Flat plate free liquid level coaxial electrostatic spinning method and device

A coaxial electrospinning, flat electrode technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of uneven electric field strength, inconvenient cleaning, low production efficiency, etc. Simple, uniform structure, uniform electric field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

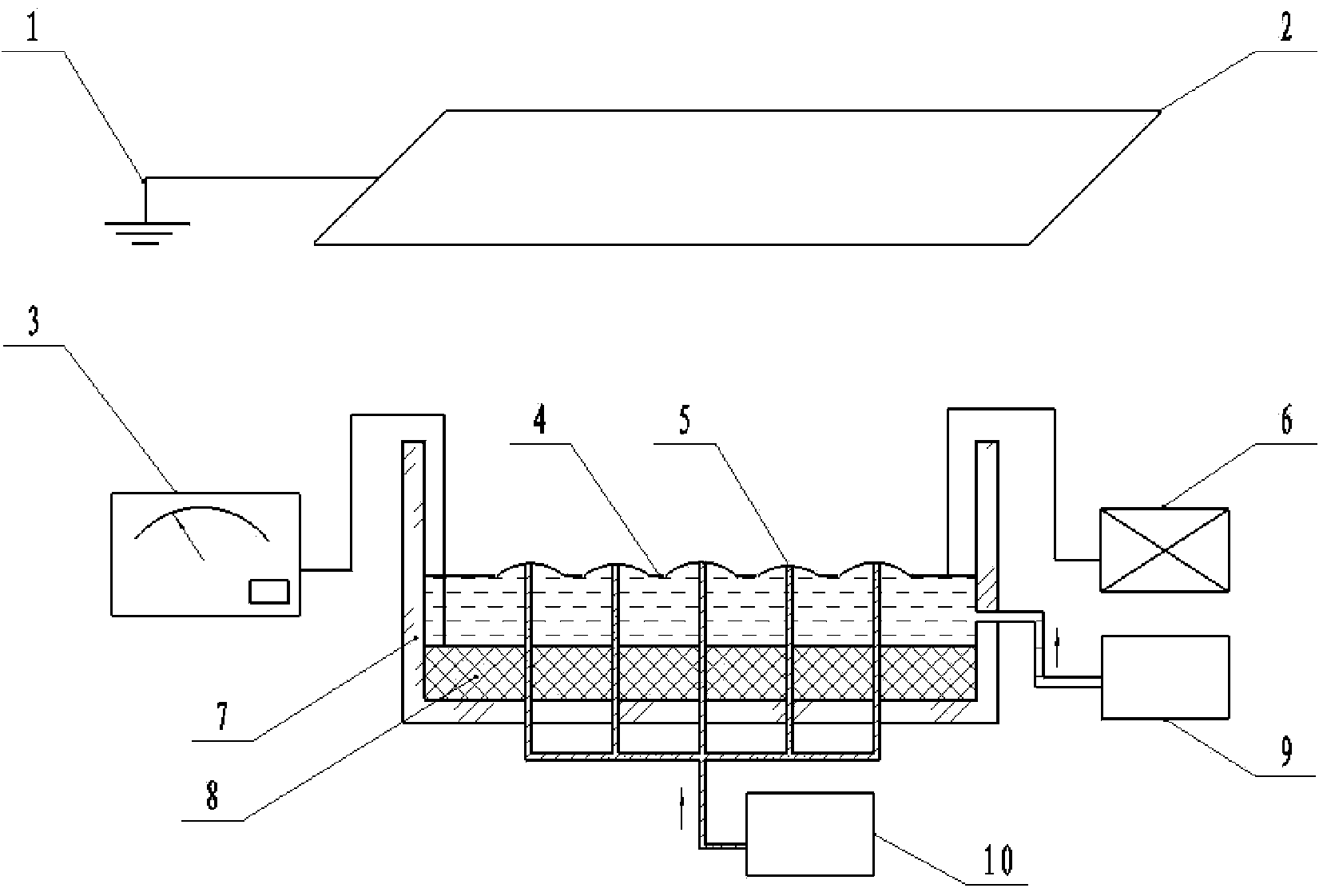

[0027] A flat free liquid surface coaxial electrospinning method, the shell layer spinning liquid polyethylene oxide solution (a certain amount of polyethylene oxide powder with a relative molecular mass of 600,000, dissolved in absolute ethanol and pure water The mixed solvent, whose volume ratio is 1:2, forms a homogeneous solution with a mass volume concentration of 2%) into the liquid storage tank (7) through the shell liquid supply pump (9) and ensures the liquid level of the shell solution (4 ) covers the needle tip of the core needle (5) under the action of surface tension to form a shell of the composite fiber; at the same time, the liquid level sensor (6) detects the height of the liquid level (4) of the shell solution and controls the supply of the shell The injection volume of the liquid pump (9); dissolve the core layer spinning liquid polyvinyl alcohol solution (a certain amount of polyvinyl alcohol powder with a relative , forming a homogeneous solution with a ma...

Embodiment 2

[0029]A flat free liquid surface coaxial electrospinning method, the shell spinning solution (a certain amount of polyvinyl alcohol powder with a relative molecular mass of 30,000-70,000, polyethylene oxide powder with a relative molecular mass of 600,000, According to the mass ratio of 10:1, it is dissolved in the mixed solvent of absolute ethanol and pure water, and its volume ratio is 1:2, forming a homogeneous solution with a mass volume concentration of 10%) injected through the shell liquid supply pump (9) In the liquid storage tank (7), ensure that the liquid level of the shell layer solution (4) covers the needle tip of the core needle (5) under the action of surface tension to form a shell layer of the composite fiber; at the same time, the liquid level sensor (6) detects The height of the liquid level (4) of the shell layer solution, and control the injection volume of the shell layer liquid supply pump (9); A homogeneous solution with a mass volume concentration of ...

Embodiment 3

[0031] A flat free liquid surface coaxial electrospinning method, the polystyrene solution of the shell spinning solution (a certain amount of polystyrene powder with a relative molecular weight of 350,000 is dissolved in tetrahydrofuran and N,N-dimethyl The mixed solvent of amide, whose volume ratio is 1:4, forms a homogeneous solution with a mass volume concentration of 25%) into the liquid storage tank (7) through the shell liquid supply pump (9) and ensures the liquid level of the shell solution ( 4) Cover the needle tip of the core needle (5) under the action of surface tension to form a shell of the composite fiber; at the same time, the liquid level sensor (6) detects the height of the liquid level (4) of the shell solution and controls the shell layer The injection rate of the liquid supply pump (9); the polyurethane solution of the core layer spinning solution (a certain amount of relative density 1.12g / m 3 Polyurethane particles, dissolved in N,N-dimethylamide to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com