Anti-falling pair roller

A technology for rollers and rollers, used in elevators, elevators in buildings, transportation and packaging, etc., can solve the problem of not changing the dominance of wire rope traction elevators, and achieve flexible and changeable shapes, simple overall structure, and long-term performance. The effect of distance carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

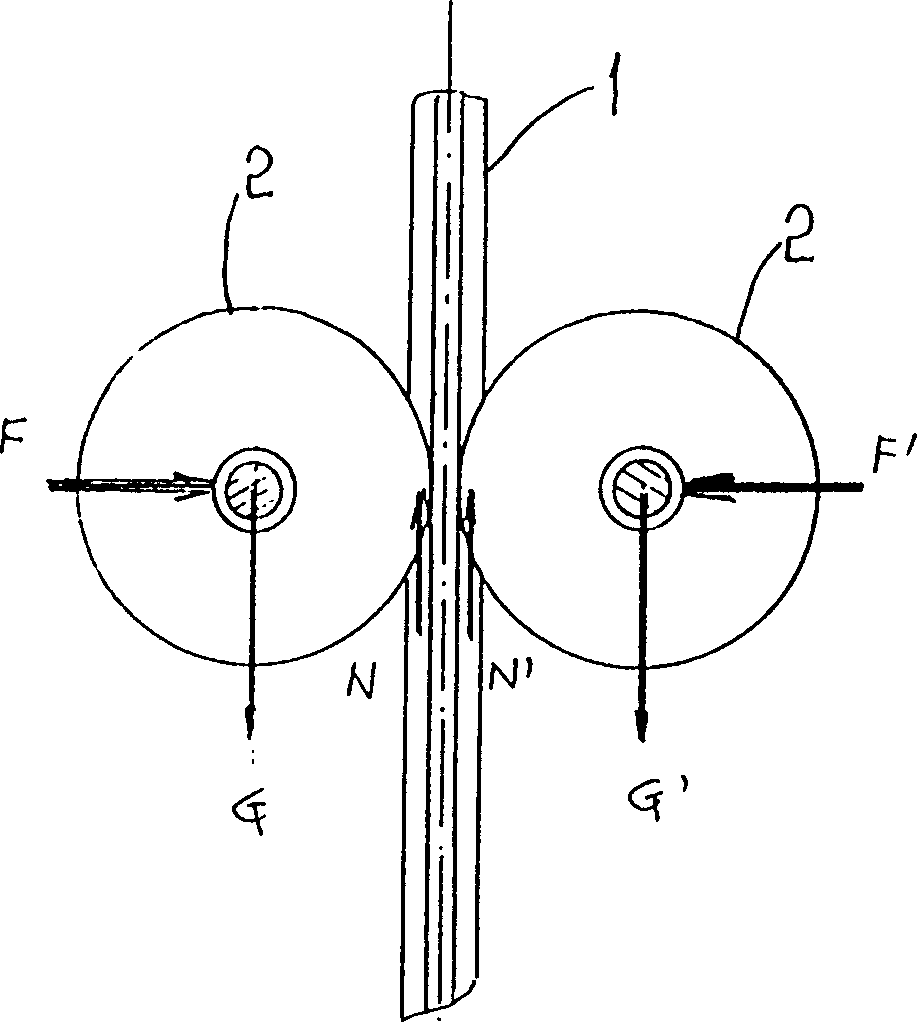

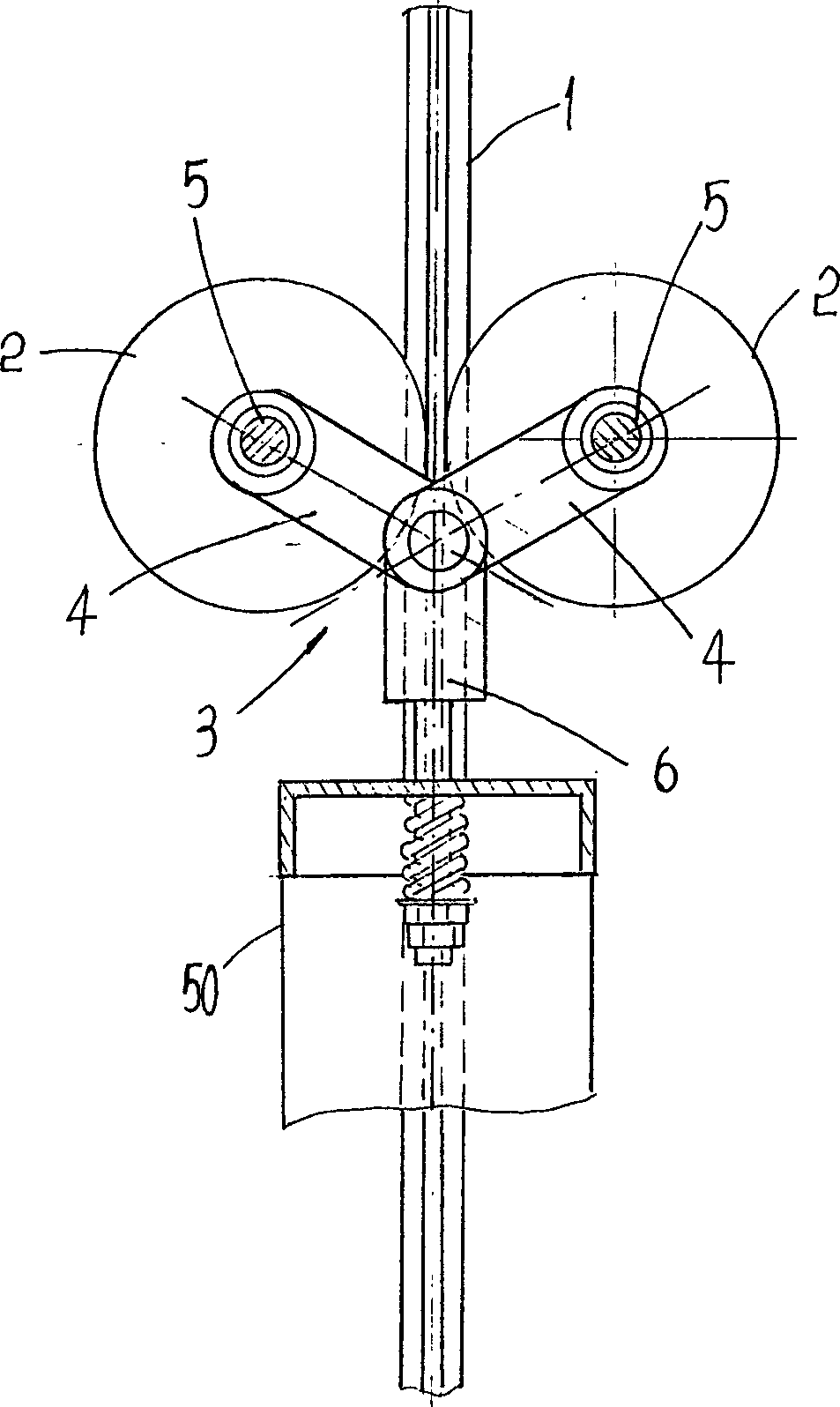

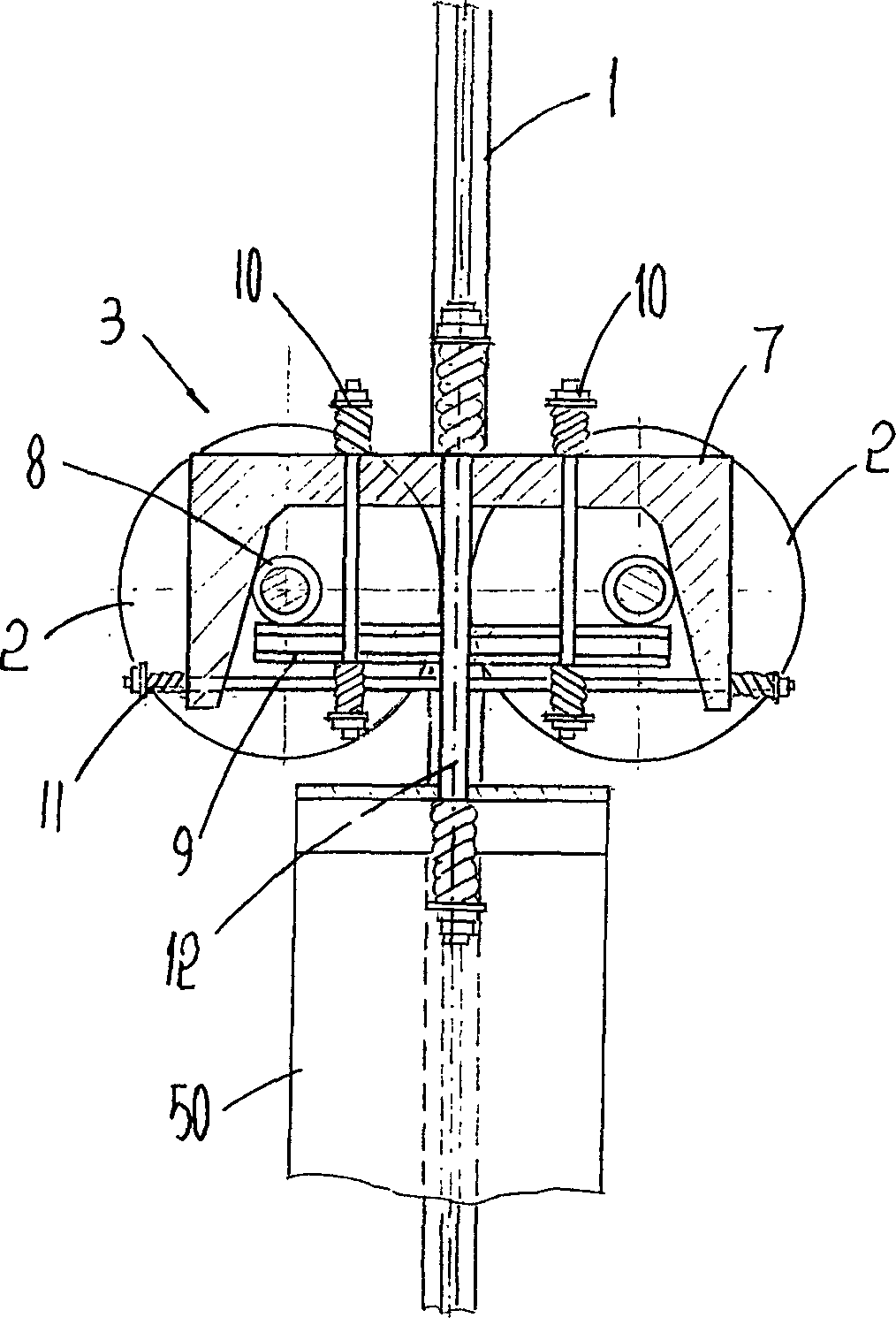

[0032] Such as figure 1 Shown, the present invention provides a kind of anti-falling roller that can rise, descend or stop along rail 1 (or other supports), and its basic structure is to go out a pair of distribution on rail (or other supports, such as I-beam, Two rollers 2 with equal value and opposite acting force are applied on both sides of column, utility pole, suspension tape, etc.). These two rollers 2 are usually symmetrical and opposite, and are called twin wheels (Twin Wheels). The applied equal and opposite action force is essentially the action force and reaction force described by Newton's third law. This group of action force and reaction force is transmitted to the surface of rail 1 (or other supports) through two rollers 2 to generate positive pressure, thereby generating static friction in the tangential direction of the surface of rail 1 (or other supports) (in the figure N, N'). If the direction of the force (F, F' in the figure) applied to the two rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com