Patents

Literature

742results about How to "Convenient on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be openedin 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

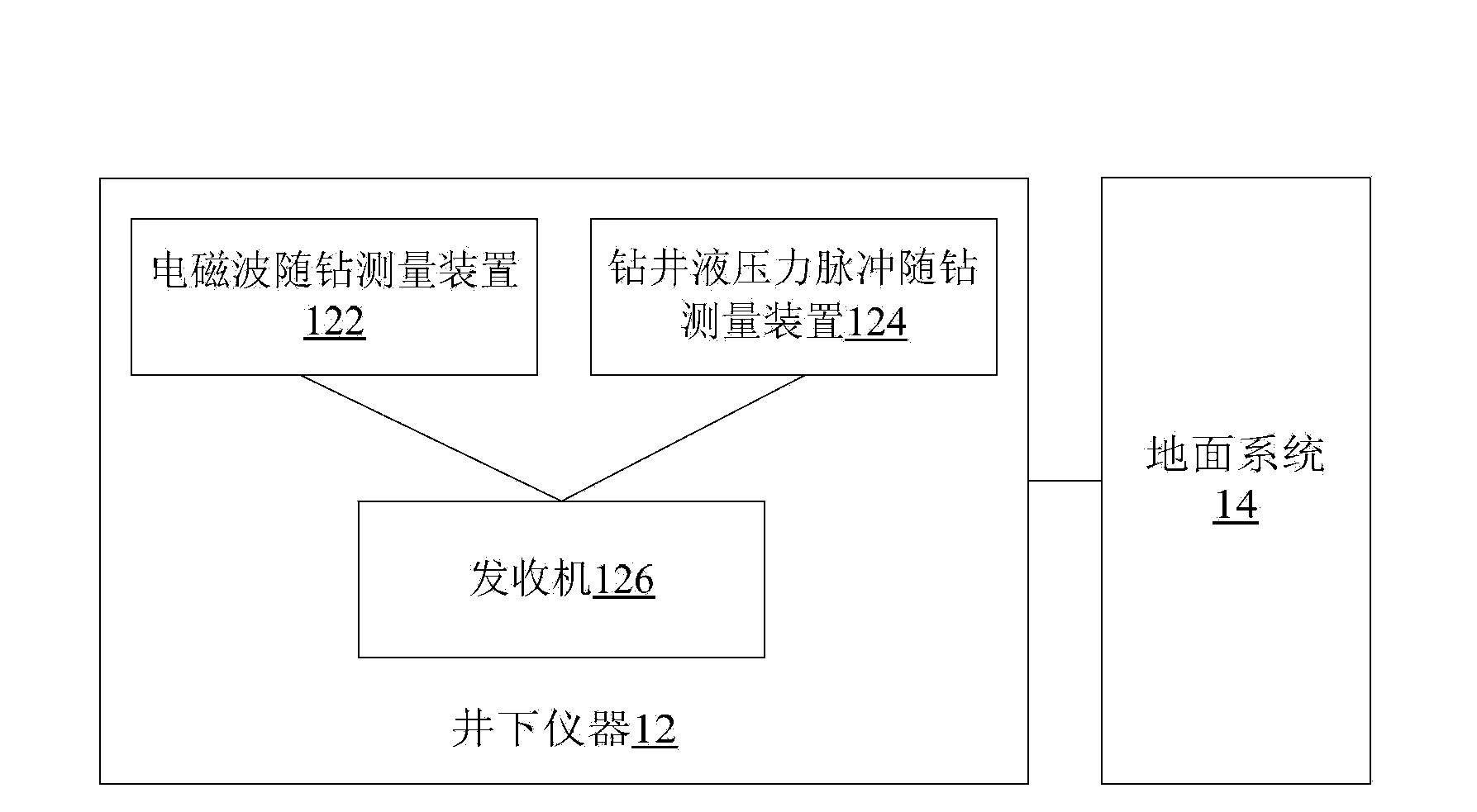

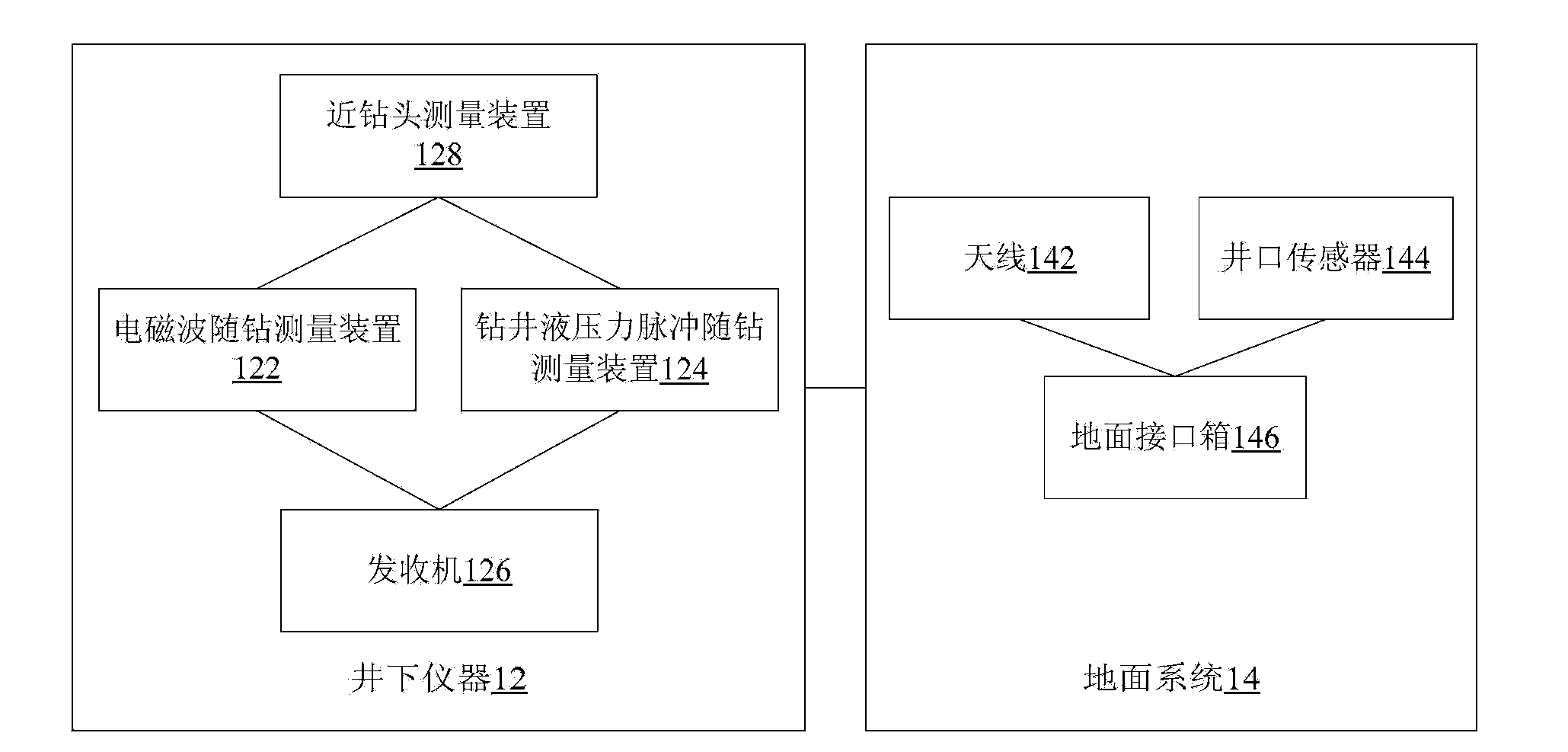

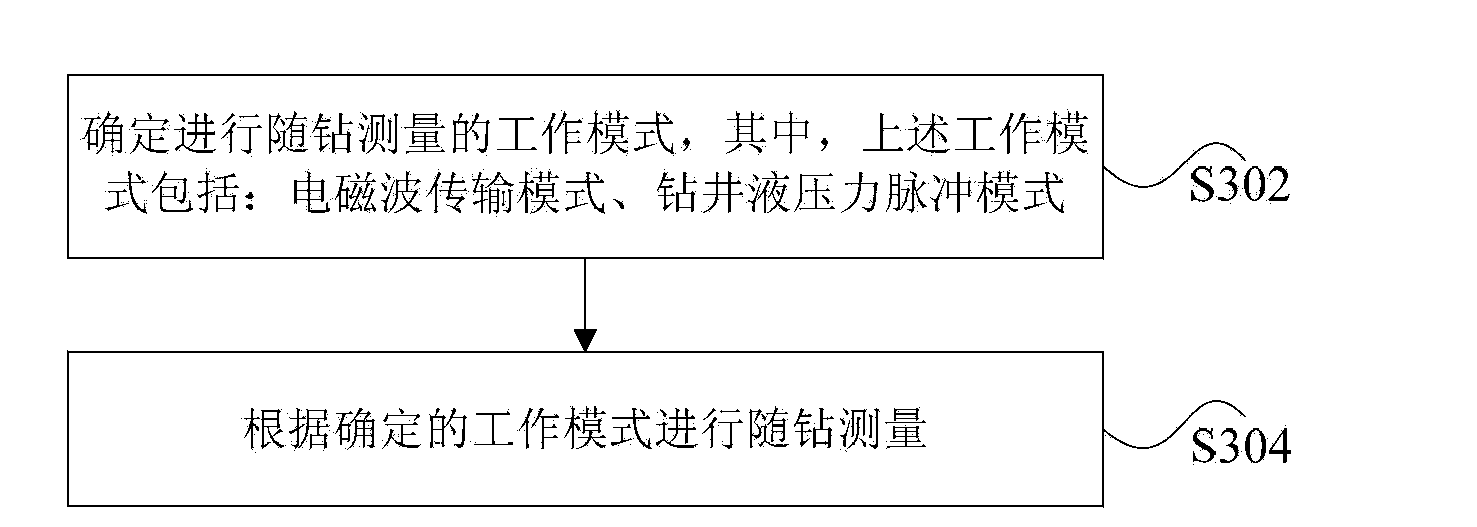

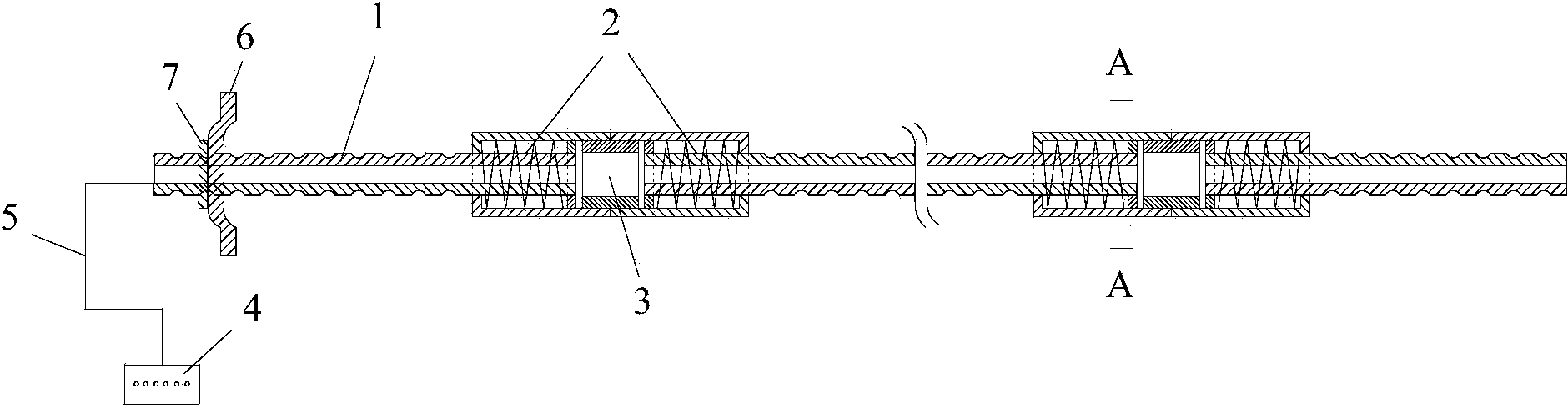

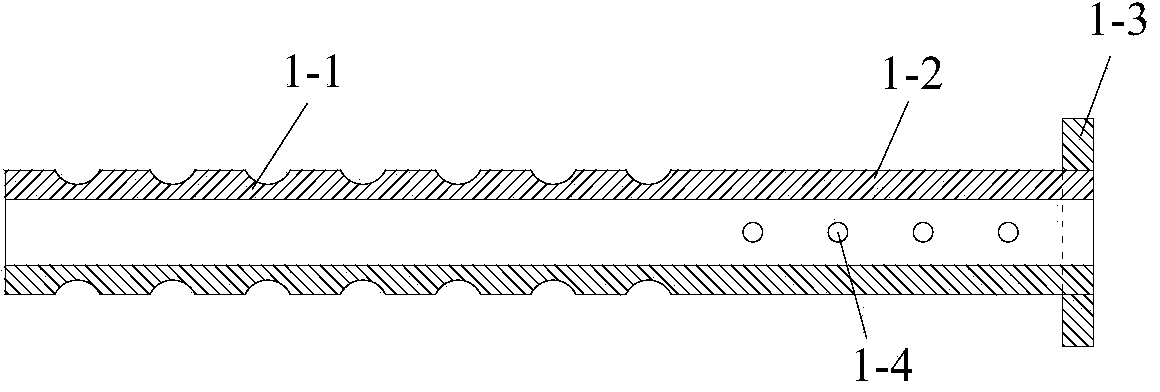

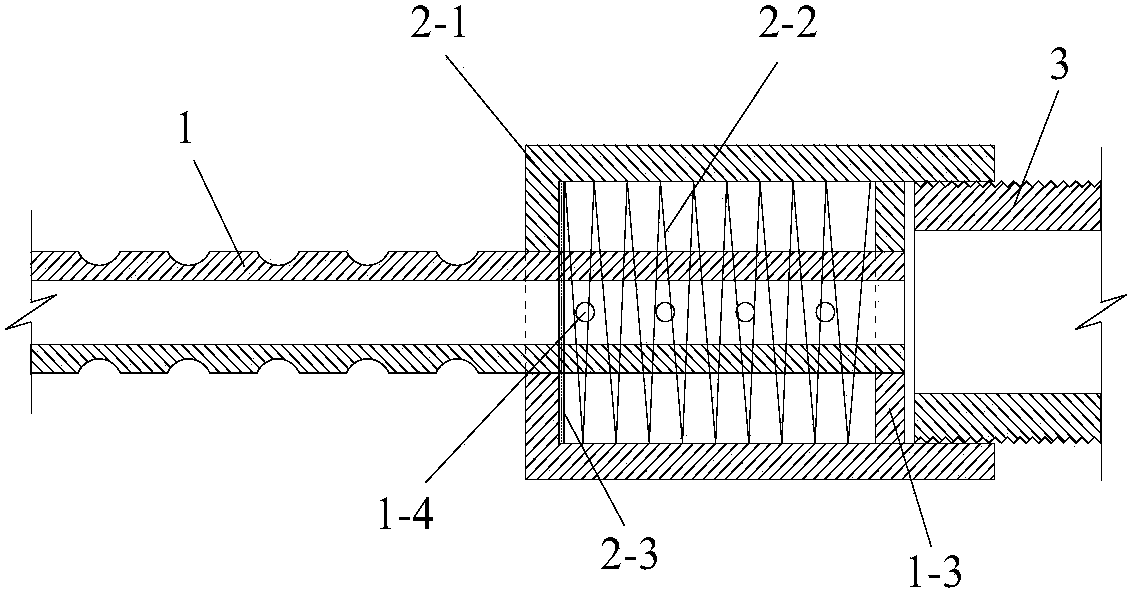

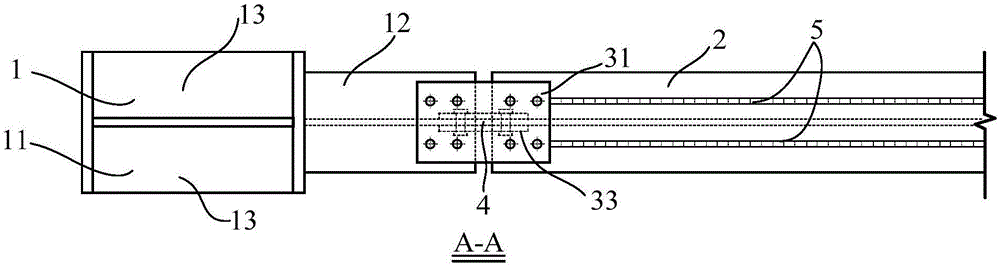

Wireless measurement while drilling system and method

InactiveCN103899301AImprove compatibilityConvenient on-site constructionSurveyConstructionsDigital signal processingWell logging

The invention discloses a wireless measurement while drilling system and method. The system comprises an underground instrument and a ground system. The underground instrument comprises an electromagnetic wave measurement while drilling device used for carrying out measurement while drilling through electromagnetic waves, a drilling fluid pressure pulse measurement while drilling device used for carrying out measurement while drilling through drilling fluid pressure, and a transmitting and receiving machine connected to the electromagnetic wave measurement while drilling device and the drilling fluid pressure pulse measurement while drilling device and used for controlling switching of the work modes of the underground instrument according to signals from the ground system. The work modes comprise an electromagnetic wave transmission mode and a drilling fluid pressure pulse mode. The ground system is compatible with demodulating and decoding of the two work modes and is used for carrying out digital signal processing on the signals generated under the electromagnetic wave transmission mode and / or the drilling fluid pressure pulse mode. According to the system, well logging combination of different transmission modes is achieved, and underground working of the two modes can be selected at the same time or underground working of one mode can be selected according to needs. The system is flexible, compatible and high in applicability.

Owner:THE 22ND RES INST OF CHINA ELECTRONICS TECH GROUP CORP

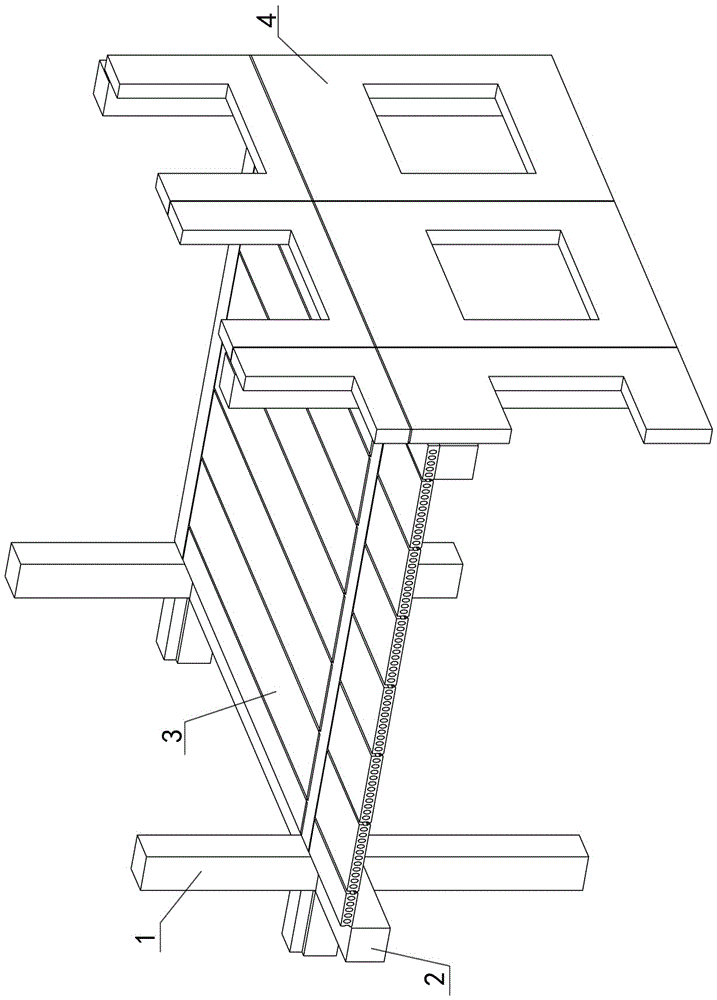

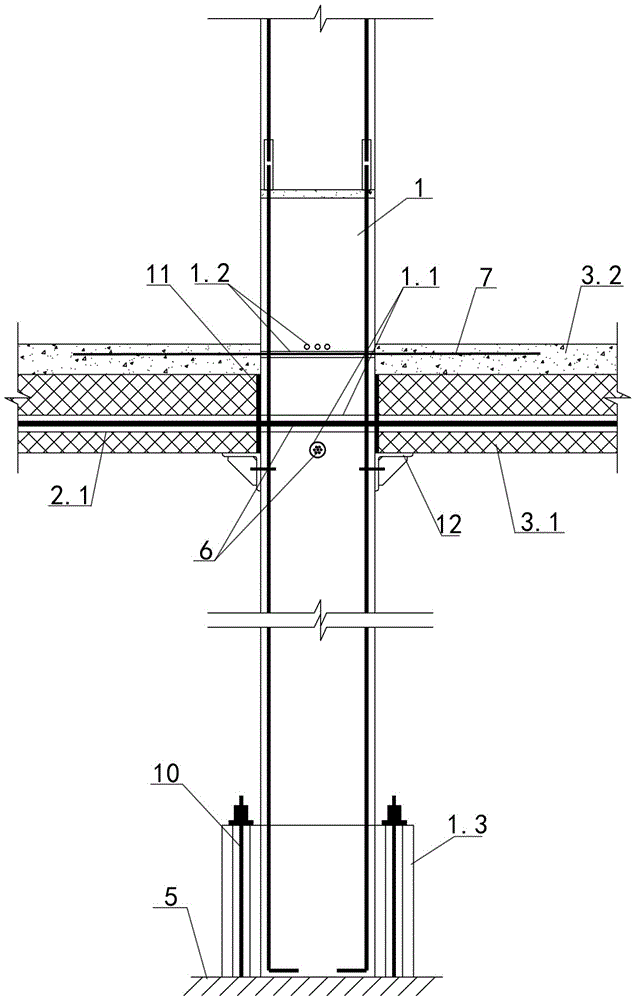

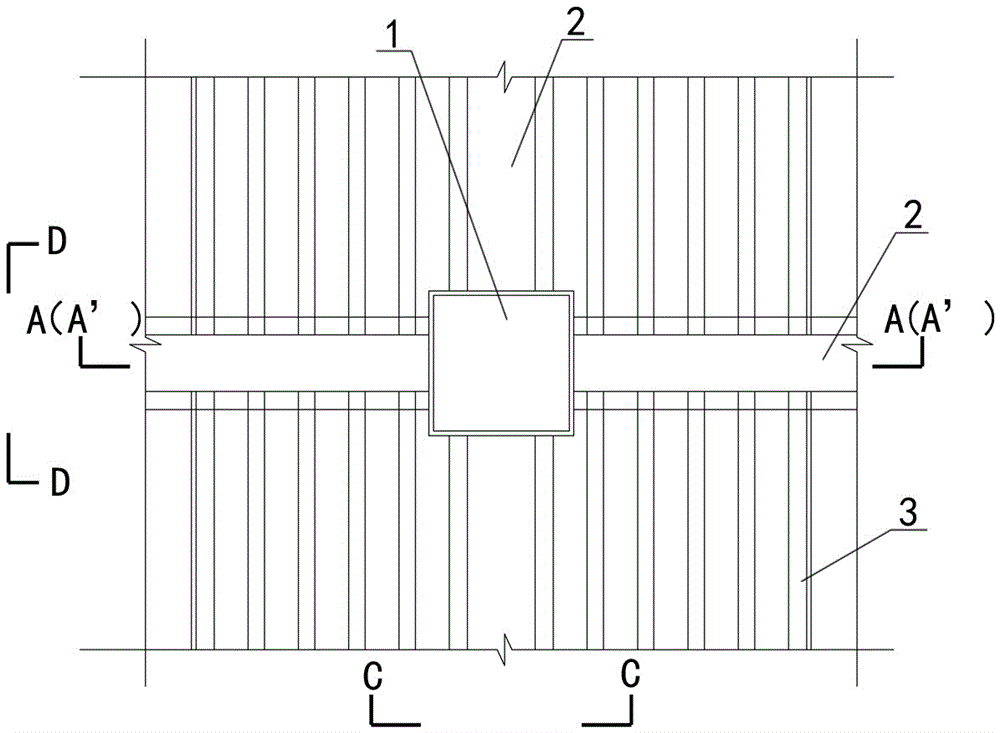

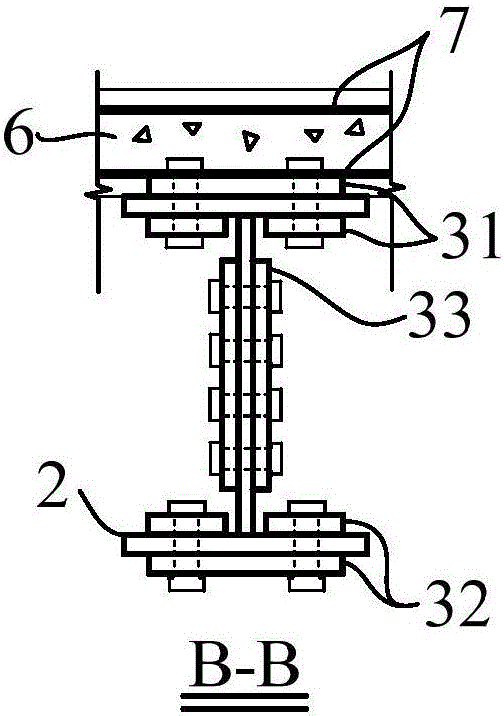

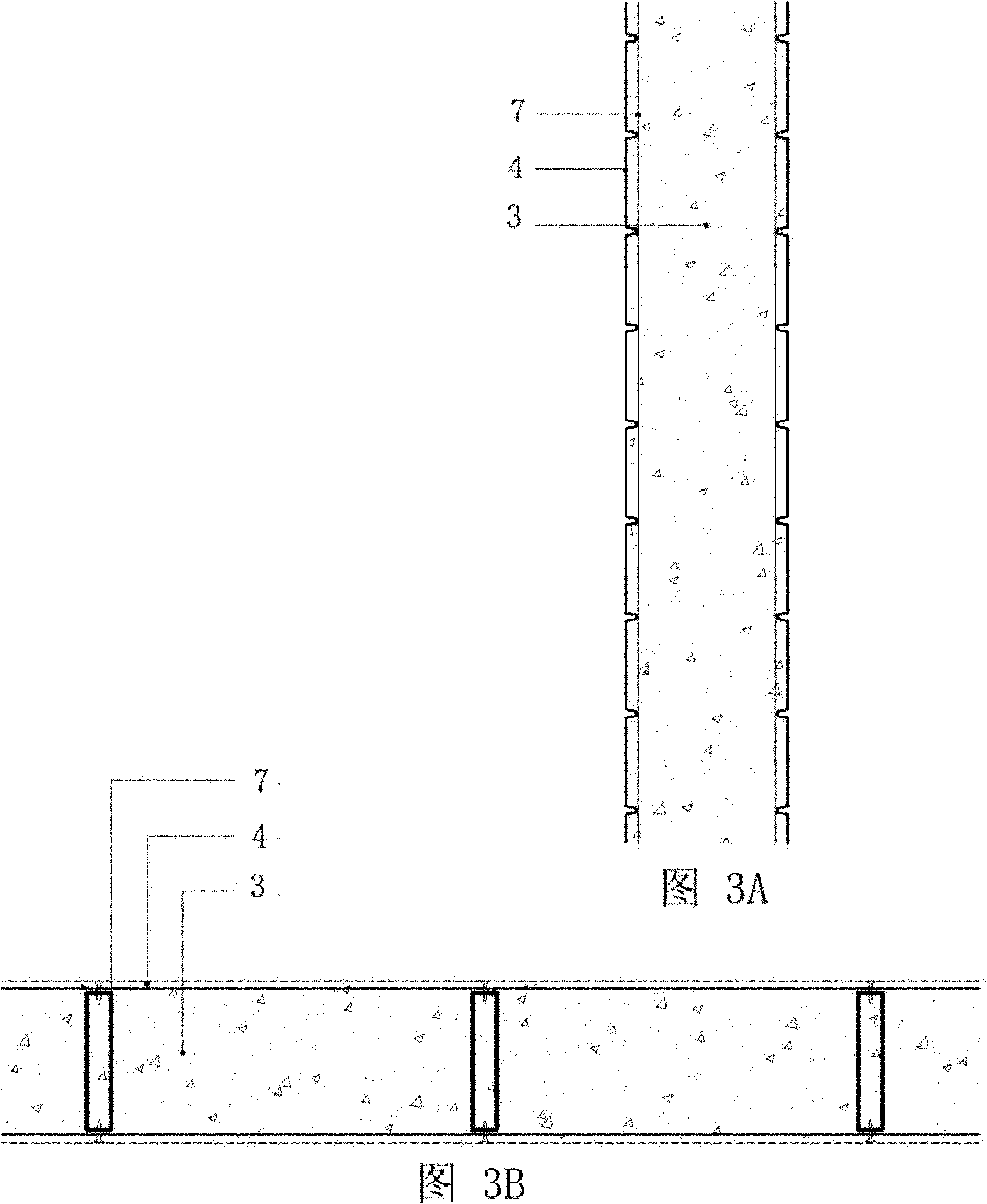

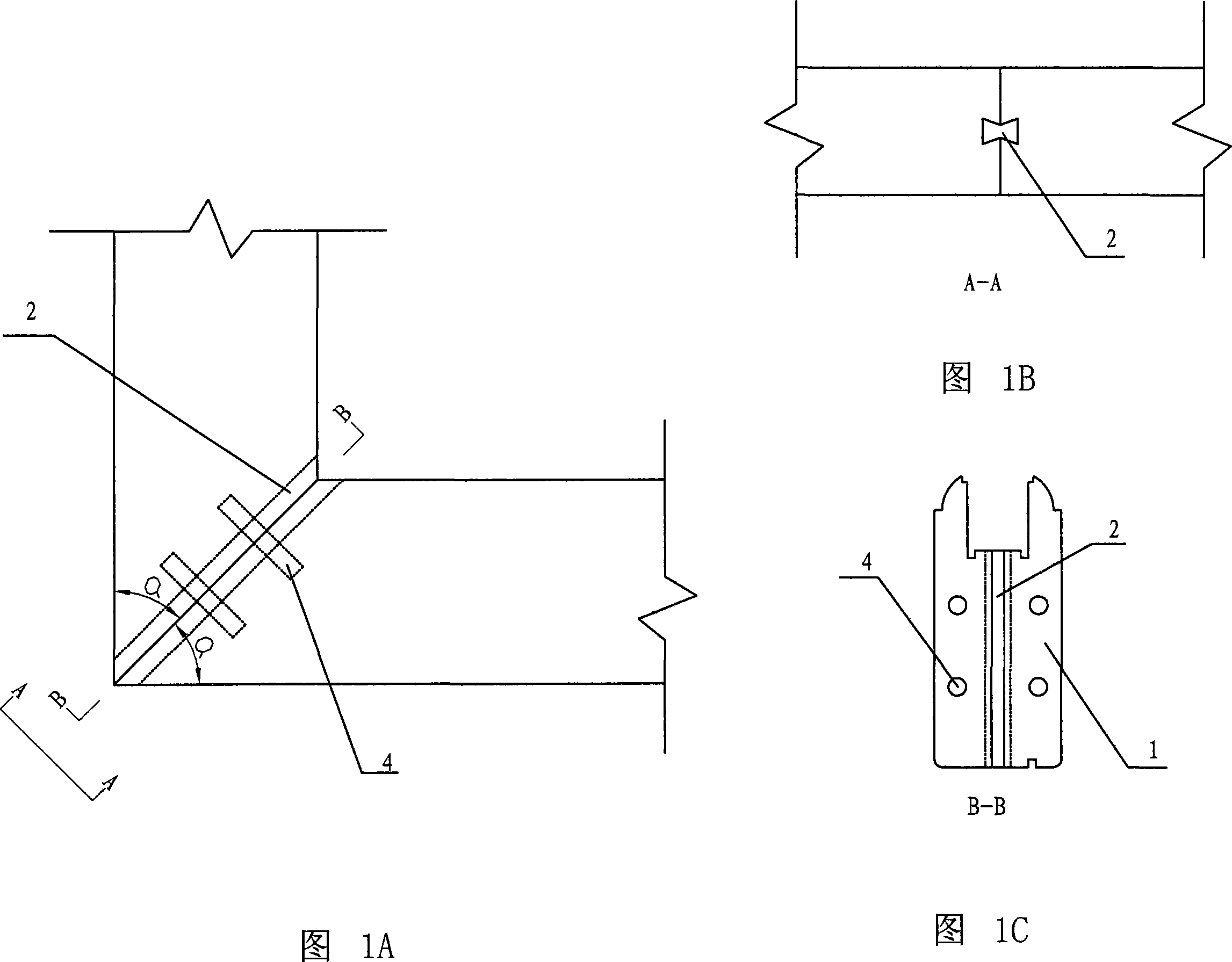

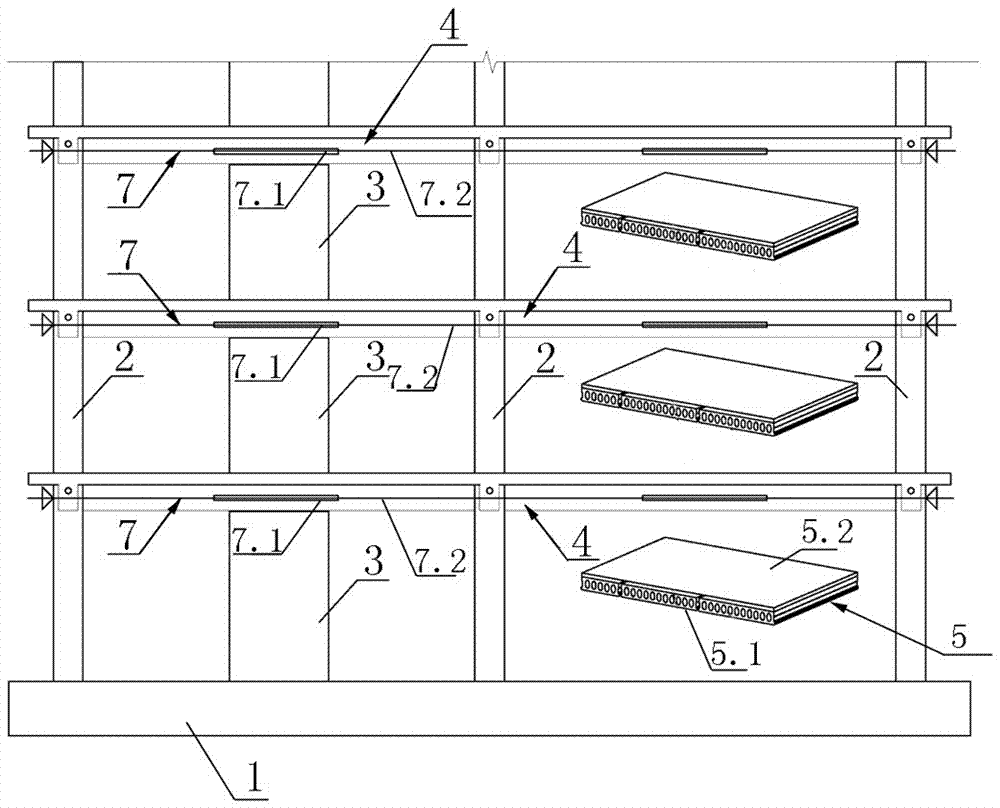

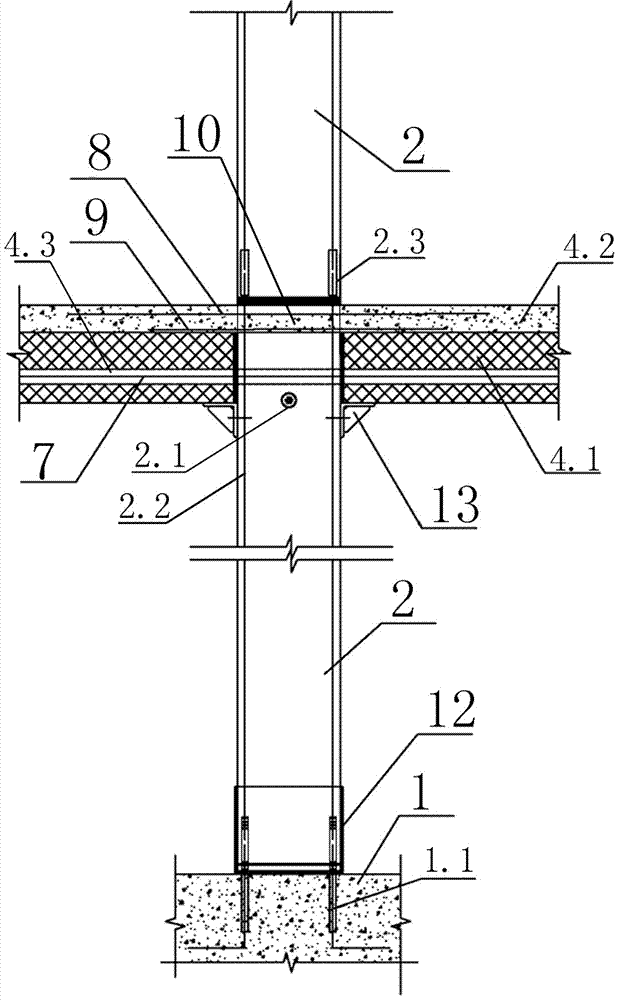

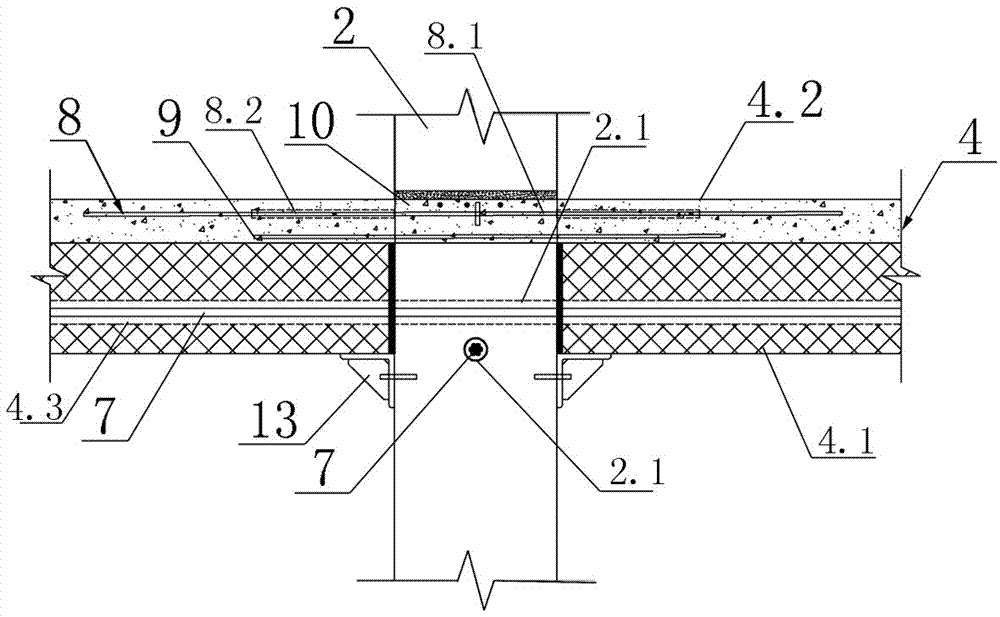

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

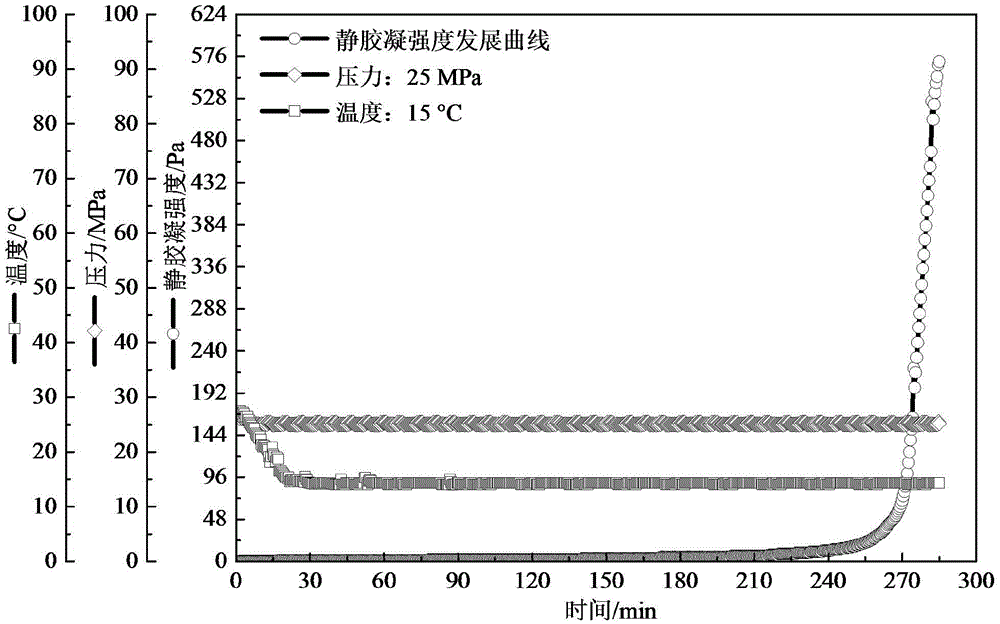

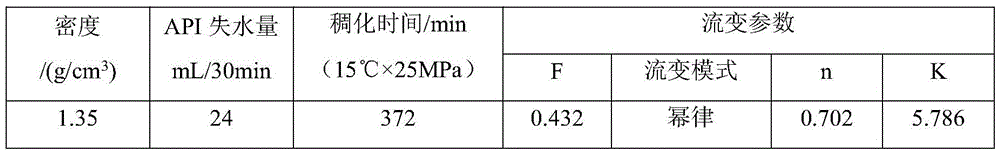

Deepwater well cementing mortar architecture

InactiveCN101134892AAdjustable densityThickening time adjustableDrilling compositionOrganic acidInorganic salts

The present invention provides one kind of cement slurry system for deep water well cementing. The cement slurry system consists of silicate-sulfoaluminate composite cement 100 weight portions, hollow bead 0-100 weight portions, water loss reducing agent of hydroxyethyl cellulose or carboxymethyl hydroxyethyl cellulose 1.5-3.0 weight portions, dispersant of sulfonated formaldehyde-acetone polycondensate or sulfonated formaldehyde amidate-acetone polycondensate 0.3-1.0 weight portion, early strength agent of inorganic salts 2.0-4.5 weight portions, setting retarder of low molecular organic acids 0.1-1.2 weight portions, and water 60-120 weight portions. It has excellent low temperature early strength and 'rectangular thickening' performance, and possesses broad application foreground in deep water well cementing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

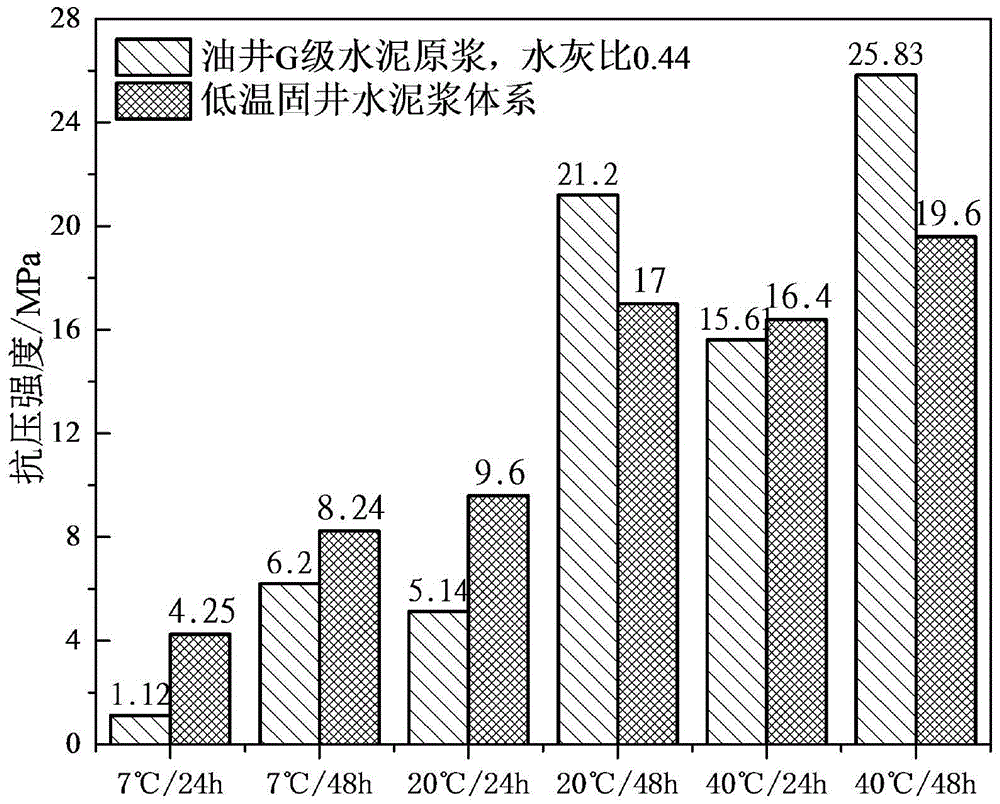

Low-temperature cementing slurry system and composition thereof

InactiveCN105462571AReduce intensityHigh strengthDrilling compositionMicrofine cementCalcium silicate

The present invention provides a low-temperature cementing slurry system. The slurry system has the characteristics of low density, low temperature early strength and low water loss, and has performances such as thickening time and compressive strength meeting the requirements of deepwater cementing construction site. The low-temperature cementing slurry system comprises the following components by weight: 100 parts of oil well cement, 62-175 parts oil well superfine cement, 7.3-23 parts of nano-silica, 10-32 parts active calcium silicate, 15-50 parts of hollow glass microballoon, 3.6-10 parts of an early strength agent, 3.2-8.6 parts of a fluid loss agent, 0.8-2.0 parts of a dispersing agent and 120-195 parts of water. The low-temperature cementing slurry system has density between 1.30-1.60 g / cm<3>, and is particularly suitable for cementing operations on a deepwater low-temperature surface casing segment. The invention has important significance in reducing the offshore cementing cost, and offshore oil and gas resource exploitation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

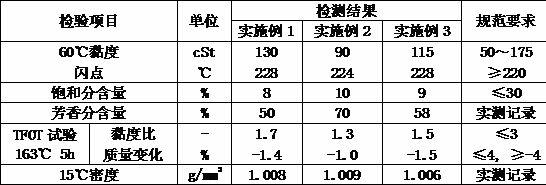

Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

The invention discloses an asphalt recycling agent for hot recycling of asphalt on an asphalt road surface. The recycling agent comprises the following components by weight: 19-70% of an aromatic oil, 20-60% of heavy oil, 5-30% of liquid petroleum resin and 0.2-1% of a stabilizer. The invention also provides a preparation process of the asphalt recycling agent and a method for preparing recycled asphalt by use of the asphalt recycling agent. The recycling agent disclosed by the invention is good in recycling effect, easy for raw materials purchase, stable in quality, low in equipment investment, simple in processing steps, short in processing time of finished products, good in storage stability, stable in physicochemical property, and convenient for on-site operation, and is suitable for on-site hot recycling construction as a special recycling agent.

Owner:YINGDA HEAT REGENERATION

Full-anchor partition pressure transferring grouting anchor rod and application method thereof

ActiveCN103643977AActively control the rate of rupture developmentHigh initial preloadAnchoring boltsEngineeringRock bolt

The invention discloses a full-anchor partition pressure transferring grouting anchor rod and an application method thereof. The anchor rod comprises a hollow anchor rod body, an anchor rod tray and a lockset nut. The hollow anchor rod body is cut into long section bodies, and rod body pressure transferring devices which are connected together through hollow connecting bolts, wherein one hollow connecting bolt is arranged between every two adjacent long section bodies. Each rod body pressure transferring device comprises a sleeve, wherein a pressure transferring grouting pipe section is sleeved with the sleeve, a flat type pressure sensor and a compression spring abutting against a blocking nut are arranged inside the sleeve in sequence, and all flat type pressure sensors are connected with a partition grouting indicator through wires. According to the full-anchor partition pressure transferring grouting anchor rod, automatic multi-point pressure transferring can be carried out on a plurality of fracture partitions of a deep surrounding rock, the non-coordination deformation breakdown pressure inside the surrounding rock can be effectively released, the anchor rod body can be prevented from being pulled broken and being out of operation, the optimal grouting time points of surrounding rock fracture partitions can be accurately grasped, independent grouting reinforcement is carried out on all fracture partitions timely in a targeted mode, and the stability of the deep roadway partition fracture surrounding rock is effectively improved.

Owner:CHINA UNIV OF MINING & TECH

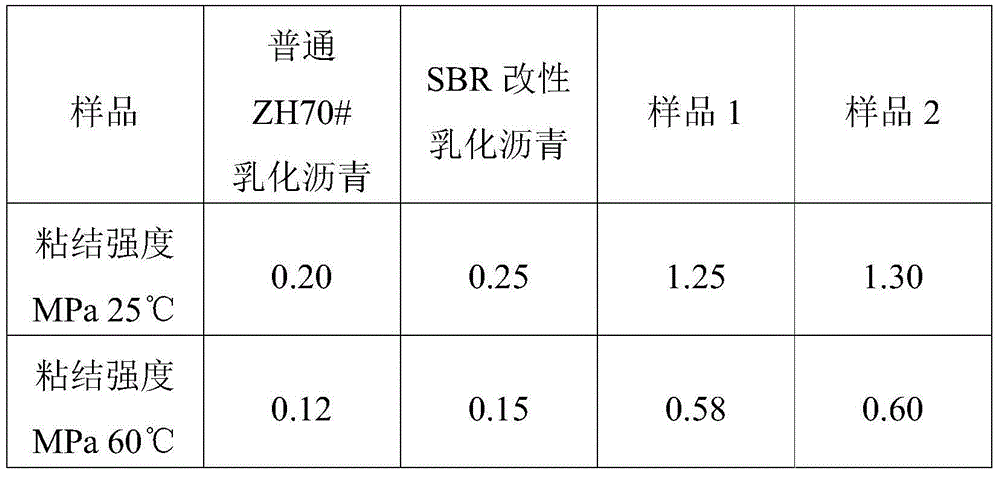

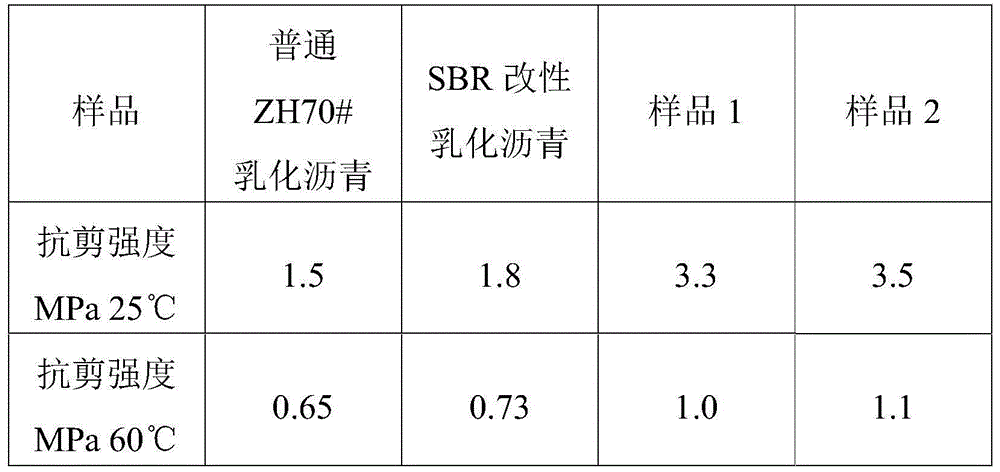

Aqueous epoxy resin modified emulsified asphalt, and preparation method and application thereof

InactiveCN105985656AHigh strengthImprove high temperature stabilityBuilding insulationsEpoxyPavement maintenance

The invention discloses an aqueous epoxy resin modified emulsified asphalt, and a preparation method and an application thereof. The aqueous epoxy resin modified emulsified asphalt comprises 100 parts of emulsified asphalt, 10-300 parts of aqueous epoxy resin, and a curing agent accounting for 3-60% of the use amount of the epoxy resin. The modified emulsified asphalt obtained in the invention has high-temperature stability and low-temperature flexibility, and the bonding strength of the modified emulsified asphalt at a low temperature and a high temperature of 60DEG C is 2-6 times that of commercial common emulsified asphalt or SBR and SBS modified emulsified asphalt when used as road bonding oil. The aqueous epoxy resin modified emulsified asphalt is a single-component system, has excellent storage stability, can be directly applied in field, is simple to construct, can be mechanically constructed, and overcomes the disadvantage of wheel sticking of common or the SBR and SBS modified emulsified asphalt bonding oil in the construction process. The modified asphalt has good bonding performance with stones, concrete pavements and asphalt pavements, and can be widely applied to pavement maintenance or preventive maintenance.

Owner:上海龙孚材料技术有限公司

Assembly type steel frame connection node with post-seismic recoverable function

InactiveCN106638961AGuarantee the construction qualityReduce labor intensityProtective buildings/sheltersShock proofingSteel columnsFloor slab

The invention discloses an assembly type steel frame connection node with a post-seismic recoverable function. A frame steel column comprises a column body and an outward extending short beam which are vertically fixedly connected, a post-seismic replaceable energy consumption connecting plate comprises an upper flange cover plate, a lower flange cover plate and a web cover plate, an upper flange of the outward extending short beam is fixedly connected to an upper flange of a body steel beam through the upper flange cover plate, an lower flange of the outward extending short beam is fixedly connected to a lower flange of a body steel beam through the lower flange cover plate, and a web of the outward extending short beam is fixedly connected to a web of the body steel beam through the web cover plate; a gap reserved between the outward extending short beam and the body steel beam is filled with a rubber pad plate; the upper flange of the body steel beam is fixedly connected to a concrete floor slab through a lift-resistant tooth-and-slot plate connecting piece. Through the double effects of connection and energy consumption exerted by the post-seismic replaceable energy consumption connecting plate, the structural damage and failure mechanism are actively controlled, it is guaranteed that the body structure keeps elasticity, damage occurs on a specified position, as a replaceable component, the post-seismic replaceable energy consumption connecting plate facilitates post-seismic replacement and repair, and a shear force connecting piece guarantees structural integrity and full exertion of combined stressed performance.

Owner:BEIJING JIAOTONG UNIV

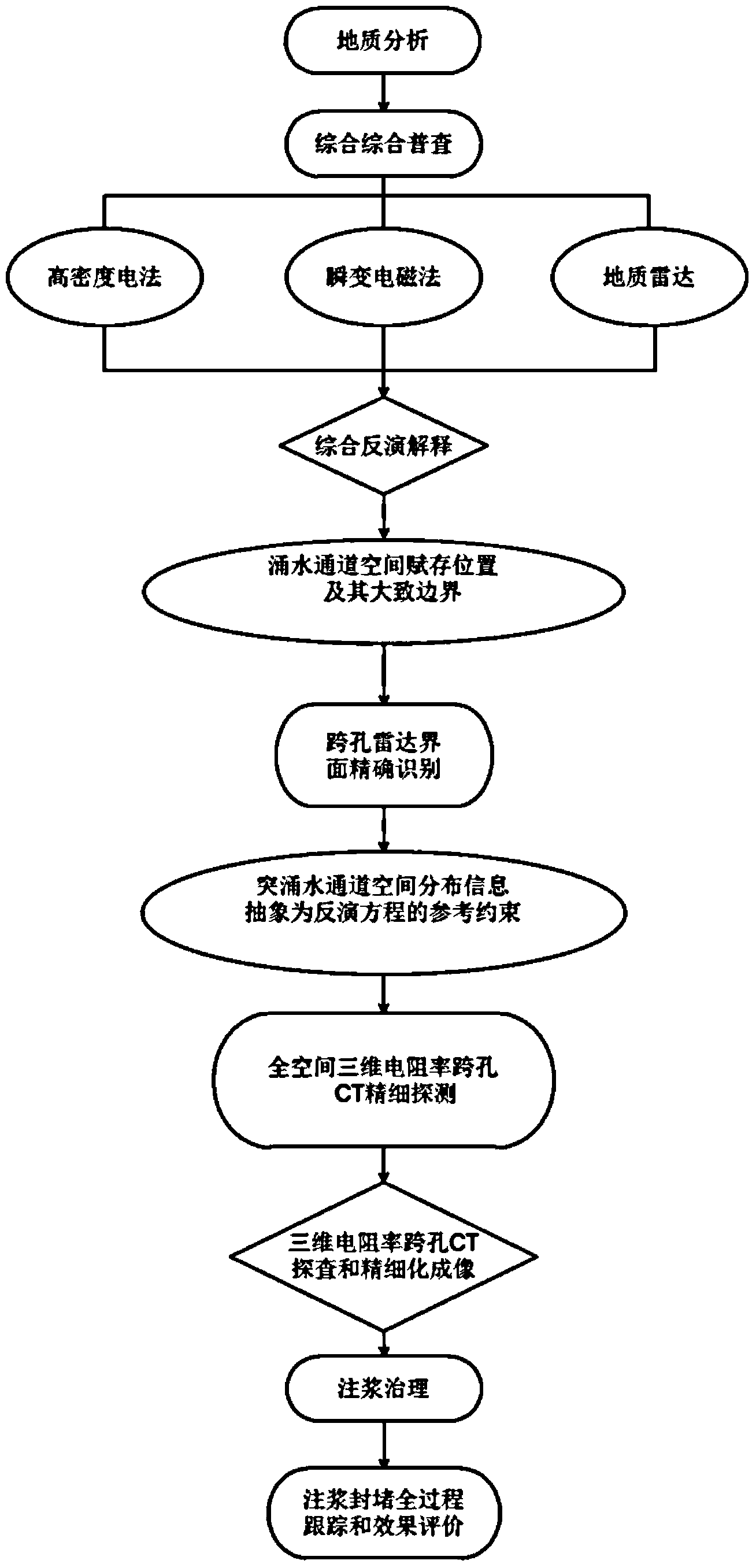

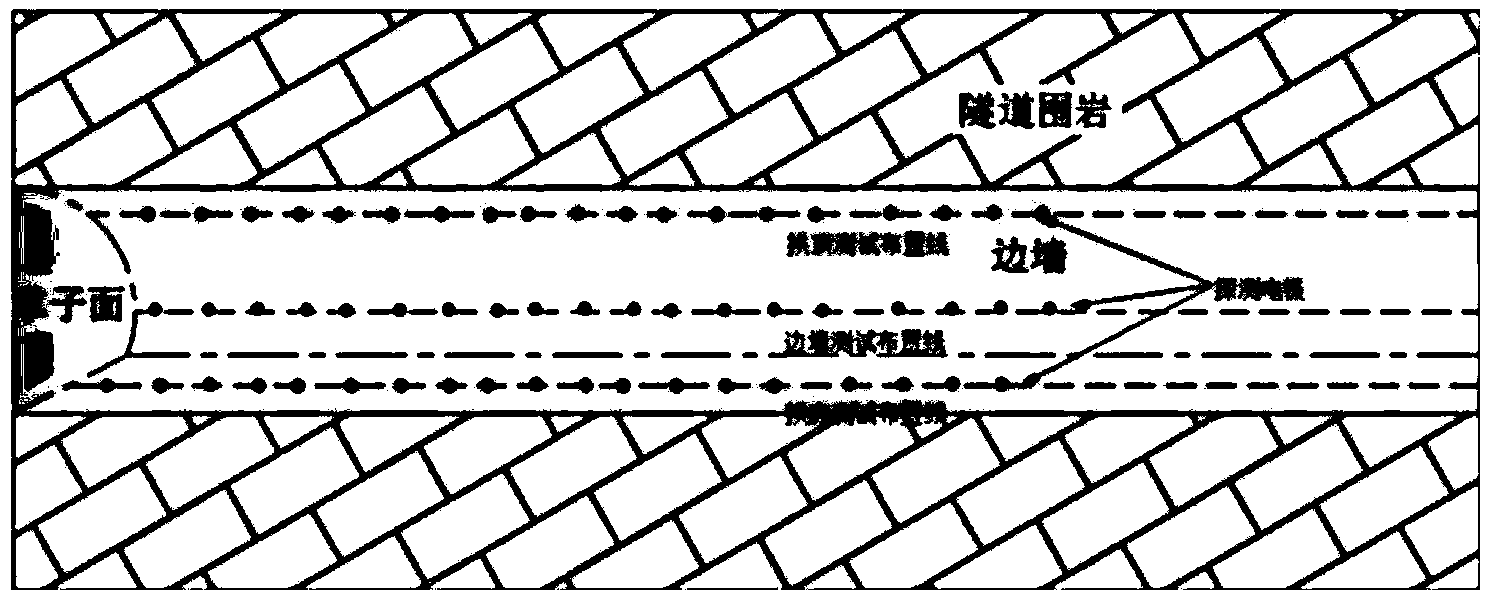

Method applied to fine detection of sudden water burst channel in underground engineering and evaluation of grouting and plugging effects of sudden water burst channel

ActiveCN104330838AScientific and effective detection methodImprove resolutionMaterial resistanceGeological measurementsReference modelRadar detection

The invention discloses a method applied to the fine detection of a sudden water burst channel in underground engineering and evaluation of grouting and plugging effects of the sudden water burst channel. The method comprises the following steps: carrying out complex geophysical prospecting general survey and primarily determining the occurrence range, the scale and the general boundary of the space of the sudden water burst channel; carrying out fine detection of a cross-hole geological radar; implementing cross-hole CT fine detection of a three-dimensional resistivity; and tracking, monitoring and evaluating the whole process of grouting and plugging by virtue of a time-lapse-inversion-based full-space three-dimensional resistivity cross-hole CT method. The method has the advantages that results of complex geophysical prospecting general survey and cross-hole radar detection are mapped to a structural reference model, the three-dimensional resistivity cross-hole CT inversion is taken as a carrier, and the location accuracy of the sudden water burst channel and interface resolution effect are obviously improved; the time-lapse-inversion-based full-space three-dimensional resistivity cross-hole CT detection method is used for monitoring the whole process of grouting and plugging; the beneficial reference is provided for finding and plugging loopholes in time and further guiding the grout replenishing operation.

Owner:SHANDONG UNIV

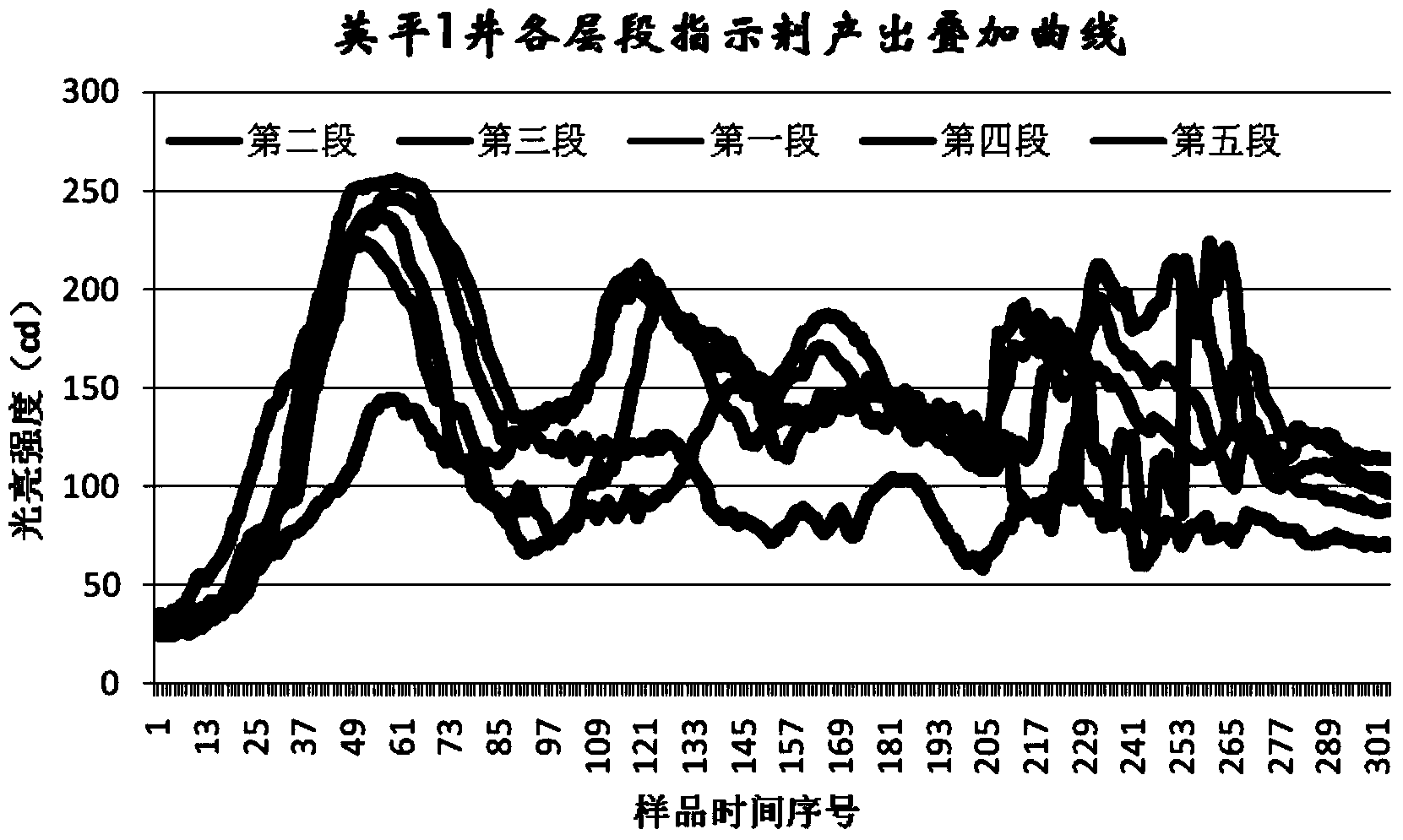

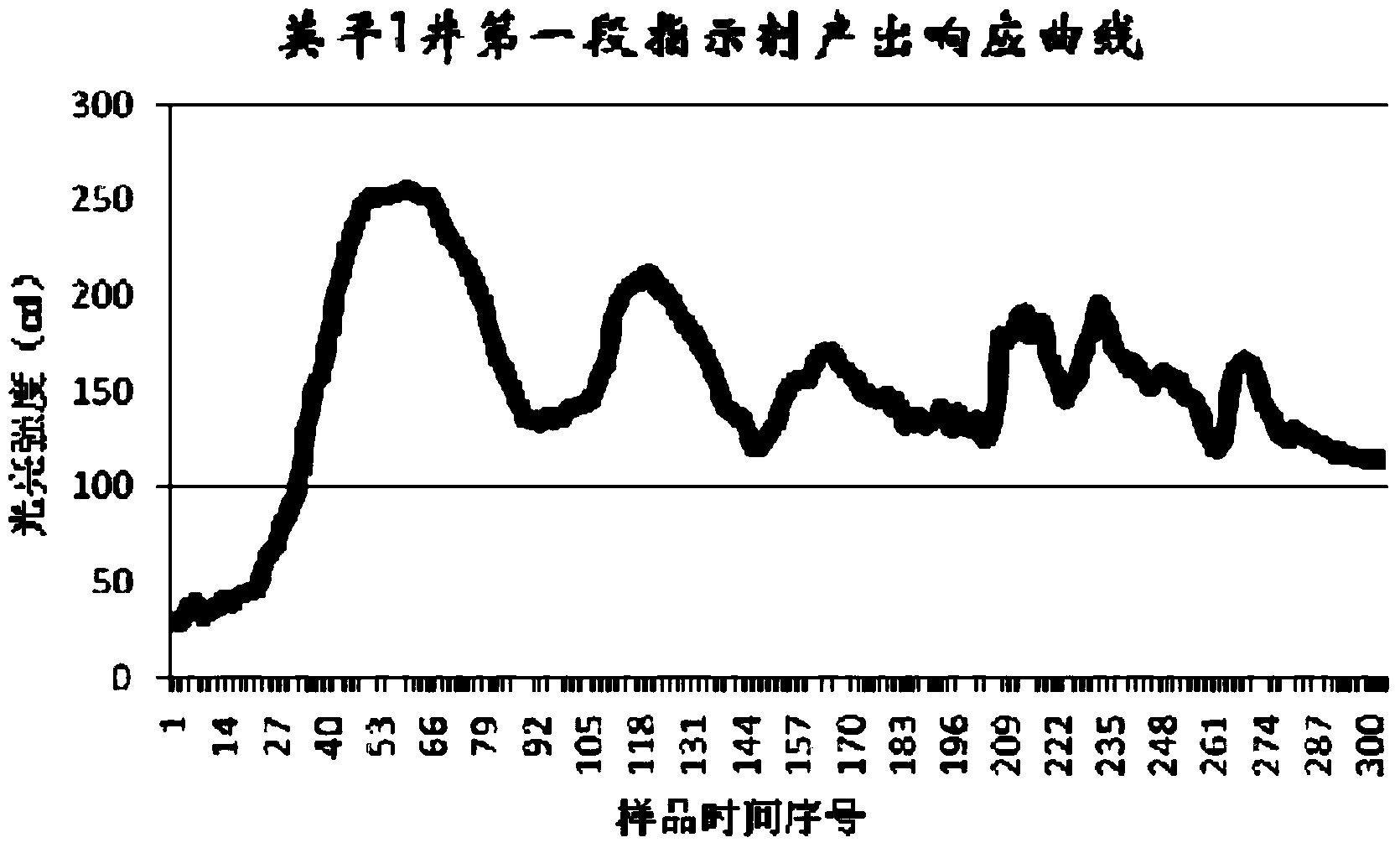

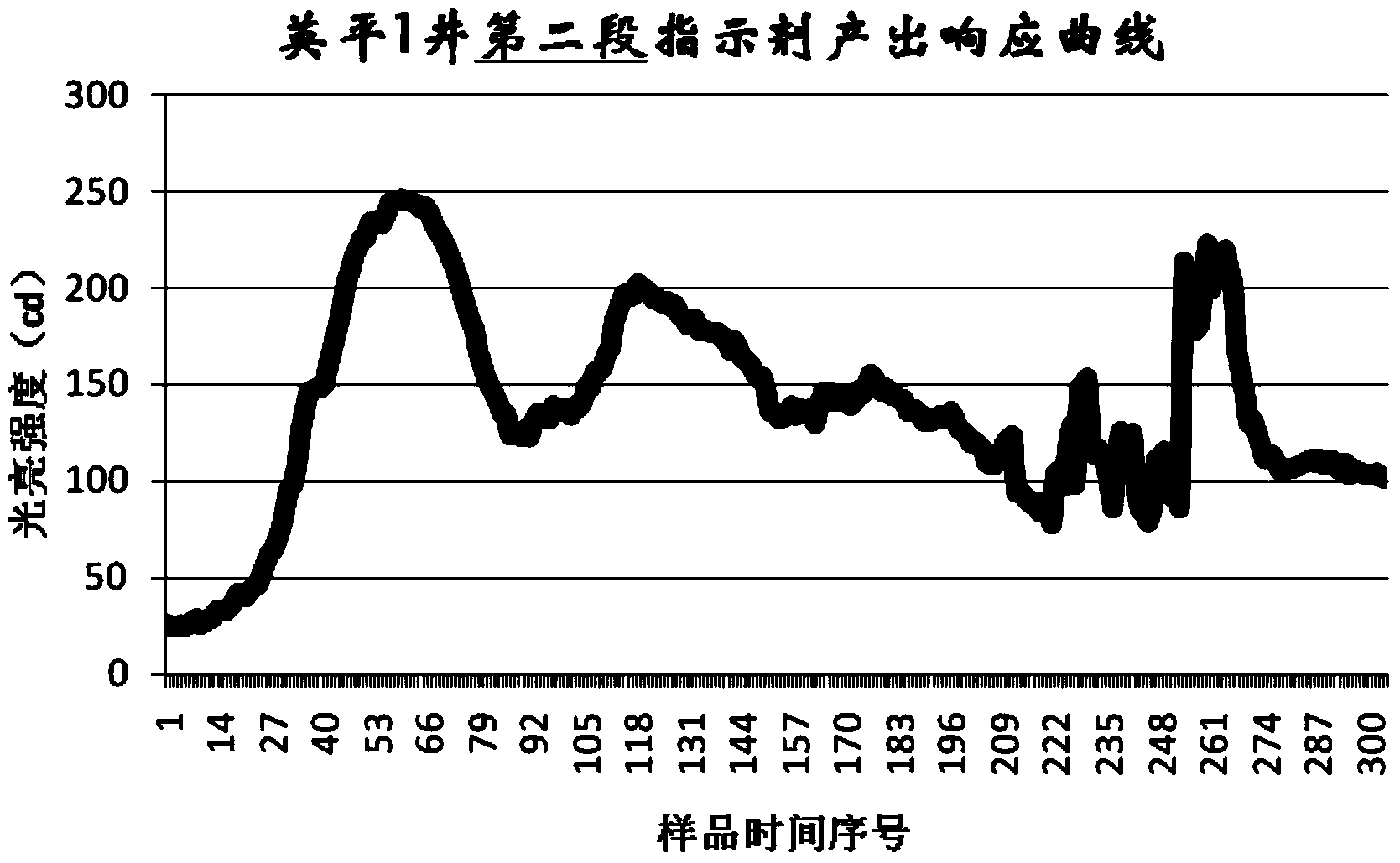

Oil production well productivity tracking and evaluating method

ActiveCN103556990ANo pollution in the processNon-toxicConstructionsFluid removalRelevant informationFracturing fluid

The invention relates to an oil production well productivity tracking and evaluating method. The method comprises the following steps of 1) during a fracture construction process, adding liquid indicator agent into a blending truck when preparing prepad fluid and carrying fluid; 2) during the fracture fluid recovery process, performing continuous tracking, monitoring, sampling and measuring; 3) during a pumping overlayer production process, performing sampling at the mouth of a well or a measuring station, obtaining the amount of tracked pumped fluid during normal operation, wherein sampling includes different requirements on different wells; 4) respectively measuring the concentration of liquid indicator agent and the illumination intensity of every preprocessed sample through analyzing instruments to calculate out contribution rate, recovery rate, recovery amount and the like. According to the oil production well productivity tracking and evaluating method, by means of classification, analysis, processing and study of the liquid indicator agent, relevant information such as production liquid component status, productivity (contribution rate), fracture effects and the like.

Owner:DAQING YONGCHEN PETROLEUM TECH +2

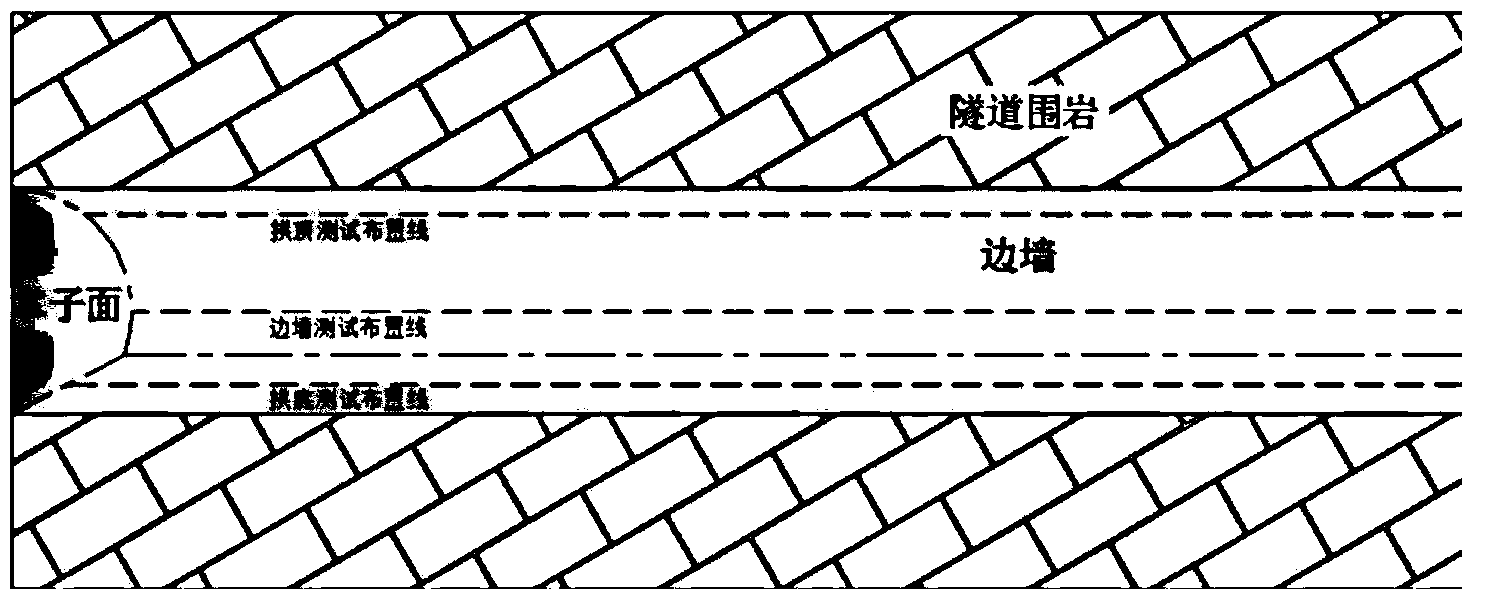

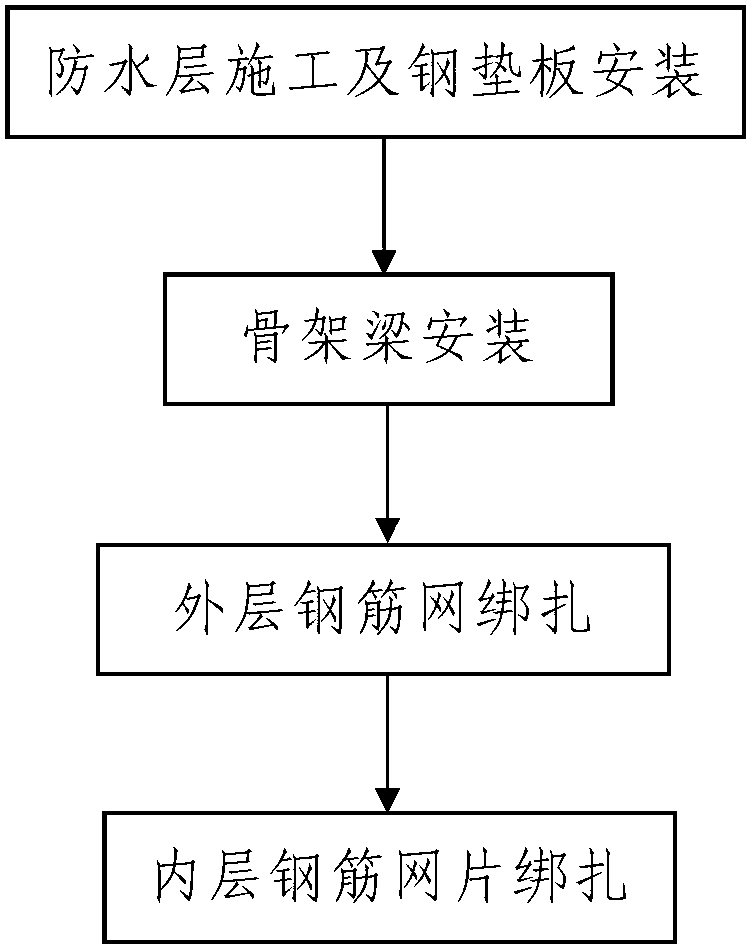

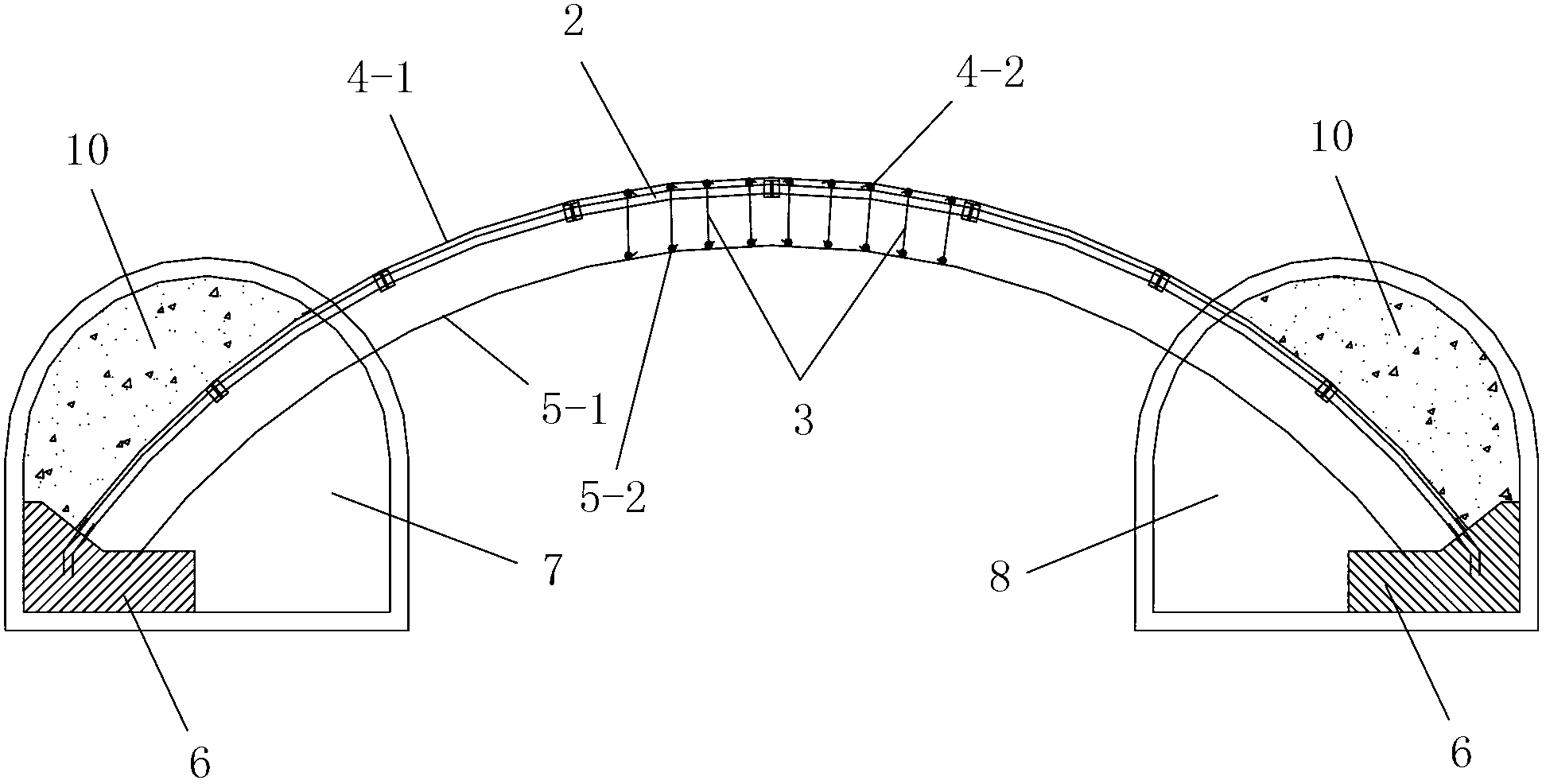

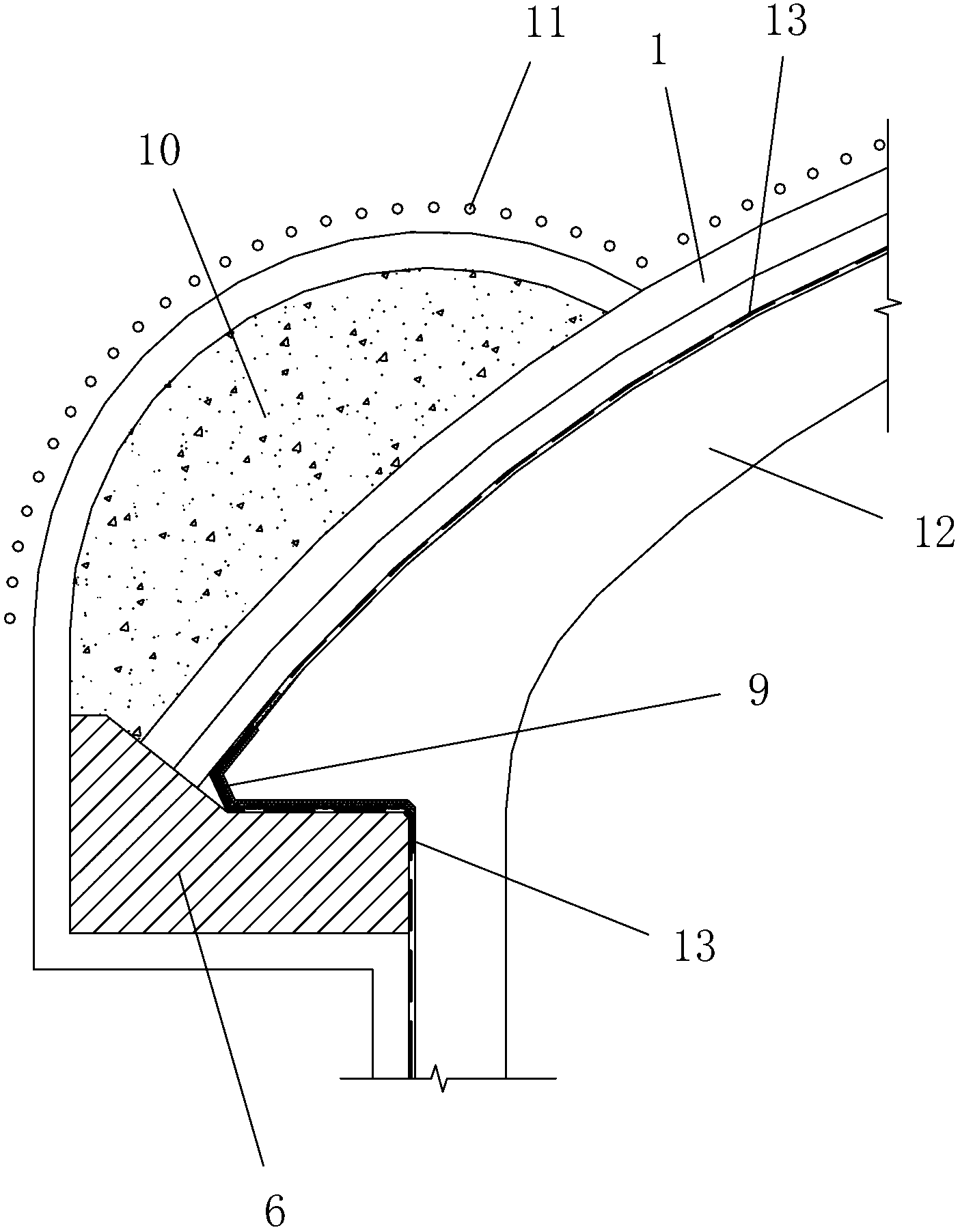

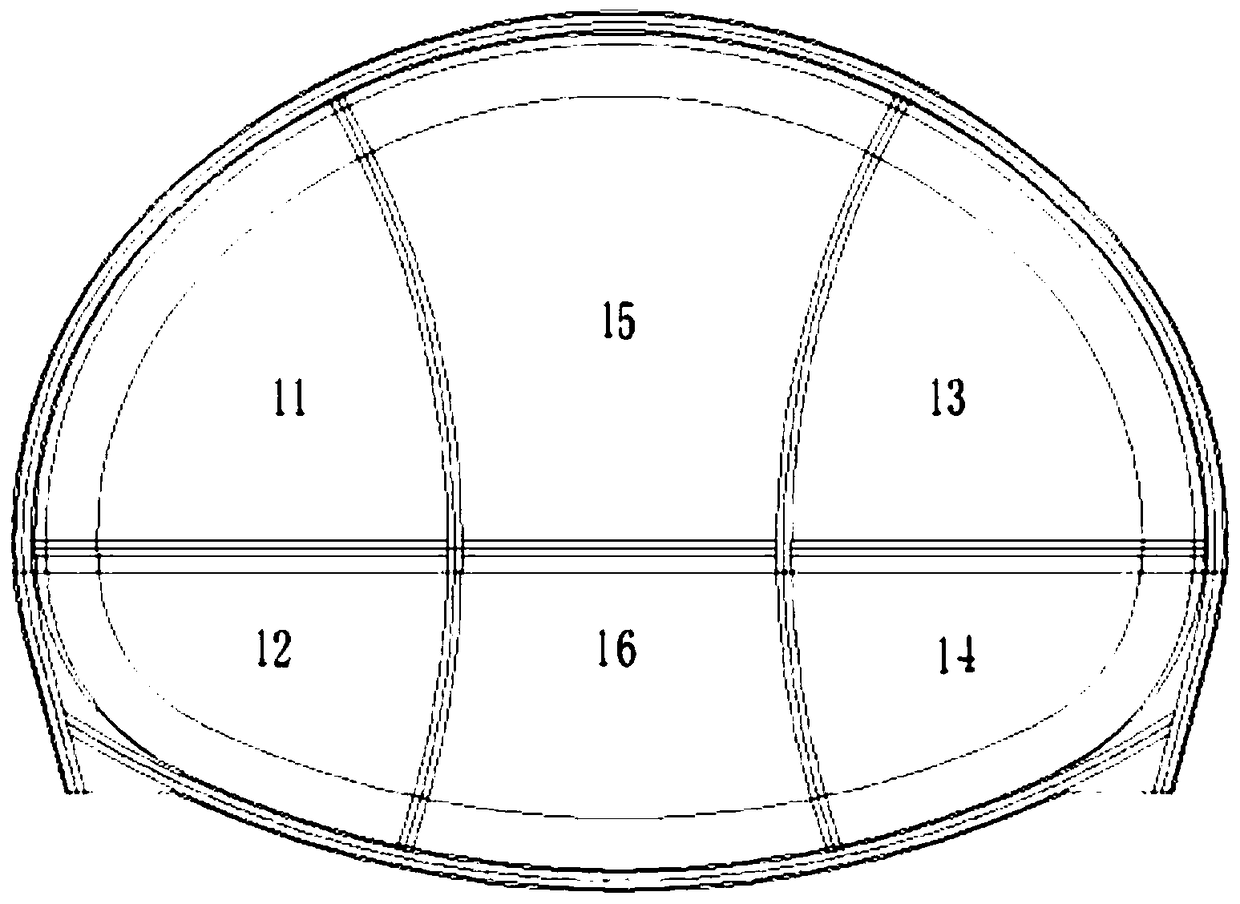

Large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams

The invention discloses a large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams. A bound tunnel arch secondary lining steel bar comprises an outer layer reinforcement mat, an inner layer reinforcement mat and a vertical connecting bar for connecting the outer layer reinforcement mat with the inner layer reinforcement mat. The construction method comprises the following steps of: arranging skeleton beam: arranging a plurality of skeleton beams below a tunnel arch primary supporting structure from front to back, wherein the skeleton beams are arch-shaped beams of which the radiuses are the same as that of the outer layer reinforcement mat, and the plurality of skeleton beams construct a load bearing structure of a tunnel arch secondary lining steel bar; and II, binding the tunnel arch secondary lining steel bar: binding the outer layer reinforcement mat on the upper parts of the plurality of skeleton beams, and suspending the inner layer reinforcement mat on the outer layer reinforcement mat through the vertical connecting bar. The method has the advantages of simple construction process, convenience in constructing, good use effect, high practical value, no damage to a paved waterproof structure and easiness and convenience in controlling the deflection of a large-span station arch secondary lining steel bar.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

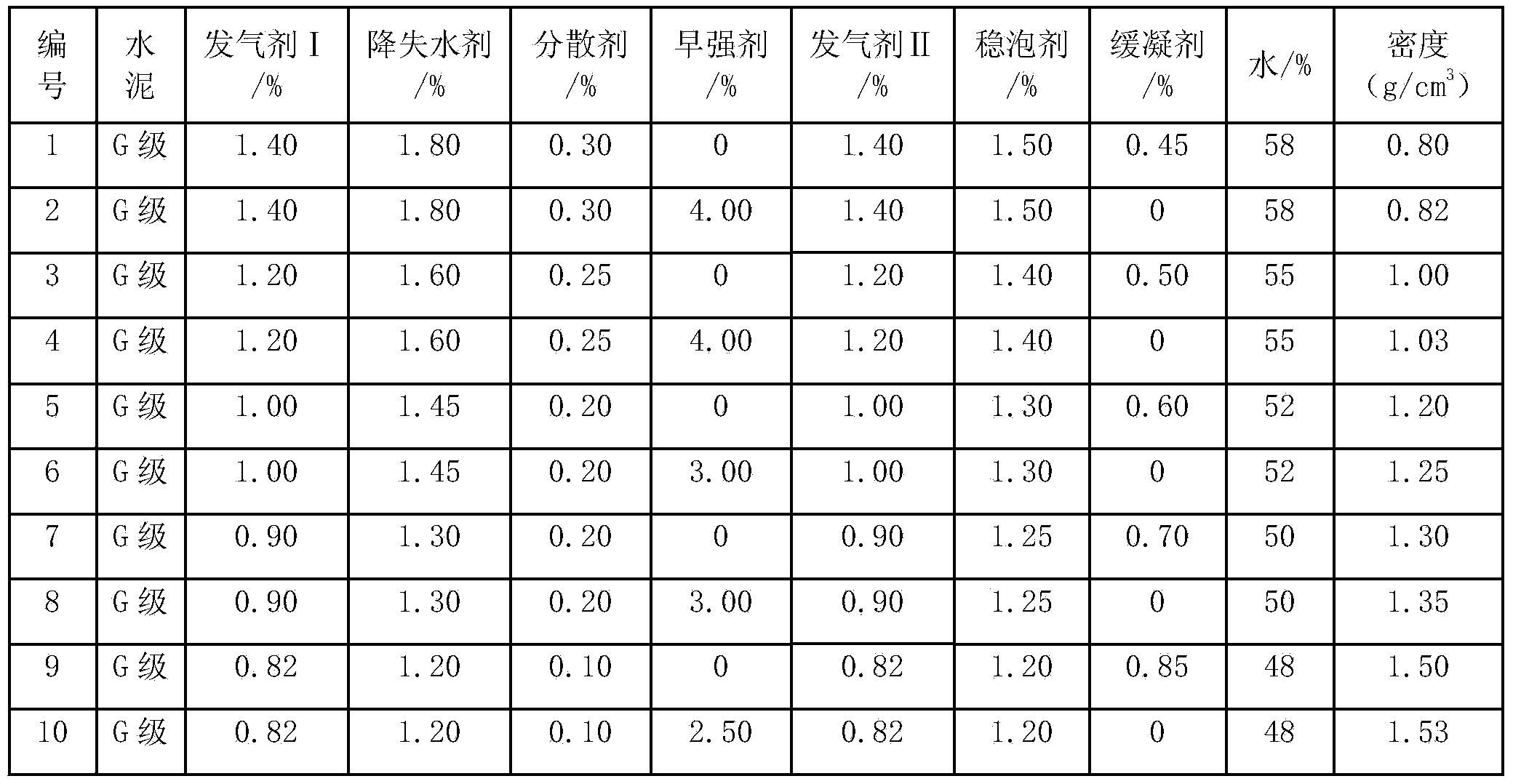

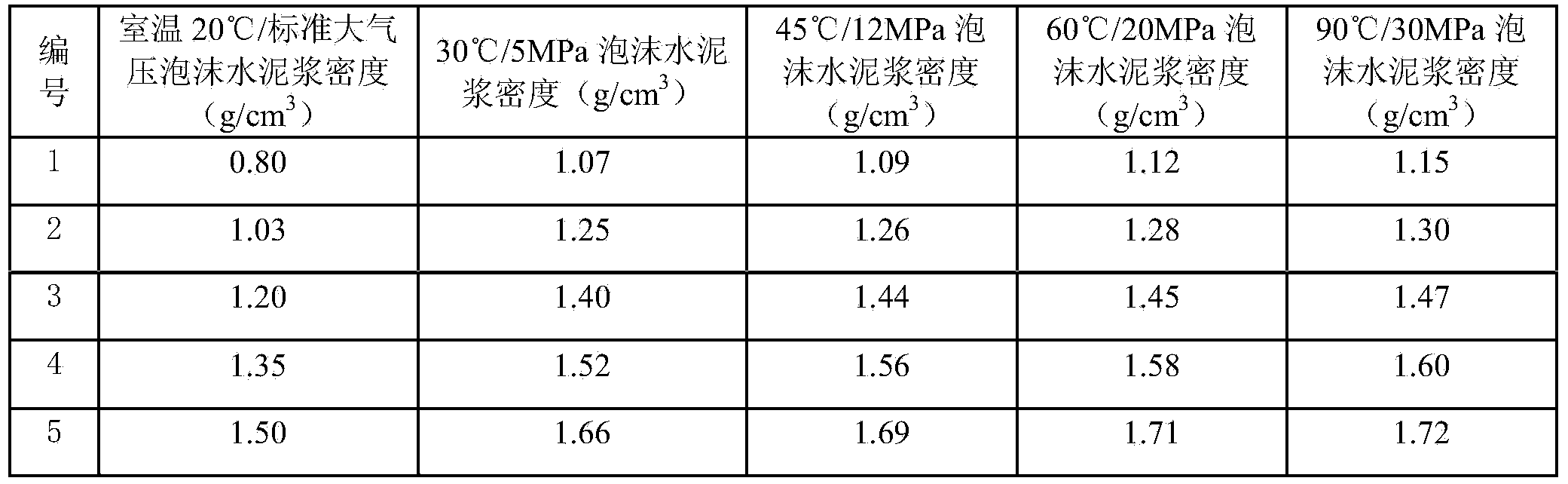

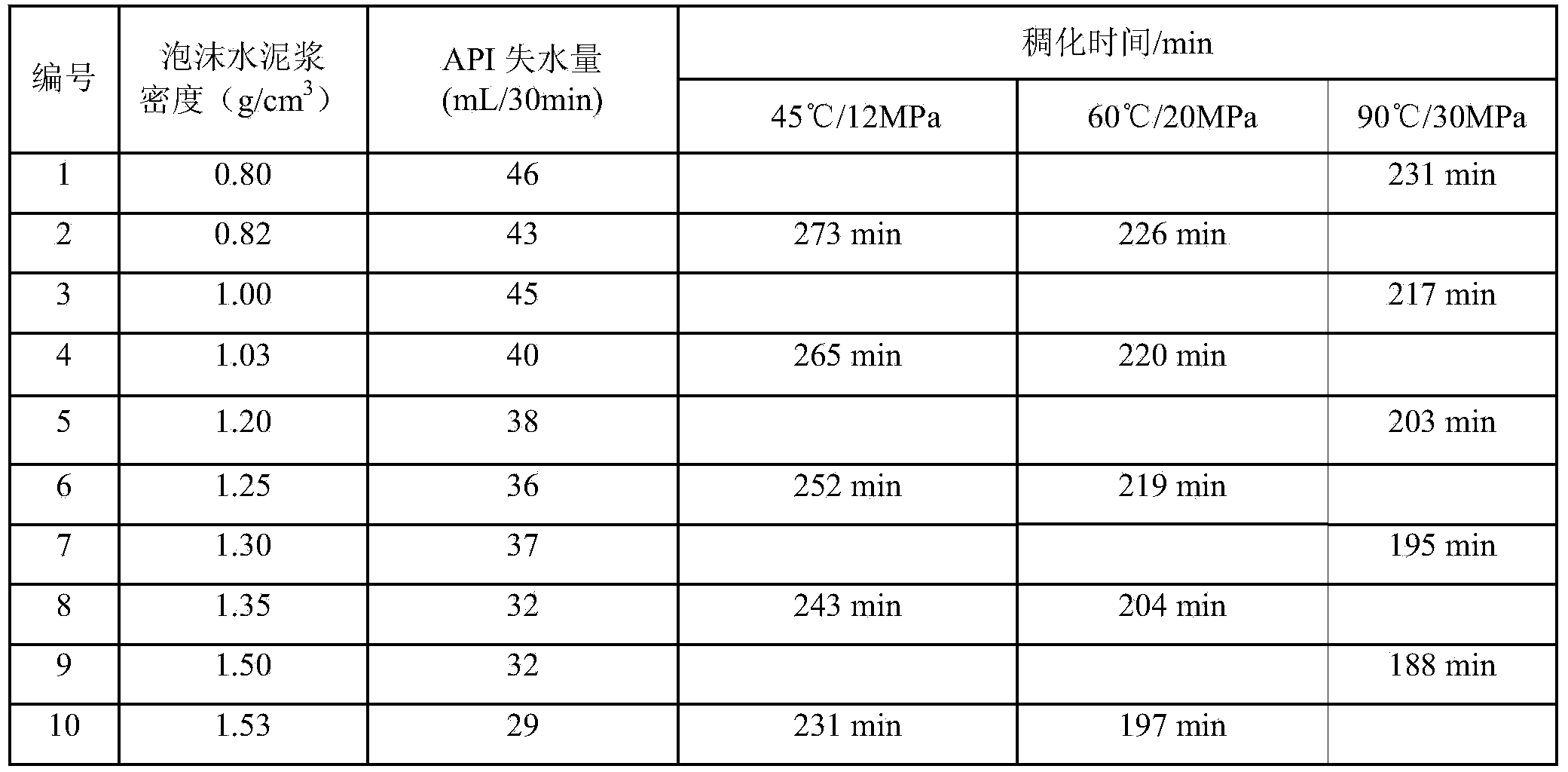

Foam cement slurry system and composition

ActiveCN103525387ALow toxicityFast dissolutionDrilling compositionCeramicwareFoaming agentWell cementing

The invention provides a novel chemical nitrogen-charge foam cement slurry, mainly solves the problems that the density is high and the stability is poor in a conventional chemical nitrogen-charge foam cement slurry, and is applicable to the field of oil and gas well cementing. The novel chemical nitrogen-charge foam cement slurry system comprises the components in parts by weight as follows: 100 parts of oil well cement, 0.5-2.0 parts of a foaming agent I, 0.5-2.0 parts of a foaming agent II, 0.7-2.5 parts of a foam stabilizing agent, 1.0-10 parts of a fluid loss agent, 1.0-1.5 parts of powder, 0.3-1.0 part of a retarder, 1.0-4.0 parts of an early strength agent and 48-70 parts of water. The density of the chemical nitrogen-charge foam cement slurry can be adjusted in a range of 0.80-1.50 g / cm <3>, the slurry is applicable to oil and gas well cementing operations in a range of 10-95 GEG C and has the advantages of simple site operation and foam cement cost reduction, the problems of low pressure leakiness and formation cementing leakage can be effectively solved, pollution of the cement slurry to an oil and gas production layer is reduced, and the application prospect is wide.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

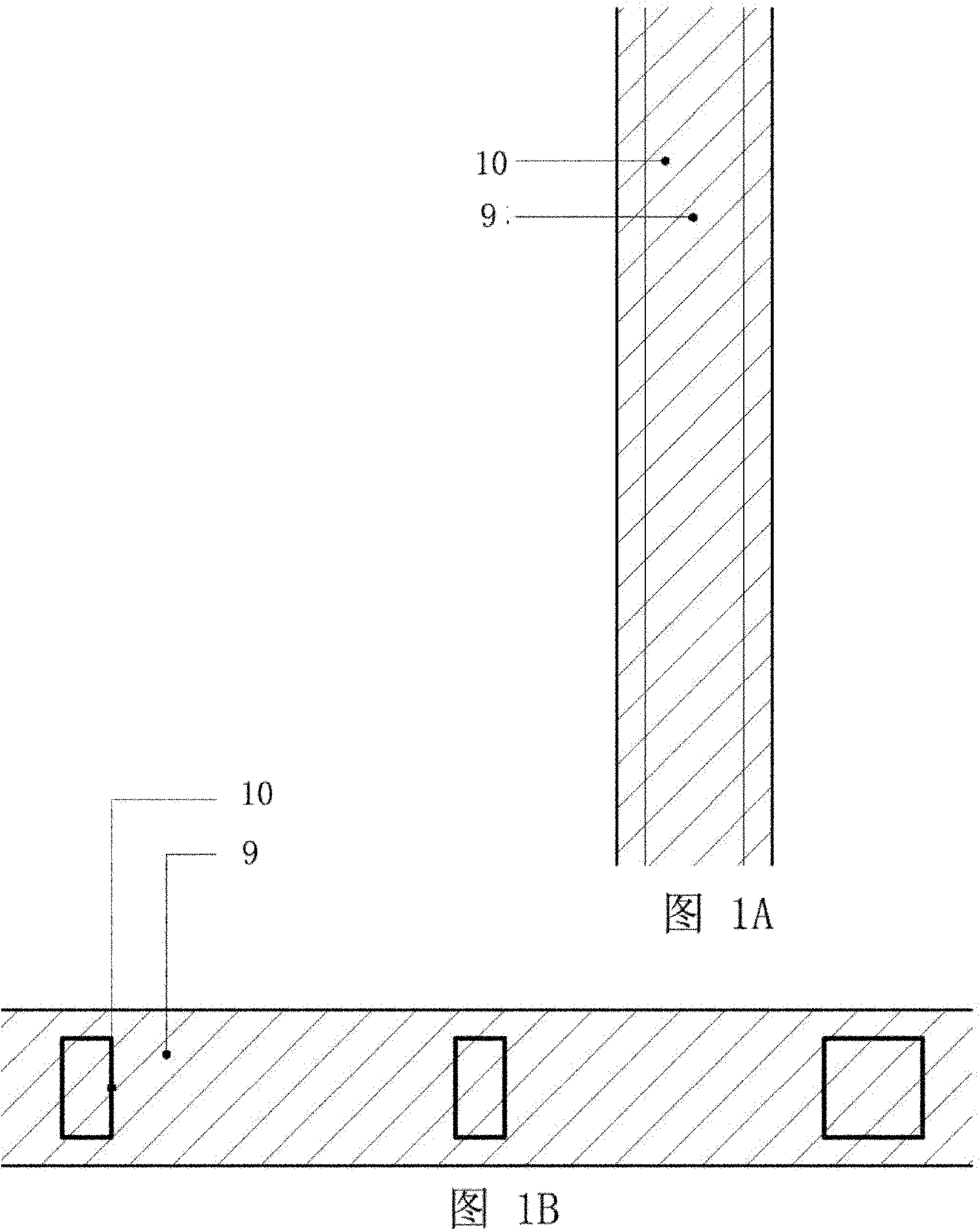

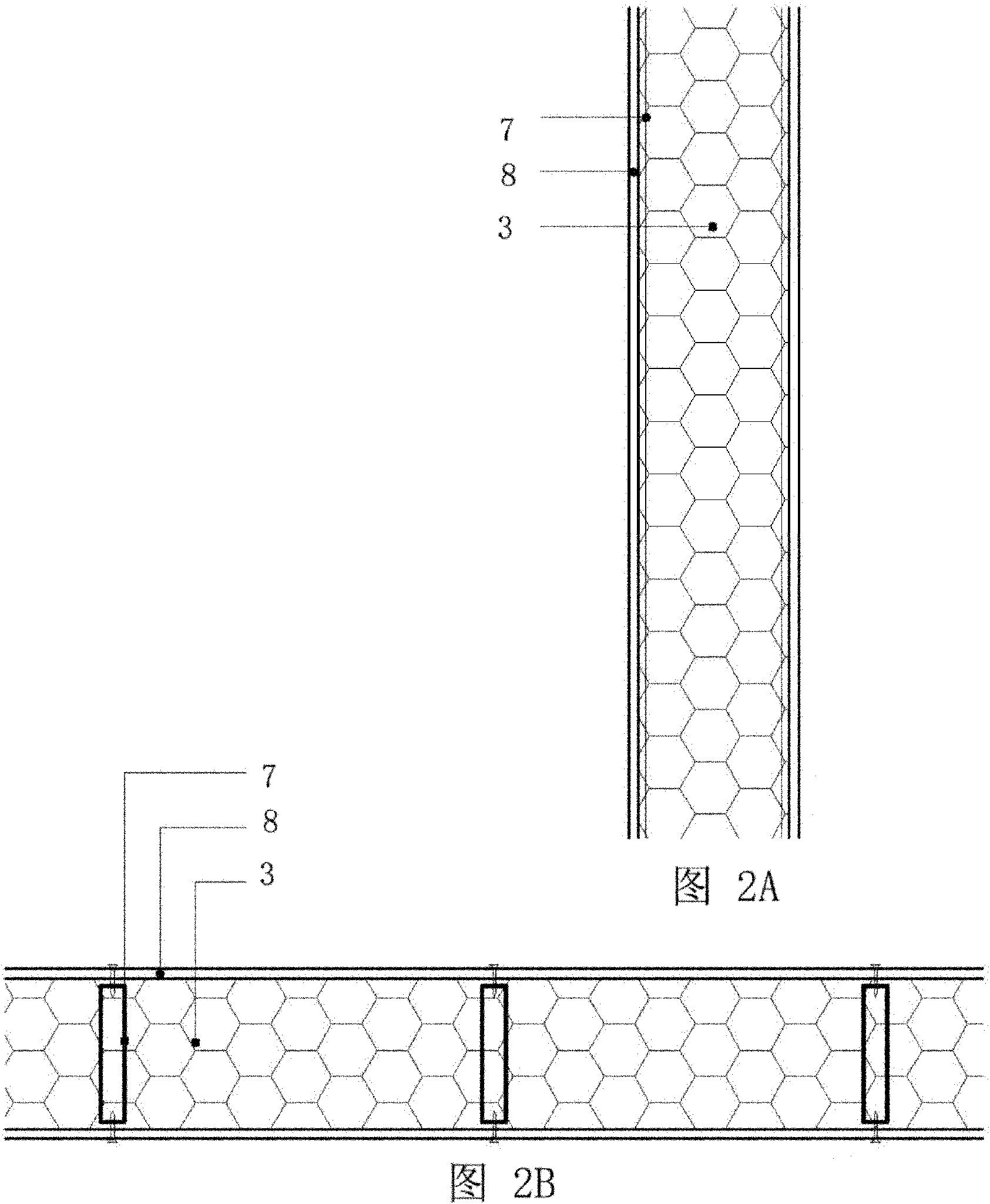

Wall with tie steel mesh structure

The invention relates to a wall with a tie steel mesh structure. The wall comprises steel meshes, a transverse tie member, a longitudinal positioning supporting member and a filling layer, wherein the filling layer is filled between the steel meshes on the two sides; the steel meshes on the two sides are fixedly connected with the longitudinal positioning supporting member; the transverse tie member passes through the filling layer, and the two ends of the transverse tie member are respectively fixed on the longitudinal positioning supporting member which is fixedly connected with the steel meshes on the two sides; and the steel meshes, the transverse tie member, the longitudinal positioning supporting member and the filling layer are integrated into the wall with the tie steel mesh structure. The invention has the advantages that: the wall with the tie steel mesh structure is safer and more environmental-friendly, has higher thermal insulation property and water resistance, is convenient to construct on site, and saves materials and cost more.

Owner:谢英俊

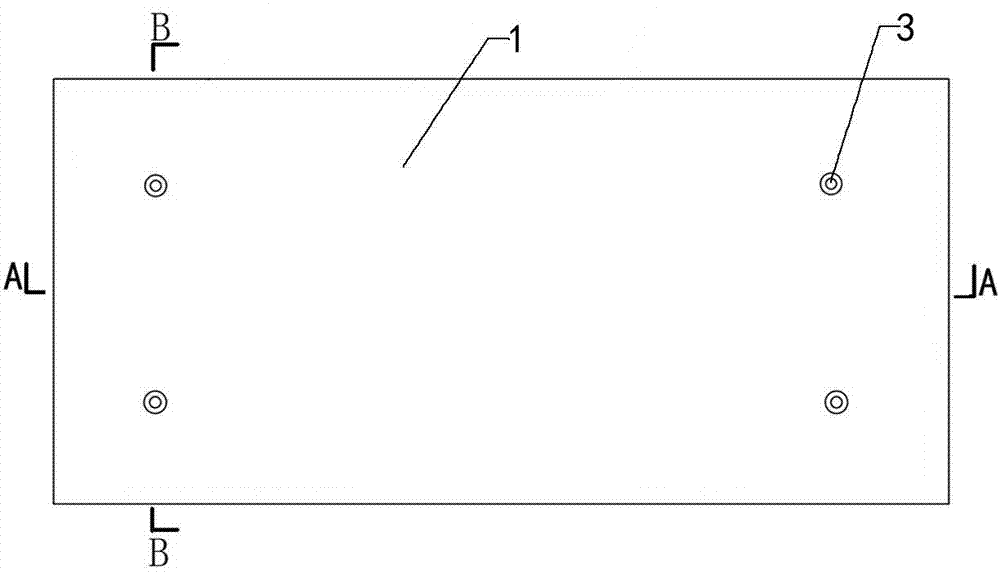

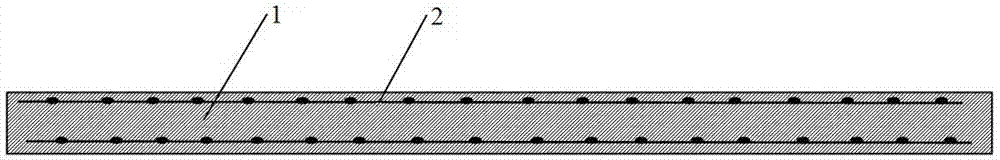

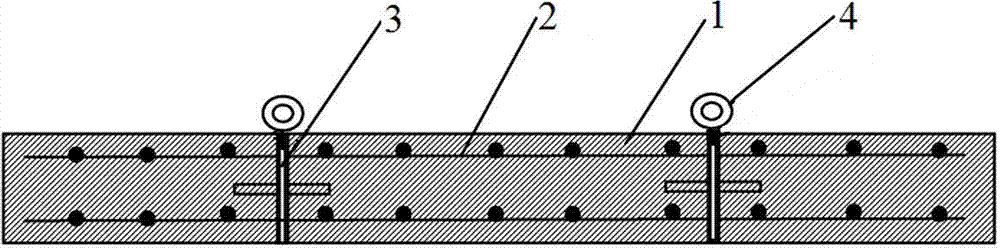

Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

ActiveCN104294728AStrong bending resistanceHigh compressive strengthSingle unit pavingsCeramic shaping apparatusWire gauzeWeather resistance

The invention discloses a fabricated type reactive powder concrete prefabricated pavement slab without a reinforcing rib and a manufacturing method thereof. A slab body is a material plate made from reactive powder concrete; layers of horizontal steel wire gauzes are respectively spread in the reactive powder concrete material plate and are close to upper and lower surfaces; hoisting embedded parts which run through in the vertical direction are respectively arranged at the four corners, wherein the two ends of the hoisting embedded parts are connected with lifting appliances. When the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is manufactured, the fluidity of the reactive powder concrete is controlled to avoid deformation of the pavement slab in the later-period manufacturing process, and the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is maintained naturally indoors to ensure the total quality of the pavement slab. Compared with a common concrete pavement slab, the pavement slab has the advantages of no reinforcing rib in structure, small thickness, portability, light weight, convenience in transportation and installation, high intensity, wear resistance, high bearing capability, good anti-impact performance, good anti-fatigue performance, good weather resistance, and fast and efficient construction, repeated use, and can be widely applied to road construction of temporary building living quarters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

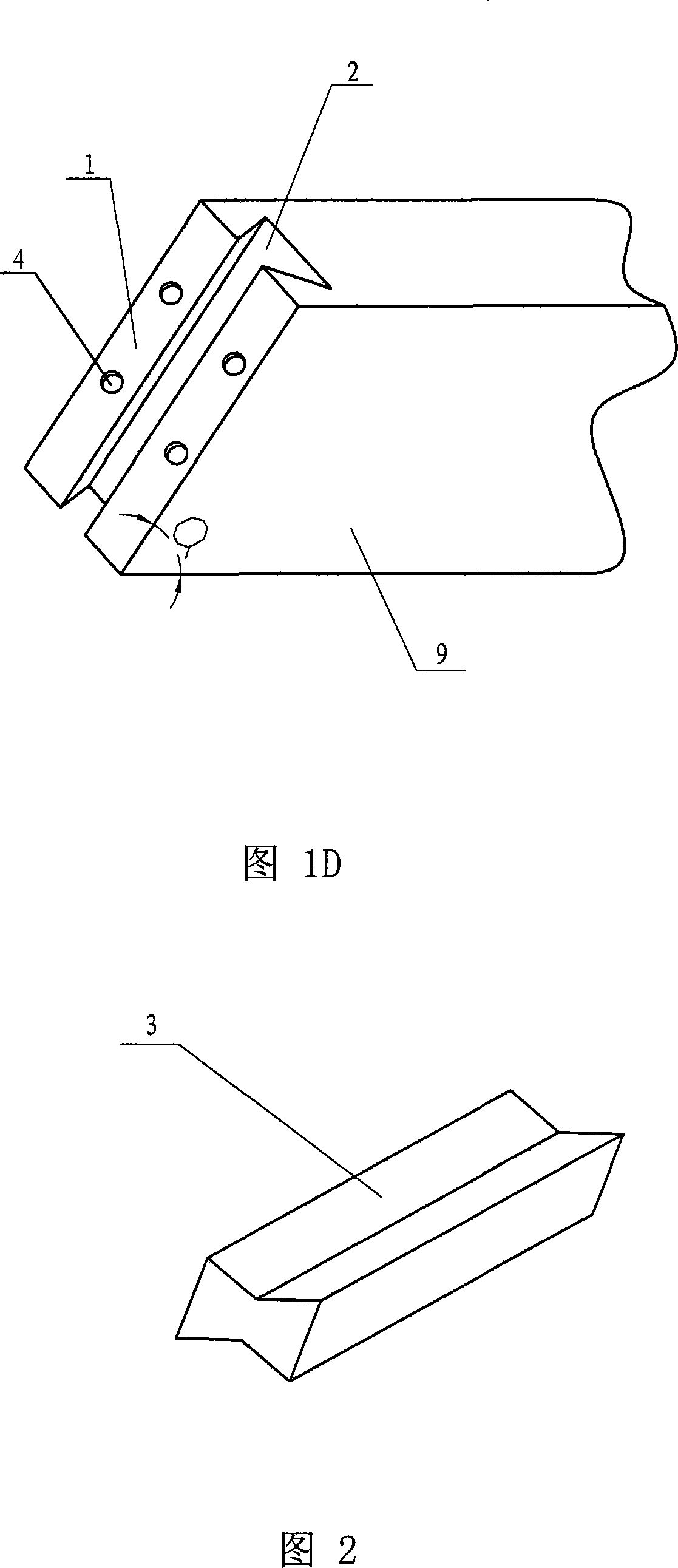

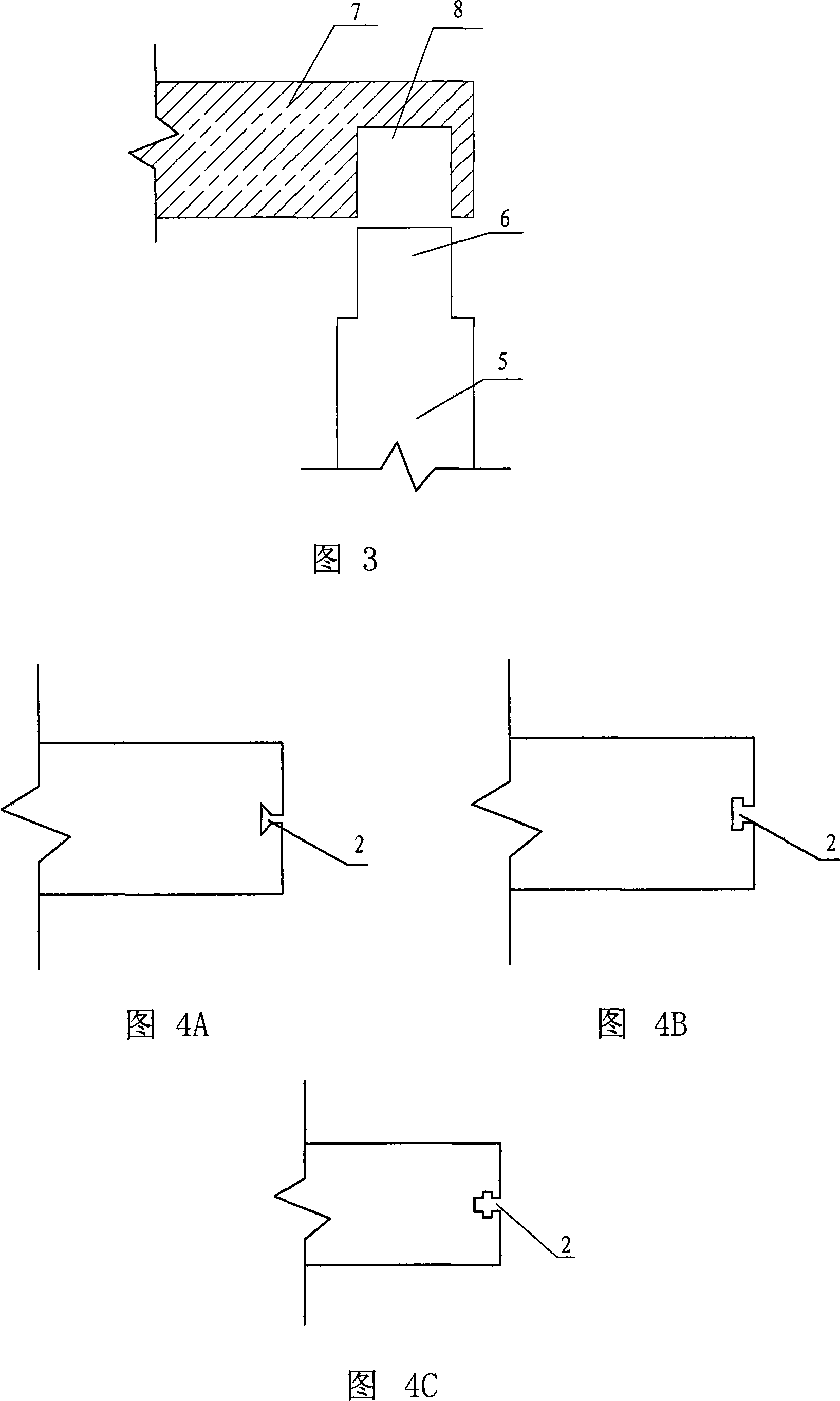

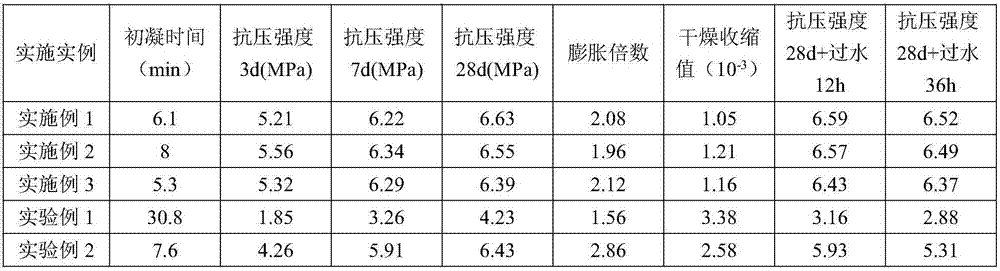

Method for manufacturing wooden sash section bar and method for assembling wooden window and door by using the same

InactiveCN101117874AImprove connection strengthReduce connection strengthCorner/edge jointsWindow/door framesEngineeringBuilding construction

A manufacturing method for assembling wood and door frame section material in field comprises the following steps: firstly, the wood is cut as per specified size and section shape; secondly, after cut, combination surfaces are formed on both ends of the wood, a key channel is formed at the combination surface, after the key channel is assembled into a frame parallel to the wood door section material and extended at the plane where is located and arranged between two surfaces of the frame, after the wood door and the window section material are matched at the corresponding combination surfaces, a pin key lock is used to fix with the adaptive key channel shapes; thirdly, surface treatment is done for wood of all the formed combination surfaces and key channels to be applicable for the wood door and the window section material for assembly at the construction site. The present invention is applicable for the manufacturing method for the wood door and the window section material in field and the method for assembling the wood door and the window with the section material for on-site arrangement. Structural strength of tenon is high, thus not damaging the surface of the section material and keeping the door and the window nice.

Owner:北京市木材厂有限责任公司

Light filling material for mines

ActiveCN107337412AGood expansion performanceImprove stress resistanceCeramicwareSpontaneous combustionUltrasound attenuation

The invention discloses a light filling material for mines. The filling material is prepared from components in parts by mass as follows: 65-85 parts of a base material, 10-15 parts of a coagulant, 1-5 parts of an excitant, 1-10 parts of an adjusting admixture, 0.1-1 part of a foaming agent and 0.1-1 part of a foam stabilizer. To meet the demands for upper corner filling and airtight wall construction, the light filling material has the characteristics of being light in weight, non-ignitable, small in density, adjustable in strength and setting time, excellent in expansibility and crushing resistance, free of obvious attenuation of water passing strength, environment-friendly, low in cost and the like and has remarkable effects on filling in a drilling site and upper corners of the mine, and the problems of gas accumulation and spontaneous combustion of coal can be effectively solved.

Owner:SHANDONG ANSHI GREEN MINING TECH DEV

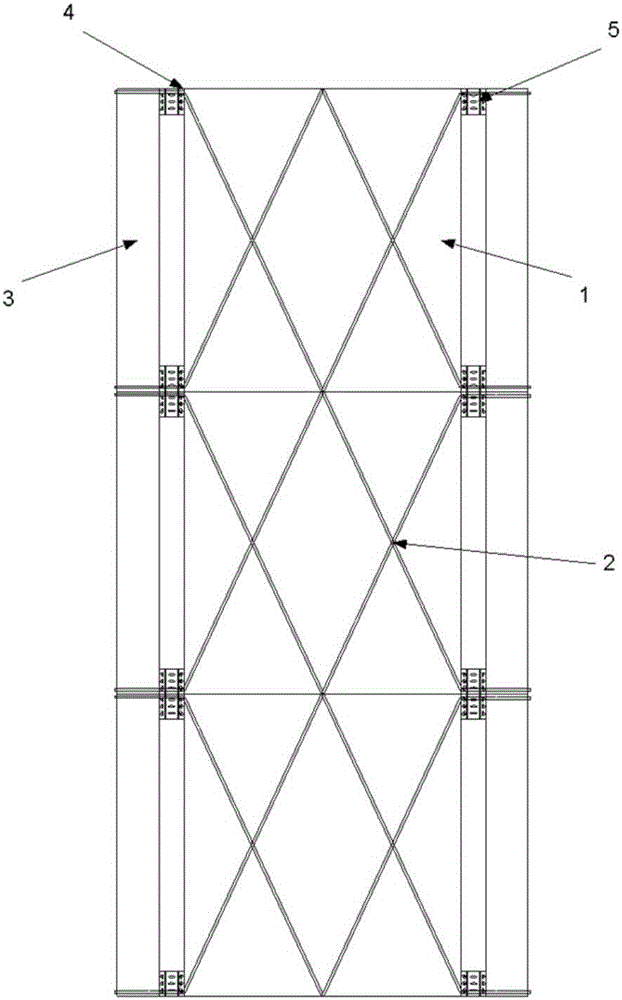

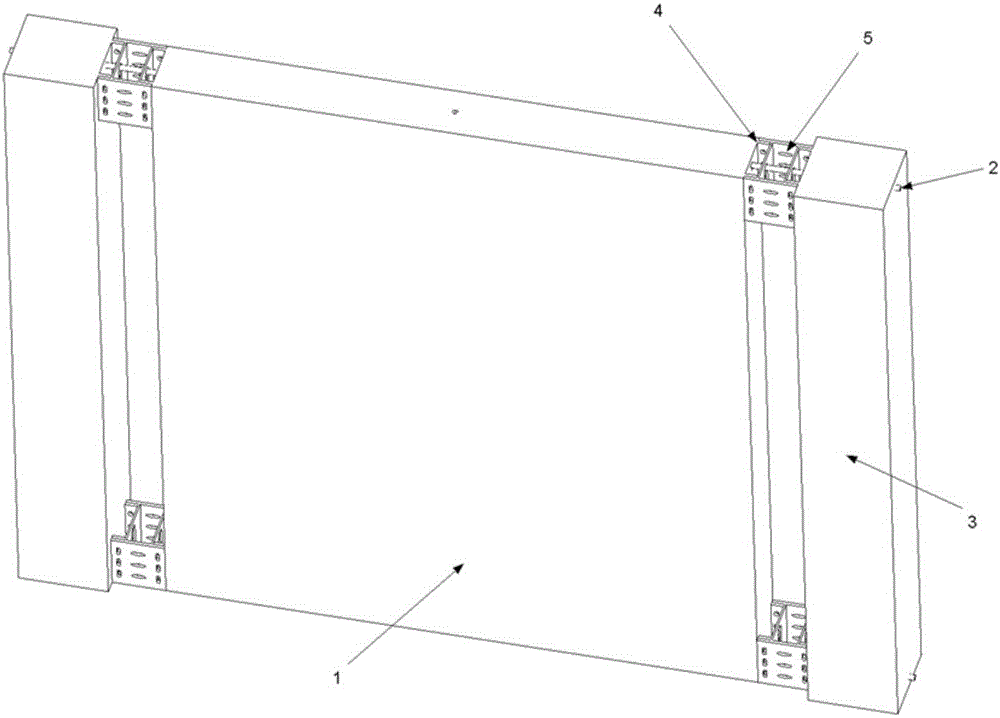

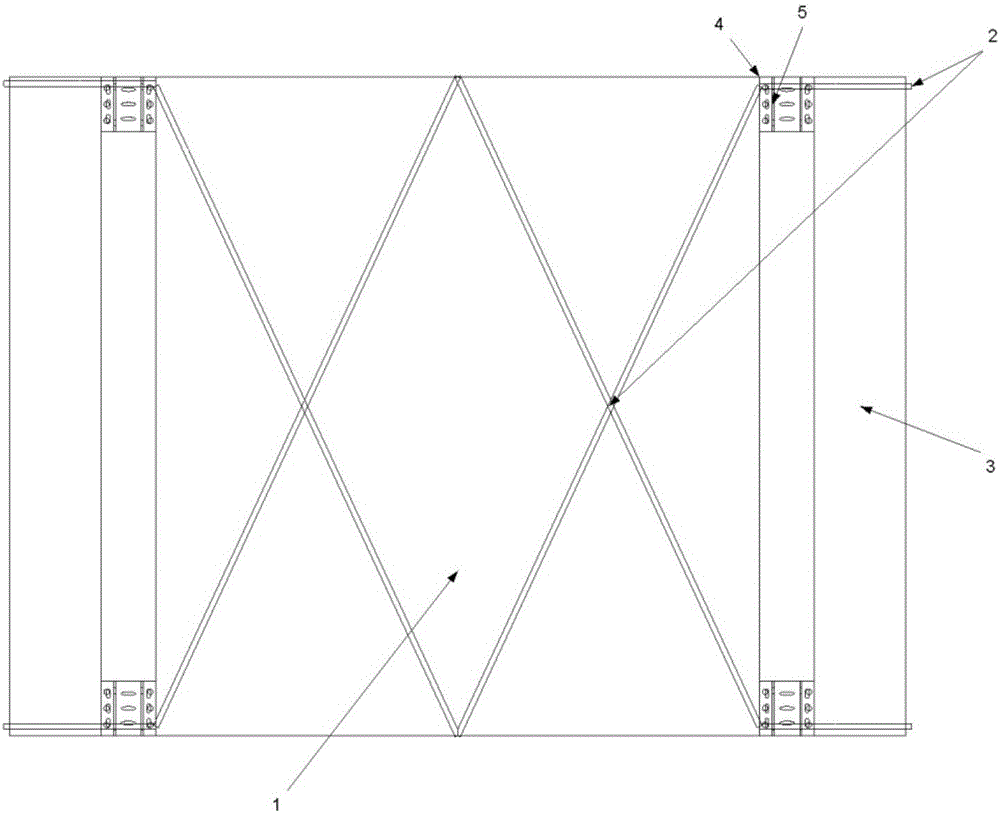

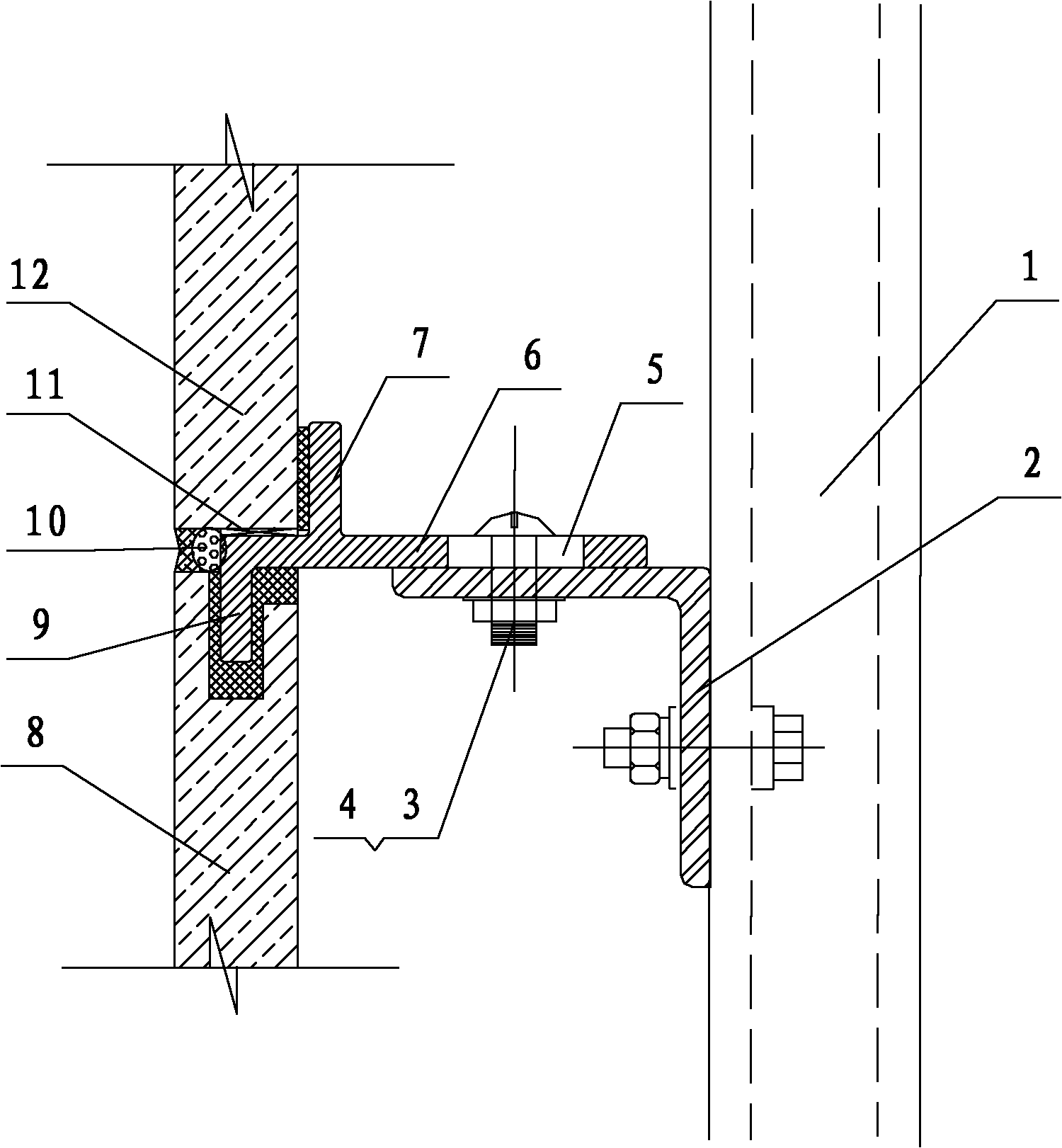

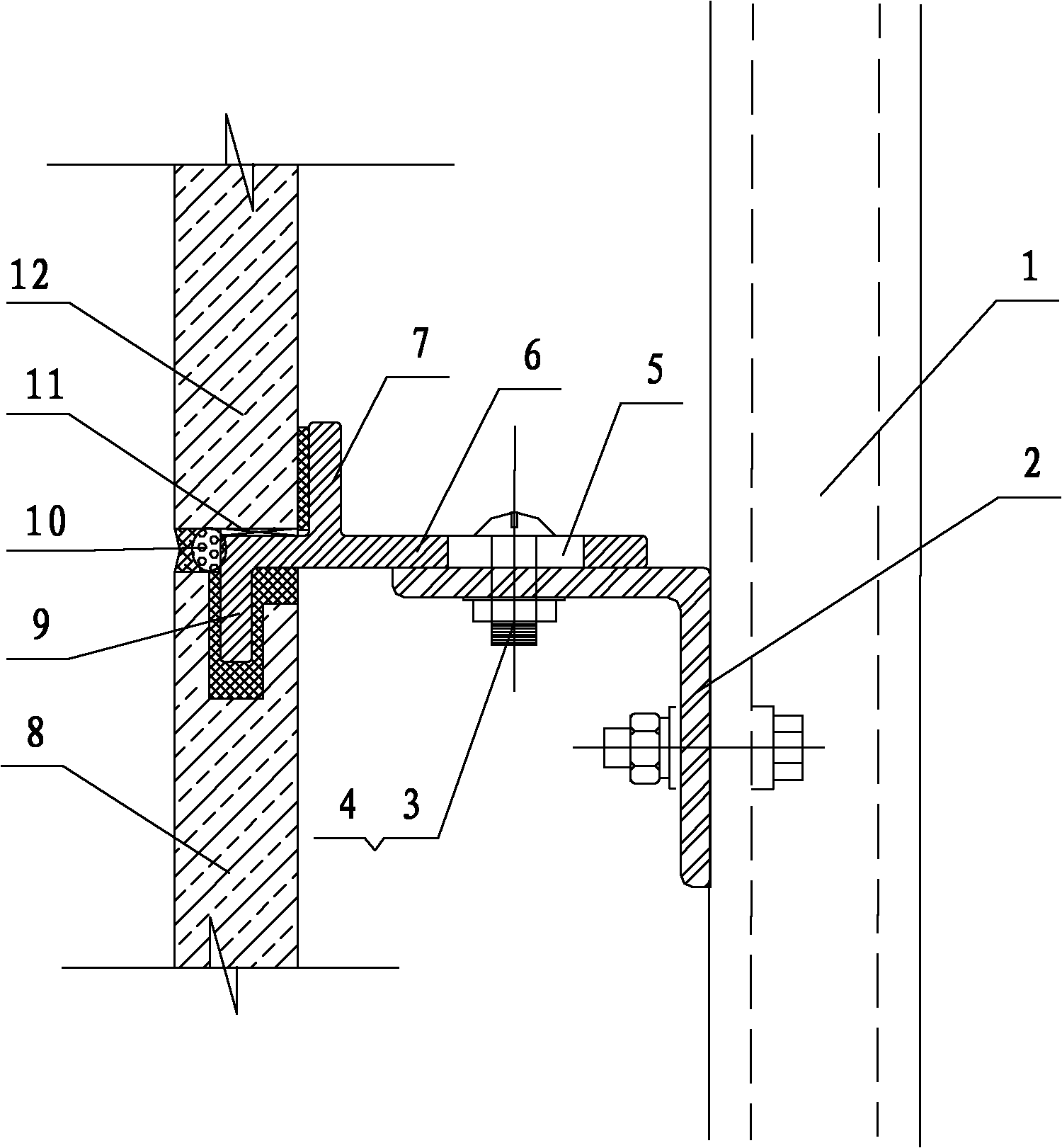

Energy-dissipation and seismic-mitigation oblique prestress shear wall structural system suitable for prefabrication and assembly construction

InactiveCN106639037AReduce lossesGive full play to the characteristics of energy consumptionWallsProtective buildings/sheltersTurn anglePre stress

The invention relates to the field of building structure seismic resistance and energy-dissipation seismic-mitigation control, in particular to an energy-dissipation and seismic-mitigation oblique prestress shear wall structural system suitable for prefabrication and assembly construction. The structural system includes a prefabricated shear wall, a prestressed inhaul cable, a prefabricated frame column, turning angle constraint connection pieces and an energy-dissipation component; corrugated hoses are embedded in the prefabricated shear wall and internally provided with the prestressed inhaul cable, the four corners of the prefabricated shear wall are provided with the turning angle constraint connection pieces, and the turning angle constraint connection pieces are connected with the energy-dissipation component. The structural system has the advantages that the overall deformation of an upper wall body and the overall deformation of a lower wall body are consistent, a whole control structure is laterally displaced, at the same time, the shear wall structure has a certain self-resetting ability, the overall deformation helps energy-dissipation steel plates give full play to energy dissipations characteristics, a single weak link does not appear, the assembly efficiency of the overall structure is improved, site construction is convenient to achieve, the construction period is effectively shortened, and the cost is saved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Ceramic coating with high-temperature resistance and wear resistance and preparation method of ceramic coating

ActiveCN106007678AImprove high temperature resistanceWide temperature rangeCeramic coatingBond properties

The invention discloses a ceramic coating with high-temperature resistance and wear resistance. The ceramic coating is prepared from components in parts by weight as follows: aluminum oxide, silicon oxide, silicon carbide, silicon nitride, boron carbide, titanium carbide, magnesium oxide, zinc oxide, calcium oxide, a binder, a stabilizer and a thickener; the preparation method comprises steps as follows: aluminum oxide, silicon oxide, silicon carbide, silicon nitride, boron carbide, titanium carbide, magnesium oxide, zinc oxide and calcium oxide are subjected to ball milling respectively, then dried, sintered, ground, sieved and mixed, and mixed powder is prepared; the binder, the stabilizer, a defoaming agent and the thickener are added to the mixed powder and mixed uniformly. The ceramic coating has the advantages that the prepared coating has high high-temperature resistance and wear resistance, good surface compactness and high bonding capability; besides, the prepared coating is applied to the surface of equipment, so that the hardness and the surface compactness of the coating are increased after the equipment runs for a period of time, and the bonding property of the coating with a metal matrix is enhanced; besides, materials used during preparation are simple, and site operation is convenient.

Owner:南京亮而彩新材料有限公司

Steel ladle cover light mullite castable material and preparation method thereof

The invention discloses a steel ladle cover light mullite castable material including an aggregate and a matrix and including the components in parts by weight: the aggregate comprising 30-70 parts of light mullite balls, and the matrix comprising 0-15 parts of tabular corundum, 0-15 parts of mullite particles, 5-15 parts of an alumina micro powder, 5-15 parts of a mullite micro powder, 0-8 parts of a silicon micro powder, 5-15 parts of a binder, and 0.1-0.4 part of a water reducer. The invention also discloses a preparation method of the steel ladle cover light mullite castable material, wherein the preparation method comprises the following steps: firstly, mixing the matrix parts evenly; and then adding the light mullite balls, and then mixing evenly and packing. The steel ladle cover light mullite castable material has the advantages of simple production, high production efficiency, convenient field construction, low volume density, low thermal conductivity coefficient, excellent thermal shock resistance, high strength, and good high temperature volume stability and the like, and has the use temperature reaching up to 1550 DEG C.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Stone curtain wall construction method

The invention discloses a stone curtain wall construction method, which comprises the following steps of: 1) arranging a main joist on a structural wall; 2) arranging a sub-joist on the main joist; 3) arranging a dry-hanging fitting on the sub-joist, wherein the dry-hanging fitting is a tin-coated steel piece and comprises a horizontal web, a vertically downward plugboard and a vertically upward baffle plate, which are formed at one time, the plugboard is arranged at the front end of the web, the baffle plate is arranged on the middle front part of the web, the web is provided with a mounting slot hole; and the slot hole is positioned behind the baffle plate; and 4) arranging stone slabs of which the upper parts are provided with notches layer by layer upwards in turn from the bottom of the curtain wall, wherein the plugboard is inserted in the notch of the below stone slab, the lower end of the upper stone slab is positioned at the front end of the web, the baffle plate limits the stone slab and controls the verticality of the stone slab, the stone slabs are adhered to the dry-hanging fitting through a structural adhesive, foam strips are inserted at the periphery of each stone slab and a sealant is used for caulking. The method facilitates the maintenance of the curtain wall.

Owner:CHINA CONSTR SIXTH ENG DIV NO 3 CONSTR ENG +1

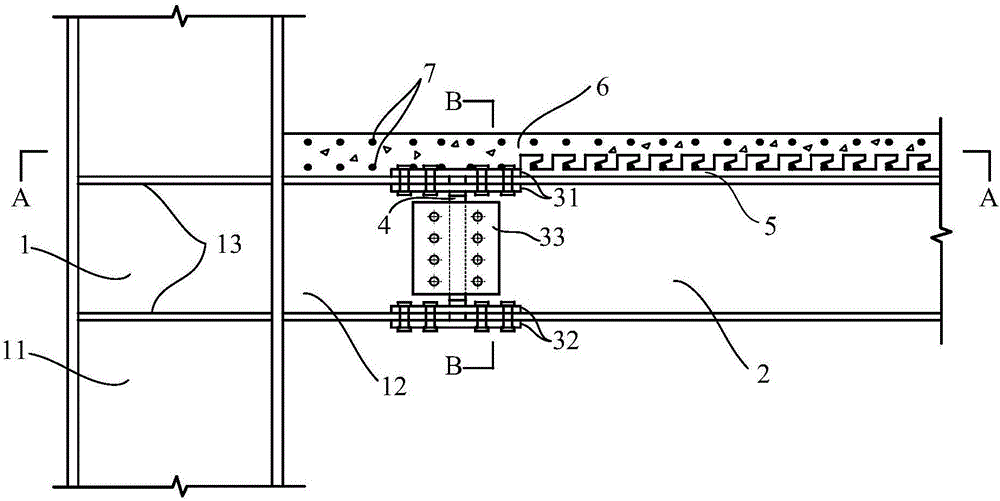

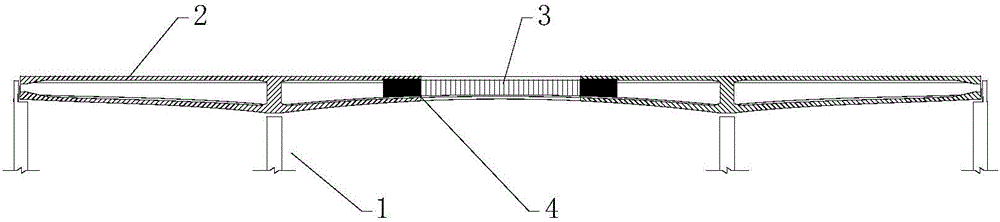

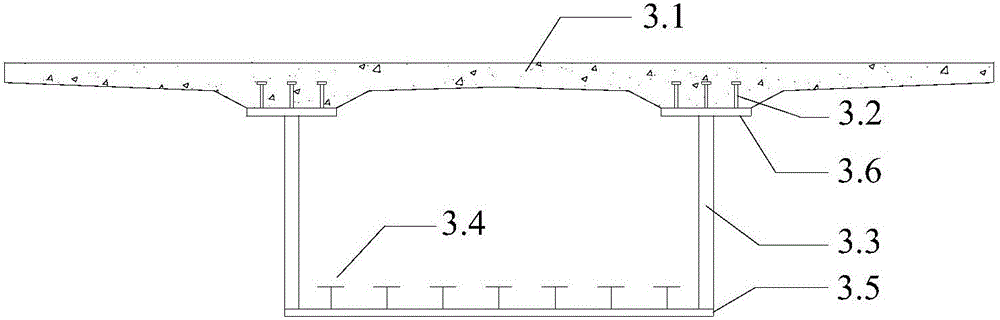

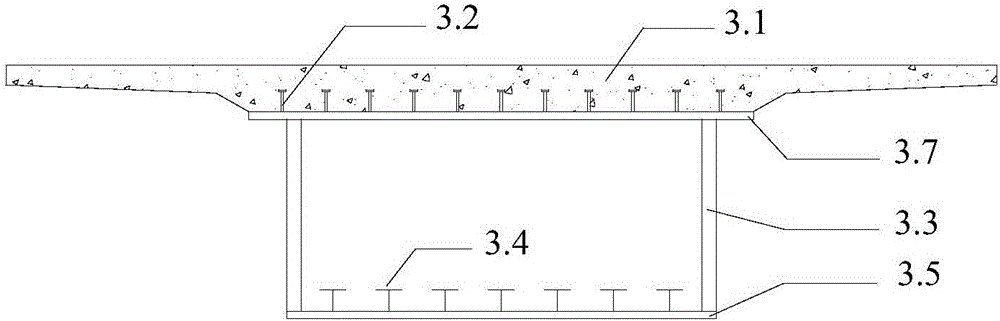

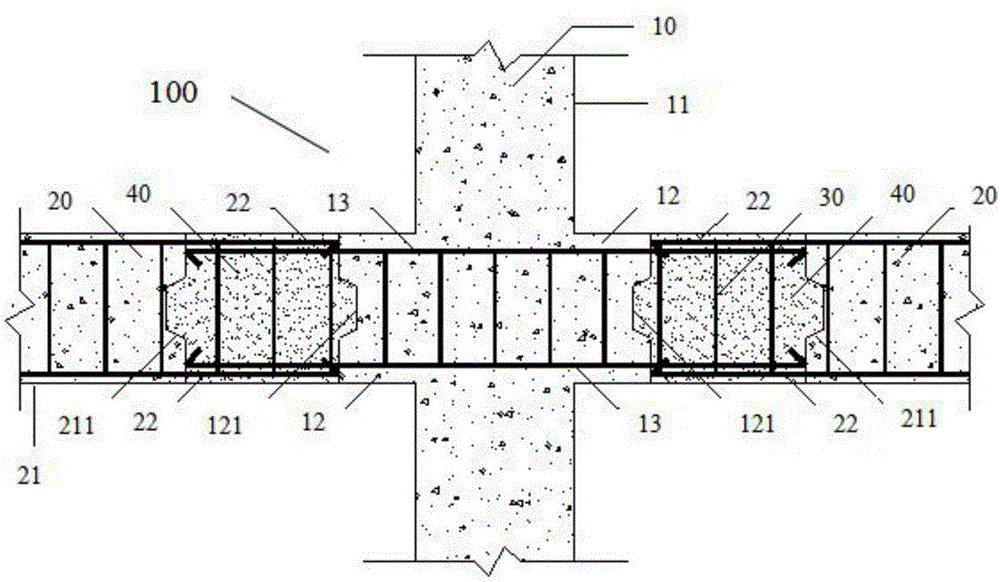

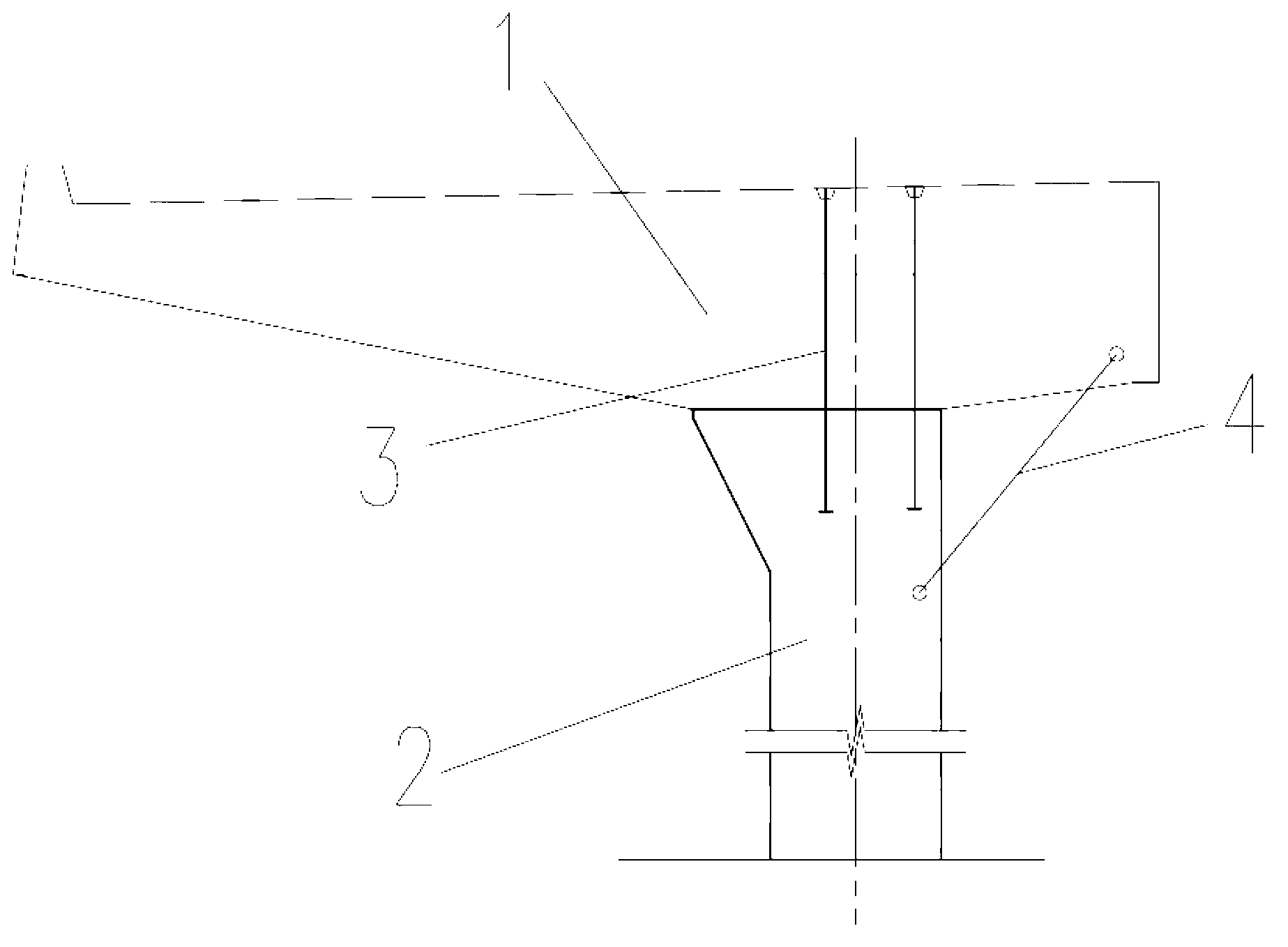

Post-tensioned prestressing assembling concrete frame anti-seismic and energy-consuming component system and construction method

A post-tensioned prestressing assembling concrete frame anti-seismic and energy-consuming component system and a construction method are disclosed. The concrete frame anti-seismic and energy-consuming component system comprises a foundation, frame columns, composite main beams, anti-seismic and energy-consuming components and composite floor slabs. The frame columns are arranged in a layered mode, concrete connection layers are poured between the frame columns of the adjacent upper layers and the lower layers, the composite main beams comprise prefabricated concrete main beams and main beam concrete composite layers, and the composite floor slabs comprise prefabricated hollow slabs and floor slab concrete composite layers cast in situ at the tops of the prefabricated hollow slabs; and prestressing steel tendons are post-tensioned prestressing steel tendons and comprise prestressing steel tendon sticking sections and prestressing steel tendon no-sticking sections, the prestressing steel tendon sticking sections are arranged on the position of the midspans of the prefabricated concrete main beams, and the length of each prestressing steel tendon sticking section is 2-3 m. According to the post-tensioned prestressing assembling concrete frame anti-seismic and energy-consuming component system and the construction method, the technical problems that the transporting and hoisting difficulty of an existing structural system is high, the structure robust performance is not high, the wet working amount is large, the column base rehabilitation cost is high after an earthquake, and the cost is high and manufacturing is complex because energy-consuming reinforcing steel bars are arranged in the beams are solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Assembly type reinforced concrete frame beam column joint and preparation method

InactiveCN106592759AShorten the lap lengthGuaranteed integrityBuilding constructionsReinforced concreteLap joint

The invention provides an assembly type reinforced concrete frame beam column joint. The assembly type reinforced concrete frame beam column joint is characterized by comprising a prefabricated column and a prefabricated beam, wherein the prefabricated column is provided with a prefabricated column body, an extension section and at least one pair of column lap joint longitudinal ribs; the extension section is arranged in the center of the prefabricated column body and extends to the two sides; each pair of column lap joint longitudinal ribs are arranged in the extension section, penetrate through the whole extension section and extend out from the two ends of the extension section; the prefabricated beam is provided with a prefabricated beam body and at least one pair of prefabricated beam longitudinal ribs arranged on the prefabricated beam body; one ends of each pair of prefabricated beam longitudinal ribs extend out from the end, close to the prefabricated column, of the prefabricated beam body; the prefabricated column and the prefabricated beam are connected through a plurality of stirrups and ultra-high performance concrete; and the column lap joint longitudinal ribs and the prefabricated beam longitudinal ribs are fixed through the multiple stirrups according to a certain interval.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

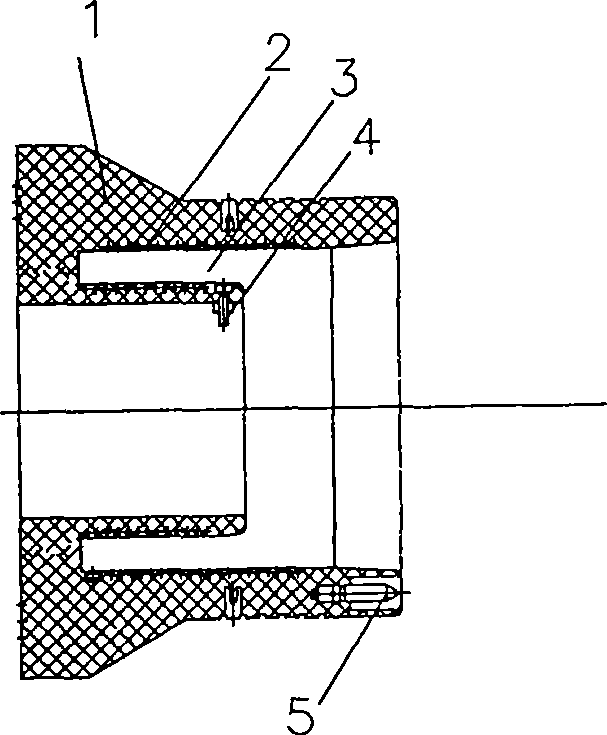

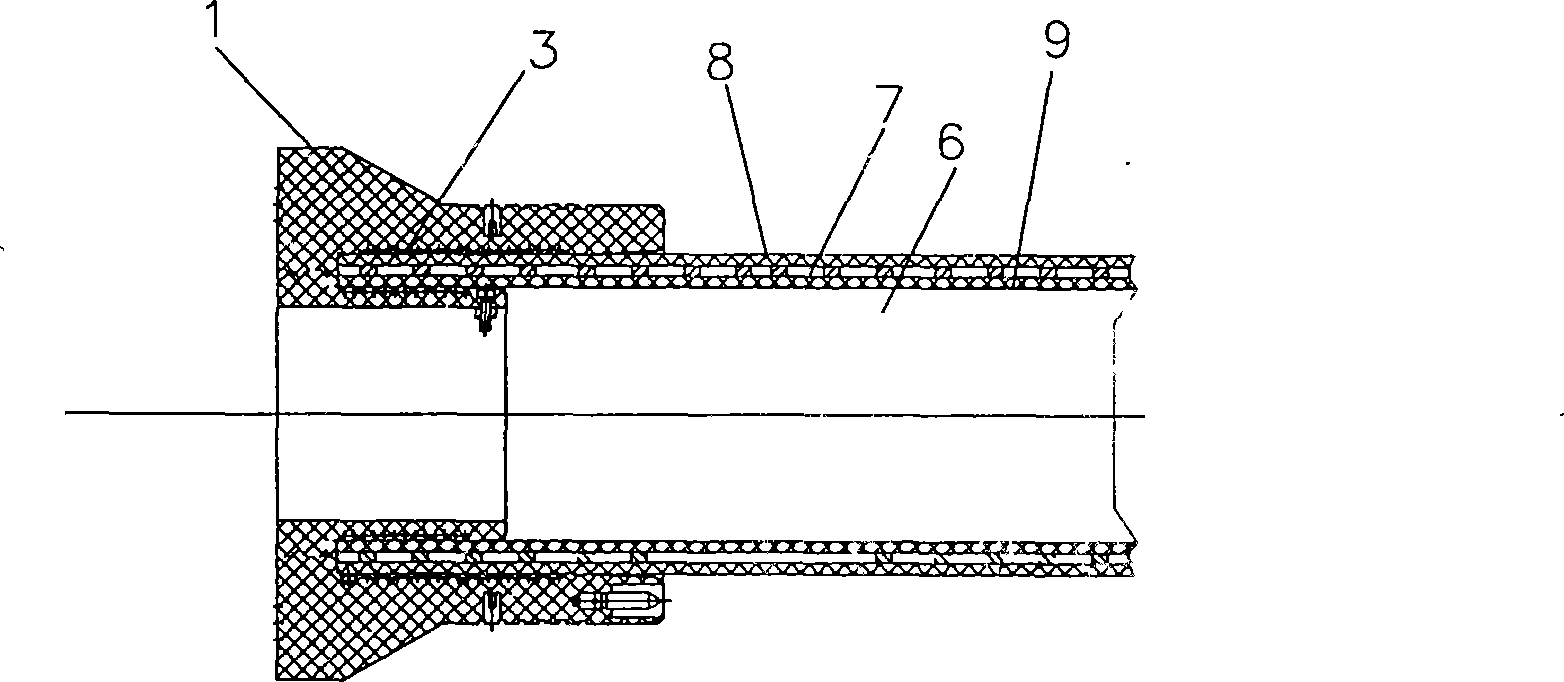

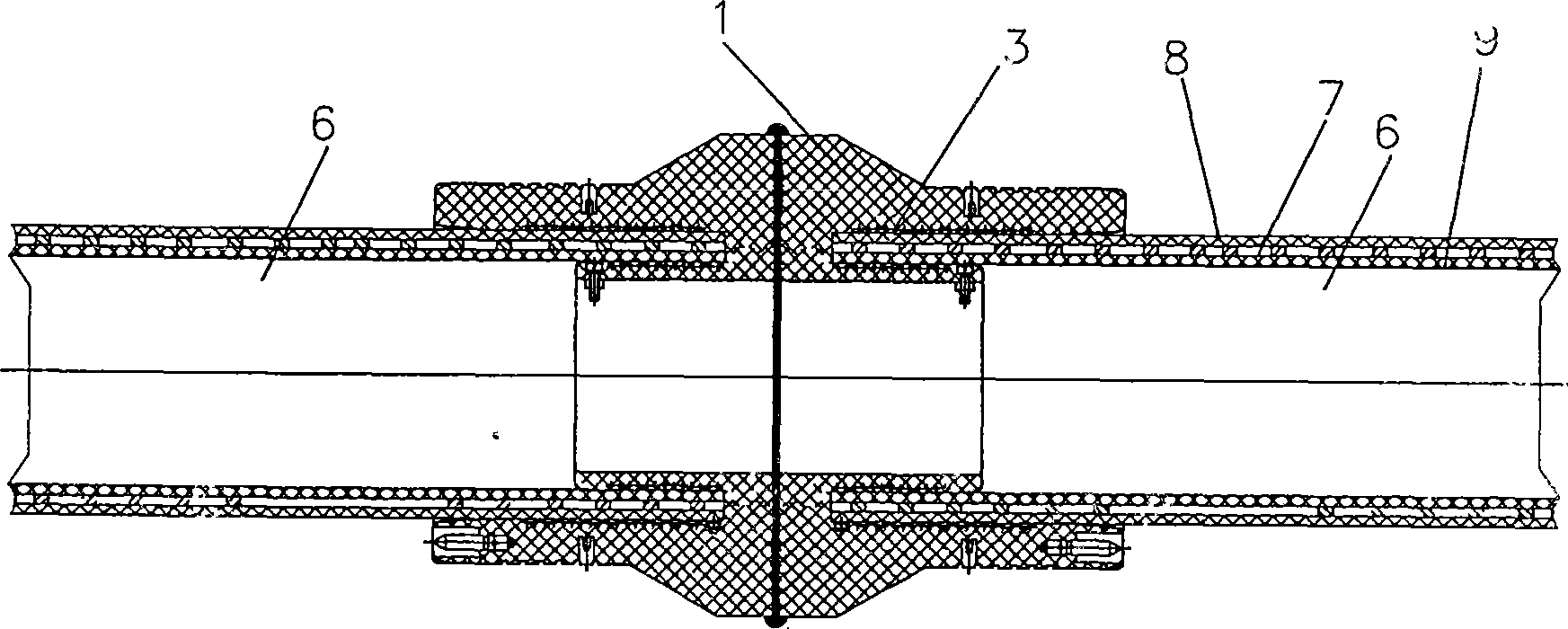

Metal framework reinforced plastic composite pipes and method for manufacturing the same

InactiveCN101498385AGuaranteed service lifeHigh mechanical strengthPipe connection arrangementsRigid pipesMetal frameworkWorking pressure

The invention provides a metal skeleton reinforced plastic composite pipe which is provided with a pipeline connecting piece which can connect a pipeline with another pipeline or the pipeline with a pipeline joint to form a pipe network in satisfying the working pressure. The end of the pipeline connecting piece connected with the metal skeleton reinforced plastic composite pipeline is provided with an annular U-shaped bell and spigot hole which totally wraps the plastic external layer and the plastic internal layer of the end of the metal skeleton reinforced plastic composite pipeline and the end surface of the metal skeleton reinforced plastic composite pipeline; and the pipeline connecting piece is connected with the metal skeleton reinforced plastic composite pipeline in a hot melting way or electric melting way. The annular U-shaped bell and spigot hole of the pipeline connecting piece totally and tightly wraps the plastic external layer and the plastic internal layer of the end of the metal reinforced composite pipeline and the end surface of the metal skeleton reinforced plastic composite pipeline, the connection is firm and reliable without leakage, the connection position has high mechanical strength and prevents fluid from entering into a metal skeleton to corrode the metal skeleton, and the service life of the pipeline is long. The invention further provides a method for manufacturing the metal skeleton reinforced plastic composite pipe.

Owner:甘国工

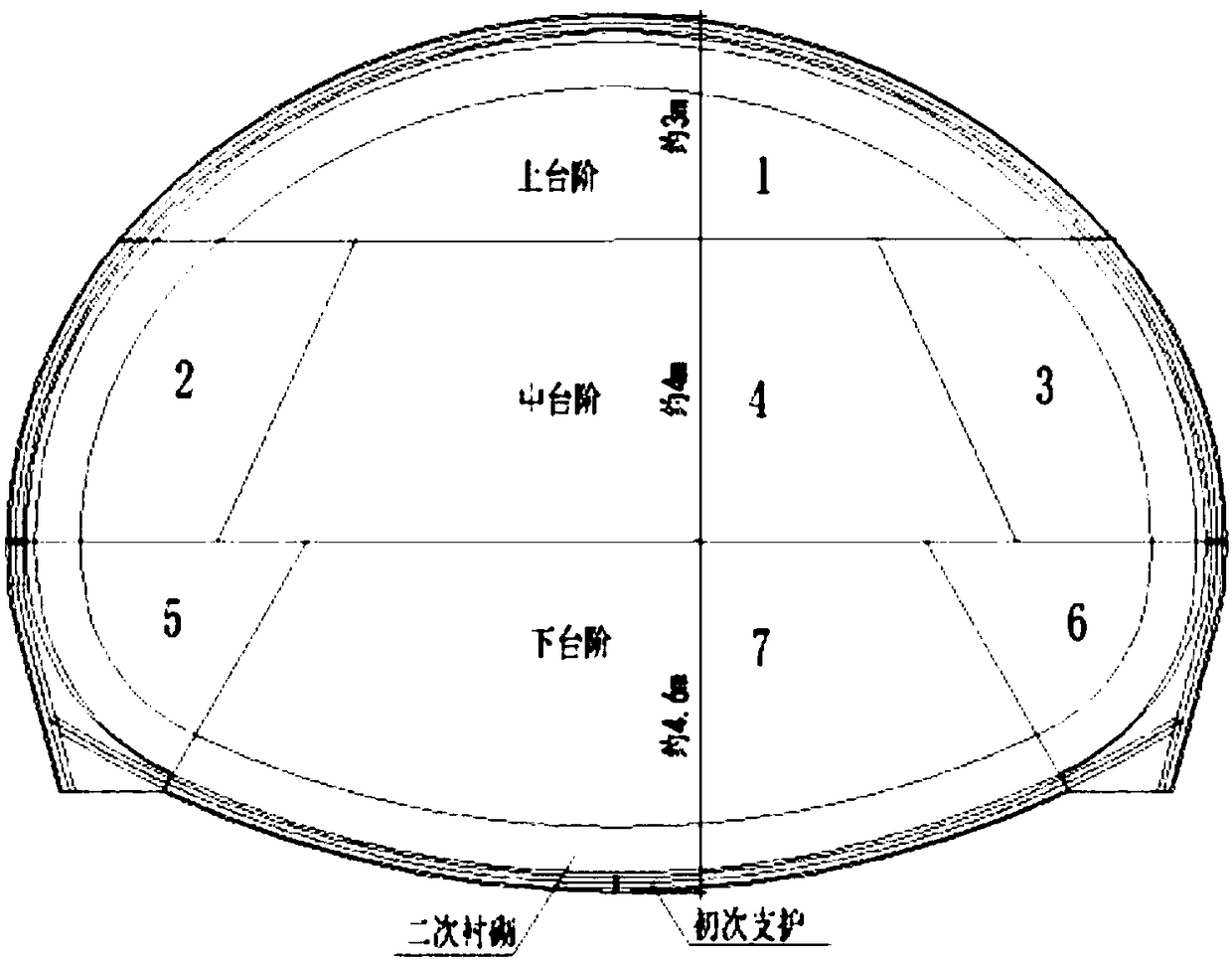

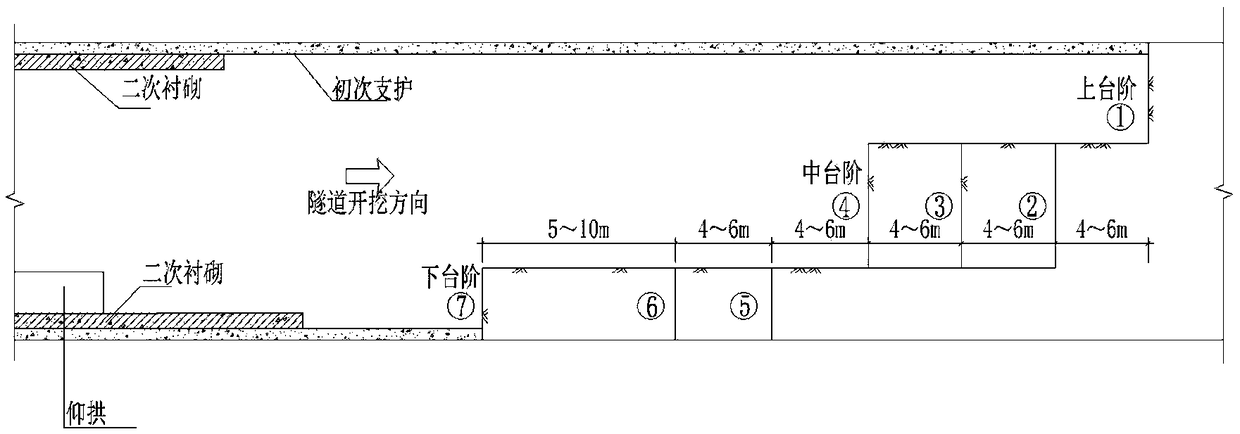

Construction method suitable for penetrating water supply pipe below tunnel in composite stratum with soft upper part and hard lower part

InactiveCN109372517ASmall deformation perturbationReduce disturbanceUnderground chambersBlastingStructure of the EarthSteel frame

The invention discloses a construction method suitable for penetrating a water supply pipe below a tunnel in a composite stratum with the soft upper part and the hard lower part, and belongs to the technical field of civil engineering. The construction method aims to strictly control tunnel arch settlement and prevent the situation that settlement overrun affects the water supply pipe to cause a structure (arch culvert) failure. By synthesizing the factors, the overall construction scheme is as follows: firstly, an advance support is constructed; after the design effect is achieved, the composite stratum with the soft upper part and the hard lower part is constructed through a three-step method, specifically, the upper step, namely the soft stratum is excavated through a mechanical method,the middle and lower steps, namely rock strata are excavated through a blasting method, and the circulation footage of a control area is one steel frame interval; manual work cooperates with mechanical excavation as far as possible, timely closure for ring forming is achieved, and arch sinking is inhibited; a secondary lining closely follows the excavation surface, and one-time pouring forming isachieved through a formwork trolley arch wall; and hole interior and ground surface settlement monitoring of the control area, as well as vibration speed monitoring within the blasting impact range are strengthened, and information is fed back in time to guide the design and construction.

Owner:BEIJING JIAOTONG UNIV +2

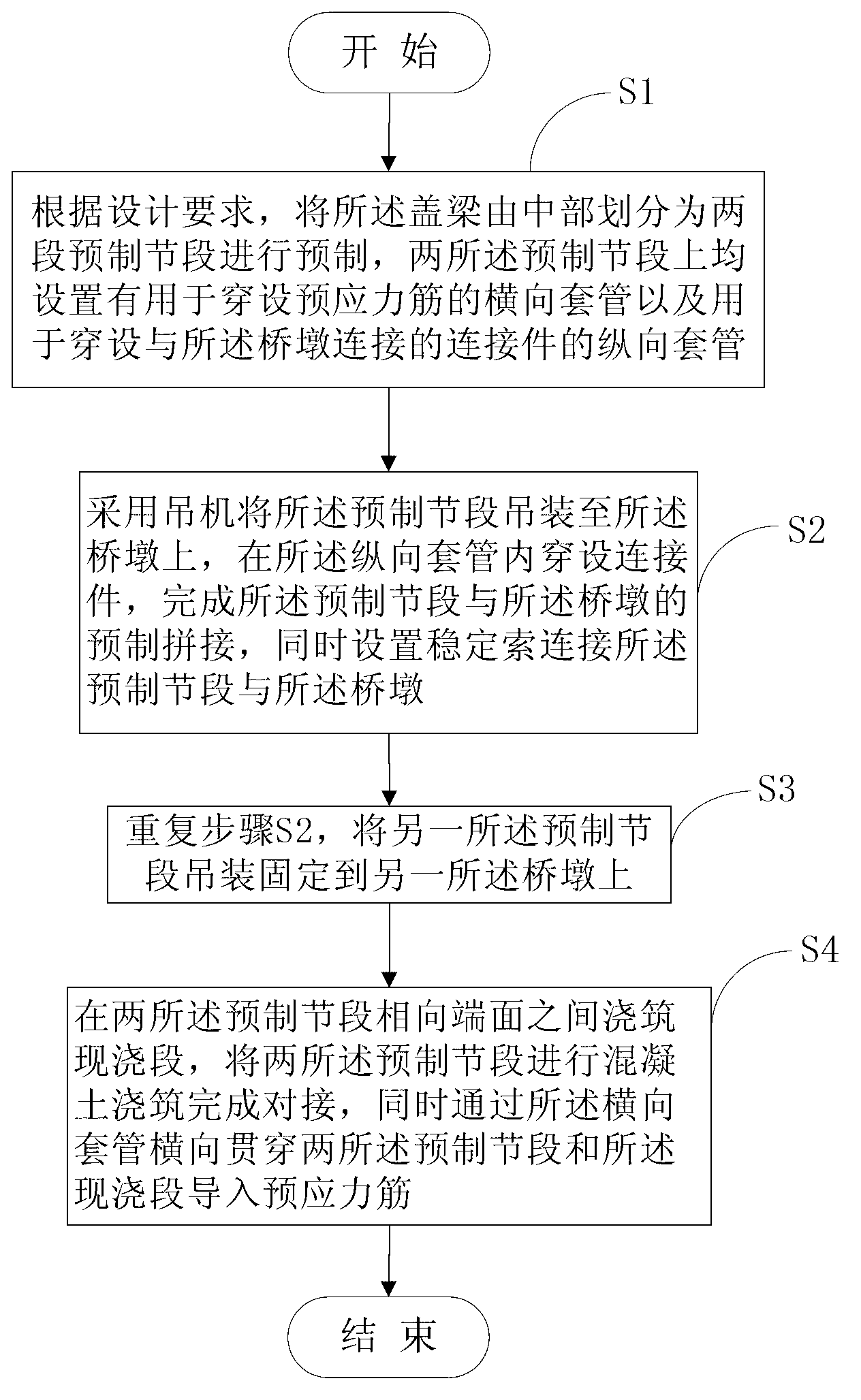

Method for prefabricated assembly of middle-divided sections of large-sized capping beam and assembly structure of middle-divided sections of large-sized capping beam

InactiveCN103215893AThe overall structure is simple and reliableLow construction difficultyBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention discloses a method for prefabricated assembly of middle-divided sections of a large-sized capping beam. The method for the prefabricated assembly of the middle-divided sections of the large-sized capping beam comprises the steps that the capping beam is divided into two prefabricated sections from the middle of the capping beam to be prefabricated, and the two prefabricated sections are respectively provided with a transverse sleeve and a longitudinal sleeve; a crane is used for lifting one of the two prefabricated sections on a bridge pier, connecting pieces are arranged inside the longitudinal sleeve in a penetrating mode, prefabricated assembly between the prefabricated section and the bridge pier is accomplished, and a stable cable is arranged to connect the prefabricated section and the bridge pier at the same time; the other prefabricated section is lifted and is fixed on another bridge pier; a cast-in-place section is poured, concrete pouring is carried out on the two prefabricated sections, abutting joint is accomplished, and prestressed tendons are guided into the two prefabricated sections and the cast-in-place section in a crosswise penetrating mode. The invention further discloses a prefabricated assembly structure of the middle-divided sections of the large-sized capping beam. The prefabricated assembly structure of the middle-divided sections of the large-sized capping beam comprises the two prefabricated sections and the cast-in-place section. The method for the prefabricated assembly of the middle-divided sections of the large-sized capping beam and the prefabricated assembly structure of the middle-divided sections of the large-sized capping beam are low in construction requirement for prefabrication of the capping beam and site lifting, and are applicable to construction of the large-sized capping beam.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

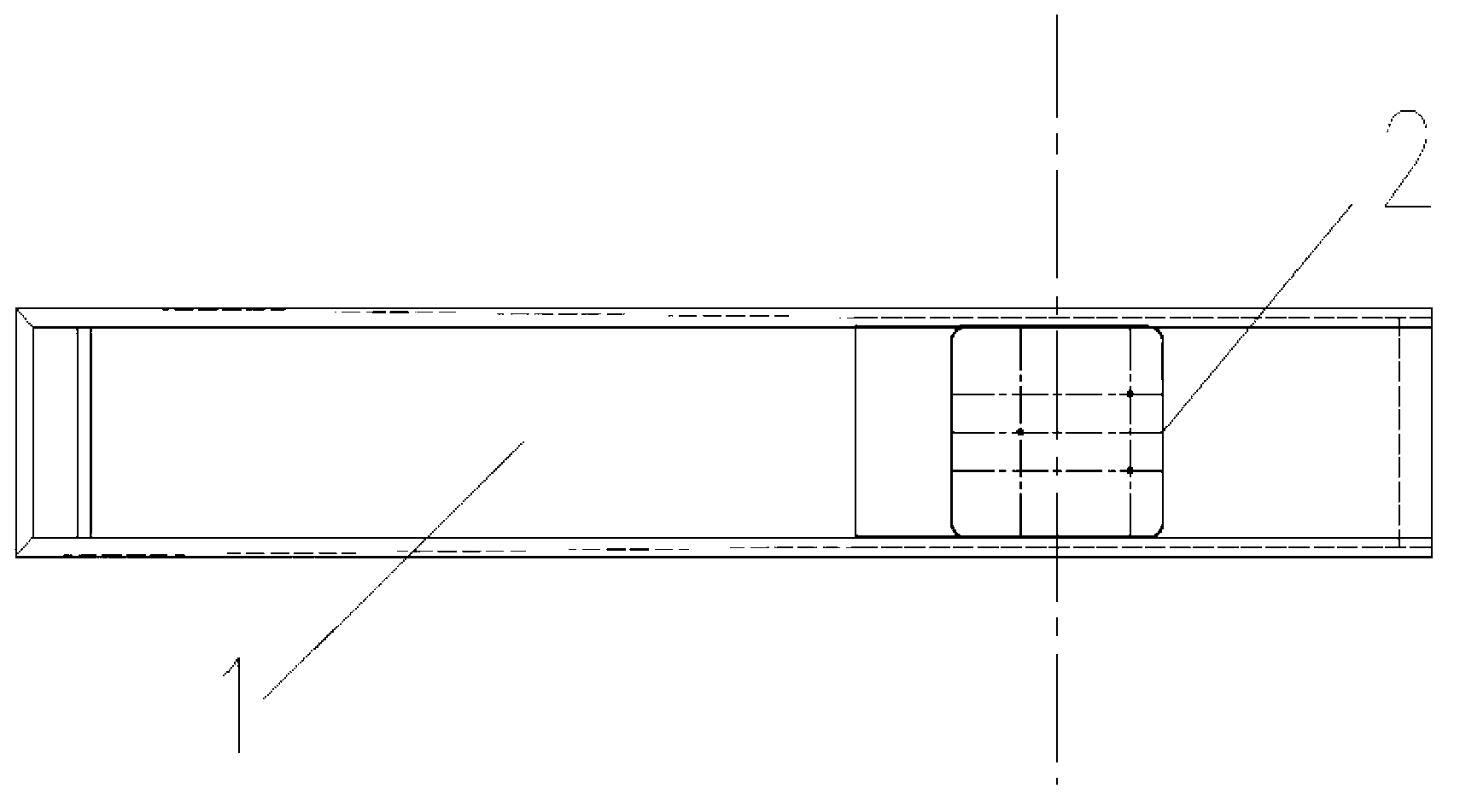

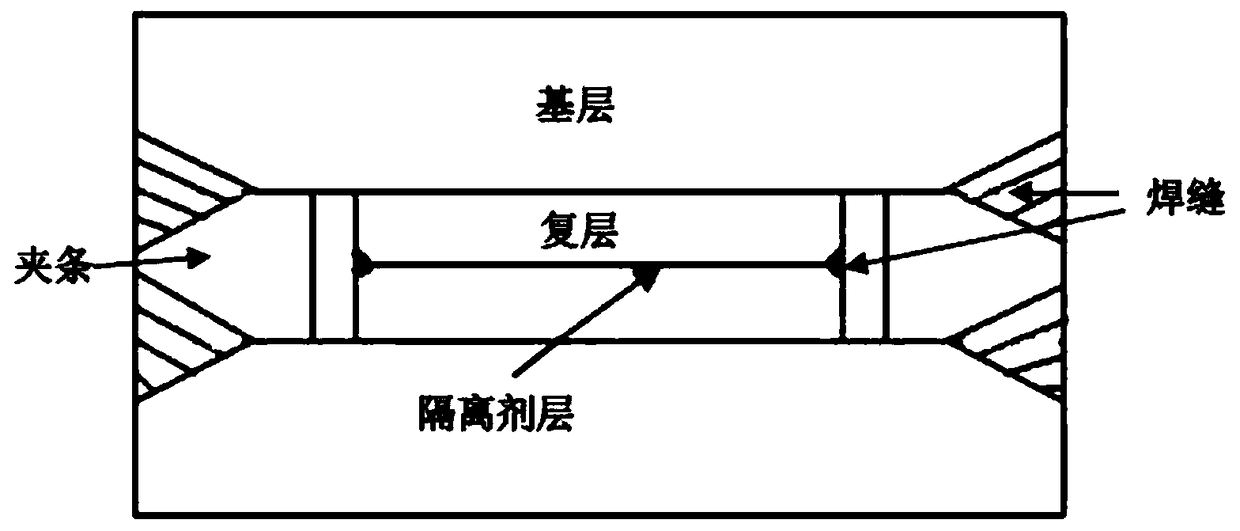

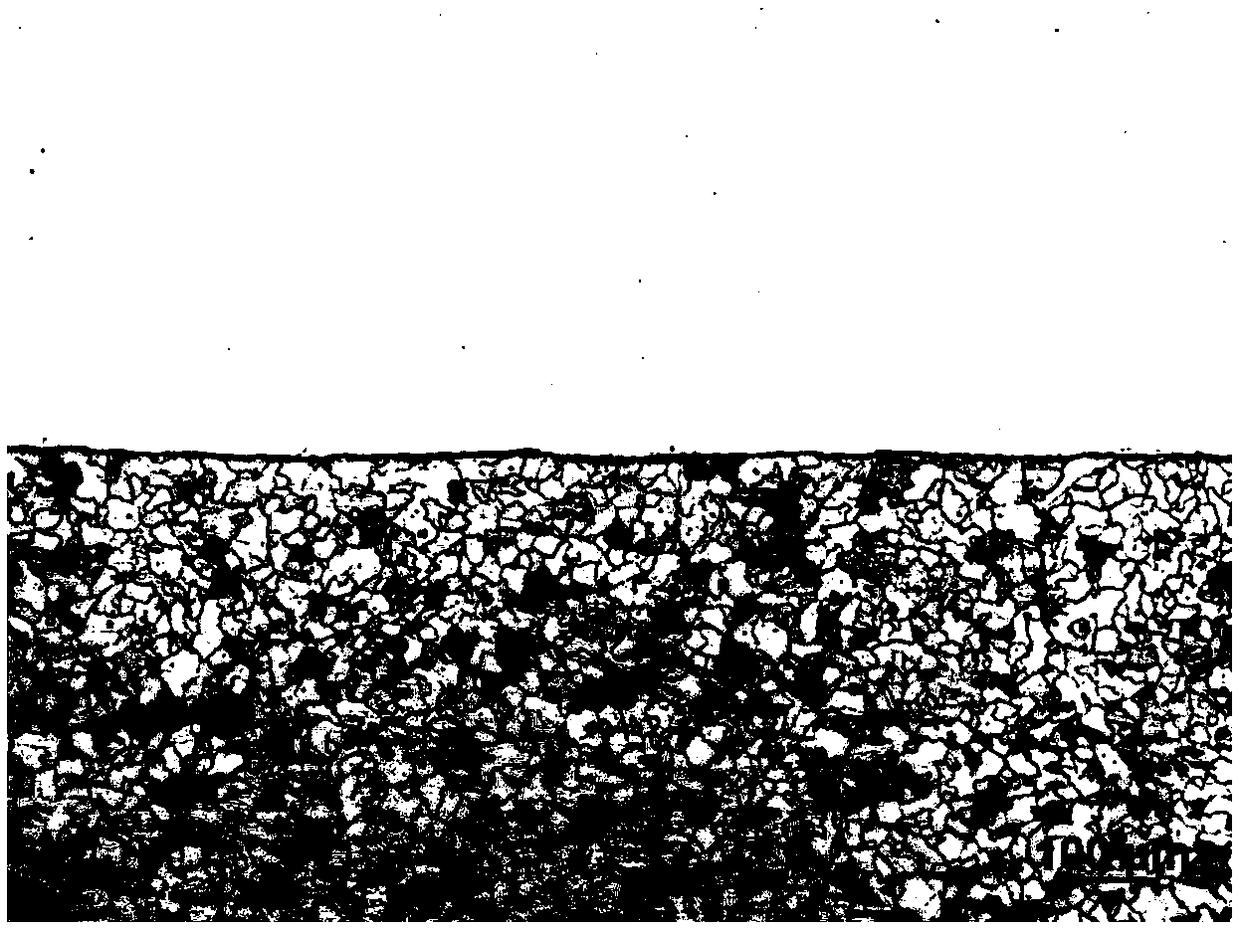

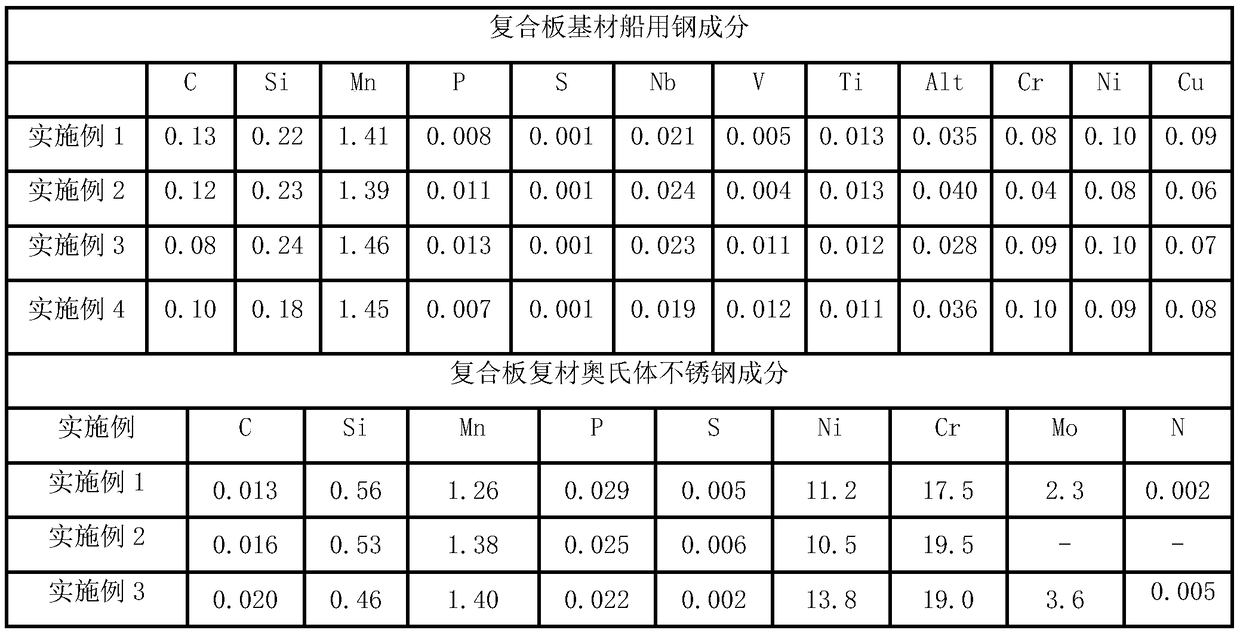

TMCP type marine austenitic stainless steel composite plate and preparation method thereof

InactiveCN108943911ASolve the problem of corrosion resistanceSimple processLamination ancillary operationsLaminationAustenitic stainless steelAusforming

The invention discloses a TMCP type marine austenitic stainless steel composite plate and a preparation method thereof and relates to the technical field of bimetal composite manufacture. The preparation method comprises blank preparation, surface grinding, isolating agent brush-coating, assembly blank sealing, electron beam soldering and sealing, heating, rolling and cooling, straightening, and cutting separation. The TMCP type marine austenitic stainless steel composite plate effectively solves the problem of corrosion resistance of the composite austenitic stainless steel in the composite plate, and in the blank preparation process, the steps of drilling and vacuuming are avoided. The preparation method has simple processes and a high rolling yield.

Owner:NANJING IRON & STEEL CO LTD

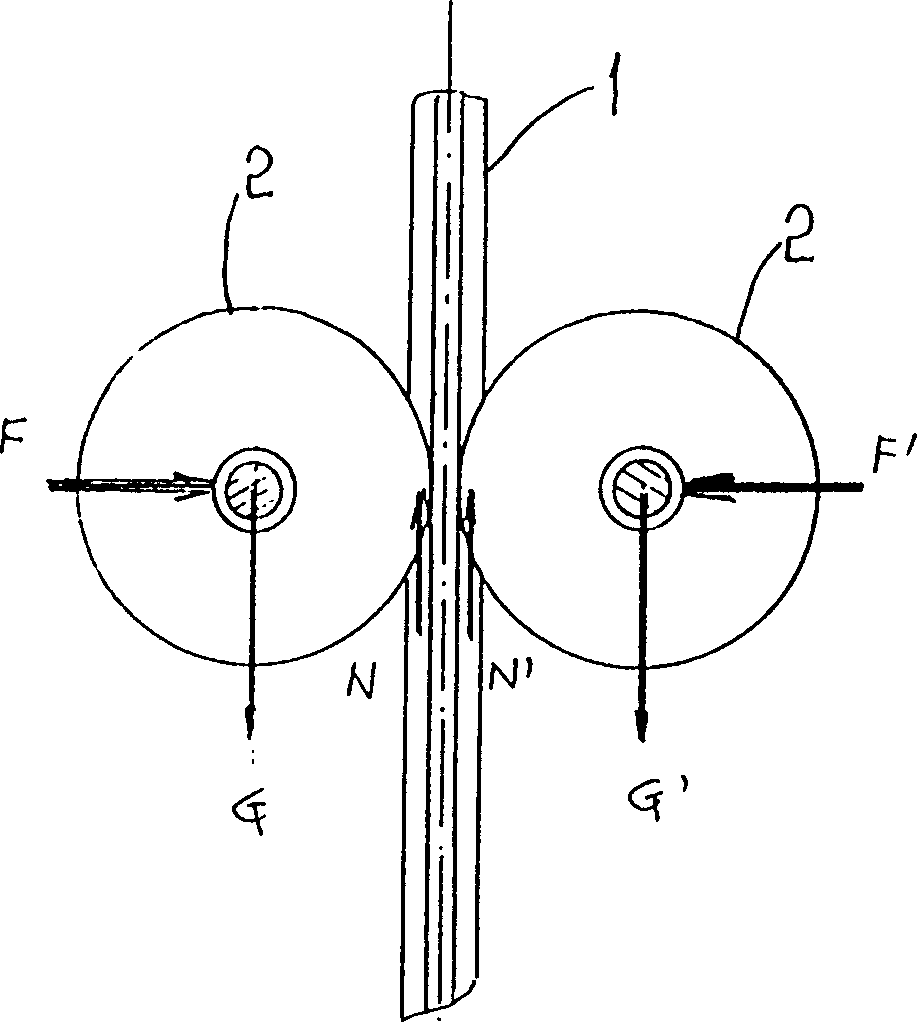

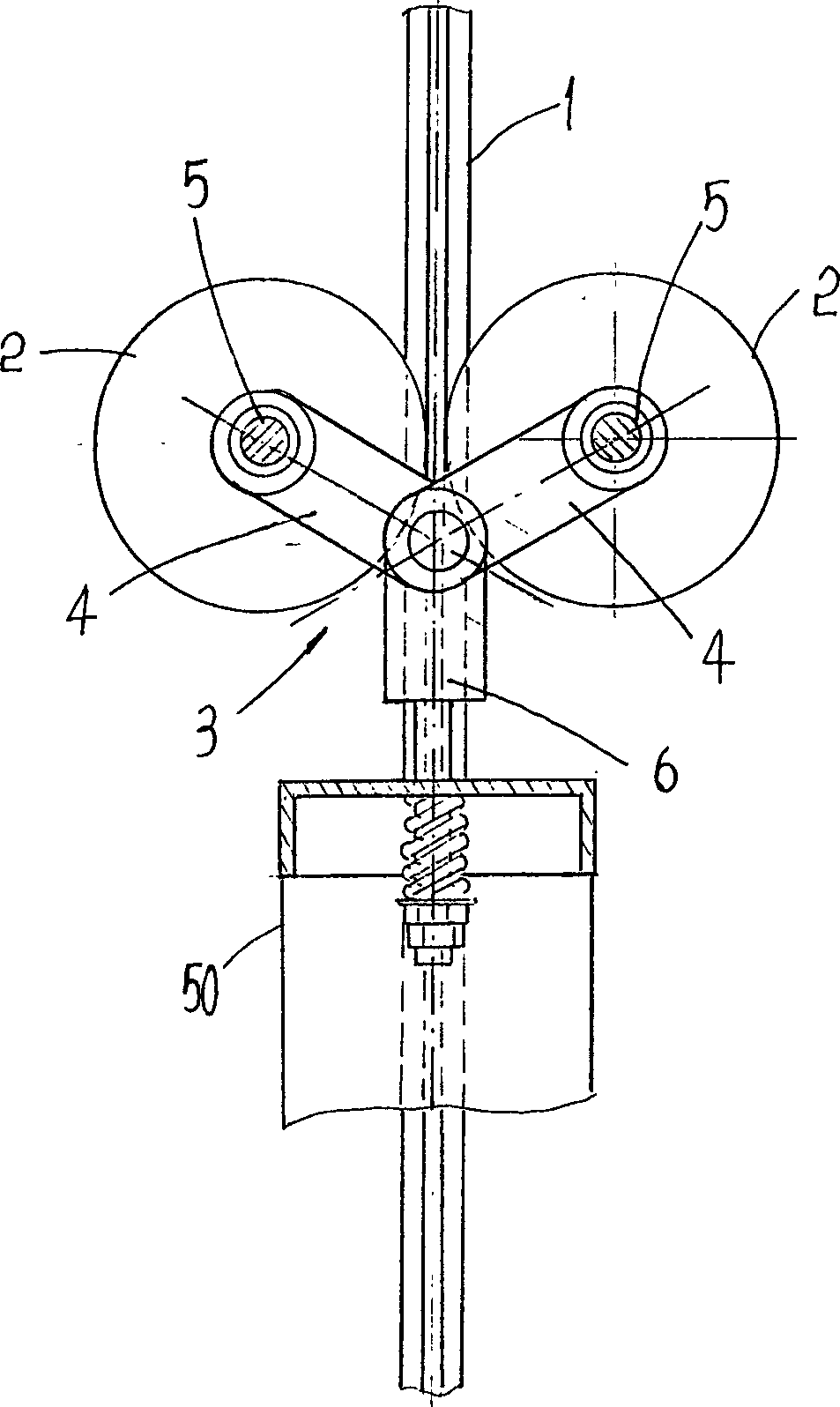

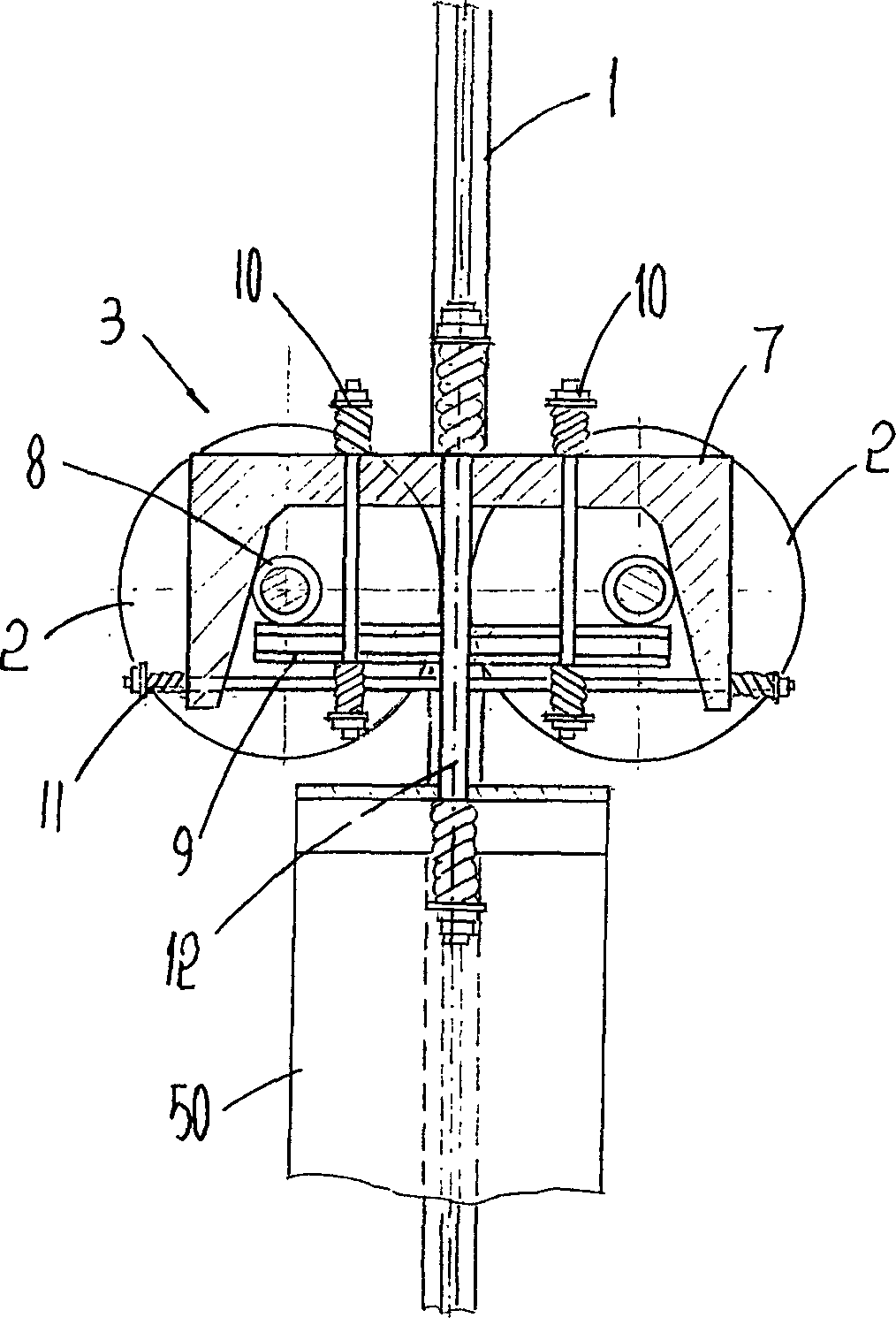

Anti-falling pair roller

InactiveCN1715168AInnovative designSpacious installationElevatorsBuilding liftsGravitational forceMechanical engineering

The falling preventing paired roller apparatus includes track, and two rollers in the basically same structure and set on two sides of the track. Of the two rollers, at least one is active roller with axle controlled by a drive mechanism and a normally closed brake. The rollers on the two sides of the track contact the track to form a basically symmetric arrangement. One force applying unit makes the two rollers generate equal and opposite pressures on the track to overcome gravitational force. The present invention has the advantages of simple structure and wide use, and may be used widely in vertical or inclined transportation machines.

Owner:周友仁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com