Metal framework reinforced plastic composite pipes and method for manufacturing the same

A technology of metal skeleton and reinforced plastic, which is applied in the direction of pipes, rigid pipes, pipeline connection layout, etc., can solve the problems of not meeting the sealing requirements, achieve the effects of preventing corrosion, convenient construction, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

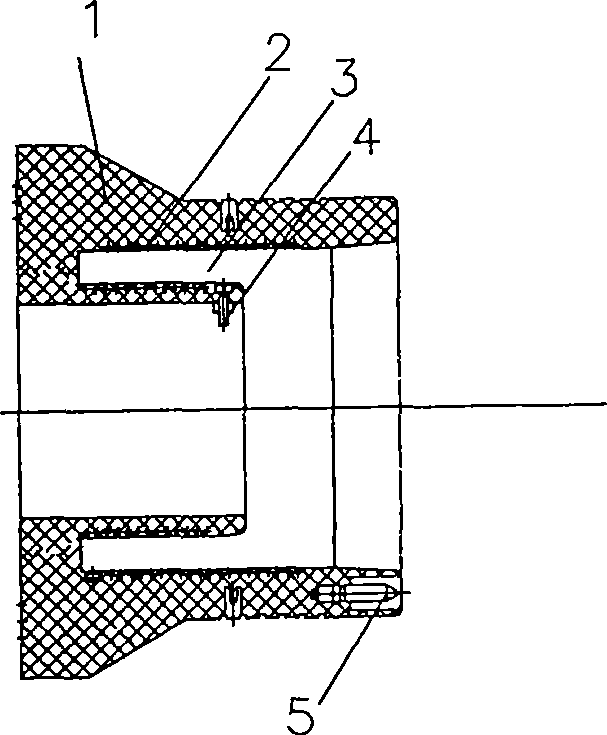

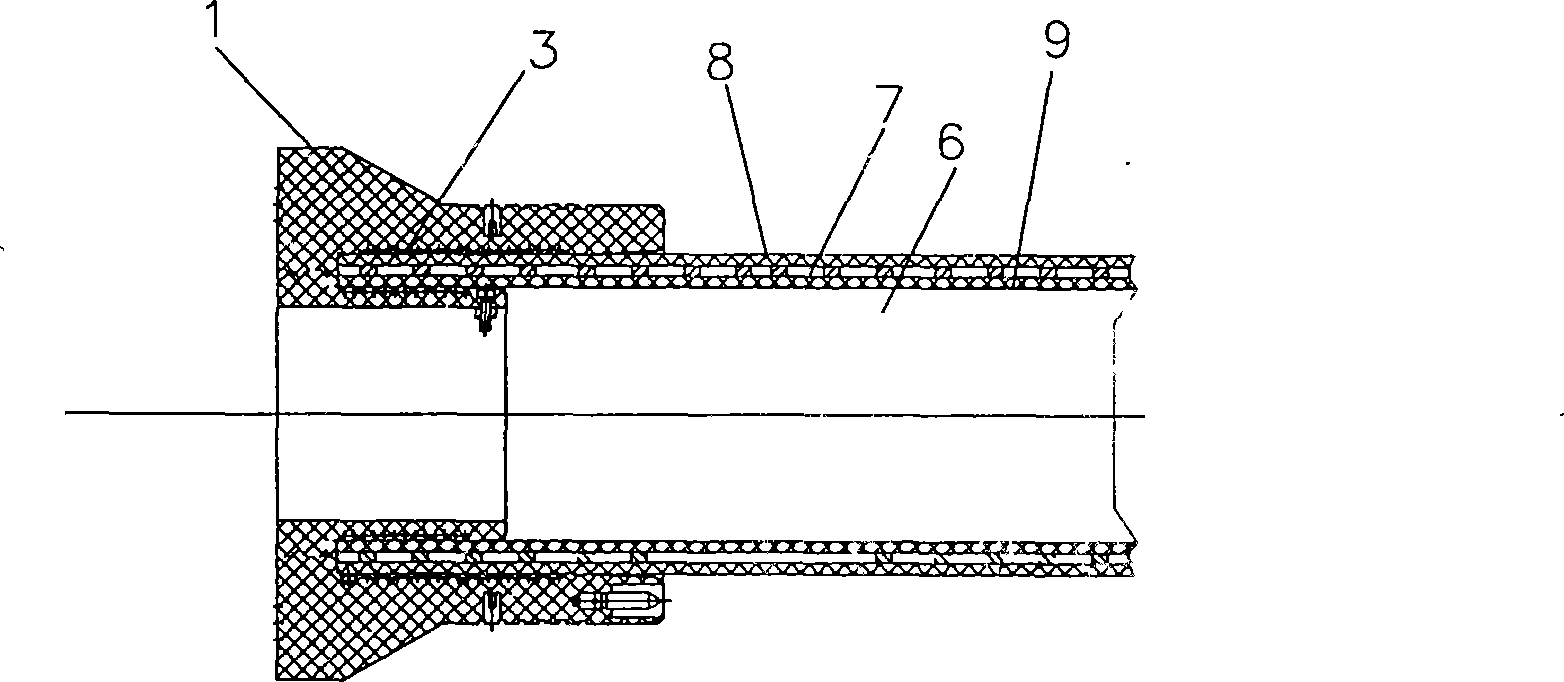

[0034] Figure 1 ~ Figure 3 Figure 1 of this example is given. In this embodiment 1, a two-way pipe connector 1 that satisfies the working pressure is first produced. There is an annular U-shaped socket 3 in the pipe connector 1, and heating wires 2 are arranged on both sides of the socket 3. The heating wire passes through the first A terminal 4 and a second terminal 5 are energized. Such as figure 2 Shown, there is the perforated steel plate metal skeleton 7 with holes covered by the plastic outer layer 8 and the plastic inner layer 9 in the metal skeleton composite plastic pipe 6 (or the warp direction steel wire is wound with the latitude steel wire and its contact point is welded Formed cylindrical metal skeleton, or steel wire left-handed and / or right-handed helical winding formed cylindrical metal skeleton, or steel wire braided cylindrical metal skeleton, or longitudinally butted or lapped with aluminum strips and Cylindrical metal skeleton formed by welding). The...

Embodiment 2

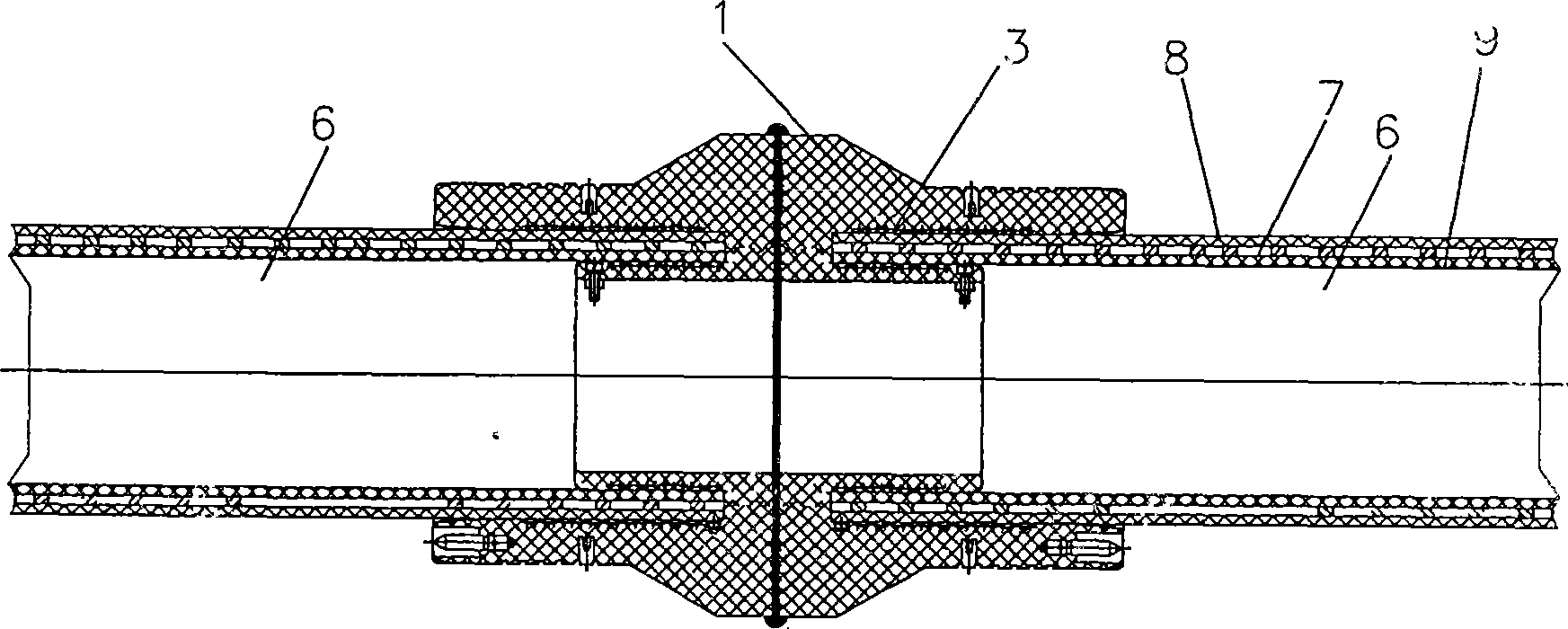

[0036] Figure 4 , Figure 5 , Figure 6 Figure 2 of Embodiment 2 of the present invention is given. Embodiment 2 is basically the same as Embodiment 1. The difference is that the pipe connector 1 has no electric heating wire, and the ring-shaped U-shaped socket 3 in the pipe connector 1 completely covers the plastic outer layer and plastic inner layer of the end of the metal skeleton reinforced plastic composite pipe and the end face of the pipe. The method melts and connects the pipe connector and the metal skeleton reinforced plastic composite pipe.

Embodiment 3

[0038] Figure 7 , Figure 8 Figure 3 of Embodiment 3 of the present invention is given. Embodiment 3 is basically the same as Embodiment 1. The difference is that when the pipe connector 1 is melt-connected with the metal skeleton reinforced plastic composite pipe 6, the inner hole support fixture 10 is used to press the inner wall of the pipe connector to the plastic inner layer 9 in the composite pipe 6, and the outer ring is used to The clamp 22 presses the outer layer wall in the pipe connector to the plastic outer layer 8 in the composite pipe 6, and exerts pressure on the fusion connection surface, so that the connection of the fusion connection surface is more firm and reliable. There are two movable rings 11 and 12 hinged to each other in the inner hole support fixture 10, and an adjusting mechanism 13 positioned in the movable ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com