Patents

Literature

637results about How to "Reduce drying costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

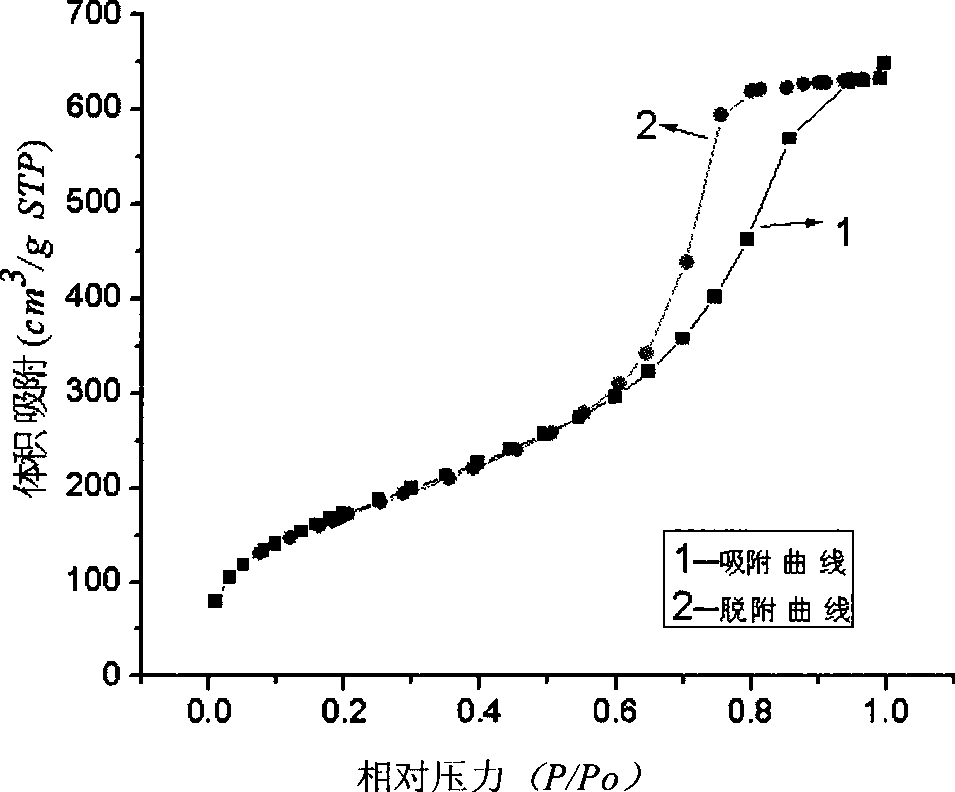

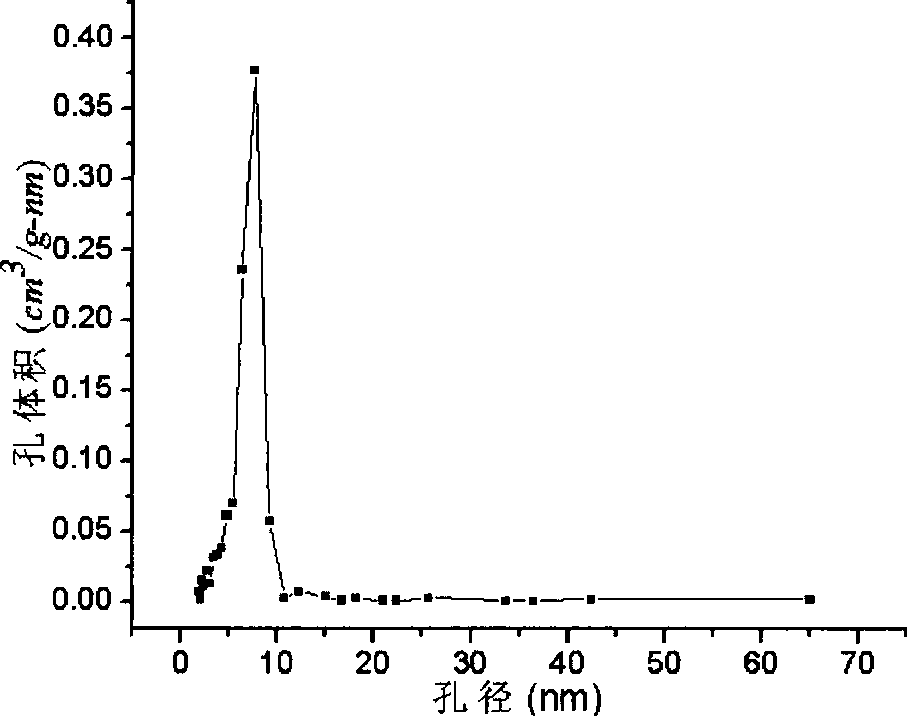

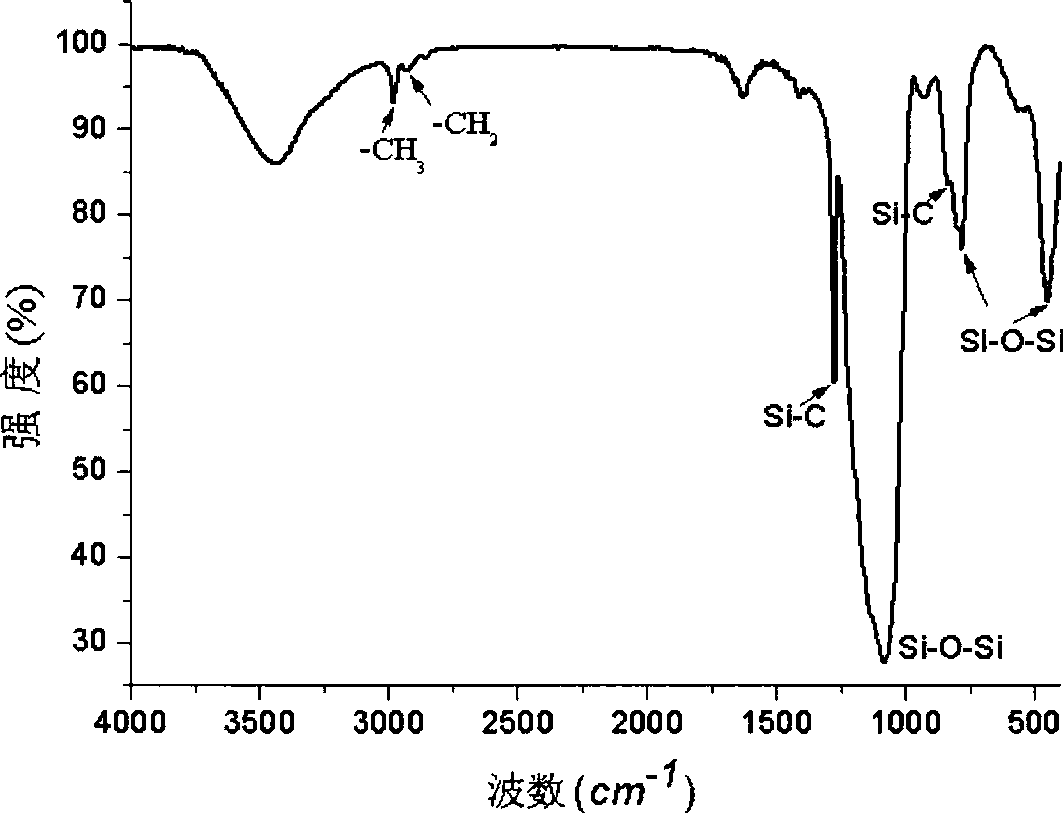

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

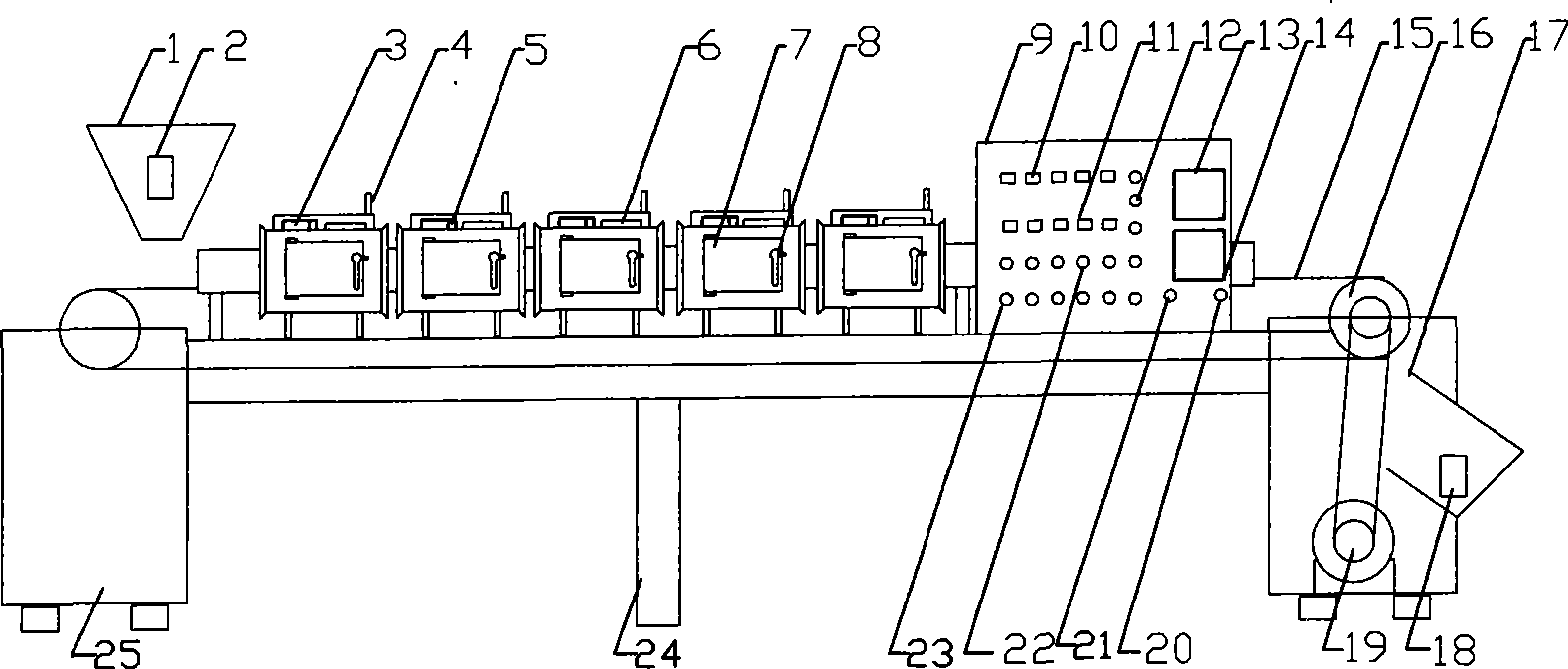

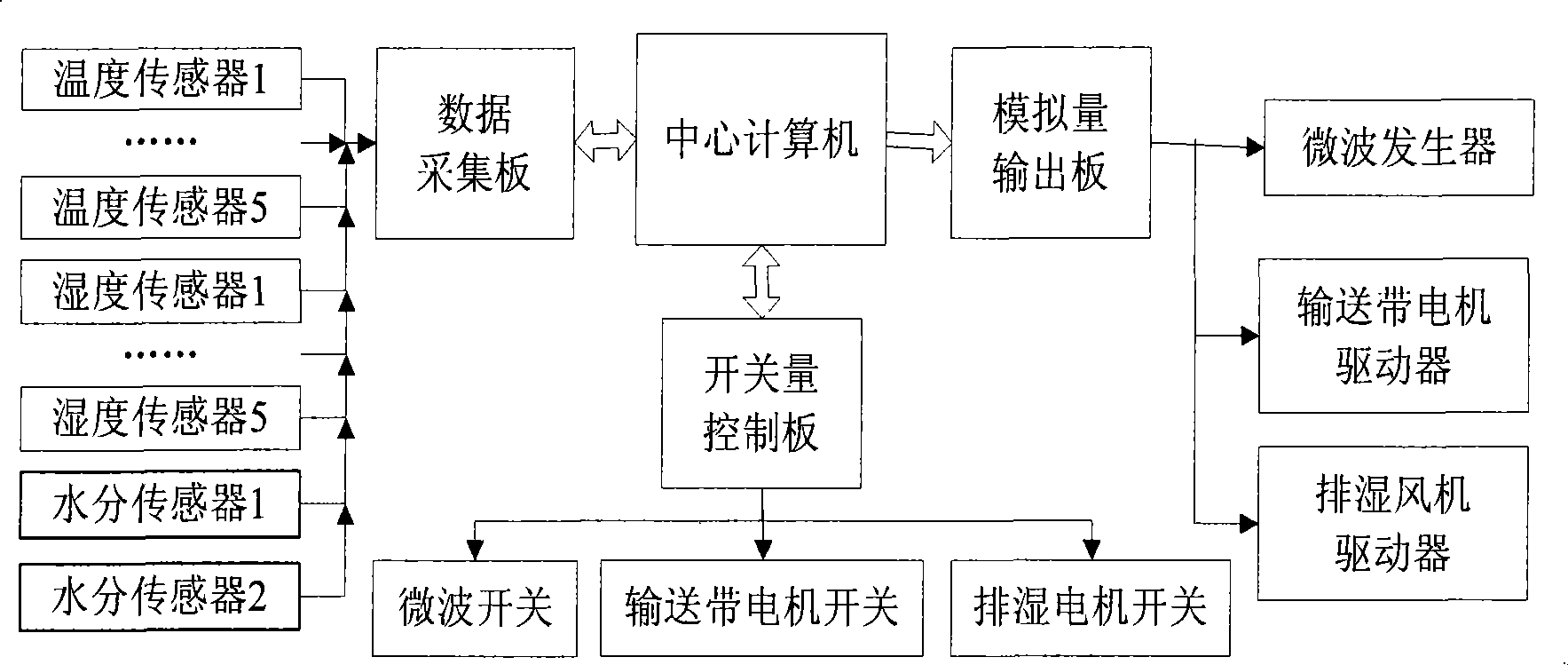

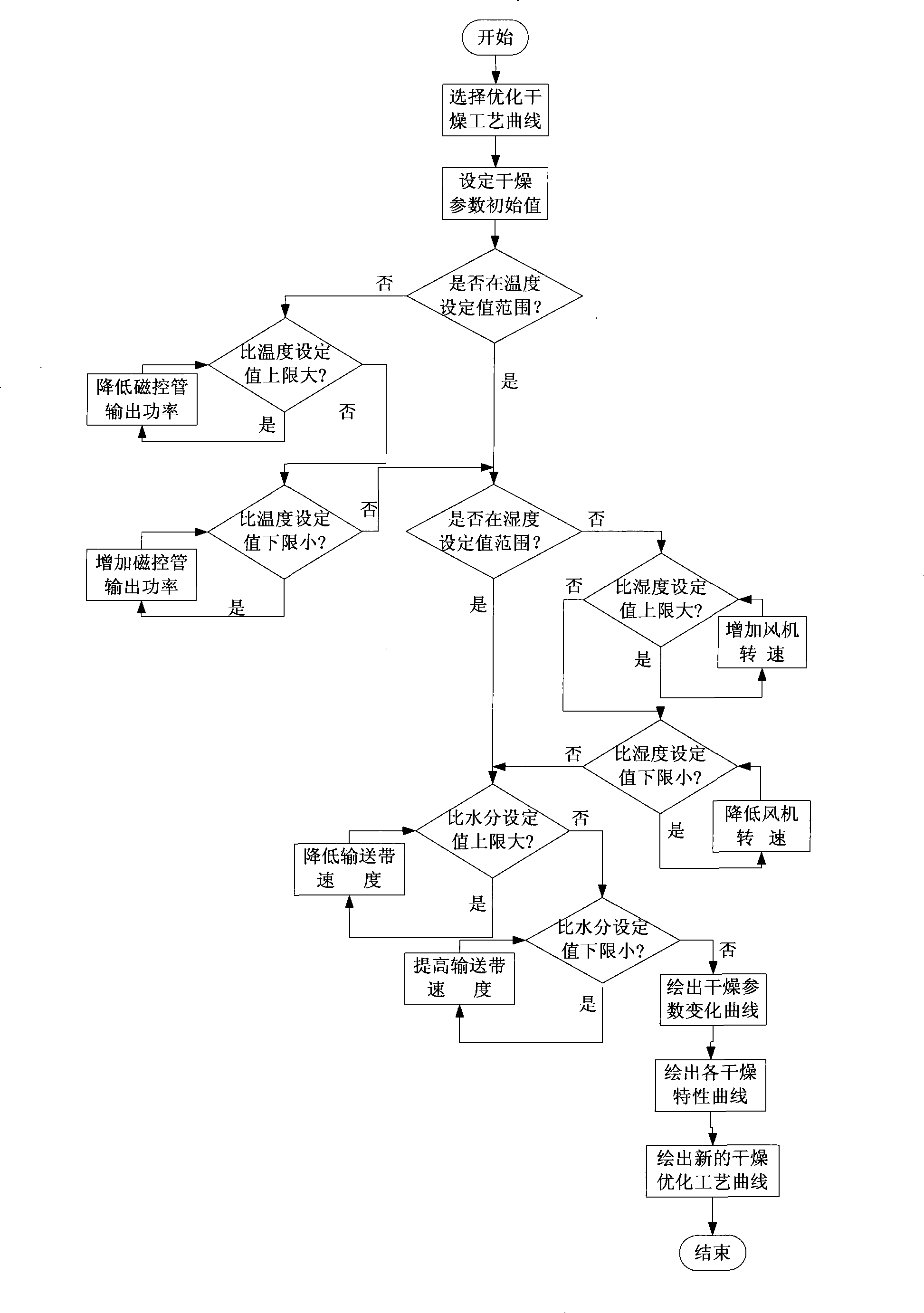

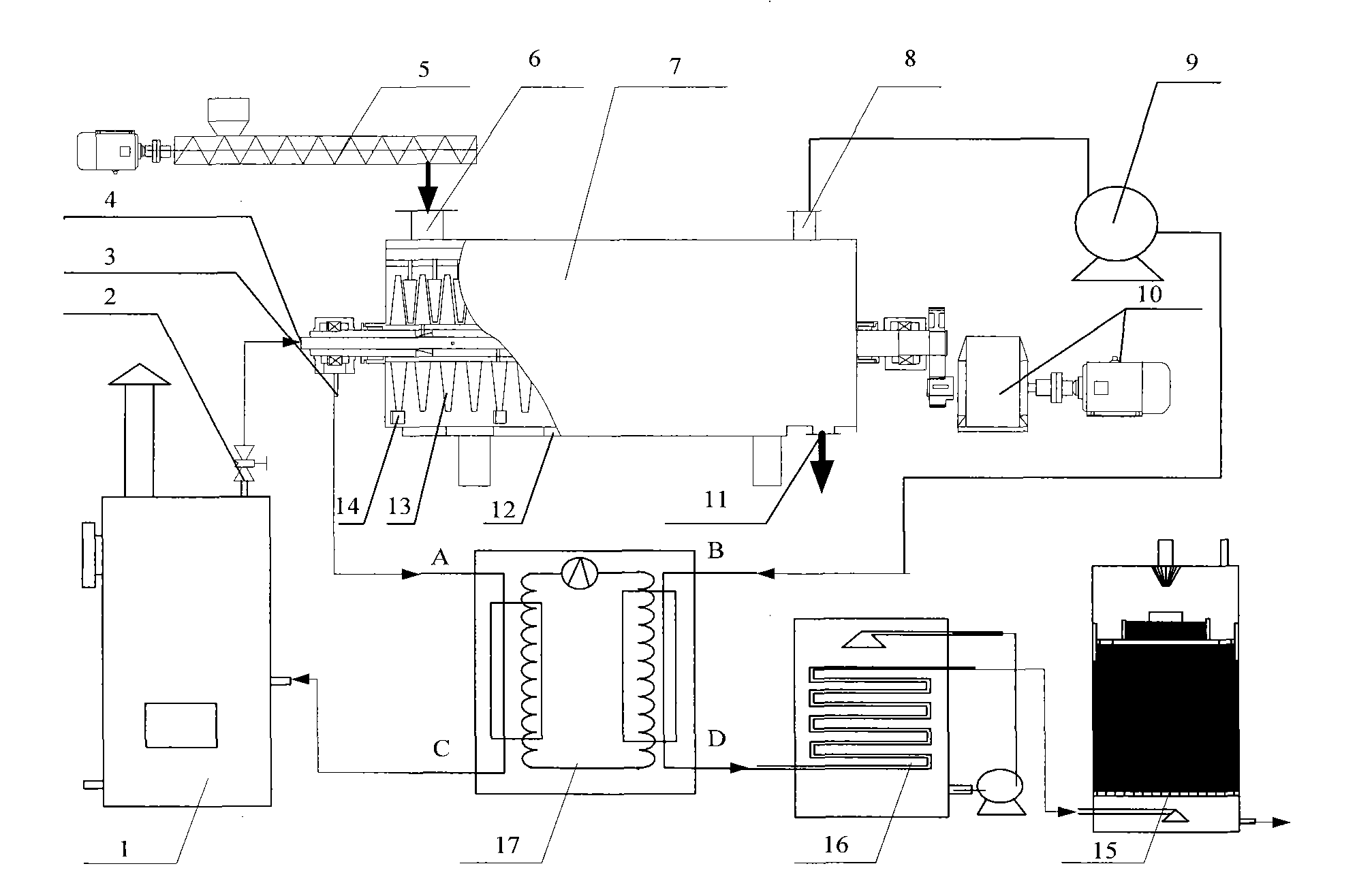

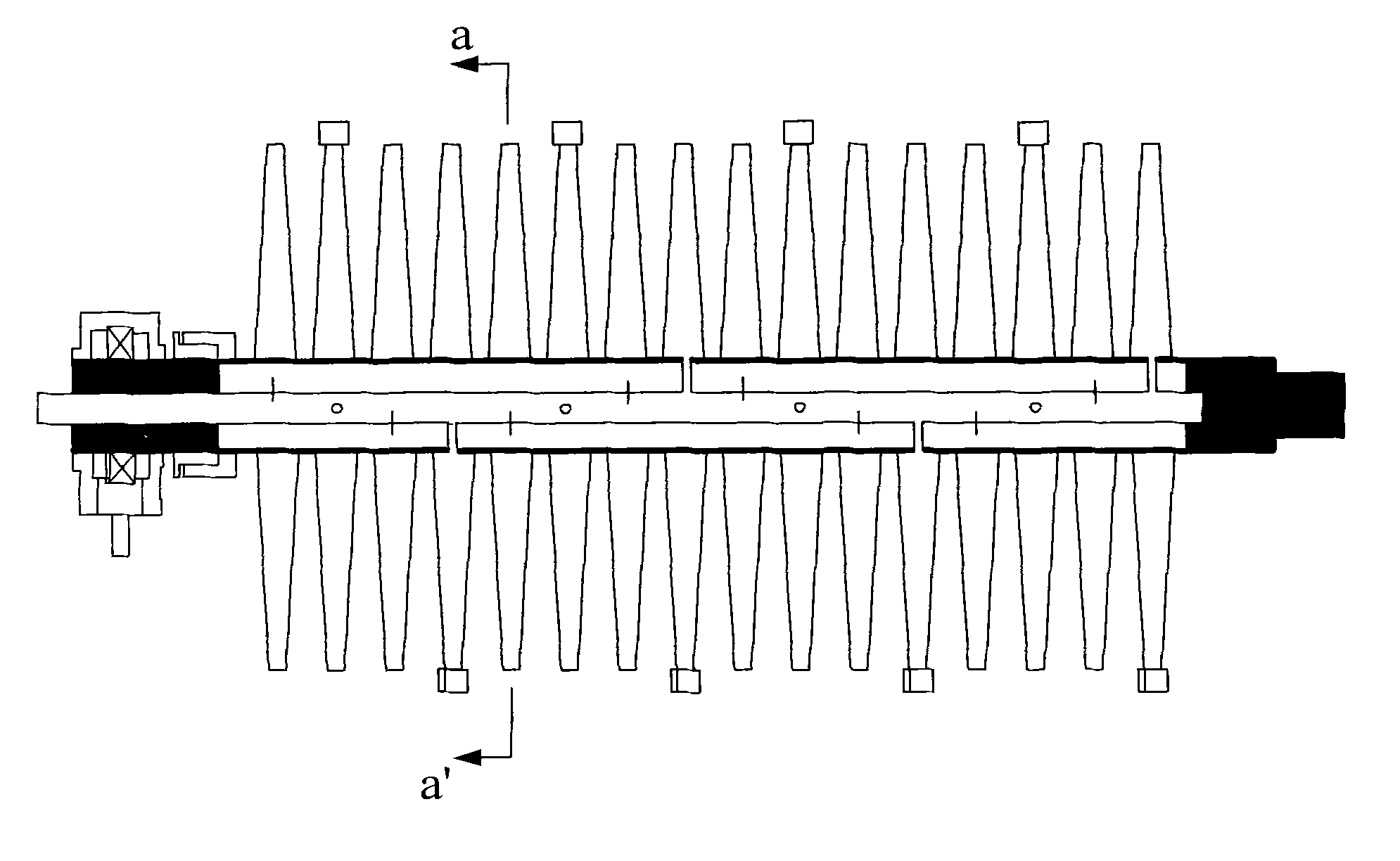

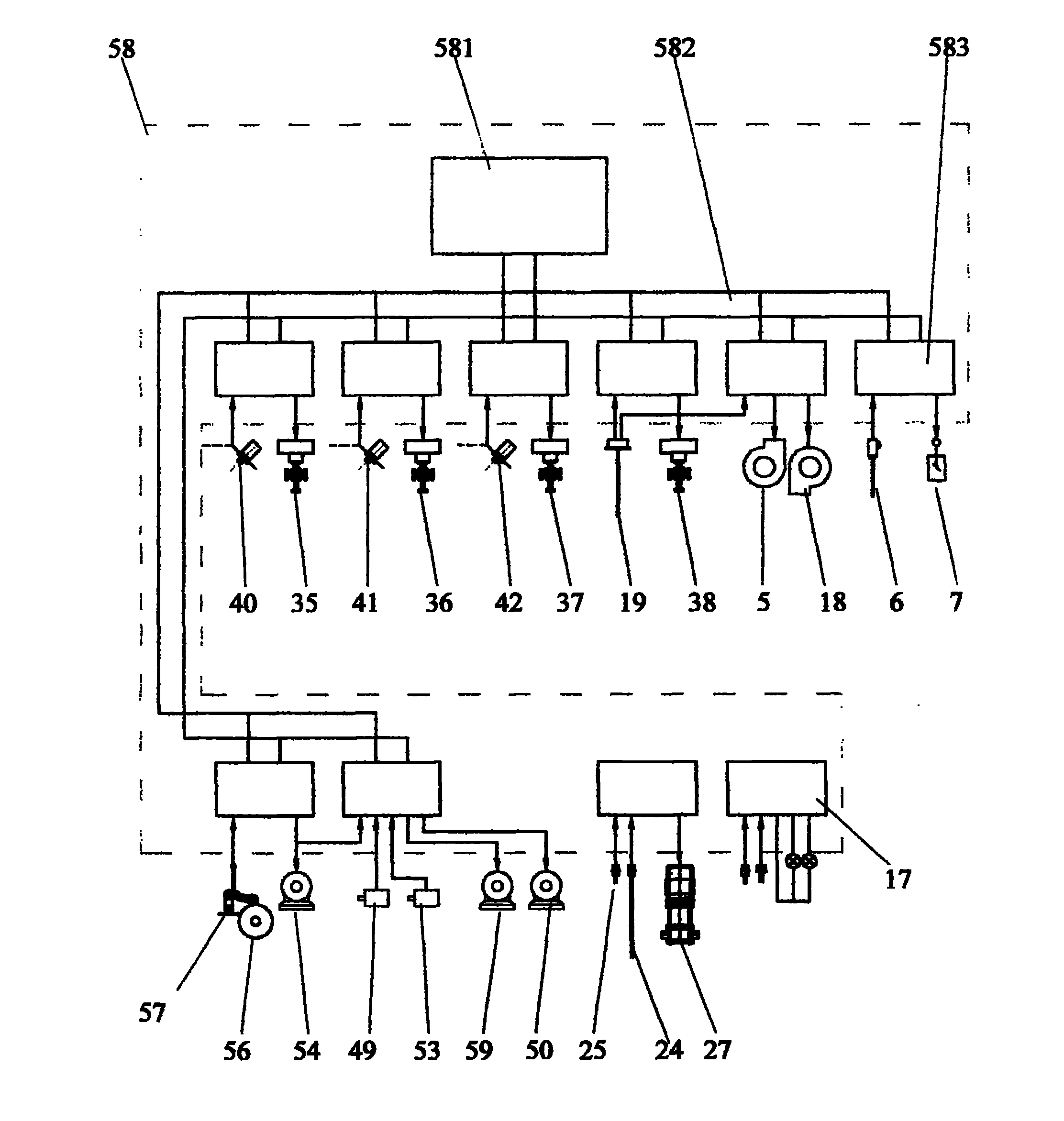

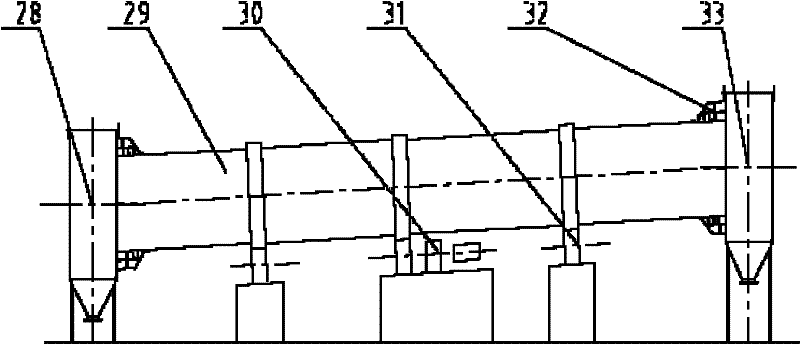

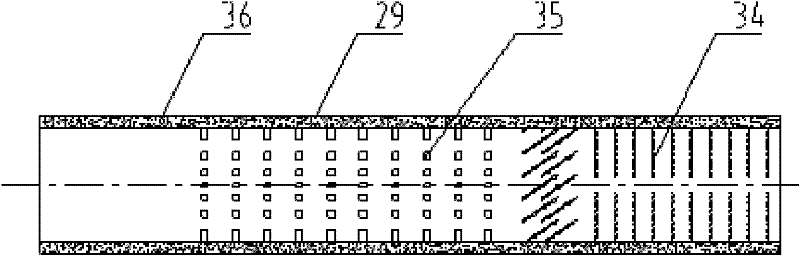

Intelligent microwave continuous drier and control method thereof

InactiveCN101382379AImprove drying qualityEasy to operateDrying solid materials with heatDrying machines with progressive movementsFrequency changerDrive motor

The invention discloses an intellectualized microwave continuous drier and a control method thereof; the drier comprises a rack, a conveying belt, a conveying belt wheel, a driving motor, an instrument control box and a computer; two ends of the conveying belt are respectively provided with a feed hopper and a discharge hopper and the conveying belt runs through a plurality of microwave drying cavities with doors; each microwave drying cavity is internally provided with a microwave magnetron, a temperature sensor, a humidity sensor and a speed-regulating fan; the feed hopper and the discharge hopper are respectively provided with a moisture sensor, and the conveying belt is driven by a speed-regulating motor controlled by a frequency converter. A control system can automatically draw variation curves of the temperature and the humidity of the materials in each drying cavity and the water content ratio of the discharged materials in the drying process of the materials in shorter time according to the collected data of the temperature, the humidity and the water content ratio of the materials in the drying process of the materials, can optimize control parameters continuously according to the change of the temperature, the humidity and the water content ratio in the drying process of the materials, and can regulate the system parameters automatically and realize the dynamic optimization of the drying technique parameters.

Owner:ANHUI AGRICULTURAL UNIVERSITY

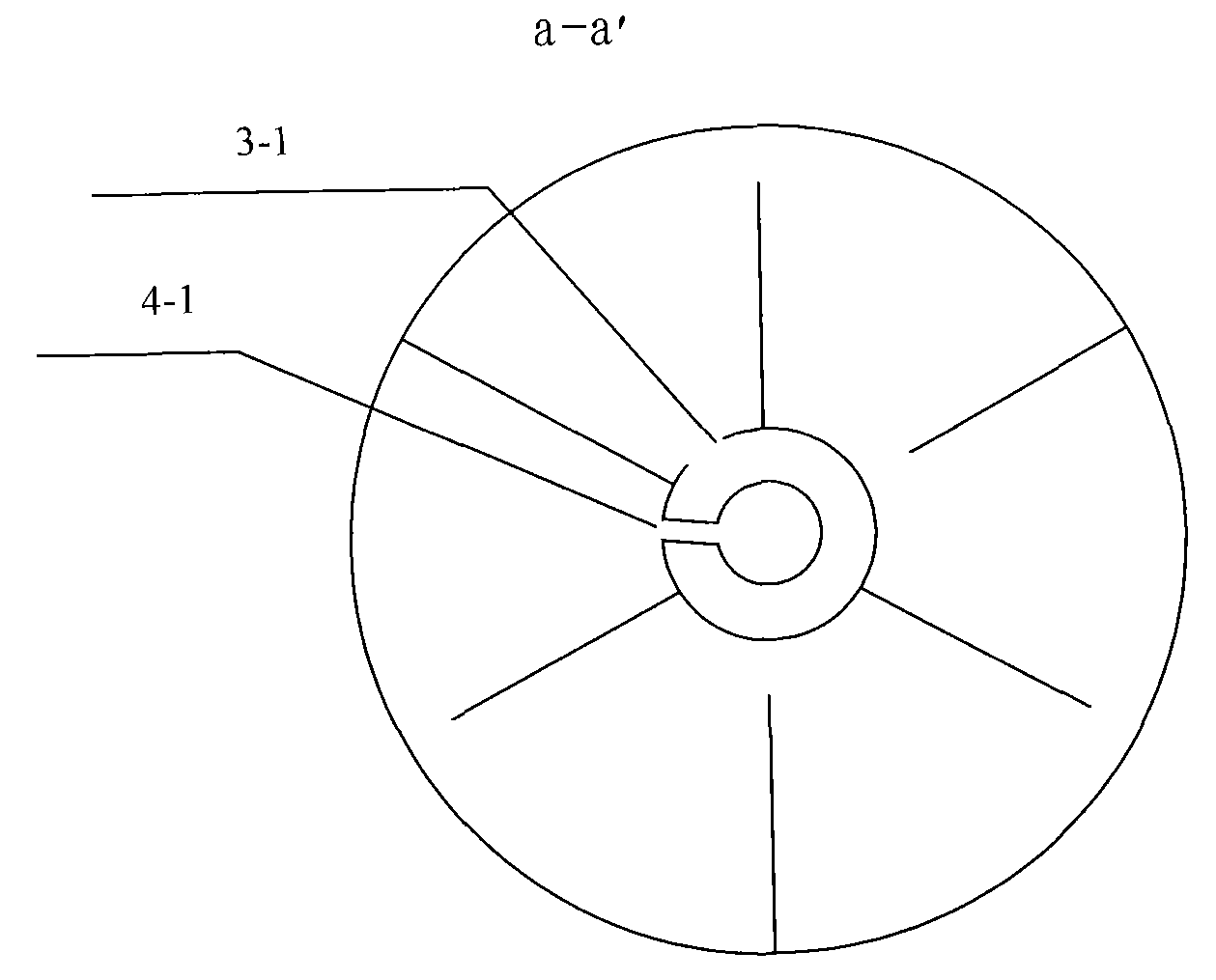

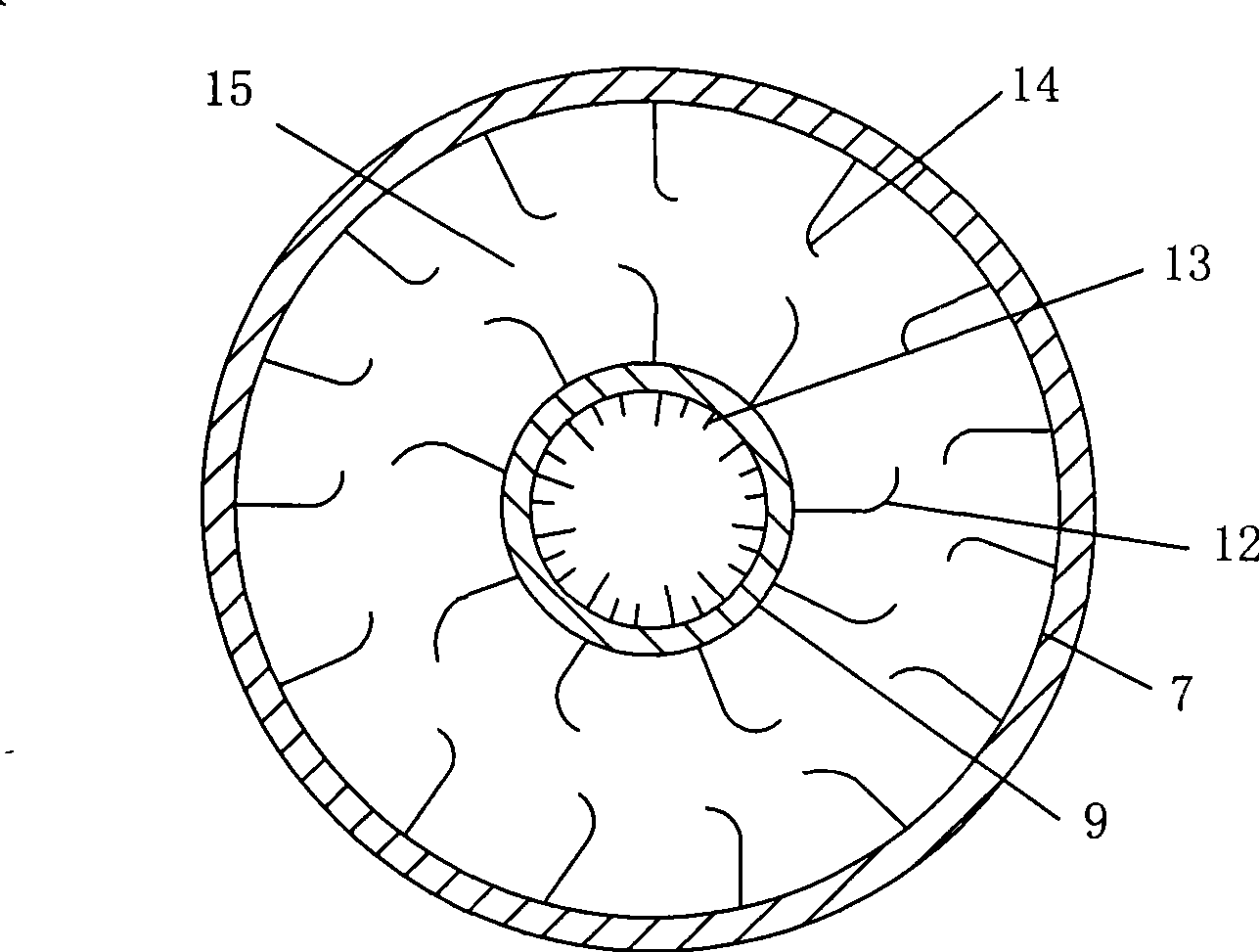

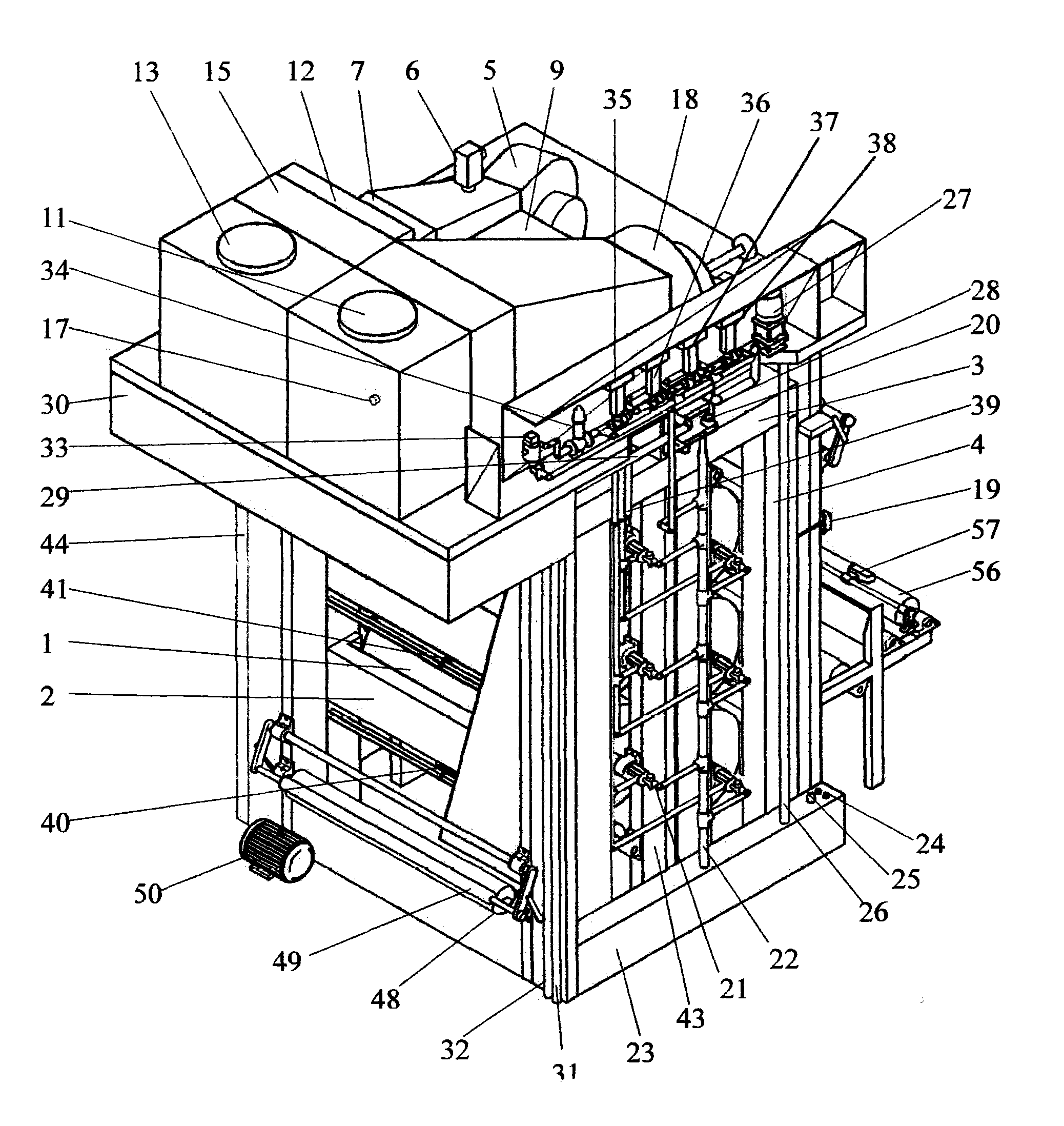

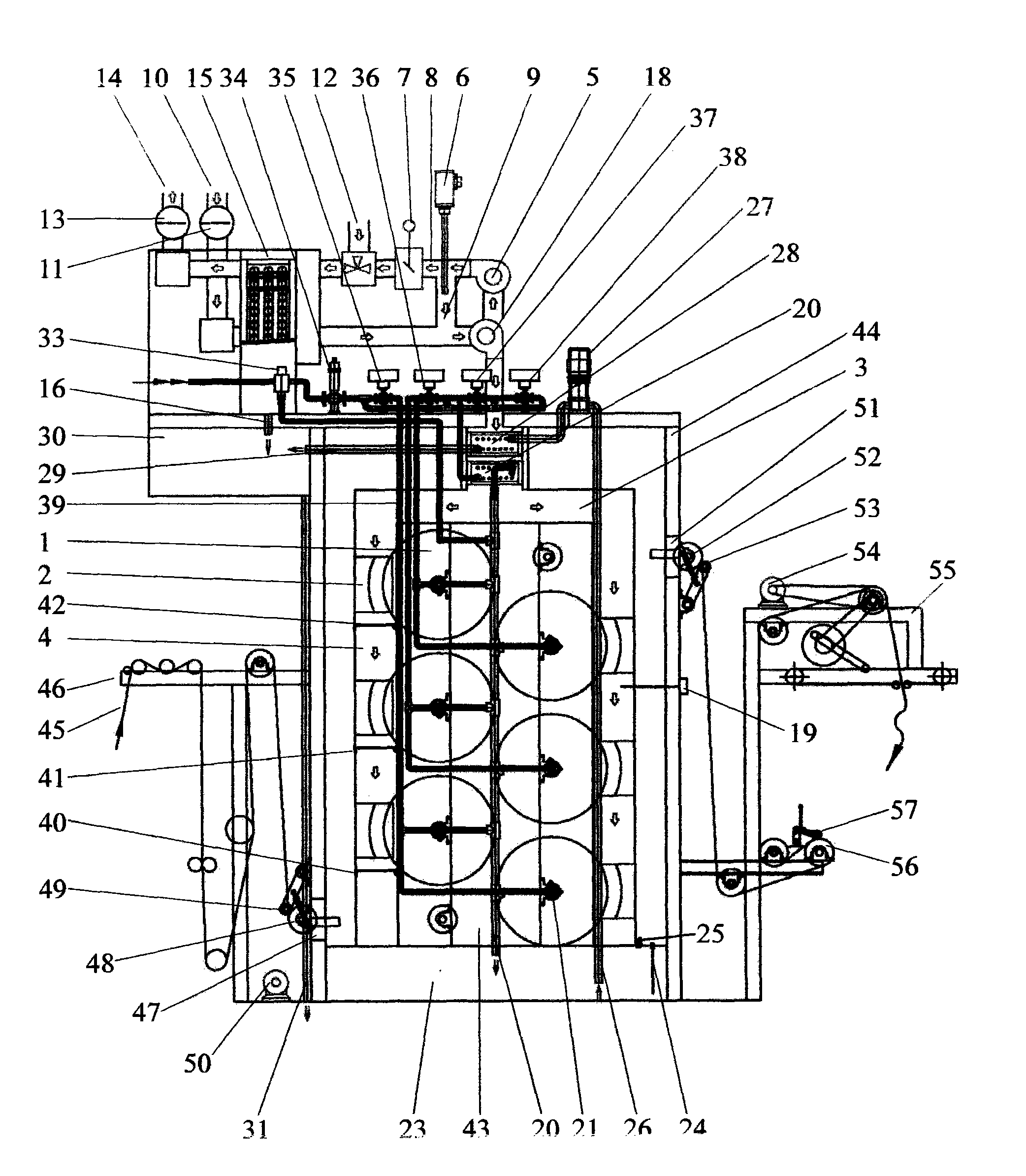

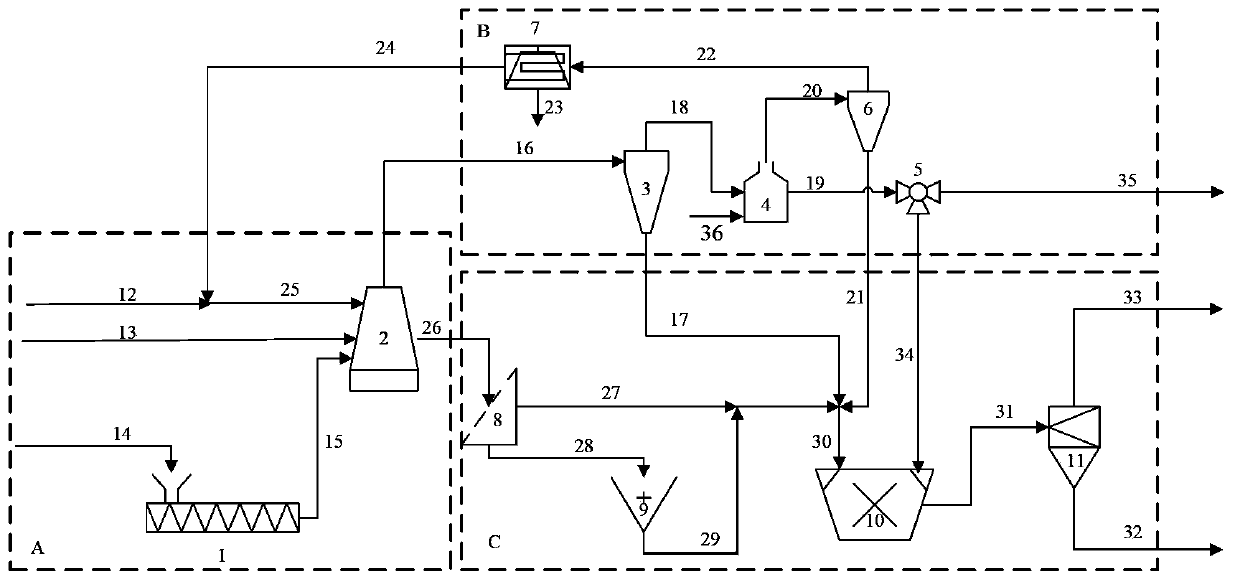

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

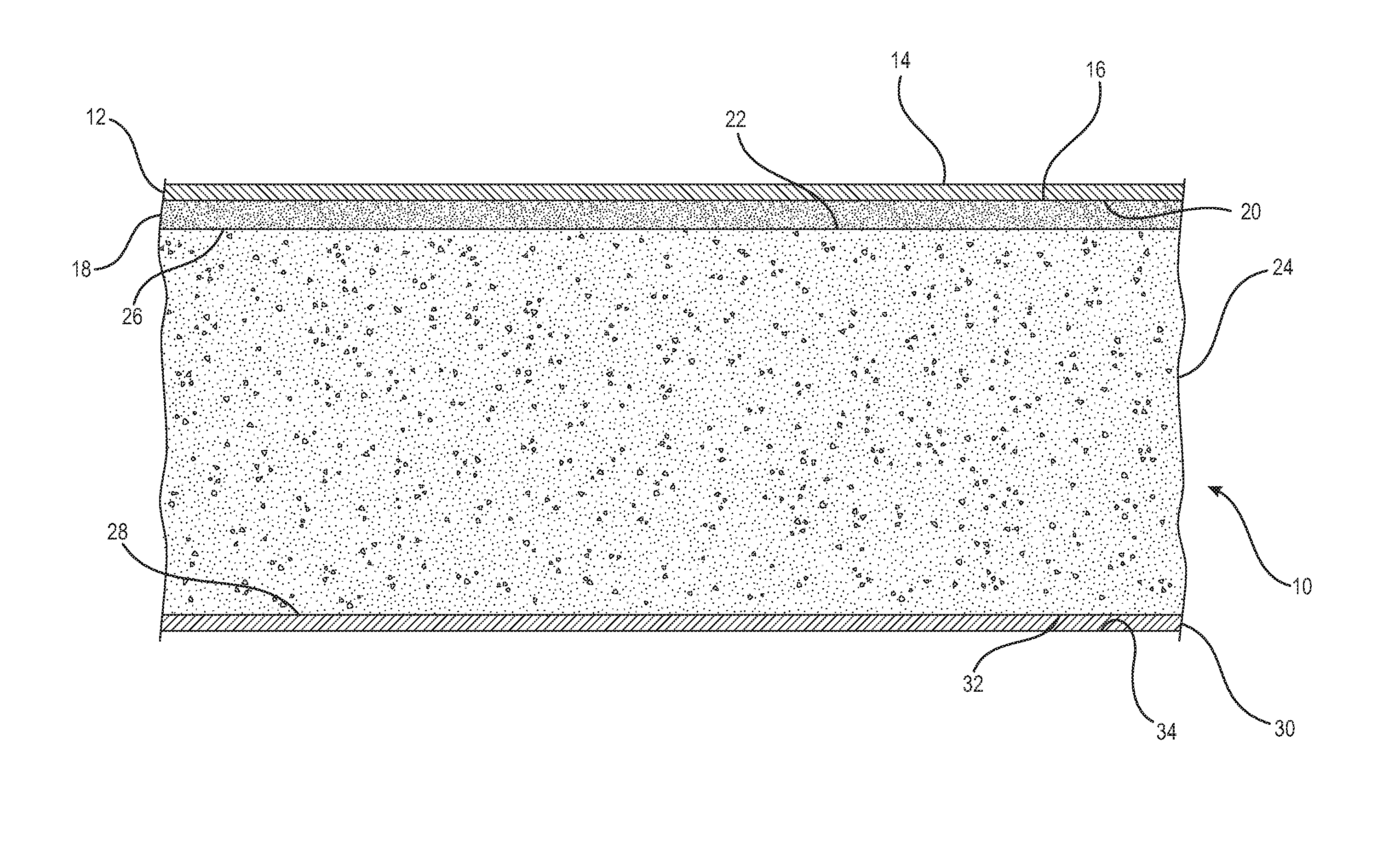

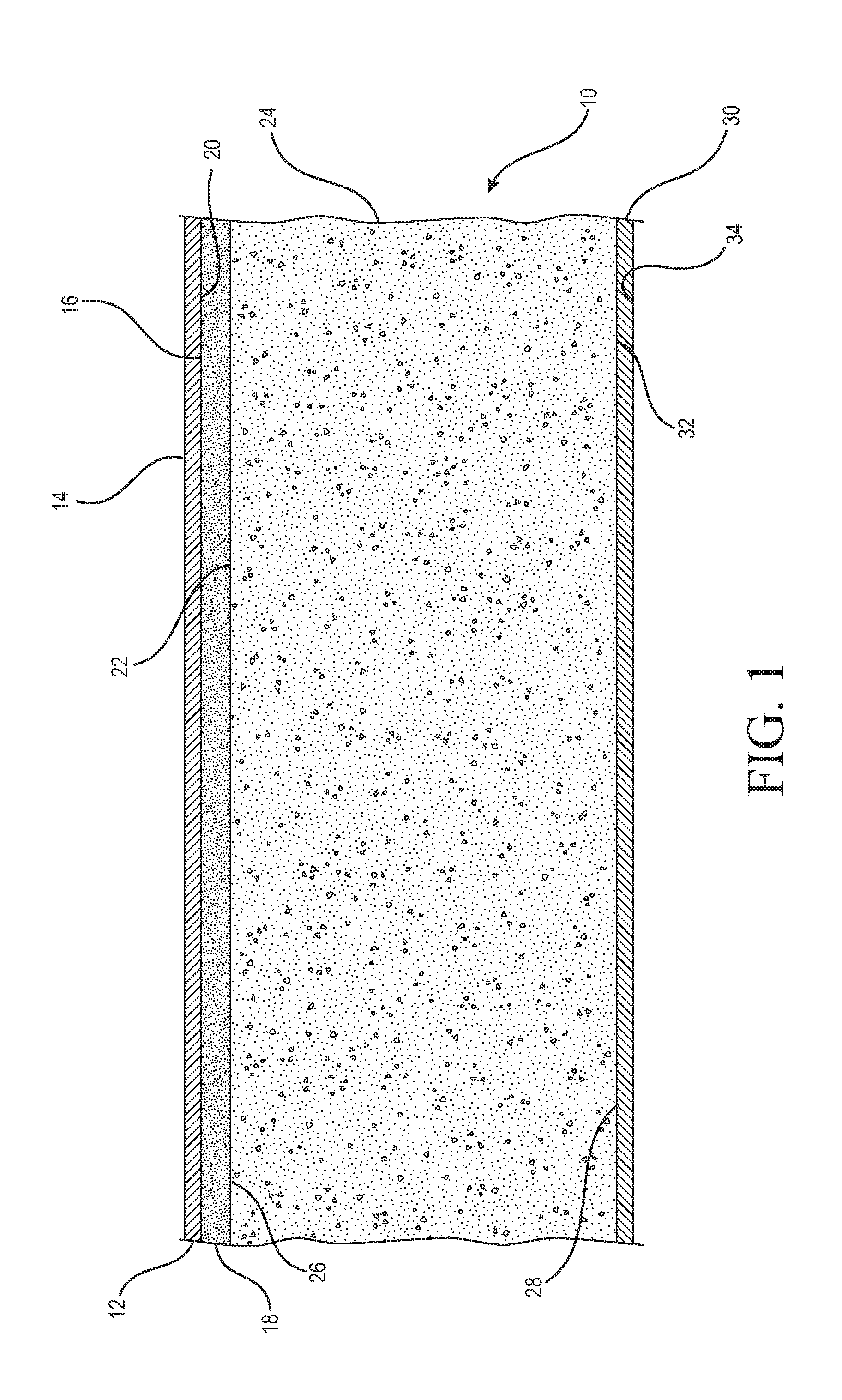

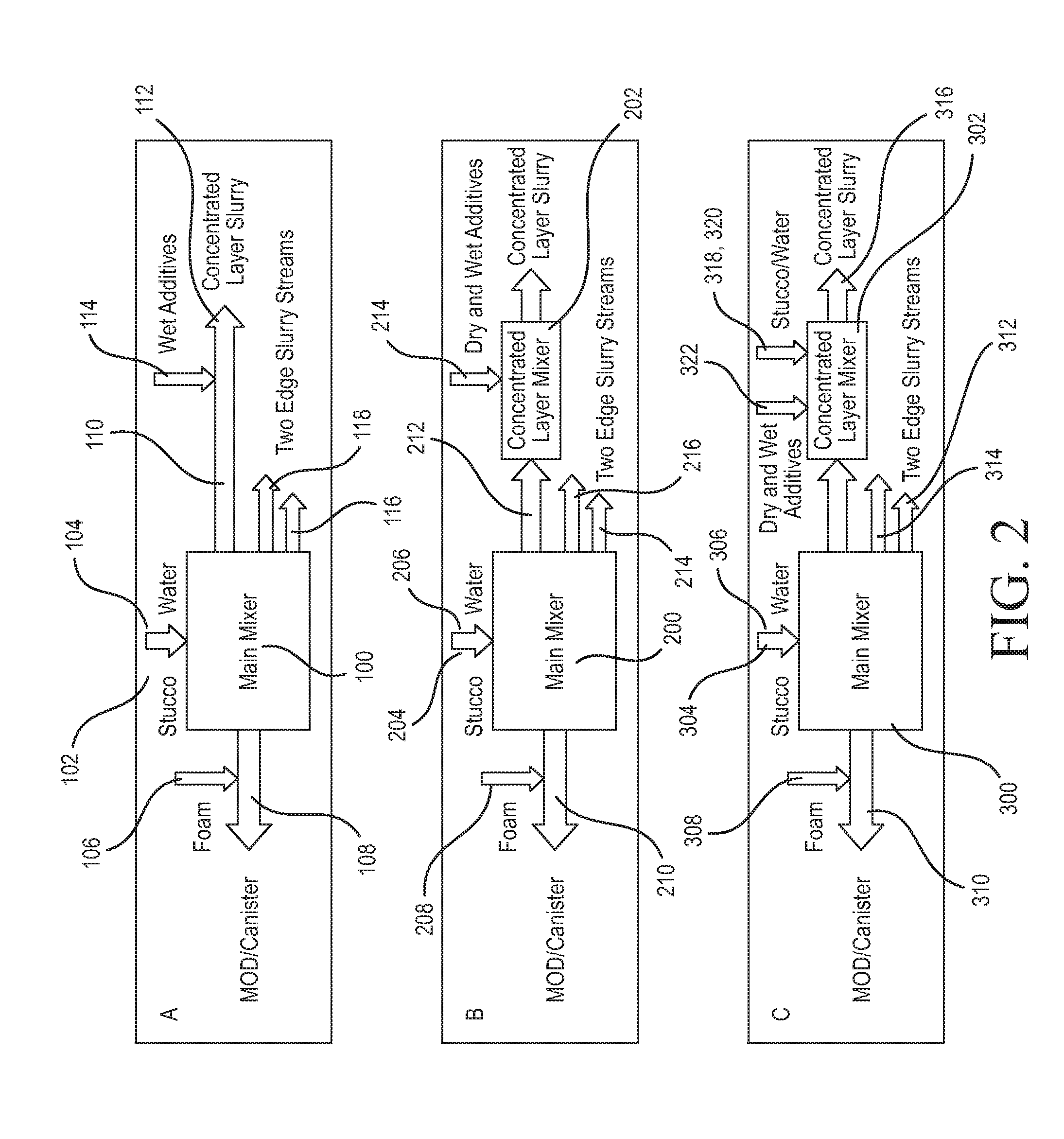

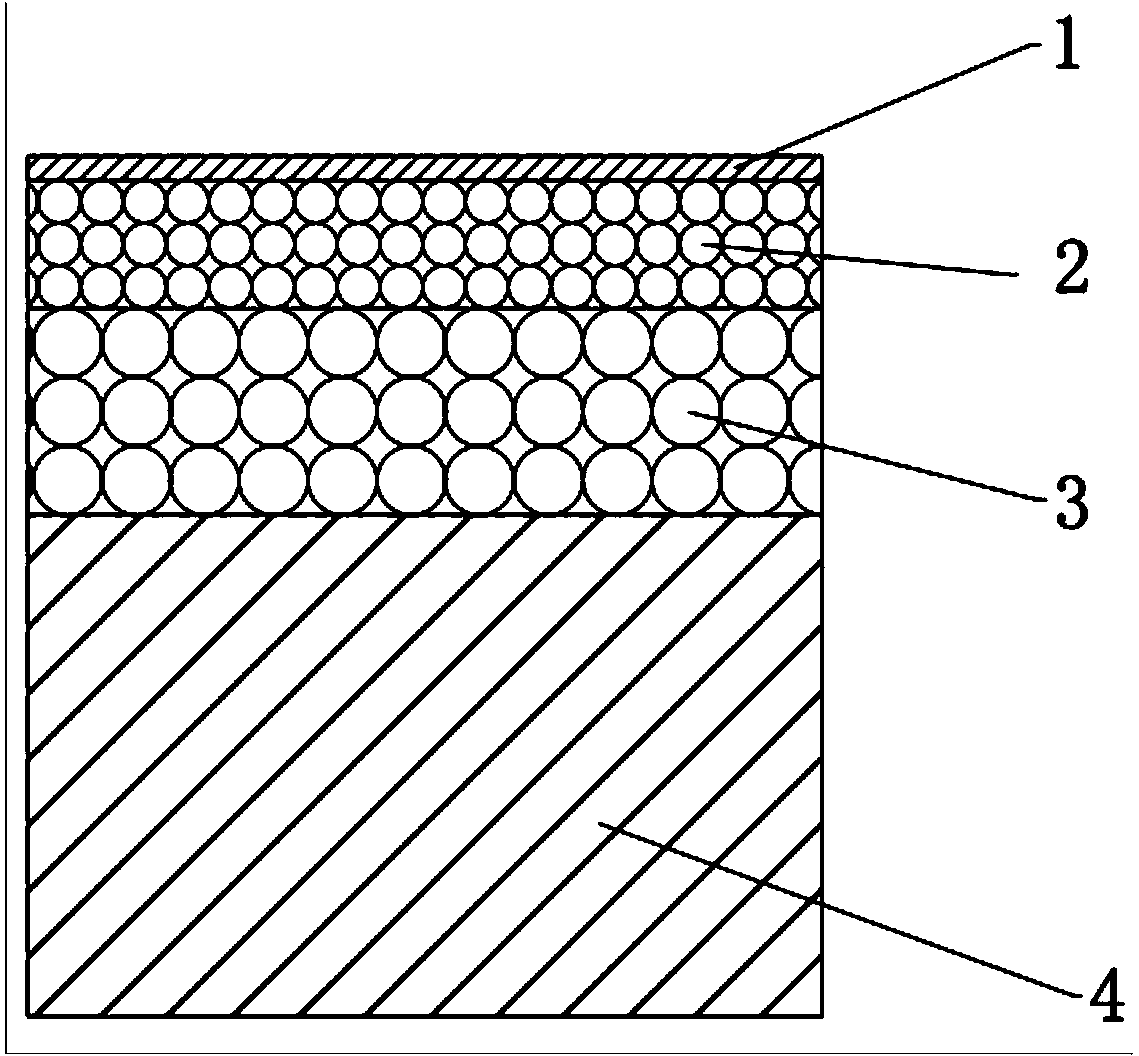

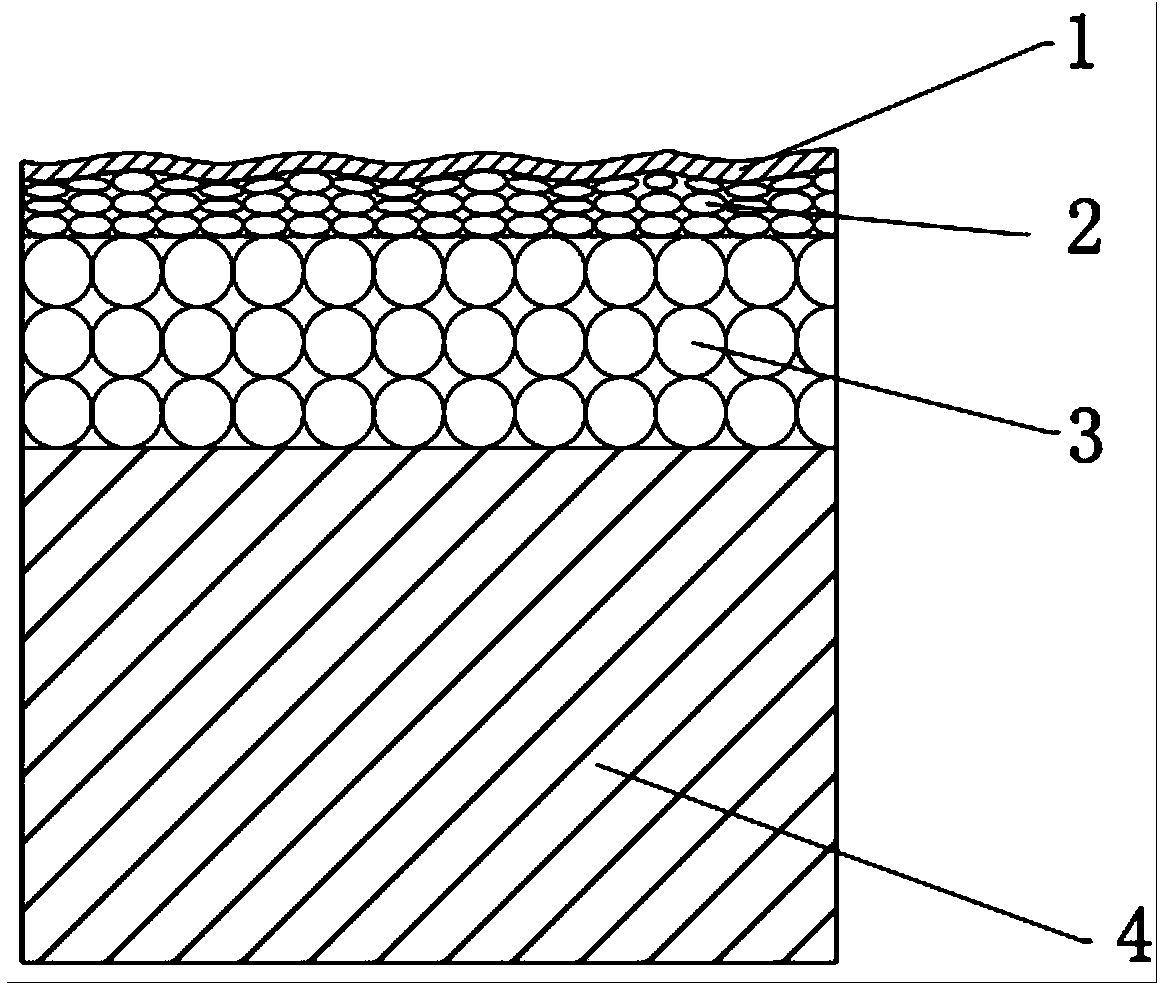

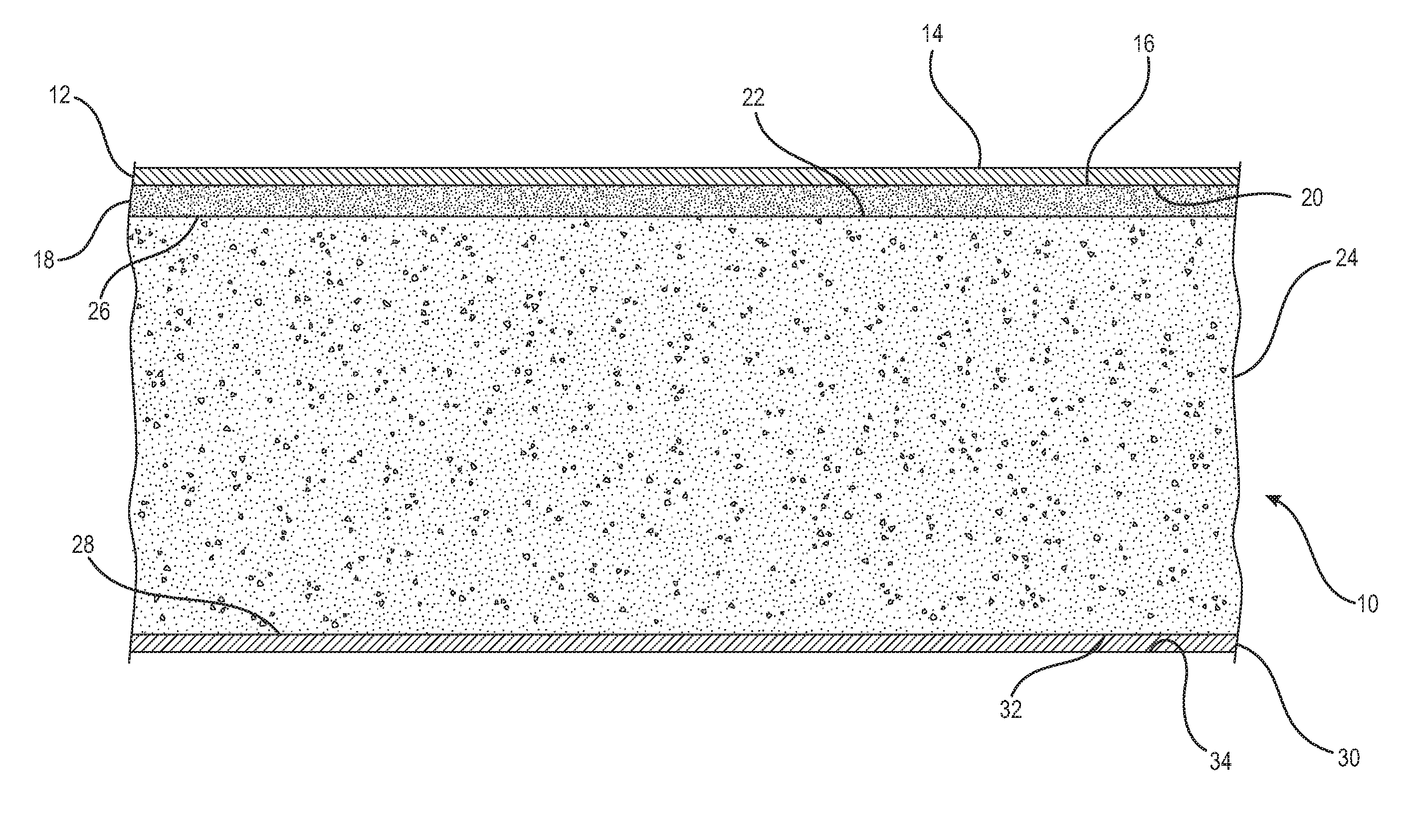

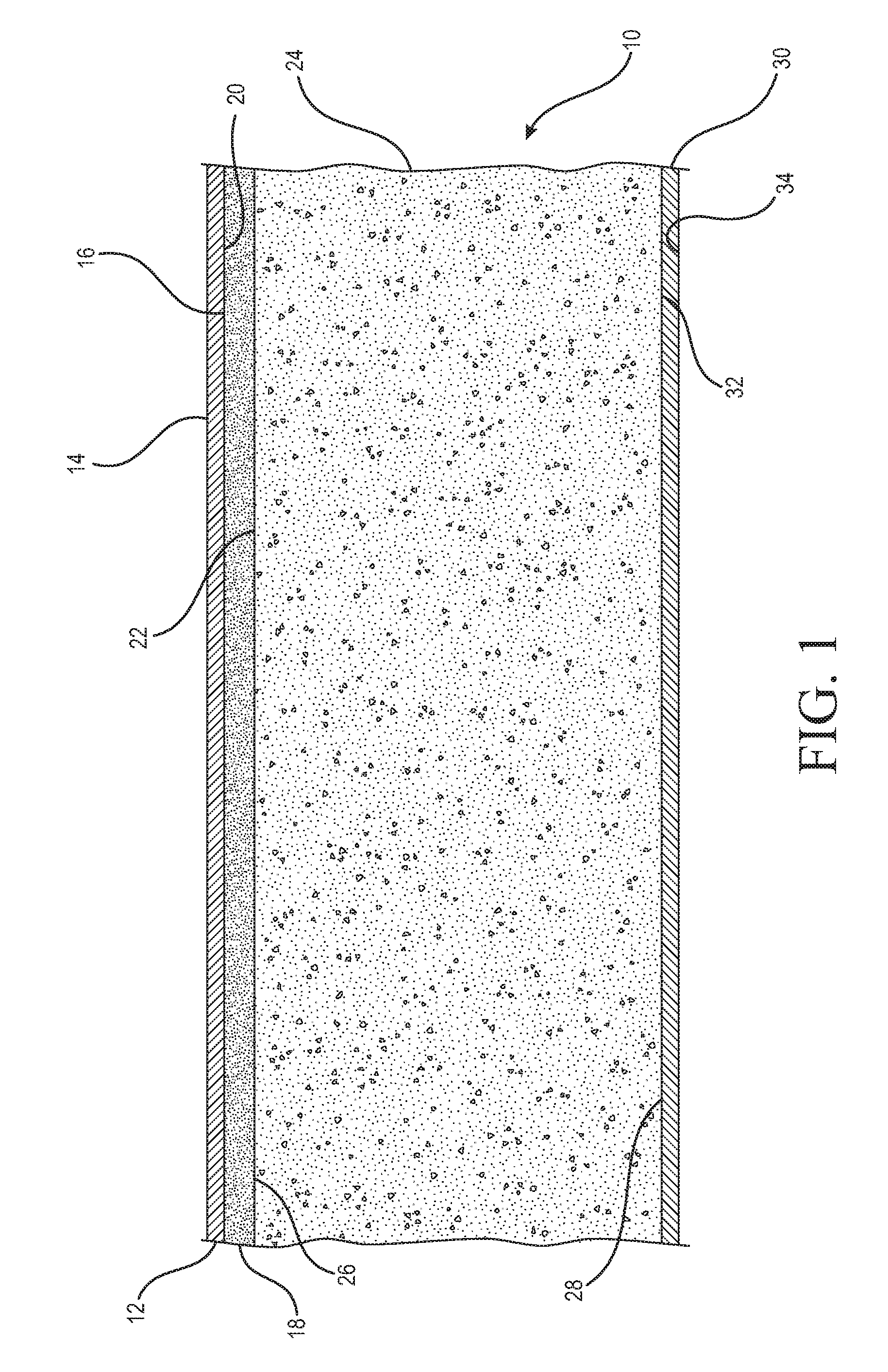

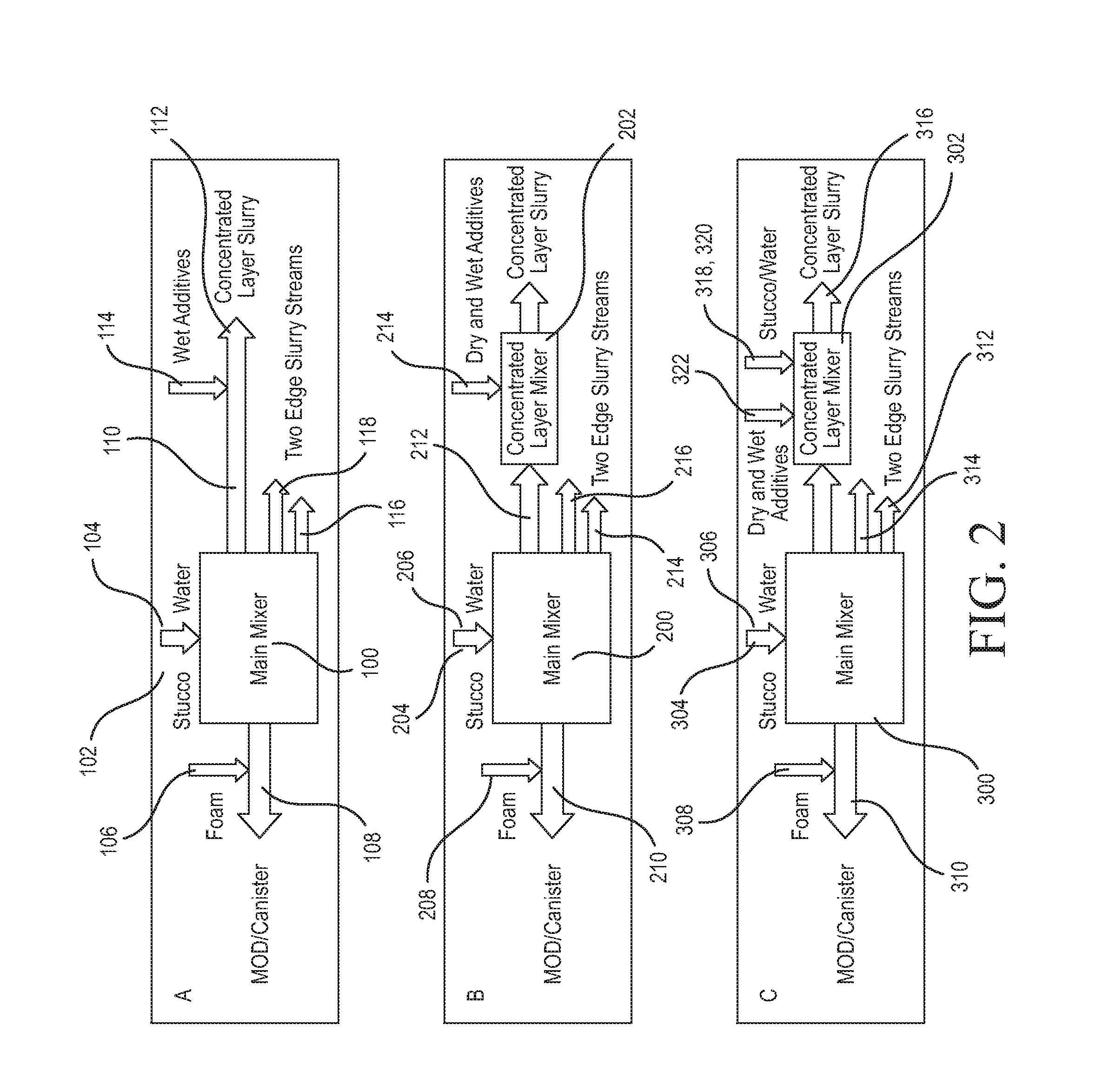

Composite gypsum board and methods related thereto

ActiveUS20160375655A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

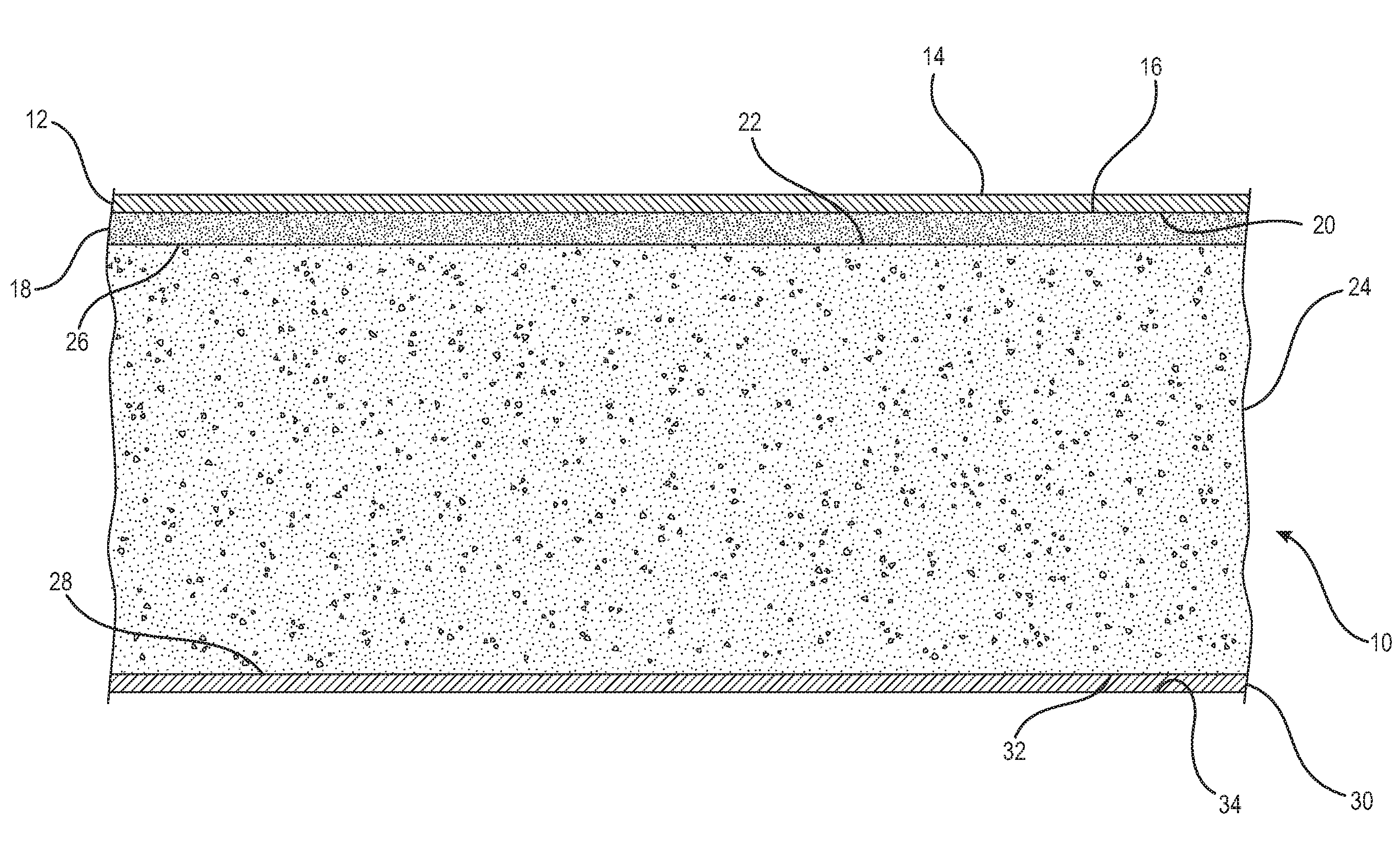

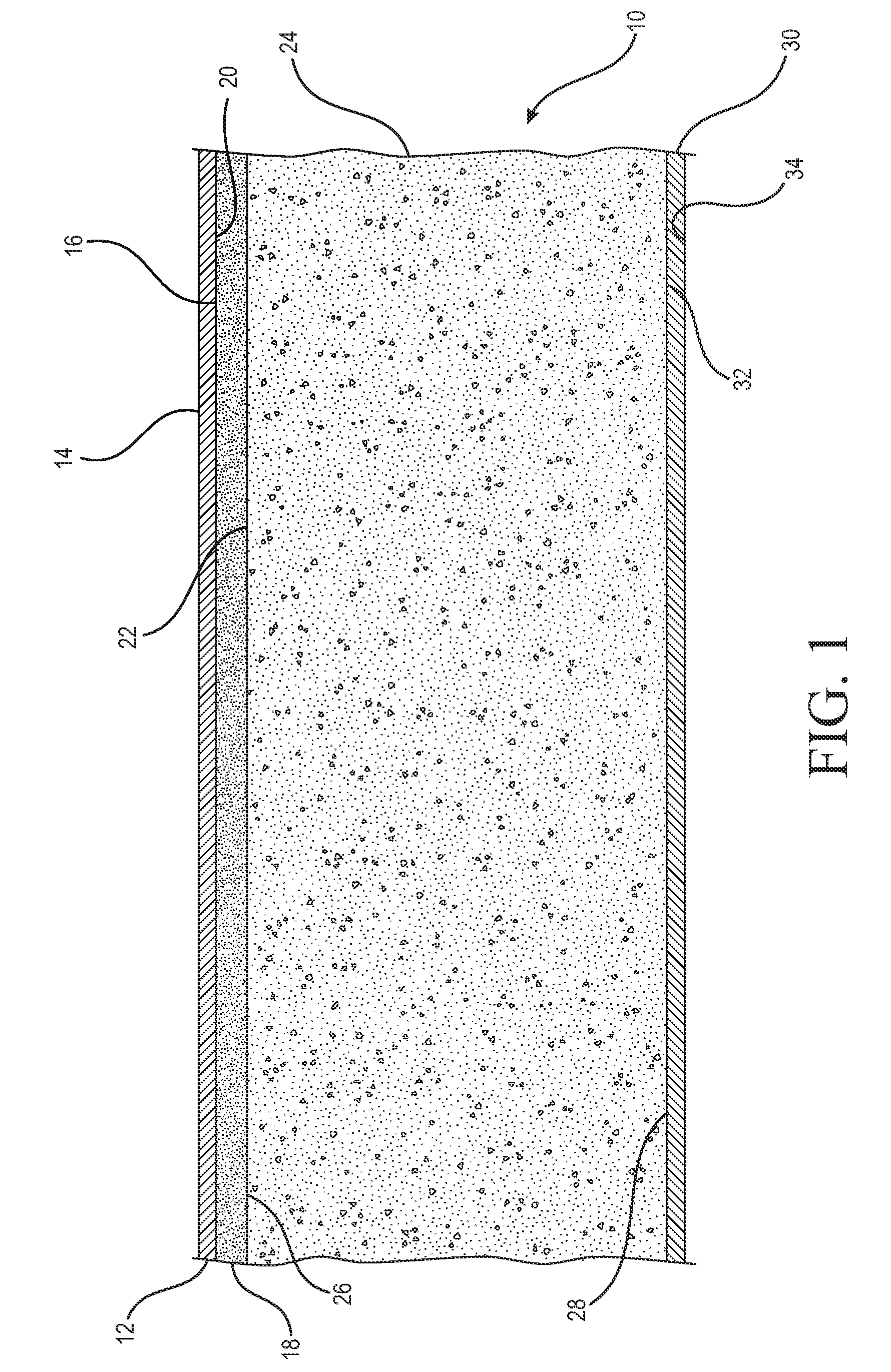

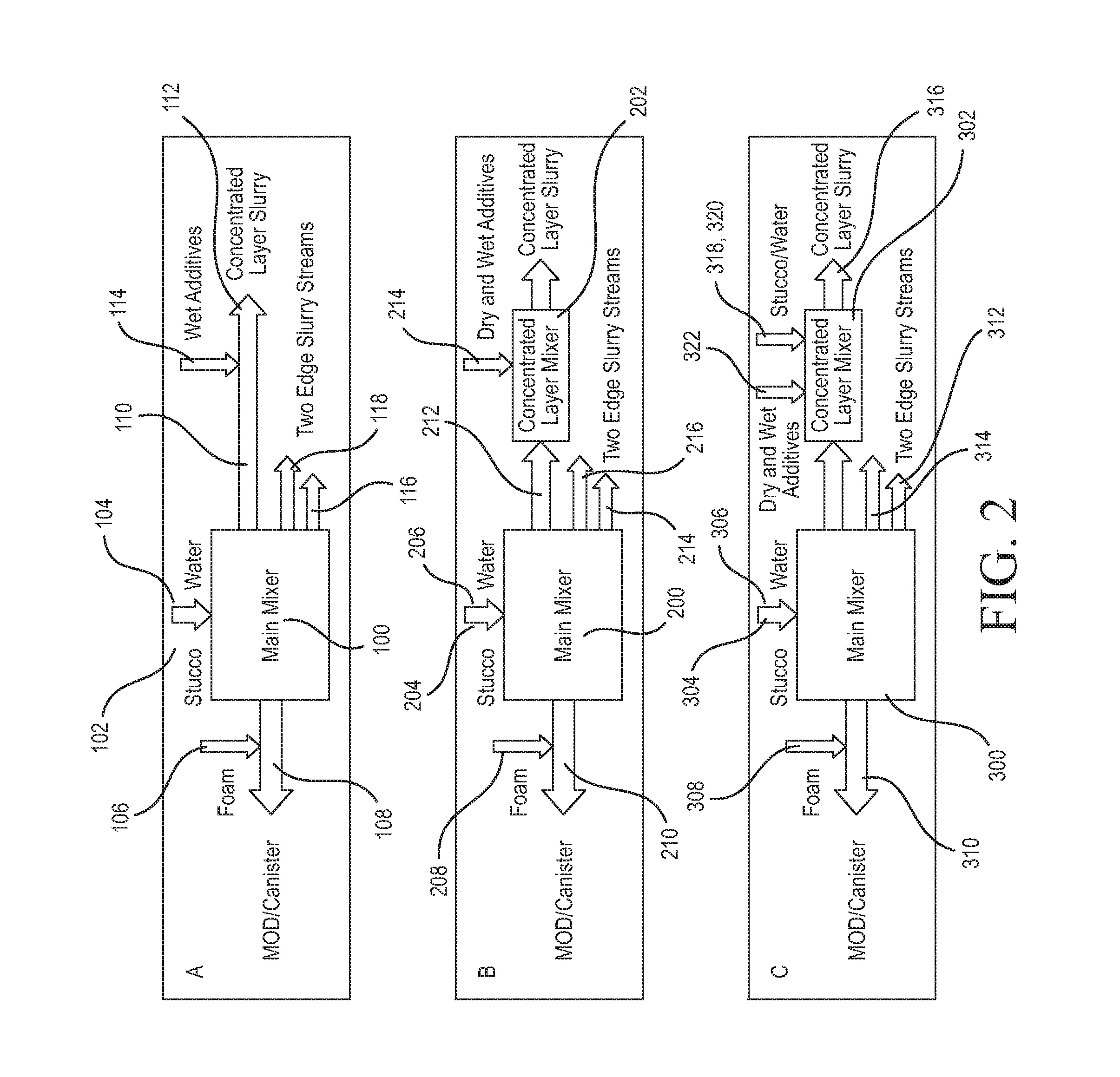

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

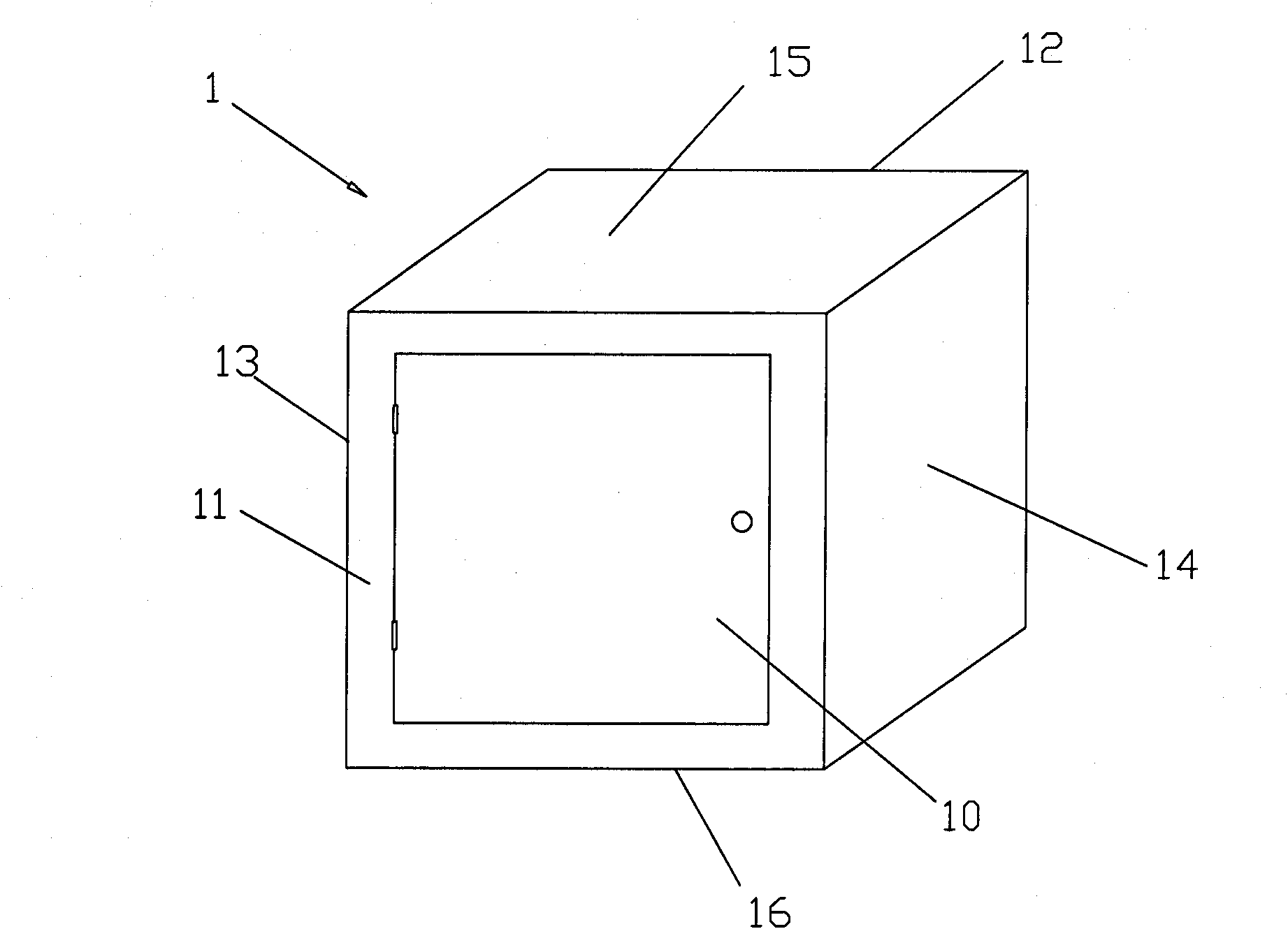

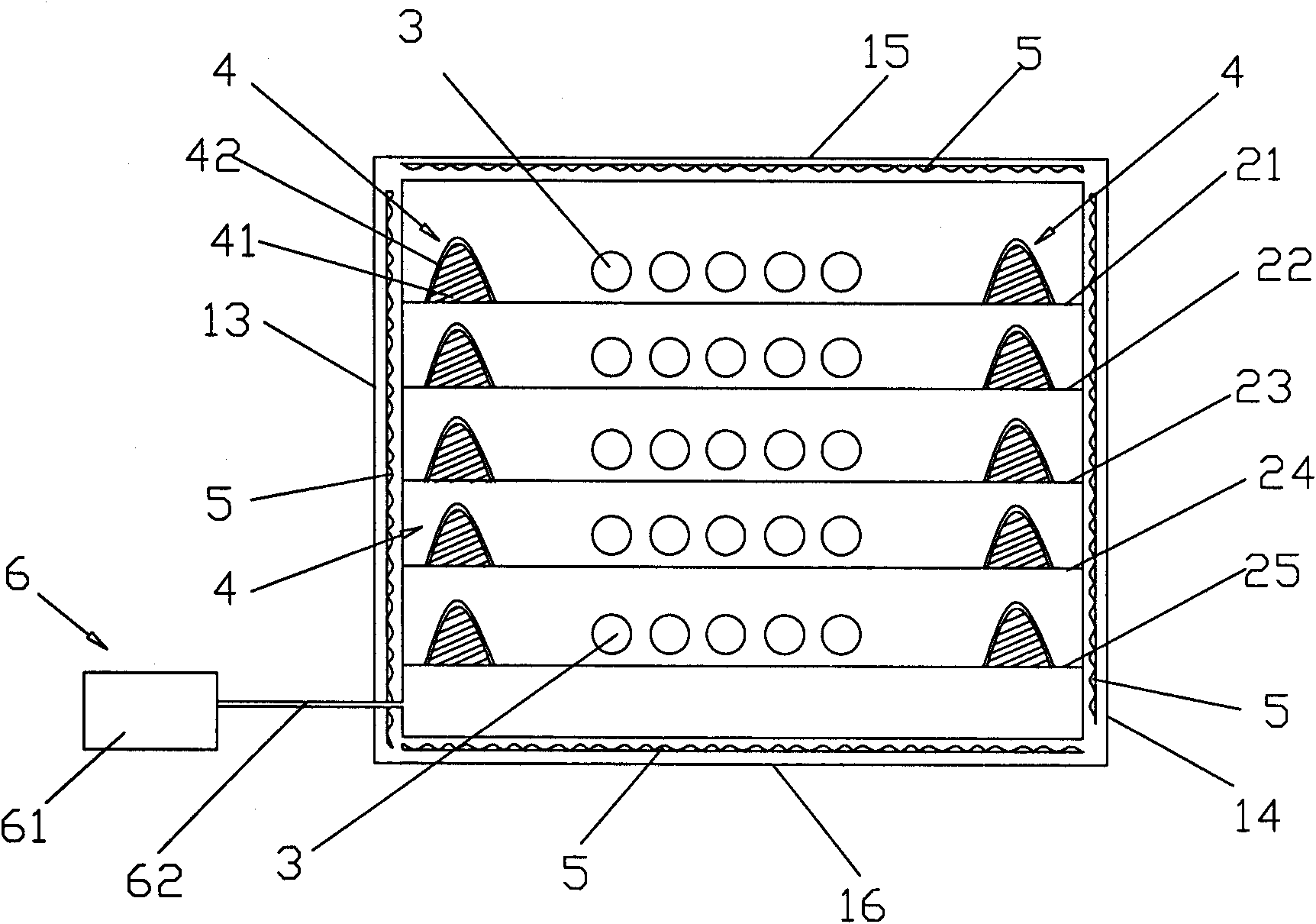

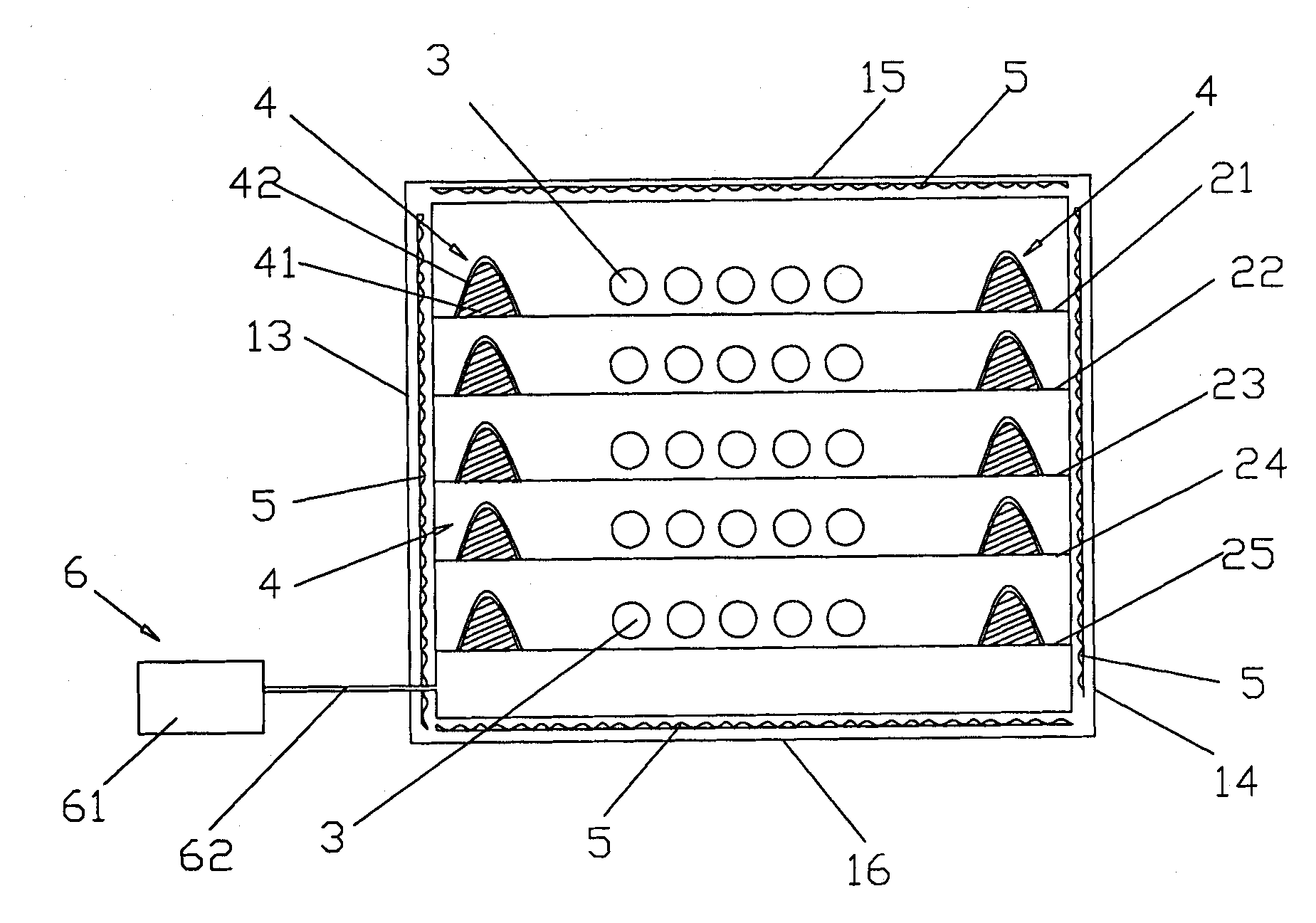

Drying device of battery pole shoe and drying method

InactiveCN102338550AImprove drying efficiencyReduce drying costsCell electrodesDrying solid materials without heatVacuum pumpingWater vapor

The invention provides a drying device of a battery pole shoe. The drying device comprises a drying box body, a vacuum-pumping unit and a heating unit, wherein the heating unit is arranged on the drying box body; the vacuum-pumping unit is connected with a drying box; a drying agent which is used for drying a battery is arranged in the drying box; and the drying agent is arranged at one side of the battery pole shoe. After the technical scheme is adopted, the drying agent is arranged in the battery drying device and can effectively absorb and dry water vapor generated by the battery pole shoe; therefore, when the battery pole shoe is dried, nitrogen is not needed to be injected into the battery driving device at intervals, thereby the drying efficiency is obviously improved, and the drying cost is effectively reduced. The invention also provides a drying method of the battery pole shoe.

Owner:OPTIMUM BATTERY CO LTD

Drum-type vacuum pulsing temperature-variable drying method and apparatus

InactiveCN101261073AKeep drySolve delivery difficultiesDrying using combination processesDrying solid materials with heatControl systemChemical products

The invention discloses a drum-type vacuum pulsing transformation temperature drying method and a device, comprising a sealed circular roller, a heating circulating system, a pulsing vacuum system connected with the roller and a control system, wherein, the vacuum degree of the pulsing vacuum system connected with the roller varies with the material arranging from 0.097 MPa to 0 MPa, the heating temperature of the heating circulating system varies with the state of the material. The device has good heat transmitting performance, preserves the nutrient content and the active material of the material as well as the color and luster of the material well, greatly raises the drying speed, shortens the drying time, reduces the drying energy consumption and lowers the drying cost. The drum-type vacuum pulsing transformation temperature drying method and the device are suitable for drying the foods, the biological products, the drugs and the chemical products with good fluidness, particularly for drying the products thermally sensitive; especially, the effect for drying the foods and the biotechnology products with high added value is better.

Owner:CHINA AGRI UNIV

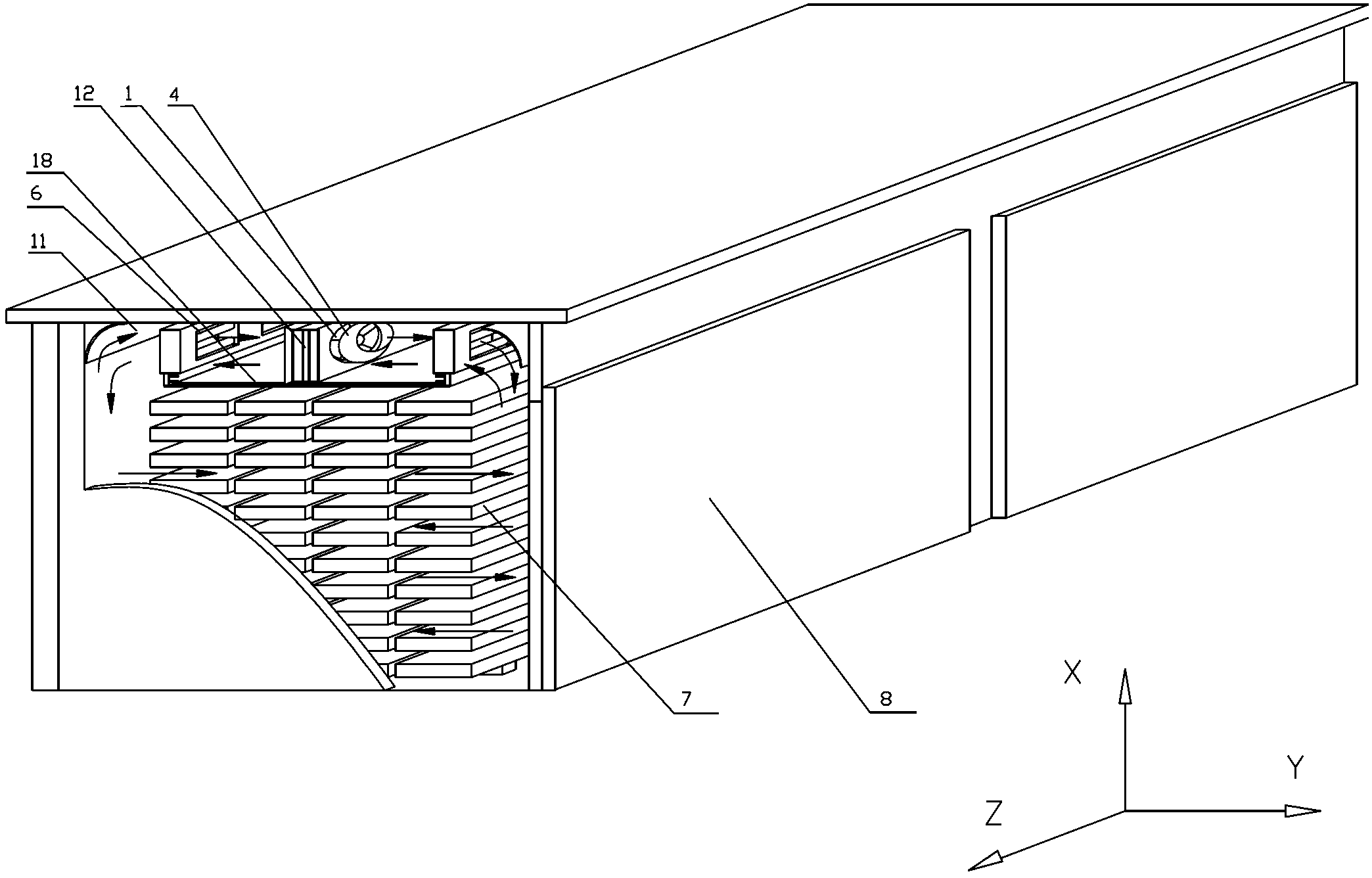

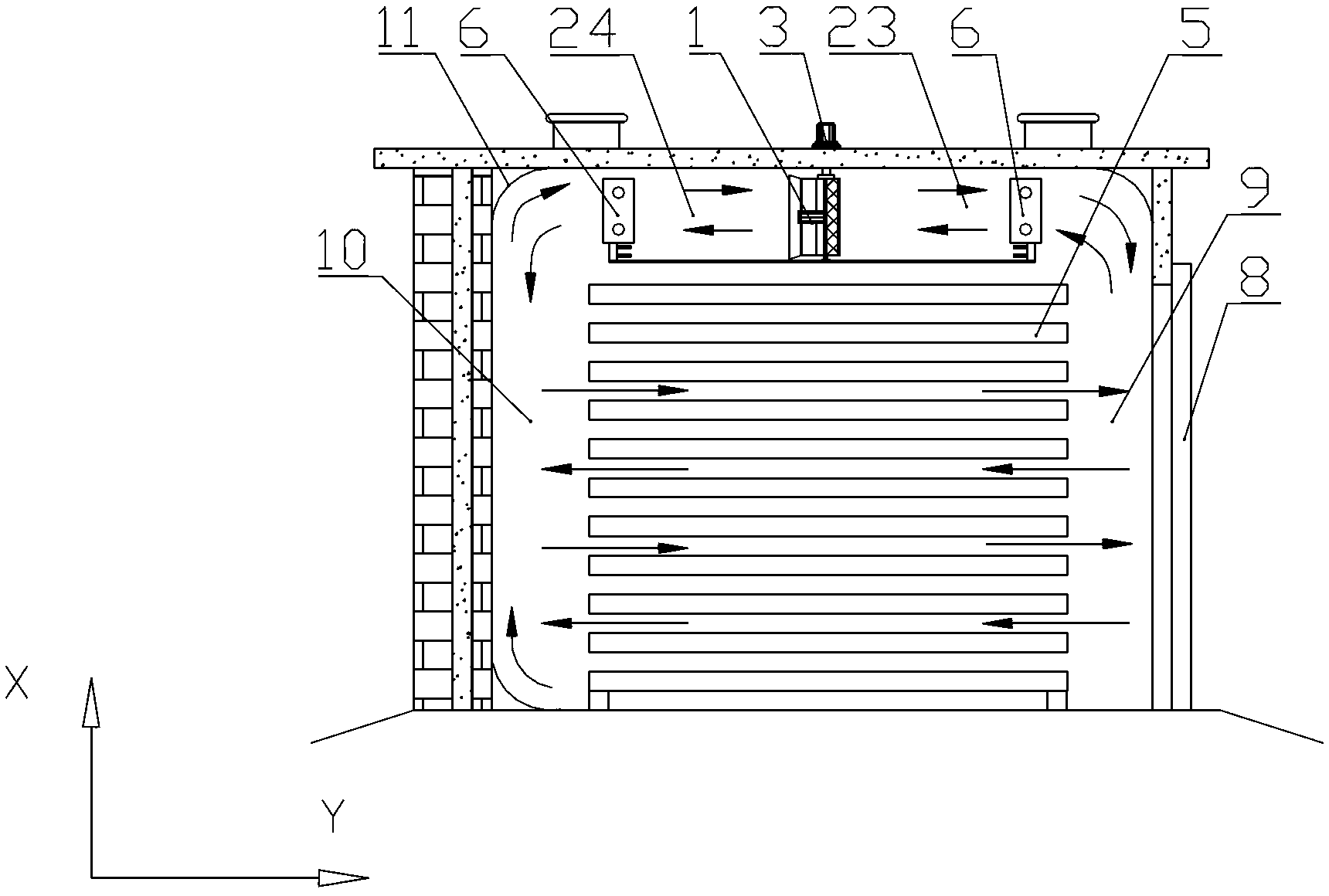

Heating and blowing device for large hot air drying room

InactiveCN103292590AStable forward and reverse air supplyThe same wind pressure and air volumeDrying gas arrangementsChemical productsEngineering

The invention relates to timbers, pharmaceuticals, foods and chemical products, in particular to a heating and blowing device for a large hot air drying room. A plurality of fans (1) are disposed in a rectangular fan support frame (12). Gaps among the fans (1) are blocked by air blocking plates (13). The fans are linked by a synchronization rotation linkage mechanism (2) for synchronous horizontal rotation. The fan support frame (12) is fixed on a rectangular movable frame (17). Rollers (19) embedded into guide rails (18) on two sides are disposed on two sides of the fan support frame (12). An air guide component (4) is disposed on a blowing side of each fan (1). A plurality of radiators (6) corresponding to the fans (1) are disposed at two ends of the guide rails. Three arc flow deflectors (11) are disposed at three inner included angles of the drying room. By the heating and blowing device, power consumption is lowered greatly, operation cost and drying cost are lowered, the drying room is enabled to be efficient, energy-saving and widely applicable, timbers of two or more different kinds or of different thicknesses can be evenly dried simultaneously, production efficiency is increased, and drying operations are highly flexible.

Owner:SHANGHAI UNIV OF ENG SCI

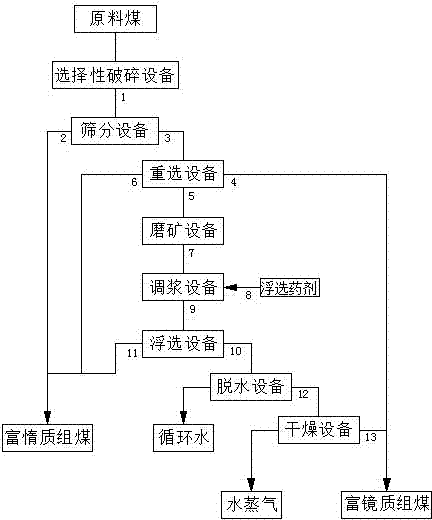

Deep preparation technology of coal for direct coal liquefacation

The invention discloses a deep preparation technology of coal for direct coal liquefacation. Feed coal is selectively crushed and then is sieved with a 0.5 mm particle size to grade; products passing through the sieving are separated through gravity concentration equipment, so as to obtain gravity treated cleaned coal, gravity treated middlings and gravity treated tailings; the gravity treated middlings is ground and fed into size mixing equipment; flotation reagent is added to the size mixing equipment, size mixing is performed, and then products are pumped into flotation equipment to perform separation, so as to obtain flotation cleaned coal and flotation tailings; the flotation cleaned coal is filtered and dried and then mixed with the gravity treated cleaned coal to form rich-vitrinite coal which is served as coal for direct coal liquefacation; and the products of the feed coal not passing through the sieving after crushing and sieving, the gravity treated tailings and the flotation tailings are mixed into rich-inertinite coal which can be served as high-quality steam coal, coal for gasification and the like. The technology is based on coal petrography maceral, adopts the differences in terms of densities and surface natures of different coal petrography maceral, and adopts the method of the combination of gravity concentration and flotation, so as to realize the large-scale separation and enrichment of coal maceral, increase the hydrogen-to-carbon ratio of coal for liquefacation, greatly improve the oil yield of direct liquefacation of coal, and obviously increase the economic benefit of direct liquefacation of coal.

Owner:CHINA UNIV OF MINING & TECH

Fast drying gypsum products

Owner:UNITED STATES GYPSUM CO

Composite gypsum board and methods related thereto

PendingUS20160376191A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the hoard core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

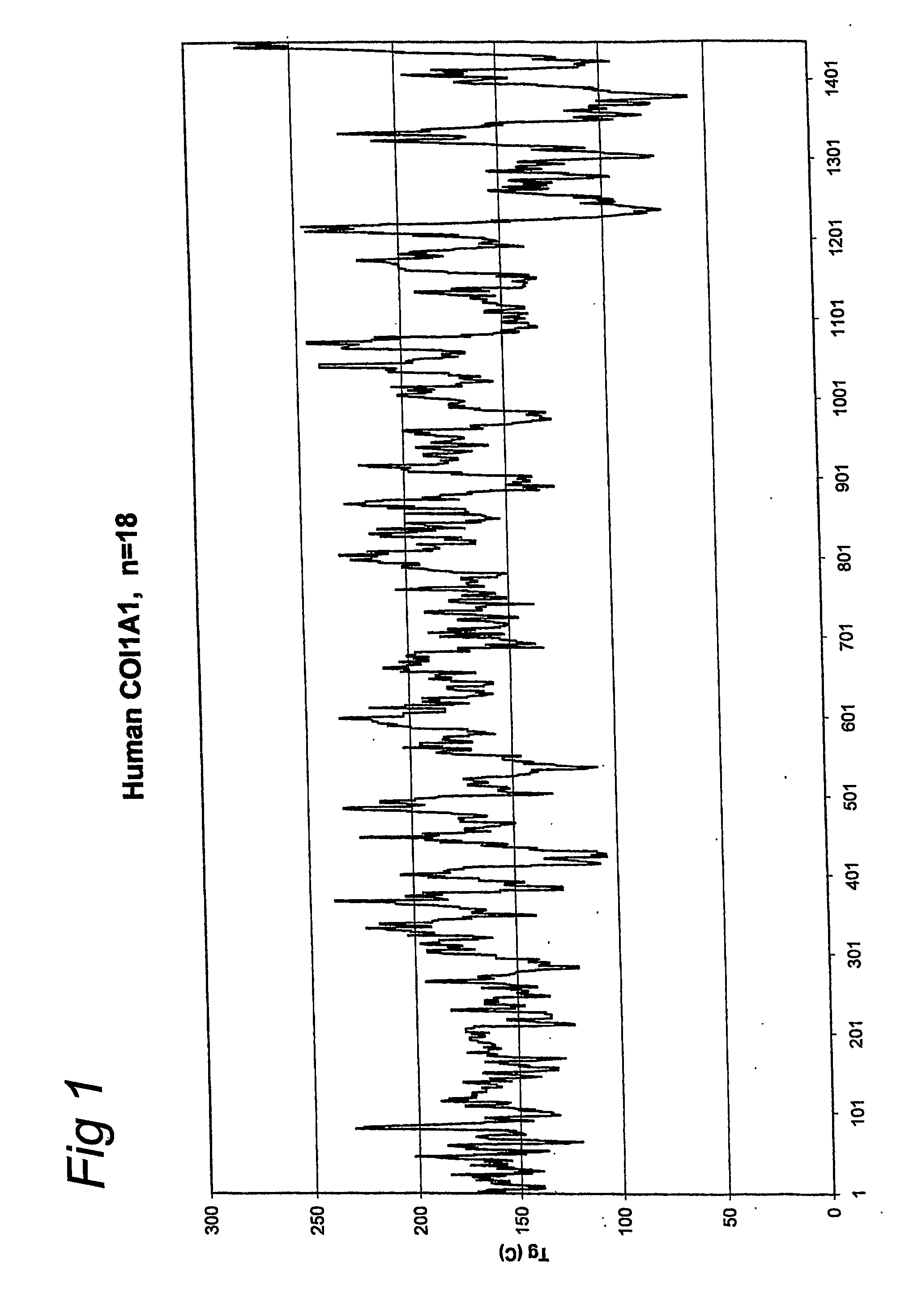

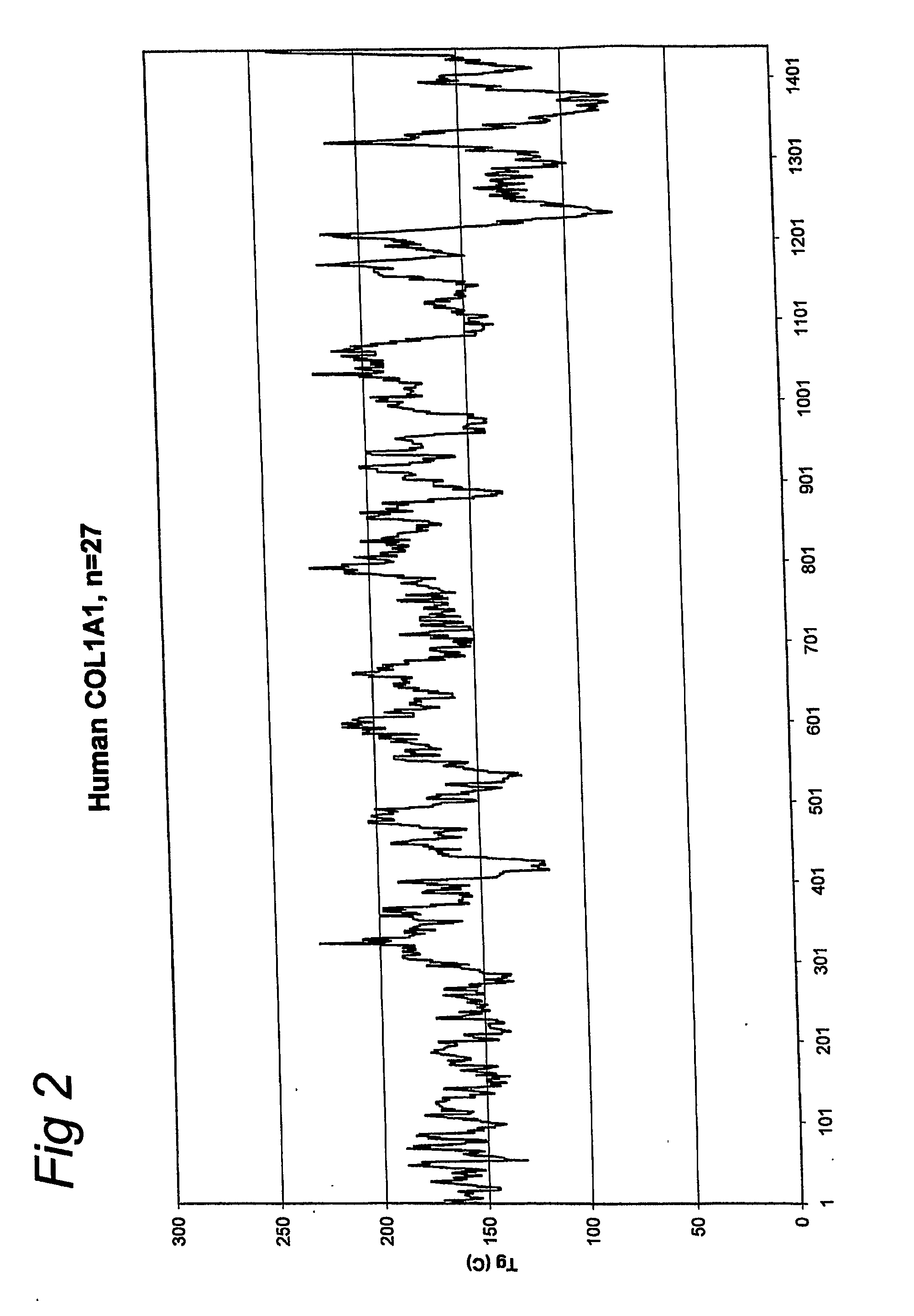

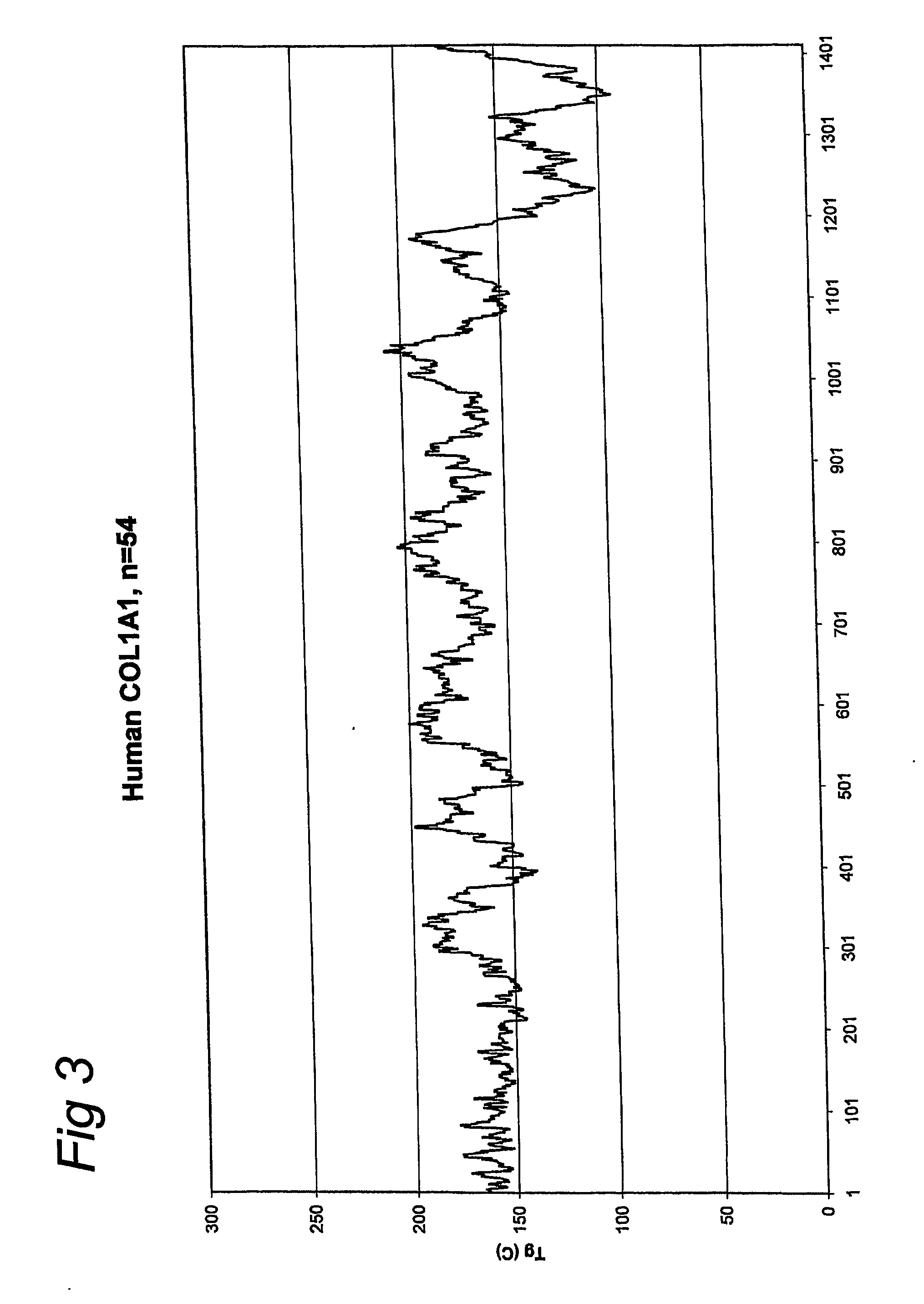

Use of recombinant or synthetic gelatin-like proteins as stabiliser in lyophilized pharmaceutical compositions

InactiveUS20070031501A1Prevent gelReduce the amount of solutionPowder deliveryConnective tissue peptidesVitrificationGelatin

The invention relates to the use of gelatin-like proteins, or polypeptides, with an increased calculated glass transition temperature as stabilisers in lyophilized biological or pharmaceutical compositions.

Owner:FUJIFILM MFG EURO

Dry formed hydrophobic ceramic fiber building fireproof plate and preparation method thereof

The invention relates to a dry formed hydrophobic ceramic fiber building fireproof plate and a preparation method thereof. The dry formed hydrophobic ceramic fiber building fireproof plate is characterized by consisting of the following raw materials in part by weight: 50 to 90 parts of aluminium silicate fibers, 0 to 20 parts of expanded vermiculite powder, 0 to 20 parts of clay, 2 to 8 parts of resin powder, 0.2 to 0.6 parts of mineral grease and 0.1 to 0.5 parts of organic silicone emulsion. In the ceramic fiber plate prepared by the method, ceramic fibers are used as a substrate; and due to the addition of the expanded vermiculite powder (light packing) and clay packing according to a suitable proportion, the heat resistance, the fireproof performance, the heat insulation performance and the strength of the building fireproof plate can be effectively improved, and the volume, the density and the production cost of the building fireproof plate are greatly reduced. Moreover, the dry formed hydrophobic ceramic fiber building fireproof plate can be used as an upgrade product of conventional building fireproof plates such as a magnesium oxychloride inorganic fireproof plate, a calcium silicate plate and the like.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Puffing fruit vegetable crisp slices processed by hot vapor and method thereof

InactiveCN101301055AReduce energy costsReduce processing costsFood shapingFood preparationAdditive ingredientDeep frying

The invention provides a vegetable chip processed by swelling using superheated steam and method thereof. The vegetable chip of the invention is swelled by superheated steam and the process method comprises vegetable selecting, cleaning, slicing, color protecting, washing and dehydrating. The product of vegetable chip is produced by drying to a low water ratio after swelling by superheated steam. The vegetable chip is swelled using superheated steam by the invention with advanced scientific method, little service time, little used equipment, low energy consumption and process cost, and better economic benefit. The prepared vegetable chip is provided with fine looking, good color, flavor and taste, crisp mouth-feel, high retention ratio of nutritional ingredients and low energy without external fats. Quality of the product is superior to the vegetable chip swelled by deep frying, and the product is apt to preserve, propitious to human health and suitable for obese people and three highs people.

Owner:FUJIAN AGRI & FORESTRY UNIV

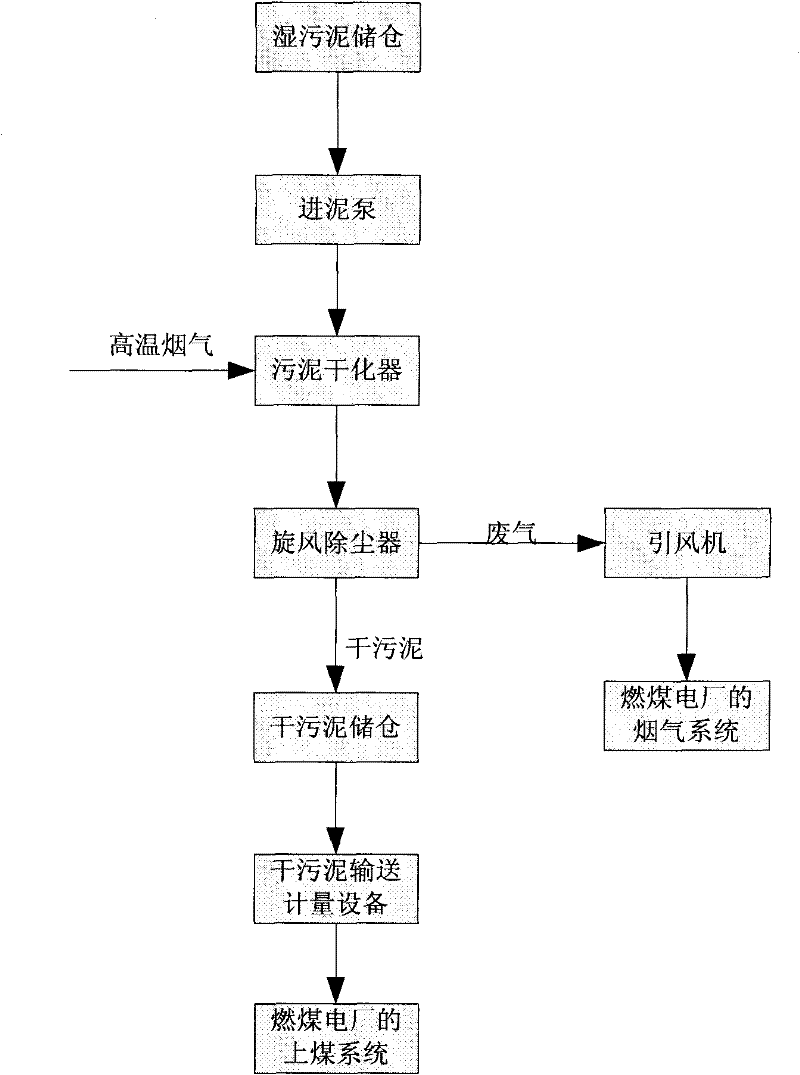

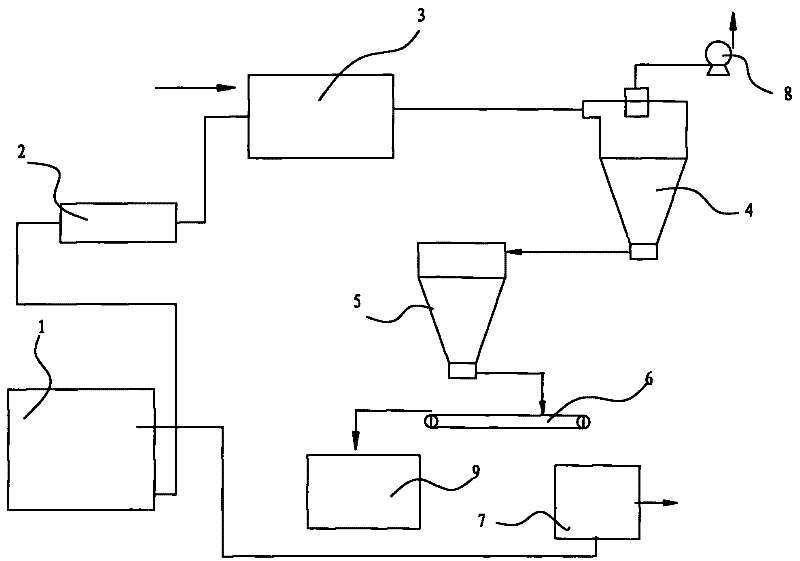

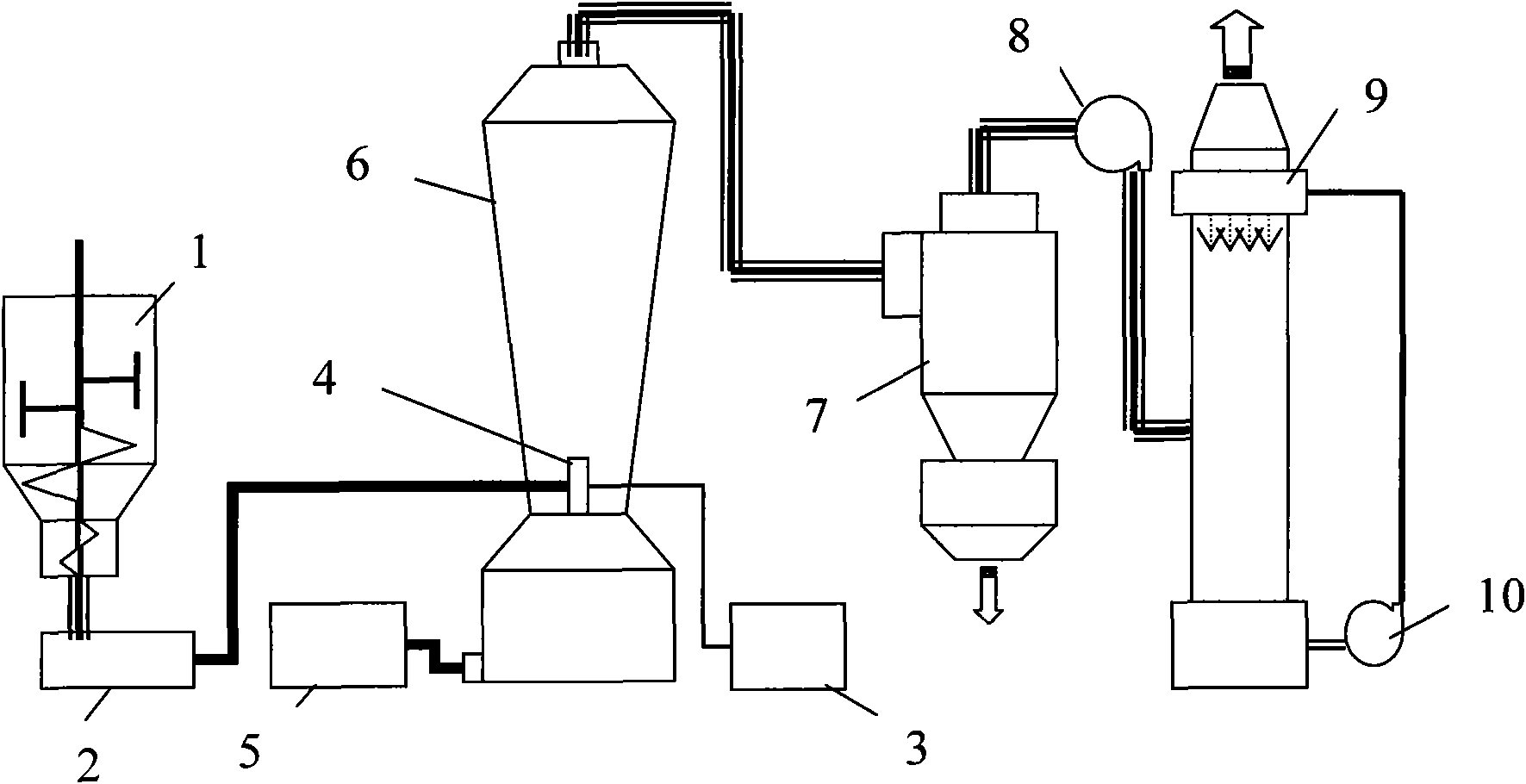

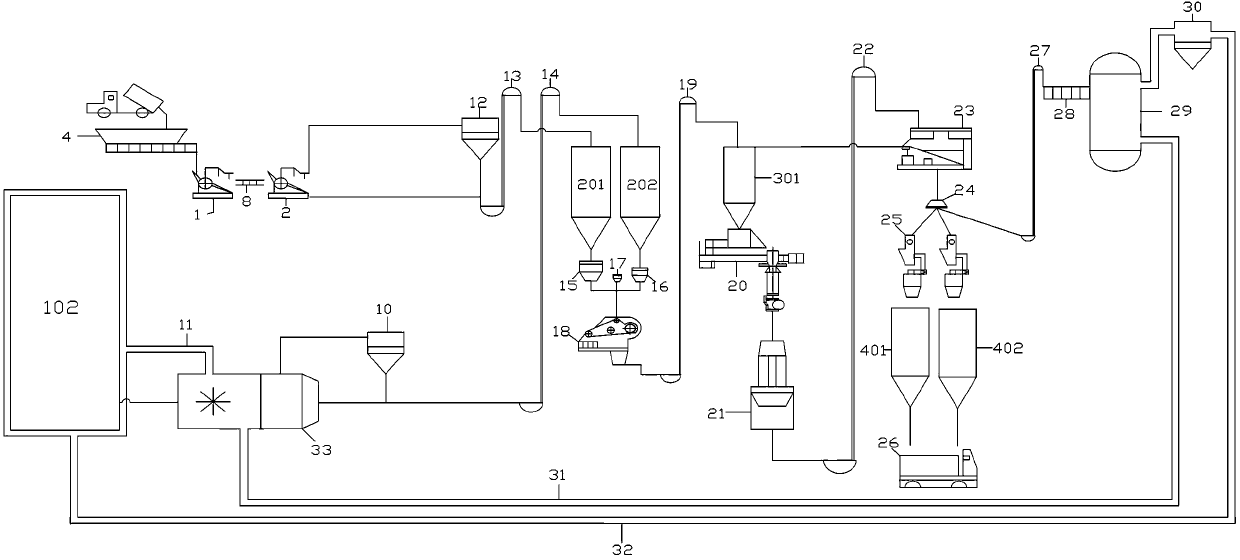

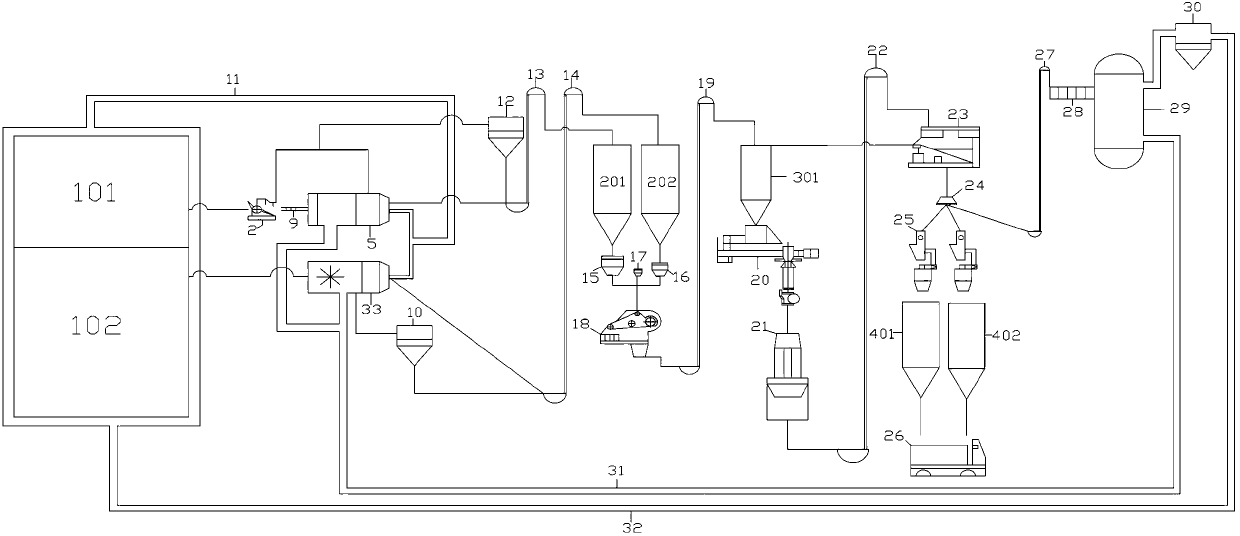

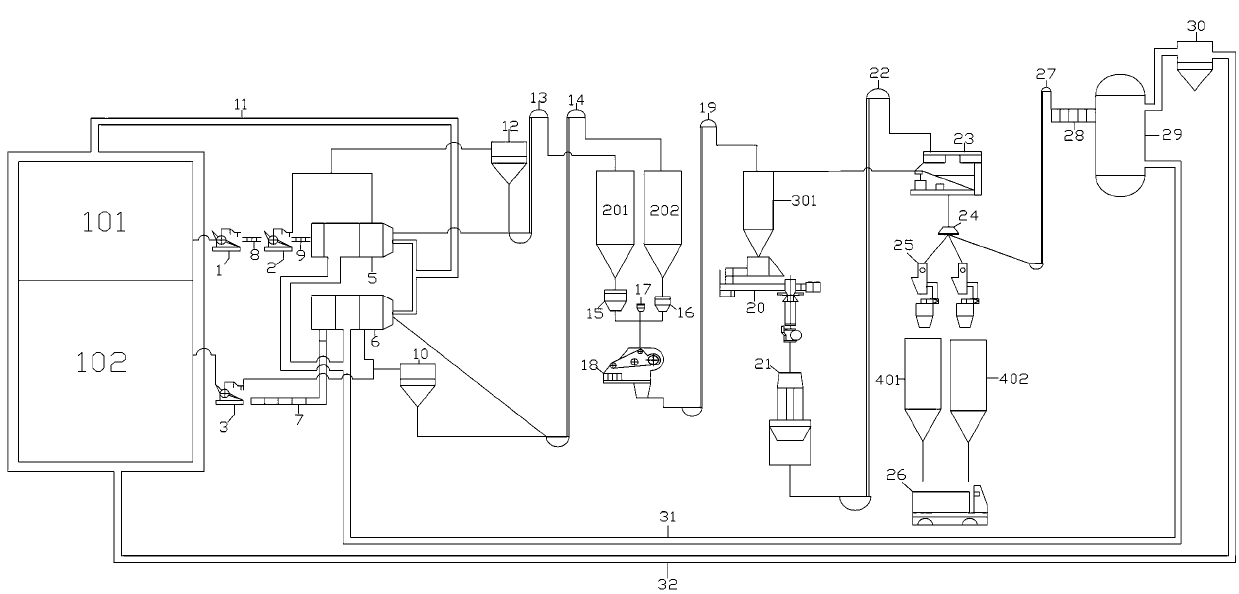

Sludge treatment and disposal system and method

ActiveCN102211845AReduce drying costsReduce environmental costsSludge treatment by de-watering/drying/thickeningIncinerator apparatusCyclonic spray scrubberDewatered sludge

The invention discloses a sludge treatment and disposal system, which is used for conveying dewatered sludge discharged by a sludge plant to a coal fired power plant to be combusted in a blended way after the dewatered sludge is dried. The sludge treatment and disposal system comprises a wet sludge storage bin, a sludge dryer, a sludge feeding pump, a cyclone dust collector, a dried sludge storage bin, dried sludge conveying equipment and a draught fan. The sludge feeding pump is respectively connected with the wet sludge storage bin and the sludge dryer. The cyclone dust collector is communicated with the sludge dryer so as to perform gas-solid separation on dried sludge and waste gas of the dryer. The dried sludge storage bin is connected with the cyclone dust collector so as to receivethe separated dried sludge. The dried sludge conveying equipment is connected with the dried sludge storage bin and used for conveying the dried sludge to a coaling system of the coal fired power plant. The draught fan is connected with a waste gas hole of the cyclone dust collector. According to the sludge treatment and disposal system disclosed by the invention, the sludge treatment and disposal cost can be effectively reduced; vast high-quality resources can be saved; and a way of using waste to treat waste is realized. The invention further discloses a sludge treatment and disposal method.

Owner:国能朗新明环保科技有限公司

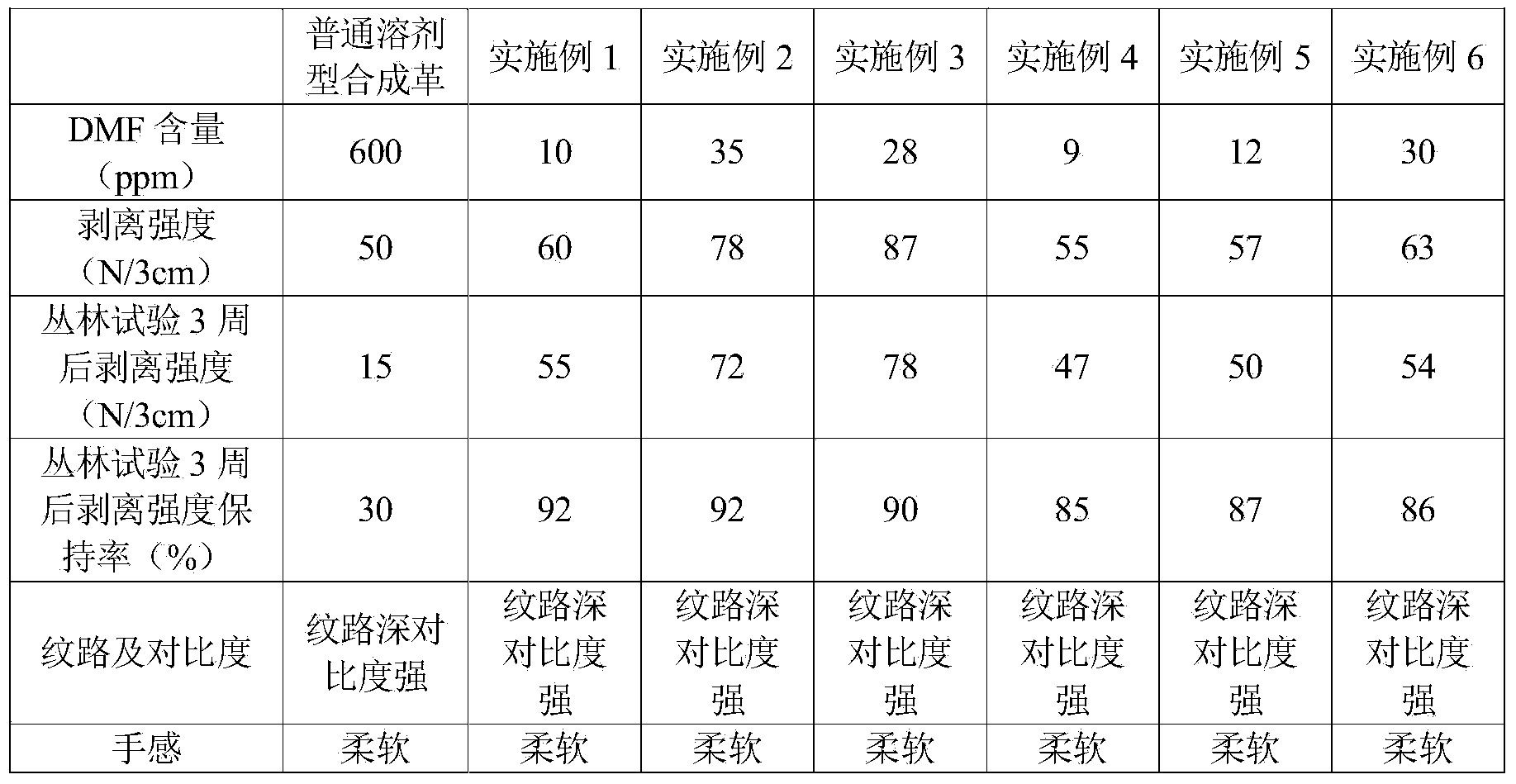

Method for preparing embossable solvent-free synthetic leather

ActiveCN104032587AHigh resistance to aging and hydrolysisReduce the amount of sizingLaminationLamination apparatusProduction linePolymer science

The invention discloses a method for preparing embossable solvent-free synthetic leather. The method comprises the following steps: (a) preparing an embossable solvent-free synthetic leather dry-method half-finished product, namely, uncoiling a piece of release paper, coating a surface layer, drying, cooling, coating a thermoplastic foaming middle layer, drying, cooling, coating a thermoplastic foaming adhesive bottom layer, pre-drying, semi-crosslinking, semi-foaming, adhering to a substrate, cross-linking, solidifying, and peeling off the release paper, so as to obtain an embossable solvent-free synthetic leather dry-method finished product; and (b) embossing and performing aftertreatment, namely, uncoiling the embossable solvent-free synthetic leather dry-method finished product, embossing, and performing other aftertreatment, so as to prepare an embossable solvent-free synthetic leather finished product. The made synthetic leather is of a two-layer foaming structure, the upper layer is a relatively thin thermoplastic foaming middle layer which can be softened, cooled and reformed and deforms at certain temperature, so that the synthetic leather has the characteristic of embossability; the lower layer is a relatively thick thermoplastic foaming bottom layer which can show main physical properties and the hand feeling of the synthetic leather. The synthetic leather can be produced by using an ordinary synthetic leather production line.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Composite gypsum board and methods related thereto

ActiveUS20160375651A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a hoard core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

Process for preparing yeast culture by taking hulled spirit distilled grains as raw material

ActiveCN103549116AReduce crude fiber contentHigh nutritional valueFood processingAnimal feeding stuffYeastNutritive values

The invention discloses a process for preparing a yeast culture by taking hulled spirit distilled grains as a raw material. The process comprises the following steps: hulling the spirit distilled grains; preparing materials; activating a strain; inoculating and mixing; controlling temperature to ferment; performing enzymolysis and wall breaking, and the like. The hulls are separated by using a mechanical method, so that the coarse fiber content of the yeast culture product is reduced, and the nutritive value and the application range of the product are improved. The hulls which are separated from the spirit distilled grains can be used as a boiler fuel after being mixed with coal to provide a heat source for drying the product, so that the drying cost is reduced, comprehensive utilization is realized, and no pollution is caused. The coarse fiber content of the product is over 50 percent less than the coarse fiber contents of the conventional spirit distilled grains and similar products, the situation that the conventional spirit distilled grain product is only suitable for ruminating animals is solved, the application range of the product is expanded, and the development of the market is facilitated.

Owner:江苏益元泰生物技术有限公司

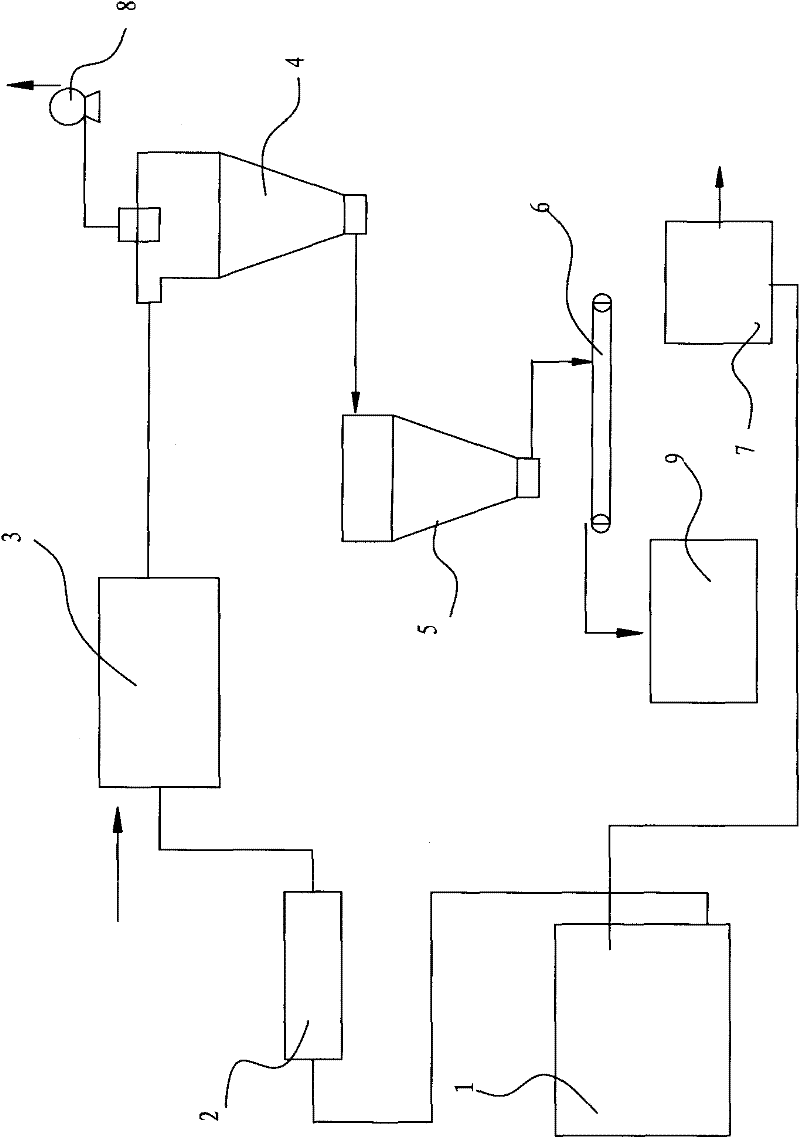

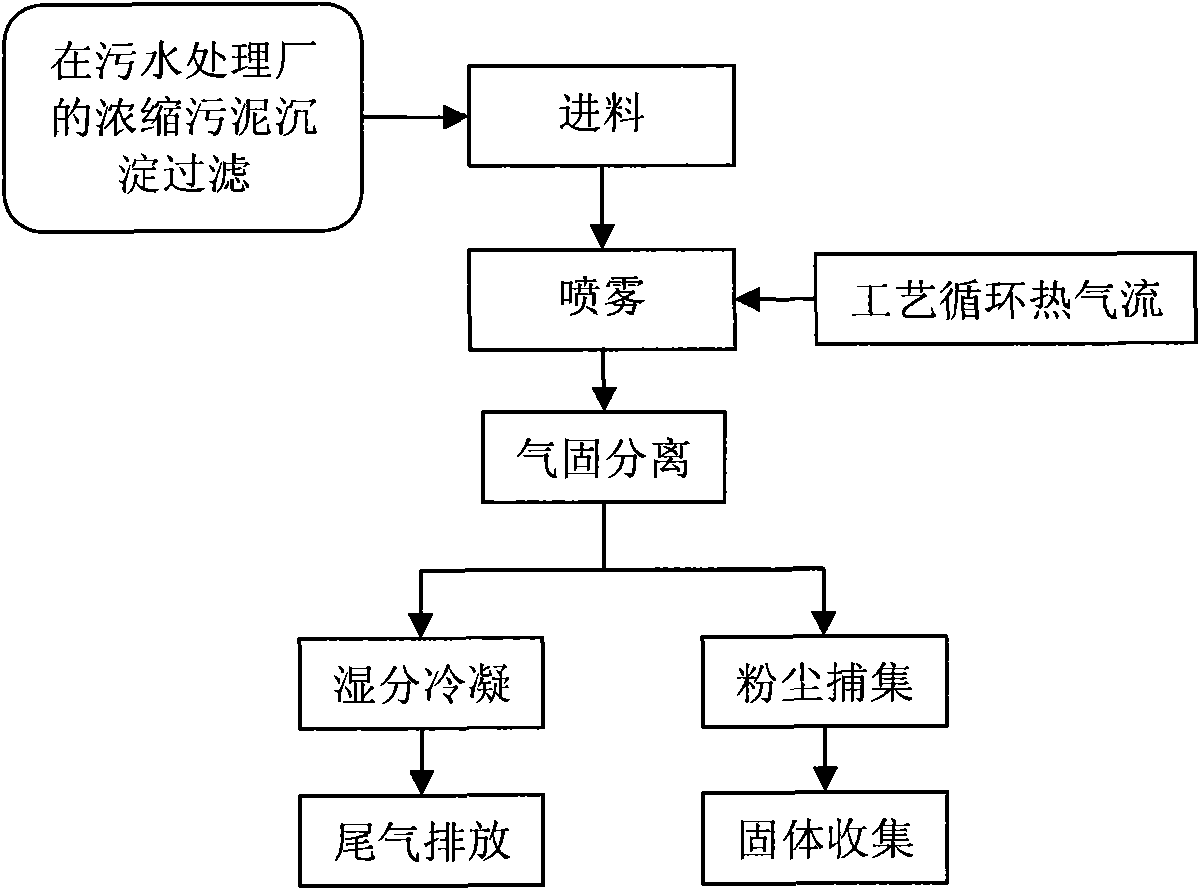

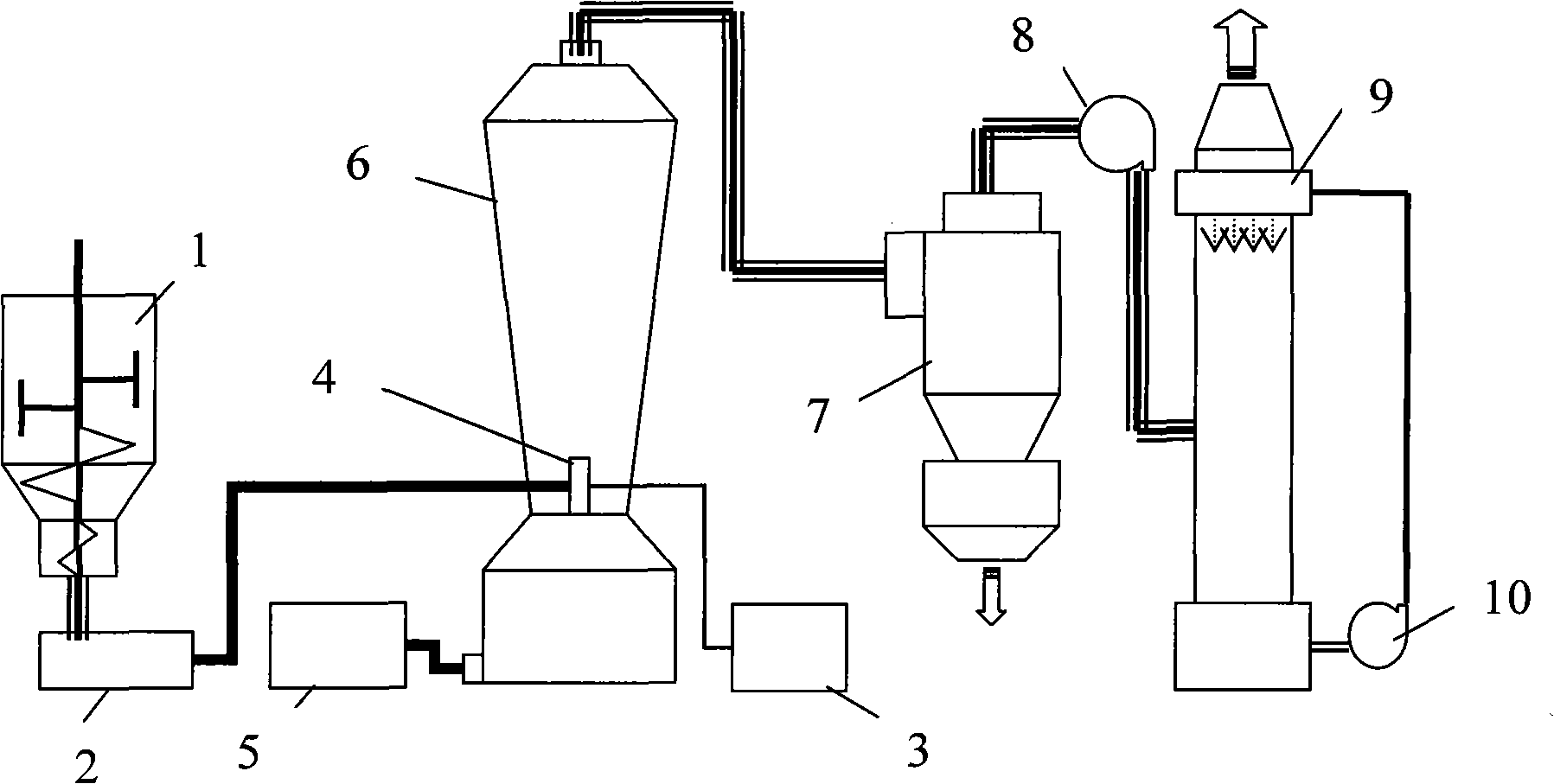

System device for directly and effectively spray-drying high-solid-content sludge and method thereof

InactiveCN101781078ASmall particlesLow and small sludge particles after atomizationSludge treatment by de-watering/drying/thickeningPorositySludge

The invention provides a system device for directly and effectively spray-drying high-solid-content sludge, which comprises a hopper, wherein the hopper is connected with a feed pump and used for feed agitation, the feed pump is connected with one end of a nozzle in a spray drying tower through a pipeline, and the other end of the nozzle is connected with an air compressor; an air inlet at the lower part of the spray drying tower is connected with a hot blast furnace through the pipeline, the top of the spray drying tower is connected with a dust remover through the pipeline, the dust remover is connected with a smoke gas wet recovery tower through the pipeline provided with an exhaust fan, and the recovery tower is communicated with a pool arranged at the bottom of the recovery tower and a nozzle at the top through the pipeline provided with a water pump. The invention also provides a method adopting the system device for directly and effectively spray-drying the high-solid-content sludge. The invention has the effects that the energy consumption is low by using the method, and the atomized sludge has small grains, uniform diameter, good drying effect, high loosening degree and high porosity and is markedly superior to other drying forms. The produced drying sludge is adaptable to the paths of combustion heating, cement manufacture, greening, landfill and the like.

Owner:星河航天科技(天津)有限公司

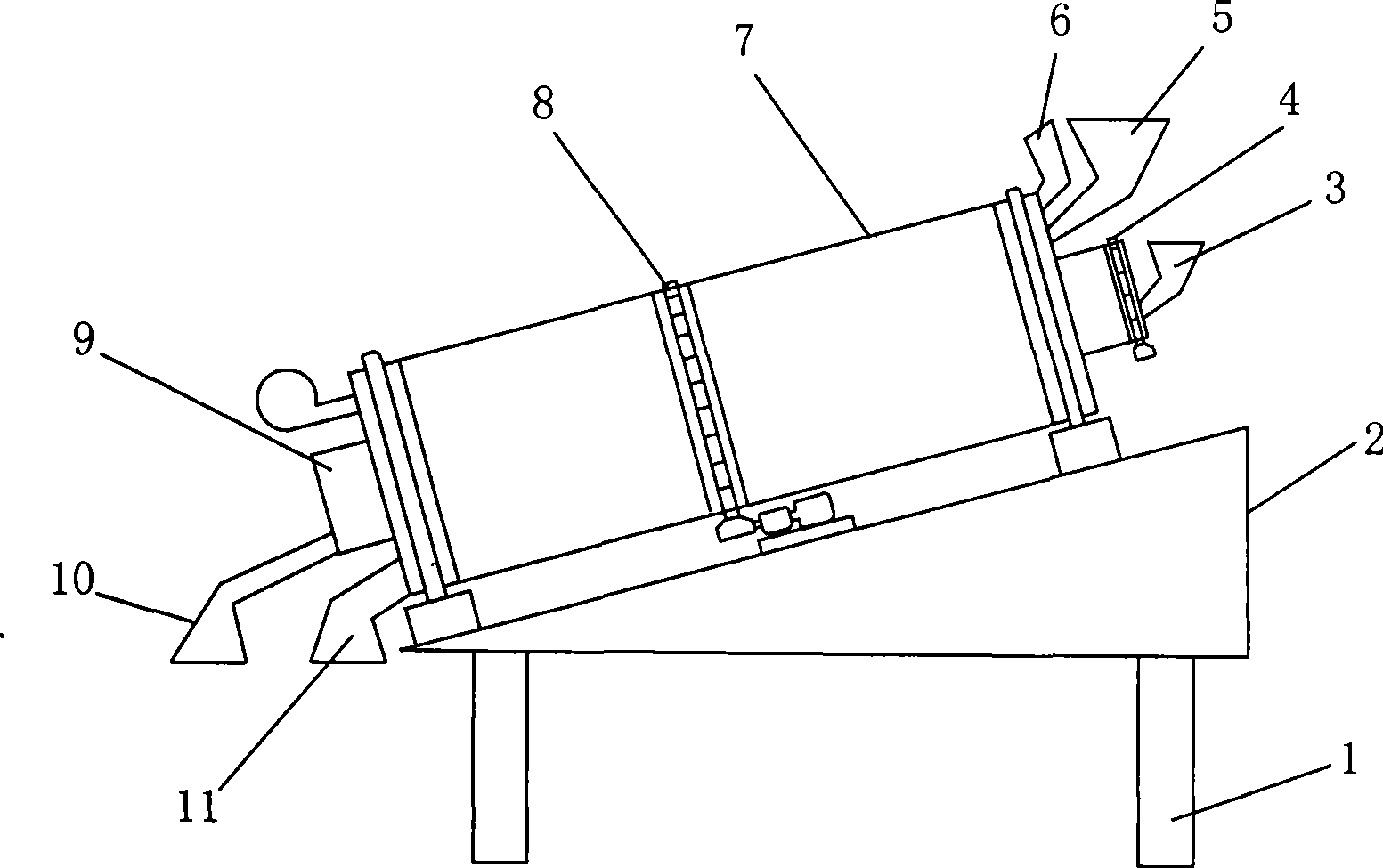

Sewage sludge drying method and drying machine

InactiveCN101508515AReduce lossReduce heat lossSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a sludge drying method and a drying machine. The sludge drying method is used to dry the sludge through the afterheat from the burning of tailings. The sludge drying method adopts a drum type drying machine in which an inner drum is sleeved with an outer drum. The method comprises the following steps: putting a heat source and the sludge respectively in the inner drum or in an interlayer between the inner drum and the outer drum; rotating the inner drum and the external drum so as to make the heat source and the sludge in the inner drum or in the interlayer between the inner drum and the outer drum roll continuously; and transferring the heat of the heat source evenly to the sludge through the wall of the inner drum so as to dry the sludge. The sludge drying machine comprises a machine frame, a supporting mechanism, the inner drum, the outer drum and a driving device, wherein the outer drum is arranged on the machine frame through the supporting mechanism; the inner drum is positioned in the middle of the outer drum; the driving device respectively drives the outer drum and the inner drum to rotate; an outer material inlet and an outer material outlet are arranged at the two ends of the outer drum respectively; and an inner material inlet and an inner material outlet are arranged at the two ends of the inner drum respectively. The sludge drying method is scientific and practical and brings about high thermal efficiency; and the sludge drying machine has a reasonable structure and low drying cost.

Owner:ZHEJIANG HUAZHANG TECH

Manufacturing method of wedge joint board

The invention relates to a manufacturing method of a wedge joint board. The wedge joint board is formed by lengthwise and widthwise splicing of wedge joint slices; the wedge joint slices are cuboid eucalyptus slices with equal width and equal thickness through machining improvement treatment; the short-edge end surfaces of the wedge joint slices are provided with finger-shaped teeth with the same tooth shapes; meshed teeth are jointed to form long wedge joint strips; the long wedge joint strips are jointed by glue in parallel to form the wedge joint board. The manufacturing method comprises the following steps: A, log sawing; B, drying; C, machining improvement treatment; D, width fixing, length fixing and sorting of base materials; E, teeth combing; F, lengthwise and widthwise splicing; G, plate blank repairing, polishing and edge cutting; H, inspecting, packaging and warehousing. The manufacturing method solves the problem that fast-growing eucalyptus is easy to be shrunk and deformed when drying better; through the machining improvement treatment, the machining performance of eucalyptus is greatly improved, the polishing cost, material wastage and glue using amount are reduced, and the production cost is lowered; the manufacturing method has greater promotional value, and contains tremendous economic and social benefits.

Owner:广西贺州恒达板业股份有限公司 +1

Electronic jet drying cylinder dryer

InactiveCN102183128AMeet production needsSatisfy productivityDrying gas arrangementsLiquid/gas/vapor removalTextile printerWaste heat recovery unit

The invention discloses a textile printing and dyeing electronic jet drying cylinder dryer and a jet drying cylinder, waste gas heat recovery and condensate water recovery thereof and a method for setting a moisture regain reference roller. The electronic jet drying cylinder dryer consists of a heat insulating and preserving drying room, the jet drying cylinder, a heat recovery and jet system and an electronic information system, wherein exhaust air is divided into exhausted air and circulating air according to humidity of the exhaust air; heat of the exhausted air is recovered by fresh air; the fresh air is mixed with the circulating air; the heat of condensate water is then recovered and the condensate water is sprayed to a textile; heating is performed and drying conditions are improved; complete on-line detection and control are performed on temperature, tension and moisture regain of the textile and humidity, temperature and speed of an air flow; therefore, heat application efficiency and drying efficiency are increased, production cost is reduced and production requirement of high-grade textiles is met in a scientific, strict, careful and reliable drying mode. The electronic jet drying cylinder dryer can be used for substituting a drying cylinder dryer or is made by modifying the drying cylinder dryer; a waste gas heat recovery system and a condensate water recovery system are suitable for various heating production occasions; and by the method for setting the moisture regain reference roller, reliability and validity of moisture regain control are solved.

Owner:段新顺 +1

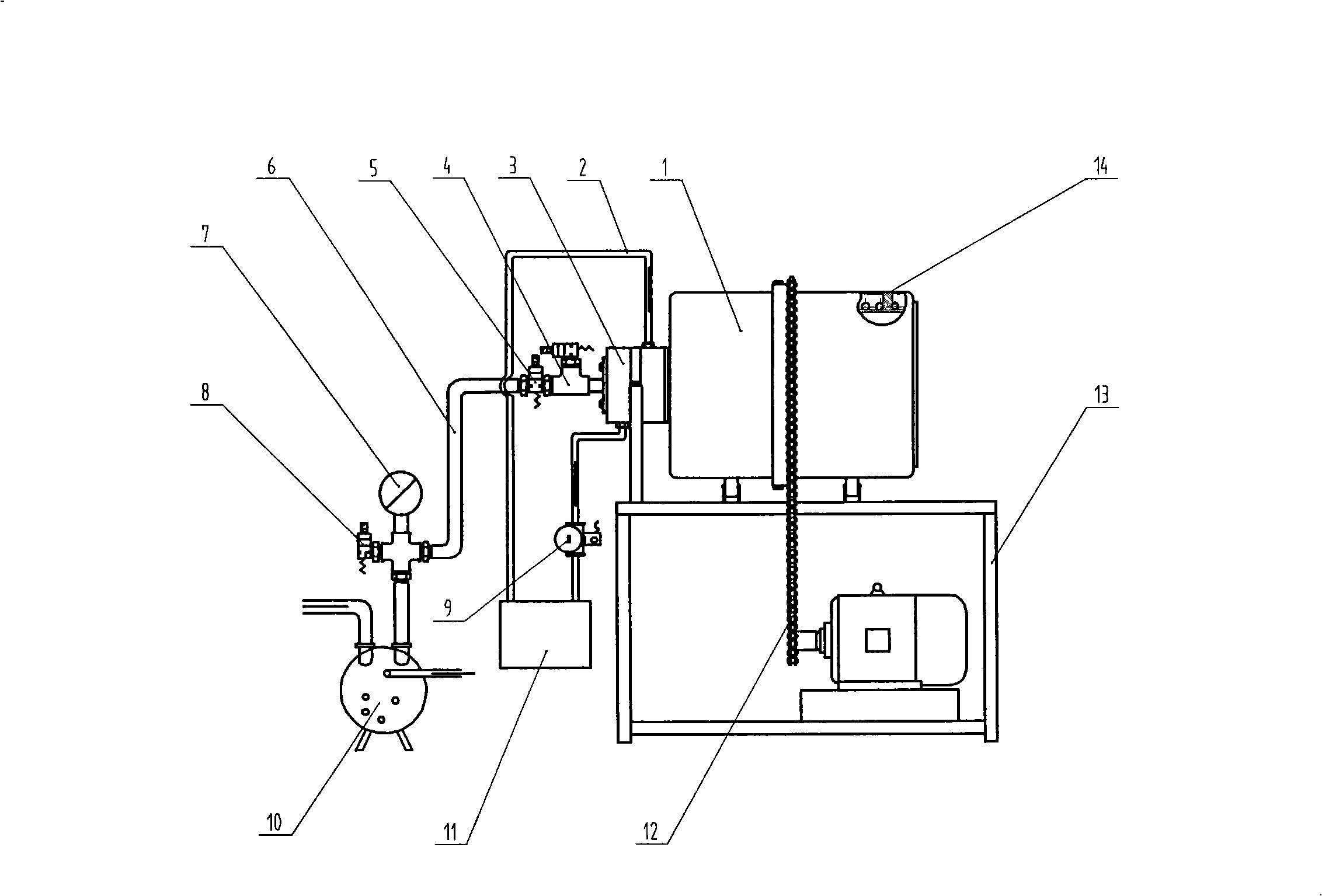

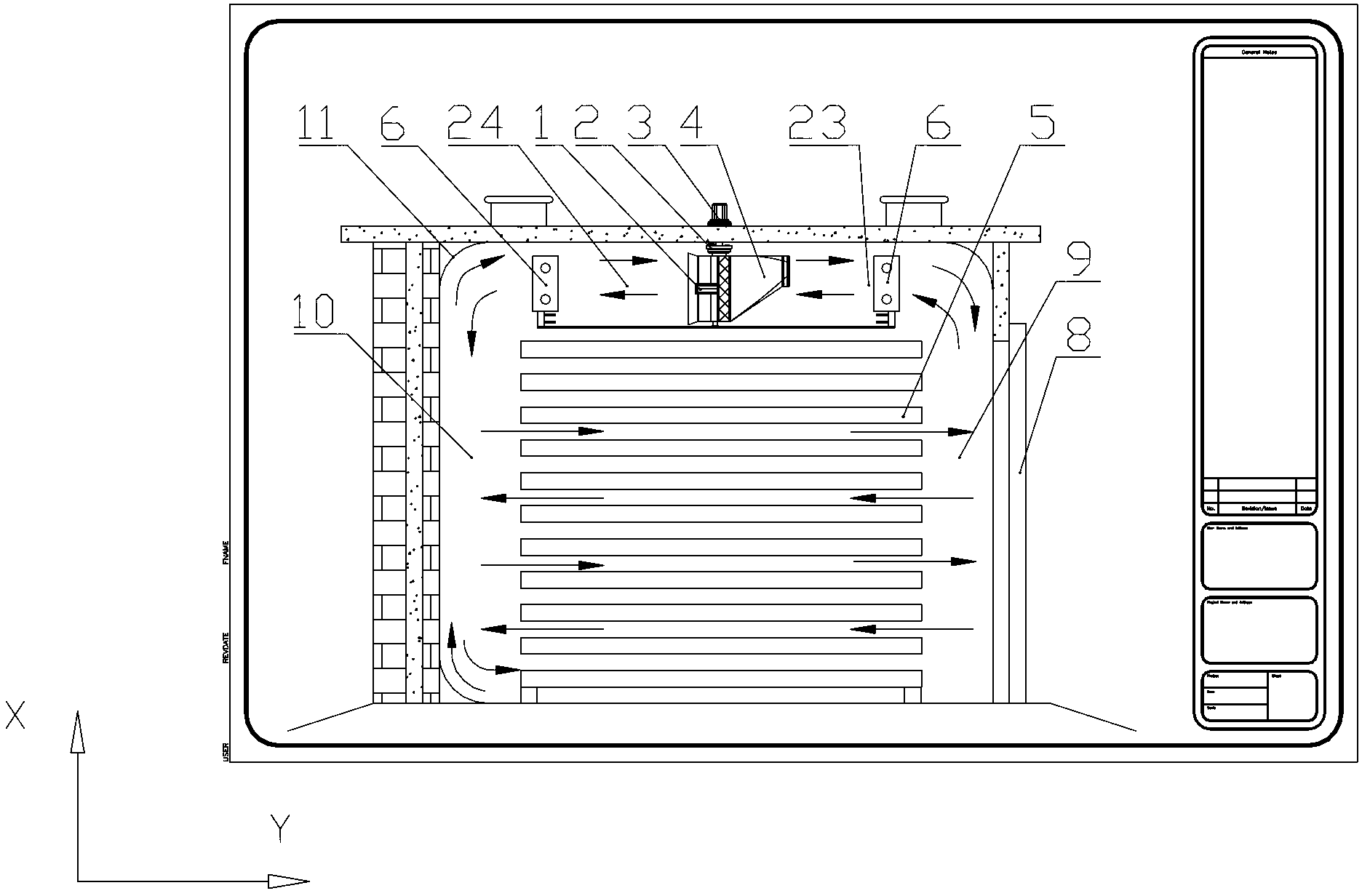

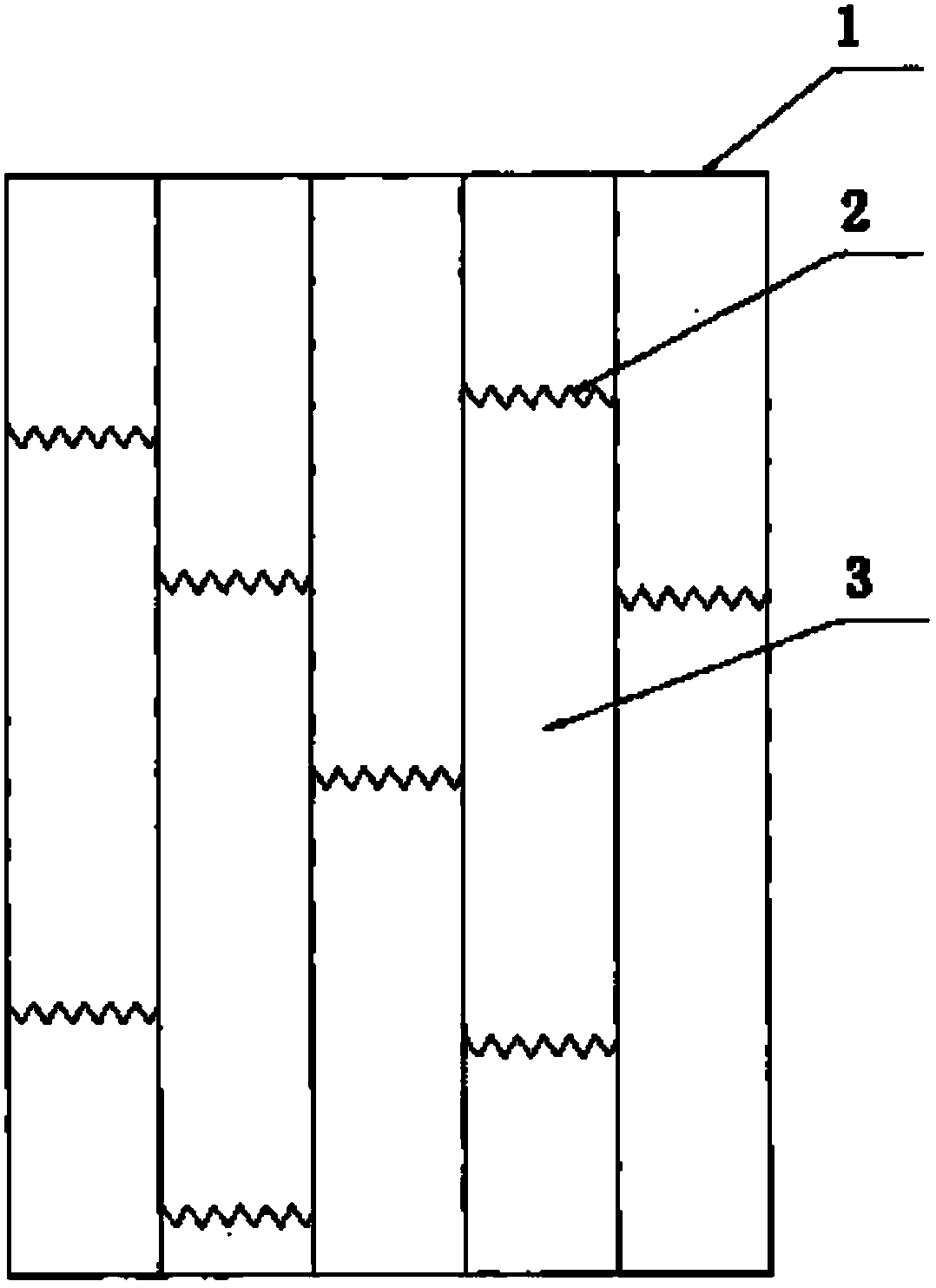

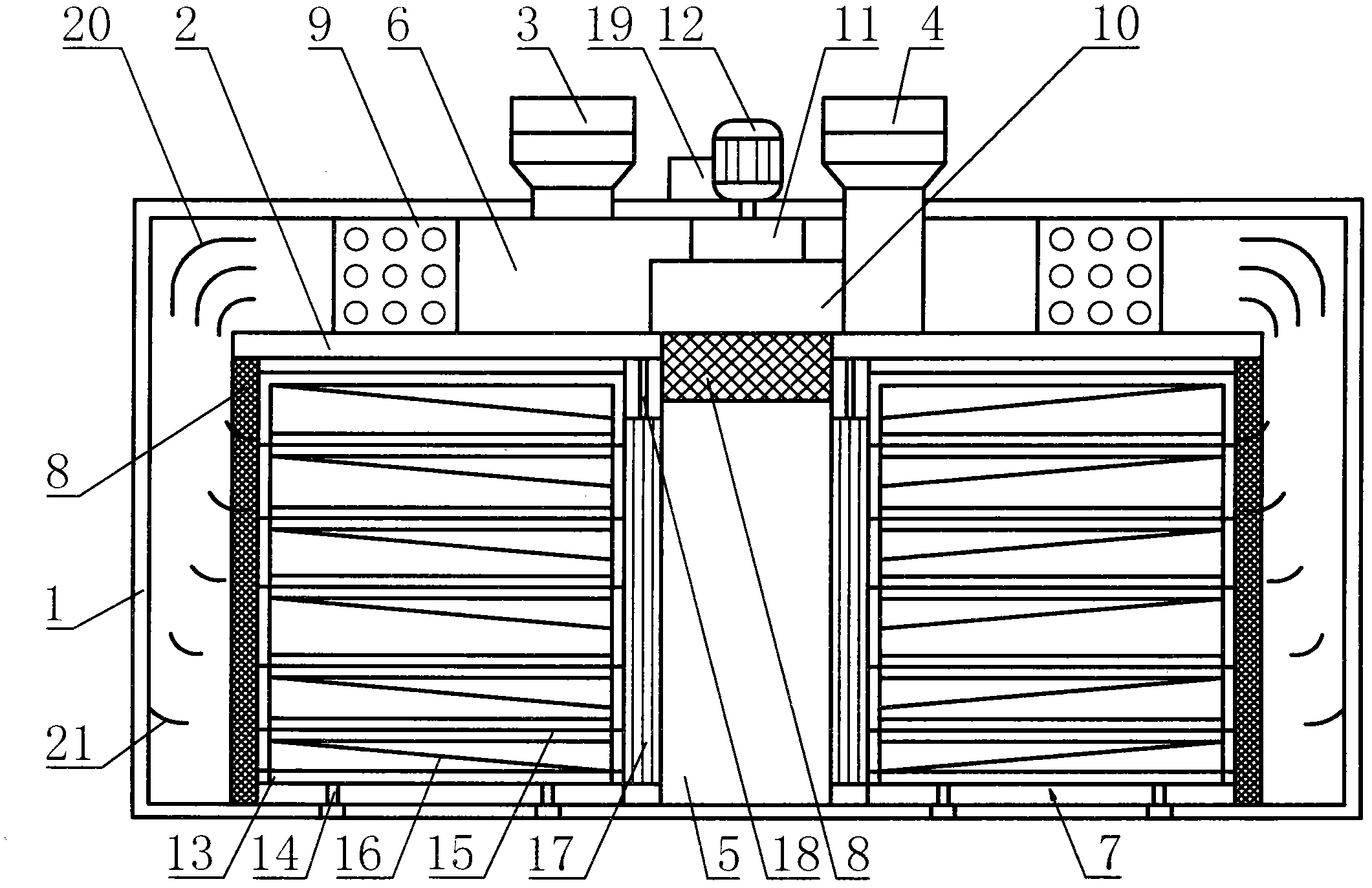

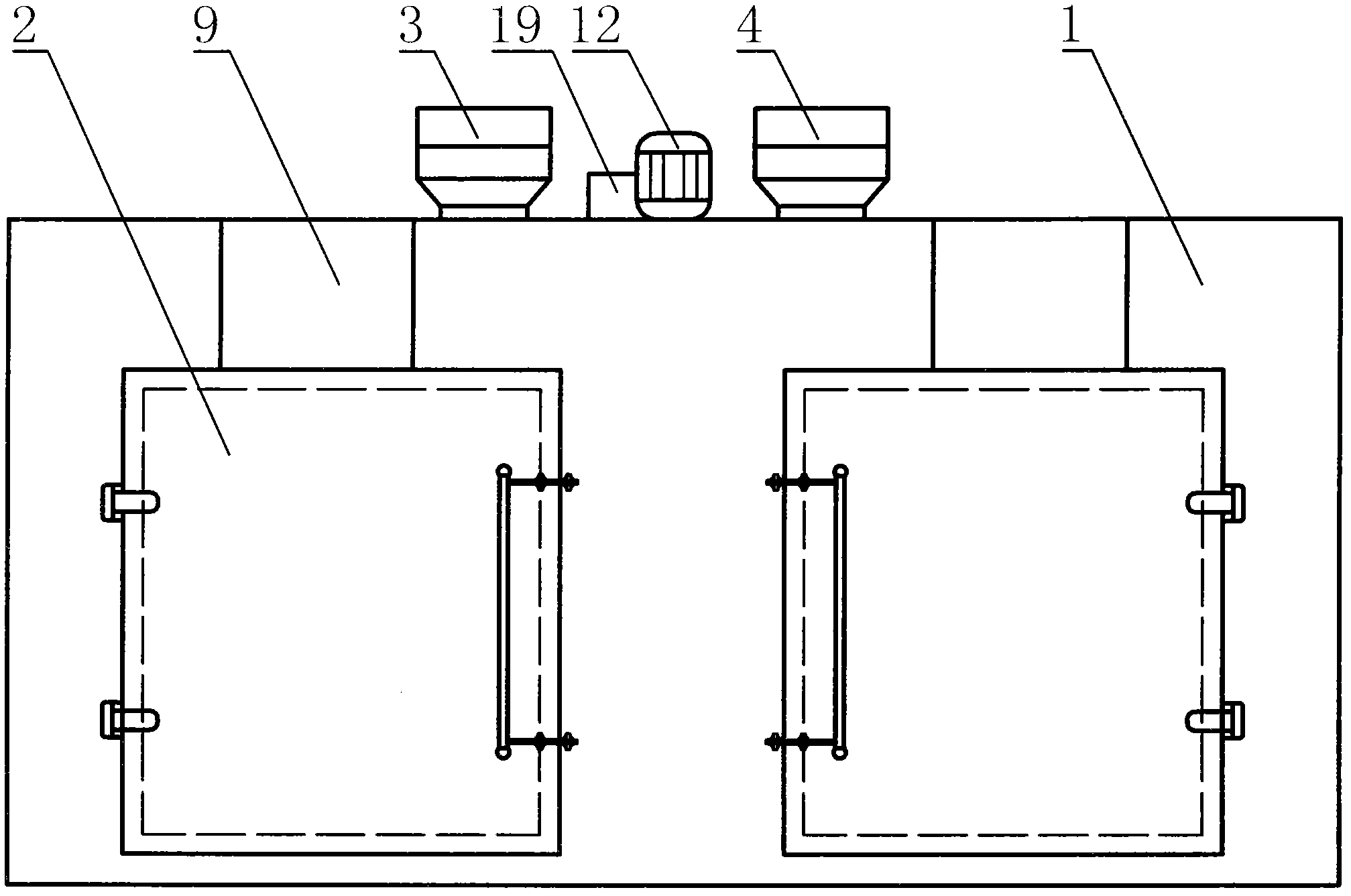

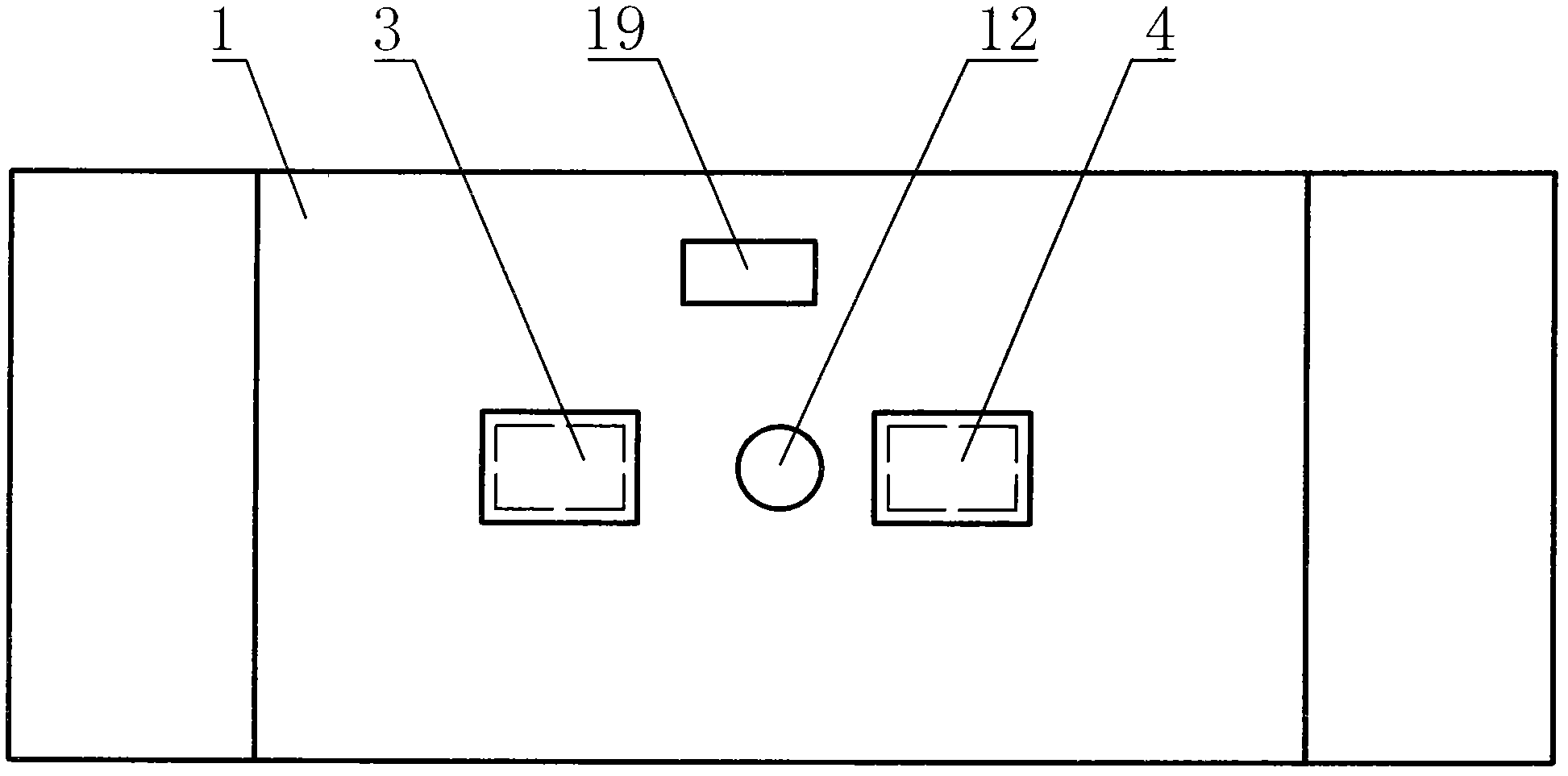

Inflatable-seal-type cross-flow drying oven with dual drying cars

InactiveCN102620533AIncrease throughputReduce drying costsDrying gas arrangementsDrying solid materialsFresh airMoisture

The invention relates to the field of drying equipment, in particular to an inflatable-seal-type cross-flow drying oven with dual drying cars, which has the advantages of even drying, large processing capacity, good sealing property and high heat utilization rate. The drying oven comprises a oven body (1); two drying chambers (2) are arranged in the oven body (1) symmetrically; a fresh air inlet (3), a moisture outlet (4) and an air draft device are arranged at the top of the oven box (1) respectively; an air-out chamber (5) is arranged between the drying chambers (2); an air-in chamber (6) is formed among the top of the drying chamber (2), the side of the drying chambers (2) close to the oven body (1) and the oven body (1); drying cars (7) are arranged in the drying chambers (2); a filter (8) is arranged at the side, close to the air-in chamber (6), of the drying chambers (2) and the other side is communicated with the air-out chamber (5) by an inflatable-seal device; the filter (8) is arranged at the part corresponding to the air draft device, above the air-out chamber (5); the fresh air inlet (3) is communicated with the drying chambers (2) by a heater (9) arranged in the air-in chamber (6); and the moisture outlet (4) is connected with the air draft device.

Owner:马文

Preparation process of high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket

The invention provides a preparation process of a high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket. The high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket is mainly prepared by doping magnesium hydroxide into a glass fiber compound silicon dioxide aerogel by virtue of a sol-gel method and a supercutical fluid CO2 drying technology based on excellent characteristics of magnesium hydroxide. The high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket prepared by the process provided by the invention has excellent insulating property and mechanical property, good high-temperature-resistant hydrophobic property, and is convenient to construct. The preparation method avoids a step of replacing a solvent, and is simple to operate, controllable in process and continuous in production. The preparation process provided by the invention belongs to the technical field of chemical materials.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

Aassociation drying Method for preparing dehydrated vegetable and fruit

InactiveCN101156623AReduce qualityImprove qualityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by dehydrationOrganic structureFreeze-drying

The invention relates to a dehydrating and drying method for the top-grade vegetable and fruit. After being sliced, the vegetable and the fruit are placed in a microwave vacuum dryer for being dried, the exerting microwave power density is between 0.5 w / g and 1.2 w / g (watt / gram), the vacuum rate is between 2.5KPa and 4.5KPa (remaining pressure), the materials to be dried can do reciprocating movement along with the drying dish in the microwave vacuum dryer. After being dehydrated by about 40-50 percent of the total moisture by the microwave vacuum drying, the materials are taken out and positioned on a stainless steel dish and then are positioned in a freezing dryer, and are frozen and sublimed dry under 25 DEG C below zero, the drying time is about 7-10 hours, and the moisture is lowered to the safe moisture of 6-7 percent. The preserving of the color, the scent, the taste, and the nutritious components of the dehydrated vegetable and fruit which are produced by the invention are quite approximate to that of the single freezing dried products, the volume is 60-70 percent of the volume of the single freezing dried products, the appearance and the organic structure are approximate too, the drying cost is low, and the energy can be saved by 40 percent above.

Owner:JIANGNAN UNIV

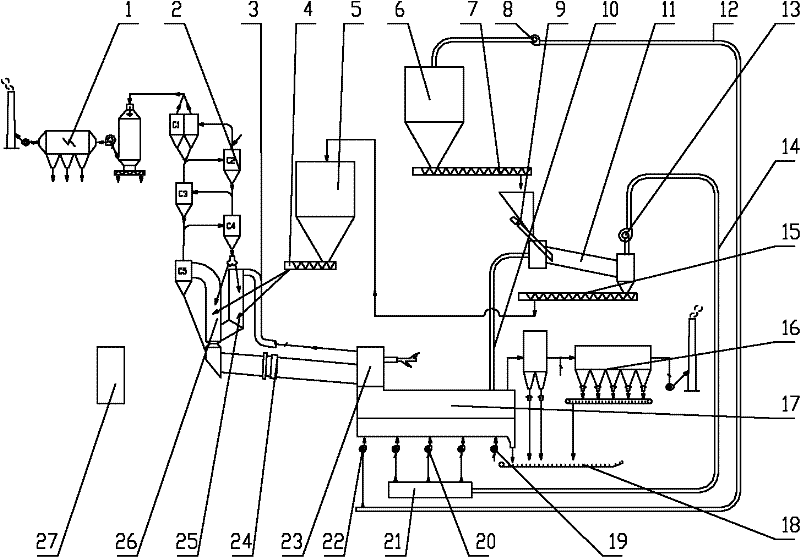

Process method and process system for preparing solid fuel through biomass and sludge

The invention discloses a process method and a process system for preparing solid fuel through biomass and sludge. The method comprises the step of mixing biomass dried raw materials with sludge dried raw materials which are aired, ground and dried to obtain the solid fuel, wherein sludge airing energy is one or the combination of any two or three of solar energy, waste gas generated by drying sludge raw materials and high-temperature fume generated by combusting the solid fuel, and sludge raw material drying energy is high-temperature and high-pressure steam generated by combusting the solid fuel. The system comprises a raw material treatment system, a molding system and a boiler system, wherein the raw material treatment system and the boiler system transfer heat energy to each other through first, second and third gas delivery pipelines. According to the method, the cost is low, the effect is good, environmental protection is realized and the solid fuel is suitable for large-scale production. The system is resource-saving and stable to operate.

Owner:东莞市图美环保科技有限公司

Natural color fluff pulp and preparation method thereof

InactiveCN103850145AAvoid harmAvoid pollutionNatural cellulose pulp/paperCellulose material pulpingFluff pulpPulp and paper industry

The invention aims to provide a natural color fluff pulp which is really healthy and environmentally friendly. The natural color fluff pulp is characterized by being prepared from one raw material or a plurality of raw materials through mixing, and has performance parameters meeting the fluff pulp national standard GB / T21331-2008. The materials adopted by the natural color fluff pulp are not blanched, not added with a brightener or a color developing agent during the production process; a natural color fluff pulp product does not contain cancerogenic substance such as dioxin or adsorptive organic halide, harm to the human body and pollution to the environment caused by chemicals used in the blanching or brightening process are eliminated, 100% natural color of plant fiber is kept; the natural color fluff pulp is applicable to the field of hygienic products; a manufactured hygienic product has excellent performances and improved practicability; the natural color fluff pulp is sanitary, safe and environmentally friendly, and has good protection property for physiological hygiene and physical and psychological health of the human body.

Owner:BEIJING ZHENGLI HENGFENG PULP & PAPER

A kind of tilapia pulp feed protein and processing method thereof

InactiveCN102283327ANutritional balanceHigh protein contentFood processingClimate change adaptationWeight gainingFeed conversion ratio

A tilapia pulp feed protein and a processing method thereof, using peanut meal, rapeseed meal, cottonseed meal or a mixture to absorb tilapia pulp, adding bacterial strains for solid-state fermentation, drying and pulverizing to make fish paste feed Protein is used as protein raw material for feed industry and aquaculture industry. The method of the invention has the advantages of simple process, less investment in equipment, low cost, strong aroma of fish paste feed protein, good food attractant, high protein content, high small peptide content, easy digestion and absorption, and can reduce anti-nutritional factors in rapeseed meal and cottonseed meal , rich in probiotics, plays a positive role in increasing weight gain and feed conversion rate, enhancing the immune function of the body, and improving production performance. It can greatly replace fish meal in livestock and poultry feed, significantly reduce feed cost, and turn fish paste into waste It is a treasure, which is conducive to environmental protection and energy saving.

Owner:GUANGDONG OCEAN UNIVERSITY

System for drying and handling sludge with waste gas from cement production

InactiveCN102173554AIncrease heat transfer areaImprove heat transfer efficiencySludge treatment by de-watering/drying/thickeningCement productionSludgeClinker (waste)

The invention discloses a system for drying and handling sludge with waste gas from cement production and is characterized in that the system comprises a novel dry-method cement clinker firing system, a wet sludge drying system, a dry sludge storage and cement kiln feeding system, an electrical dragging and automatic control system; the gas inlet pipe and the gas outlet pipe of a sludge dryer of the wet sludge drying system are both connected with a cooler of the cement clinker firing system; the dry sludge storage and cement kiln feeding system is connected with a cement kiln exhaust decomposing furnace or an uptake flue; and the sludge dryer is a rotary sludge dryer with chains. The system makes full use of the high-temperature waste gas of the cement cooler to dry the sludge, the drying waste gas returns to the cooler, the waste gas is dried by the high-temperature purified sludge, and the dried sludge is burned in the cement kiln, so that the harmful substances are decomposed, theheat energy is used for cement firing and the burning ash forms cement. Therefore, the system achieves the effect of pollution-free full-utilization disposal of sludge and is significant in environmental and economic benefits.

Owner:袁文献

Device and method for preparing pulverized coal with low energy consumption

ActiveCN103421521AReduce moisture contentReduce drying costsCoke quenchingGrain treatmentsCoke ovenQuenching

The invention provides a device and a method for preparing pulverized coal with low energy consumption. The device comprises a dry quenching cooling system, a heat energy recovery system and a coking coal grinding system, wherein the dry quenching cooling system comprises a dry quenching furnace. The dry quenching furnace takes high-temperature semi-coke generated by raw coal and a pyrolysis device as a raw material and inert gas as a heat exchange atmosphere, the high-temperature semi-coke reacts in the dry quenching furnace to obtain high-temperature quenching gas and a coal and coking coal mixture, a high-temperature quenching gas outlet of the dry quenching furnace is connected with an inlet of the heat energy recovery system, gas generated by the heat energy recovery system is recovered and returns to the dry quenching cooling system, and a coking coal mixture outlet of the dry quenching furnace is connected with an inlet of the coking coal grinding system to serve as the raw material for producing coking coal.

Owner:SHAANXI COAL & CHEM TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com