Patents

Literature

110 results about "Core needle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

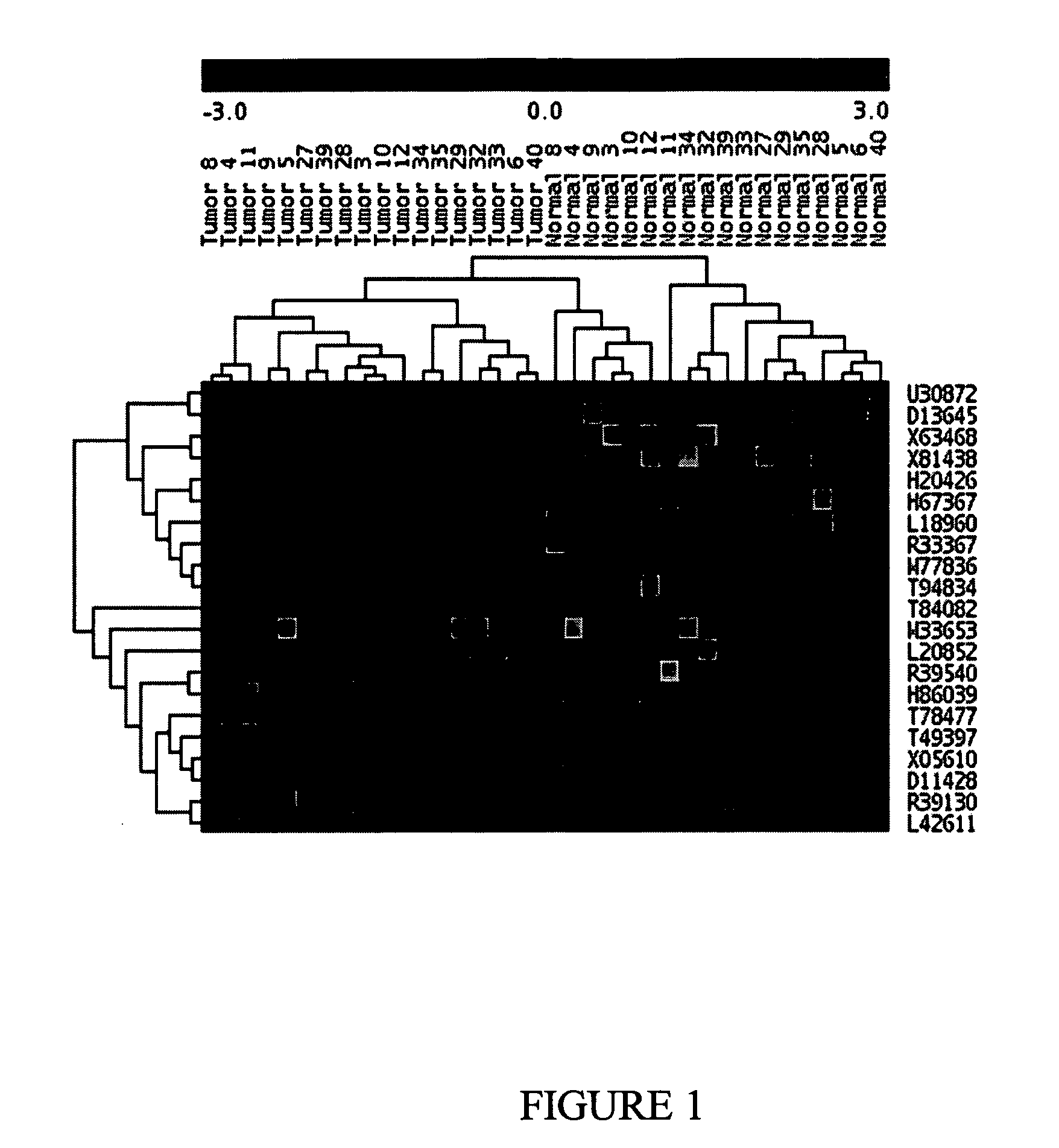

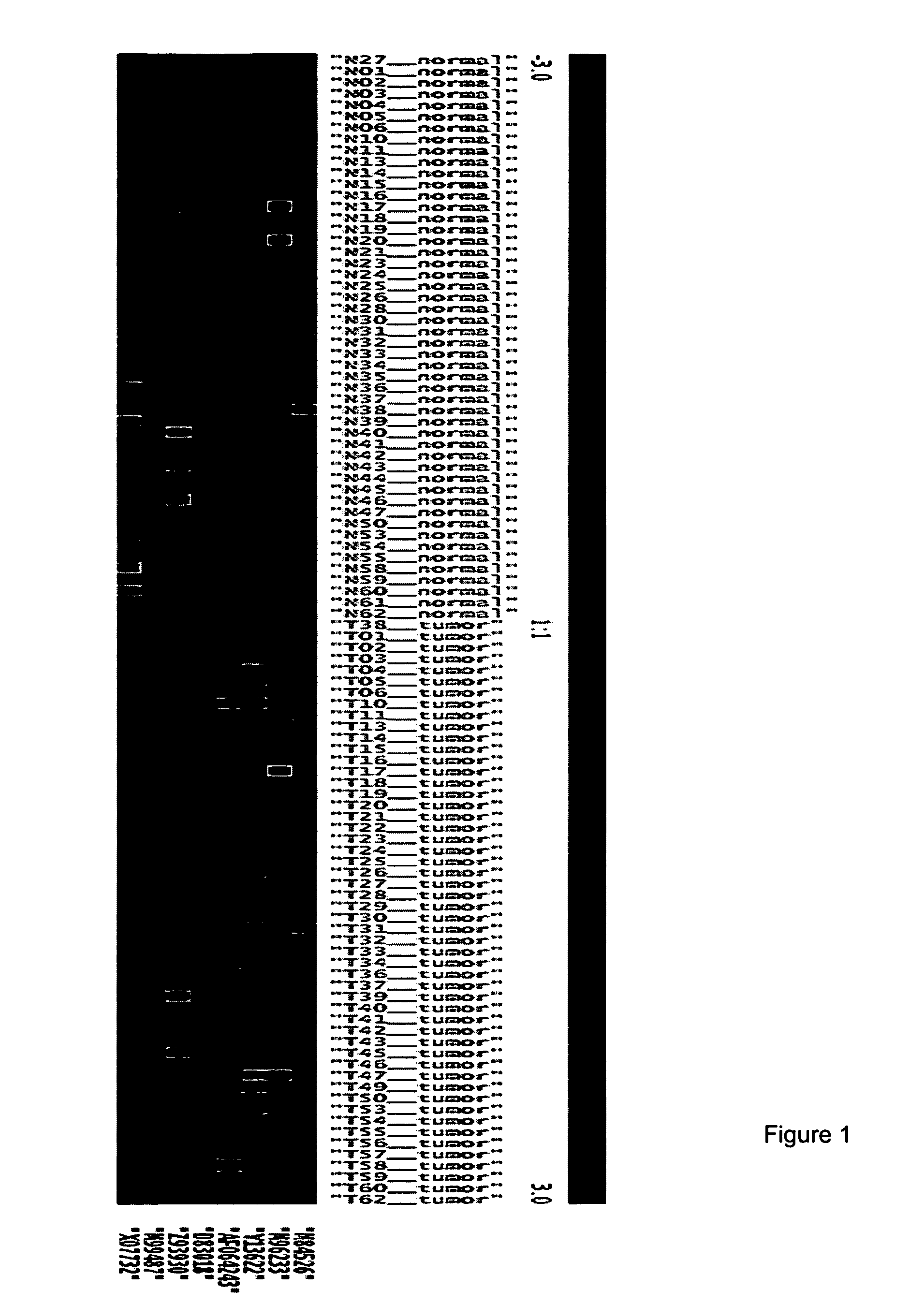

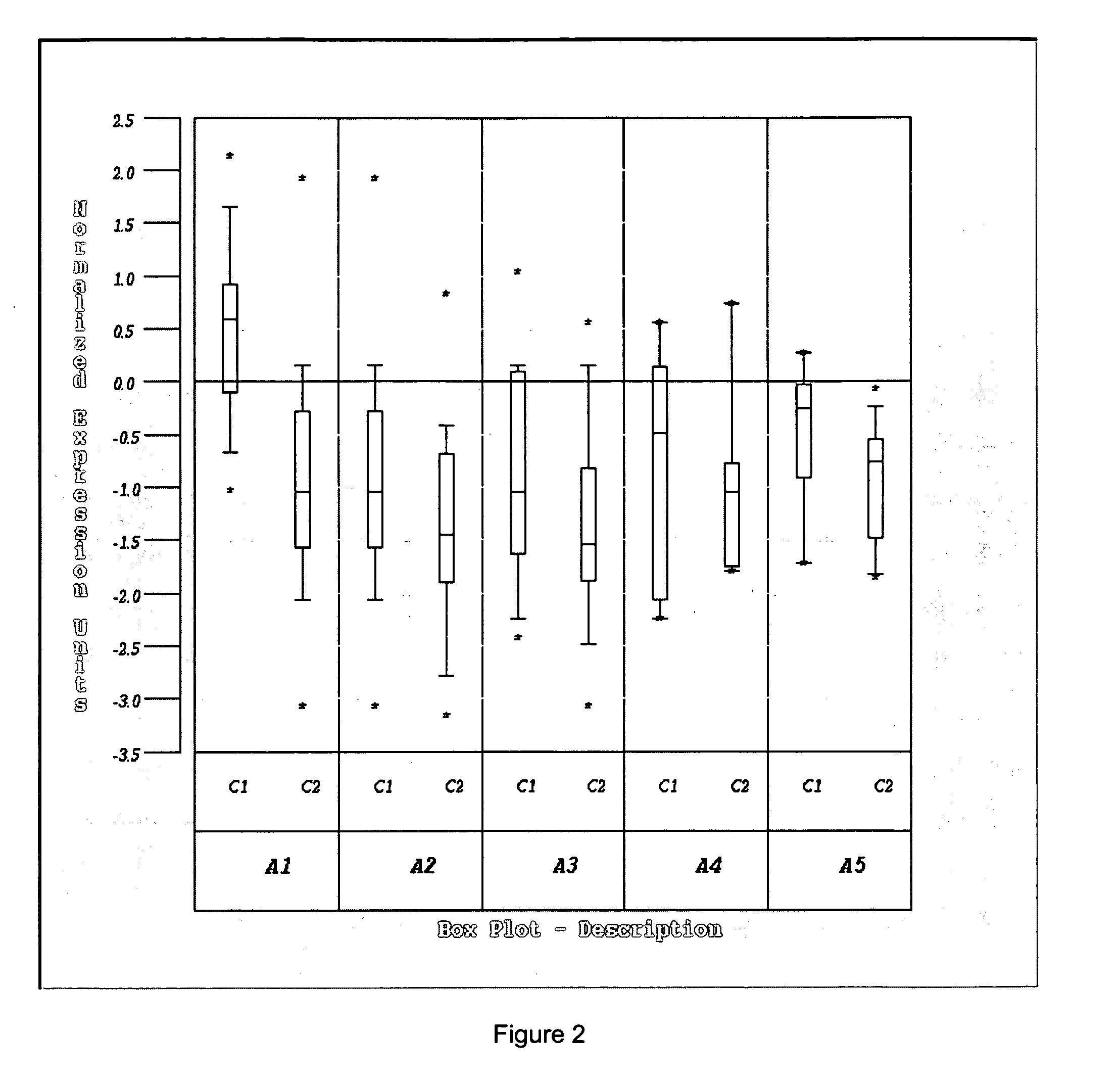

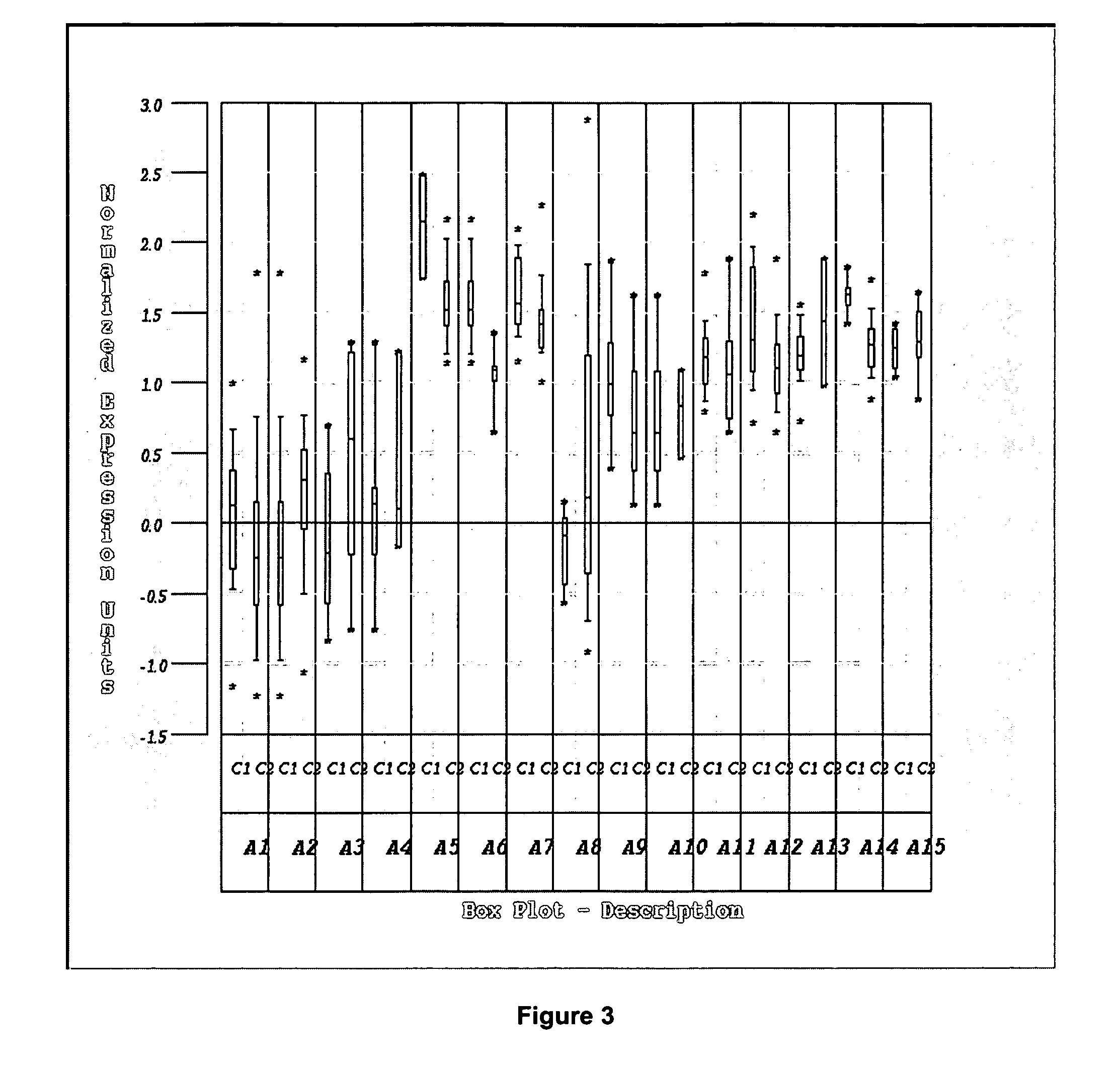

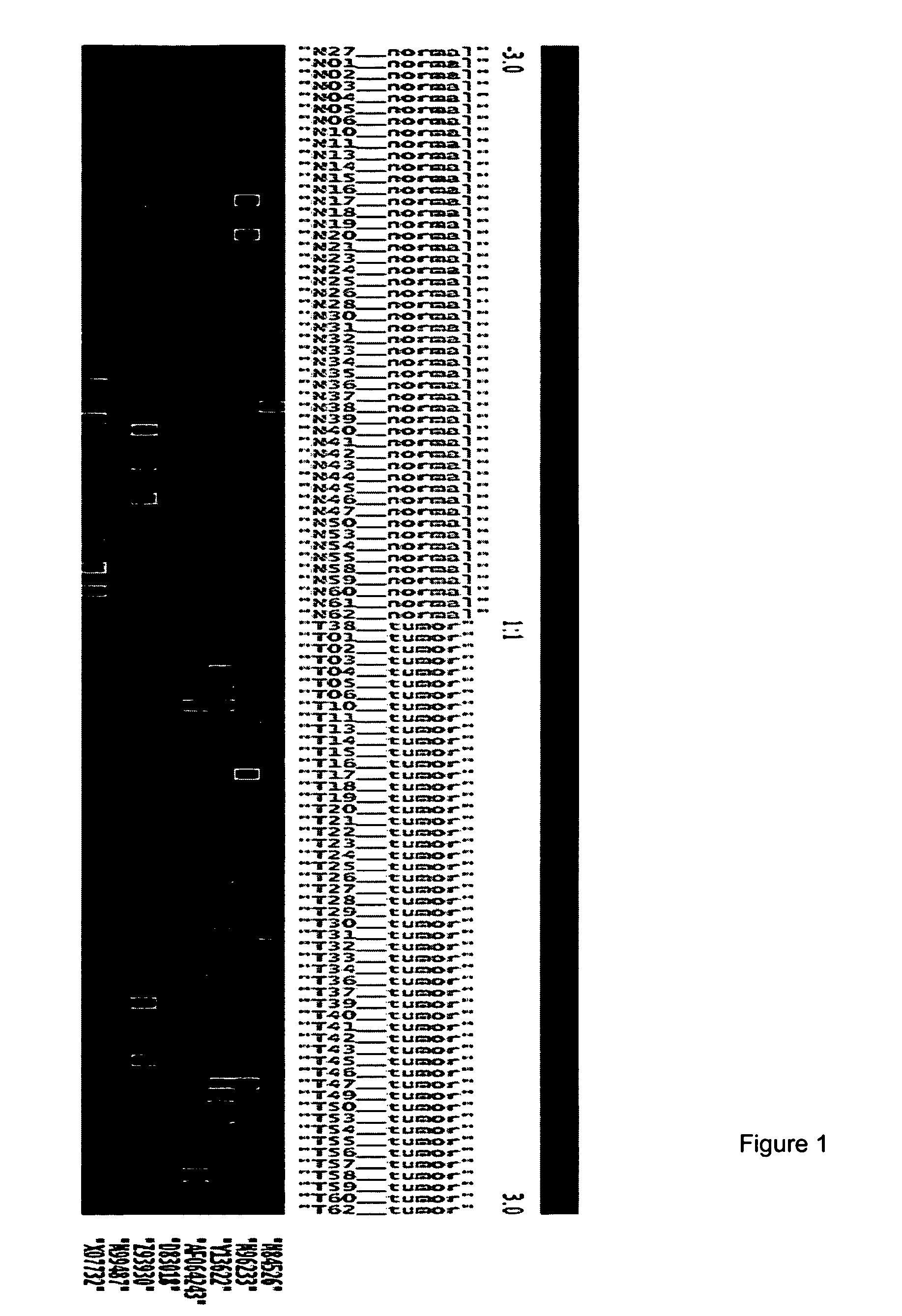

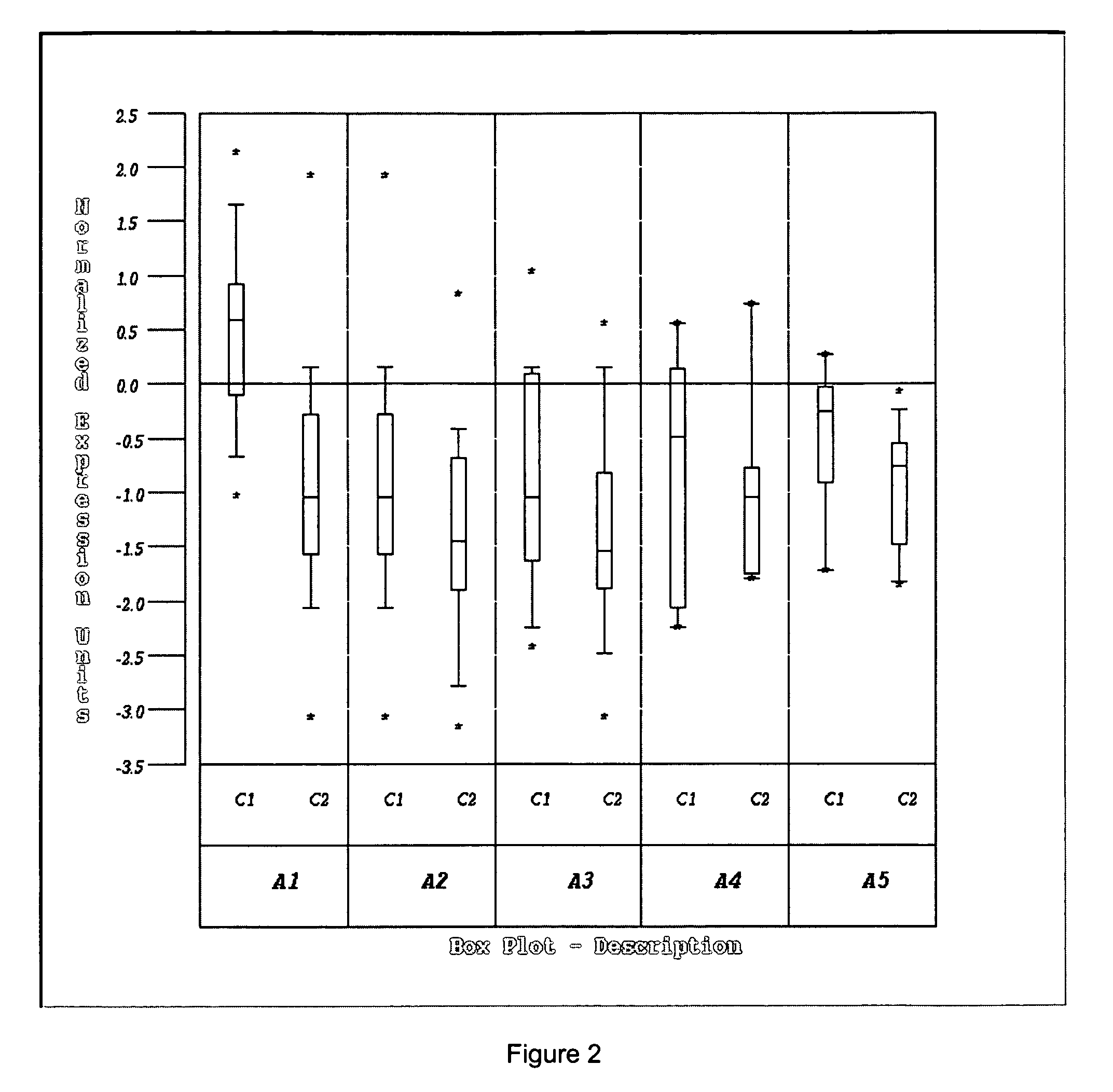

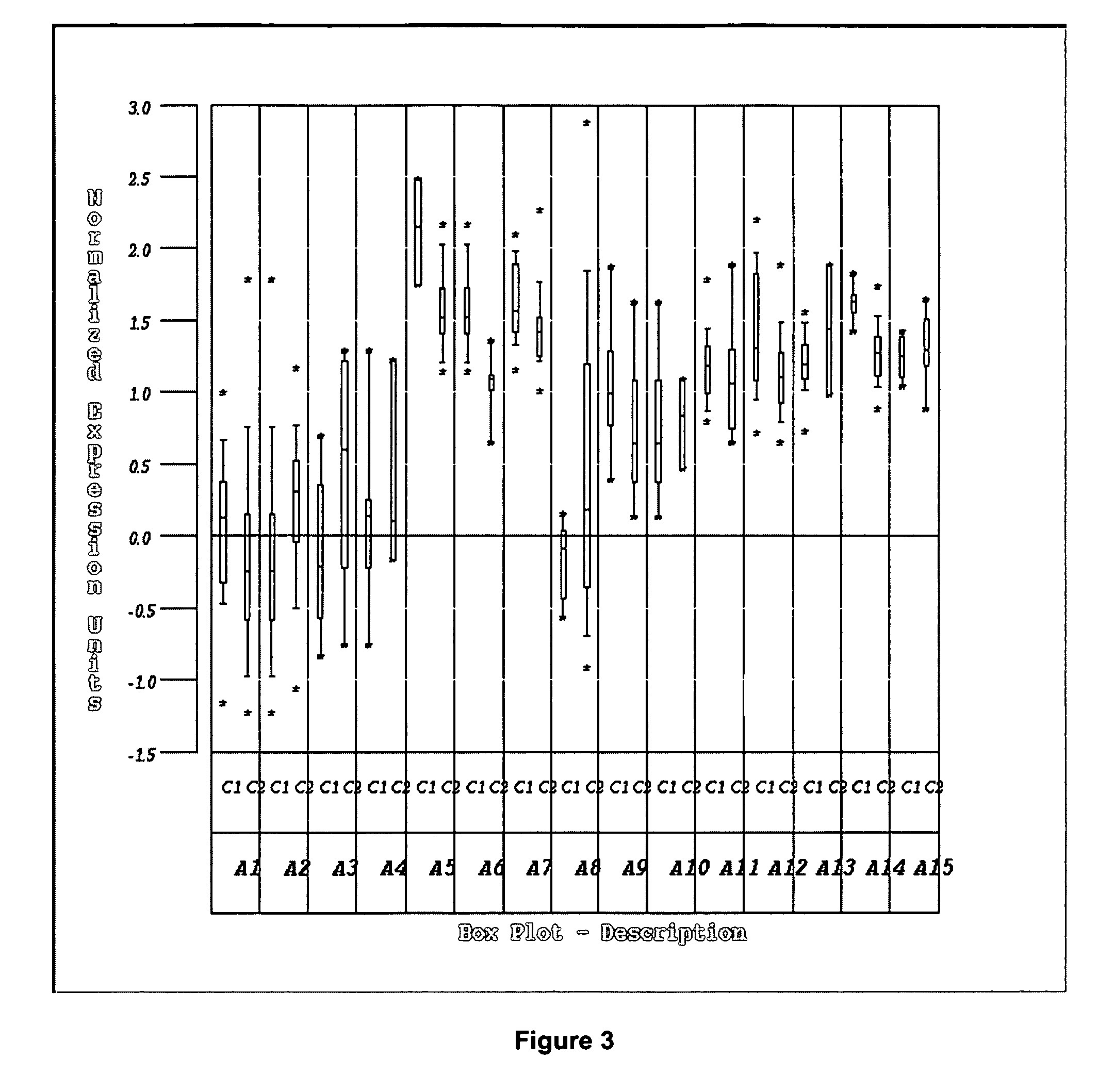

Molecular method for diagnosis of colon cancer

Methods for diagnosing or detecting cancerous colon tissue. A panel of 21 specific marker genes are provided. The overexpression of some of these marker genes compared to their expression in normal colon tissue and the underexpression of the rest of these marker genes are indicative of cancerous colon tissue. By using these 21 marker genes as a diagnostic tool, smaller tissue samples, such as those obtained by core needle biopsies and from patient stool samples, can be used.

Owner:NAT RES COUNCIL OF CANADA

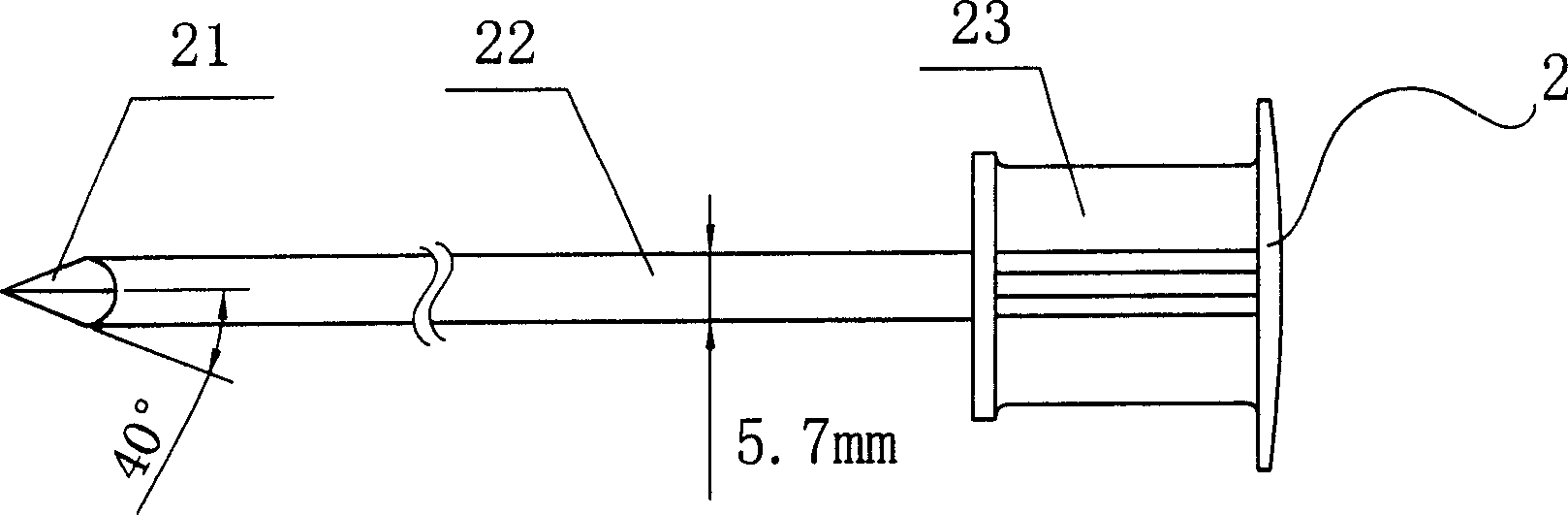

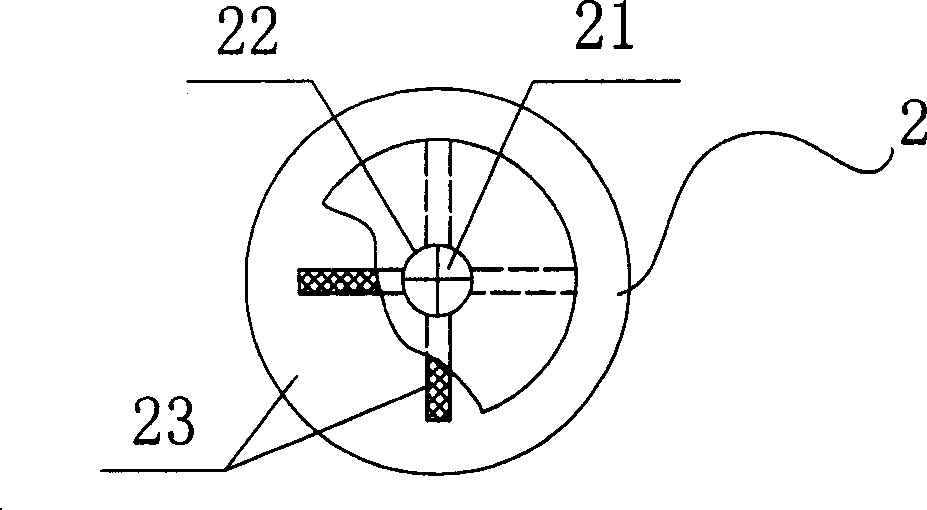

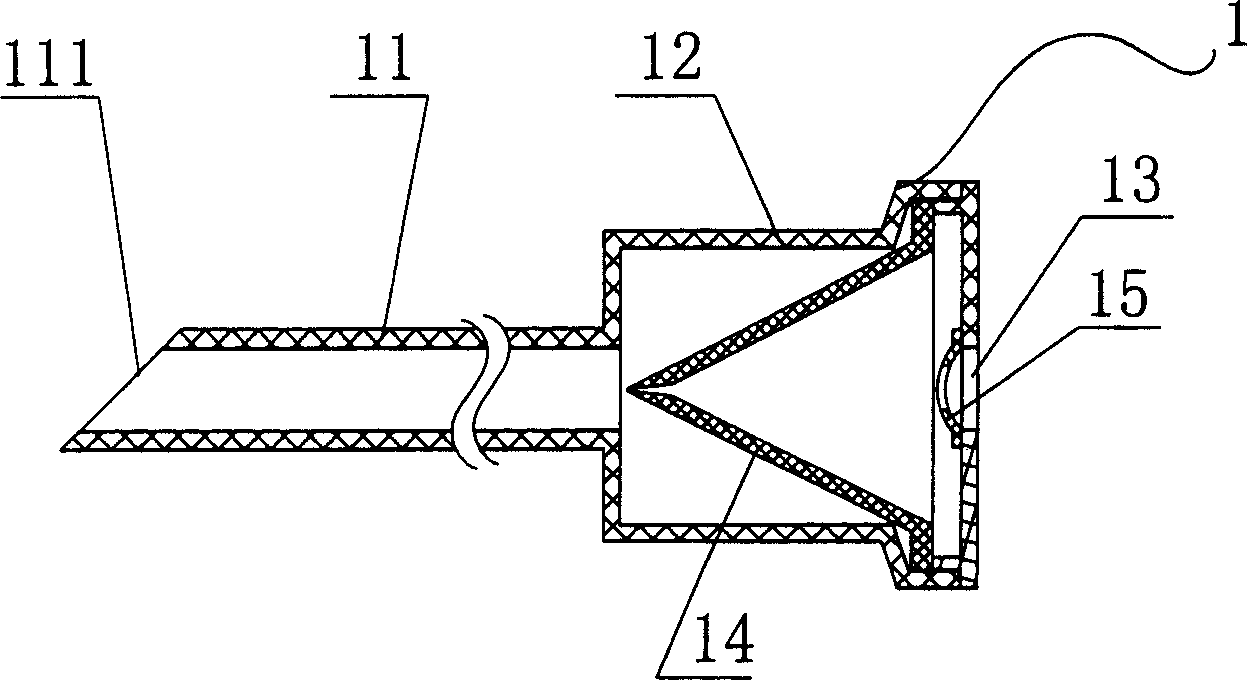

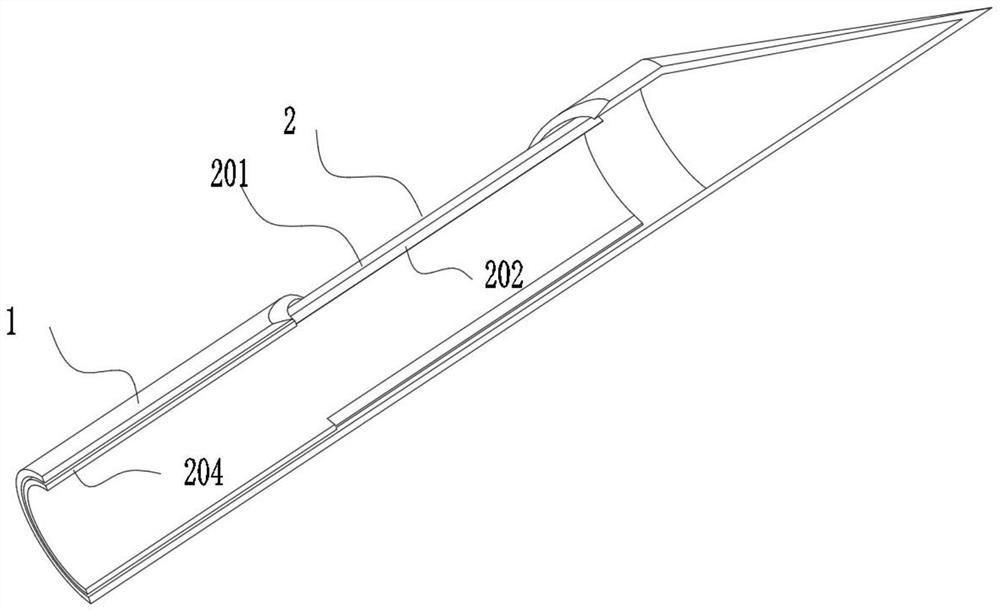

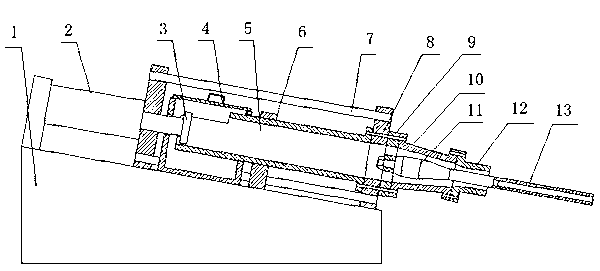

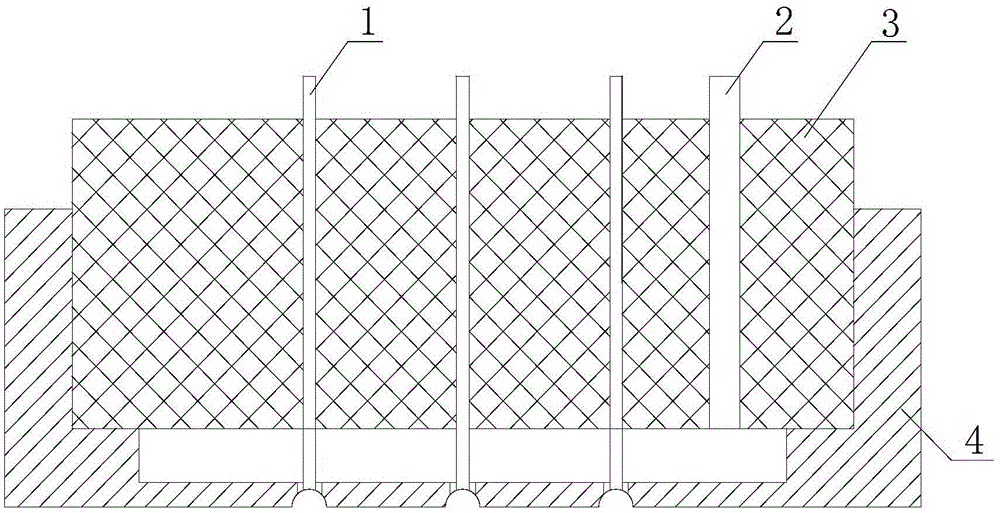

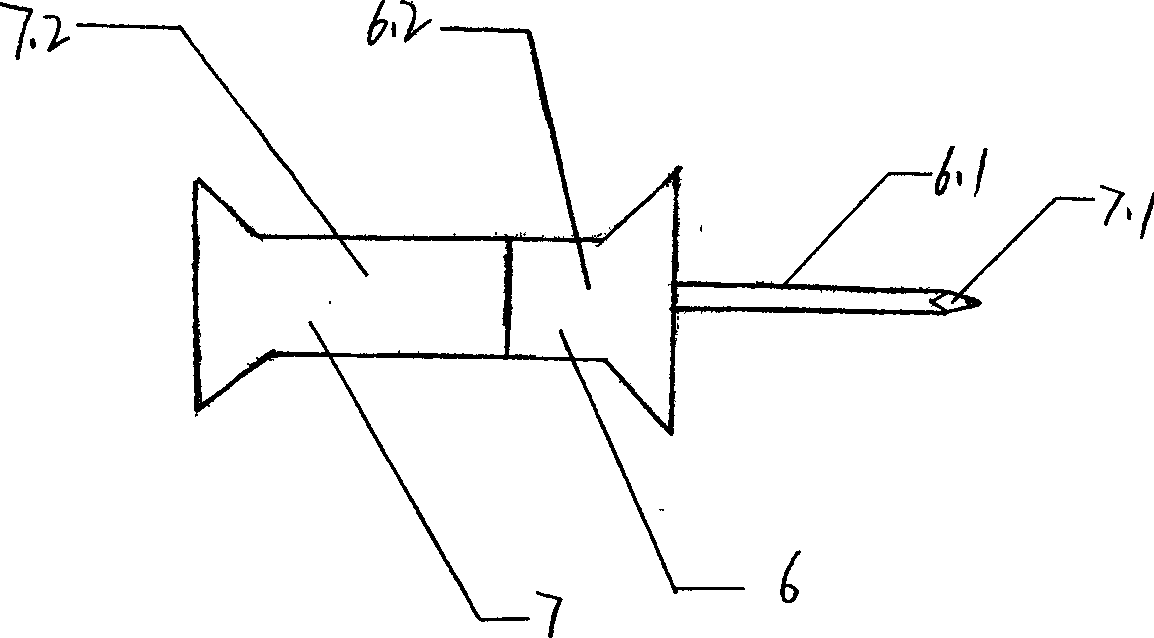

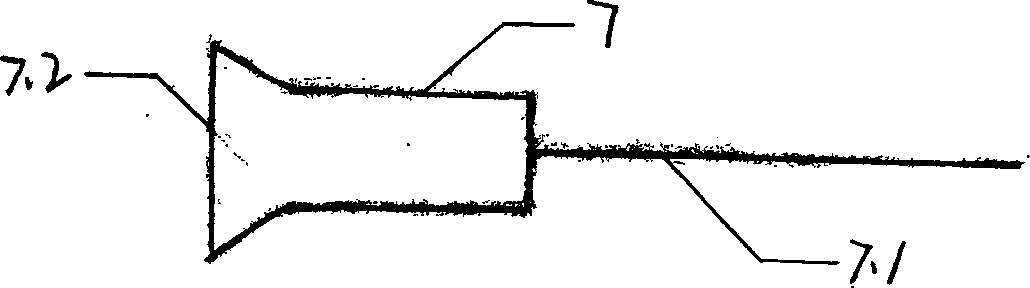

Sleeving puncture of laparoscope

InactiveCN1745722AEasy to implementEfficient implementationSurgical needlesTrocarCore needleLaparoscopy

A sleeve tube type puncture device for the peritoneoscope operation is composed of a sleeve tube with a tubular sheath, and a core needle consisting of needle rod fit movably in said tubular sheath, needle tip with polygonal cone shape, and handle. Said core needle is made of medical hard high-molecular material. Its advantages are simple structure and no damage to blood vessel in abdominal wall.

Owner:佛山特种医用导管有限责任公司

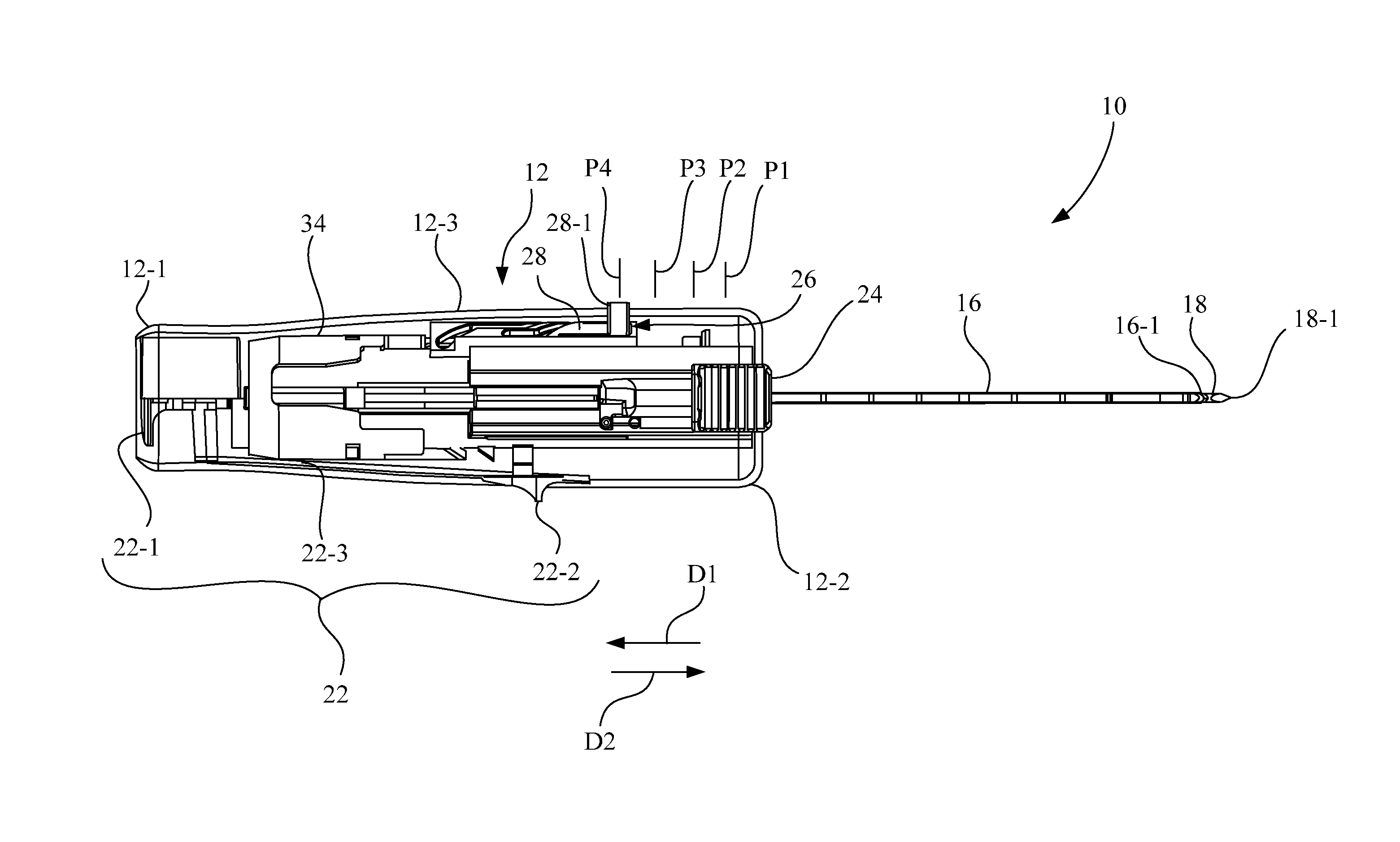

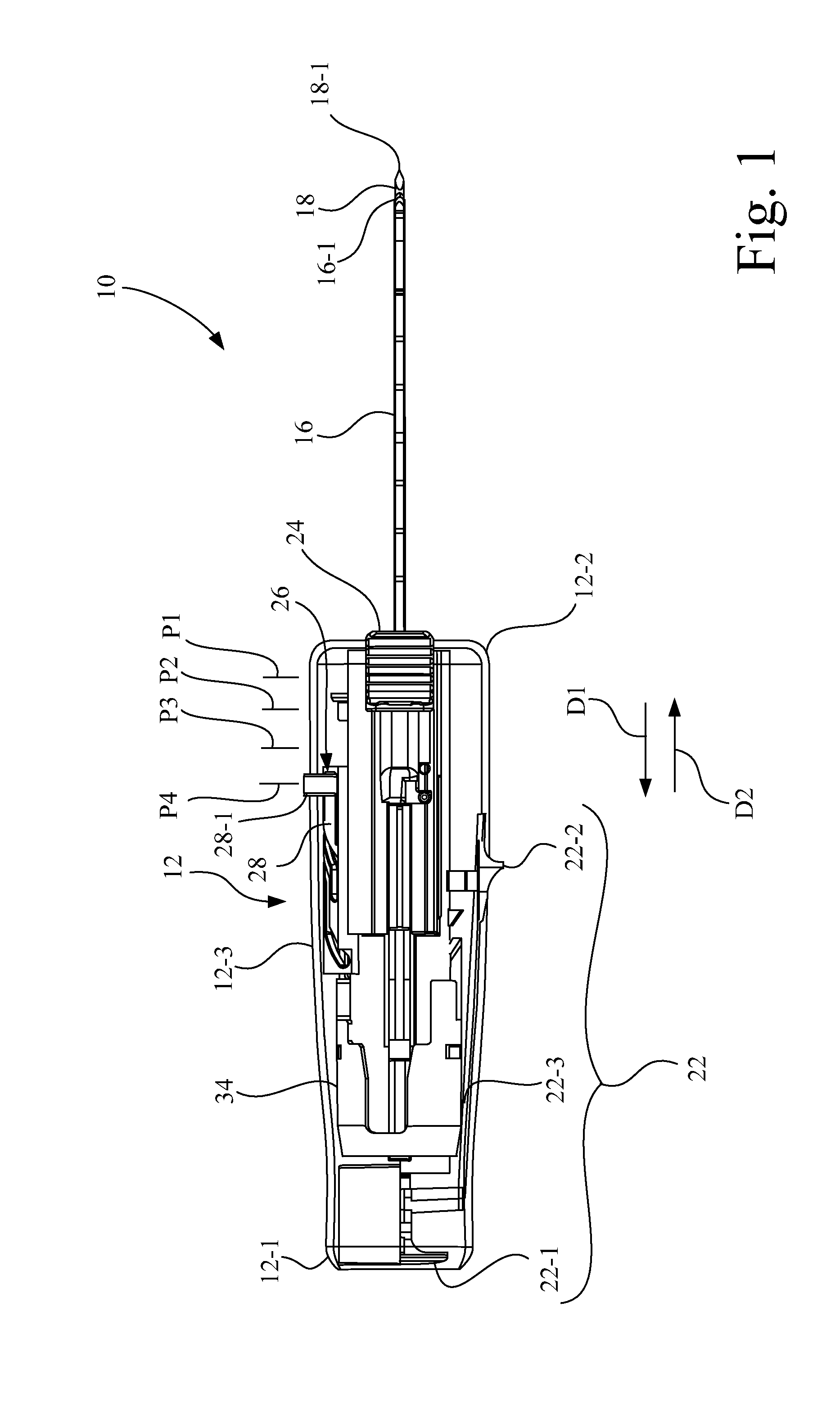

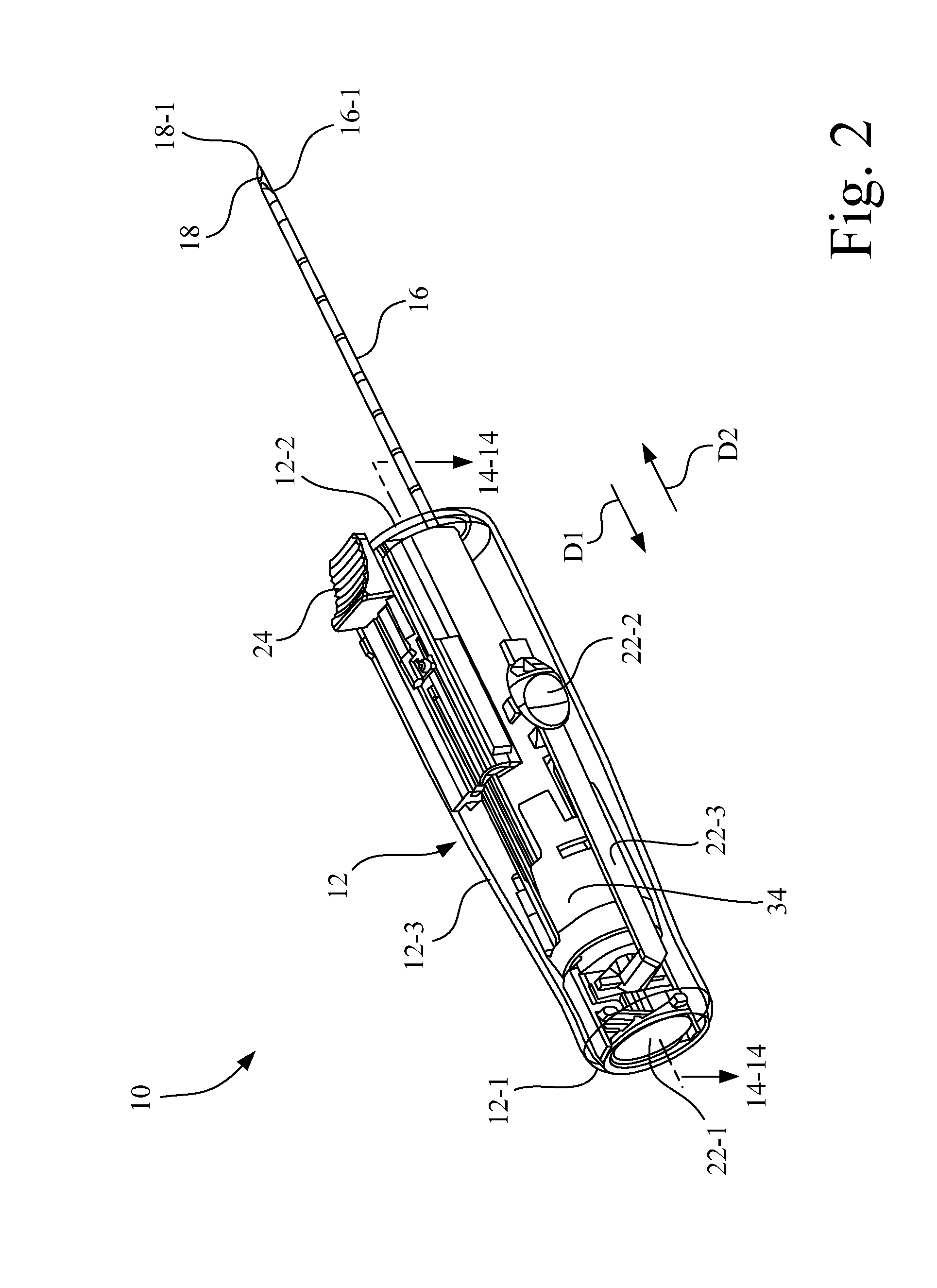

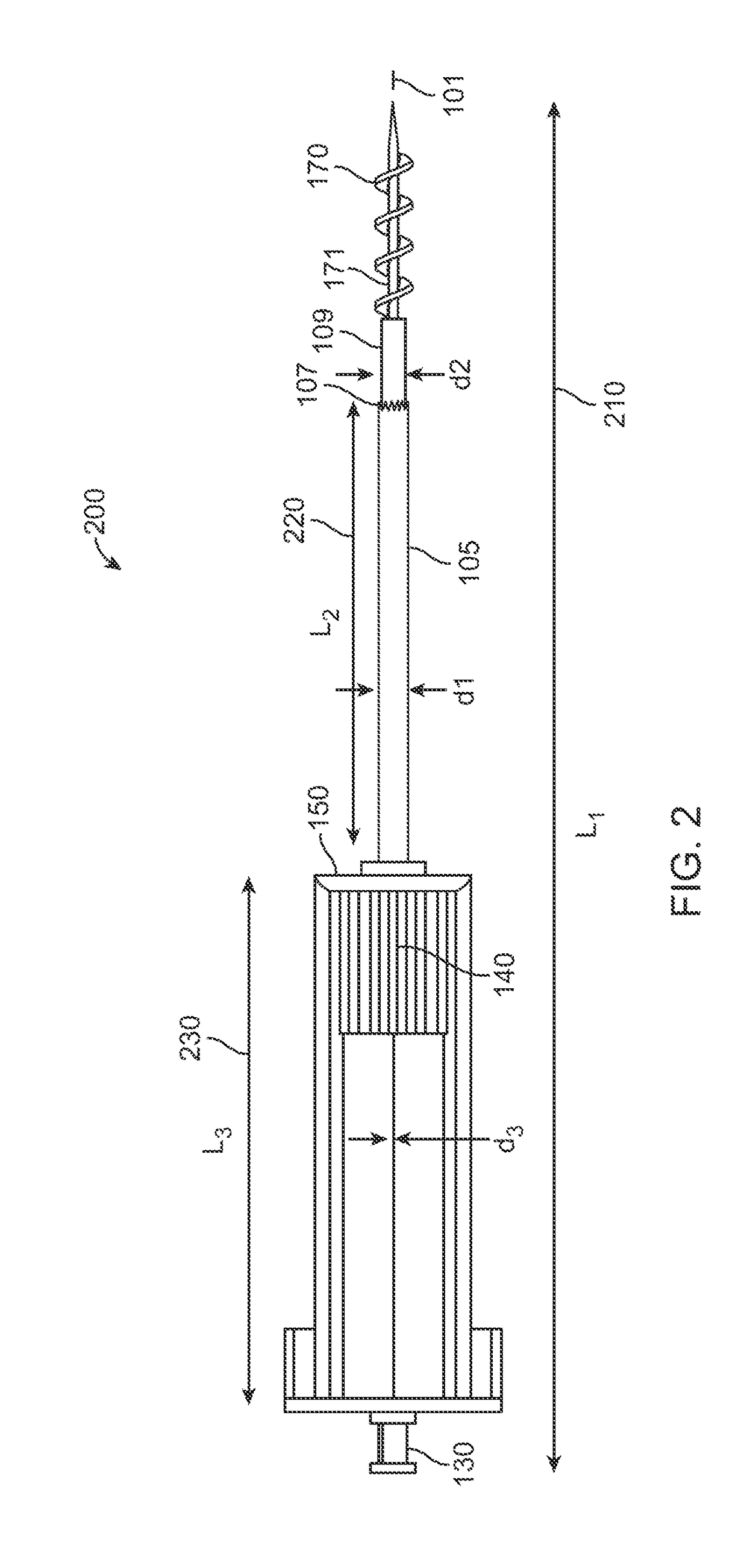

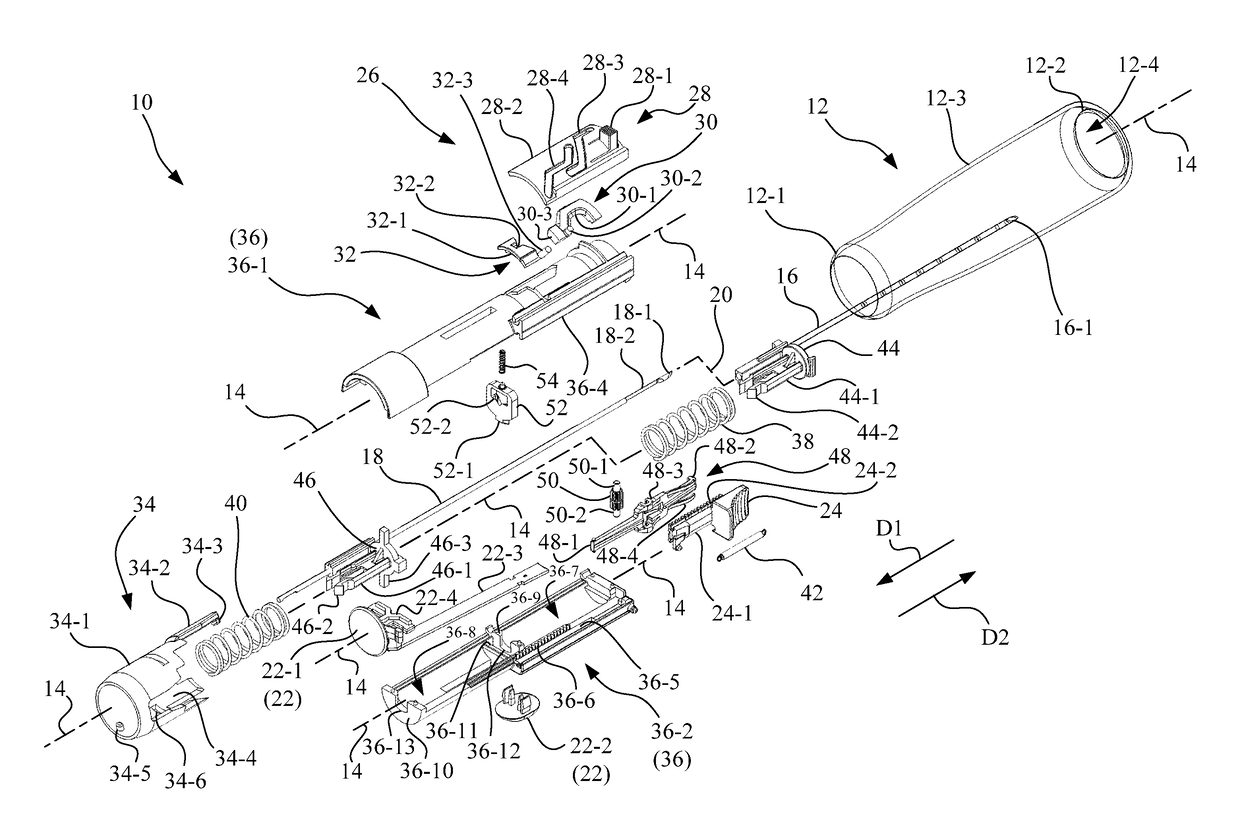

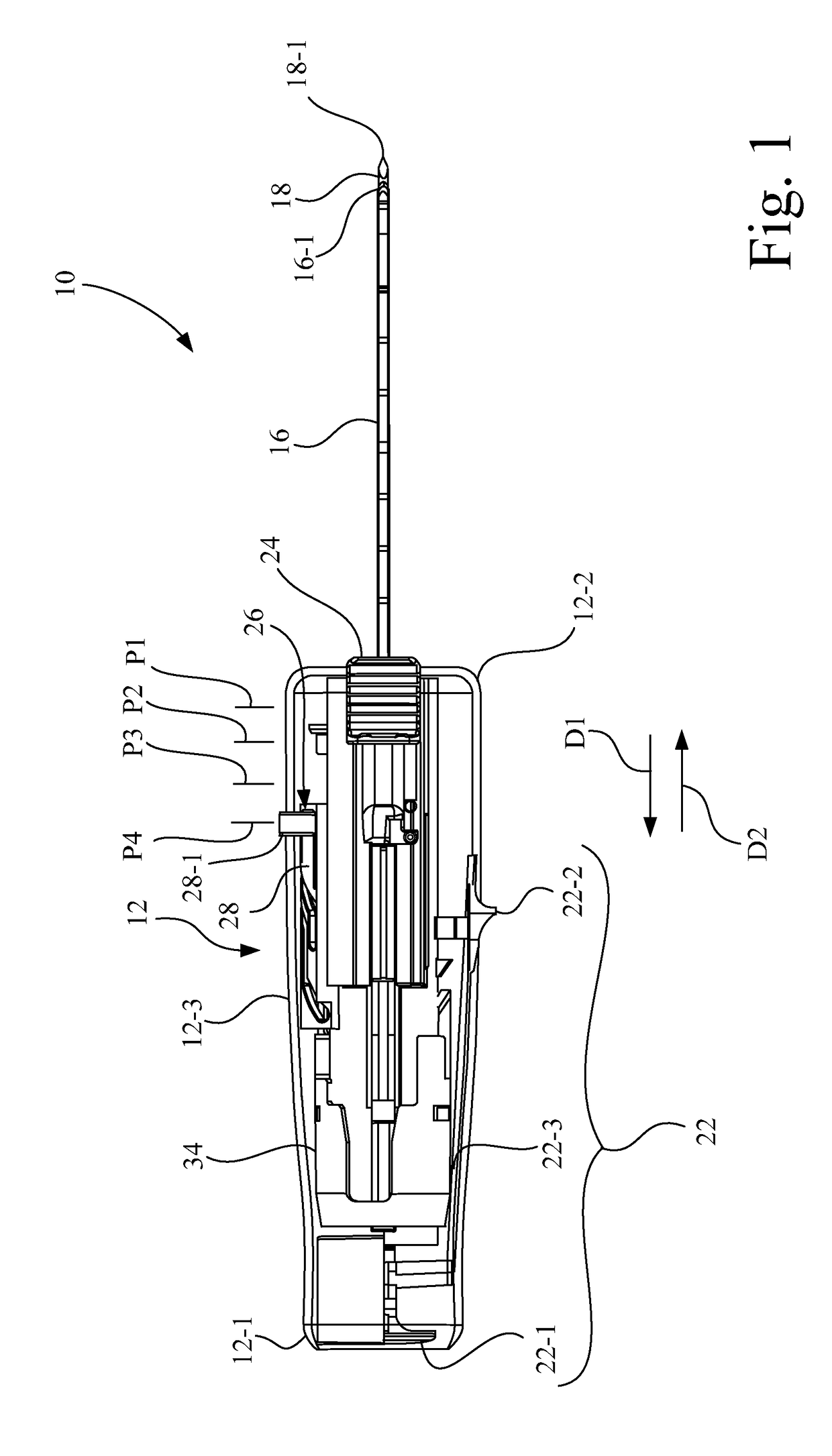

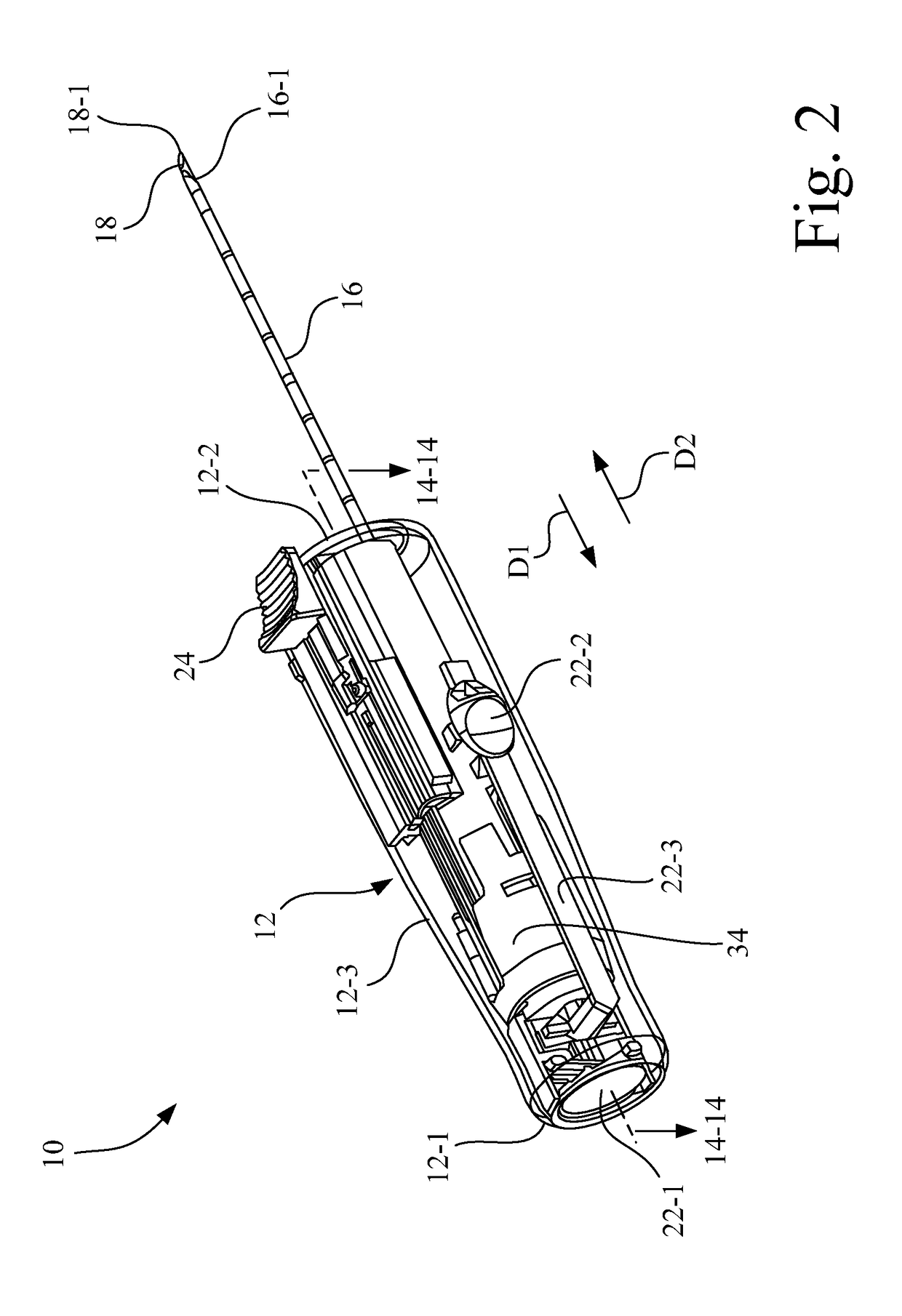

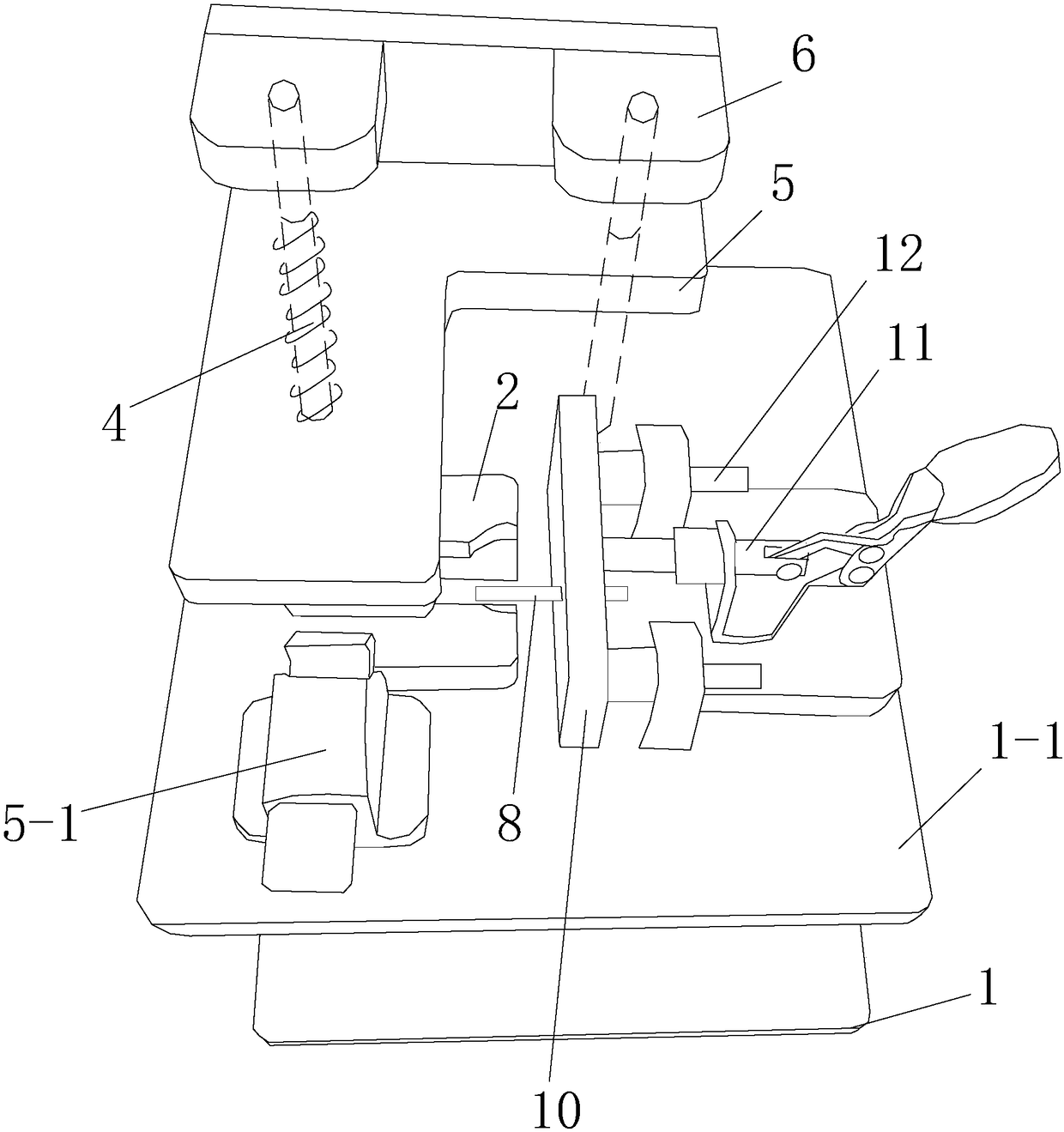

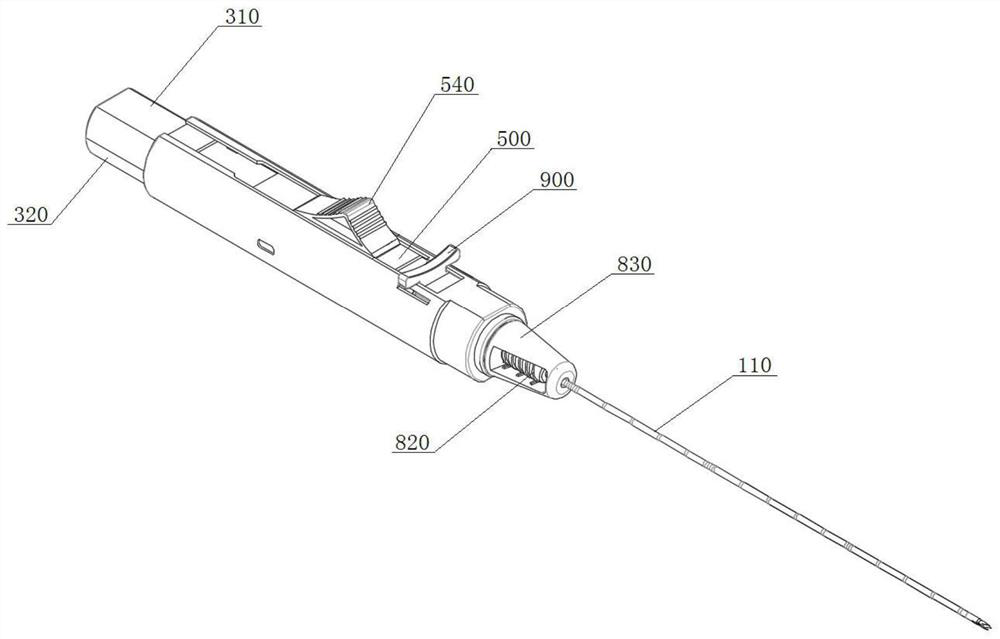

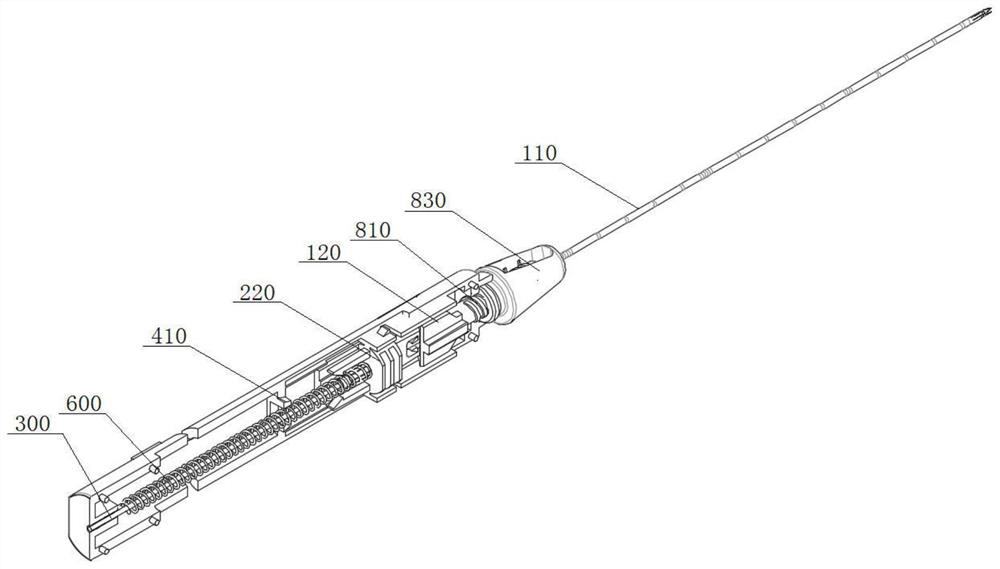

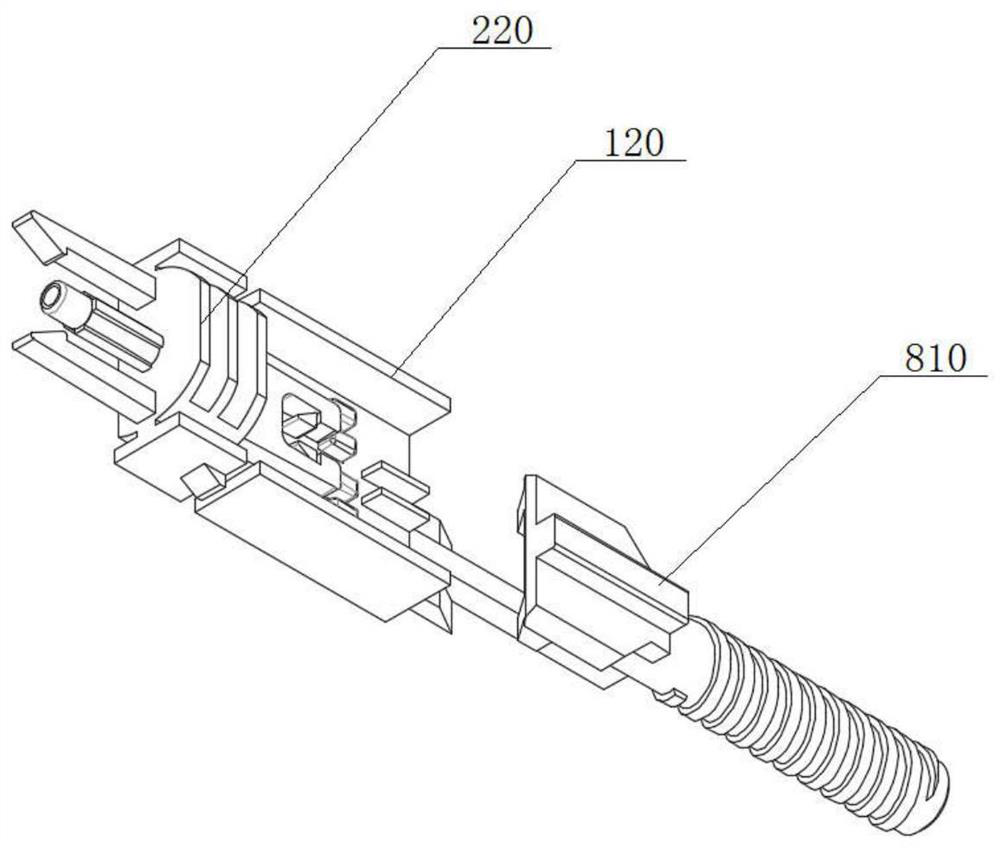

Core needle biopsy device

ActiveUS20150238171A1Little strengthSurgical needlesVaccination/ovulation diagnosticsCore needleBiopsy device

A biopsy device includes a cutting cannula mechanism having a cutting cannula and an inner stylet mechanism having an inner stylet coaxial with the cutting cannula. A cocking mechanism is configured to cock the cutting cannula mechanism and the inner stylet mechanism by retracting each of the cutting cannula and the inner stylet in a proximal direction to a cocked position. A trigger device is configured to fire at least one of the inner stylet mechanism and the cutting cannula mechanism to advance a respective at least one of the inner stylet and the cutting cannula from the cocked position in a distal direction. A selector assembly includes a selector switch having an exterior tab accessible by a user. The selector assembly is configured to select between at least two user selectable operating modes and at least two user selectable firing distances.

Owner:CR BARD INC

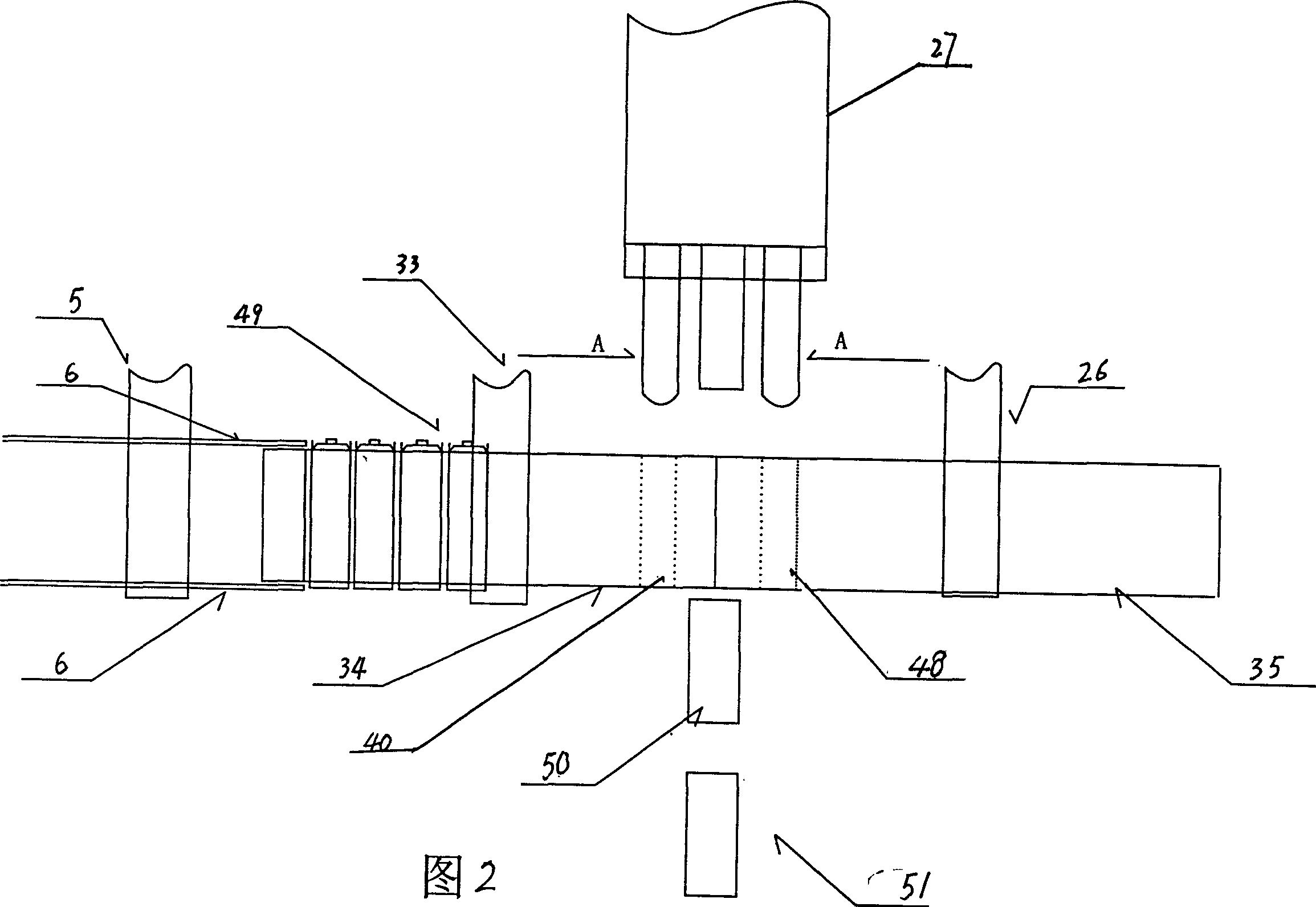

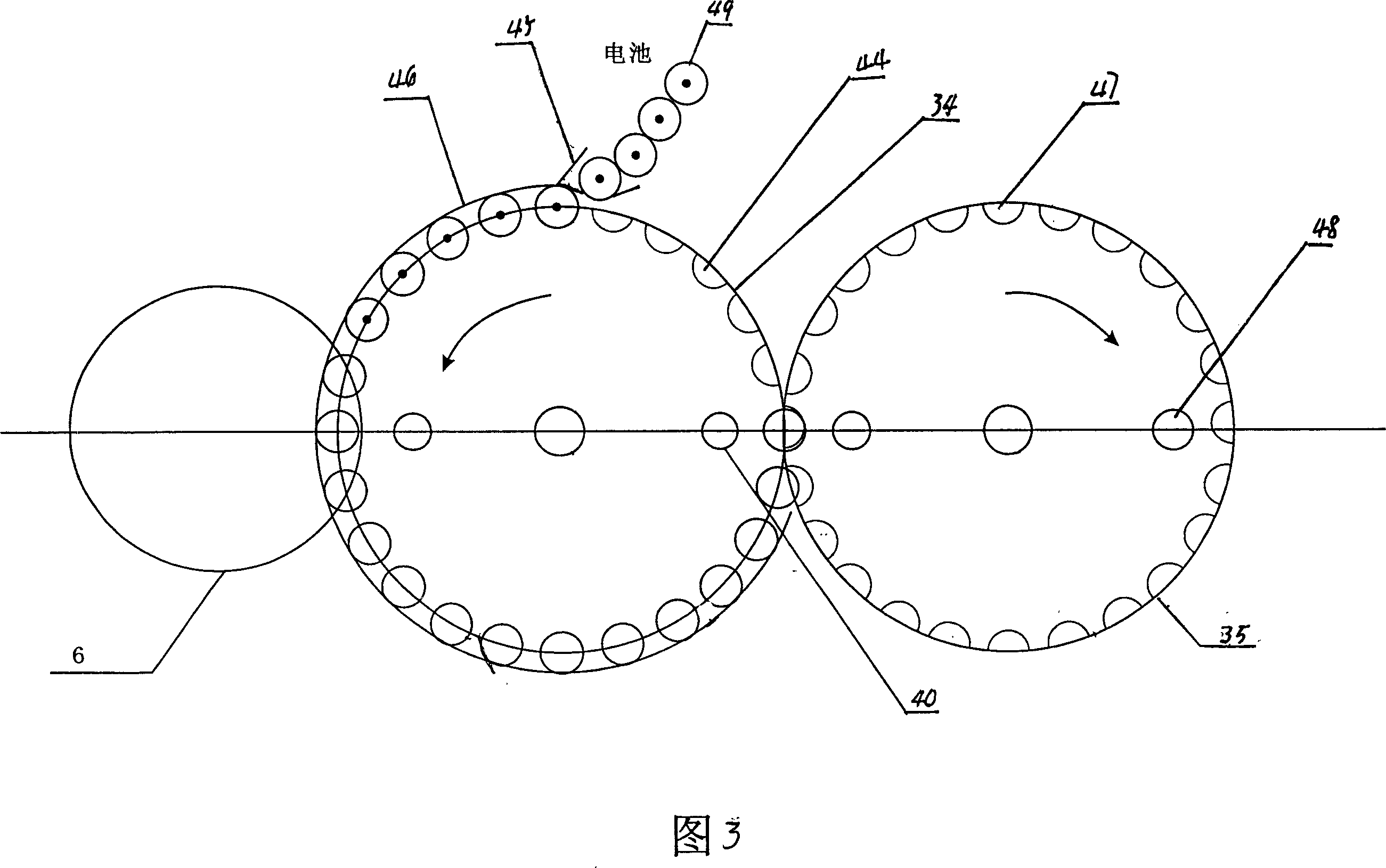

Dismantler of abandoned battery

InactiveCN101034744AEasy to separateEfficient separationSolid waste disposalReclaiming serviceable partsCore needleMechanical engineering

The invention relates to a worn out battery open machine, it is equipped with the positioning device, the saw cut installment and clush core installment on the rack. It is equipped with the primary wheel and accessory mark in the positioning device, and on the primary wheel and accessory mark separately equipped with the index hole and the battery pot holes, the sawblade installed on the saw cut installment, in clush core installment equipped with clush core needle, clush shell needle and guide pin, clush core needle, clush shell needle and guide pin and the guide pin correspond with the primary wheel and accessory mark on the positioning device. The machine structure novel, ease of operation, opens wornout battery quickly, the opened battery waste material can recycle and regeneration use, in the opening process not cause secondary pollution, and high opening efficiency; the machine is an environmental protection technology with developping prospect.

Owner:郭焕林

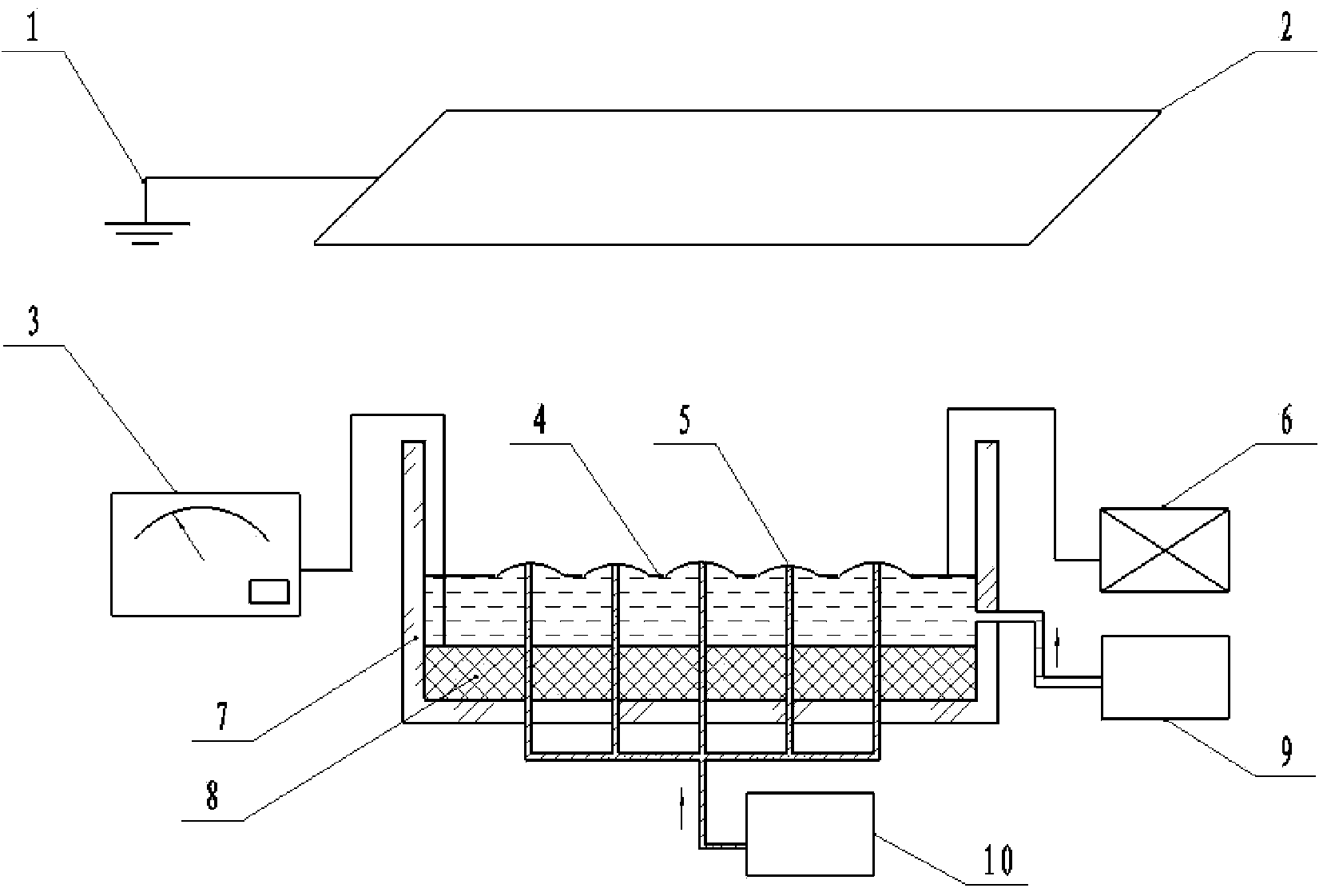

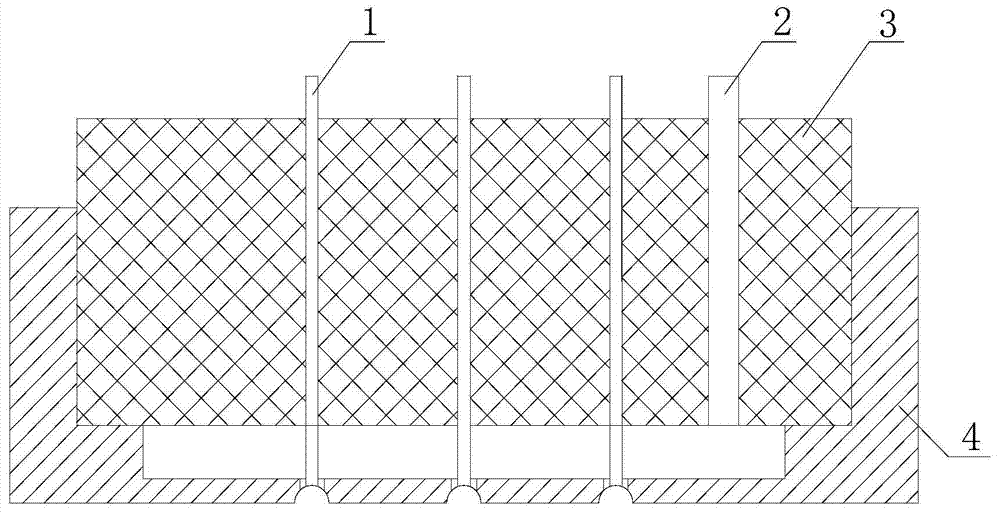

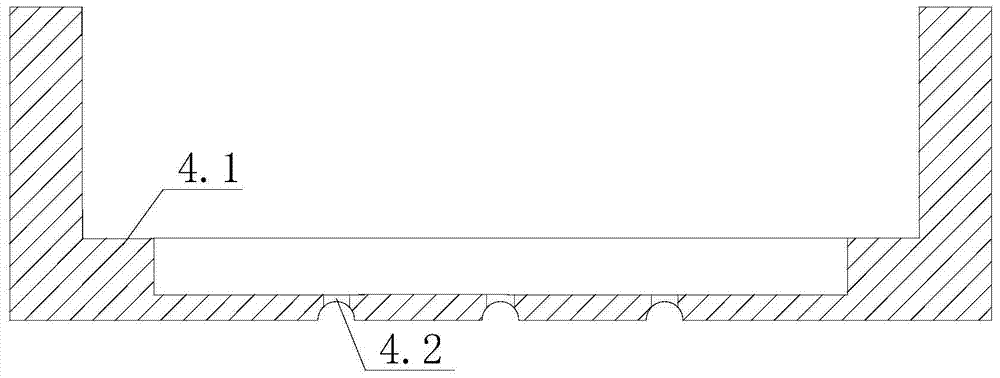

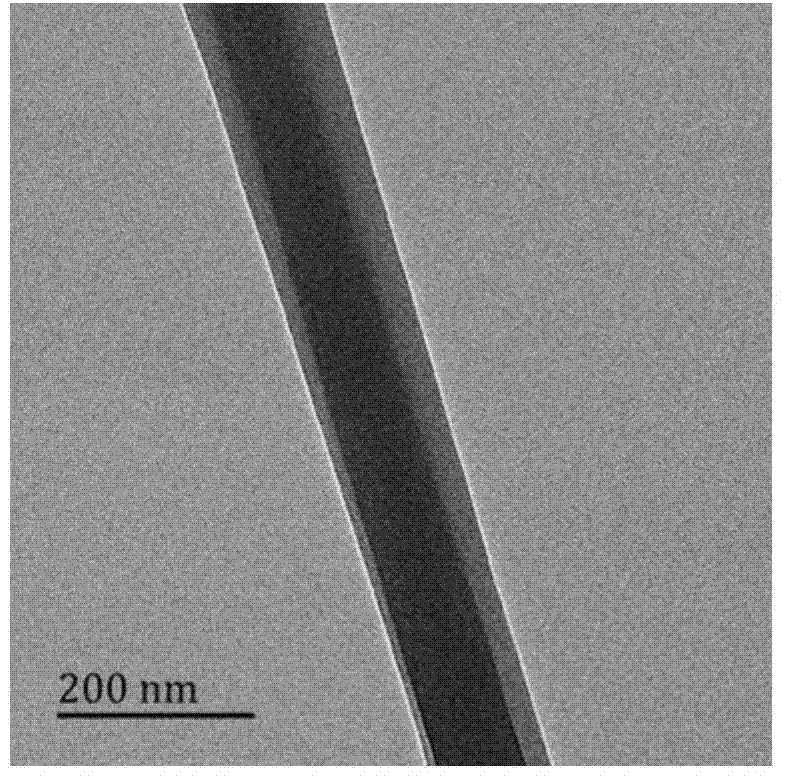

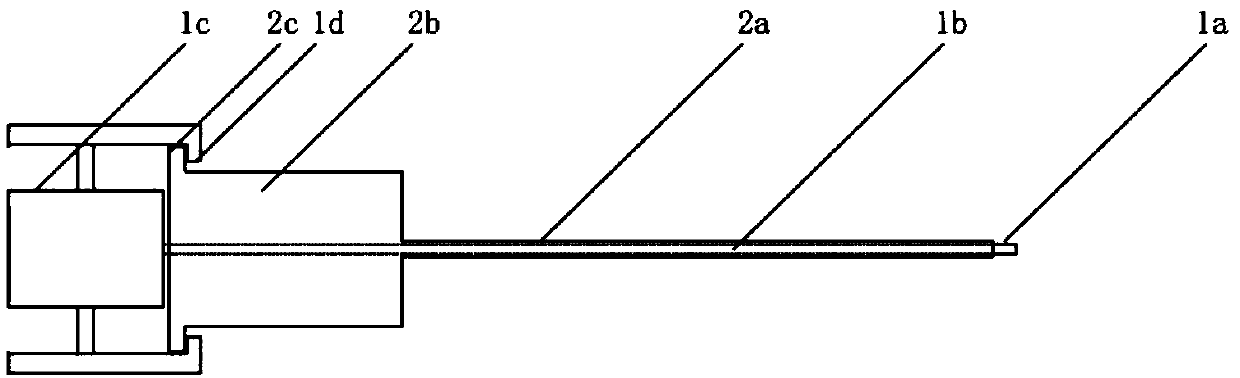

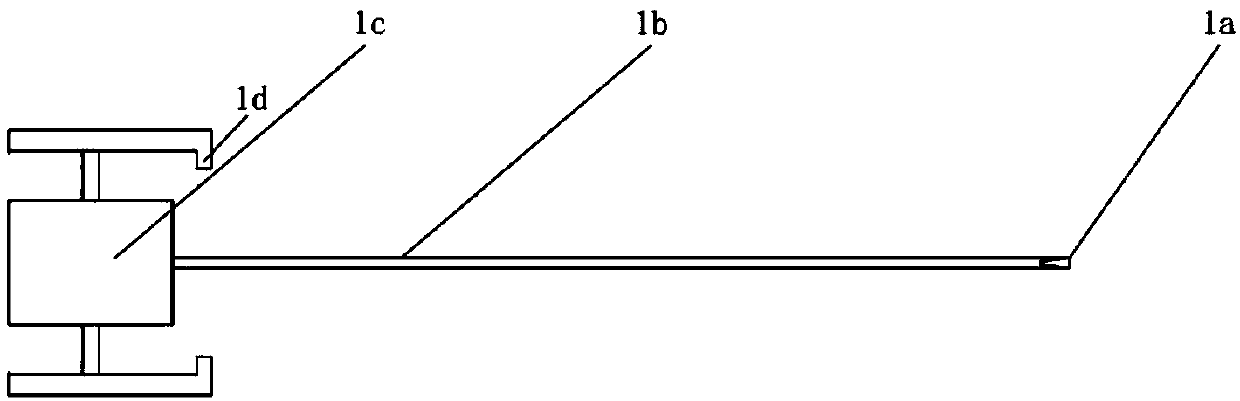

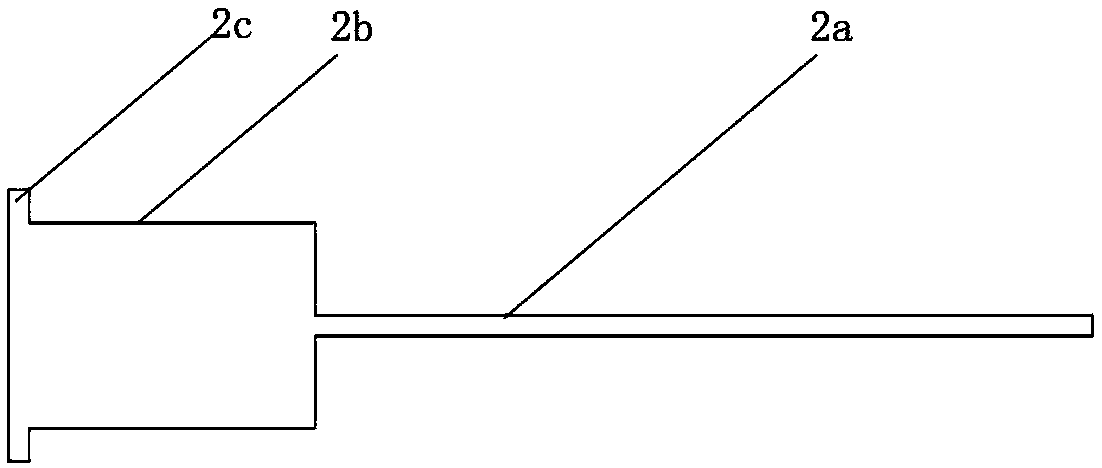

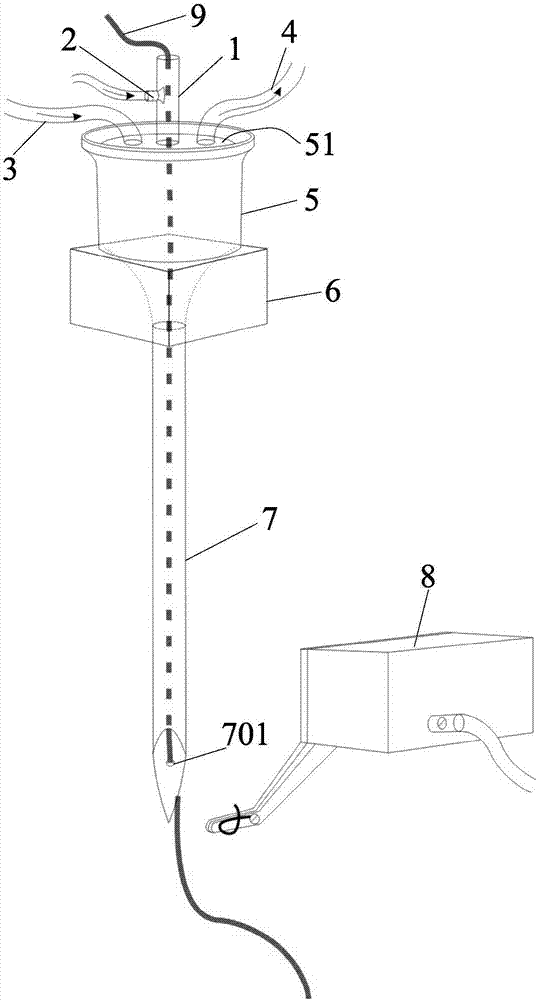

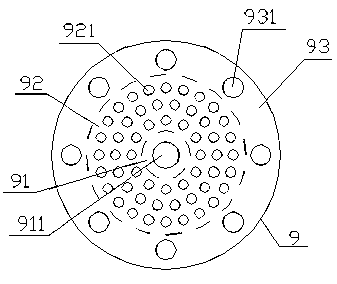

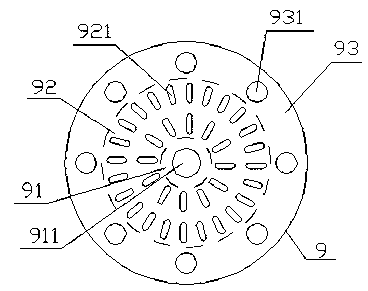

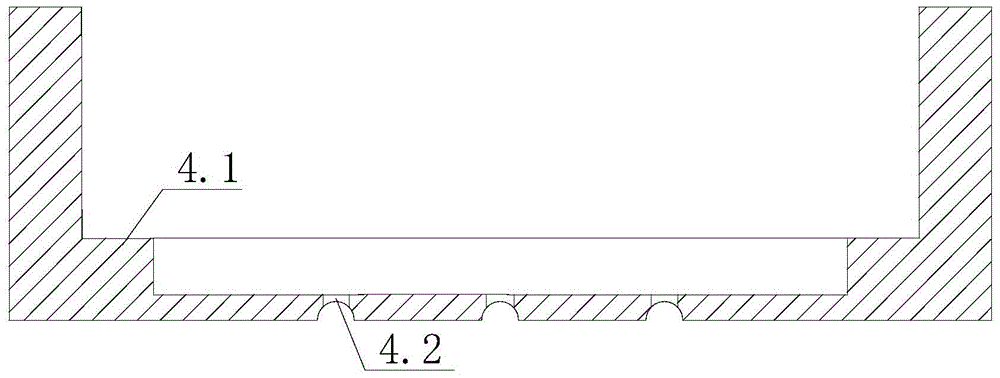

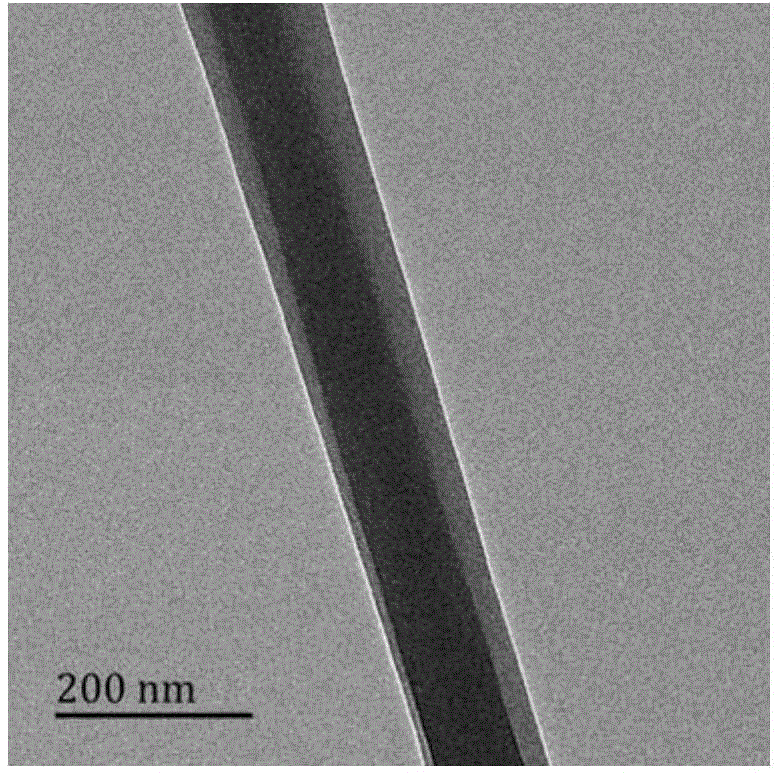

Flat plate free liquid level coaxial electrostatic spinning method and device

The invention relates to a flat plate free liquid level coaxial electrostatic spinning method and device, in particular to an upwards spinning flat plate free liquid level coaxial electrostatic spinning method and device. The method includes the steps that shell spinning liquid is filled into a liquid storage tank, core spinning liquid is filled into core needles, and the two kinds of liquid combines at the tips of the core needles to form composite liquid drops, and the composite liquid drops are stretched and solidified on a receiving pole plate under the effect of high voltage electric fields to form ultrathin fiber felt of a core-shell structure. The method has the advantages that the effective coverage effect of the shell spinning liquid and the thickness of a shell can be adjusted according to the concentration and the viscosity of the shell spinning liquid, and therefore the requirement for preparing composite fibers of the specific core-shell structure is met. The upwards spinning flat plate free liquid level coaxial electrostatic spinning device is composed of the liquid storage tank, the core needles, a flat plate electrode, the receiving pole plate and a high voltage electrostatic generator and has the advantages that the device is easy to manufacture, the formed electric fields are uniform, and the multifunctional composite fibers of the more uniform structure can be massively prepared by increasing the number of the core needles and changing core liquid.

Owner:DONGHUA UNIV

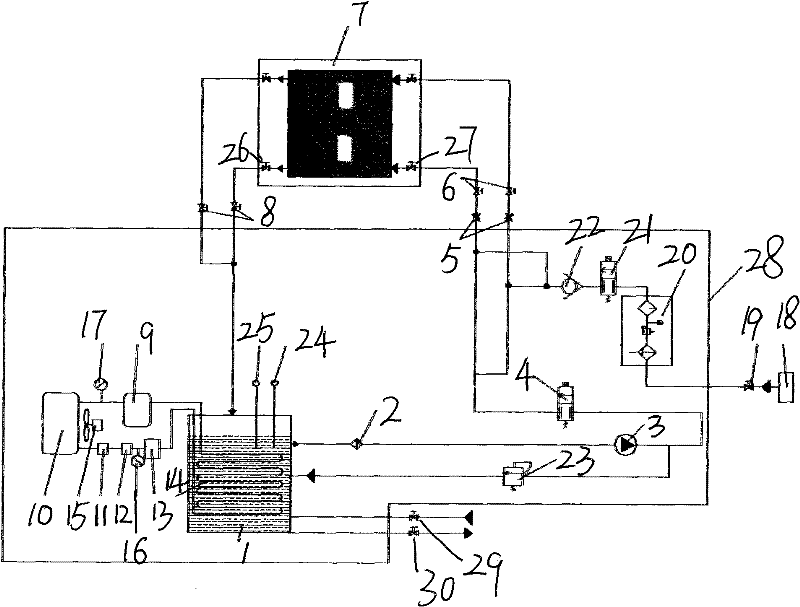

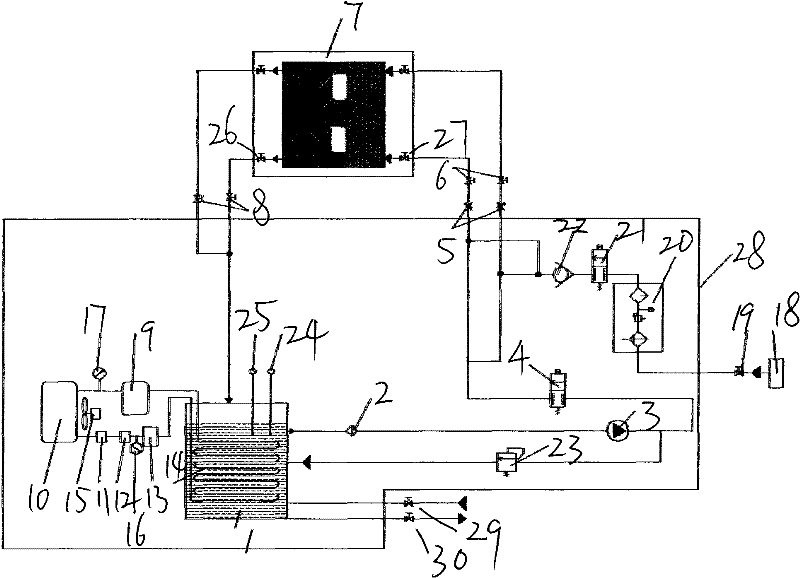

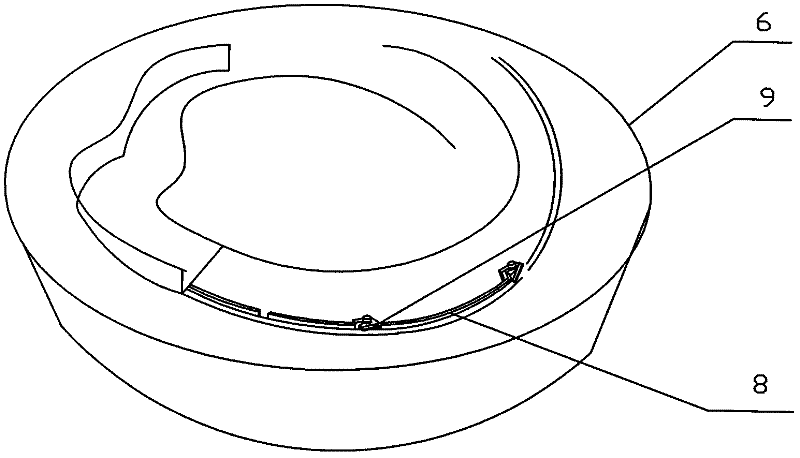

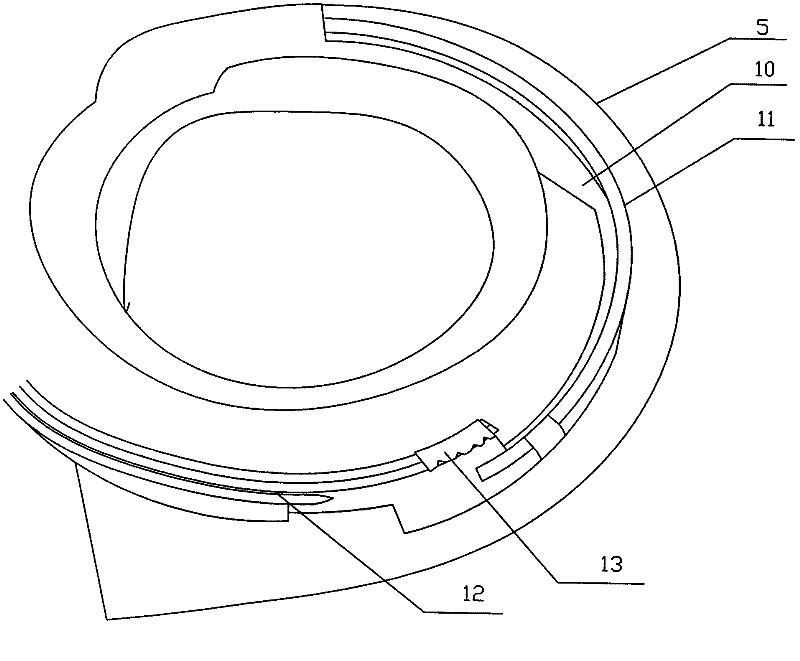

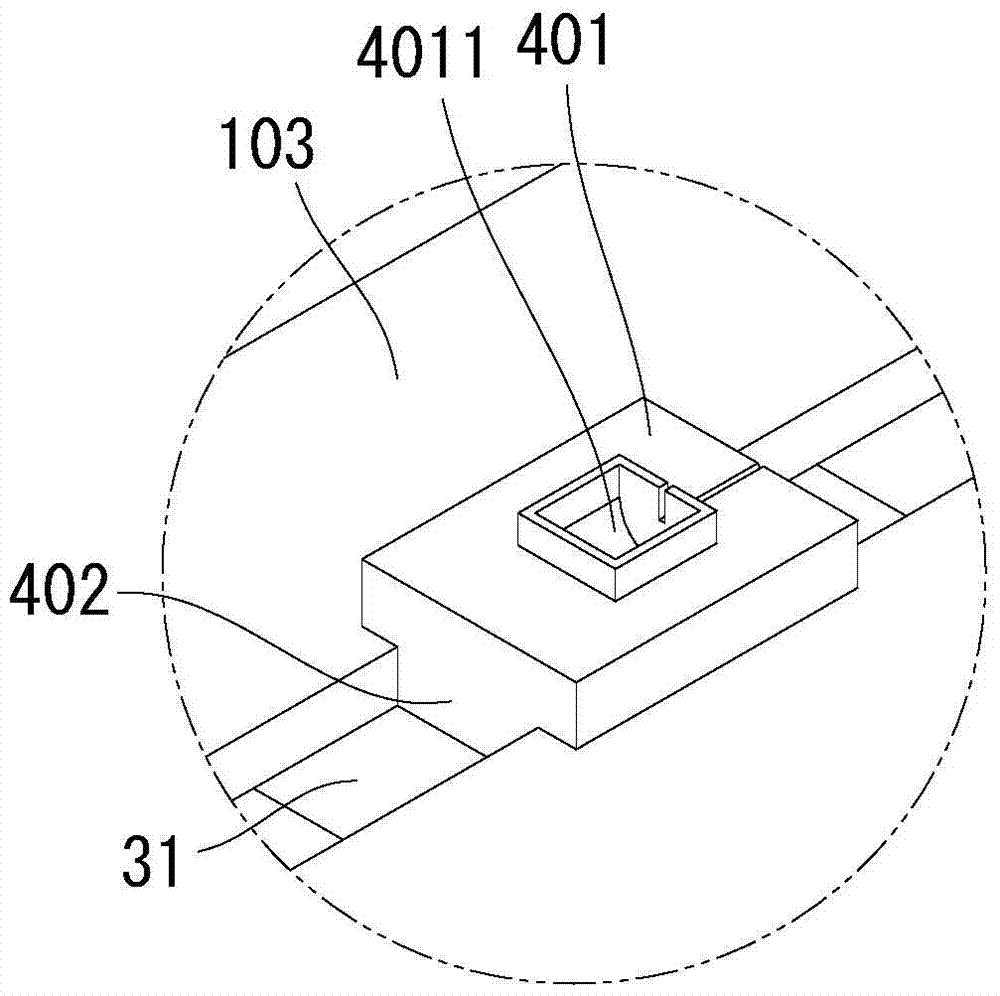

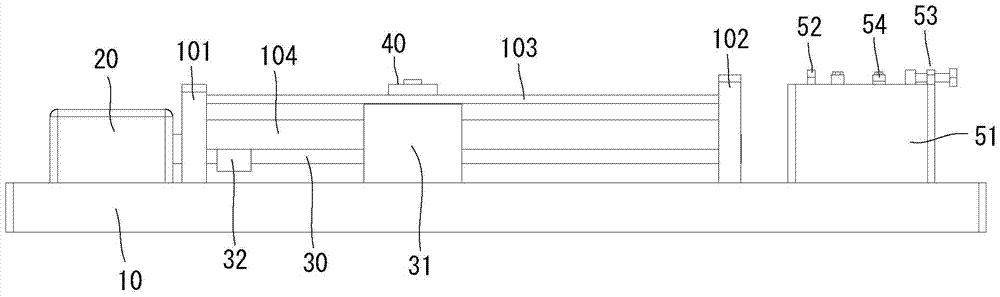

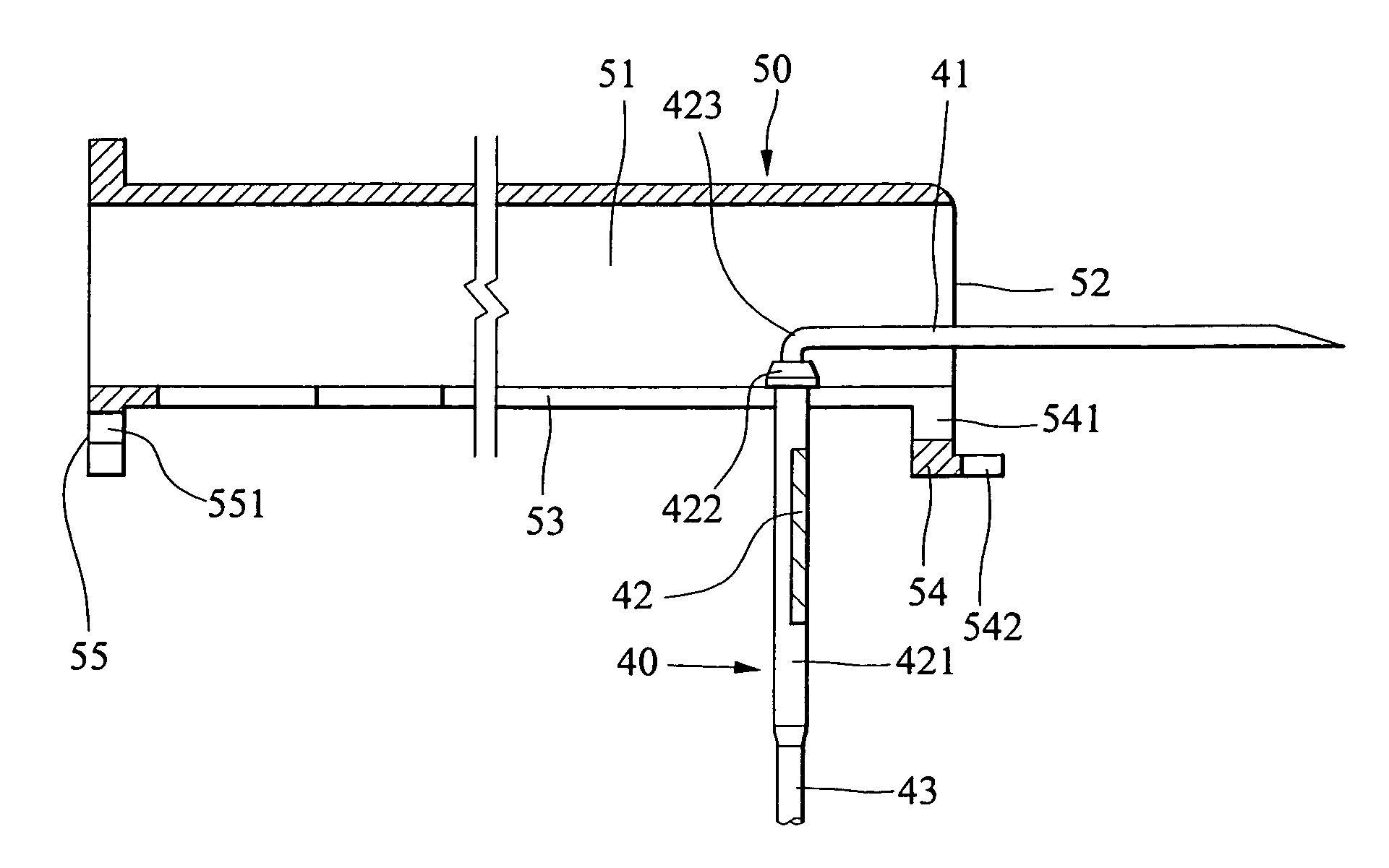

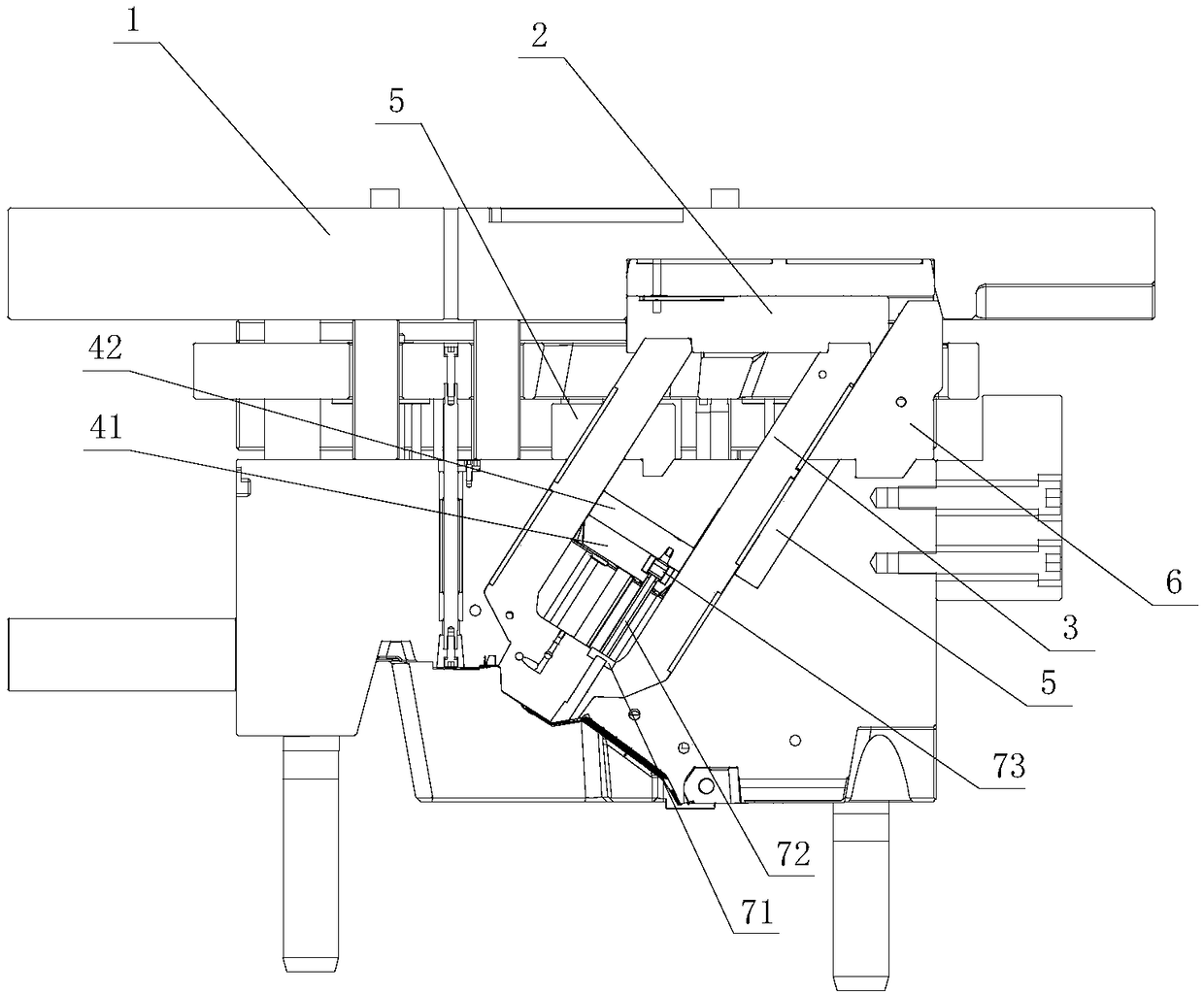

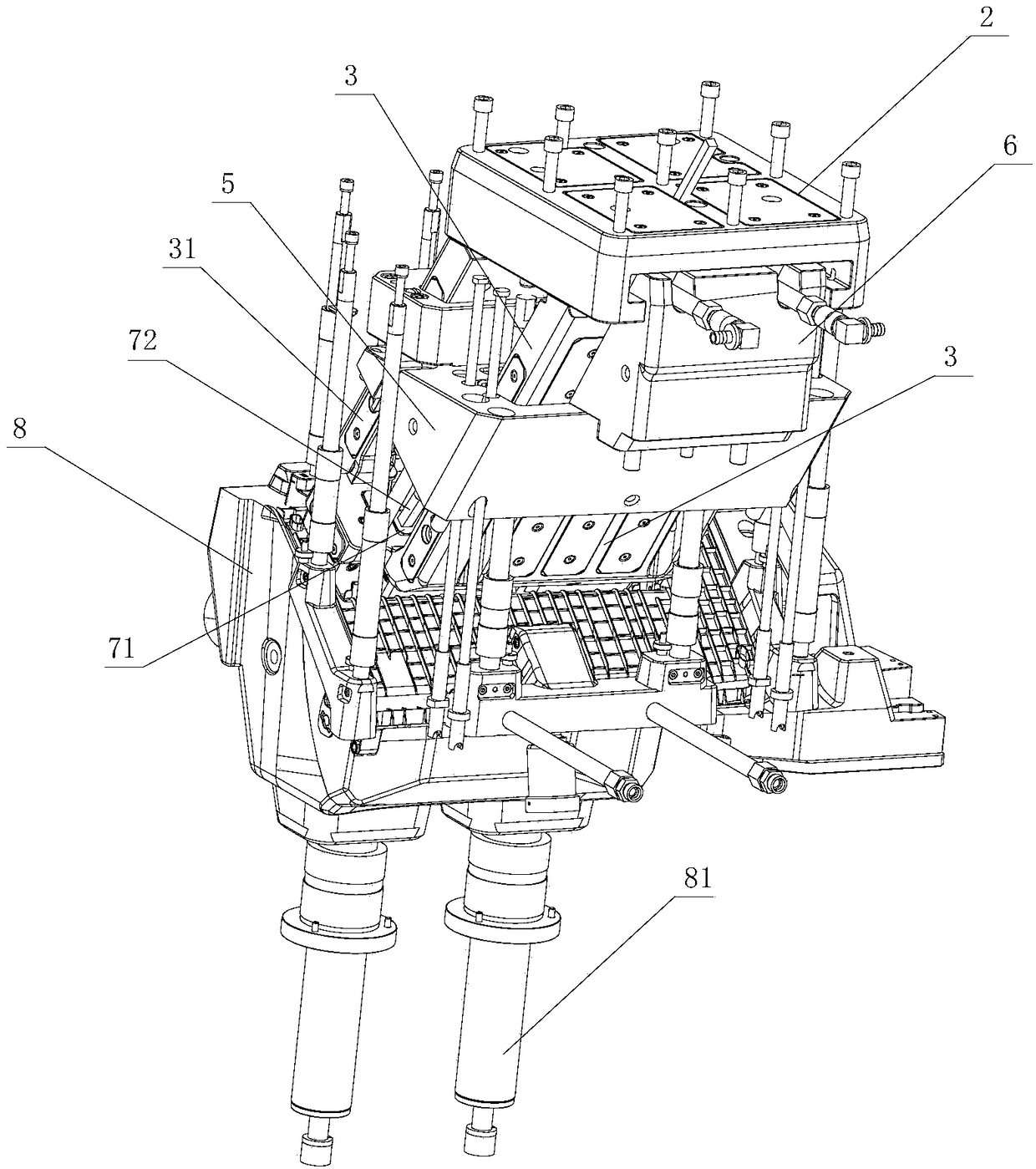

Cooling control method and device for mold core needle of die casting mold

The invention discloses a cooling control method for a mold core needle of a die casting mold. The method comprises the following specific steps of: firstly introducing cooling water with pressure of 1 MPa and then introducing compressed air with pressure of 0.6 MPa for cooling and air-drying the mold core needle of the die casting mold. The invention also discloses a device for implementing the method. Compared with the prior art, the device has a simple structure and is convenient to use, and a user can set the temperature of the cooling water according to process requirements so as to maintain the temperature of the mold core needle in a certain range constantly, and therefore the product quality is improved and casting defects are reduced.

Owner:广东鸿图(南通)模具有限公司 +1

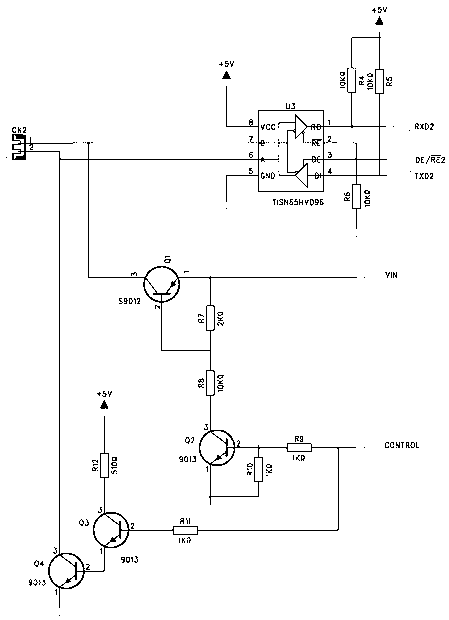

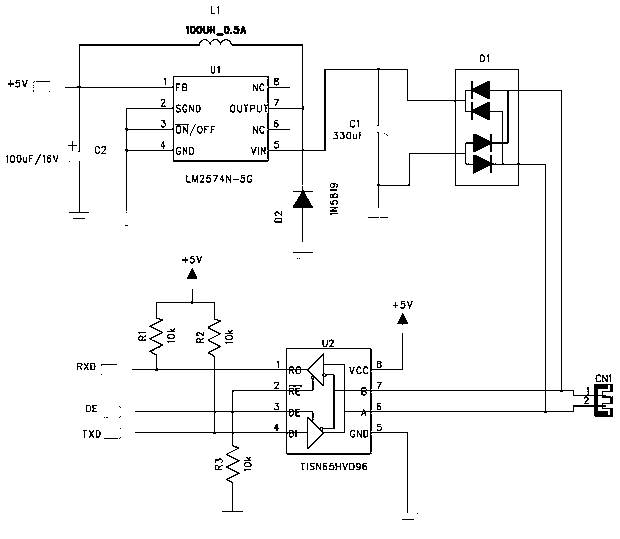

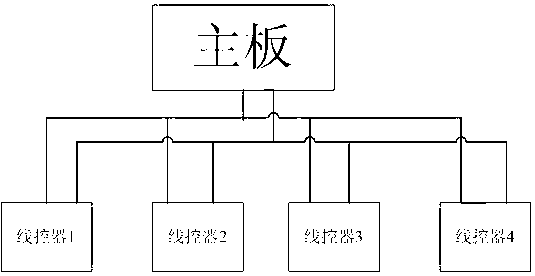

Air conditioner, RS485 bus system thereof and bus system control method

ActiveCN103162372ASolving Polarity ProblemsIncreased installation difficultySpace heating and ventilation safety systemsLighting and heating apparatusFailure rateCore needle

The invention provides an RS485 bus system which comprises a power supplier circuit and a power taker circuit, and the power supplier circuit and the power taker circuit are connected with each other. The power supplier circuit comprises a double-core needle base CN2 which is connected with wired controller cables, one end of the double-core needle base CN2 is connected with a grounding port, and the other end of the double-core needle base CN2 is communicated with a power supply port. The power supplier circuit further comprises a control end which is connected with an input / output (IO) of a microprogrammed control unit (MCU). The power taker circuit comprises a double-core needle base CN1 which is connected with mainboard cables, two pins of the double-core needle base CN1 are connected with a rectifier bridge in a crossed mode and are connected with an energy storage capacitor and a power supply chip, the double-core needle base CN2 of the power supplier circuit and the double-core needle base CN1 of the power taker circuit are respectively connected with a communication circuit. The invention further provides a bus system control method which uses the RS485 bus system. The bus system control method includes the following steps: controlling an input level value of the MCU, controlling the power taker circuit to communicate or not, and enabling the energy storage capacitor to take power or discharge power. The RS485 bus system and the bus system control method aim at a small-sized terminal device which is smaller in power, double core wires are adopted to achieve the functions of supplying power and communicating, half cable cost is reduced, and engineering installation difficulty and failure rate are greatly reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Apparatus and methods for tissue reduction

ActiveUS20180140319A1Easy to controlMaintain positionLaproscopesExcision instrumentsCore needleMedicine

Apparatus and methods for tissue reduction are described where one embodiment of the tissue resection device may generally comprise an external clamping mechanism having at least two distally extending members shaped with an atraumatic distal end and defining a confined region between the distally extending members sized to receive a tissue region therebetween. Additionally, an elongate coring needle defining a lumen and having a proximal end attached to a handle and a distal end which defines a cutting mechanism may also be included, wherein the coring needle is translatable adjacent and / or relative to the external or internal clamping mechanism defined by the confined region.

Owner:CORIT LLC

Flat plate pinhole coaxial electrostatic spinning fiber composite spinning jet and spinning method thereof

InactiveCN103572386AUniform electric fieldEasy to manufactureFilament/thread formingCore needleFiber

The invention relates to a flat plate pinhole coaxial electrostatic spinning fiber composite spinning jet and a spinning method thereof. The spinning method comprises the steps that (1) a flat plate conductive electrode, an auxiliary spinneret plate and a core needle are configured into a coaxial fiber composite spinning jet, wherein a through hole is formed in the auxiliary spinneret plate, and a groove is formed at the silk outlet surface of the through hole, and thus the advantages that a uniform electric field is formed between the flat plate conductive electrode and a receiving plate, so the formation and the batch production of coaxial fibers are facilitated are realized; (2) being respectively injected into a core layer and a shell layer, spinning liquid are converged in the through hole and the groove to form composite liquid drops; the voltage and the spinning distance are properly adjusted, and the composite liquid drops reach the receiving plate after being high-frequency drawn, bent and swung under electric field force and is cured to form core-shell structured ultrathin electrostatic spinning fibers. The flat plate pinhole coaxial electrostatic spinning fiber composite spinning jet and the spinning method thereof have the advantages that the coaxial composite needle is simple to prepare, the preparation of coaxial fiber composite needles in batch is facilitated, and multifunctional composite fibers meeting the demands of various aspects can be prepared by replacing needle cores.

Owner:DONGHUA UNIV

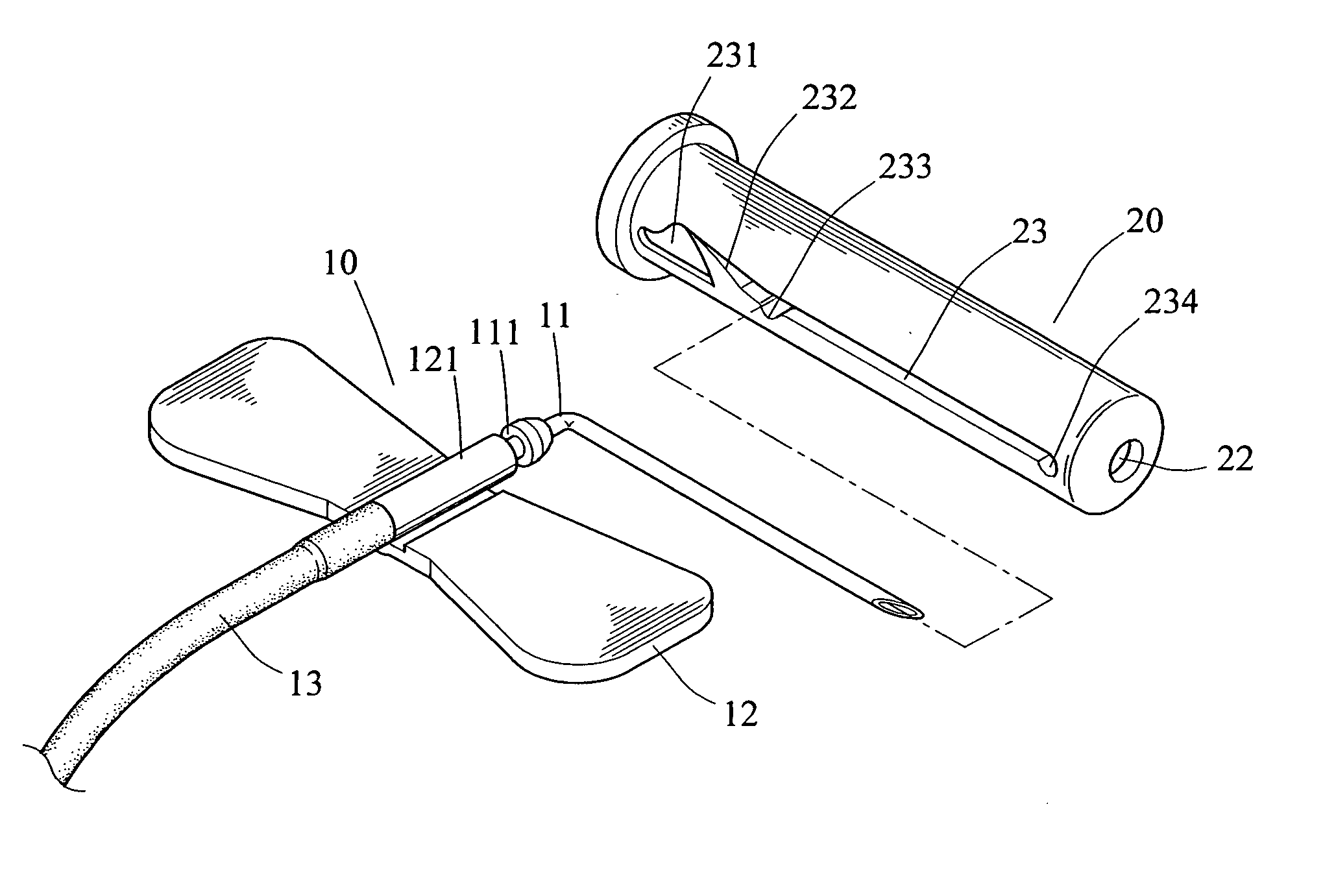

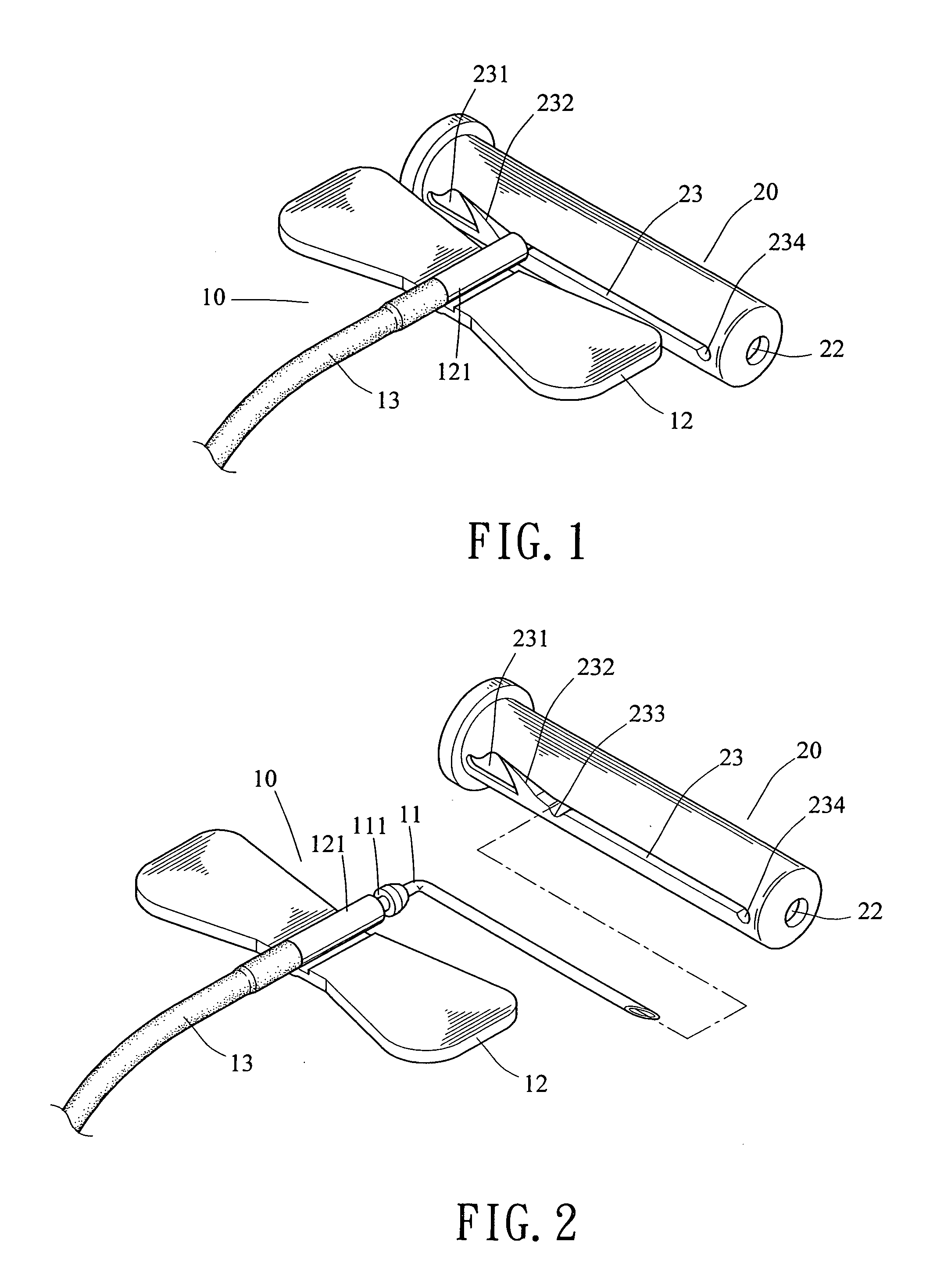

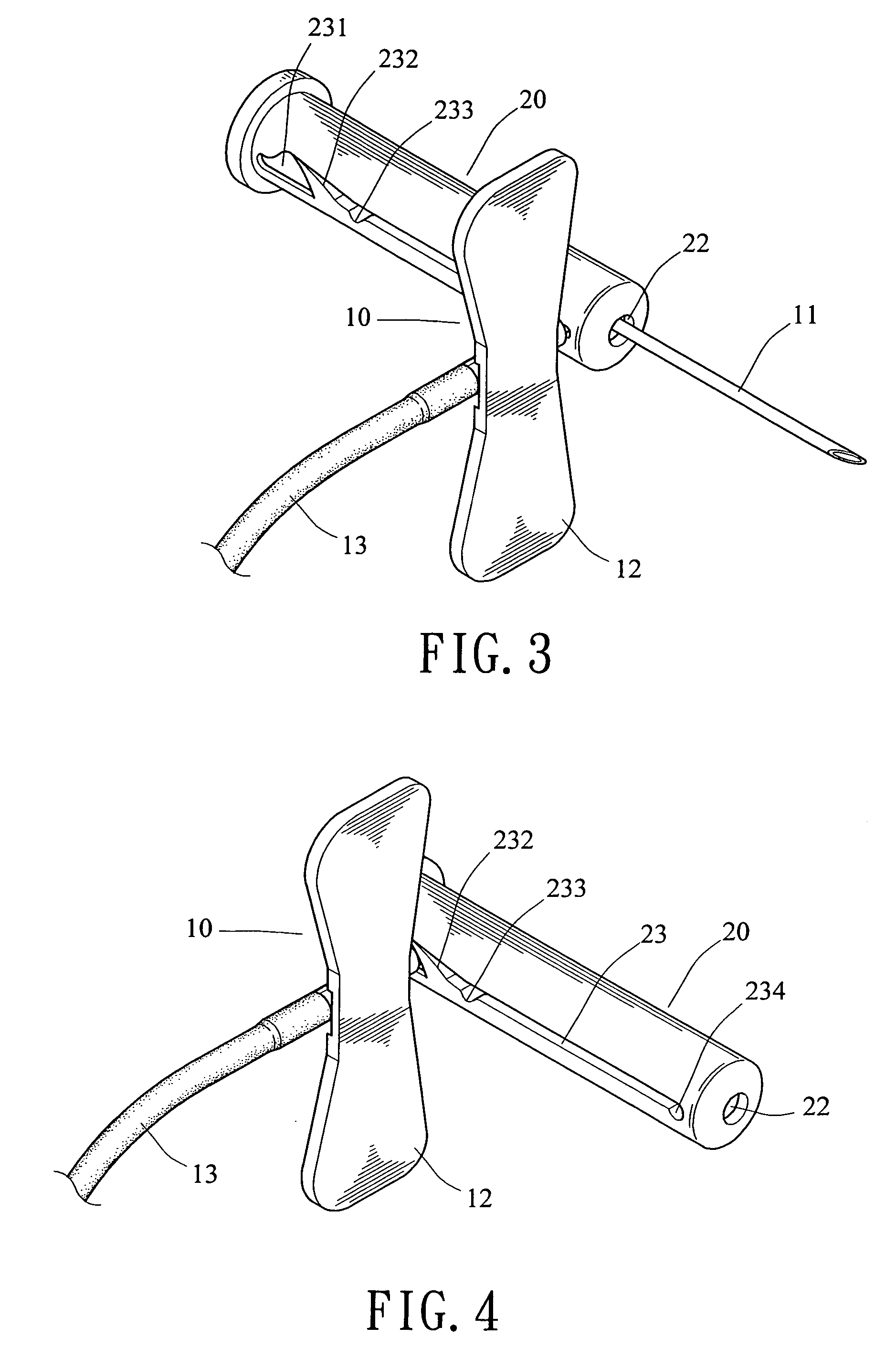

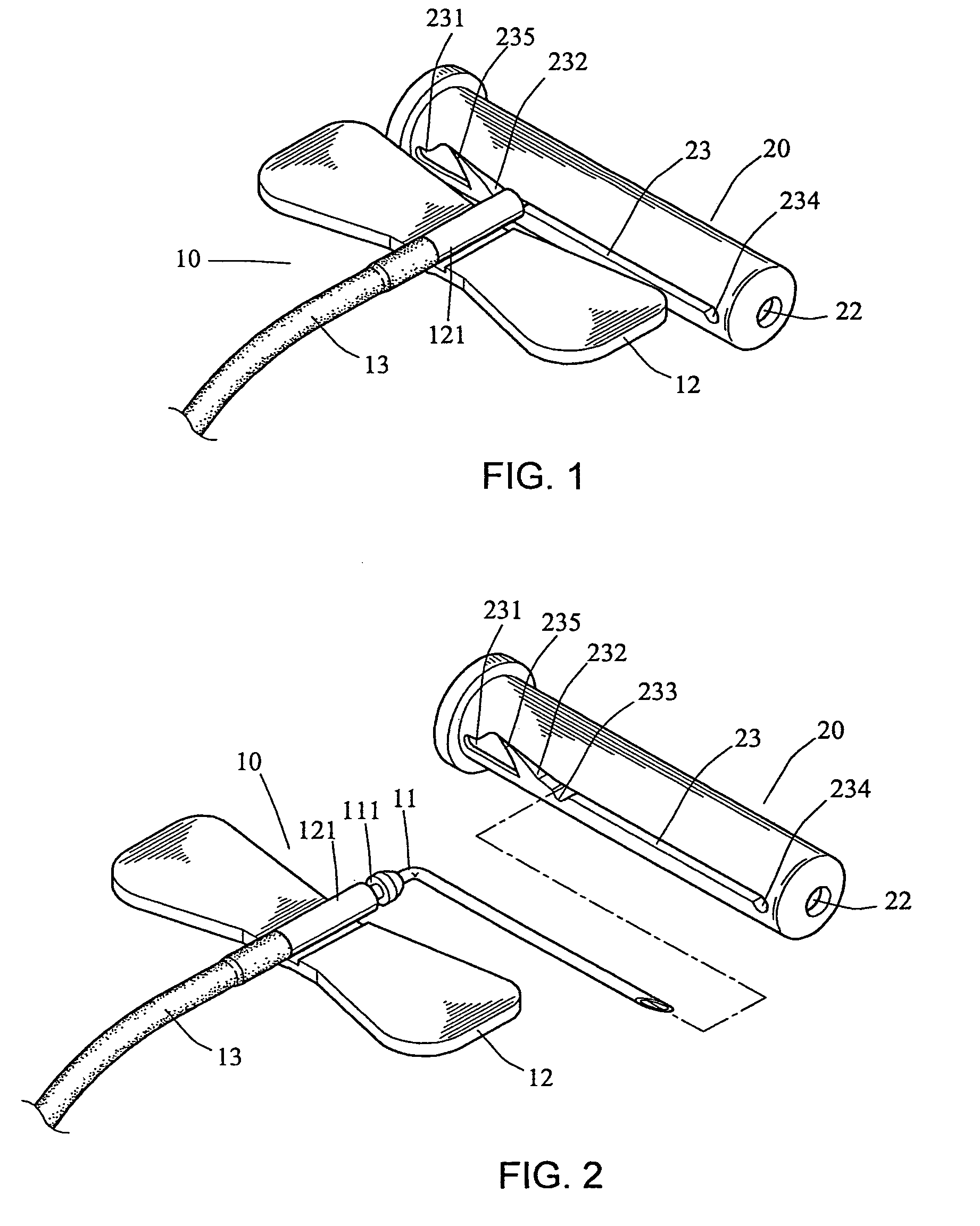

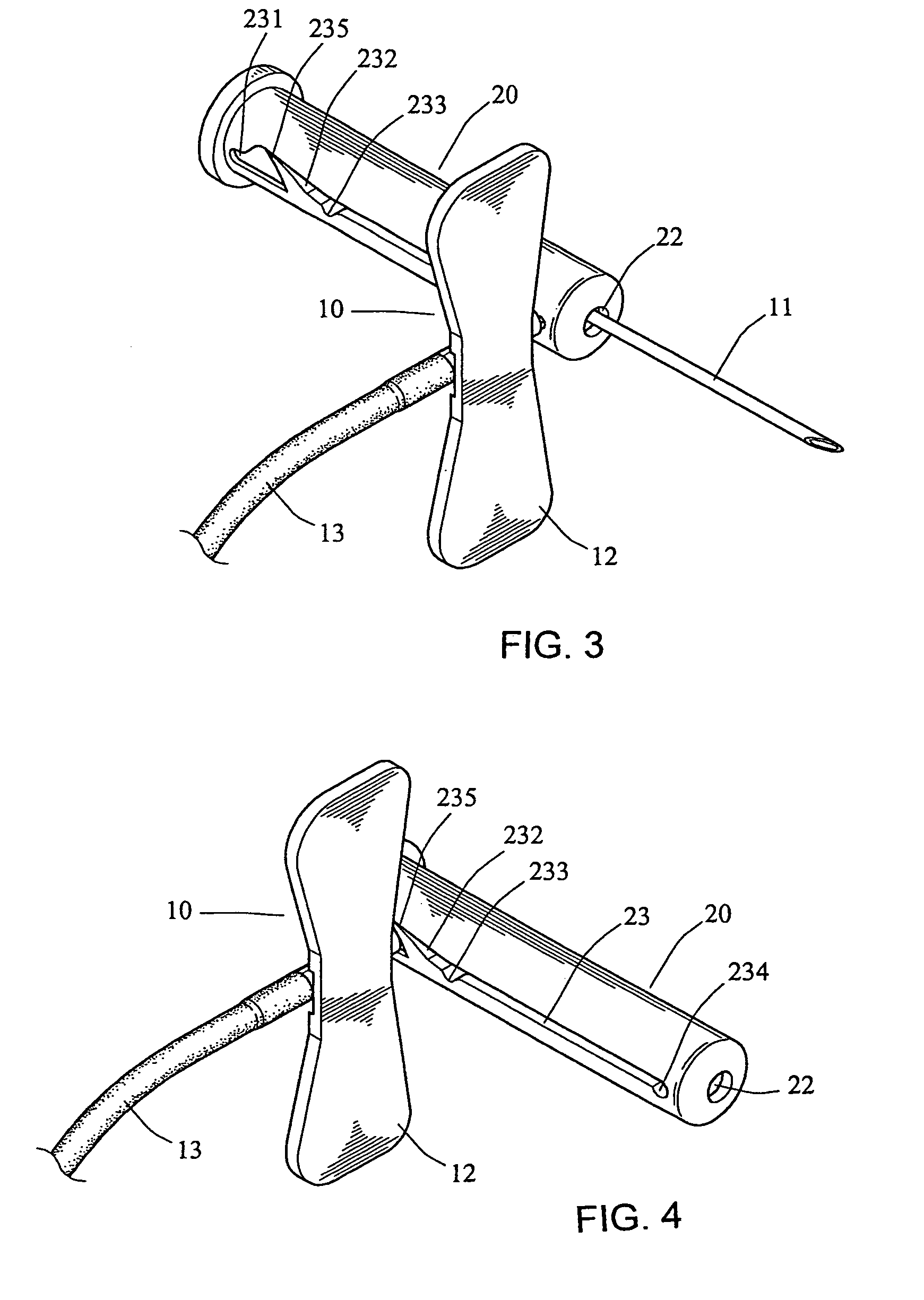

Safety non-coring needle

Provided is a non-coring needle for venous access implantatable port. In one embodiment the non-coring needle comprises a puncturing assembly comprising two wings having a central sleeve, an L-shaped needle coupled to the sleeve, the needle including an annular groove or enlargement on its bent portion, and a plastic tubing coupled to the sleeve; and a syringe barrel comprising an internal chamber having a forward opening, and an elongate slot formed on the syringe barrel and being in communication with the chamber. The groove or enlargement is located at a first dent of the slot when the needle is concealed in the chamber in a non-use position, the groove or enlargement is located at a forward second dent of the slot when the needle is fully extended from the opening for use, and the groove or enlargement is permanently locked at a rear triangular recess of the slot when the needle is fully retracted into the chamber.

Owner:WANG HSIEN TSUNG

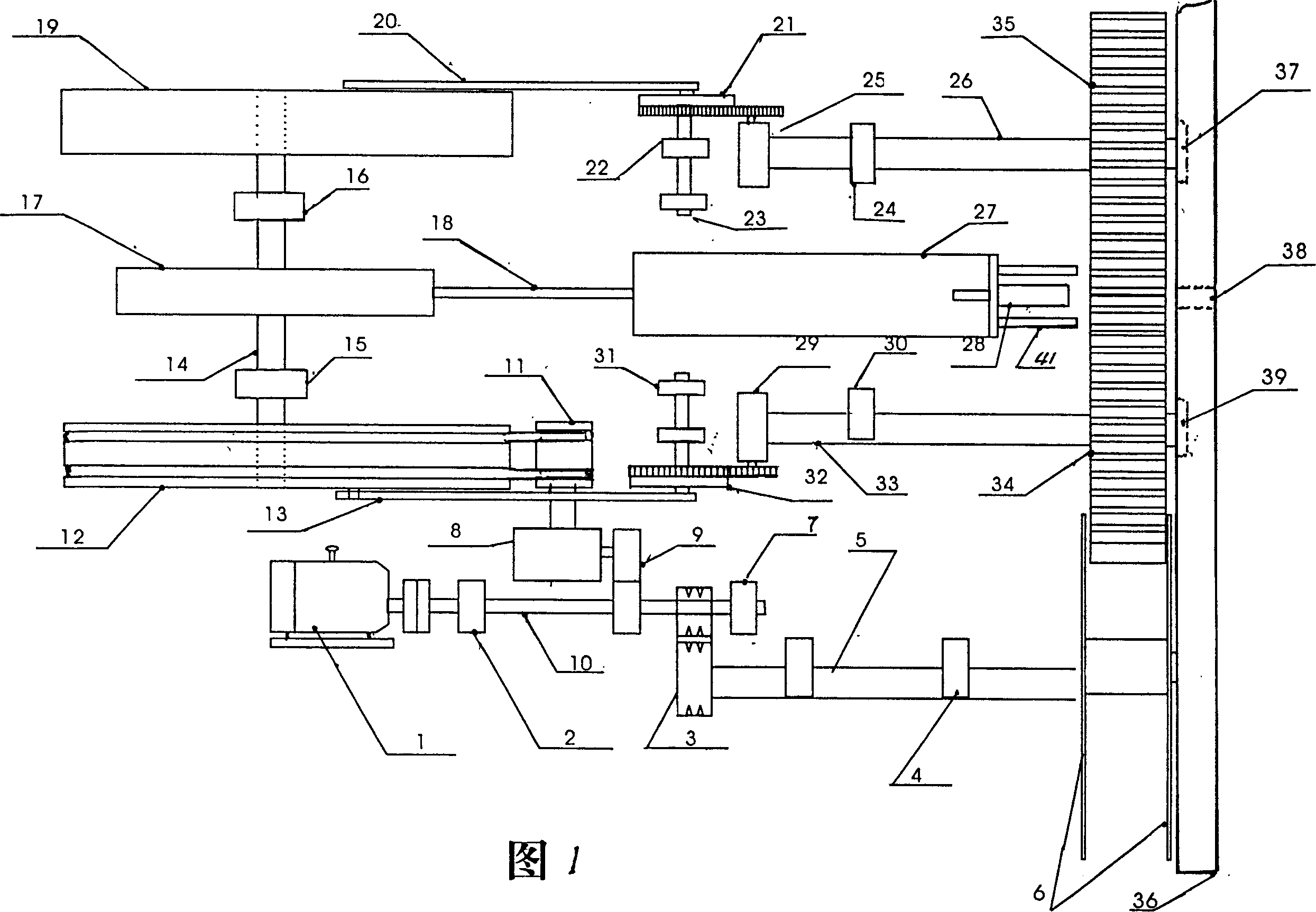

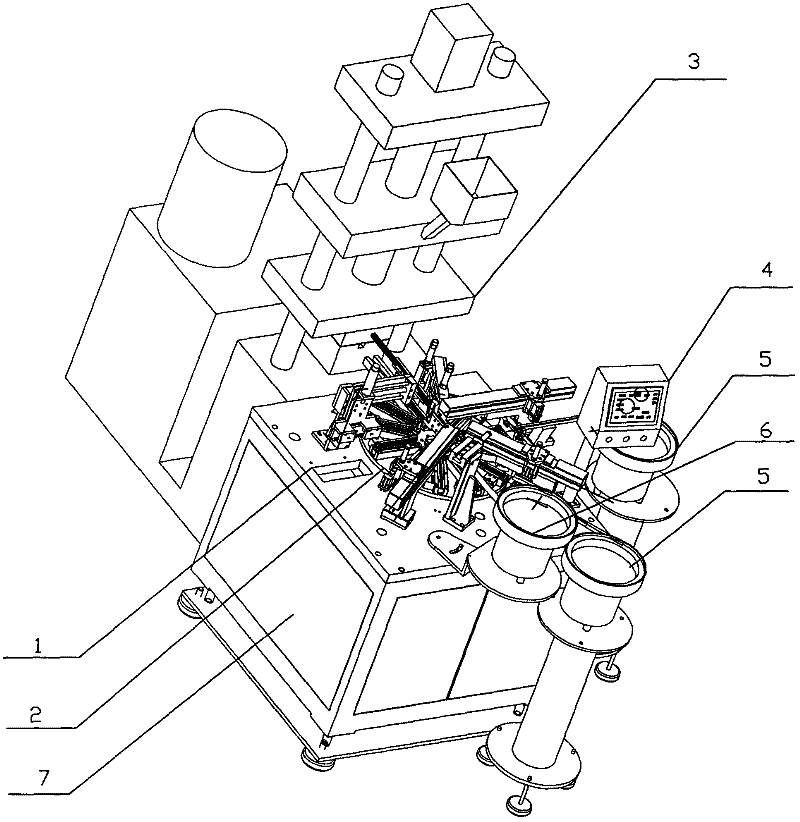

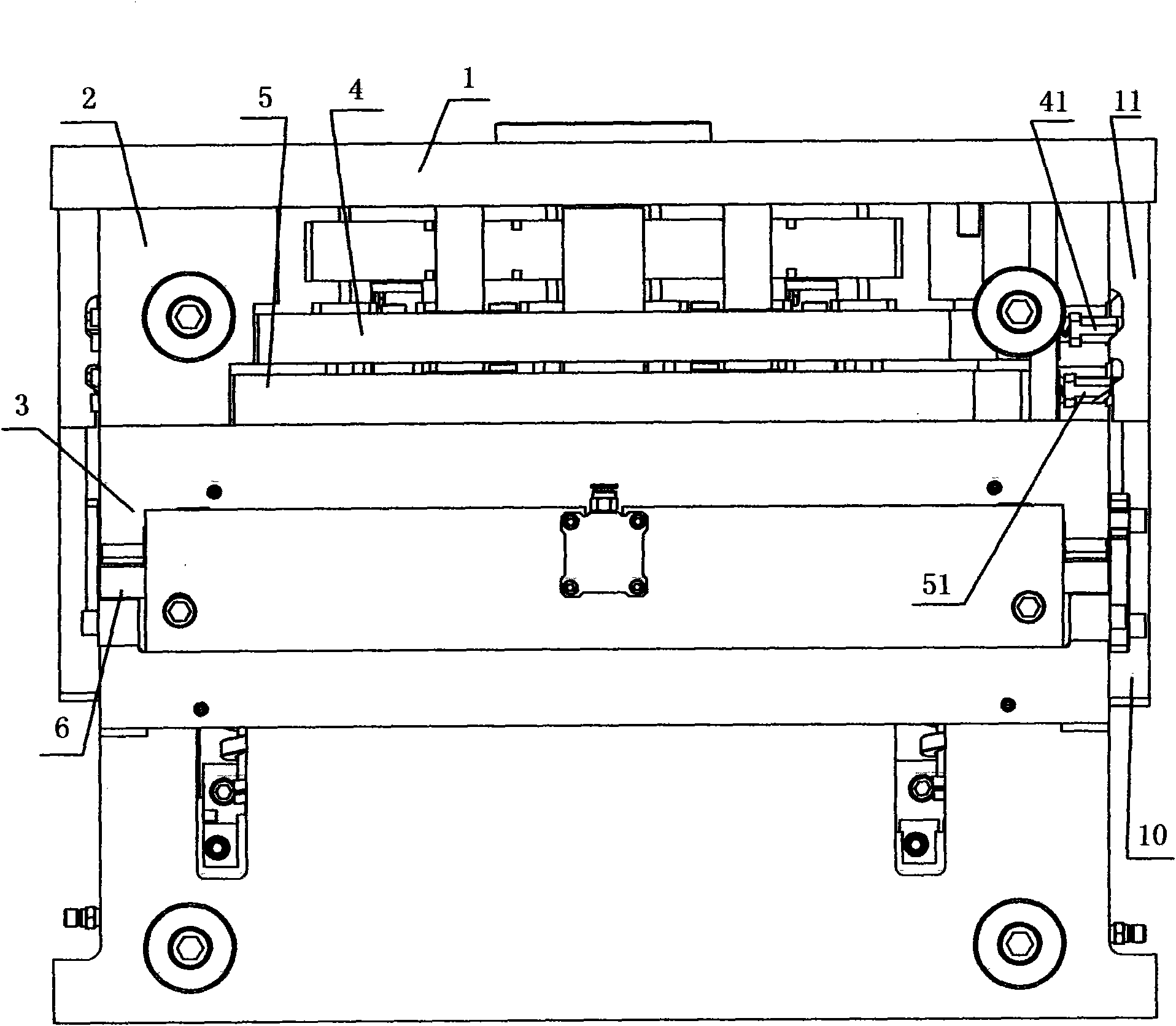

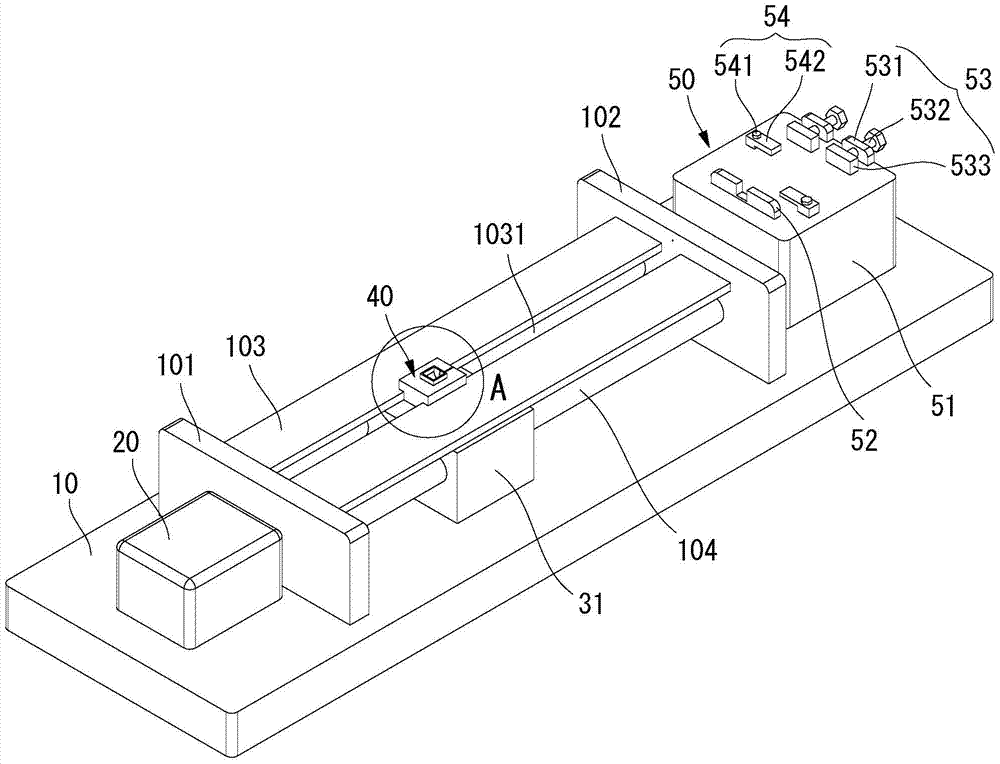

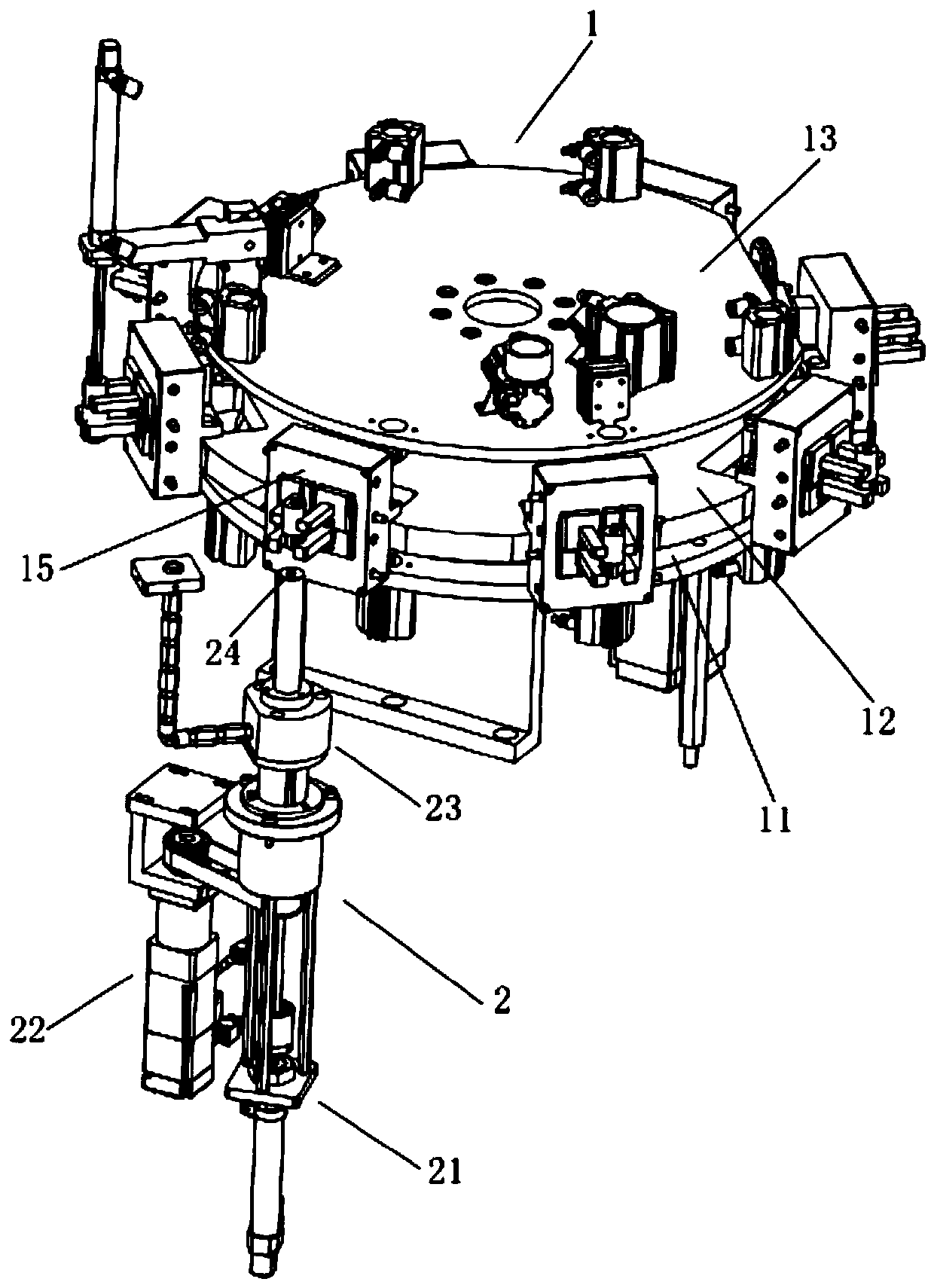

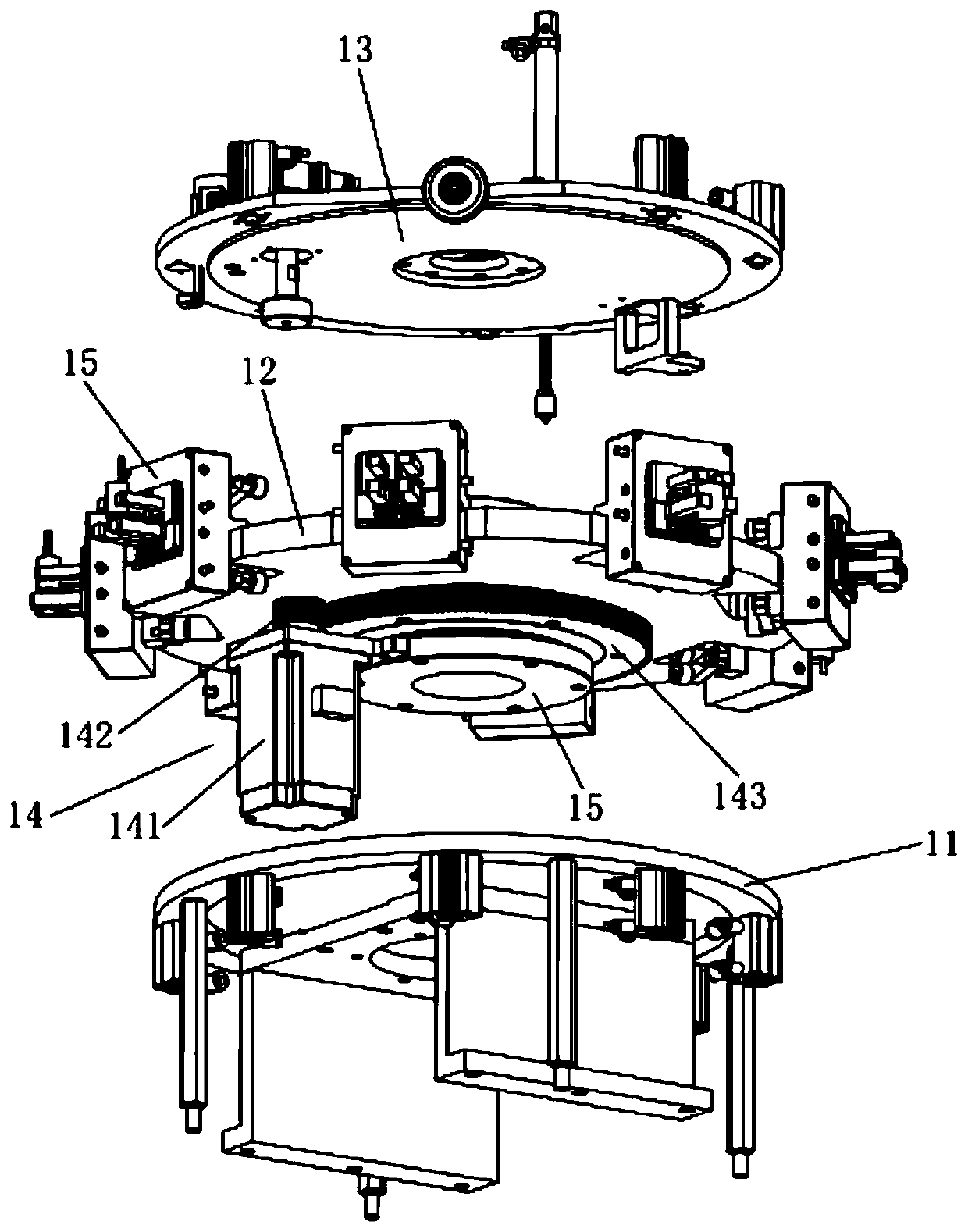

Combination machine forming by automatic assembly and injection molding of RCA connectors

InactiveCN102386544ALow costReasonable controlContact member cases/bases manufactureContact member assembly/disassemblyCore needleCopper

The invention relates to a combination machine forming by automatic assembly and injection molding of RCA connectors, which comprises a base. A rotating disk is arranged on the base and connected with a screwing mechanism, and clamping moulds are sequentially arranged in all radial directions of the rotating disk. A needle feeding mechanism for enabling copper cored needles to be installed on theclamping moulds, a shell feeding mechanism for enabling copper shells to be installed on the clamping moulds, a positioning mechanism for positioning the copper shells, an injection molding mechanismfor enabling the copper cored needles and the copper shells on the clamping moulds to be made into connectors in injection molding mode, a discharging mechanism for discharging the connectors and a controller for coordinating operation of each parts are respectively arranged on the periphery of the rotating disk. The combination machine can perform assembly and integral injection molding of the RCA connectors full-automatically, is reasonable in control of the whole process, greatly improves working efficiency and reduces cost of various aspects including staff and the like.

Owner:宁波神博电子有限公司

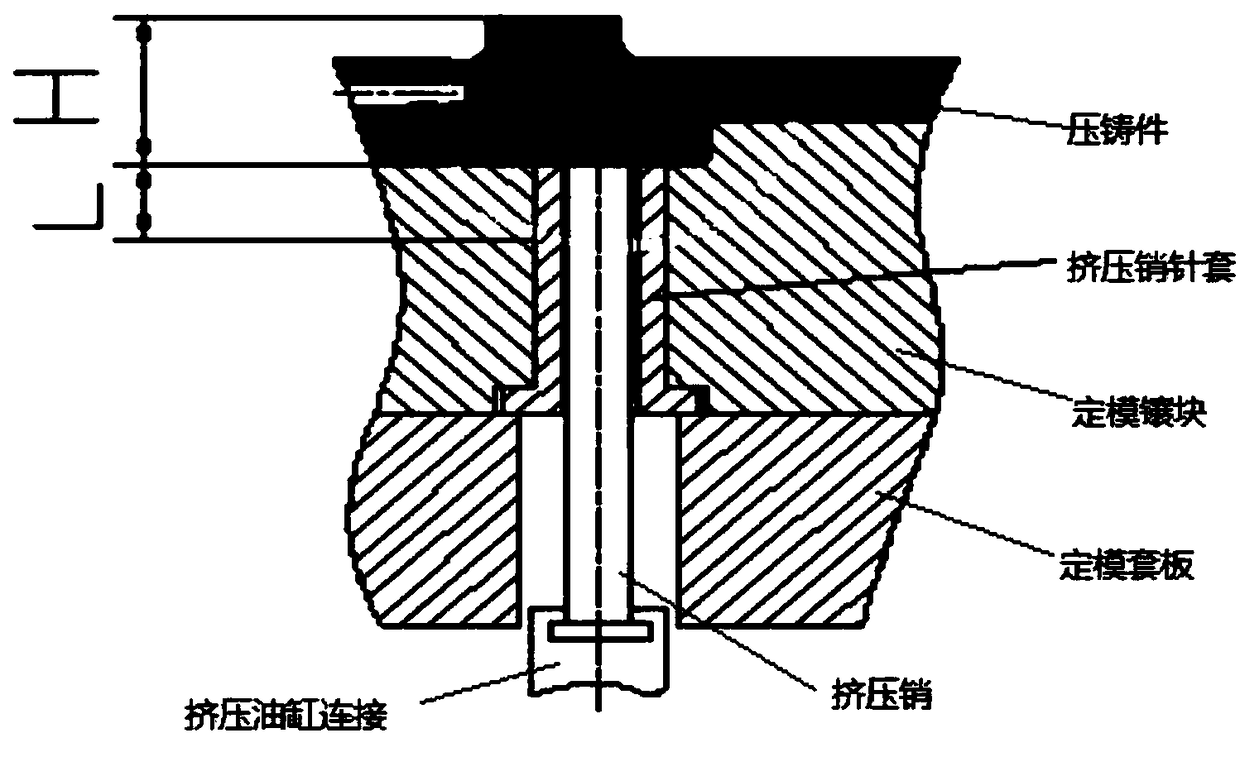

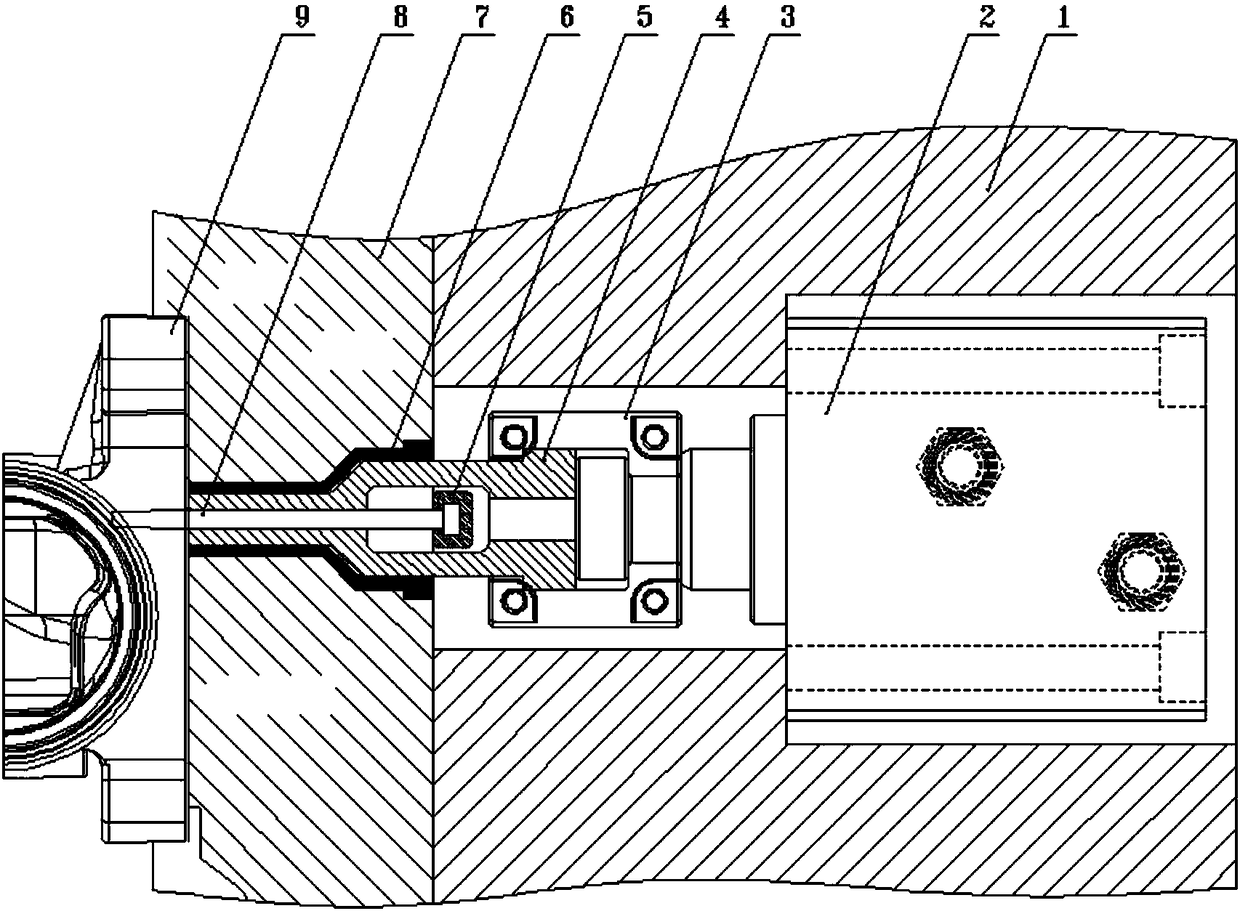

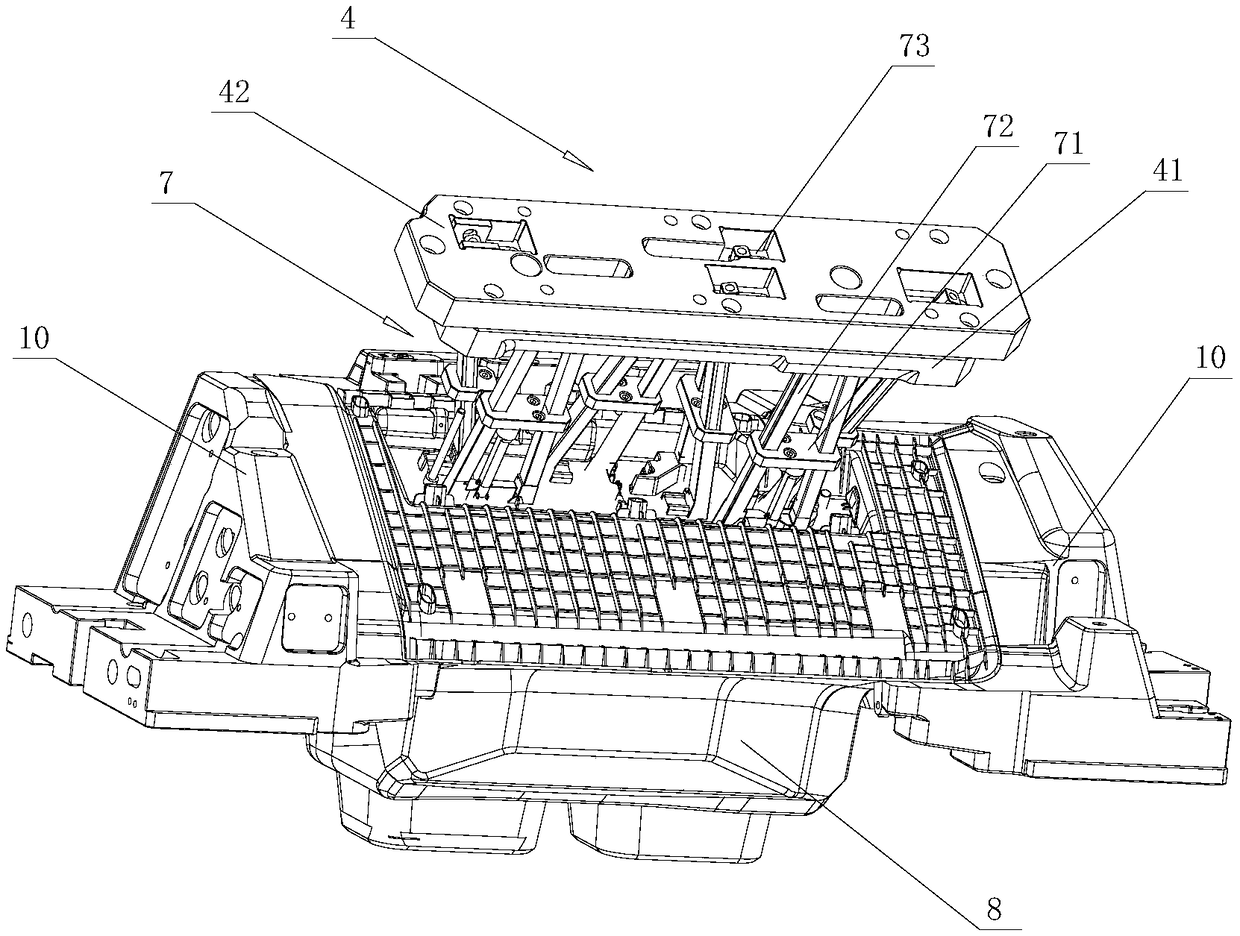

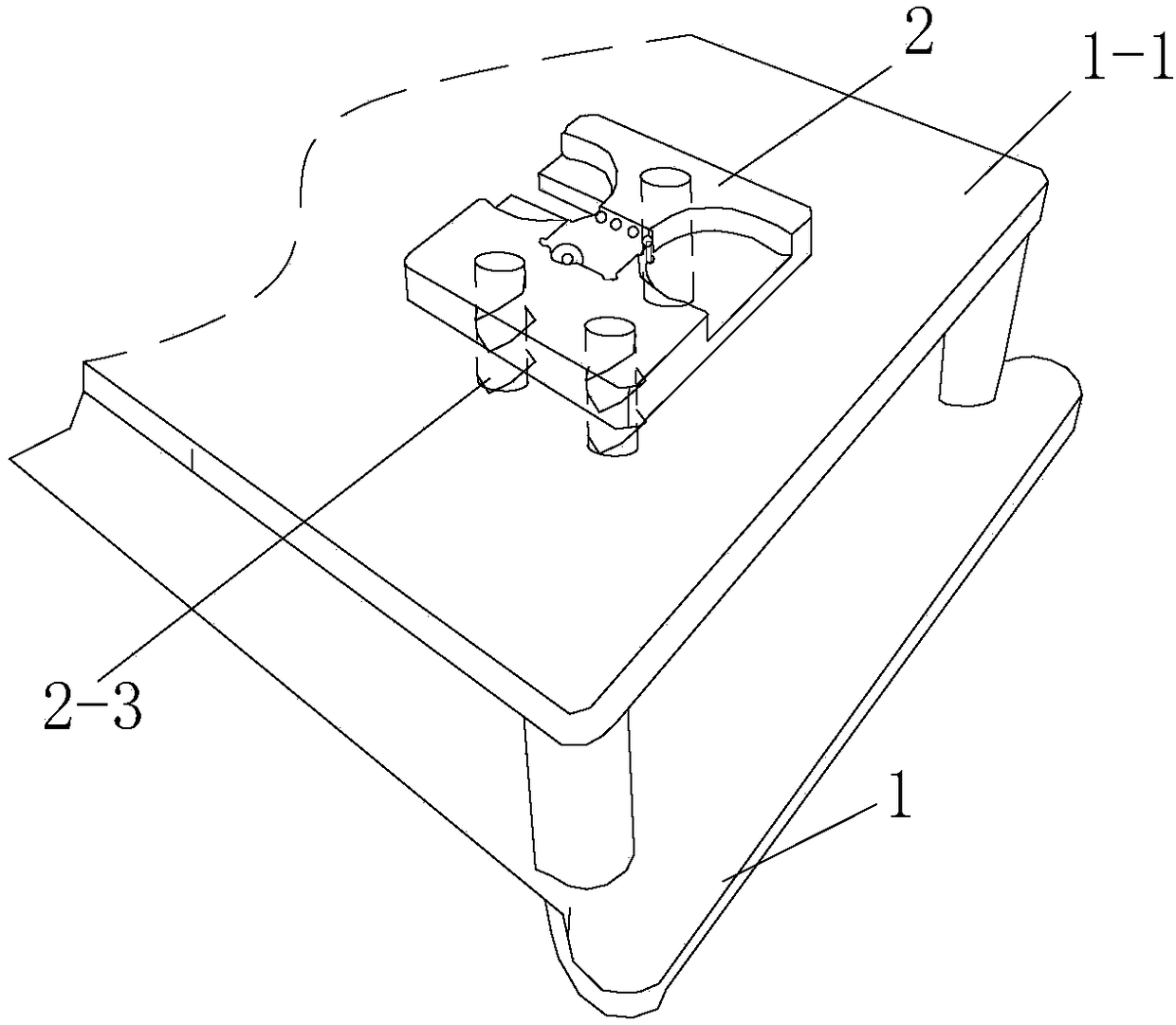

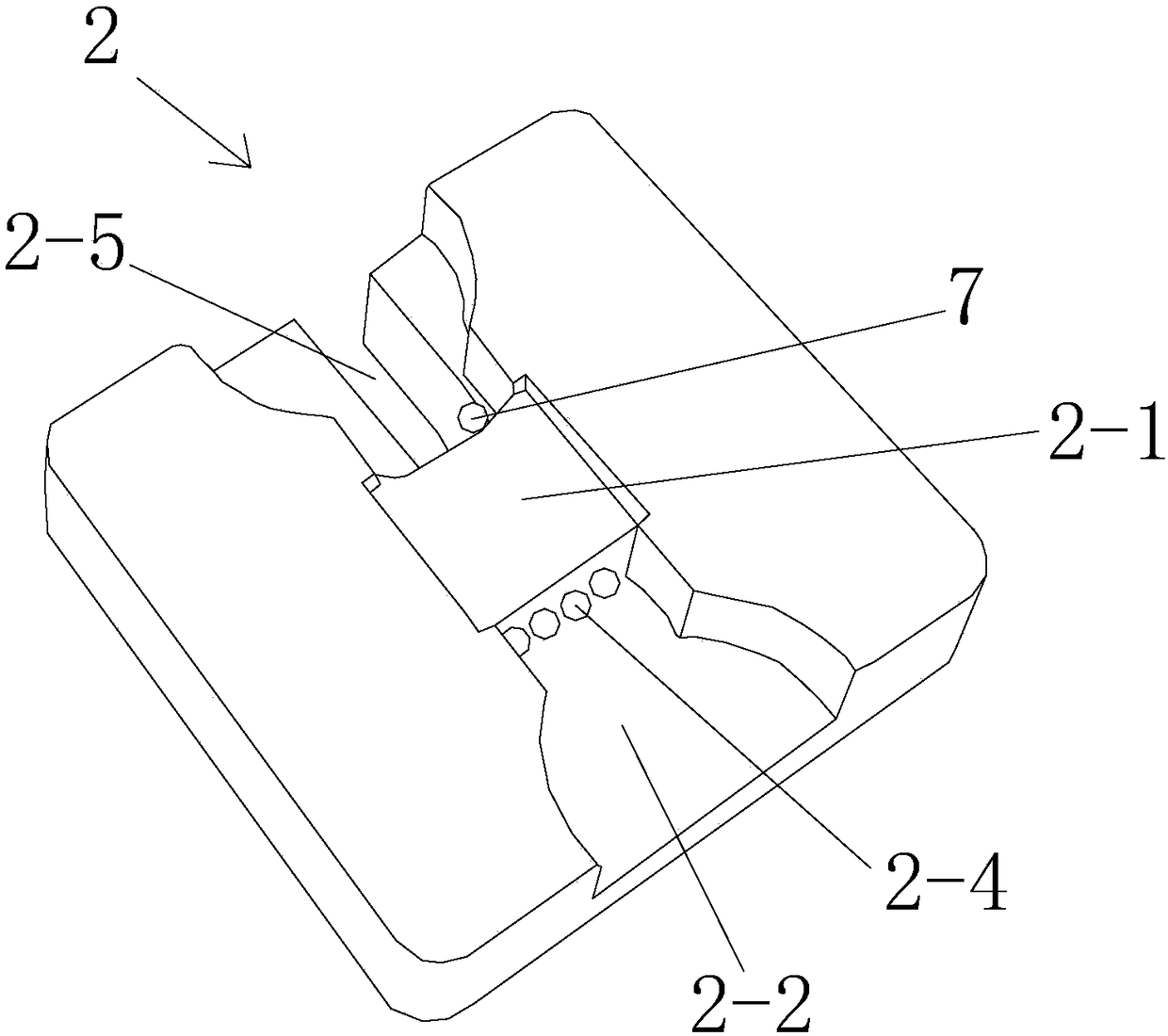

Die casting die extruding pin special structure

The invention discloses a die casting die extruding pin special structure. The die casting die extruding pin special structure comprises a fixed die sleeve plate and a fixed die insert connected withthe fixed die sleeve plate in a matched mode. The fixed die sleeve plate is internally provided with a first hollow structure and a second hollow structure. The first hollow structure is internally provided with an extruding oil cylinder. The second hollow structure is internally provided with a connecting plate. An extruding pin is arranged on the connecting plate. A T-shaped hollow cavity is formed in the extruding pin. A core needle is detachably arranged in the T-shaped hollow cavity. An extruding pin needle sleeve is detachably arranged between the extruding pin and the fixed die insert.According to the die casting die extruding pin special structure, the extruding oil cylinder is used for pushing the extruding pin to move and combined with the extruding pin needle sleeve and the core needle for extruding the outside and / or inside of a die casting while precasting a needle hole so that outside and / or inside shrinkage cavity and porosity defects can be eliminated, meanwhile, the effect that the position of the core needle is not deviated in the operation process can be ensured, and the effect that the size of the core needle hole is stable and unchanged is ensured.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

Secondary ejecting mechanism of improved type invertedly-buckled bottle cap plastic injection mold

ActiveCN101954723ASimple structureReduce the probability of production accidentsDomestic articlesCore needleEngineering

The invention relates to a secondary ejecting mechanism of an improved type invertedly-buckled bottle cap plastic injection mold, which comprises a fixed mold and a movable mold, wherein an ejector sleeve needle ejecting plate and an ejector sleeve core needle ejecting plate are arranged between the fixed mold and a fixed mold plate; an ejector sleeve is installed on the ejector sleeve needle ejecting plate; an ejector sleeve core is installed on the ejector sleeve core needle ejecting plate; the ejector sleeve core is positioned in the ejector sleeve; the ejector sleeve needle ejecting plateand the ejector sleeve core needle ejecting plate are driven by a hook mechanism; the hook mechanism comprises a first sliding block, a second sliding block, a guide frame which is fixed on the fixedmold plate and a hook which is positioned in the guide frame; the other end of the hook is fixed on the movable mold; a first sliding guide groove and a second sliding guide groove are arranged on the guide frame; the lower walls of the two sliding guide grooves are both slopes; springs are both arranged between the two sliding blocks and the needle ejecting plates; a first convex block and a second convex block are arranged on the hook; the first convex block drives the first sliding block and is matched with the first sliding guide groove; the second convex block drives the second sliding block and is matched with the second sliding guide groove; and the thickness of the second convex block is larger than the thickness of the first convex block.

Owner:浙江西诺模具有限公司

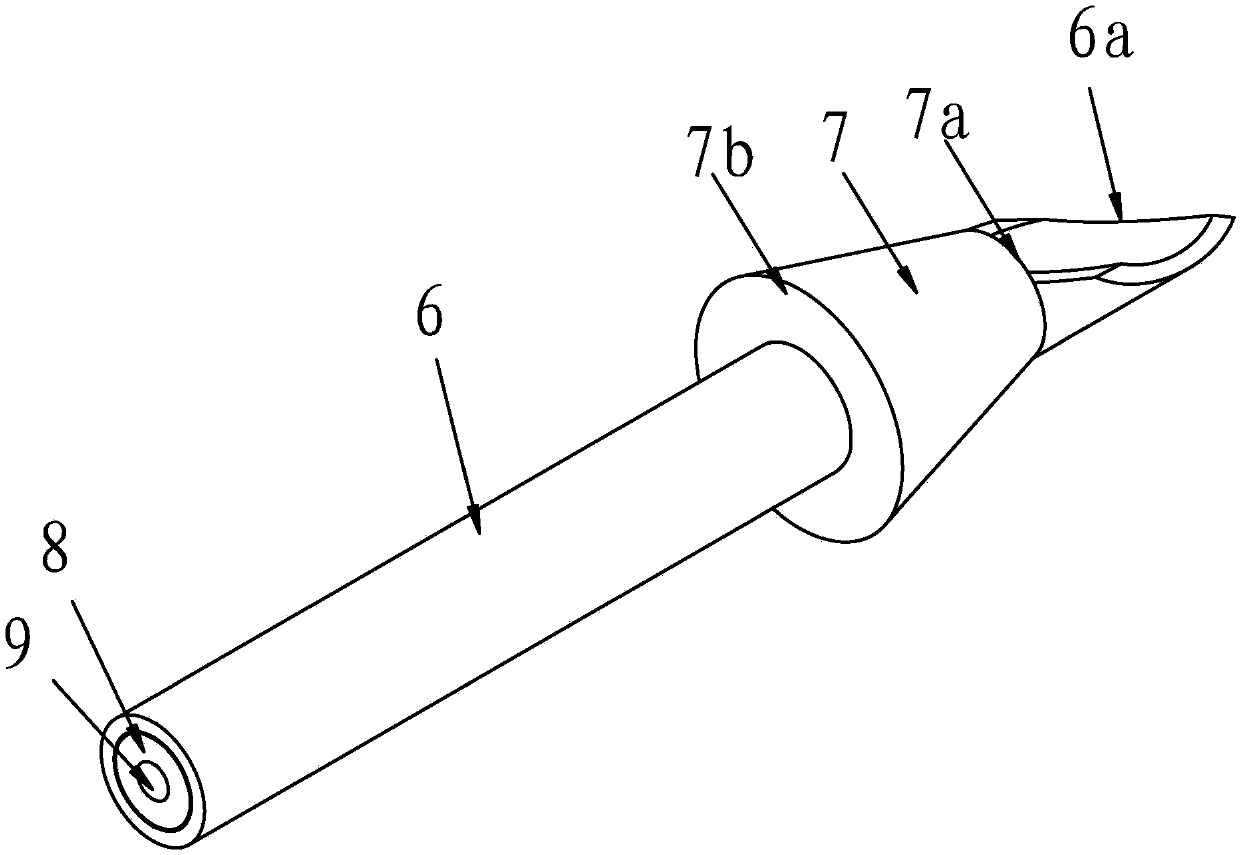

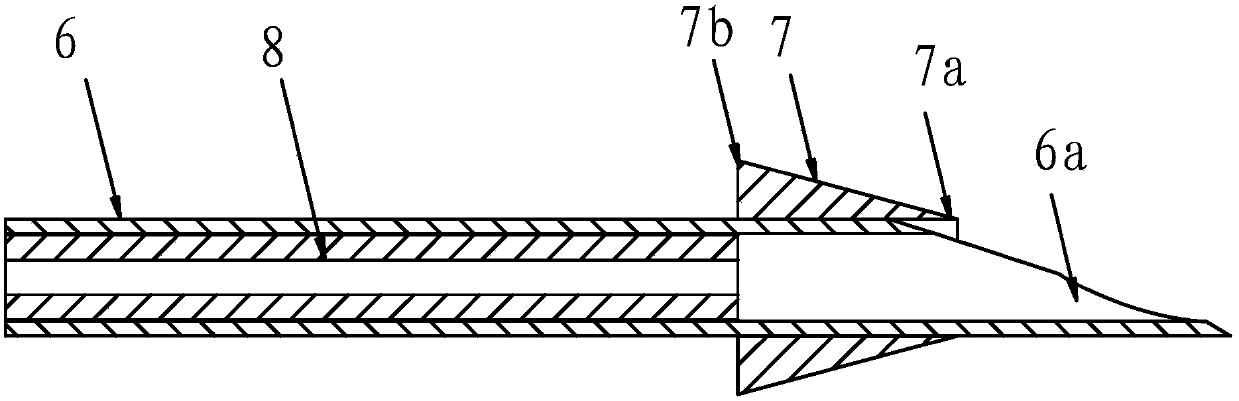

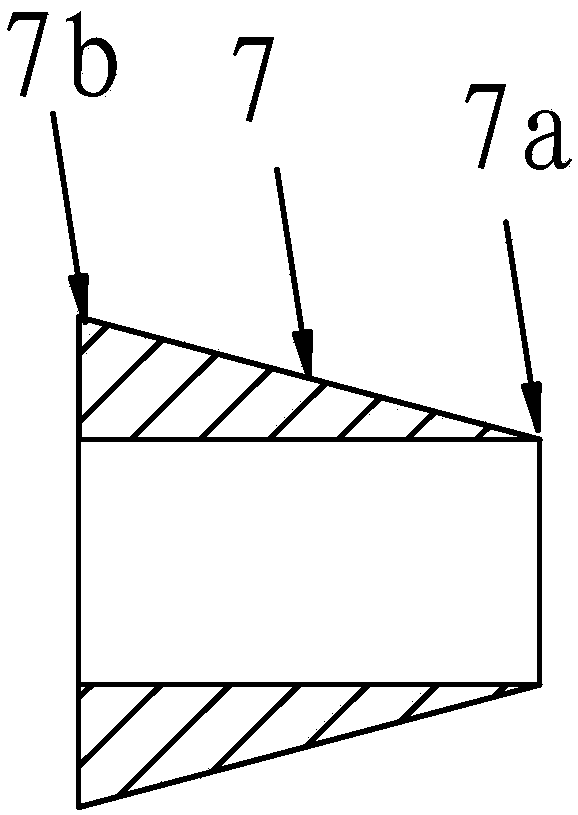

Medical multifunctional dredging needle

ActiveCN107928787AImprove effectivenessAvoid cloggingDevices for heating/cooling reflex pointsAcupunctureTemperature controlCore needle

A medical multifunctional dredging needle comprises a core needle and a tubular needle. The core needle is sleeved with a tube hole of the tubular needle, and the core needle is in clearance fit withthe tubular needle. The core needle comprises a needle head, a needle body and a needle handle, wherein the needle head, the needle body and the needle handle are sequentially connected into one body,the needle head is in smooth connection with the needle body, the needle head of the core needle stretches out of the head end of a needle body of the tubular needle, and the needle handle of the core needle stretches out of the tail end of a needle base of the tubular needle; the needle body of the core needle is a cylinder or a long cone, the needle body is solid or hollow and tubular, and thehollow tube is directly connected with the most front end of the needle head of the core needle; a temperature-control electric-heating treatment material, a temperature-control fluid treatment material, a laser treatment material, a radio-frequency temperature-control treatment material and other treatment materials can be added into the core needle, so that various medical multifunctional dredging needles are formed correspondingly. The tubular needle of a hollow and tubular structure comprises the needle body and the needle base which are sequentially connected into one body, the needle body of the tubular needle is cylindrical or in a long cone shape; the needle handle of the core needle can be locked the needle base of the tubular needle up. Due to the innovation of the core needle and the tubular needle, the needle treatment safety and scientificity are improved fundamentally, and pathological factors caused by soft tissue injury are removed.

Owner:周建斌

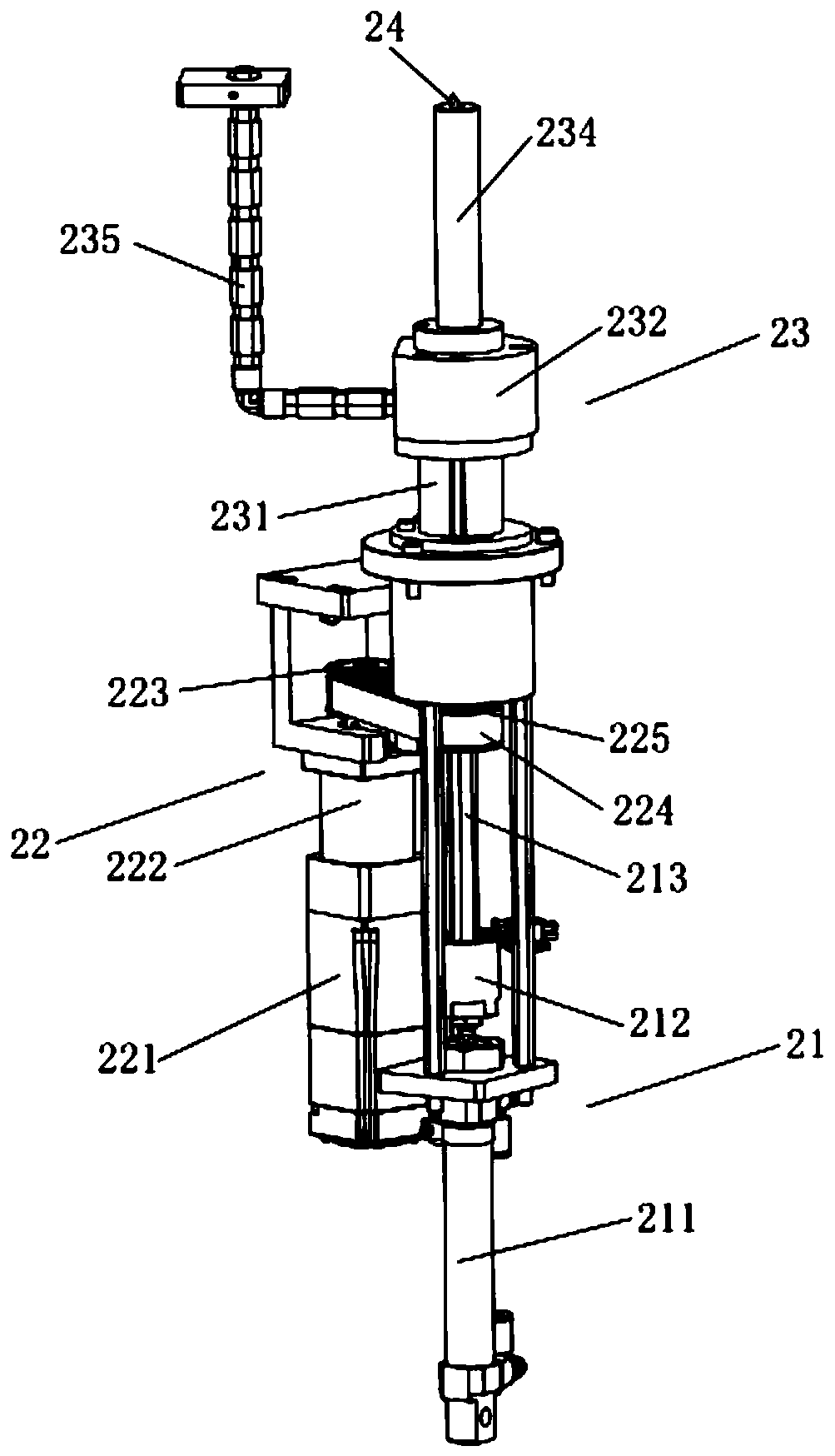

Radioactive Seed Implantation Devices

The invention discloses a device for implanting radioactive particles, which includes a fixed base, a motor, a transmission assembly, a needle core fixing piece and an implant gun clamp. The fixed base has opposite first ends and second ends, and the motor is fixedly mounted on the fixed base. The first end of the first end; the transmission assembly includes a screw and a moving block threaded with the screw, the screw is rotatably arranged on the fixed seat, and one end of the screw is fixedly connected to the output shaft of the motor; the needle core fixing part is fixedly connected to the moving block, The implant gun clamp is arranged on the second end of the fixed base and is opposite to the needle core holder, so that the needle core on the needle core holder is suitable for moving in the implant gun on the implant gun clamp and implanted into the patient's body radioactive particles. The radioactive particle implantation device of the present invention can continuously implant particles, has high working efficiency, and is simple and convenient to operate. At the same time, the needle core is pushed in and pulled out at the same speed each time, which can avoid problems such as particle jam and implantation failure.

Owner:PEKING UNIV SHENZHEN HOSPITAL

Safety non-coring needle

Provided is a non-coring needle for venous access implantatable port. In one embodiment the non-coring needle comprises a puncturing assembly comprising two wings having a central sleeve, an L-shaped needle coupled to the sleeve, the needle including an annular groove or enlargement on its bent portion, and a plastic tubing coupled to the sleeve; and a syringe barrel comprising an internal chamber having a forward opening, and an elongate slot formed on the syringe barrel and being in communication with the chamber. The groove or enlargement is located at a first dent of the slot when the needle is concealed in the chamber in a non-use position, the groove or enlargement is located at a forward second dent of the slot when the needle is fully extended from the opening for use, and the groove or enlargement is permanently locked at a rear triangular recess of the slot when the needle is fully retracted into the chamber.

Owner:WANG HSIEN TSUNG

Automatic thread nail beating device and automatic thread sewing system

The invention provides an automatic thread nail beating device. The automatic thread nail beating device comprises a lead pipe for being penetrated by a sewing thread, a control valve, an automatic thread feeding pipe, an air cavity, a fixing piece and a core needle main body; the control valve is mounted on the pipe wall of the lead pipe, and the lower end of the lead pipe is connected with the top of the air cavity; one end of the automatic thread feeding pipe is used for connecting an air supply system, and the other end of the automatic thread feeding pipe is connected with the top of the air cavity; the air cavity is hollow, the bottom end of the air cavity is tapered, and the lower-end tapered port of the air cavity is connected with the tail end of a pipeline of the core needle main body; the pipeline for being penetrated by the sewing thread is arranged inside the core needle main body, and the other end of the core needle main body which is not connected with the air cavity is taken as a needle tip; the fixing piece is connected with the air cavity and / or the core needle main body. The automatic thread nail beating device disclosed by the invention can improve the thread nail beating efficiency and greatly improve the operability of a worker for beating thread nails.

Owner:HEILAN HOME

Pulled core oblique roof structure and injection mold

The invention discloses a pulled core oblique roof structure. The pulled core oblique roof structure comprises a rear mold top plate and a pulled core sliding base which are arranged on the outer sideof a rear mold, a pulled core base arranged inside the rear mold, a pulled core needle plate and a guide block. The pulled core sliding base is fixedly installed on the rear mold top plate. The rearmold top plate is connected with the rear mold through a drag hook. The rear mold is connected with a front mold through the drag hook. The guide block is fixedly installed inside the rear mold. The side wall of the pulled core base is in sliding fit with the guide block. One end of the pulled core base is slidingly connected with the pulled core sliding base. The pulled core needle plate is located on the inner side of the pulled core base and fixed to the rear mold. Multiple pulled core oblique roof sets are arranged on the pulled core needle plate. Each pulled core oblique roof set comprises an oblique roof guide sliding block and one or more pulled core oblique roofs. One end of each pulled core oblique roof is in movable connection with the pulled core needle plate. Each oblique roofguide sliding block is fixedly connected with the pulled core base. A pulled core oblique roof in the same set is driven to move by the corresponding oblique roof guide sliding block. The invention further discloses an injection mold. According to the pulled core oblique roof structure and the injection mold, the structural design is ingenious; the fabricating cost is lowered; the mold opening time is reduced; production efficiency is improved; and the rate of finished products is high.

Owner:青岛海泰科模具有限公司

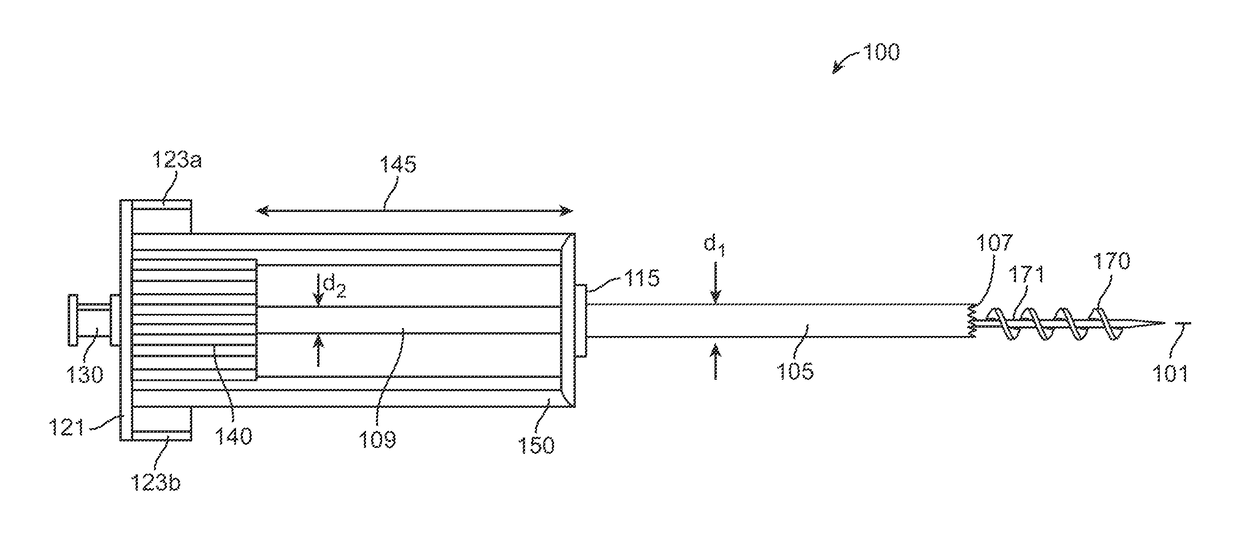

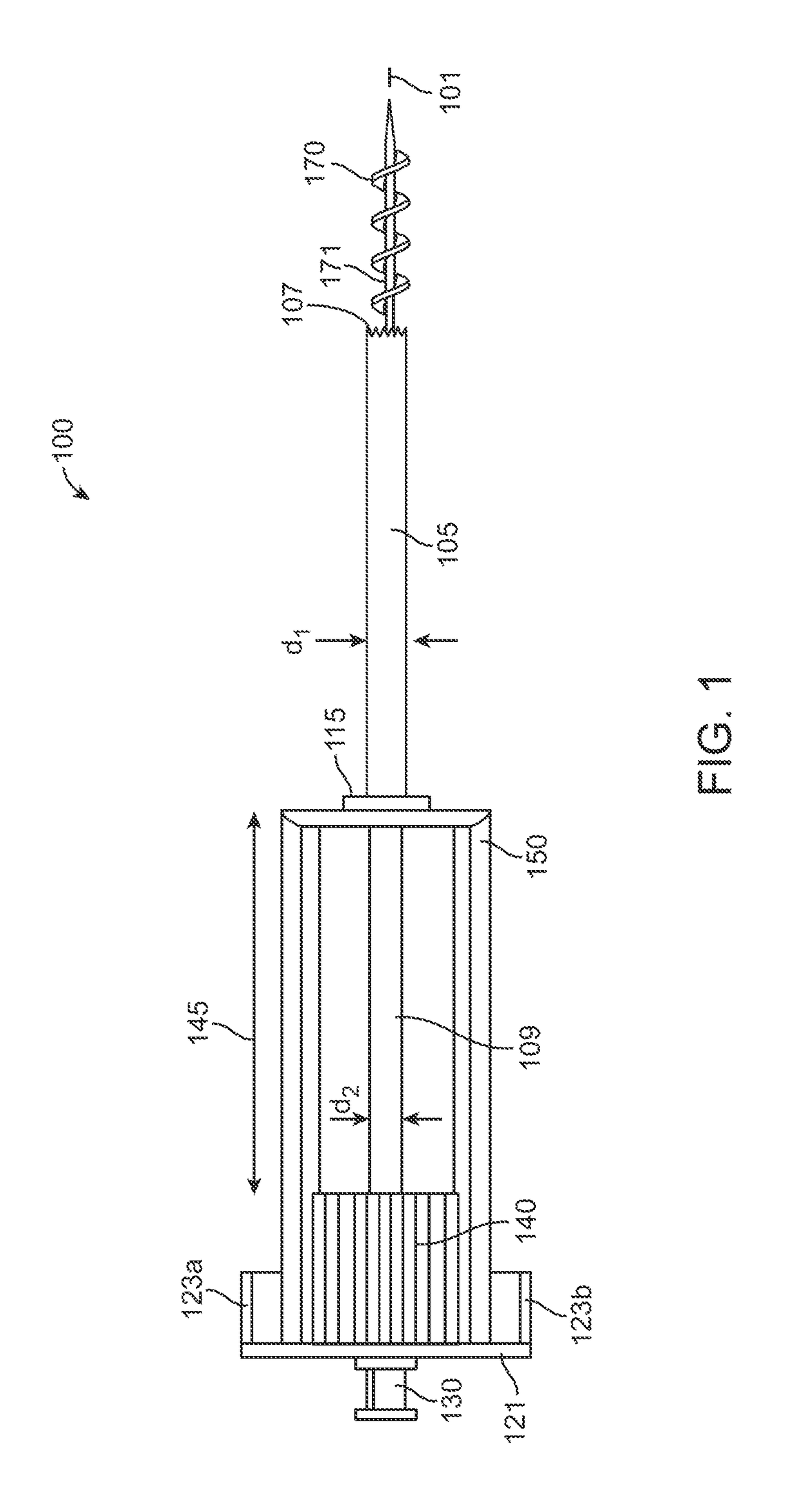

Core needle biopsy device

ActiveUS9968338B2Little strengthSurgical needlesVaccination/ovulation diagnosticsCore needleMedicine

A biopsy device includes a cutting cannula mechanism having a cutting cannula and an inner stylet mechanism having an inner stylet coaxial with the cutting cannula. A cocking mechanism is configured to cock the cutting cannula mechanism and the inner stylet mechanism by retracting each of the cutting cannula and the inner stylet in a proximal direction to a cocked position. A trigger device is configured to fire at least one of the inner stylet mechanism and the cutting cannula mechanism to advance a respective at least one of the inner stylet and the cutting cannula from the cocked position in a distal direction. A selector assembly includes a selector switch having an exterior tab accessible by a user. The selector assembly is configured to select between at least two user selectable operating modes and at least two user selectable firing distances.

Owner:CR BARD INC

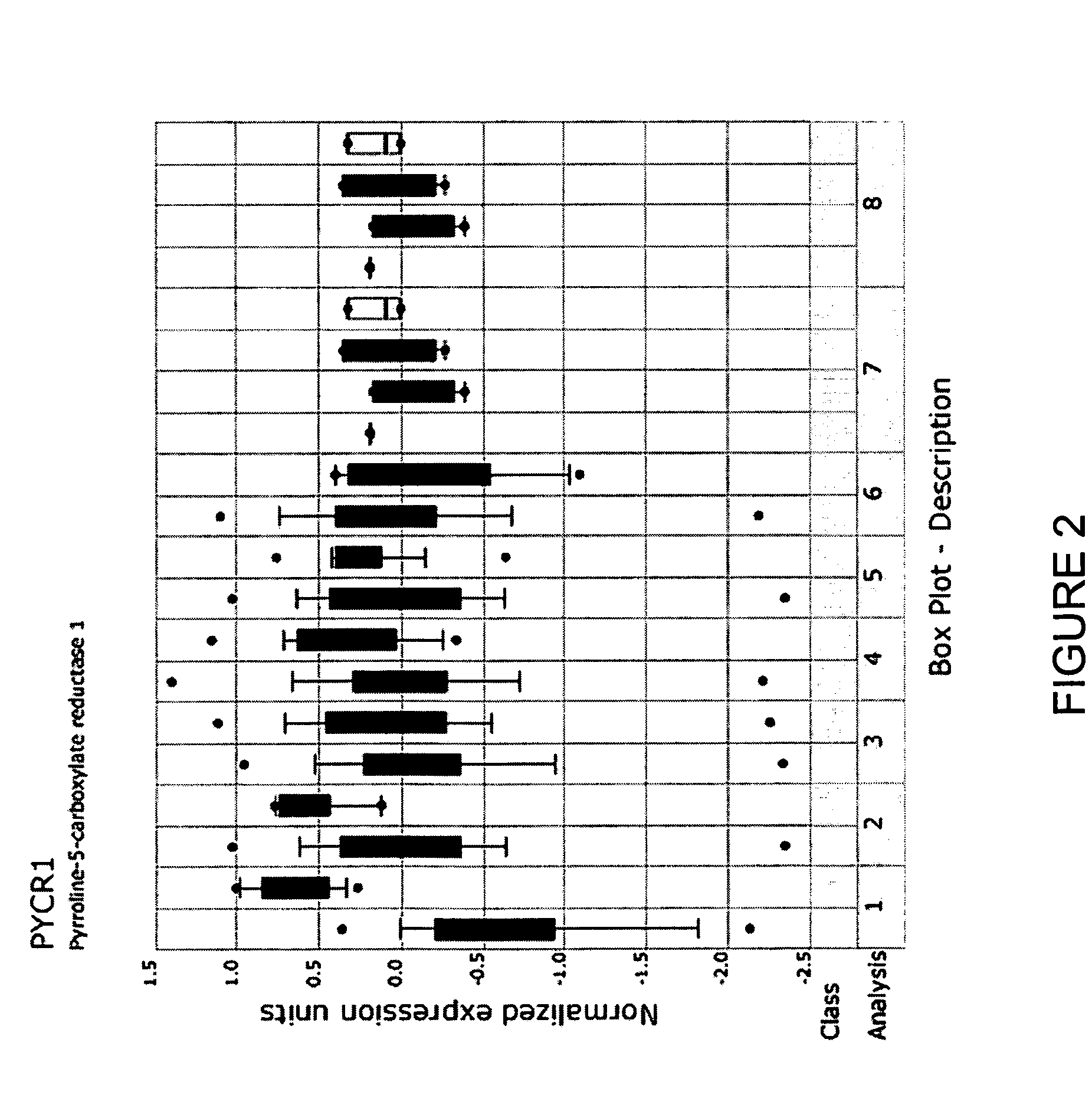

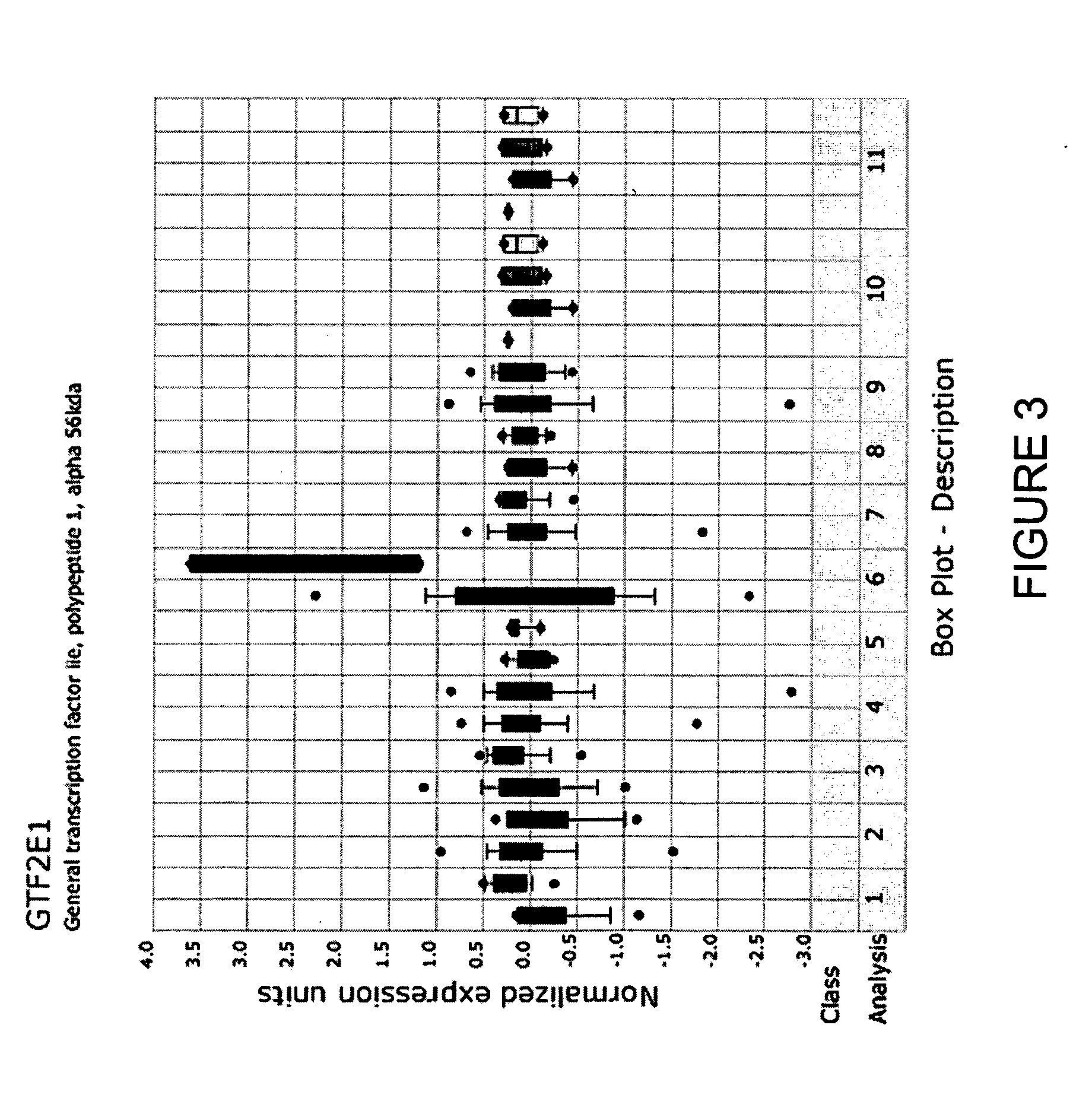

Molecular method for diagnosis of prostate cancer

InactiveUS20070065856A1Microbiological testing/measurementMaterial analysisCore needleProstate cancer

Methods for diagnosing or detecting cancerous prostate tissue. A panel of 8 specific marker genes are provided. The overexpression of some of these marker genes compared to their expression in normal prostate tissue and the underexpression of the rest of these marker genes are indicative of cancerous prostate tissue. By using these 8 marker genes as a diagnostic tool, smaller tissue samples, such as those obtained by core needle biopsies can be used.

Owner:NAT RES COUNCIL OF CANADA

WIFI module test tool having high reliability and working method thereof

PendingCN108196097AIncrease contactImprove reliabilityMeasurement instrument housingElectricityCore needle

The invention discloses a WIFI module test tool having high reliability and a working method thereof. The WIFI module test tool includes a module mounting seat arranged above a table surface; four power supply needles for proving power for a WIFI module and distributed longitudinally, and a metallic needle for connecting an outer conductor of a radio frequency cable are fixed on the table surface;a gap is formed in an edge of the module mounting seat; a front end of a radio-frequency head high frequency probe stretches into the gap; the metallic needle longitudinally passes through an inner corner of the gap; a limiting groove for holding and limiting the WIFI module is formed in the module mounting seat; when the WIFI module is pressed downward, all the power supply contact points contact the corresponding power supply needles, the metallic needle passes through a semicircular gap of a first signal contact point, and a core needle is aligned with a concave arc surface of a semicircular gap as a second signal contact point on an edge of the WIFI module horizontally; the radio-frequency head high frequency probe is controlled to move forward horizontally so as to allow the core needle to electrically contact the second signal contact point, and the metallic needle tightly attaches onto the first signal contact point.

Owner:徐志明

Tissue biopsy needle

PendingCN112155610AEasy to detectAvoid harmSurgical needlesSurgical navigation systemsTissue biopsyCore needle

The invention relates to the technical field of clinical medical treatment, and discloses a tissue biopsy needle. The tissue biopsy needle comprises a power mechanism, an outer sleeve needle and an inner core needle, wherein the inner core needle is embedded in the outer sleeve needle, a groove is formed in the side wall of the tail end of the outer sleeve needle, a semi-ring cutter correspondingto the groove is arranged on the inner core needle, and the power mechanism drives the semi-ring cutter to transversely rotate in the outer sleeve needle through a needle rod. The tissue biopsy needlehas the beneficial effects that in the process that a cutter opening of the inner core needle and a side cutter act together to cut tissue, the power mechanism drives the semi-ring cutter to rotate rapidly through the needle rod, rapid rotary cutting of the tissue to be detected is achieved to form a complete cylindrical sample, and the tissue is convenient to detect. In the cutting process, dueto the fact that rotary cutting is adopted, the outer sleeve needle and a needle tip are static, shaking cannot occur, damage to surrounding important organs is avoided, safety is greatly improved, and biopsy can be conveniently carried out on tissue such as large vascular gaps, dangerous organ sides, small nodules and lymph nodes.

Owner:ANHUI PROVINCIAL CANCER HOSPITAL +4

Scooper core needle

InactiveUS20160030019A1Surgical needlesVaccination/ovulation diagnosticsCore needleTissue Collection

A device for collecting a tissue sample includes Needle and Stylet. Needle is extending longitudinally from a proximal to a distal end and includes a lumen extending therethrough. Stylet is movably housed in the lumen and extending along a longitudinal axis from a proximal to a distal end and includes a scooper at the distal end thereof. The scooper is connected to a proximal portion of Stylet via a hinge biased toward a bent position in which the scooper is bent away from the longitudinal axis. Stylet is movable between a constrained configuration and a tissue-collecting configuration. The scooper includes a channel extending longitudinally therethrough and a window extending laterally through a wall thereof in communication with the channel to collect a tissue sample therethrough as Stylet is moved from the tissue-collecting to the constrained.

Owner:BOSTON SCI SCIMED INC

Hydraulic extruding machine for ceramic roller billet tube

The invention discloses a hydraulic extruding machine for a ceramic roller billet tube. The hydraulic extruding machine is used for extrusion molding of the ceramic roller billet tube. The hydraulic extruding machine comprises an oil cylinder, a vacuum box, a charging barrel first supporting seat, and a charging barrel second supporting seat, wherein the oil cylinder is provided with an oil cylinder pressure head; the oil cylinder, the vacuum box, the charging barrel first supporting seat and the charging barrel second supporting seat are installed on a machine frame; a charging barrel is fixed between the charging barrel first supporting seat and the charging barrel second supporting seat; the oil cylinder pressure head is placed in the charging barrel; a cone-shaped pipe and a middle core needle bed are installed on the charging barrel second supporting seat; a pipe outlet nozzle is arranged on the cone-shaped pipe; a middle core needle is arranged on the middle core needle bed; and a pipe core is inserted on the middle core needle in a sleeved mode. According to the hydraulic extruding machine, the equipment structure is simple, replacement of the charging barrel and spare parts is easy, the pipe squeezing speed is flexible and adjustable, extruding force is large, a ceramic roller with a large specification can be produced, the extruded billet tube is high in density, not prone to deformation, and large in strength, and the hydraulic extruding machine is capable of meeting technical requirements of the ceramic roller produced in a cold static pressure method.

Owner:广东金刚新材料有限公司 +1

Molecular method for diagnosis of prostate cancer

Methods for diagnosing or detecting cancerous prostate tissue. A panel of 8 specific marker genes are provided. The overexpression of some of these marker genes compared to their expression in normal prostate tissue and the underexpression of the rest of these marker genes are indicative of cancerous prostate tissue. By using these 8 marker genes as a diagnostic tool, smaller tissue samples, such as those obtained by core needle biopsies can be used.

Owner:NAT RES COUNCIL OF CANADA

A flat pinhole coaxial electrospinning fiber composite spinneret and spinning method thereof

InactiveCN103572386BUniform electric fieldEasy to manufactureFilament/thread formingFiberCore needle

The invention relates to a flat pinhole coaxial electrospinning fiber composite spinneret and its spinning method, including: (1) a coaxial fiber composite spinneret configured by a flat conductive electrode, an auxiliary spinneret and a core needle There is a through hole on the auxiliary spinneret plate, and a groove is provided on the thread outlet surface of the through hole. The advantage is that a uniform electric field is formed between the flat conductive electrode and the receiving plate, which is more conducive to the formation of coaxial fibers and mass production. Production. (2) After the core layer and the shell layer spinning solution are injected separately, they merge into composite droplets in the groove of the through hole; by properly adjusting the voltage and spinning distance, the composite droplets reach the destination through high-frequency stretching, bending and swinging under the force of the electric field. The sheet is received and cured to form a core-shell structure of ultrafine composite electrospun fibers. The advantage is that the preparation of the coaxial composite needle is simple, and it is convenient for batch preparation of the coaxial fiber composite needle, and the multifunctional composite fiber meeting various demands can be prepared by changing the core needle.

Owner:DONGHUA UNIV

Core needle and core pack inner hole expanding mechanism

PendingCN110190321AImprove the heating effectHeating evenlyPrimary cell manufactureAssembling battery machinesCore needleHollow core

The present invention discloses a core needle and a core pack inner hole expanding mechanism. The core needle is arranged in a hollow mode; the core pack inner hole expanding mechanism comprises a heating element comprising a core needle mentioned above, the heating element heats the core needle; the core needle is arranged in a hollow mode so that the core needle is easier to be heated and is uniformly heated to ensure the uniformity and the consistency of the core pack forming; the top portion of the core needle is provided with a small hole to exhaust hot wind out of the core needle to further make the core needle uniform heated; the top portion of the core needle is subjected to eccentric taper-shaped arrangement which is not easy to damage a separator in a jacking mode so as to ensurethe processing quality of the battery cell; the heating fins of the heating element are adopted to heat the core needle, the core needle is configured to perform thermal expanding of the hole for thecenter hole of the battery cell, the separator of the battery cell after the inner hole expanding is not easy to deform and rebound to ensure automatic welding in the shell in the later production, and the separator of the center hole cannot be damaged to cause short circuit; and moreover, the heating element is compact in structure, an air blow pipe is adopted with heating so that the core needle is quickly heated and uniformly heated, and the thermal efficiency is high.

Owner:东莞士格电子集团有限公司

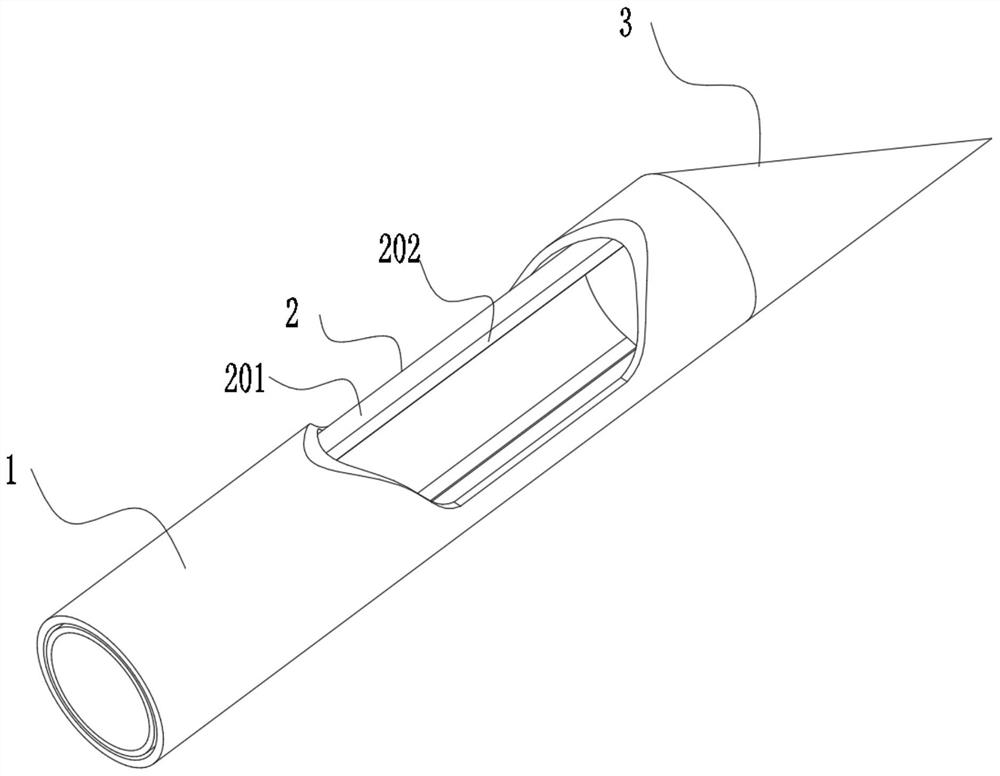

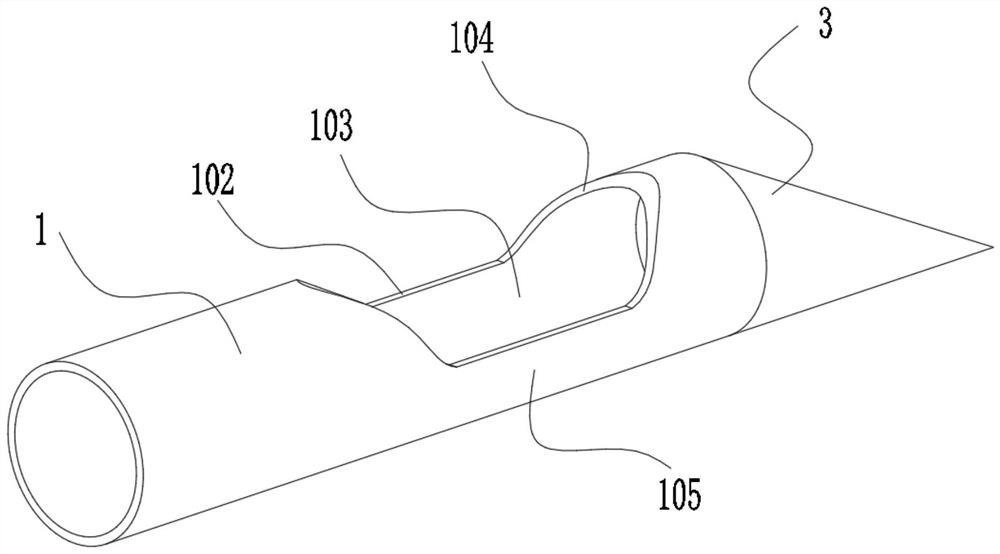

Splitting reducing microwave needle

PendingCN107802343APuncture safetyGood for postoperative recoverySurgical instruments using microwavesCore needleMicrowave

The invention provides a splitting reducing microwave needle. The splitting reducing microwave needle comprises a puncture needle core, a reducing taper head is arranged at the rear outer ring of thehead end of the puncture needle core and comprises a reducing taper head head end and a reducing taper head tail end, the diameters from the reducing taper head head end to the reducing taper head tail end are gradually increased, and a sleeve is arranged inside the tail end of the puncture needle core. In an operation, the splitting reducing microwave needle can directly puncture the skin of a patient, and directly enters a focus position; hemorrhage is reduced, and the postoperative healing time is shortened, which is beneficial to postoperative recovery of the patient.

Owner:MICRO TECH (NANJING) CO LTD +1

End cutting biopsy gun

PendingCN113261997AGuaranteed accuracyTake out thickSurgical needlesVaccination/ovulation diagnosticsCore needleBiopsy guns

An end cutting biopsy gun comprises an outer sleeve assembly, a cutting tube assembly, an inner core needle and a handle assembly, the outer sleeve assembly comprises an outer sleeve and an outer sleeve fixing piece, the cutting tube assembly comprises a cutting tube and a cutting tube fixing piece, the inner core needle is fixedly installed on the handle assembly, and an upper shell and a lower shell form a handle inner cavity; a first step is arranged in the inner cavity of the handle, a sliding groove for the cutting pipe fixing piece to drive the outer sleeve fixing piece to move front and back is formed in the inner cavity of the handle, and a push handle is arranged on the outer side of the inner cavity of the handle. Compared with the prior art, the cutting space is the cylindrical cutting groove, the amount of tissue taken out at a time is equal to more than two times that of a traditional semicircular cutting groove, the taken-out amount is thicker, and the accuracy of case analysis is guaranteed; in addition, the sampling length of the cylindrical cutting groove can be achieved by adjusting the gear piece, a doctor can adjust the sampling amount of the tissue according to requirements, and therefore quantitative sampling is achieved. One-key shooting is realized, and the operation is simple.

Owner:ZHEJIANG JIANAIWEI MEDICAL TECH

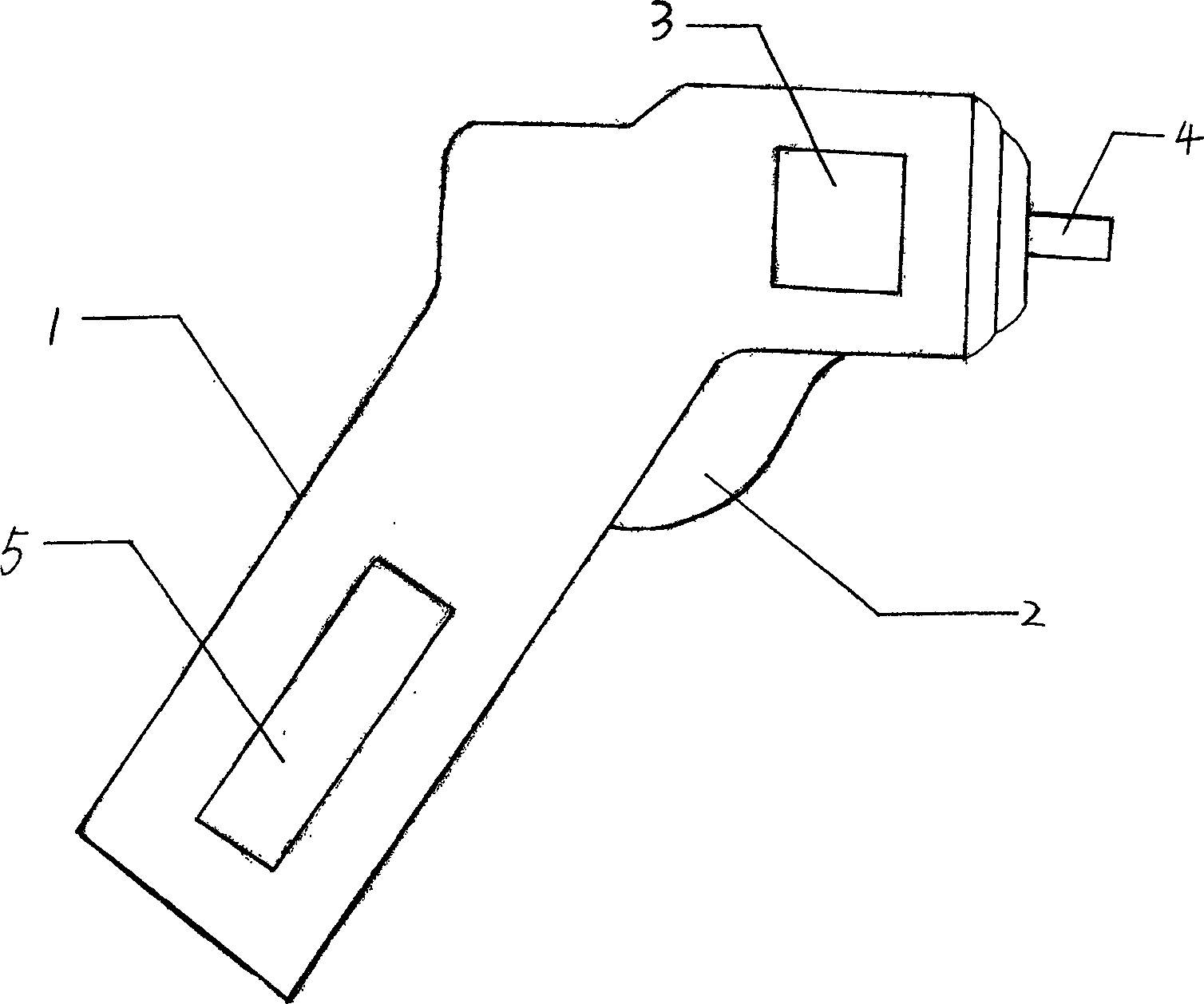

Bone marrow in-cavity injection apparatus

The invention discloses an injection device of marrow cavity in the shape of pistol, comprising a handle, a switch, a driving device, a connector of rotary head, a special rotary head of sleeve needle and a power source. Wherein, the power source, the switch and the driving device are connected in series while the driving device is the main part of said pistol-shaped injection device whose head is the connector of converter which is the external working part of said pistol-shaped injection device; the inner part of pistol-shaped injection device is connected to the driving device while its outer part is connected to the special rotary head of sleeve which is comprised by a injection needle whose tip is in the structure of double inclined blade and the inner core needle whose tip is in the structure of cone. The invention has the advantages of small volume, using the battery as power, carrying portably, safe and reliable usage, reduced time and improved rescue success ratio.

Owner:北京望升伟业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com