Patents

Literature

418results about How to "Uniform electric field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

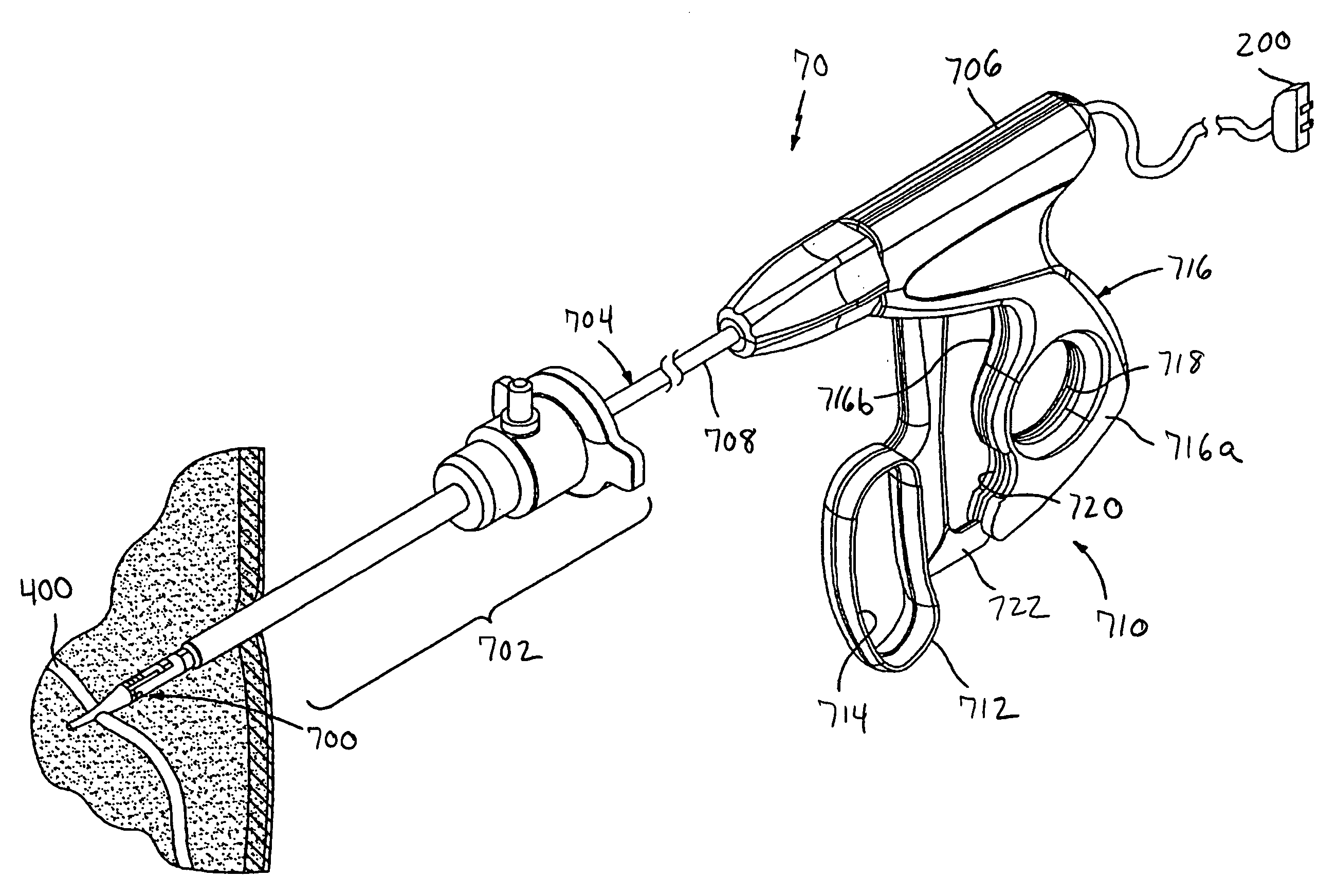

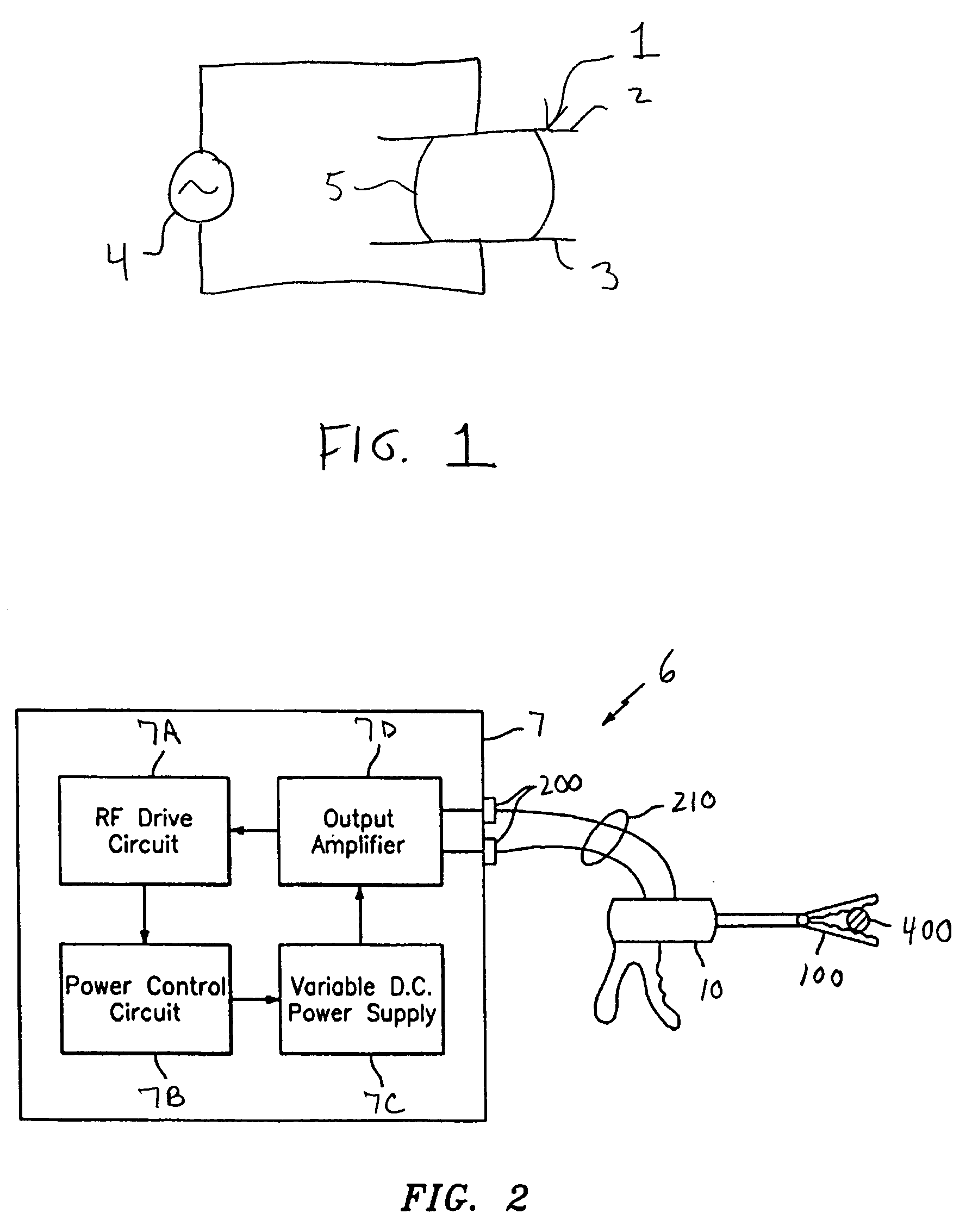

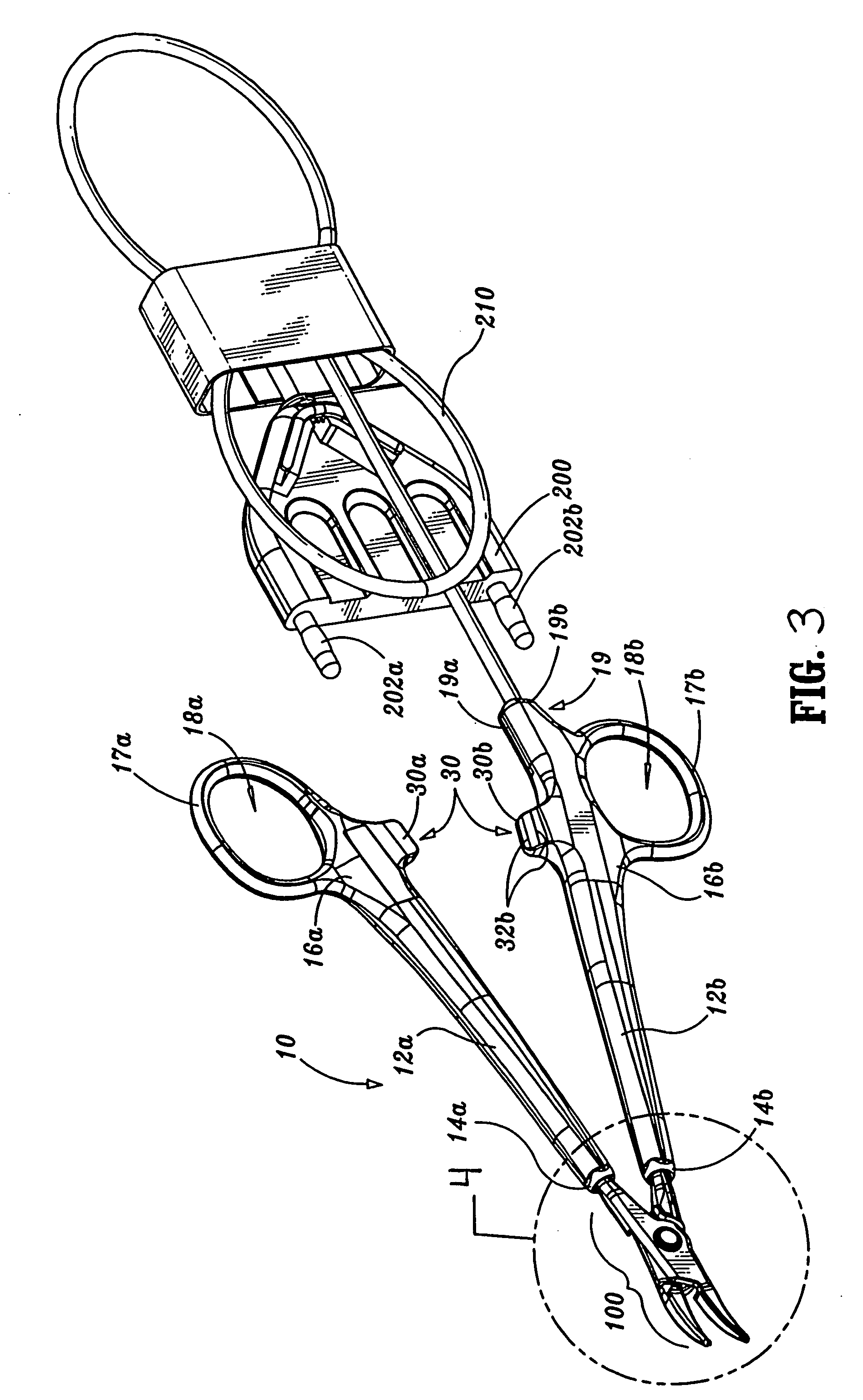

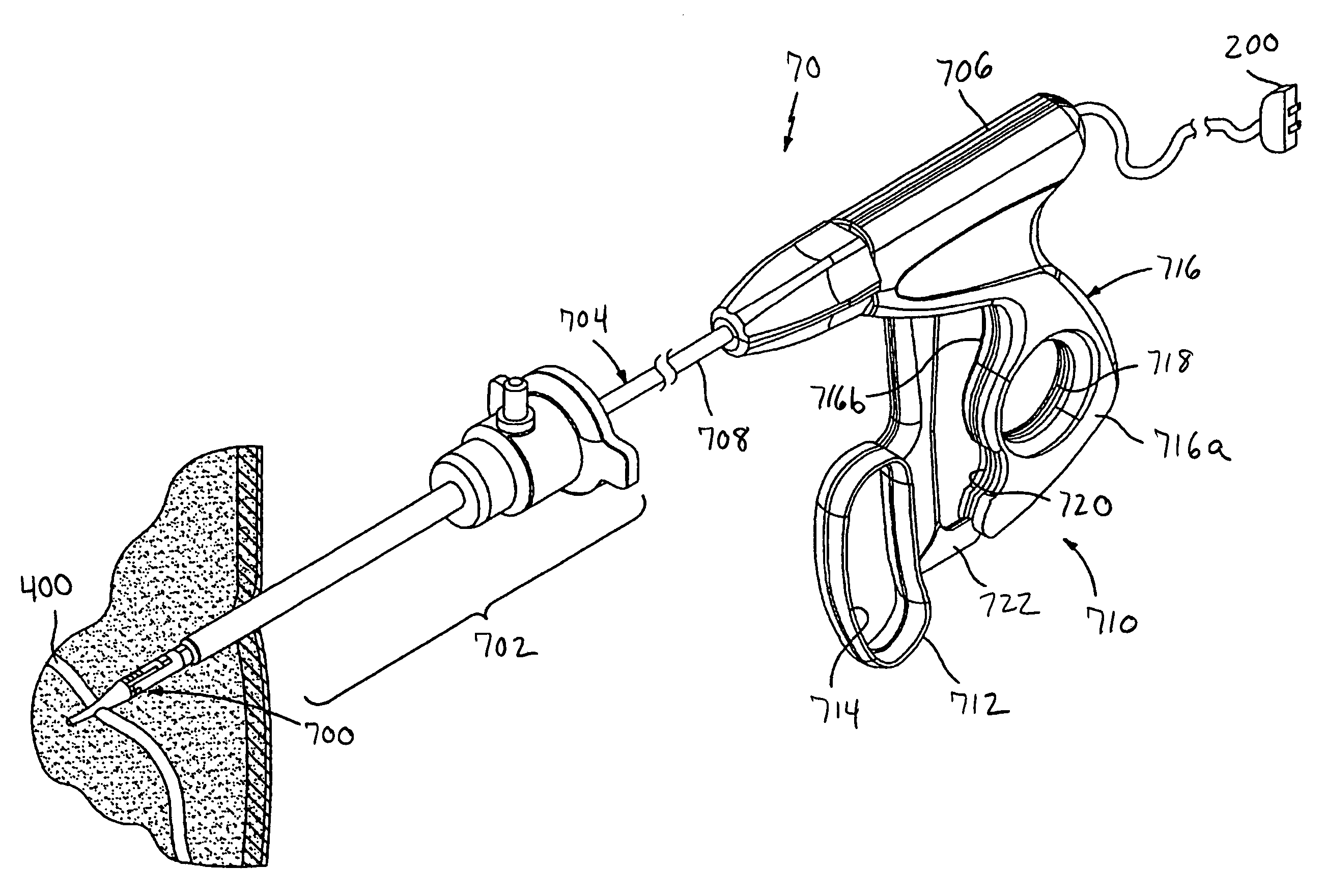

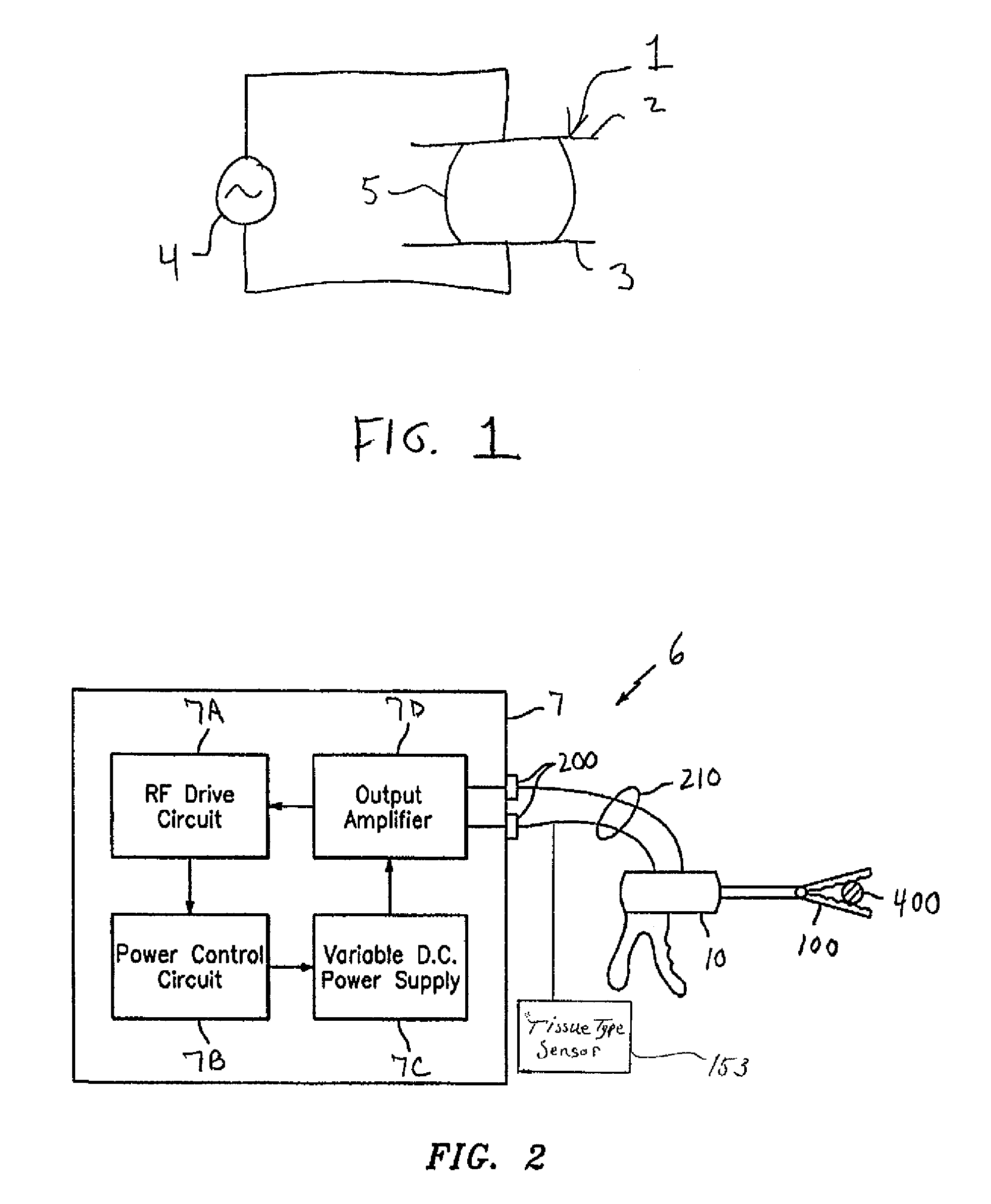

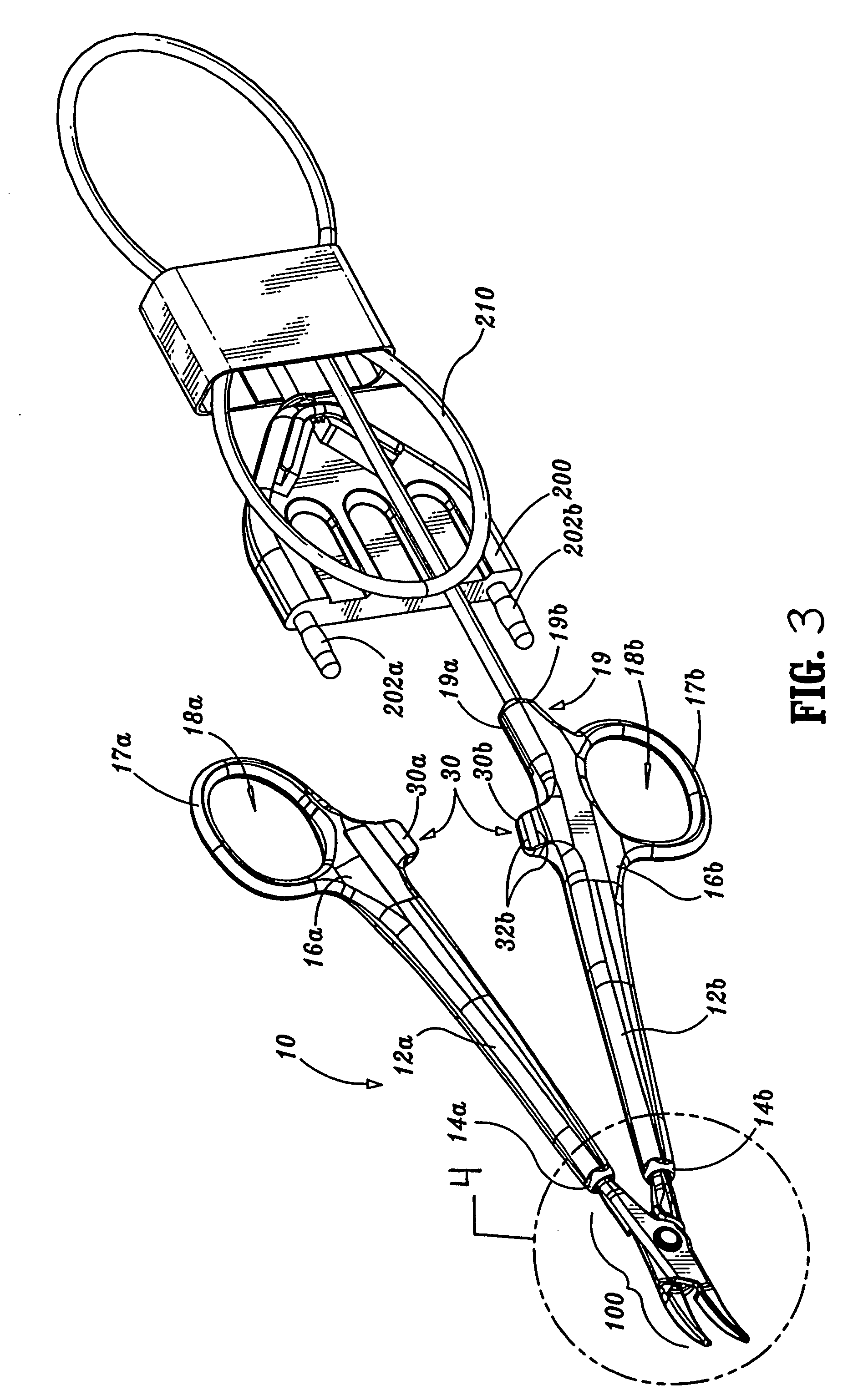

Vessel sealing system using capacitive RF dielectric heating

ActiveUS20050197659A1Heating evenlyReduce heat spreadSurgical instruments for heatingCoatingsCapacitanceVessel sealing

An electrosurgical system for sealing vessels using capacitive (RF) dielectric heating and a method thereof are provided. The system includes an electrosurgical instrument having an end effector with parallel plate electrodes that will clamp onto a vessel and maintain a specified gap distance; however, the electrodes will be coated with a non-conductive dielectric material. Such an end effector will ensure that direct conduction between the electrodes does not occur through tissue or fluids and effectively creates a parallel plate capacitor with a dielectric, e.g., tissue and coating, in between the plates. The electrosurgical instrument will be activated with an AC signal at a specified RF frequency, e.g., a Debye resonance frequency, via an electrosurgical generator. An effective AC current will flow through the tissue and cause heating due to fictional losses from rotating polar molecules in the tissue.

Owner:COVIDIEN AG

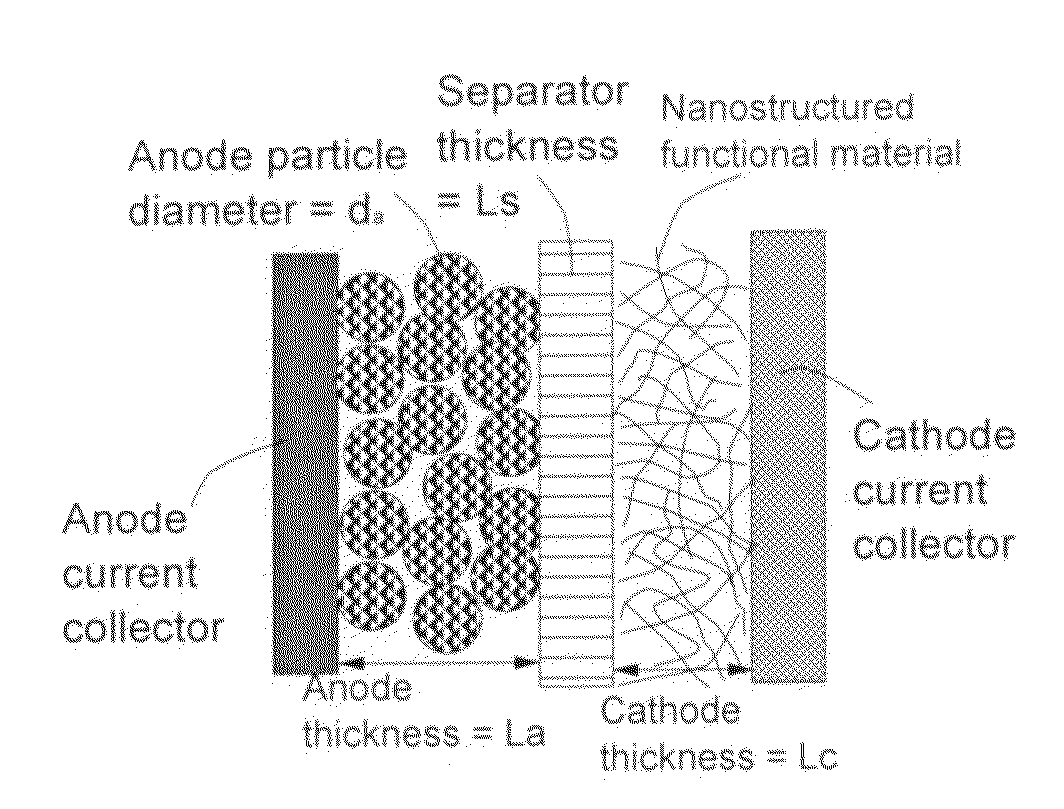

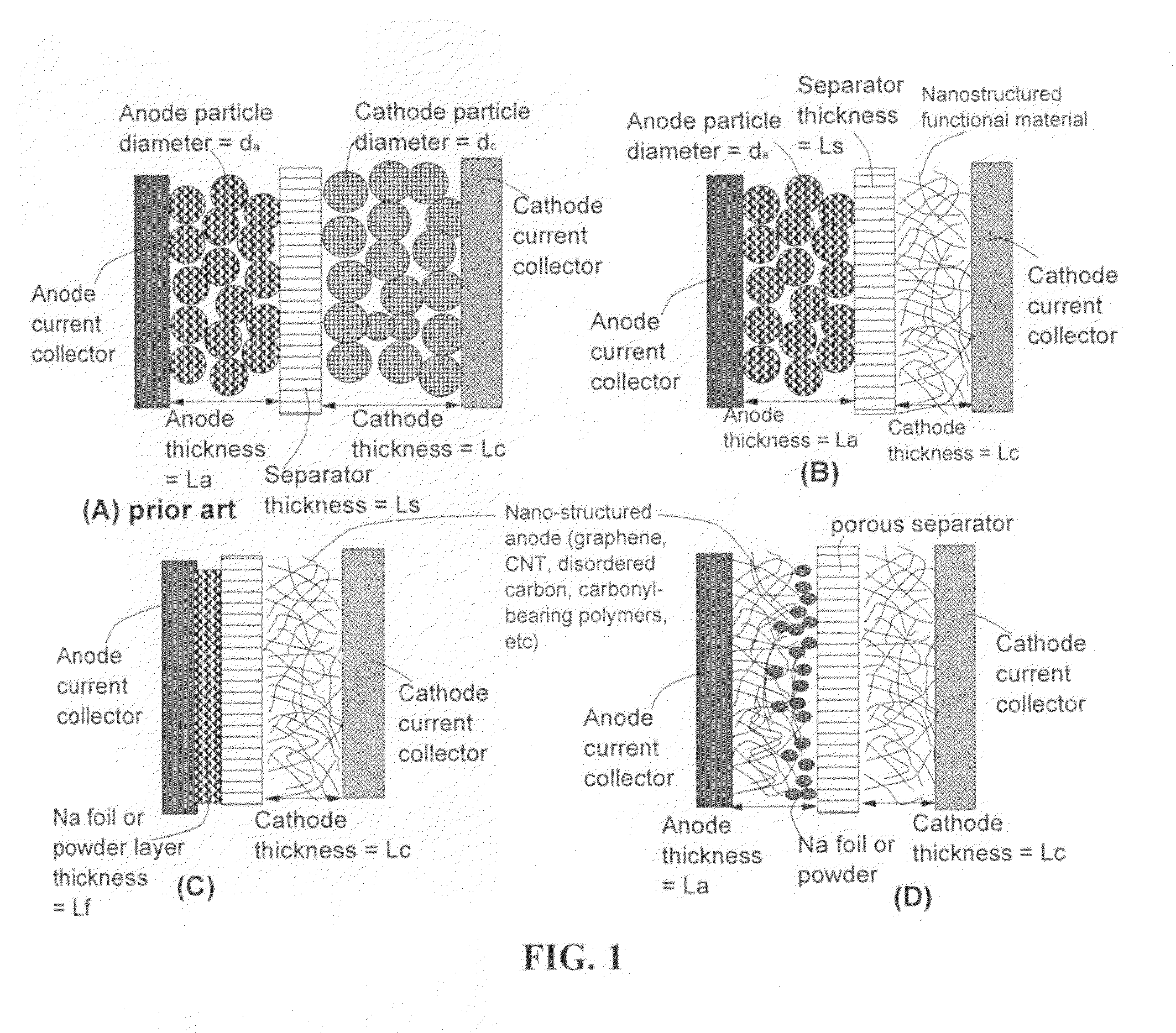

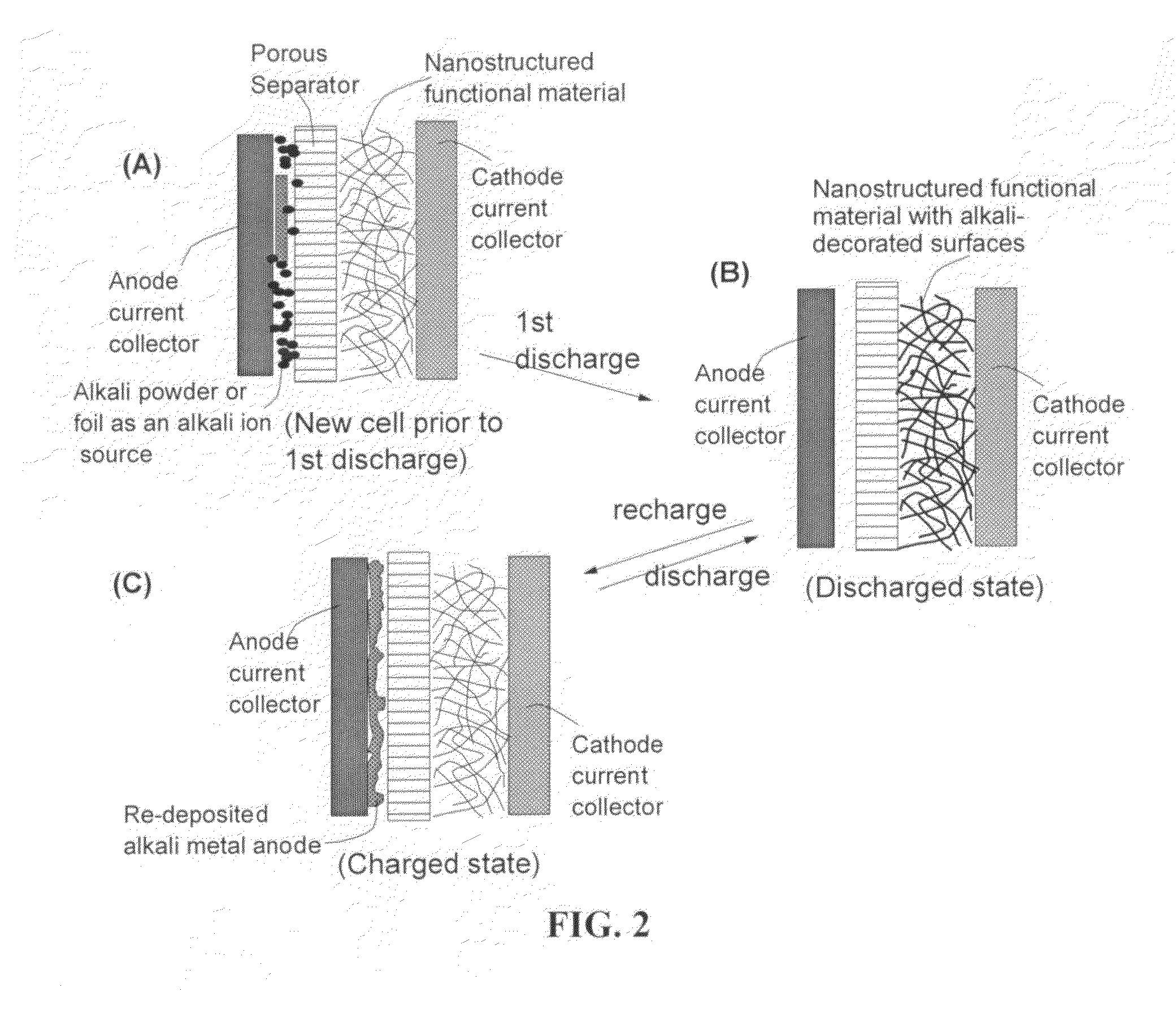

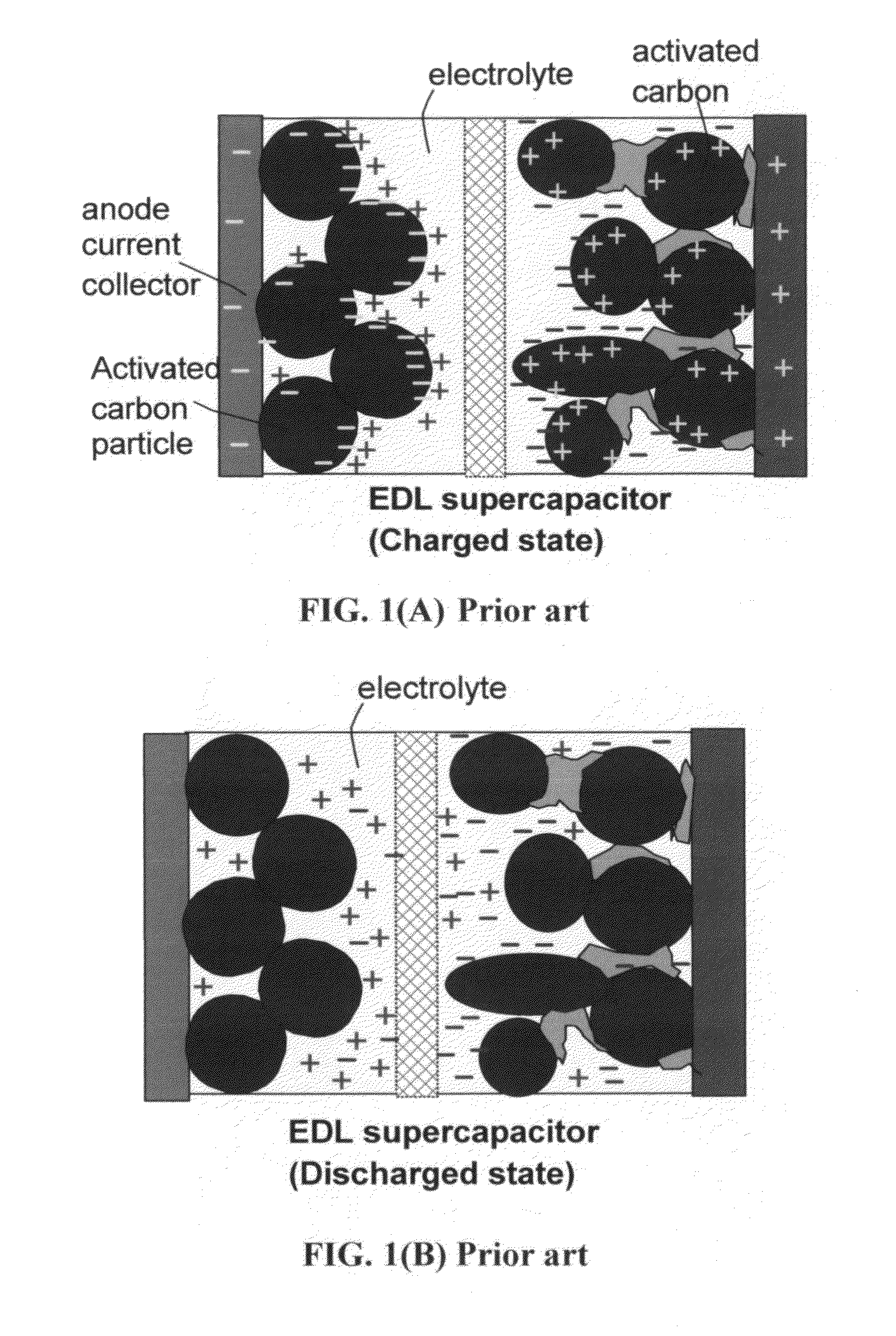

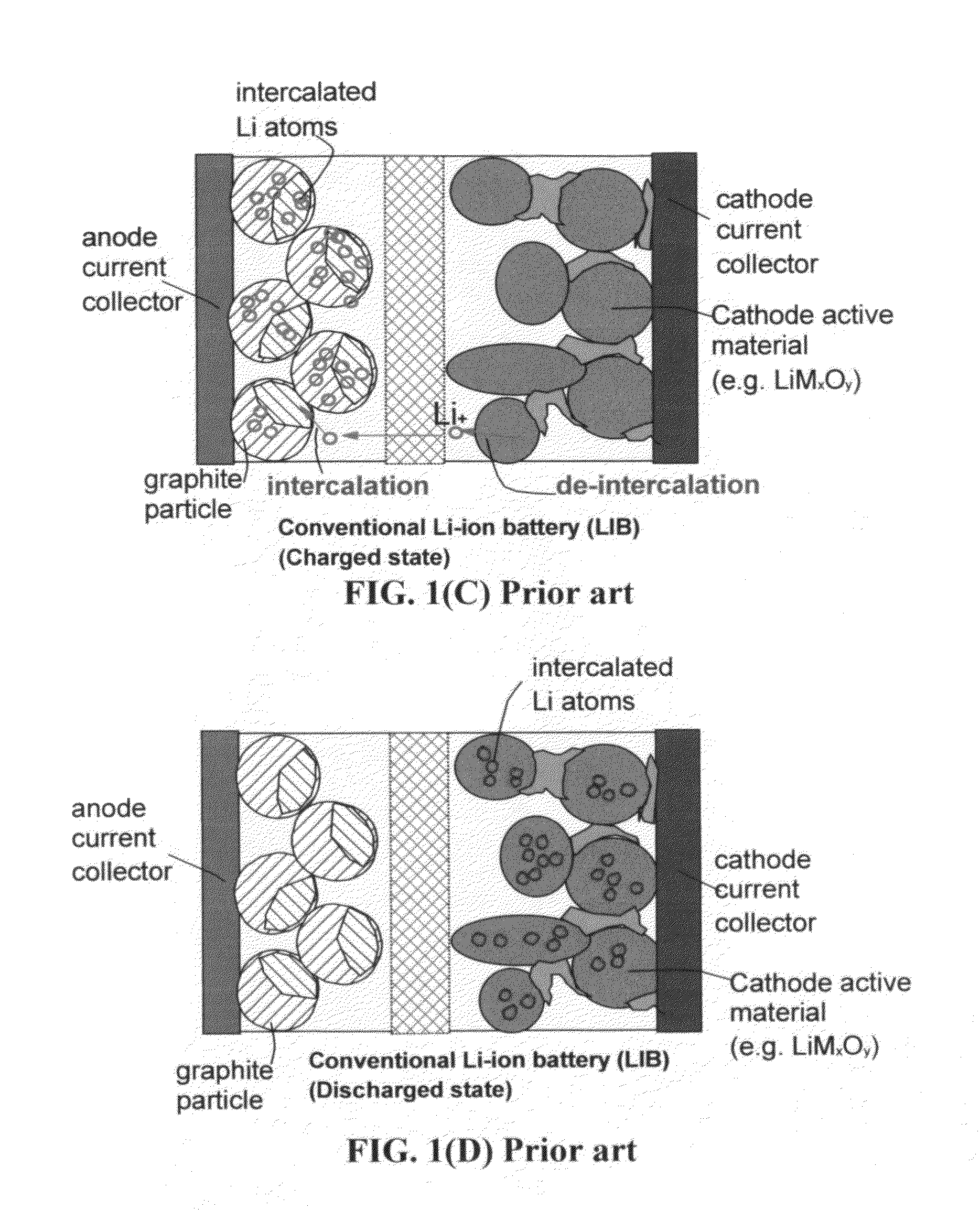

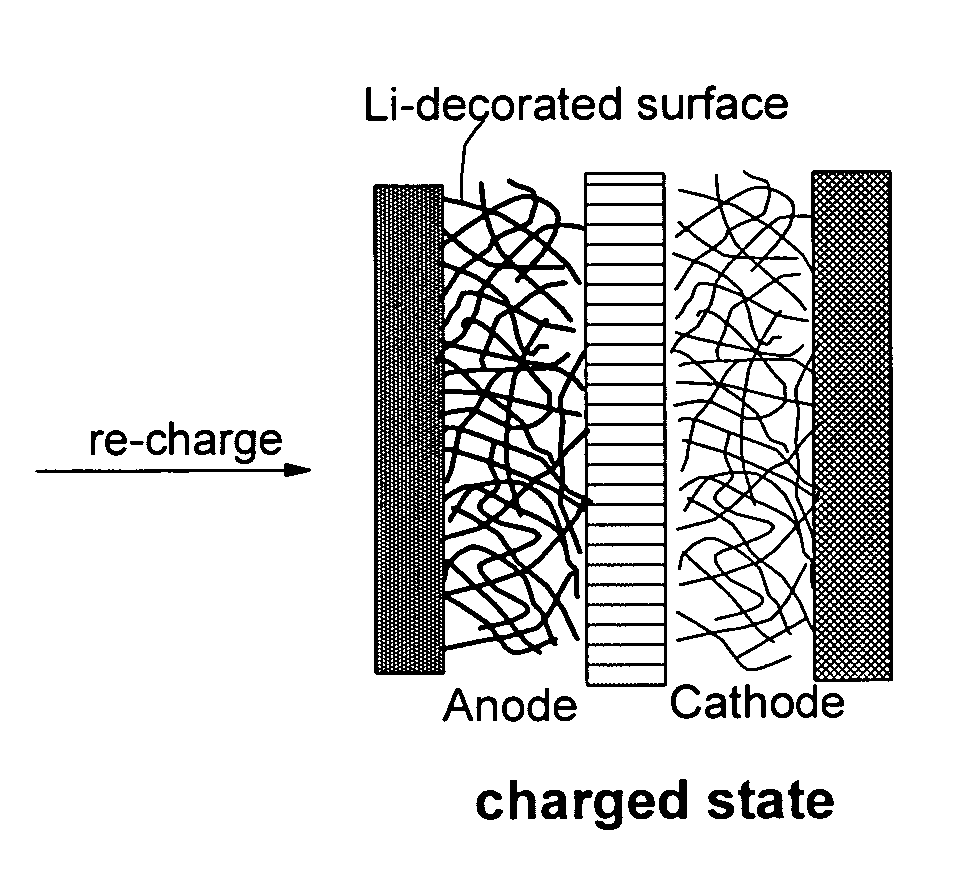

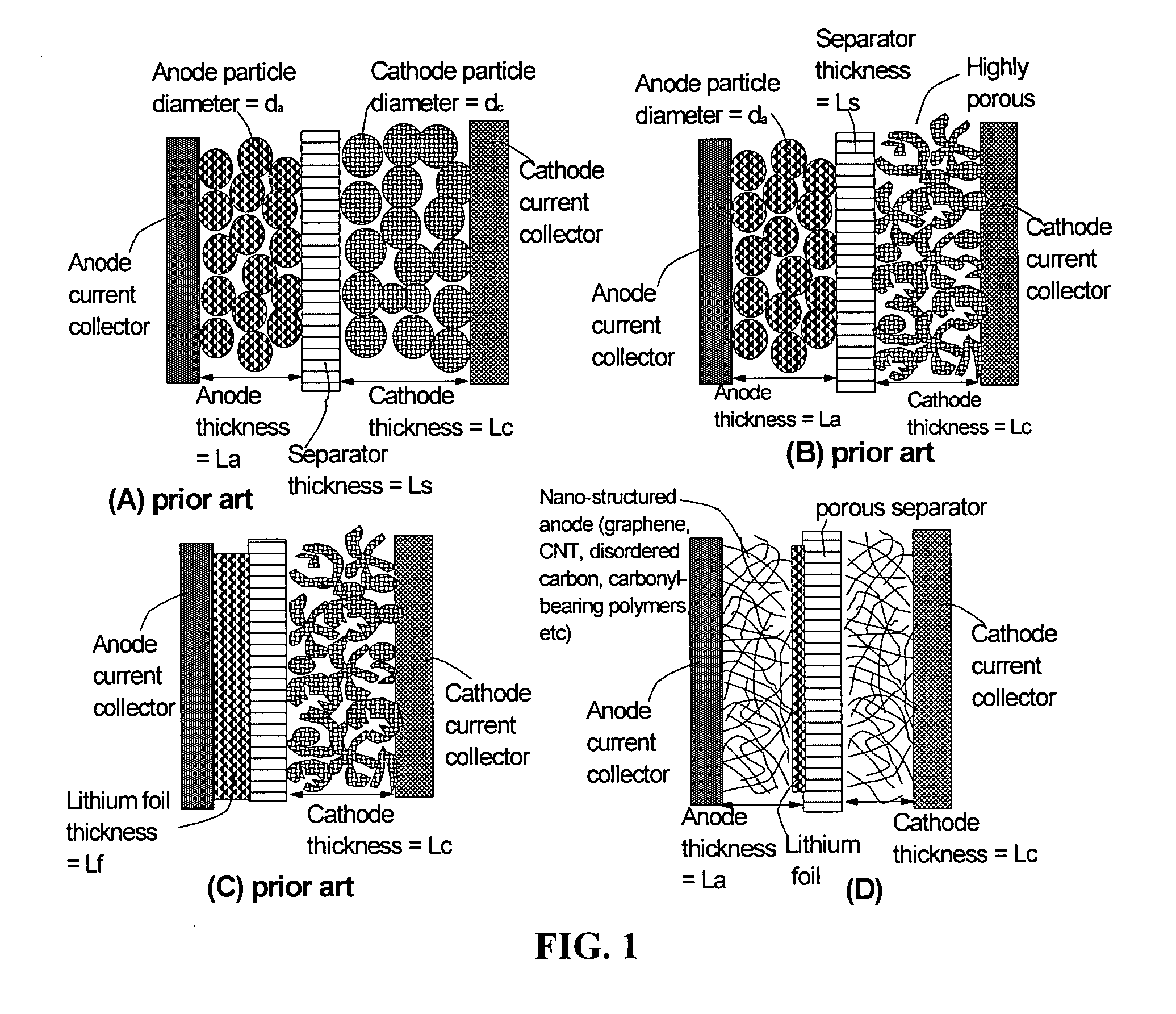

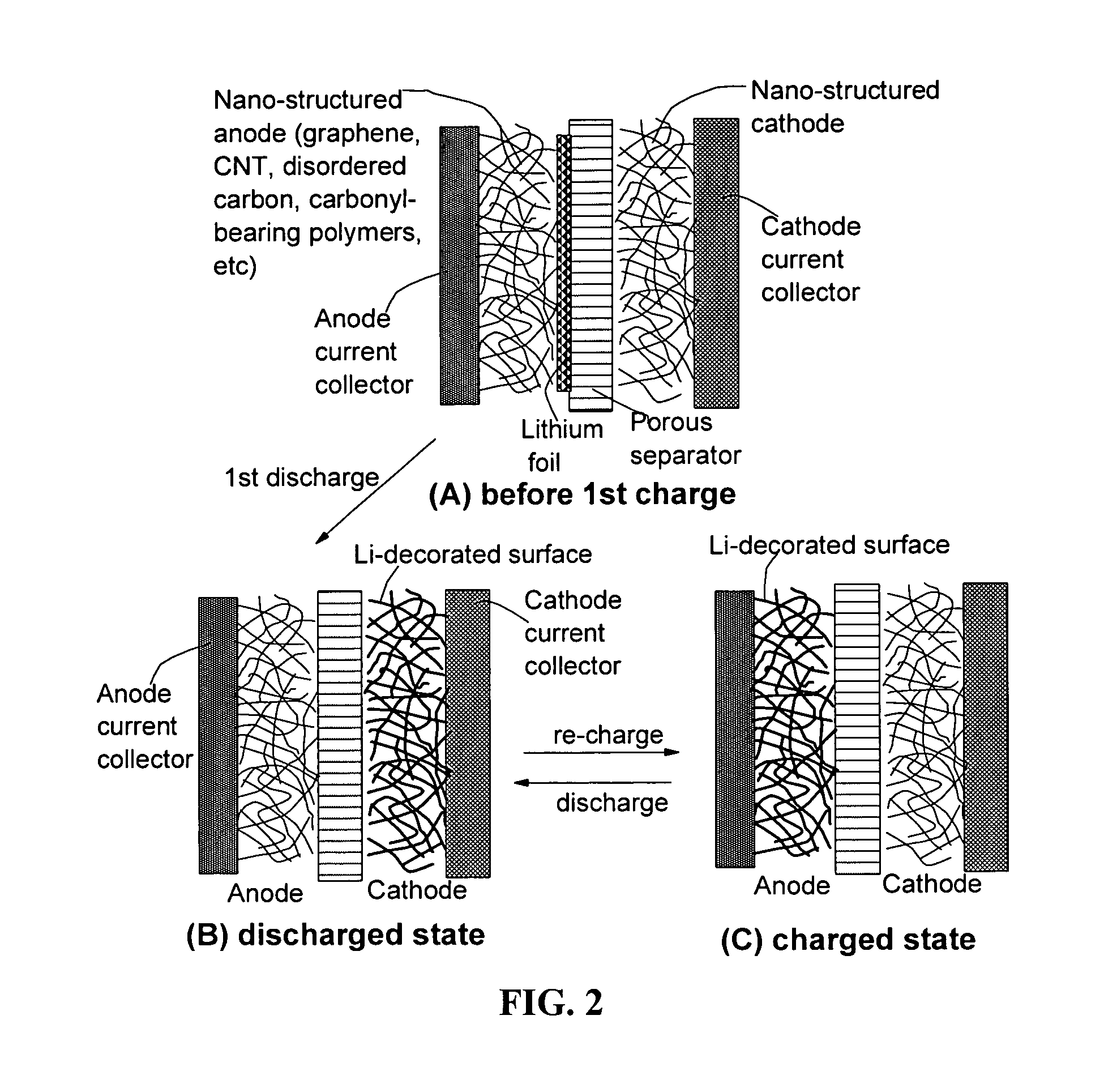

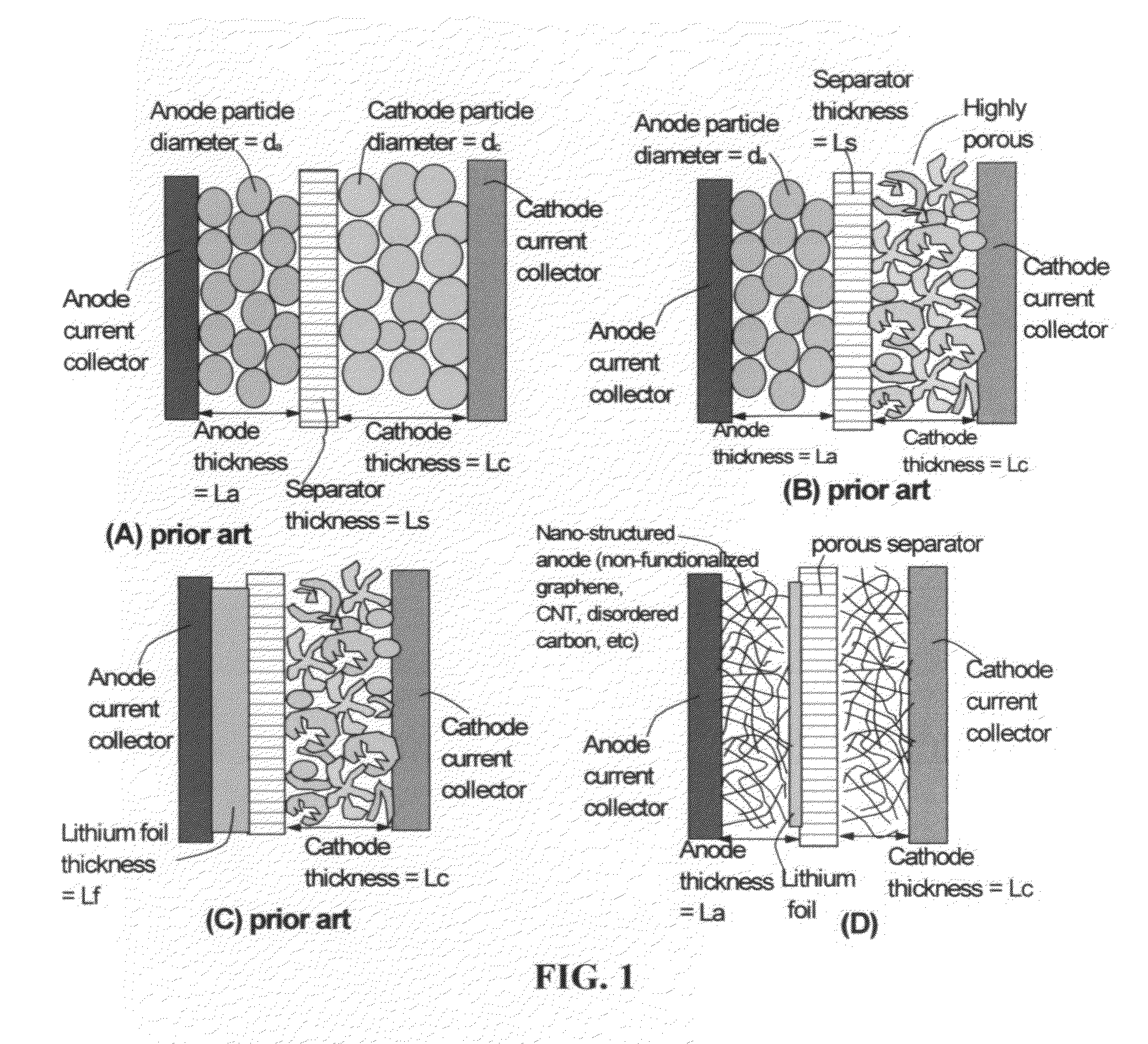

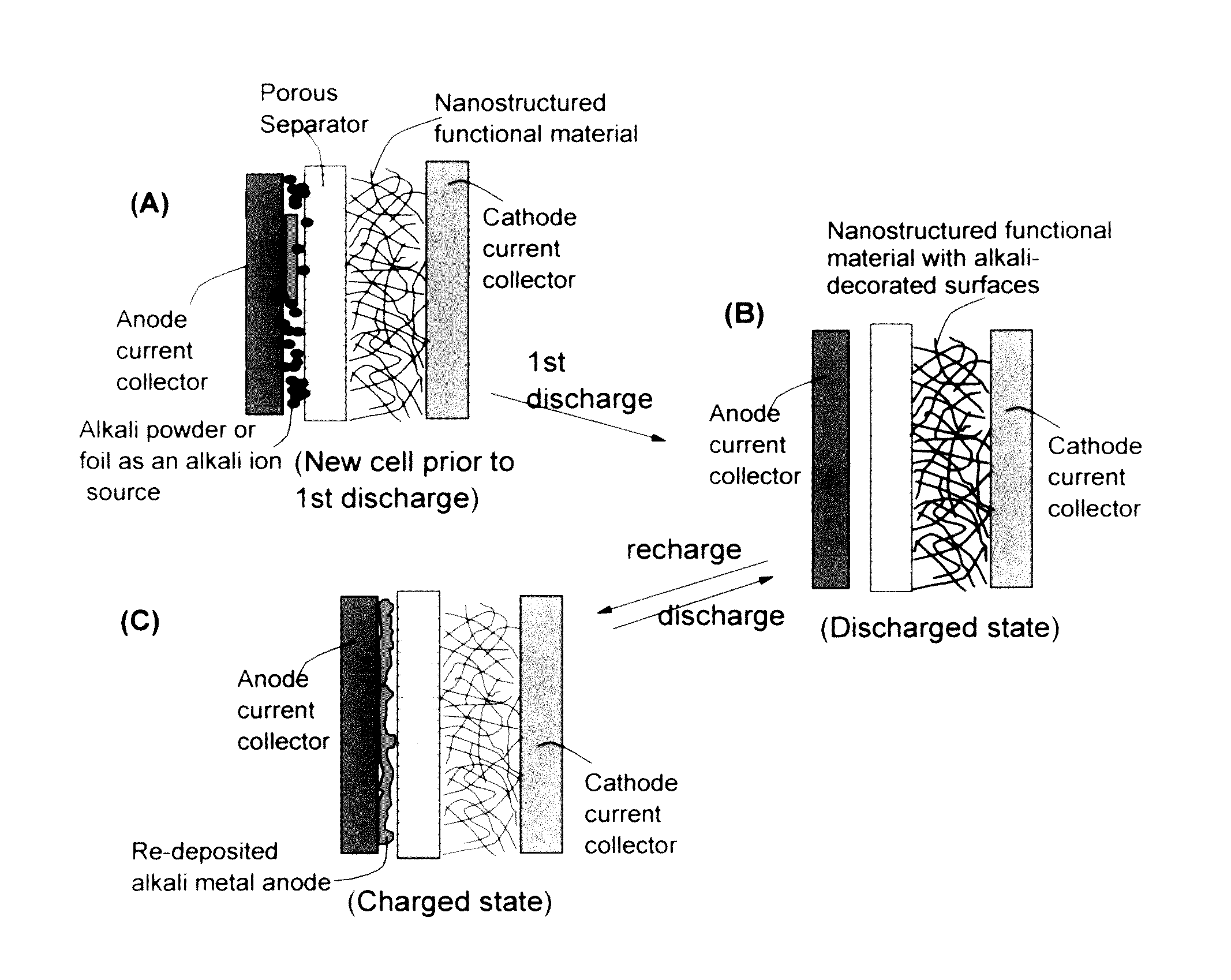

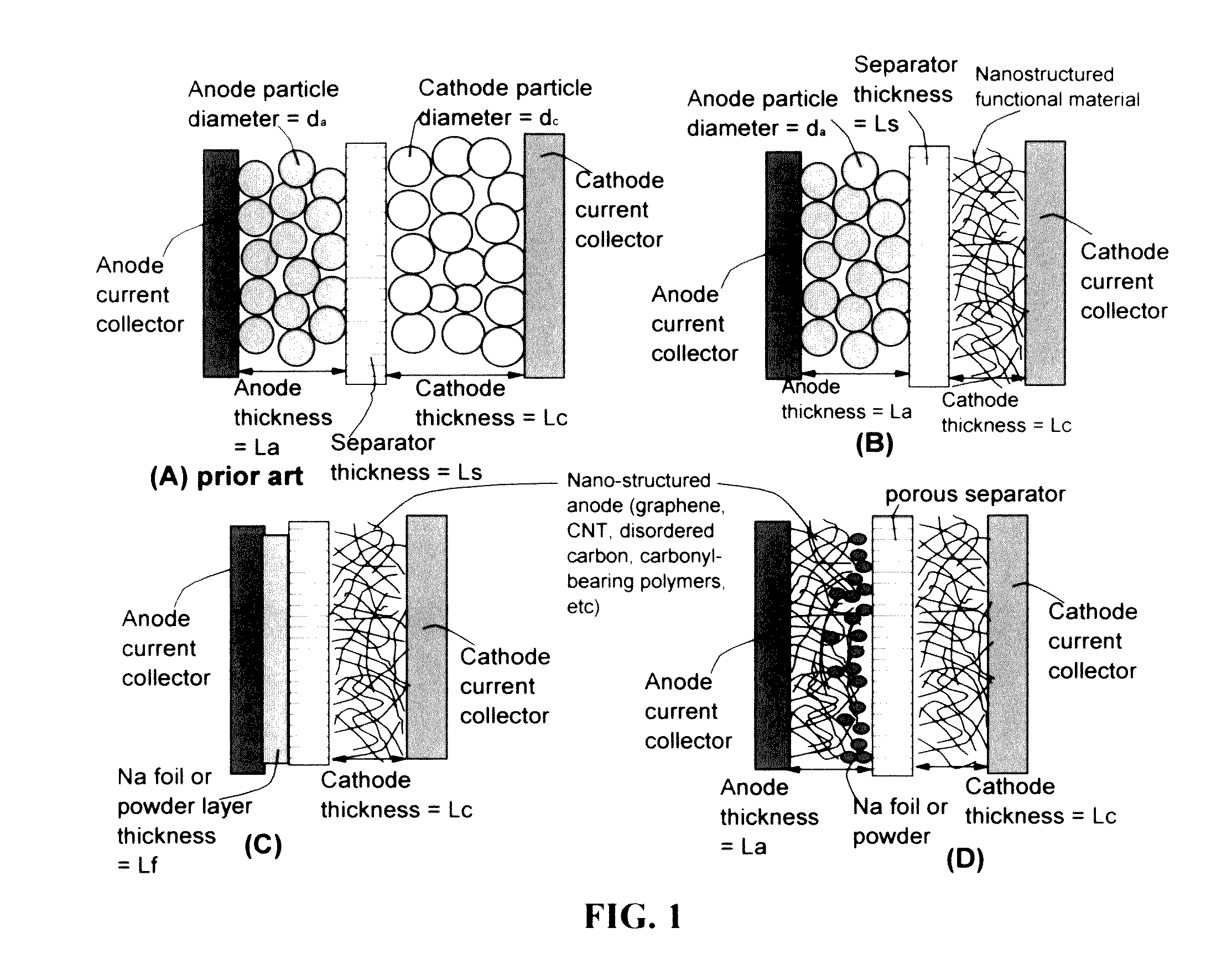

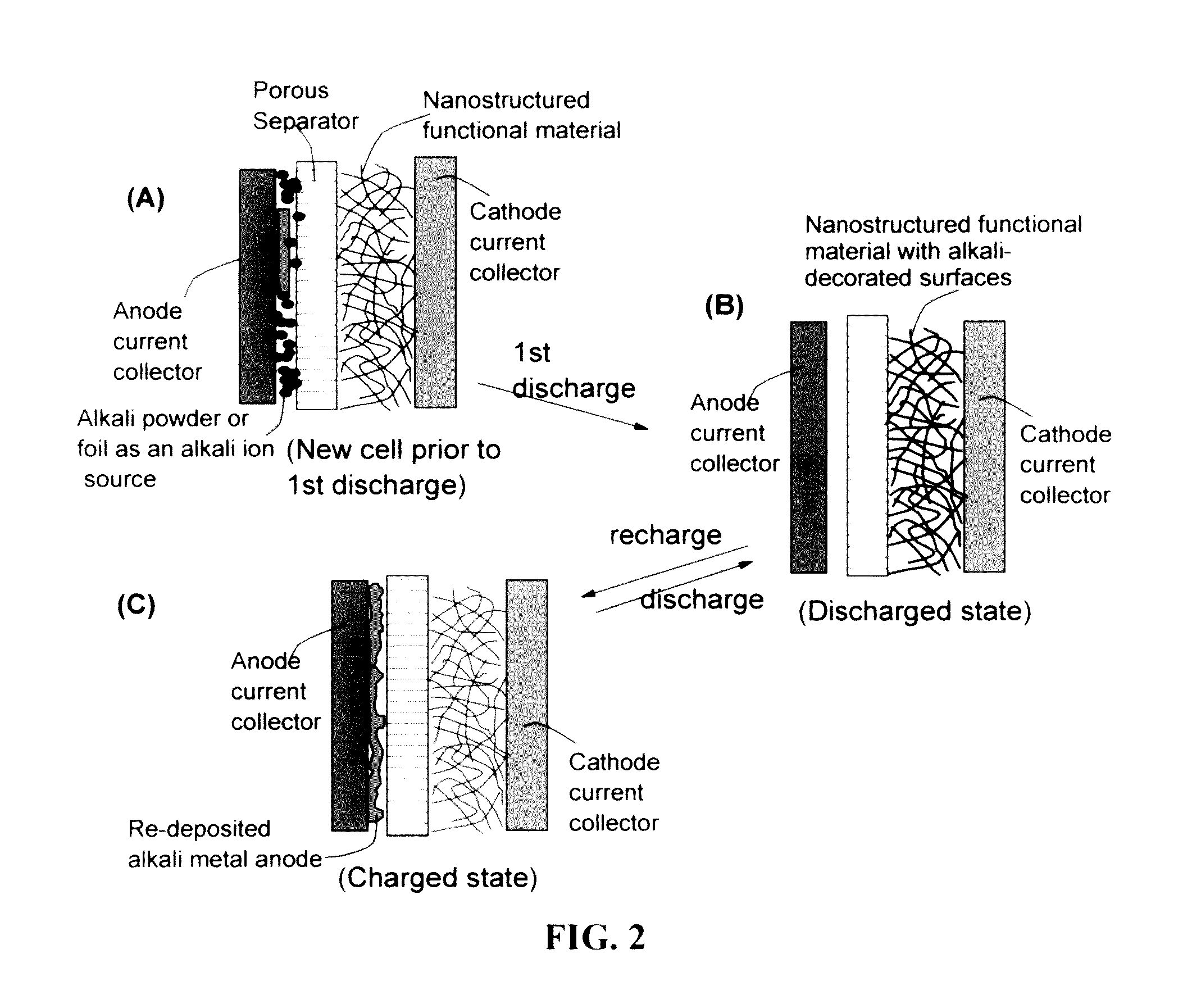

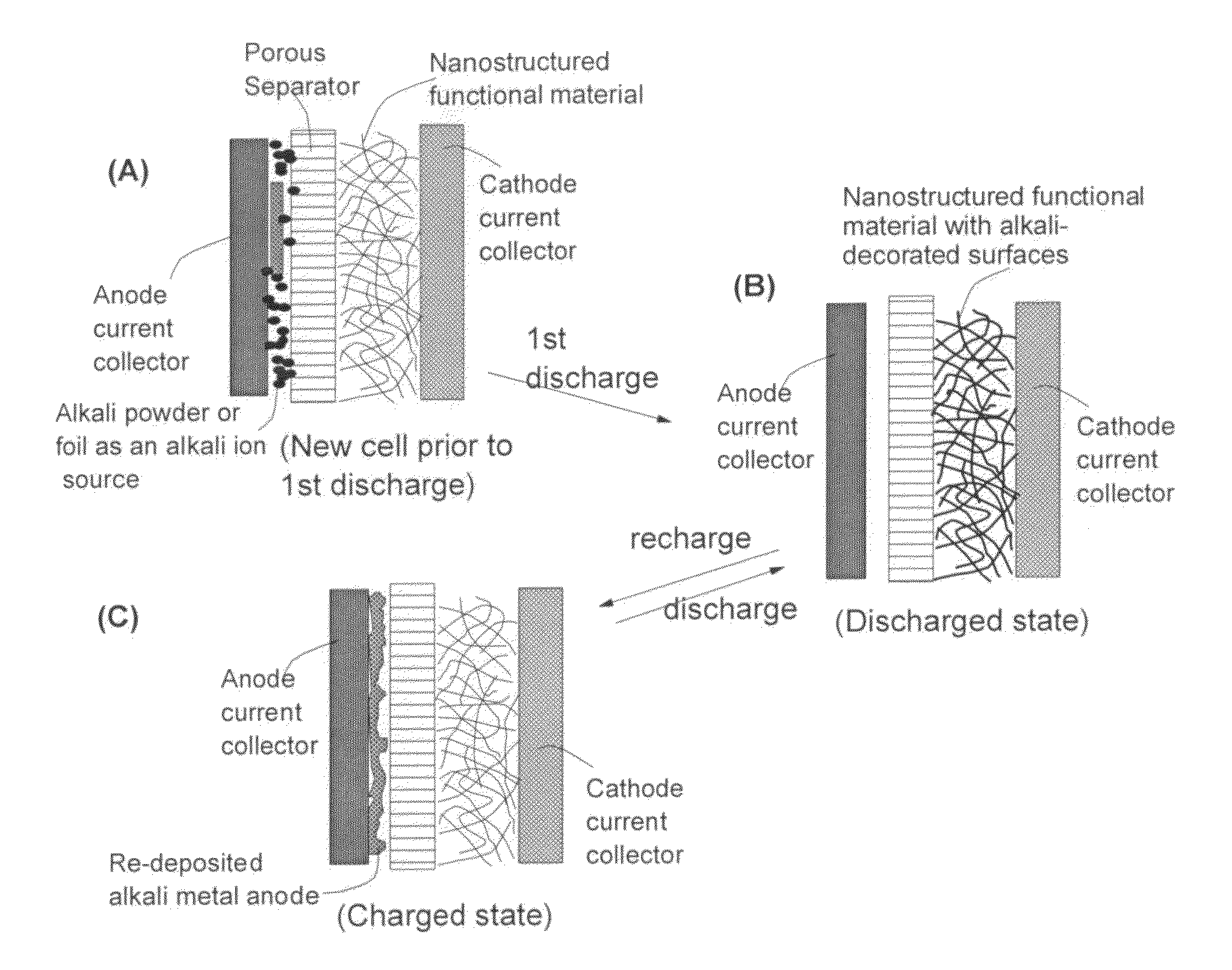

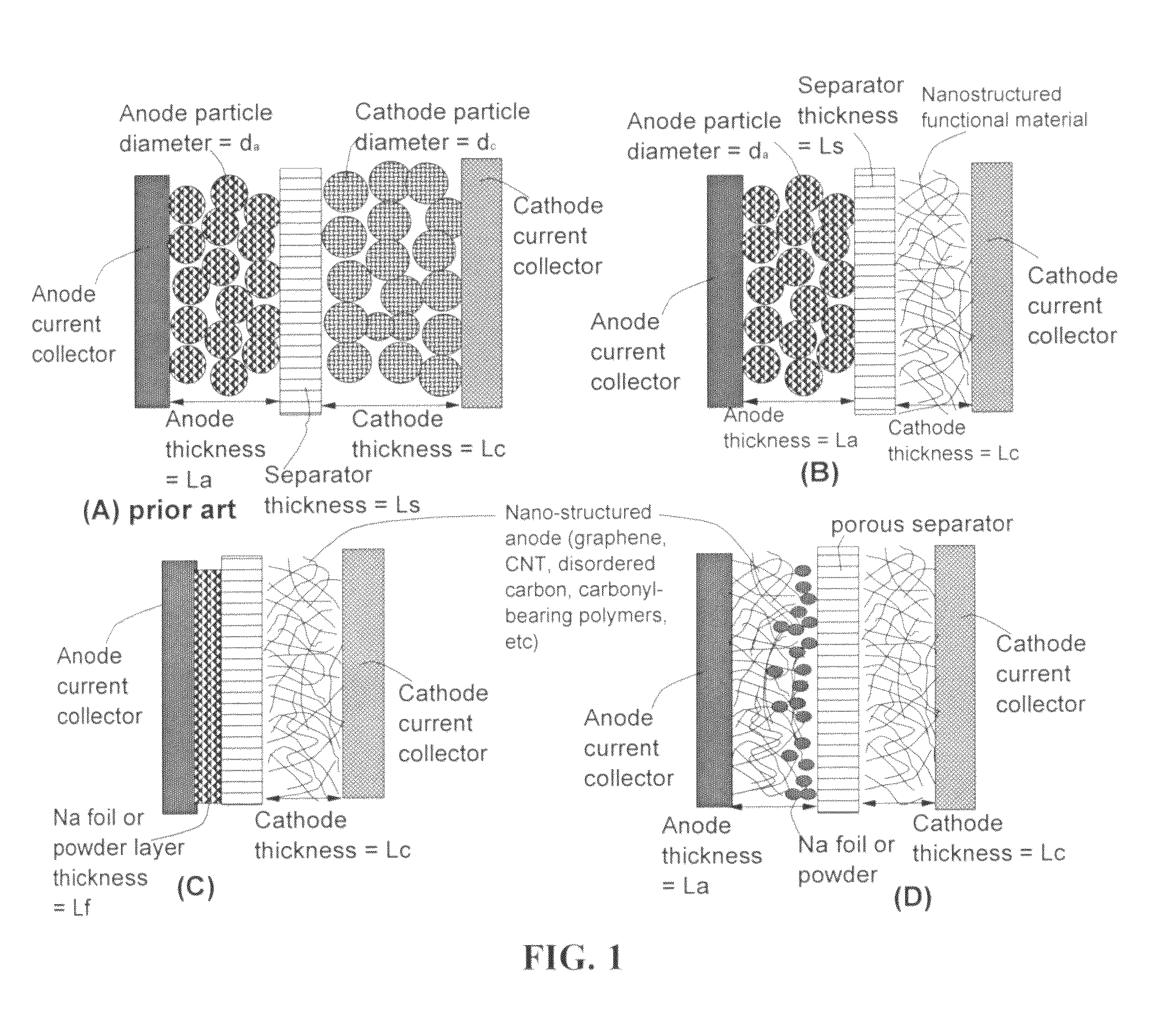

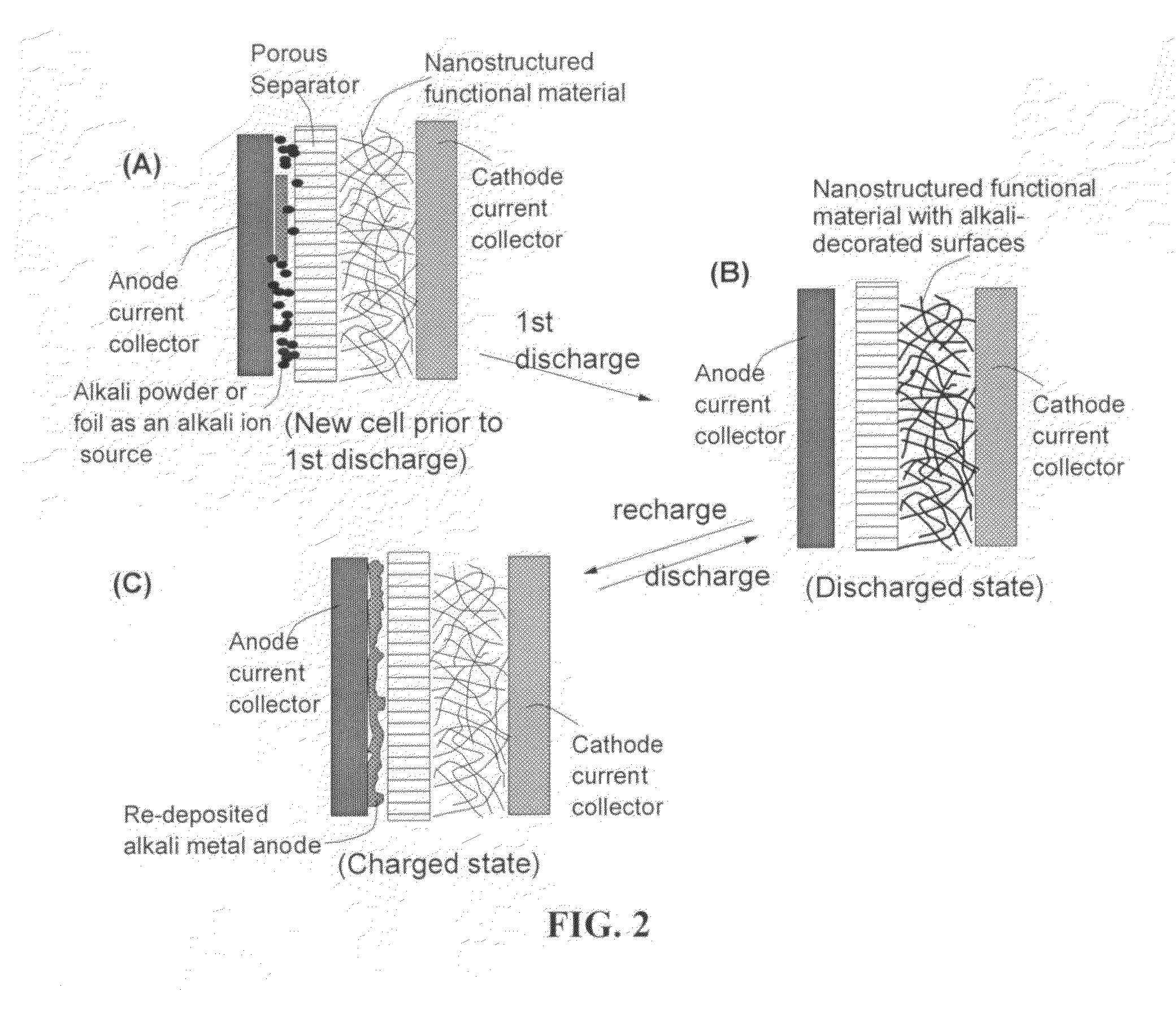

Partially and fully surface-enabled metal ion-exchanging energy storage devices

ActiveUS20120171574A1Eliminates potential formation of dendriteUniform depositionMaterial nanotechnologyHybrid capacitor electrolytesIon exchangeLithium electrode

A surface-enabled, metal ion-exchanging battery device comprising a cathode, an anode, a porous separator, and a metal ion-containing electrolyte, wherein the metal ion is selected from (A) non-Li alkali metals; (B) alkaline-earth metals; (C) transition metals; (D) other metals such as aluminum (Al); or (E) a combination thereof; and wherein at least one of the electrodes contains therein a metal ion source prior to the first charge or discharge cycle of the device and at least the cathode comprises a functional material or nano-structured material having a metal ion-capturing functional group or metal ion-storing surface in direct contact with said electrolyte, and wherein the operation of the battery device does not involve the introduction of oxygen from outside the device and does not involve the formation of a metal oxide, metal sulfide, metal selenide, metal telluride, metal hydroxide, or metal-halogen compound. This energy storage device has a power density significantly higher than that of a lithium-ion battery and an energy density dramatically higher than that of a supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC

Vessel sealing system using capacitive RF dielectric heating

ActiveUS7780662B2Heating evenlyReduce heat spreadSurgical instruments for heatingCoatingsElectricityVessel sealing

An electrosurgical system for sealing vessels using capacitive (RF) dielectric heating and a method thereof are provided. The system includes an electrosurgical instrument having an end effector with parallel plate electrodes that will clamp onto a vessel and maintain a specified gap distance; however, the electrodes will be coated with a non-conductive dielectric material. Such an end effector will ensure that direct conduction between the electrodes does not occur through tissue or fluids and effectively creates a parallel plate capacitor with a dielectric, e.g., tissue and coating, in between the plates. The electrosurgical instrument will be activated with an AC signal at a specified RF frequency, e.g., a Debye resonance frequency, via an electrosurgical generator. An effective AC current will flow through the tissue and cause heating due to fictional losses from rotating polar molecules in the tissue.

Owner:COVIDIEN AG

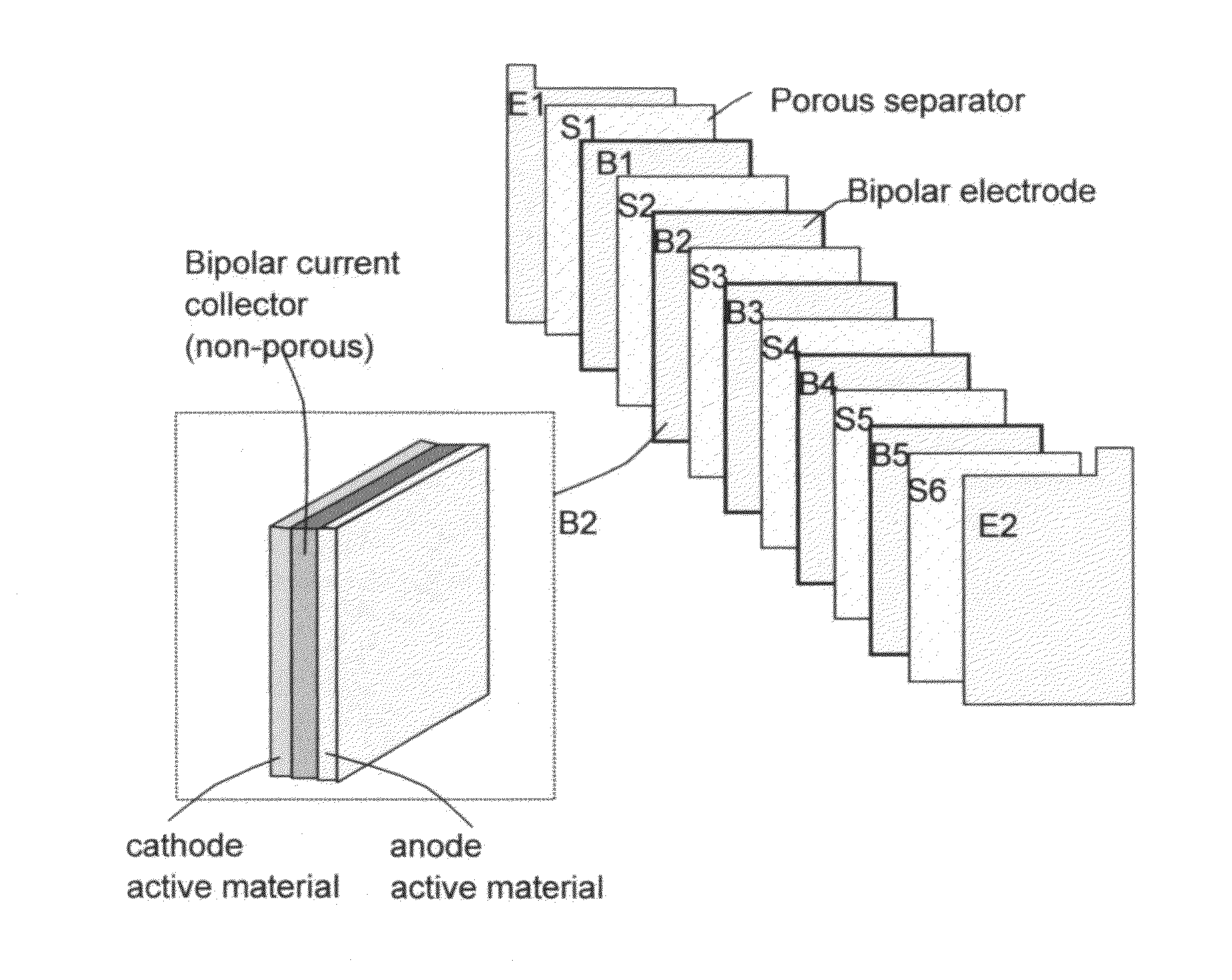

Stacks of internally connected surface-mediated cells and methods of operating same

ActiveUS20130162216A1Improve power densityEasy dischargePrimary cell to battery groupingBatteries circuit arrangementsSupercapacitorEngineering

An energy storage stack of at least two surface-mediated cells (SMCs) internally connected in parallel or in series. The stack includes: (A) At least two SMC cells, each consisting of (i) a cathode comprising a porous cathode current collector and a cathode active material; (ii) a porous anode current collector; and (iii) a porous separator disposed between the cathode and the anode; (B) A lithium-containing electrolyte in physical contact with all the electrodes, wherein the cathode active material has a specific surface area no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; and (C) A lithium source. This new-generation energy storage device exhibits the highest power densities of all energy storage devices, much higher than those of all the lithium ion batteries, lithium ion capacitors, and supercapacitors.

Owner:GLOBAL GRAPHENE GRP INC +1

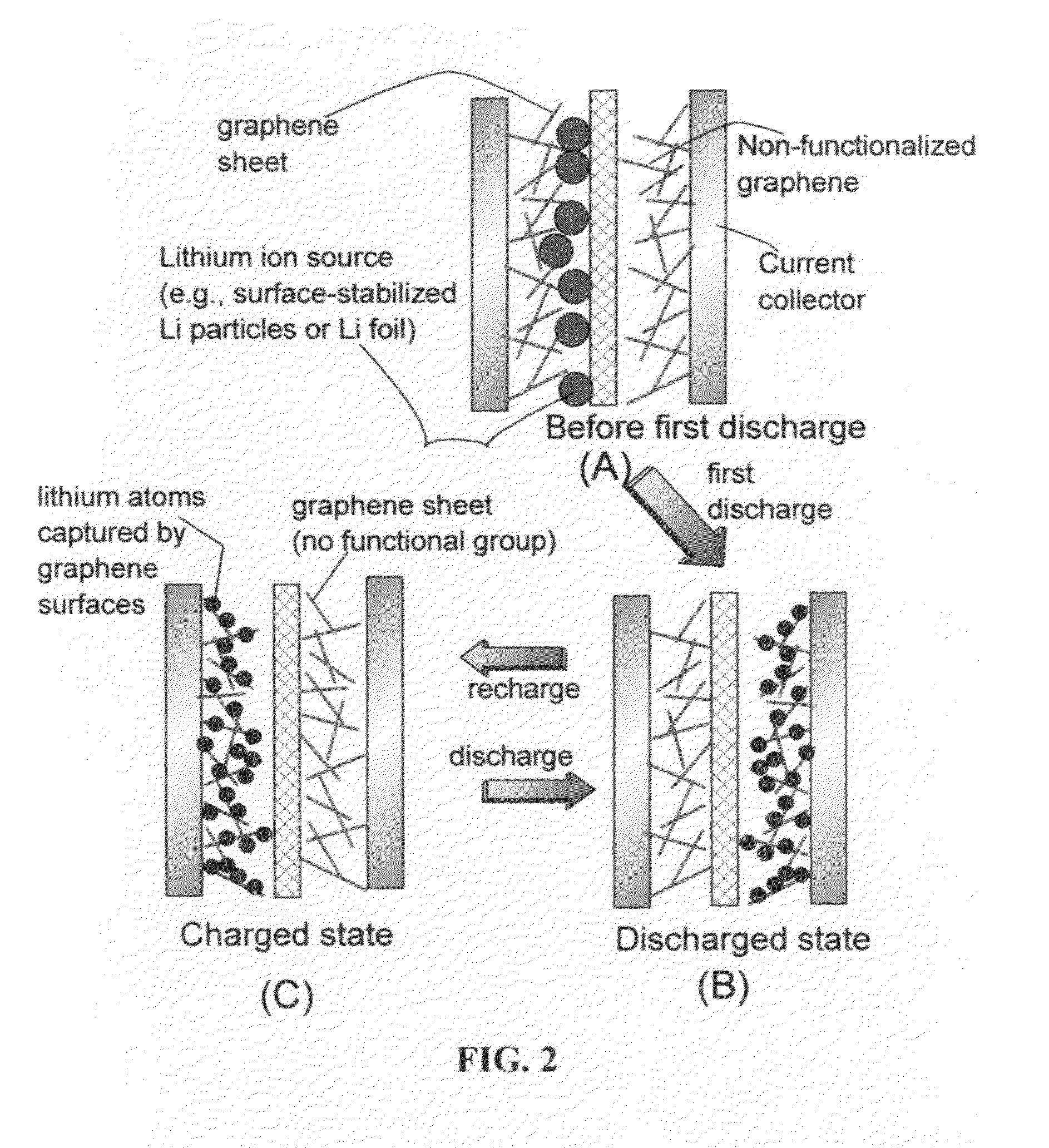

Surface -controlled lithium ion-exchanging energy storage device

ActiveUS20120164539A1Easy to handleShort charging timeAlkaline accumulatorsHybrid capacitor electrolytesElectrical batterySupercapacitor

A surface-controlled, lithium ion-exchanging battery device comprising: (a) A positive electrode (cathode) comprising a first functional material having a first lithium-capturing or lithium-storing surface; (b) A negative electrode (anode) comprising a second functional material having a second lithium-capturing or lithium-storing surface; (c) A porous separator disposed between the two electrodes, and (d) A lithium-containing electrolyte (preferably liquid or gel electrolyte) in physical contact with the two electrodes; wherein at least one of the two electrodes contains therein a lithium source (e.g., lithium foil, lithium powder, stabilized lithium particles, etc) prior to the first charge or the first discharge cycle of the battery device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

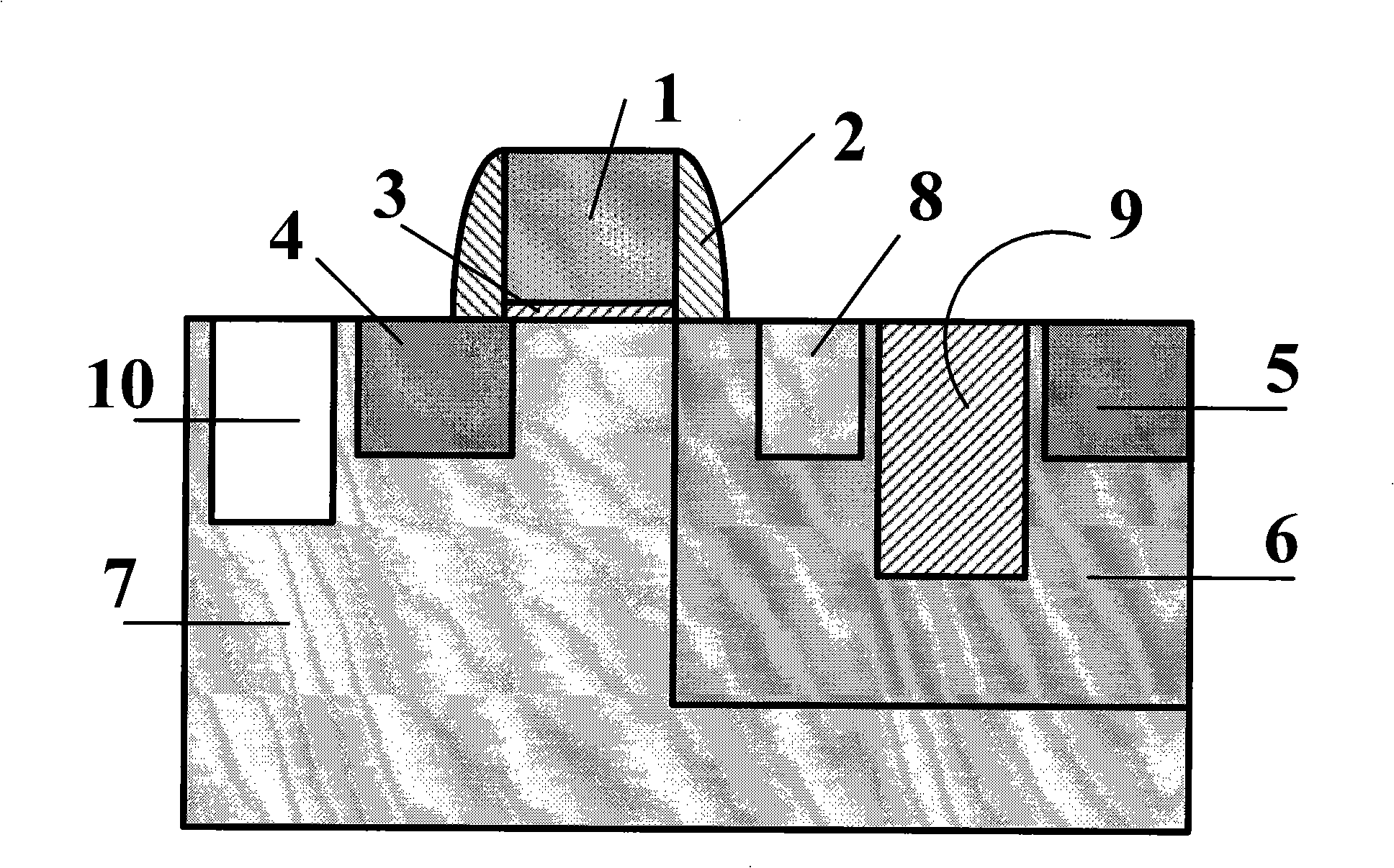

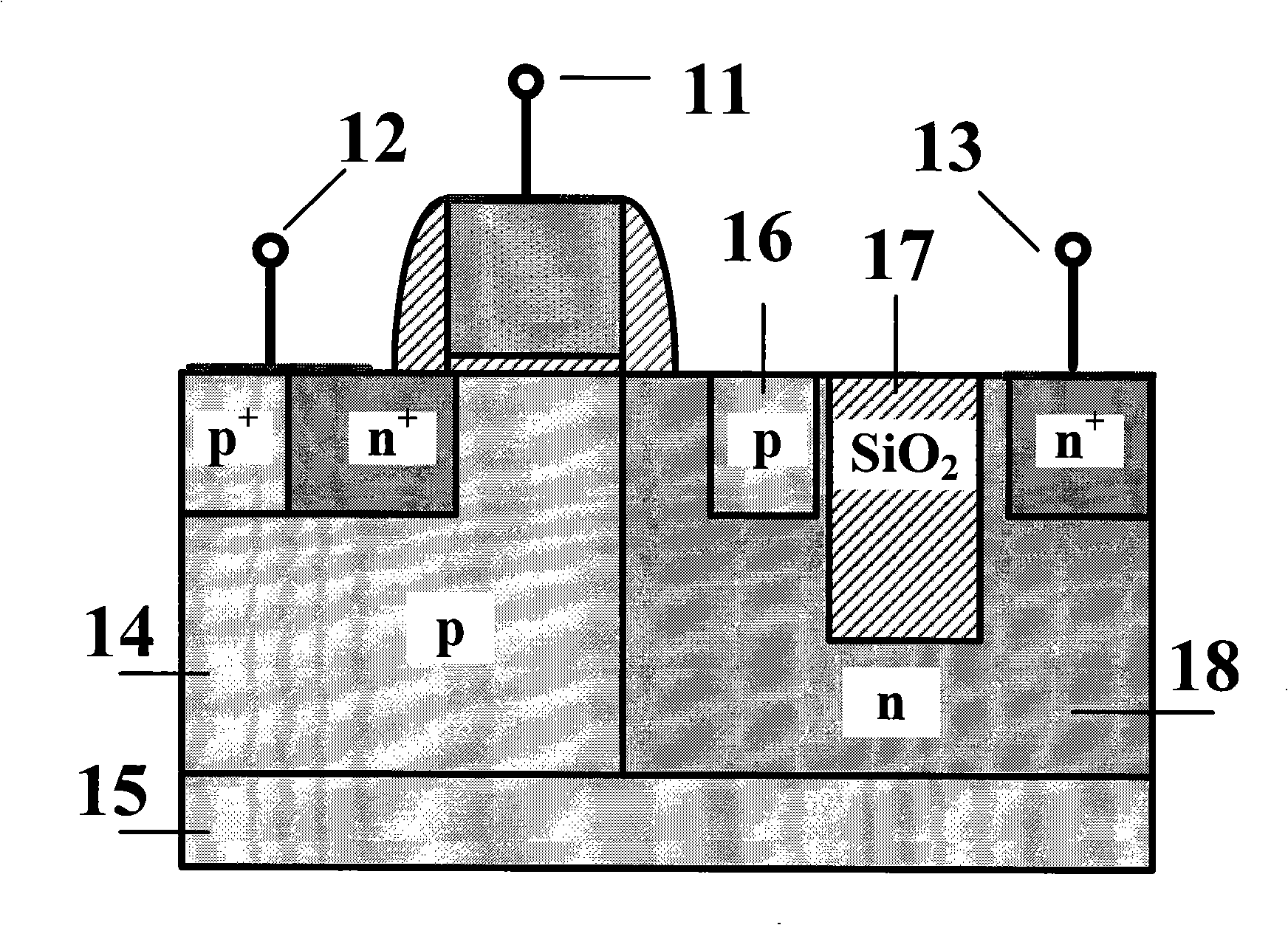

High pressure resistant lateral direction bilateral diffusion MOS transistor

InactiveCN101257047AImprove breakdown voltageIncrease the doping concentrationSemiconductor devicesEngineeringHigh pressure

The present invention discloses a transversal bilateral diffusion MOS transistor with high pressure resistant, which belongs to micro-electronics semi-conductor device field. The device includes a gate region, a source area, a drain region, a tagma, a gate medium and a drift region, the setting drift region is placed between the tagma and the drain region, and the doping type is opposite to the tagma, an insulating medium region and a doping region which is opposite to the doping type of the drift region are equipped in the drift region, and the doping concentration of the doping region is higher than that of the drift region, the doping region is adjacent to the tagma, however the insulating medium region is adjacent to the drain region. Because the insulating medium region and the doping region are inducted into the drift region at the same time, the effective depth of the drift region is reduced effectively to make the electric field more uniform and increase the equivalent length of the drift region, the resistant high Voltage characteristic of the transversal bilateral diffusion MOS transistor device of the present invention is good.

Owner:PEKING UNIV

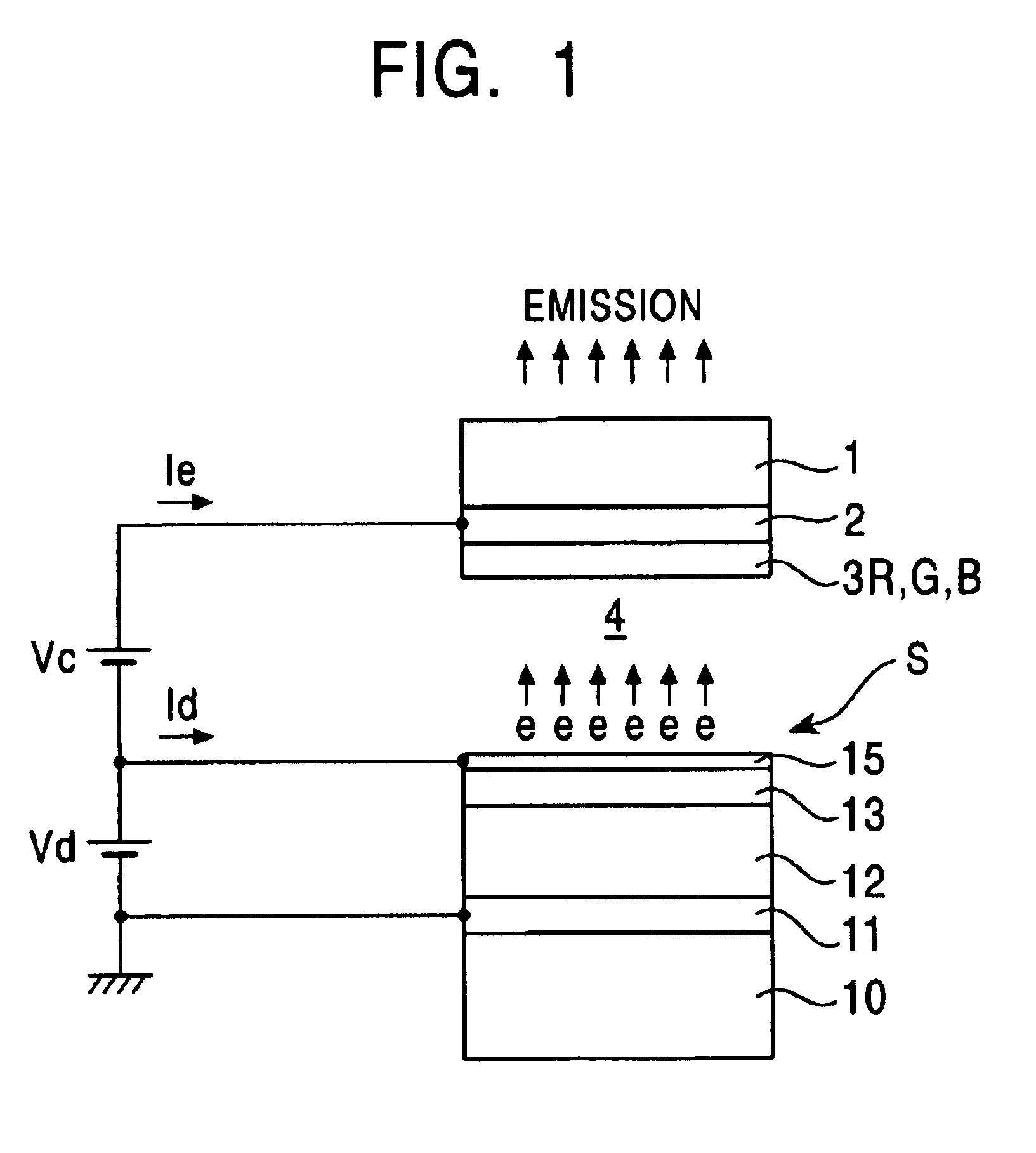

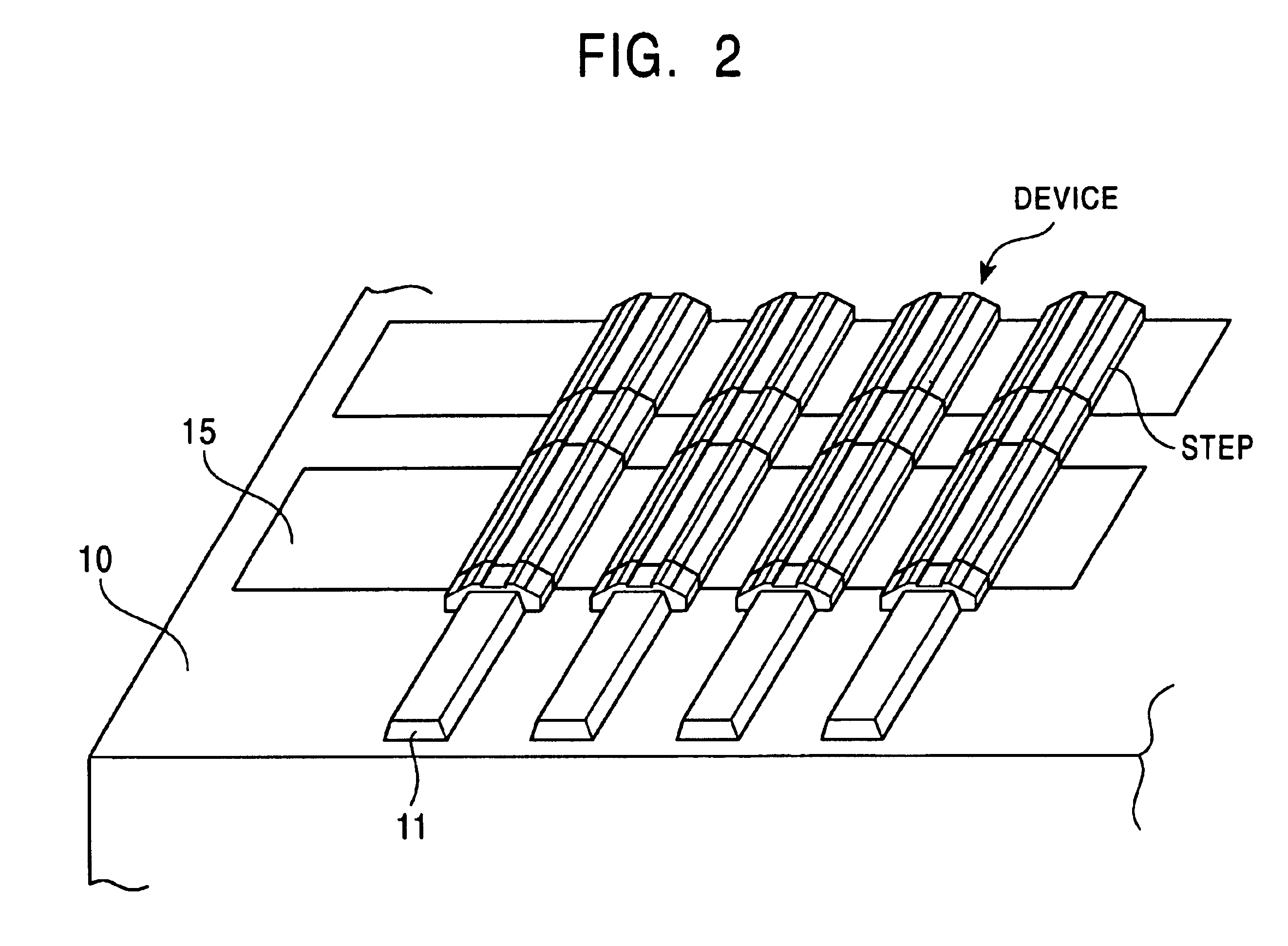

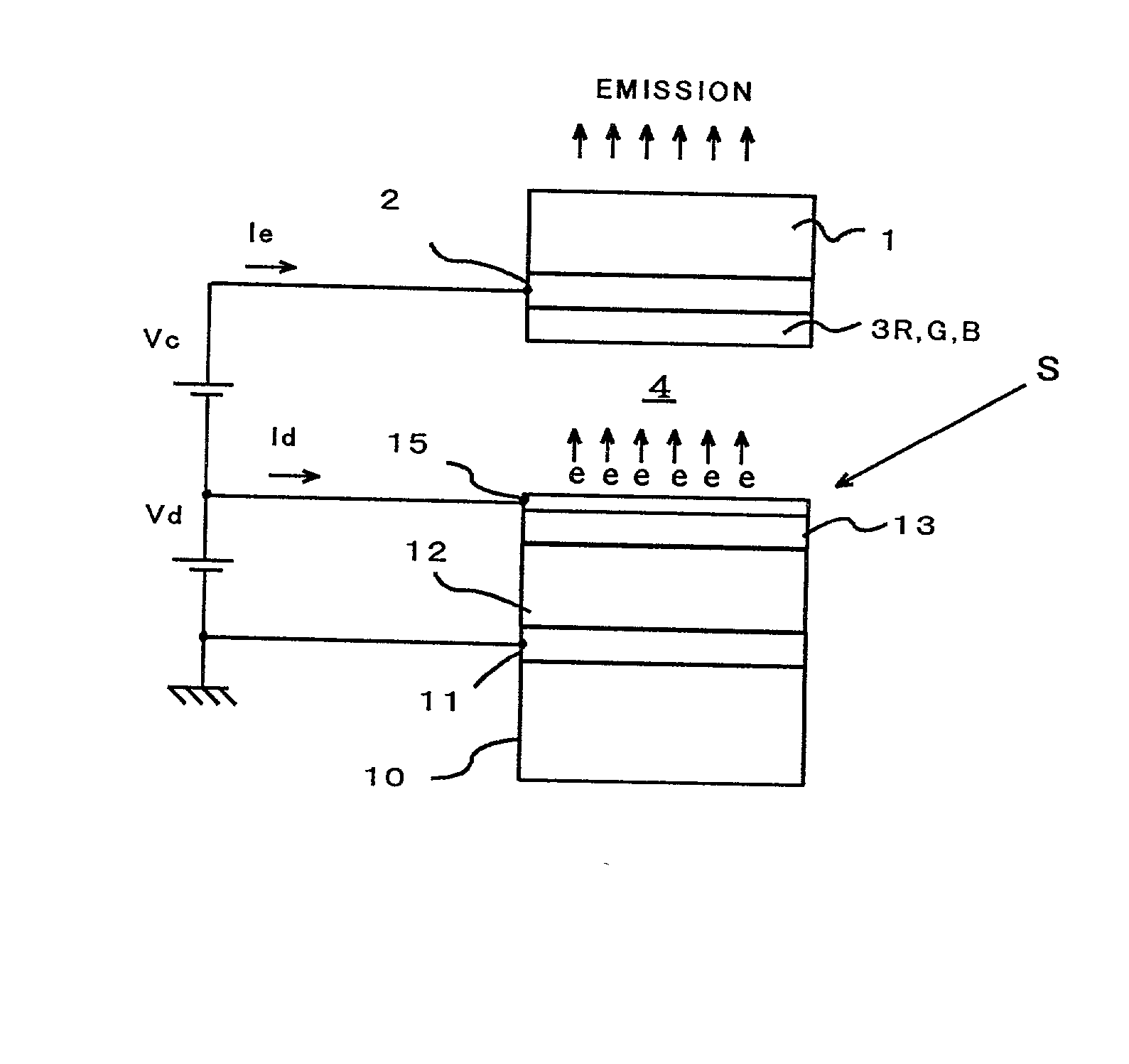

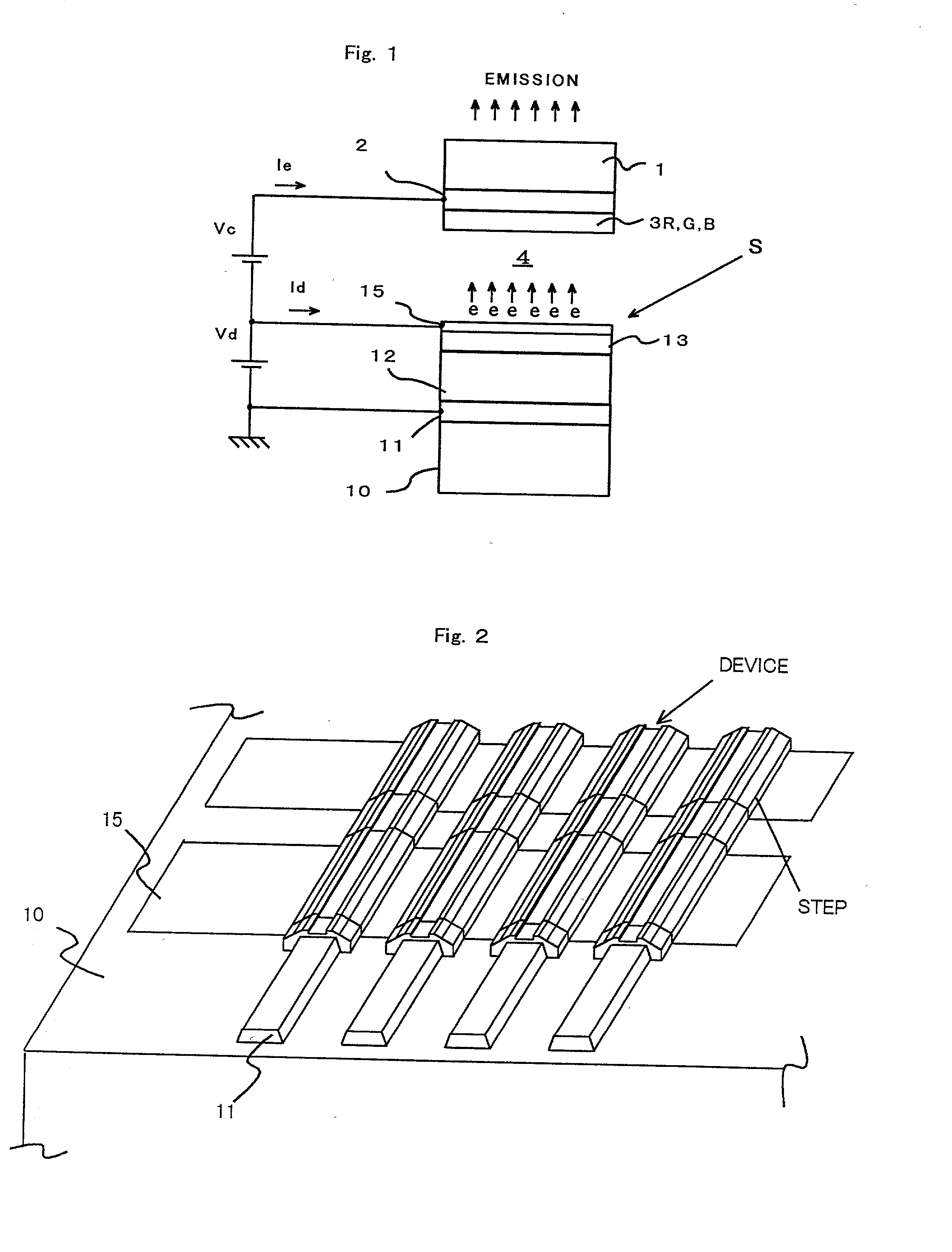

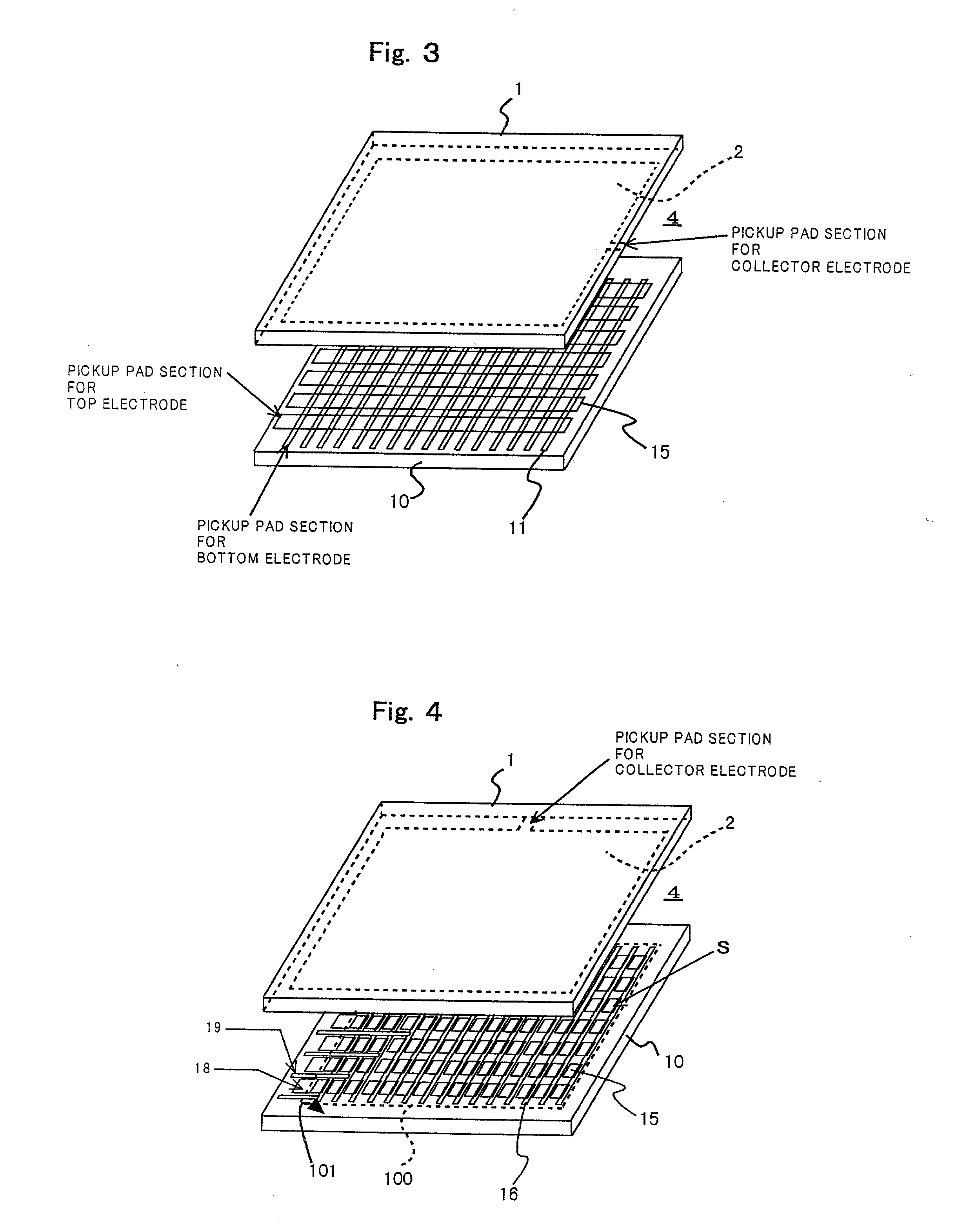

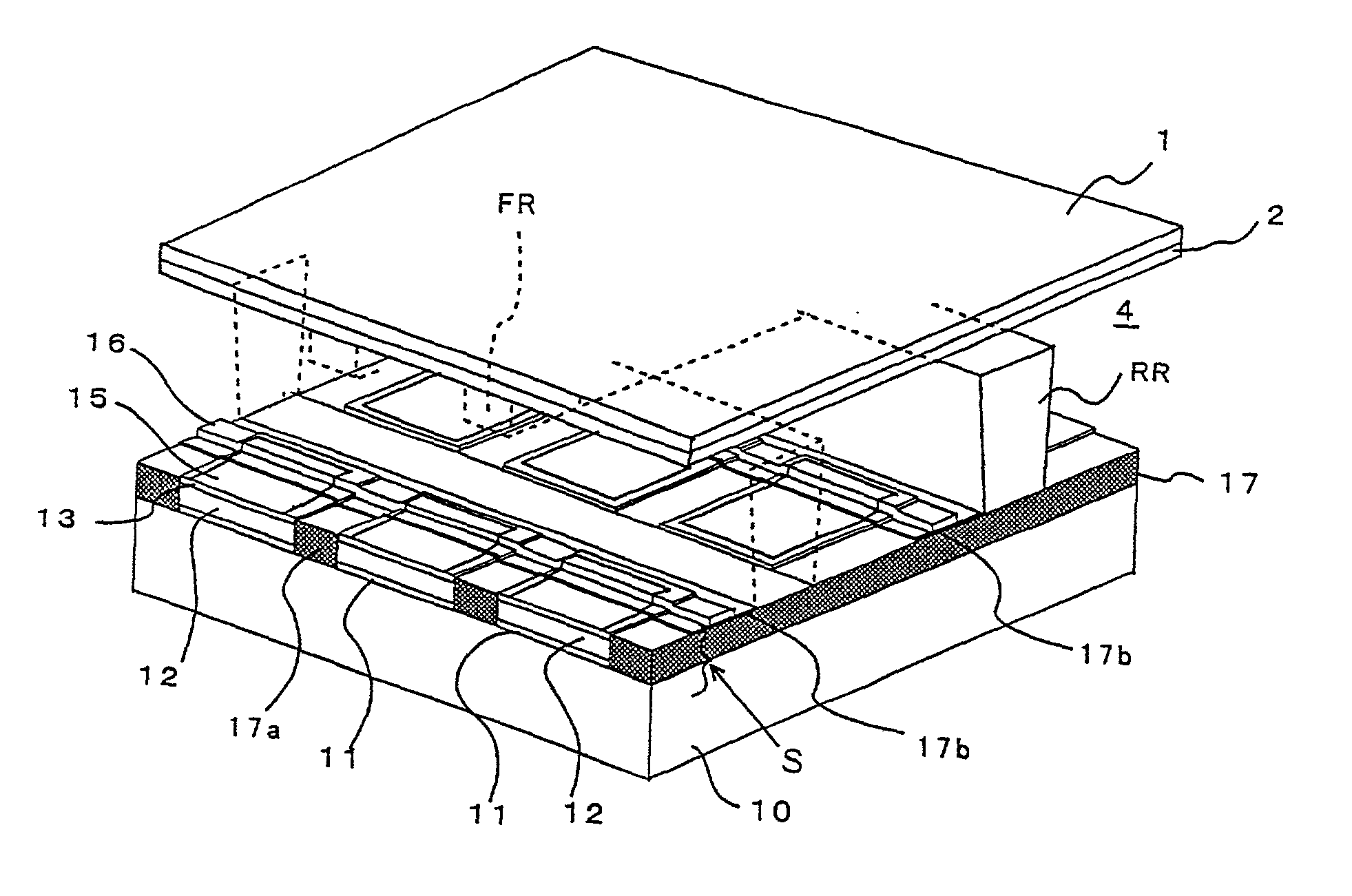

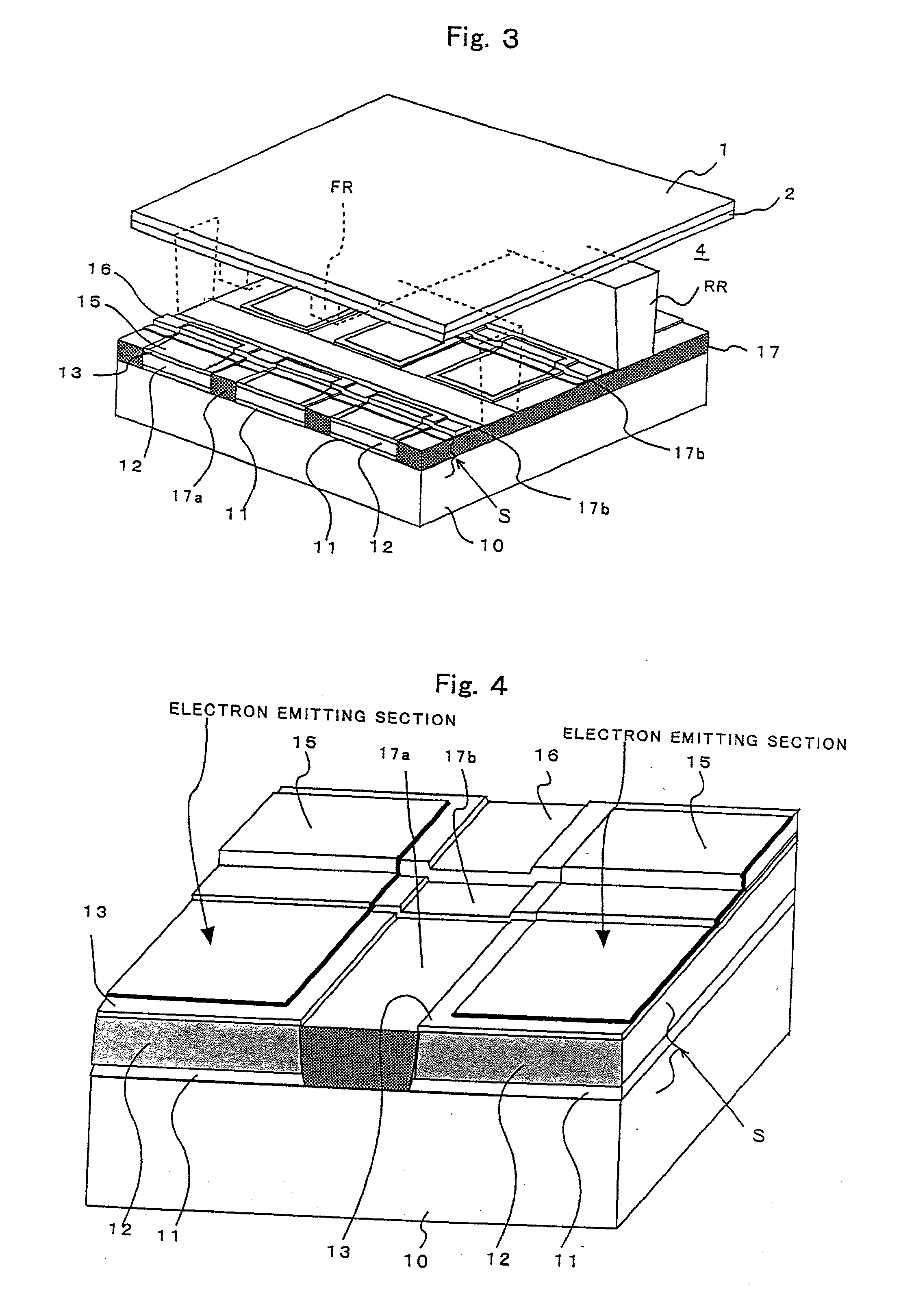

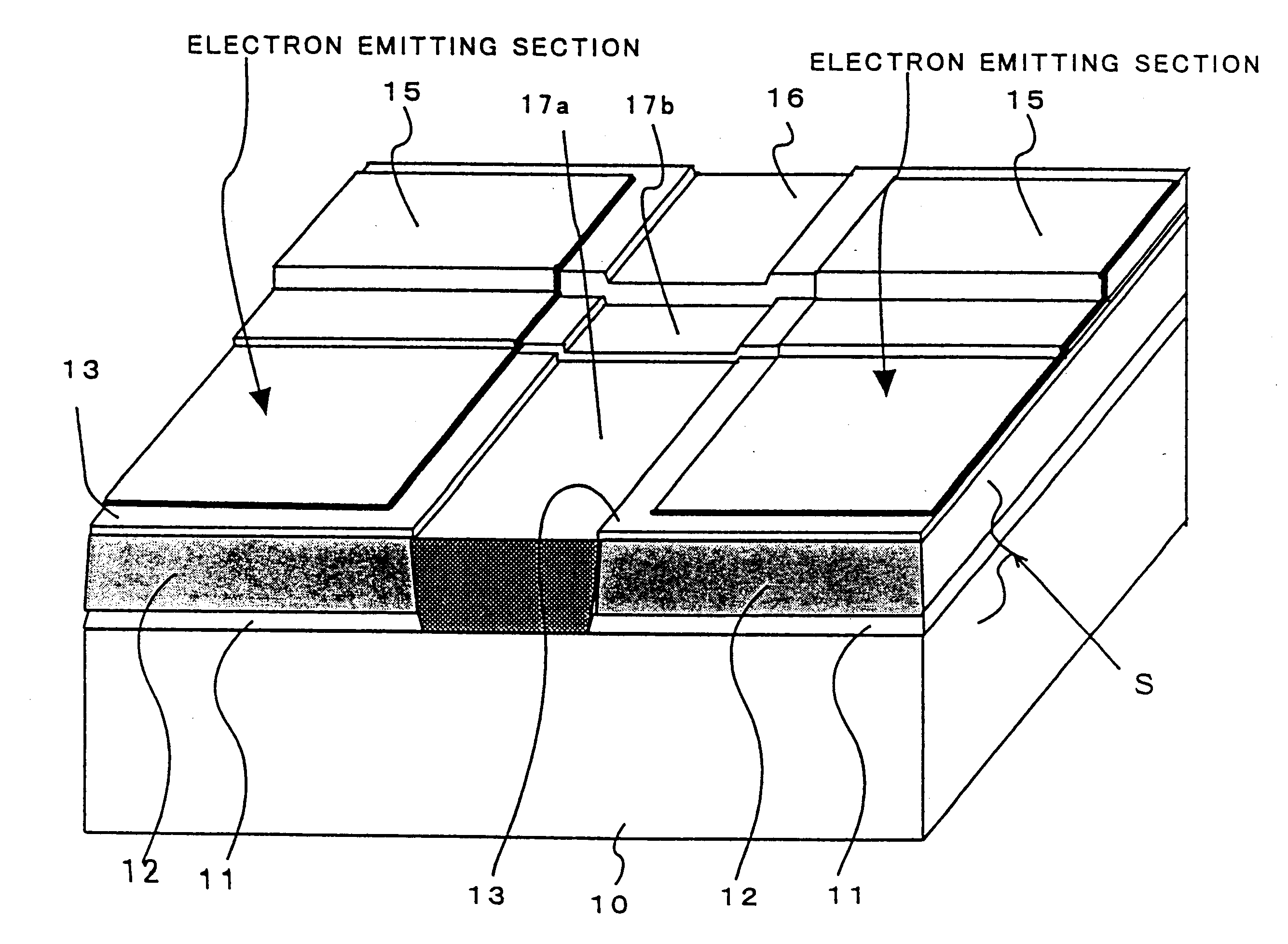

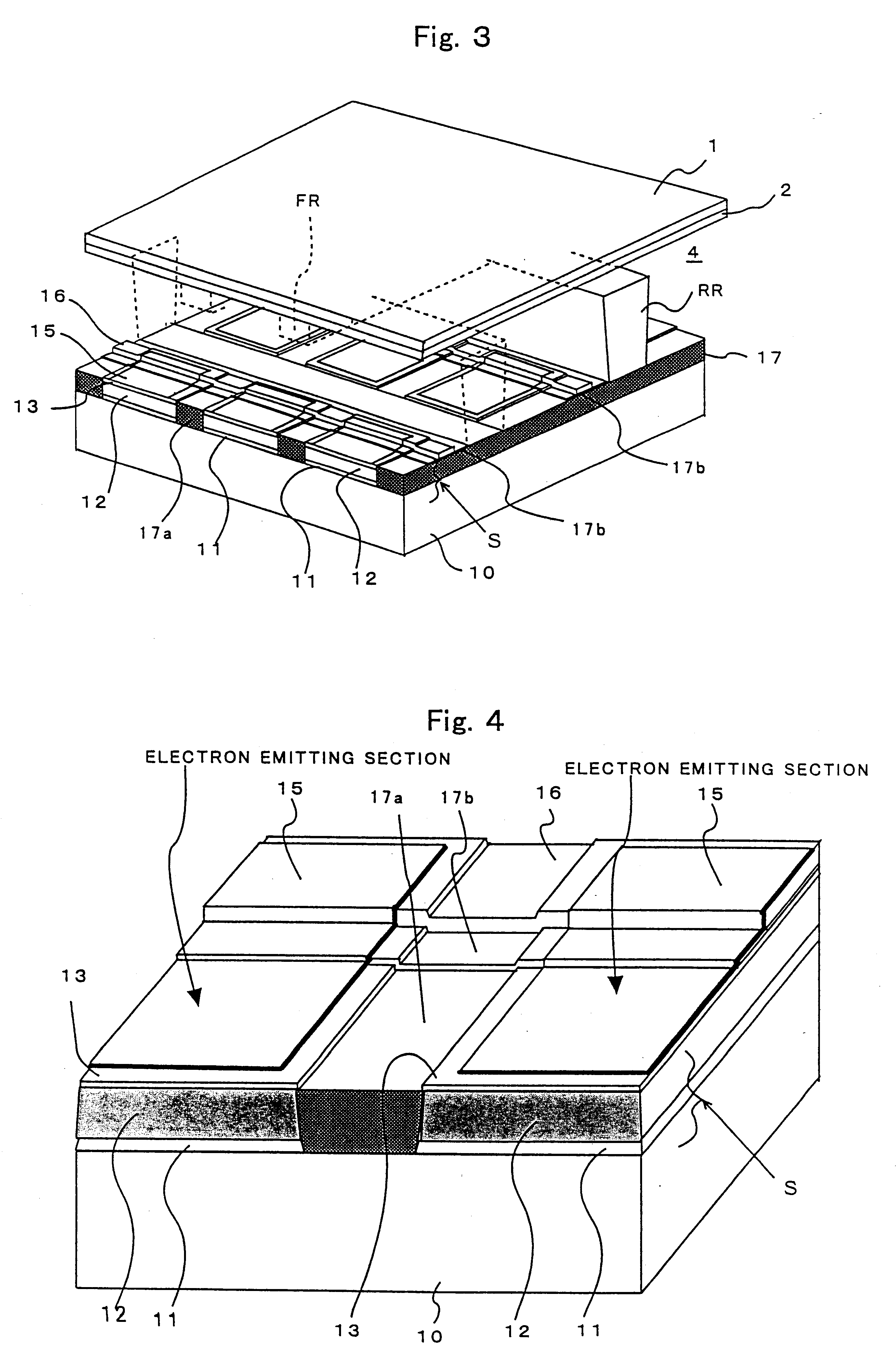

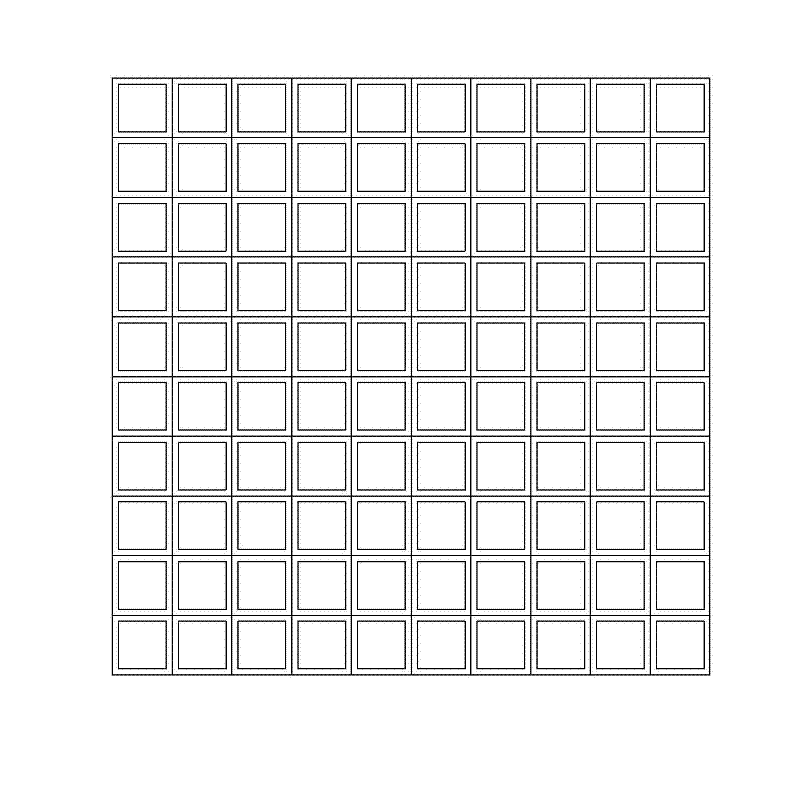

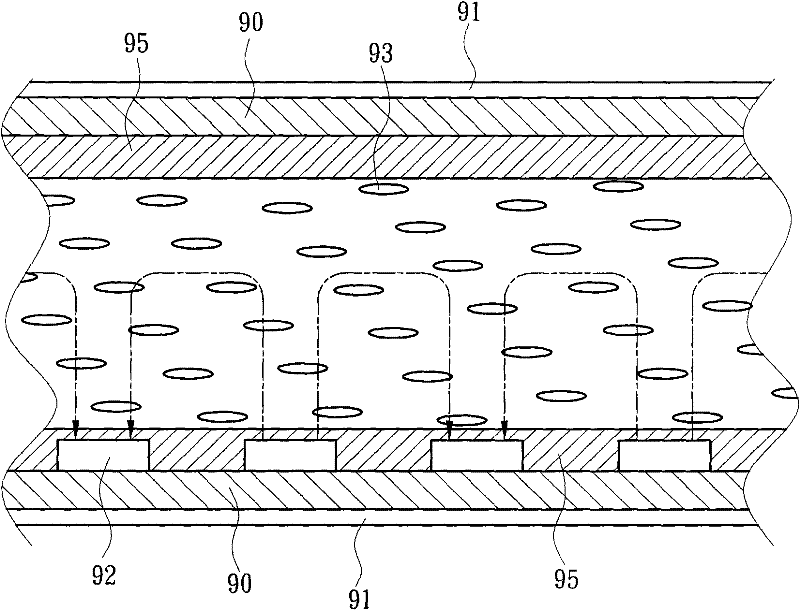

Display device of flat panel structure with emission devices of matrix array

InactiveUS6787992B2Avoid shortingUniform electric fieldCathode-ray/electron-beam tube electrical connectionNanoinformaticsDisplay deviceOptoelectronics

A display device has an emitting region constituted by a plurality of first electrodes provided on a substrate and extending in parallel, a plurality of second electrodes provided on the first electrodes and extending substantially perpendicularly to the first electrodes, and a plurality of emission sites for emitting electrons or light respectively connected to a plurality of intersections between the first and second electrodes and arranged on the substrate and has a peripheral region surrounding the emitting region on the substrate. In this display device, first and second groups of external repeating terminals for the first and second electrodes are collectively provided side by side in a part of the peripheral region.

Owner:PIONEER CORP

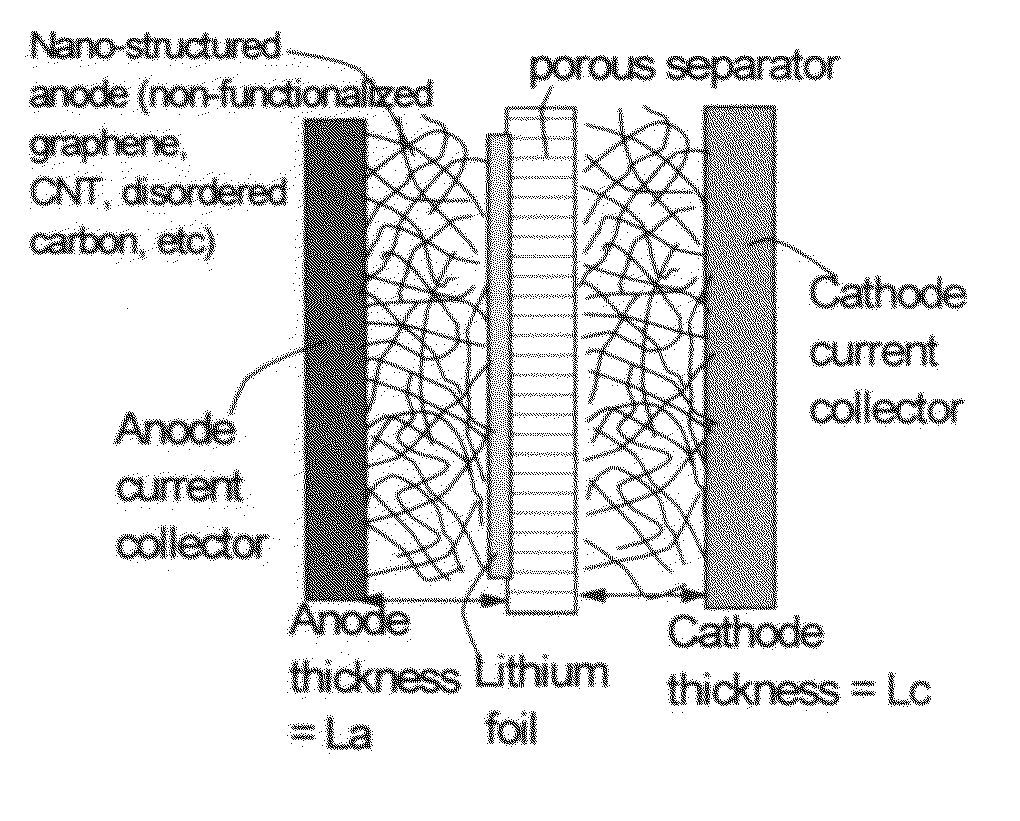

Surface-mediated lithium ion-exchanging energy storage device

ActiveUS20130052489A1High dischargeEliminates potential formation of dendriteMaterial nanotechnologyHybrid capacitor electrolytesElectrical batteryIon exchange

A surface-mediated, lithium ion-exchanging energy storage device comprising: (a) A positive electrode (cathode) comprising a cathode active material that is not a functional material (bearing no functional group reactive with lithium), but having a surface area to capture or store lithium thereon; (b) A negative electrode (anode) comprising an anode active material having a surface area to capture or store lithium thereon; (c) A porous separator disposed between the two electrodes; and (d) A lithium-containing electrolyte in physical contact with the two electrodes, wherein the anode active material and / or the cathode active material has a specific surface area of no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; wherein at least one of the two electrodes contains therein a lithium source prior to a first charge or a first discharge cycle of the energy storage device. This new generation of energy storage device exhibits the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

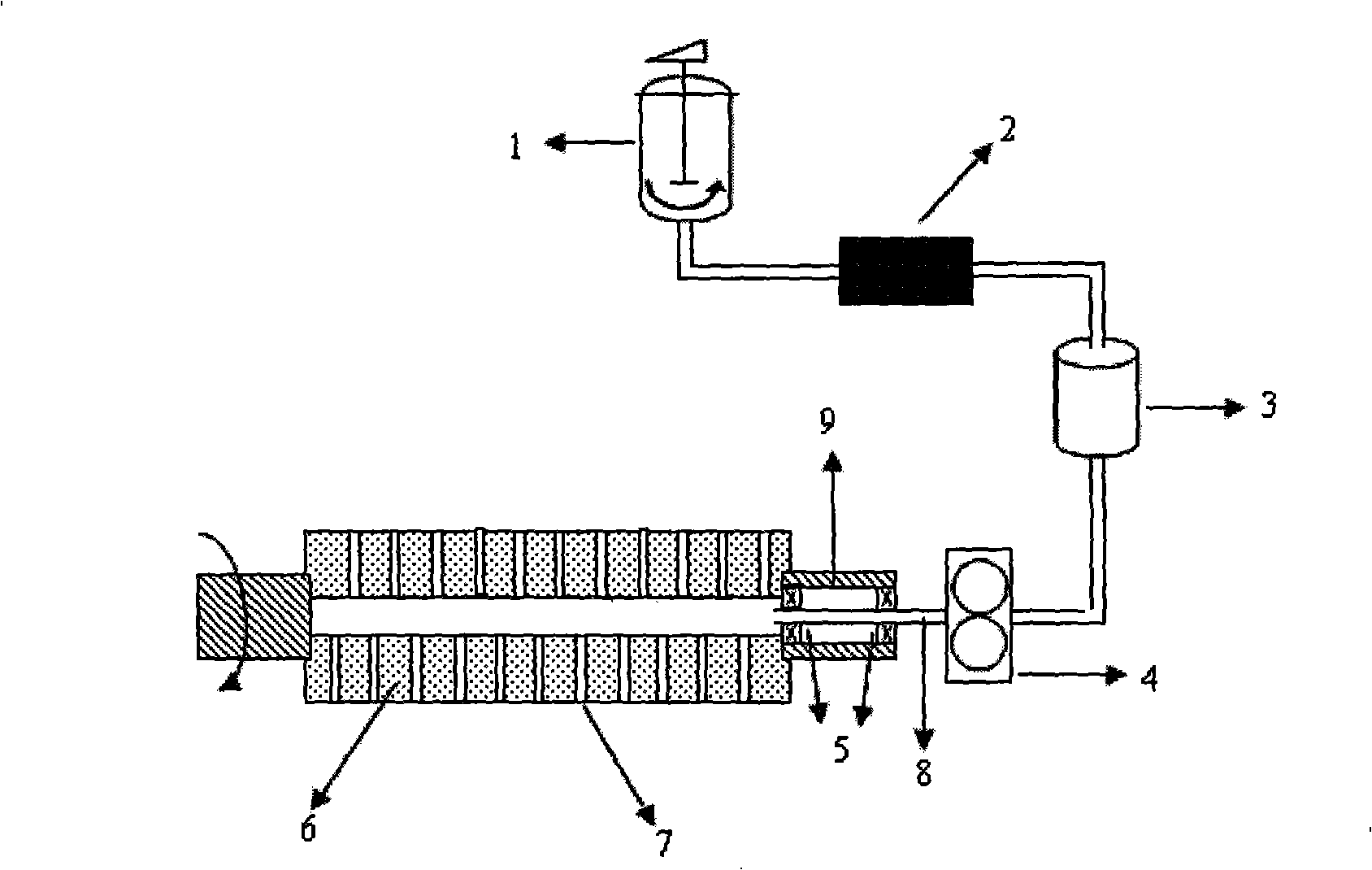

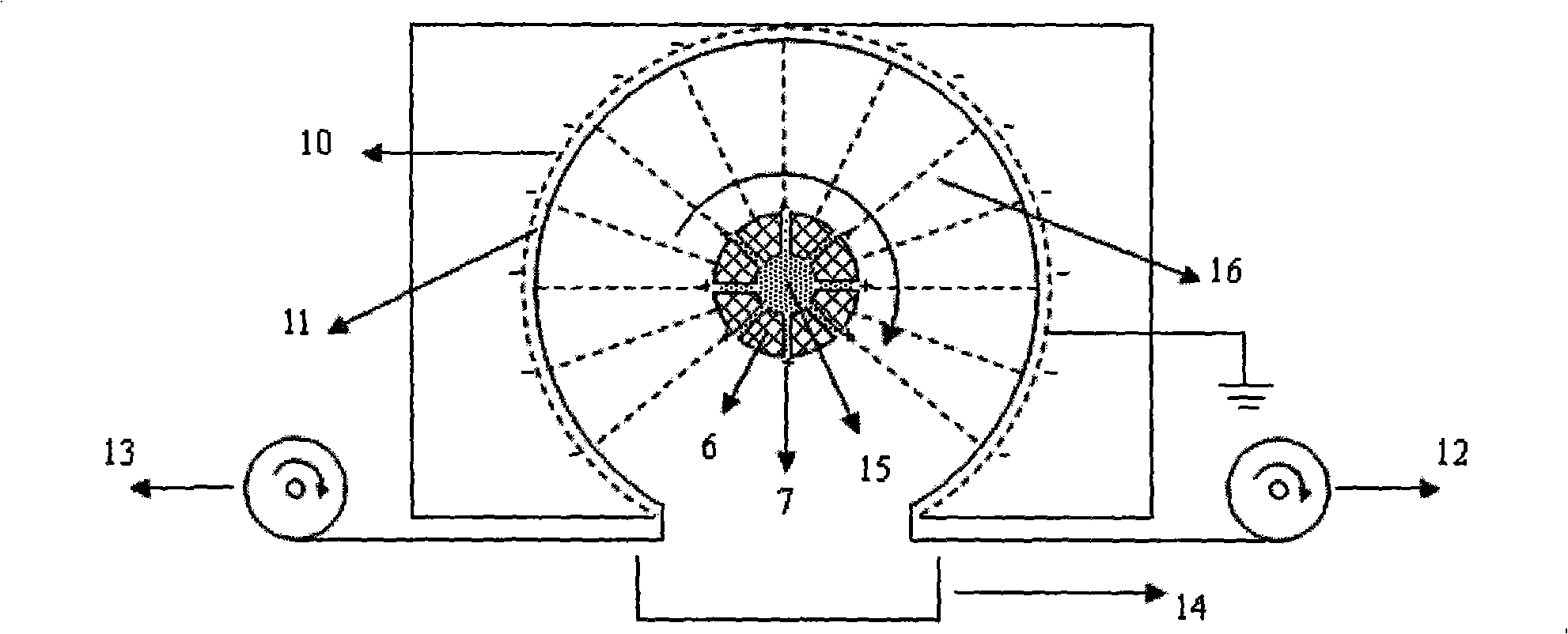

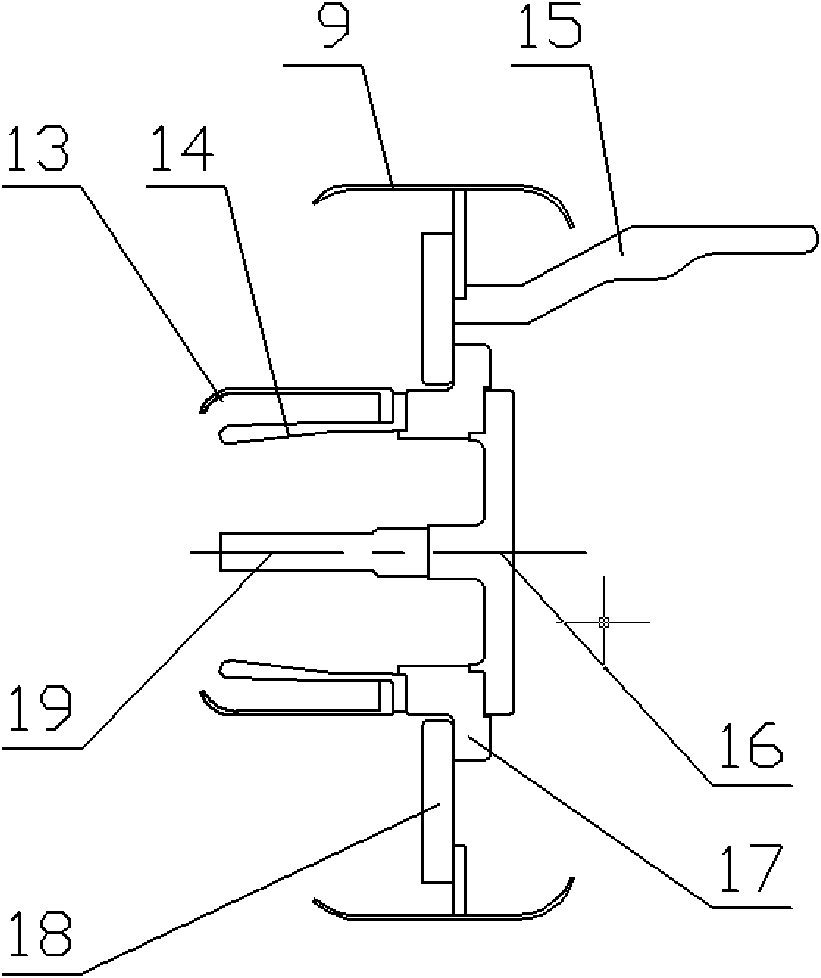

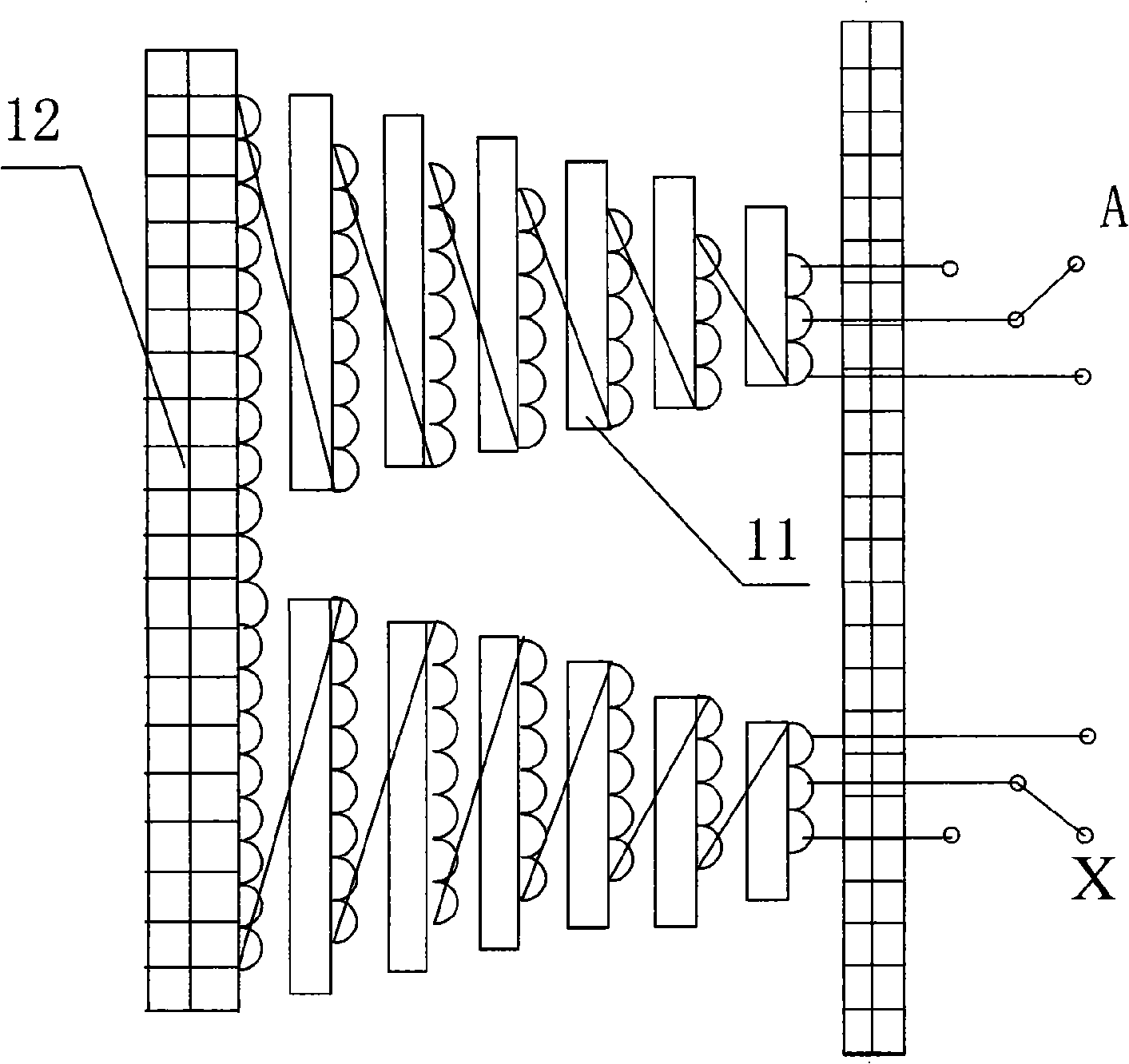

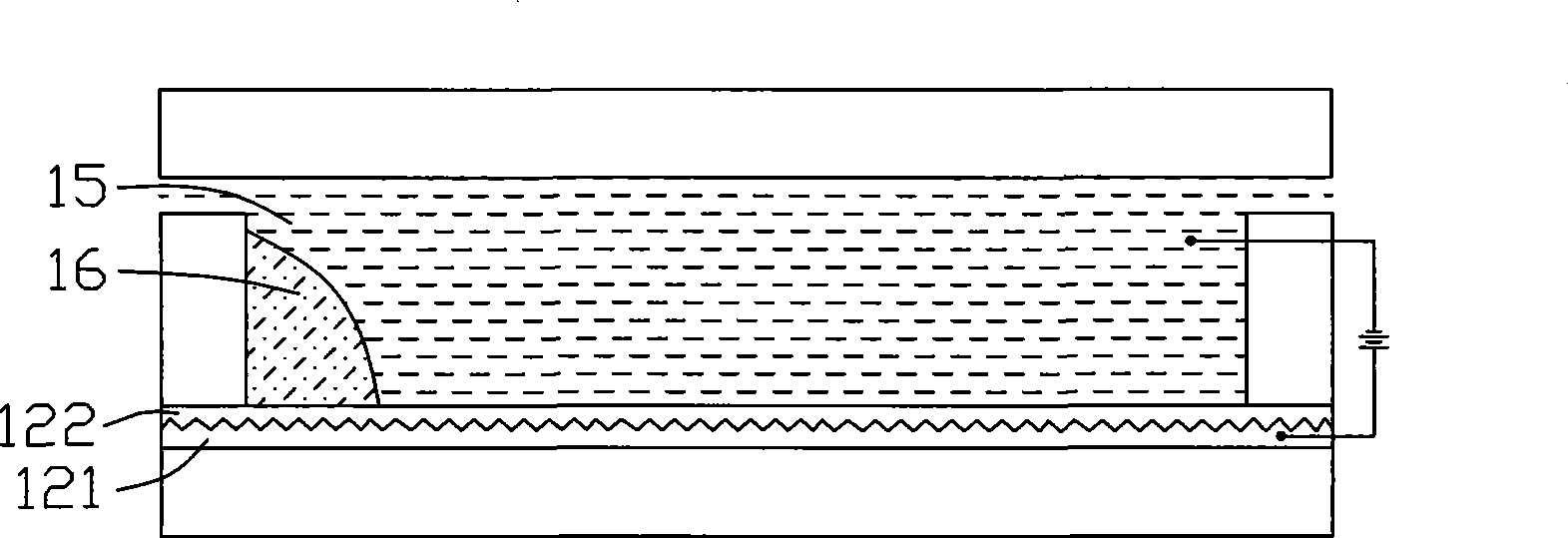

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

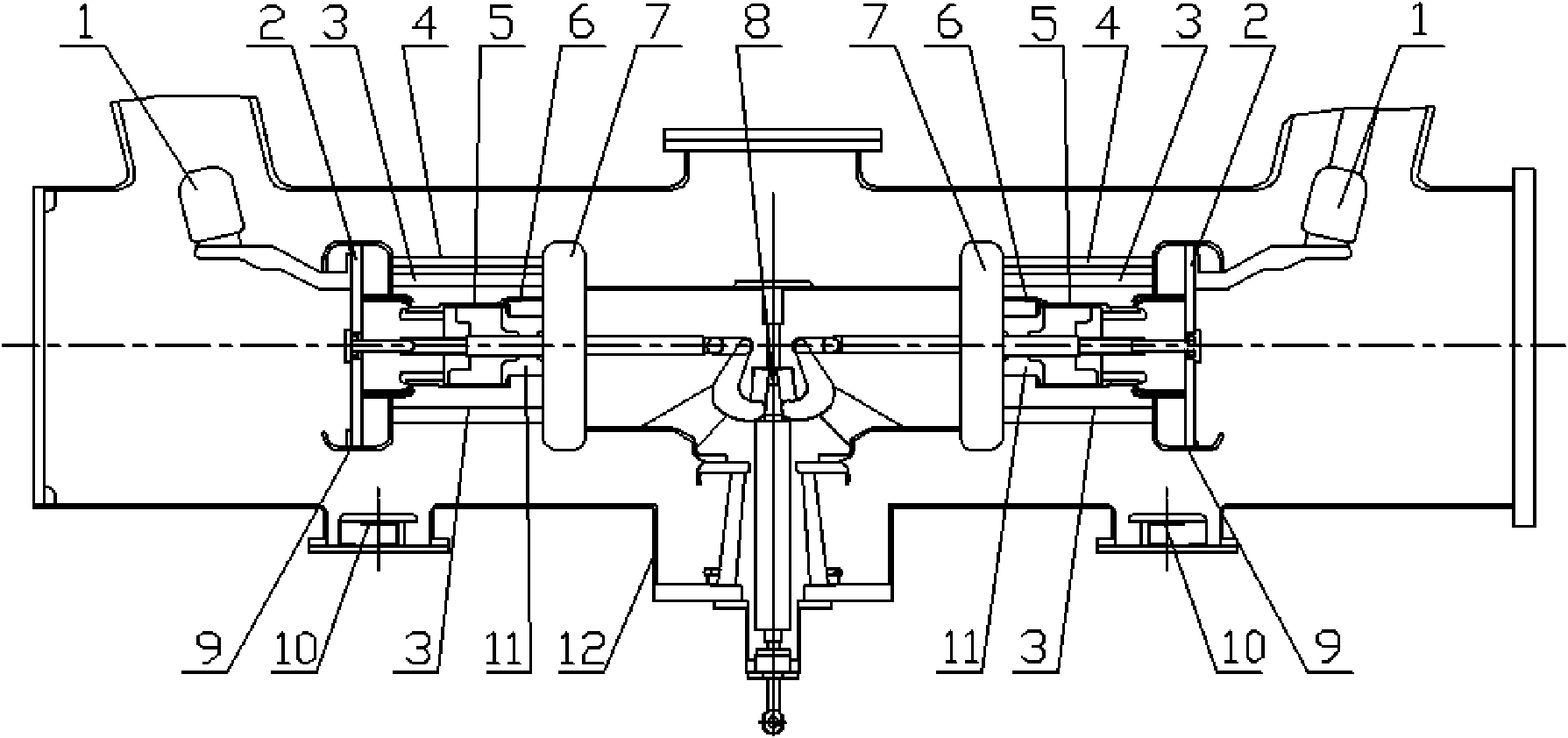

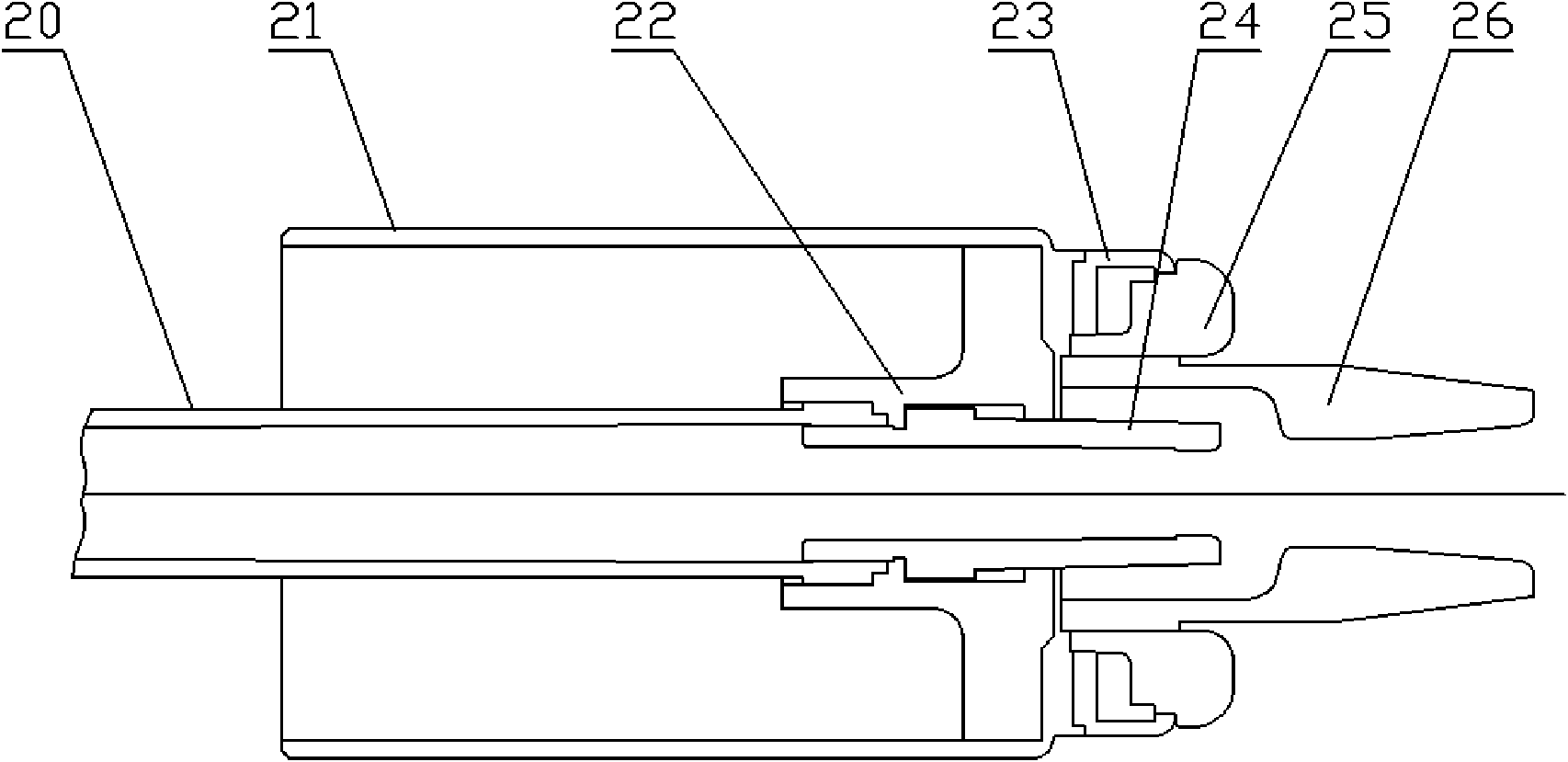

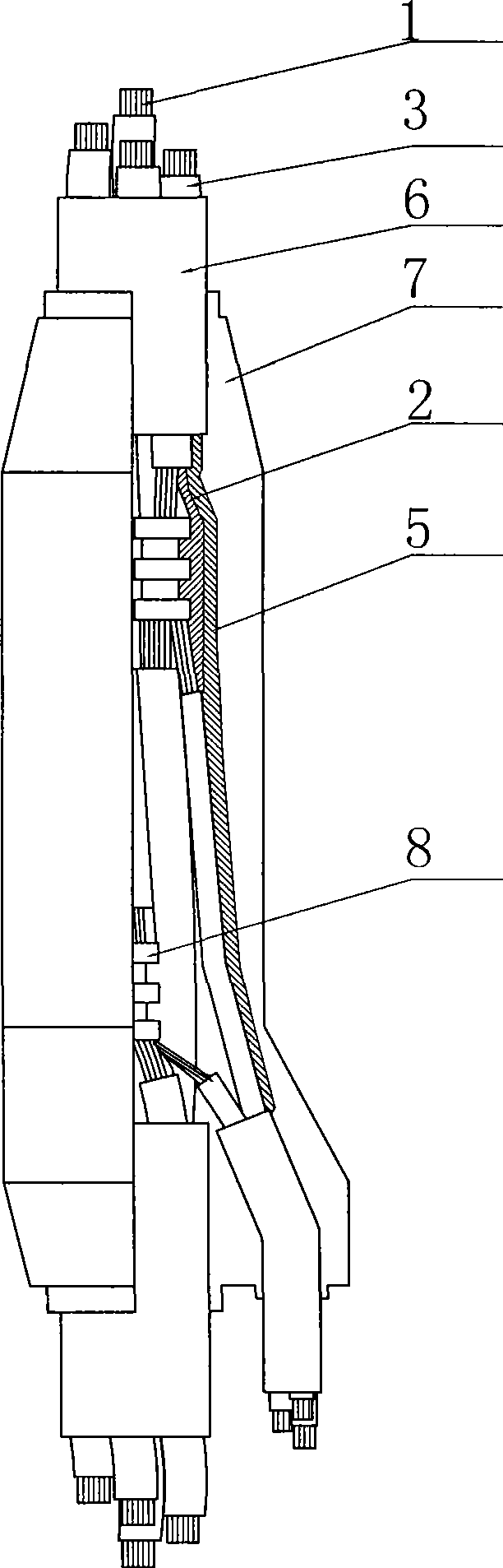

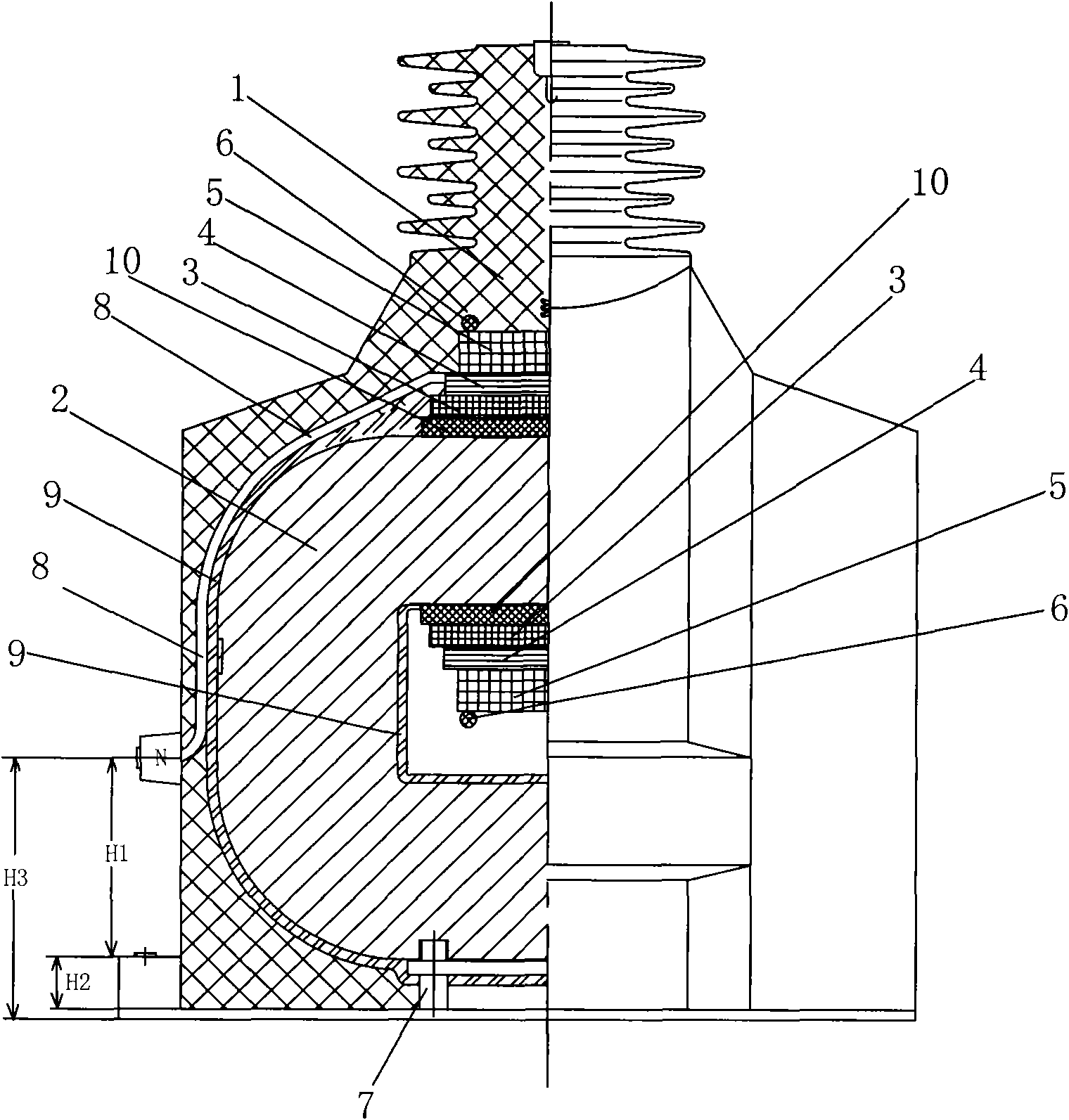

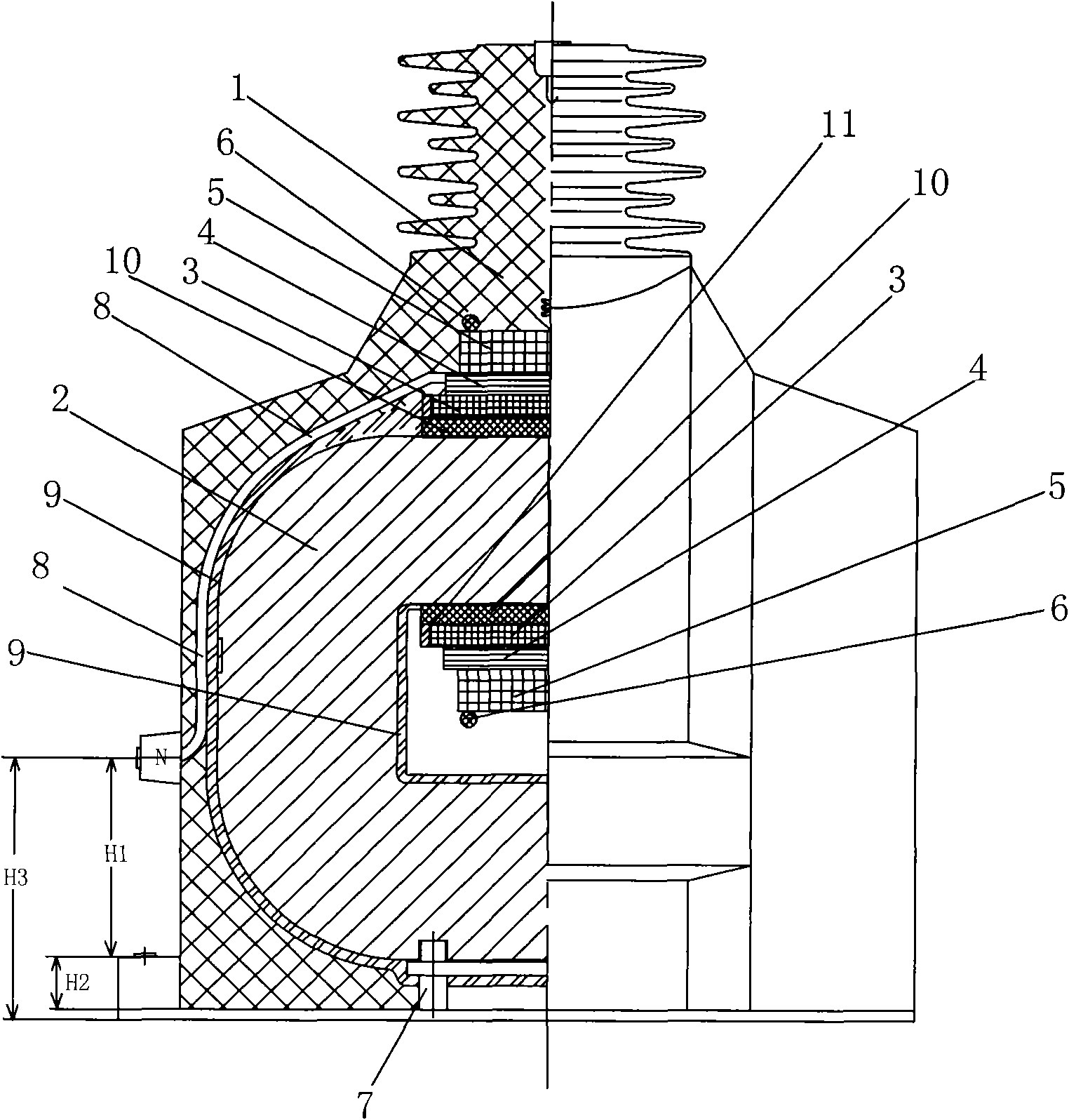

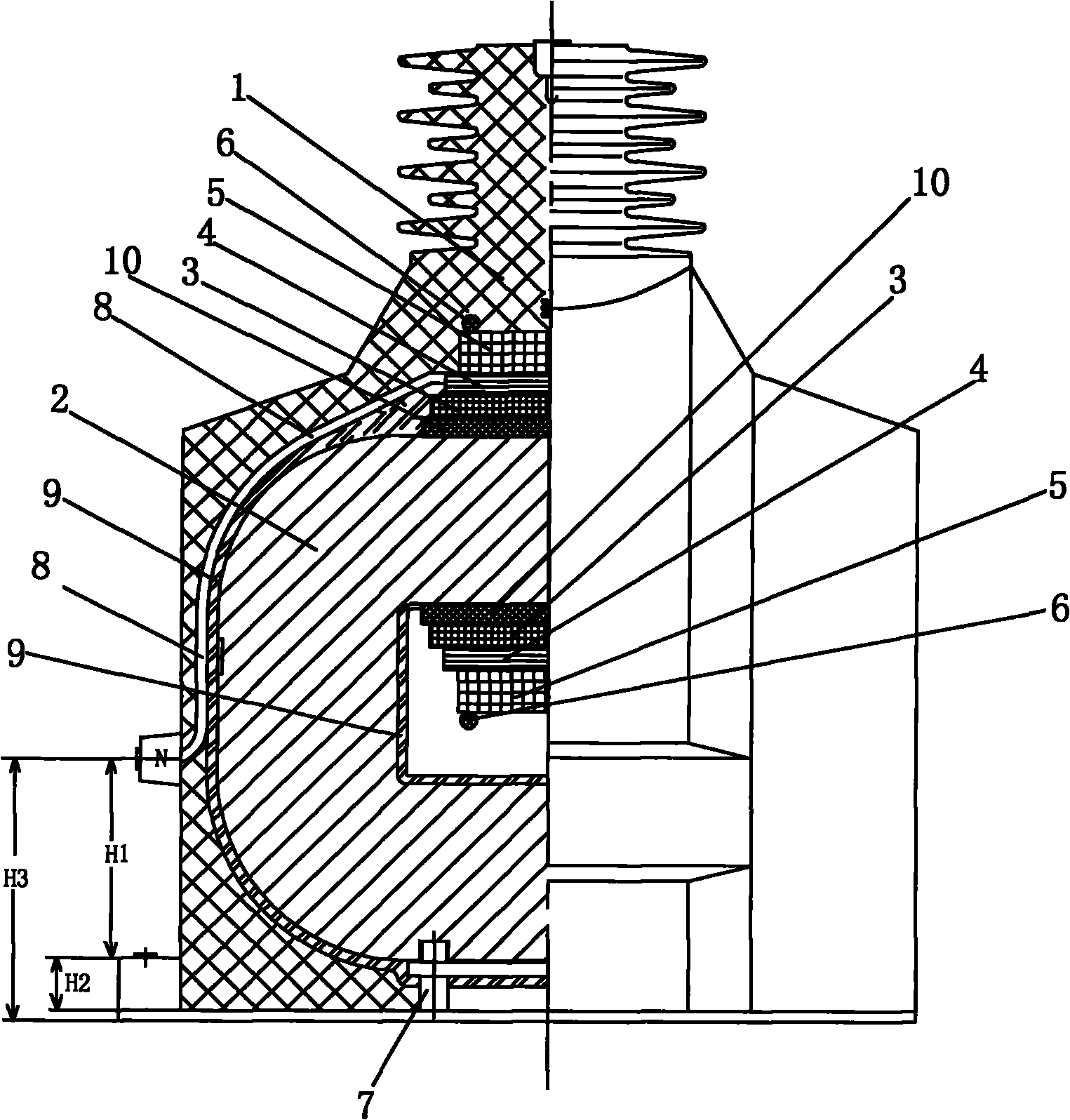

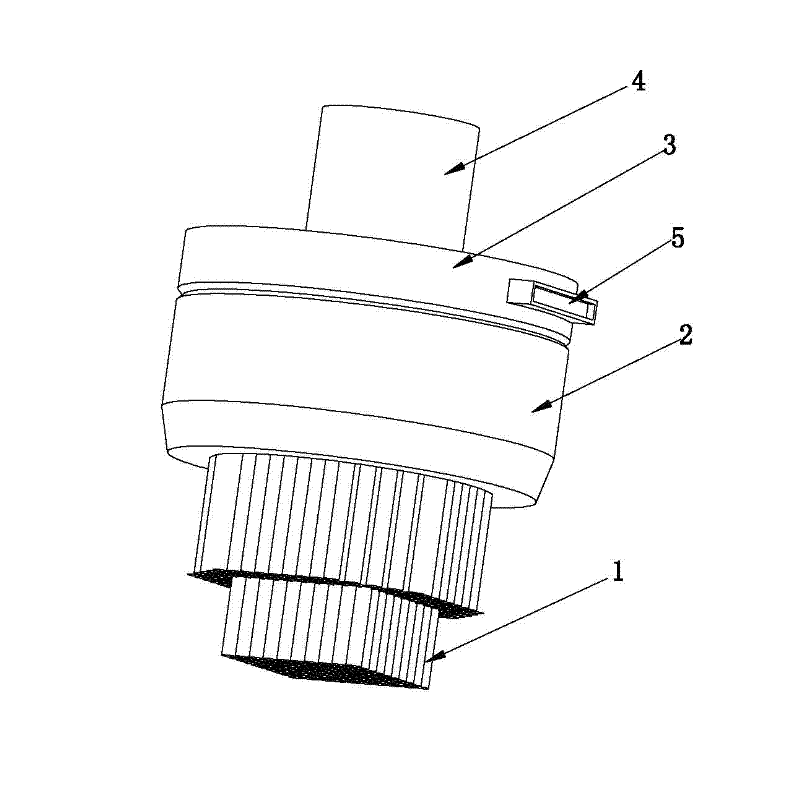

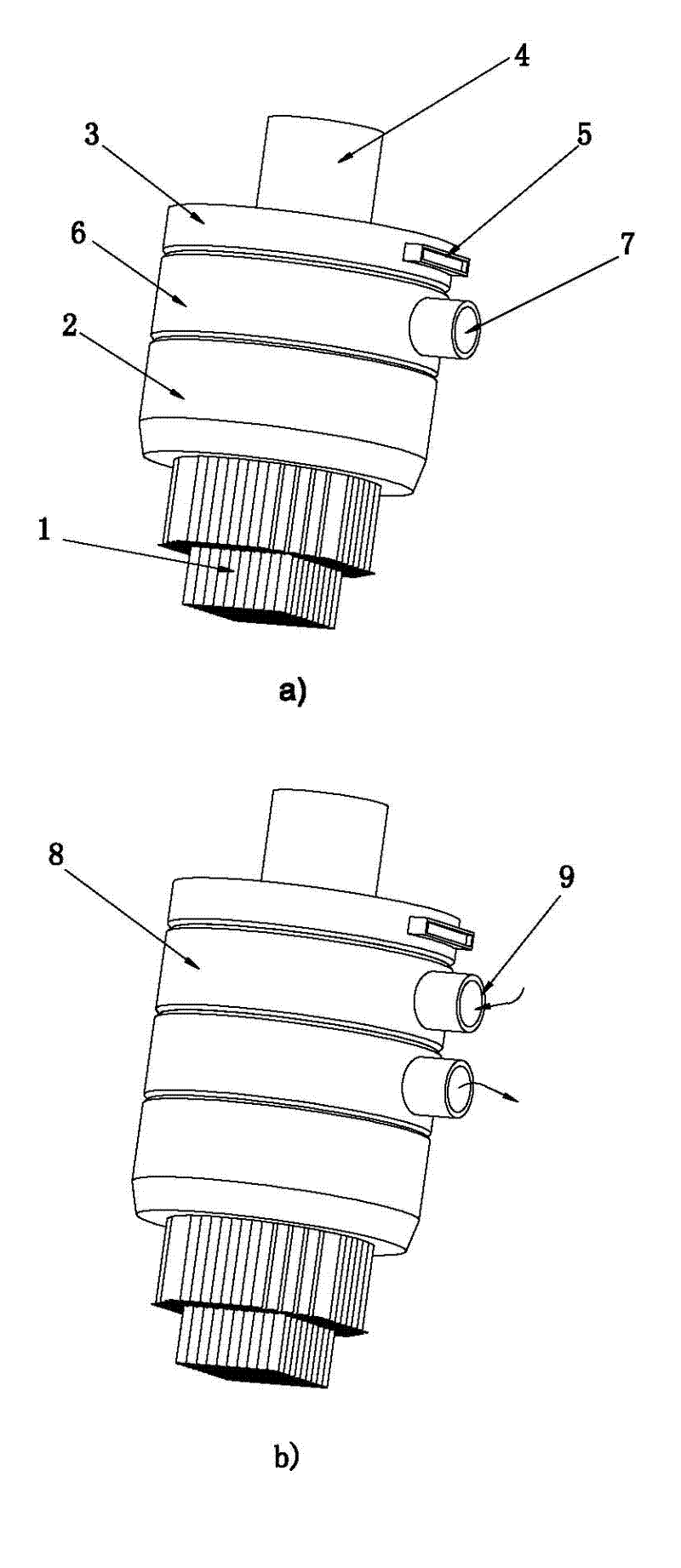

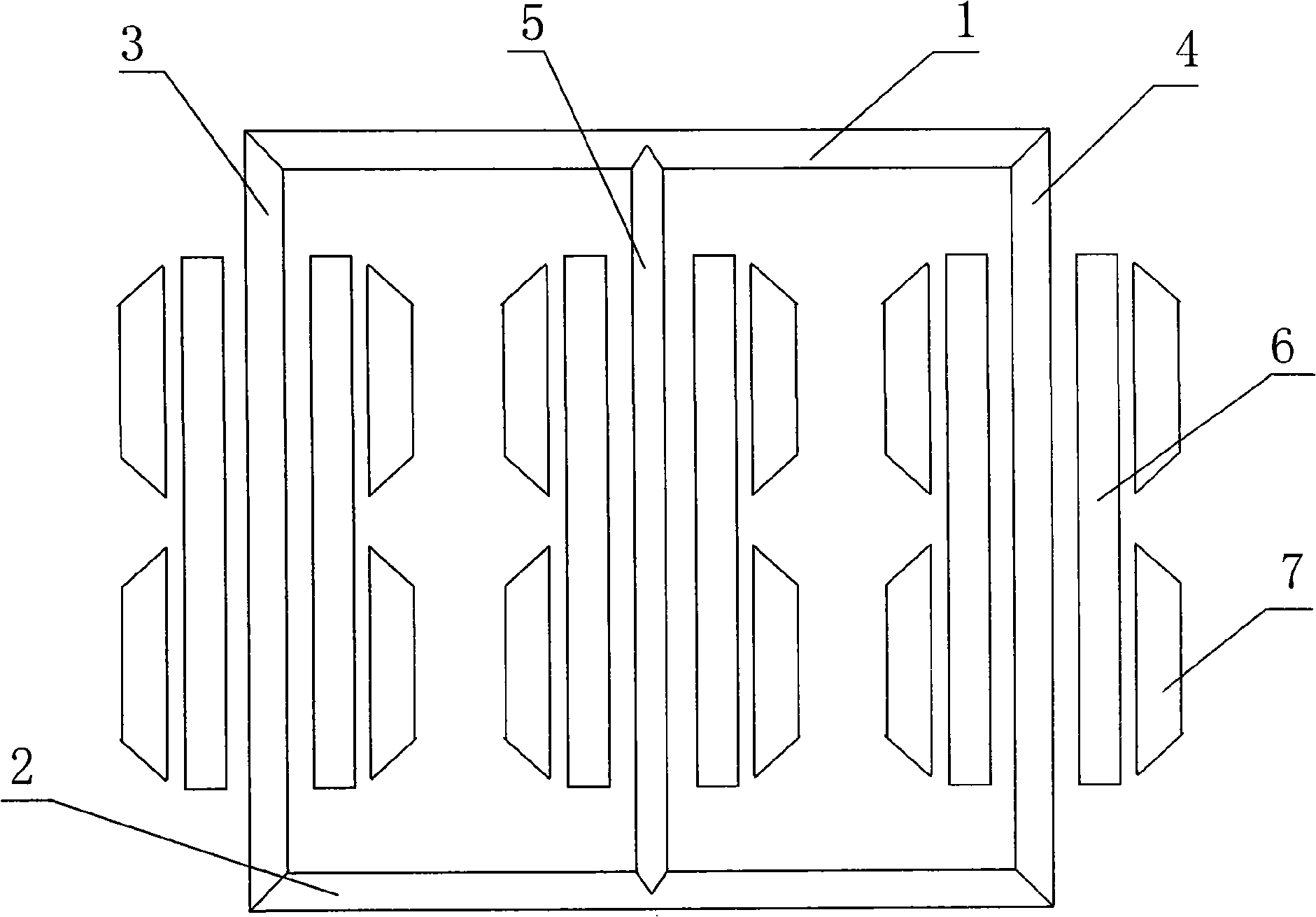

Arc extinguish chambers of high voltage alternating current SF6 pot-type breaker

ActiveCN102013356AImprove environmental adaptabilityImprove safety and reliabilityHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh current

The invention discloses arc extinguish chambers of a high voltage alternating current SF6 pot-type breaker. The invention is characterized in that an arc extinguish chamber system comprises a shell with the arc extinguish chambers, plum blossom contact systems, fixed contact systems, capacitor assembling units, air cylinder systems, a mechanical drive system, ion capturing systems, compressed airpiston assembling units, intermediate contact assembling units, insulation supporting bars, moving end large shields and fixed end large shields; the arc extinguish chambers are of double-break structure and are symmetrically distributed, with the mechanical drive system as the center; the middle mechanical drive system moves along the vertical direction; and vertical movement of the mechanical drive system is transformed to horizontal movement through crankarms and connecting rods in the mechanical drive system to drive the two air cylinder systems of the arc extinguish chambers to move horizontally to switch off and switch on the switchgear. Through promoting the technology of the integral arc extinguish chamber of the breaker, the arc extinguish chambers have more uniform electrical field, high insulation level, stronger breaking capability and high current-carrying capability and is safer to operate.

Owner:CHINA XD ELECTRIC CO LTD

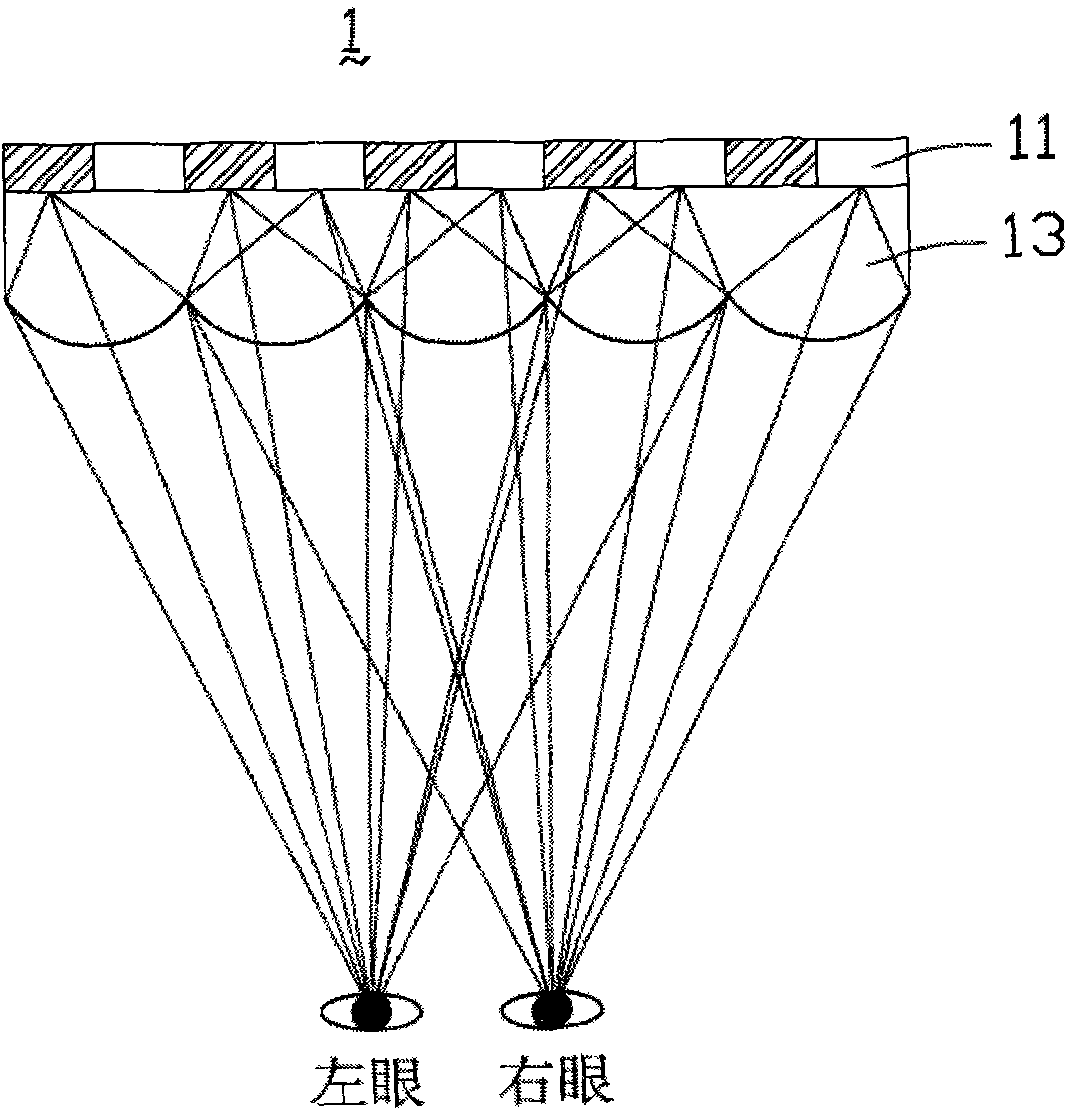

Optical guide module and stereo display device adopting optical guide module

ActiveCN101915987AReduce distortionGuaranteed continuitySteroscopic systemsOptical elementsElectricityOptical Module

Owner:SUPERD CO LTD

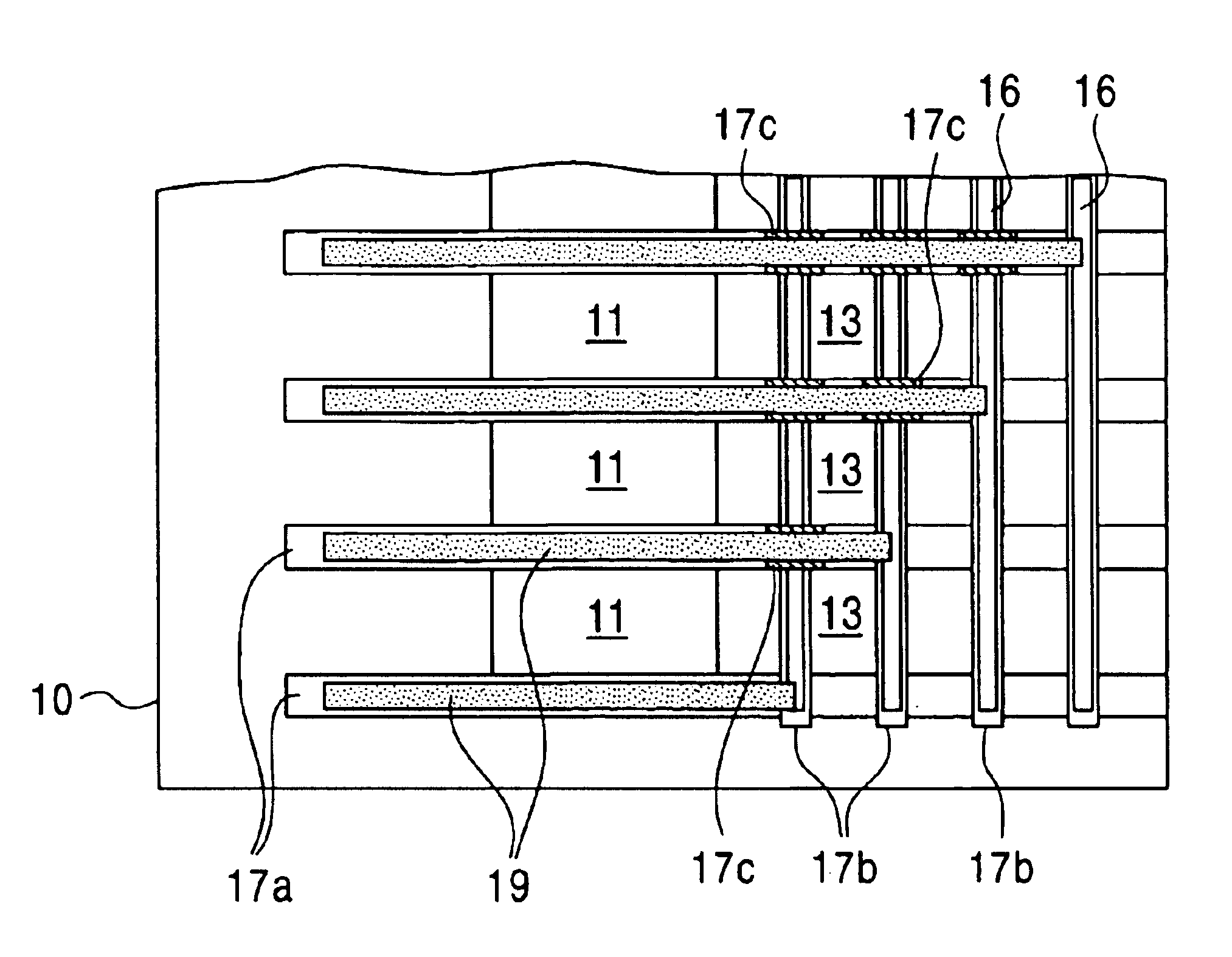

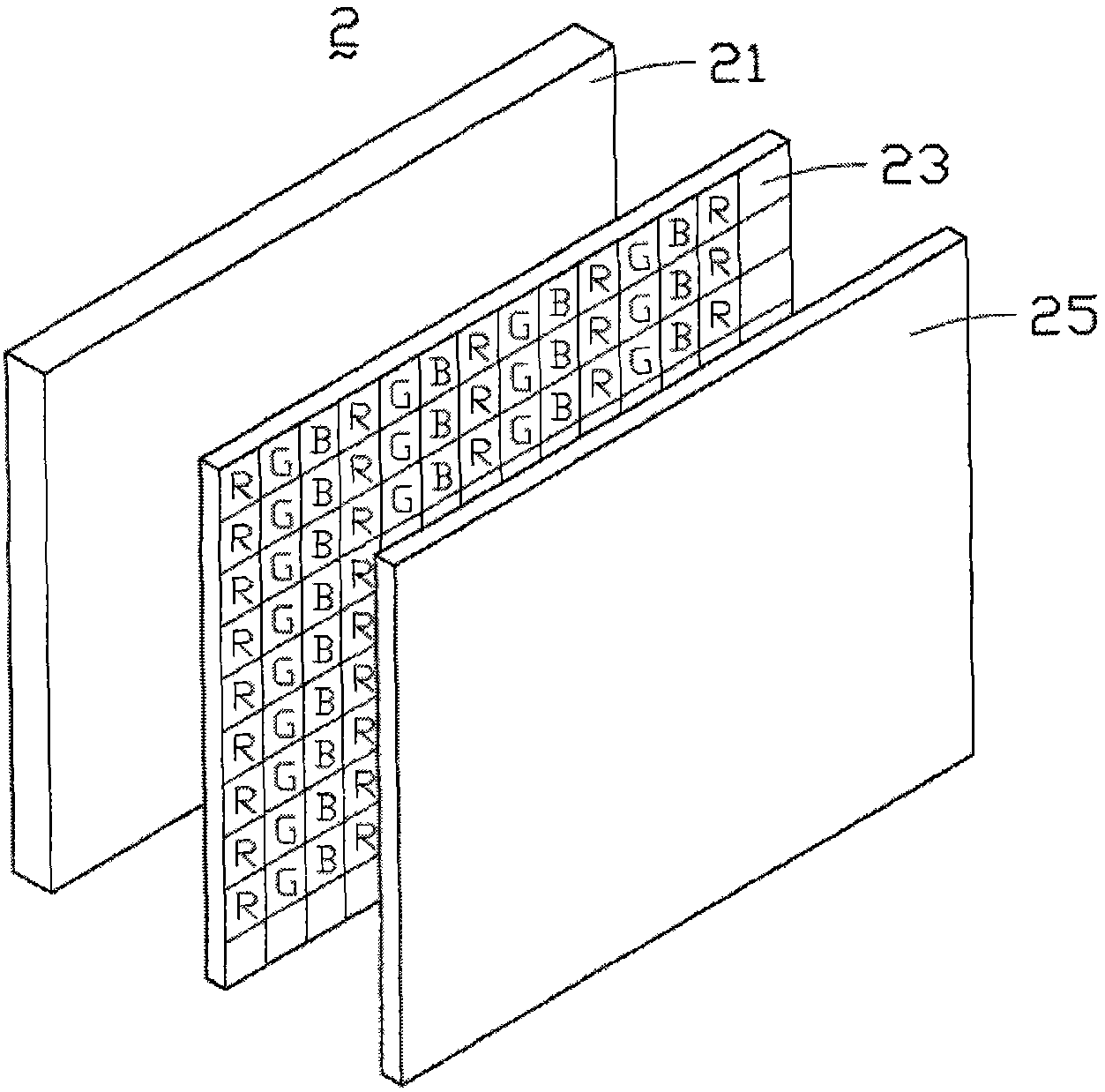

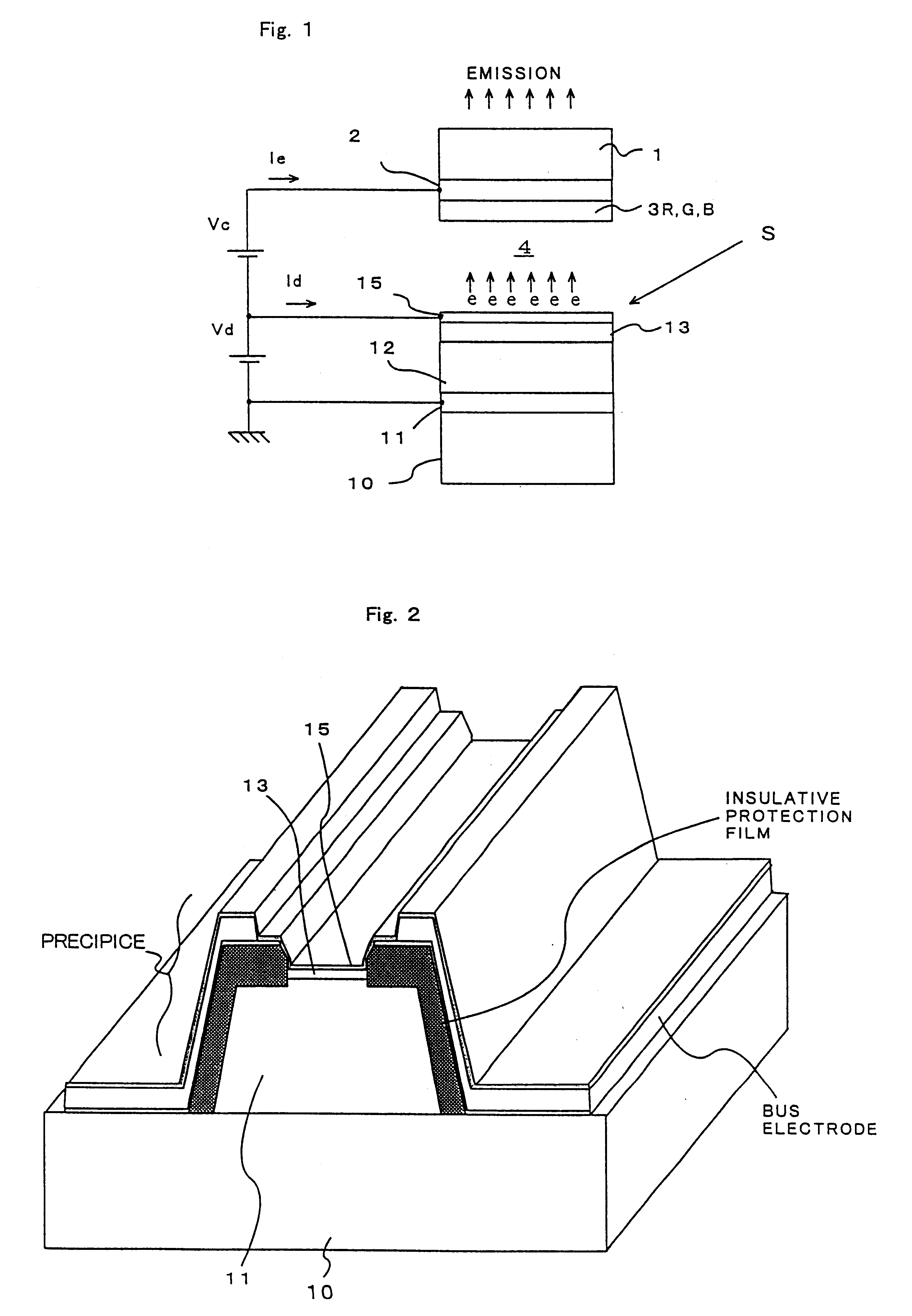

Flat panel display device

InactiveUS20020117963A1Avoid breakingAvoid shortingCathode-ray/electron-beam tube electrical connectionNanoinformaticsDisplay deviceFlat panel display

A display device has an emitting region constituted by a plurality of first electrodes provided on a substrate and extending in parallel, a plurality of second electrodes provided on the first electrodes and extending substantially perpendicularly to the first electrodes, and a plurality of emission sites for emitting electrons or light respectively connected to a plurality of intersections between the first and second electrodes and arranged on the substrate and has a peripheral region surrounding the emitting region on the substrate. In this display device, first and second groups of external repeating terminals for the first and second electrodes are collectively provided side by side in a part of the peripheral region.

Owner:PIONEER CORP

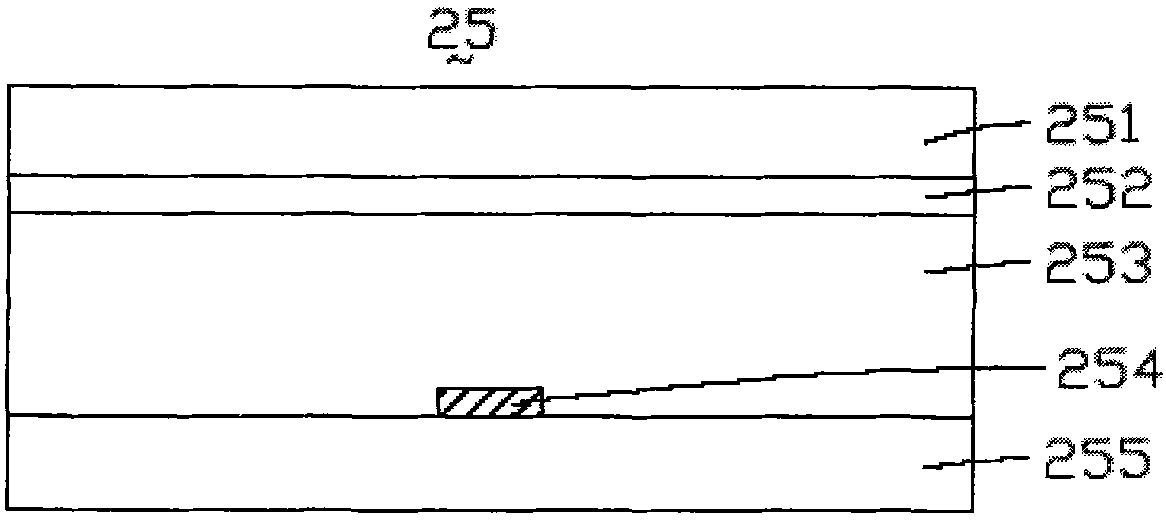

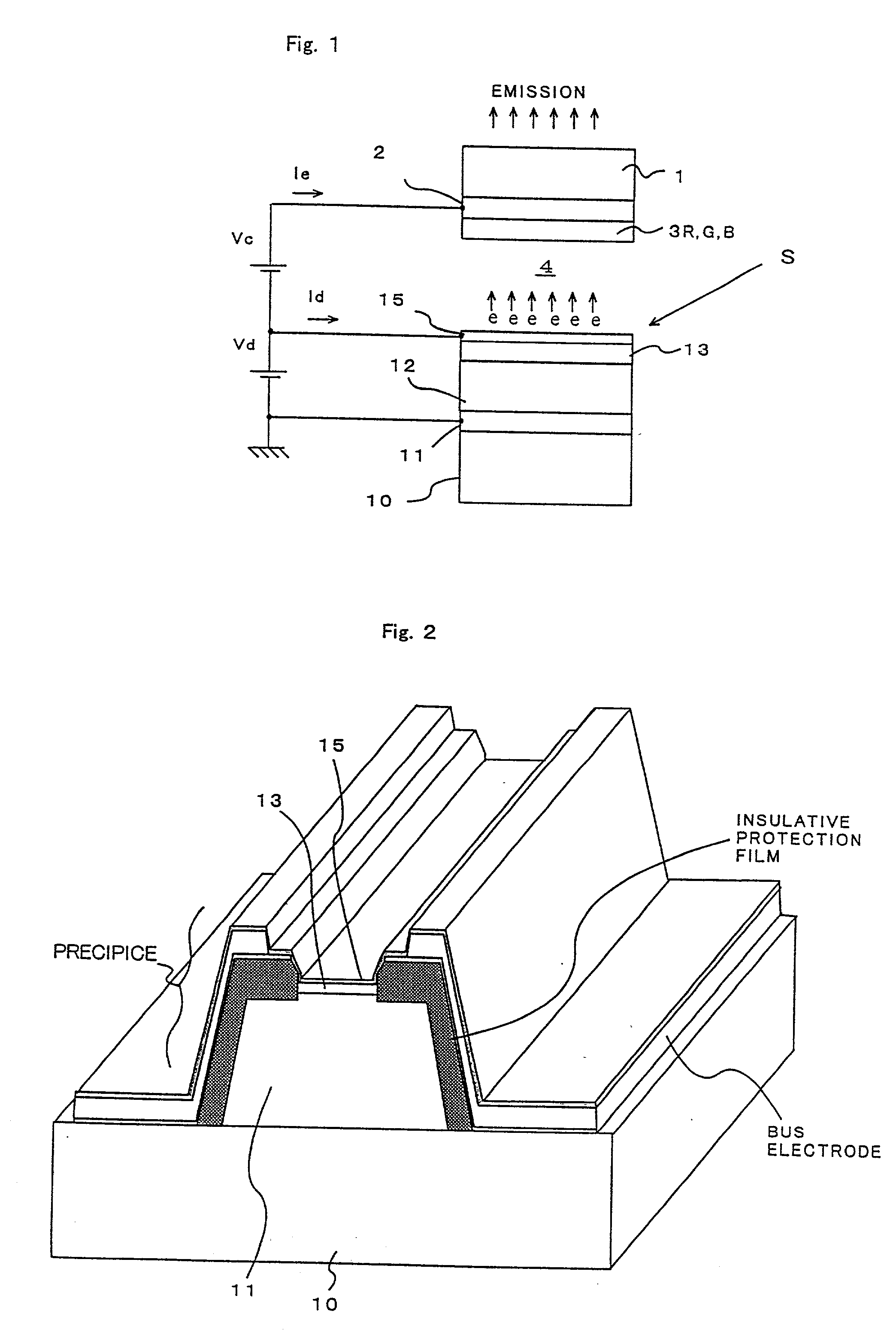

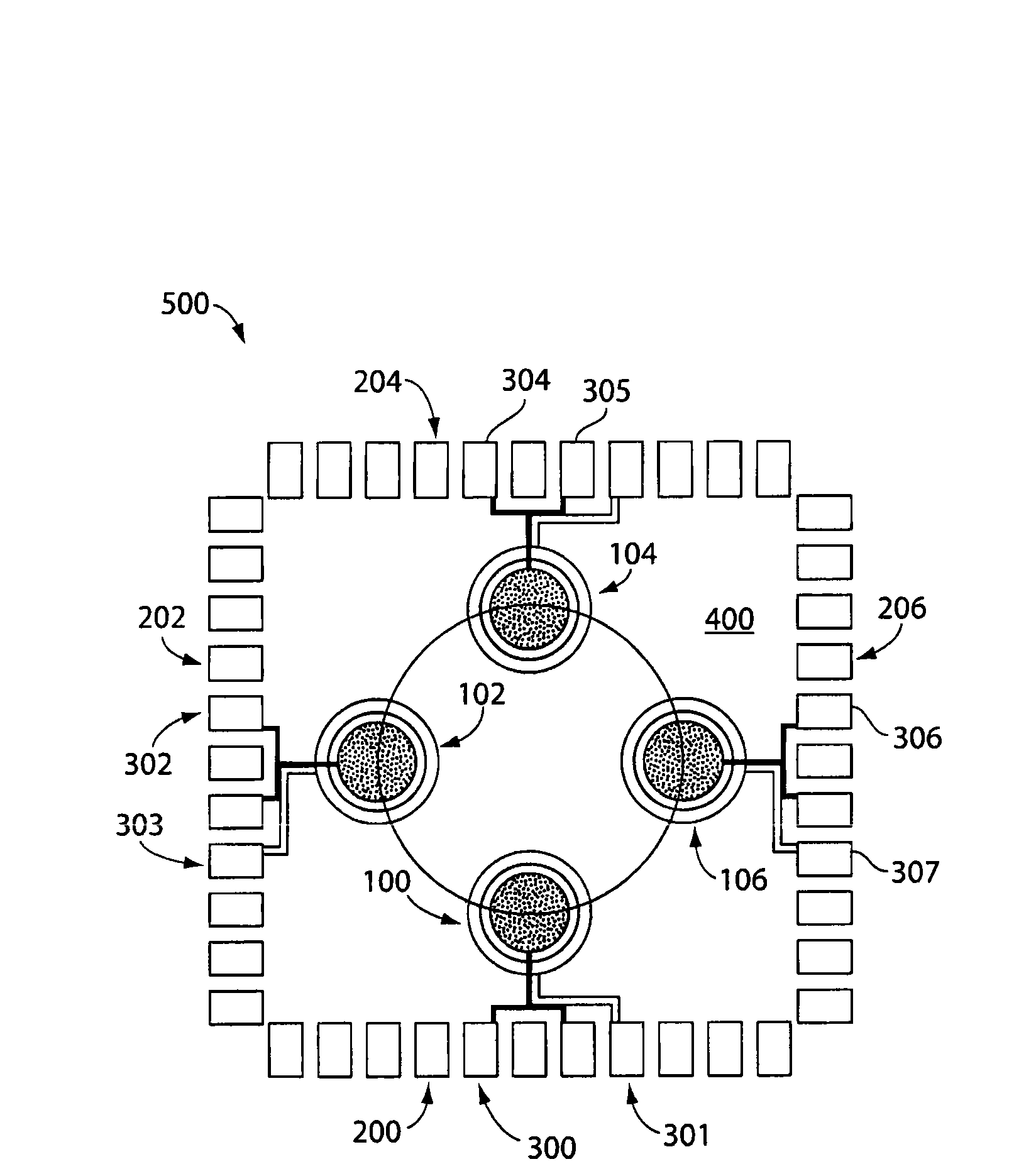

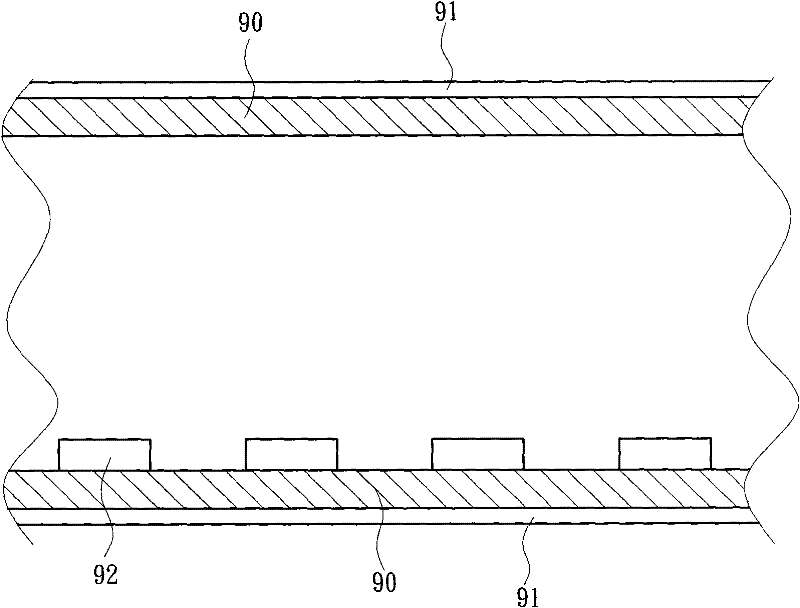

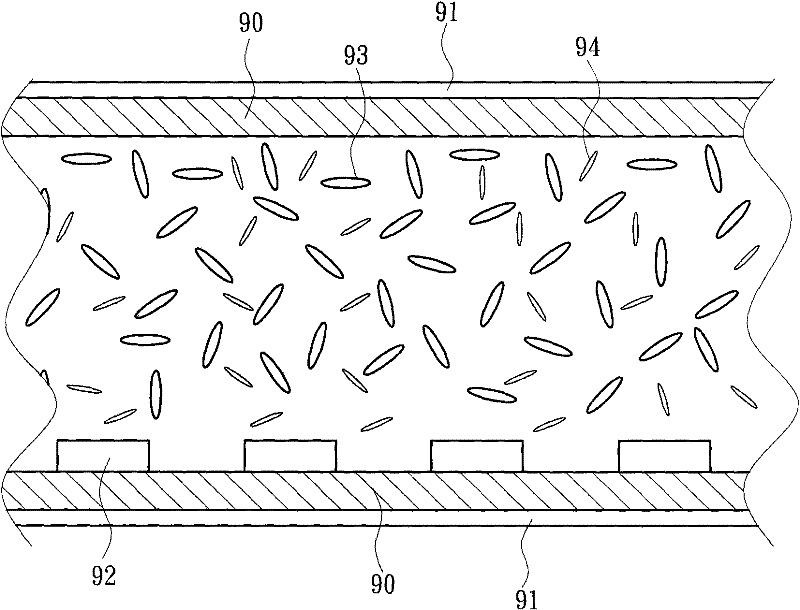

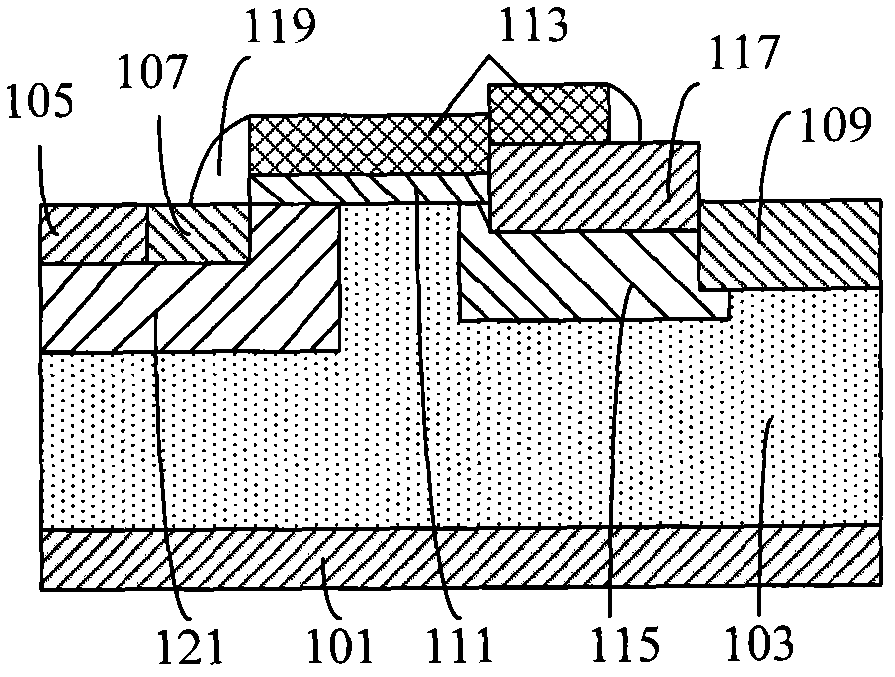

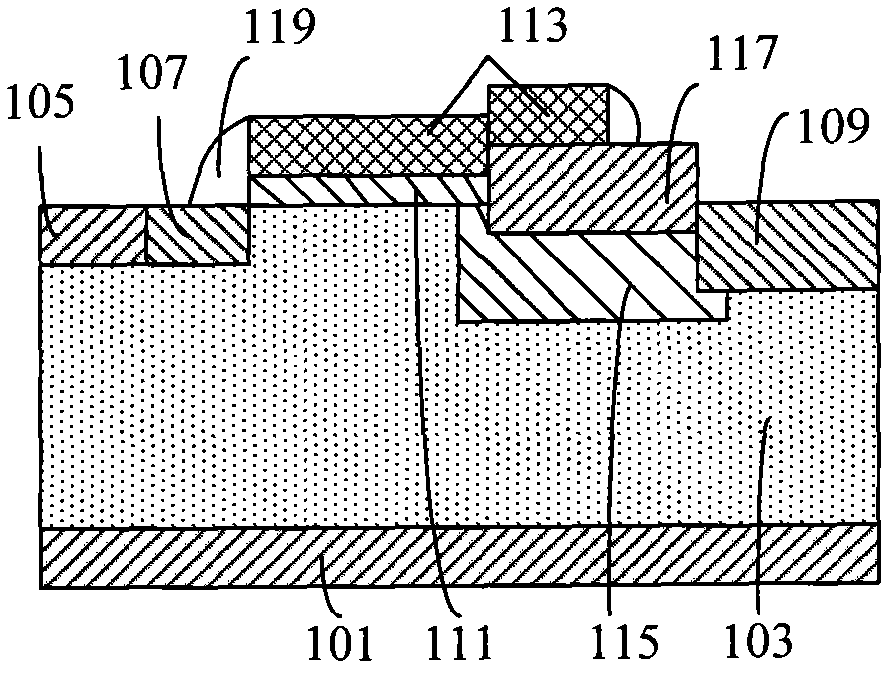

Flat panel display device utilizing electron emission devices

InactiveUS20020125490A1Stable emissionsUniform electric fieldDischarge tube luminescnet screensNanoinformaticsDisplay deviceFlat panel display

A display device includes a backside and a front-side substrates facing each other with a vacuum space therebetween; and a plurality of electron emission sites provided on the backside substrate. Each electron emission sites includes a bottom electrode formed on a surface of the backside substrate proximate to the vacuum space, an insulator layer formed over the bottom electrode, and a top electrode formed on the insulator layer and arranged individually apart from each other and facing the vacuum space. The display device also includes a plurality of bus electrodes for electrically connecting the neighboring top electrodes; and insulating protective films each provided between the bus electrode and the insulator layer and between the bus electrode and the backside substrate.

Owner:PIONEER CORP

Partially and fully surface-enabled transition metal ion-exchanging energy storage devices

InactiveUS20160293954A1Eliminates potential formation of dendriteUniform depositionHybrid capacitor electrolytesHybrid capacitor electrodesNano structuringIon exchange

A surface-enabled, metal ion-exchanging battery device comprising a cathode, an anode, a porous separator, and a metal ion-containing electrolyte, wherein the metal ion is selected from transition metals and at least one of the electrodes contains therein a metal ion source prior to the first charge or discharge cycle of the device and at least the cathode comprises a functional material or nano-structured material having a metal ion-capturing functional group or metal ion-storing surface in direct contact with the electrolyte. This energy storage device has a power density significantly higher than that of a lithium-ion battery and an energy density dramatically higher than that of a supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC

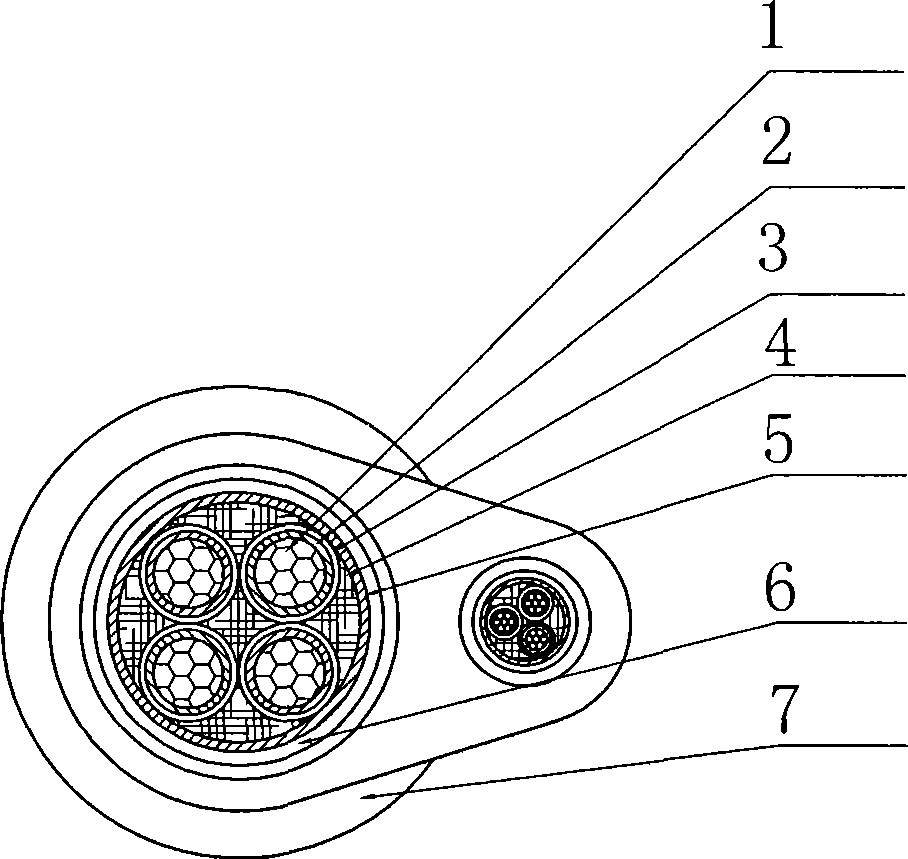

Multi-core integrated branch cable and production method thereof

InactiveCN101521052AUniform electric fieldUniform magnetic fieldRubber insulatorsPlastic/resin/waxes insulatorsCross-linkCopper conductor

The invention relates to a multi-core integrated branch cable and a production method thereof. The multi-core integrated branch cable comprises a main cable, branch cables, connecting fixtures and the like, wherein the main cable or each branch cable is formed by twisting 2 to 5 insulated conductors into a core wire, winding, coating and binding the core wire by bags into a cable core, and coating a layer of plastic outer sheath on the cable core through extrusion; the main cable is provided with phase conductor openings connected with terminations of the branch cables; the phase conductor openings are staggered at equal intervals in turn; copper conductors of the terminations of the branch cables with the same phase are in crimp connection with copper conductors at the phase conductor openings of the main cable into a branch connecting body through the connecting fixtures and a compression mould; the crimp connection part is coated with an ethylene propylene rubber self-adhesive tape which is coated with a cross-linked polythene insulation layer; and a sheath of the branch connecting body is moulded on the insulation layer. The multi-core integrated branch cable has a reasonable and compact structure, realizes that a single cable replaces four or five single core cables for use, and has simple laying and small occupied space.

Owner:BAOSHENG SCI & TECH INNOVATION

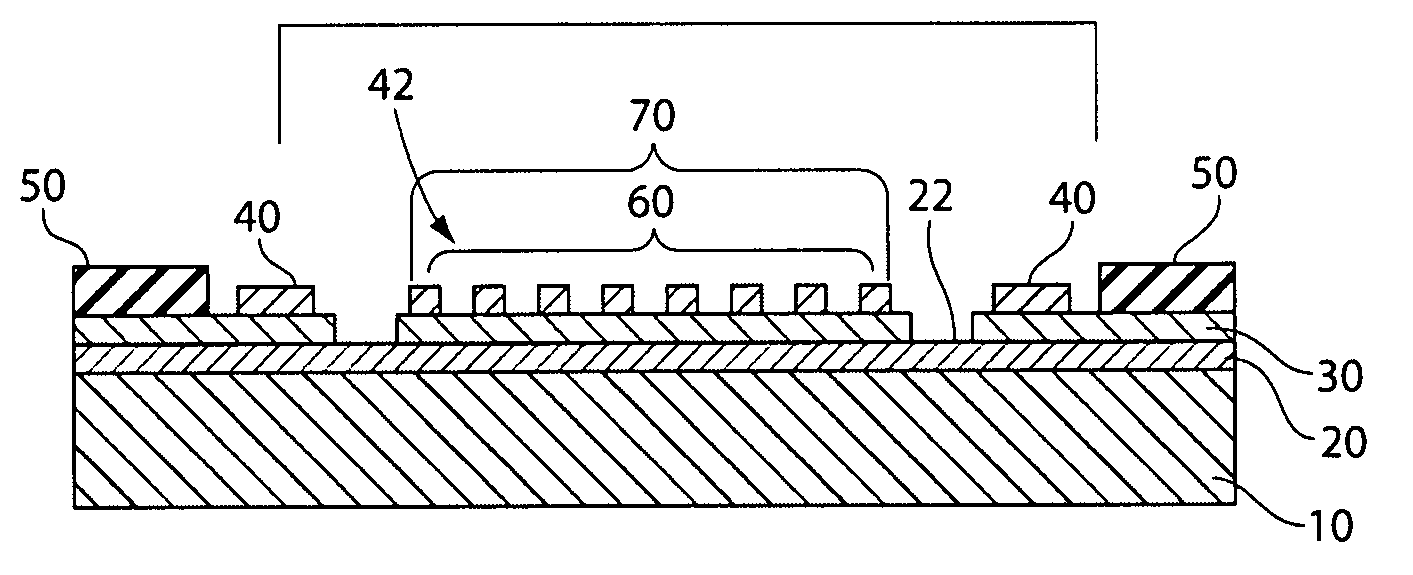

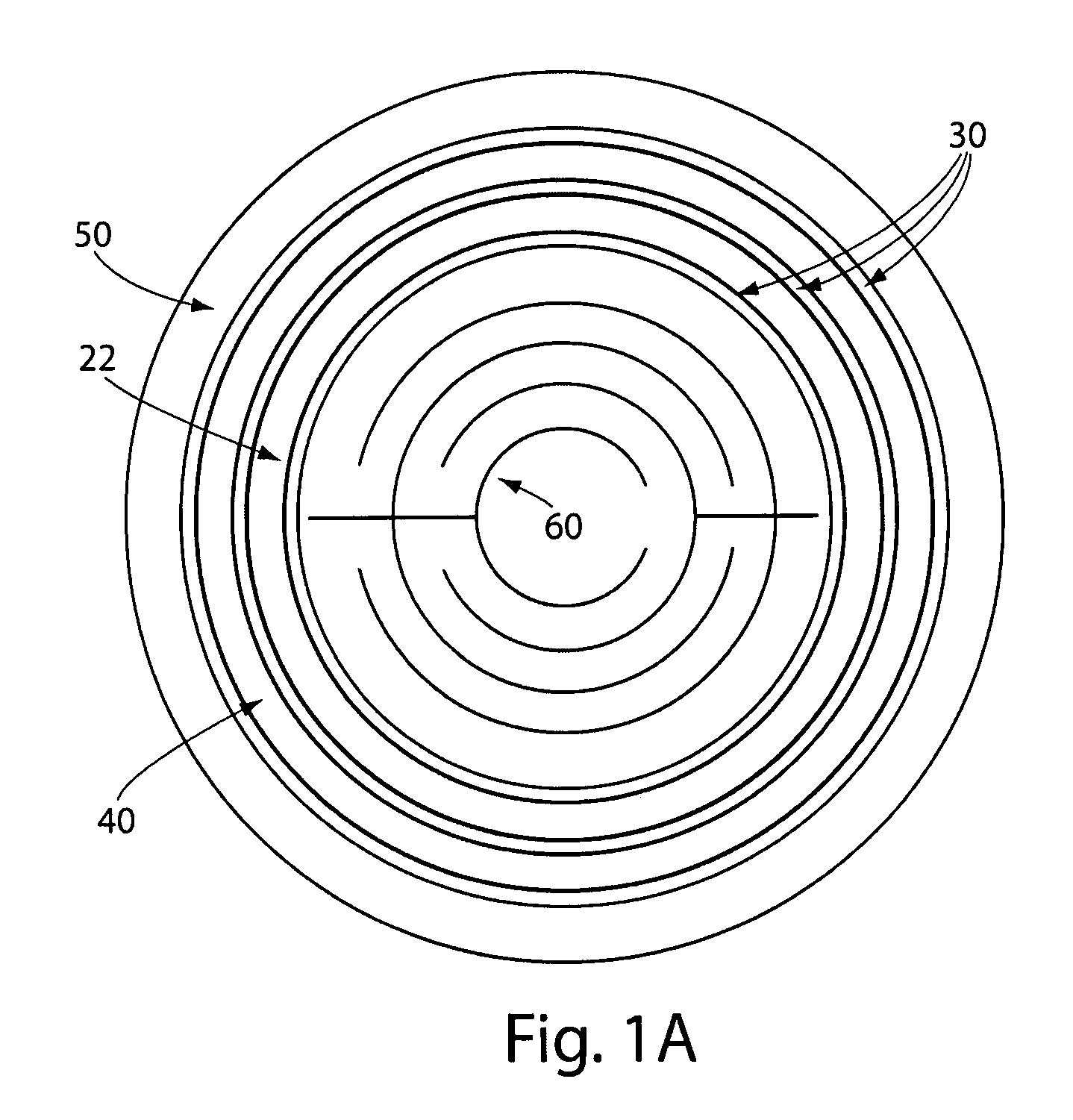

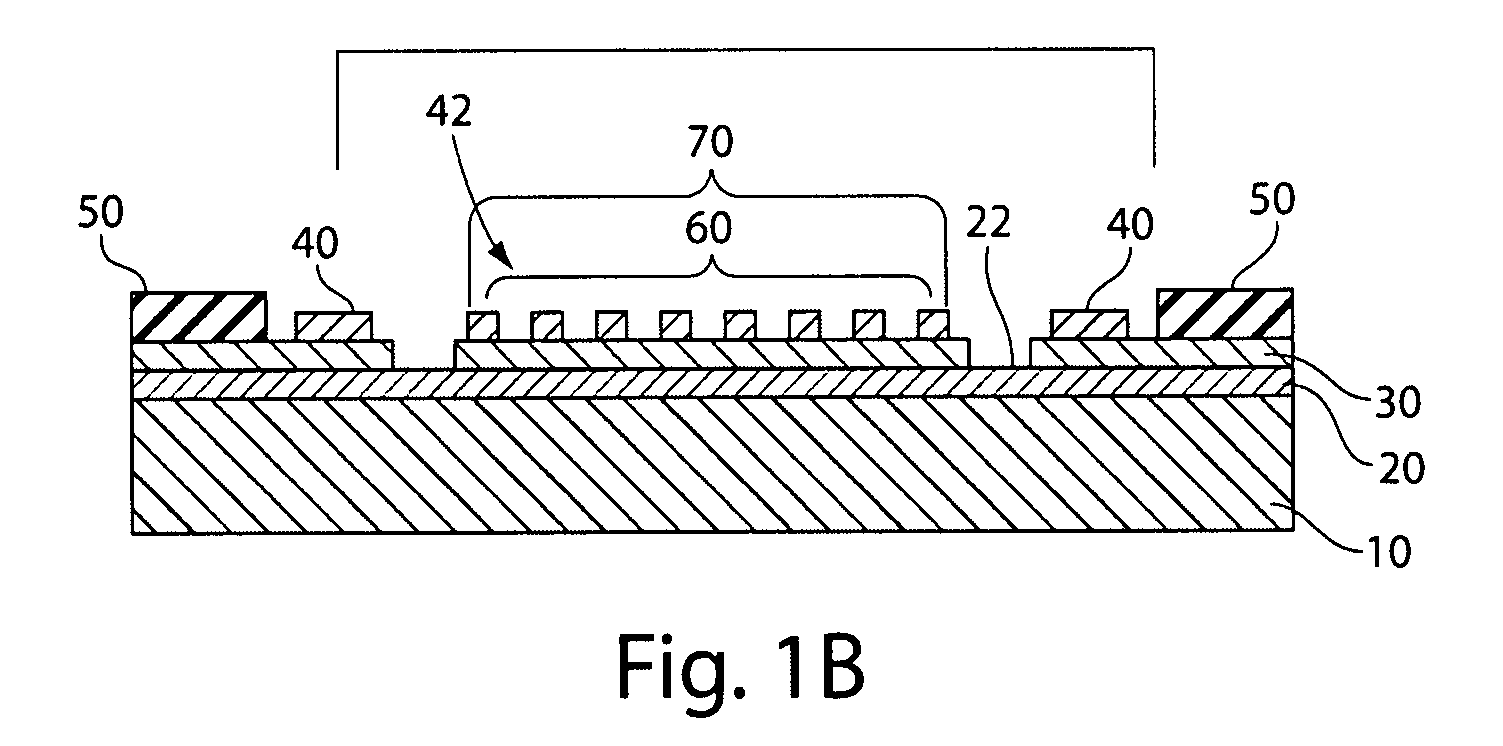

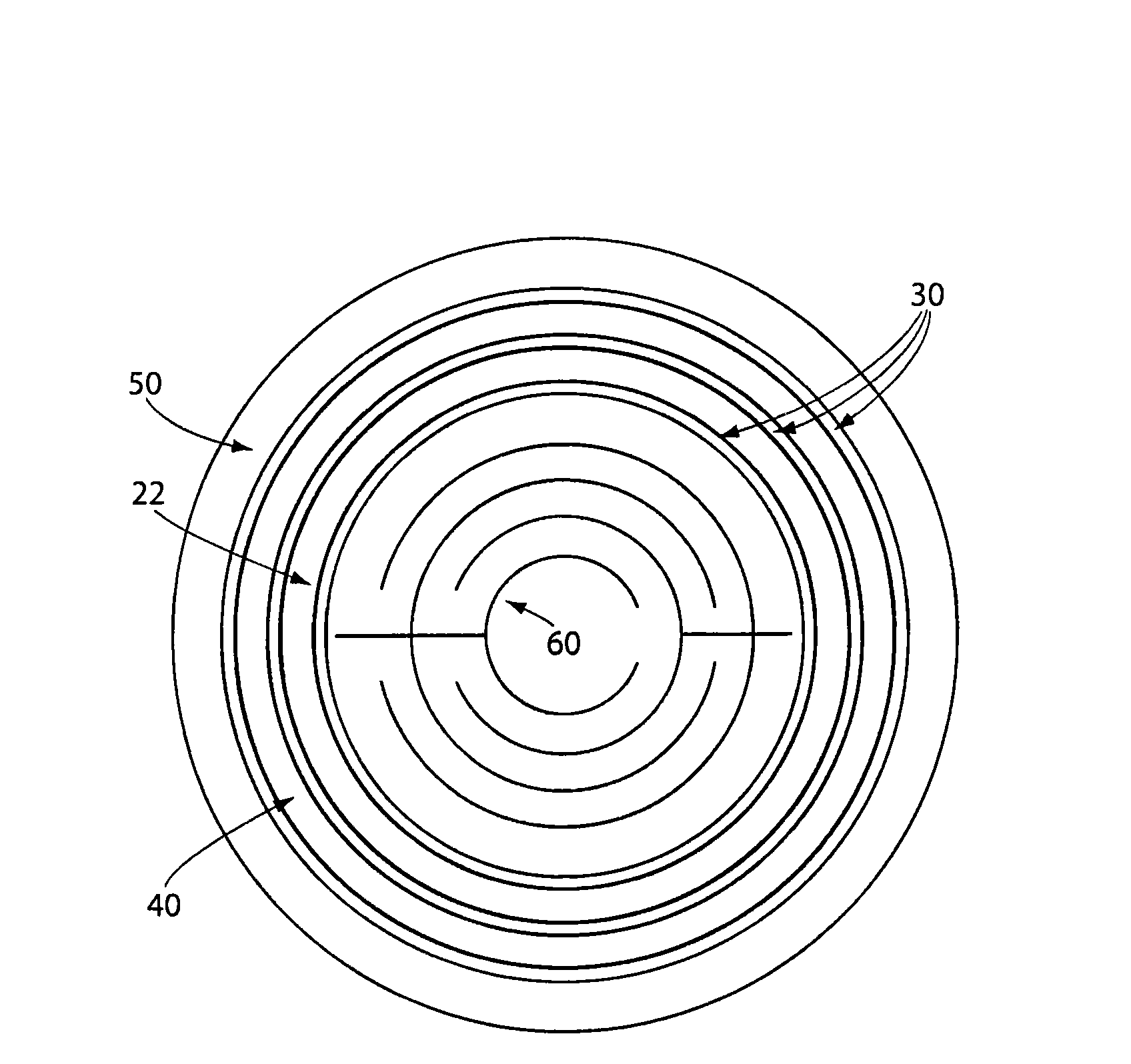

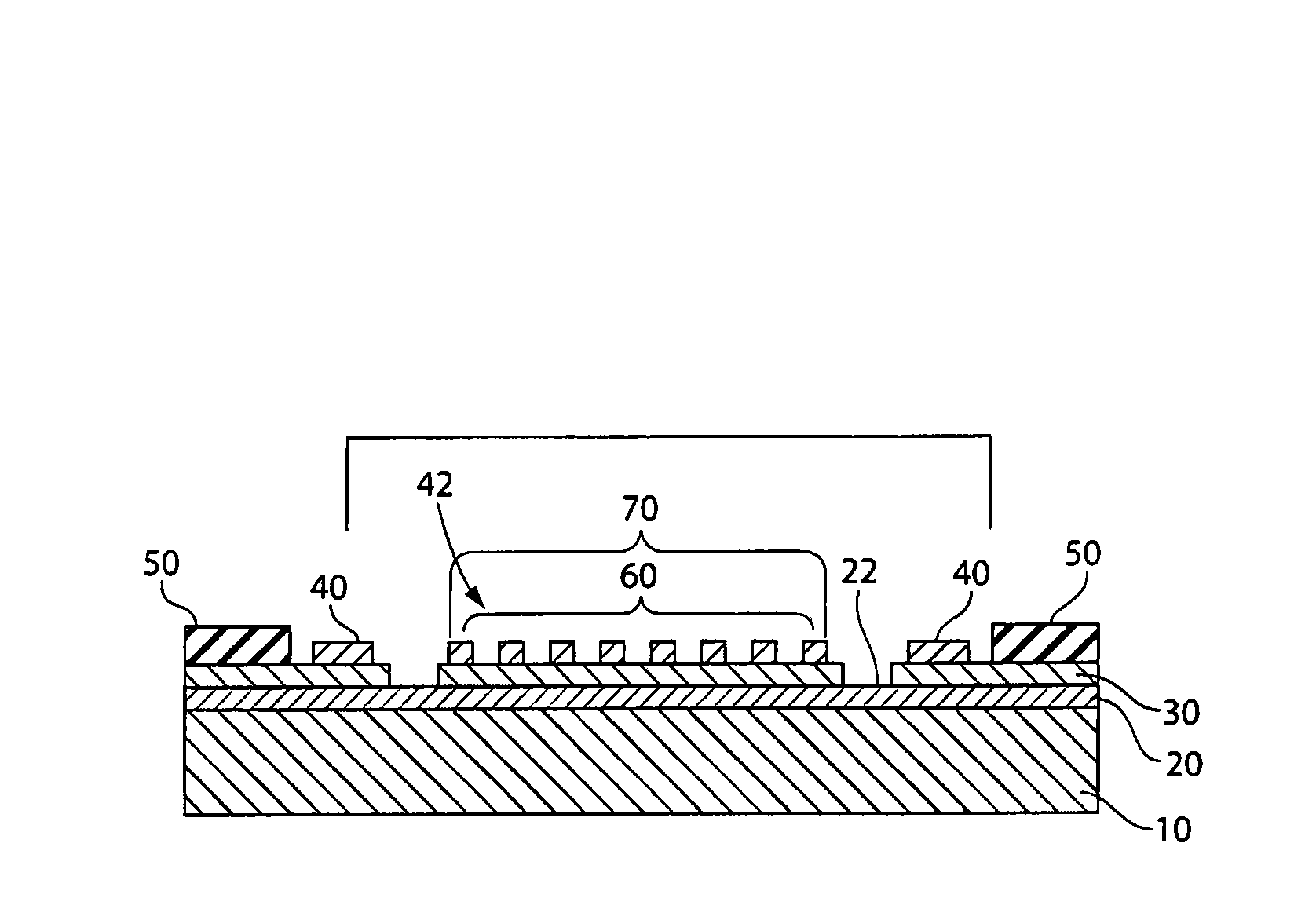

Electrochemical sensor with interdigitated microelectrodes and conducted polymer

InactiveUS20100116682A1Uniform electric fieldElectrolysis componentsWeather/light/corrosion resistanceConductive polymerMicroelectrode

The present invention generally relates to electronic devices and methods. In some cases, the invention provides a sensor device comprising a pair of interdigitated microelectrodes (60), coated with an electrically conducting polymer material (70). The microelectrodes (60) may be surrounded by a first electrode (22), a second electrode (40), and a hydrophobic wall (50).

Owner:AGENCY FOR SCI TECH & RES

Partially and fully surface-enabled metal ion-exchanging energy storage devices

ActiveUS8859143B2Easy dischargeImprove power densityMaterial nanotechnologyHybrid capacitor electrolytesAlkaline earth metalNano structuring

A surface-enabled, metal ion-exchanging battery device comprising a cathode, an anode, a porous separator, and a metal ion-containing electrolyte, wherein the metal ion is selected from (A) non-Li alkali metals; (B) alkaline-earth metals; (C) transition metals; (D) other metals such as aluminum (Al); or (E) a combination thereof; and wherein at least one of the electrodes contains therein a metal ion source prior to the first charge or discharge cycle of the device and at least the cathode comprises a functional material or nano-structured material having a metal ion-capturing functional group or metal ion-storing surface in direct contact with said electrolyte, and wherein the operation of the battery device does not involve the introduction of oxygen from outside the device and does not involve the formation of a metal oxide, metal sulfide, metal selenide, metal telluride, metal hydroxide, or metal-halogen compound. This energy storage device has a power density significantly higher than that of a lithium-ion battery and an energy density dramatically higher than that of a supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC

Flat panel display device utilizing electron emission devices

InactiveUS6700132B2Stable emissionsUniform electric fieldDischarge tube luminescnet screensNanoinformaticsDisplay deviceFlat panel display

Owner:PIONEER CORP

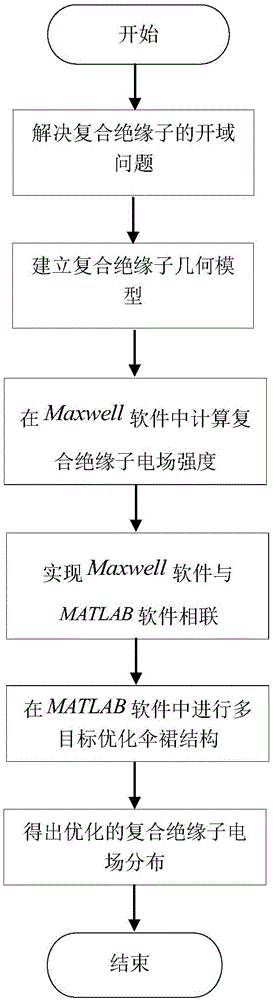

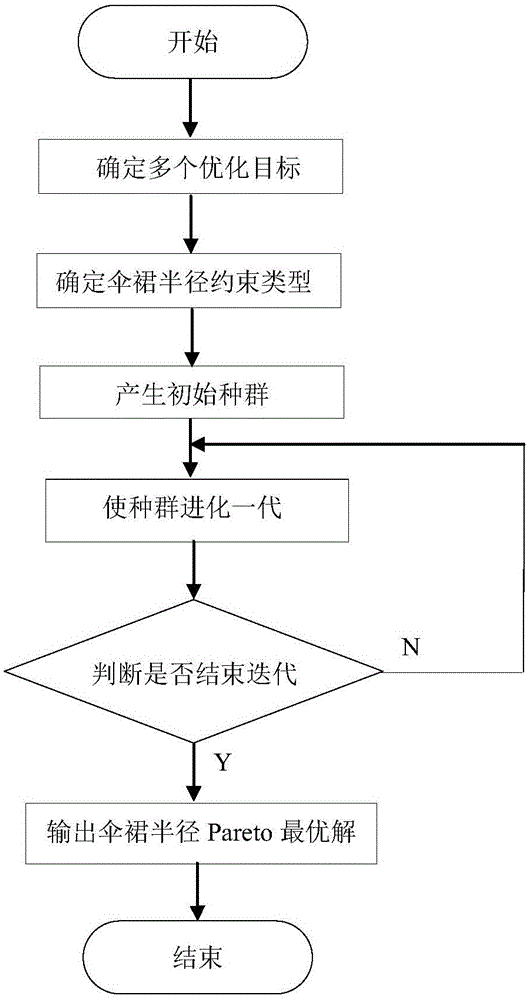

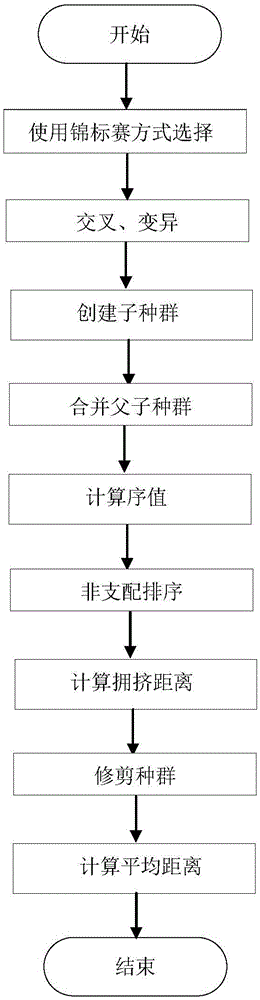

Composite insulator electric field optimization method based on multi-target genetic algorithm

ActiveCN105005675AGuaranteed correctnessDominant Field Strength DistributionGenetic modelsSpecial data processing applicationsData connectionVisual Basic

The invention discloses a composite insulator electric field optimization method based on a multi-target genetic algorithm. The method comprises steps as follows: 1) solving an electrostatic field open domain problem; 2) establishing a composite insulator geometric model; 3) performing numerical computation on the composite insulator electric field intensity in Maxwell software; 4) in order to break through the limitation of a Maxwell software optimization module, adopting the VB (visual basic) script of the Maxwell software to realize data connection of the Maxwell software and MATLAB software; 5) in the MATLAB software, optimizing shed radiuses with the multi-target genetic algorithm; 6) obtaining optimized composite insulator electric field distribution. According to the method, the field intensity Range_E minimization and the field intensity gradient Max_GradE minimization are taken as multiple optimization targets, and large, medium and small shed radiuses of a composite insulator are optimized, so that the composite insulator electric field distribution is more uniform.

Owner:HOHAI UNIV CHANGZHOU

Preparation method of non-linear composite material having adaptive uniform electric field

ActiveCN102424576ASolve the problem of bearing uneven electric fieldUniform electric fieldSilicon oxideSlurry

The invention relates to a preparation method of a non-linear composite material having adaptive uniform electric field, belonging to the technical field of electric materials. The method comprises the following steps: using zinc oxide, bismuth oxide, manganese oxide, cobalt oxide, chrome oxide, antimony oxide and alumina as raw materials, mixing after weighing in proportion, adding alcohol in the mixture, grinding with a grinding ball prepared by pure silicon oxide, and drying and crushing the grinded slurry; adding a vulcanizing agent in methyl vinyl silicone rubber, dissolving with tetrahydrofuran to obtain a mixed solution, mixing the mixed solution with zinc oxide pressure-sensitive powder to obtain a mixture, and carrying out hot forming on the mixture to obtain the non-linear composite material. The prepared non-linear composite material disclosed herein can effectively reduce electric field intensity when being applied in high voltage power transmission and transformation system insulation parts having strong nonuniform electric field, and can keep good insulation characteristic in low electric field intensity regions.

Owner:TSINGHUA UNIV +1

Voltage transformer

InactiveCN102064011AImprove the insulation levelHigh precisionTransformersTransformers/inductances coils/windings/connectionsSemiconductor materialsTransformer

The invention relates to a voltage transformer, comprising a winding part wound on an iron core, wherein the winding part and the iron core are both sealed in an insulator, the voltage transformer is characterized in that the winding part comprises a secondary winding directly wound on an external surface of the iron core, an insulating layer wound on an external surface of the second winding, a primary winding wound on an external surface of the insulating layer, and a grading ring wound on an external surface of the primary winding. Compared with the prior art, the voltage transformer of the invention has the following advantages: insulation level of a tail end of the primary winding is improved to 20kV so as to satisfy high voltage caused by voltage division of a resonance eliminator, secondary load is large, precision is high, surface creepage distance is large, the grading ring is placed on the primary winding, and the iron core is covered with semiconductor materials, so that the whole product has uniform electric field and has no suspension potential. If the product has unsatisfactory error after casting, the product can be adjusted by externally adding a compensation coil so as to achieve optimal state of the error.

Owner:宁波三爱互感器有限公司

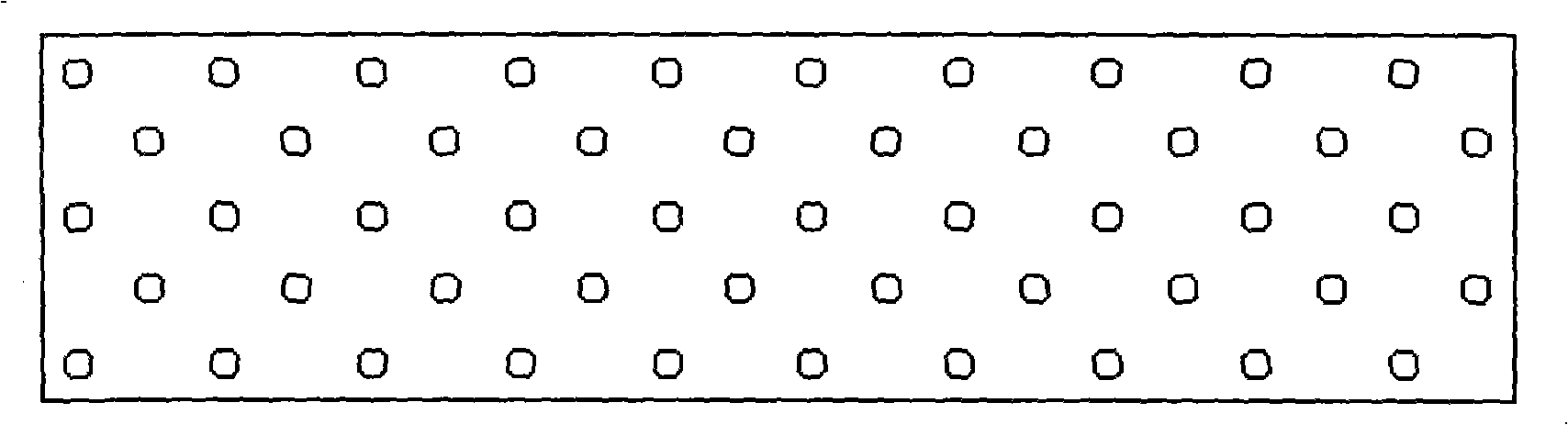

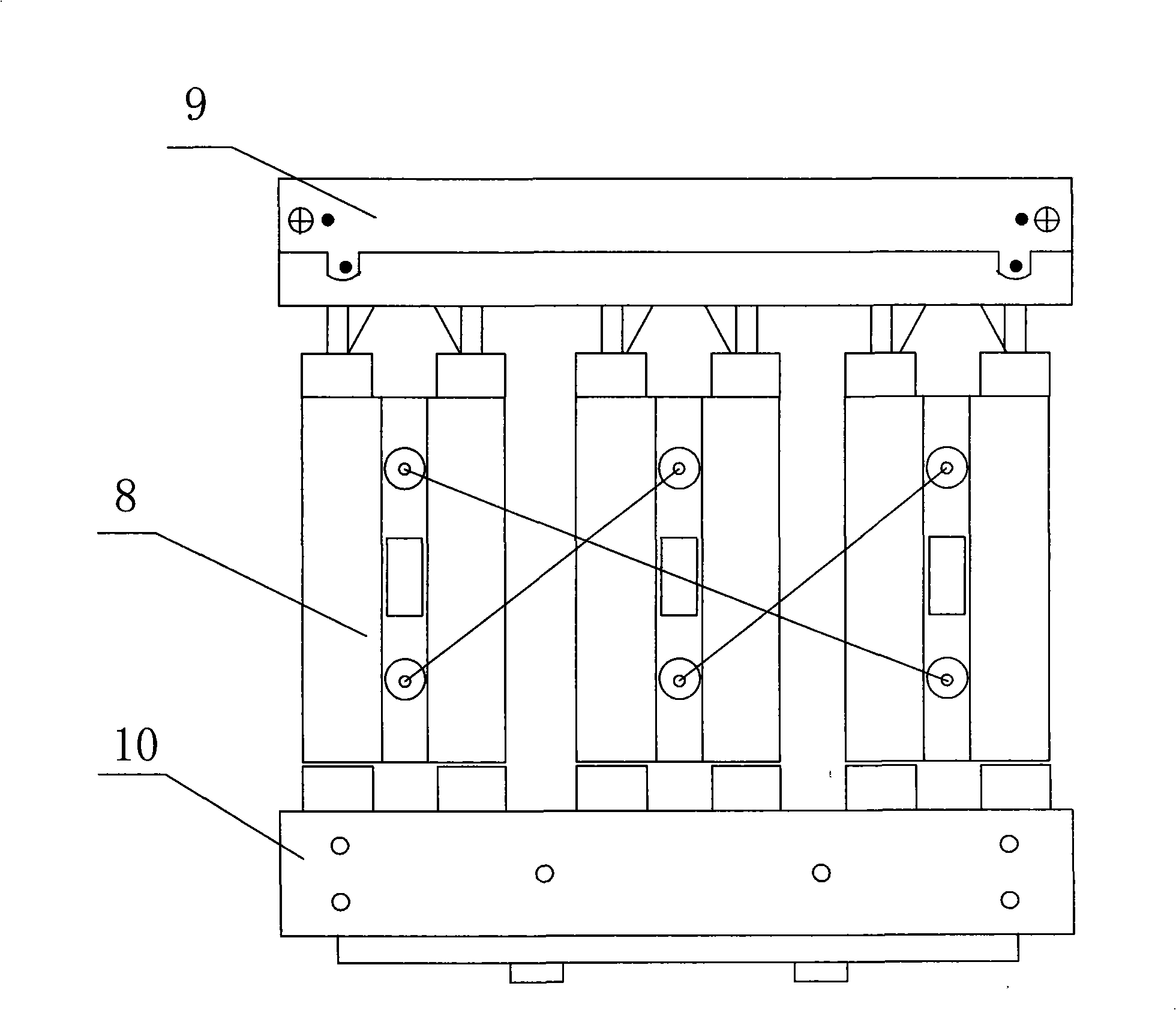

Electrochemical machining array electrode

InactiveCN102357689AEasy to processShort manufacturing cycleMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses an electrochemical machining array electrode which is characterized by comprising electrode units, an array electrode clamp, a power module and an electrode clamp joint. The electrode unit is a strip-shaped solid, or a thin-wall hollow or grooved structure; the electrode units are clustered to form an array electrode unit cluster; the array electrode unit cluster is clamped by an electrode unit clamp; the bottom end of the array electrode unit cluster can form an end surface of any contour shape; and if the electrode unit is a thin-wall hollow structure or grooved structure, the electromechanical machining array electrode also comprises an electrolyte module so that the electrode units realize liquid flushing or absorption, or partial liquid flushing and partial liquid absorption. Through the invention, the electrode production time of electrolytic formation machining can be obviously shortened, the cost and difficulty in the electrode production are reduced, the utilization rate of the electrode material is improved, and the machining efficiency and speed are improved; and meanwhile, the electric field and flow field during the electromechanical machining are homogenized, selective machining can be realized at different positions of the electrode, and the machining accuracy and quality are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Epoxy cast dry transformer

InactiveCN101308721AReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyLow voltage

Disclosed is an epoxy resin cast dry type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp, and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to the outer layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost and requires no daily maintenance. The epoxy resin cast dry type transformer is of strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

Electrochemical sensor with interdigitated microelectrodes and conductive polymer

InactiveCN101517403AUniform electric fieldSolid-state devicesMaterial analysis by electric/magnetic meansConductive polymerOptoelectronics

The present invention generally relates to electronic devices and methods. In some cases, the invention provides a sensor device including a pair of interdigitated microelectrodes (60) coating with conductive polymer material (70). The microelectrode (60) may be enclosed by a first electrode (22), a second electrode (40) and a drainage wall (50).

Owner:AGENCY FOR SCI TECH & RES

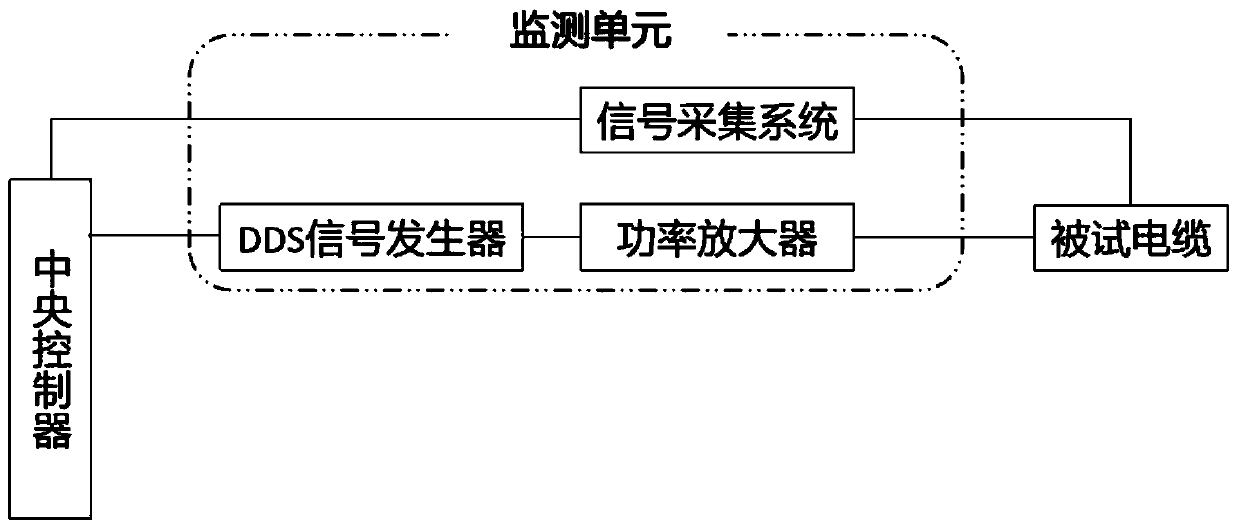

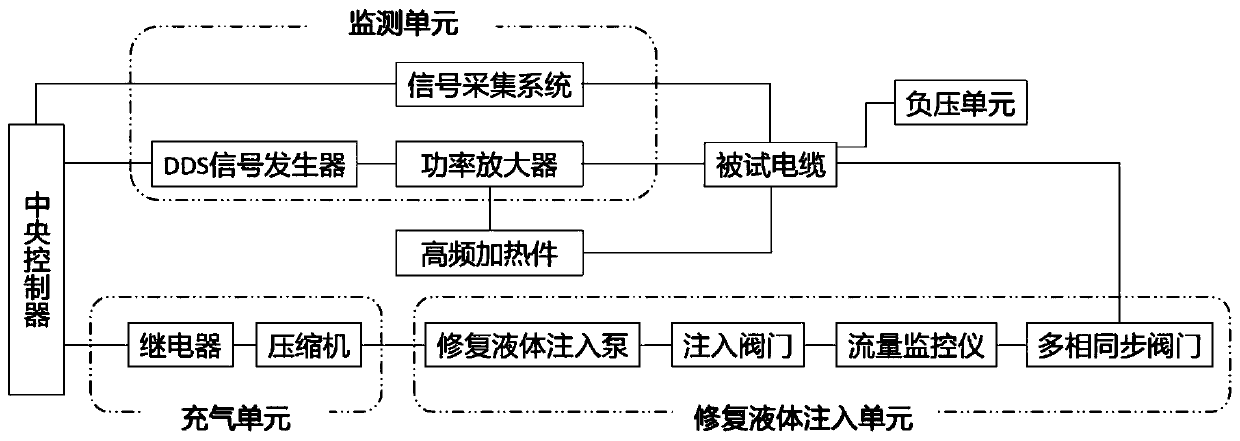

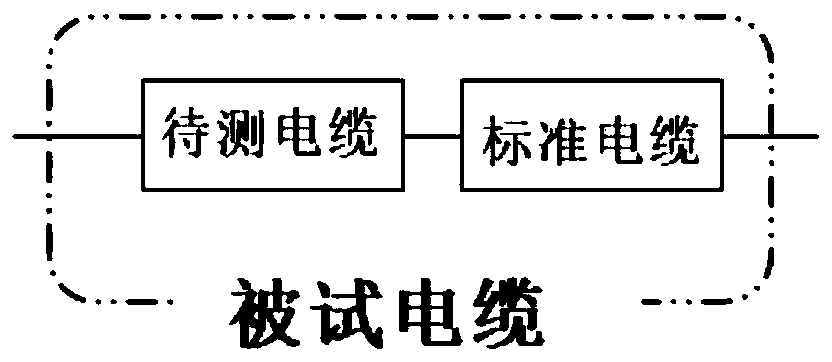

Cable aging treatment and monitoring method and device

PendingCN110082656AMonitoring the process of aging repairReliable and economical meansSpectral/fourier analysisTesting dielectric strengthFrequency spectrumEngineering

The invention provides a cable aging treatment and monitoring method, which is characterized by assembling a cable to be measured and a standard cable with fixed length into a tested cable, wherein the standard cable has a stable dielectric constant; outputting a signal source through a DDS signal generator, wherein the signal source passes through a power amplifier and then, passes through the tested cable; obtaining calculated length L1 of the tested cable through a frequency domain analysis method of impedance spectrum or phase spectrum or a time-domain reflectometry method containing powerenergy; and comparing the calculated length L1 of the tested cable and actual length is L0 of the tested cable. With the help of the standard cable and cable length calculation, the method not only can evaluate the aging condition of the cable to be measured, but also can monitor the aging repair process, and is a very reliable and economical method.

Owner:GAUSS ELECTRONICS TECH

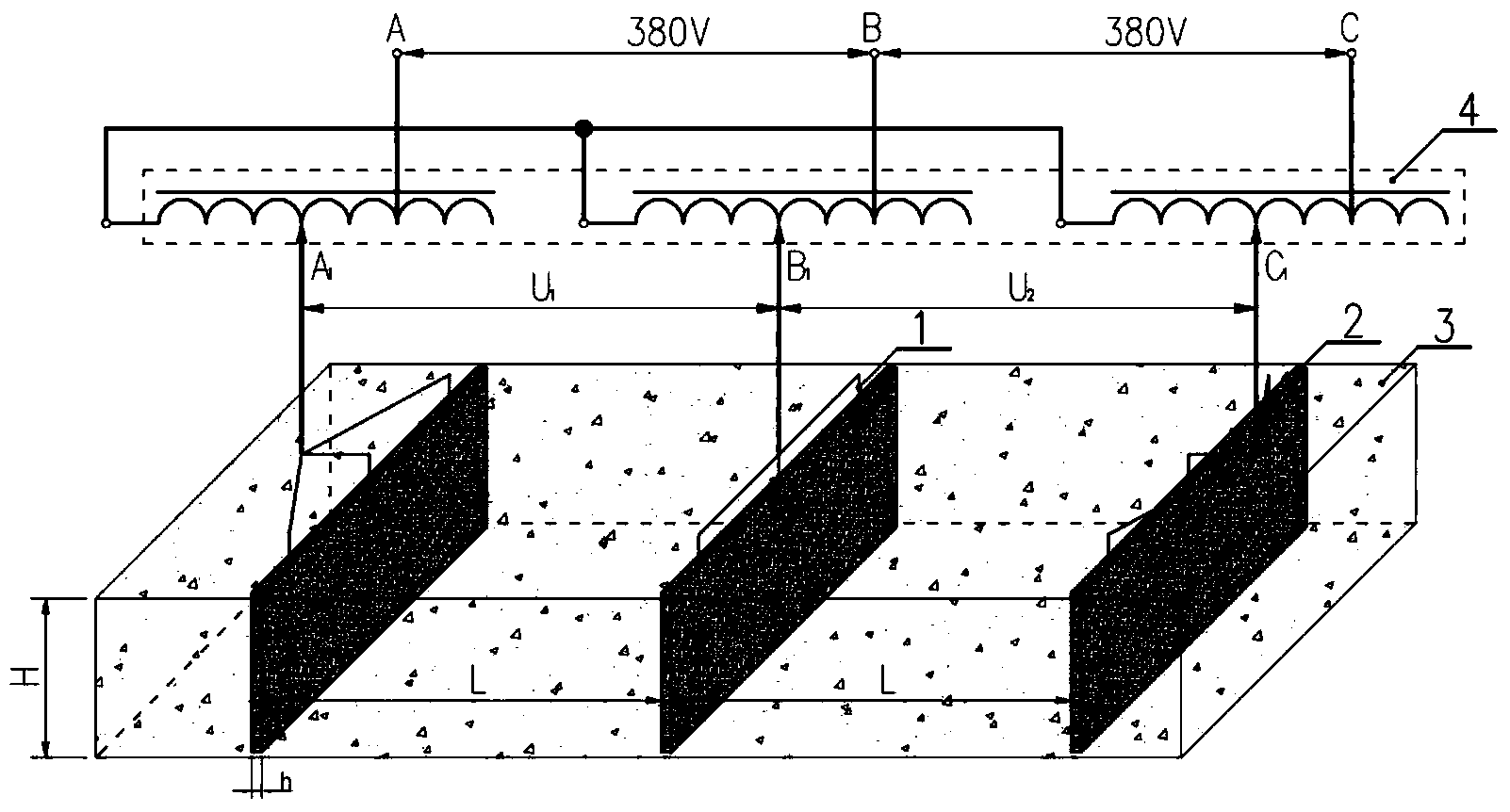

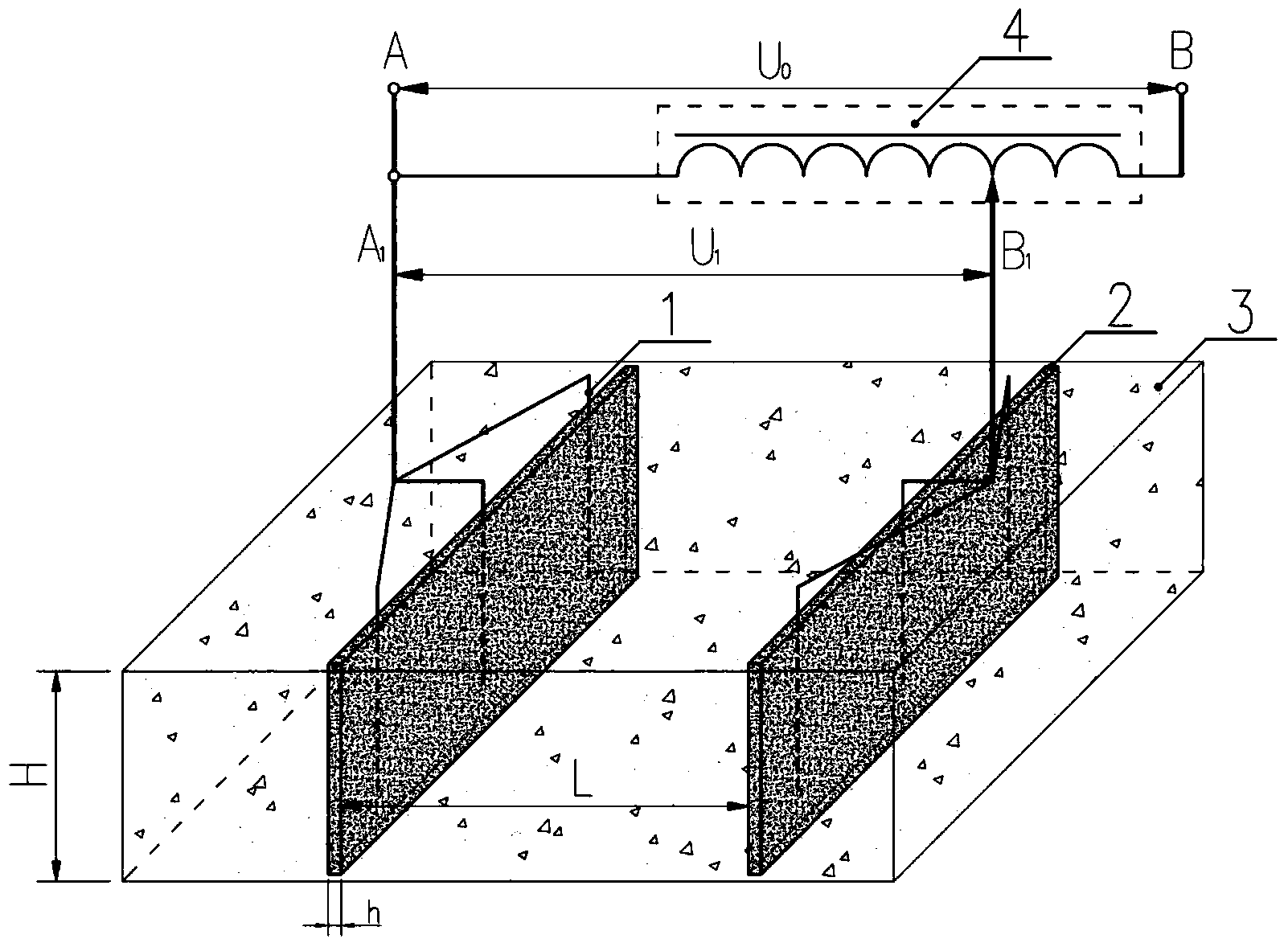

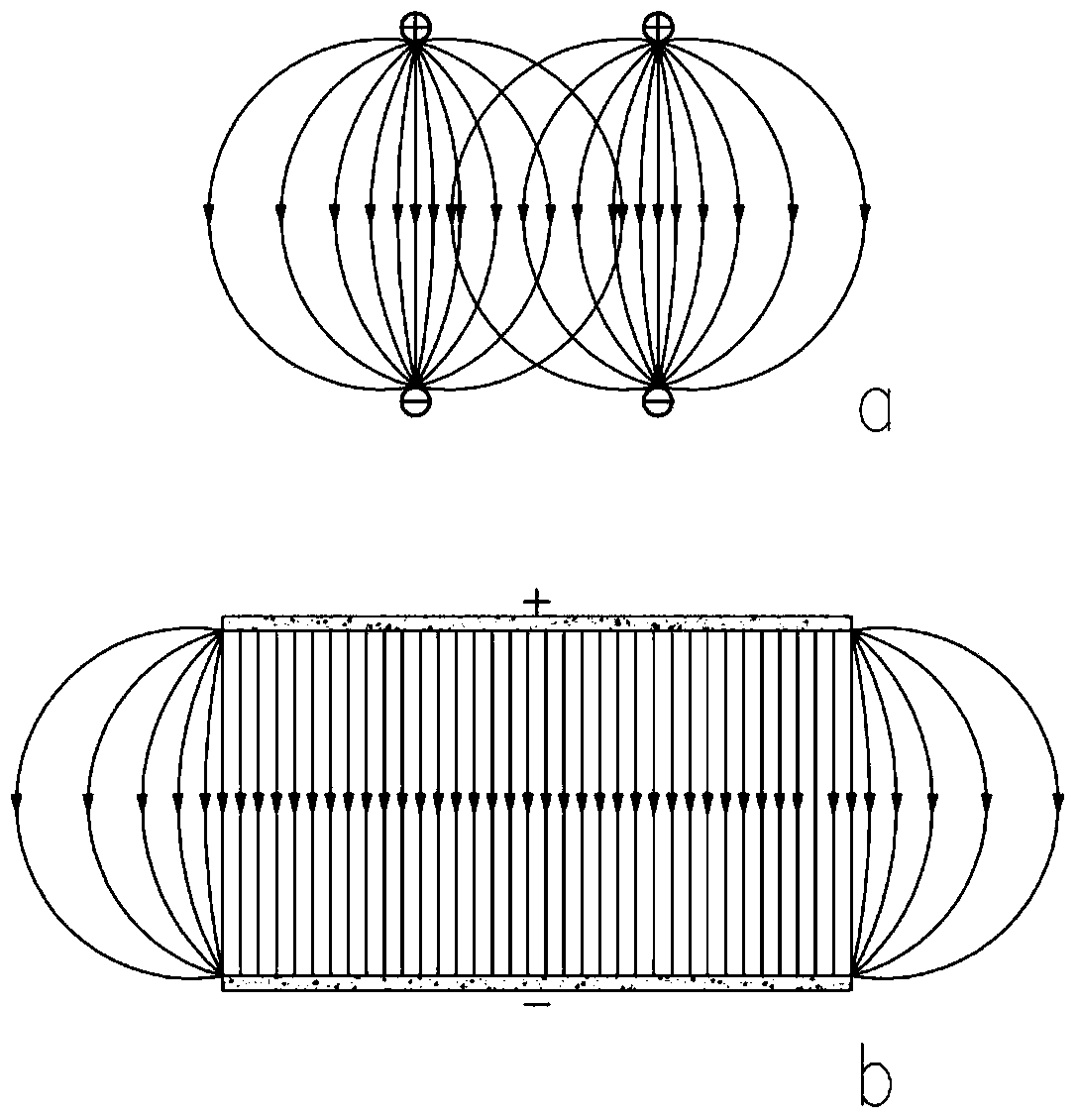

Method and device for obtaining uniform electric field for electrically repairing polluted soil

ActiveCN103706622ALow costUniform heating effectContaminated soil reclamationCarbon particleElectric field

The invention discloses a method for obtaining a uniform electric field for electrically repairing polluted soil. The method comprises the following steps: digging grouped channels or grooves of certain widths and depths at certain intervals in a field needing soil repair; filling current-conducting carbon particles being phi1.5-phi5 millimeters in particle sizes into the grouped channels or grooves; placing leading-in terminals of a power supply into the current-conducting carbon particles in the grouped channels or grooves to form parallel electrodes, wherein the number of the electrodes is 2*N or 3*N, and N is a positive integer. By adopting the method, a uniform soil repair electric field can be provided, spindle type electric field distribution is eliminated, and the problems of the need of repairing microorganism-polluted soil with a completely symmetrical electric field and the like are particularly solved. Compared with the distribution of linear electrodes or matrix electrodes, the method has the advantages of simplicity and easiness in making electrodes, low cost and higher efficiency.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

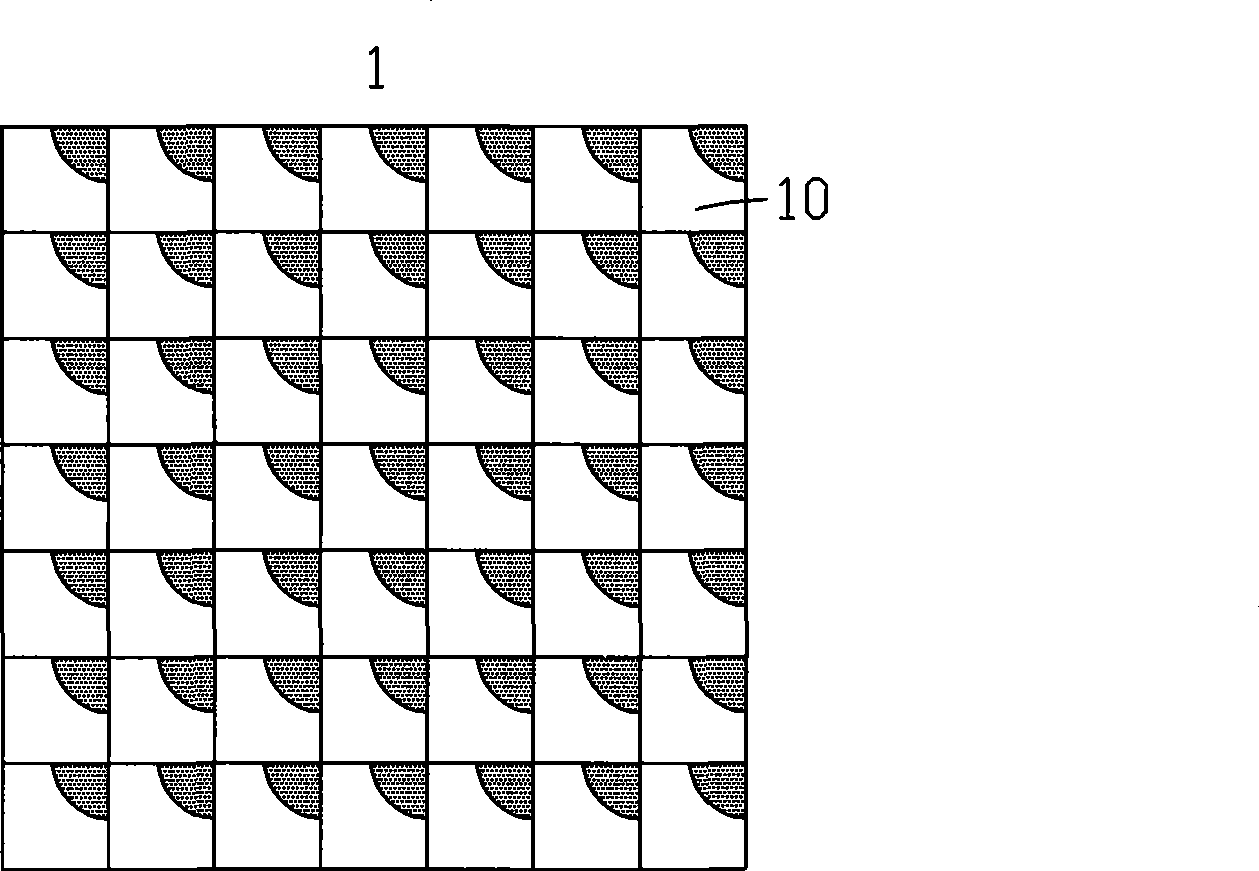

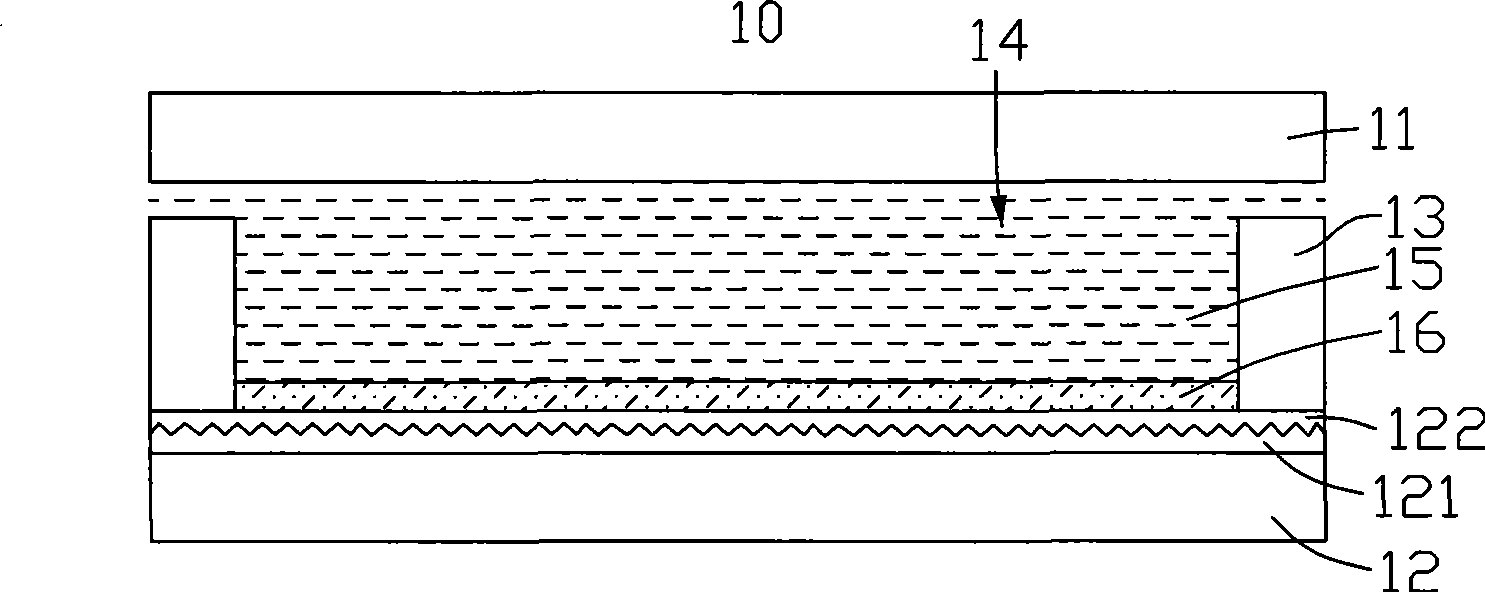

Thin-film transistor substrate, electric moistening type display apparatus method for manufacturing the thin-film transistor substrate

ActiveCN101373777AImprove reliabilityAvoid punctureStatic indicating devicesSemiconductor/solid-state device detailsDisplay deviceOptoelectronics

The invention provides a thin film transistor base plate, an electrowetting displaying device and a production method for the thin film transistor base plate. The thin film transistor base plate comprises a substrate, a plurality of thin film transistors arranged on the substrate, a plurality of reflecting electrodes arranged on the substrate and a water-repellent insulating layer arranged on the reflecting electrodes, wherein each reflecting electrode comprises a first metal layer and a transparent protective layer, and the first metal layer is arranged between the protective layer and the substrate.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

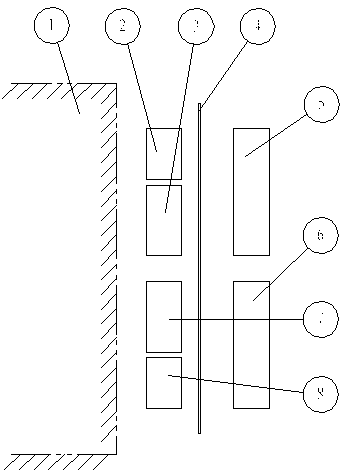

132kv-class 36-pulse-wave transmission rectifier transformer

InactiveCN103280305AReduce volumeReduce lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionPower qualityOvervoltage

The invention relates to a 132kV-class 36-pulse-wave transmission rectifier transformer and belongs to the technical field of transformers. According to the technical scheme, the rated voltage of a primary side is 132kV, and the primary side is subjected to D connection and in an all-insulation structure; and a secondary side is subjected to double split and phase shifting, and the difference between phase shifting angles is 10 degrees. A single transformer outputs 12 pulse waves, and three transformers output 36 pulse waves. Low-voltage windings comprise an axially arranged low-voltage basic winding I (2) and low-voltage phase shifting winding I (3) and an axially arranged low-voltage basic winding II (7) and low-voltage phase shifting winding II (8). High-voltage windings comprise a high-voltage winding I and a high-voltage winding II which are connected in parallel vertically. By means of the rectifier transformer, the utility rate of space of the transformer is improved, and the size of the transformer and the production cost are reduced; effects of grid-side overvoltage on valve-side rectifying elements and effects of valve-side harmonic components on power grids are reduced; and the transformer is reliable in insulation, high in short-circuit bearing capacity and phase shifting angle accuracy and capable of improving power quality.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

Method for forming liquid crystal alignment layer

InactiveCN102279486AUniform electric field componentGood molecular alignmentNon-linear opticsPositive typeSubstrate surface

A method for forming a liquid crystal alignment layer. First, a first substrate is provided, and a conductive layer, an insulating layer covering the conductive layer, and a plurality of alignment electrodes arranged on the surface of the insulating layer are sequentially formed on the surface of the first substrate. Then a second substrate is arranged parallel to the first substrate, and then a liquid crystal alignment composition and a positive type liquid crystal material are mixed and injected between the first and second substrates, and placed between the conductive layer and the alignment electrode A voltage is applied between the first and second substrates, so that an electric field is generated between the first and second substrates. After the liquid crystal alignment composition is deflected to a predetermined direction, the liquid crystal alignment composition is polymerized to form an alignment layer. Since the arrangement of the conductive layer and the alignment electrodes can make the distribution of the electric field more uniform, the alignment consistency of the liquid crystal alignment composition can be improved.

Owner:TO YOUNG TRADE CO LTD

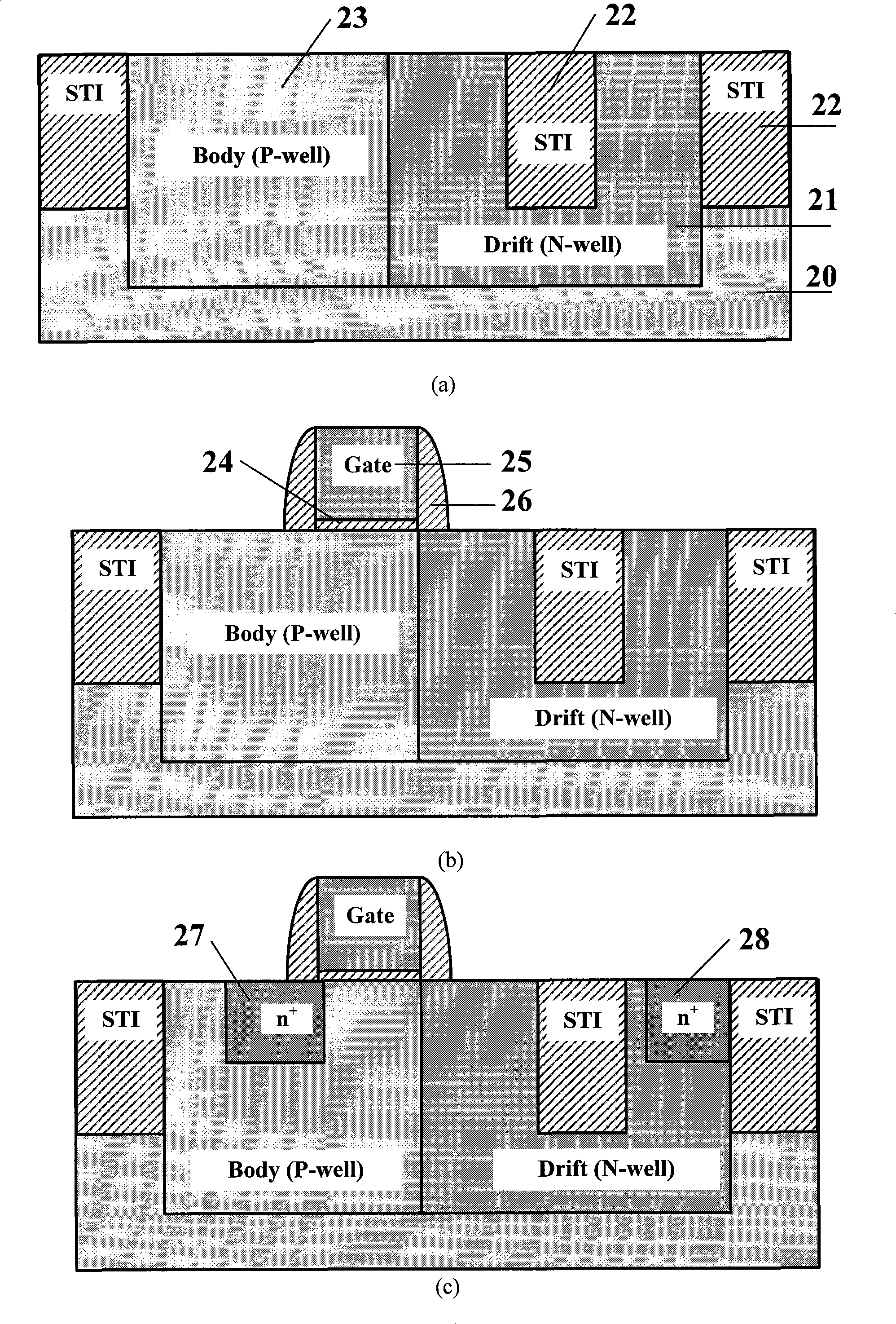

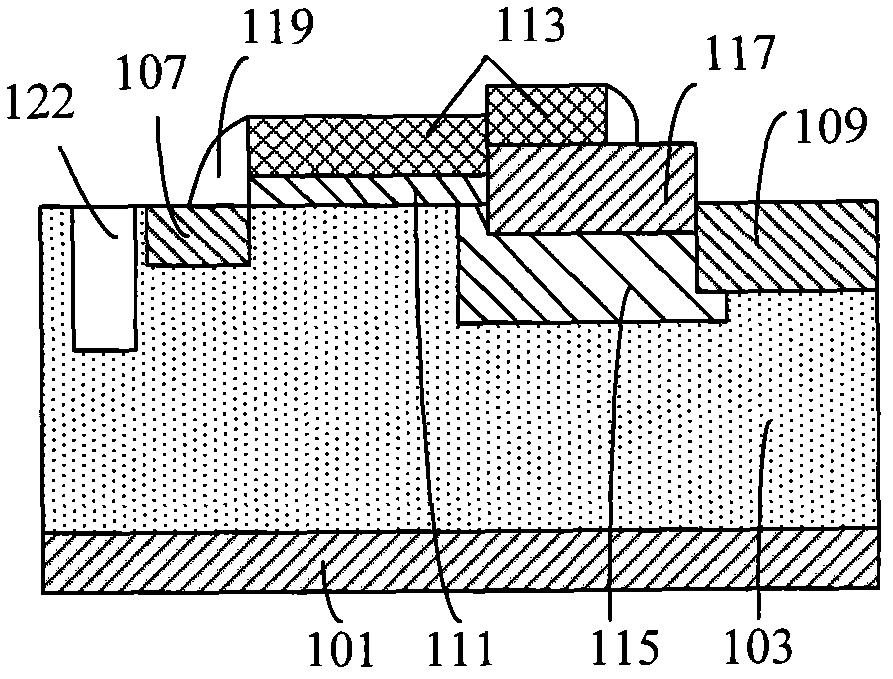

LDMOS device and fabrication method thereof

ActiveCN102386211AIncreasing the thicknessReduce junction depthSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSBody region

The invention discloses a laterally diffused metal oxide semiconductor (LDMOS) device; the LDMOS device comprises a source region, a gate region, a drain region, a body region, and a drifting region with doped type opposite to the body region; the body region is arranged on a substrate region, and the drifting region is arranged between the drain region and the body region. The LDMOS device also comprises an insulated dielectric layer, and the insulated dielectric layer is positioned on the drifting region and below the gate region. By using the structure of the LDMOS device provided by the invention, the puncture voltage of the device can be enhanced, so that the on-resistance is lowered and the power consumption of the device is reduced; and in the adjusting and fabricating process, junction depth for adjusting the insulated dielectric layer and the drifting region has smaller effect on the other devices.

Owner:CSMC TECH FAB2 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com