Titanium steel flange casting machining equipment and machining process thereof

A technology for processing equipment and castings, which is applied in the field of processing equipment and processing technology for titanium steel flange castings, can solve the problems of low processing efficiency, high processing cost, and large manpower consumption, and achieve compact processing equipment and precise grinding and polishing precision , to ensure the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

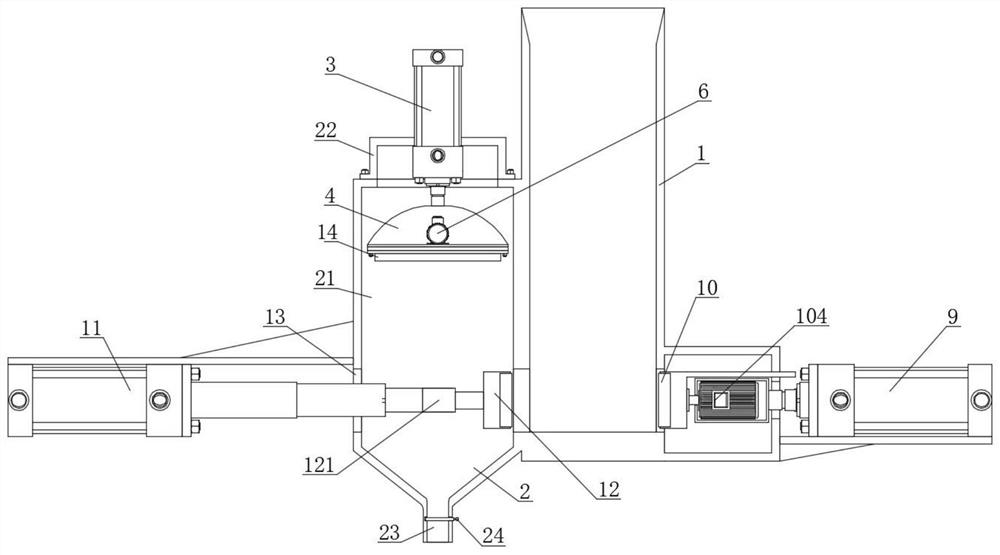

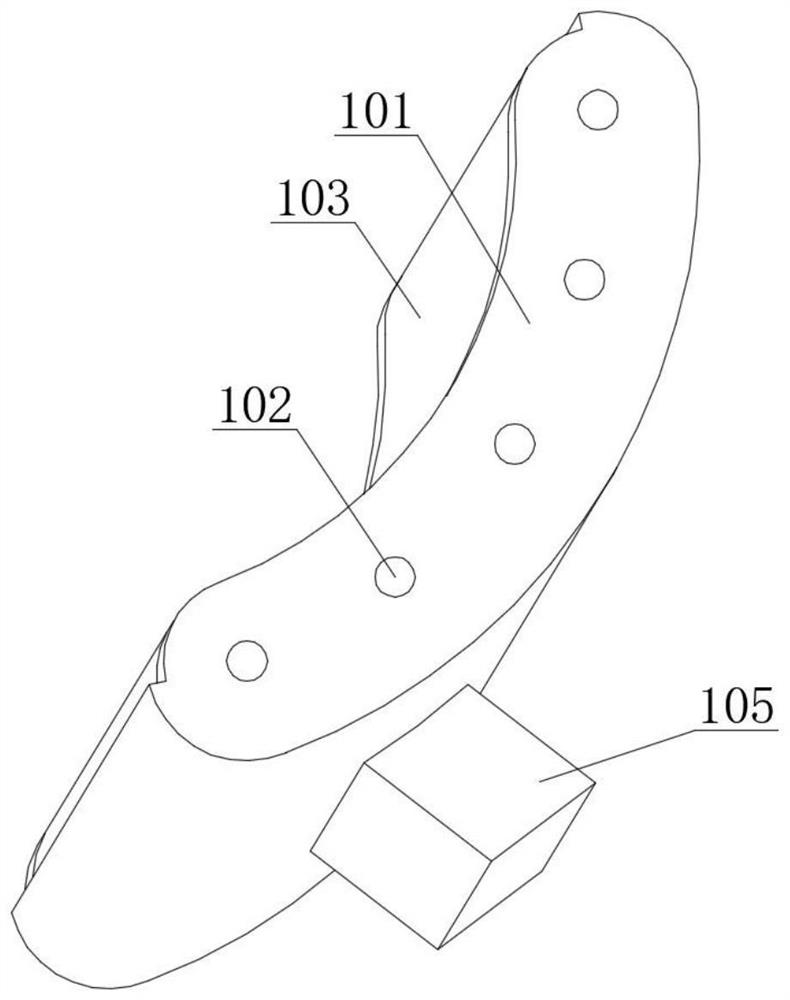

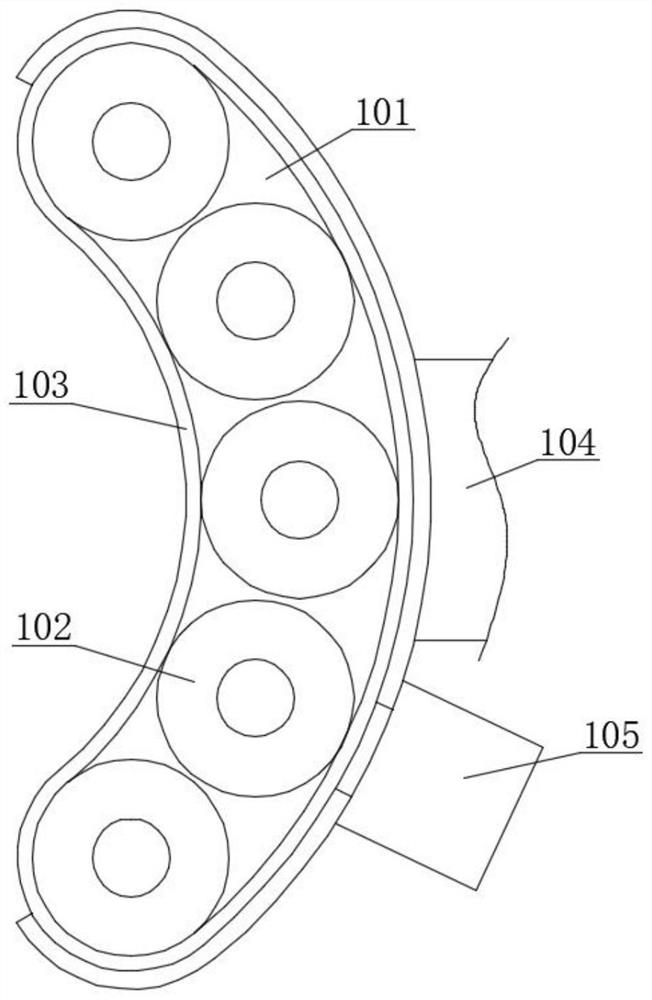

[0041] see figure 1 , In the present invention, a processing equipment for titanium steel flange castings includes a feeding barrel 1, the left side of the feeding barrel 1 is fixedly connected with a processing barrel 2 that communicates with it, and the inner top wall of the processing barrel 2 is fixedly installed with a The first electric push rod 3, the output shaft of the first electric push rod 3 is fixedly connected with an annular mounting block 4, and the bottom of the annular mounting block 4 is connected with an annular grinding sheet 14.

[0042] The processing cylinder 2 includes a collection cylinder 21 with a funnel-shaped bottom, the right side of the collection cylinder 21 is fixedly connected with the feeding cylinder 1, the top of the collection cylinder 21 is fixedly connected with a cylinder cover 22 by bolts, and the first electric push rod 3 Installed on the cylinder cover 22 . The collecting cylinder 21 and the cylinder cover 22 are fixed by bolts, an...

Embodiment 2

[0057] A processing technology for titanium steel flange castings, comprising the above-mentioned processing equipment for titanium steel flange castings, comprising the following steps:

[0058] S1. Put titanium steel flange castings of the same specification in batches at the entrance of feeding barrel 1 as pre-processing castings;

[0059] S2. The second electric push rod 9 is energized to work, the bottommost titanium steel flange casting is driven to move by driving the clamping mechanism 10, and the titanium steel flange casting is clamped with the stable clamping mechanism 12. The second electric push rod 9 Work synchronously with the third electric push rod 11 to drive the titanium steel flange casting to move to the inside of the processing cylinder 2;

[0060] S3, the first electric push rod 3 moves down, and the first drive motor 5 is energized to drive the annular grinding plate 14 to rotate to grind the upper surface of the titanium steel flange casting;

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com