High-voltage terminal device for transformer

A high-voltage outgoing line and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of uneven electric field distribution, easy nesting, etc., achieve uniform electric field distribution, reduce insulation distance, and eliminate internal cavity nests The effect of gas problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

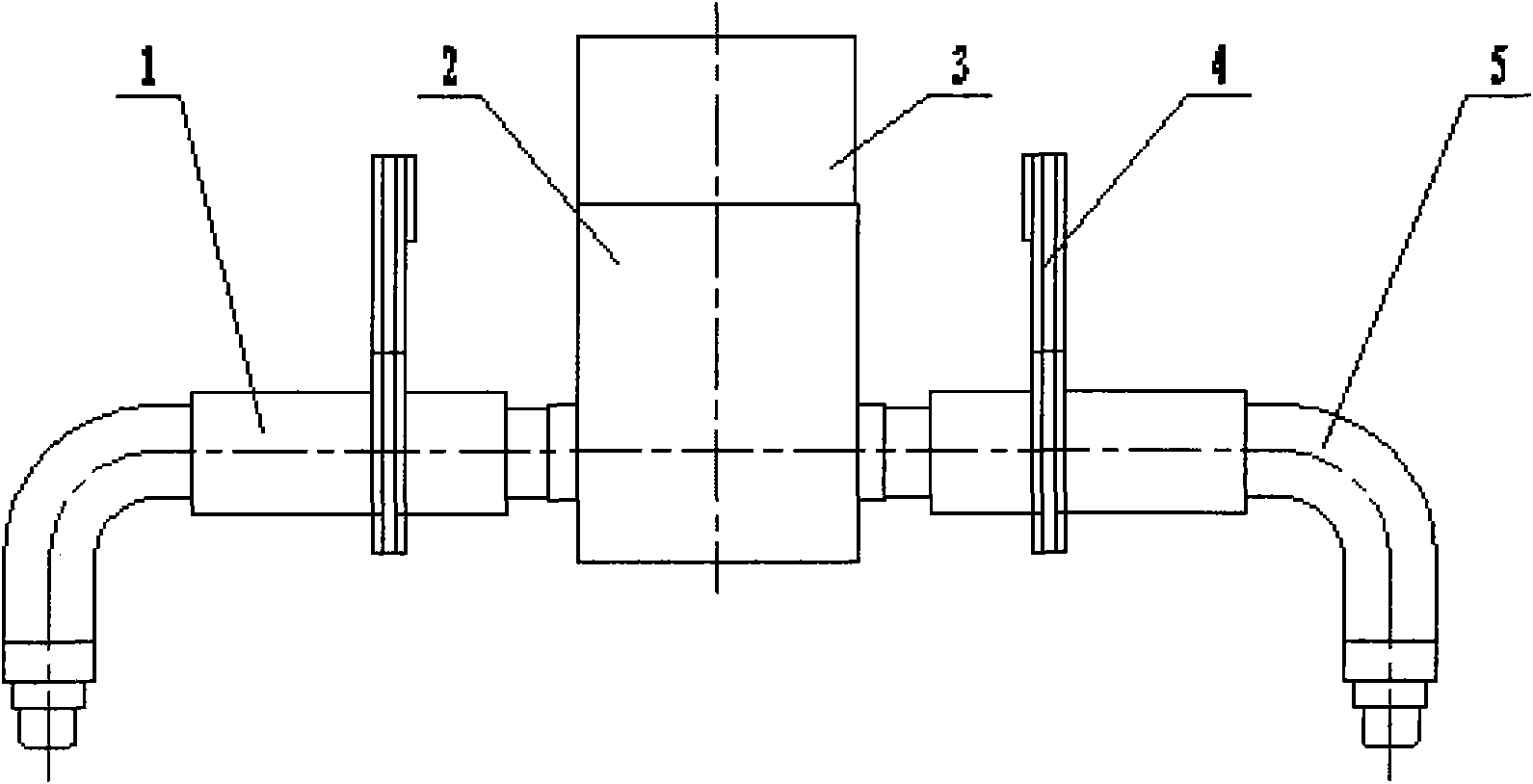

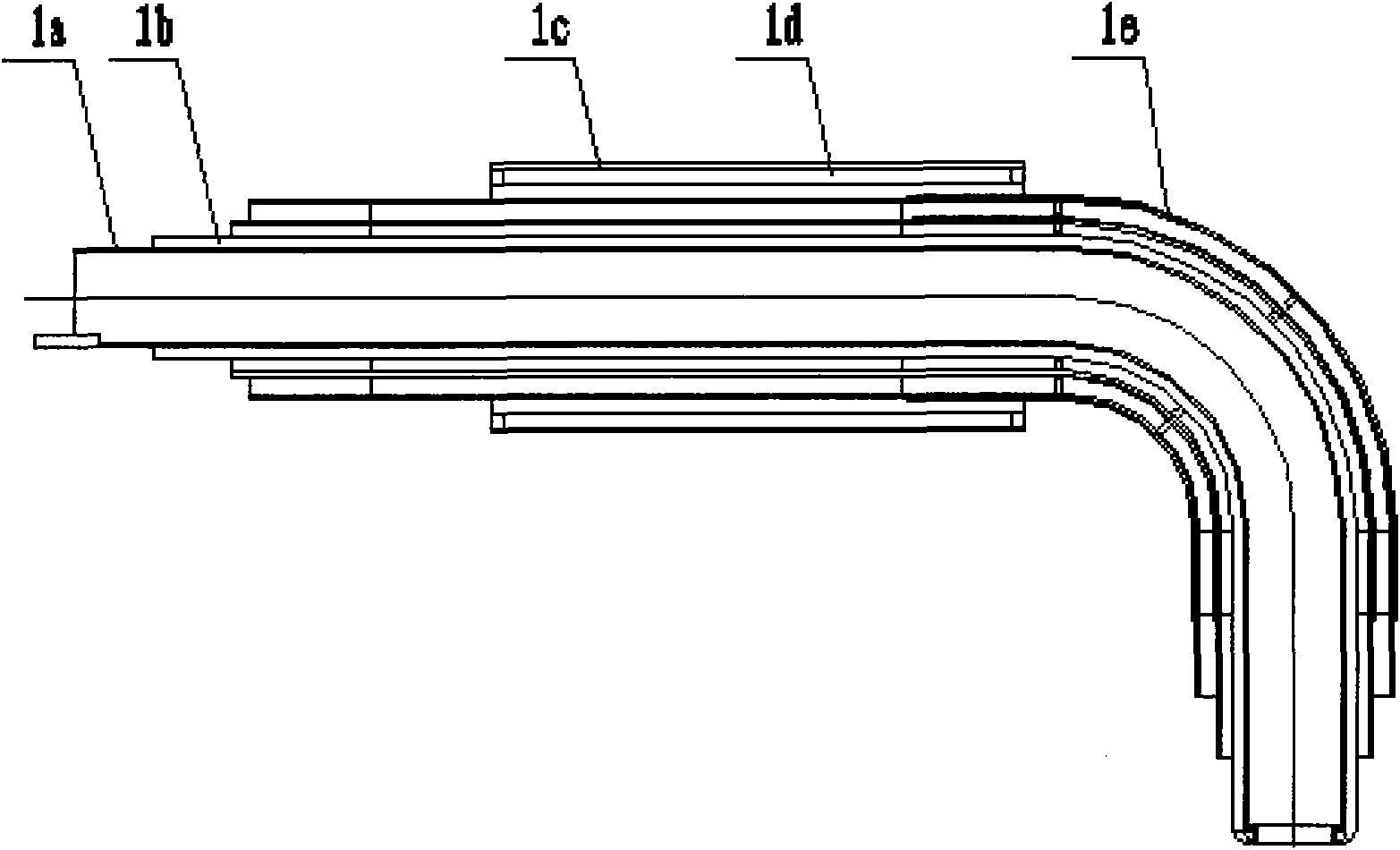

[0015] Such as figure 1 , 3 , 4 and 5, the utility model is applied to the high-voltage outlet of the transformer, including the outlet tube, the pressure equalizing ball 2, the movable paper tube 3, the wire clip 4, the copper braid 6, the fixing part 7 and the terminal 8, etc. In this embodiment, there are two outlet barrels (i.e., outlet barrels 1 and 5), which are inserted symmetrically from both sides of the pressure equalizing ball 2, and the outer surface of the equalizing ball 2 is tightly wrapped by hand with Insuldur heat-resistant crepe paper to ensure , no gap will be formed between the outer surface of the pressure equalizing ball and the insulation; the equalizing ball 2 is mainly composed of a shielding cylinder 2f, and an insulating layer 2g is arranged outside it, and a paper tube 2d is arranged on the outside of the insulating layer 2g through a stay 2e; the insulating layer The upper and lower parts of 2g are bent inward; the two sides of the lower part of ...

Embodiment 2

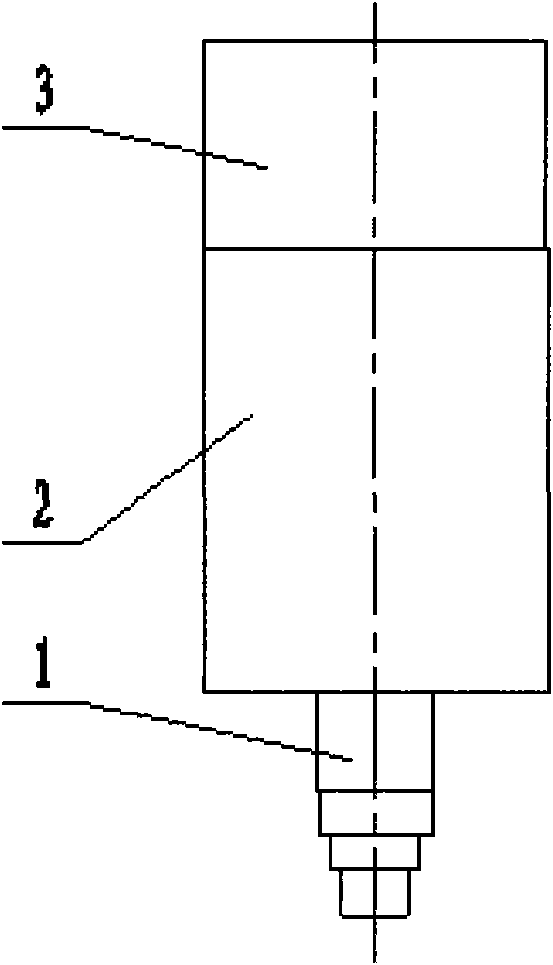

[0020] Such as figure 2 As shown, the difference from Embodiment 1 is that there is one outlet barrel 1, and the pressure equalizing ball 2 is inserted from the bottom and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com