High performance fireproof magnesite board and manufacturing process thereof

A manufacturing process, magnesite board technology, applied in the direction of fire prevention, hydraulic material layered products, building components, etc., can solve problems such as poor bending resistance, shearing and impact resistance, difficulty, and failure to meet market demand. , to achieve the effect of strong bending resistance, wide range of use, and meet the needs of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

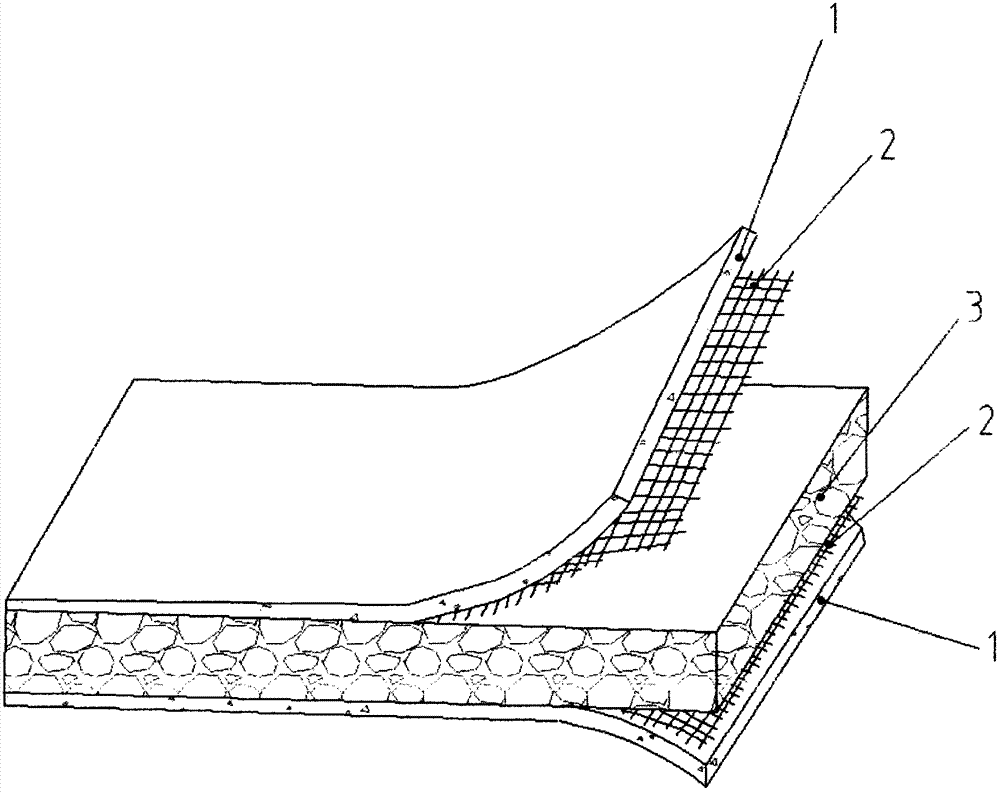

[0016] The high-performance fireproof magnesite board described in the embodiments of the present invention is mainly composed of magnesium oxide, magnesium chloride, wood bran, vermiculite, glass fiber mesh, talcum powder, perlite and water. The weight of the various raw materials The percentages are: Magnesium Oxide: 48.8%, Magnesium Chloride: 20.7%, Wood Bran: 1%, Vermiculite: 1.4%, Fiberglass Mesh: 2.0%, Talc: 4%, Water: 21.2%, Perlite: 0.9% , or the weight percentages of various raw materials are: magnesium oxide: 48%, magnesium chloride: 21.2%, wood bran: 0.9%, vermiculite: 1.3%, glass fiber mesh: 2.1%, talcum powder: 4.2%, water: 21 %, Perlite: 1%.

[0017] The manufacturing process of the high-performance fireproof magnesite board includes stirring, pouring and roll forming, curing and curing, trimming, sanding, inspection and packaging.

[0018] The concrete process of described stirring is:

[0019] 1) The percentage by weight of each raw material is: magnesium oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com