Patents

Literature

272results about How to "Reduce partial discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite insulating tube type bus and method for preparing the same

ActiveCN101339824AImprove insulation performanceImprove securityRigid-tube cablesManufacturing rigid-tube cablesState of artElectrical conductor

The invention discloses a compound insulating tube busbar and a preparation method thereof in the technical field of high voltage insulated conduction. The compound insulating tube busbar comprises a conductor tube, a compound insulating layer, a semiconductor electric strip layer, a shielding layer and a sleeve, wherein, the conductor tube is positioned on the innermost layer; a plurality of the compound insulating layers and the semiconductor electric strip layers are crosswise arranged at the external part of the semiconductor tube; a copper foil layer is arranged at the external part of the semiconductor electric strip layer and the sleeve is arranged at the external part of the copper foil layer. The preparation method of the invention adopts different properties of a solid buddle-free insulating film strip and insulating liquid to enwind and solidify the shaped insulating tube busbar on the surface of the tubular conductor, which causes the production procedure to be simple and the maintenance to be simple and convenient; compared with the prior art, the compound insulating tube busbar has better insulating property and longer service life, and can be applied to bitter environments.

Owner:SHANGHAI XIBANG ELECTRIC

Dry type high-voltage capacitor core and manufacture method thereof

ActiveCN102013322AHigh mechanical strengthImprove cooling effectFixed capacitor electrodesFixed capacitor dielectricEpoxyCapacitance

The invention relates to a capacitance type major insulation structure used in a power system high-voltage electrical apparatus device and a manufacture method thereof. A dry type high-voltage capacitor core comprises a zero screen, an insulation layer, a capacitor screen, a grounding end screen, a measuring leading-out wire and an insulation outer protecting layer, wherein the inner insulation layer is wound to the required size by using glass fiber roving in a certain manner; the capacitor screen is uniformly wound into the required size by using an aluminum foil or metal wire net or semiconductor material or carbon fiber; and the capacitor screen and the insulation layer are alternatively wound to the required sizes, and then an epoxy resin curing system is poured under the vacuum state, and subjected to temperature rise and cured into a multi-layer pure solid and interface-free concentric round serial capacitor voltage-sharing structure. The capacitor core made by using the method has the advantages of high mechanical strength, good heat radiation, low local discharge capacity, high product qualified rate, low manufacture cost, short manufacture period and the like.

Owner:NANJING ELECTRIC HIGH VOLTAGE BUSHING

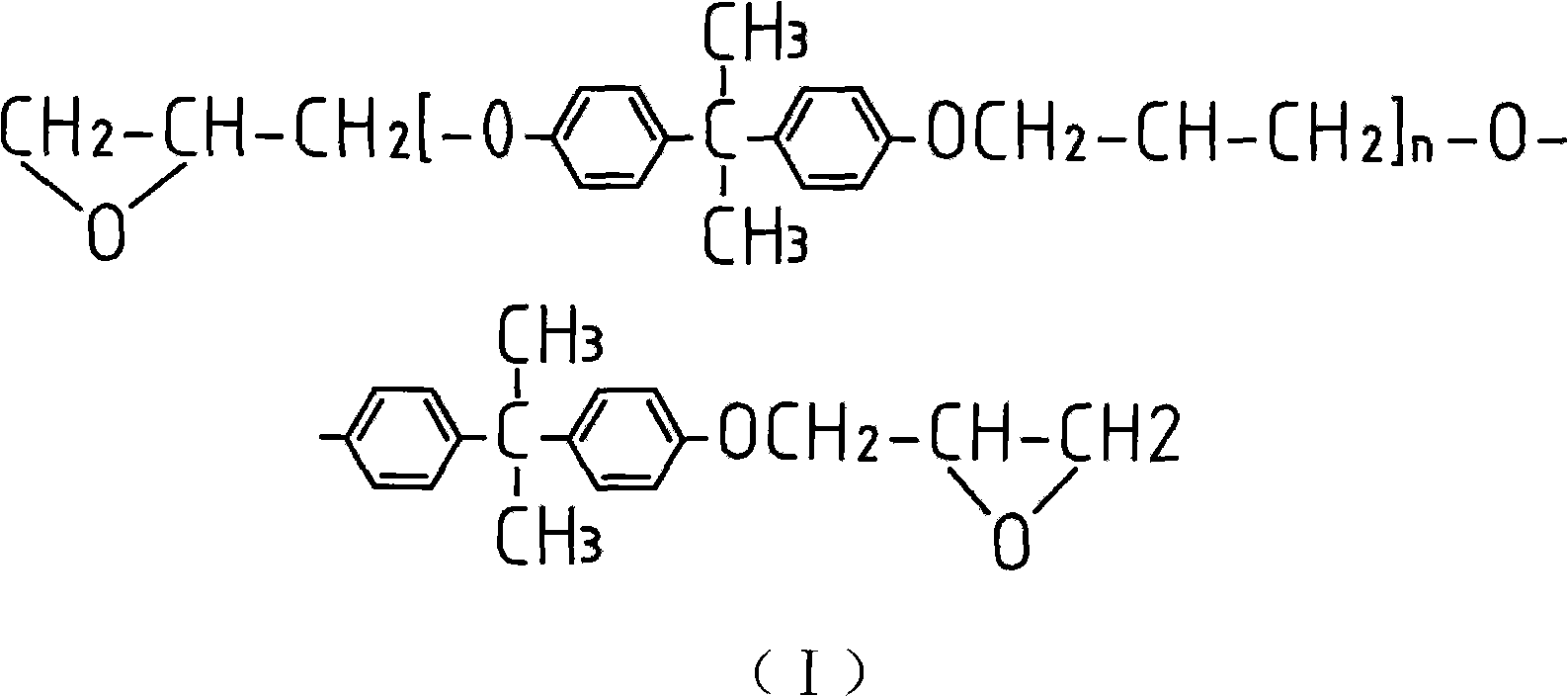

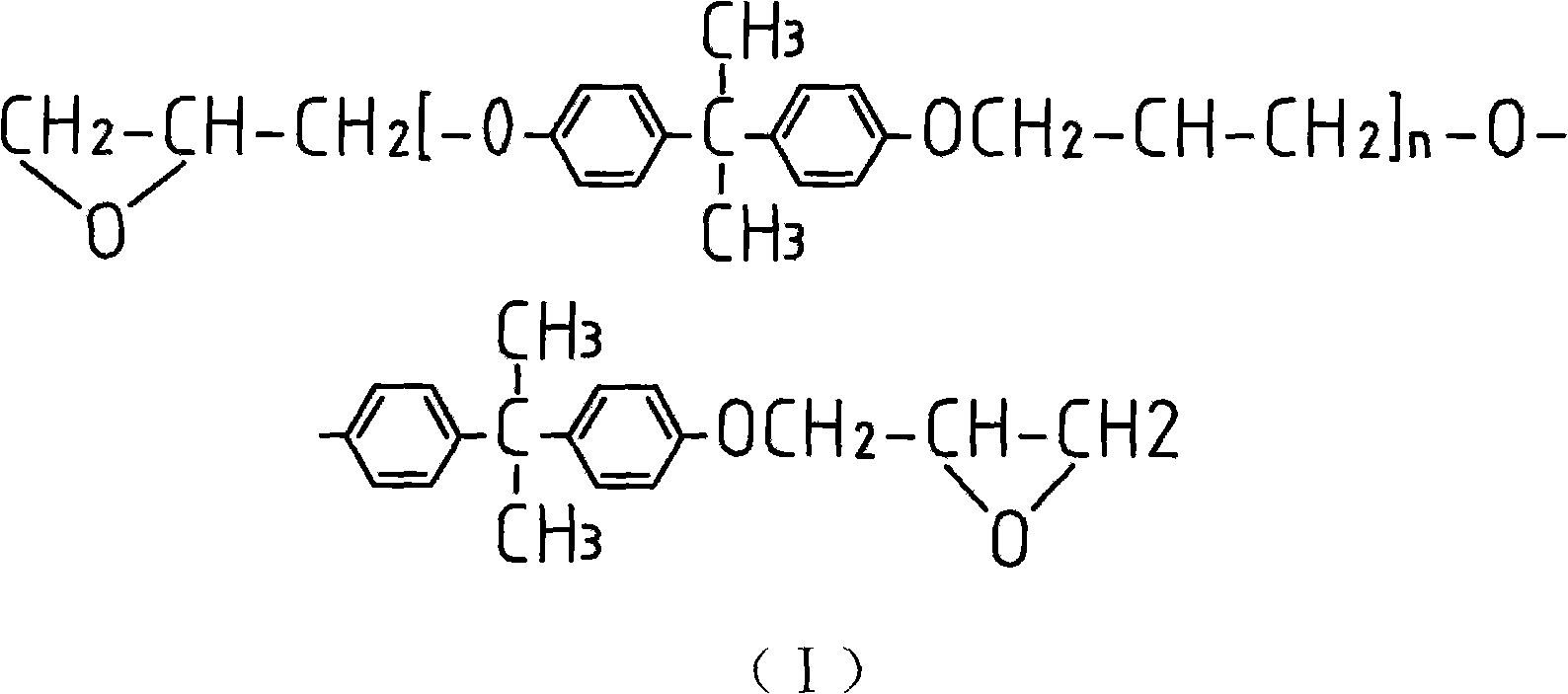

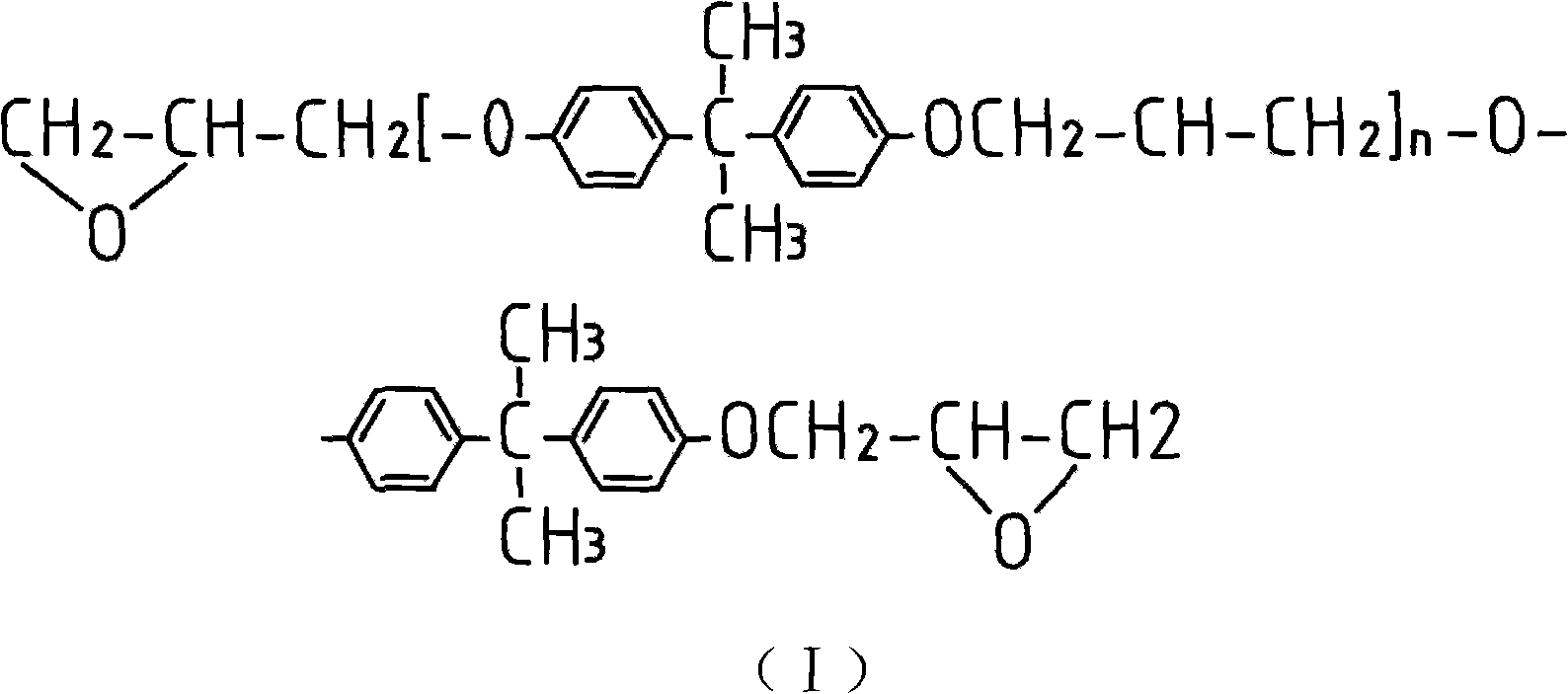

Epoxy resin composition for transformers and process for casting transformer by composition

The invention relates to the technical field of resin, in particular to an epoxy resin composition for transformers and a process for casting a transformer by the composition. The composition comprises epoxy resin, a curing agent, a toughening agent and an accelerating agent, the epoxy resin is a mixture of general formula (I), the epoxy groups on both terminals have reactive activity in the composition unit of the general formula (I), bisphenol A framework provides strong toughness and thermal endurance, a methylene chain has flexibility, ether bond has chemical resistance, and hydroxyl has reactivity and adhesiveness. Brominated epoxy resin of halogenated epoxy resin is taken as an fire retardant, and can be reactive fire retardant and also as flame retardant epoxy resin, thus fire resistance of the cast coil is good, and local discharge is small.

Owner:广东康德威电气股份有限公司

Halogen-free flame retardant epoxy resin composition and dry type transformer poured by same

ActiveCN103146148AReasonable design structureNo pollutionTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEpoxyCombustion

The invention provides a halogen-free flame retardant epoxy resin composition and a dry type transformer poured by the same. The transformer comprises a base, an iron core which is vertically arranged on the base and transformer coils, wherein an upper iron core clamps are arranged above the transformer coil; lower iron core clamps are arranged between the position below the transformer coil and the base; halogen-free flame retardant insulating cushion blocks are respectively arranged between the upper iron core clamps and the transformer coil and between the lower iron core clamps and the transformer coil; the transformer coil comprises a halogen-free flame retardant foil type winding and a halogen-free flame retardant coiling winding; each transformer coil is supported by halogen-free flame retardant foil type coil supporting board, a halogen-free flame retardant iron core clamp insulating piece is arranged between the upper iron core clamp pieces; a conductive copper bar is arranged on the lateral face; and a hanging ring and a pin are further arranged on the upper iron core clamp. According to the transformer provided by the invention, an insulating material is flame-retardant; the burning capacity of a non-metal part is very low; and no smoke exists in high-temperature combustion, and toxic substances are not decomposed, so that no environment pollution is caused, security and environmental friendliness can be achieved.

Owner:PEARL ELECTRIC

Epoxy cast dry transformer

InactiveCN101308721AReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyLow voltage

Disclosed is an epoxy resin cast dry type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp, and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to the outer layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost and requires no daily maintenance. The epoxy resin cast dry type transformer is of strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

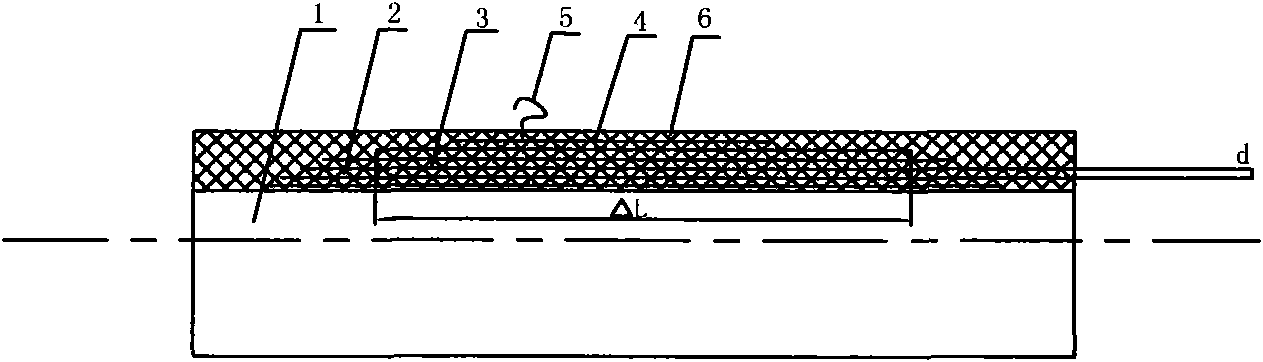

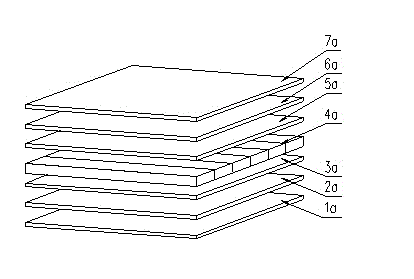

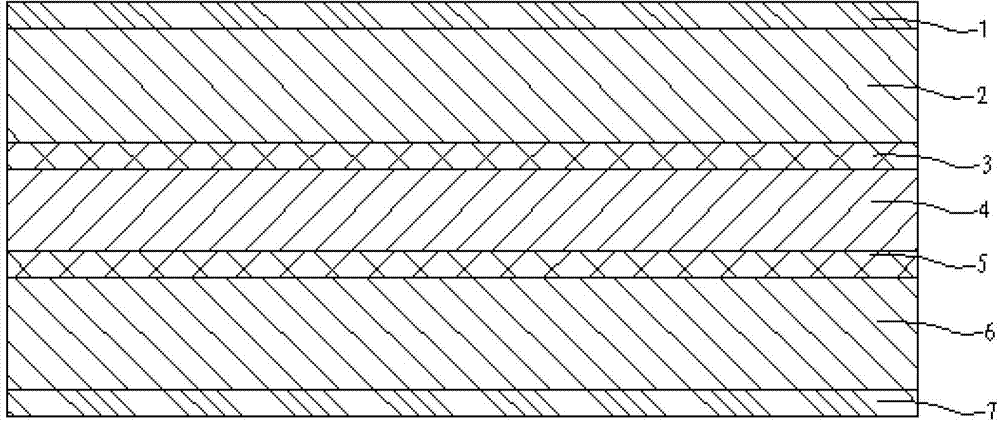

Corona-resistant groove insulation material and preparation method thereof

ActiveCN103400638AImprove corona resistanceReduce partial dischargeWindings insulation materialPlastic/resin/waxes insulatorsNanometreMica

The invention relates to a corona-resistant groove insulation material and a preparation method thereof. The groove insulation material sequentially comprises a first adhesive layer, a first mica paper layer, a second adhesive layer, a film layer, a third adhesive layer, a second mica paper layer and a fourth adhesive layer from top to bottom, wherein the first adhesive layer, the second adhesive layer, the third adhesive layer and the fourth adhesive layer are respectively formed by nano modified adhesive, the nano modified adhesive is the adhesive which is mixed with nano powder body, the content of the nano powder body in the nano modified adhesive is 15 to 25 percent, and the granularity of the nano powder body is 20nm to 100nm. The corona-resistant service life of the insulation material can be improved by more than 50 times compared with the existing groove insulation material; and meanwhile, the paint quantity in the resin immersing process can be increased, and the mechanical property and the electric insulation performance of a curing system can be improved. In addition, the cost of the groove insulation material is lower, so that the industrialized mass production and popularization of the groove insulation material can be favored.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

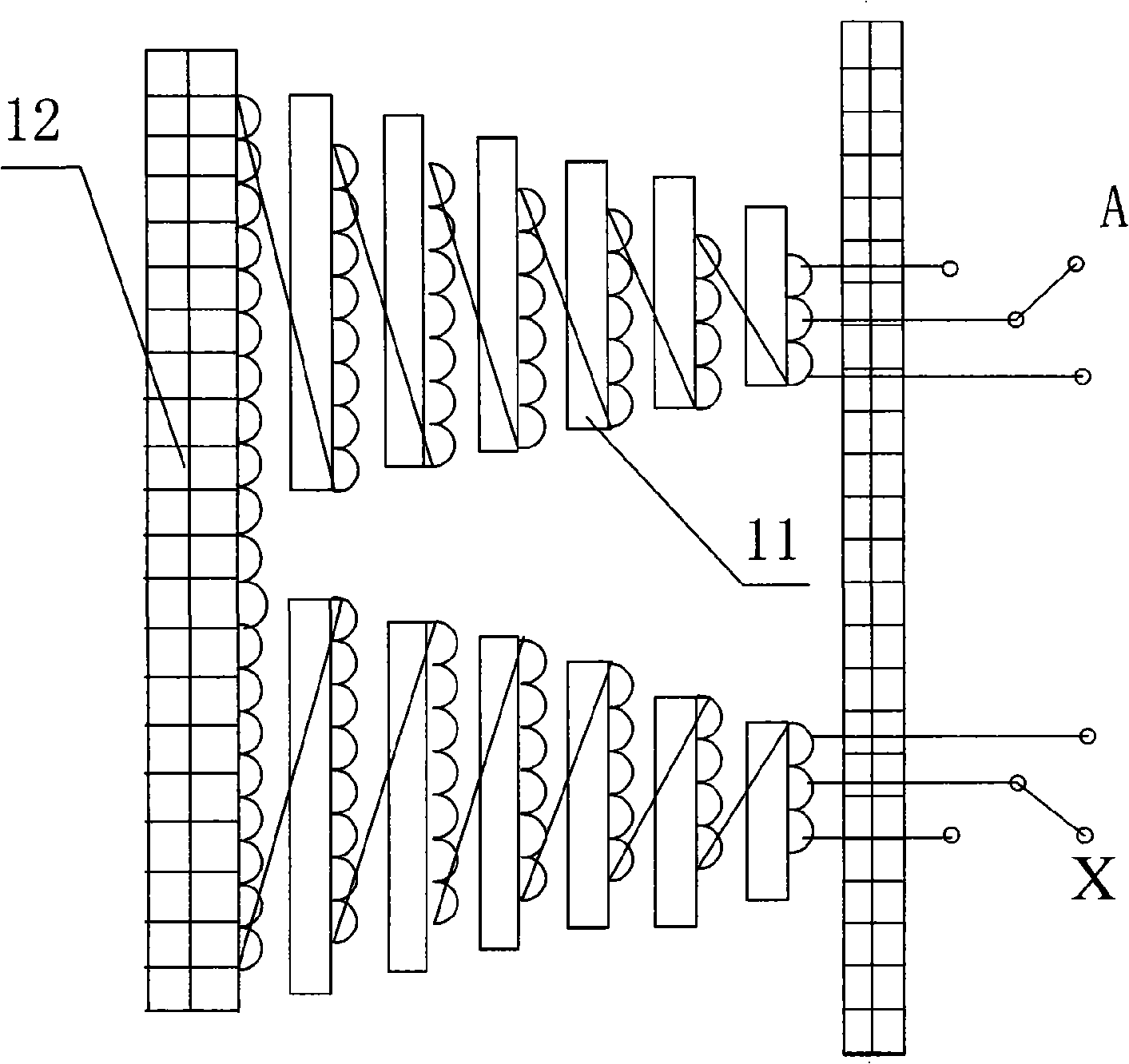

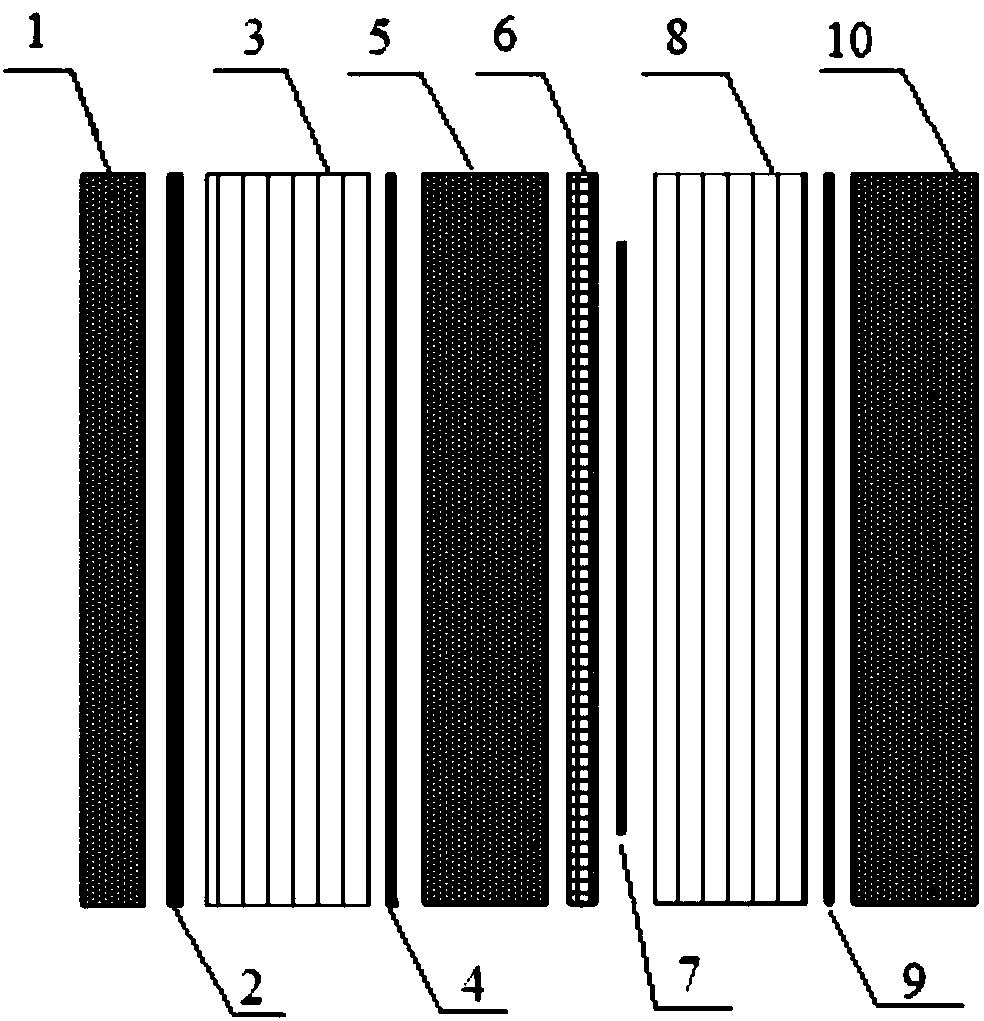

132kv-class 36-pulse-wave transmission rectifier transformer

InactiveCN103280305AReduce volumeReduce lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionPower qualityOvervoltage

The invention relates to a 132kV-class 36-pulse-wave transmission rectifier transformer and belongs to the technical field of transformers. According to the technical scheme, the rated voltage of a primary side is 132kV, and the primary side is subjected to D connection and in an all-insulation structure; and a secondary side is subjected to double split and phase shifting, and the difference between phase shifting angles is 10 degrees. A single transformer outputs 12 pulse waves, and three transformers output 36 pulse waves. Low-voltage windings comprise an axially arranged low-voltage basic winding I (2) and low-voltage phase shifting winding I (3) and an axially arranged low-voltage basic winding II (7) and low-voltage phase shifting winding II (8). High-voltage windings comprise a high-voltage winding I and a high-voltage winding II which are connected in parallel vertically. By means of the rectifier transformer, the utility rate of space of the transformer is improved, and the size of the transformer and the production cost are reduced; effects of grid-side overvoltage on valve-side rectifying elements and effects of valve-side harmonic components on power grids are reduced; and the transformer is reliable in insulation, high in short-circuit bearing capacity and phase shifting angle accuracy and capable of improving power quality.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

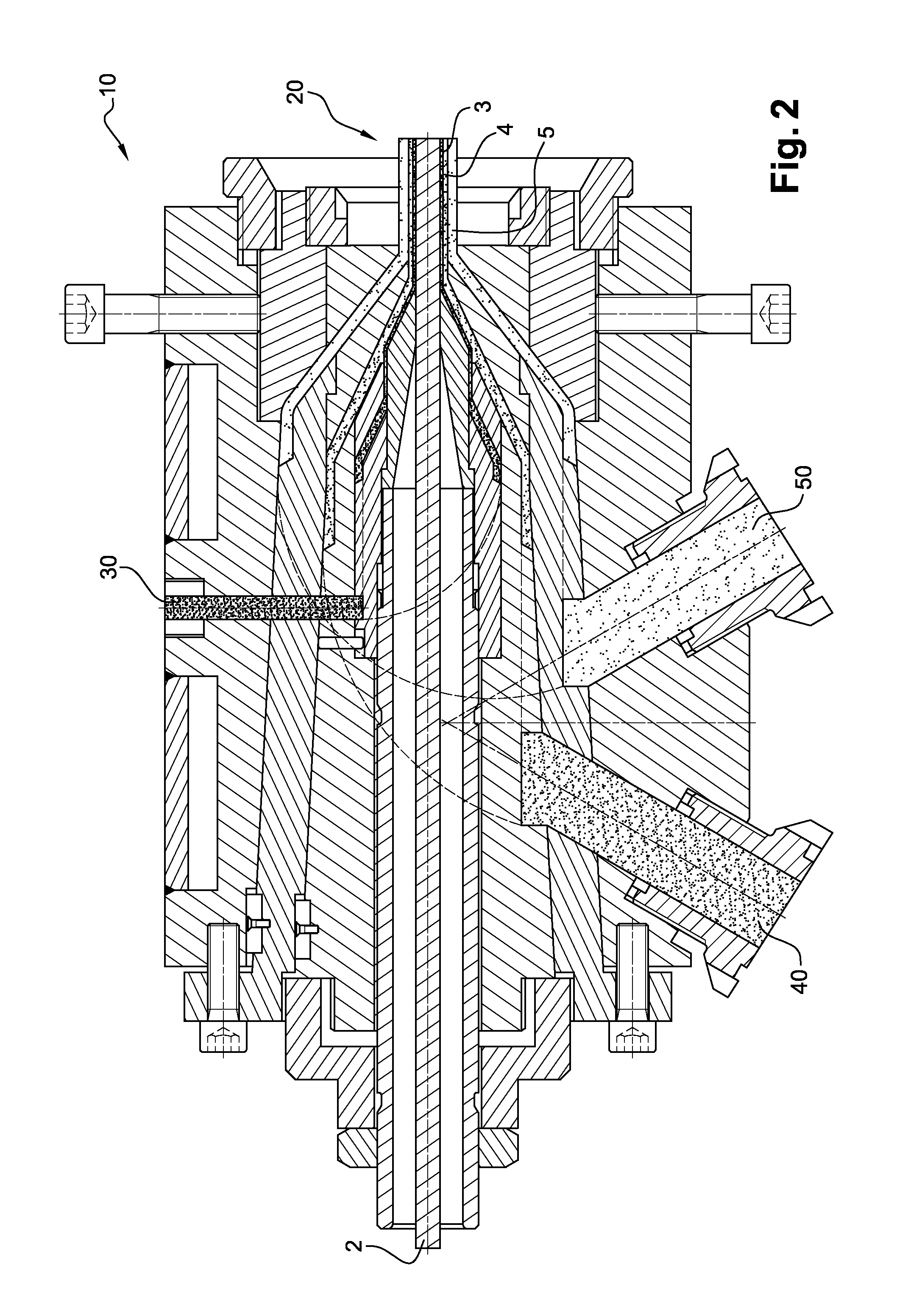

Epoxy resin dipping fibre high voltage insulation core body

InactiveCN1409328AImprove performanceInsulation level will not dropTransformers/inductances coils/windings/connectionsInsulating bodiesCapacitanceEpoxy

A high-voltage insulating core of epoxy resin-impregnated fiber contains a conductor set up in the center of the insulator core whose peripheral surface is wrapped alternately by an epoxy resin-impregnated fiber layer and a capacity polar plate. The epoxy resin fiber-impregnated insulator is wrapped by an umbrella shaped sheath and the capacity polar plate is made of metal mesh or carbon fiber non-woven fabric having good adhesive strength to the epoxy resin-imprengated fibre layer seldom appearing seams of separation in-between. The metal mesh or carbon fiber non-woven fabric has the performance of high-low temperature resistance and keeps stable in long term operation, avoiding carbon powder dropping or mixing into the liquid epoxy resin to guarantee its isolation ability when they are used as the condense screen in the operation of wet process winding.

Owner:BEIJING RUIHENG XINYUAN INVESTMENT

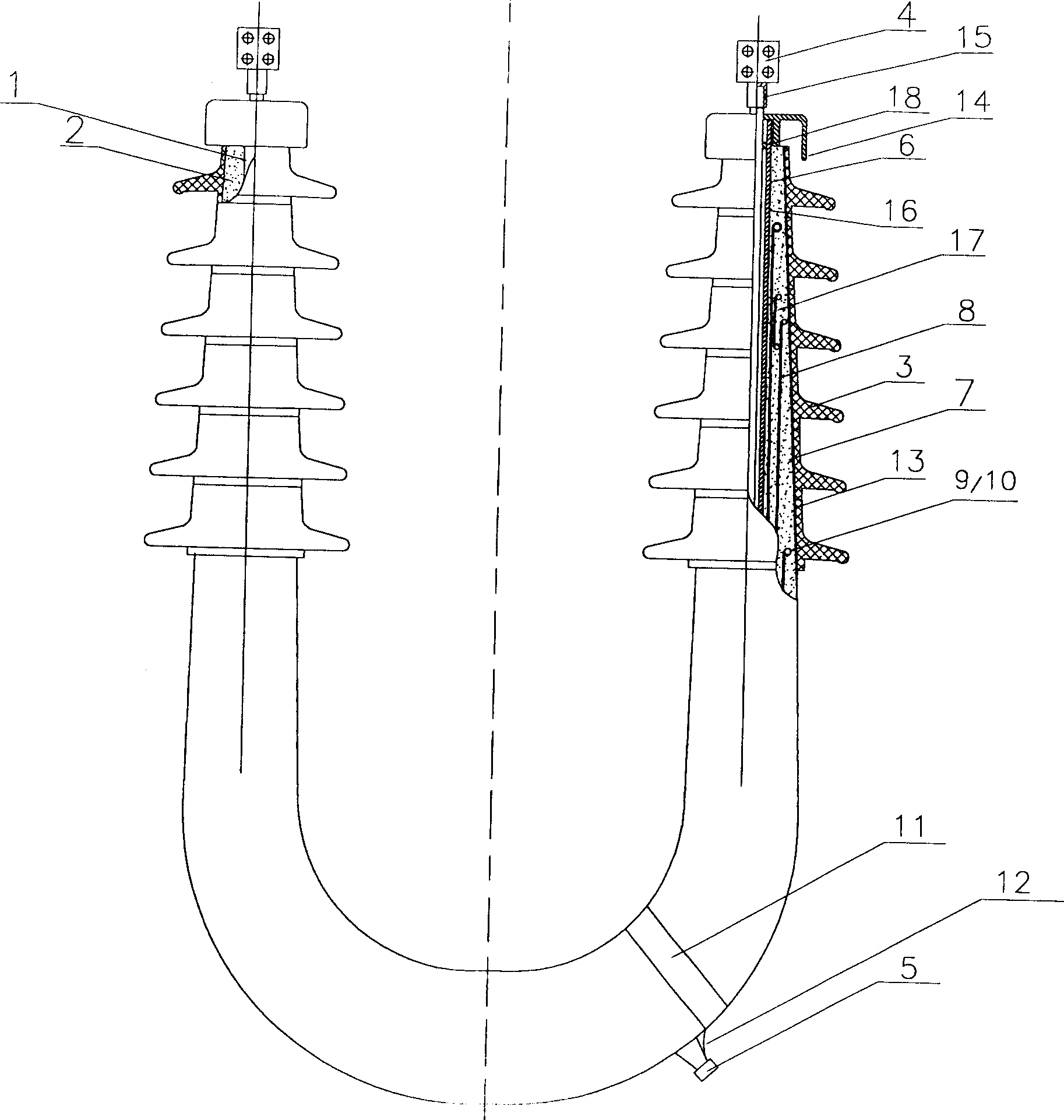

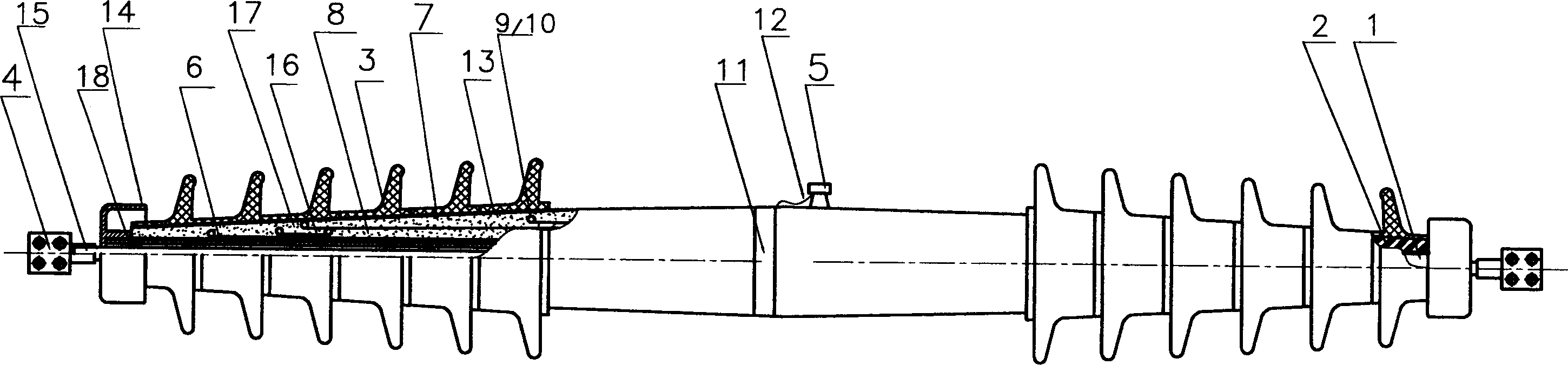

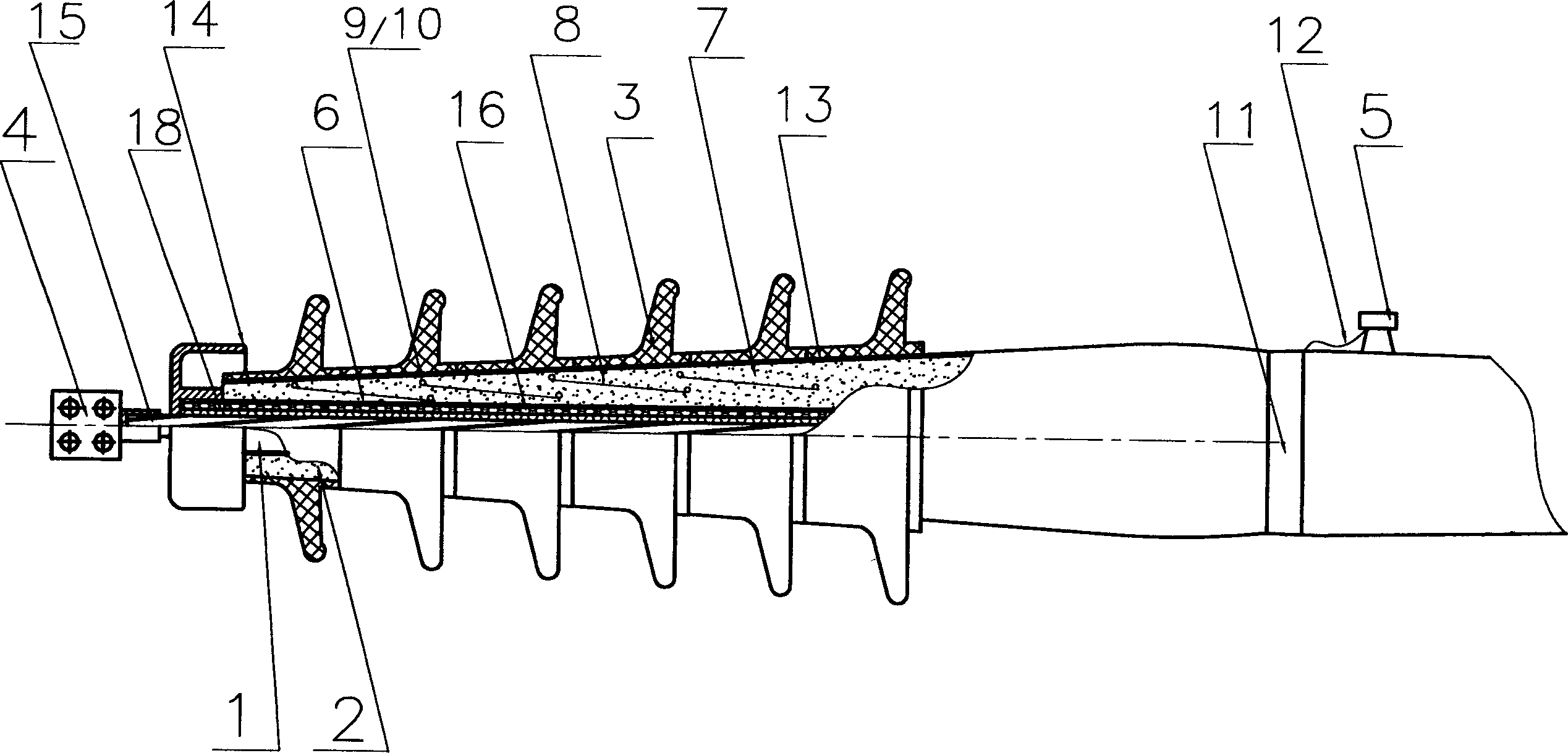

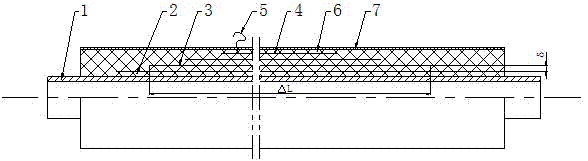

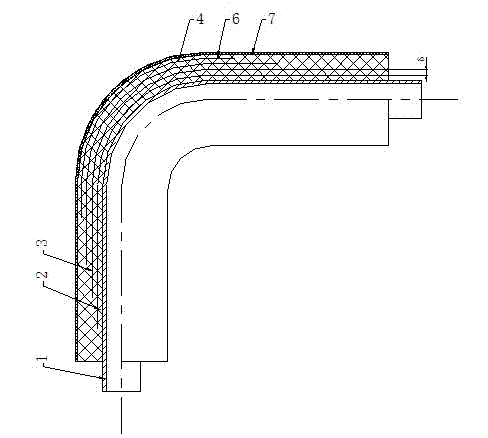

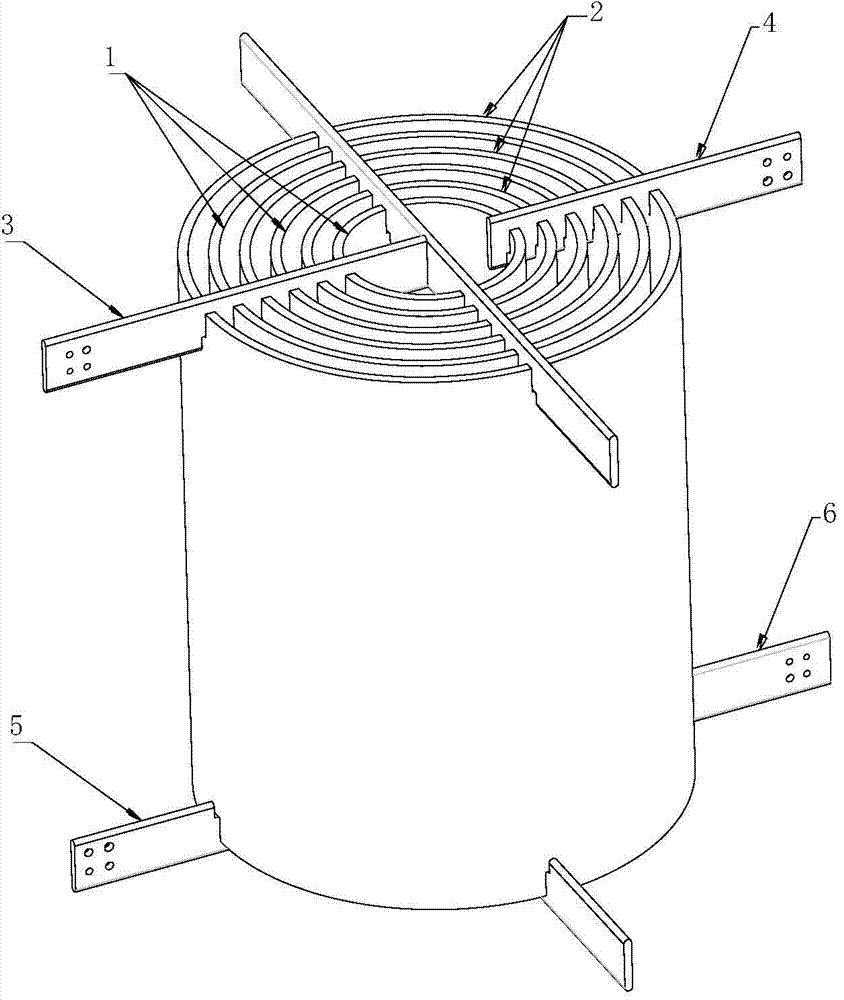

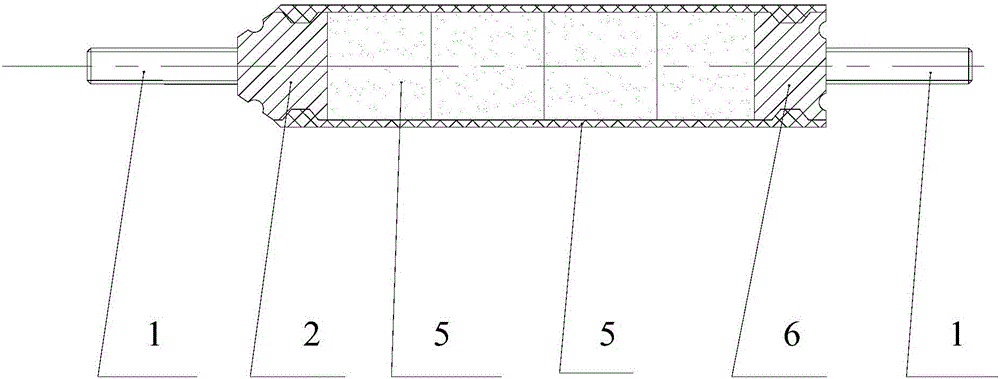

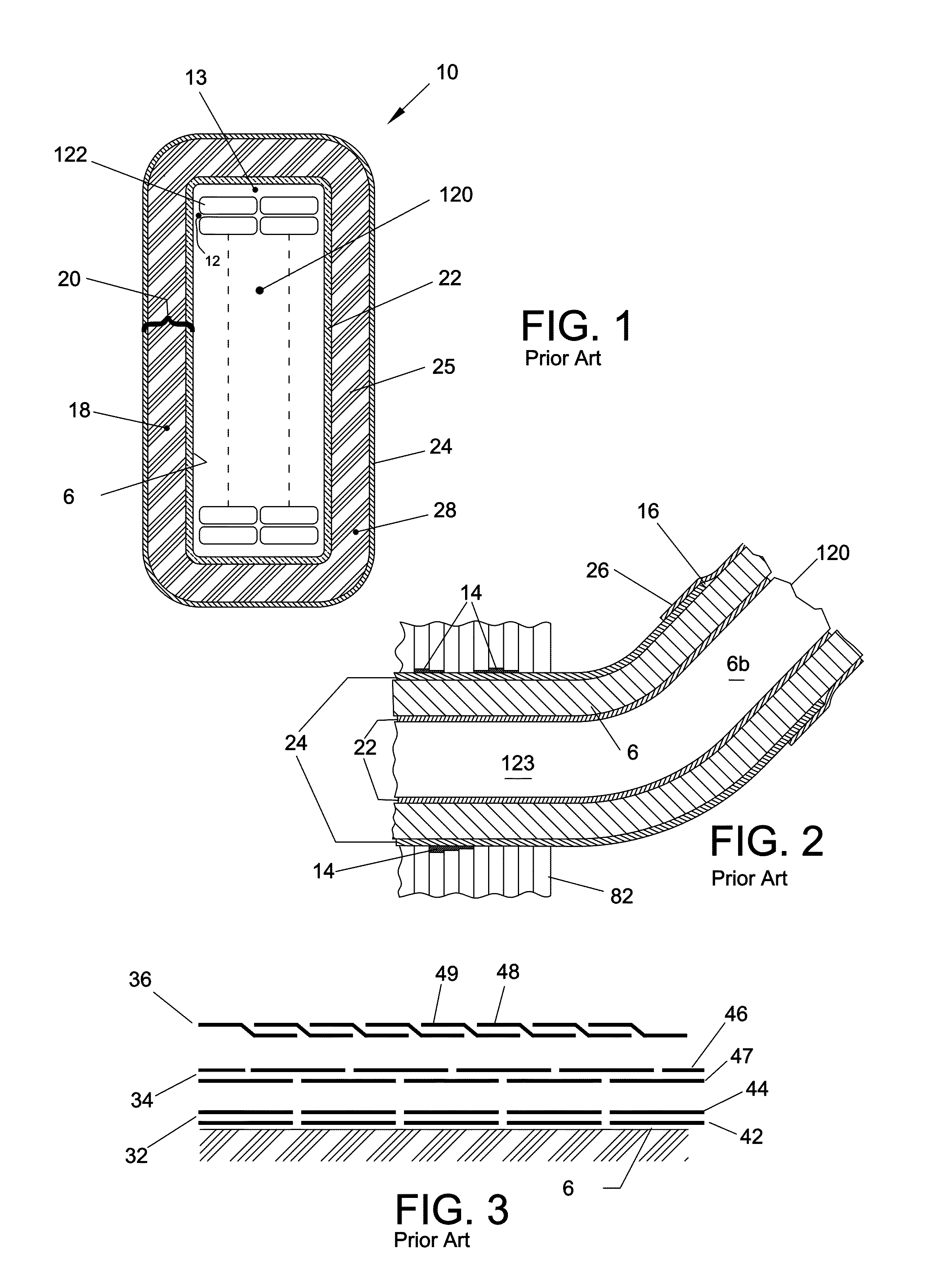

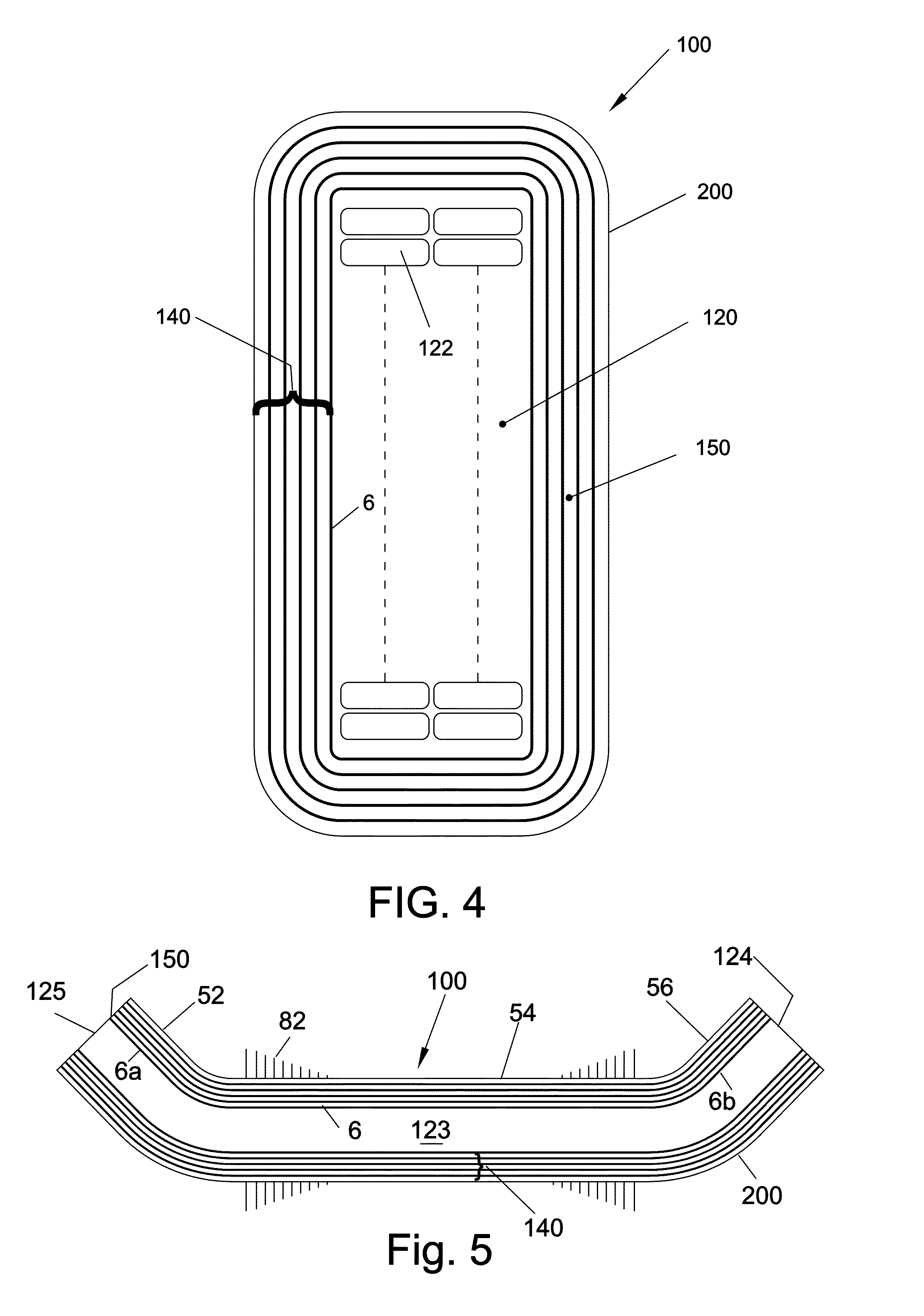

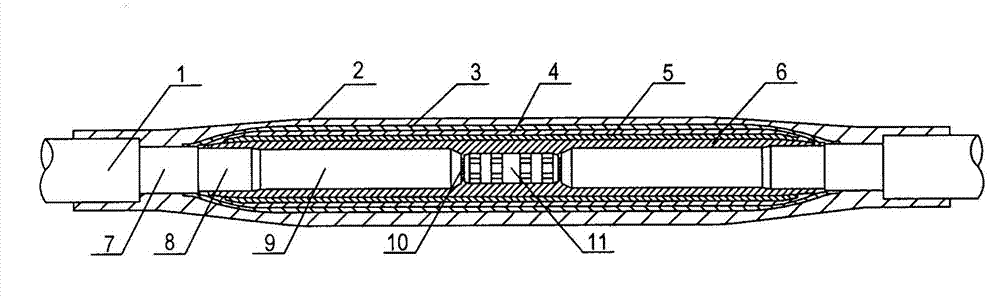

Insulation tube bus and manufacturing method thereof

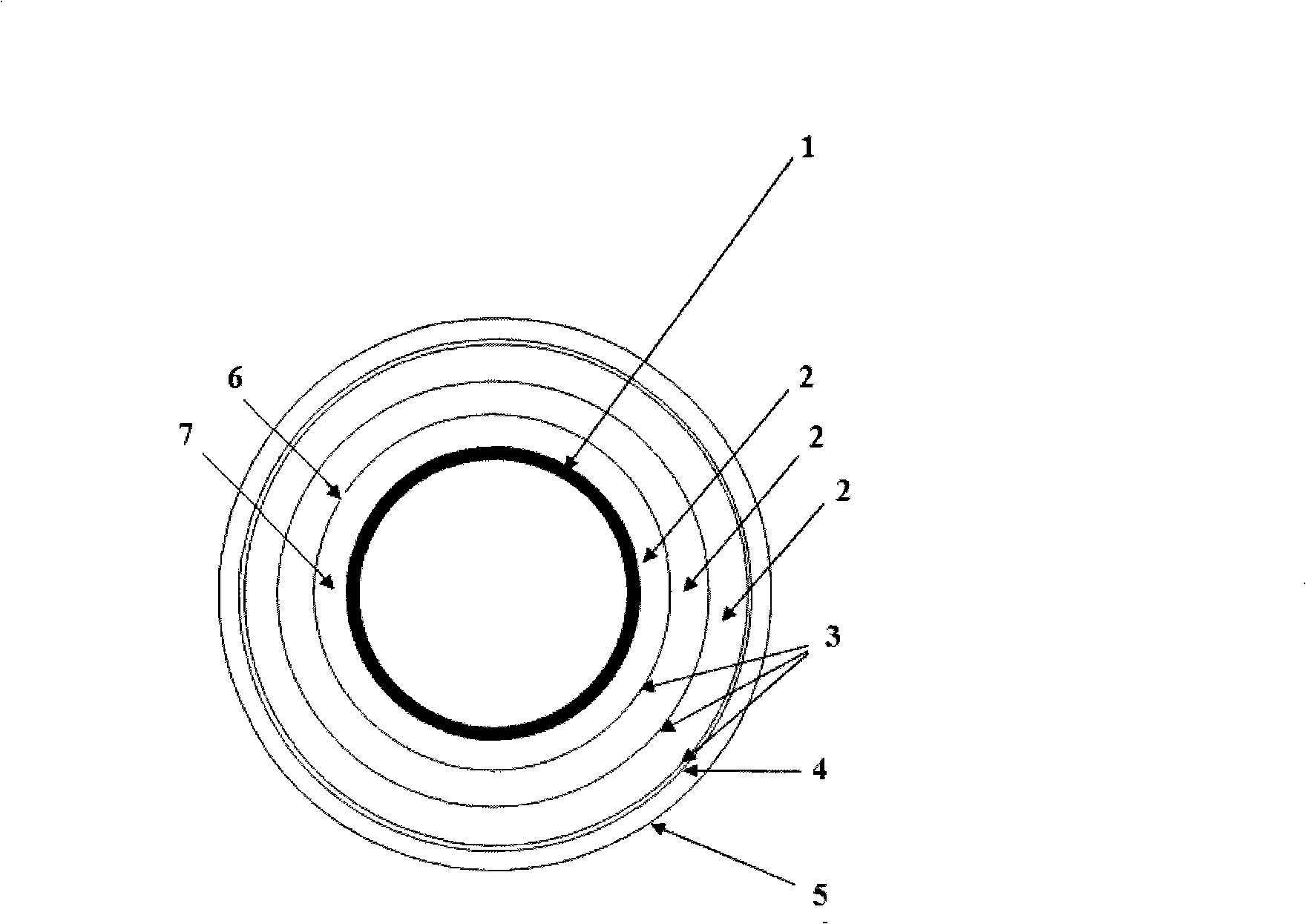

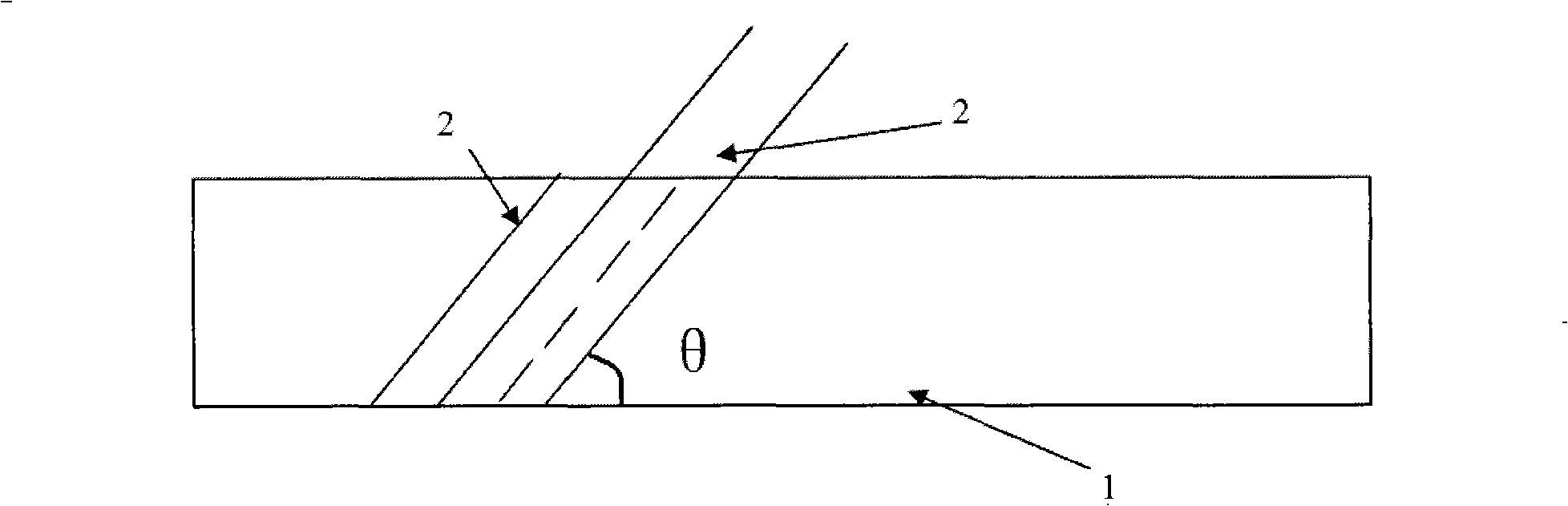

InactiveCN103117117AHigh mechanical strengthImprove cooling effectClimate change adaptationInsulated cablesSemiconductor materialsElectrical conductor

The invention relates to a material technology and a method for manufacturing an insulation tube bus. The insulation tube bus is composed of an electric conduction tube, an insulating layer, a pressure equalizing screen, an external shielding layer, a ground lead, an insulating external protection layer and an ageing resistance layer, wherein the electric conduction tube is manufactured from an aluminum tube or a copper tube, the insulating layer is wound on the electric conduction tube through glass fiber dipping insulating glue and reaches a needed size, the pressure equalizing screen is formed by evenly twining banding or filament bundle conductor or semiconductor materials, the external shielding layer is wound on the pressure equalizing screen and the insulating layer after the pressure equalizing screen and the insulating layer are alternately twined to needed sizes, the ground lead is pre-buried in a set position of the external shielding layer, the insulating external protection layer is wound on the exterior of the external shielding layer, solidification is performed under set temperature and time, and finally the ageing resistance layer is manufactured on the surface of the insulating external protection layer. The insulation tube bus manufactured by using the method has the advantages of being high in mechanical strength, good in heat dispersion, low in magnitude of partial discharge, high in product percent of pass, low in manufacturing cost, short in production cycle, convenient to construct on site, safe and reliable in running, maintenance-free and the like.

Owner:孙闻峰

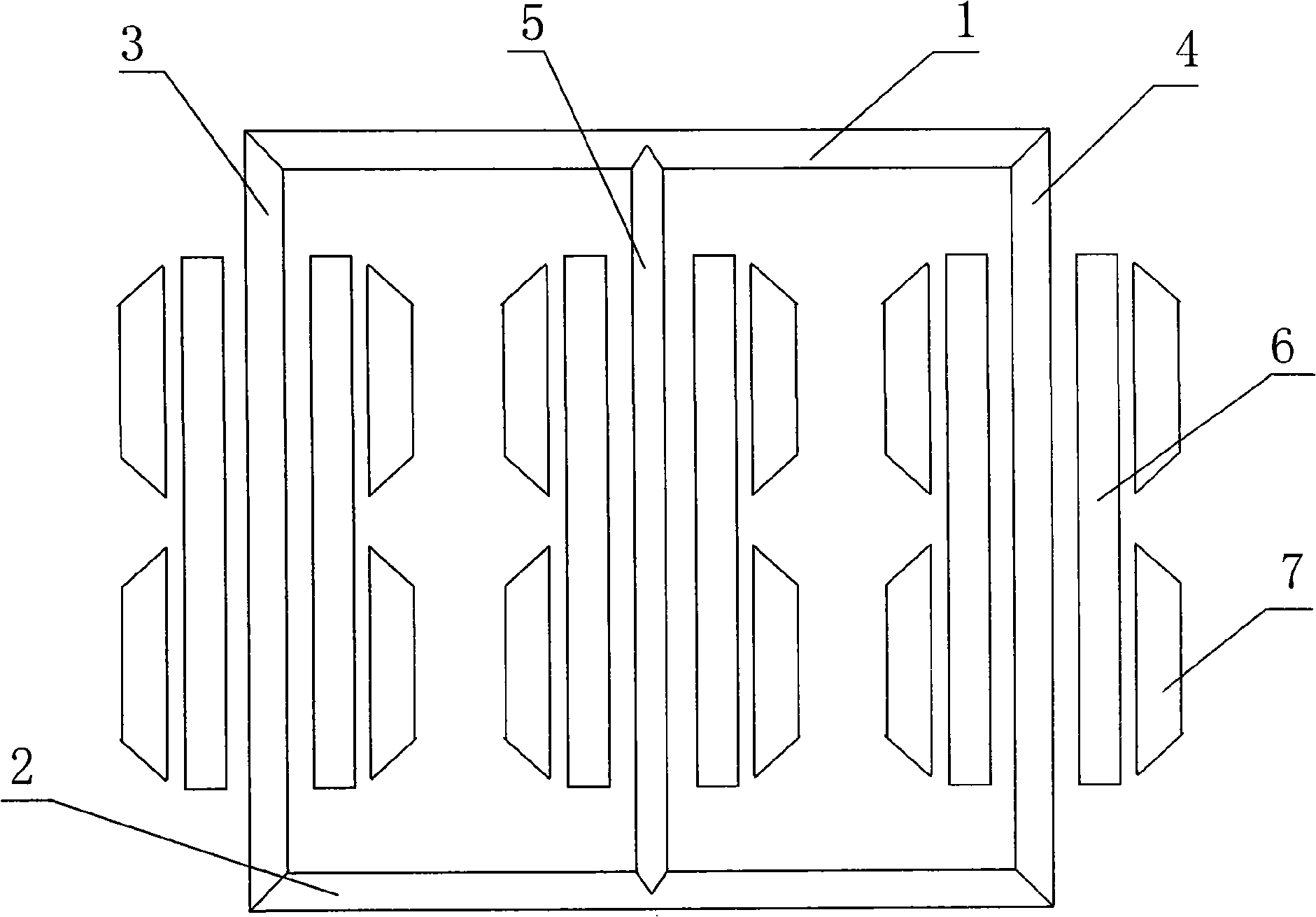

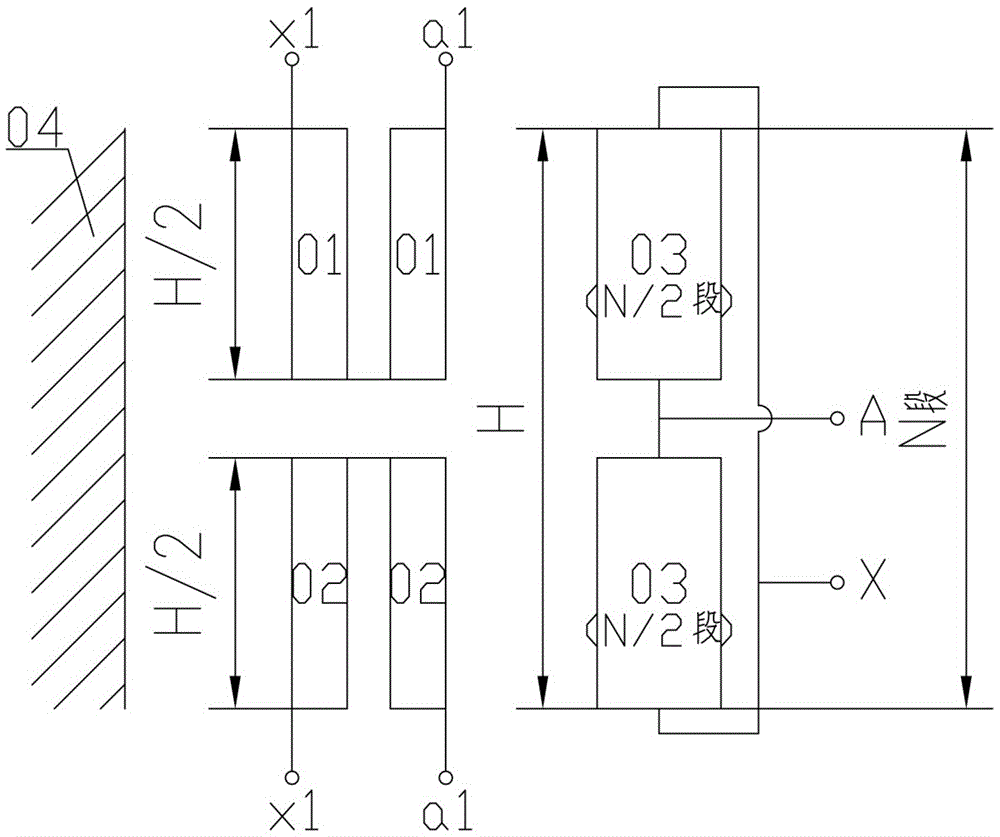

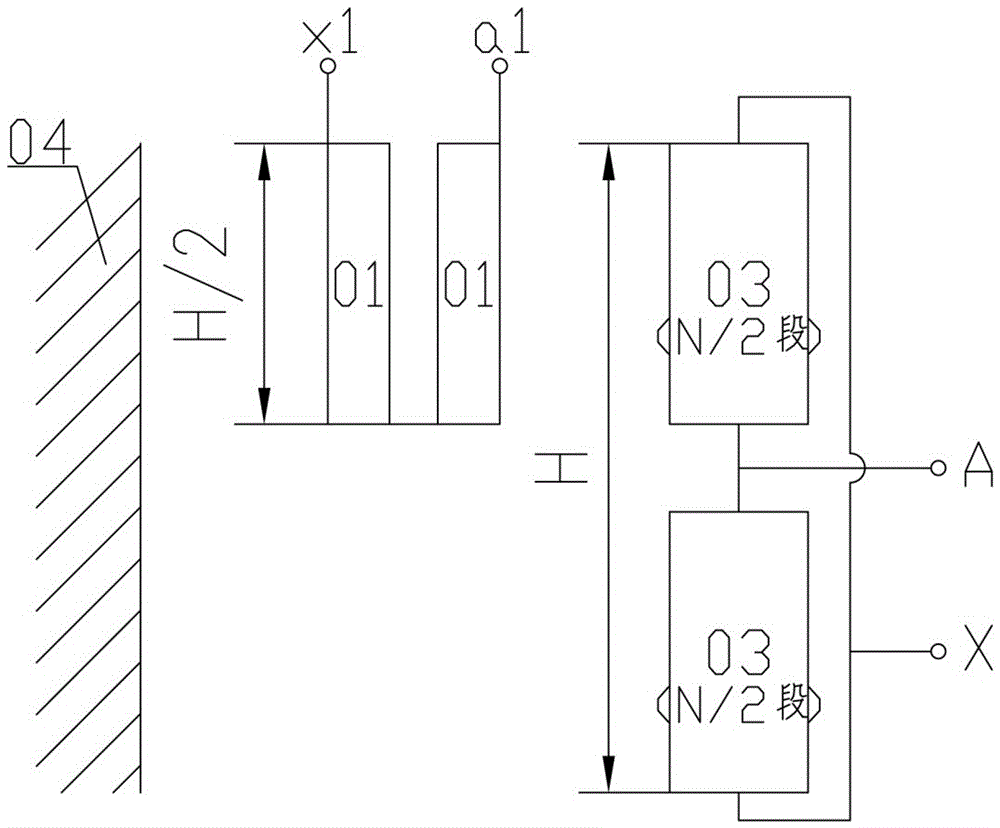

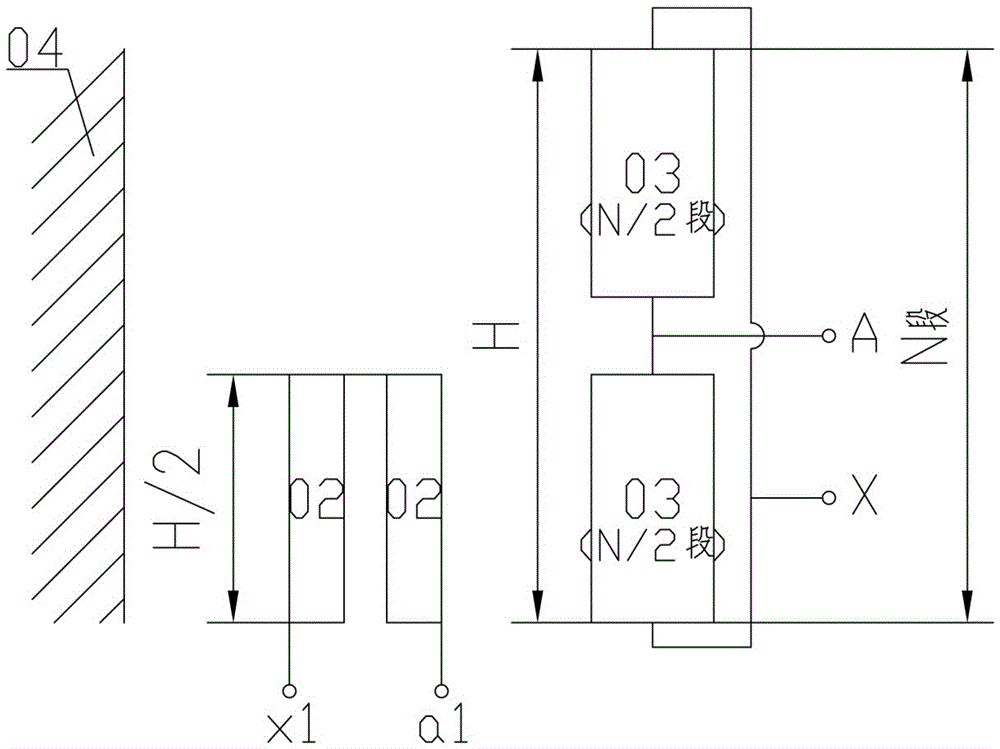

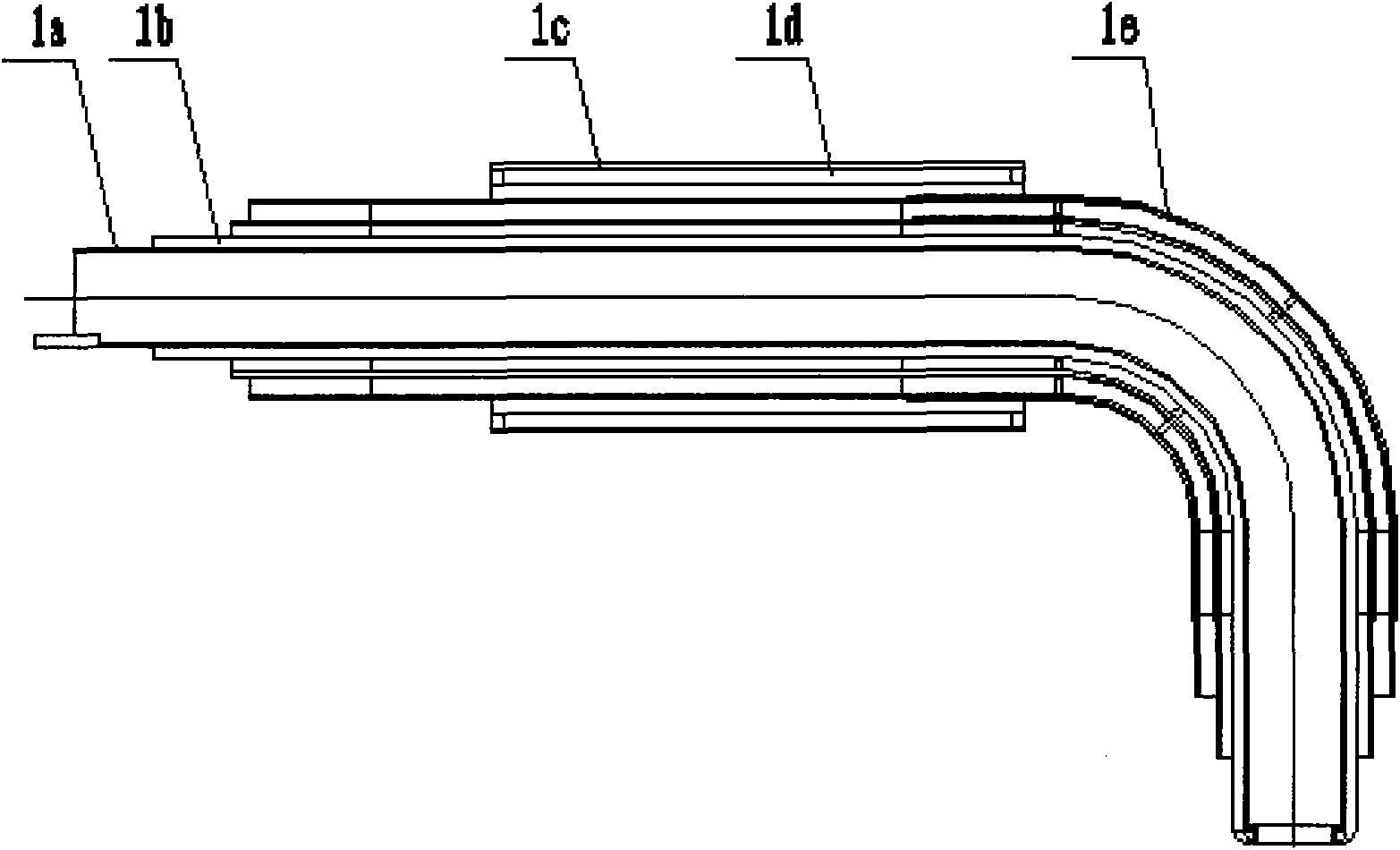

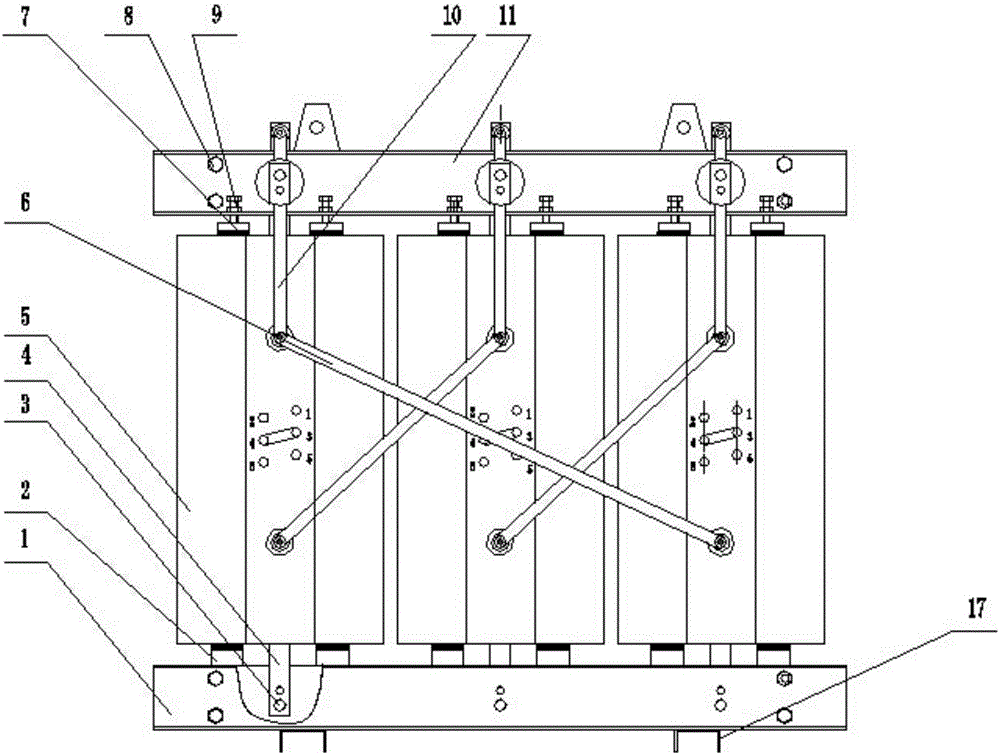

Axial double-split dry-type transformer coil structure with same connection groups and winding method

InactiveCN105590734AReduce partial dischargeHigh mechanical strengthTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureTransformerLow voltage

The invention discloses an axial double-split dry-type transformer coil structure with the same connection groups and a winding method. The axial double-split dry-type transformer coil structure comprises a first low-voltage coil, a second low-voltage coil and a group of high-voltage coils, wherein each of the first low-voltage coil and the second low-voltage coil is provided with two low-voltage coil sections, the two low-voltage coil sections of the first low-voltage coil and the two low-voltage coil sections of the second low-voltage coil are distributed in a cross mode, and two sections of leads for winding forming of the first low-voltage coil and the second low-voltage coil are leaded in and out from the upper end and the lower end respectively. The high-voltage coils are provided with multiple high-voltage coil sections distributed in the axial direction, the high-voltage coil sections are sequentially and mutually connected in series, and leads for winding forming of the high-voltage coils are leaded in and out from the upper end and the lower end respectively. The axial height of the first low-voltage coil and the axial height of the second low-voltage coil are both consistent to the axial height of the high-voltage coils.

Owner:GUANGDONG GUANGTE ELECTRIC

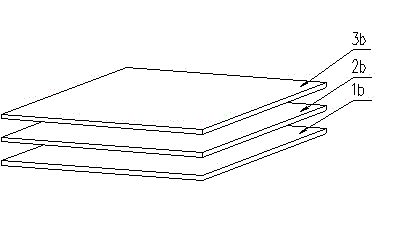

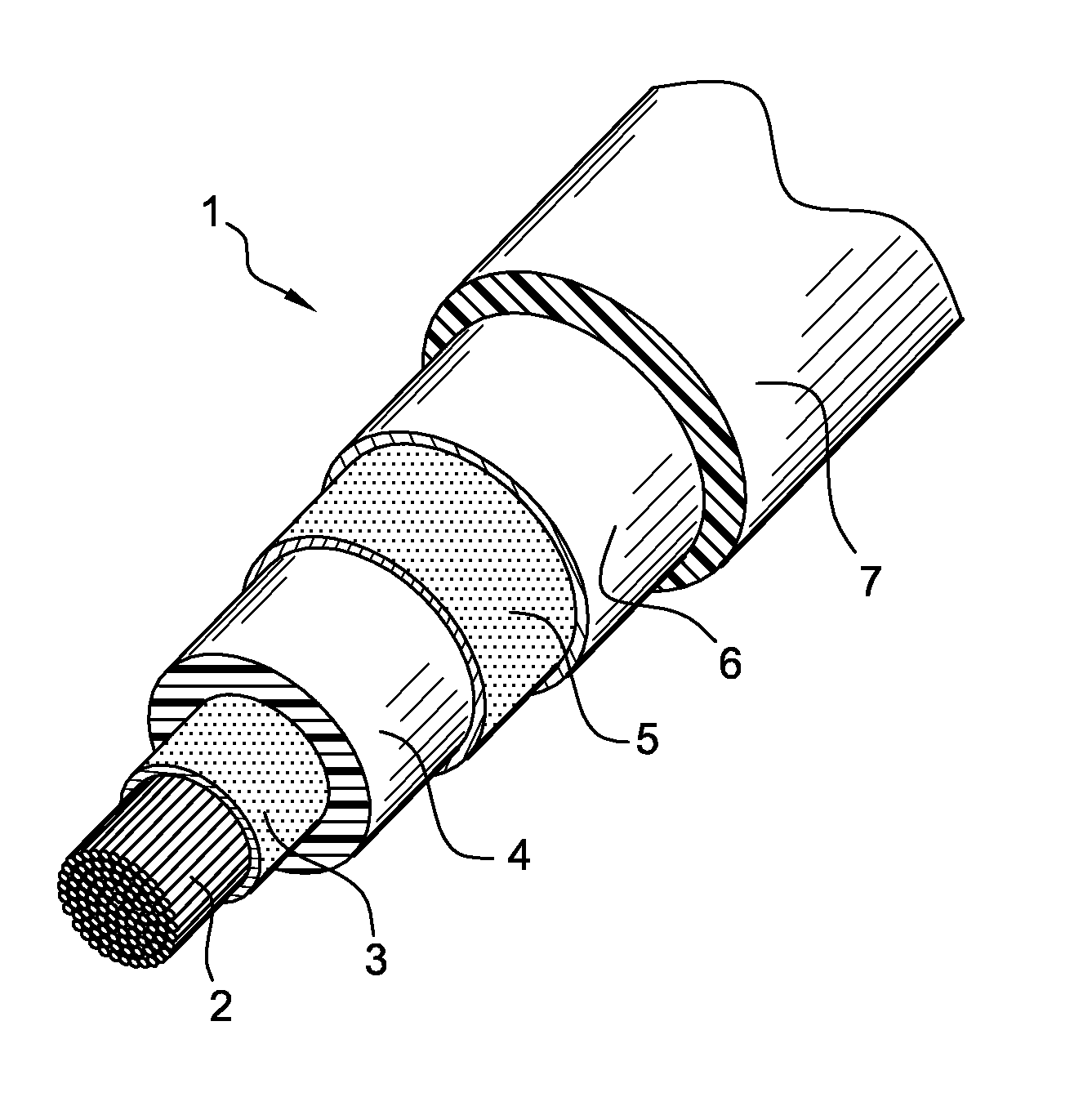

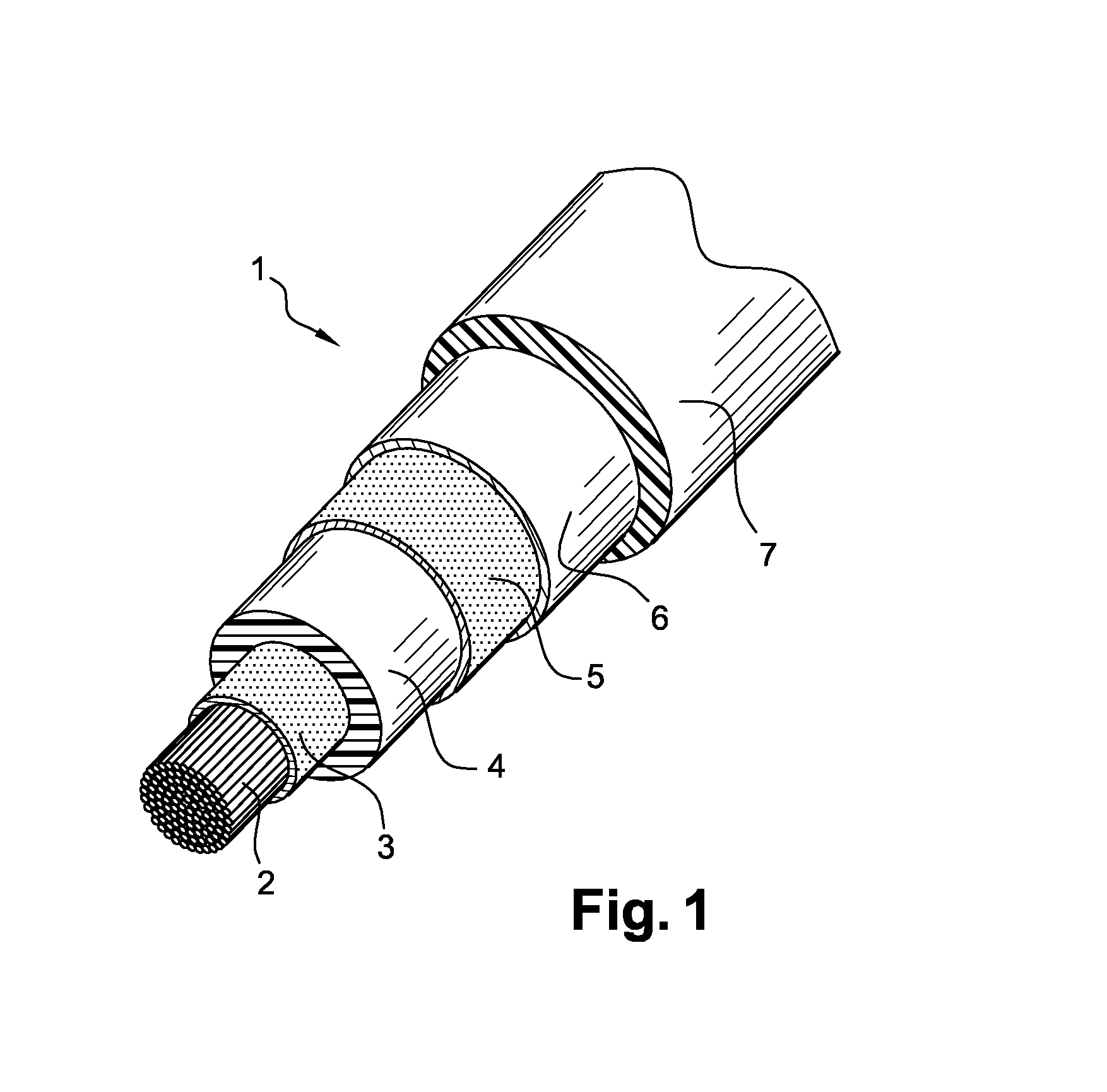

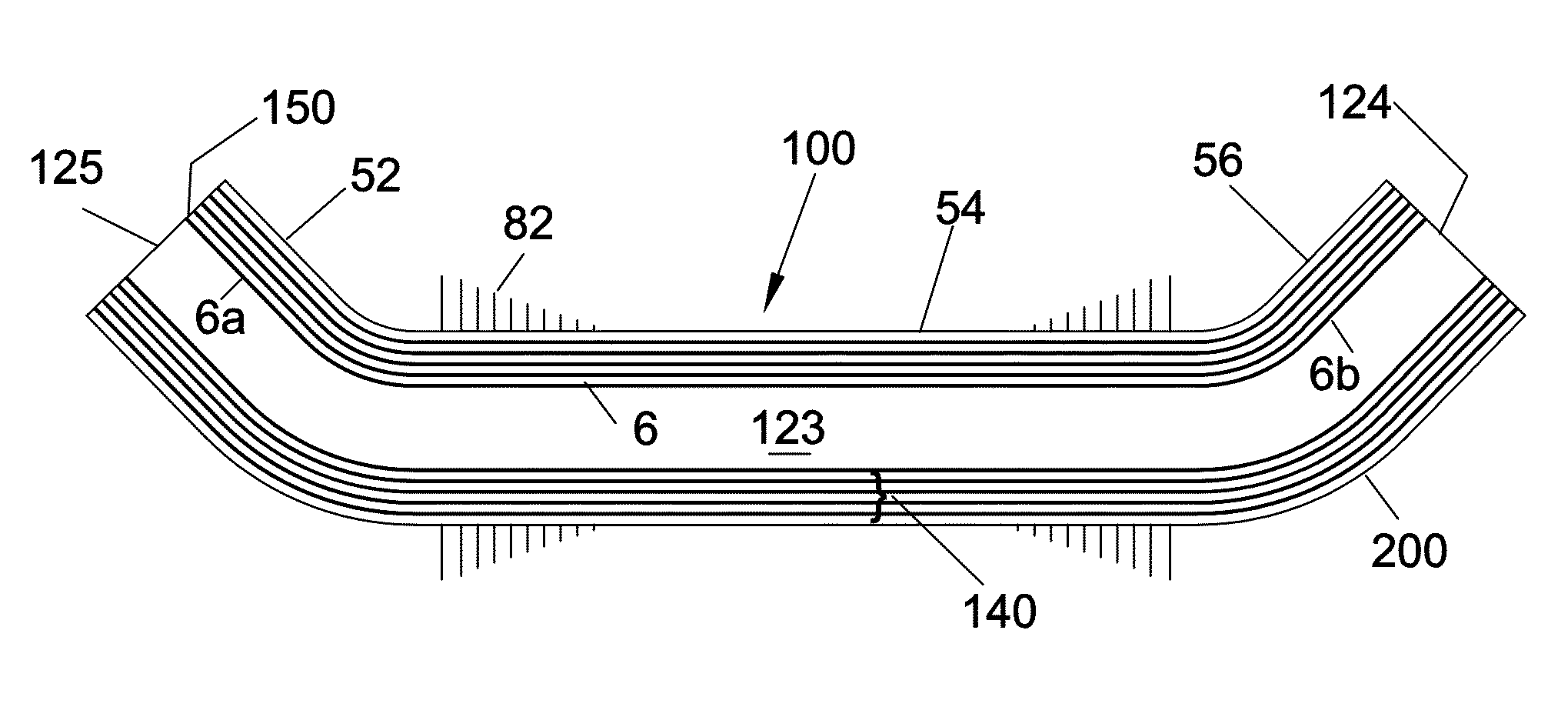

Silicone multilayer insulation for electric cable

InactiveUS20140083739A1Limit presenceReduce partial dischargePlastic/resin/waxes insulatorsInsulated cablesEngineeringElectrical conductor

An electric cable made from at least one elongated electric conductor and a multilayer insulation surrounding the electric conductor. The multilayer insulation has a first semiconducting layer and an electrically insulating layer, where the two layers are made from a silicone rubber based composition. The semiconducting silicone rubber based composition of the first semiconducting layer has carbon rovings as conductive filler.

Owner:NEXANS

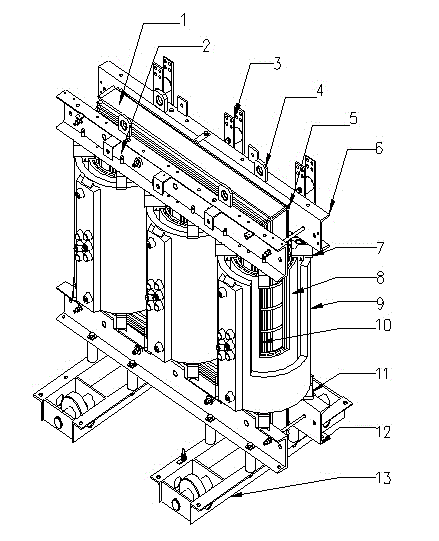

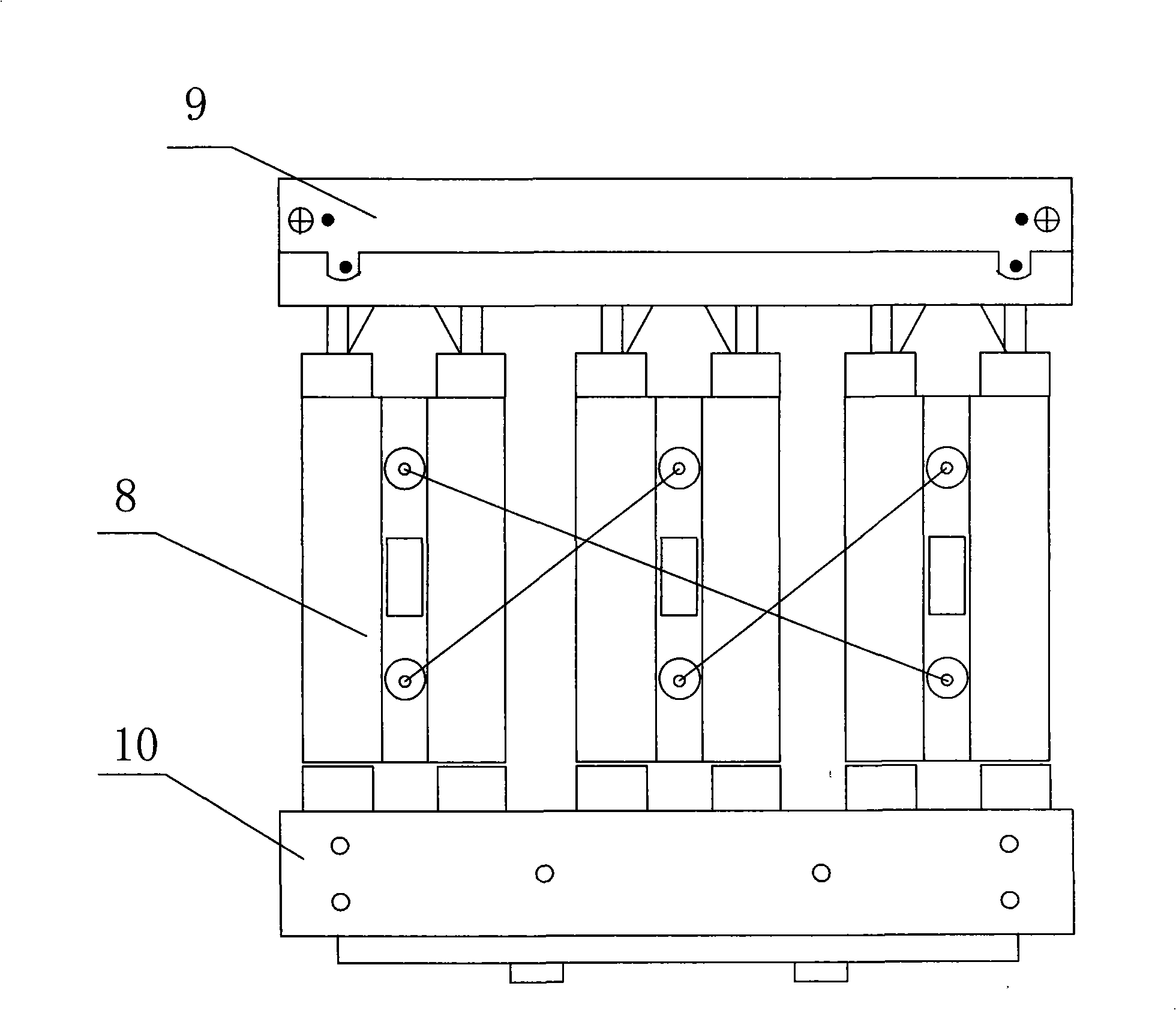

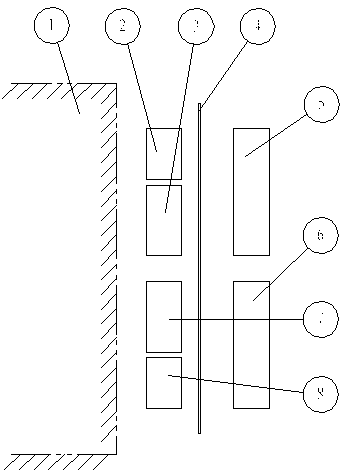

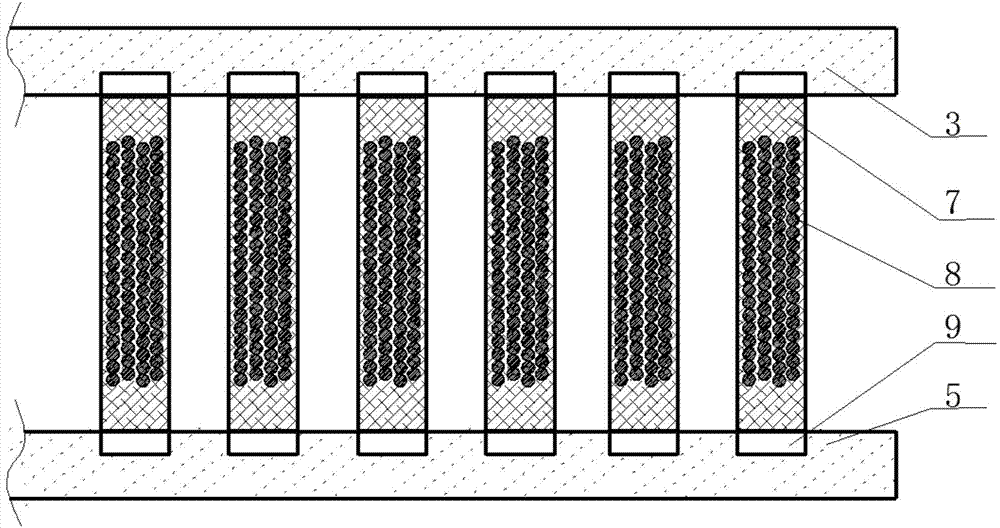

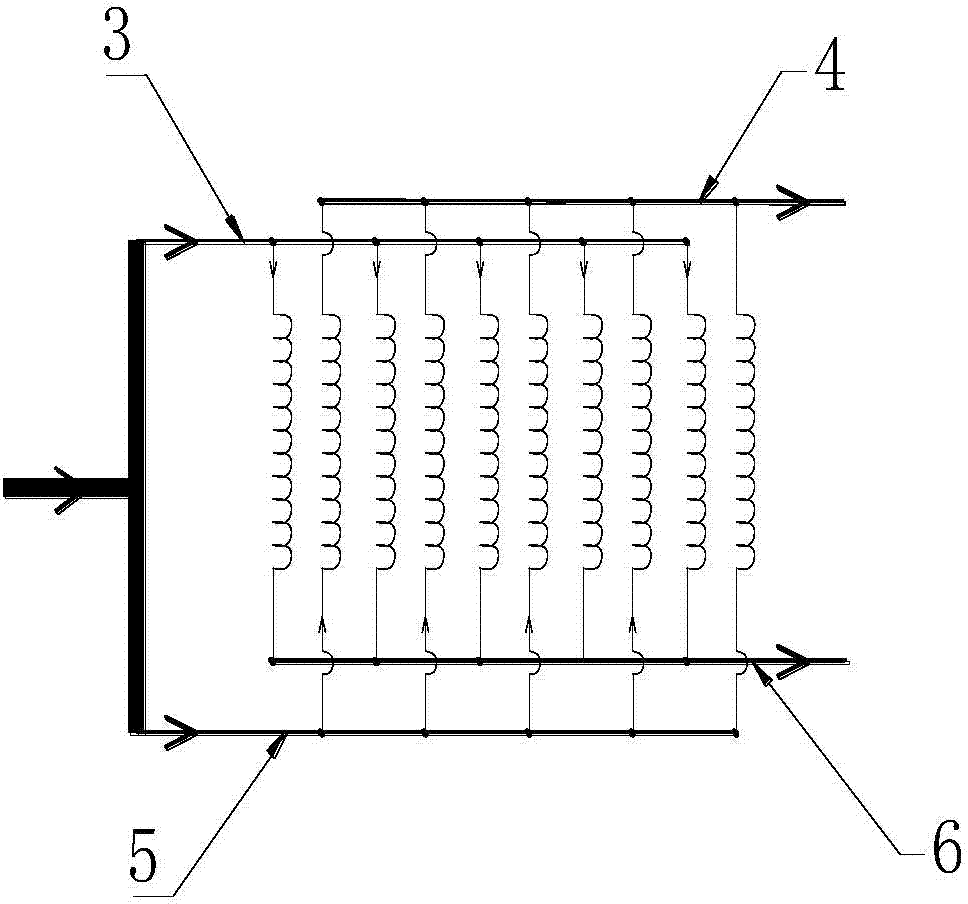

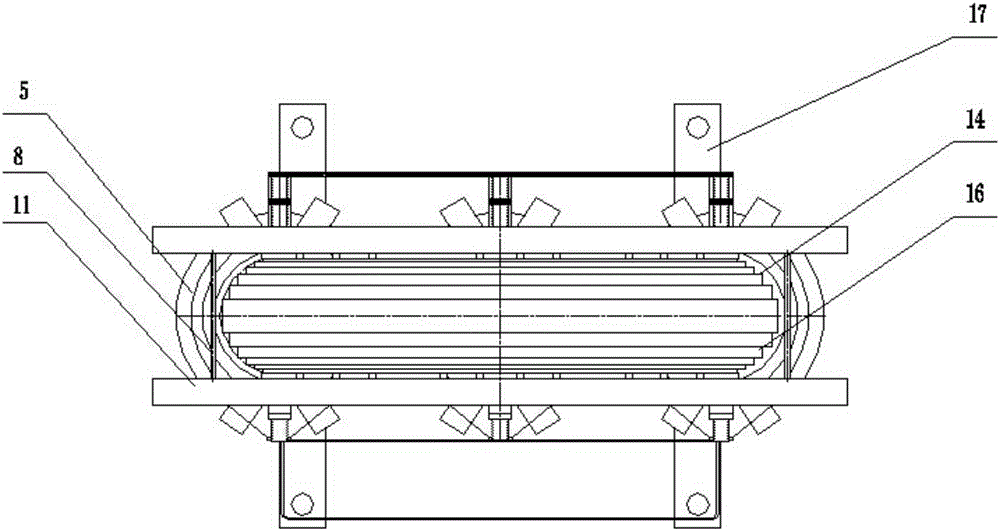

Casting type split reactor

InactiveCN104124043AEnsure consistencyAvoid uneven thicknessTransformers/inductances coils/windings/connectionsInsulation layerCasting types

The invention discloses a casting type split reactor. A coil of the casting type split reactor comprises a first winding and a second winding which are arranged coaxially, and encapsulation parts of the first winding and encapsulation parts of the second winding are arranged alternatively from inside to outside in sequence. A first wire inlet bar and a second wire outlet bar are arranged at an interval radially and fixed at the upper end of the coil, and the other first wire inlet bar and a first wire outlet bar are arranged at an interval radially, connected with a current introducing end of the second winding in a conductive mode and fixed at the lower end of the coil. Each encapsulation part comprises a conductive part formed by winding a plurality of multi-layer round leads, and an insulation part formed by casting epoxy resin in a vacuum mode is arranged outside the conductive part. According to the casting type split reactor, the encapsulation parts are formed by casting epoxy resin in the vacuum mode through a casting mould, consistency of sizes of the insulation layers can be ensured, and uneven thicknesses of the insulation layers are avoided. In addition, no bubbles exist in the windings, partial discharge is reduced, occurrence of air gaps can be avoided effectively, and therefore, insulation performance of the insulation layers can be improved.

Owner:STATE GRID CORP OF CHINA +2

High-voltage terminal device for transformer

ActiveCN101656143AEvenly distributedReduce insulation distanceTransformers/inductances coils/windings/connectionsTransformerHeat resistance

The invention relates to a high-voltage terminal device for a transformer, which is arranged at a high-voltage terminal of the transformer and is provided with a shielding ball and an outgoing line cylinder in insert connection with the shielding ball. The external surface of the shielding ball is wrapped by heat-resistance insulated paper, an insulated layer in an internal cavity is an extended part of the heat-resistance insulated paper, and an air pocket position of the part is poured with epoxy resin. The outgoing line cylinder is sequentially provided with a shielding tube, an insulated layer and a paper cylinder from the inside to the outside, wherein the paper cylinder has a plurality of layers; supporting bars are arranged between layers; and the insulated layer is insulated paperwrapped outside the shielding tube. The whole terminal device of the invention is greatly improved in working voltage due to uniform electric field distribution and reduces local discharge quantity bysolving the gas pocket problem in the internal cavity of the shielding ball. In addition, under a condition of the same insulation level, the insulation distance between electrodes is reduced.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD +1

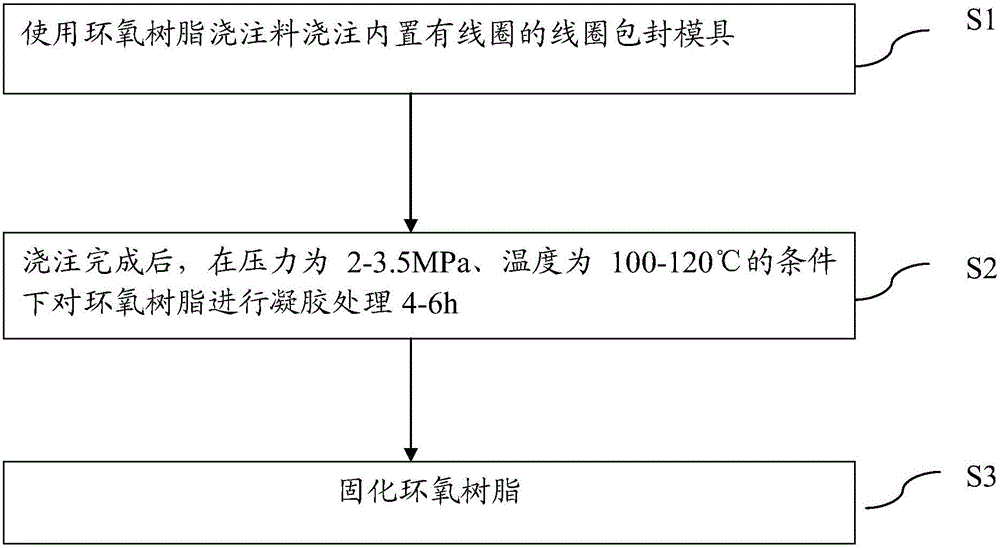

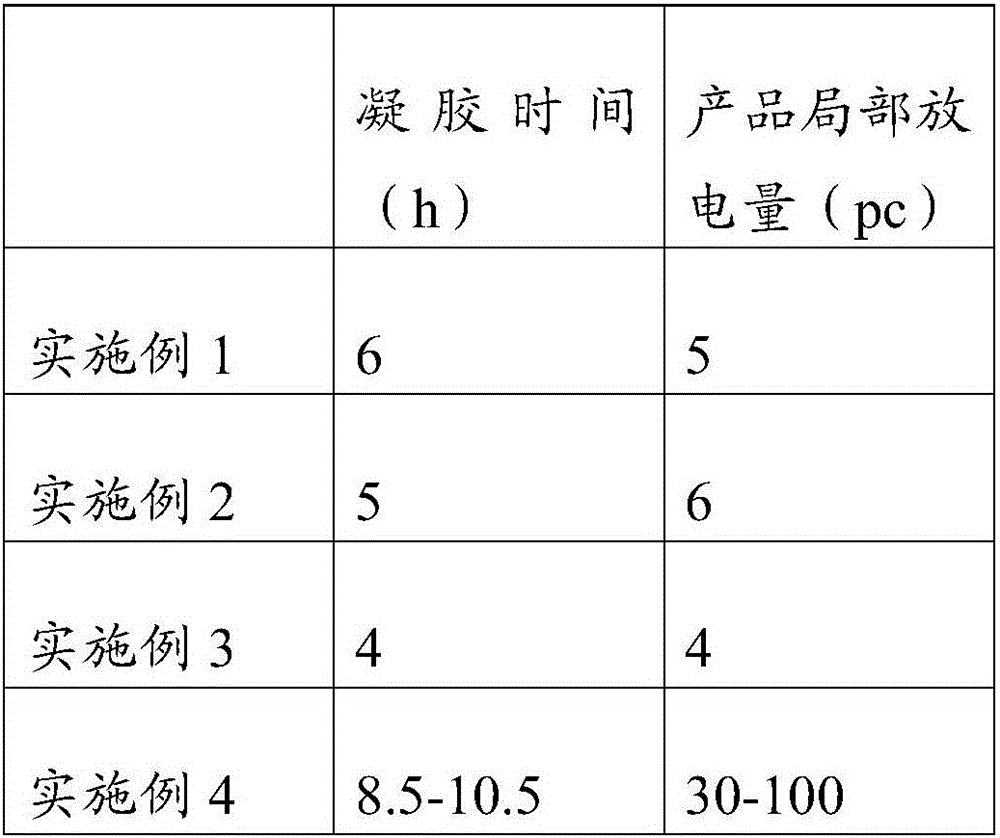

Pressure gel molding method of resin insulating dry-type transformer coil

The invention discloses a pressure gel molding method of a resin insulating dry-type transformer coil. The pressure gel molding method comprises the following steps: (1) casting a coil packaging mold internally provided with coil through utilizing epoxy resin castable; (2) after casting, carrying out gel treatment on epoxy resin under the conditions that the pressure is 2MPa-3.5MPa and the temperature is 100-120 DEG C; and (3) curing the epoxy resin. With the adoption of the method disclosed by the invention, the gel time is shortened, the viscosity of the epoxy resin is reduced and the penetration capability of the epoxy resin is greatly reduced under the action of pressure; and meanwhile, the partial discharge amount of the coil is reduced.

Owner:广州市特宏电器有限公司

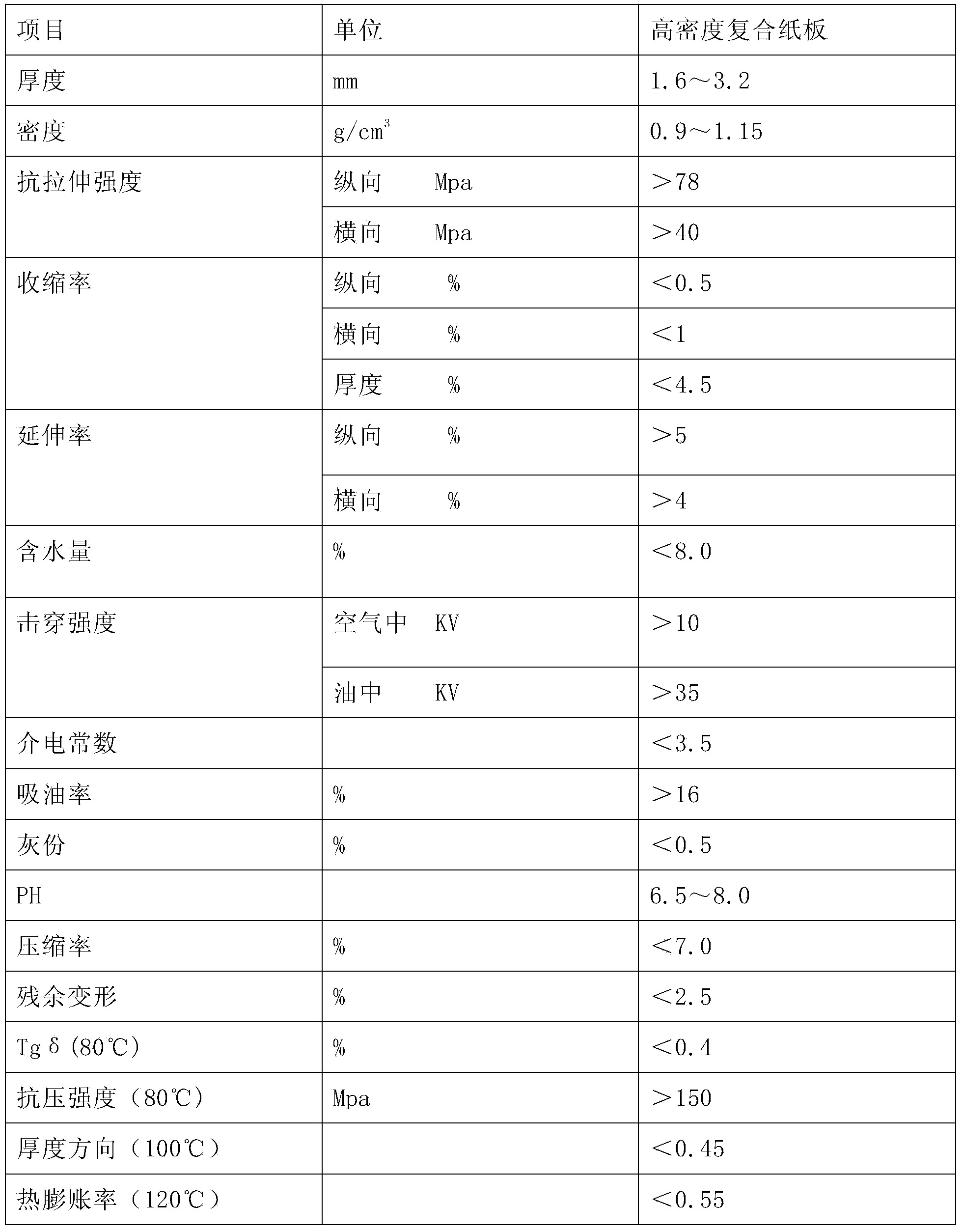

Method for manufacturing extra-high-voltage composite insulation paper board

ActiveCN103489542AHigh temperature resistanceLow dielectric constantInsulating bodiesCardboardElectric intensity

The invention discloses a method for manufacturing an extra-high-voltage composite insulation paper board. The method comprises the following steps that 1) stem grafting modification is conducted on aramid fiber pulp; 2) an aramid paper board is manufactured. The high-temperature (220 DEG C) resistant performance of aramid fiber is utilized, so that the temperature which the insulation paper board is resistant to is increased to 140 DEG C-150 DEG C; the low dielectric constant of the aramid fiber ranges from 1.6 to 3.7 so that the partial discharge of extra-high-voltage transformer oil can be reduced, the electric intensity of the extra-high-voltage transformer oil and paper insulation are completely used, and the dielectric constant of the paper is reduced. The surface modification technology is conducted on the aramid fiber so that the aramid fiber can be completely merged with wood pulp fiber.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH CO LTD

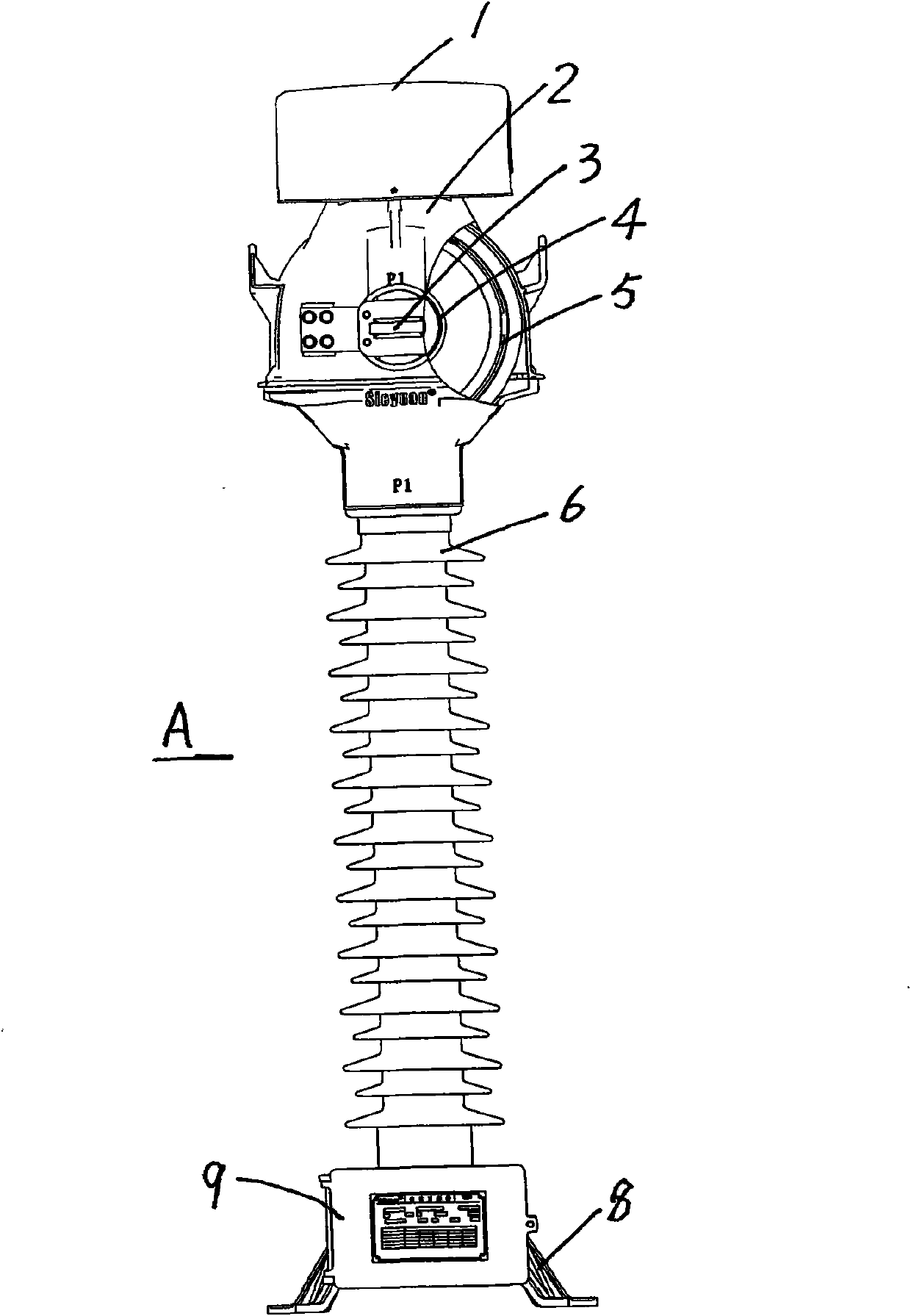

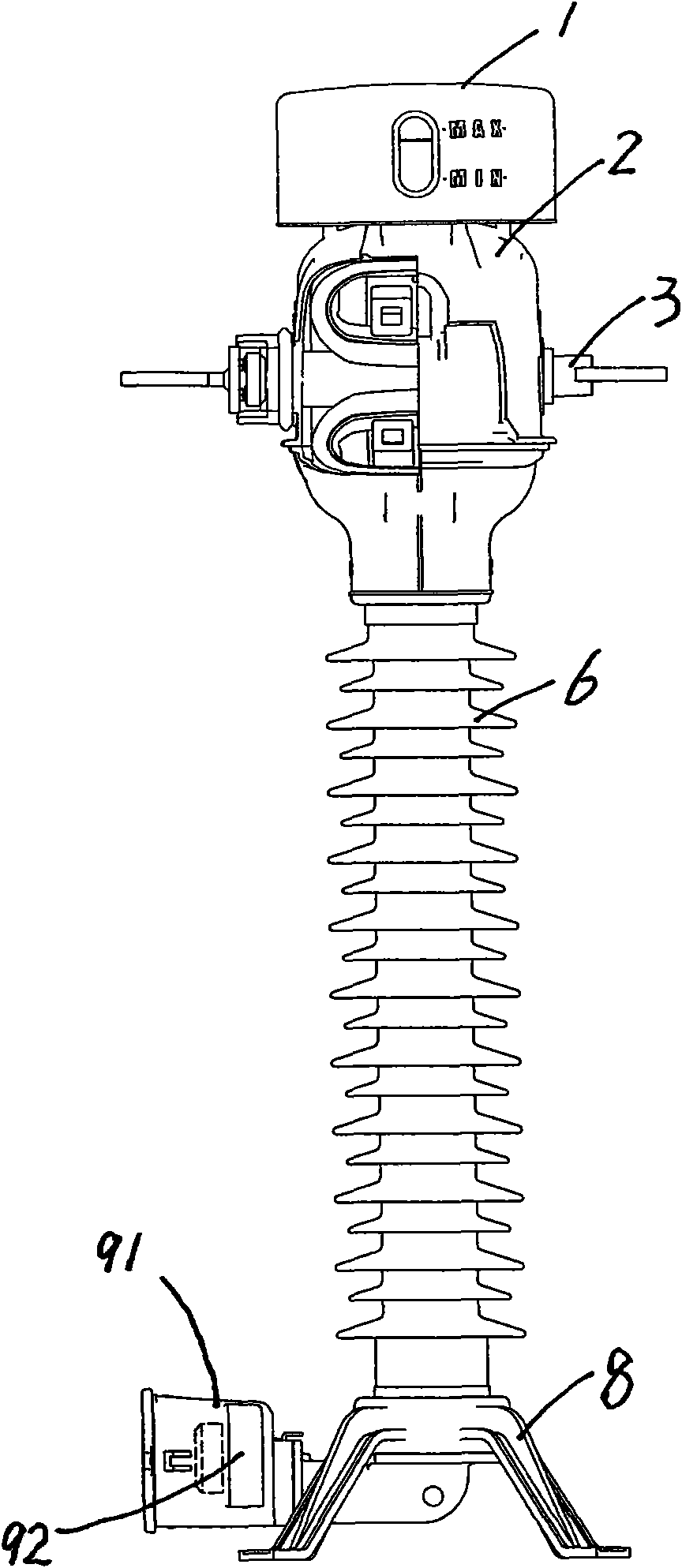

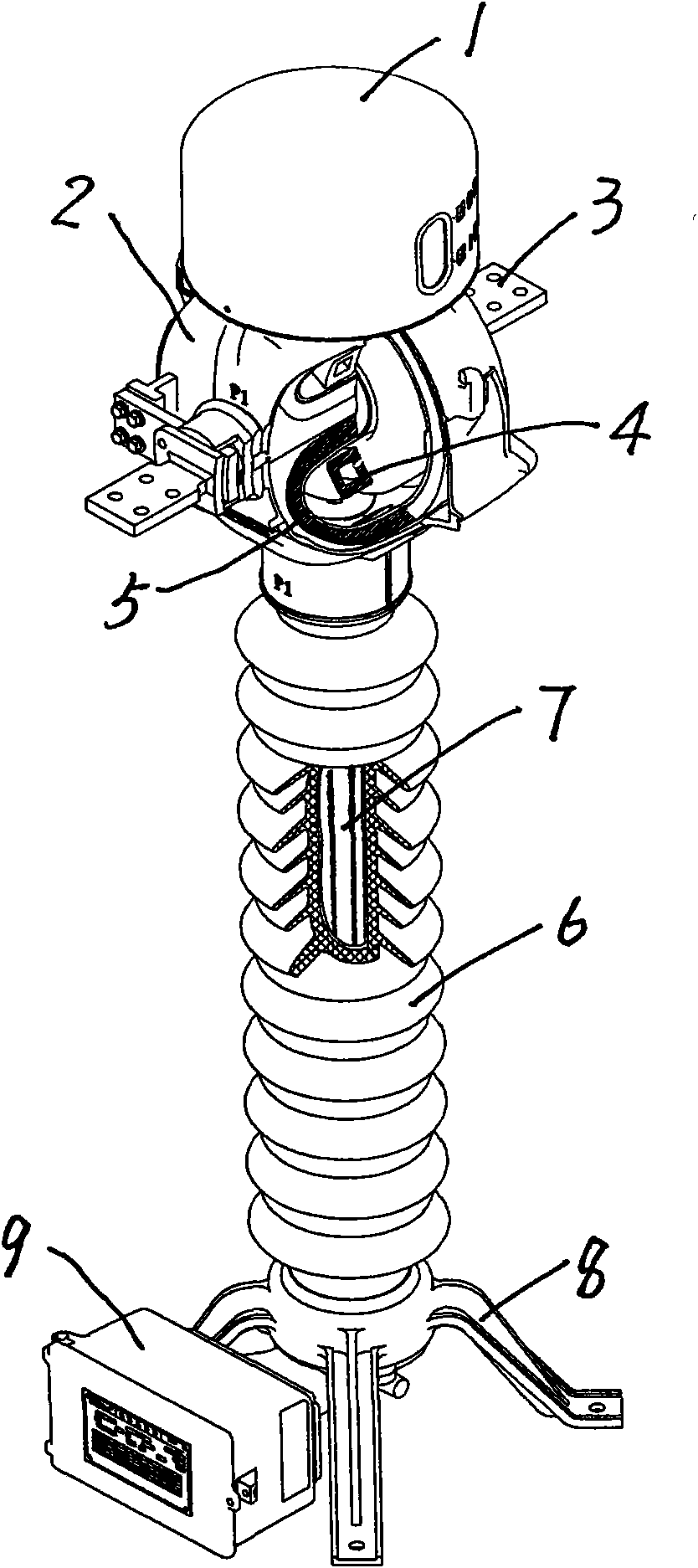

Electronic type current transformer

ActiveCN102024557AImprove the ability to resist electric field interferenceImprove versatilityTransformersTransformers/inductances coils/windings/connectionsElectrical conductorCopper wire

The invention relates to an electronic type current transformer comprising an oil temperature compensator, a shell, a primary conductor, a secondary conductor, an insulating medium, an insulating strut, a conductive body, a support and a secondary output control box, wherein the primary conductor passes through an inner shield and extends out of the shell through a secondary winding; the insulating strut is arranged below the shell; and the secondary output control box is fixed on the support and connected with the secondary winding through the conductive body. The electronic type current transformer has the advantages that an electric filed is uniformly distributed because the shell is made of alloy aluminum and is similar to the secondary winding in shape; the skeleton in the secondary winding is provided with an expansion compensation groove for the skeleton to obtain the expansion compensation when the temperature rises and the pressure changes; the position of the ending head of the winding is symmetric to the position of the starting head when an enameled round copper wire is wound, and the winding is arranged in a shielding case so as to effectively enhance the capability for resisting the electric field disturbance of the winding and guarantee the measuring accuracy; and the weight is lightened and the generality of components and parts is enhanced because a magnetic induction iron core is eliminated and insulating oil is used as the insulating medium.

Owner:JIANGSU SIYUAN HERTZ TRANSFORMER

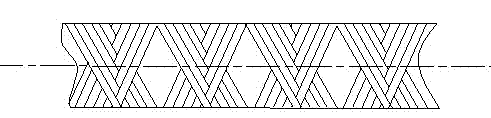

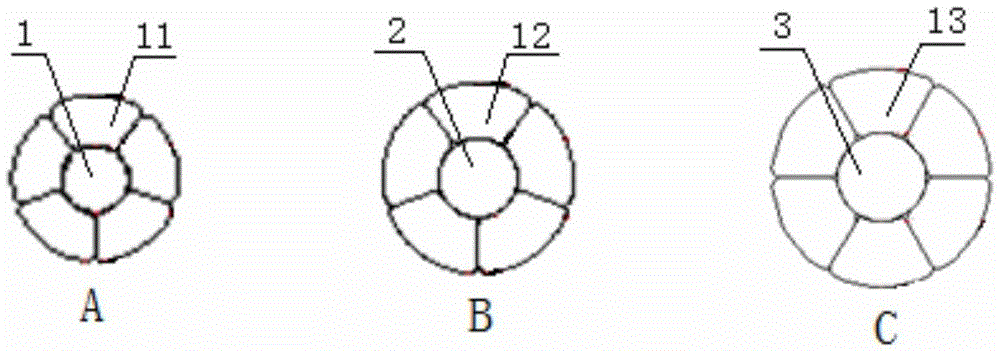

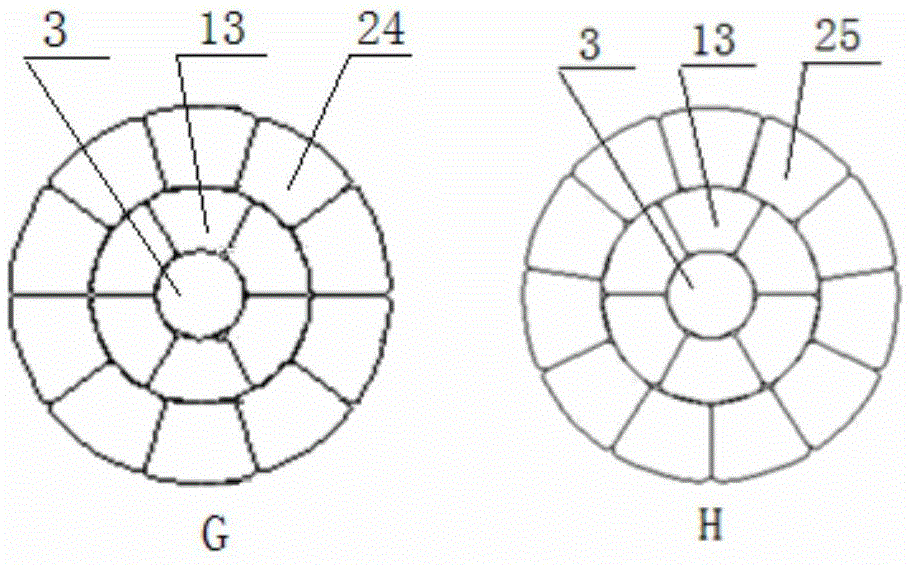

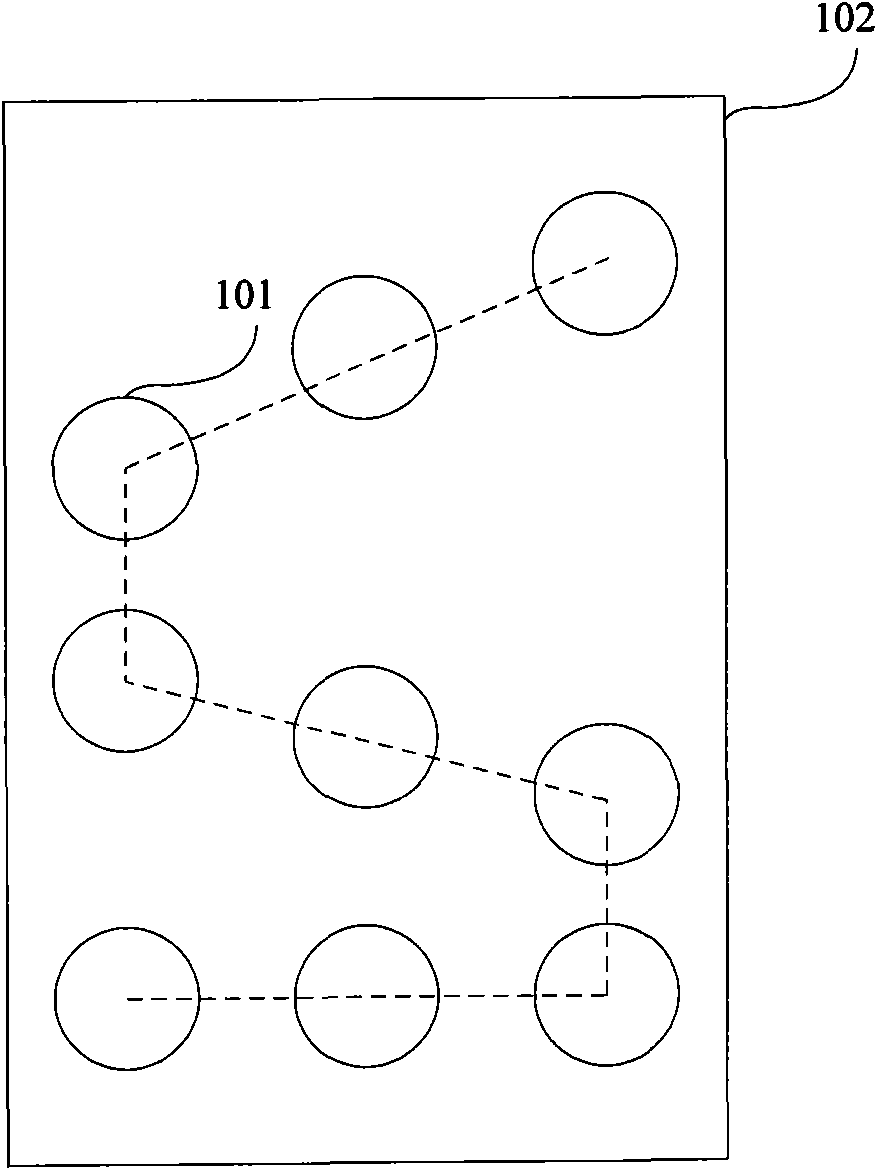

Shaped wire stranded cable conductor and production method thereof

ActiveCN104064256BStable structureStable structure and no loose stocksNon-insulated conductorsCable/conductor manufactureElectrical conductorEngineering

The invention relates to a special-shaped wire strand cable conductor and a production method of the special-shaped wire strand cable conductor and relates to a wire and cable special-shaped wire strand round conductor with the nominal cross section ranging from 25 mm<2> to 630 mm<2>. The cable conductor comprises a single round wire and special-shaped wires with all the strand layers designed in the tile-shaped structure according to the specifications of cables. The production method includes the steps that first, according to the designed special-shaped wire structure, the single round wire in the center is manufactured in a drawing mode through a drawbench, and then the special-shaped wires of various specifications of strand layer structures are manufactured on a water tank type or sliding type or fractional motor type drawbench in a drawing mode through a special-shaped high-speed wire drawing die; the round line in the center is placed on a payoff rack of a wire stranding machine, and all the stranding layer special-shaped wires are placed on a frame winch or fork winch and manufactured into the special-shaped wire strand cable conductor through stranding. The outer surface of the cable conductor is smooth and free of burrs, the gap between single wires is small, the filling coefficient is larger than 0.98, and the strand cable conductor is stable in structure. The production method is high in technology universality, and updating and upgrading of the products can be achieved in small and medium-sized enterprises through the technology.

Owner:湖北易缆通模具有限公司

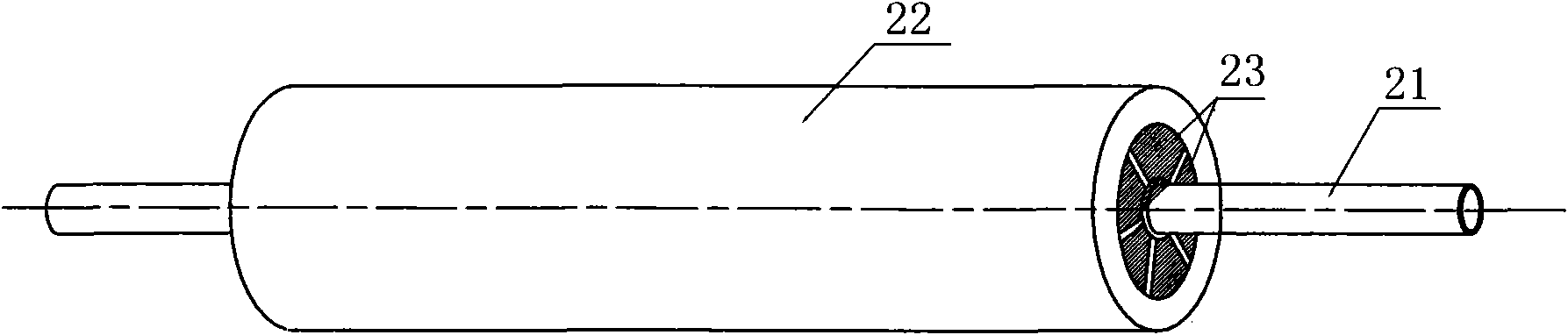

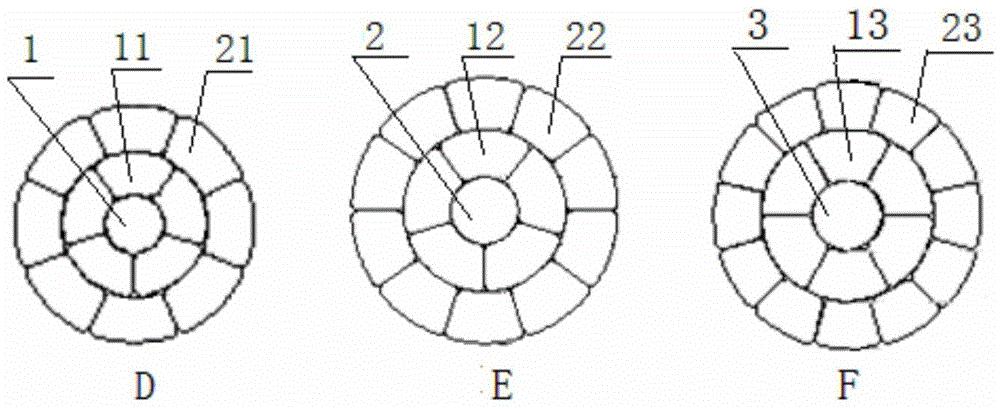

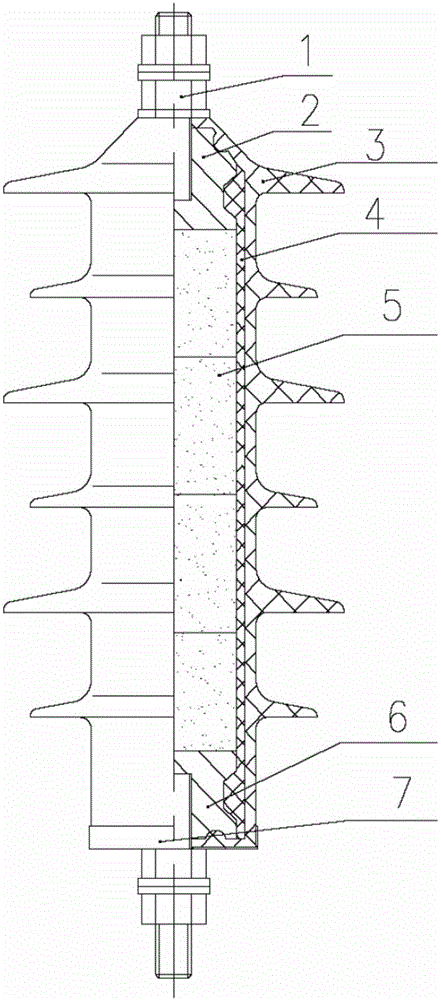

10kV and below gapless metal oxide arrester and manufacturing method for same

InactiveCN105006318AEasy to useExtended service lifeResistor manufactureOvervoltage protection resistorsCooking & bakingAlkali free

The invention discloses a 10kV and below gapless metal oxide arrester and a manufacturing method for the same. The 10kV and below gapless metal oxide arrester comprises upper and lower binding posts (1), a core body and a rubber sheath (3), wherein the core body is manufactured by wrapping a core group sequentially consisting of an upper electrode (2), a plurality of stacked zinc oxide varistors (5) and a lower electrode (6) from top to bottom with an alkali-free glass cloth tape (4) and performing baking; the upper electrode (2) at the upper end of the core body and the lower electrode (6) at the lower end are connected with the binding posts (1) respectively; the rubber sheath (3) on the outer lateral surface of the core body is compressed-molded at one time from mixed silicone rubber. The 10kV and below gapless metal oxide arrester is convenient to manufacture, high in sealing performance and low in partial discharge, and the performance is substantially kept unchanged in a boiling test consistent with a national standard. Therefore, the stability of the arrester in use is ensured, and the service life is prolonged. The product smoothly meets each requirement in standard GB11032-2000.

Owner:大连北方避雷器有限公司

Amorphous alloy transformer coil winding method

The invention discloses a production method for windings of an amorphous alloy transformer, which comprises the following steps: making a low-voltage winding: fixing start leads in rows with an assistant tool and locking inside a rabbet of an insulating cylinder, winding the start leads without tension, and removing the assistant tool after the start lead winding is completed and regulating the size; making the low-voltage winding under tension: winding while knocking the surface of a copper foil, compressing the low-voltage winding to the specified size after the low-voltage die is removed, drying and painting; winding a high-voltage winding on the low-voltage winding to obtain an amorphous alloy transformer winding. Based on the combination of low-voltage and high-voltage windings, the invention can eliminate the influence of positive deviation of the low-voltage winding and ensure the insulation distance between the low-voltage and high-voltage windings.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

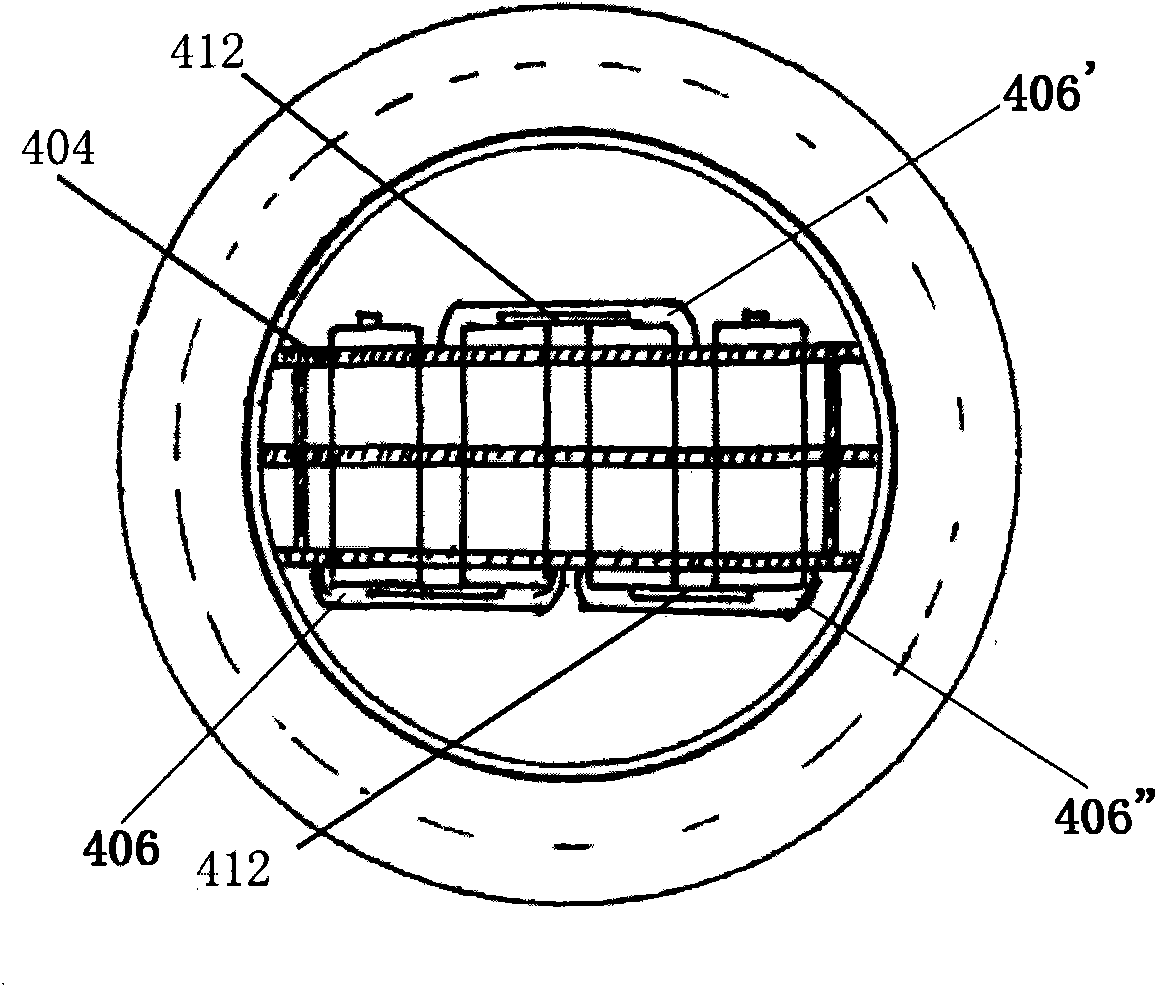

High-insulativity, high-precision and environment-friendly capacitive divider

InactiveCN101908416AReduce partial dischargeReduce volumeMultiple fixed capacitorsThin/thick film capacitorCapacitive dividerHigh voltage capacitors

The invention relates to the technical field of electrics, in particular to a high-insulativity, high-precision and environment-friendly capacitive divider. The embodiment of the invention provides a plurality of self-healing type high-voltage capacitors with inner series structures and an outer shell, wherein the self-healing type high-voltage capacitors with the inner series structures are arranged in the outer shell, and the outer shell is filled with nitrogen gas; the series approaches among the self-healing type high-voltage capacitors with the inner series structures are arrayed in the outer shell in a cosine curve law. The embodiment of the invention can reduce the local discharge among capacitors and can reduce the size of the high-voltage capacitive divider.

Owner:陈琳 +1

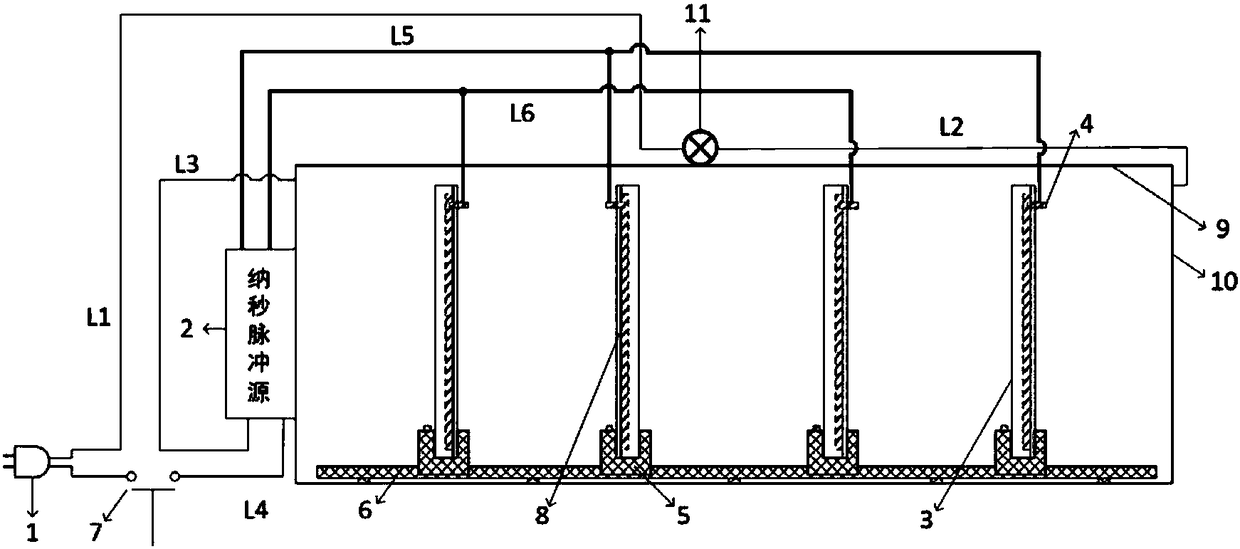

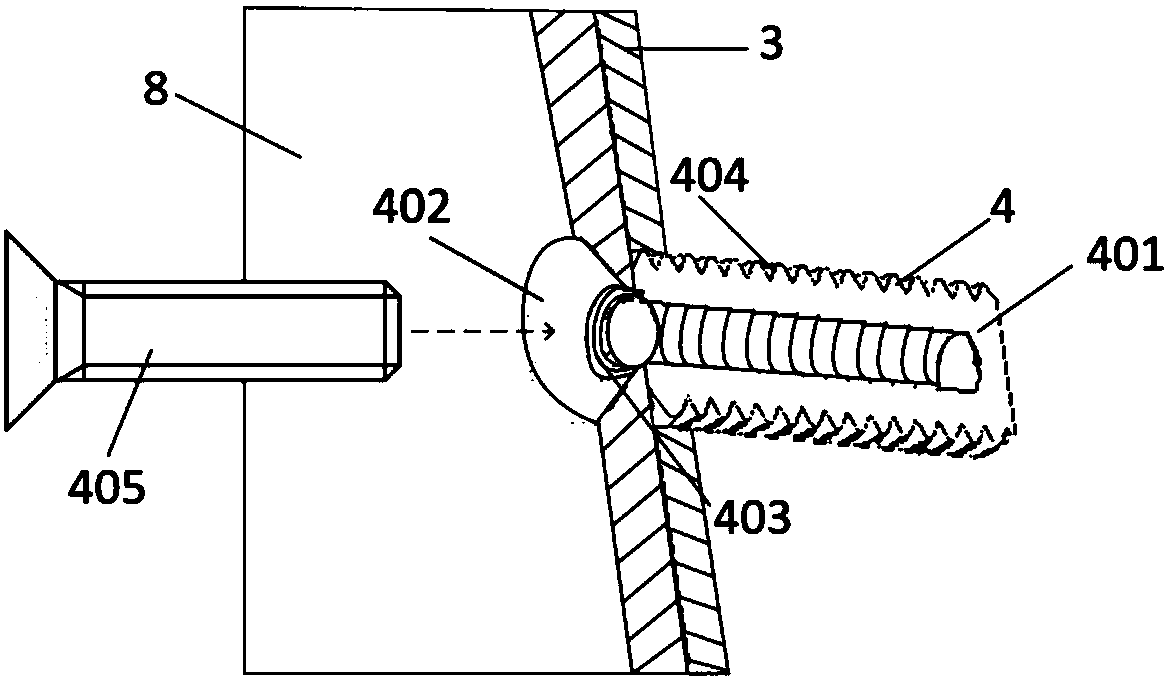

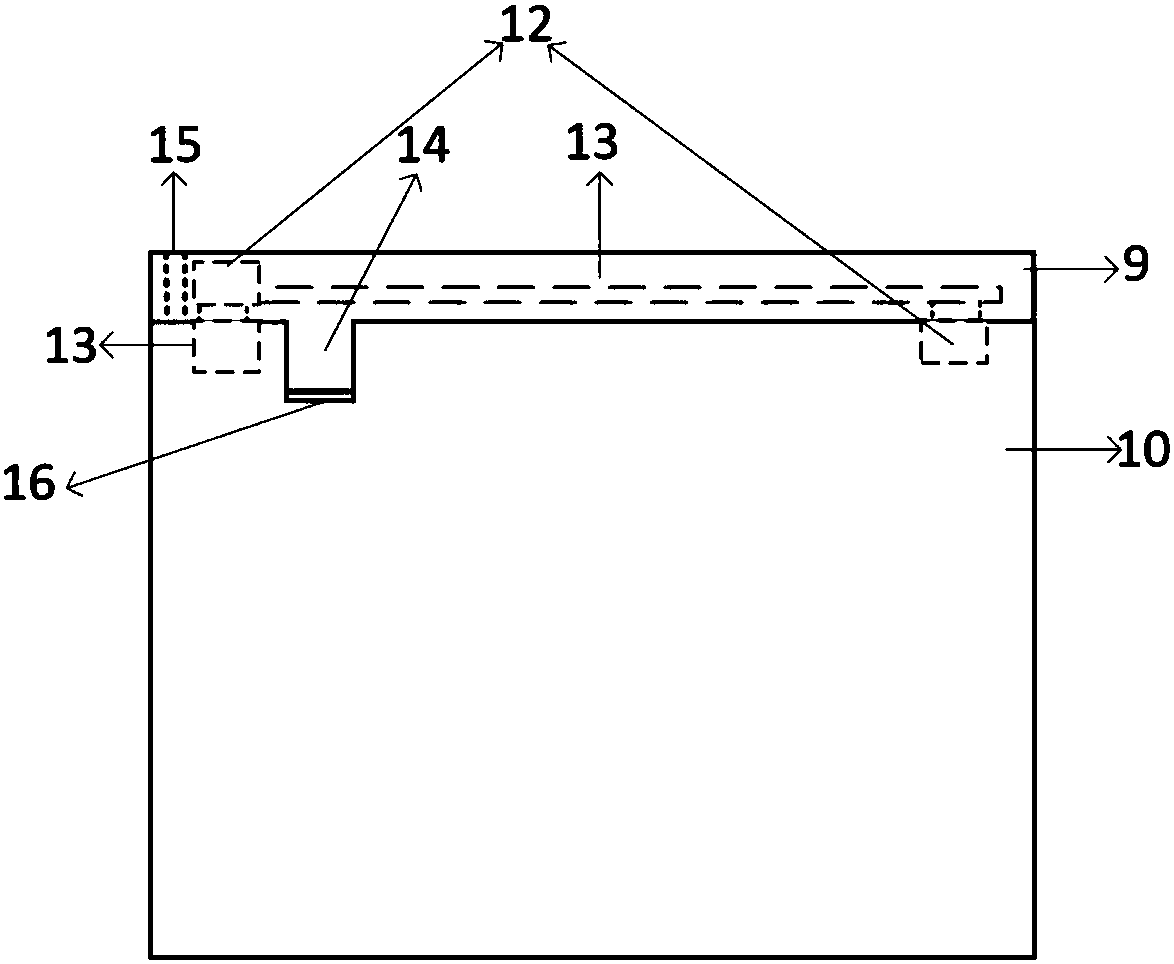

Fruit and vegetable preservation device based on nanosecond pulse low-voltage electric field

ActiveCN108271856AFlexible arrangementEnsure safetyFruits/vegetable preservation by irradiation/electric treatmentFood electrical treatmentDevice formLow voltage

The invention discloses a fruit and vegetable preservation device based on a nanosecond pulse low-voltage electric field. The fruit and vegetable preservation device comprises a treatment chamber anda nanosecond pulse electric field generating device, wherein the treatment chamber comprises a closed cavity, a box body with an open top and an upper cover arranged at the open top of the box body, the upper cover contains a copper sheet protecting path, the box body matches with the upper cover by virtue of a positioning assembly, and an electromagnetic device, the copper sheet protecting path and a work indicating lamp form a safety protection device together; and the nanosecond pulse electric field generating device comprises a nanosecond pulse power with adjustable parameters and a multichannel dual electrode sealed in an insulating barrier, and the multichannel dual electrode is connected with an electrode outgoing post. The electric field generating device forms a nanosecond pulse electric field in the box body, and fruits and vegetables are put in the nanosecond pulse electric field for performing electric field treatment, thereby achieving an enzyme inactivating effect by changing the inherent electric fields of the fruits and vegetables, inhibiting the respiratory action of the fruits and vegetables and achieving a good cold sterilization effect. The fruit and vegetable preservation device based on the nanosecond pulse low-voltage electric field has a convenient operation method, is pollution-free and suitable for preserving various perishable fruits and vegetables and has very high application value.

Owner:XI AN JIAOTONG UNIV

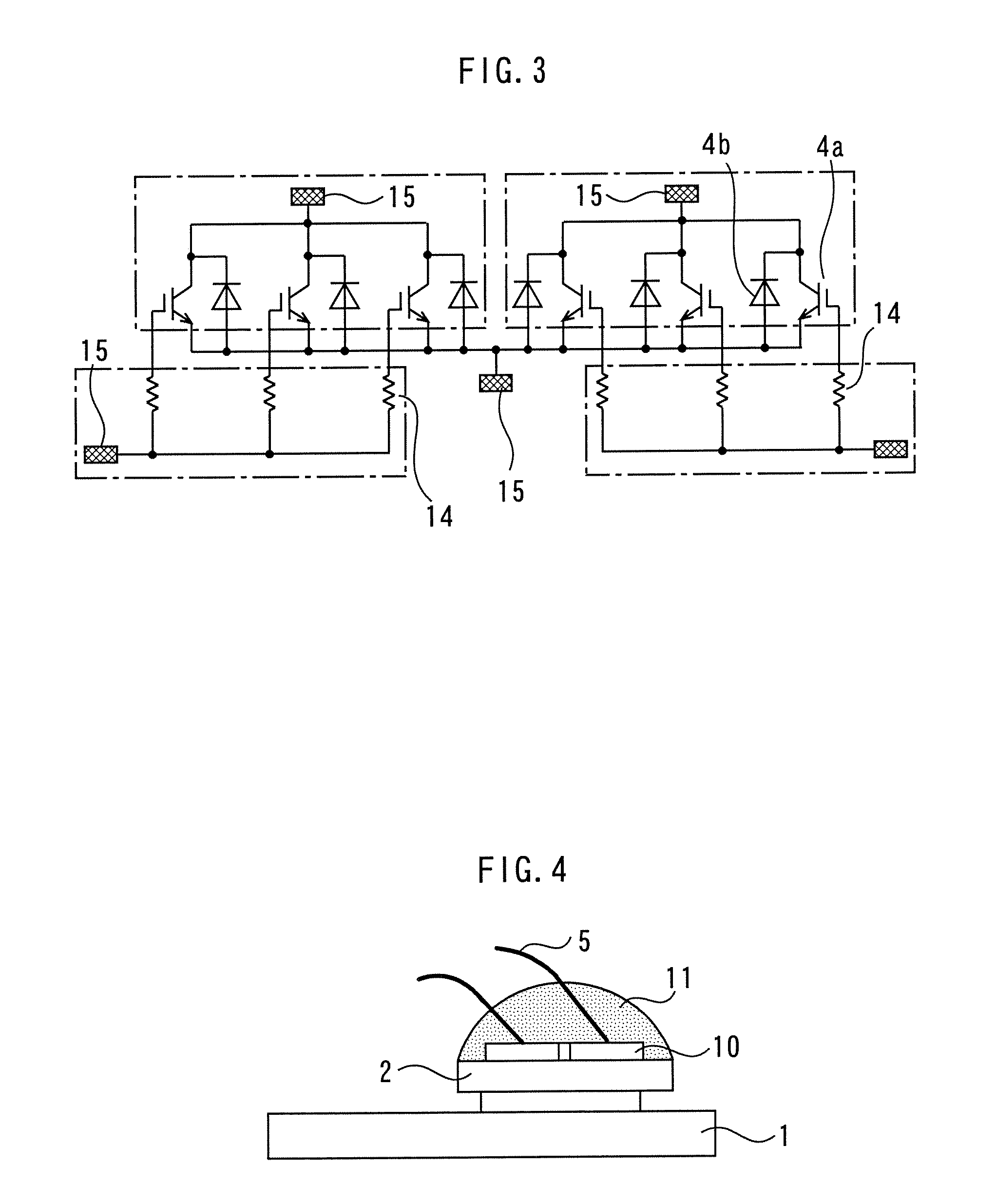

Insulation system for a stator bar with low partial discharge

InactiveUS9059616B1Reduce partial dischargeCost reductionWindings insulation materialWindings insulation shape/form/constructionOperating temperatureThermal conductivity

Owner:RAO DANTAM K

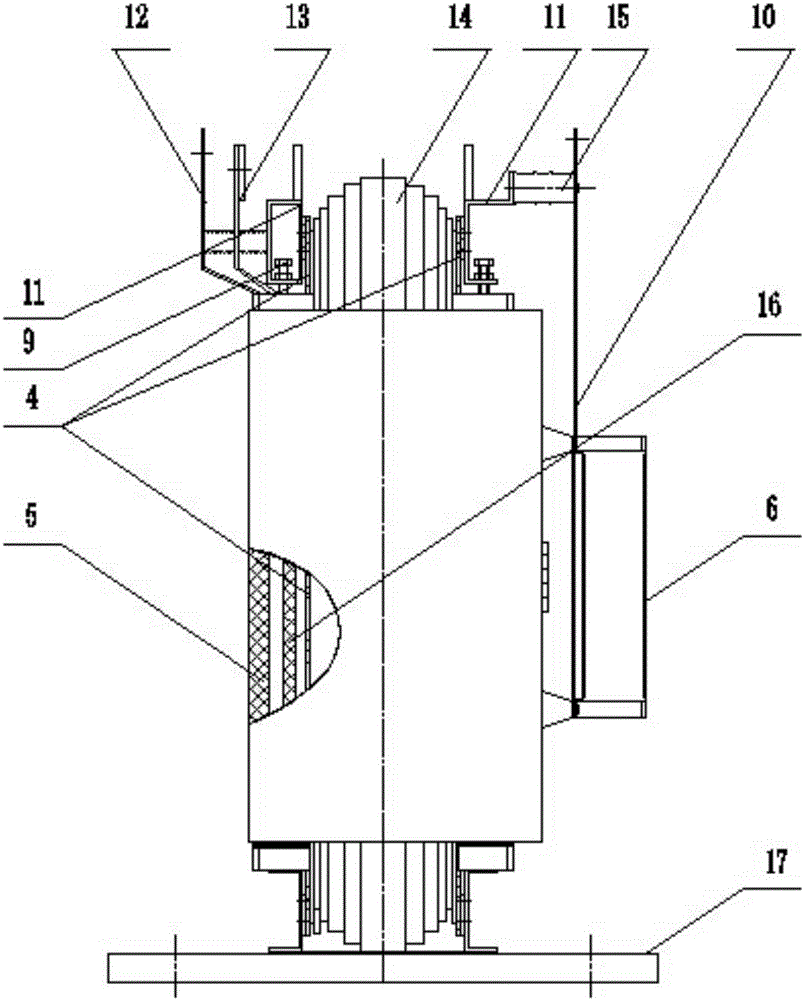

Resin casting coil dry-type transformer structure and assembling method thereof

ActiveCN106158284AIngenious structural designImprove performanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerLow voltage

The invention relates to a resin casting coil dry-type transformer structure and an assembling method thereof. The resin casting coil dry-type transformer structure comprises a transformer body arranged on a base, wherein the transformer body comprises an iron core, an upper clamping part, a lower clamping part and high-voltage and low-voltage resin coils; the low-voltage resin coil and the high-voltage resin coil sleeve the external circumference of a core column of the iron core respectively; the bottoms of the high-voltage and low-voltage resin coils are mounted on a cushion block and an embedding part of the lower clamping part by piers; a pressing block, an embedding part and a pressing plate are arranged at the top of the high-voltage and low-voltage resin coils and the pressing plate is tightly pressed by rotating a pressing stud through an upper clamping part screw hole, so that the high-voltage and low-voltage resin coils are tightly pressed and fixed; pull plates are arranged on the two sides of the core column of the iron core; and the upper and lower ends of the pull plates are fixedly connected with the upper clamping part and the lower clamping part through pins respectively. With the adoption of the dry-type transformer structure provided by the invention, the stability of the iron core and the coils is enhanced and a displacement phenomenon of the high-voltage and low-voltage resin coils in a transportation process of a transformer can be avoided. The creeping distance is increased through a pressing block reinforcing rib and a partial discharging condition is reduced; and the properties of the transformer are effectively improved.

Owner:鑫大变压器有限公司

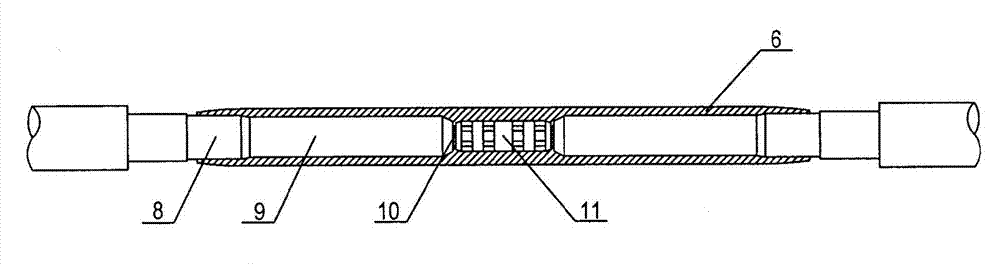

Integral heat shrinkable cable middle connector

InactiveCN102761094ARealize electrical stress control functionImprove insulation performanceCable fittingsElectrical conductorEngineering

The invention discloses an integral heat shrinkable cable middle connector which comprises a conductor connecting pipe, a stress multiunit pipe, an inner insulating pipe, an outer insulating pipe, a semiconducting pipe and a sleeve multiunit pipe, wherein two ends of the conductor connecting pipe are respectively connected with the cores of two segments of cables; the stress multiunit pipe is coated outside the connection pipe, and the two ends of the stress multiunit pipe are respectively in lap joint with the insulation shielding layers of two segments of cables; the inner insulating pipe is coated outside the stress multiunit pipe; the outer insulating pipe is coated outside the stress multiunit pipe and the inner insulating pipe, and the two ends of the outer insulating pipe are respectively in lap joint with the insulation shielding layers of the two segments of cables; the semiconducting pipe is coated outside the outer insulating pipe, and the two ends of the semiconducting pipe are respectively in lap joint with copper shielding layers of the two segments of cables; and the sleeve multiunit pipe is coated outside the semiconducting pipe, and the two ends of the sleeve multiunit pipe are respectively in lap joint with the outer sleeves of the two segments of cables. Due to the adoption of the connector provided by the invention, the magnitude of partial discharge is reduced, sealing and insulating performance is strengthened. Moreover, the connector has the advantages of prolonged service life and simplicity in installation.

Owner:江苏华侃核电器材科技有限公司

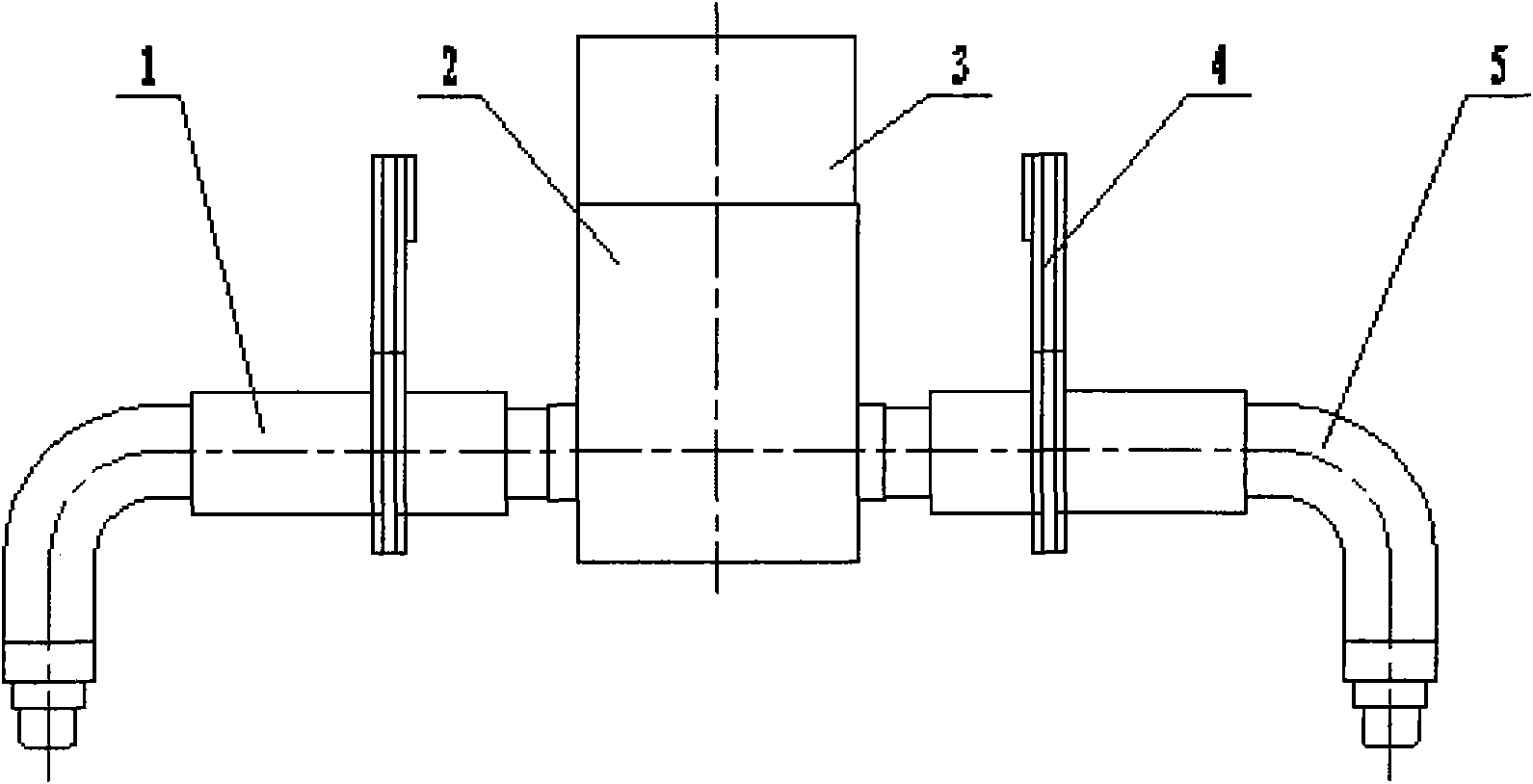

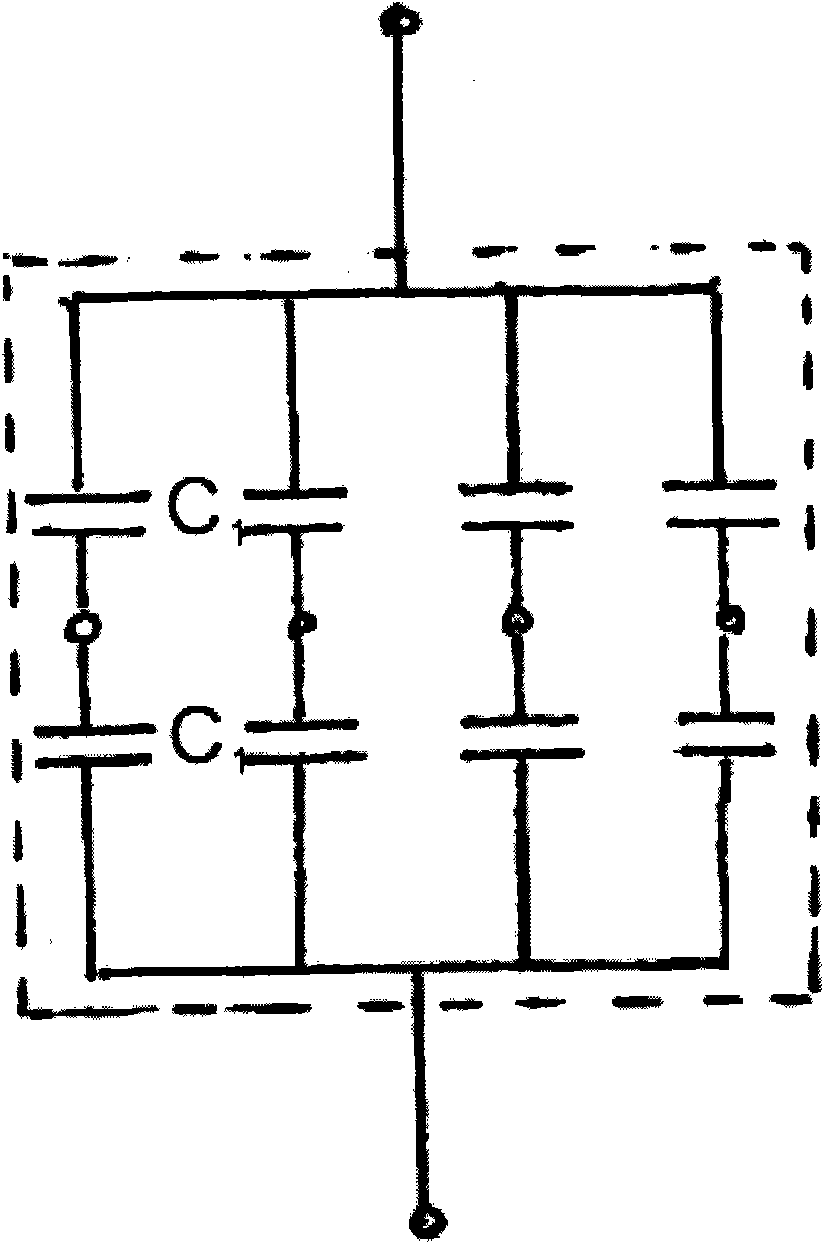

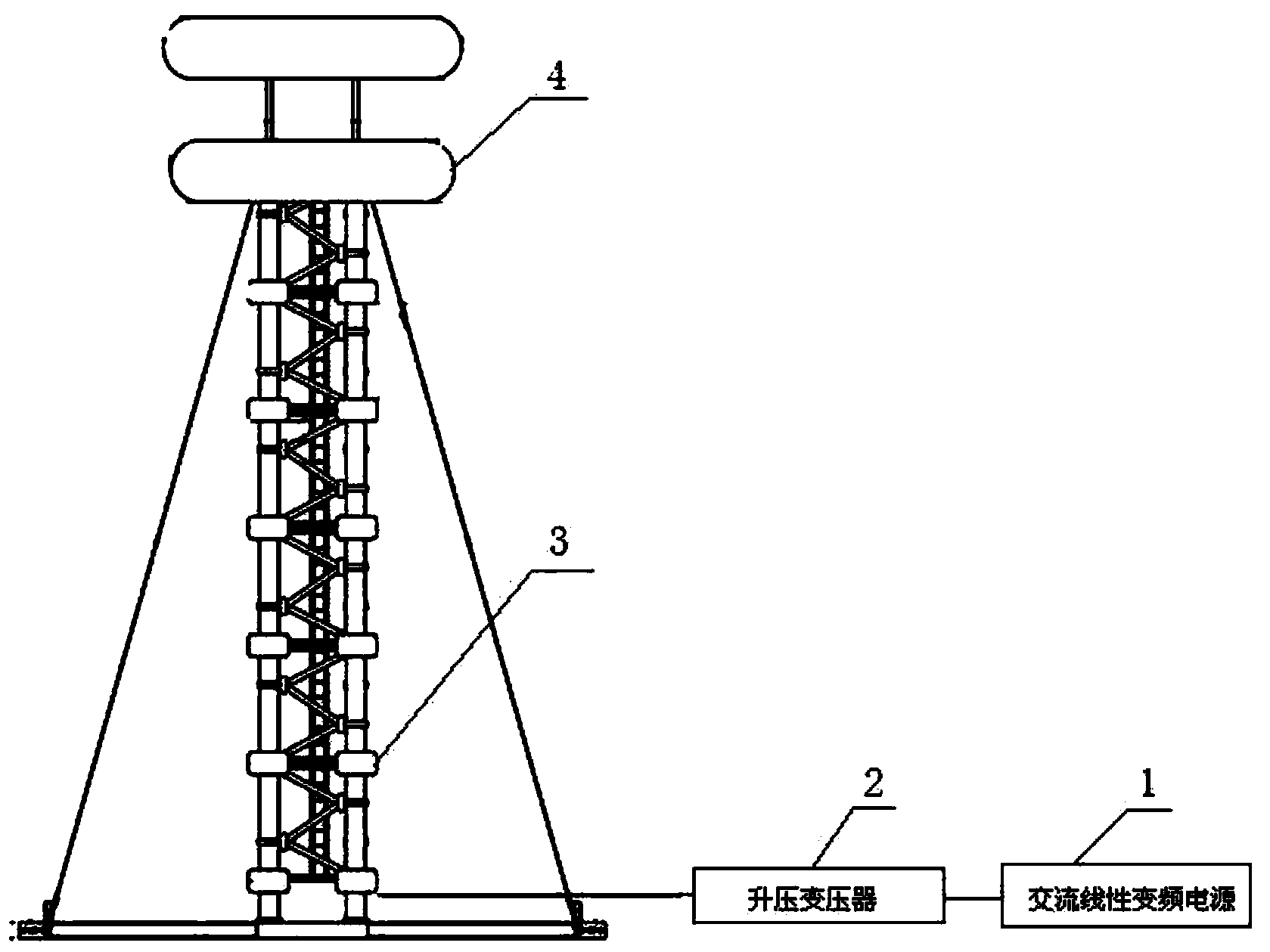

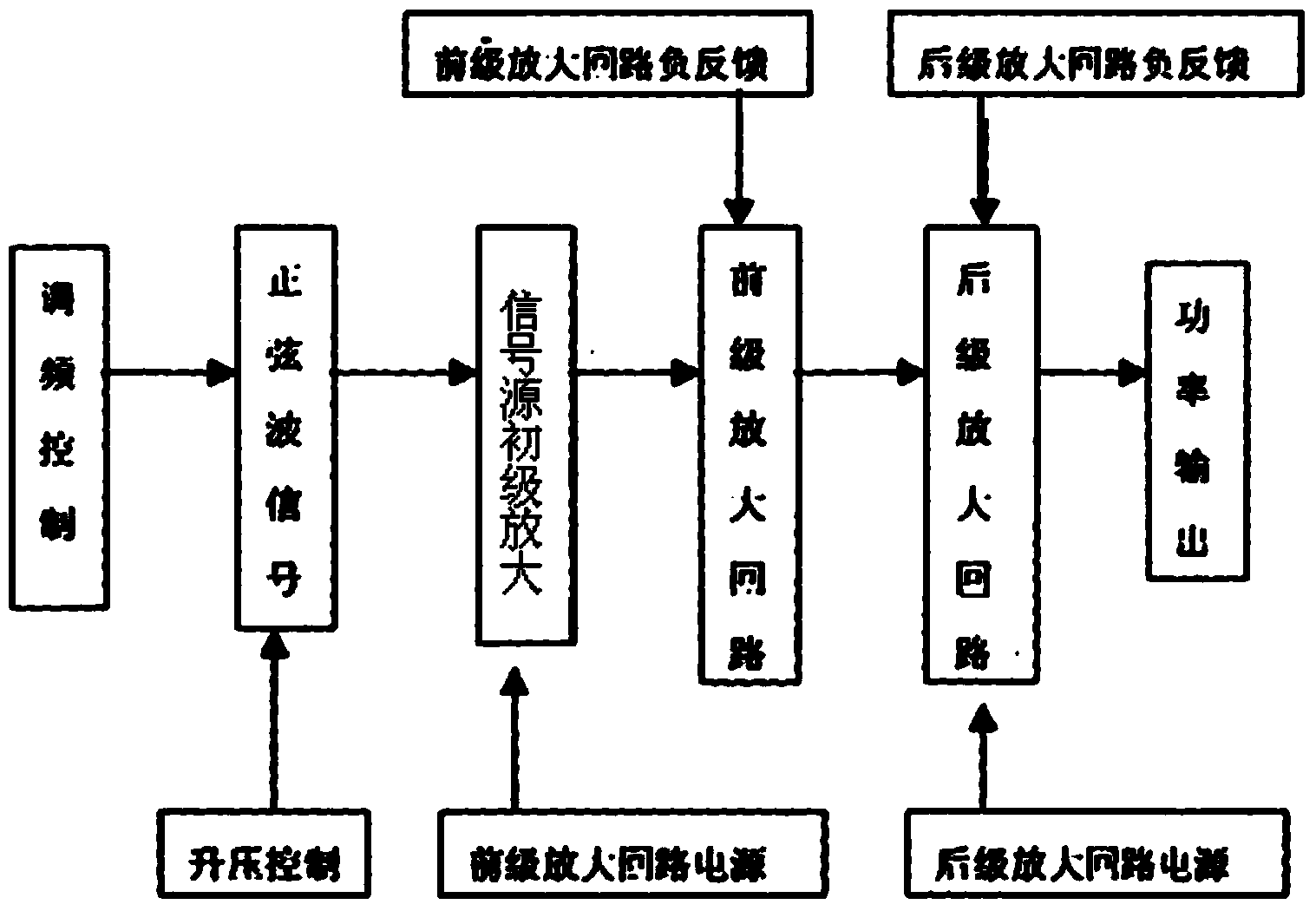

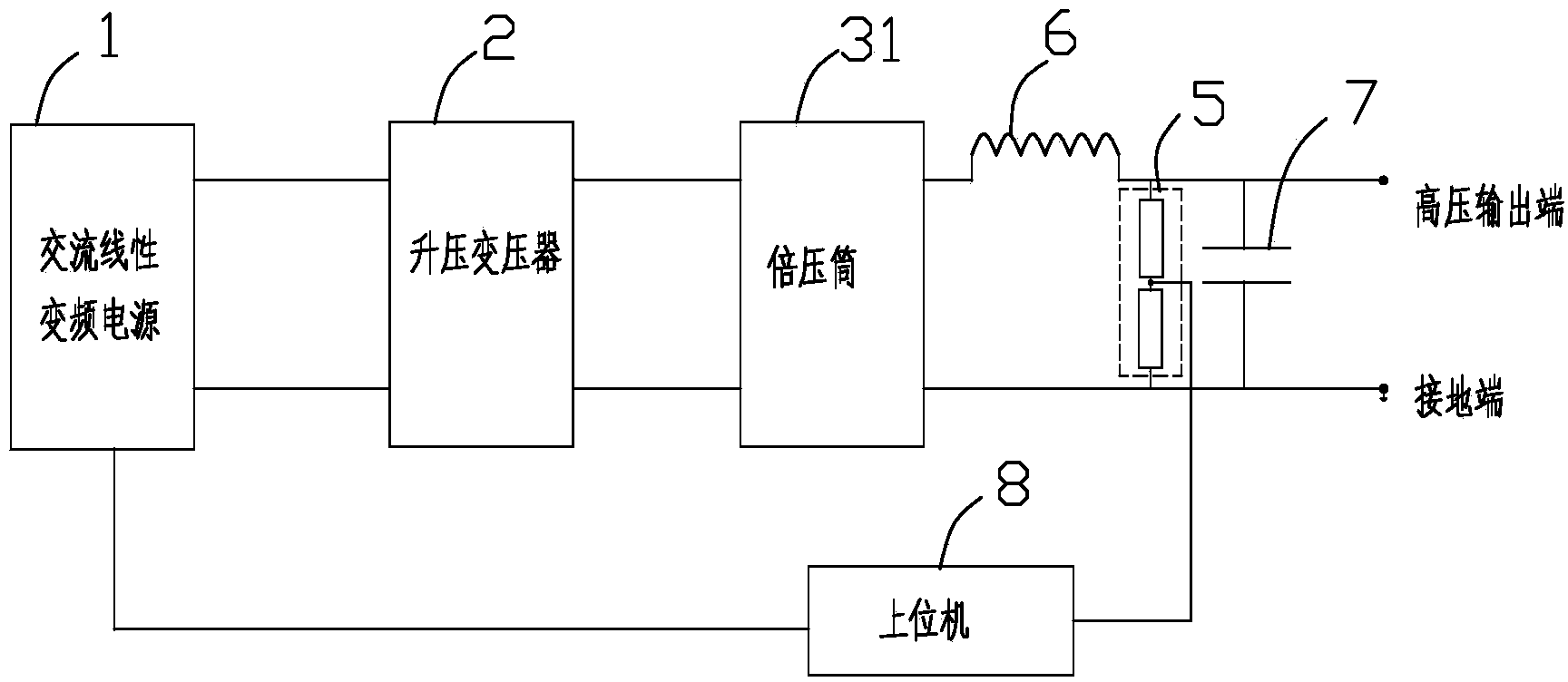

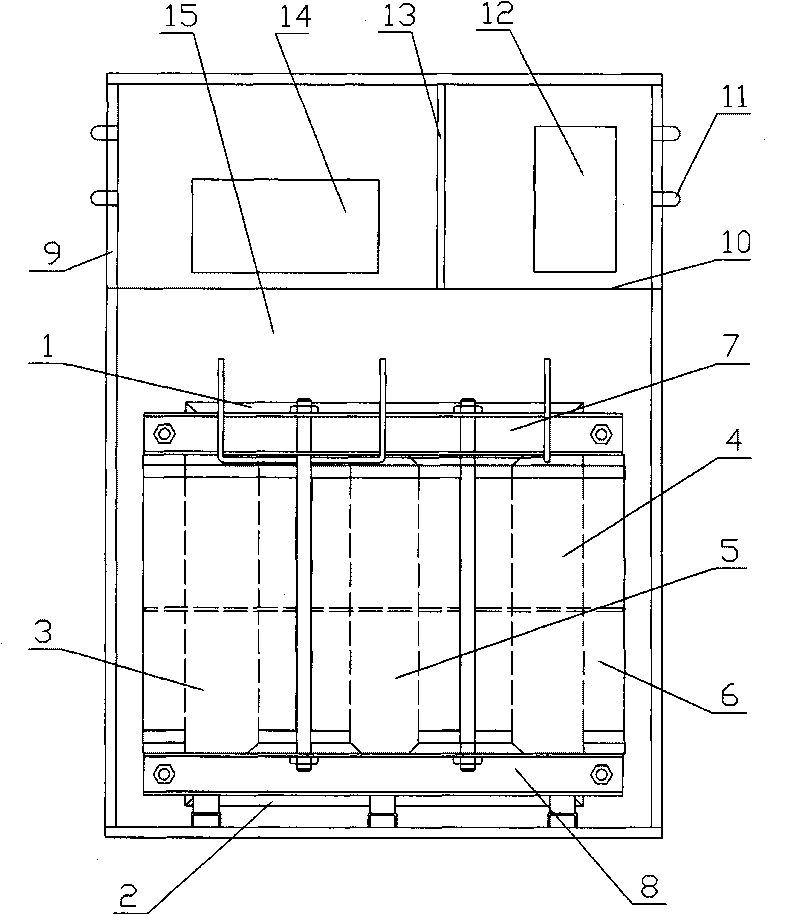

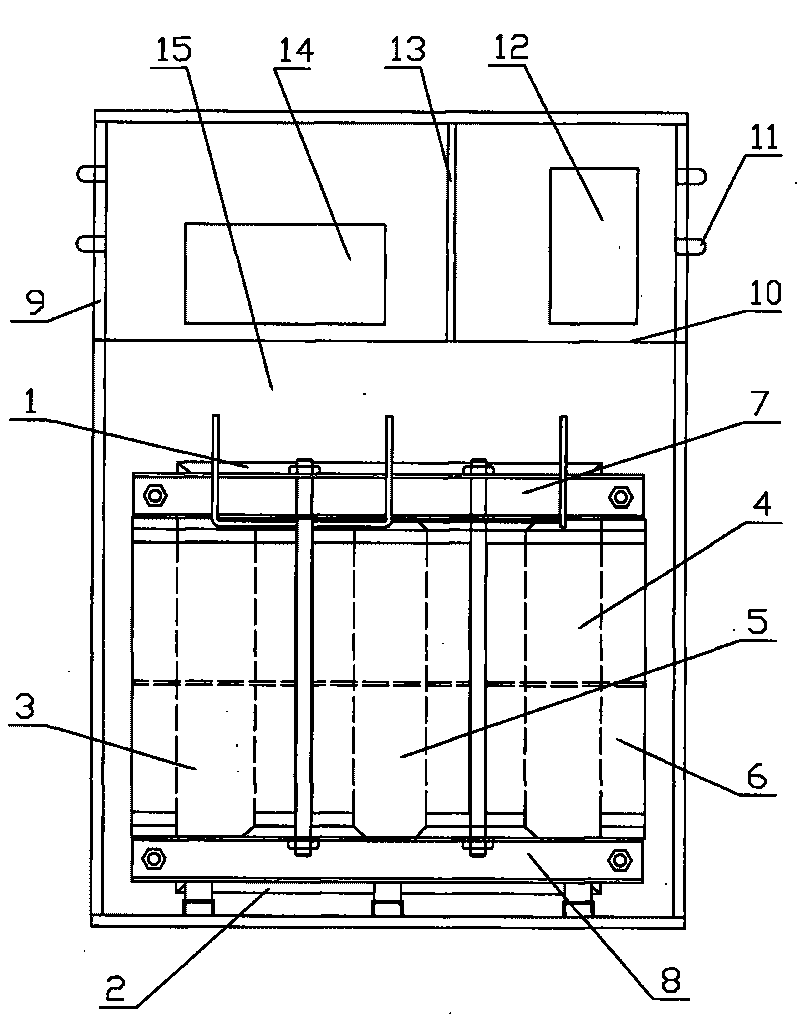

2,400kV/30mA movable partial-discharge-free direct-current high-voltage generator

The invention discloses a 2,400kV / 30mA movable partial-discharge-free direct-current high-voltage generator. The 2,400kV / 30mA movable partial-discharge-free direct-current high-voltage generator comprises an alternating current linear variable-frequency power supply, a boosting transformer, a voltage-multiplying assembly and a voltage-equalizing ring which are connected in sequence, wherein the alternating current linear variable-frequency power supply is used for performing three-stage amplification on a sine wave signal and then outputting a variable-frequency power signal; the boosting transformer is used for further boosting the variable-frequency power signal into a high-voltage alternating current power signal; the output end of the voltage-multiplying assembly is connected with one end of a high-frequency chocked flow inductor; the other end of the high-frequency chocked flow inductor is connected with the grounded end of the voltage-multiplying assembly through a filtering capacitor; nodes of the high-frequency chocked flow inductor and the filtering capacitor serve as the high-voltage output end and the grounded end of the voltage-multiplying assembly to access a voltage measuring module; the signal output end of the voltage measuring module is connected with the signal input end of an upper computer; the control signal output end of the upper computer is connected with the control signal input end of the alternating current linear variable-frequency power supply. The 2,400kV / 30mA movable partial-discharge-free direct-current high-voltage generator has the advantages that the size and the weight of a device can be reduced, and meanwhile, the overall partial discharge magnitude level of the device is controlled; 2,400kV / 30mA direct current output can be completed.

Owner:STATE GRID CORP OF CHINA +1

Dry-type transformer and reactor casting process

InactiveCN102623163AGood voltage resistanceEasy to wrapInductances/transformers/magnets manufactureEpoxyPositive pressure

The invention relates to the manufacture of both a transformer and a reactor, in particular to a dry-type transformer and reactor casting process. The casting process comprises the steps of fixing, curing, casting, pressurizing, heating and testing, and products successfully passing the test are accepted products. The invention has the characteristics that firstly, as epoxy resin is cured in the positive pressure state, that the epoxy resin can wrap the products according to the design requirements is effectively ensured, the voltage resisting strength of the products is improved, meanwhile, the partial discharge of the products is remarkably reduced, and the appearances of the products are improved; secondly, as the epoxy resin is cured in constant-temperature state, setting can be performed according to the optimal curing temperature of the adopted epoxy resin, on one hand, the wrapping performance of the epoxy resin to the products is improved, on the other hand, the curing time is effectively shortened, and the qualification rate and the production efficiency of the products are greatly improved.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

Built-in transformer of wind power tower barrel

InactiveCN101740202AReduce hysteresis consumptionHigh dielectric strengthTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow noiseLow voltage

The invention provides a built-in transformer of a wind power tower barrel, comprising a low-voltage winding, a high-voltage winding and an iron core. The structural key points are as follows: the iron core is provided with an upper iron yoke and a lower iron yoke; a side column is respectively arranged between the left end and the right end of the upper iron yoke and the lower iron yoke; the upper and lower ends of the side column are respectively connected with the left end and the right end of the iron yoke in an overlapping manner; the middle part of the iron yoke is provided with a middle column; the upper end and the lower end of the middle column are respectively connected with the middle part of the iron yoke in an overlapping manner; the side column and the middle column are respectively provided with the winding; the inner layer of the winding is provided with low-voltage coil; the outer layer of the low-voltage coil is sheathed with a high-voltage coil; clamping units are respectively arranged at the front and rear sides of the iron yoke; the low-voltage coil is wound with a copper foil; the materials pre-impregnated by DMD resin is used as the insulation between layers; a flexible grid cloth is arranged between two adjacent layers of the high-voltage winding; and the periphery of the high-voltage is provided with the solventless grid materials. The invention is characterized by compact structure, long service life, low noise, free maintenance, high reliability, no pollution, flame retardancy and the like, the probability of partial discharge is approximately zero, and the invention can be recycled after the service life is ended up.

Owner:沈阳福林特种变压器有限公司

Dry-type high-frequency transformer

ActiveCN108305764AImprove insulation performanceReduce partial dischargeTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesInsulation layerTransformer

The invention belongs to the technical field of a dry-type high-frequency transformer, and particularly relates to the dry-type high-frequency transformer which can be used for improving insulation performance and reducing local discharging quantity of the transformer and is provided with an insulation structure. By additionally arranging a transition layer having a buffer effect between the winding coil and the insulation layer, favorable linkage between the winding and the insulation layer is achieved, phenomena such as gap and crack between the insulation layer and the winding in the priorart are prevented, and the local discharging level can be effectively reduced; and moreover, an insulation elastic material and an electrostatic shielding material are preferably used as transition layers, a potential risk of large local discharging quantity of the insulation layer at a high-voltage side and a low-voltage side is prevented, the insulation performance of the dry-type high-frequencytransformer is greatly improved, the service lifetime of the dry-type high-frequency transformer is greatly prolonged, and the long-term running reliability of a power electronic transformer device is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

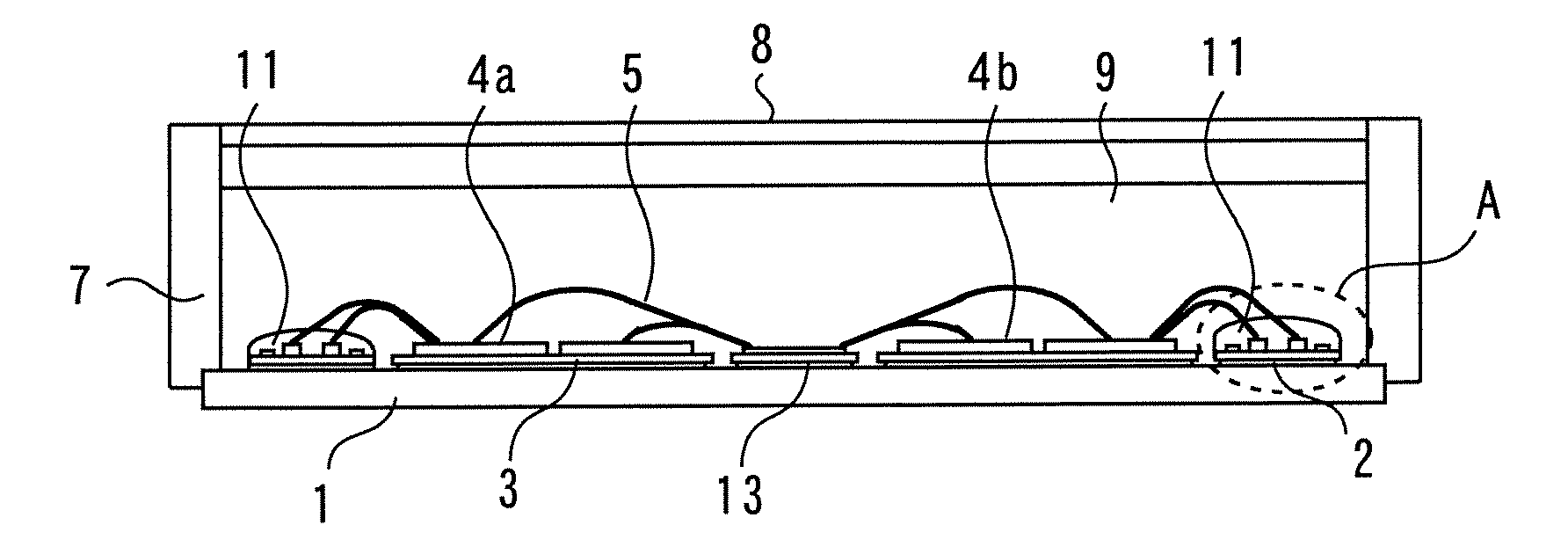

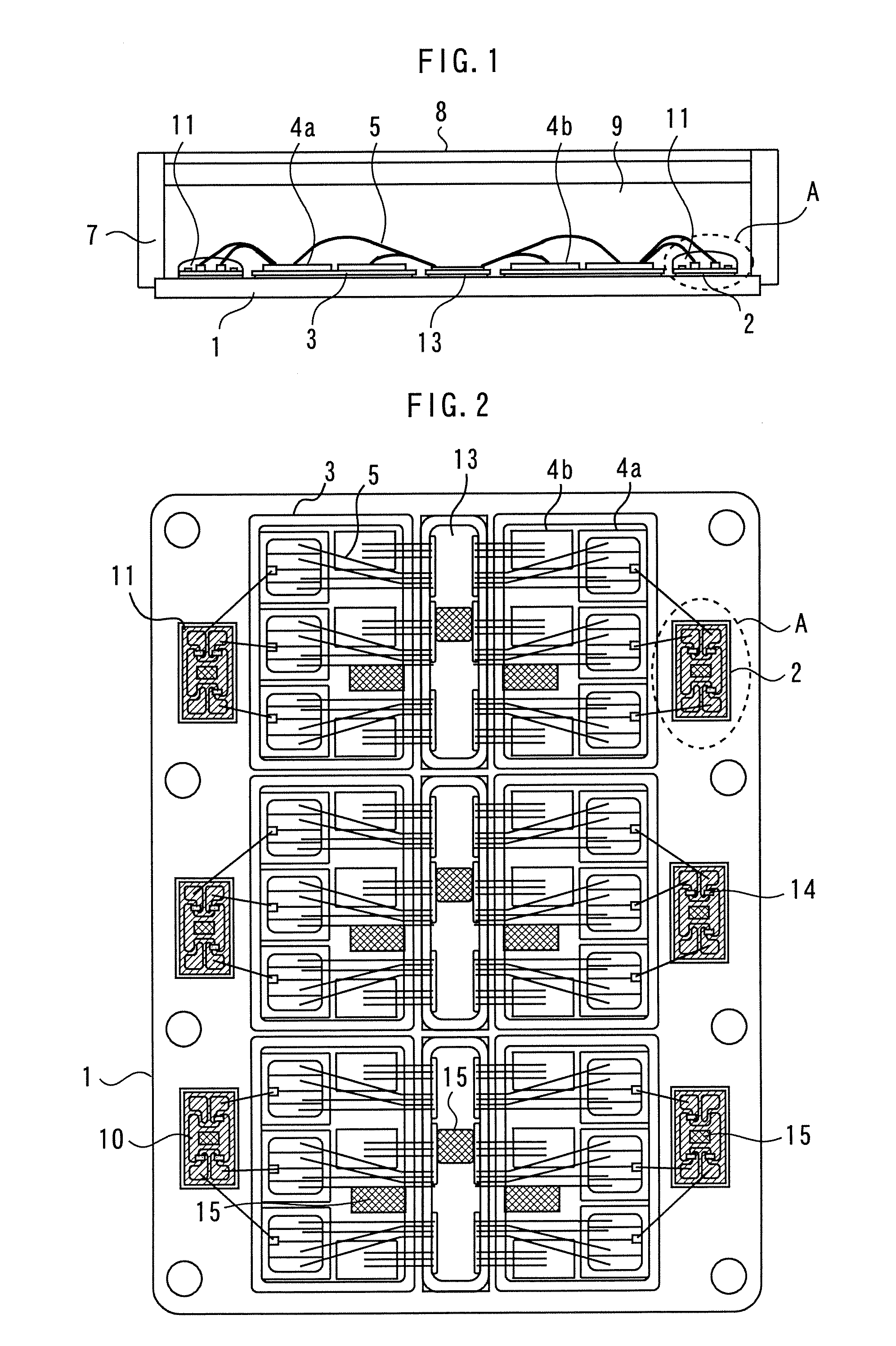

Power semiconductor module

ActiveUS7514777B2Increased operating lifeReduce partial dischargeSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon rubber

Owner:MITSUBISHI ELECTRIC CORP

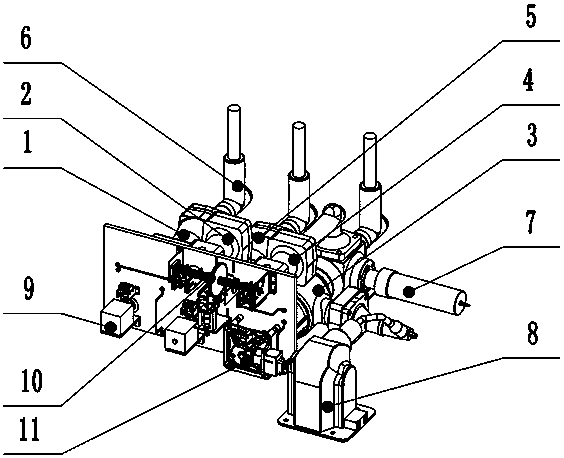

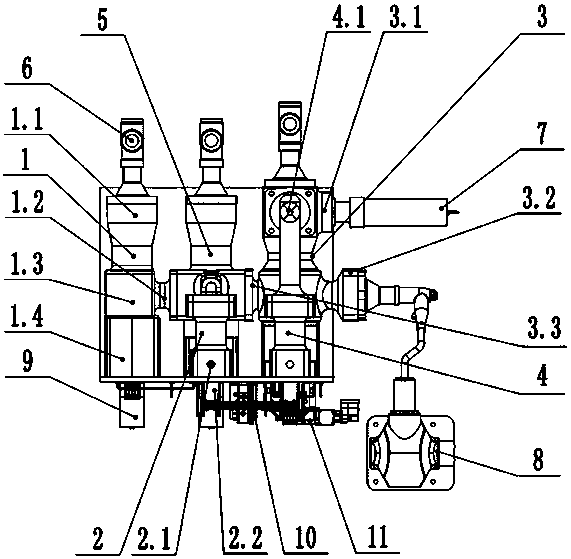

Electrified locomotive high-voltage switching device

PendingCN108173159AReduce volumeEasy to operateSwitchgear arrangementsHigh-tension/heavy-dress switchesTransformerElectrical devices

The invention relates to the field of high-voltage electrical devices, and in particular relates to an electrified locomotive high-voltage switch. The electrified locomotive high-voltage switch comprises a main isolating switch, a standby isolating switch, a circuit breaker, a grounding switch, an actuator, an arrester and a voltage transformer, which are horizontally arranged in a gas tank side by side; a vacuum arc-extinguishing chamber and a solid insulating material are adopted; a permanent magnetic mechanism is adopted in an isolating switch actuator; and a pneumatic actuator is adopted in the circuit breaker. According to the electrified locomotive high-voltage switching device disclosed by the invention, the volume of the switch is reduced; the local discharge capacity of the product is reduced; the service life of the product is prolonged; the actuator is simplified; and the reliability is improved.

Owner:BEIHAI GALAXY SWITCH DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com