Aqueous epoxy resin modified emulsified asphalt, and preparation method and application thereof

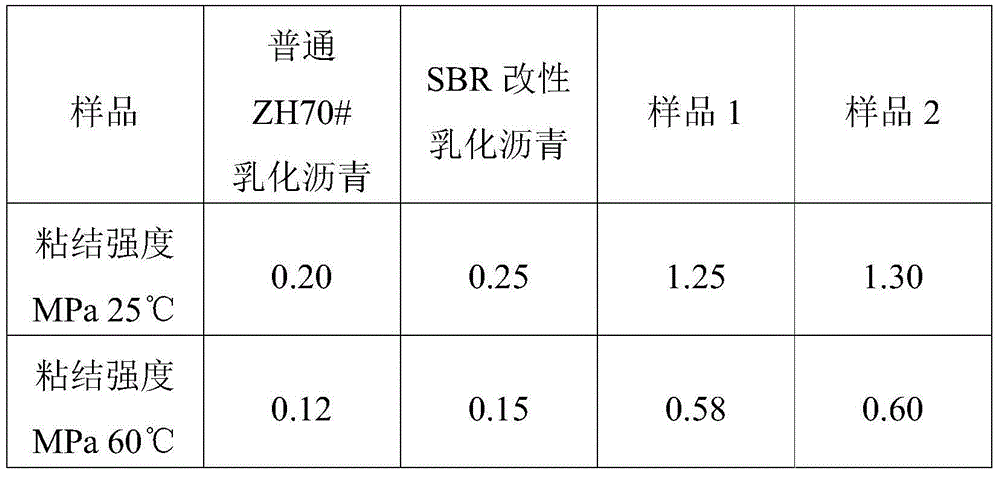

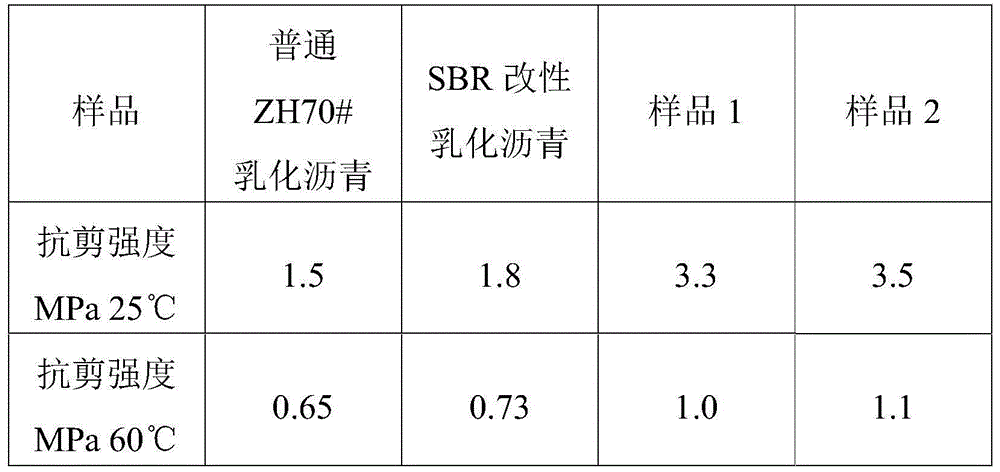

A technology of water-based epoxy resin and emulsified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of insufficient bonding strength, poor high temperature stability, and poor low temperature flexibility, etc., to facilitate on-site construction, Good storage stability, the effect of improving the shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of emulsified asphalt: 500g of Sinopec Zhenhai 70# base asphalt, 25g of Ancamide 375A polyamide curing agent (from Air Products, USA), heated and mixed at 135°C, and then used EM-520 prepared in advance (Shanghai Longfu Material Co., Ltd.) Technology Co., Ltd. cationic asphalt emulsifier, 2.0% dosage) of 60 ℃ soap solution is fully mixed and emulsified in the colloid mill, and the emulsification time depends on the emulsification situation, usually 1 to 2 minutes;

[0054] 2. Place the prepared emulsified asphalt in a 60°C oven to cool down slowly, then let it stand at room temperature and cool to room temperature. Then mix it with 450g CYDW-112W50 modified water-based epoxy resin emulsion (from Baling Petrochemical, epoxy equivalent 1200-1850, solid content 50%) to form epoxy resin modified emulsified asphalt.

Embodiment 2

[0056] 1. Preparation of emulsified asphalt: Mix 500 g of Sinopec Zhenhai 70# base asphalt, 25 g of Ancamide 375A polyamide curing agent (from Air Products, USA), heat and mix evenly at 135°C, and then use pre-prepared EM-310 (Shanghai Longfu Materials Co., Ltd.) Technology Co., Ltd. cationic asphalt emulsifier, 0.8% dosage) of 60 ℃ soap solution is fully mixed and emulsified in the colloid mill, and the emulsification time depends on the emulsification situation, usually 1 to 2 minutes;

[0057] 2. Place the prepared emulsified asphalt in a 60°C oven to cool down slowly, then let it stand at room temperature and cool to room temperature. Then mix it evenly with 500g of water-based epoxy resin emulsion Ancarez AR550 (from Air Product Company of the United States, with an epoxy equivalent of 550) to form epoxy resin modified emulsified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com