Semi-hollow pile having drainage and skid resistance effects and construction method of semi-hollow pile

A semi-hollow, functional technology, applied in the direction of sheet pile walls, soil protection, foundation structure engineering, etc., can solve the problems of clogged drainage pipes, poor shear and flexural strength, and affect the drainage effect, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

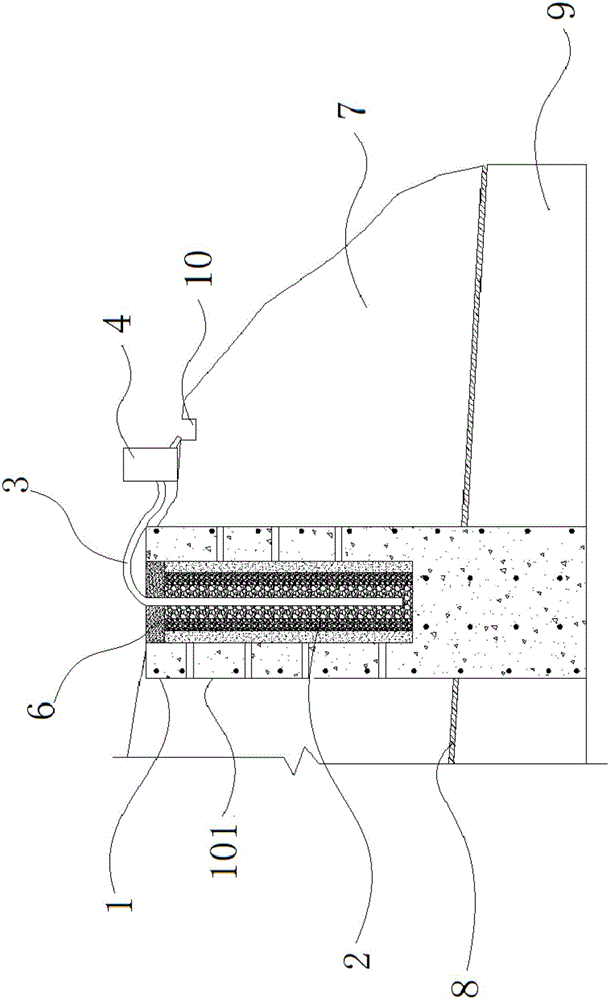

[0040] This embodiment discloses a semi-hollow pile with drainage and anti-slide function, including a prefabricated reinforced concrete semi-hollow pile 1 and a siphon 3 implanted in a landslide body 7 .

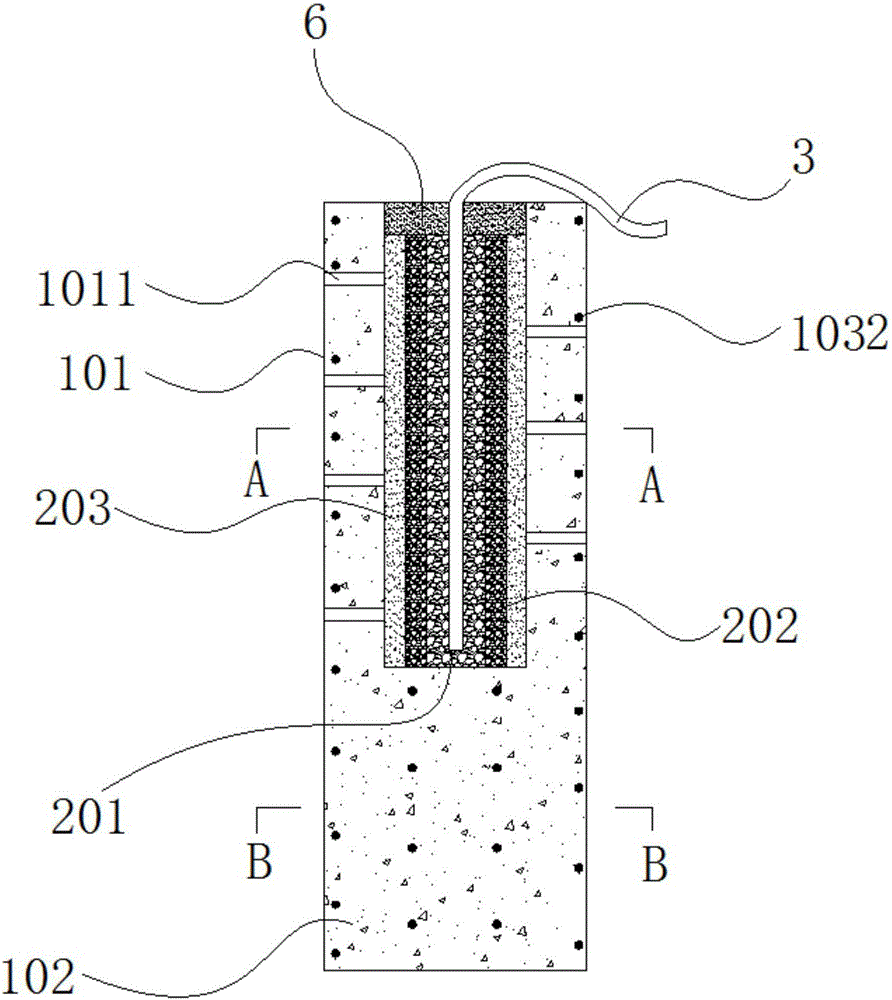

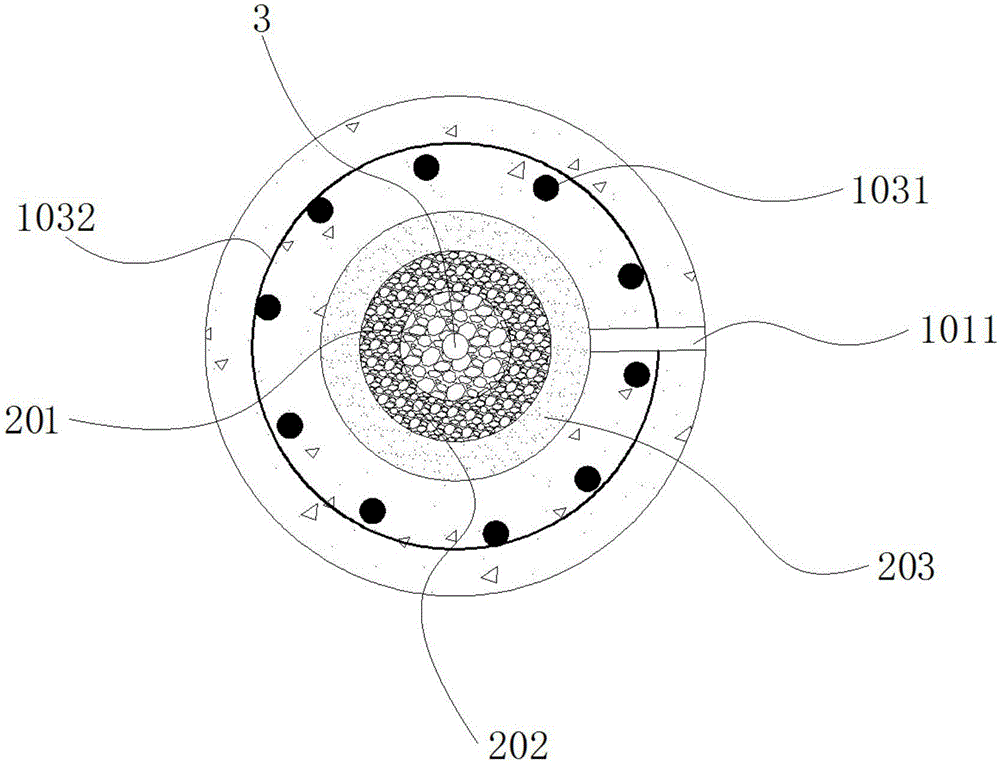

[0041] see figure 2 , image 3 and Figure 4 , the prefabricated reinforced concrete semi-hollow pile 1 includes a hollow pipe pile 101 and a solid cylindrical pile 102 . The solid cylindrical pile 102 is disposed at the bottom of the hollow pipe pile 101 . The hollow pipe pile 101 and the solid cylindrical pile 102 are integrated. The prefabricated reinforced concrete semi-hollow pile 1 has the main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body. The main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body together form a reinforcement cage 103 .

[0042] see figure 1 , after the solid cylindrical pile 102 passes through the sliding surface 8, it is embedded in the stable bedrock 9 below. The height of ...

Embodiment 2

[0048]This embodiment discloses a construction method of the semi-hollow pile with drainage and anti-sliding effect described in Embodiment 1, comprising the following steps:

[0049] 1) Manufacture the prefabricated reinforced concrete semi-hollow pile 1 according to the designed pile diameter and pile length, and reserve the water collection hole 1011.

[0050] 2) Excavate the pile hole to the design depth. Wherein, the diameter of the pile hole is larger than that of the pile body.

[0051] 3) Lift the prefabricated reinforced concrete semi-hollow pile 1, align the pile position, adjust the verticality of the prefabricated reinforced concrete semi-hollow pile 1, and then put the prefabricated reinforced concrete semi-hollow pile 1 into the pile hole to the design elevation.

[0052] 4) Thin-walled casings with different diameters are used to construct the fine sand layer 203 , the medium-coarse sand layer 202 and the gravel layer 201 in layers, and the siphon pipe 3 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com