Patents

Literature

117results about How to "Meet the market demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

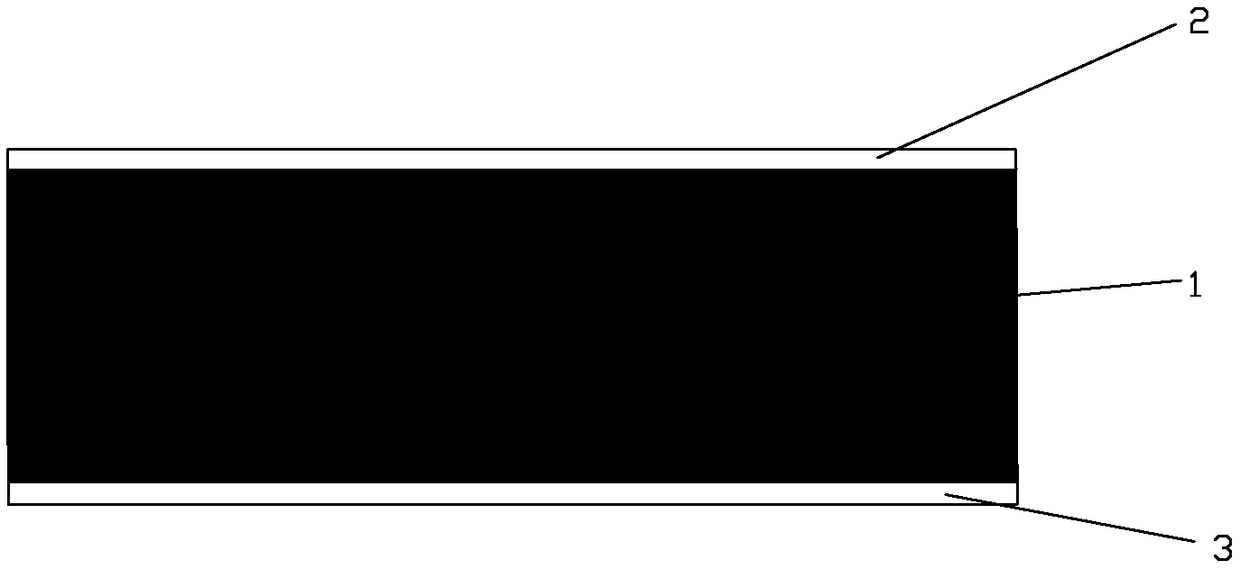

High performance fireproof magnesite board and manufacturing process thereof

InactiveCN102731058AStrong bending resistanceStrong shear resistanceWater-setting substance layered productFire proofingShock resistanceFire prevention

The invention relates to a high performance fireproof magnesite board which comprises magnesium oxide, magnesium chloride, sawdust, vermiculite, glass fiber sieve cloth, talcum powder, pearlite and water. The manufacturing process of the high performance fireproof magnesite board comprises the steps of agitating, pouring, rolling and forming, maintaining and curing, edge cutting, sanding, and inspecting and packaging. The specific process of agitating comprises 1) preparing raw materials by weight percentage; 2) setting the agitating time; and 3) adding magnesium chloride, vermiculite, glass fiber sieve cloth, talcum powder, magnesium oxide, sawdust and glue into purified water; adding pearlite at 2 minutes of countdown and discharging. The invention has the beneficial effects that the high performance fireproof magnesite board has the advantages of strong resistance to deflection, shear-resistance, shock resistance, fire prevention, no smoke spreading, no deformation after being dipped into water, moth-prevention, and mildew prevention.

Owner:台山先驱建材有限公司

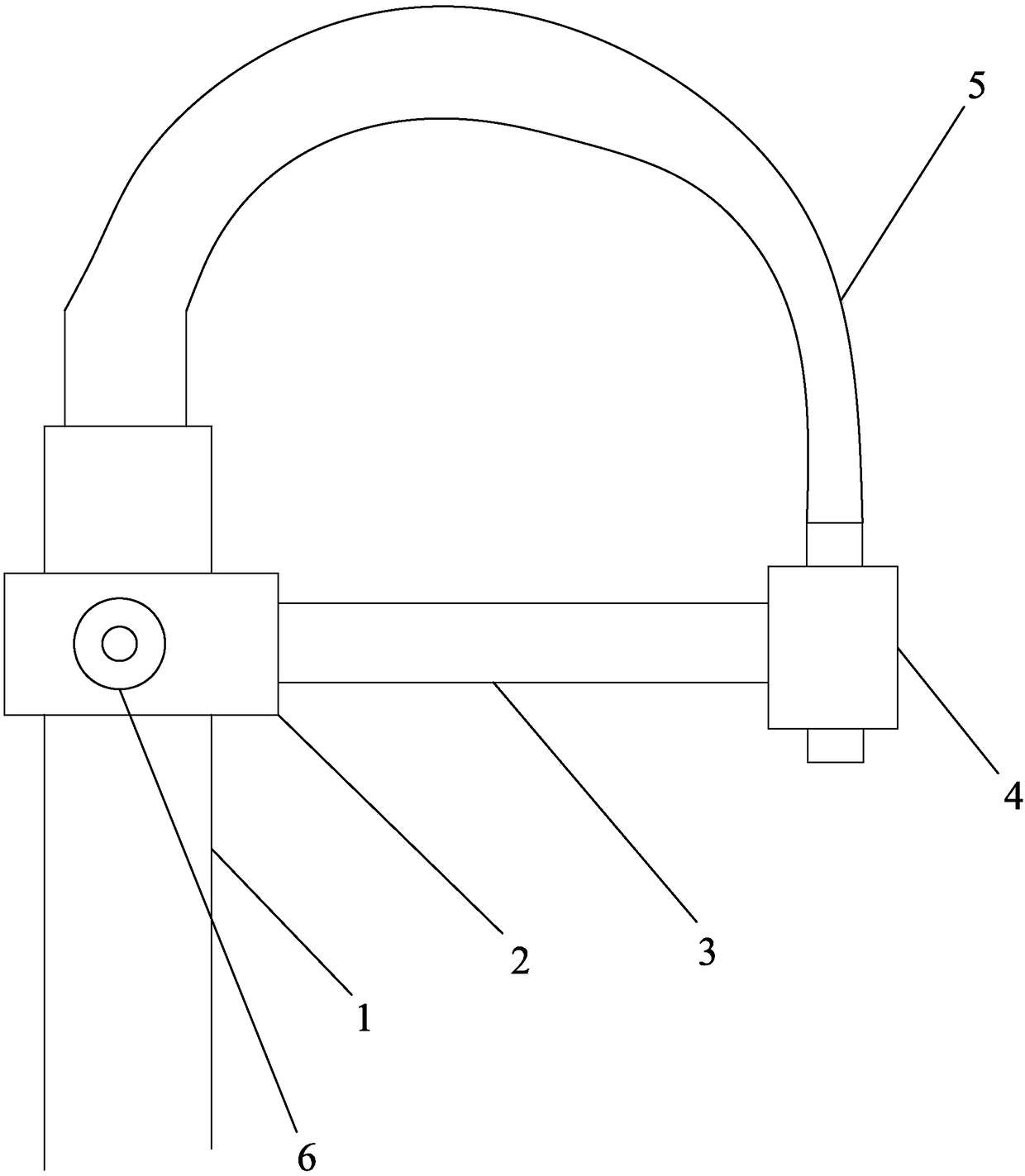

Water faucet with adjustable height

InactiveCN109340429AHeight adjustableSimple structural designValve housingsWater sourceWater resources

The invention discloses a water faucet with the adjustable height. The water faucet with the adjustable height comprises a stainless steel water pipe, a cross frame, a flexible pipe, a lifting seat and a faucet, wherein the upper part of the stainless steel water pipe is fixed to one end of the cross frame; the other end of the cross frame is fixed to the lifting seat; the faucet is fixed into thelifting seat in a height adjustable way; a faucet channel is arranged in the faucet; the upper end of the faucet is fixed to one end of the flexible pipe in the way of sealed communicating with the faucet channel; and the other end of the flexible pipe is in sealed connection to the upper end of the stainless steel water pipe. The water faucet with the adjustable height is simple in structure design and convenient to use; and the height of the faucet can be adjusted, and a water source is prevented from spilling, so that the water resource is saved, and the water faucet meets the market use demand and is beneficial to product popularization.

Owner:开平市澳林卫浴有限公司

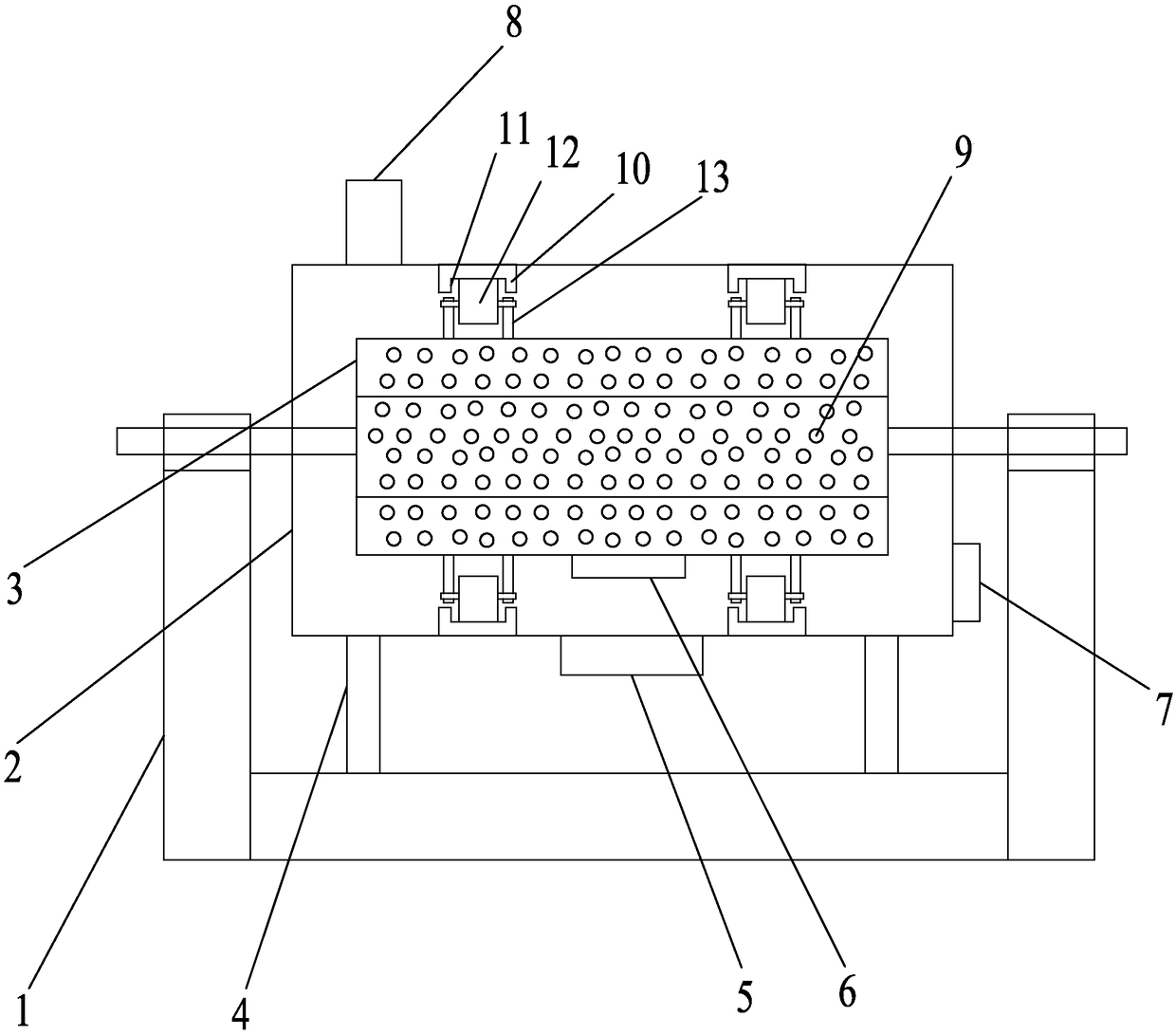

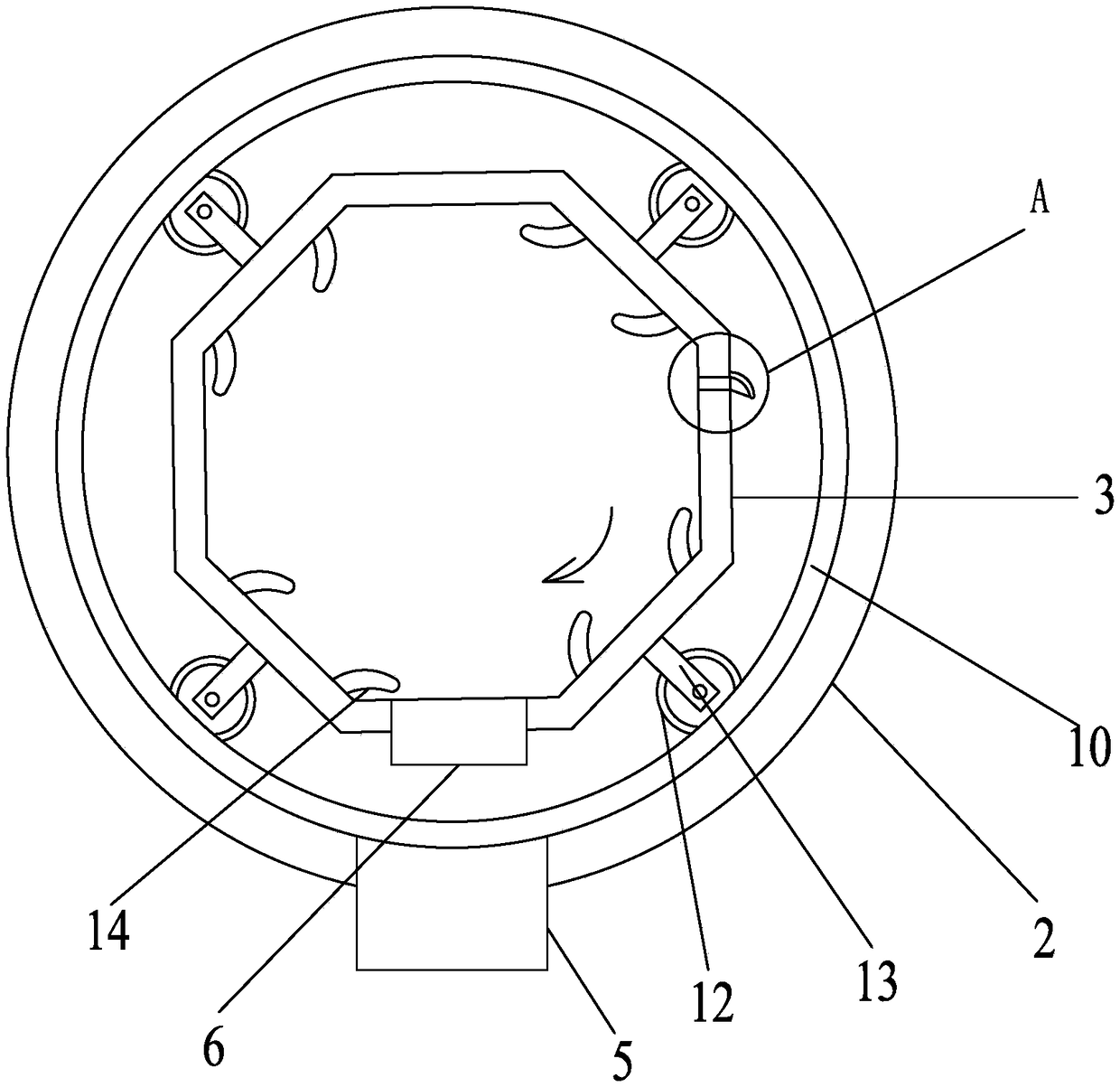

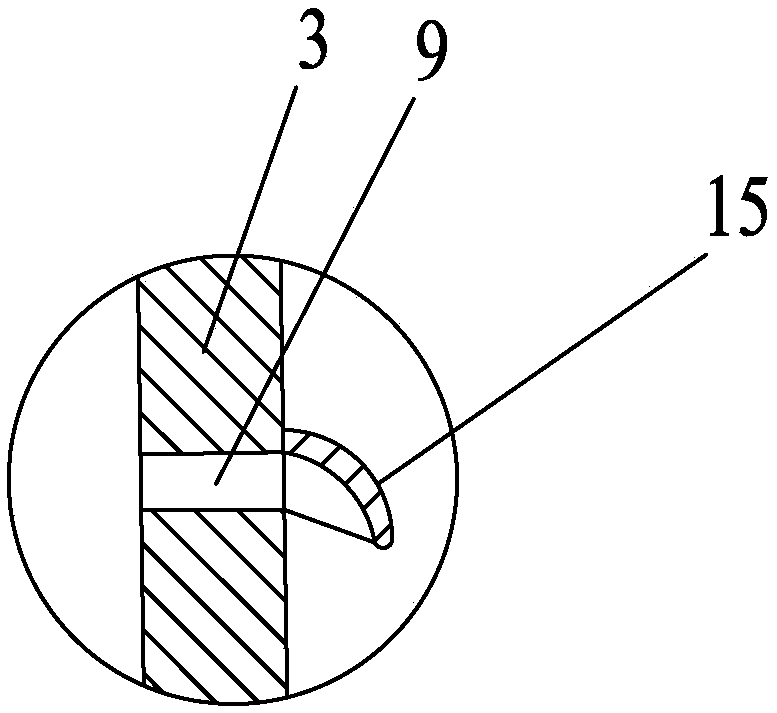

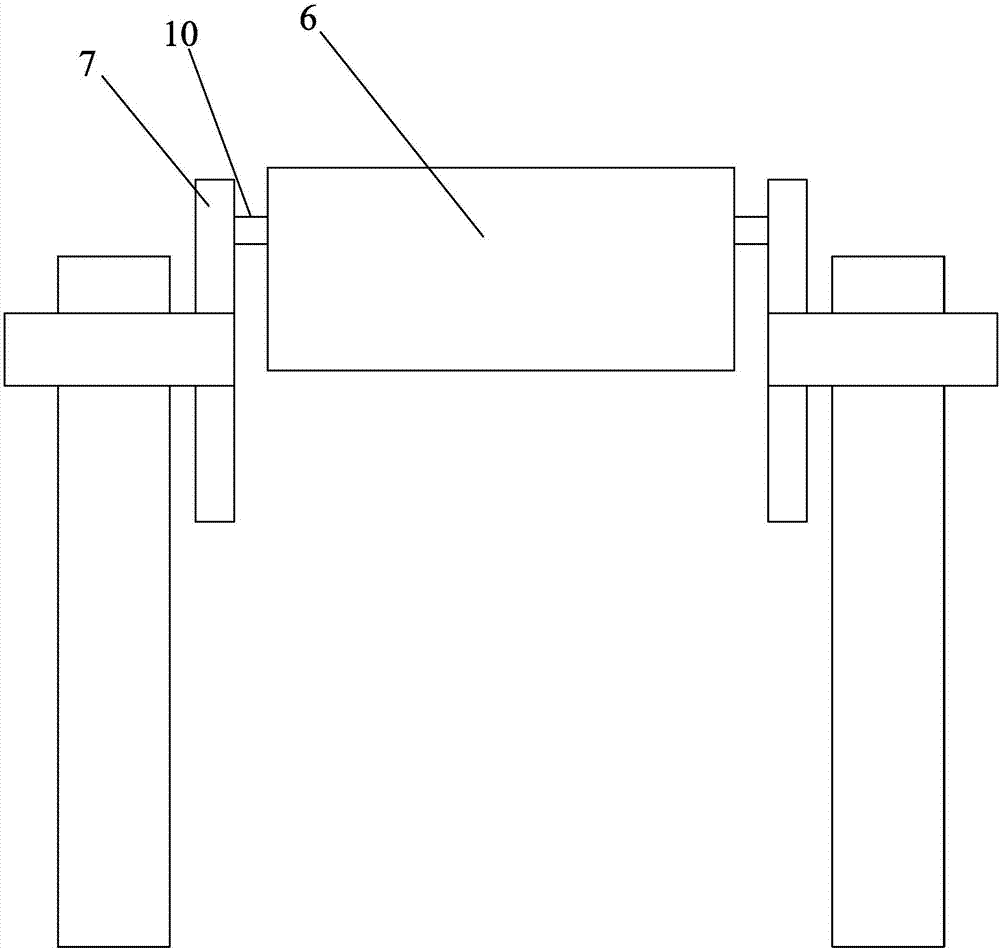

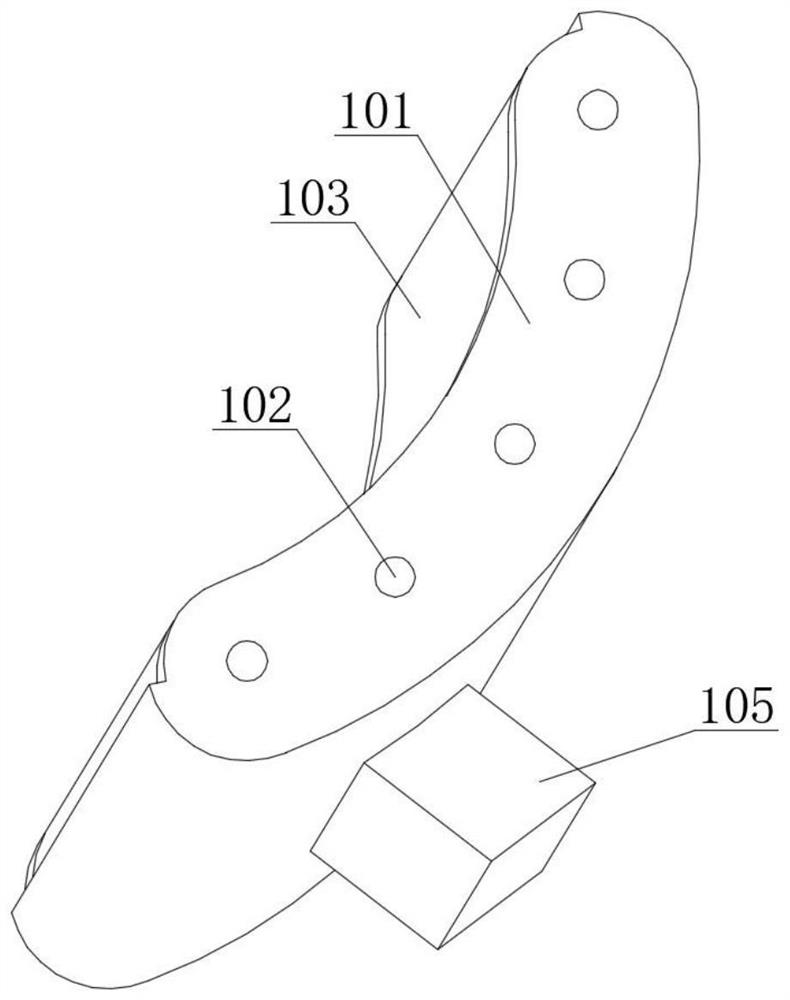

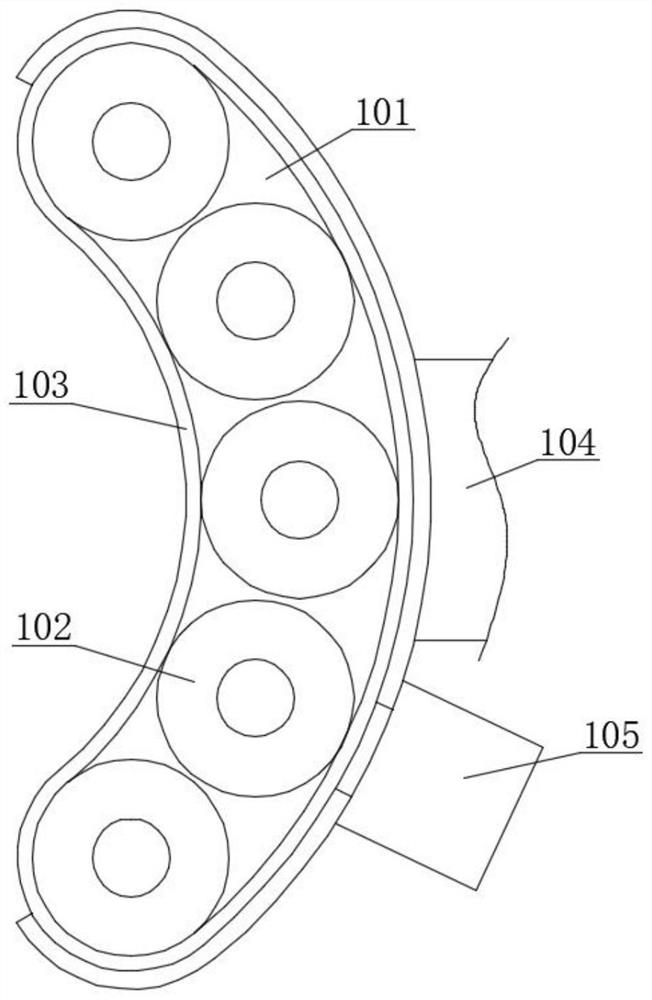

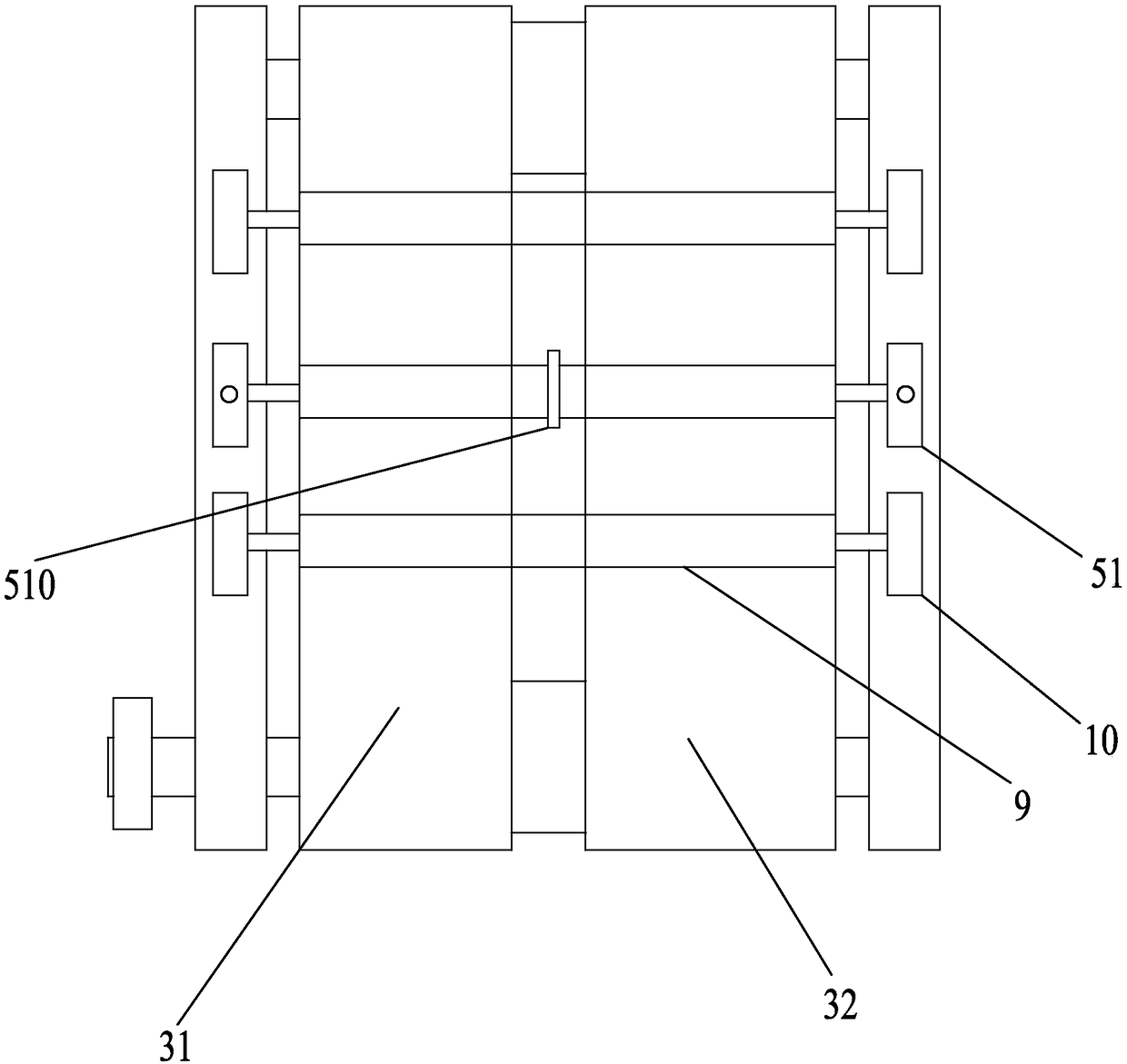

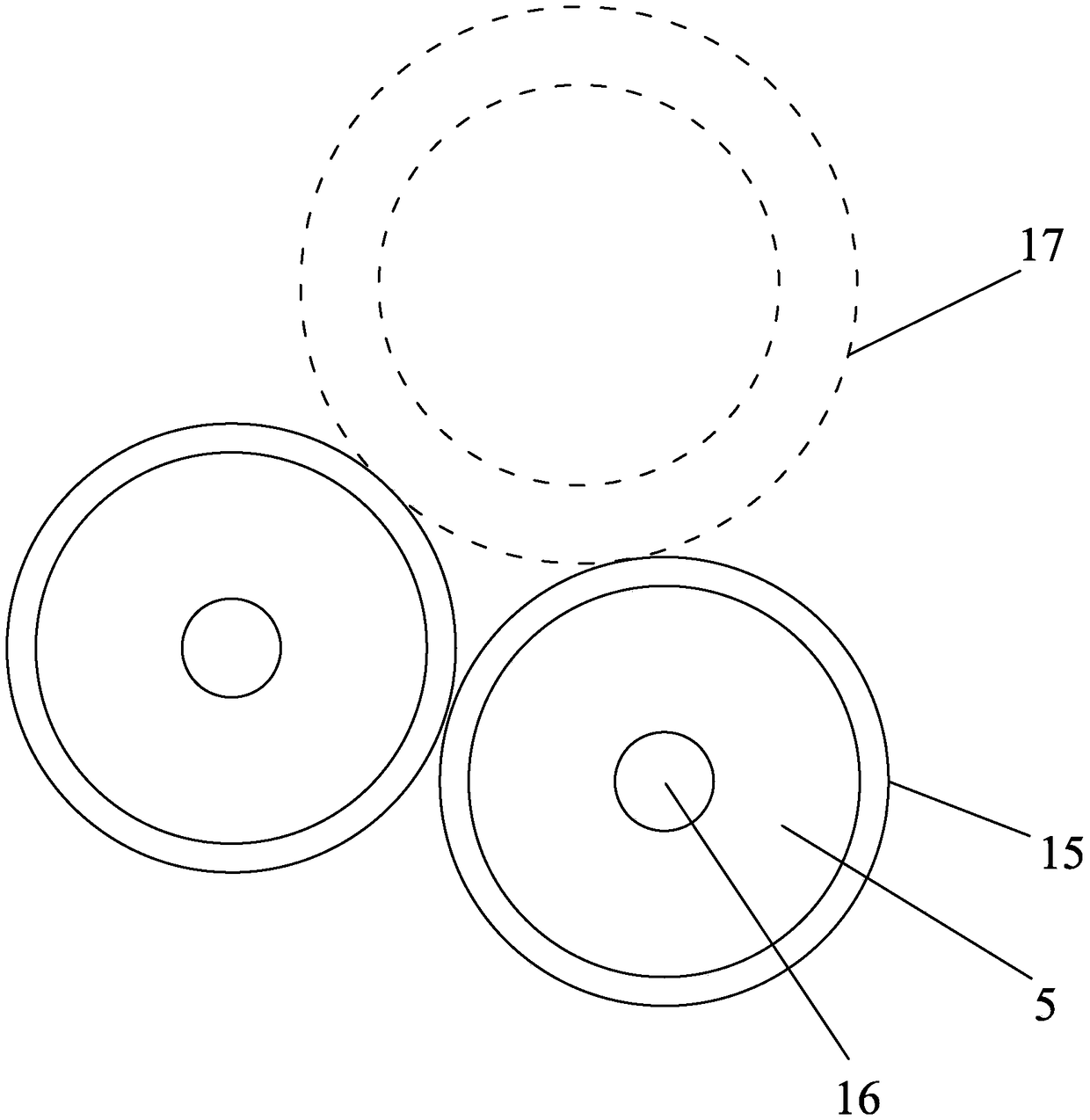

Leather softening device

PendingCN109234470ASimple structural designEasy to useLeather softeningEngineeringInternal temperature

The invention discloses a leather softening device. The leather softening device comprises two side frames, an outer barrel, an inner rotating drum, two or more support seats, wheels and wheel supports; rotating shafts at two ends of the inner rotating drum are respectively sleeved with the top ends of the side frames, arranged side by side, through bearing components; the rotating shaft at one end of the inner rotating drum is connected to a motor through a synchronous belt, and is used for driving the inner rotating drum to rotate; the cross section of the inner rotating drum is polygonal; the outer barrel is arranged outside the inner rotating drum; a gap is formed between the outer barrel and the inner rotating drum; the support seats are arranged on the inner wall of the outer barrelside by side; four or more wheels are evenly distributed on each support seat and opposite to the outer wall of the inner rotating drum, and the wheels are rotatably fixed to the outer wall of the inner rotating drum through the wheel supports. The leather softening device has the advantages that a support structure is arranged on the outer wall of the inner rotating drum, and accordingly, the stability is improved, and the service life is prolonged; meanwhile, through the design of an exhaust structure, hot air is exhausted through an exhaust pipe, so that sticky leather caused by the ultrahigh internal temperature of the inner rotating drum is avoided.

Owner:开平市才文龙鞋业有限公司

High-strength corrugated paper processing method

PendingCN109703109AHigh strengthIncreased burst indexMechanical working/deformationReinforcing agents additionPulp and paper industryUltimate tensile strength

The invention discloses a high-strength corrugated paper processing method comprising the following step I of preparing base paper pulp; the step II of adding reinforcing agents to the base paper pulp; the step III of performing heat treatment to base paper; the step IV of performing sizing treatment to the surface of the base paper; the step V of compounding the base paper through a corrugating machine to obtain corrugated paper; the step VI of performing cooling treatment after drying to obtain the high-strength corrugated paper. According to the processing method, the burst index and the ring crush index of the corrugated paper are improved, so that the corrugated paper is higher in strength, and the service life of a corrugated box is prolonged; and the market use requirements are met,and the promotion of products is benefited.

Owner:国腾彩色纸品(鹤山)有限公司

LED sign board

The invention discloses anLED sign board. The board comprises a display board, a vertical side support, a transverse side support, a lamp bar, an LED chip and a base which is connected on a wall in alocking mode, the lamp bar is connected on the base in a locking mode, and the LED chip is arranged on the lamp bar; the lower side and the upper side of the base are connected with the transverse side support in a sandwiched mode, the two ends of the transverse side support are connected with the vertical side support in a fastening mode, and the outer ends of the vertical side support and the transverse side support are connected with the display board in a sandwiched mode. The structure of the LED sign board is simple in design and convenient to use, install and disassemble, electric energyis saved, the usage cost is reduced, the maintenance efficiency is improved, manpower consumption is reduced, market usage demands are met, and product popularization is facilitated.

Owner:方步雄

Silicon-cored pipe production technology

InactiveCN105566935AHigh tensile strengthHigh elongation at breakEngineeringUltimate tensile strength

The invention provides a silicon-cored pipe production technology. The technology comprises the following steps: 1, selecting and proportioning 100 parts by weight of a special material for silicon-cored pipes, 40-60 parts by weight of high density polyethylene, 15-20 parts by weight of a metallocene modified master batch, 3.5 parts by weight of a black master batch and 4 parts of an antioxidant master batch; 2, synchronously extruding and compounding above materials through three extruders; 3, carrying out vacuum cooling shaping: cooling and shaping extruded and compounded pipes through a vacuum refrigerator and an immersion cooling water box; 4, carrying out meter counting printing to make the length of every silicon-cored pipe coil be 2000-3000m; and 5, pulling and reeling the silicon-cored pipe coil to obtain the finished silicon-cored pipes to be sold and used. The silicon-cored pipes produced through the technology have high tensile strength and good elongation at break, and can well meet market use demands.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

Treatment method for velboa

InactiveCN107780208ASimple processGood flexibilityFibre treatmentRoom temperatureOperational approach

The invention discloses a treatment method for velboa. The treatment method for the velboa comprises the following steps: firstly, weighing all the raw materials in parts by mass: secondly, mixing allthe raw materials, stirring for 5-15 minutes at room temperature, and naturally placing for 30-60 minutes, so that impregnation liquid is obtained; thirdly, soaking the velboa into the impregnation liquid for 2-5 hours; fourthly, putting the soaked velboa on a setting machine to be subjected to setting, wherein setting temperature is 60-80 DEG C, and setting time is 10-15 minutes; and fifthly, putting the velboa subjected to the setting in a drying oven to be dried, wherein drying temperature is 100-120 DEG C, and drying time is 10-30 minutes. The treatment method disclosed by the invention has simple technology and operational approach, the treated product has the characteristics of softness and good heat retention property and also has the characteristics of good handfeel and high comfort level, market usage requirements are met, and popularization of the product is facilitated.

Owner:鹤山弘扬制衣有限公司

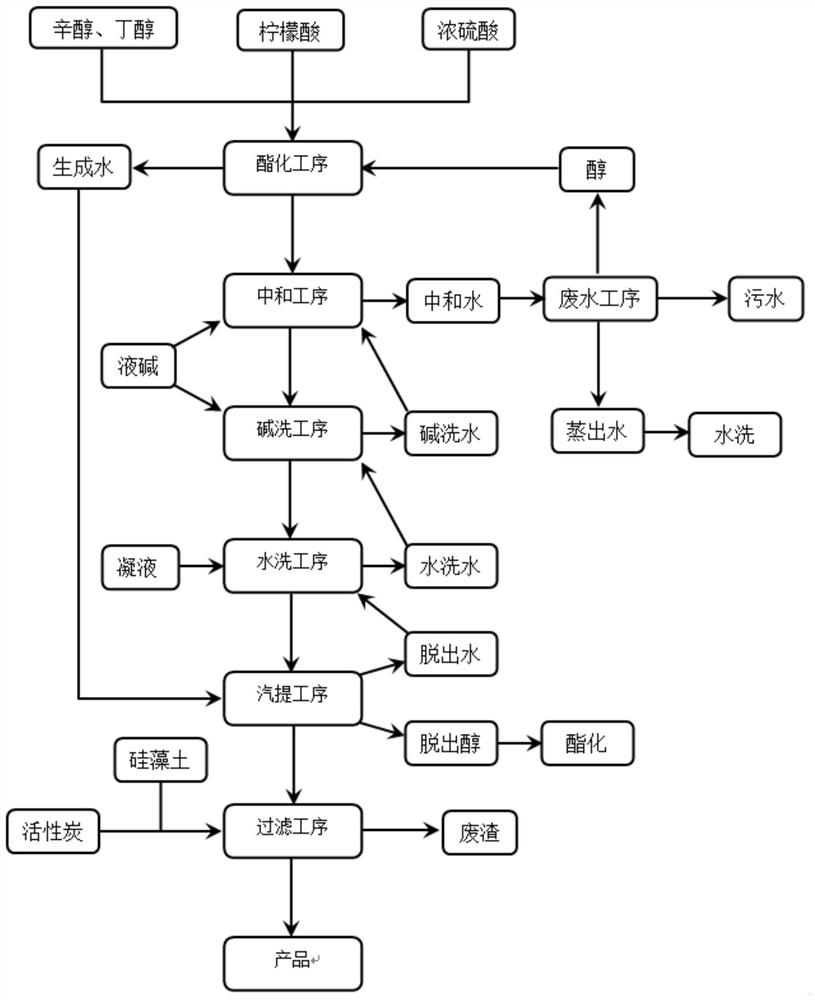

Citric acid mixed ester production method

PendingCN112209824ANo precipitationHigh activityOrganic compound preparationCarboxylic acid esters separation/purificationTRICAPRYLYL CITRATEPtru catalyst

The present invention relates to the technical field of plasticizers, and discloses a citric acid mixed ester production method, which comprises the steps of: an esterification process; a neutralizingand washing process; a steam stripping process; and a filtration process. According to the citric acid mixed ester production method, concentrated sulfuric acid is adopted as a catalyst, the catalystactivity is high, the reaction temperature is low, the reaction speed is high, the catalyst cost is low, the esterification synthesis temperature is controlled within 145 DEG C, it is ensured that the color number of the produced mixed citrate product is within 45, the market use requirement is met, and by adjusting the added butanol according to the market requirement, tetrabutyl citrate, dibutyl-octyl citrate, monobutyl dioctyl citrate and trioctyl citrate in different proportions can be obtained according to the octanol proportion, it is ensured that the produced citric acid mixed ester does not have the phenomena of precipitation and oil seepage in the using process, meanwhile, the using requirements of production of different customers are met, an intermittent esterification processis adopted, the operation elasticity is high, the strain capacity is high, and market requirements can be met.

Owner:山东朗晖石油化学股份有限公司

Screen type cleaning mechanism for beautiful millettia roots

InactiveCN107470240ASimple structural designStructural Design ScienceSievingScreeningEngineeringMechanical engineering

The invention discloses a screen-type cattle cleaning mechanism, which includes a water tank, a nozzle, a cleaning pipe, a screen, and an eccentric wheel. The upper side of the water tank is provided with a screen, and the four corners of the screen are respectively axially connected to the eccentric wheel. Near the edge, the shaft of the eccentric wheel is connected to the bracket, and through the rotation of the eccentric wheel, the screen connected to the shaft on the eccentric wheel is driven to move up and down; a cleaning pipe is provided on the upper side of the screen, and a nozzle is provided on the cleaning pipe, and the spray nozzle is sprayed through the nozzle. Water, and then clean the cattle in the screen. Its structural design is simple and scientific, easy to use, reduces manpower, saves human resources, reduces costs, has high cleaning efficiency and high speed, meets the needs of the market, and is conducive to product promotion.

Owner:广东柏丽源美妆科技有限公司

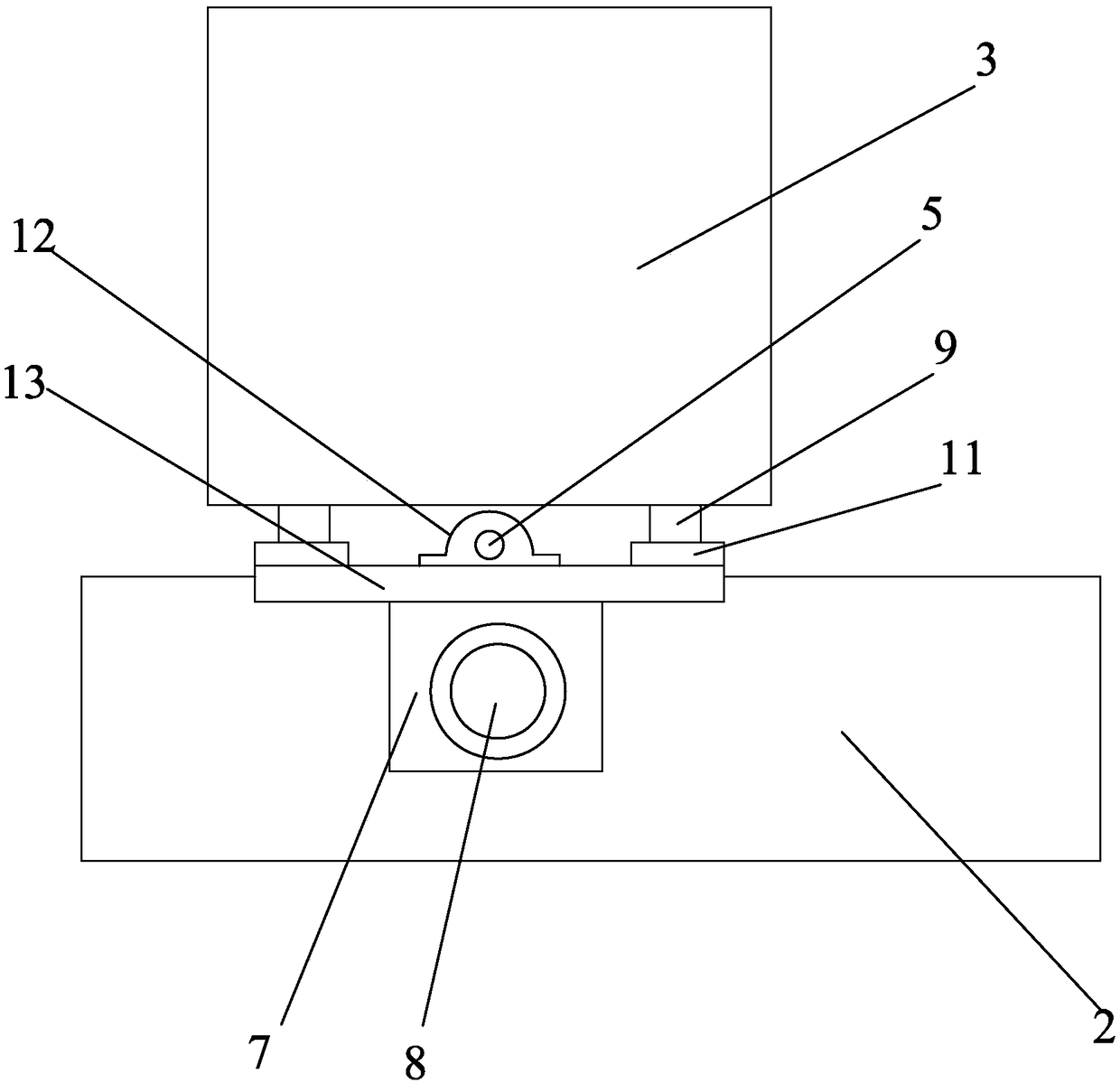

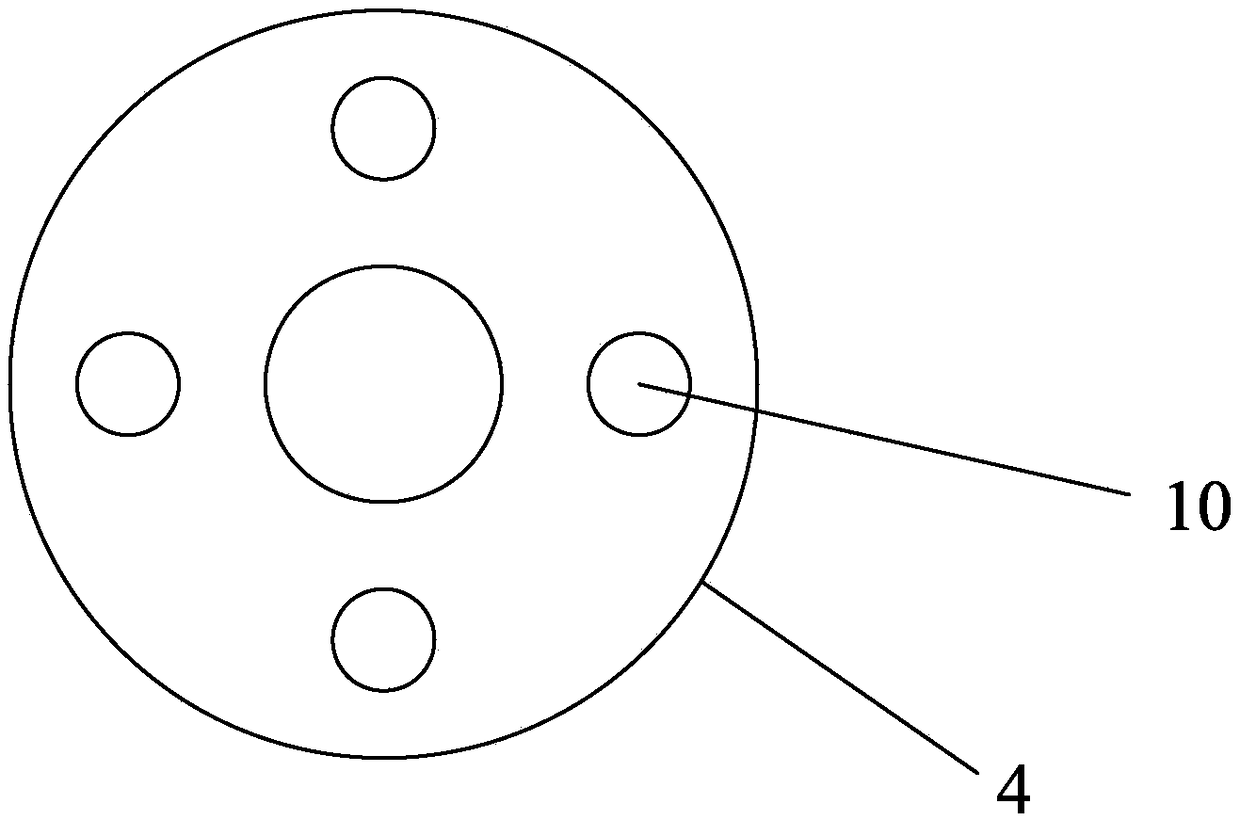

Titanium steel flange casting machining equipment and machining process thereof

ActiveCN114800096AHigh degree of automationImprove processing efficiencyEdge grinding machinesGrinding drivesMachining processIndustrial engineering

The invention discloses titanium steel flange casting machining equipment and a machining process thereof, and belongs to the technical field of titanium steel flange casting machining. The titanium steel flange casting machining equipment comprises a feeding barrel, the left side of the feeding barrel is fixedly connected with a machining barrel communicating with the feeding barrel, and a first electric push rod is fixedly installed on the inner top wall of the machining barrel; an output shaft of the first electric push rod is fixedly connected with an annular mounting block, and the bottom of the annular mounting block is connected with an annular grinding piece. The machining postures, such as double-face overturning and casting vertical states, of the pre-machined casting can be adjusted, comprehensive grinding machining is conducted on the outer surface of the pre-machined casting in cooperation with the annular grinding pieces, and compared with a traditional grinding machining mode, the automation degree is higher, the machining efficiency is higher, and the grinding and polishing precision is more accurate; and automation is guaranteed, meanwhile, machining equipment is more compact, a plurality of machining equipment bodies can be arranged at the same time to work, and the market use requirement is met.

Owner:WENZHOU FUTONG PIPE FITTINGS MFG

Waste gas treatment technology

InactiveCN108970311AImprove processing efficiencyEmission reductionHuman health protectionCombination devicesDecompositionSpray tower

The invention discloses a waste gas treatment technology. The waste gas treatment technology is characterized by carrying out dust removal treatment by collecting a waste gas through a collection pipeline and conveying the waste gas to a cyclone dust remover; uniformly feeding the waste gas of which the temperature is 35 to 40 DEG C and the pressure is 4000 to 12000 Pa into a heat accumulation chamber through a gas distributor, and absorbing heat accumulated in a heat accumulator in the heat accumulation chamber by the waste gas; heating the temperature of the waste gas to be higher than the temperature of a decomposition point of an organic matter in the waste gas, then introducing the waste gas from an air pipe into a purifying tower, enabling the waste gas to pass through a filler layer, and carrying out gas-liquid two-phase sufficient contact absorption reaction on the waste gas and absorption liquid; dewatering and demisting through a demisting plate after purifying the waste gas,and then discharging the waste gas by a draught fan; downwards spraying the absorption liquid from the tower top after being pressurized by a water pump at the tower bottom, and finally refluxing tothe tower bottom for recycling; then enabling the absorption liquid to pass through a spraying tower, spraying water through the water pump, and carrying out UV (Ultraviolet) photolysis purification treatment after adhering most of organic matters and dust to water, and discharging a small amount of organic waste gas.

Owner:安徽正马环境工程有限公司

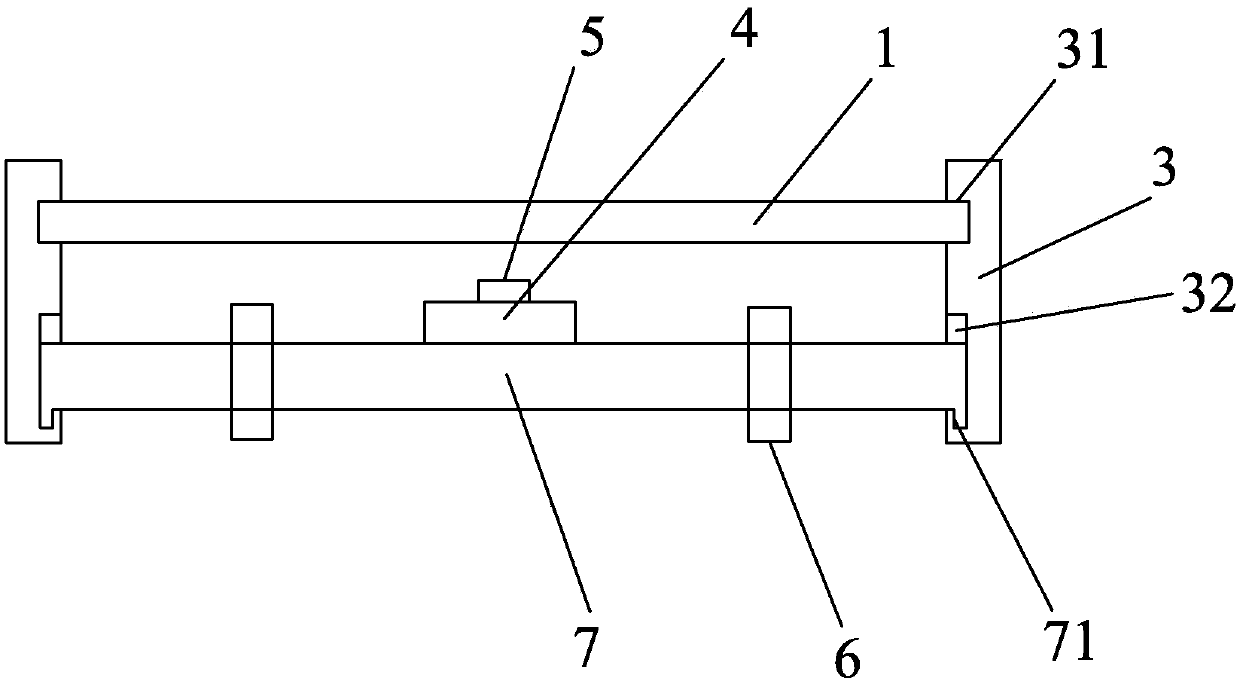

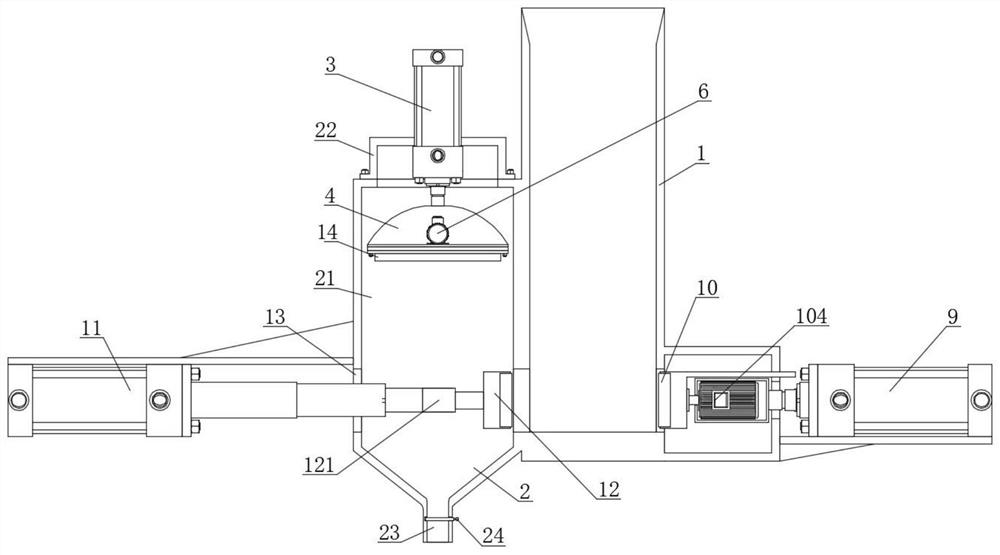

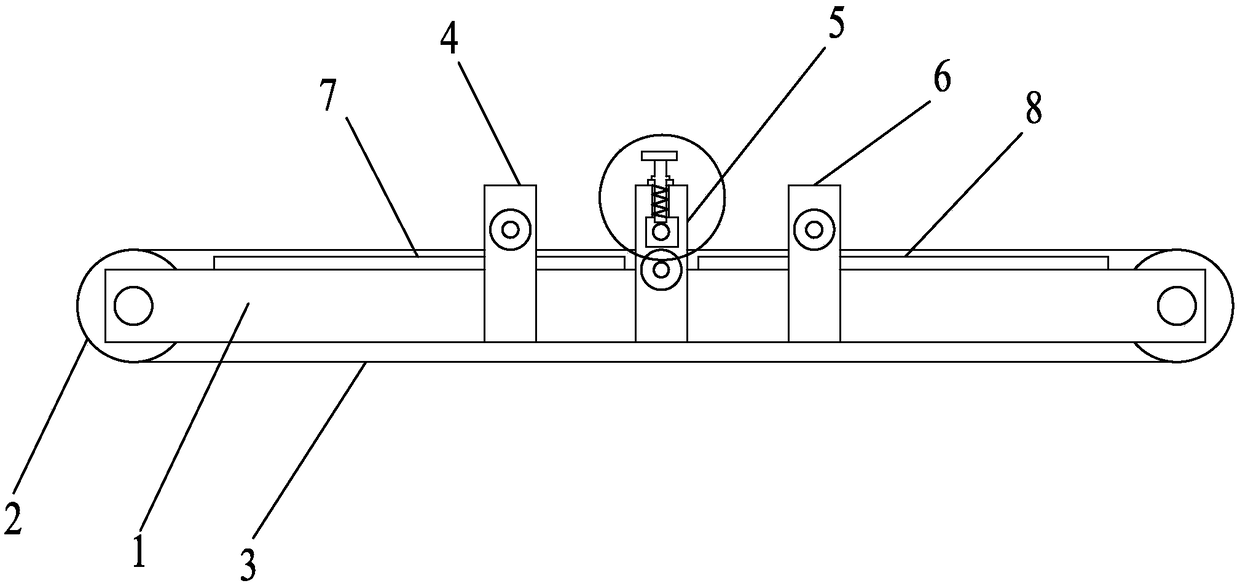

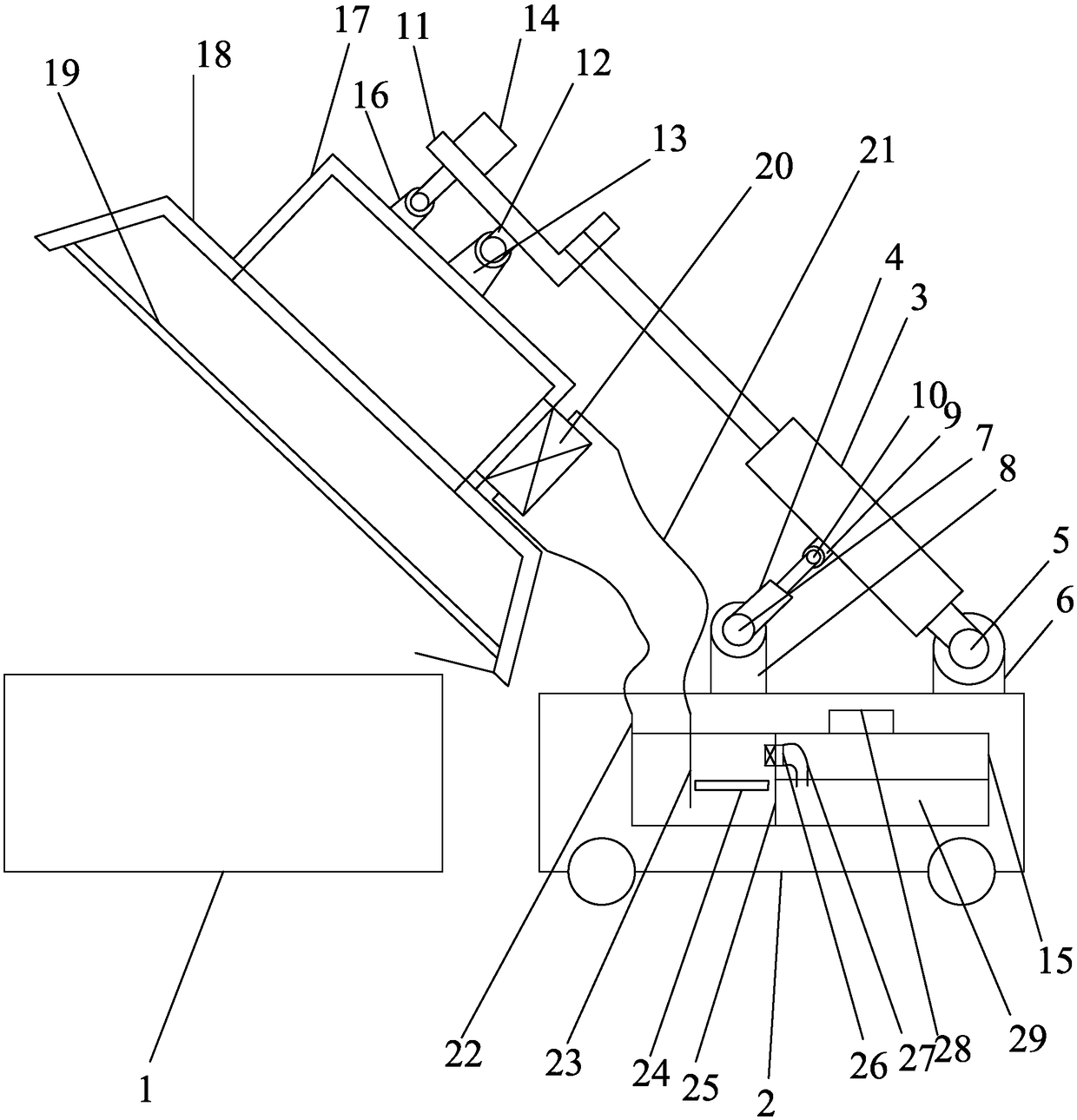

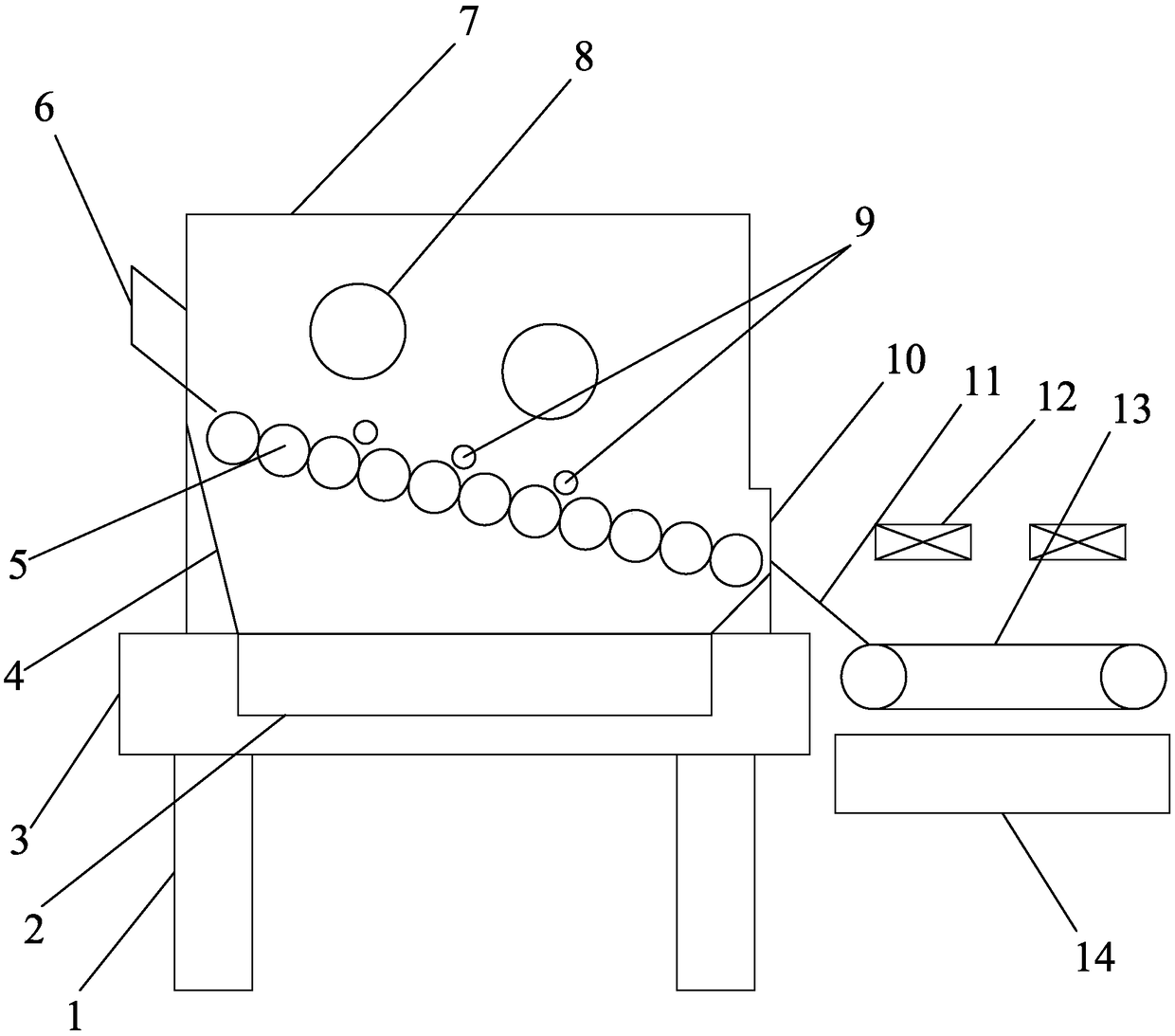

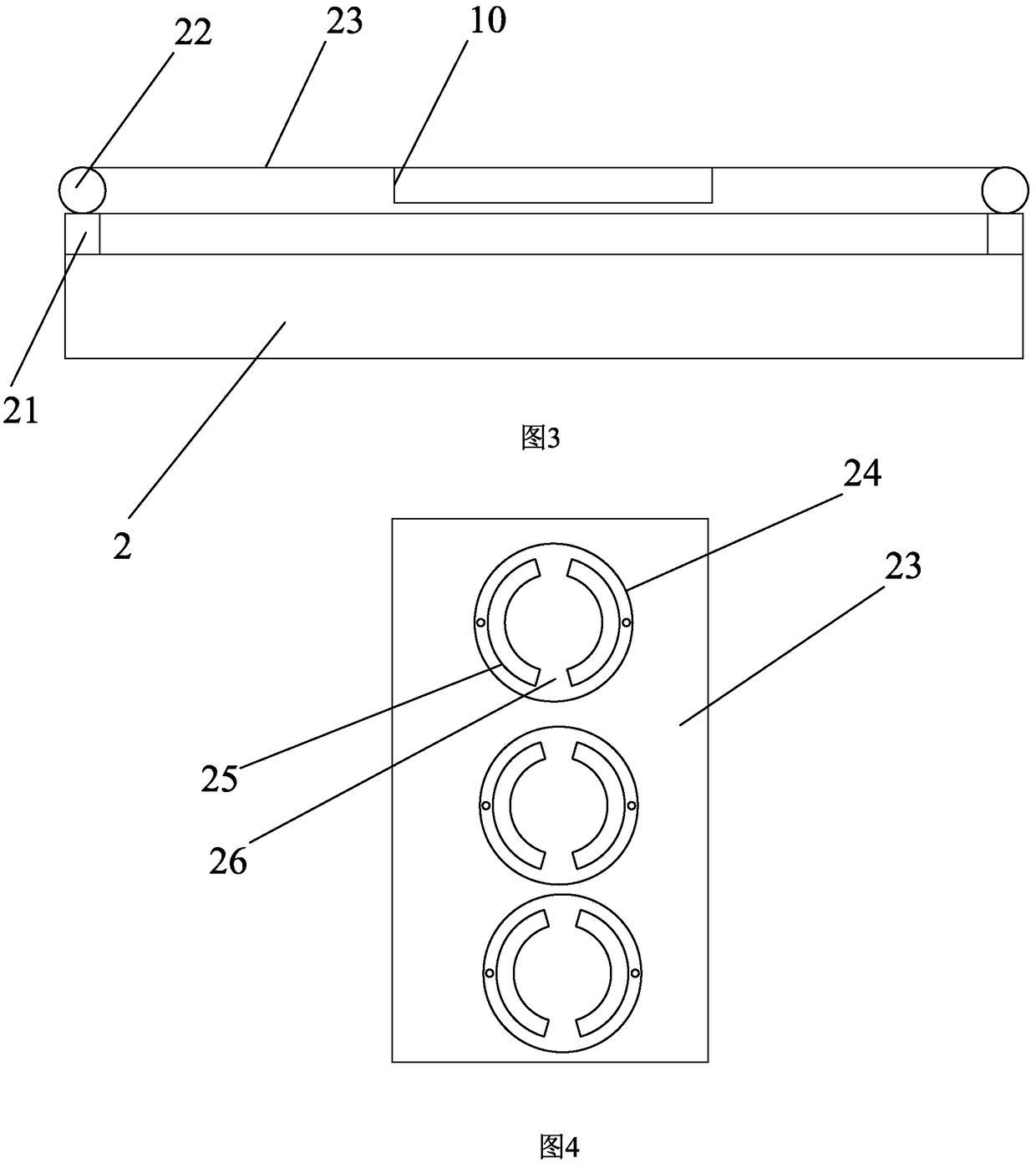

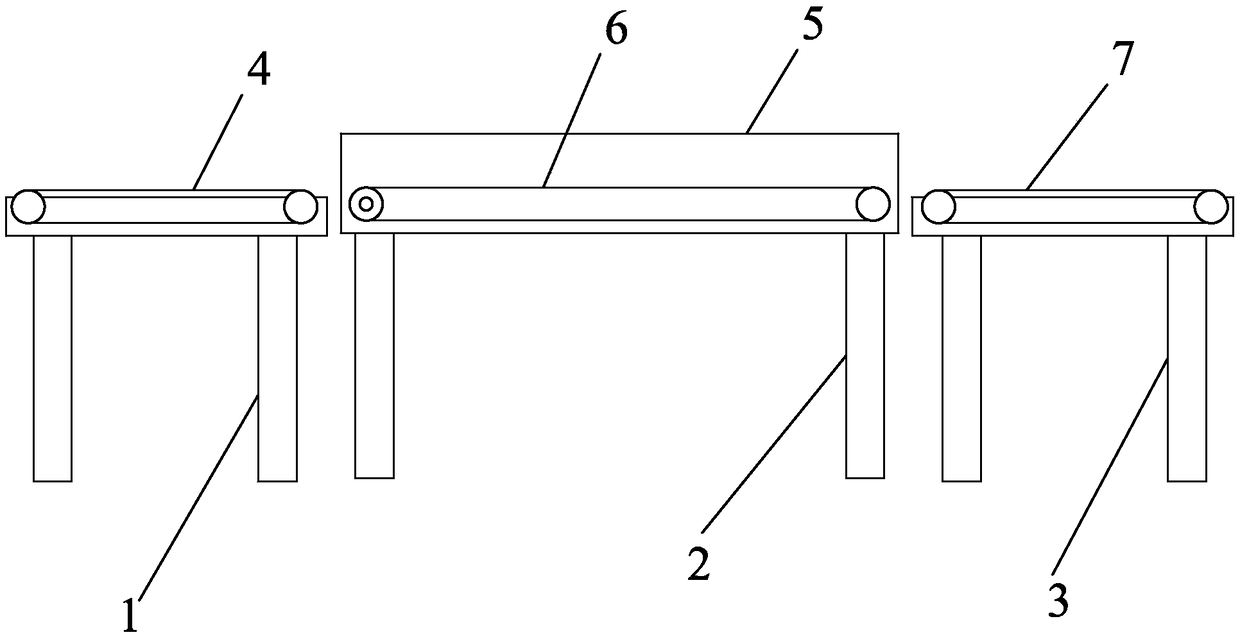

Leather splitting device

InactiveCN109234474ASimple structural designEasy to useLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringConveyor belt

The invention discloses a leather splitting device. The leather splitting device comprises a frame, wheels, a conveyor belt and a splitting mechanism; the wheels are fixed to two ends of the frame, and the wheels are sleeved with the conveyor belt; the splitting mechanism horizontally arranged on the frame comprises two splitting side frames, a lower splitting shaft and an upper splitting shaft; the splitting side frames are oppositely fixed to the frame, and the upper splitting shaft and the lower splitting shaft are vertically arranged between the splitting side frames side by side; a synchronously rotating splitting cutter is arranged on the upper splitting shaft; a splitting groove is formed in the lower splitting shaft and opposite to the splitting cutter. The leather splitting devicehas the advantages of simple structural design, convenience in use, automatic splitting, high efficiency, reduced labor, low production cost, safety, and capability of meeting the market demands andbenefiting product promotion.

Owner:开平市才文龙鞋业有限公司

Movable type dust removal device

InactiveCN109260870AEffective absorptionReduce pollutionUsing liquid separation agentSeparation devicesMovable typeEngineering

The invention discloses a movable type dust removal device which comprises a stirring building, a dust removal vehicle, a dust removal tank, a dust collection cover seat and a dust collection cover. The dust collection cover is obliquely arranged on the upper side of the top of the stirring building, first mist spray pipes are arranged close to the outer end of the dust collection cover in a crossstaggered manner, the dust collection cover seat which is communicated with the dust collection cover is hermetically arranged at the upper end of the dust collection cover, one end of a delivery pipe is hermetically connected with the dust collection cover seat, the other end of the delivery pipe extends to an inlet of the dust removal tank fixed into the dust removal vehicle, an isolation plateis arranged in the dust removal tank in a downwardly extending manner along the inlet, a second mist spray pipe is horizontally arranged on the right side of the isolation plate, a sealing plate is hermetically arranged on the right side of the second mist spray pipe, a dust removal space is arranged on the right side of the sealing plate, water is arranged in the dust removal space, a guide pipeis arranged on the upper portion of the sealing plate, one end of a guide gas pipe is hermetically connected with an outlet end of the guide pipe, and the other end of the guide gas pipe extends intothe water in the dust removal space. The movable type dust removal device has the advantages of quick movement and convenience in use.

Owner:开平市建和管桩有限公司

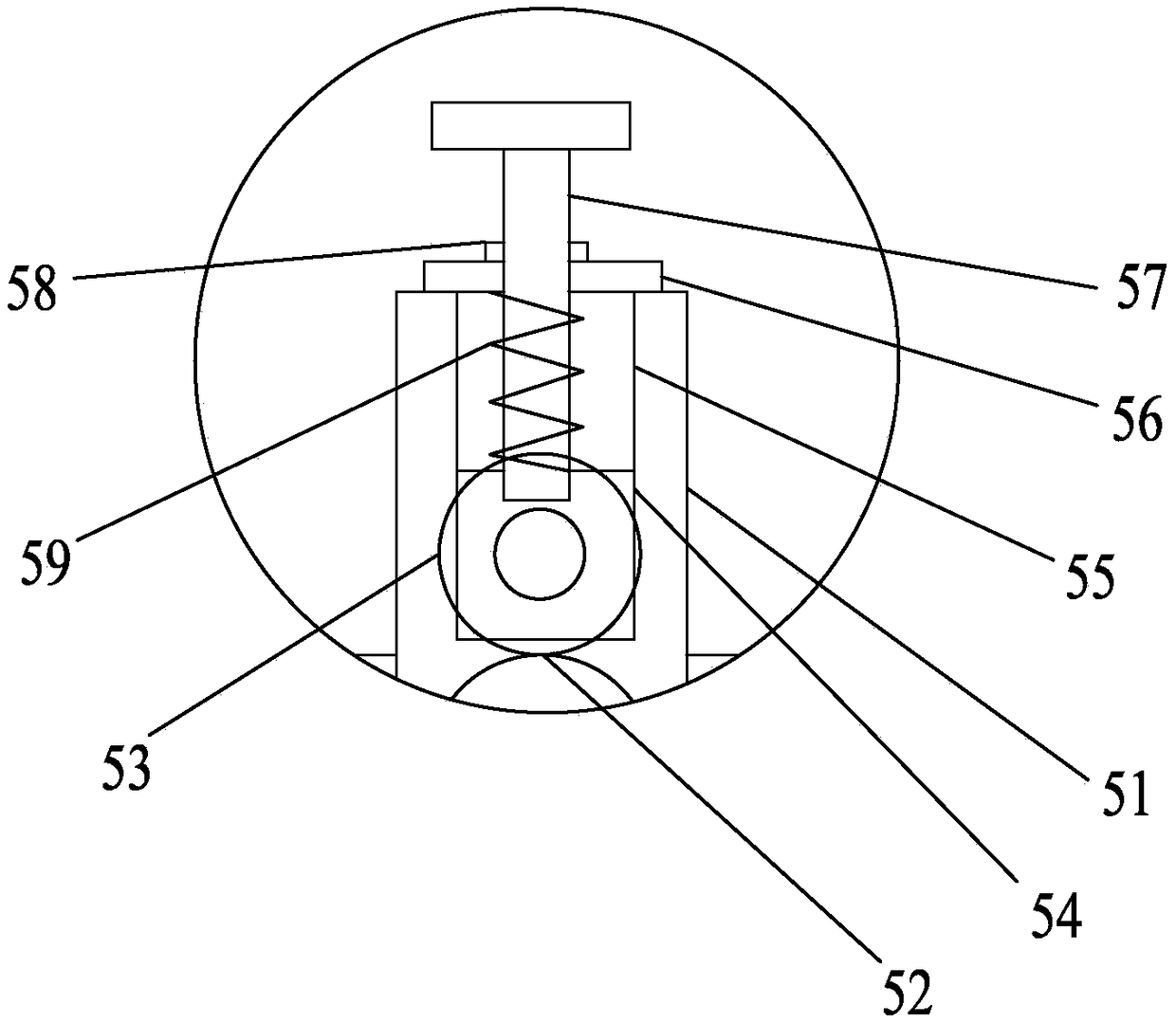

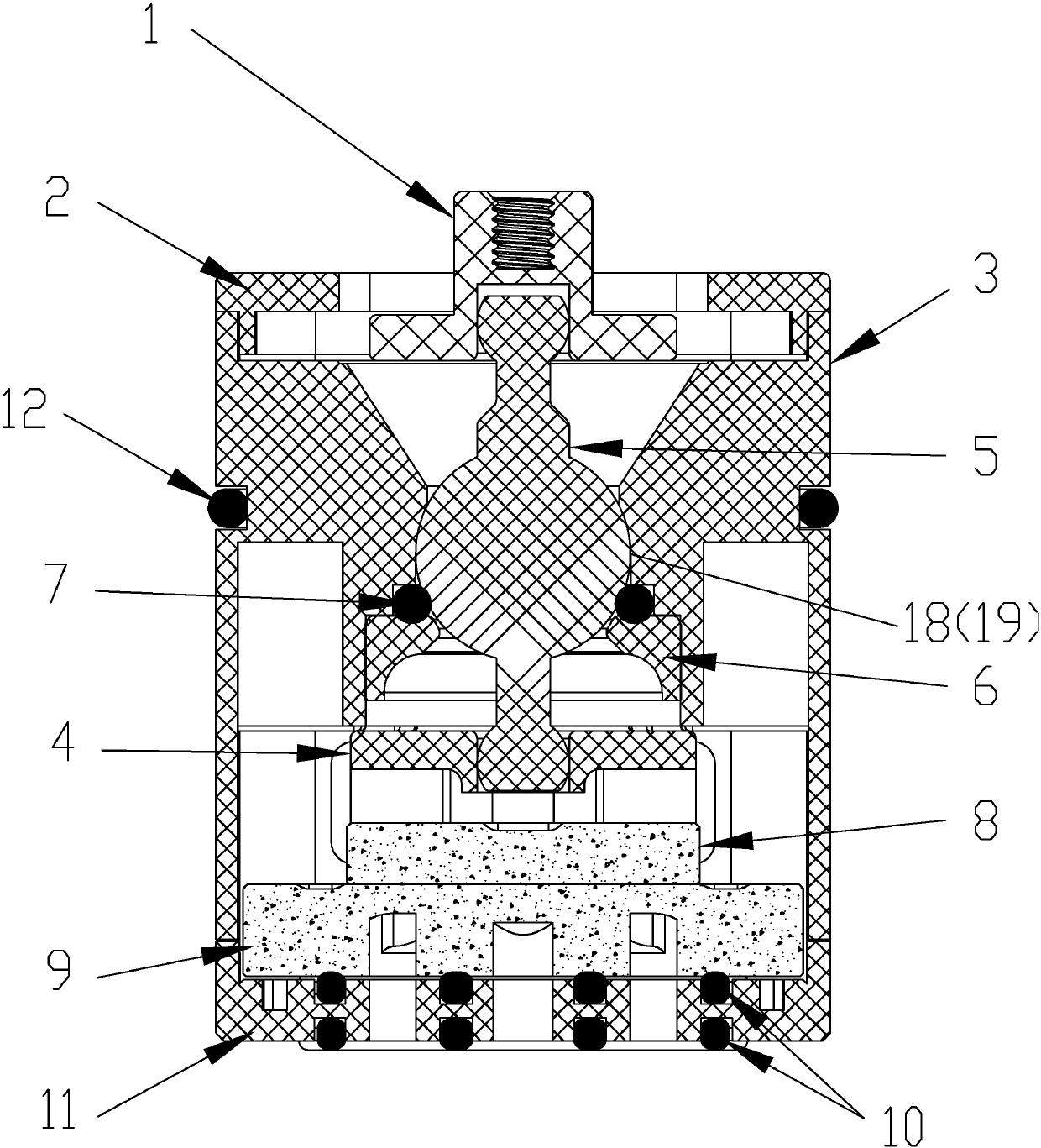

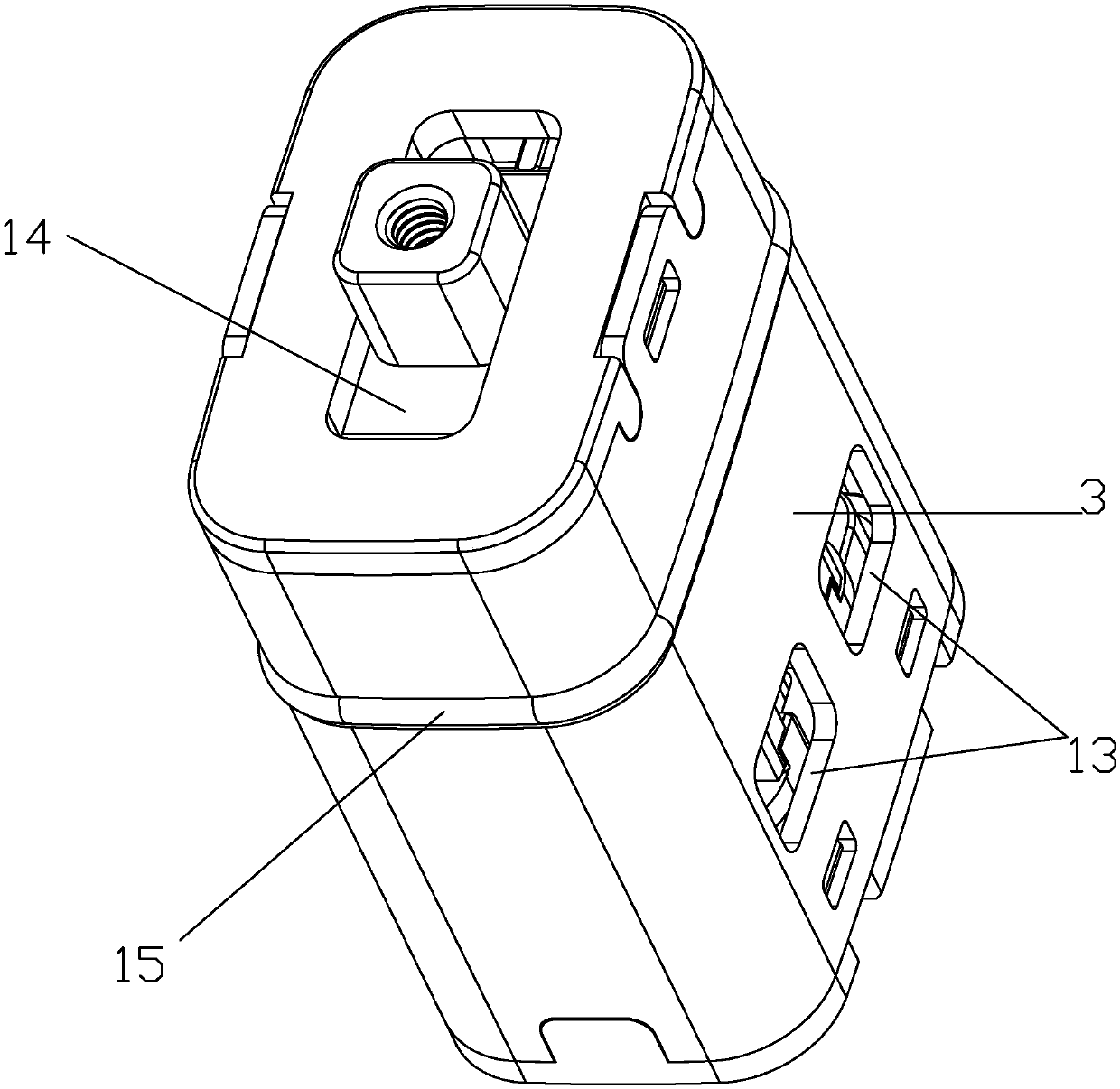

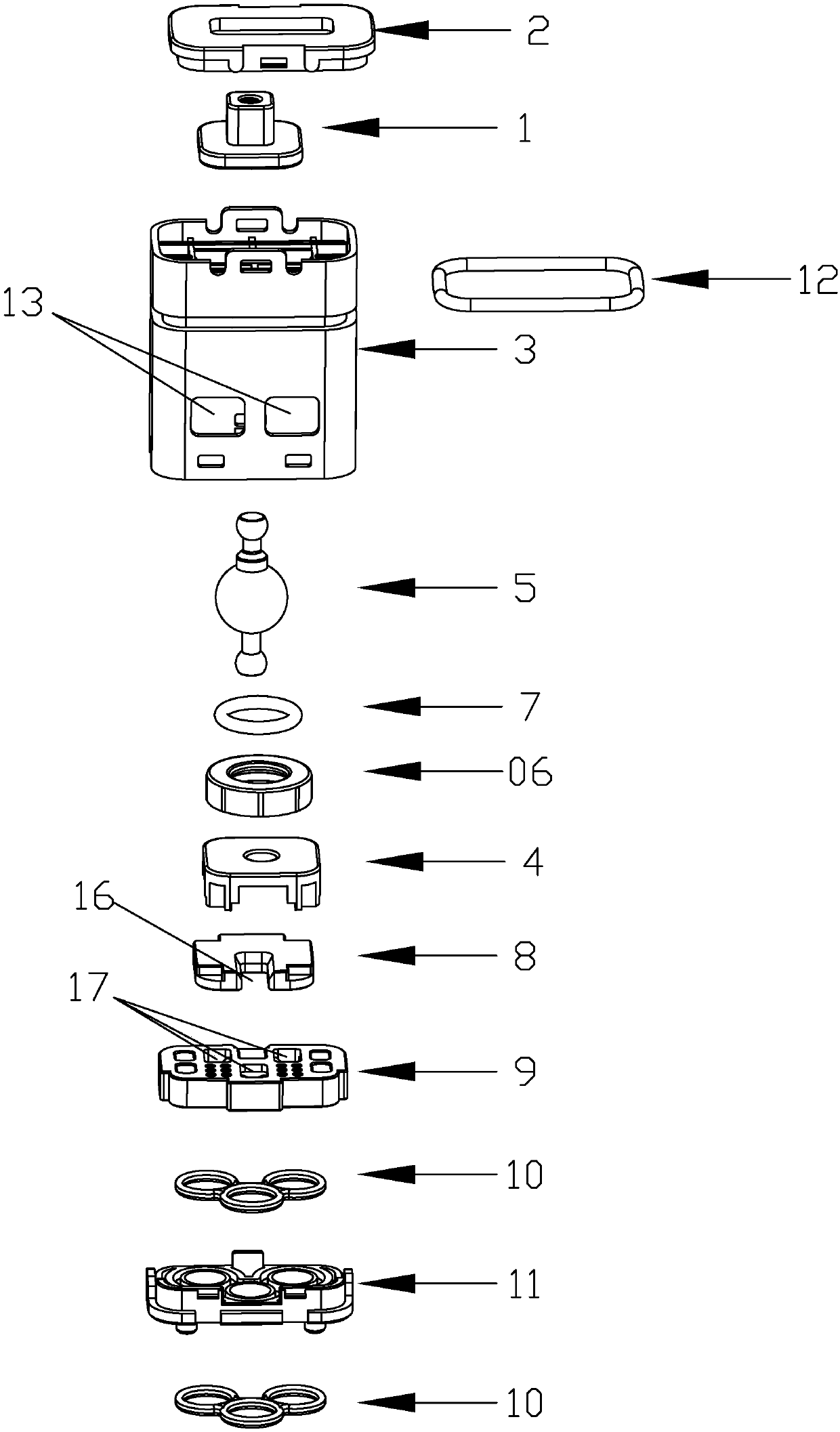

Stirring key type temperature regulating valve

InactiveCN107701759AExtend the scope of developmentSimple structureOperating means/releasing devices for valvesMultiple way valvesEngineeringSpherical form

Owner:KAIPING WHITE SPOOL CO LTD

Intelligent music lamp control system

InactiveCN107333369AEasy to useRealize automatic remote controlElectrical apparatusElectric light circuit arrangementRemote controlControl system

The invention discloses an intelligent music lamp control system which comprises the following steps of: firstly, opening a lamp control interface preinstalled in a cell phone; secondly, clicking 'search' to automatically search a lamp with a preinstalled signal nearby; thirdly, clicking a lamp required to be controlled to enter an intelligent light control mode; fourthly, clicking a selected lamp to enter a control operation interface in order to switch on / off the lamp, to adjust the brightness, the lighting mode, the cold and warm change, and the color light switching of the lamp, and matching and saving the right music; fifthly, clicking cell phone 'music' to enter a music interface after returning; and sixthly, clicking 'mode' to enter a music mode interface to set a light effect and a sound effect. The intelligent music lamp control system is easy to use, achieves automatic remote control of the lamp, meets the needs of the market, and is easy to promote.

Owner:GUANGDONG JUNJIE IND CO LTD

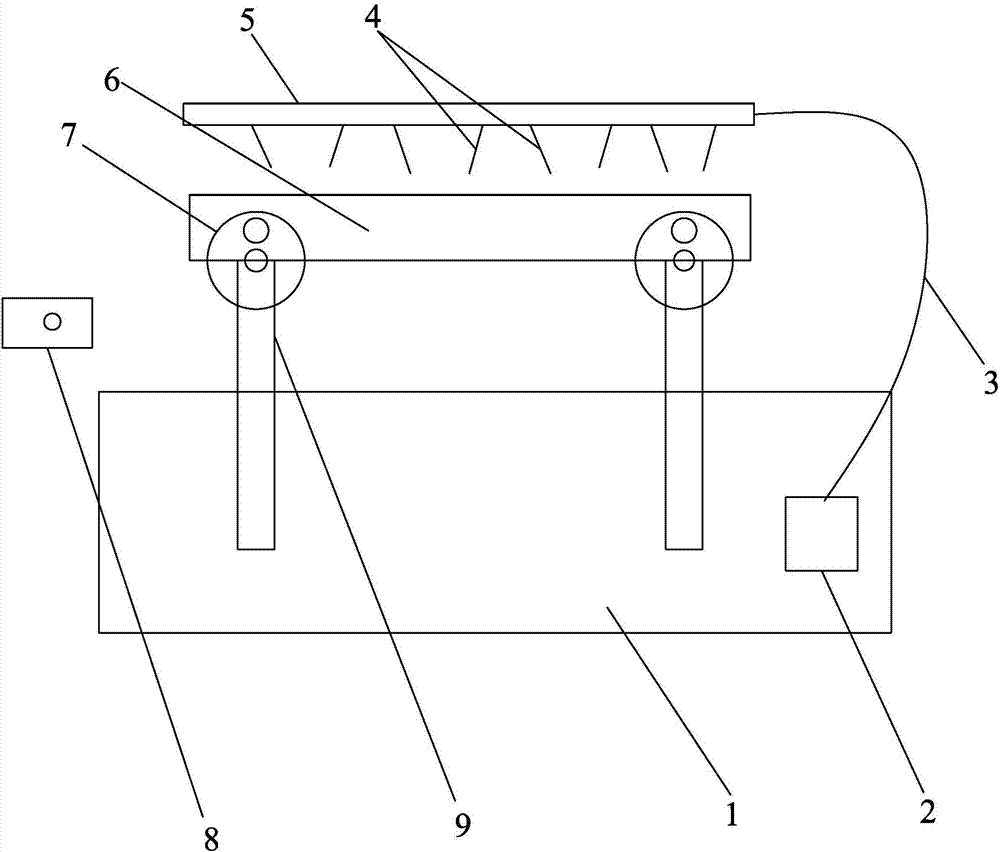

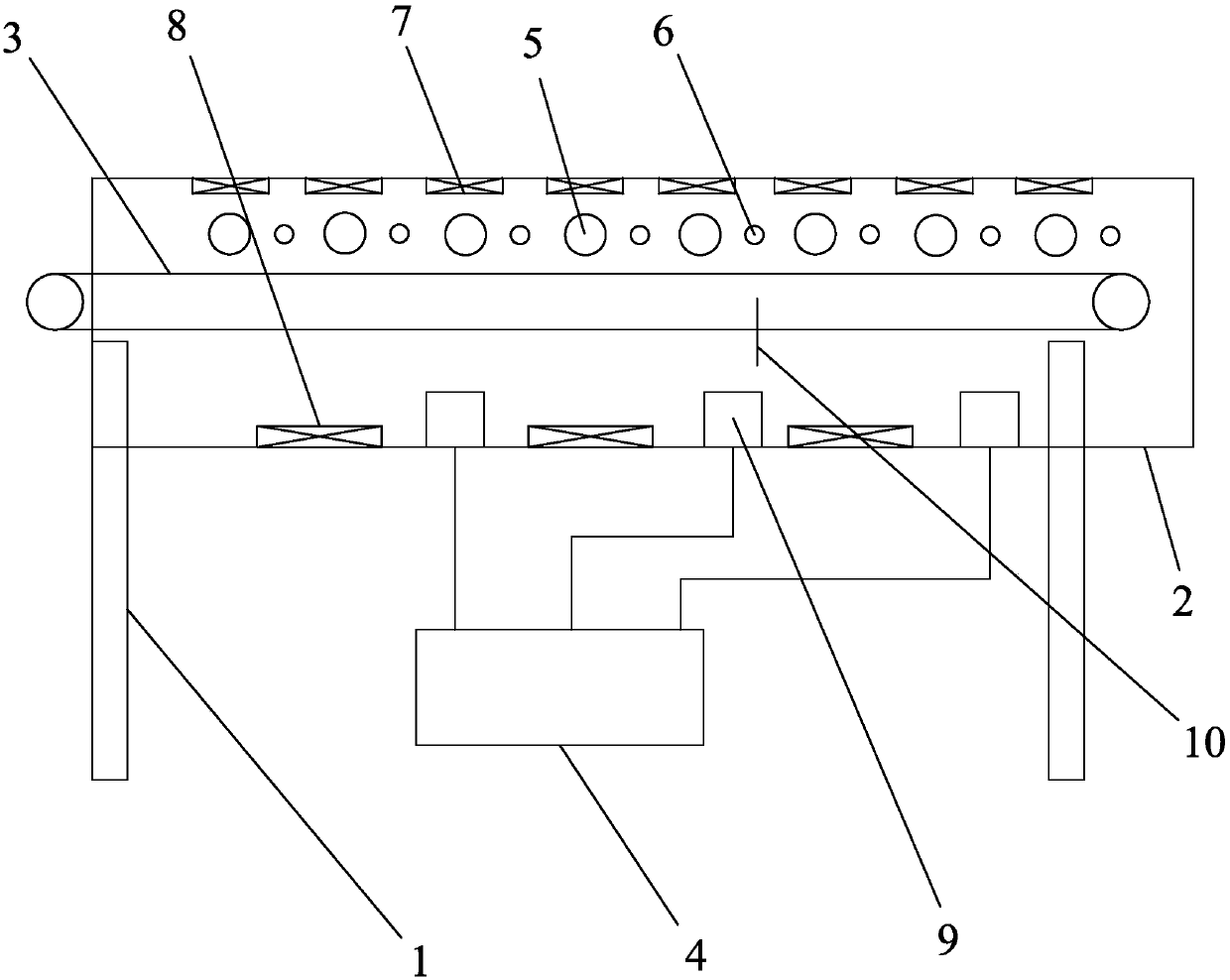

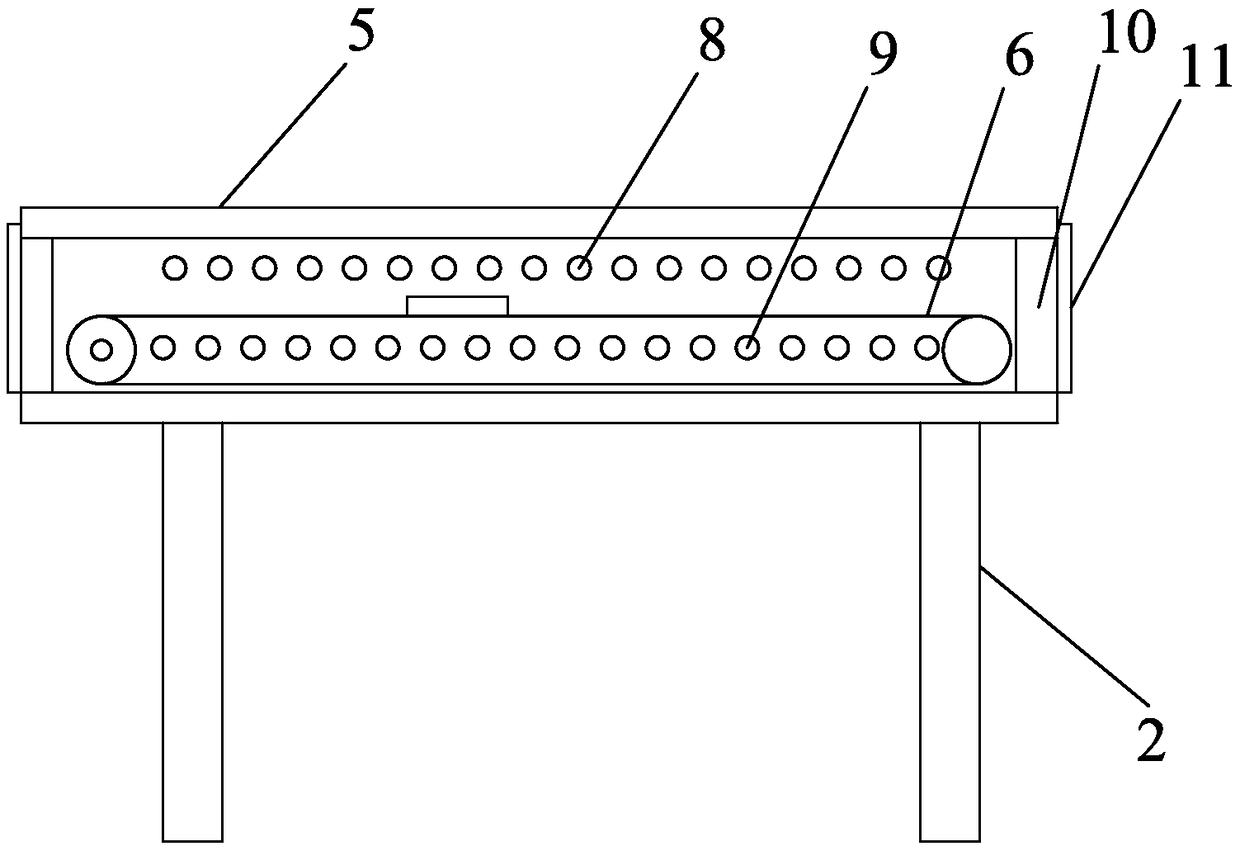

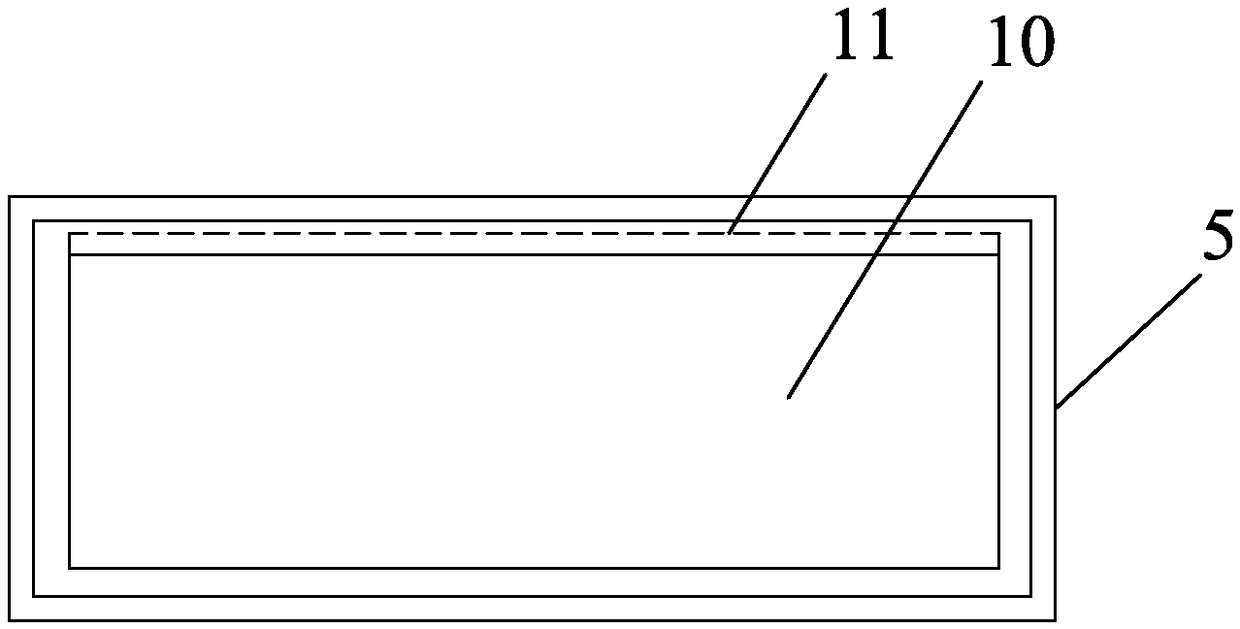

Conveying drying device for washing

InactiveCN107858815ASimple structural designEasy to useTextiles and paperLaundry driersInsertion stentUltraviolet

The invention discloses a conveying drying device for washing. The device comprises a bracket, a drying box, a mesh conveyor belt, drying lamp tubes, ultraviolet lamp tubes and fans. The drying box isarranged at the upper end of the bracket, the mesh conveyor belt is arranged in the drying box, both ends of the mesh conveyor belt extend out of the drying box, the fans are arranged at the top endof the drying box and are used for blowing downward, the drying lamp tubes and the ultraviolet lamp tubes which are arranged on the drying box are arranged on the lower sides of the fans, the drying lamp tubes are used for thermal drying and the ultraviolet lamp tube are used for sterilization. The device has simple structural design, convenient use, good drying effect, high efficiency and cleanerand more sanitary effects, meets the needs of market use, and is conducive to product promotion.

Owner:GUANGDONG TIANMEI WASHING CO LTD

Poking key type water distribution valve element

InactiveCN107701760AEasy to shapeExtend the scope of developmentOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanical engineering

Owner:KAIPING WHITE SPOOL CO LTD

Cleaning mechanism for filter

InactiveCN109224640ASimple structural designEasy to useFilter regenerationEngineeringCleansing Agents

The invention discloses a cleaning mechanism for a filter. The cleaning mechanism for the filter comprises a stand, a recycling box, a base, a front guiding plate, a plurality of roll shafts, an inlet, a cleaning box, a cleaning pipe, flushing mechanisms, an outlet, a guiding plate, a fan, a conveying net belt and a second recycling box, wherein the base is fixed to the upper end of the stand, thesealed cleaning box is arranged at the upper end of the base, the left side of the cleaning box is provided with the inlet, the right side of the cleaning box is provided with the outlet, the inlet is higher than the outlet, the multiple roll shafts arranged side by side are arranged in the cleaning box, the roll shafts are horizontally arranged, and the multiple roll shafts are sequentially staggered downwards from the inlet to the outlet; the cleaning pipe is arranged on the upper sides of the roll shafts, the flushing mechanisms arranged face to face are arranged at the positions, close totwo ends, of the roll shafts, the flushing mechanisms are connected with a detergent, and the flushing mechanisms are used for being inserted into the two ends of the cylinder type filter, and flushfrom the interior of the filter to the outer part; and the guiding plate is arranged on the outer side of the outlet, and the conveying net belt fixed to the stand is arranged at the tail end of the guiding plate. The cleaning mechanism can achieve automatic cleaning, saves manpower, lowers the cost and improves the efficiency.

Owner:开平市富立润滑剂有限公司

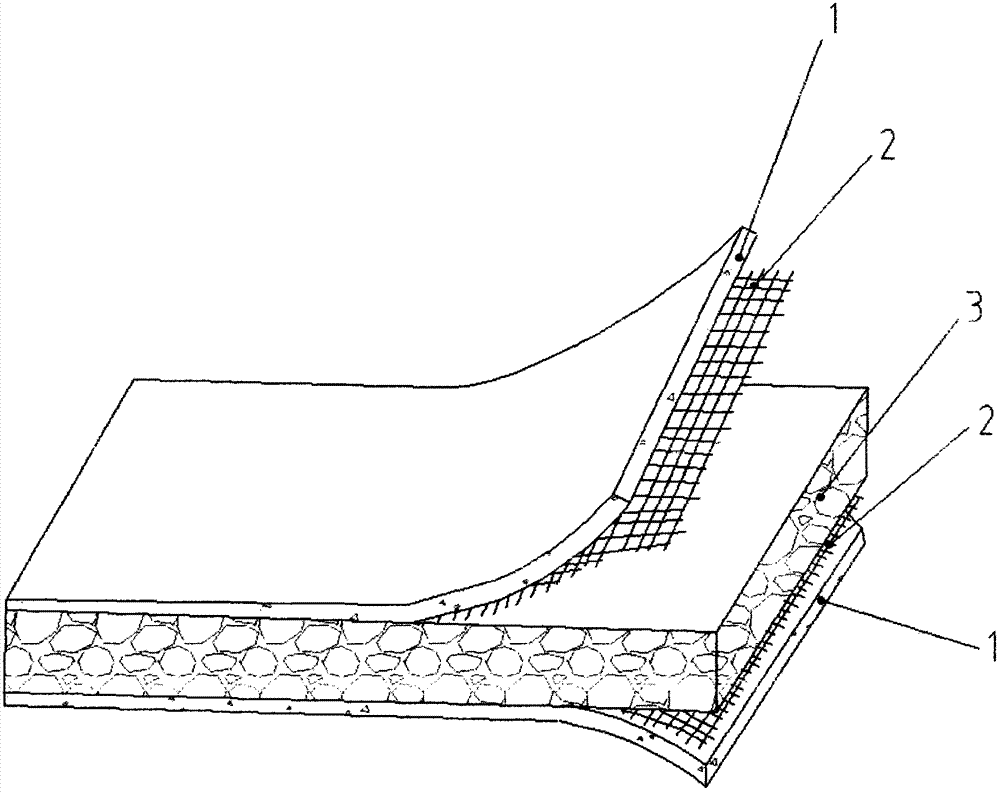

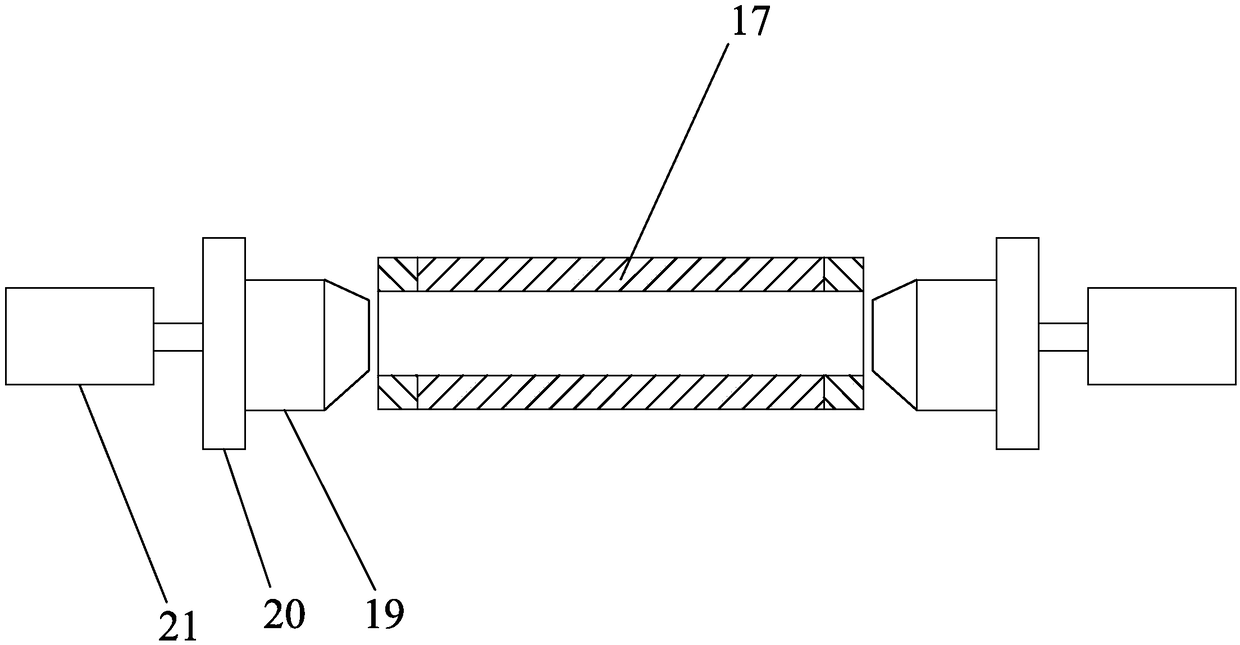

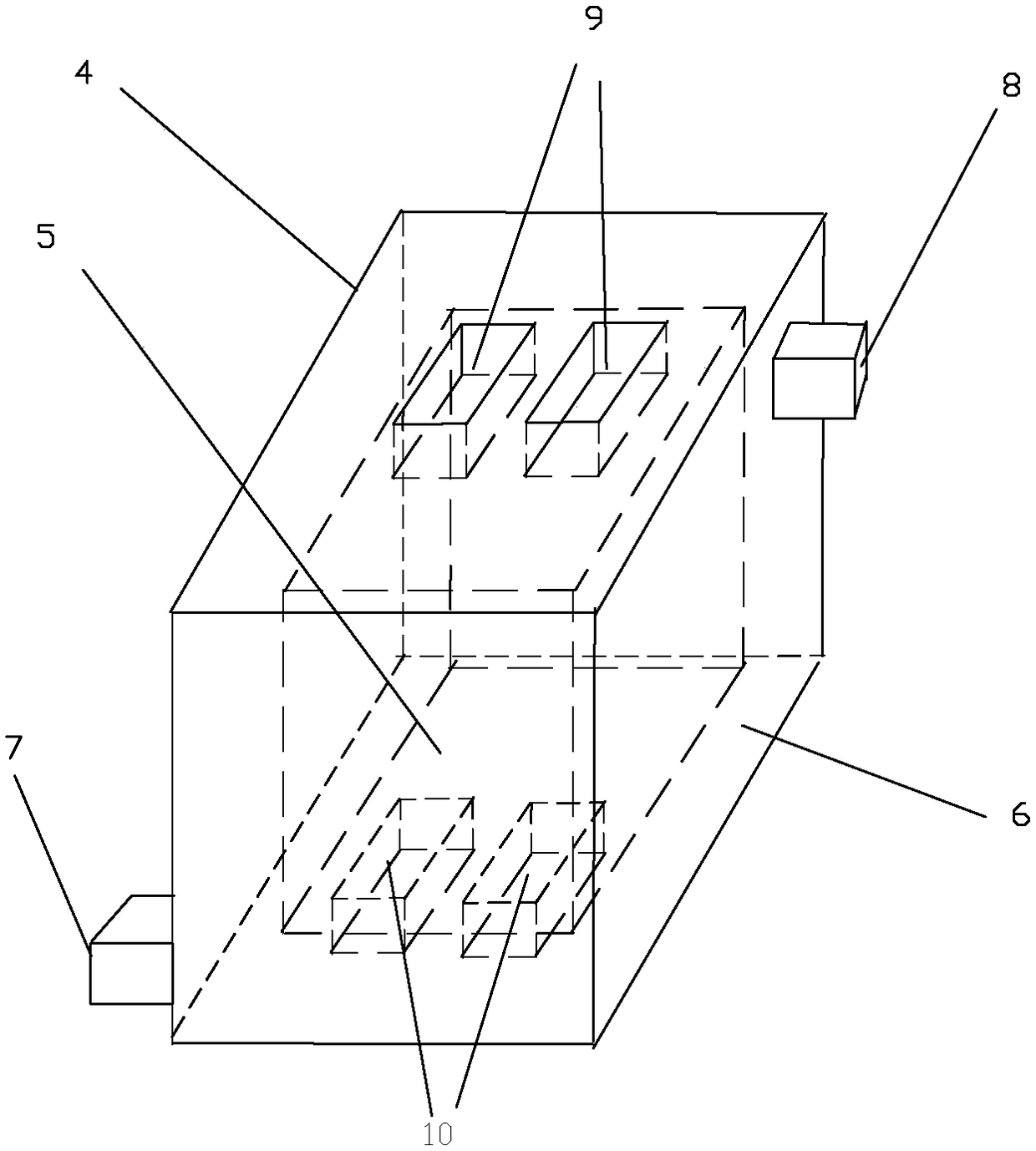

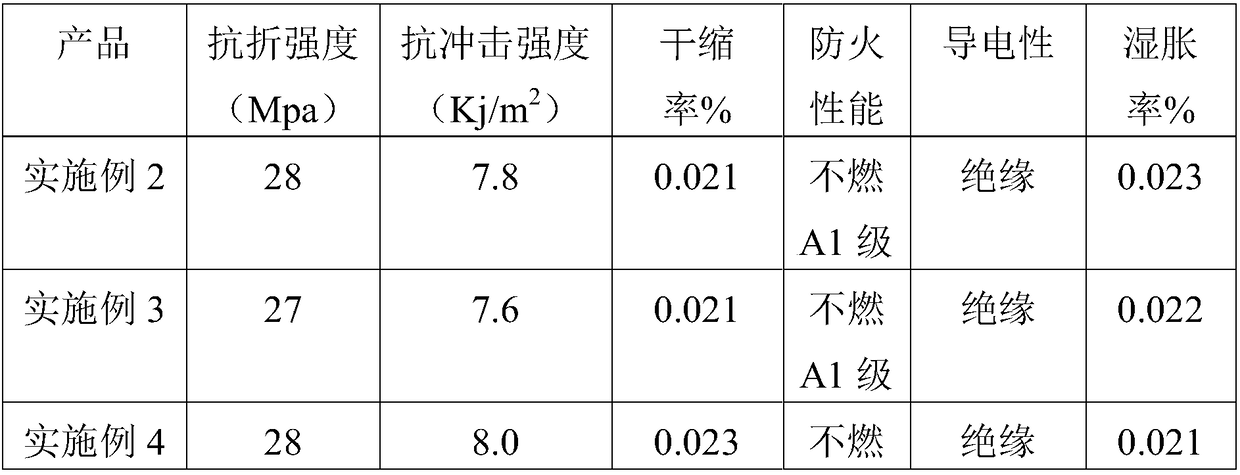

Modified carbon fiber magnesite board prepared with industrial waste acid and preparation process thereof

InactiveCN108215382ALow costImprove flexural strengthLamination ancillary operationsLaminationFiberCarbon fibers

The invention relates to a modified carbon fiber magnesite board prepared with industrial waste acid and a preparation process thereof and solves the technical problems that a process in the prior arthas complex steps, has to greatly increase production cost for improving breaking strength and anti-impact strength of magnesite material, and is high in dry shrinkage rate and wet swelling rate. Themodified carbon fiber magnesite board is composed of three layers, which are tightly successively arranged from the top to the bottom: a first glass fiber net, a carbon fiber magnesite board inner layer and a second glass fiber net. The carbon fiber magnesite board inner layer is prepared from, by weight, 0.6-2.0 parts of carbon fibers after surface oxidizing treatment, 40-50 parts of sawdust, 160-180 parts of magnesite powder, and 580-700 parts of the industrial waste acid being 8-16% in concentration. The invention also provides a preparation method of the modified carbon fiber magnesite board. The modified carbon fiber magnesite board is extensively applied to the field of building materials.

Owner:山东昇昀国际贸易有限公司

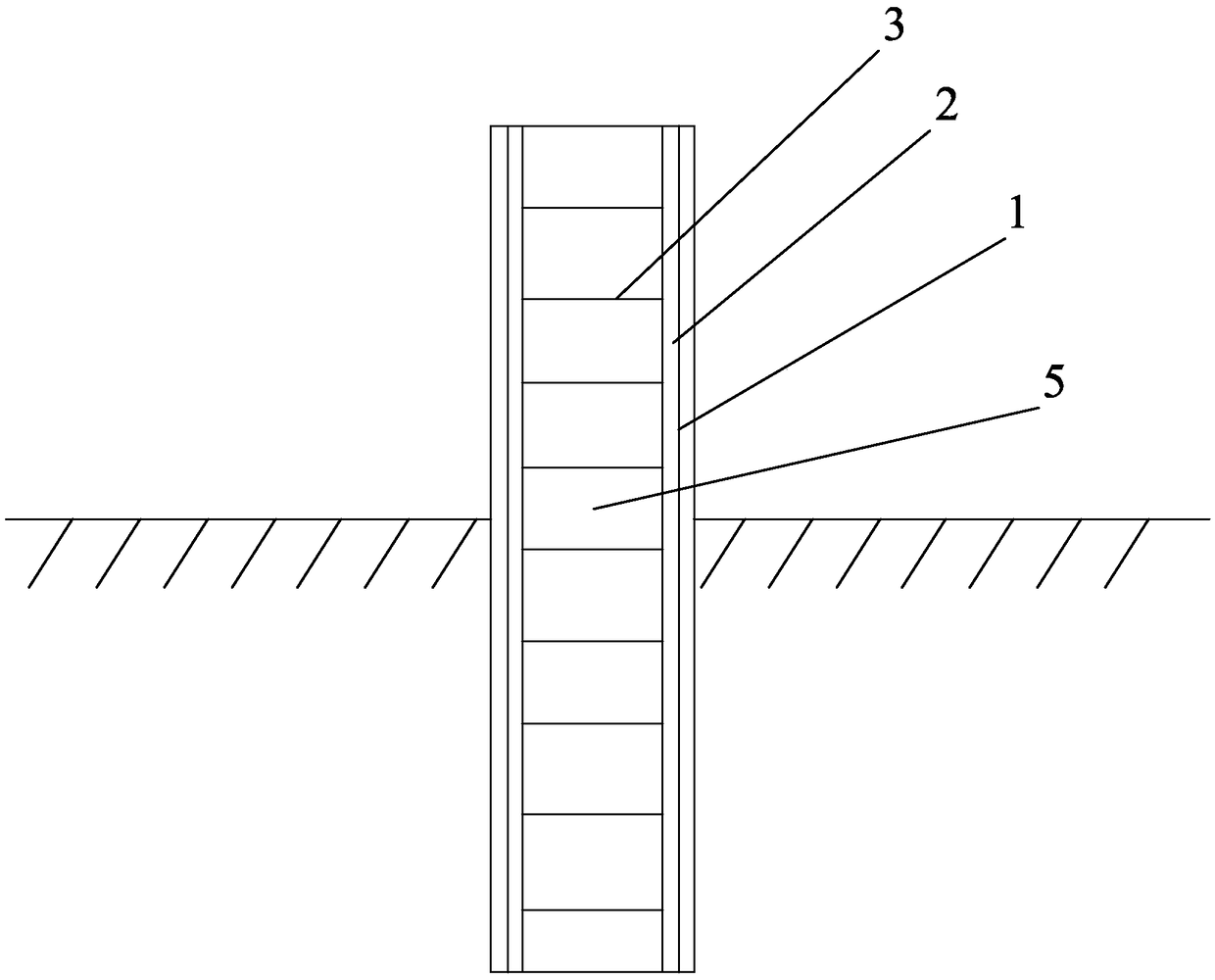

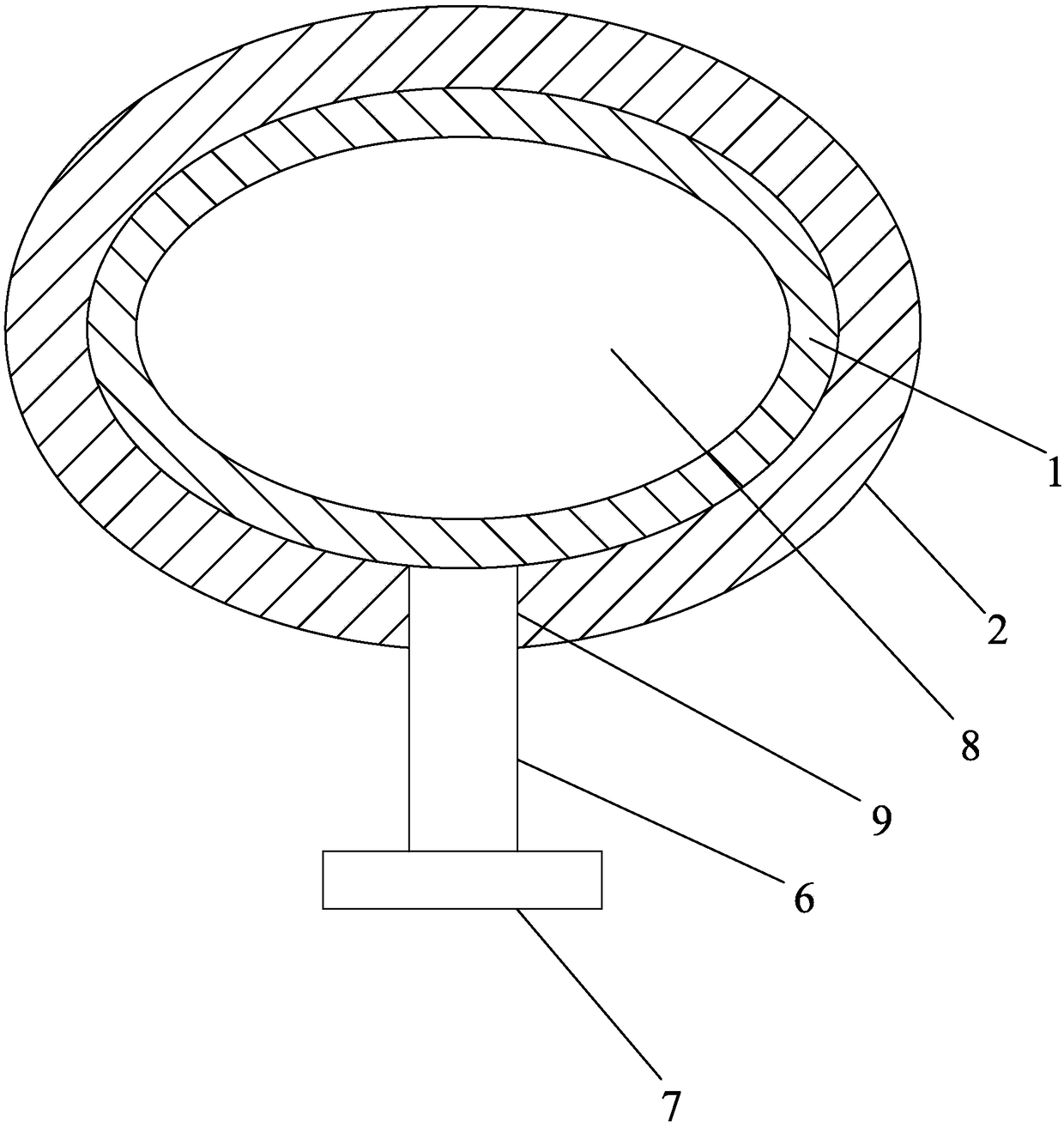

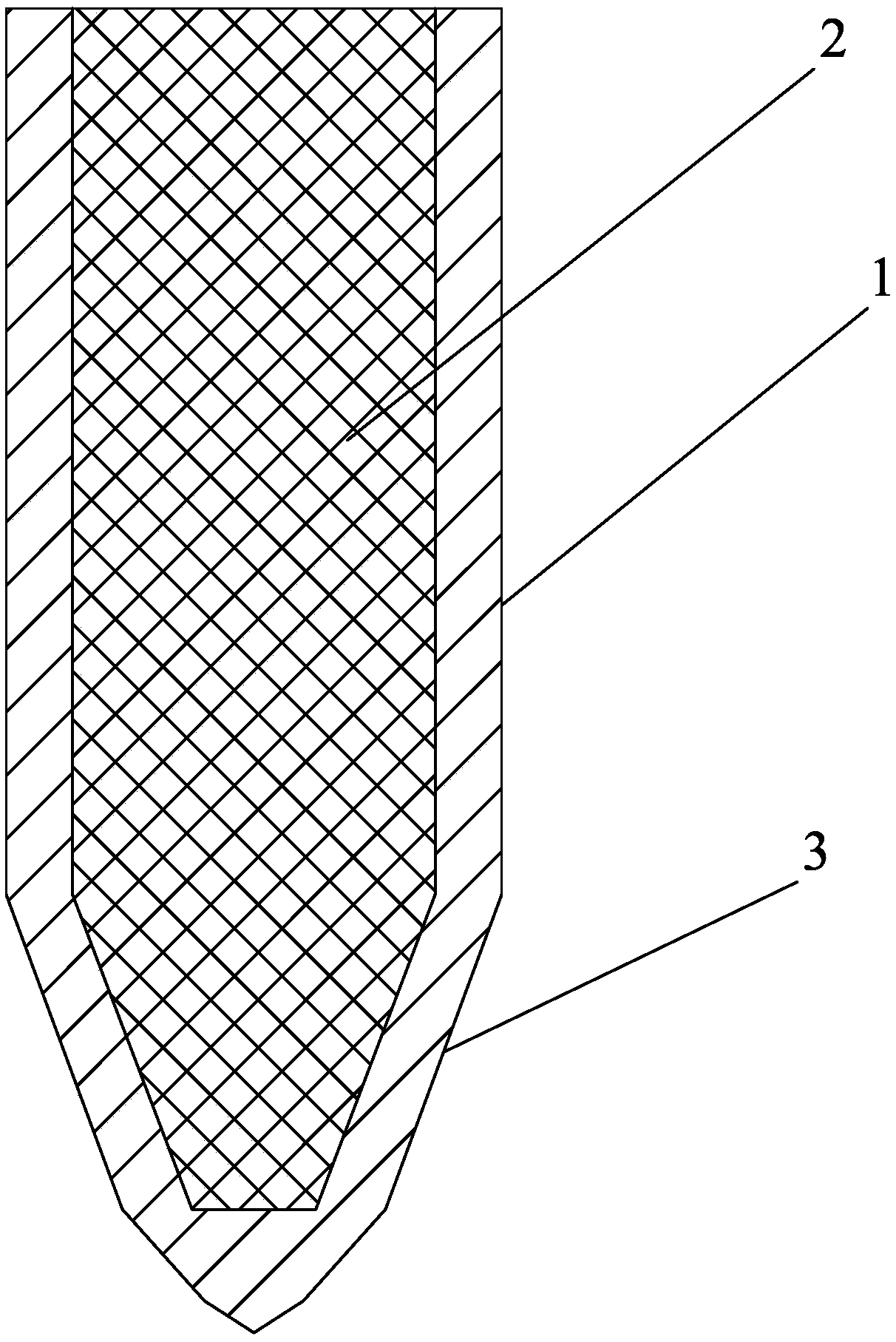

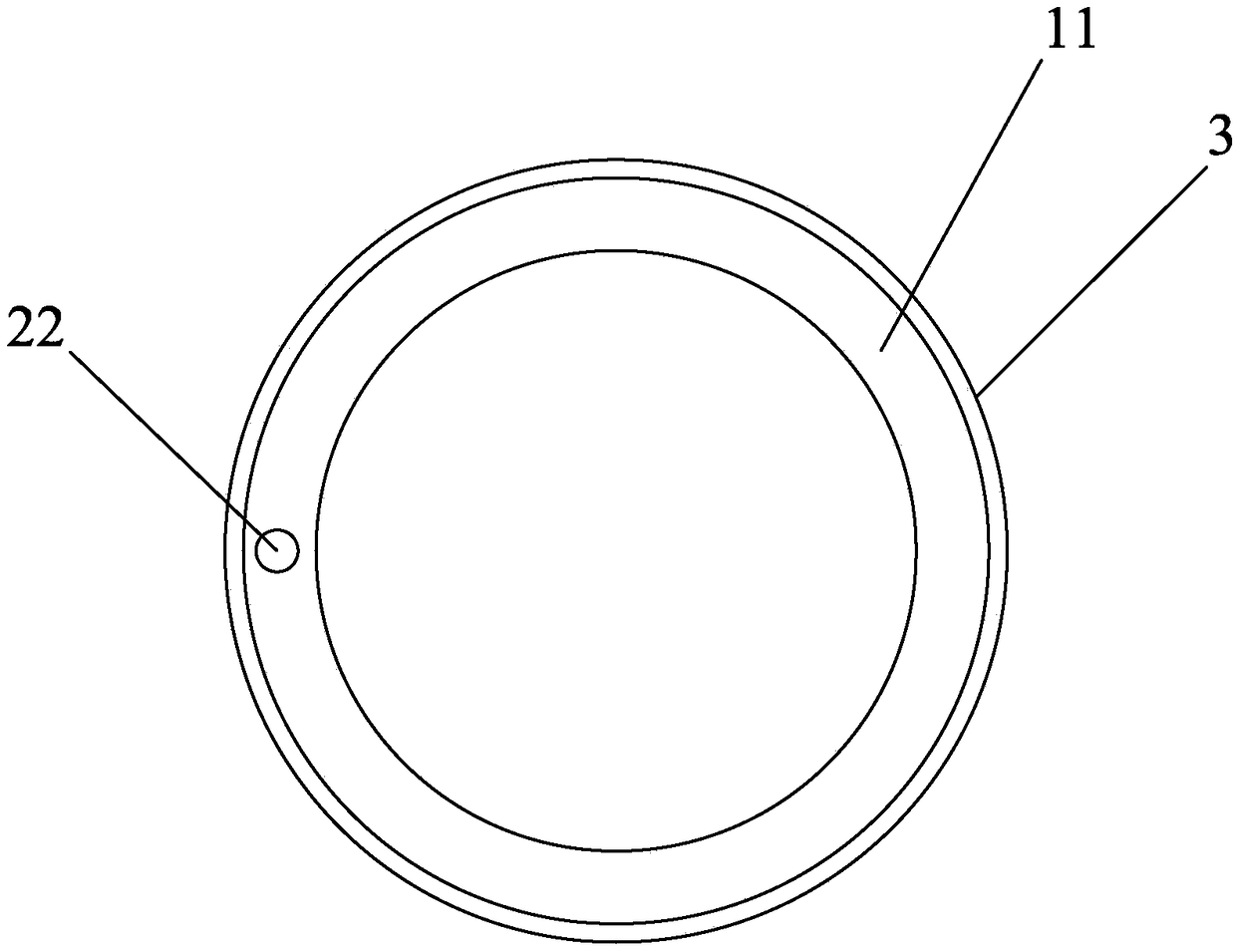

Anti-corrosion pile

InactiveCN109252516AAvoid compromising structural stabilitySimple structural designProtective foundationBulkheads/pilesEngineeringStructural engineering

The invention discloses an anti-corrosion pile, which comprises a pile foundation, vertical ribs, ring ribs and pouring cement, wherein the pile foundation mainly consists of a plurality of ring ribswhich are arranged side by side coaxially; a plurality of the ring ribs are welded axially through a plurality of the vertical ribs; and the vertical ribs and the ring ribs are combined into a frame to be wrapped in the pouring cement to form the whole pile foundation. The anti-corrosion pile is simple and reasonable in structural design, and has good anti-corrosion performance, the underground corrosion is avoided, the structural stability is affected, the market demands are met, and the product promotion is beneficial.

Owner:开平市建和管桩有限公司

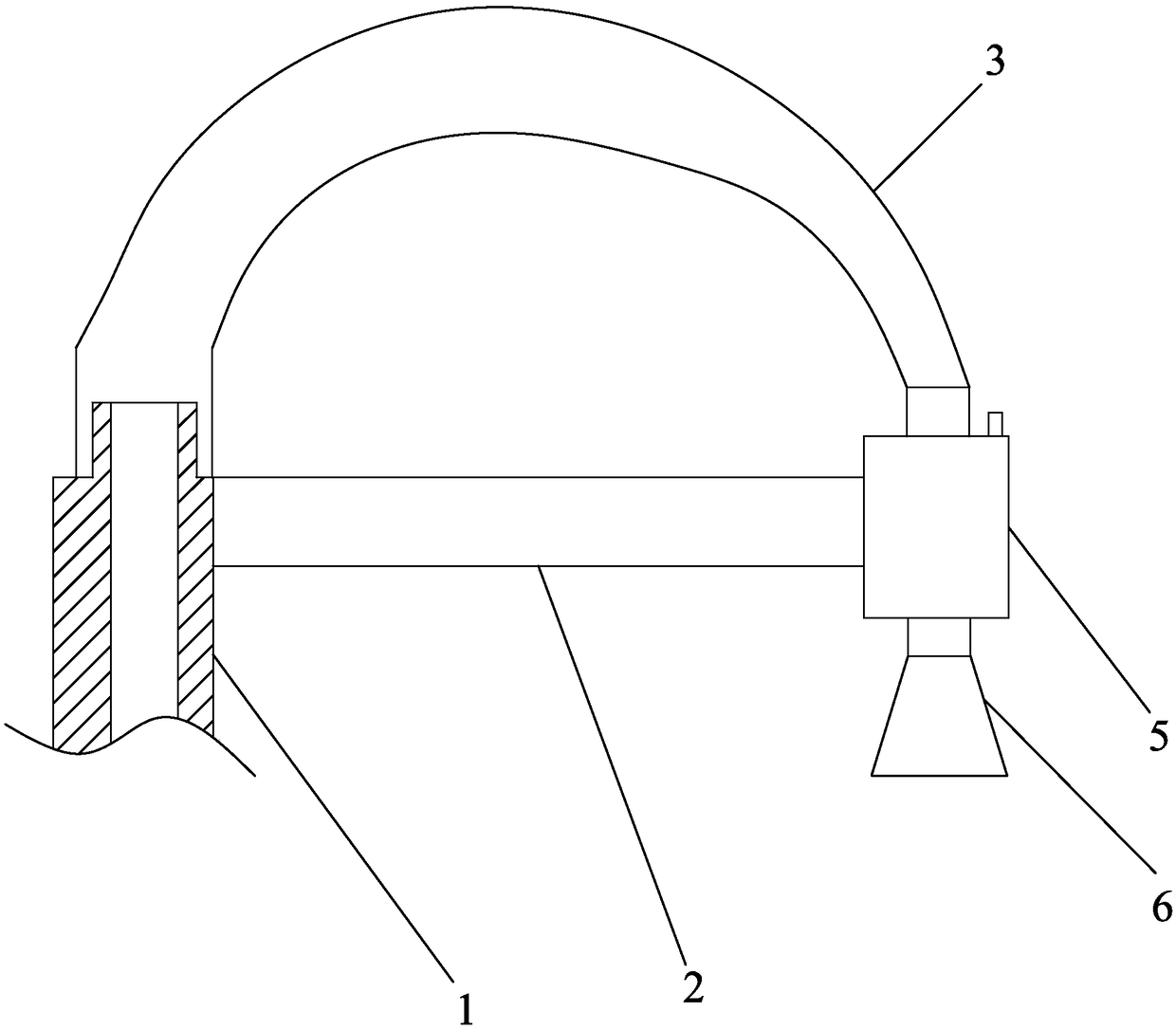

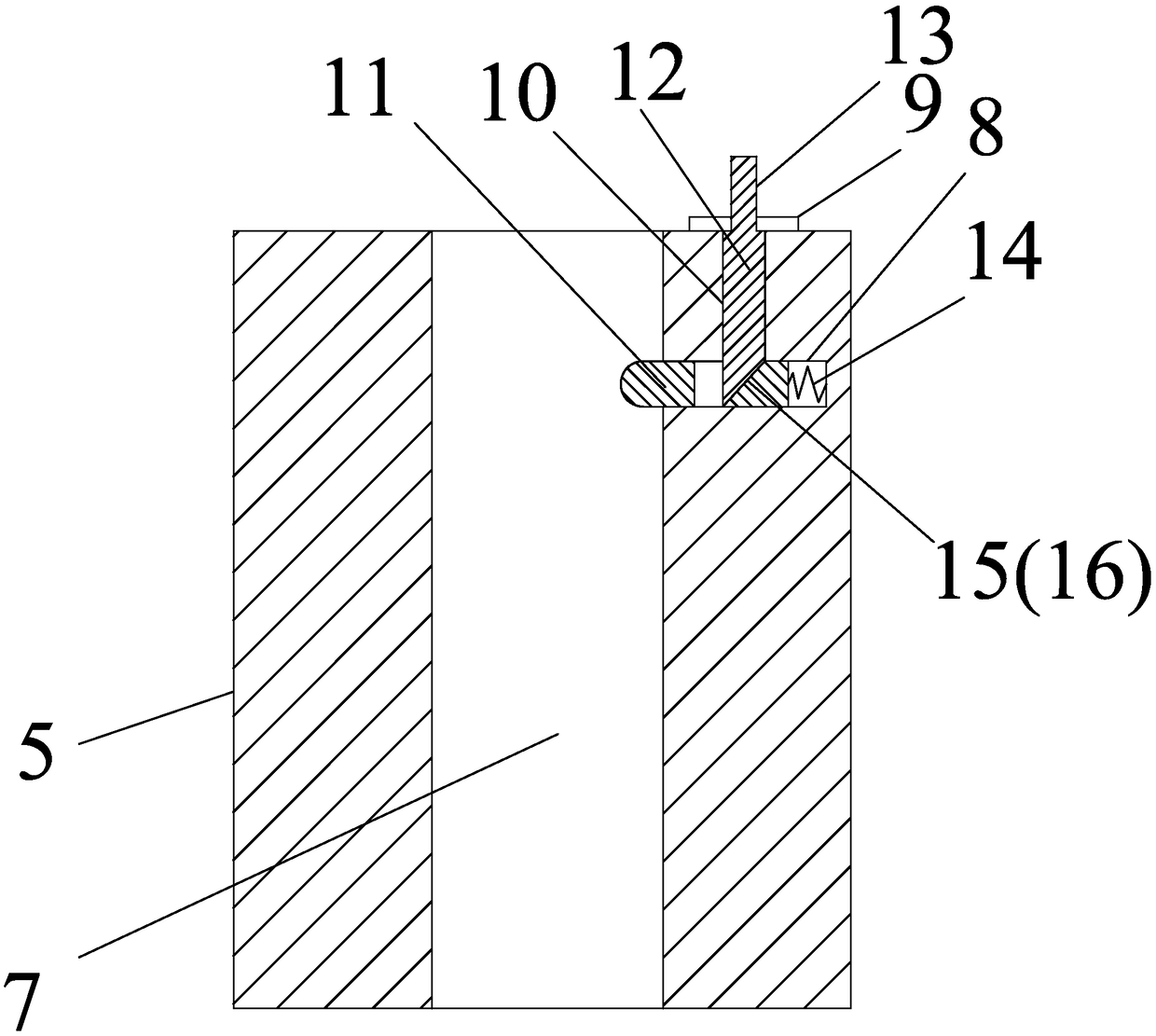

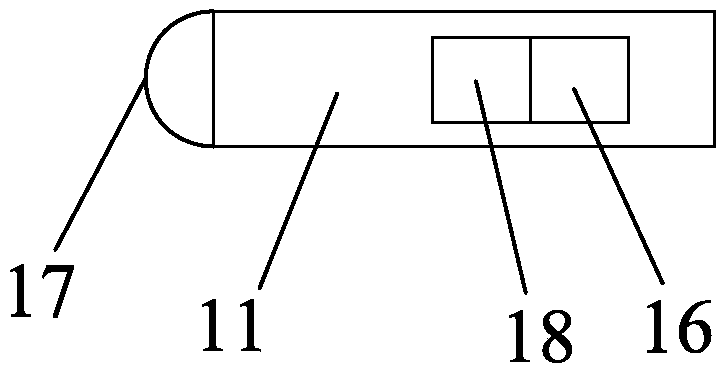

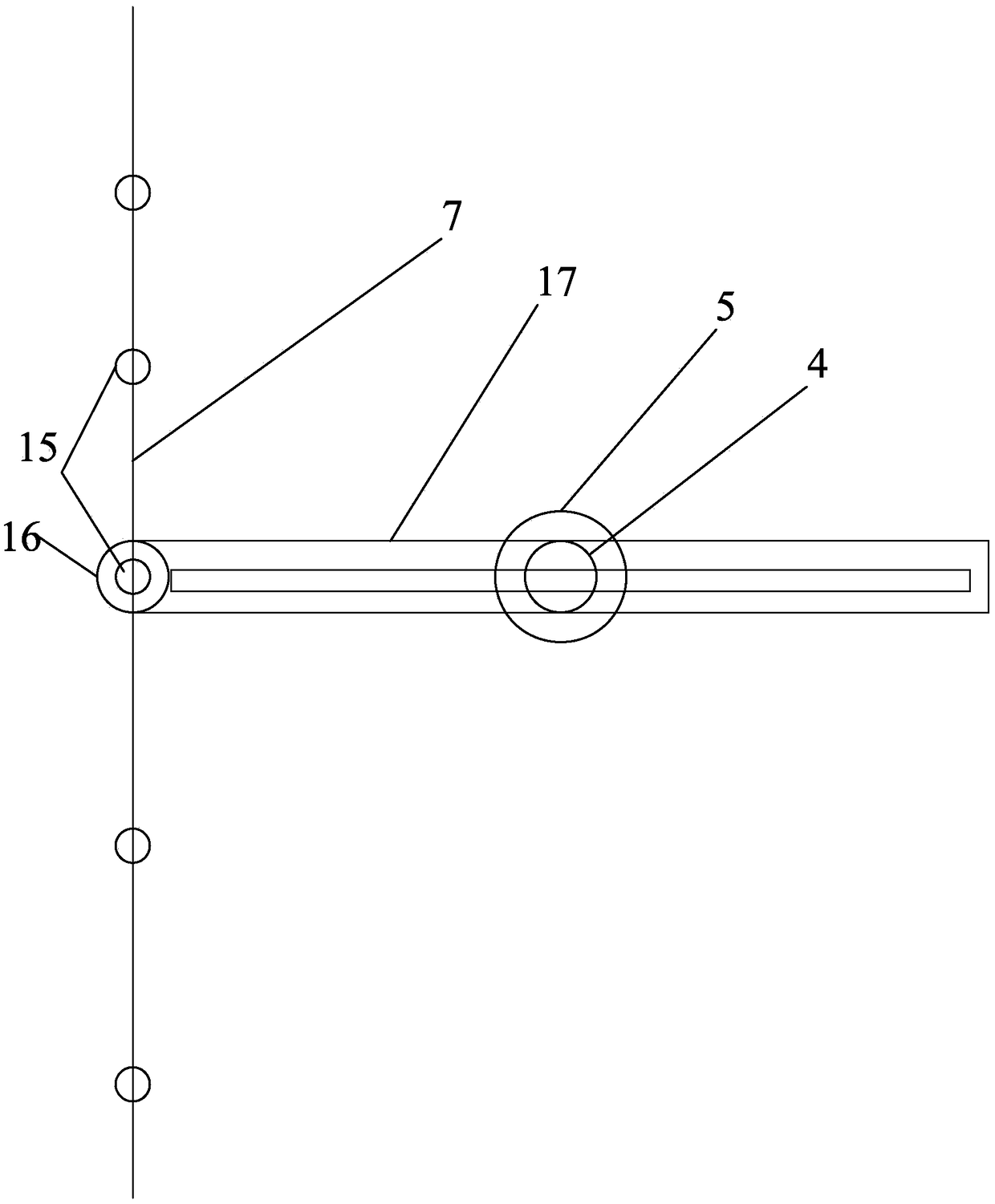

Liftable faucet

InactiveCN109268555AAvoid spillingSimple structural designDomestic plumbingValve housingsEngineeringPiping

The invention discloses a liftable faucet. The lifetable faucet comprises a stainless steel water pipe, a lifting seat, a cross frame, a faucet, a hose and a water outlet channel, wherein the stainless steel water pipe is liftably in a sleeved connection with the lifting seat, the side face of the lifting seat is provided with an integral cross frame, the faucet is fixed to the tail end of the cross frame, a water inlet of the faucet seals and fixes one end of the hose, the other end of the hose is in sealed connection with the upper end of the stainless steel water pipe and is connected withthe water outlet channel in the stainless steel water pipe. The lifetable faucet is simple in structural design and convenient to use, can be liftable, prevents water from being splashed, saves waterresources, meets the use demand of the market and is conductive to product popularization.

Owner:钱昌宝

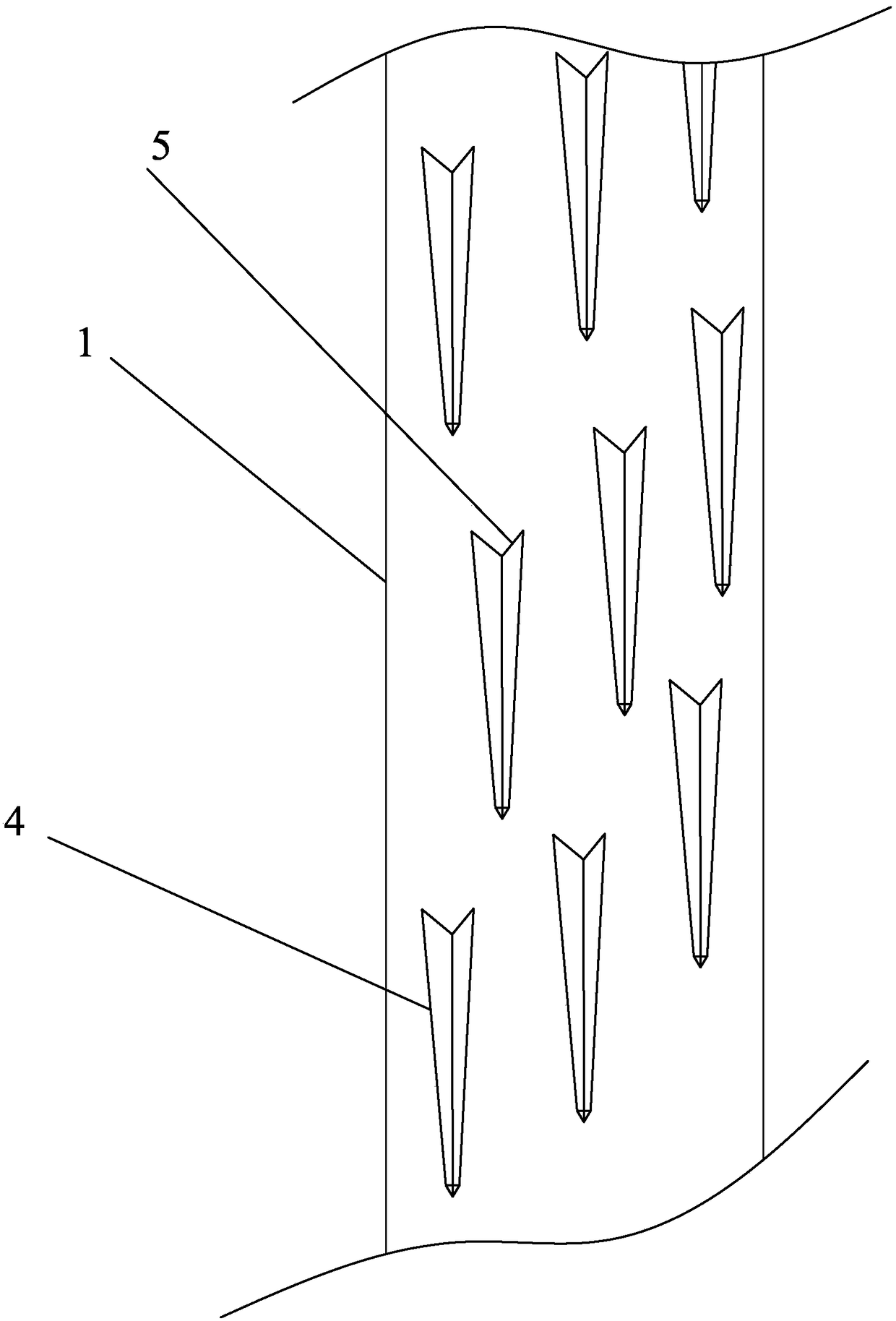

Automatic gas filling equipment

InactiveCN109340558ASimple structural designEasy to useGas handling applicationsFluid handling accessoriesInductorBottle

The invention discloses automatic gas filling equipment, which comprises a base, a conveying device, a vertical frame, a lifting plate and a filling head. The vertical frame is fixed to the upper endof the base, and the lifting plate is arranged on the front side of the vertical frame in a lifting mode; the filling head is fixed to the lifting plate, and the conveying device fixed to the upper end of the base is arranged on the lower side of the filling head and mainly comprises a conveyor belt; the conveyor belt is connected to a servo motor synchronously, and a fixed base is locked onto theconveyor belt; a clamping ring is fixed to the upper end of the fixed base, and a bottle is clamped in the clamping ring; and an inductor is arranged at the filling head and connected to the servo motor through a circuit, wherein the servo motor is synchronously connected with the conveyor belt. The structural design is simple, using is convenient, gas filling is conducted automatically, manpoweris saved, the cost is lowered, the efficiency is improved, the market using demands are met, and product popularization is facilitated.

Owner:开平市富立润滑剂有限公司

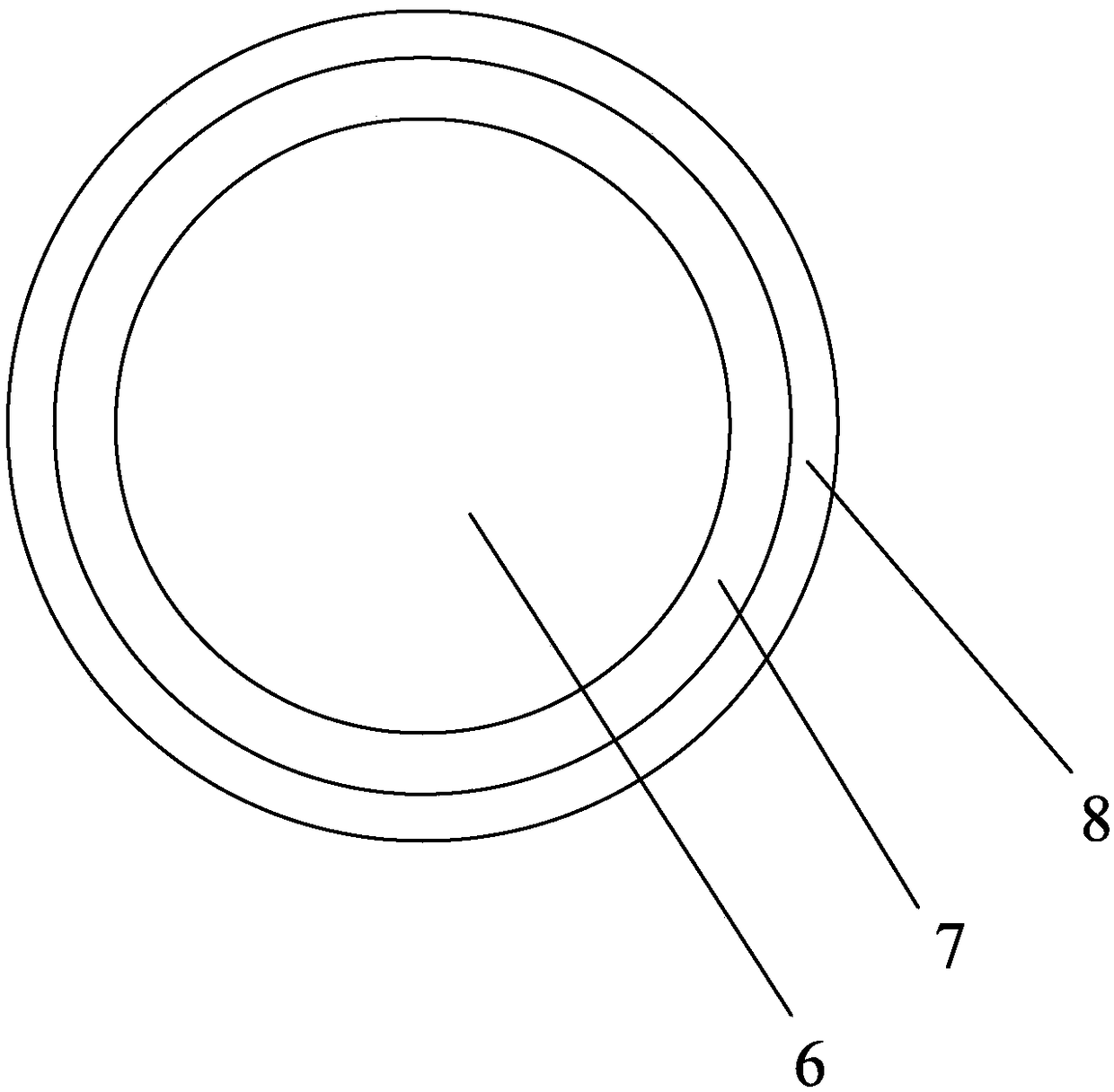

Integrated pipe pile

The invention discloses an integrated pipe pile which comprises a pile body, a pile head, pouring cement and ribs. The pile body is of a hollow tubular structure, a pile cap with an integral structureis arranged at the lower end of the pile body, and the pile cap is of an enclosed conical structure extending downward; the pile body is provided with the pouring cement, and the outer wall of the pile body is provided with the uniformly distributed ribs. The lower end of the pile body is more reasonable in structure, prone to squeeze out the soil and not easy to deform. The strength of the pipepile is improved, the market demand is met, and the pipe pile is favorable for product promotion.

Owner:开平市建和管桩有限公司

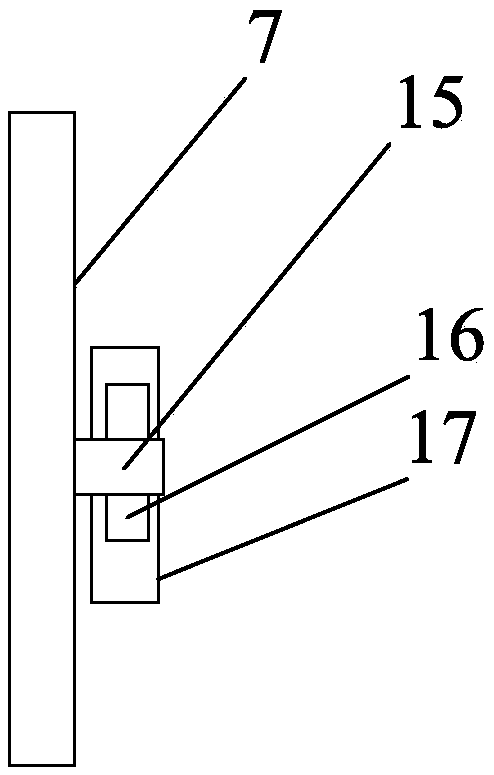

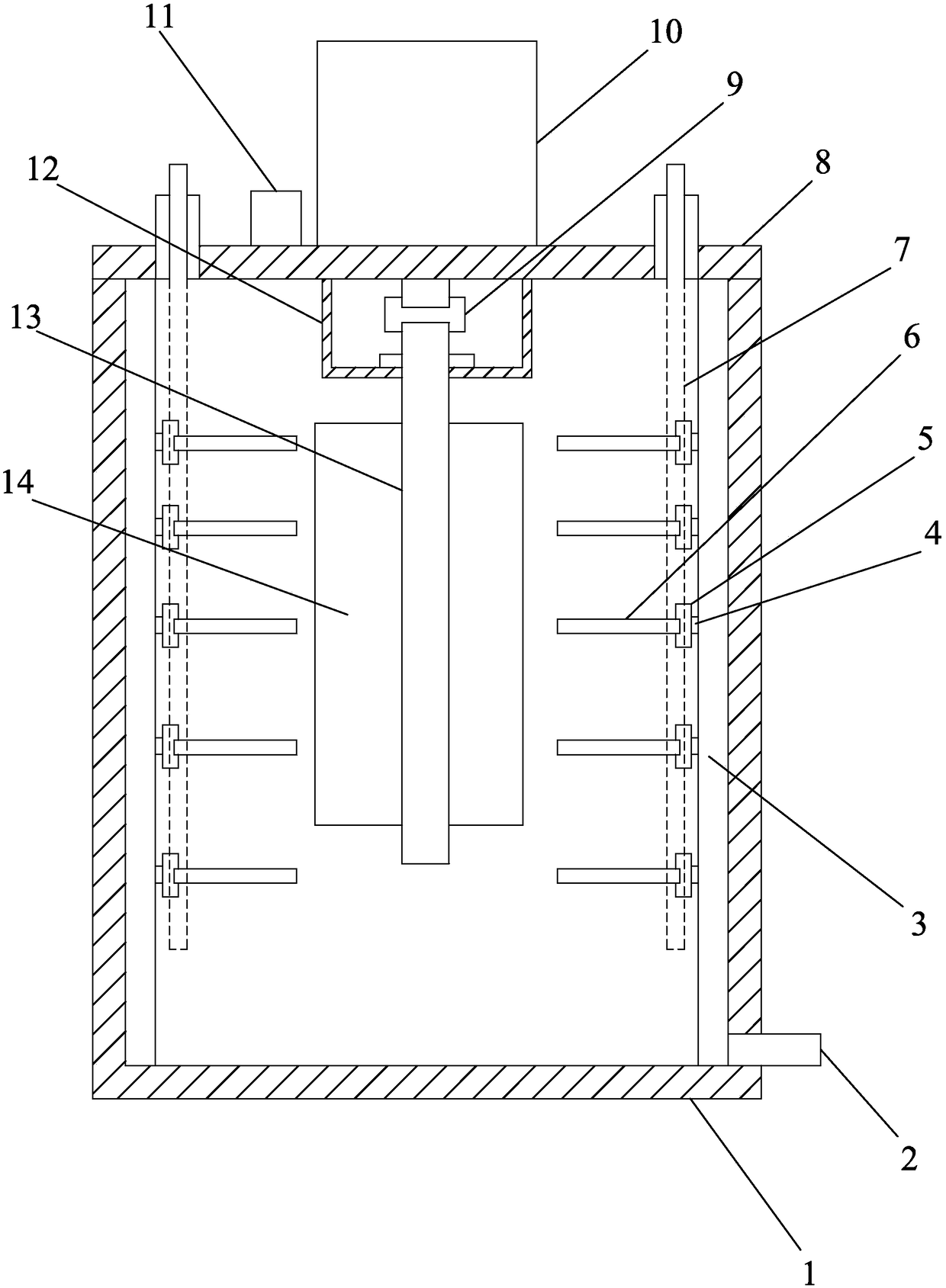

Novel resin purifying device

InactiveCN109126201AAdjustable angleSimple structural designSolid sorbent liquid separationEngineeringAdsorption effect

The invention discloses a novel resin purifying device. The novel resin purifying device comprises a barrel, a liquid outlet, a support, resin plates, a liquid inlet and a stirring shaft, wherein theinner wall of the barrel is provided with the support, and a plurality of horizontally arranged resin plates capable of adjusting angles are arranged on the support; the top of the barrel is covered with a barrel cover, a motor is fixedly arranged at the upper end of the barrel cover, the motor is synchronously connected to the stirring shaft arranged in the center of the inner side of the barrel,a blade is arranged on the stirring shaft, the liquid inlet is formed in the barrel cover, and the liquid outlet is formed in the lower end of the barrel. The novel resin purifying device is simple in structural design, convenient to use, good in adsorption effect and high in effect, the angles of the resin plates can be adjusted, the operation is convenient, the adsorption efficiency is furtherimproved, the using requirement of the market is met, and the device is beneficial for product popularization.

Owner:开平市狮山林场松香厂

One-component water-based white light finish

The invention discloses a one-component water-based white light finish. The one-component water-based white light finish comprises, by mass, 30-50 parts of an aqueous hydroxyl acrylic emulsion, 10-15parts of water-based baking enamel resin, 60-80 parts of water, 2-4 parts of a waterborne polyurethane thickener, 3-5 parts of a water-based wetting agent, 2-4 parts of a water-based antifoaming agent, 2-4 parts of a water-based leveling agent and 3-5 parts of a water-based rheological additive. The one-component water-based white light finish has the advantages of high hardness, good glossiness,use without heating, meeting market use demands, and facilitation of product promotion.

Owner:HESHAN MICKEY PAINT

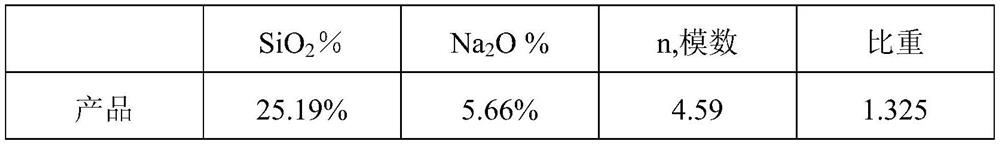

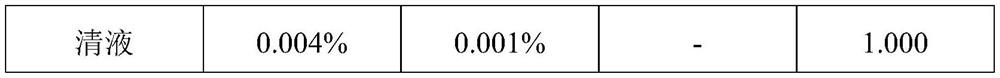

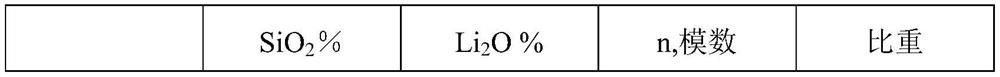

Preparation method of silicate aqueous solution

PendingCN114180590ASimplify the raw material refining processReduce energy consumptionAlkali metal silicatesPotassium hydroxideCalcium carbonate

The invention relates to a preparation method of a silicate aqueous solution, and belongs to the technical field of silicate preparation. An active silicic acid-containing solution obtained by reaction of fluosilicic acid and calcium carbonate is used as a silicon source, and an aqueous solution of sodium hydroxide, potassium hydroxide or lithium hydroxide is used as an alkali source; and reacting the two solutions at room temperature and normal pressure to obtain a corresponding silicate dilute solution product, and concentrating the dilute solution in a membrane filtration manner to obtain a product meeting market requirements. The production process is simple, the energy consumption is low, and the obtained product is clear and transparent; according to the silicate preparation method provided by the invention, the product is low in energy consumption and does not need to be heated and pressurized, and the prepared water glass product is high in modulus which can be controlled between 1 and 12 as required.

Owner:KUNMING DAOERSEN TECH

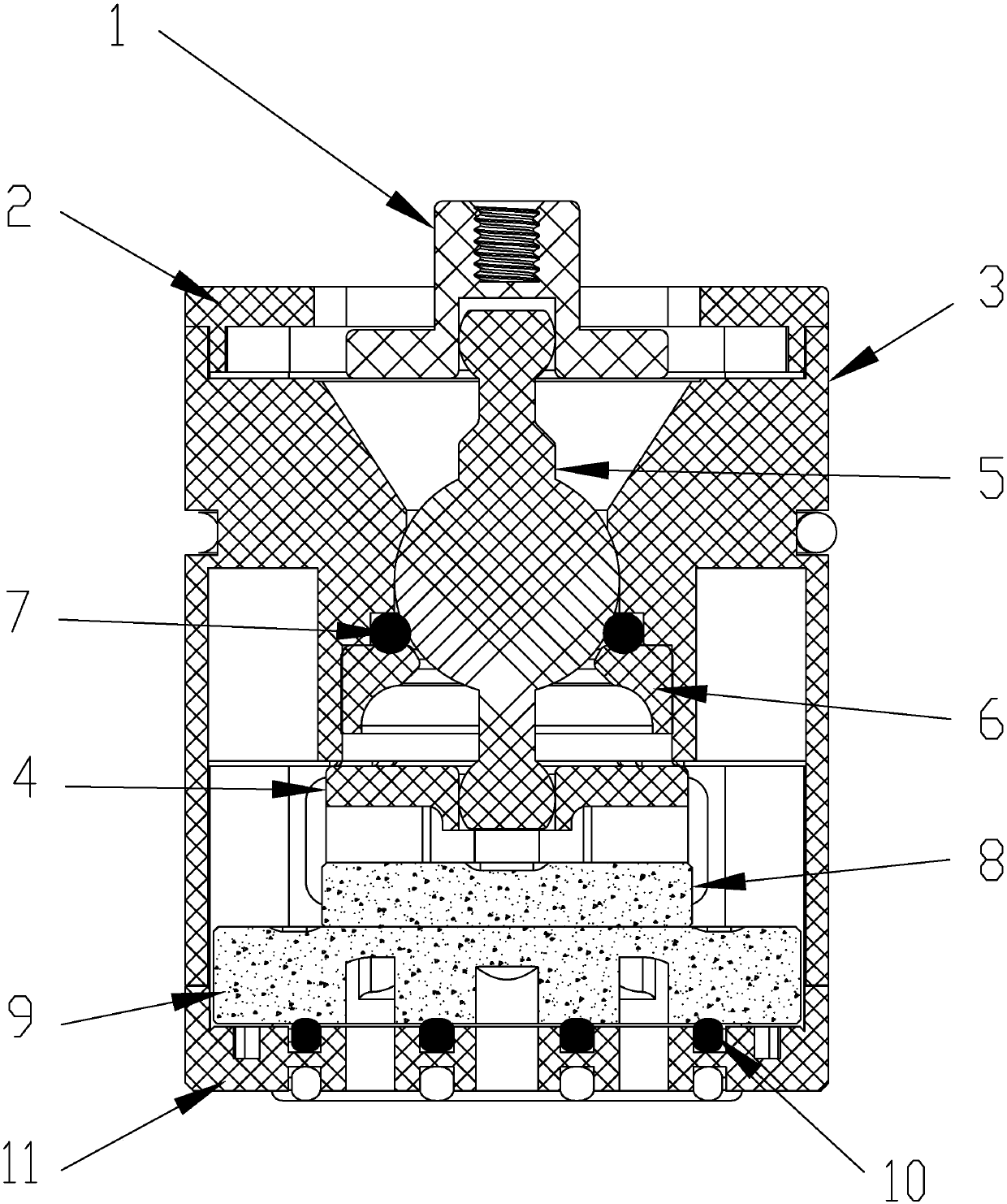

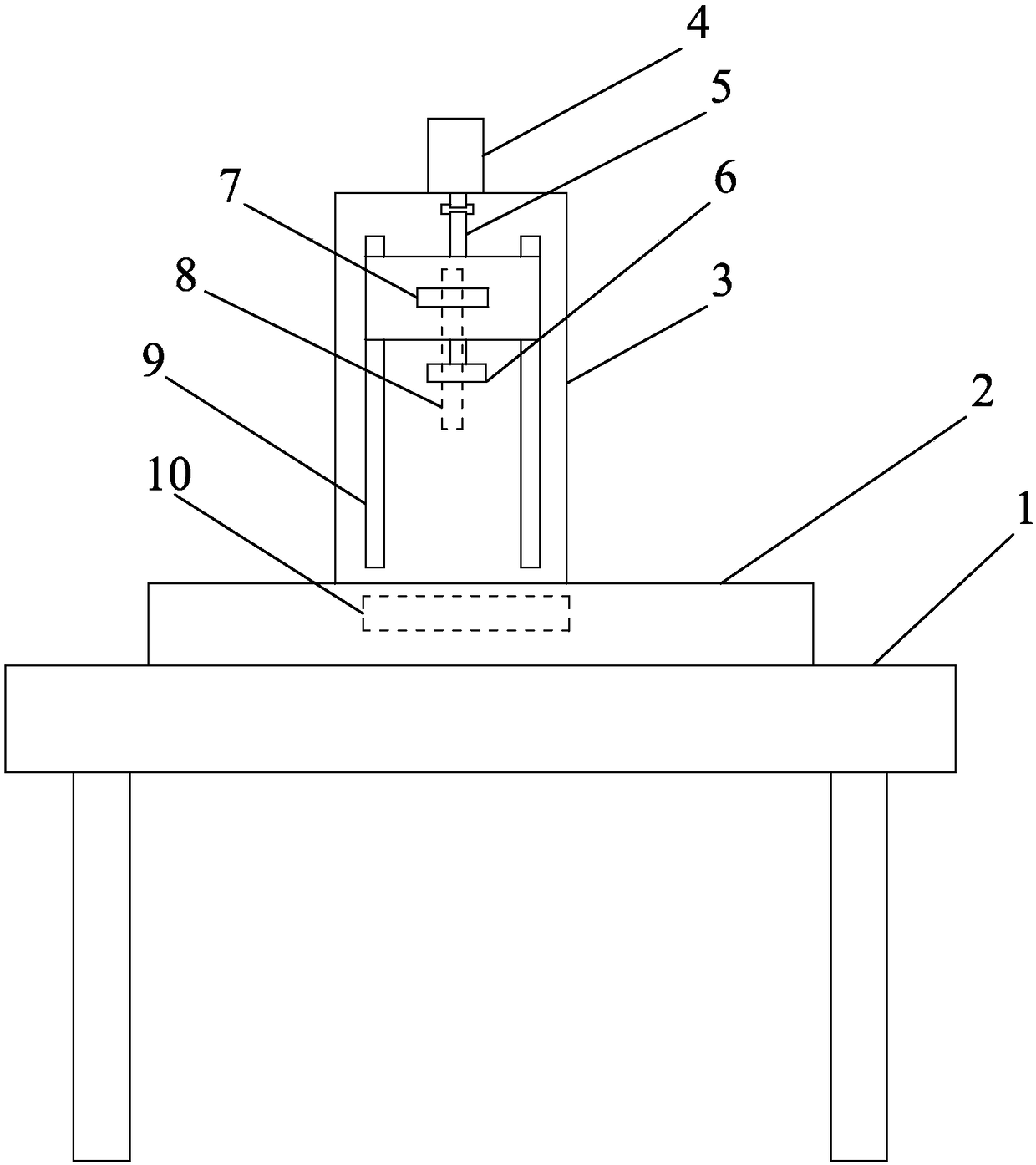

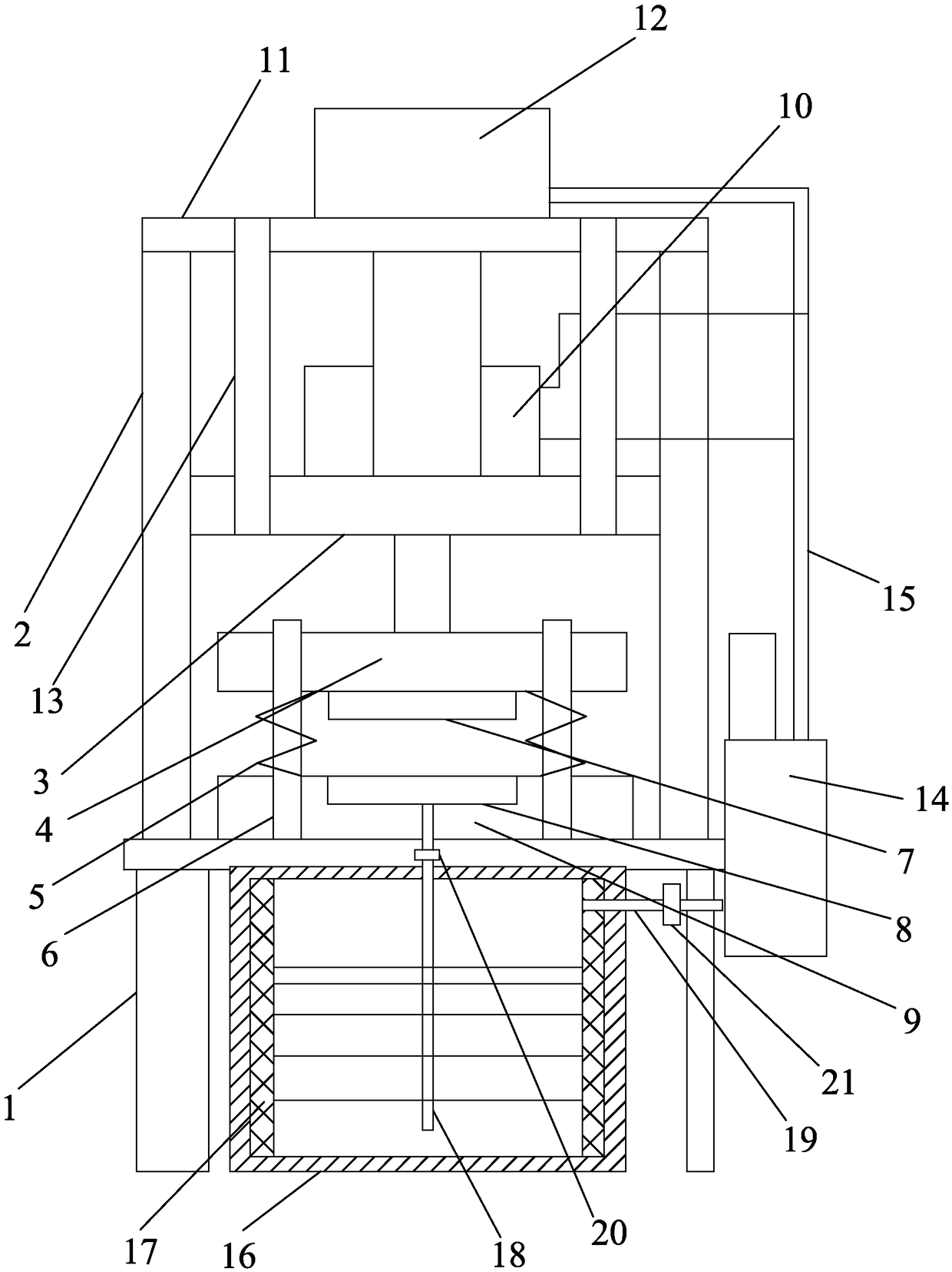

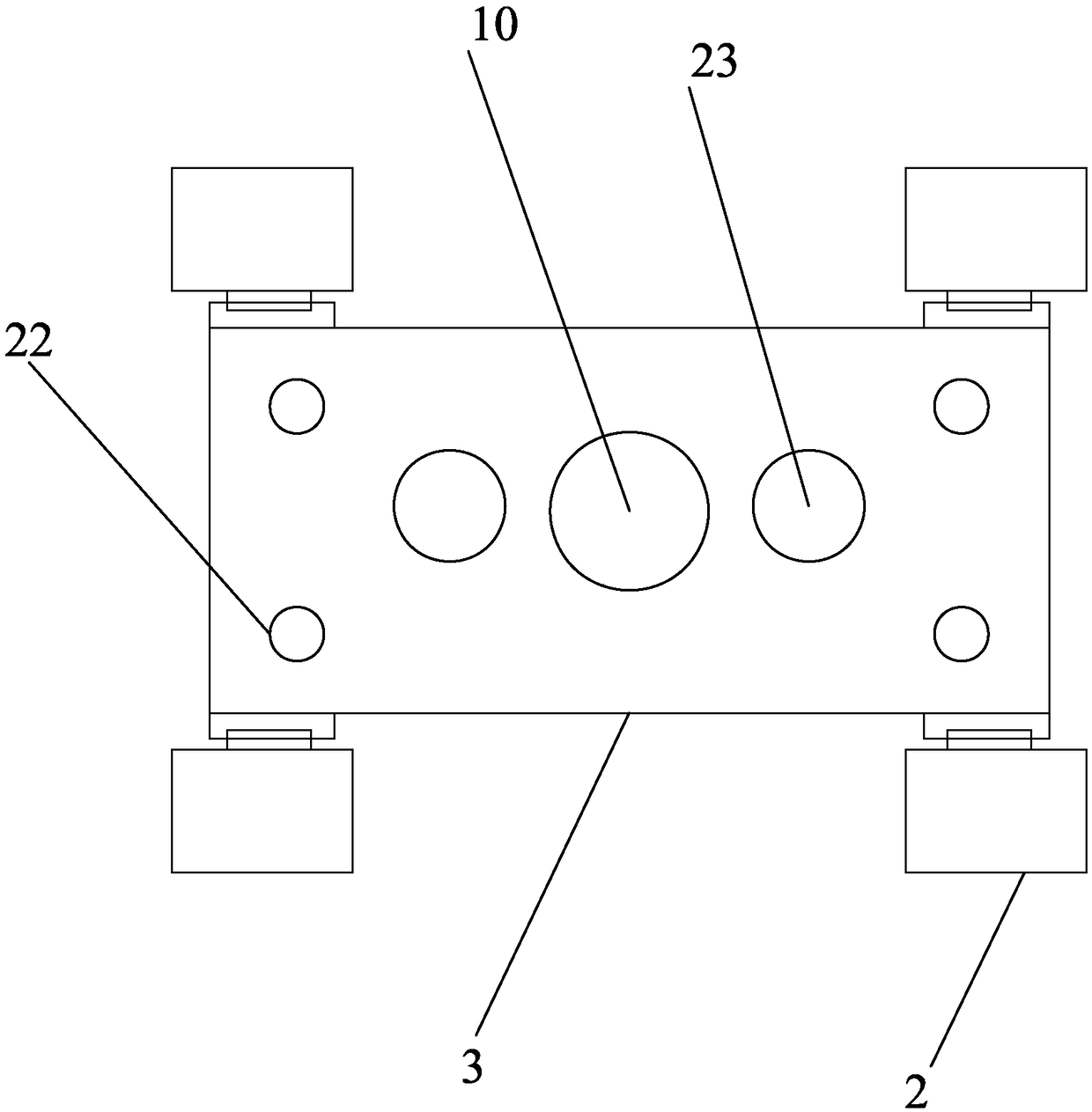

Lift-type hub casting device

The present invention discloses a lift-type hub casting device. The device includes a pedestal, a vertical frame, a lifting seat, an upper mould stand, an upper mould, a lower mould, a lower mould stand and an upper mould oil cylinder. Four vertical bars are disposed at corners of the pedestal. A fixed lifting seat capable of lifting is disposed on the middle part of the vertical bars. The upper mould oil cylinder is fixed on the upper side of the lifting seat. A piston rod of the upper mould oil cylinder passes through the lifting seat and fixes the upper mould seat with the tail end thereof.The upper mould is disposed on the upper side of the upper mould seat. The lower mould is correspondingly disposed on the lower side of the upper mould. The lower mould is fixed on the upper side ofthe lower mould seat. The lower mould seat is fixed on the upper end of the pedestal. The device has a simple structure design and convenient use; the height between the upper and lower moulds is adjustable, so that mounting and maintenance are convenient; and the device satisfies the market use demands and benefits product promotion.

Owner:KAIPING ZHONGLV IND

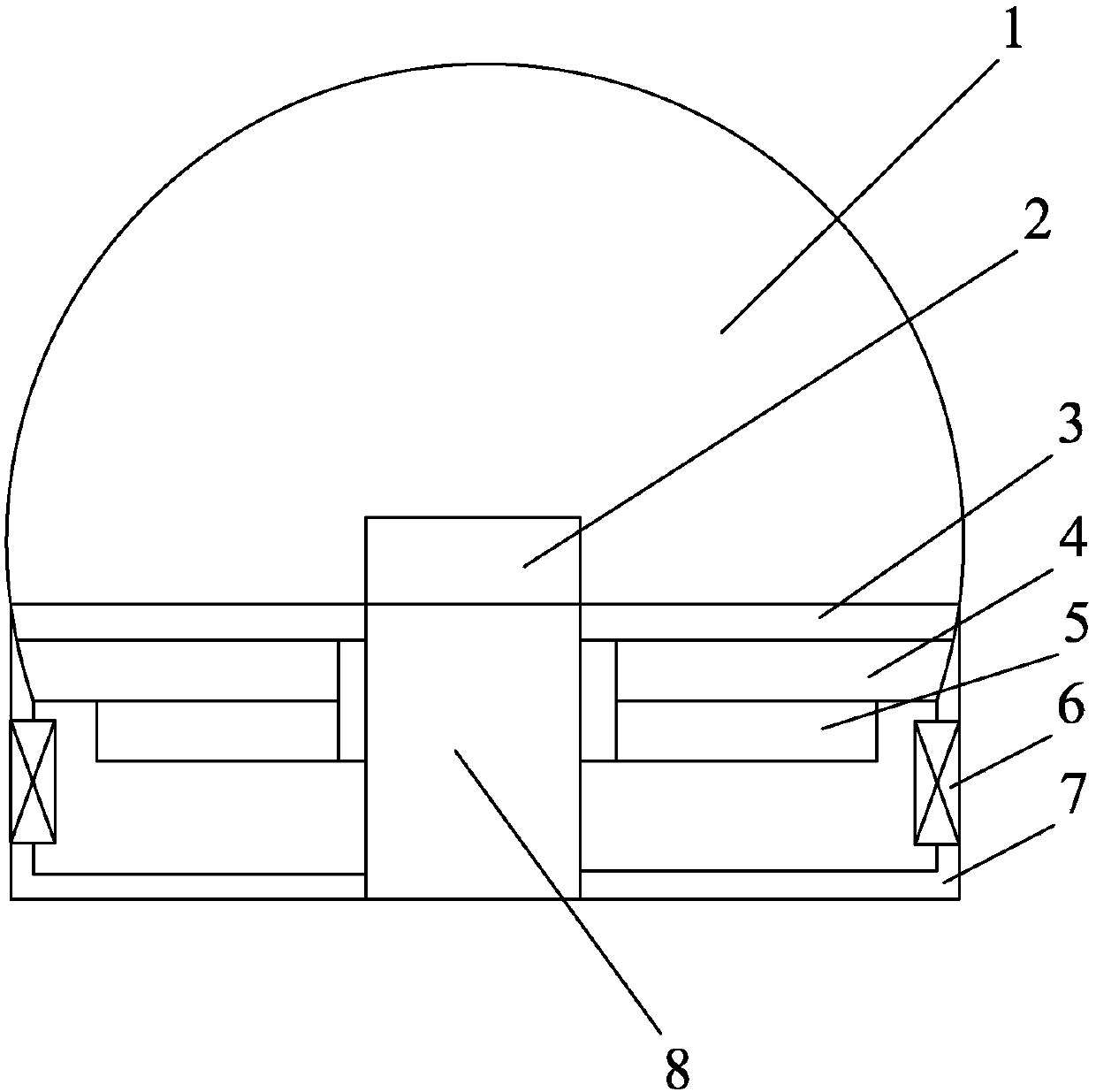

Novel LED lamp

InactiveCN107642700AImprove cooling effectExtended service lifeLighting heating/cooling arrangementsLight fasteningsEngineeringLED lamp

The invention discloses a novel LED lamp which comprises an outer cover, an LED chip, a heat dissipation plate, fans, a base plate and a ceramic base. The outer cover is fastened on the base plate ina covering manner, the ceramic base is fixed to the middle of the inner side of the base plate, the LED chip is fixed to the top of the inner side of the ceramic base, the heat dissipation plate is fixed to a position close to the top of the inner side of the ceramic base, and air flow spaces are formed by the outer side of the heat dissipation plate and the inner side wall of the base plate; thefans are fixed to the side walls of the base plate and are opposite to the air flow spaces. The novel LED lamp has the advantages that good heat dissipation effects can be realized, the service life of the novel LED lamp can be prolonged, the work stability of the novel LED lamp can be improved, service requirements of markets can be met, and accordingly the novel LED lamp can be advantageously popularized.

Owner:方步雄

Novel plastic package device

InactiveCN109110221AReduce lossesSimple structural designWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a novel plastic package device. The novel plastic package device comprises a feeding conveying belt, a heat sealing conveying belt, a discharge conveying belt, upper heating pipes and lower heating pipes; the heat sealing box is internally provided with the heat sealing conveying belt, the upper side and the lower side of the heat sealing conveying belt are provided with the upper heating pipes and the lower heating pipes, the upper heating pipes and the lower heating pipes are symmetrically arranged on the upper side and the lower side of the upper end of the heat sealing conveying belt, and thus, materials conveyed at the upper end of the heat sealing conveying belt is uniformly heated; and the front side of the heat sealing box is provided with a feed conveying belt, and the rear side of the heat sealing box is provided with the discharge conveying belt. The novel plastic package device is simple in structure and convenient to use and has the guiding function, automatic collecting is achieved, manpower is saved, the cost is reduced, the market using requirements are met, and product popularization is facilitated.

Owner:张湘

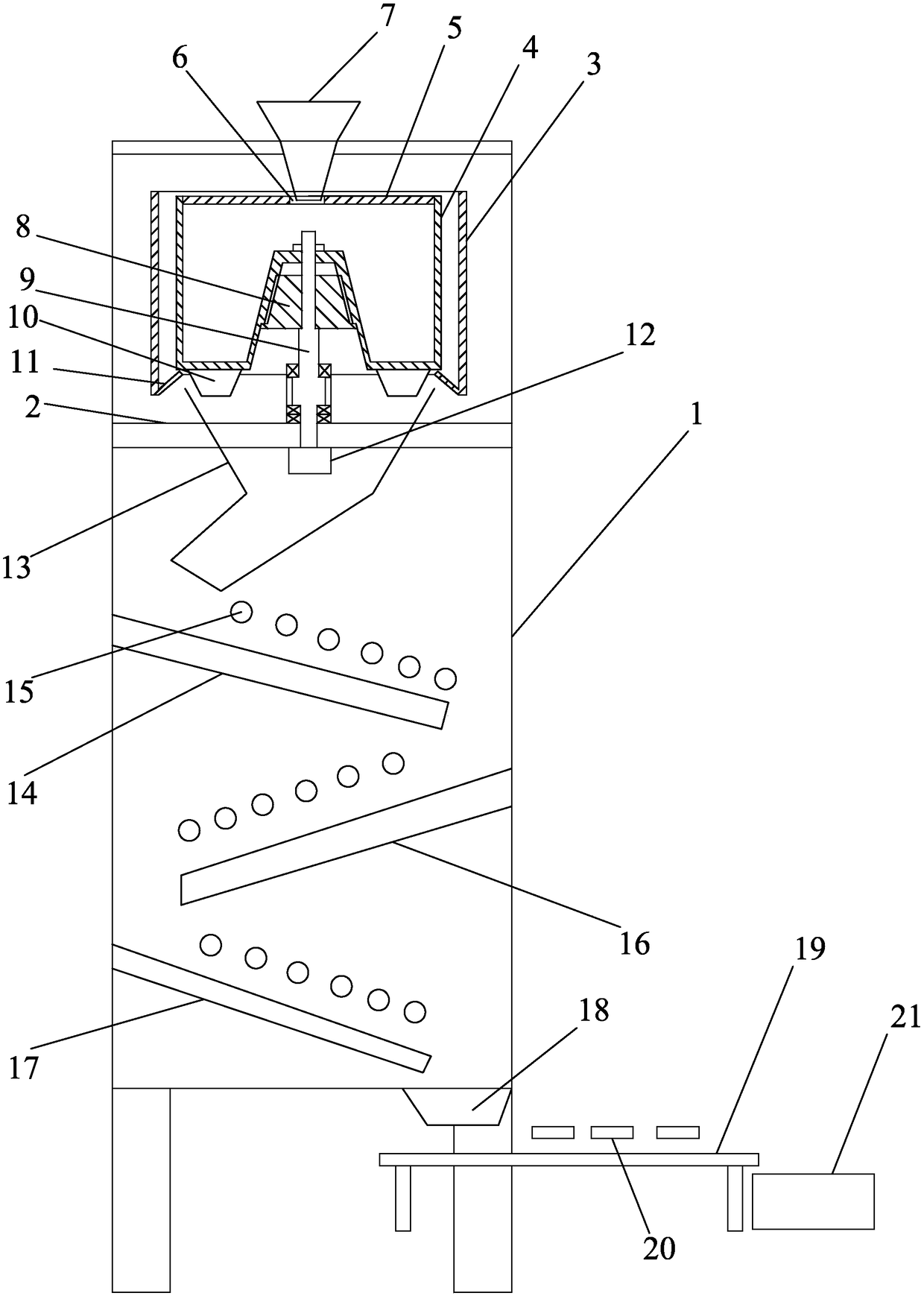

Plastic processing device

The invention discloses a plastic processing device. The plastic processing device comprises a box body, a feeding hopper, a discharging opening, a material pouring hopper, a first inclined plate, infrared lamp tubes, a second inclined plate, a third inclined plate, a discharging hopper, a conveyor belt, a fan and a material receiving box, wherein the feeding hopper is arranged at the top end of the box body; the lower end of the feeding hopper and a centrifugal device are arranged oppositely; the discharging opening at the lower end of the centrifugal device and the material pouring hopper are arranged oppositely; the first inclined plate, the second inclined plate and the third inclined plate, which are used for drying, are arranged at the lower end of the material pouring hopper; the plurality of infrared lamp tubes, which are arranged in parallel, are arranged at the upper sides of the first inclined plate, the second inclined plate and the third inclined plate respectively; the discharging hopper fixed at the bottom of the box body is arranged at the lower side of a notch at the lowest end of the third inclined plate; the conveyor belt is arranged at the lower side of the discharging hopper; the fan is arranged in the middle of the conveyor belt; the material receiving box is arranged at the tail end of the conveyor belt. The plastic processing device adopts a spin-drying,drying and air-drying combined manner and has the advantages of rapid drying speed and high efficiency, and the drying cost is reduced.

Owner:开平市合美纸塑复合包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com