Patents

Literature

204 results about "Pins needles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

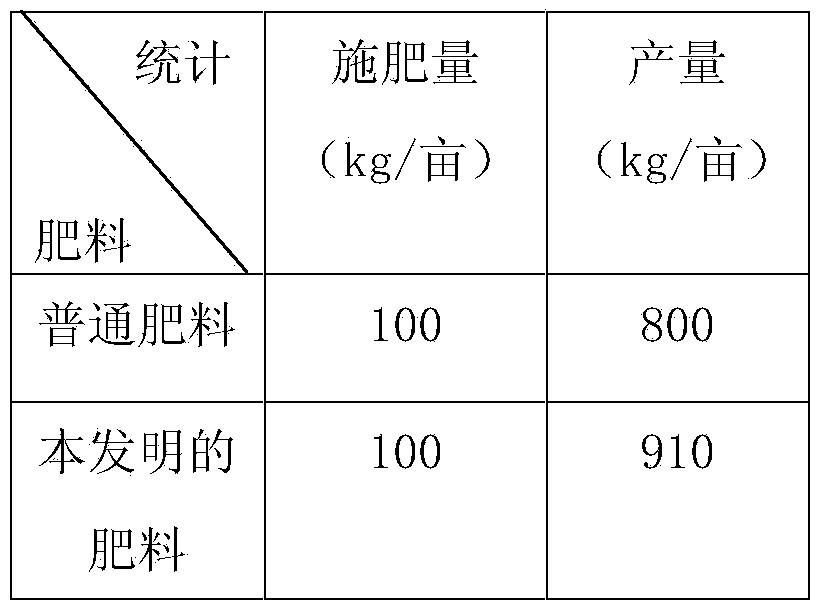

Biological multi-effect fertilizer

ActiveCN101492324AEffective controlReduce reproductive rateOrganic fertilisersFertilizer mixturesMedicinal herbsPins needles

The invention discloses a multi-effect biofertilizer, comprising sarcandra glabra, cortex fraxini, radix stemonae, lightyellow sophora root, pin needles, isatis root, phellodendron, aloe, humic acid and inorganic fertilizers of nitrogen, phosphorus and potassium; the weight percentages of the components are as follows: 1-2.5% of sarcandra glabra extract, 1-2.5% of radix stemonae extract, 1-2.5% of phellodendron extract, 5-10% of aloe extract, 10-15% of pin needles, 7-10% of isatis root, 7-10% of cortex fraxini, 10-15% of lightyellow sophora root, 15-20% of humic acid, 10-20% of available nitrogen, 5-10% of phosphorus pentoxide and 5-10% of potassium oxide. The Chinese medicinal herbs of the invention have the advantages of sterilization and disinfestation, safety without pollution, combined herbs and fertilizers, compound multielements, comprehensive nutrition, long-acting slow release and improved utilization rate. The multi-effect biofertilizer can be widely applied to such cash crops as corn, cotton, rapeseed plants, peanuts, legume, silkworm and mulberry, tea forests, fruit grove and various vegetables.

Owner:何同林

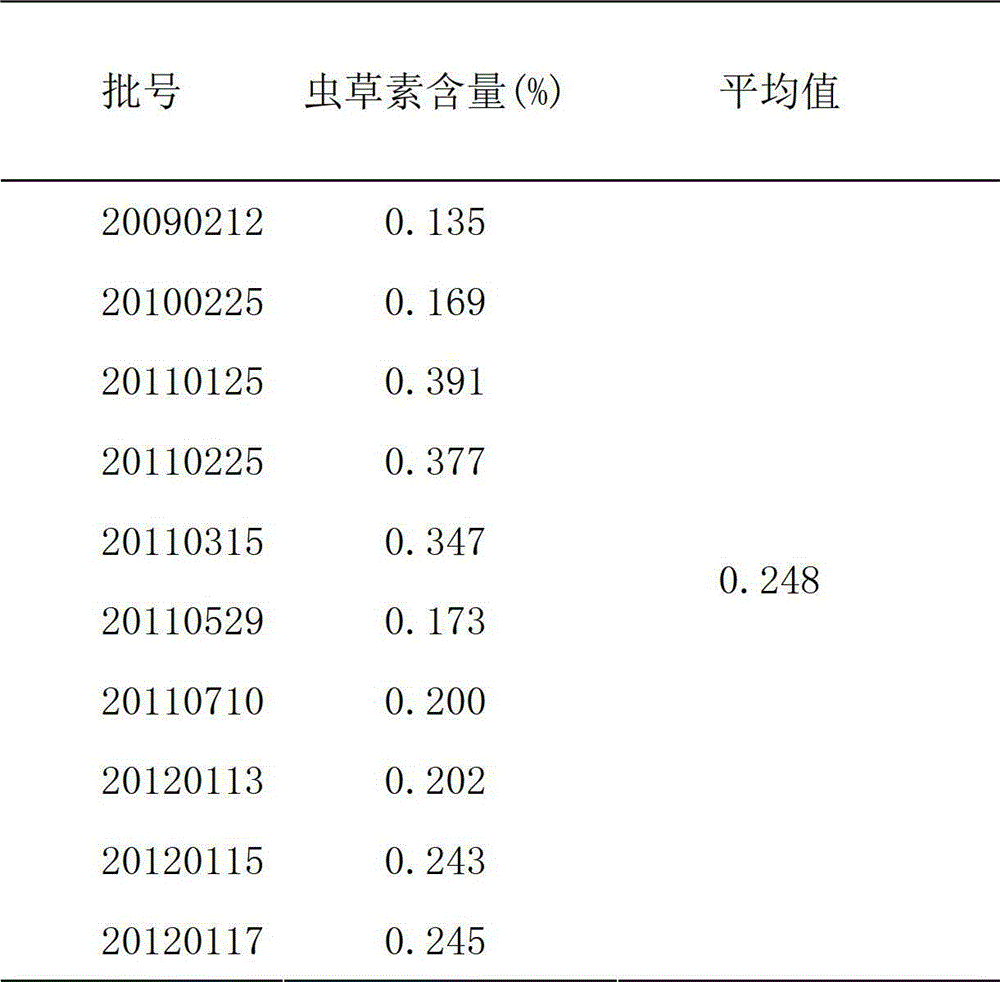

Cordyceps militaris fruit body cultivation technology for stabilizing cordycepin content

The invention provides a cordyceps militaris fruit body cultivation technology for stabilizing cordycepin content. The major ingredients of a culture medium consist of at least three of corn grit, sorghum, oat, millet, rice, wheat and soybean meal, and the content of each component is (1 / N)+ / -5% by mass, wherein N is the component number; the major ingredients of the culture medium are soaked with a pine needle nutrient solution; and the use amount of the pine needle nutrient solution is 1.2-1.4 times the weight of the major ingredients of the culture medium based on the condition that the liquid is completely absorbed by the major ingredients. A preparation method of the pine needle nutrient solution comprises the following steps of: fetching the dry Chinese pine needle growing in an environment without industrial and pesticide pollution for over 6 years, wherein the use amount of the pin needle is 1.0-1.4 times the weight of the major ingredients of the culture medium; adding 9-11 times of water and boiling for 1.5-2 hours; fetching the filtrate, and adding water to obtain initial liquid amount; and adding sucrose, VB1 and silkworm chrysalis meal, or mashing a whole egg and adding to replace the silkworm chrysalis meal, wherein the addition amount of the sucrose, VB1 and silkworm chrysalis meal or whole egg is 1.8-2.2%, 0.015-0.025% and 18-22% of the weight of the major ingredients of the culture medium respectively; and the total culture period is 62-75 days.

Owner:SHANXI WANHAIAO BIOLOGICAL TECH CO LTD

A novel organic compound fertilizer and a preparation method thereof

InactiveCN103641580ARealize comprehensive utilizationImprove fertilizer efficiencyFertilizer mixturesLivestock manureSodium Bentonite

The invention discloses a novel organic compound fertilizer. The fertilizer is prepared from following raw materials in parts by weight: 45-50 of livestock manure, 7-9 of silkworm excrement, 20-23 of rice hull, 11-13 of dry pine needle, 20-25 of sawdust, 10-15 of peat, 15-20 of bentonite, 12-14 of natural zeolite, 5-7 of calcium oxide, 2-4 of magnesium oxide, 10-13 of vinasse, 9-12 of a soil activator and a proper amount of water. The fertilizer is prepared from the livestock manure, the sawdust, the rice hull, and other agricultural and sideline products, thus achieving utilization of waste products, increasing the soil fertilizer efficiency and reducing environment pollution. The silkworm excrement is excrement excreted after silkworms eat mulberry leaves, and contains crude proteins, crude fat, crude fiber, soluble nitrogen-free compounds, ash, etc., and is rich in chlorophyll, vitamin E, K pectin, and the like. The dry pin needle is rich in amino acids, vitamins, a plurality of trace elements, and phytocidin and vitamins, and has functions of diseases prevention and disease resistance, wherein the amino acids, the vitamins, and the plurality of trace elements are essential for growth and development of animals. The peat is rich in nitrogen, potassium, phosphor, calcium, manganese, etc., and is capable of improving a soil hardening phenomenon, and the like, enhancing water retention capability, air permeability, and fertilizer retention capability and increasing nutrients, thus improving the product quality and achieving better economic benefit.

Owner:MAANSHAN KEBANG ECO FERTILIZER

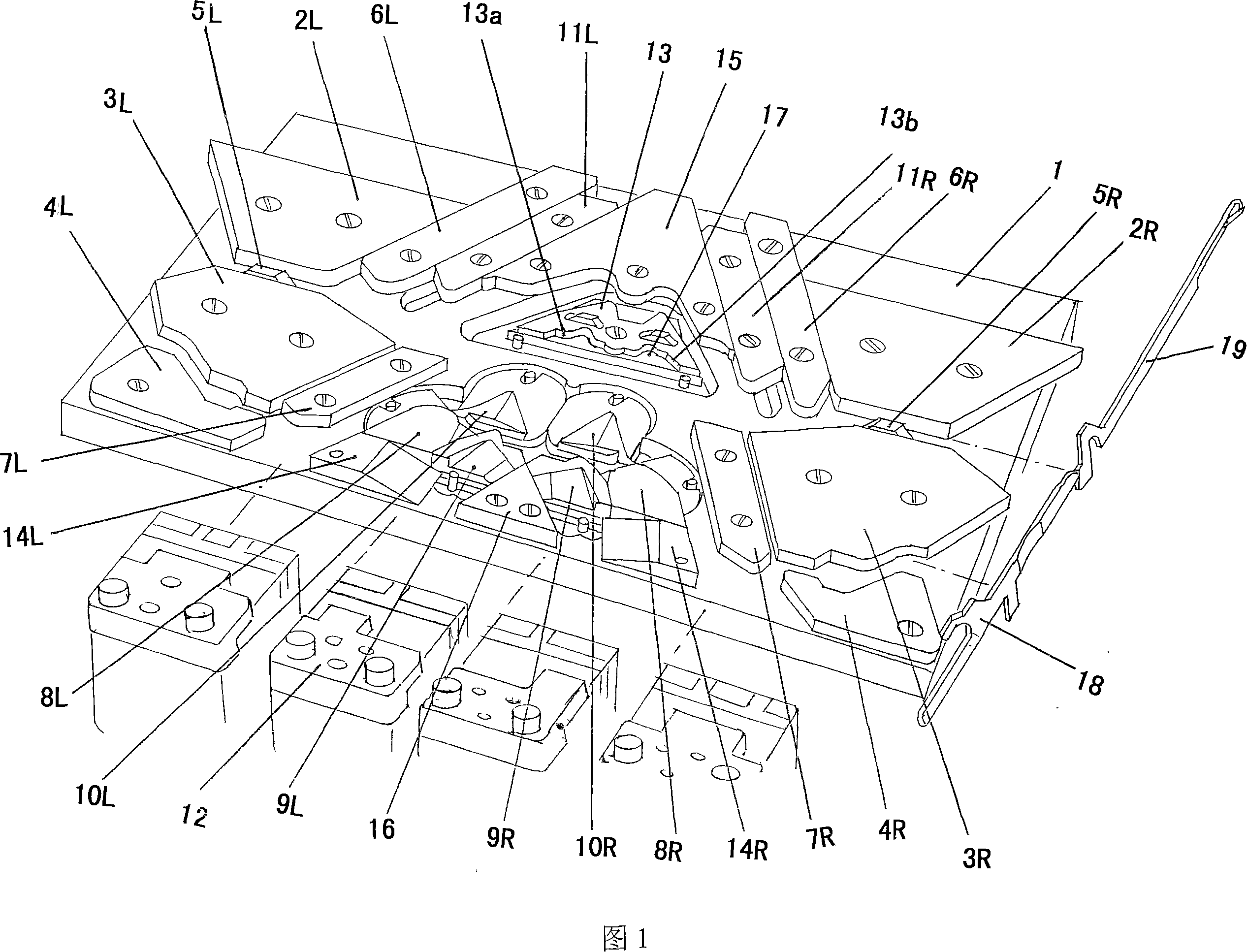

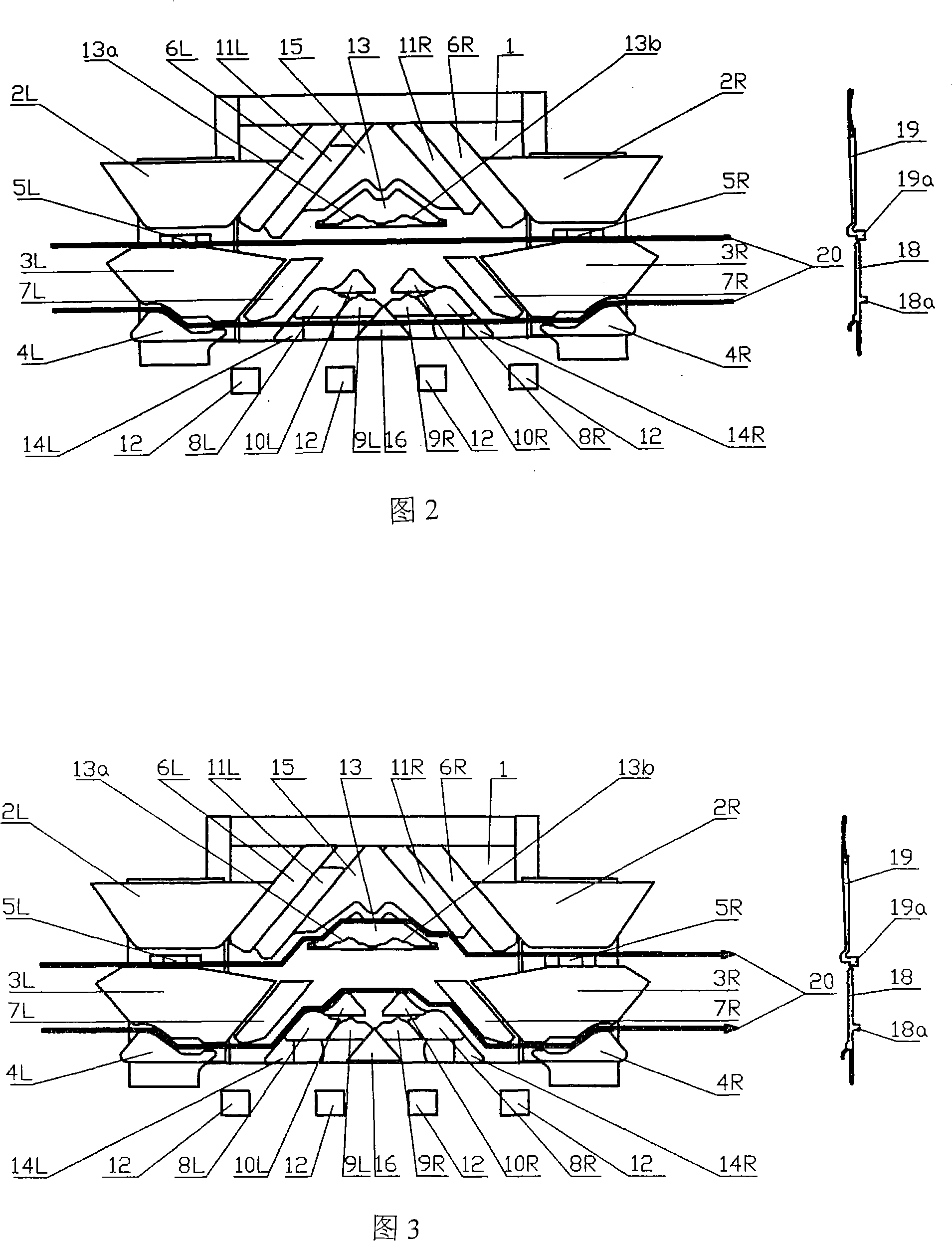

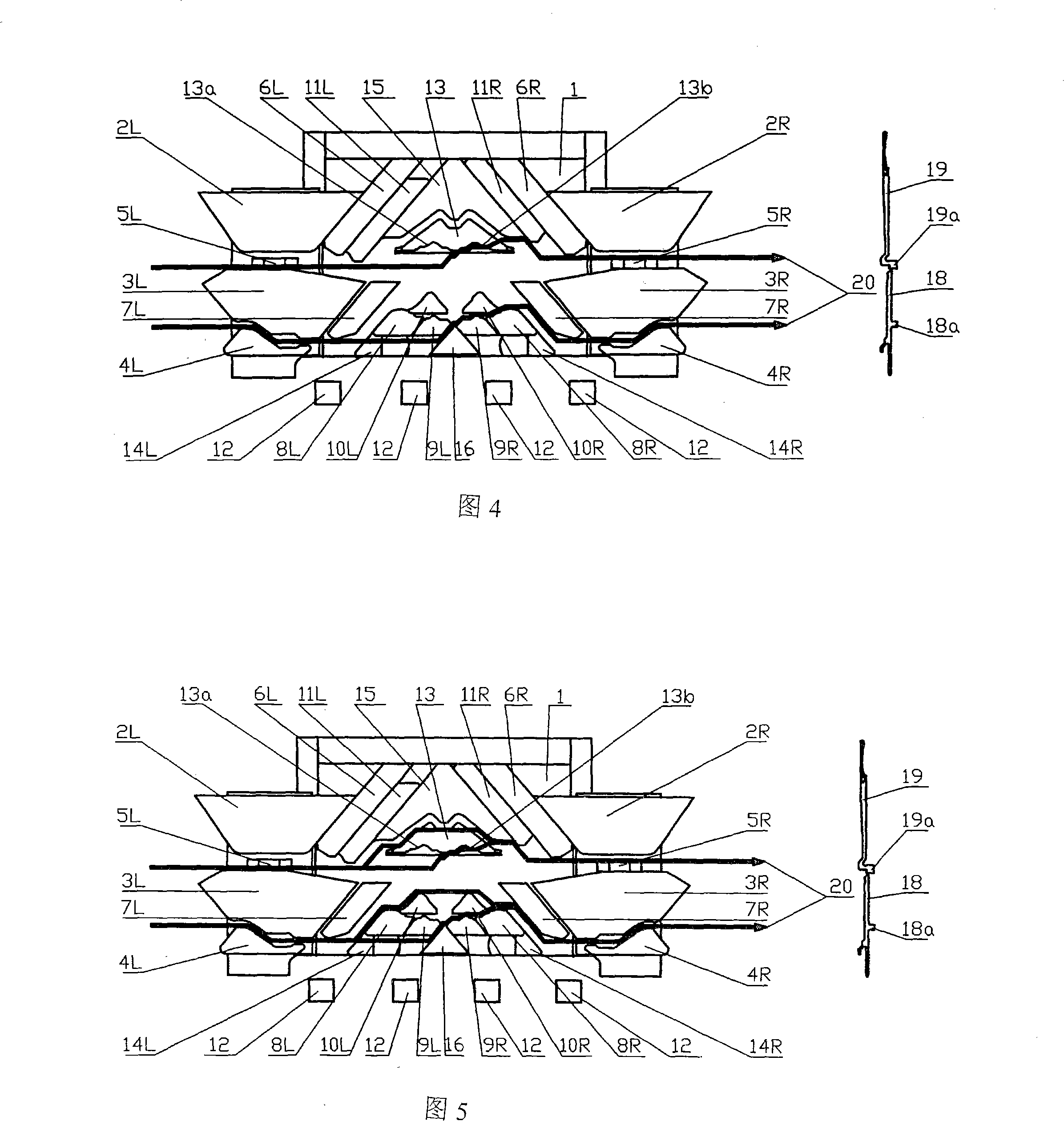

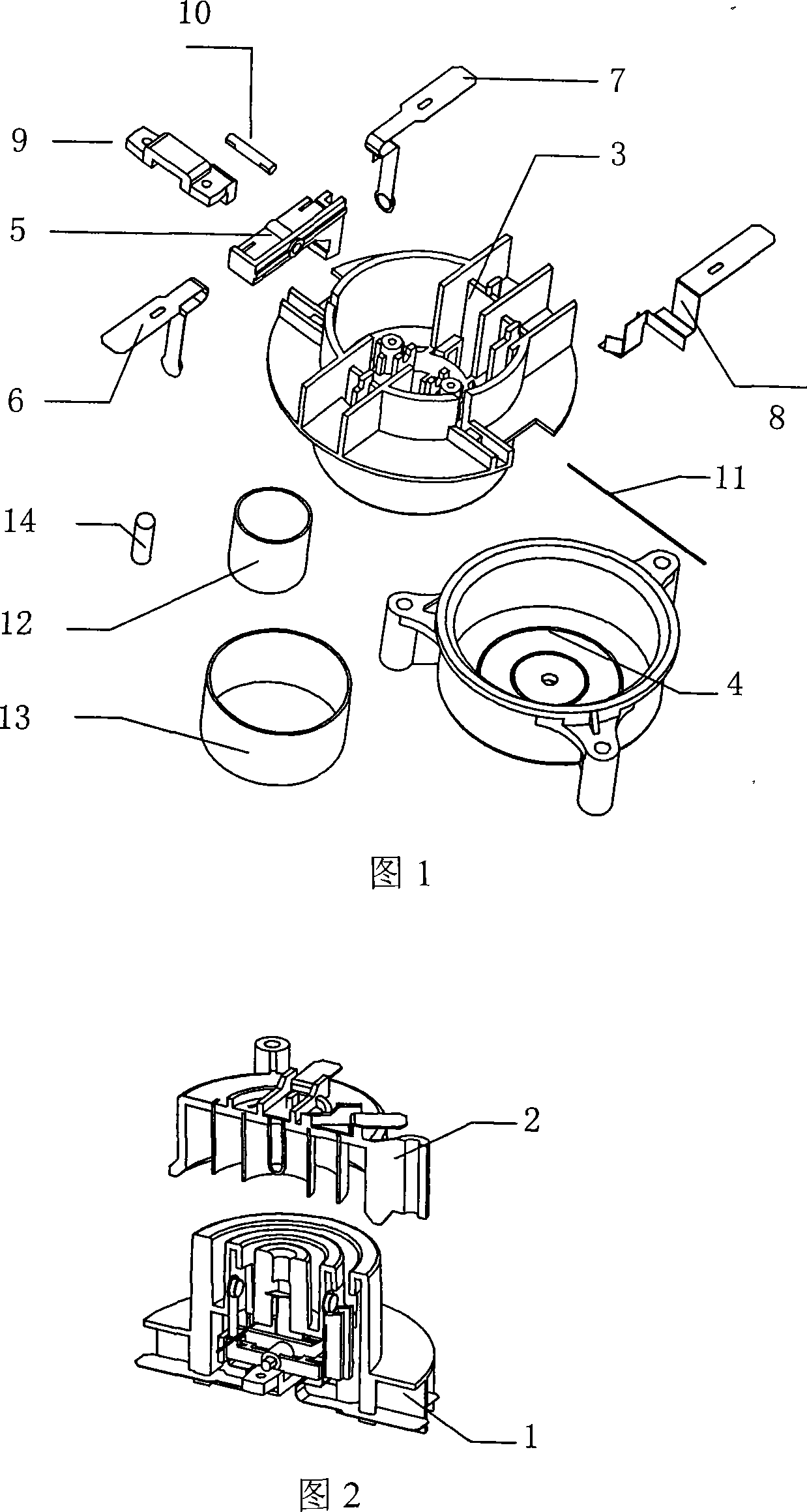

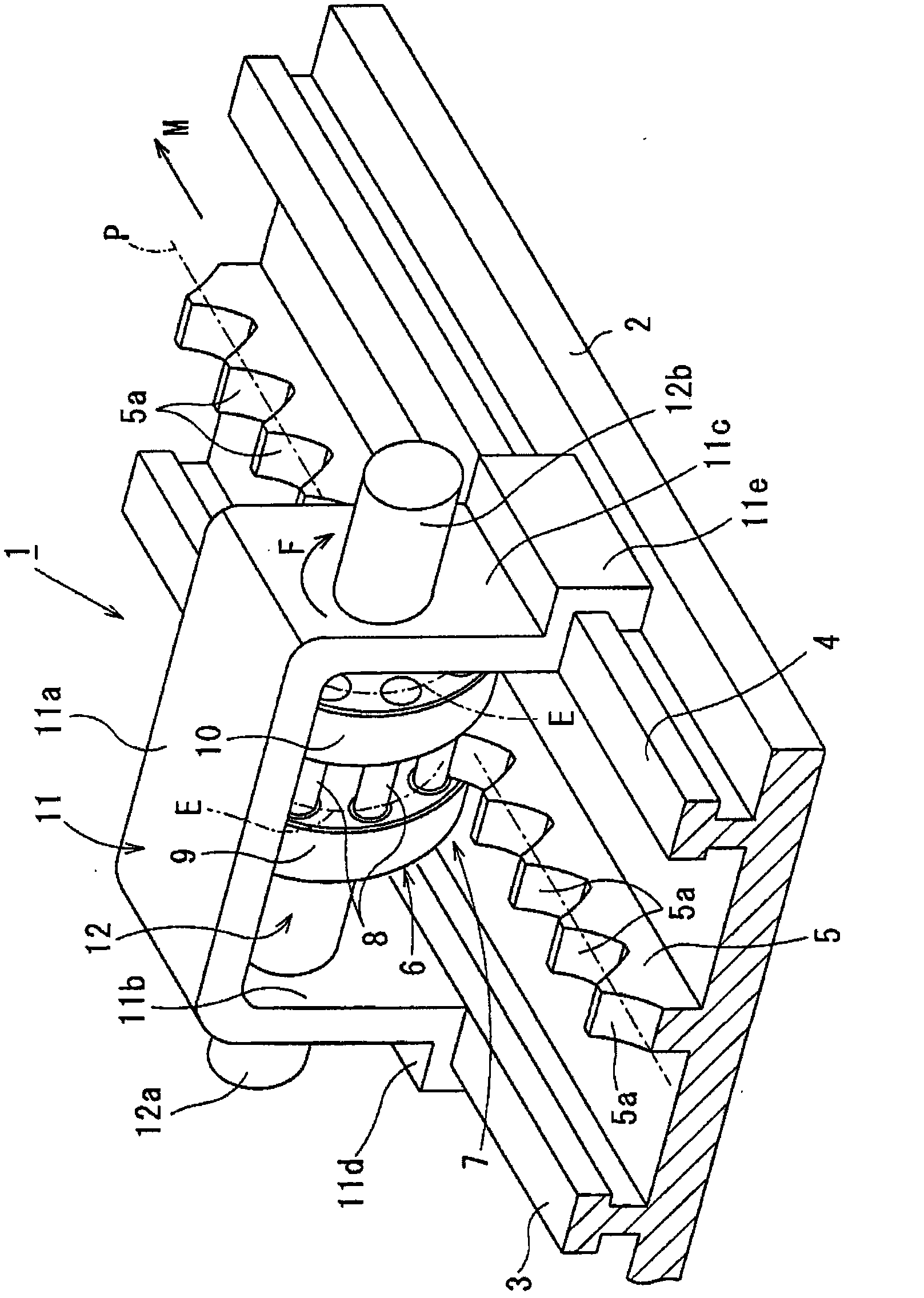

Triangle mechanism of computer plain flat knitter

The invention relates to a cam apparatus for a computer flat knitting machine belonging to the knitting machine technical field, which comprises a cam base, a first, a second and a third left and right external horizontal cams and outer left and right pressing cams, a left and a right needle limit cams, a left and a right pin limit cams and a group of needle selecting devices arranged on the cam base; a needle turning cam, a pair of left and right pin needle turning cylinder cams, a pair of left and right tuck cams, a pair of left and right needle connecting cams, a pair of left and right jack knitting cams and a pair of left and right density cams arranged on the cam base. The cam apparatus is characterized in that a guard against error cam and a selective tucking cam are also fixed on the cam base; the guard against error cam is arranged above the cam base and between the left and the right density cams; the selective tucking cam is arranged below the central section of the cam base and contacts with the left and the right needle connecting cams. The cam apparatus for a computer flat knitting machine has the advantages of simple structure, easy manufacturing and assembly, compact size of the completer machine, less abrasion, non-harsh processing requirements and no firing pin.

Owner:常熟市碧溪新区和宝纺织机械厂

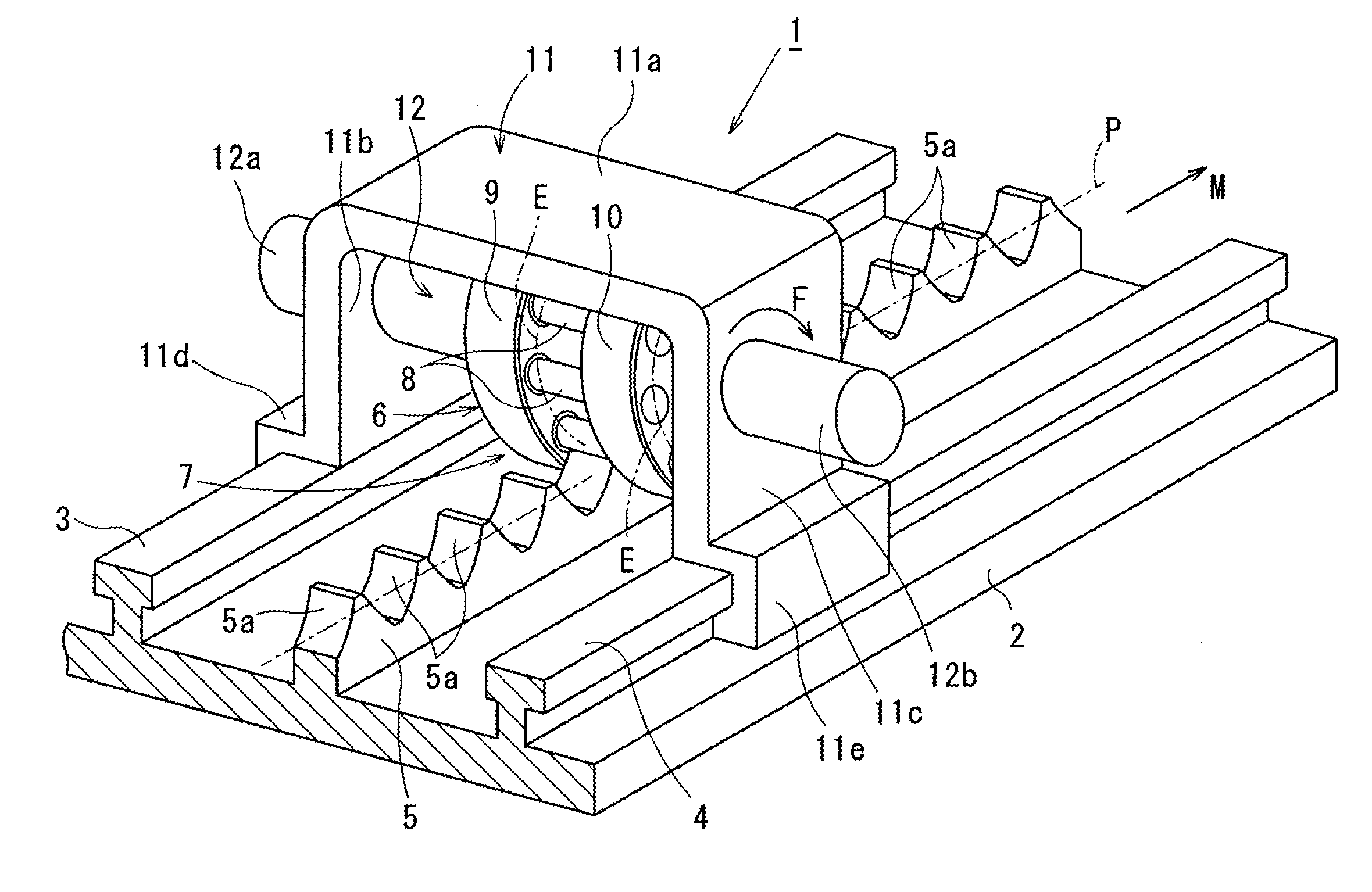

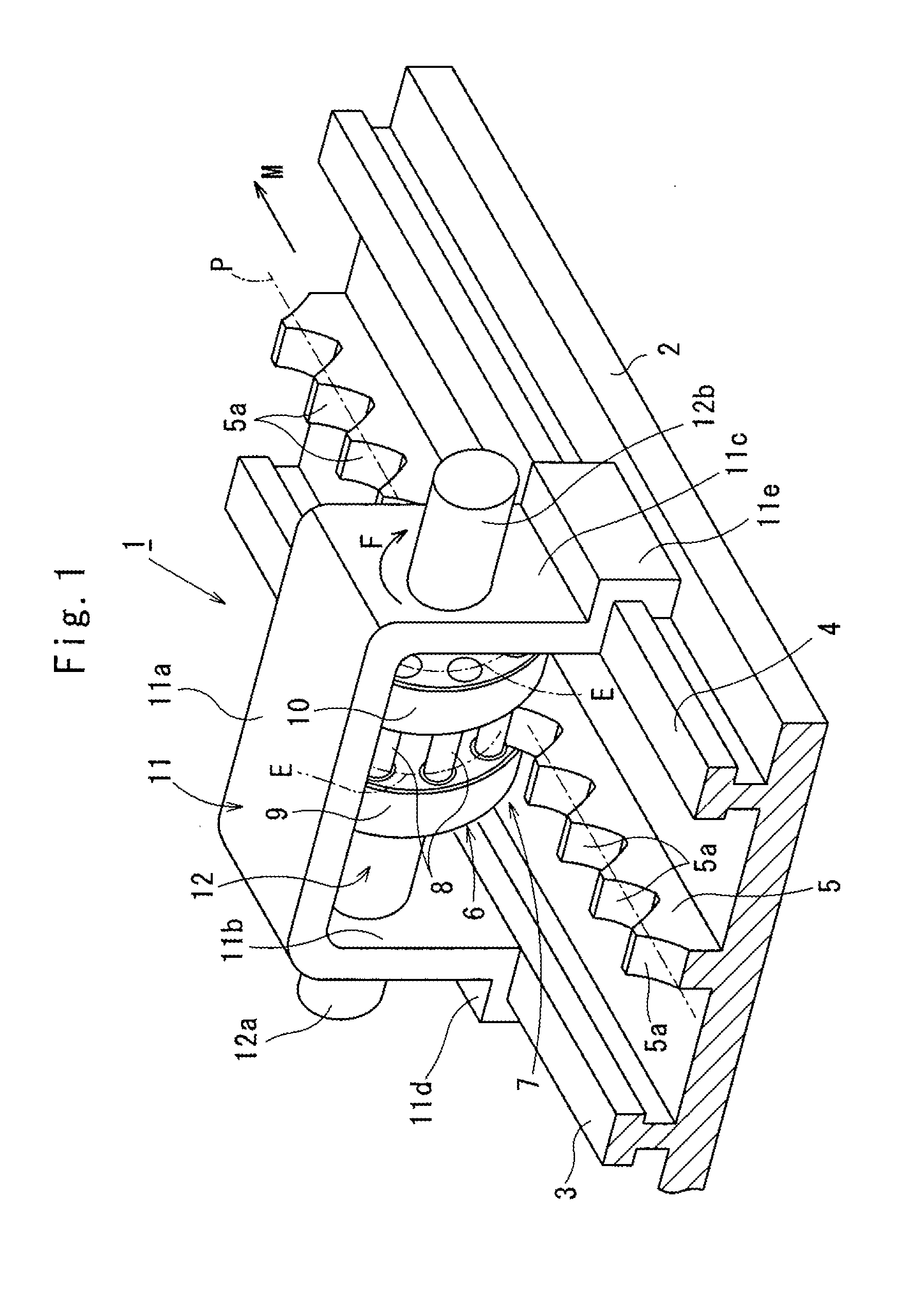

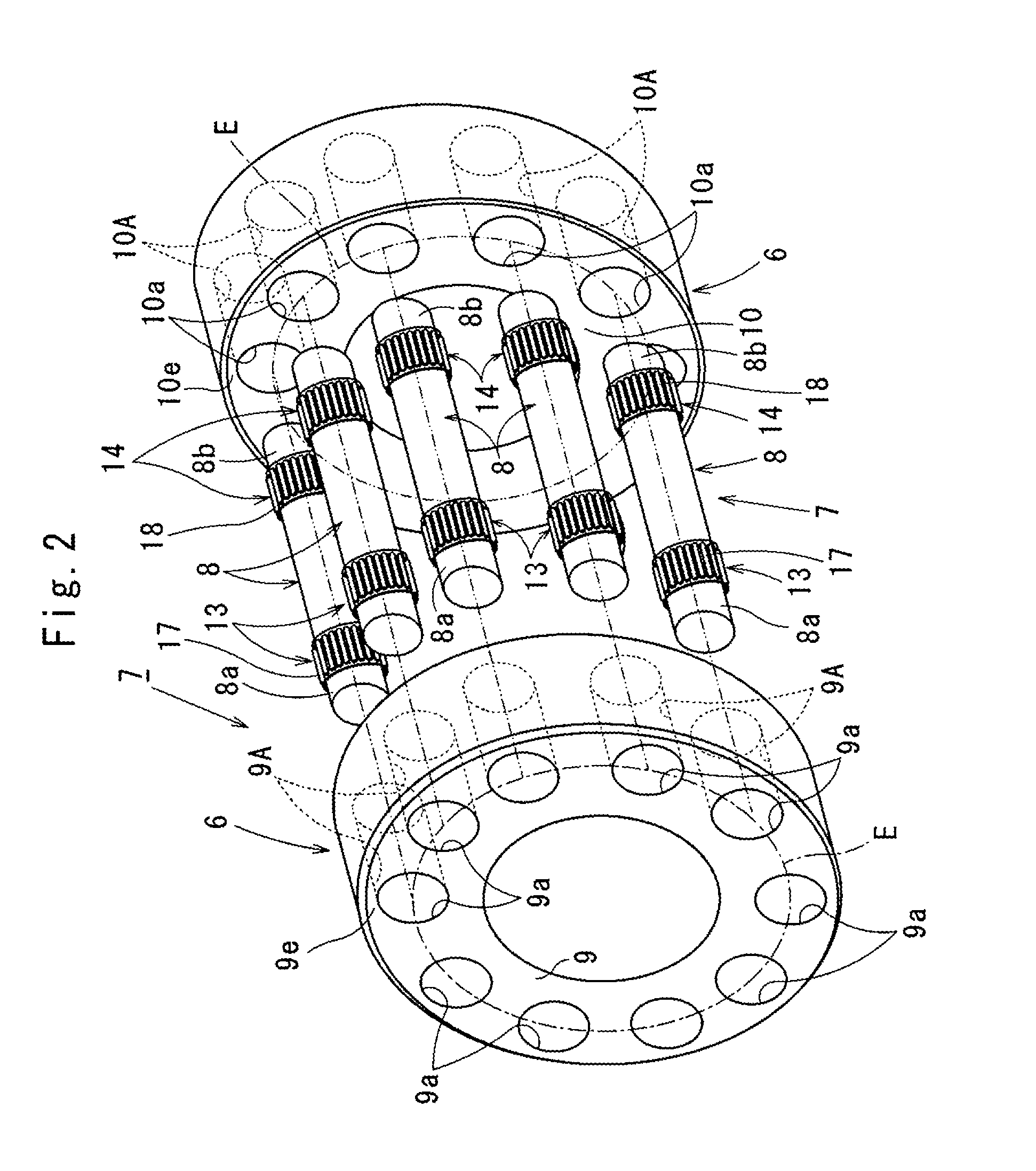

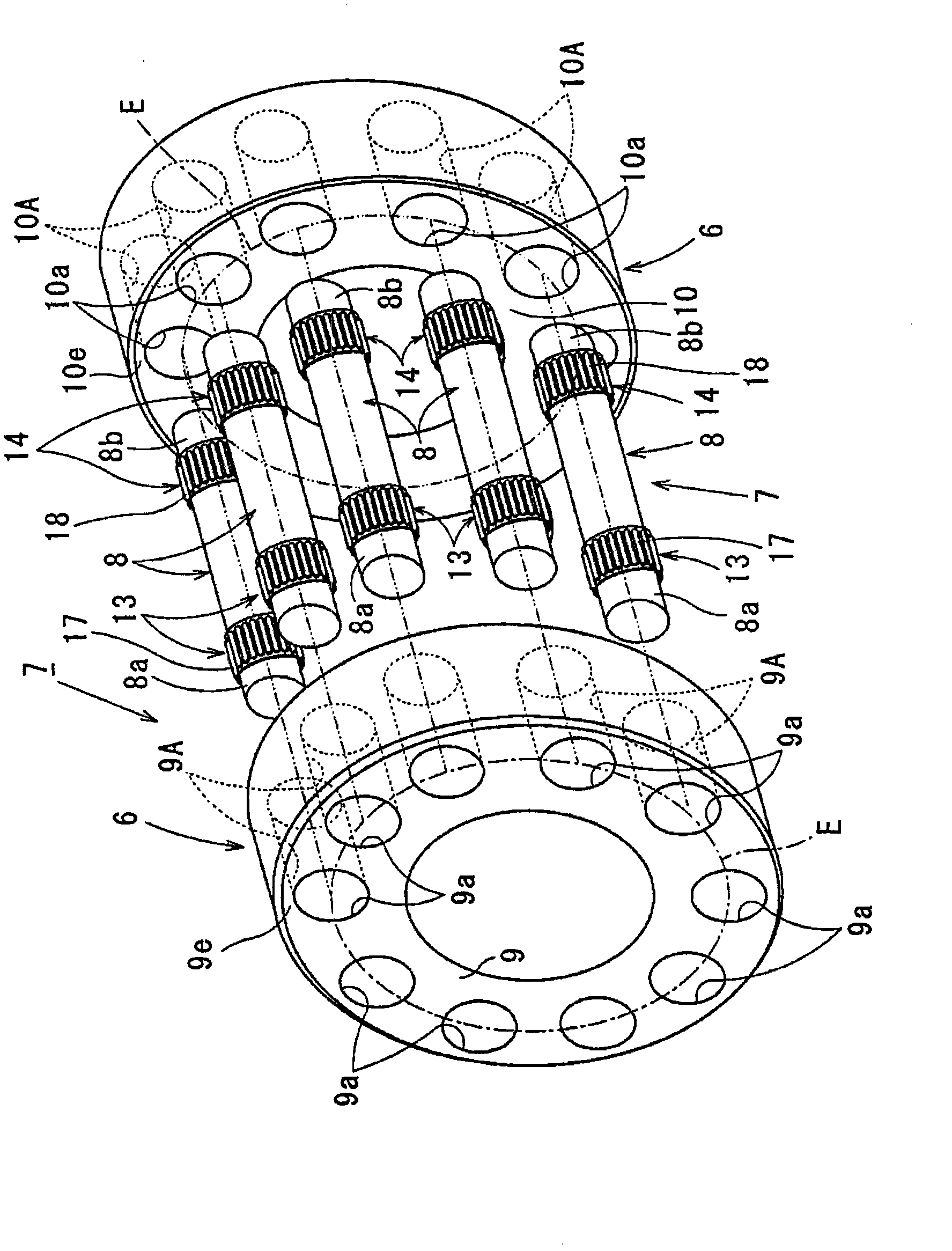

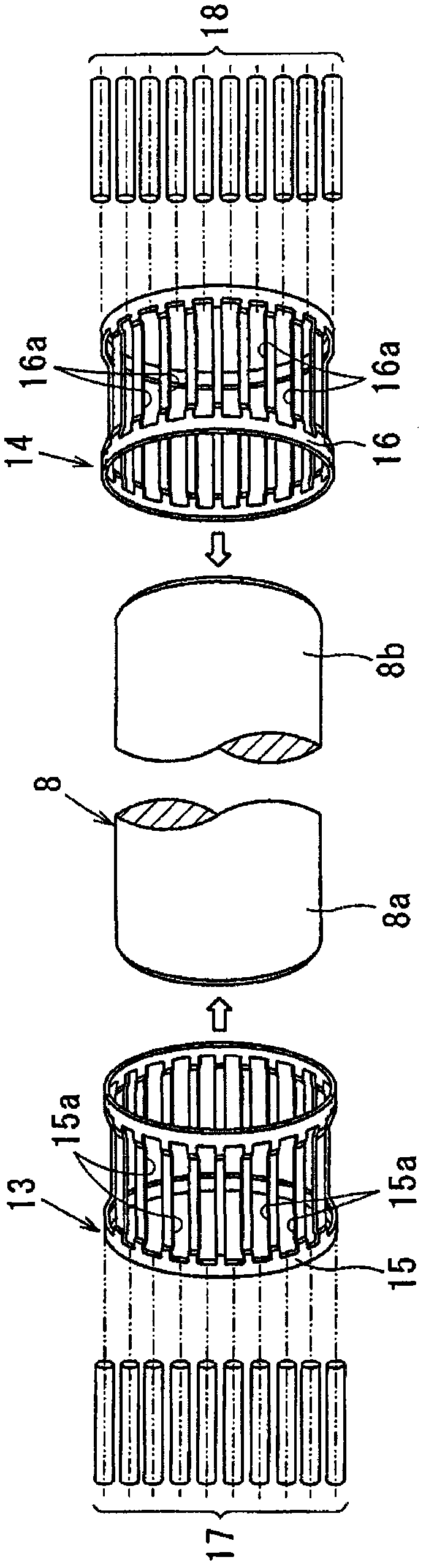

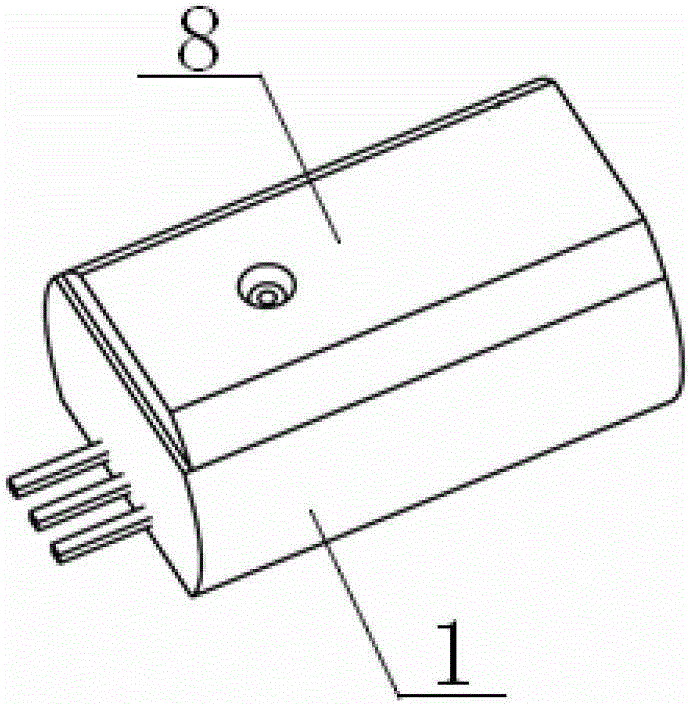

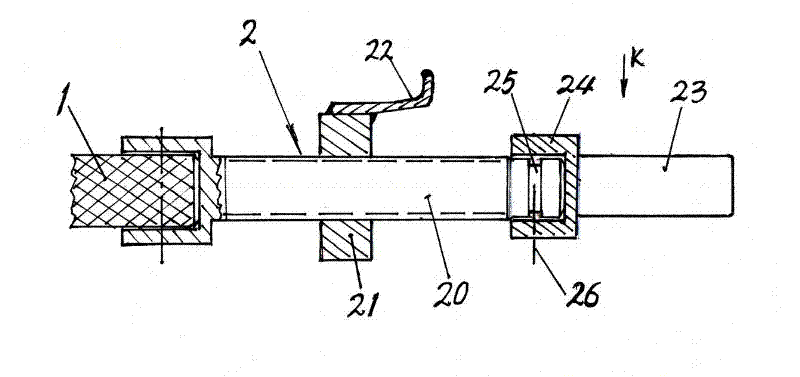

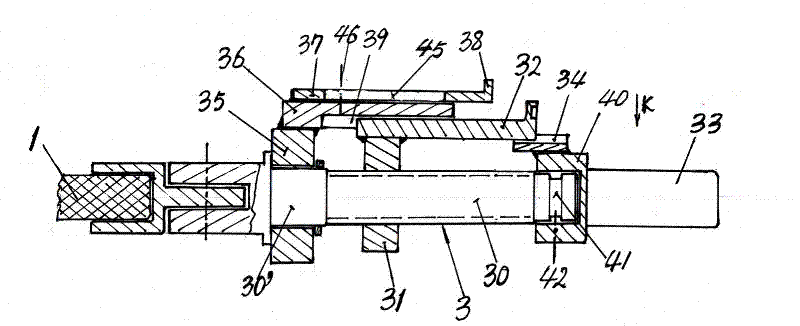

Pin Roller Type Pinion Device

InactiveUS20130031996A1Increase their wear-resistant propertyEnhance their rupture strengthShaftsPortable liftingPins needlesPinion

In a pin roller type pinion device, a first bearing has first pin needles rollably arranged around pin rollers between an inner surface of first circular holes and one end portion of the pin rollers. A second bearing has second pin needles rollably arranged around the pin rollers between an inner surface of second circular holes and the other end portion of the pin rollers. This prevents an external pressure from developing on the inner surface of the circular holes when inserting the pin needles between the inner surface of the circular holes and the end portions of the pin rollers.

Owner:KAMOSEIKO

Layer feed containing wooden fish stone

ActiveCN101491306AReduce manufacturing costEasy to transportFood processingAnimal feeding stuffNutritive valuesAnimal science

The invention relates to a laying hen feedstuff containing limonite, which solves the problem that the prior laying hen feedstuff cannot provide enough microelements to satisfy health requirements of people, and has the advantages of having low cost, being rich in various rare trace elements, and effectively improving the nutritive value of hen eggs. The formulation of the feedstuff comprises the following components in portion by weight: 70 to 80 portions of corn, 10 to 15 portions of bean cake, 3 to 7 portions of pin needle meal, 1 to 4 portions of flour weevil, and 6 to 10 portions of limonite powder.

Owner:SHANDONG HUAXIA WEIKANG AGRI ANIMAL HUSBANDRY TECH

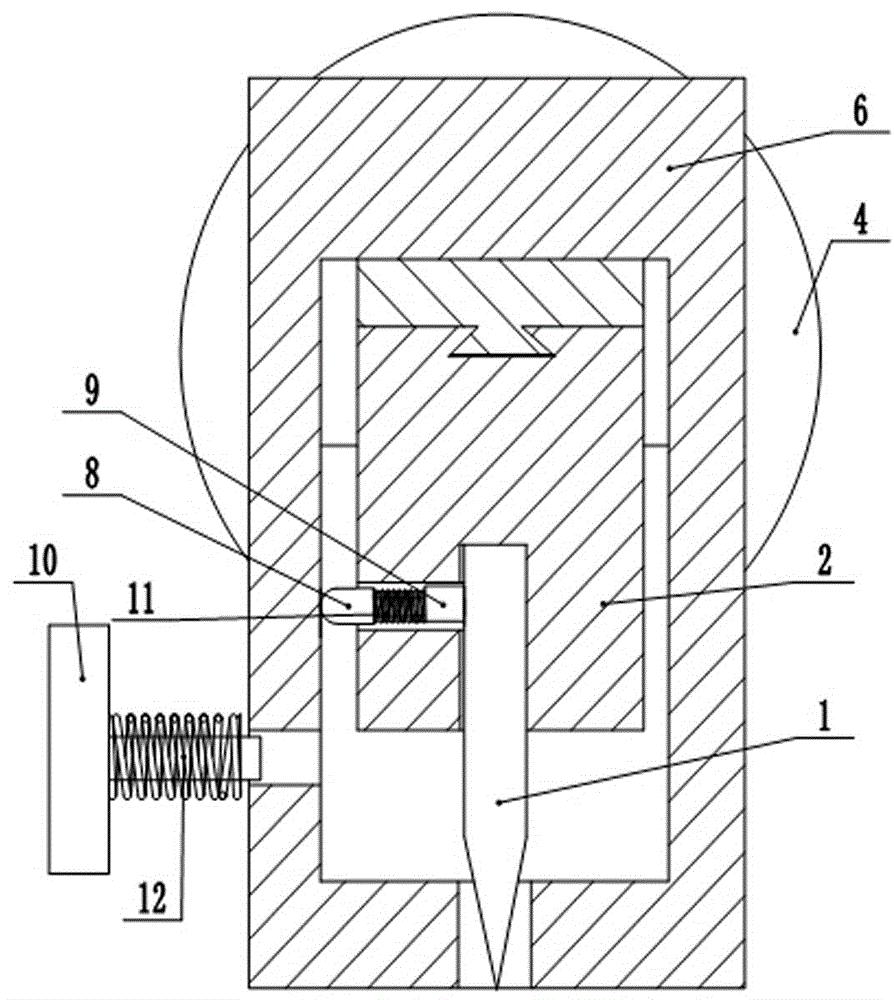

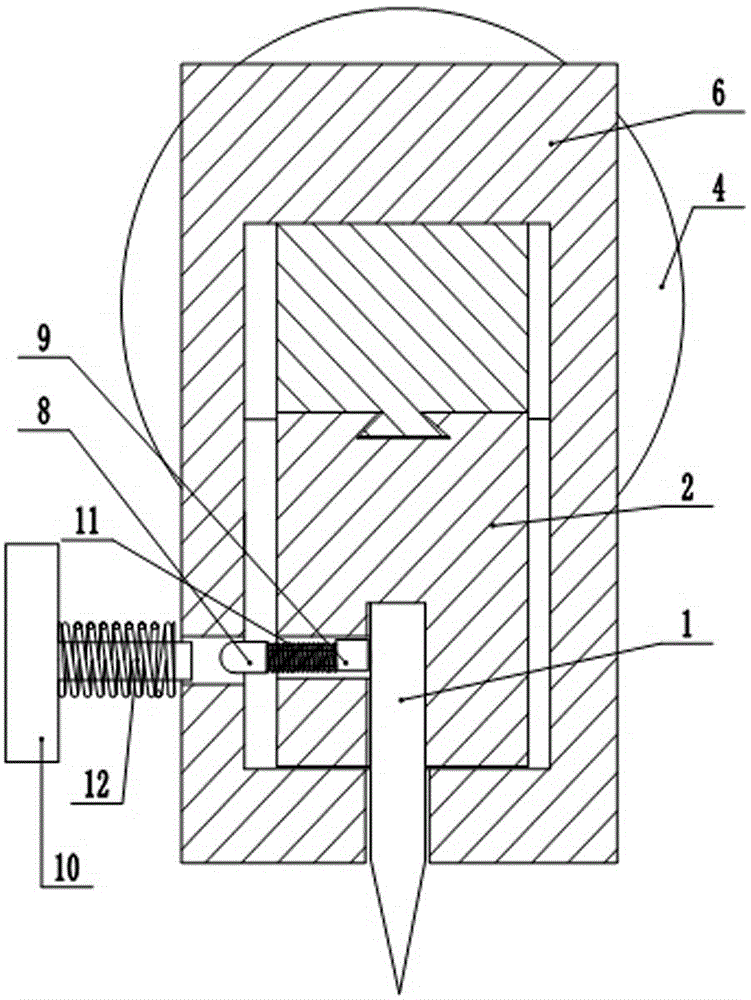

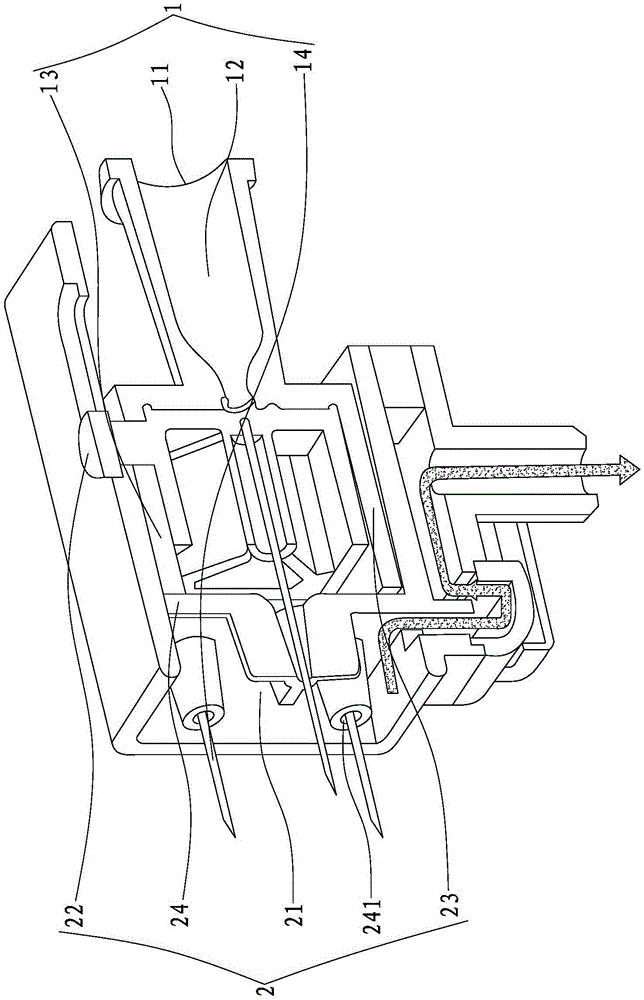

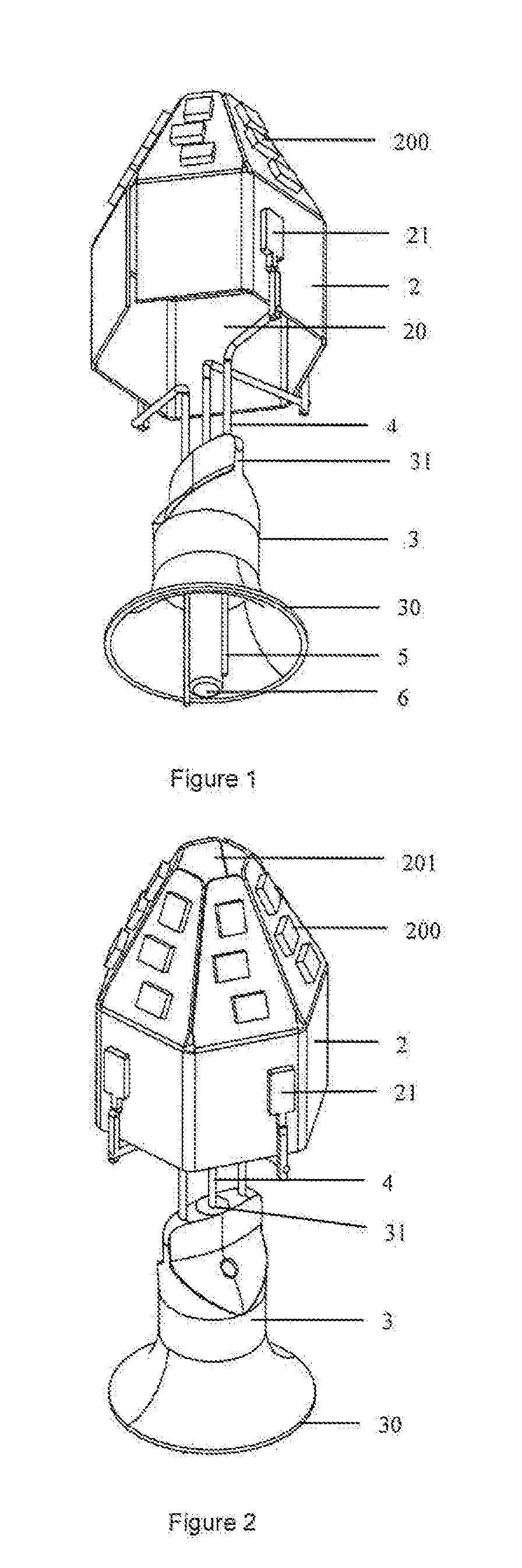

Skin prick test slope pushing block elastic pin needle

InactiveCN104605893AControl depthControlSurgeryVaccination/ovulation diagnosticsPins needlesEngineering

The invention provides a skin prick test slope pushing block elastic pin needle. The skin prick test slope pushing block elastic pin needle comprises a needle head, a needle seat, a slope pushing rod and a shell. A transverse hole and a vertical hole which are formed at a certain angle and communicated with each other are formed in the shell. The needle seat is arranged in the vertical hole. The slope pushing rod is arranged in the transverse hole. A slope is arranged at the tail of the needle seat. A dovetail groove is formed in the slope and matched with a protrusion of the slope pushing rod, the protrusion can only slide in the dovetail groove, thus, the slope pushing rod moves in the transverse hole to make the needle seat move in the vertical hole, the tail of the slope pushing rod stretches out of the shell and is provided with a pushing disc, a thick spring is arranged between the pushing disc and the shell, the thick spring can be compressed by pushing the pushing disc, and the thick spring can automatically rebound after the pushing disc is released.

Owner:陈建宝

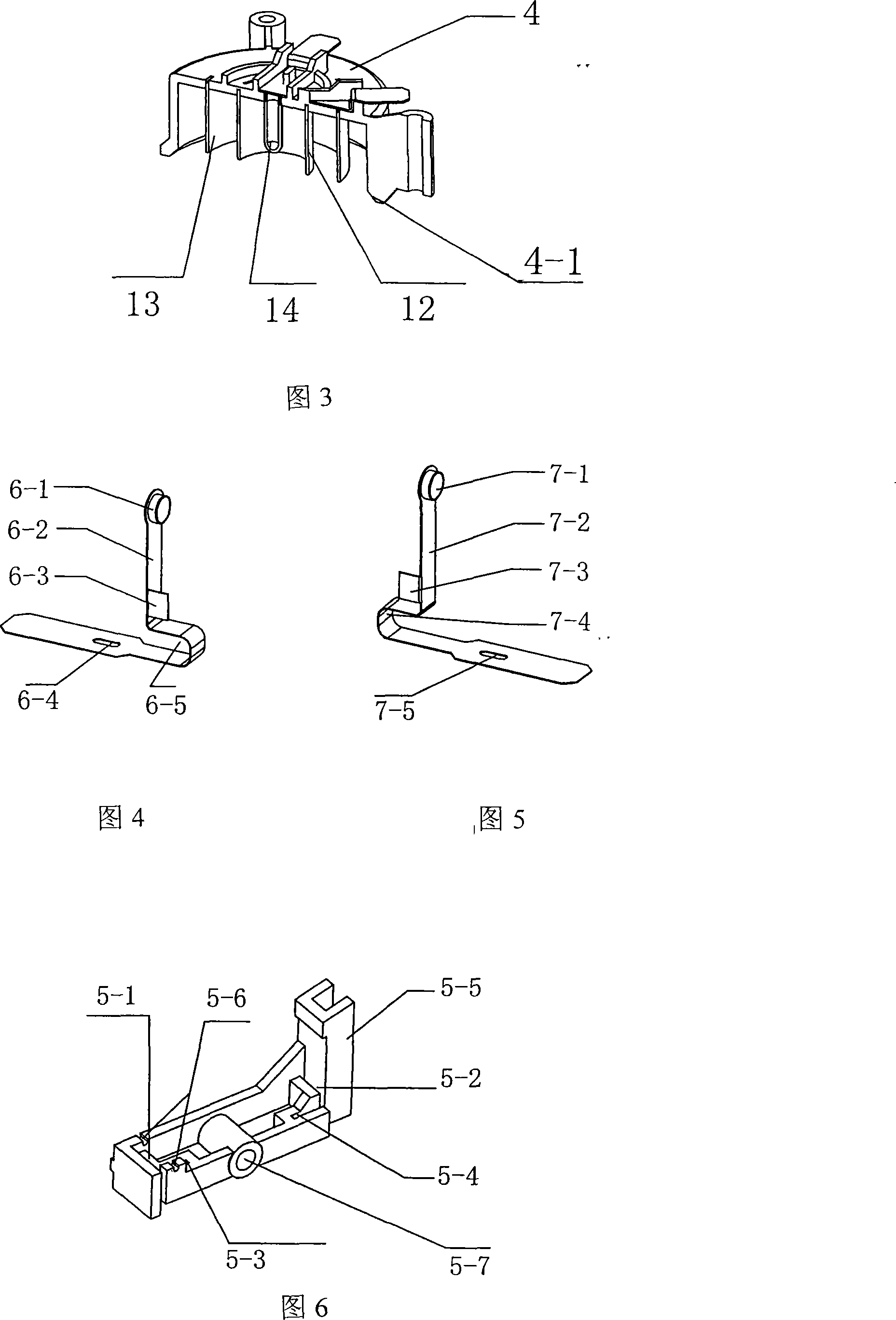

Ropeless electric connector

InactiveCN101170226AImprove securityTwo-part coupling devicesLive contact access preventionElectricityPins needles

The invention discloses a cordless electric connector, which is nested by a positive joint and a negative joint, the positive joint is provided with a center ground stud, a power wire ring, as well as a zero wire ring, the negative joint base structure is provided with a center hole and two concentric ring grooves, the center hole is arranged with a ground lug, and the two concentric ring grooves are separately arranged with a power wire electric contact and a zero wire electric contact. The installation post of base structure lower basal surface is arranged with a push pin through a pin shaft, two ends of the push pin are respectively provided with slim grooves, two grooves are separately embedded with deflection arms on the power wire electric contact and the zero wire electric contact, a needle spring middle part is embedded in the push pin needle spring groove, two ends of the needle spring are separately inserted into two needle spring fixed grooves of the base structure, thereby making the push pin elastically position, and maintaining electric contact points of deflection points of the power wire electric contact and the zero wire electric contact in the groove-shaped matte cavity of the base structure. Because the negative joint is increased with the push pin mechanism, when the push pin is operated to the preset position, the electric contacts are in the covered positions, thereby improving safety performance for electric connectors.

Owner:ZHEJIANG UNIV

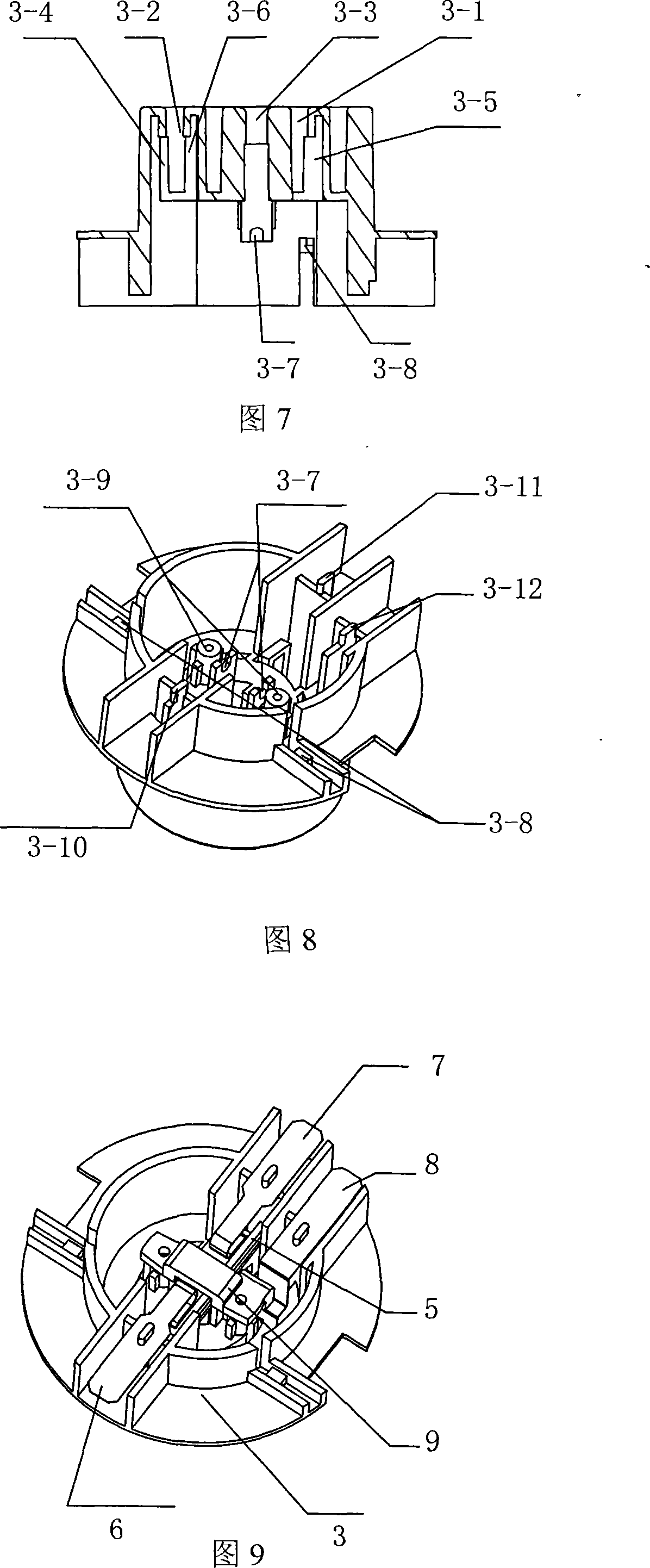

Electrohydrodynamic conduction pump

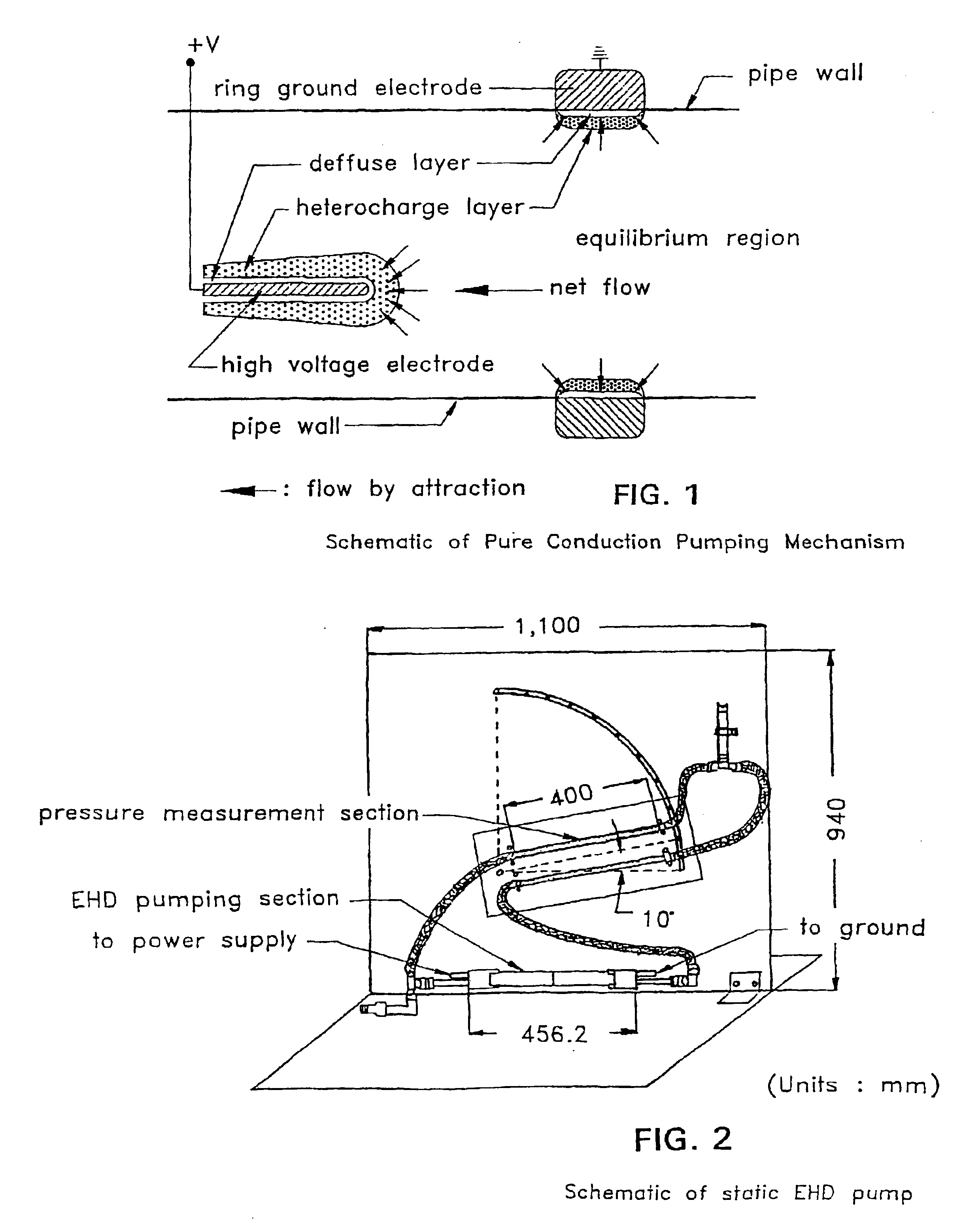

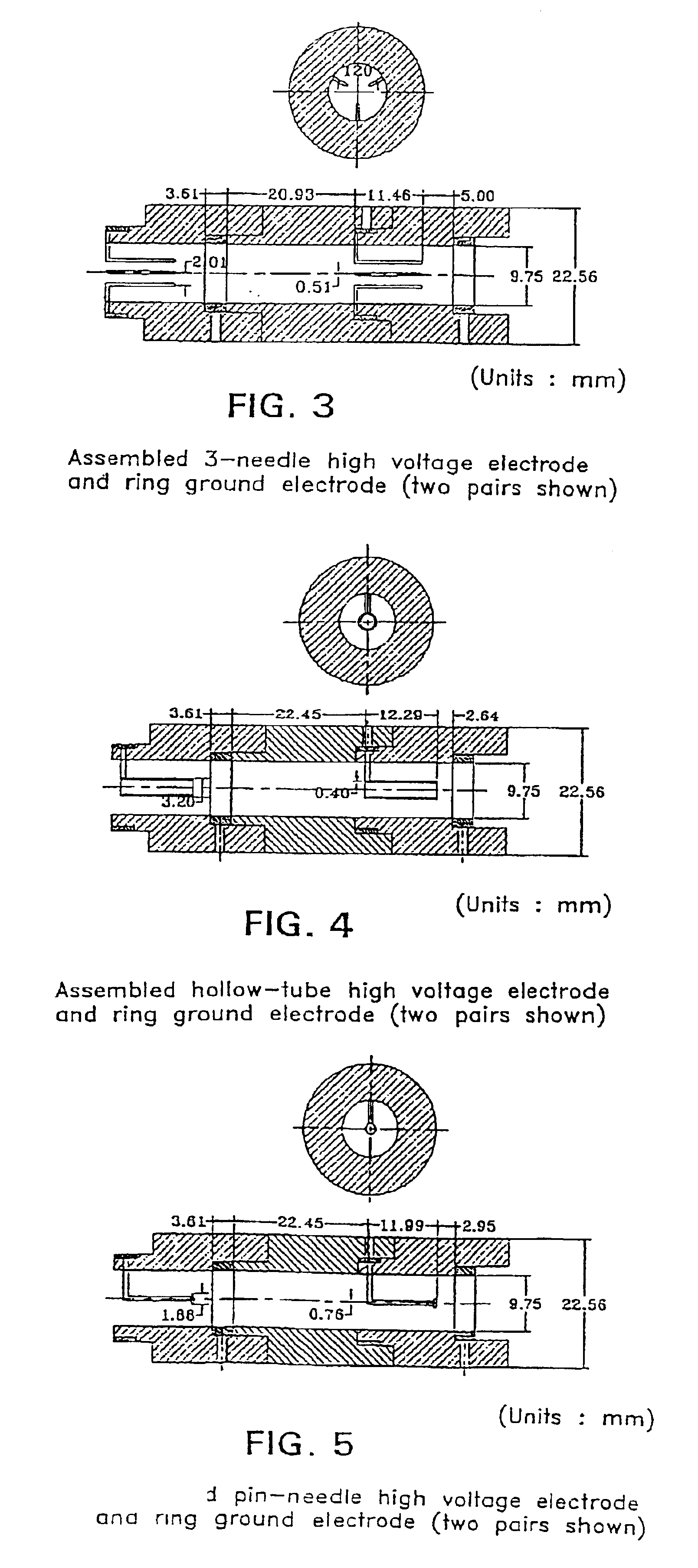

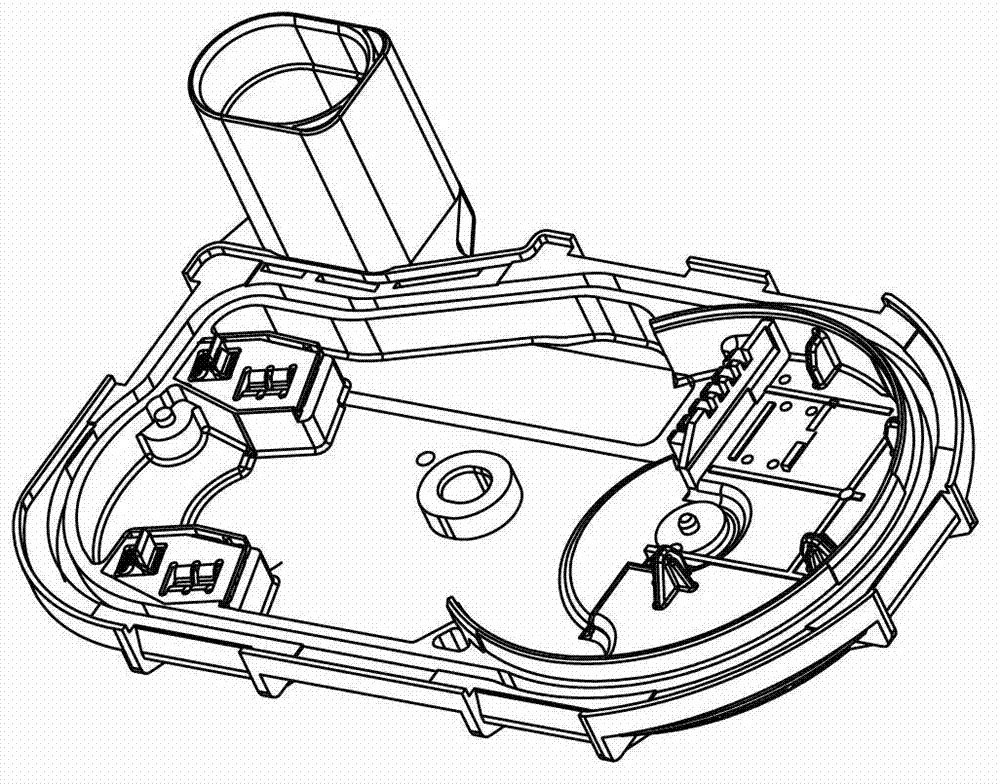

InactiveUS6932580B2Simple designQuickly performing controlPump componentsFlexible member pumpsDielectricPins needles

An electrohydrodynamic (EHD) conduction pump is provided for pumping dielectric liquids, and a particular adaptation for mass transport of isothermal and non-isothermal single phase liquids. The EHD conduction pump does not require direct injection of electric charges into the fluid. The EHD conduction pump includes an EHD pumping section and associated connecting tubes with electrodes arranged in series in the pumping section. The electrodes are coupled to a high voltage low current dc power supply. A positive polarity dc voltage is applied to the electrodes. Various electrode configurations may be used, such as three-needle, hollow-tube, or pin-needle electrode configuration.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

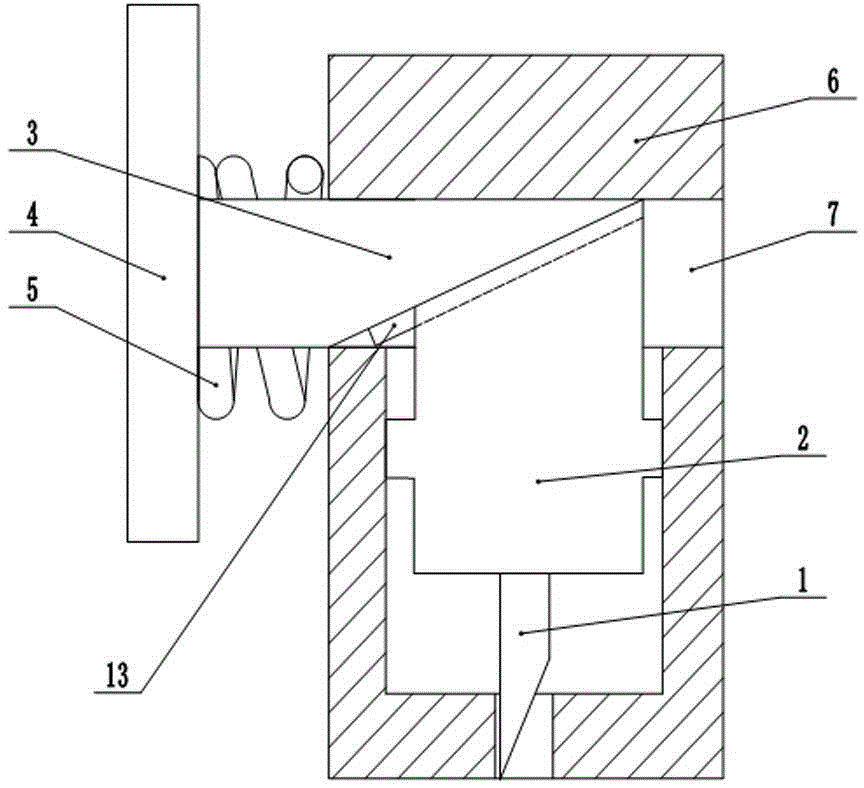

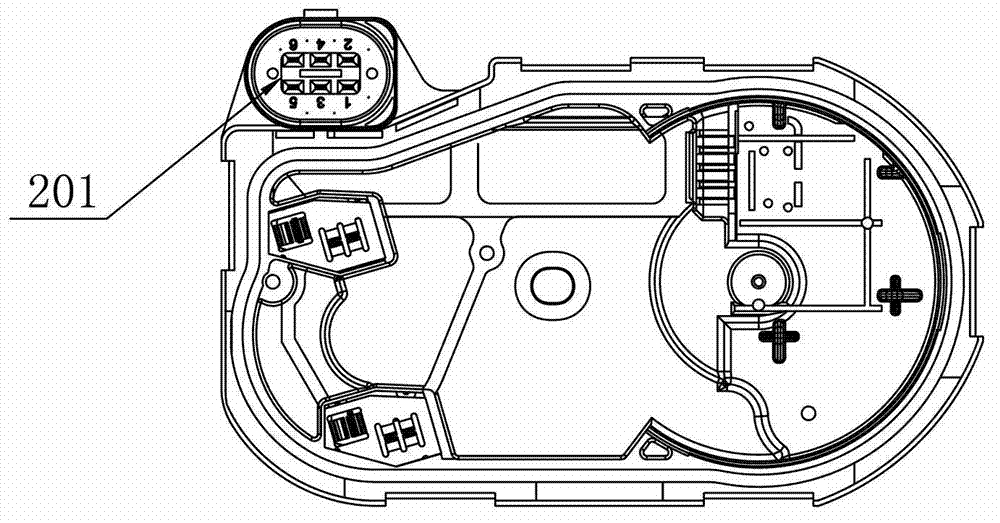

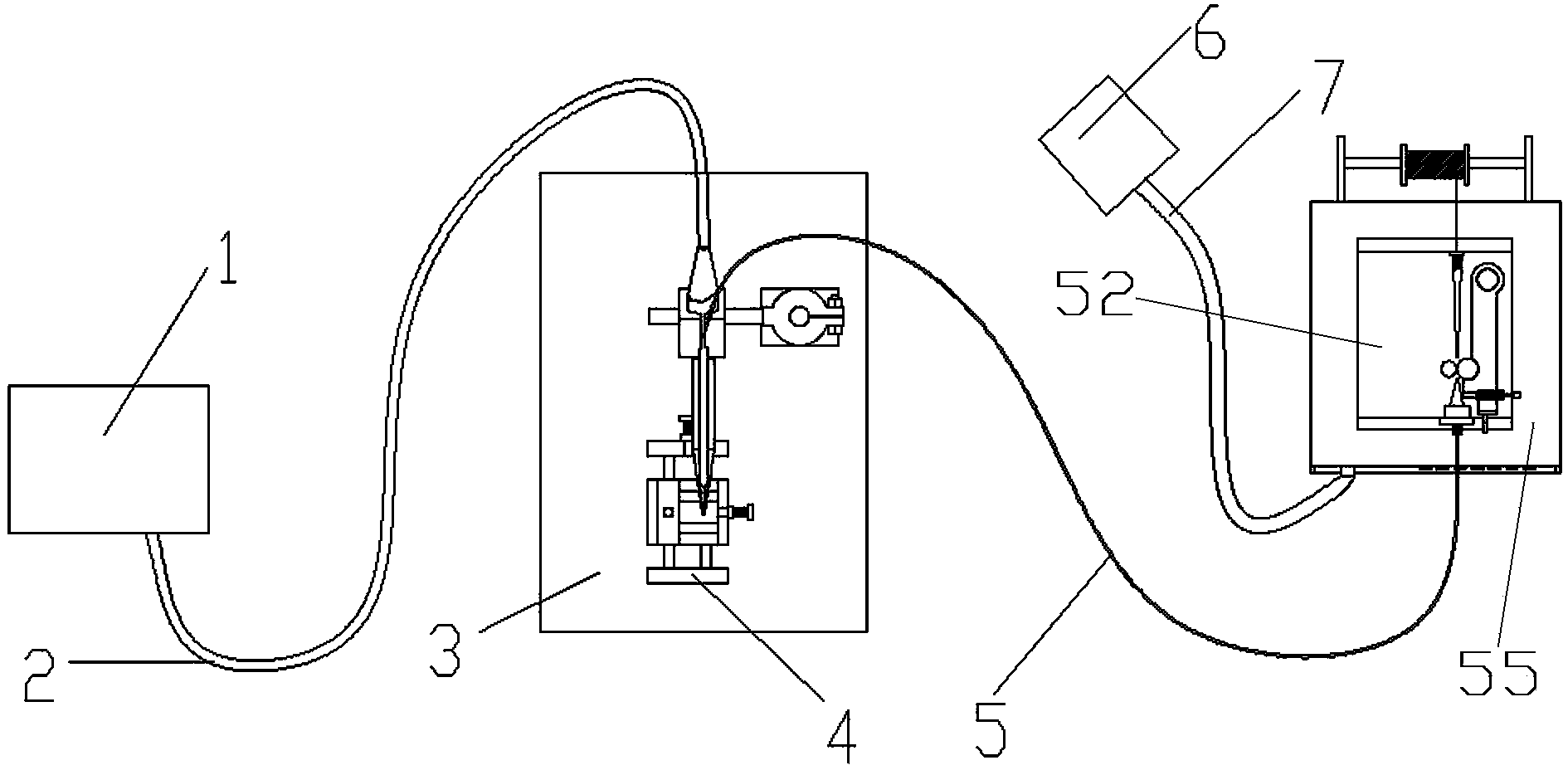

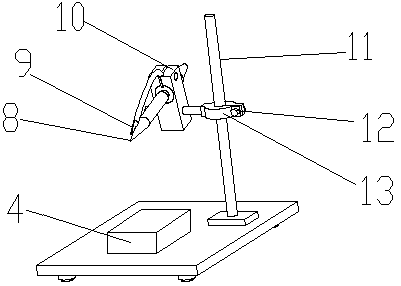

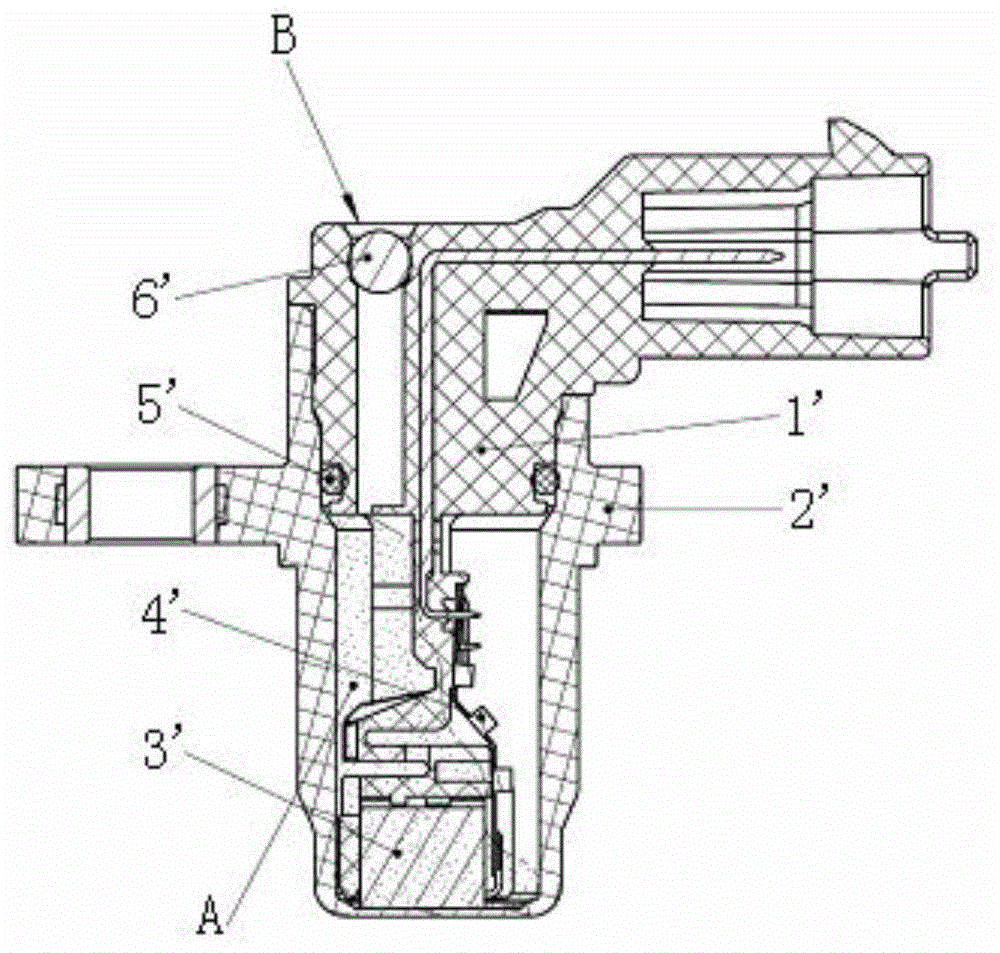

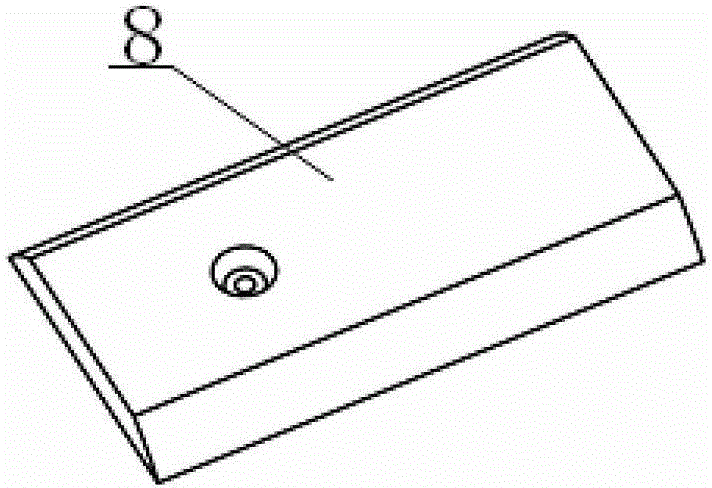

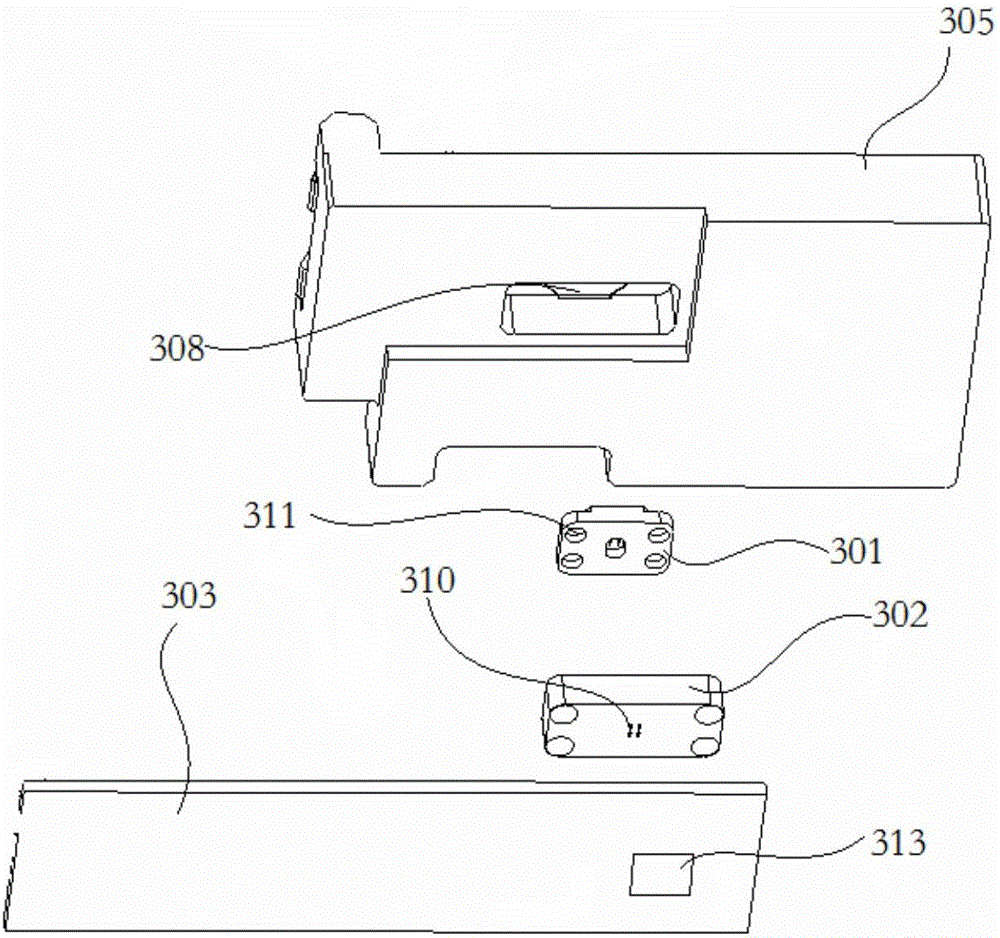

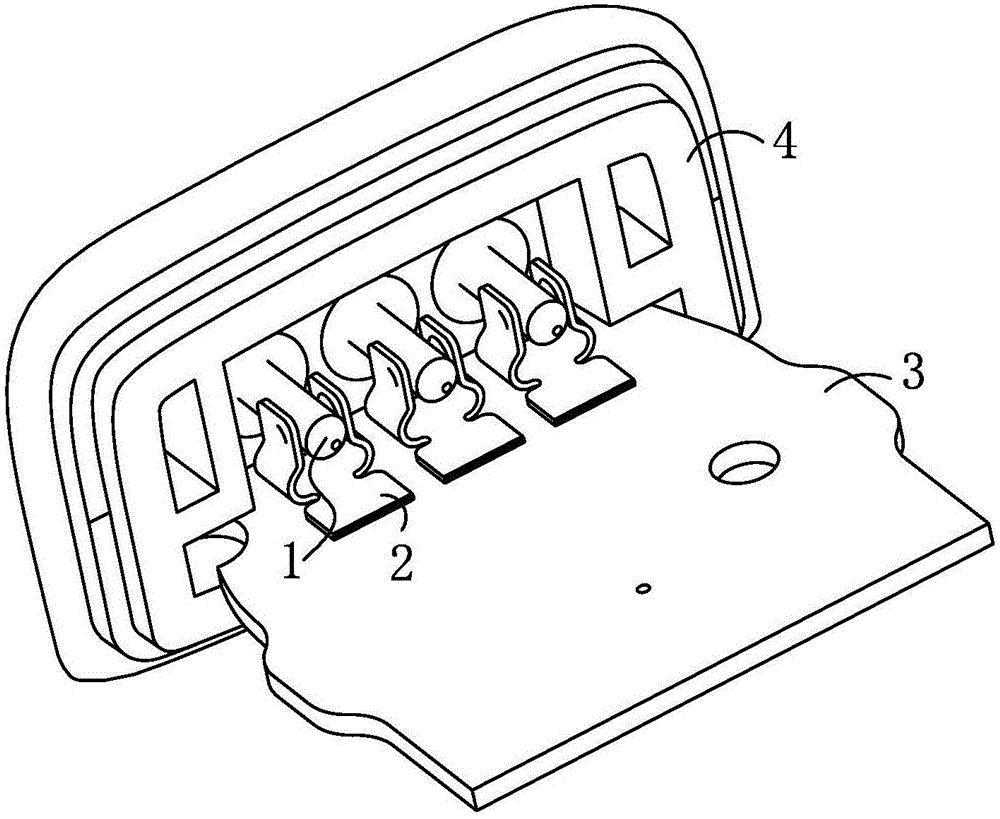

Device and method for detecting height of PIN needle in cover board component of automotive throttle valve

ActiveCN102829710AImprove detection efficiencyAccurate measurementUsing electrical meansPins needlesControl circuit

The invention discloses a device for detecting a height of a PIN needle in a cover board component of an automotive throttle valve, and is characterized by comprising a workbench, a servo control system, a mould used for placing the cover board component of the throttle valve, a control circuit and a signal module, wherein the mould is arranged on the workbench, a first contact group is fixedly arranged in the mould, a slider block is fixedly arranged on the upper end of the servo control system, a second contact group capable of sliding vertically is arranged in the slider block, a first spring is arranged between each contact in the second contact group and the upper end of the servo control system, a pressure block is arranged above the mould, and a pressure block drive mechanism is fixedly arranged on the workbench. The device has the advantages that the cover board component is reversely buckled in the mould, the motion of the second contact group is controlled through the servo control system so as to detect whether the height of the PIN needle conforms to requirements, the conventional manual detection is replaced, and the device is accurate in measurement, convenient, quick and high in detection efficiency.

Owner:CIXI XINYUE ELECTRIC APPLIANCE

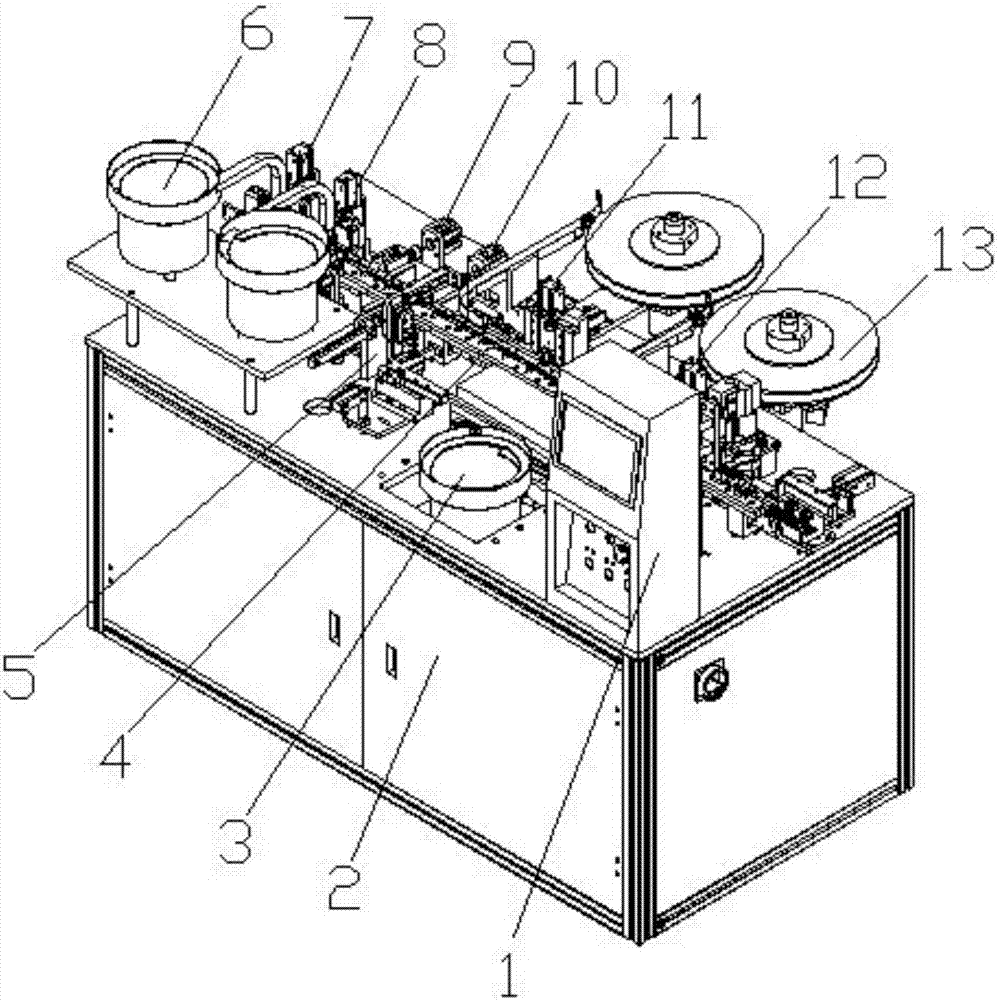

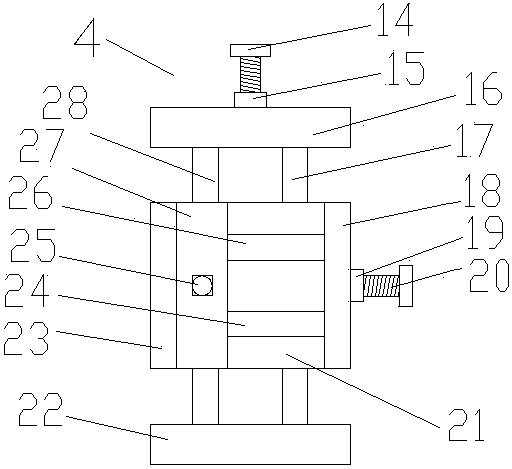

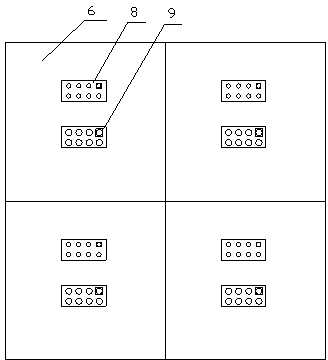

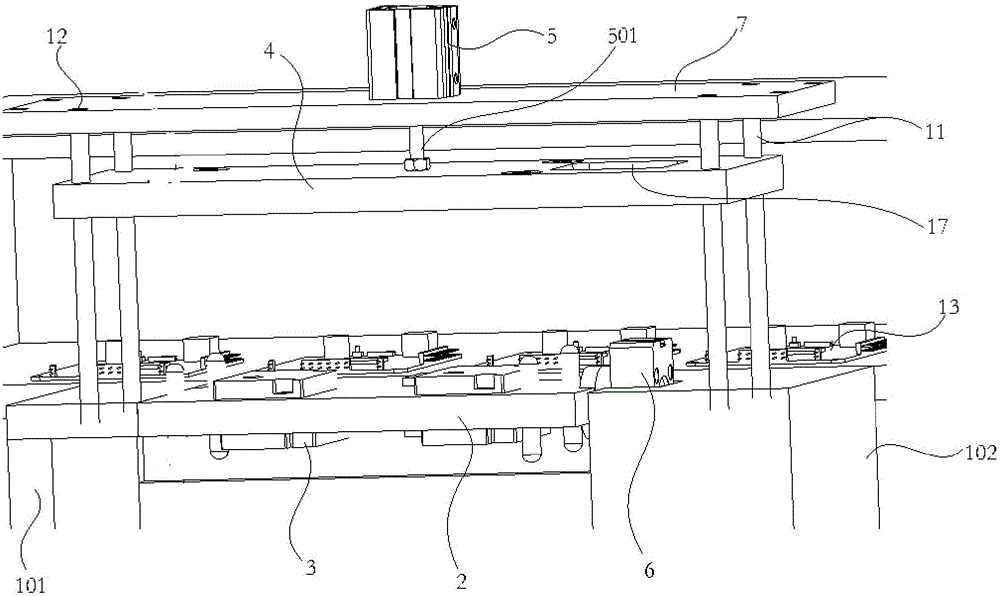

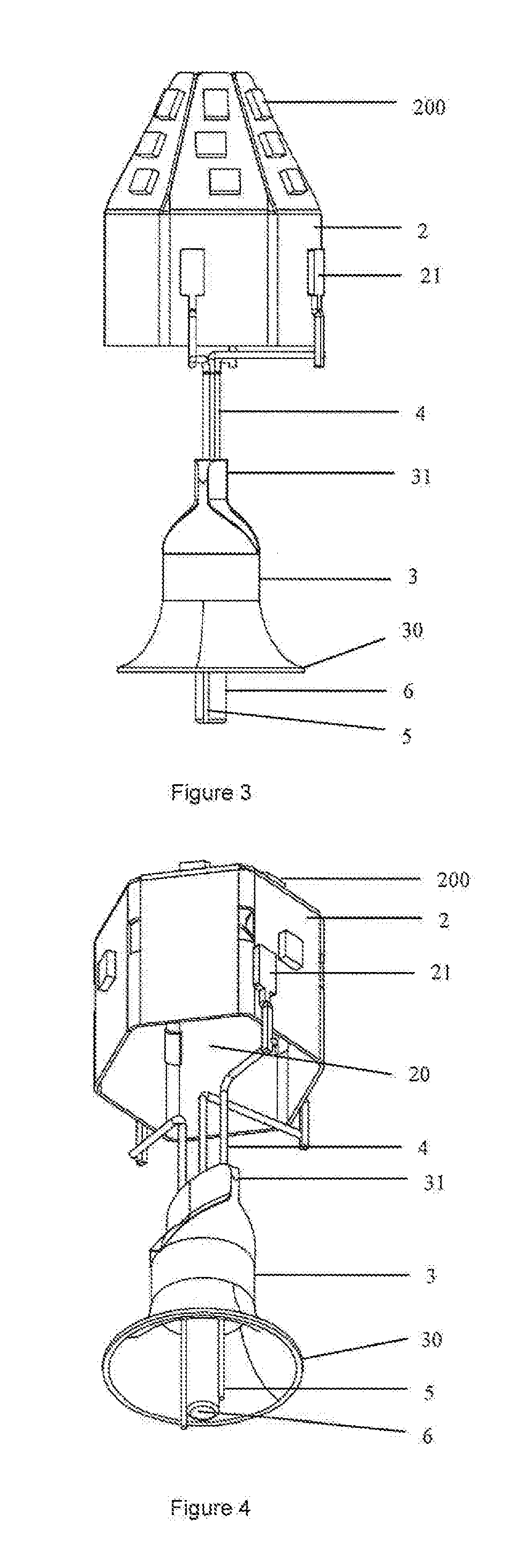

Automatic assembling machine of double-row eight-pin connector

InactiveCN107959214AHigh degree of automationImprove assembly efficiencyContact member assembly/disassemblyPins needlesPlastic materials

The invention relates to an automatic assembly machine for a double-row eight-pin connector, which includes a frame, a control box and a feeding track arranged on the frame, above the feeding track along the conveying direction, a first pin insertion device, a second Pin insertion device, plastic parts feeding device, first bending device, second bending device, first blade insertion device, second blade insertion device and detection device, the first pin insertion device and the second pin insertion device are connected There is a PIN needle feeding plate, the plastic parts feeding device is connected to the plastic parts vibrating plate, the first inserting device and the second inserting device are connected to the shrapnel vibrating plate, and the entrance end of the feeding track is equipped with a CCD detection head and a tail end. Equipped with a detection device; it can automatically assemble the parts of the connector into a double-row eight-pin connector, which has a high degree of automation and assembly efficiency, reduces labor, stable product quality, and can automatically detect the conduction performance of the product at the same time , can effectively improve the product qualification rate.

Owner:DONGGUAN UNIV OF TECH

Precision spot welder

InactiveCN103752979AReasonable designCompact structureSoldering ironMetal working apparatusMicrocomputerPins needles

The invention relates to precision spot equipment suitable for no-pin needle type miniature frameworks and products with small welding spots and provides a precision spot welder. The precision spot welder is suitable for precision frameworks and the occasions that welding spots are required to be smooth, plump and small and the requirements for welding spot positions are high. The precision spot welder comprises a soldering iron control instrument, an automatic tin wire discharge device and a tin soldering operating device. The soldering iron control instrument is provided with a control box, the control box is provided with an operation panel, and a microcomputer controller is arranged in the control box; the automatic tin wire discharge device is formed by a tin wire mounting rack, an automatic tin wire discharge control box, a tin wire feed nozzle, a locating nut, a tin wire transmission wheel, a tin wire transmission motor, a tin wire clamping wheel, a tin wire passing nozzle, an adjusting spanner, a spring, a first screw, a connecting piece, a vertical piece at the front end of the connecting piece, a mounting table, a tin wire guide pipe and a pedal. The tin soldering operating device is formed by a base, a support, a movable flame, an installation block, a locating screw, a tin wire discharge nozzle, a soldering iron head and a tin soldering product locating movable device.

Owner:惠涌

A pin roller type pinion device

InactiveCN102913600AImprove anti-wear performanceHigh breaking strengthRoller bearingsShaftsCircular discPins needles

Owner:KAMOSEIKO

LED (Light Emitting Diode) display screen module with separated lamp boards and driving boards

InactiveCN104252842AShorten the timeImprove connectivityStatic indicating devicesLED displayPins needles

The invention discloses an LED (Light Emitting Diode) display screen module with separated lamp boards and driving boards. The LED display screen module comprises a circuit board, wherein the circuit board comprises a plurality of groups of LED lamp boards and a plurality of groups of driving boards, which are matched and connected mutually; each module comprises the plurality of groups of LED lamp boards and the plurality of driving boards, which are matched and connected mutually, and the large module is divided into a plurality of independent display units, so that signal interfaces and power supply interfaces can be more accurately butted; a PIN needle is not easy to bend and break and the connectedness of signals is enhanced; the frame loss rate of signal transmission is reduced and the time consumed in a module mounting process is reduced; meanwhile, the heat dissipation effect is further enhanced.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

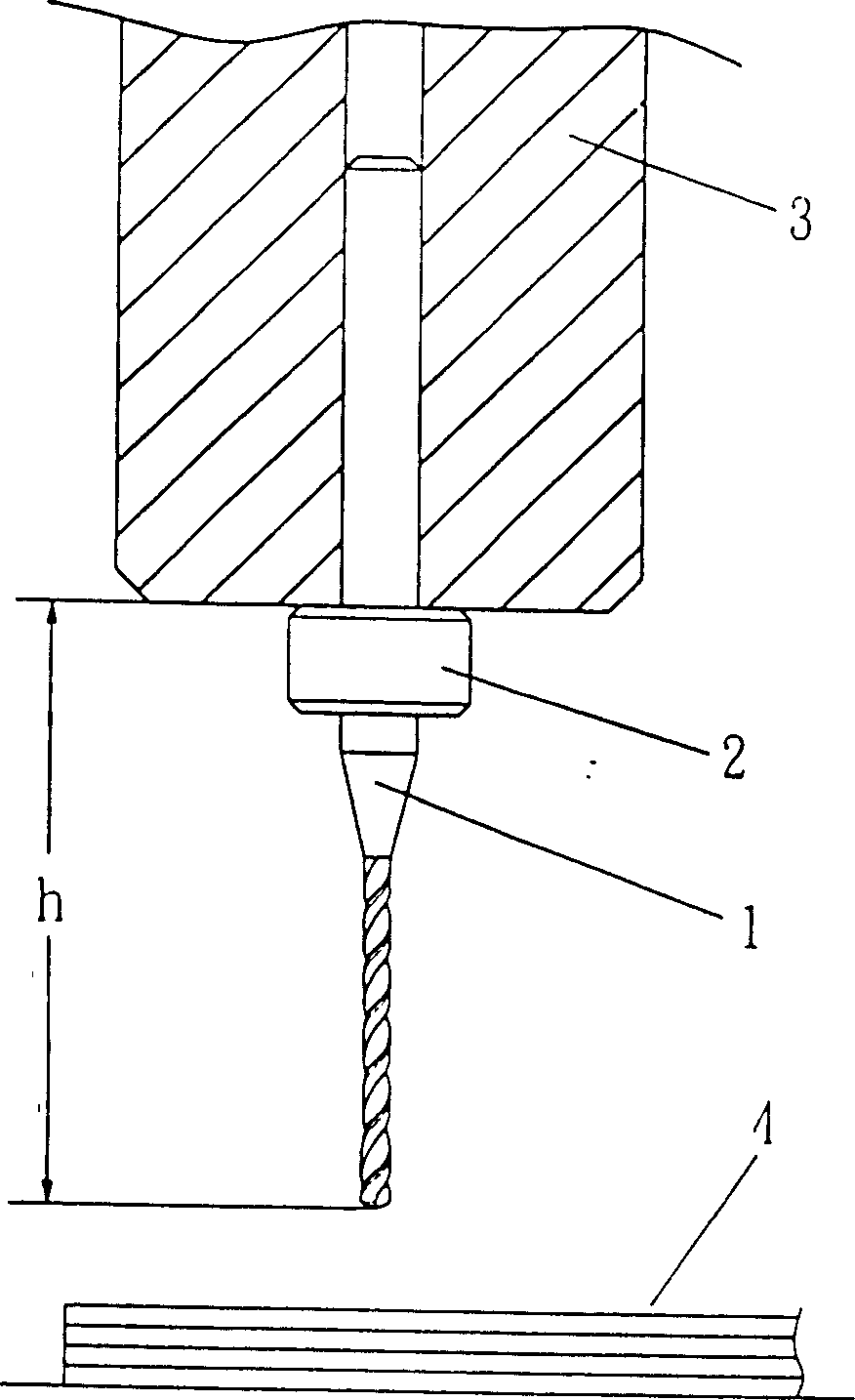

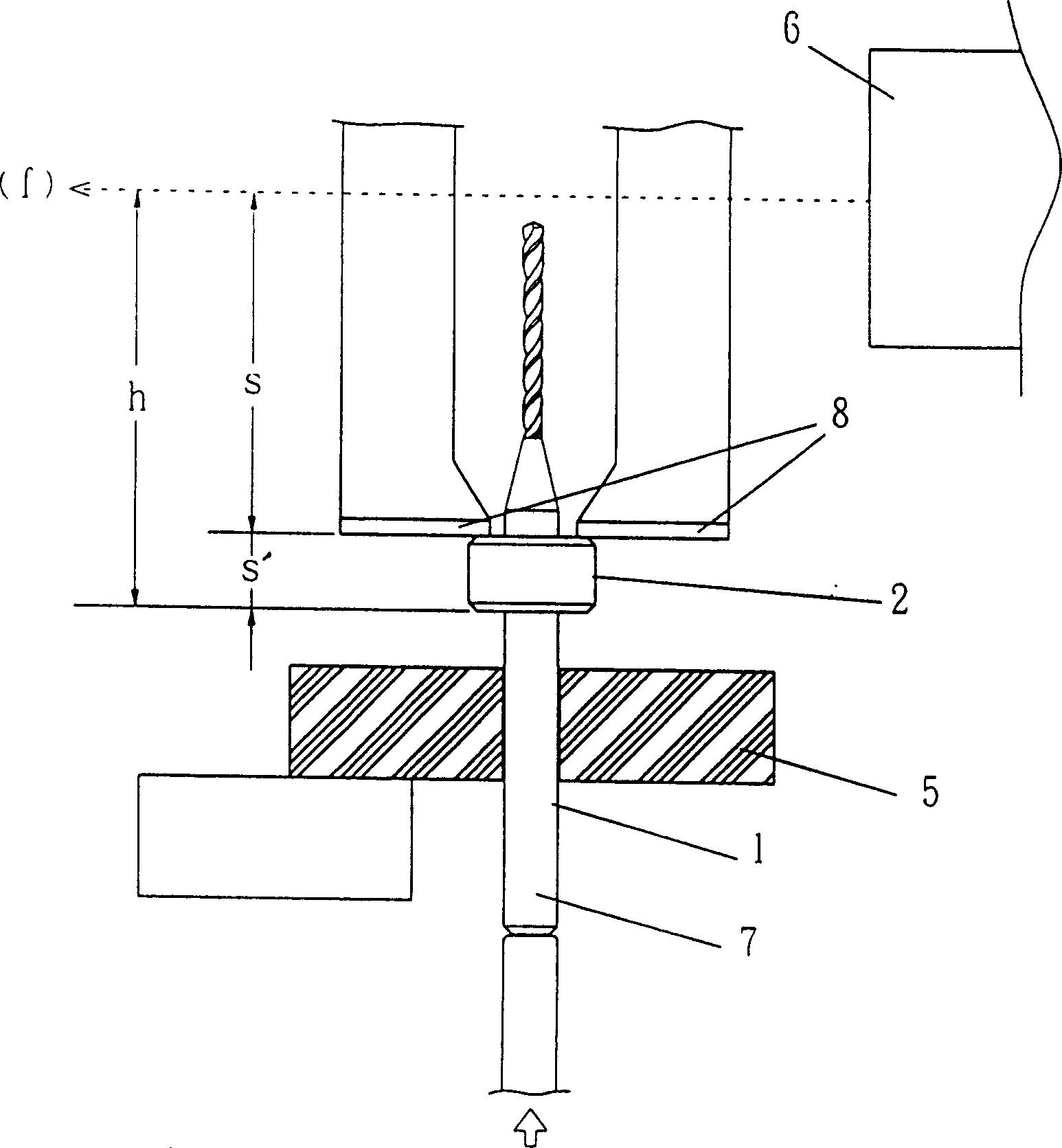

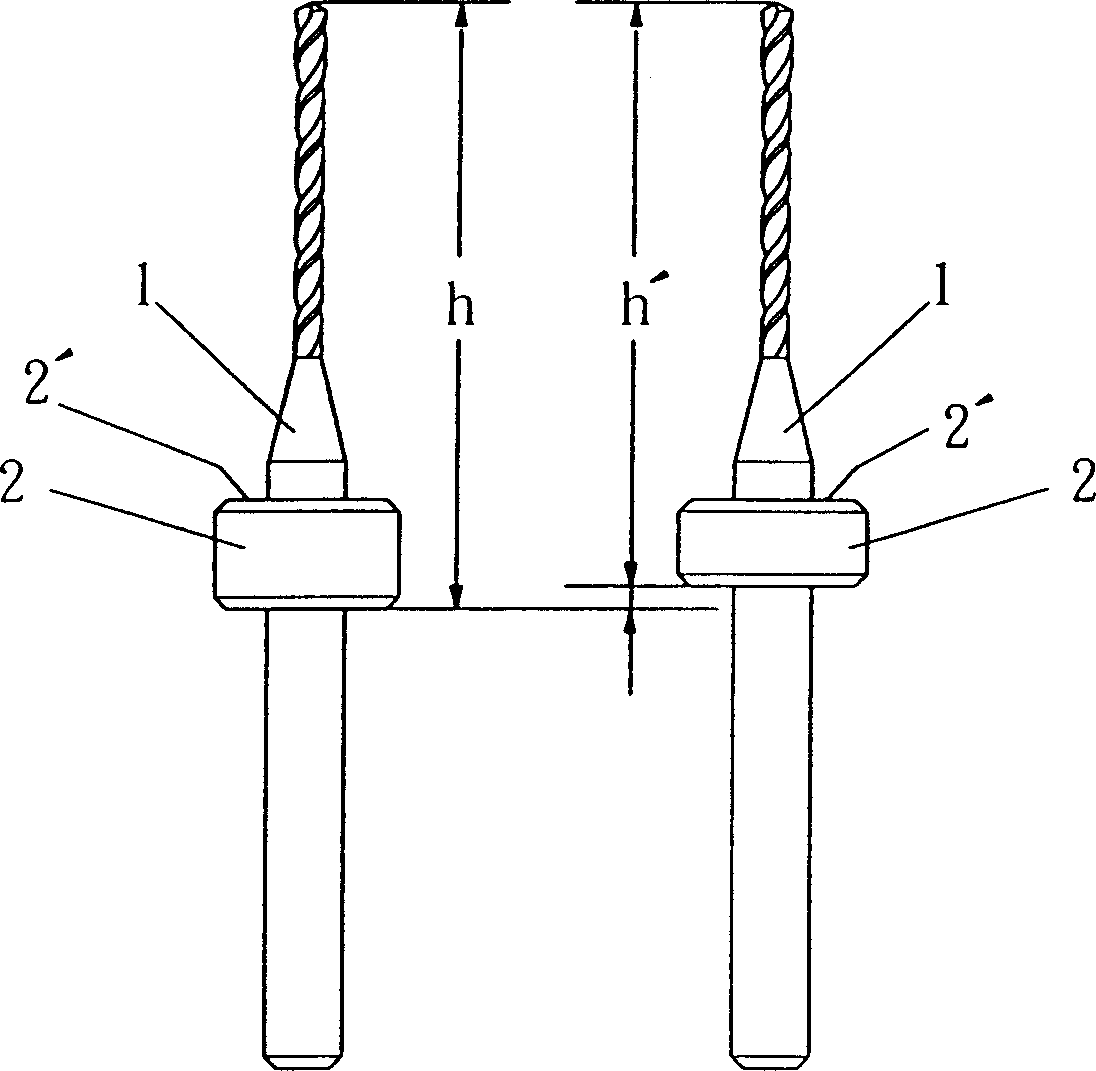

Adjusting-calibrating-positioning method for PC board boring needle ringer

This invention relates to a calibration and location method for PC board drill pin collar including: sticking a drill pin with a collar on a base for the drill, utilizing a side face CCD image generator to set a quasi-height above the drill base to let the vertical distance from the quasi-height to the top surface of the base equal to the standard collaring height of the collar, utilizing a ring squeezing piece to make the collar bottom to closely adhere to the top of the base and locate it, then using a lifter to push the pin till the needle part arrives at the quasi-position to avoid collide by the pin needles or broken so as to increase the collaring efficiency, accuracy and quality for drill pins.

Owner:邱博洪

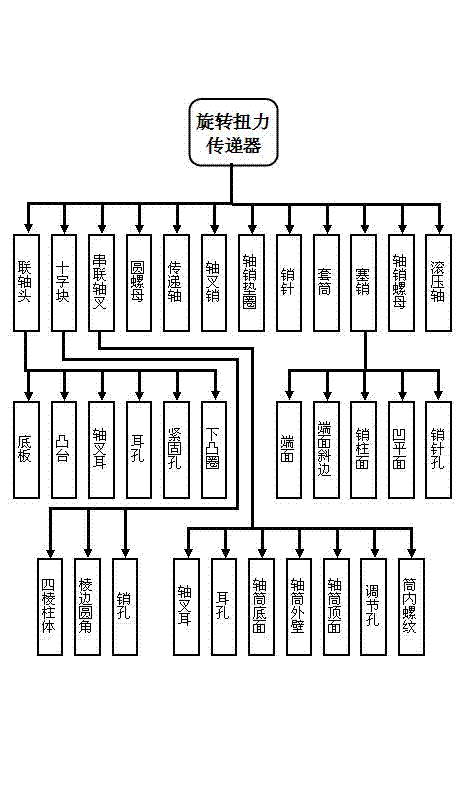

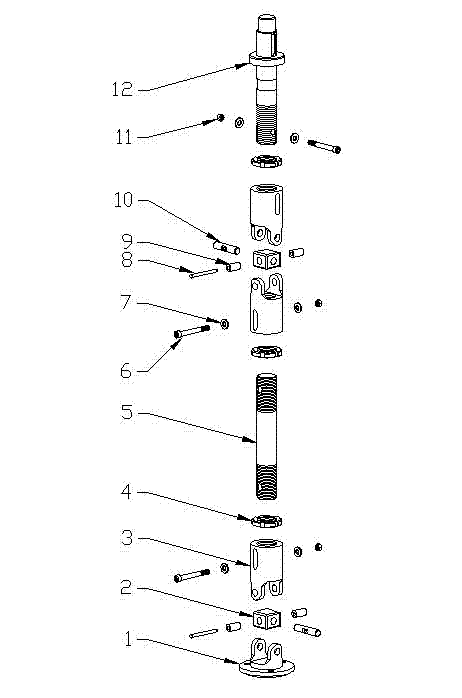

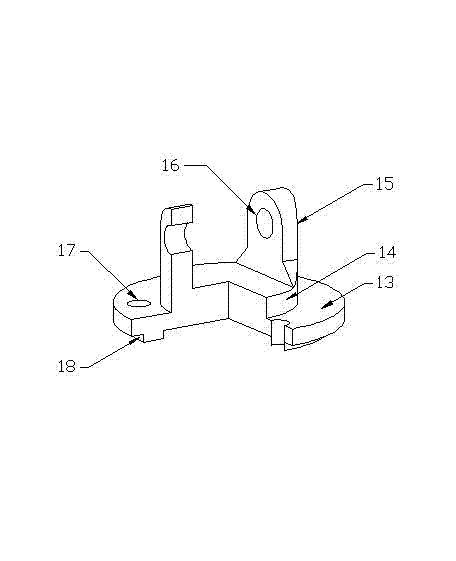

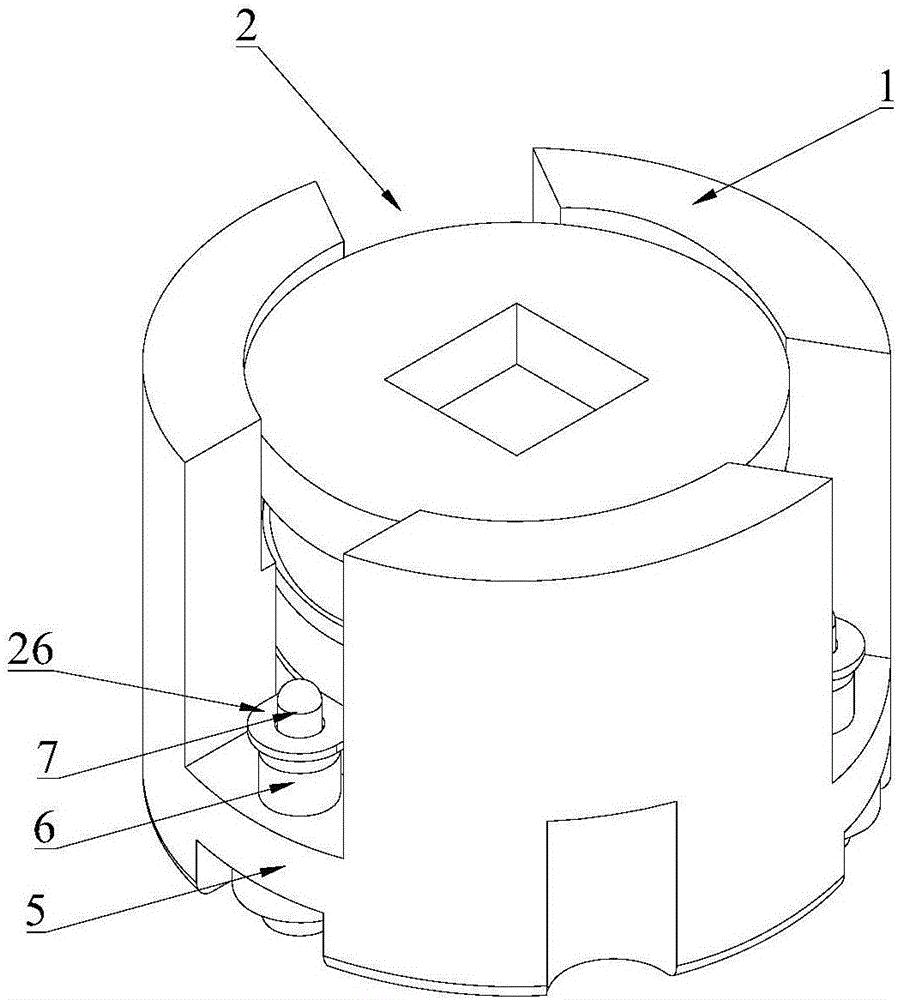

Rotating torsion conveyer

The invention relates to a rotating torsion conveyer, and particularly relates to a strip-shaped rotating torsion conveyer which is formed by connecting multiple parts in series. The rotating torsion conveyer comprises 12 parts, namely a shaft coupling head, cross-shaped blocks, serial shaft forks, round nuts, a delivering shaft, shaft fork pins, shaft pin gaskets, pin needles, sleeves, plug pins, shaft pin nuts and a rolling pressing shaft, wherein the shaft coupling head structurally comprises 21 parts, namely a bottom plate, a boss, shaft fork ears, a lower protruding ring, a quadrangular body, seamed edge round angels, pin holes, a beam barrel bottom surface, a beam barrel outer wall, a beam barrel top surface, regulation holes, a barrel internal thread, end surface bevel edges, pin cylindrical surfaces, concave flat surfaces and pin needle holes. The defects that the present known rotating torsion conveyer has decayed torsion and is lagged and delayed, the structure is large and the like are overcome, and the rotating torsion conveyer with a simple structure, strong deliverability and wide adaptability is formed and has the advantages that the implement is simple, the manufacture is simple and easy, the structure of a formed product is beautiful, elegant, solid and durable, the use is convenient, the market space is wide, and high economic added value is achieved.

Owner:钟婕

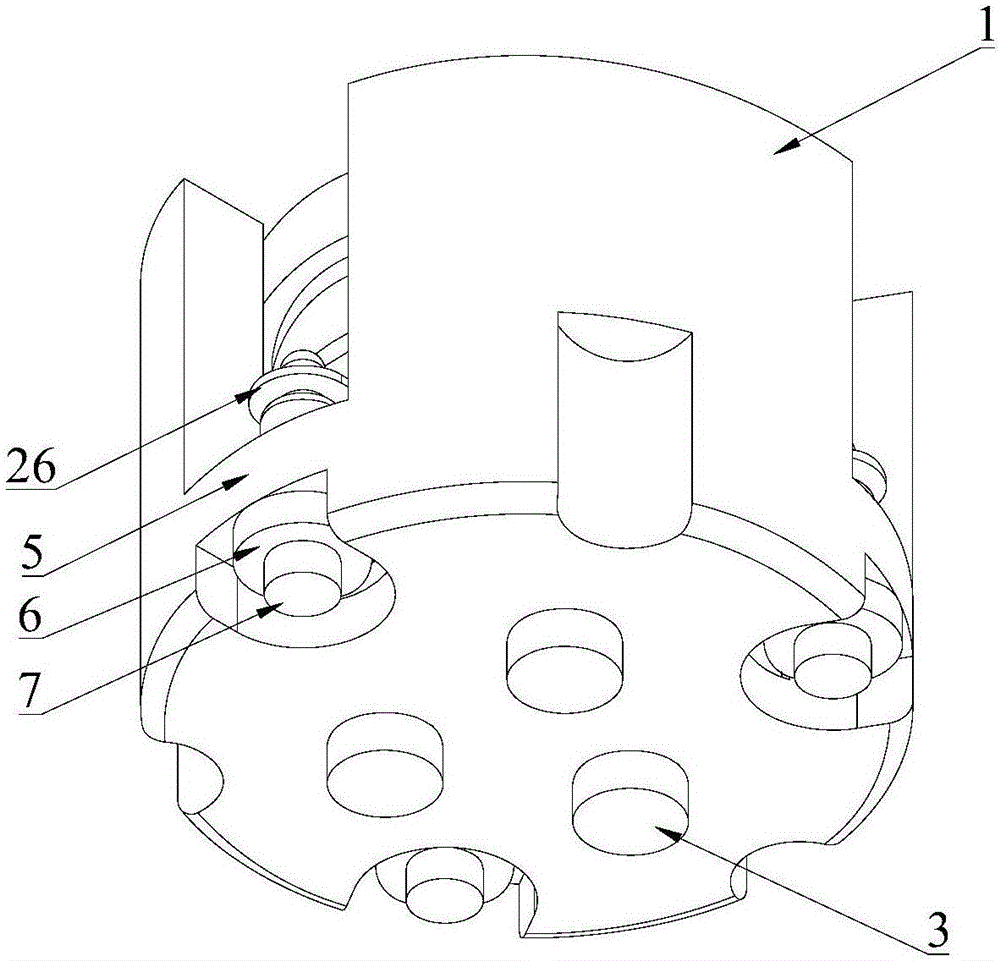

Surface-mount-type microwave ferrite circulator

InactiveCN106505284APrecise positioningImprove welding precisionWaveguide type devicesBroadbandPins needles

The invention discloses a surface-mount-type microwave ferrite circulator, comprising a half-open cylindrical cavity with three through slots in the side wall and a stack part arranged in the cavity. The bottom of the cavity is provided with at least one positioning element. By arranging the positioning element, the circulator is enabled to be convenient to position in the subsequent welding process, and the welding precision is greatly improved. The low file design is adopted, the electromagnetic interference is reduced, and the improvement of the broadband performance is facilitated. A PIN needle is adopted for fixing a center conductor, so that the circulator is convenient in integrated installation. Iron-nickel alloy is used for manufacturing a temperature compensation sheet, so that the circulator is enabled to work stably and reliability at the limiting temperature. The cavity is plated with silver, so that the welding is enabled to be more reliable, and the conduction effect is better.

Owner:HUAYANG TECH DEV

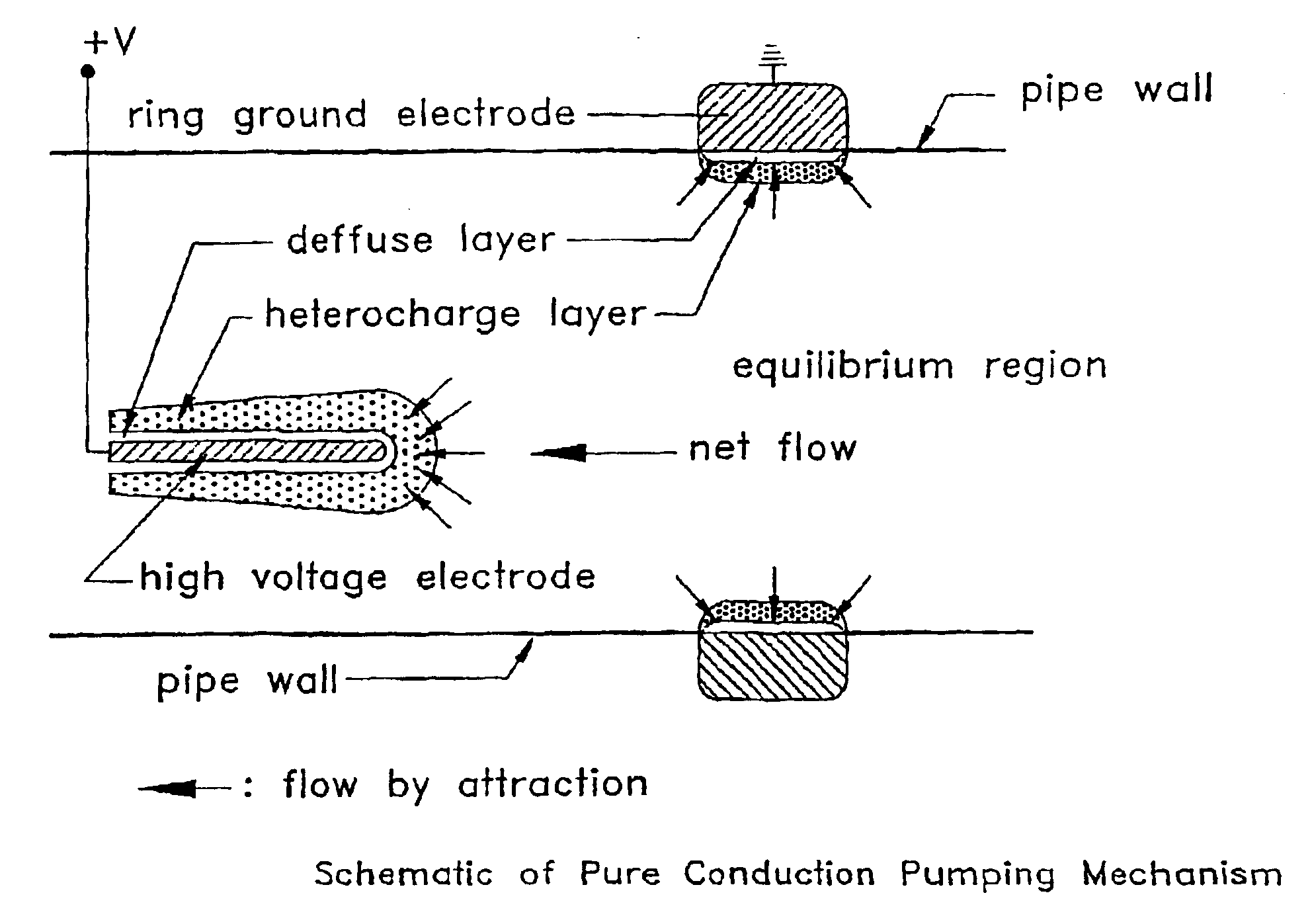

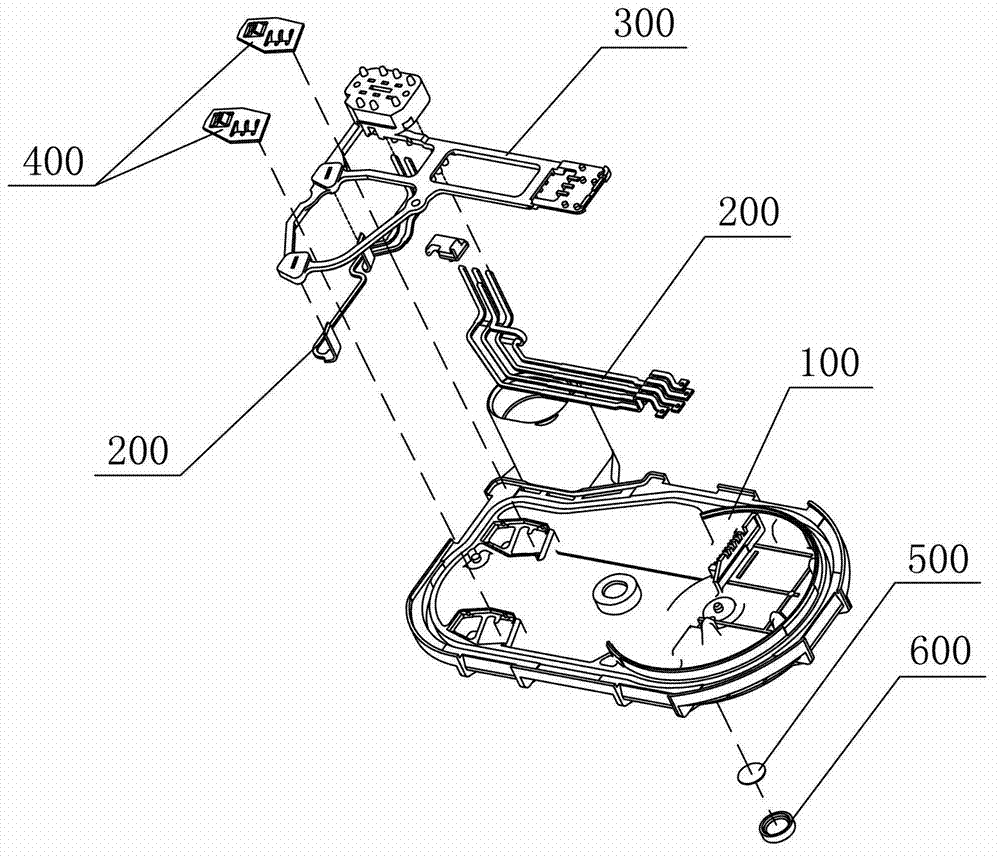

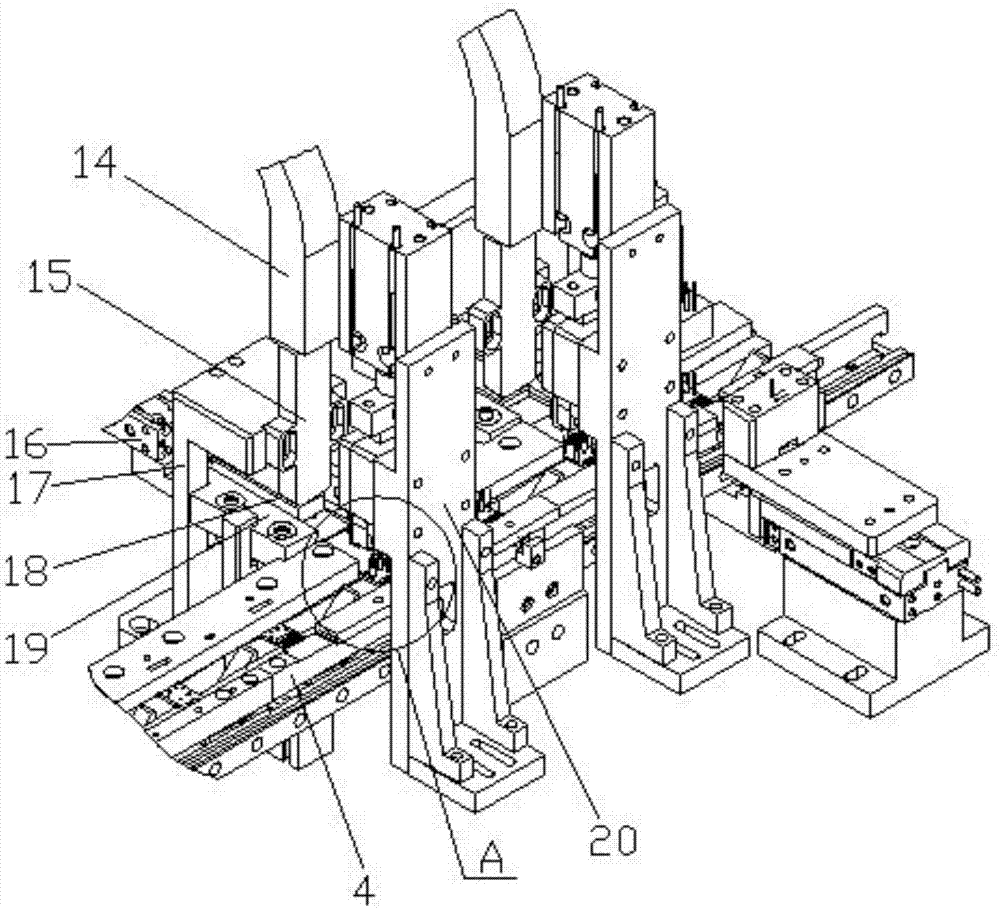

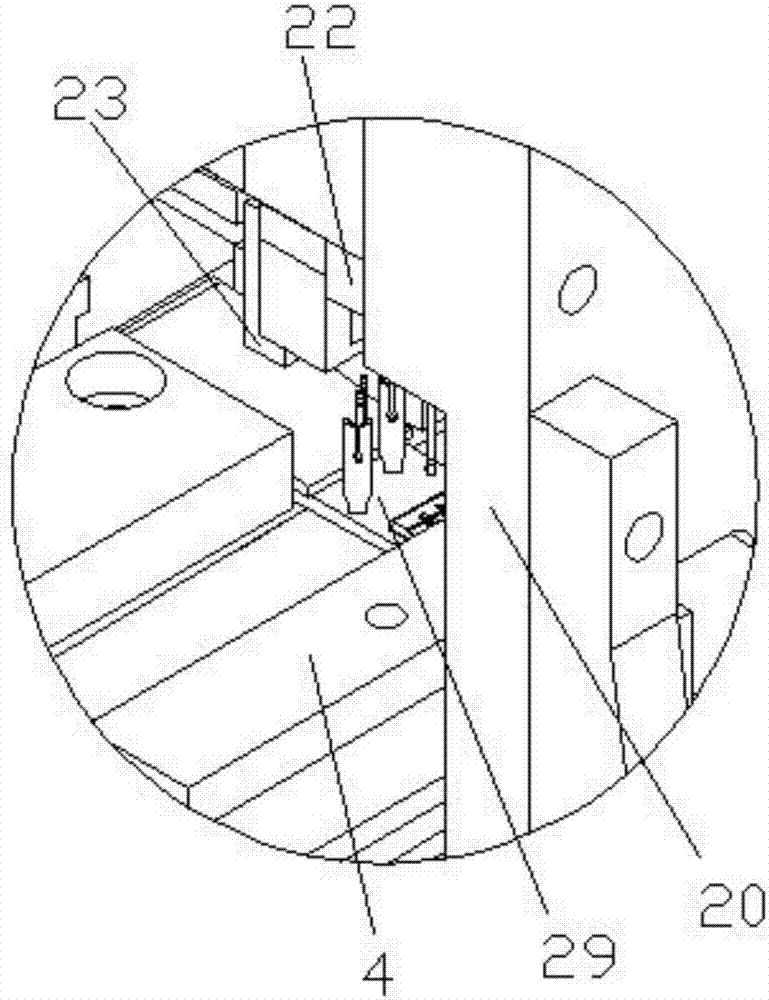

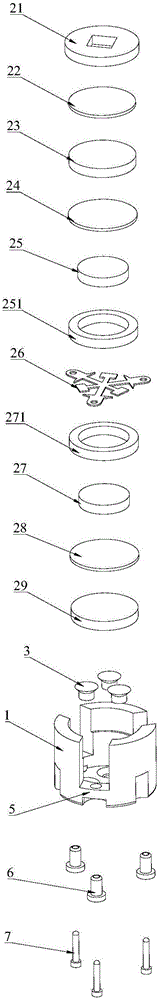

Modular sensor and manufacturing technique thereof

ActiveCN103336139AAccurate and stable positioningPrecise positioningSpeed/acceleration/shock instrument detailsDevices using electric/magnetic meansPins needlesComputer module

The invention discloses a modular sensor and a manufacturing technique thereof. The modular sensor comprises a cavity module, a framework module, a circuit board, a Hall chip and a cover plate, the top of the cavity module is opened, a positioning groove is formed in the bottom of the cavity module, and the cavity is integrally injected and molded with PIN needle module; strip through holes are formed in the rear end of the framework module, two position spacing tables are arranged on the upper end surface of the framework module, a positioning lug boss is arranged on the lower end surface of the framework module, and a clamp groove comprising two buckles and one support table and used for accommodating the hall chip is formed in the outer part of the front end of the framework module. The buckle adopts an inner side interference pointed hook part and an end surface hot riveting spur, so as to enable the hall chip to be fixed and confined in the space; the elasticity of the metal PIN needle and the matching structure of the cavity module and the framework module guarantee the framework module to be accurately positioned and fixedly connected in the cavity body module, and prevent the electric element from being damaged after glue flowing uncontrolled cover the electronic element temperature shock; the front end surface of the hall chip and the front cavity surface of the cavity module are closely pressed, but the compression force is not so large as to cause deformation and damage of the cavity module front end, so as to effectively guarantee sensor information.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

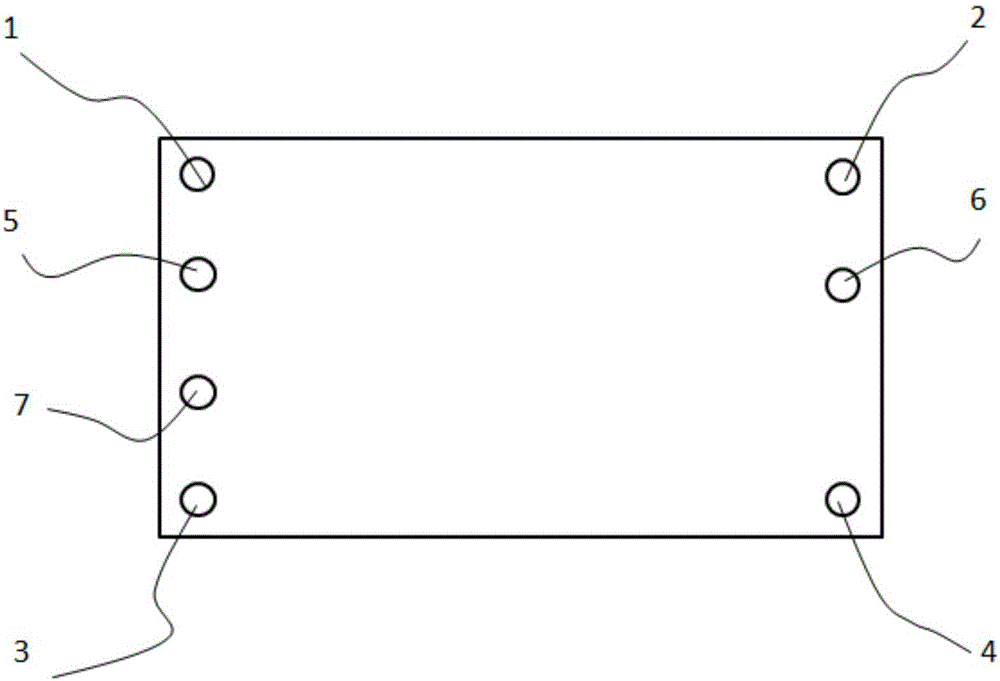

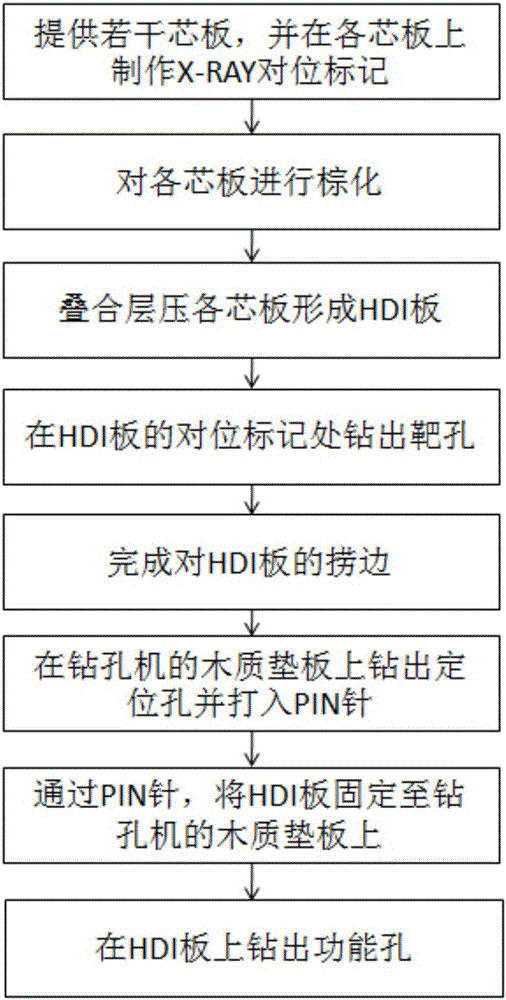

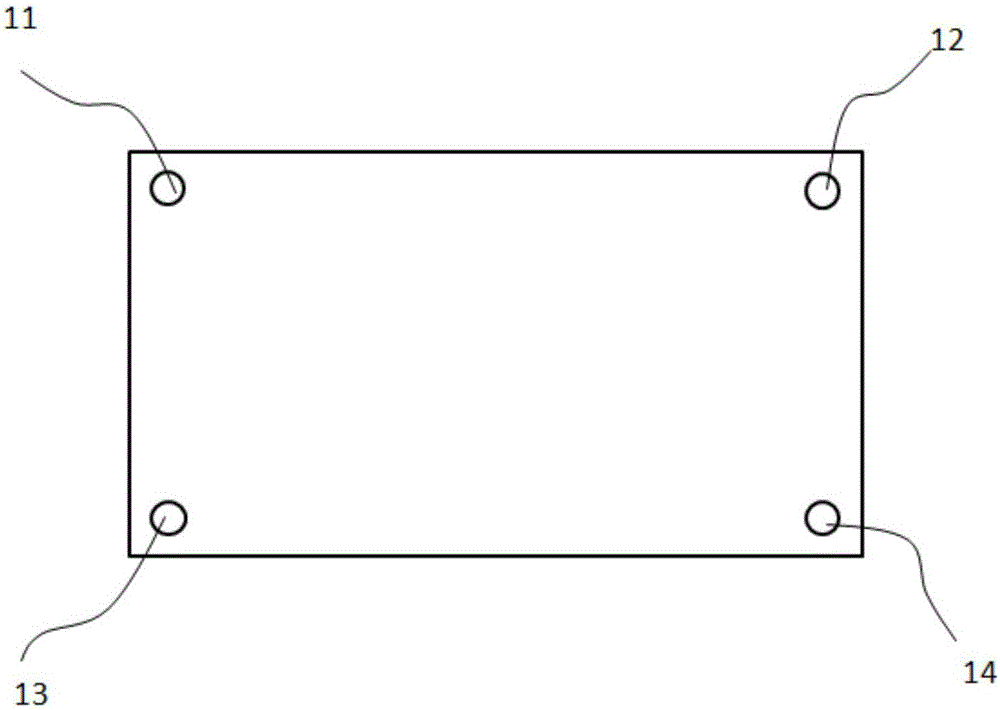

Manufacturing method of HDI circuit board

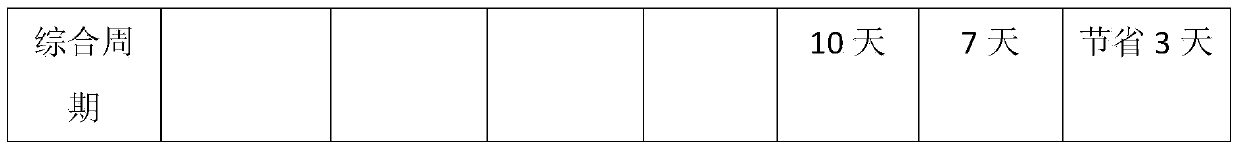

InactiveCN106211637AReduce manufacturing costShorten the production periodMultilayer circuit manufacturePins needlesX-ray

The invention discloses a manufacturing method of an HDI circuit board. The method comprises the following steps of (1) providing a plurality of core boards, and arranging X-RAY alignment marks at four corners of each core board; (2) sequentially superimposing and laminating the core boards to form the HDI circuit board; (3) drilling target holes which run through the HDI circuit board on the alignment marks by employing an X-RAY target drilling machine; (4) routing the HDI circuit board by using a routing machine; (5) drilling locating holes which are matched with the target holes for use in a wooden base plate of a drilling machine and driving a PIN needle into each locating hole; (6) fixing the HDI circuit board on the upper surface of the wooden base plate through the PIN needles; and (7) carrying out scanning and locating on the four target holes in the HDI circuit board through the drilling machine to determine the positions of function holes in the upper surface of the HDI circuit board and to drill the function holes. By the manufacturing method of the HDI circuit board disclosed by the invention, subsequent routing, function hole drilling and laser processes can be achieved only by drilling the four target holes in the upper surface of the HDI circuit board, so that the production cost is effectively reduced and the production period is shortened.

Owner:JIANGSU BOMIN ELECTRONICS

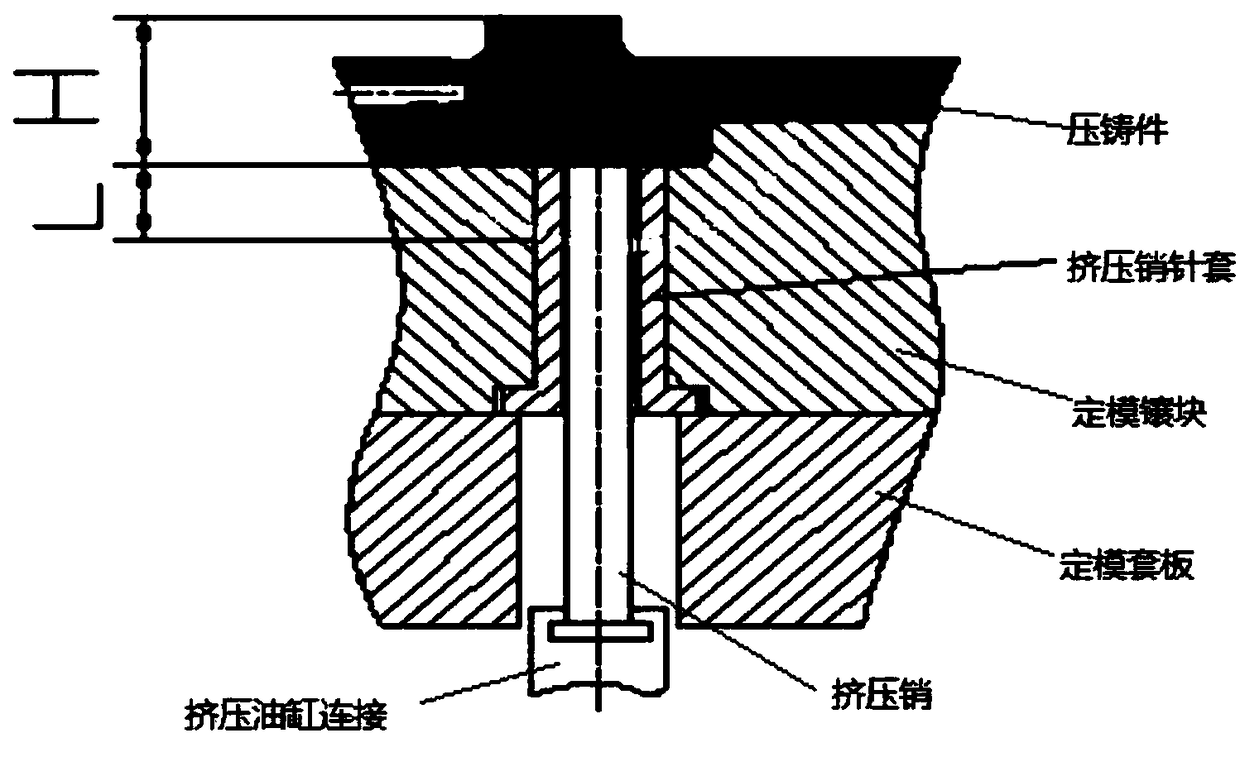

Die casting die extruding pin special structure

The invention discloses a die casting die extruding pin special structure. The die casting die extruding pin special structure comprises a fixed die sleeve plate and a fixed die insert connected withthe fixed die sleeve plate in a matched mode. The fixed die sleeve plate is internally provided with a first hollow structure and a second hollow structure. The first hollow structure is internally provided with an extruding oil cylinder. The second hollow structure is internally provided with a connecting plate. An extruding pin is arranged on the connecting plate. A T-shaped hollow cavity is formed in the extruding pin. A core needle is detachably arranged in the T-shaped hollow cavity. An extruding pin needle sleeve is detachably arranged between the extruding pin and the fixed die insert.According to the die casting die extruding pin special structure, the extruding oil cylinder is used for pushing the extruding pin to move and combined with the extruding pin needle sleeve and the core needle for extruding the outside and / or inside of a die casting while precasting a needle hole so that outside and / or inside shrinkage cavity and porosity defects can be eliminated, meanwhile, the effect that the position of the core needle is not deviated in the operation process can be ensured, and the effect that the size of the core needle hole is stable and unchanged is ensured.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

Production method for monascus pine needle tea

InactiveCN104770487ATea taste without bitternessGood health effectPre-extraction tea treatmentPins needlesWarm water

The invention relates to a production method for monascus pine needle tea. The production method comprises the following steps: cleaning, naturally wilting, wilting in hot air, rolling, fermenting (after adding monascus which accounts for 10-15% of the screened pin needle leaves in weight, utilizing a humidifier to control the relative humidity to be greater than or equal to 85%, and adding warm water of 37-40 DEG C, wherein the fermentation temperature is 36-40 DEG C, the fermentation time is 2-3 hours), and the like. The monascus pine needle tea which is free of bitter and astringent taste and good in health effect is prepared.

Owner:张淑芹

Pot culturing nutrient soil formula

InactiveCN103238504ALow costEasy to makeCultivating equipmentsSoilless cultivationAlkaline waterPins needles

The invention relates to a pot culturing nutrient soil formula. Components of the formula are all natural and organic, the proportion is scientific, pot culturing nutrient soil is easy to manufacture, well pot cultured plant cultivation can be achieved, a root portion can have sufficient nutrients and water, and ventilation is good. The pot culturing nutrient soil formula comprises coarse sand particles with particle diameter larger than 1.5cm, wherein rice grain skin and nutrient particles are mixed in the coarse sand particles, and the nutrient particles are formed by mixing and smashing pine needles, soybean cakes and roots of legume crops and kneading the mixed materials into balls. The pin needles are exposed under the sun, aired, and soaked in neutral or alkaline water for 15 days to enable the pin needles to be rotten. The root of the legume crops is the root of the crops of the current year, mud on the root is removed, and the root is exposed under the sun and aired. The weight ratio of the dried pine needles before soaking, the soybean cakes and the root of the aired legume crops is 10:2:30. The volume ratio of the sand particles, the rice grain skin and the nutrient particles is 20:5:15, the sand particles, the rice grain skin and the nutrient particles are uniformly mixed and added into a flowerpot, and a layer of vegetable sponge with the thickness larger than 2cm is overlaid on the surface.

Owner:NANJING LVCHENG TRADE CO LTD

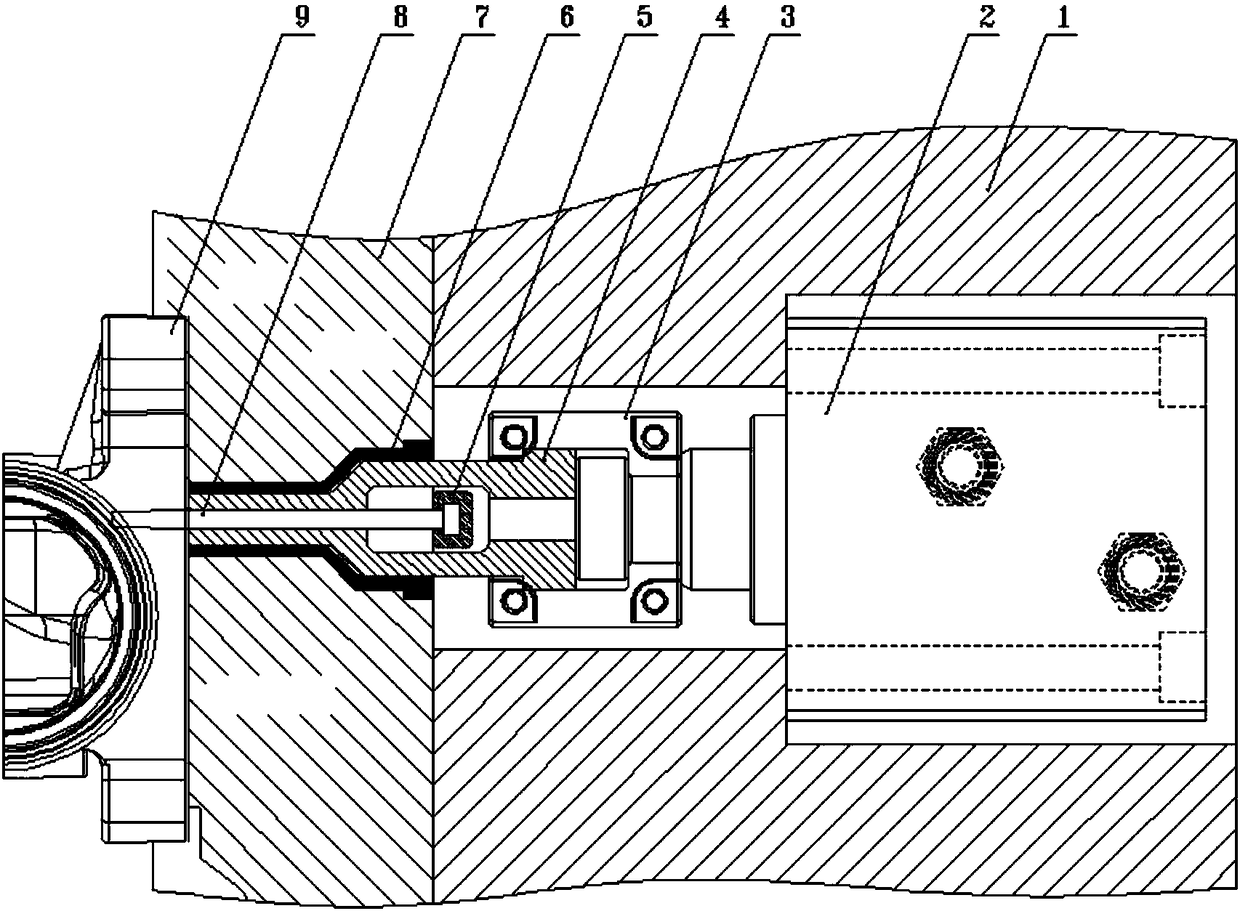

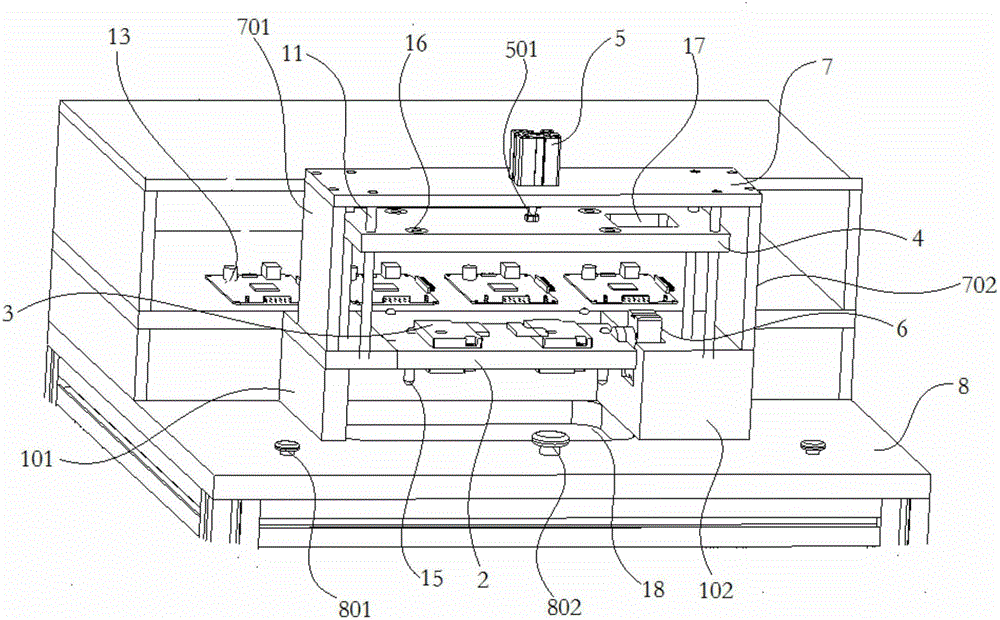

Fingerprint module testing system with overturning mechanism

PendingCN106771975AImprove work efficiencyImprove efficiencyElectronic circuit testingElectrical measurement instrument detailsPins needlesEngineering

The invention discloses a fingerprint module testing system with an overturning mechanism. The fingerprint module testing system comprises foundations, a mounting plate, a plurality of testing carrying platforms, a pressing plate, a hoisting air cylinder, an overturning air cylinder and a fixed plate, wherein the foundations are mounted on a base; two ends of the fixed plate are fixedly connected with the left foundation and the right foundation through a left side plate and a right side plate respectively; at least two guide columns are embedded into guide column through holes formed in two ends of the pressing plate respectively; a piston rod of the hoisting air cylinder penetrates through the fixed plate and the tail end of the piston rod is fixedly connected with the upper surface of the mounting plate; PIN needles are sequentially embedded into product grooves and through holes of supporting plates; the upper ends of the PIN needles are in electric contact with a connector of a fingerprint chip to be detected; the lower ends of the PIN needles are in electric contact with electric contact regions of PCB (Printed Circuit Board); a core plate is electrically connected with the PCB of the testing carrying platforms through gray flat cables; the base is provided with a starting key and a jerk key. The overturning air cylinder is arranged so that the testing carrying platforms can be mounted on two faces of the mounting plate and materials can directly fall in an overturning process; a link of manually blanking is saved and the efficiency is improved.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

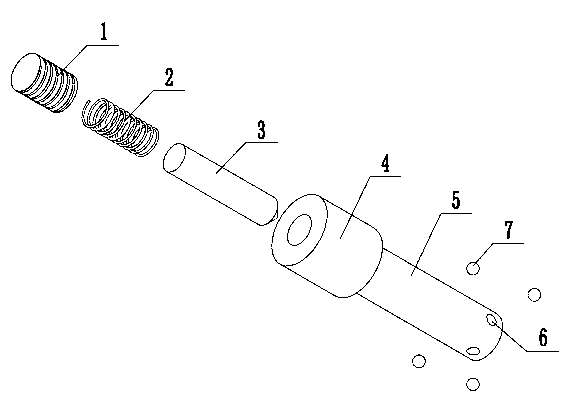

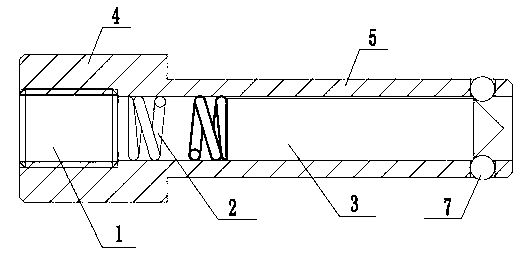

Novel fixing bolt for hole

The invention relates to a bolt, and particularly relates to a novel fixing bolt for a hole. The novel fixing bolt for the hole comprises a pin bush and a pin needle, wherein the pin bush is a T-shaped hollow structure formed by a pin head and a pin rod; the pin needle is a cylinder, and the head of the cylinder is of a cone-shaped structure; at least a group of symmetrical limit holes are arranged at the tail end of the pin rod; the pin needle is sleeved and arranged in the pin bush; the length of the pin needle is less than that of the pin bush; a locknut is in bolt connection with the pin head; a spring is arranged between the locknut and the pin needle; and steel balls are coordinately arranged between the cone-shaped head of the pin needle and the limit holes. The novel fixing bolt for the hole provided by the invention has ingenious concept and simple structure; when the bolt is needed for limit, the locknut is only needed to be tightened, the spring supports the pin needle to move forwards; the cone-shaped structure at the head of the pin needle jacks up the steel balls to enter the limit holes, and the parts of the steel balls protruding from the limit holes can play the role in limiting; and when the bolt is needed to be taken out, the locknut is only needed to be loosened, the spring recovers from deformation, the pin needle draws back, and the steel balls between the pin needle and the limit holes are loosened from the limit holes for the bolt to be conveniently taken out.

Owner:ZHEJIANG LINIX MOTOR

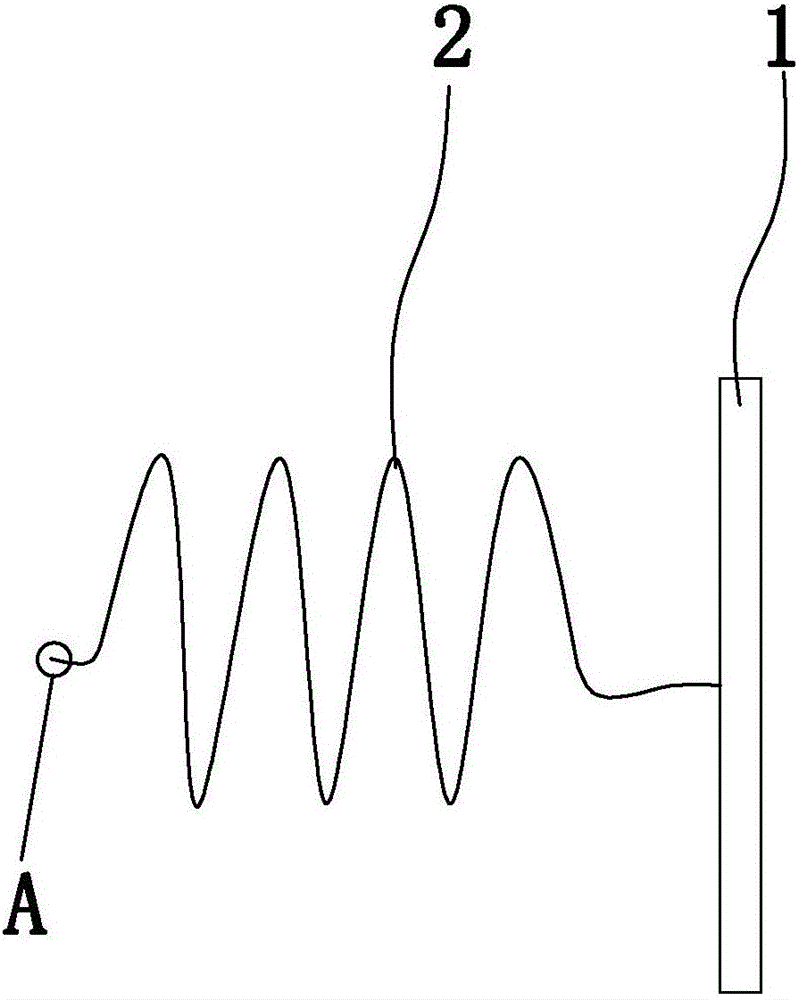

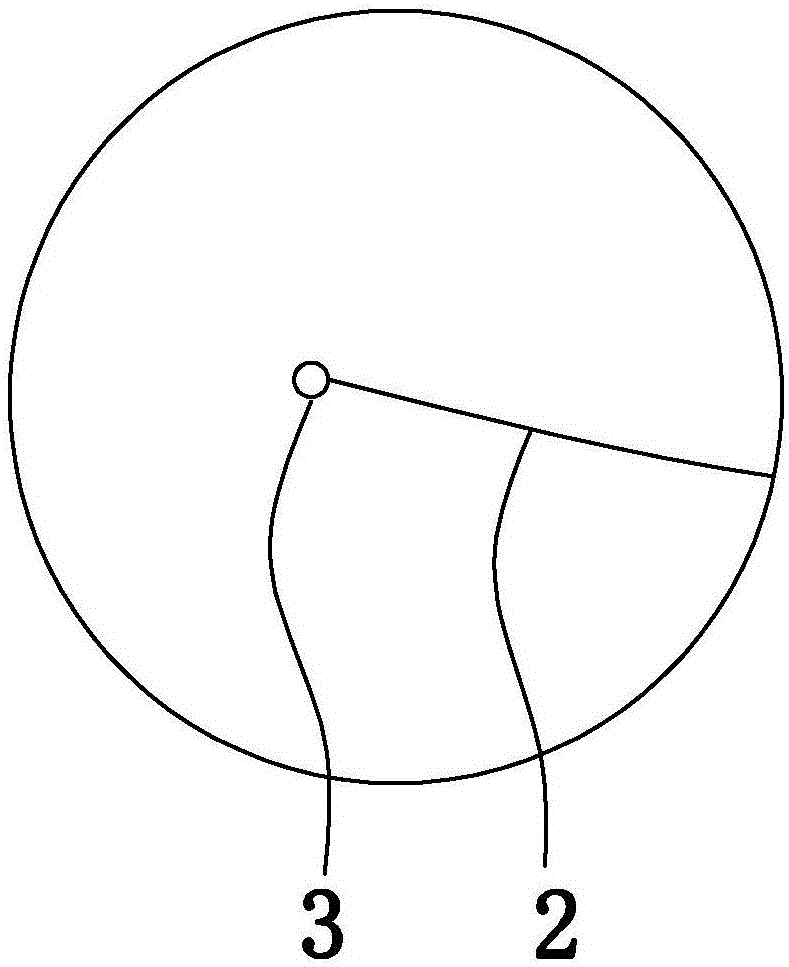

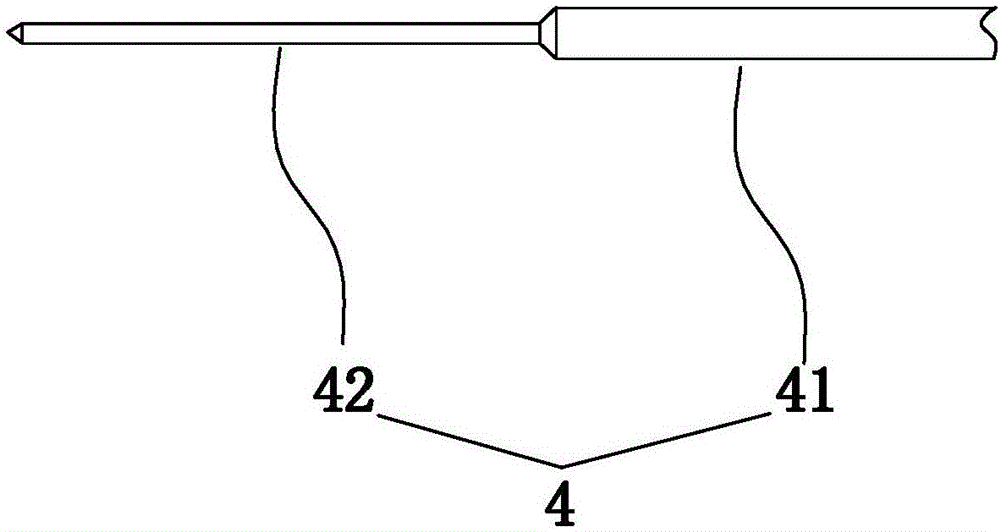

Fish tag label, fish tag device and labeling method

ActiveCN106561525AFix damageAvoid swinging aroundPisciculture and aquariaPins needlesComputer science

The invention discloses a fish tag label, a fish tag device and a labeling method and aims to provide a fish tag label capable of effectively solving a problem of separation of the tag label from a fish body or damage to the fish body due to the missing of the tag label or conditions when the tag label is hung in seaweed clusters or abandoned net tools in the prior art. The fish tag label comprises a tag label and a label line connected with the tag label, wherein the label line is an elastic spiral line; and one end of the label line is connected with the tag label and the other end is provided with a needle insertion hole. The fish tag device comprises a tag pin needle having a pin needle body and an insertion hole coaxially arranged with the pin needle body, wherein the external diameter of the insertion hole is smaller than the external diameter of the pin needle body. The fish labeling method comprises the following steps in an order of first, inserting the insertion needle into the insertion hole, second, pinning the tag pin needle into a fish body, bringing the label line to the fish body at the same time, and third, pulling out the tag pin needle and separating the label line and the tag pin needle and remaining the label line in the fish body.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Multi-pin syringe needle

InactiveCN105396205AAchieve full-thickness three-dimensional injection effectImprove work efficiencyInfusion needlesPins needlesSyringe needle

The invention discloses a multi-pin syringe needle, which comprises a multi-pin needle main body, a box body and a needle length adjusting mechanism, wherein the multi-pin needle main body is inserted on the box body. Since the multi-pin needle main body is provided with a plurality of porous needles thereon and the plurality of the needles are different in length, the multi-pin needle main body is connected to automatic auxiliary equipment by virtue of an interface, and an effect of three-dimensional injection in the whole layer of skin is achieved through one-time injection after the equipment is connected, so that the time of an operator is saved. In addition, the syringe needle is free from a negative-pressure cavity and the like on the box body and has a needle length adjusting function; and the syringe needle can conduct manual operation just by connecting to a conventional injection syringe and can achieve the effect of three-dimensional injection in the whole layer of skin through one-time injection, so that the working efficiency of the operator is improved and labor intensity is reduced; therefore, two injection modes, namely negative-pressure injection and manual injection, are achieved.

Owner:XIAMEN BONAI MOLD DESIGN CO LTD

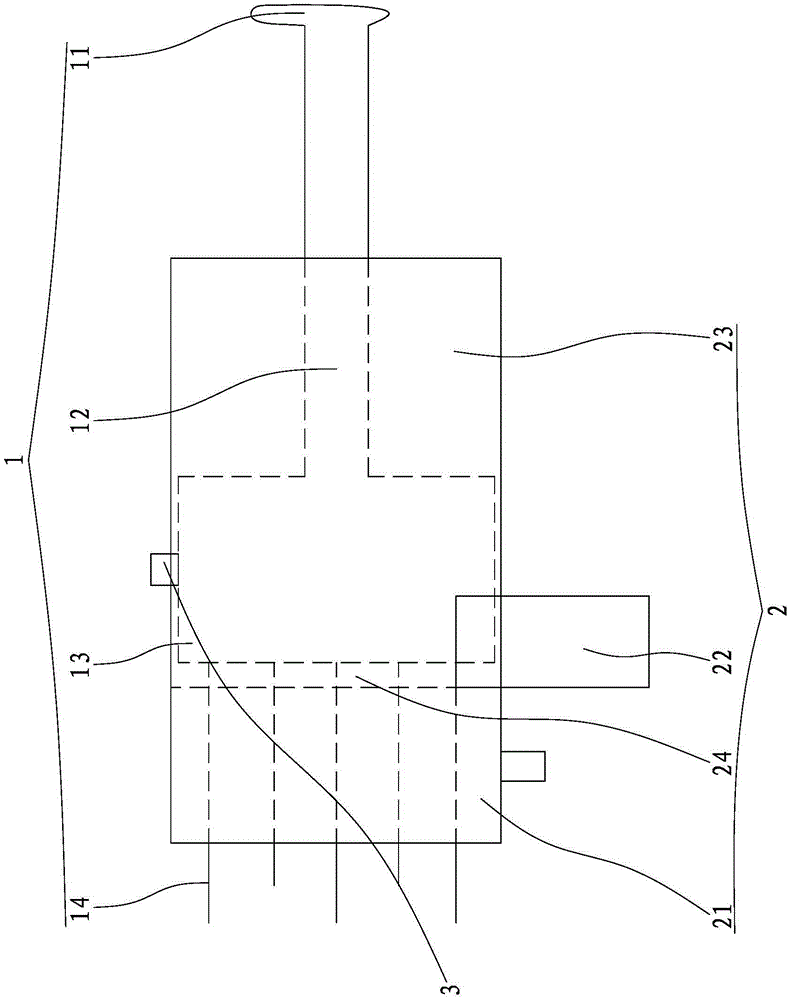

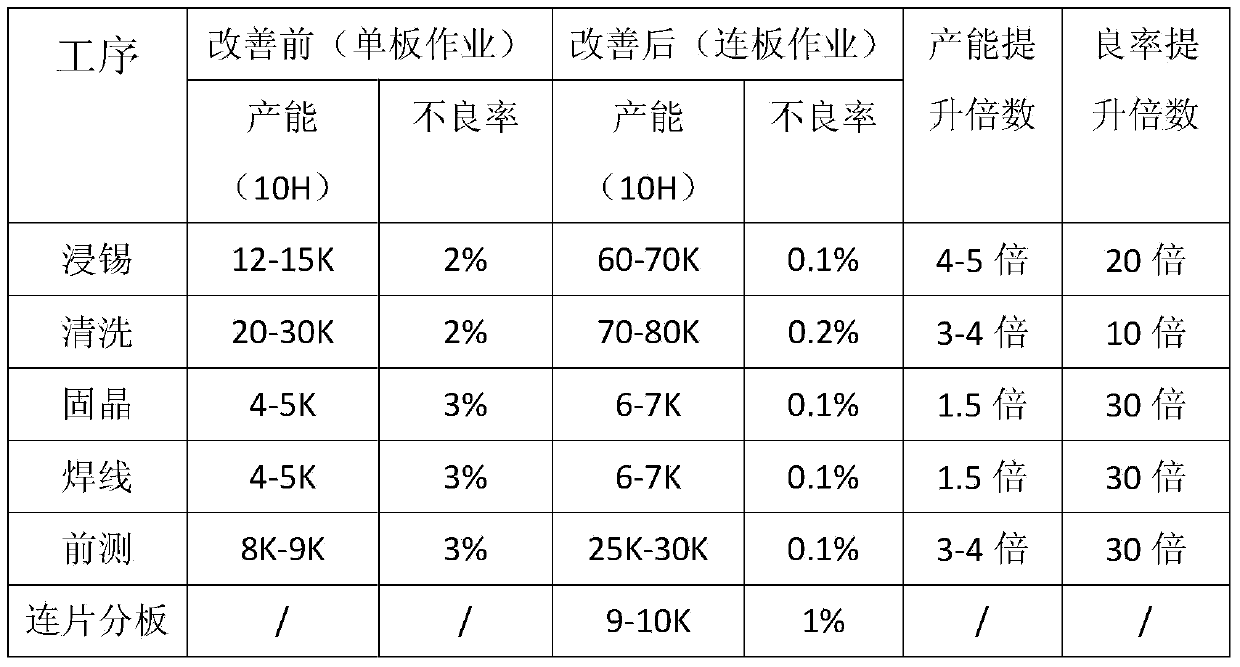

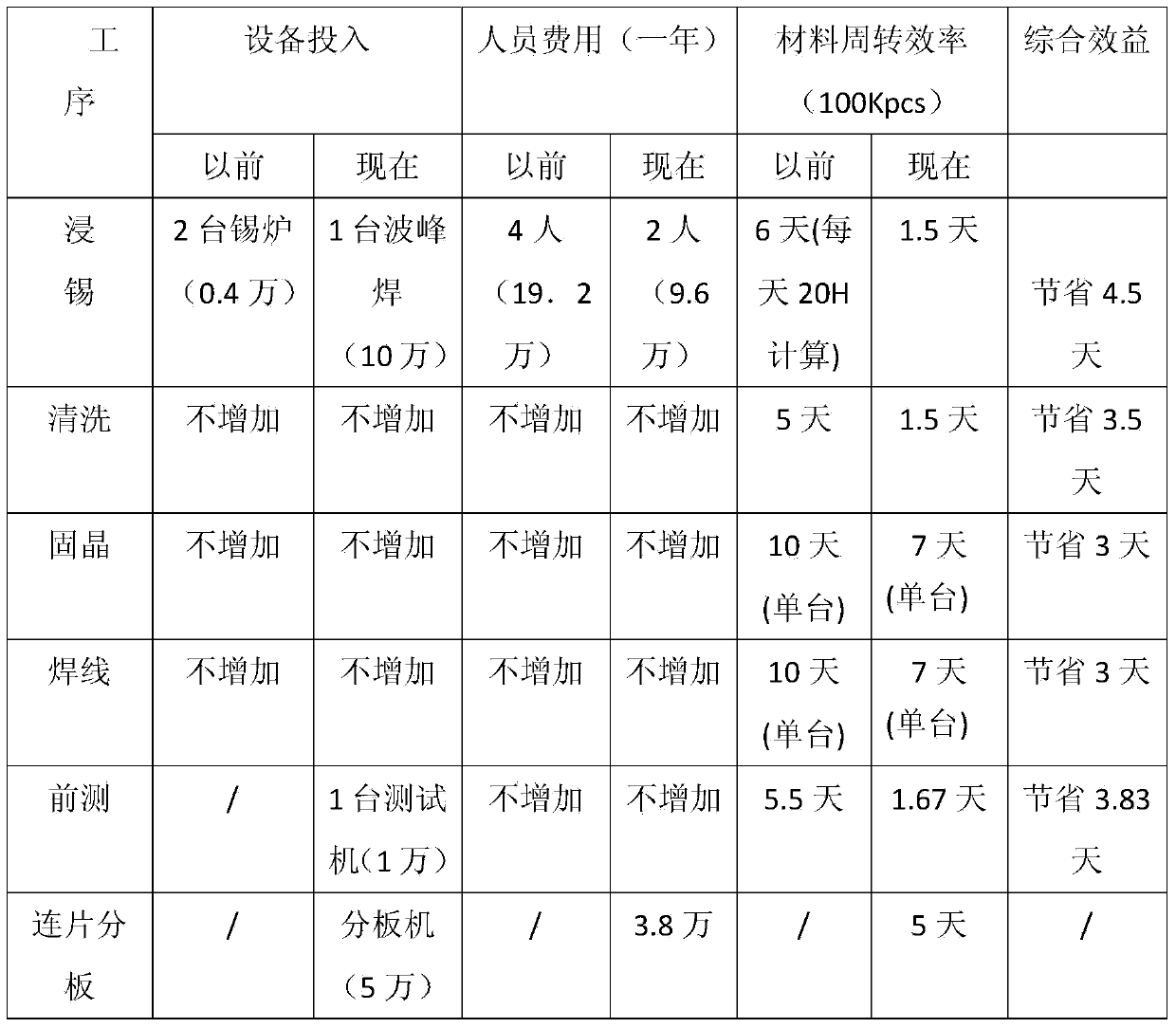

Production technology of LED nixie tube connecting board

InactiveCN103746048AReduce distortionFlexible and simplified operationIdentification meansSemiconductor devicesPins needlesEngineering

The invention relates to the technical field of LED nixie tube production technology, particularly to production technology of an LED nixie tube connecting board. The technical defects that single board die bonding, wire welding, and test operation are low in efficiency and high in reject radio are overcome. The production technology comprises the following steps: A. an early stage step: after PIN jumping and PIN pressing of a connecting board PCB, a tin dipped clamp is mounted on the connecting board PCB; B. a die bonding step: bonding an LED chip in a designated area of the connecting board PCB; C. a wire welding step: circuit connection between the LED chip and the connecting board PCB is established through a wire welding machine; D. an early stage detection step: defective positions on the connecting board are marked by a white oily pen; and E. a board division step: LED nixie tube lamp panel units on the connecting board PCB are separated and output. Compared with an original single board operating mode, 80% of bad circumstances of deformation of PIN needles, chip erasion, wire collapse and the like are reduced, and the production efficiency is improved by three to four times.

Owner:SHENZHEN GUOYEXING OPTOELECTRONICS TECH CO LTD

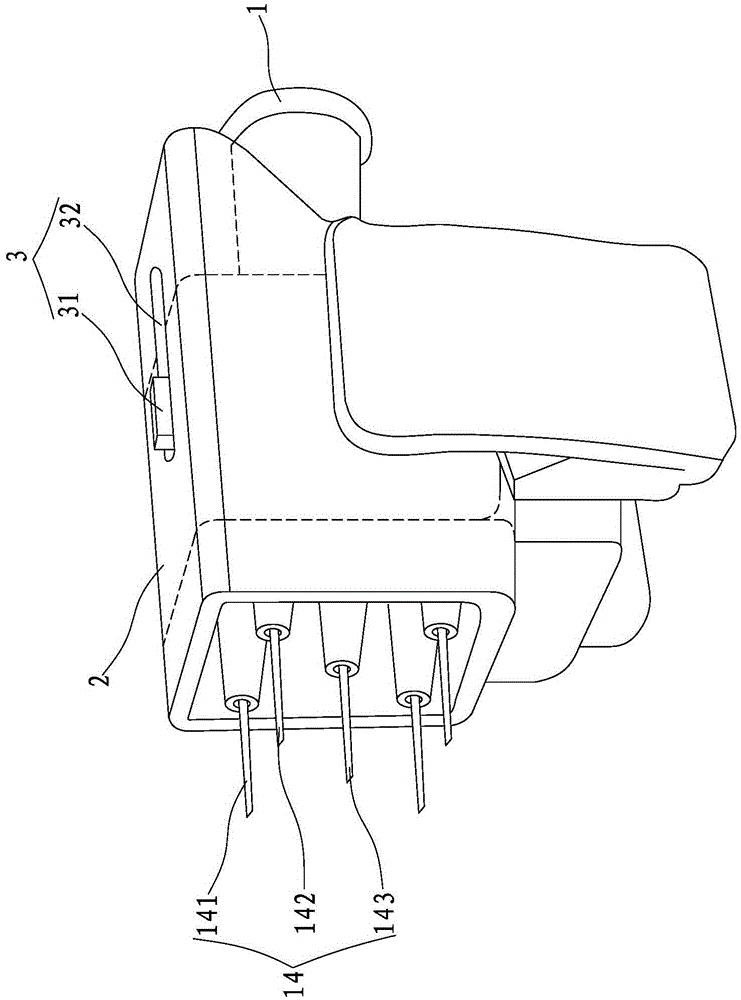

Pulling and plugging device of R pin needle of glass isolator

ActiveCN102684104ANo overhead work requiredSimple structurePliersApparatus for overhead lines/cablesPins needlesIsolator

The invention discloses a pulling and plugging device of an R pin needle of a glass isolator. The pulling and plugging device comprises an insulating rod (1), a pin puller head (2) or a bolt inserter head (3) connected and arranged on the end part of the insulating rod, or a pin puller head (2) and bolt inserter head (3) respectively arranged on two ends of the insulating rod (1). The pulling and plugging device has the advantages of convenience for manufacture, safety in using, convenience, time and labor saving, no need of suspension operation of constructors, and capability of hot-line work; and the personal can carry out earth potential working without being necessarily close to an electrified body, and stably pulls or plugs the R pin needle out or in.

Owner:DANDONG ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

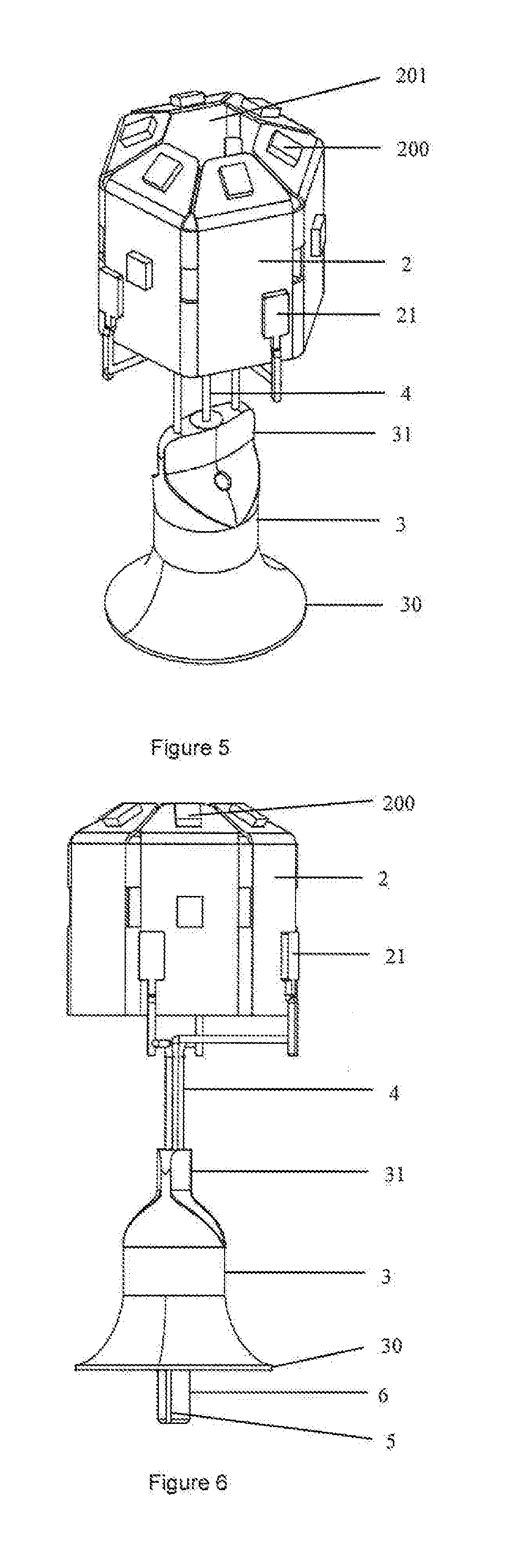

Stem structure and LED lighting device

ActiveUS20190166661A1Simple structureImprove pass rateElectrical apparatusElectroluminescent light sourcesElectricityPins needles

The present invention comprises a stem structure and an LED lighting device, wherein the stem structure comprises a substrate, configured to be bent into a substrate device with a internal hollow structure, wherein a plurality of LED lamp beads and a plurality of pin needles are attached to a surface of the substrate device; a horn mouth comprising a first wide mouth portion and a first narrow mouth portion opposite to the first wide mouth portion, the first narrow mouth portion being provided with a plurality of upper guide wires for connecting to the plurality of pin needles; a plurality of lower guide wires, disposed inside the horn mouth, and configured to be connected to the plurality of upper guide wires through the first narrow mouth portion; and a glass tube disposed inside the horn mouth and attached to the plurality of lower guide wires; wherein the LED lighting device comprises a glass bulb, wherein a lamp head is disposed at an opening of the glass bulb; a driving circuit board fixedly connected to the lamp head with a collar, an input end of the driving circuit board being electrically connected to the lamp head; and the stem structure, disposed inside the glass bulb, and configured to be electrically connected to an output end of the driving circuit board through the lower guide wire. The technical solution has the following advantages: the stem structure and the LED lighting device have a simple structure, a low cost, a high pass rate, and they can withstand external force.

Owner:KATERRA INC

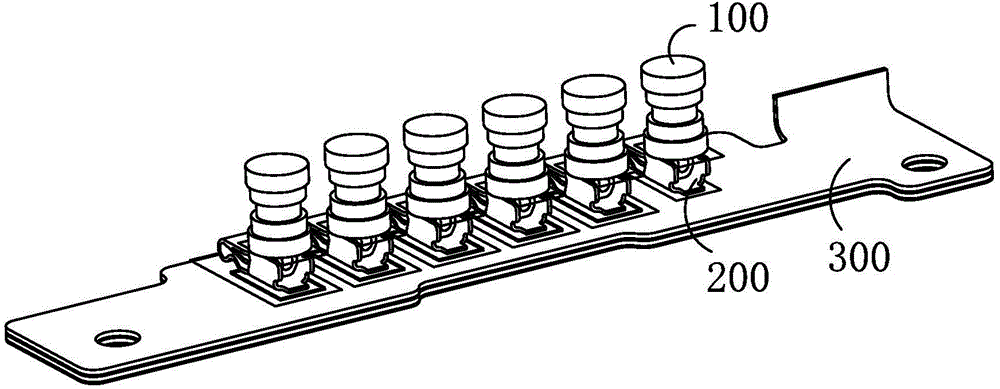

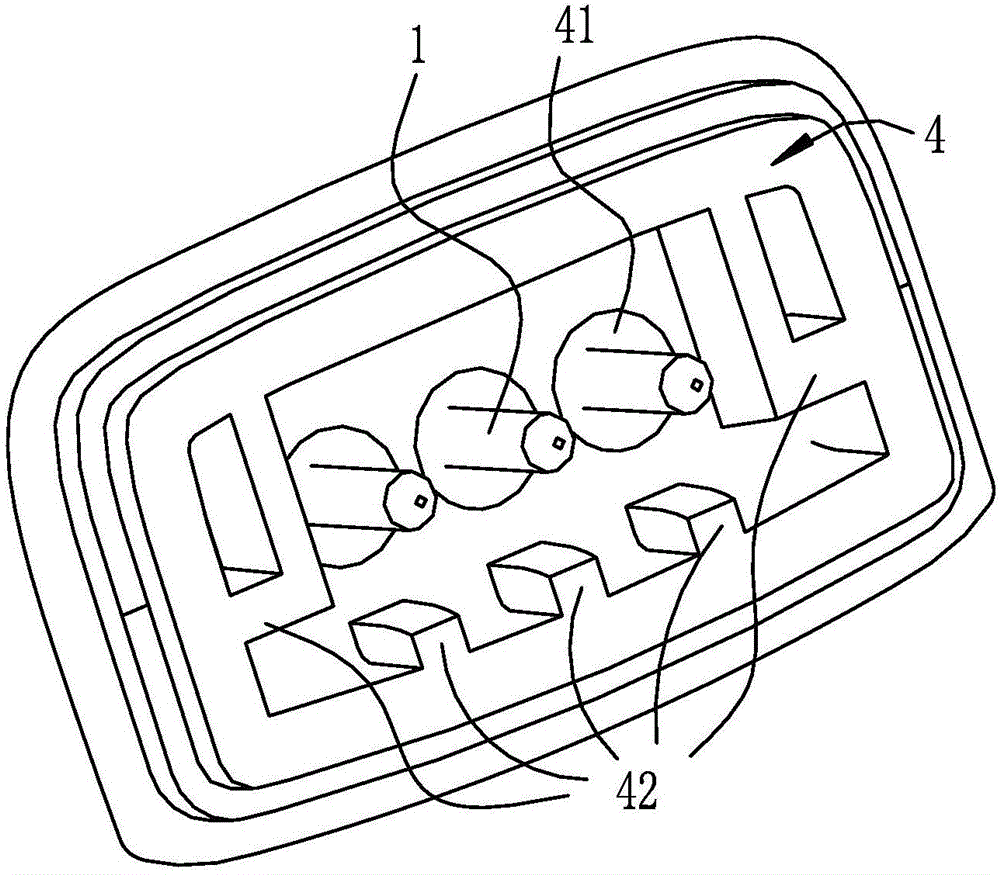

Connecting structure for pin needle and PCB

ActiveCN104577362ATo achieve parallel connectionEnables Portable ExchangeContact member assembly/disassemblyCoupling device detailsPins needlesBiomedical engineering

The invention relates to a connecting structure for pin needles and a PCB which comprises multiple pin needles, multiple spring pieces and a PCB. The spring pieces are fixed on the PCB, and the spring pieces clamp the pin needles elastically; the connecting structure further comprises a plastic shell body, the top surface of the plastic shell body dents inwards to form a containing concave chamber, one end connected with the spring pieces of the PCB is installed in the containing concave chamber in an inserting mode, the pin needles are fixedly connected in the containing concave chamber, and the pin needles are arranged parallel to the PCB in axial direction of the pin needles. By means of the special-shaped spring pieces, the parallel connection between the pin needles and the PCB is achieved, appearance completeness of electronic products are guaranteed, and portable exchange among data is achieved. Furthermore, the plastic shell body is provided, when the connecting structure is assembled, the existence of guide ribs enables the connecting structure to be more convenient and accurate during installation, and quality and efficiency of the electronic products assembly are improved.

Owner:长沙赢睿知识产权运营有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com