Plastic processing device

A processing device and plastic technology, applied in the direction of coating, etc., can solve the problems of low drying efficiency, the influence of plastic particle processing, uneven drying of plastic particles, etc., and achieve fast drying speed, which is conducive to product promotion and meets the needs of the market. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The best embodiment of the present invention will be described in further detail below.

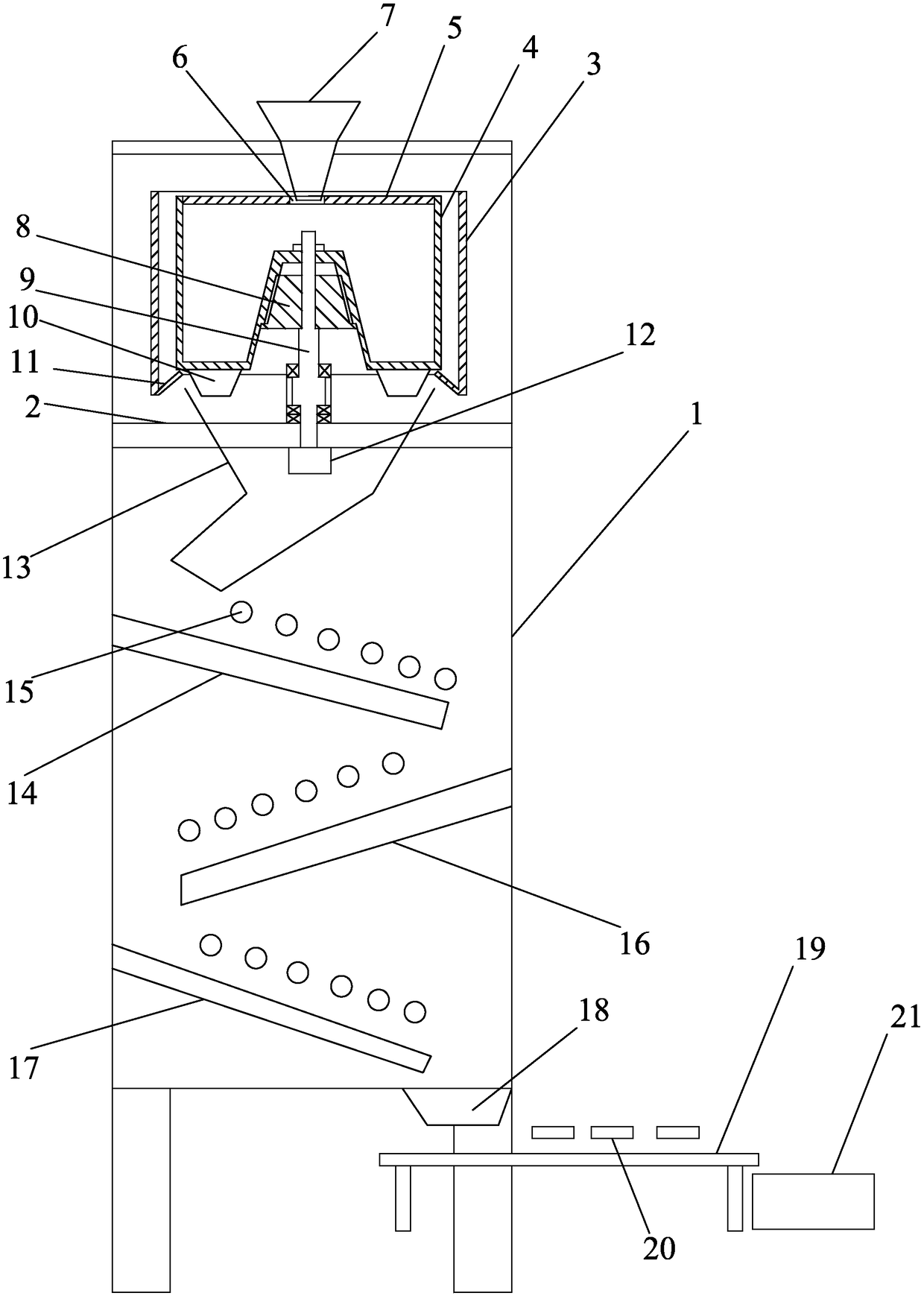

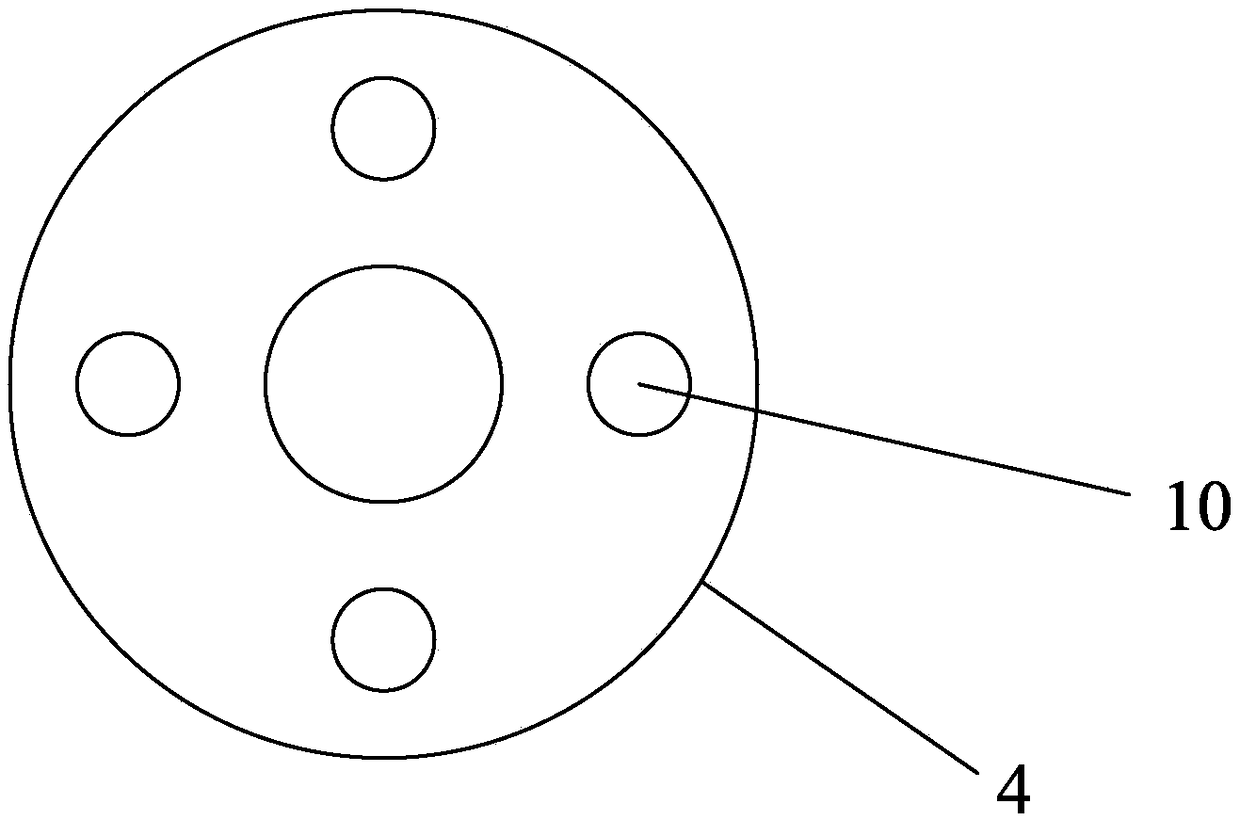

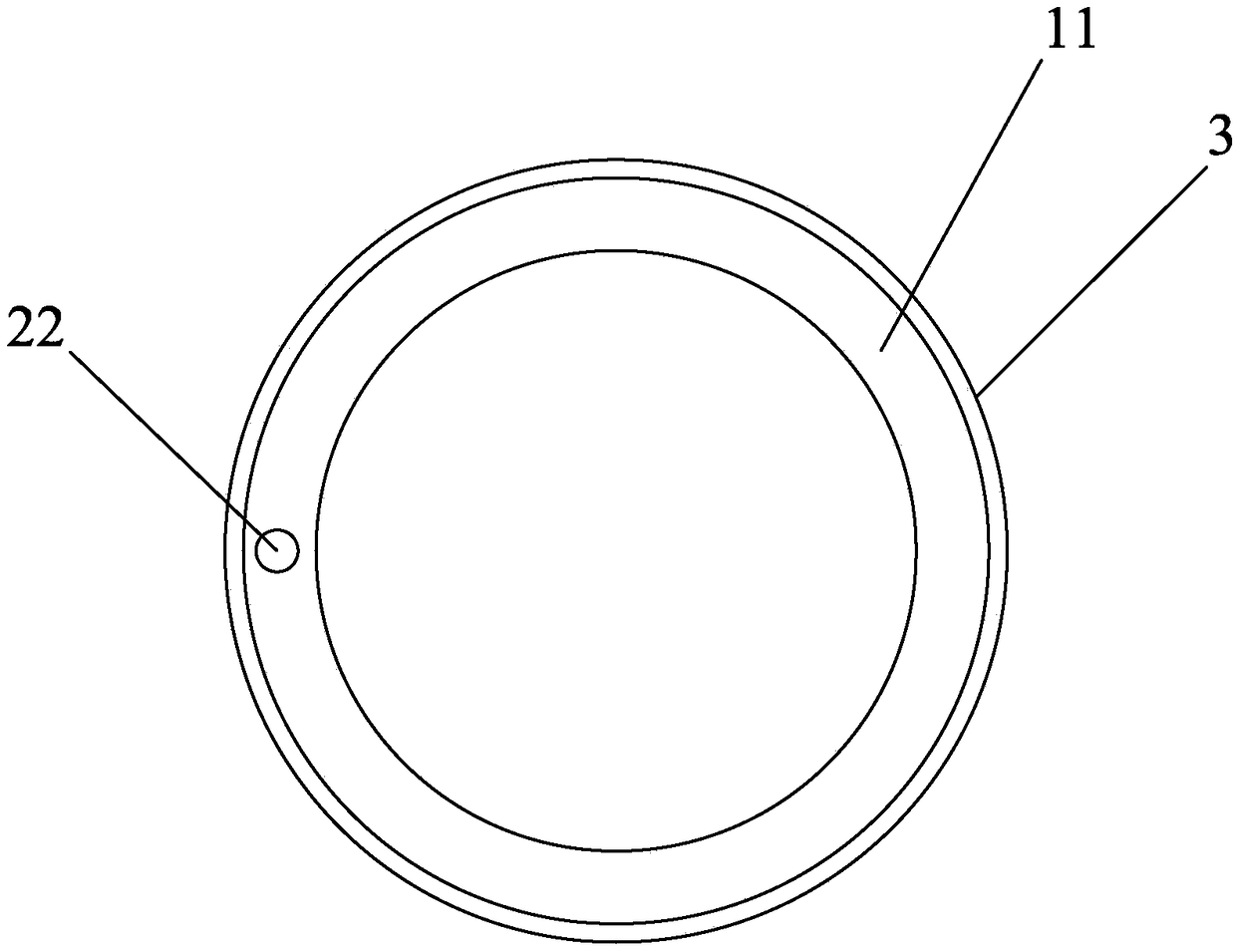

[0016] Such as Figure 1-3 As shown, in the embodiment of the present invention, the plastic processing device includes a box body 1, a feed hopper 7, a discharge port 10, a dump hopper 13, a first inclined plate 14, an infrared lamp tube 15, and a second inclined plate 16. , The third inclined plate 17, the discharge hopper 18, the conveyor belt 19, the fan 20, the receiving box 21, the top of the box body 1 is provided with a feeding hopper 7, and the lower end of the feeding hopper 7 is arranged opposite to the centrifugal device. The plastic particles are initially dried, and water is collected. The discharge port 10 provided at the lower end of the centrifugal device is arranged opposite to the dumping hopper 13, and the lower end of the dumping hopper 13 is provided with a first inclined plate 14, and the lower end of the dumping hopper 13 is connected to the first The highest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com