Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

A technology of active powder and production method, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, which can solve problems such as unstable construction quality, inconvenient on-site production, and ordinary road slabs containing reinforcement, so as to facilitate installation at any time And disassembly, transportation and on-site construction are convenient, and the effect of reducing maintenance and repair workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The content of the present invention will be further explained below in conjunction with the accompanying drawings.

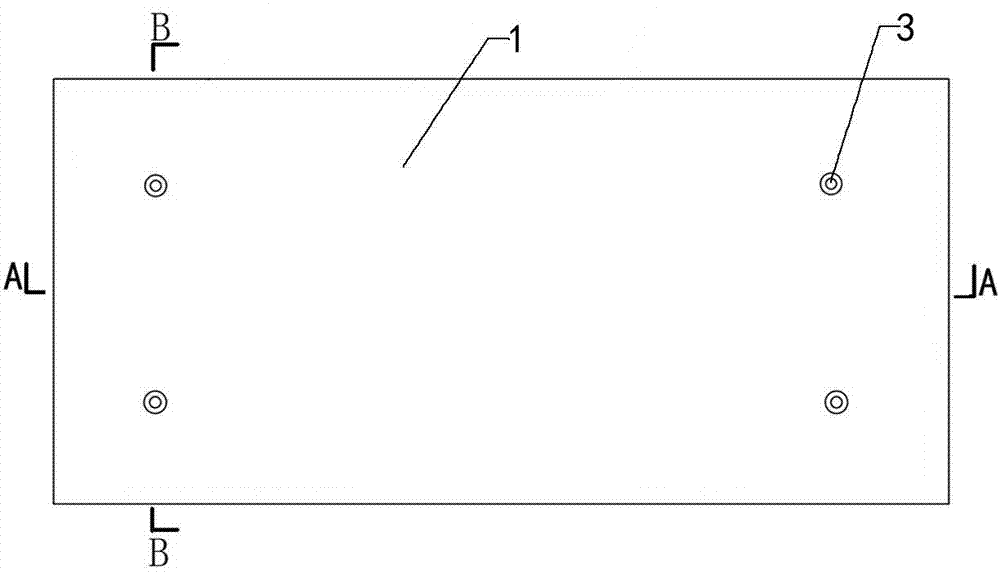

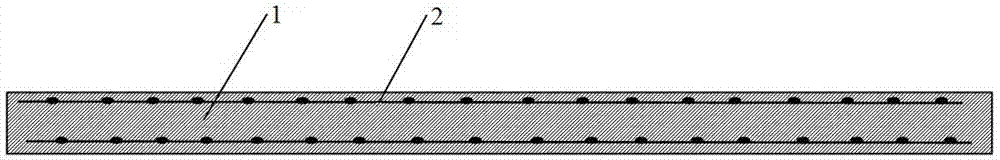

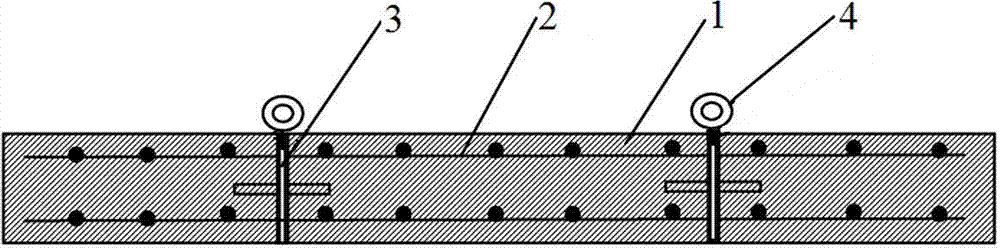

[0044] Such as Figure 1 ~ Figure 3 , an assembled reactive powder concrete non-reinforced prefabricated road slab, including a road slab body 1, characterized in that: the inside of the road slab body 1, and a layer of horizontal steel wire mesh 2 are respectively laid on the upper and lower bottom surfaces of the slab body; The four corners of the road slab body 1 are respectively pre-embedded with a hoisting embedded part 3 vertical to the upper and lower bottom surfaces. The hoisting embedded part 3 is an internally threaded casing 31 covered with a stopper 32, and the stopper 32 is located at The middle of the upper and lower layers of horizontal steel wire mesh 2 is used to clamp the internally threaded casing 31. It can be an anchor plate arranged horizontally with a reserved hole for the casing in the middle, or it can be welded to the circular r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com