron, magnesium, molybdenum, manganese and copper, 0.2-2 percent of pesticide, 0.1-2 percent of fungicide, 0.001-0.01 percent of root growth promoting agent and 0.001-0.01 percent of dwarfing agent and the rest is adsorbent. The special fertilizer with medical fertilizer slowly released and water conserved for seedlings growth of the invention has functions of good water holding and supplying, slow releasing of medical fertilizer, seedlings and roots strengthening, elements applying and growth promotion, diseases prevention, insect disinfesting and production increasing, and is characterized by less dosage, low cost and convenient application, etc., and can be applied to rice seedlings dry raising, seedling raising on plastic trays and upland crops raising.

Owner:JIANGSU LIXIAHE REGION AGRI RES INST

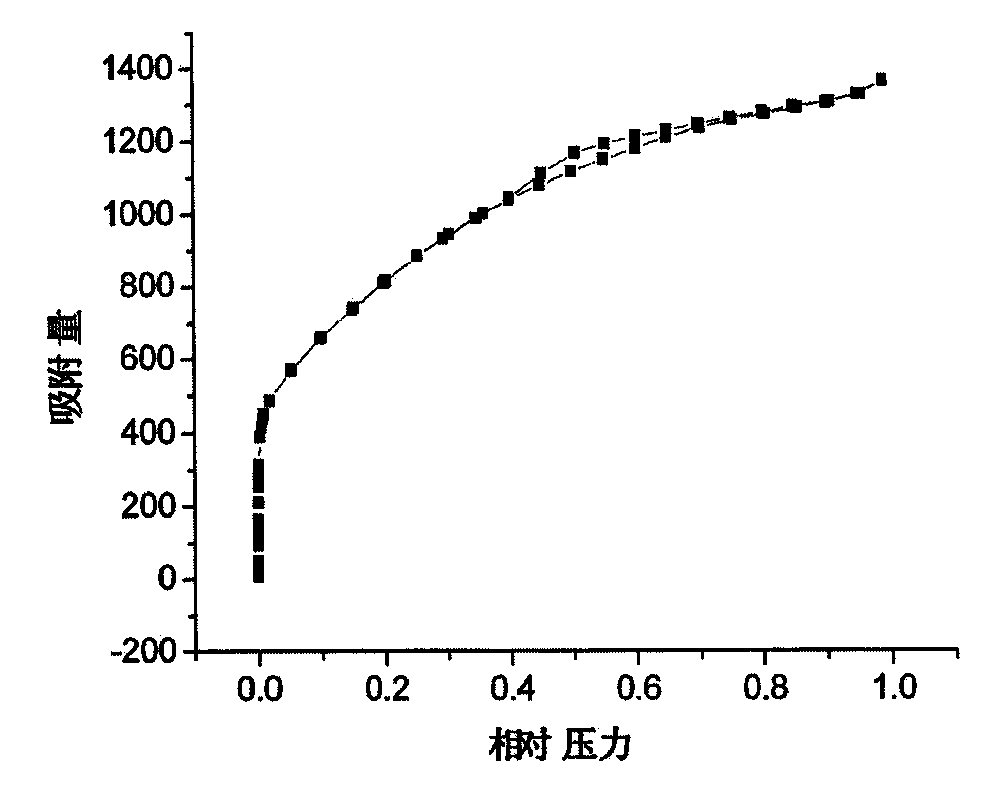

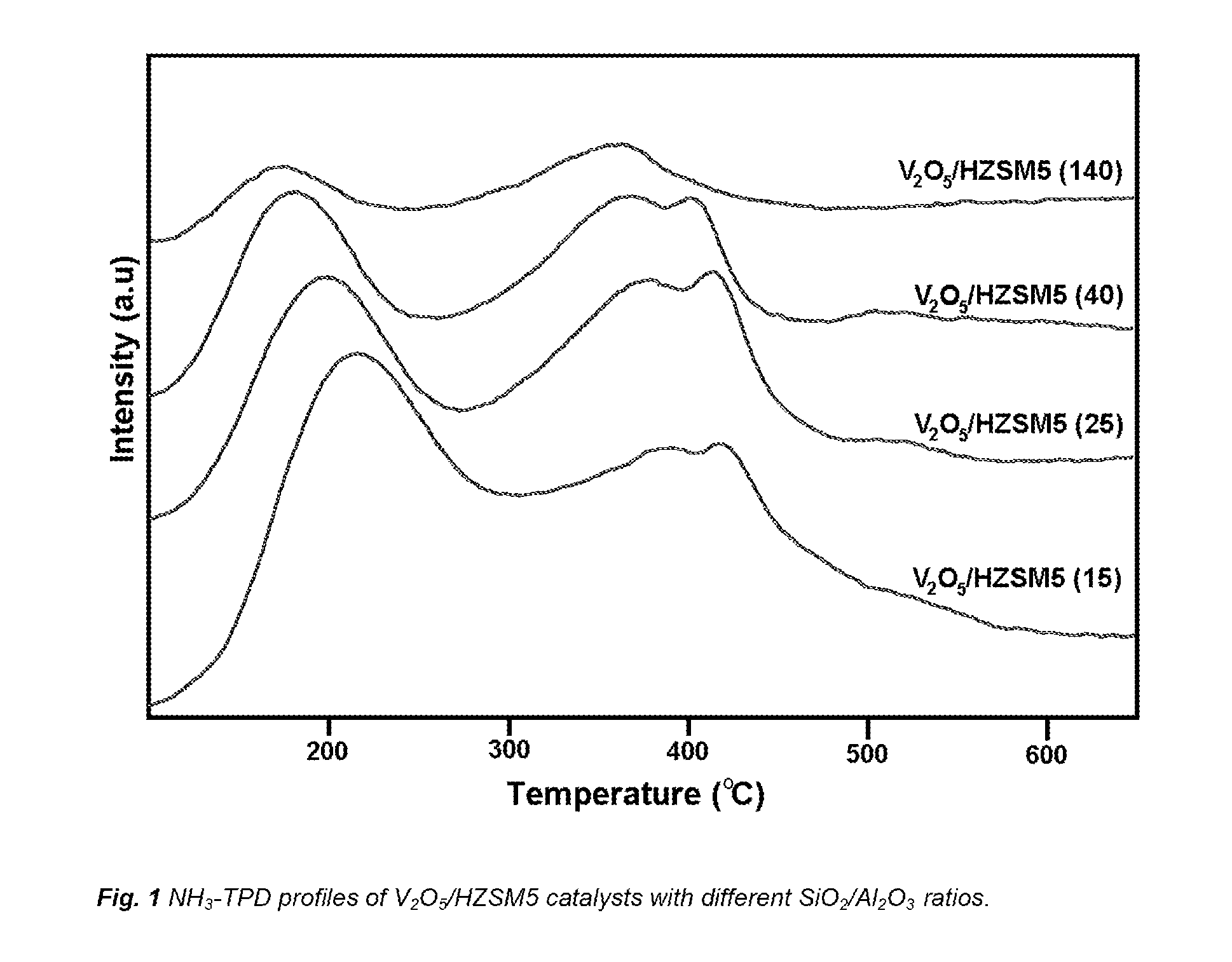

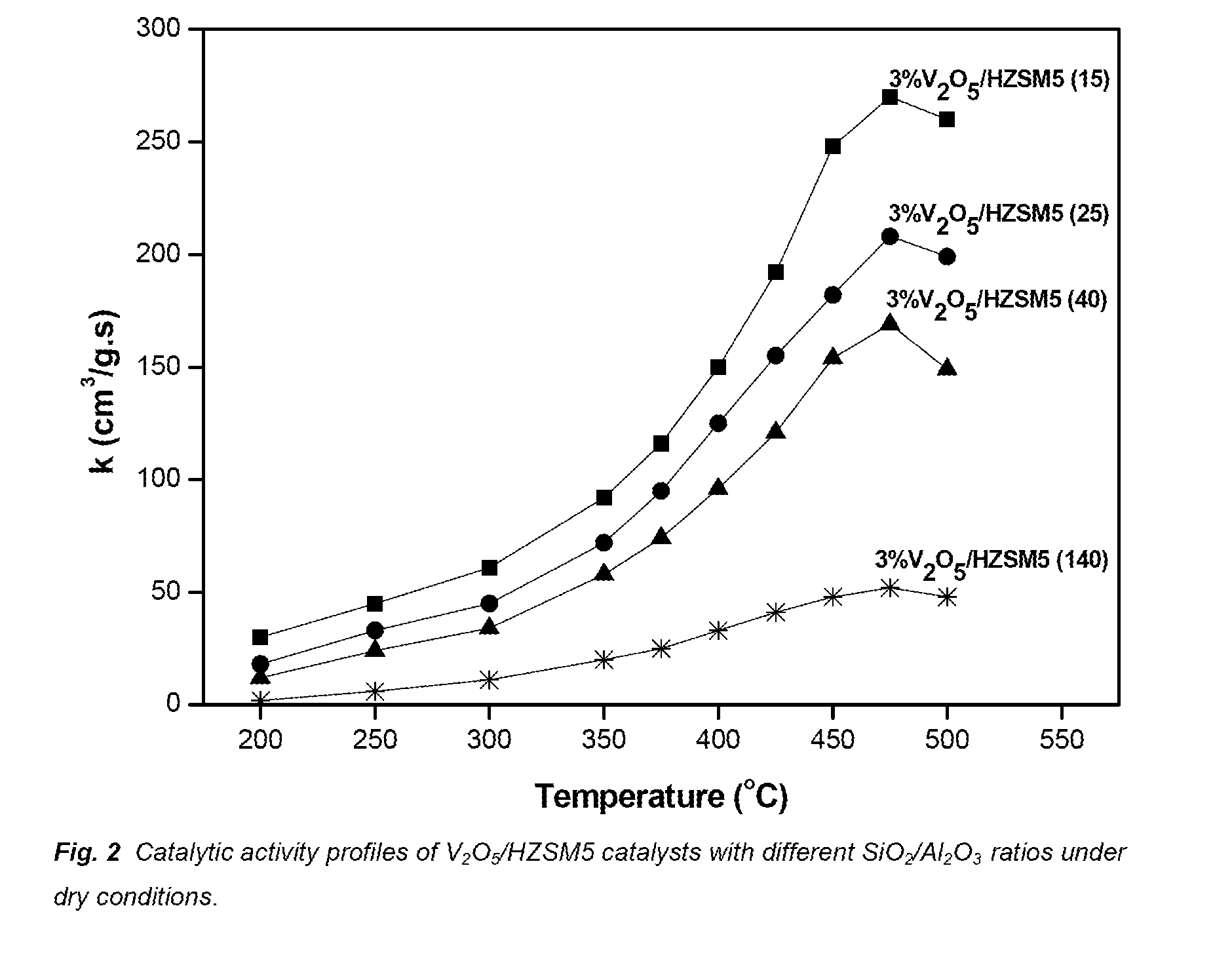

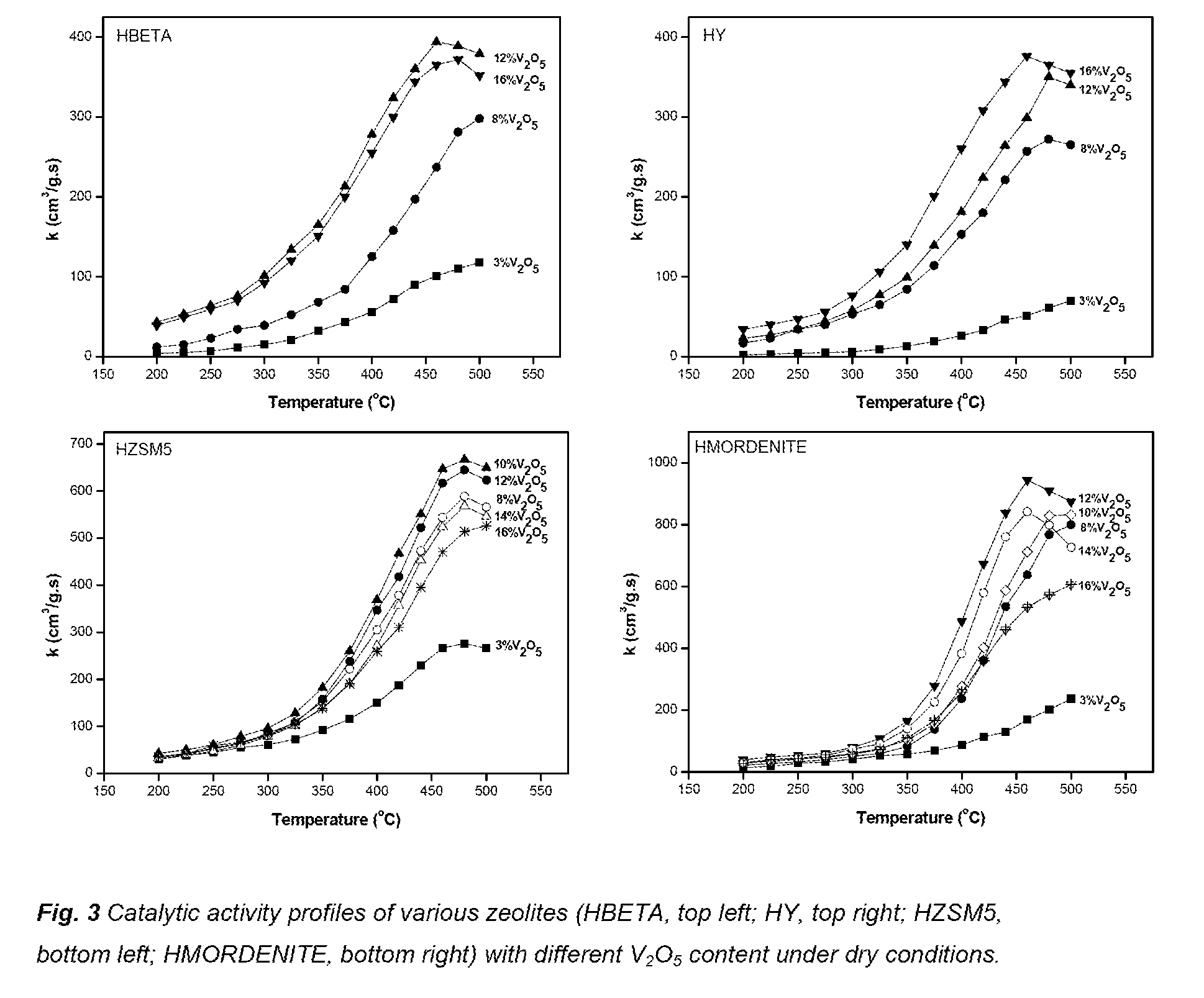

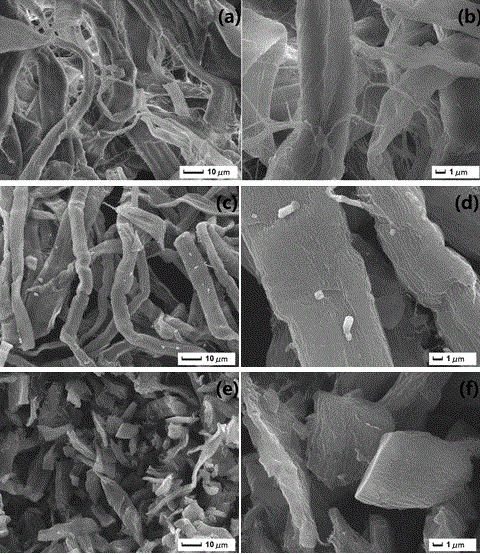

Vanadia-supported zeolites for scr of no by ammonia

The catalytic behaviour of vanadia-supported zeolite catalysts with different SiO2 / Al2O3 ratios was tested for the SCR of NO with ammonia. The SCR activity was found to be directly correlated to the total acidity of the catalysts. On the surface of these zeolites the V2O5 was highly dispersed and amorphous in nature. After the impregnation with vanadium and subsequent poisoning with potassium oxide not much change in micro-pore structure of HZSM5 was observed by N2 adsorption studies. Interestingly, potassium-doped HZSM5 and HMORDENITE catalysts showed high resistance to deactivation because of the unique nature of the material exhibiting higher surface area and acidity than the conventional V2O5—WOx / ZrO2 or TiO2 catalysts. Consequently, a possible application of these alkali-tolerant SCR catalysts in biomass fired power plants can be envisaged.

Owner:DANMARKS TEKNISKE UNIV

Preparation method for porous carbon material with high specific surface area

The invention relates to a preparation method for a porous carbon material with a high specific surface area and belongs to the technical field of the preparation for an environment function material. The preparation method comprises the following steps: firstly, carbonizing a carbon source under the nitrogen protection; secondly, utilizing a chemical activating agent potassium hydroxide to activate the carbide under the high-temperature calcination condition; lastly, utilizing the hydrochloric acid to remove the impurities, washing with deionized water or hot water till the material is neutral, thereby acquiring the porous carbon material with the high specific surface area. The parameters, such as, appearance, duct distribution, and the like, of the compound material are revealed through various representing methods. The absorbing experiment is utilized to research the property of the porous carbon material for removing the tetracycline antibiotics in the water environment.

Owner:JIANGSU UNIV

Basic glaze for ink jet printing, preparation method of basic glaze, and ceramic tile

The invention discloses a basic glaze for ink jet printing, a preparation method of the basic glaze, and a ceramic tile. The basic glaze for the ink jet printing comprises the following chemical components by weight percentage: 2.0-3.0% of igloss, 13.0-17.0% of aluminium oxide, 64.0-69.0% of silicon dioxide, 0.05-0.2% of ferric oxide, 0.3-0.9% of calcium oxide, 3.0-6.0% of magnesium oxide, 1.4-2.0% of potassium oxide, 1.4-2.0% of sodium oxide, 0.03-0.10% of titanium oxide, 5.0-10.0% of zirconium dioxide and hafnium oxide, 0.01-0.2% of lithium oxide, and 0.1-2.0% of zinc oxide. The basic glaze for the ink jet printing is free from such defects as deformation, bubbles, pin holes, sewage suction and poor color when an ink jet printing technique is used, and a fabricated product has good color, the surface of a glazed tile is fine and smooth, and the product quality and effect can be improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

Process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer

InactiveCN1974494AEmbody the scientific conceptLower activation energyCalcareous fertilisersPotassium fertilisersTrace elementCinder

The present invention discloses process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer. The composite K-Ca-Si-S fertilizer is produced with potash ore 25-55 wt%, desulfurized cinder 15-50 wt%, limestone 5-55 wt% and additive 2-5 wt%, and through mixing, milling, roasting at 1000-1050 deg.c for 2-3 hr, cooling and ball milling. The production process has desulfurized cinder as one kind of solid waste utilized and potash ore heat decomposed to produce the fertilizer with soluble potassium oxide, soluble Ca, Si and S compounds and trace elements. The additive can lower the potash ore decomposing temperature from 1100-1150 deg.c to 1000-1050 deg.c.

Owner:广州康沣农业科技有限公司

Special formulation fertilizer for rice

ActiveCN101054326APromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersFiberProcess quality

The invention belongs to fertilizer technical field, more particularly relates to a rice special formula fertilizer, which is characterized in that effective elements of the fertilizer are calculated by weight percent of pure nutrient are nitrogen 25-15, phosphorus pentoxide 15-9, potassium oxide 20-12, silicon dioxide 5-0, calcium 8-0, sulphur 5-1 and zinc 2-1. Compared with the present technique, the rice special formula fertilizer of the invention has reasonable match, accords with the nutrient absorption law of rice, can promote rice growth obviously and raise rough rice output, increase economic benefits and improve rice nutriment quality. In application test, the rice special formula fertilizer of the invention increases the rice yield by 660-820 kg per hectare, increases income 756-146 RMB, increases crude protein, raw fat, crude fiber, nitrogenfree extract and crude ash by 4.1-8.6, 0.14-0.80, 0.4-0.8, 0.1-3.0, 0.4-1.0 percentage points respectively, increases brown rice rate, integral white rice rate, white rice rate of rice processed quality by 1.4%, 1.7% and 1.8% respectively, reduces chalkiness granule rate, chalkiness by 3.2% and 1.9% respectively, reduces content of amylose by 1.0%. In the meanwhile, the fertilizer utilization efficiency is raised by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

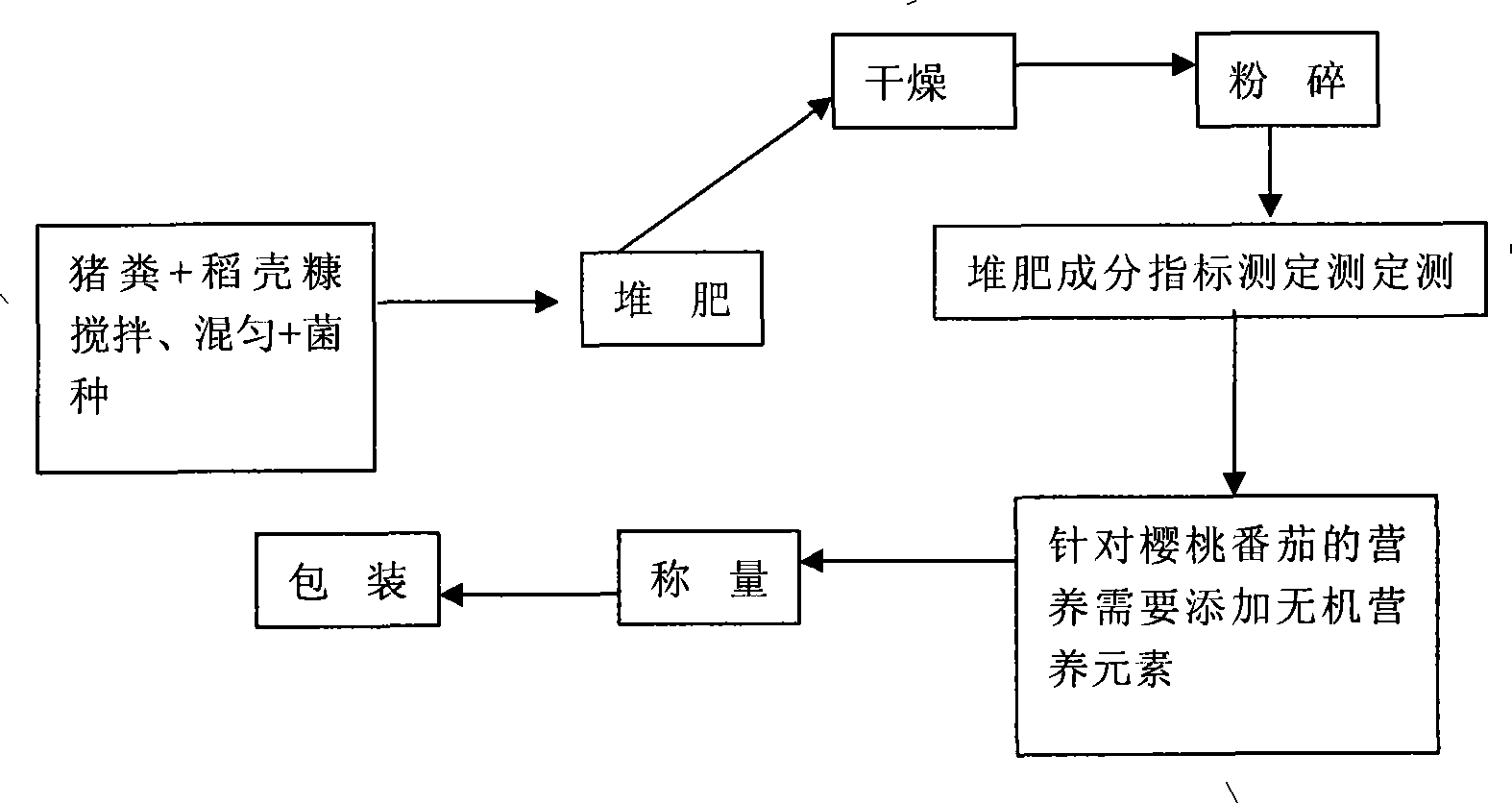

Organic-inorganic complex fertilizer special for cherry tomato with pig manure and inorganic nutritive element as raw material

InactiveCN101244961AIncrease productionImprove qualityBio-organic fraction processingOrganic fertiliser preparationPig farmsCompost

The invention belongs to the technical field of animal manure treatment and fertilizer production, and specifically relates to a special organic-inorganic compound fertilizer of producing cherries and tomatoes which uses pig manure compost and effective elements as raw materials. The weight percentages of the effective elements in the fertilizer by pure nutrients are: organic substances: 22.0; nitrogen: 15.0; phosphorus pentoxide: 5.0; potassium oxide: 10.0; calcium: 2.0; magnesium: 0.5; zinc: 0.5. The special organic-inorganic compound fertilizer of producing cherries and tomatoes which uses pig manure compost and effective elements as raw materials also discloses the production method of the organic-inorganic compound fertilizer. Compared with the prior art, the fertilizer of the invention fully uses the pig manure raw material, thus reducing pollutions of pig farms and protecting environment; meanwhile, the fertilizer of the invention provides the special organic-inorganic compound fertilizer of cherries and tomatoes which is cheap in price and complete in fertilizer efficiency.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com