Insulation tube bus and manufacturing method thereof

An insulating tube and busbar technology, which is used in the manufacture of insulated cables, insulated conductors, and cables/conductors. Safe and reliable, high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

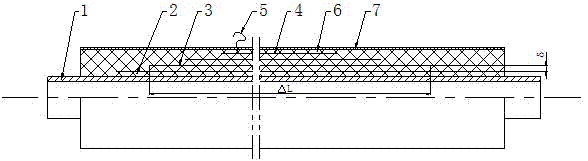

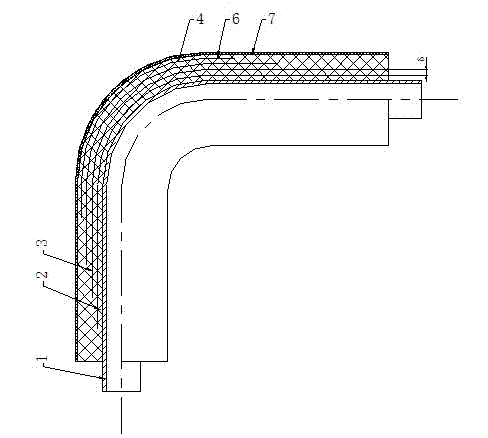

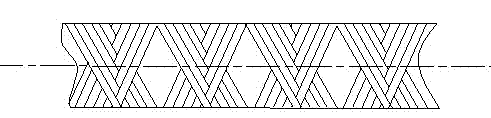

[0028] Figure 1a with Figure 1b What is shown in the figure is an insulating tube busbar, which consists of a conductive tube 1, an insulating layer 2, a voltage equalizing screen 3, an outer shielding layer 4, a grounding wire 5, an insulating outer protective layer 6, and an anti-aging layer 7, wherein the insulating layer 2 Made of glass fiber roving with figure 2 or glass fiber cloth with image 3 The intercrossing and lapping winding methods shown in the above are uniformly wound to the design size; the equalizing screen 3 is made of aluminum foil, wire mesh, ribbon or tow-shaped conductive carbon fiber or semiconductor material figure 2 The method shown is evenly wound to the required size; and after the voltage equalizing screen 3 and the insulating layer 2 are alternately wound to the required size, the outer shielding layer 4 is wound on it, and the grounding wire 5 is embedded in the set position of the outer shielding layer; The shielding layer is wrapped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com