132kv-class 36-pulse-wave transmission rectifier transformer

A rectifier transformer and transformer technology, applied in the field of transformers, can solve the problems of the rectifier transformer with few pulses, high grid-side harmonic current, and poor power quality, and achieve the effects of reducing the volume of the transformer, reducing partial discharge, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

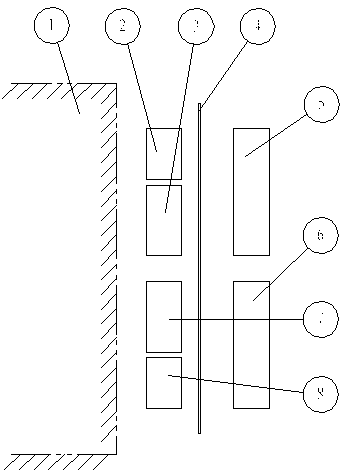

[0012] A 132kV class 36-pulse drive rectifier transformer, including iron core 1, low-voltage basic winding I2, low-voltage phase-shifting winding I3, ground shield 4, high-voltage winding I5, high-voltage winding II6, low-voltage basic winding II7 and low-voltage phase-shifting winding II8; The rated voltage of the side is 132kV, D connection, fully insulated structure; the secondary side is double-split, phase-shifted, and the phase-shift angles are 10° different from each other. A single transformer outputs 12 pulses, and three transformers output 36 pulses; each transformer includes Three-phase three-column iron core and winding, each phase winding is composed of a low-voltage winding and a high-voltage winding that are sequentially placed on the iron core from inside to outside; the low-voltage winding includes low-voltage basic winding I2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com