Cleaning mechanism for filter

A cleaning mechanism and filter technology, applied in the direction of filter regeneration, filtration separation, chemical instruments and methods, etc., can solve the problems of increased cost, low efficiency, waste of manpower, etc., and achieve improved efficiency, convenient use, and simple structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The best embodiment of the present invention will be further described in detail below.

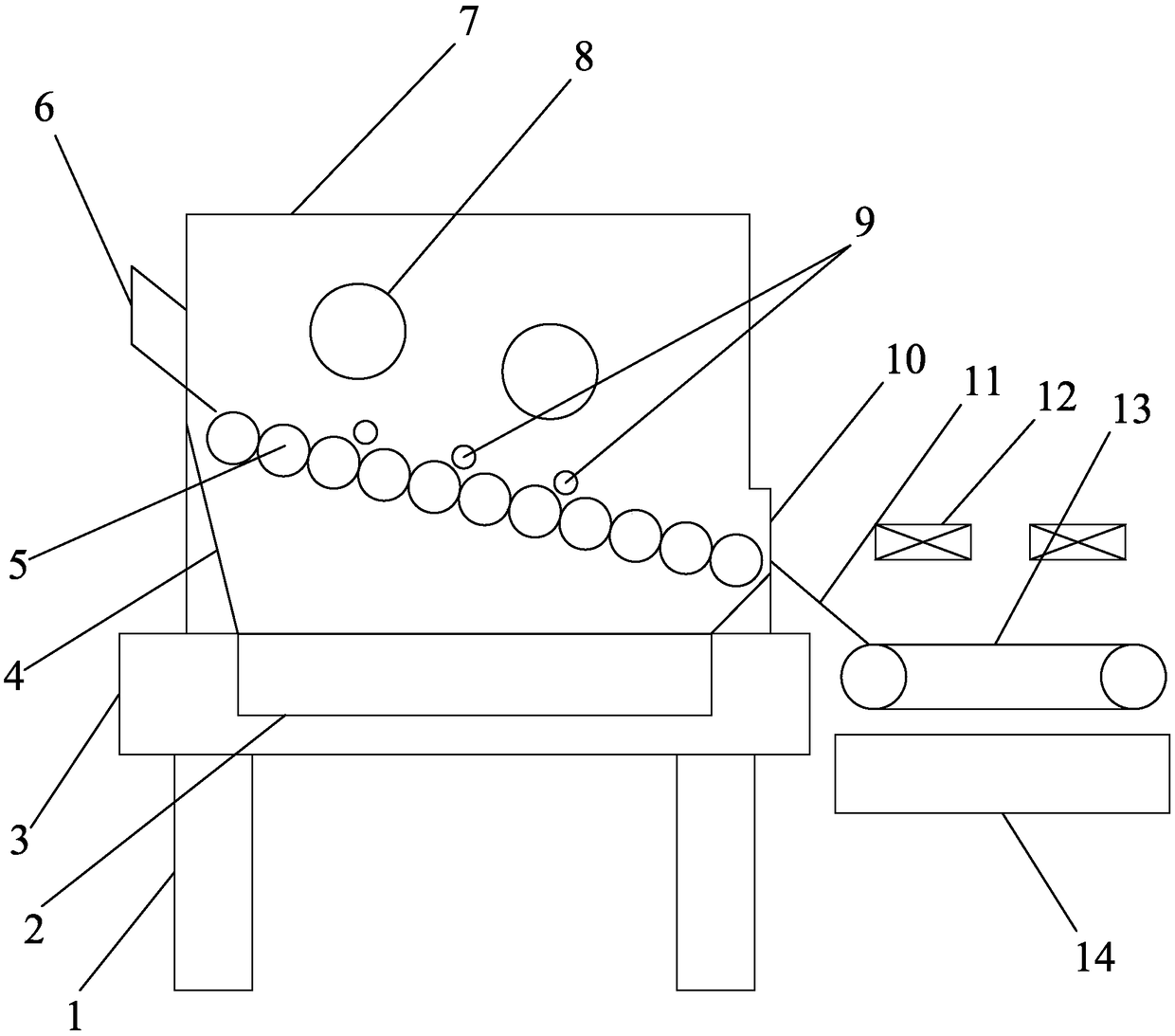

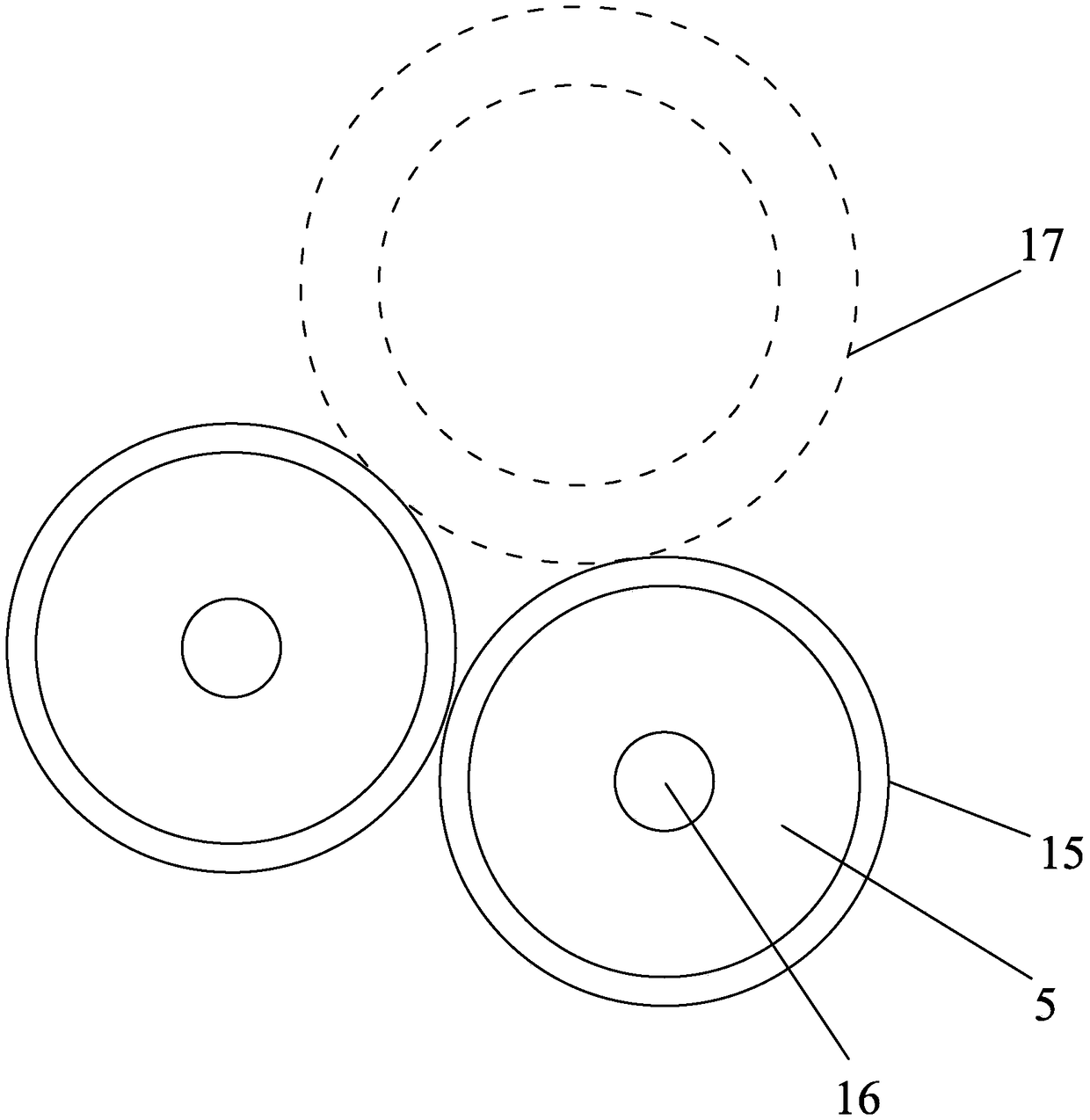

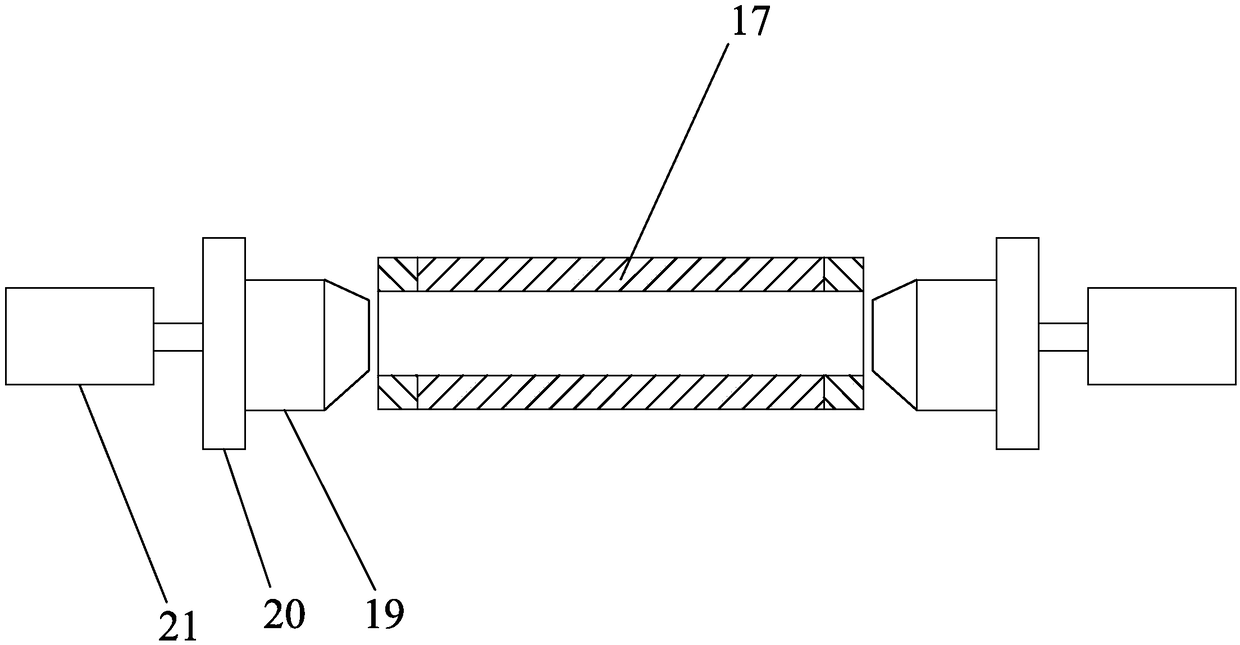

[0021] Such as Figure 1-4 As shown, in the embodiment of the present invention, the cleaning mechanism for the filter includes a bracket 1, a recovery box 2, a base 3, a front guide plate 4, a roller 5, an inlet 6, a cleaning box 7, a cleaning pipe 8, Flushing mechanism 9, outlet 10, guide plate 11, fan 12, conveying mesh belt 13, second recovery box 14, the base 3 is fixed on the upper end of the support 1, and the upper end of the base 3 is provided with a sealed cleaning box 8, the cleaning box 8 The left side is provided with inlet 6, and the right side of cleaning box 8 is provided with outlet 10. The rollers 5 are displaced downwards from the inlet 6 to the outlet 10, so that the cartridge filter 17 can roll down from the rollers 5; The type filter 17 sprays cleaning agent, and the plurality of rollers 7 are respectively provided with flushing mechanisms 9 opposite to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com